Abstract

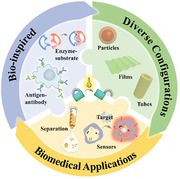

Inspired by the recognition mechanism of biological molecules, molecular imprinting techniques (MITs) are imparted with numerous merits like excellent stability, recognition specificity, adsorption properties, and easy synthesis processes, and thus broaden the avenues for convenient fabrication protocol of bio‐inspired molecularly imprinted polymers (MIPs) with desirable functions to satisfy the extensive demands of biomedical applications. Herein, the recent research progress made with respect to bio‐inspired imprinting materials is discussed in this review. First, the underlying mechanism and basic components of a typical molecular imprinting procedure are briefly explored. Then, emphasis is put on the introduction of diverse MITs and novel bio‐inspired imprinting materials. Following these two sections, practical applications of MIPs in the field of biomedical science are focused on. Last but not least, perspectives on the remaining challenges and future development of bio‐inspired imprinting materials are presented.

Keywords: bio‐inspired, biomedical applications, molecular imprint, sensitivity, specificity

Inspired by the recognition mechanism of biological molecules, molecular imprinting techniques are imparted with numerous merits and thus broaden the avenues for convenient fabrication protocol of bio‐inspired molecularly imprinted polymers with desirable functions to satisfy the extensive demands of biomedical applications. Herein, the recent research progress made with respect to bio‐inspired imprinting materials in this review is discussed.

1. Introduction

Molecular imprinting is the technique that constructs a specific rebinding system with selective and robust recognition sites to target molecules in synthetic polymers and bionics. The origin of molecular imprinting technology (MIT) dates back to the 1930 s when Polyakov found adsorption properties of silica gel and first proposed the concept of “molecular imprinting”.[ 1 ] Since then, tremendous interest has been attracted to the design, preparation, and characterization of MIT and numerous molecularly imprinted polymers (MIPs) have been gradually developed.[ 2 , 3 , 4 , 5 ] Inspired by the recognition interactions between the natural biological molecules, MIT is often described as an approach to forming a “key‐lock” structure based on the spatial topology, functional groups, or charge distribution between target templates and functional monomers, which contributes to recognizing and selectively rebinding template molecules from complex compounds, such as atom, ions or biological/chemical molecules, etc.[ 6 , 7 , 8 , 9 , 10 ] In particular, the binding sites can be flexibly designed according to the physicochemical property of target templates, meanwhile the functional monomers and cross‐linkers can also be adjustable to endow molecularly imprinted materials with more excellent mechanical capacity or biochemistry functions. Besides, the fabrication processes can be operated under relatively simple conditions and environments. Therefore, molecular imprinting bears extensive practical value and enables the generation of materials or polymers with excellent stability, adsorption properties, and easy synthesis processes that would be difficult to obtain in other approaches.[ 11 , 12 , 13 , 14 ]

The bio‐inspired MIPs can be fabricated by copolymerizing functional monomers and cross‐linkers around target template molecules, eventually forming highly cross‐linked polymers. The interactions between template molecules and functional monomers form robust binding sites based on covalent, noncovalent, and semi‐covalent interactions.[ 15 , 16 , 17 ] After the removal of template molecules by elution, the unique spatial cavities of template molecules remain in the polymer matrix, which records the shape, size, charge, or chemical functionality of templates and realizes the specific recognition to target.[ 18 , 19 , 20 ] Compared to other traditional recognition systems such as antibody‐antigen, enzyme‐substrate, and biological receptors, MIT not only mimics natural recognition mechanisms and processes, but also possesses more promising characteristics including predictable and designable structure, high chemical‐physical stability, excellent reusability, and low fabrication cost. Such features have paved the way for wider applications of MIT in biomedical fields, such as sample separation and purification, biosensing, artificial antibodies, catalysis, drug delivery, etc.[ 21 , 22 , 23 , 24 ] Therefore, great progress of MIT has brought bright development prospects in physical, chemical, biological, medical fields, and environmental science.

Due to the wide application prospect and promising potential of MIT, several classic reviews on MIT have been published, which mainly placed emphasis on certain basic aspects like fundamental preparation processes and characteristic applications of MIPs.[ 25 , 26 , 27 , 28 ] However, a comprehensive review on bio‐inspired imprinting materials about new fabrication mechanisms, working principles, and novel applications in different biomedical fields in recent years remains lacking. Thus, we believe that such a substantial and general review about all aspects of MIT would have a profound impact on this active and multidisciplinary field. Such a review could inspire scientists of different professional backgrounds to explore the development direction of MIT in various fields of science.

Here, we give an overall review of the research progress of bio‐inspired imprinting materials derived from MIT, covering the fundamentals to practical applications. First of all, we briefly introduce the fundamentals of molecular imprinting and summarize the basic mechanism and critical elements of molecularly imprinted materials. Then we focus on the classifications of diverse molecular imprinting techniques (MITs), including traditional imprinting (surface‐imprinting, nanoimprinting) and novel imprinting (multiply imprinting, stimuli‐responsive imprinting). Following these two opening sections, we mainly show concerns about the biomedical applications of bio‐inspired imprinting materials. The applications of MIT in sample separation and chemical/biological sensing are described respectively. Finally, we analyze the current status and propose the remaining challenges with future perspectives and development directions of MITs.

2. Fundamentals of Molecular Imprinting

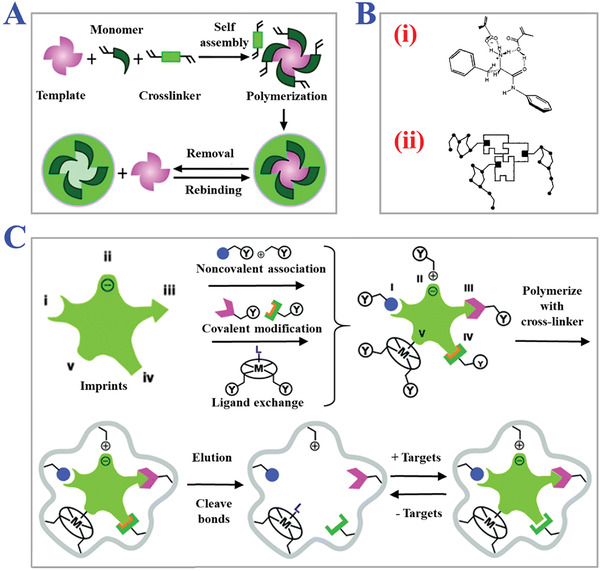

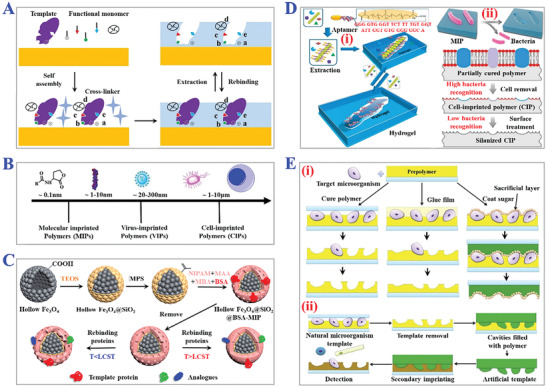

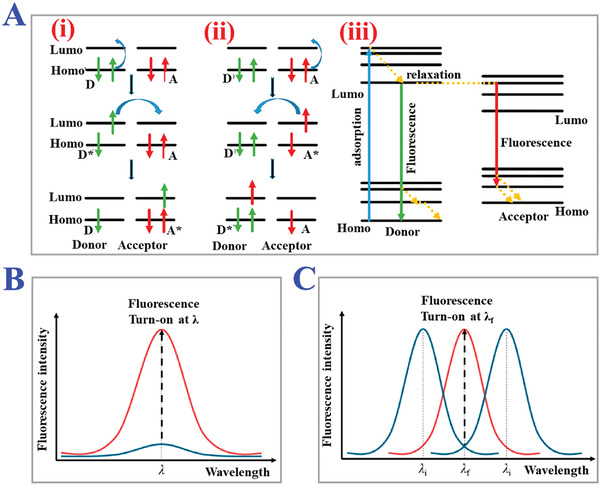

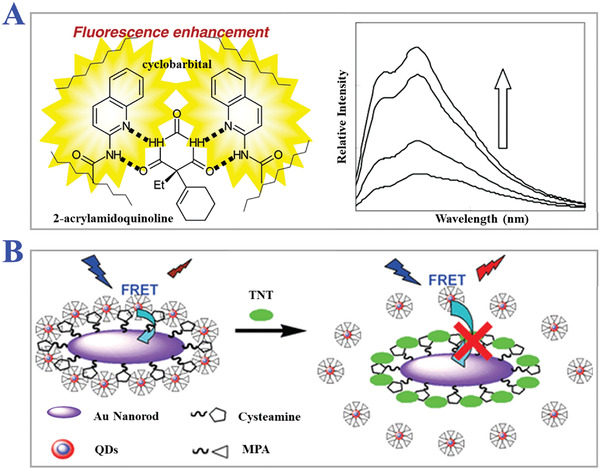

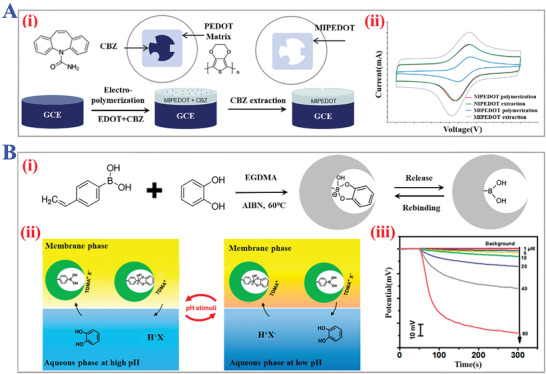

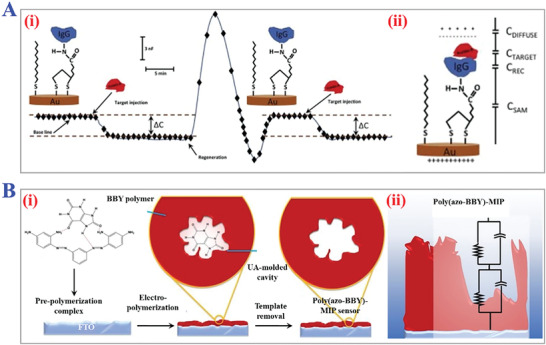

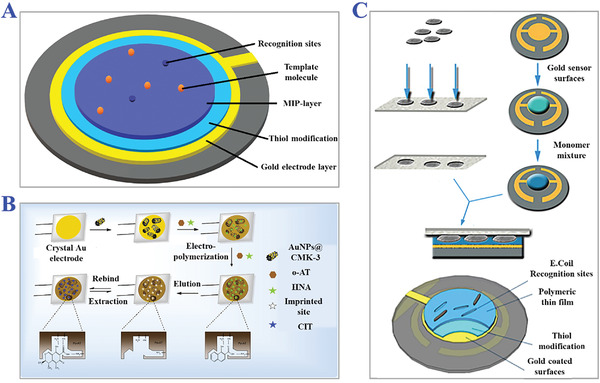

Fundamentals of MIT can be briefly described as MIPs, which are synthesized in the molecular imprinting process to play a key role in specific recognition functions. The interaction forces between the target templates and functional monomers are the basis of constructing recognition and rebinding sites in the network of polymer matrix (Figure 1A,B).[ 29 , 30 ] Besides, the copolymerization processes including polymerization methods, reaction conditions, and introduction of assistant compounds also influence the properties and performance of final polymerized MIPs. Currently, fundamental research has been further explored for the development of novel MITs.[ 31 , 32 , 33 , 34 ]

Figure 1.

Fundamental principle of MITs. A) Schematic fabrication procedure of MIPs. Reproduced with permission.[ 55 ] Copyright 2012, The Royal Society of Chemistry. B) The interaction forces between the target templates and functional monomers: i) basic interactions; ii) more complexed interactions. Reproduced with permission.[ 7 ] Copyright 2012, John Wiley & Sons, Ltd. C) Several main types of molecular imprinting, including covalent imprinting, non‐covalent imprinting, semi‐covalent imprinting, electrostatic/ionic, and metal center coordination. Reproduced with permission.[ 37 ] Copyright 2014, The Royal Society of Chemistry.

2.1. Imprinting Mechanism

The mechanism of molecular imprinting is to specifically recognize and rebind target template molecules based on the “key‐lock” structure like antibody‐antigen or enzyme‐substrate. The “lock” structure refers to the imprinting site remaining in the 3D network of polymerized matrix, and the imprinted target template molecules act as the role of “key”. The imprinting sites record the unique chemical, electronical, or structural information of target template molecules, such as functional groups, charge distribution, or spatial topological structures in MIPs, which enhance the specificity of rebinding process.[ 35 , 36 ] The fabrication of the above imprinting sites mainly relies on the robust combination and interaction between target template molecules and functional monomers, including covalent interactions, noncovalent interactions, and semi‐covalent interactions, as schemed in Figure 1C.[ 37 ]

2.1.1. Covalent Imprinting

Covalent imprinting as a typical method has been widely used for molecular imprinting due to the precisely fixed functional groups that remained during polymerization and complete removal of target template molecules. As Wulff et al. reported, the covalent linkage formed within polymerization would be cleaved when target templates were removed.[ 17 ] During rebinding process, the same covalent linkage would be reformed to specifically recognize and capture the guest target template molecules. For example, boronic acid has been demonstrated suitable for covalent imprinting.[ 38 , 39 , 40 ] The stable trigonal boronic acid esters can realize reversible condensation which forms covalent boronic acid imprinting with high affinity to compounds containing diol groups. Other covalent imprinting methods involving acetal/ketal, Schiff's base reaction, chelate complex, amide, and so on have also been widely applied for covalent imprinting.[ 41 , 42 , 43 , 44 ] However, it is difficult to realize the thermodynamic equilibrium of strong covalent interaction, which would inevitably cause slow dissociation and rebinding process. In addition, the suitable eversible condensation reactions are usually confined within the above types, which is difficult to satisfy the diverse needs of imprinting different template molecules, further limiting the wider applications of covalent imprinting.

2.1.2. Noncovalent Imprinting

Different from covalent imprinting, noncovalent imprinting constructs the binding sites between target template molecules and functional monomers with the help of noncovalent interactions involving ionic interactions, dipole‐dipole interactions, hydrogen‐bond formation, van der Waals forces, and electrostatic interactions, etc. In noncovalent imprinting, the noncovalent interaction between functional monomers and template molecules can easily reach thermodynamic equilibrium in a polymerization environment. Mosbach et al. proposed that the usages of ligand functional monomers tended to be much larger than template molecules, which ensured the occurrence of rapid and sufficient noncovalent reactions.[ 16 ] Benefitting from the advantages of the rapid dissociating and rebinding process, noncovalent imprinting has been considered as an important synthesis strategy to produce MIPs on a large scale. Moreover, the operation processes of noncovalent imprinting including reaction medium environment, reaction conditions, and catalyst systems are relatively easy compared with covalent imprinting. One typical noncovalent imprinting is based on the noncovalent binding between methacrylic acid (MAA) and amide compounds in nonpolar solvents.[ 45 , 46 , 47 ] The oxhydryl groups (‐OH) in MAA tend to form strong electrostatic interaction and hydrogen‐bond to oxygen atom in amides. These two noncovalent interactions cooperate to enhance the specificity due to the high selectivity cavities formed in MIPs. Although noncovalent imprinting has been extensively used, there still exist many shortcomings. The massive usages of functional monomers during polymerization will form excessive and non‐specific binding groups after the removal of template molecules, which hinder the formation and influence the function of MIPs (for example, catalysts).[ 48 , 49 ] Besides, noncovalent interactions are easily disrupted by the presence of water in the reaction solvent environment. Therefore, more new and robust binding groups are highly desired to explore the applications of noncovalent imprinting.

2.1.3. Semi‐Covalent Imprinting

Semi‐covalent imprinting has merged as a novel MIT that combines the advantages of covalent imprinting and noncovalent imprinting, involving stability, durability, and rapid rebinding. In semi‐covalent imprinting, the template molecules combine with functional monomers based on covalent interactions while the MIPs rebind the target molecules through noncovalent interactions.[ 50 ] There are two variations in the semi‐covalent approach which can be distinguished by the connection between the template and the monomer, including direct connection or connection with spacer groups. The covalent imprinting step of forming template‐monomers complex during polymerization can overcome the disadvantages of excessive non‐specific binding groups through noncovalent imprinting. Meanwhile, the rebinding processes mainly rely on noncovalent interaction with guest template molecules which can dramatically improve the rebinding sensitivity and efficiency.[ 51 , 52 , 53 ] The resultant MIPs tend to possess much higher specificity and sensitivity to target template molecules than those fabricated by single imprinting techniques. Therefore, semi‐covalent imprinting has been considered as a promising method to synthesize more homogeneous imprints, imparting the imprinting process with dynamic self‐correcting capabilities and fabricating more universal artificial antibodies. Zimmerman et al. have reviewed the presentative characteristics of perfect MIPs and these excellent advances can be made based on the development of semi‐covalent imprinting.[ 5 ]

Traditional mechanisms of molecular imprinting have been thoroughly investigated, and novel mechanisms are still under exploration for the better development of MIPs. Both advantages and disadvantages of several types of MIT have been reported.[ 54 , 55 , 56 ] Although there exist more and more types of molecular imprinting, the researches on mechanisms are still fundamental. The exploration about principles and mechanisms of specific recognition and rebinding to target consistently influence the development directions of MIT. Generally, the types of molecular imprinting should be selected according to the suitable mechanism, desired properties, and functions of resultant MIPs.

2.2. Fabrication Procedure

Traditional molecular imprinting fabrication procedures tend to involve the following steps (Figure 1A). First, appropriate functional monomers with robust binding capability to target template molecules should be chosen based on the physical‐chemical properties and several interaction forces. Then with the help of cross‐linkers, a complementary complex of template‐monomers is fabricated by performing a copolymerization reaction. In this step, some other assistant compounds such as initiators or porogenic solvents can be added to promote polymerization or the formation of special porous structures. Finally, target template molecules are removed, leaving the imprinting sites in the network of polymer matrix and forming desired MIPs eventually. Many factors in the fabrication procedure would influence the polymerization reaction, such as the usage ratio of compounds, chemical accessories, solvent environment, reaction temperature, polymerization time, etc.[ 57 ] In this section, we will discuss the essential elements above and their effects on the imprinting polymerization process.

2.2.1. Reagents Preparation

Typical molecular imprinting protocol comprises of three basic reagents, including template molecules, functional monomers, and cross‐linkers. The goal of molecular imprinting is to fabricate MIPs with high affinity and specificity to target template molecules. Such affinity and specificity are dramatically influenced by the selection of appropriate reagents. Generally, ideal template molecules should satisfy the following requirements.[ 58 ] First, the target as a template should contain rich functional groups to combine with functional monomers, and the binding in template‐monomer complex should not prevent polymerization or be disrupted by polymerization reaction. In addition, the template molecule itself should possess stable chemical properties and avoid resolving or inactivation during polymerization. So far, commonly used template molecules can be mainly divided into four types, including inorganic ions, organic molecules, biomacromolecules, and living biomaterials.[ 59 , 60 ] Inorganic ions, especially metal ions, have been applied as templates to fabricate ion‐imprinted polymers for the detection and removal of toxic metal ions in environmental pollutants. Ligand complexes are used to assemble with metal ions to overcome the weak selectivity due to the similar ionic radii and charge distribution, as shown in Figure 2 .[ 61 , 62 ] For example, Chen et al. designed Hg2+ ion‐imprinted polymers (IIPs) by a sol‐gel process for mercury speciation analysis in environmental and biological samples.[ 63 ] They synthesized dithizone chelated with Hg2+ as templates to copolymerize with 3‐aminopropyltriethoxysilane as a functional monomer. The resultant IIPs showed higher affinity and selectivity to Hg2+ than organic Hg and other metal ions. Biomacromolecule imprints such as proteins also arouse the great interest of researchers due to the urgent need of controlling biological form and functions for better biomedical applications.[ 64 , 65 ] Bossi and colleagues first proposed the concept of “gate effect”, which referred to the properties of transporting proteins by MIPs under external conditions based on the adjustable pore sizes in polymeric matrix.[ 66 ] They imprinted hydrophilic poly(acrylamide) membranes with proteins, and the pore sizes could be influenced under electrophoresis. The “gate effect” of MIPs has been widely used to selectively translate proteins for proteomic analysis. Additionally, organic molecules (for example, glucose, pharmaceuticals, etc.), macromolecules (for example, proteins, polysaccharides, etc.), living biomaterials (for example, cells, viruses, and bacteria, etc.) have also been reported for practical applications of MIT, as presented in Figure 3 .[ 67 , 68 , 69 ]

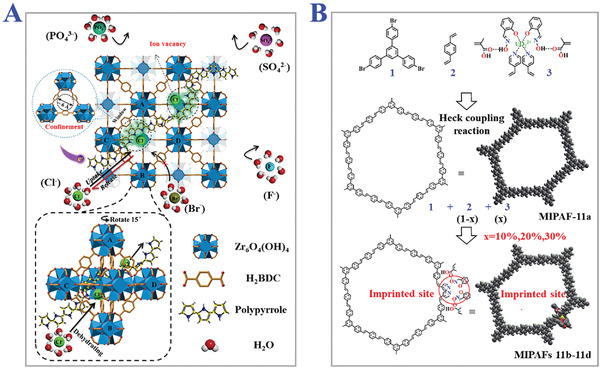

Figure 2.

Constructions of inorganic ions‐functional monomers compounds in different MIPs frameworks. A) Threaded chlorine ions‐imprints in metal‐organic frameworks. Reproduced with permission.[ 61 ] Copyright 2021, Elsevier B.V. B) Uranium ions imprint in porous aromatic frameworks. Reproduced with permission.[ 62 ] Copyright 2018, Wiley‐VCH GmbH.

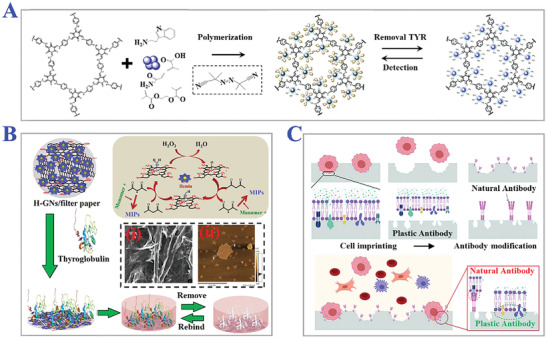

Figure 3.

Different classifications of target templates. A) Organic molecules like tryptamine as target template. Reproduced with permission.[ 67 ] Copyright 2019, Elsevier B.V. B) Biomacromolecule like thyroglobulin (Tg) as template analytes. i) SEM and ii) AFM images of Tg‐imprinted MIPs paper. Reproduced with permission.[ 68 ] Copyright 2019, Elsevier B.V. C) Living materials like circulating tumor cells (CTCs) as templates. Reproduced with permission.[ 69 ] Copyright 2021, Wiley‐VCH GmbH.

Functional monomers are commonly used to form template‐monomer complexes before polymerization by covalent or noncovalent interactions. The monomers usually contain recognition units and polymerization units. The recognition unit provides functional groups to interact and combine with template molecules, while the polymerization unit realizes the construction of a polymeric matrix with the help of cross‐linkers under certain conditions. The template‐monomer complexes have similar structures like antibody‐antigen or enzyme‐substrate substances, and the binding strength directly influences the affinity and selectivity of resultant MIPs. Hence, monomers with more stable and suitable functional groups should be chosen to better match with template molecules. Karim and coworkers have reviewed diverse strategies for the selection of effective functional monomers, including Morphological characteristics, Nuclear Magnetic Resonance (NMR), Fourier Transform Infrared Spectroscopy (FTIR), UV spectroscopic titrations, Computer simulation, Combinatorial screening, and so on.[ 70 , 71 ] Mizaikoff and colleagues have used molecular dynamics simulations and 1H NMR spectroscopy to select suitable monomers for 17β‐estradiol among 18 candidate monomers.[ 72 ] Current functional monomers can be classified into three categories, respectively corresponding to covalent, noncovalent, and semi‐covalent imprinting. Among these monomers, MAA is considered as a universe choice because of the ability to form a stable hydrogen bond with templates. Shimizu et al. studied the influence of MAA dimerization during imprinting process.[ 73 ] They designed MAA‐based MIPs imprinted with nucleobases and ethyl adeine‐9‐acetate (EA9A) severally. It was demonstrated that the large pores distributed in MIPs by high molar fractions of MAA actually could enhance the rebinding of template molecules. Apart from traditional functional monomers, some monomers with special properties and structures have also shown potential in preparing MIPs for more bio/chemical needs. For instance, Zanin's group imprinted cholesterol with β‐cyclodextrins (β‐CDs) as monomers that possessed a hydrophilic exterior and hydrophobic non‐polar cavity in the center.[ 74 ] The amphipathy contributed to forming an inclusion complex with a variety of templates, and the final β‐CD‐based MIPs achieved adsorption capacity to target cholesterol. In particular, a critical point deserving great attention in the synthesis process is the molar ratios between the templates and monomers. Too low molar ratio of monomers will cause few binding sites in the network or even hinder the polymerization, while a too high molar ratio will form excessive non‐specific binding sites and weaken the specific recognition of templates. Hence the suitable ratio should be characterized to satisfy the best reaction conditions.

Cross‐linkers are introduced into the imprinting process to help fit functional monomers around template molecules rigidly and form highly cross‐linked polymeric matrix, taking advantage of that the morphology and mechanical stability of MIPs can be controlled after the removal of templates molecules. Notably, the most important function of cross‐linkers is to stabilize complementary structures of topological shape and chemical functionality in 3D MIPs. Such cross‐linkers mainly include tetraethoxysilane (TEOS), glycidilmethacrylate (GMA), 3‐aminopropyltriethoxysilane (APTES), ethylene glycol dimethacrylate (EGDMA), etc.[ 75 , 76 ] Similar to monomers, the usages of cross‐linkers also influence the properties of resultant MIPs, which means too low usage of cross‐linkers would reduce the mechanical strength to maintain the imprinting structure. Row et al. reported that high cross‐linked ratios could be preferred to access permanently porous materials where the functional groups possessed optimal distribution and spatial configuration for better rebinding of templates.[ 77 ] However, too high usage of cross‐linkers will reduce active binding sites for recognition of targets, due to the excessively compact space where a few sites can be exposed as receptors. Thus, basic cross‐linkers ratio should be optimized previously to ensure the best polymerization. Other assistant compounds such as initiators and porogenic solvents have also been investigated to synthesize MIPs with more special structures or properties. Initiators need to correspond to the type of polymerization including heat, light, chemical, electronic, and so on. A typical initiator is azobisisobutyronitrile (AIBN), which possesses the ability to trigger and control the polymerization of methylmethacrylate towards poly(methylmethacrylate) (PMMA) under both photolysis (UV) and thermolysis.[ 78 , 79 ] Porogenic solvents with relatively low polarity and high solubility phase tend to separate later during polymerization, forming small pores and great surface areas, which provide MIPs with sufficient adsorption and rebinding area. Sellergren and Shea demonstrated that the use of porogen MeCN with poor hydrogen bonding capacity promoted the selectivity and rebinding of L‐PheNHPh.[ 80 ] Remarkably, due to the phenomenon of “solvent memory”, MIPs fabricated within organic porogenic solvents showed poor efficiency in aqueous solvent.

2.2.2. Synthesis Methods

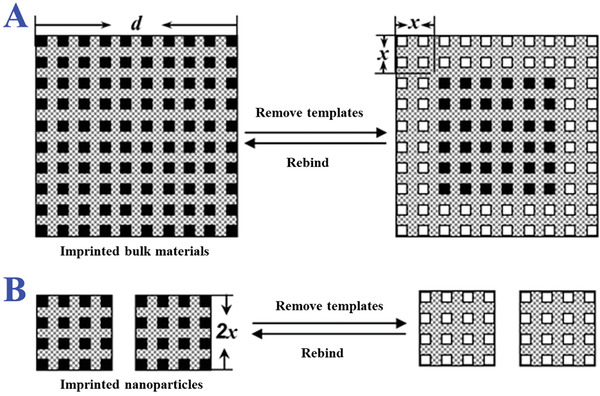

MIPs fabricated by traditional synthesis methods are generally comprised of molecularly imprinted particles and monoliths. The monoliths face complex disposing processes like crushing, sieving, and grounding, which bring great challenges for further applications. Here we mainly review the common synthesis methods of preparing molecularly imprinted particles including bulk polymerization, suspension polymerization, seed polymerization, and precipitation polymerization. Bulk polymerization has attractive advantages of rapidity, simplicity, purity, and easy operation conditions for preparing molecular imprinting particles and this method has become a popular strategy for mass production.[ 81 , 82 ] Baggiani et al. synthesized several carbamate‐imprinted polymers with different functional monomers and porogenic solvents by basic bulk polymerization and demonstrated the enhanced selectivity features.[ 83 ] However, resultant MIPs of this method usually mix with monoliths, and the following crushing and sieving operation inevitably results in irregular particle sizes and loss of rebinding affinity, as illustrated in Figure 4 .[ 84 ] Templates located within x‐nanometers from the surface were assumed to be able to remove in bulk materials with scale d. The effective volume of resultant imprinted sites can be calculated by d 3 − (d − 2x)3. Under normal conditions, x value is small for bulk materials regardless of porogens or solvents. If imprinted materials with the same size were prepared with a nanostructure scale of 2x nm, all templates could be fully removed from polymer matrix and these binding sites were effective for target species. Besides, bulk polymerization can only impart the final MIPs with heterogeneous binding sites, which confines wider applications of MIPs.

Figure 4.

Scheme of the distribution of the binding sites in the A) imprinted bulk materials and B) nanoparticles. The unnecessary heterogeneous binding sites would hinder the specific binding in imprinted bulk materials especially. Reproduced with permission.[ 84 ] Copyright 2007, American Chemical Society.

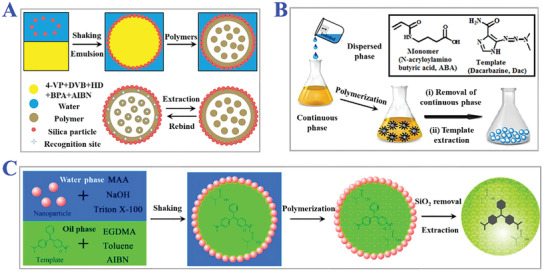

To cover the shortcomings of bulk polymerization, suspension polymerization has been chosen as an alternative with the advantages of reproducible resultants, high yields, monodispersity, and regular microspheres, as presented in Figure 5 .[ 85 , 86 , 87 ] Suspension polymerization provides liquid continuous phase to suspend the droplet of pre‐polymerization mixtures, namely oil in water (O/W) droplets and water in oil (W/O) droplets, which contain template molecules, functional monomers, cross‐linkers, and initiators. To ensure the stability of droplets, stabilizers or surfactants are added in aqueous and oil phase to reduce surface tension between the liquid interface. The sizes of droplets differ on a large scale according to the different reaction conditions, which could be disturbed by the dispersing medium. Ersoz and coworkers proposed MIPs of L‐histidine (L‐His) for high‐performance liquid chromatography (HPLC) stationary phases based on emulsion suspension polymerization.[ 88 ] The droplets comprised of N‐methacryloyl‐L‐His‐copper(II)‐L‐His, EGDMA, and crosslinkers were suspended in water. The resultant L‐His imprinted polymers were demonstrated suitable for biochromatography applications. Water, commonly used as a continuous phase, tends to hinder hydrophilic and electrostatic interactions between templates and monomers, which limits the suspension polymerization application in noncovalent imprinting. Some other continuous phases like liquid perfluorocarbon and mineral oil have been developed to avoid multi‐step swelling process caused by water.[ 89 , 90 ] Such mediums possess stable chemical inertness, which are immiscible with varieties of organic solvents and MIP reagents. On the contrary, porogens including chloroform, dichloromethane, and toluene are both miscible with the above mediums to form porous structures well during polymerization. Mosbach et al. employed acrylate perfluorocarbons as a continuous phase to suspend emulsions of noncovalent imprinting mixtures with the help of surface‐active poly‐(oxyethylene) containing fluorinated units and ester groups.[ 91 ] The resultant tert‐butoxycarbonyl‐L‐phenylalanine (Boc‐L‐Phe) imprinted polymer beads gave low back pressure and rapid diffusion, giving good separation at high flow rates of HPLC tests. However, special fluorinated surfactants are necessary for stable suspension of pre‐polymerization emulsions in different mediums, which limits the practicality of this method.

Figure 5.

Examples of suspension polymerization. A) The fabrication procedure of MIPs microrattles bearing multicore constructions induced by suspension polymerization. Reproduced with permission.[ 85 ] Copyright 2017, Elsevier B.V. B) The synthesis of MIPs nanospheres for dacarbazine via inverse suspension polymerization method. Reproduced with permission.[ 86 ] Copyright 2017, Elsevier B.V. C) Malachite green‐imprinted MIPs microspheres on the basis of pickering emulsion droplets. Reproduced under a Creative Commons (CC‐BY) license.[ 87 ] Copyright 2017, The authors. Licensee MDPI, Basel, Switzerland.

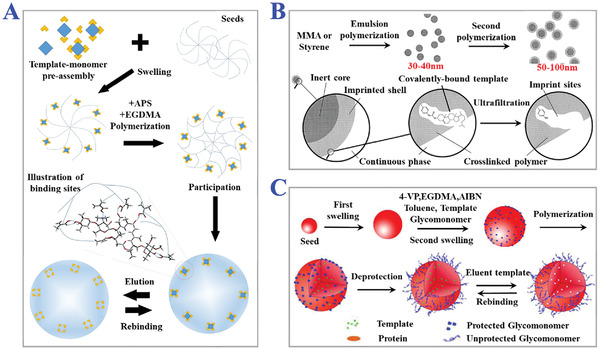

Seed polymerization is also named as a multi‐step swelling method to produce comparatively monodispersed MIP beads. During typical seed polymerization, seed particles with uniform sizes are chosen as templates which are swollen afterwards by emulsion droplets with activating solvent and prepolymerization mixtures. The swelling processes are terminated by the following polymerization to eventually form desired monodispersed particles. We enumerated several practical applications of seed polymerization in Figure 6 .[ 92 , 93 , 94 ] It was worth noting that the surface of resultant MIPs could be easily modified in situ based on seed polymerization by addition and dispersion method. The addition method meant adding polar monomers like glycerol dimethacrylate (GDMA) and glycerol monomethacrylate (GMMA) after the initiation step to modify the outer surface and macropores (>50 nm). The dispersion method meant dispersing MIPs in GDMA and GMMA mixture solution to modify the inner micropores (1–50 nm). More importantly, these two methods will not influence the structures and morphology of micropores (<1 nm). Sanbe and colleagues designed restricted access media‐imprinted MIPs (RAM‐MIP) which were modified with a hydrophilic external layer by directly adding 1:1 mixture of GDMA and GMMA to MIPs.[ 95 ] The RAM‐MIP showed excellent recognition of propranolol (PRP) and other β‐blockers due to the critical hydrophilic modification. Whereas, the multi‐step process is greatly tedious and time‐consuming including the growth of seed particles, swelling process, and modification procedure. Besides, the aqueous phase will interfere with imprinting mixtures, influence the interactions between templates and monomers, and thus lead to low selectivity and affinity finally.

Figure 6.

The applications of seed polymerization. A) The scheme of seeds‐assisting polymerization of micron‐sized MIPs particles for purification of tylosin form broth. Reproduced with permission.[ 92 ] Copyright 2020, Elsevier Ltd. B) The process of two‐stage seed polymerization for fabrication of submicron MIPs particles with cholesterol‐imprinted shells. Reproduced with permission.[ 93 ] Copyright 2000, Wiley‐VCH. C) Modifying uniform‐sized glycol‐MIPs with surface hydrophilic sugar moiety for detection of phenobarbital imprints via two‐step swelling seed polymerization. Reproduced with permission.[ 94 ] Copyright 2011, Elsevier Ltd.

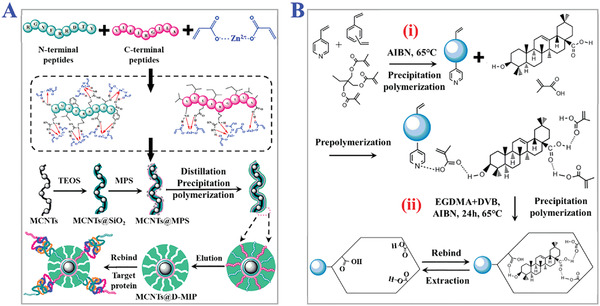

Precipitation polymerization is another promising polymerization method to produce MIP particles with more spherical surfaces and uniform sizes.[ 96 , 97 , 98 ] In the precipitation system, the growing polymer chains are insoluble with monomers, or monomer and initiators are soluble with the medium while the polymer chains are not soluble, both of which eventually lead to the precipitation of formed polymer out of the reaction system. Then the polymers undergo washing and centrifugation operations to obtain resultant MIPs. Compared to the simple operations of traditional bulk polymerization, complex solvents environment and demanding reaction conditions are necessary for precipitation polymerization. Some other applications of precipitation polymerization have been generalized in Figure 7 .[ 99 , 100 ] In general, the diameters of MIP beads prepared by precipitation polymerization range from one or a few hundred nanometers. Zourob and his colleagues designed a spiral micro‐reactor for preparing uniform MIP beads in mineral oil with no expensive reagents or equipment, which broadened the applications of precipitation polymerization.[ 101 ] By changing the reaction conditions like polymerization temperature and stirring speed, the MIP size could be controlled from nanoparticles to microbeads, and the ideal recognition affinity could be remained. Ye and coworkers investigated the precise control of particle sizes by varying the ratio of two different cross‐linkers (DVB and TRIM).[ 102 ] These advantages impart precipitation polymerization with great potential for wider applications of solid phase extraction (SPE). Marcé et al. synthesized two different MIPs microspheres with well‐fined particle sizes and distribution.[ 103 ] They described the subsequent use in MISPE protocols for selective extraction of carbamazepine and oxcarbazepine from human urine.

Figure 7.

The applications of precipitation polymerization. A) The synthesis process of dual‐templates MIPs coated on magnetic carbon nanotubes via metal‐chelation and distillation‐precipitation polymerization for recognition of PSA. Reproduced with permission.[ 99 ] Copyright 2018, Elsevier B.V. B) Schematic illustration of two‐step precipitation polymerization procedure. i) The first step is to form copolymeric microsphere, and ii) the second step is to modify such microspheres with oleanolic acid‐imprinted MIPs layer. Reproduced with permission.[ 100 ] Copyright 2018, Wiley‐VCH.

2.3. Characterization Methods

Many analytical techniques have been used to characterize the molecular imprinting processes and reveal the particular properties of MIPs. The surface and inner morphologies of MIPs are commonly investigated by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Atomic force microscopy (AFM) and fluorescence microscopy have also played important roles in morphology characterization. In addition, Brunauer–Emmett–Teller (BET) analysis can measure the specific surface areas and pore sizes of the MIPs via nitrogen adsorption experiments.[ 104 , 105 , 106 ] Apart from the basic morphography characterization, increasing studies about the concrete materials, chemical elements, and interaction mechanisms have been implying new trends in characterization methods. X‐ray photoelectron spectroscopy (XPS) is a prominent method to study the chemical composition and structure of MIP materials. Huck et al. carried out XPS analysis including depth profiling and electronic mapping of N‐isopropylacrylamide (NIPAM) patterned polymer brushes which were synthesized by surface‐initiated polymerization.[ 107 ] Besides, FTIR spectra, UV–vis spectroscopy, and NMR are considered as useful tools to characterize certain functional groups and interactions between templates and monomers.[ 108 , 109 ] The conformational information of MIPs always relates to the functions and properties, and even slight changes can cause the loss of desired functions or the influence of some properties. Hence, quartz crystal microbalance (QCM), ellipsometry, and scanning probe microscopy have been proposed to dynamically monitor conformational changes of MIPs. Li and coworkers fabricated PNIPAM‐co‐MBAA by radical polymerization, and they used scanning probe microscopy to investigate the behavior of polymer chains in the function of temperature.[ 110 ] Some new methods have been developed to obtain information about some special properties of MIPs. For example, thermogravimetric analysis (TGA) is used to examine thermal stability, and vibrating sample magnetometer (VSM) is chosen to analyze magnetic properties of magnetic MIPs. Electrochemical methods like cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) are also applied to characterize charge distribution, resistance, and capacitance of MIPs, which contribute to studying the swelling and collapse process caused by ions exchange and ionic strength changes.[ 111 , 112 , 113 ]

3. Classifies of Molecular Imprinting Technologies (MITs)

The traditional polymerization methods have been thoroughly investigated and widely used in molecular imprinting processes. The superiority of resultant MIPs has been exploited fully in certain fields. However, the MIPs fabricated by these typical MITs still face many issues such as difficulty in finding suitable groups of templates and monomers, weak recognition and rebinding capacity, incompatibility in different liquid media, and uncontrollable stability, which severely limited the wider applications of MIPs.[ 114 , 115 ] Researchers have placed great interest in the improvement of MIPs. As a result, some novel MITs have been developed to cope with the dilemma based on the traditional molecular imprinting procedures. The classifications, innovation advantages, and applications of these smart MITs will be introduced in this section.

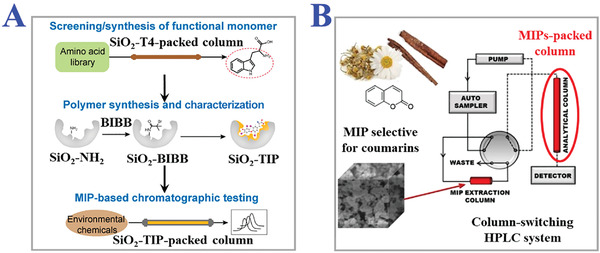

3.1. Surface Imprinting Technology

In brief, surface imprinting technology means fabricating MIPs by immobilizing template molecules on the surface of supporting substrates or materials, and then the polymerization processes happen subsequently on the basis of the above surface. During typical MITs procedure, the complete removal of templates is quite difficult due to the high cross‐linking structures of polymers, leading to low recognition capability. Fortunately, this problem can be well solved by introducing polymerization on the surface, which builds more effective recognition sites to realize fast mass transfer, good synthesis reproducibility, and template‐monomer binding kinetics. In particular, surface imprinting technology is considered as promising MIT for imprinting macromolecules like pharmaceuticals, proteins, cells, and viruses because their large sizes could prohibit dissociation and rebinding, as shown in Figure 8 .[ 116 , 117 , 118 , 119 , 120 ] Zhang et al. employed surface imprinting technique to fabricate hierarchical proteins imprinted polymers by grafting porcine serum albumin (PSA) on the surface of silica microspheres.[ 121 ] They realized selective depletion of human serum albumin (HSA) from human serum and explored the applications of MIPs for proteome study. Many spherical particles have been chosen as a suitable supporting substrate for surface imprinting technology, such as magnetic nanoparticles (MNPs), polystyrene beads, quantum dots (QDs), and silica gel.[ 122 , 123 ] For example, Fe3O4 MNPs are potential substrates with magnetic properties and direct purification for sample separation. The MIP‐coated Fe3O4 MNPs synthesis procedures usually contain three consecutive steps: fabrication of Fe3O4 MNPs; modification of hydrophobic MNPs surface with poly(vinyl alcohol), TEOS or ethylene glycol; surface imprinting of MNPs. Chen and coworkers designed MIP‐coated Fe3O4 MNPs for recognition and separation of estrone by semi‐covalent imprinting method in 2009.[ 124 ] They prepared Fe3O4 MNPs by coprecipitation method and used TEOS to form silica shells on MNPs surface by sol‐gel process. The Fe3O4@SiO2 MNPs were then imprinted with estrone by simple thermal reaction to obtain the desired MIPs. The final estrone‐imprinted polymer coating Fe3O4 magnetic hybrid nanoparticles had much higher specific recognition and saturation magnetization. However, there still exist some challenges for surface imprinting technology.[ 125 , 126 ] In general, the efficiency and stability of copolymerization mainly depend on the reactive sites and compatibility of MIPs reagents on the surface of supporting substrates. The surface areas of supporting substrates for immobilization of templates inevitably limit the amount of resultant molecular imprints in MIPs for recognition and rebinding. Besides, the selection of monomers with multiply functional groups and good compatibility is critical for the successful preparation of MIP layer on the surface.

Figure 8.

The fundamental principle and practical applications of surface imprinting technology. A) The procedure of typical surface imprinting technology. B) Spatial sizes distribution of targets templates of surface imprinting. A,B) Reproduced under the terms of the Creative Commons CC‐BY license.[ 116 ] Copyright 2020, The authors. Licensee MDPI, Basel, Switzerland. C) Fabrication scheme of thermo‐sensitive MIPs with surface imprints of BSA. Reproduced with permission.[ 117 ] Copyright 2019, Elsevier B.V. D) Preparation process of i) virus‐sensitive MIPs hydrogel and ii) cell‐imprinted MIPs for bacteria cells. Reproduced with permission.[ 119 ] Copyright 2014, Wiley‐VCH. E) Schemes of three types of i) direct and ii) indirect micro‐contact surface imprinting procedure of target microorganism. Reproduced with permission.[ 120 ] Copyright 2018, Elsevier B.V.

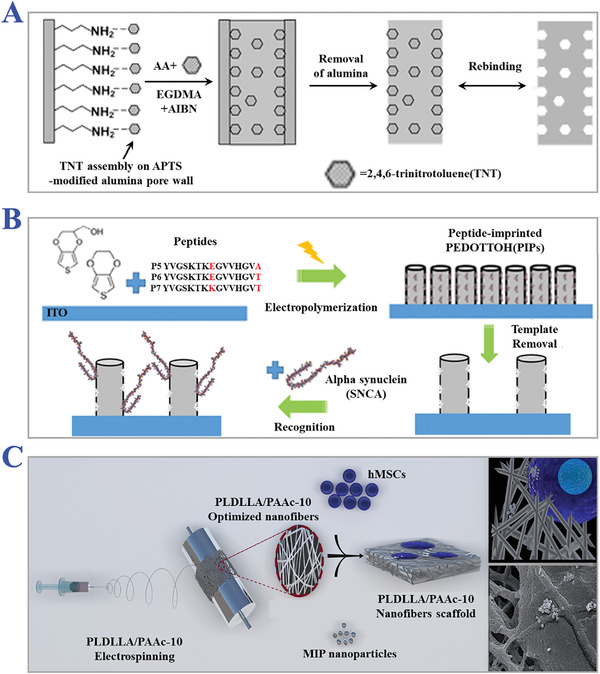

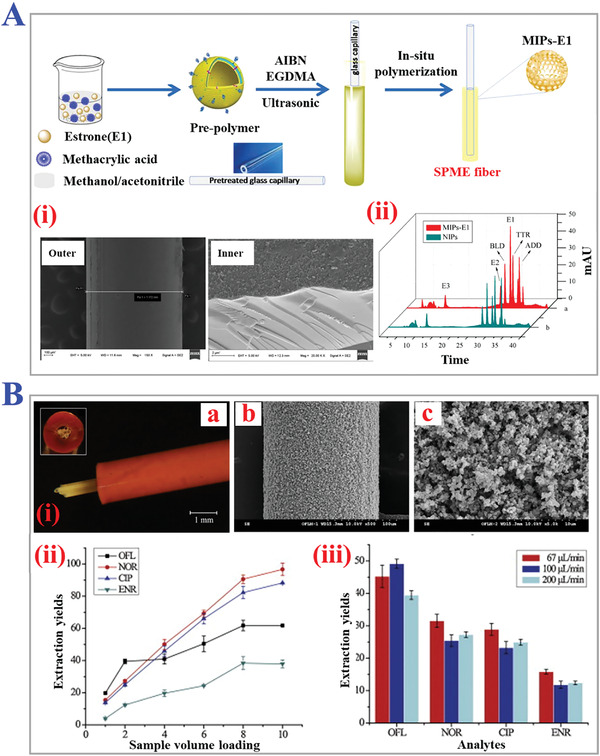

3.2. Nanoimprinting Technology

Nanoimprinting technology is a revolutionary method combining MIT with nanotechnology and nanomaterials, which fabricated MIP with nanostructures (NMIPs) like nanoparticles, fibers, nanowires, nanotubes, hybrid nanocomposites, etc., as presented in Figure 9 .[ 127 , 128 , 129 , 130 ] Different from bulk MIPs, NMIPs possess higher surface‐to‐volume ratio, thus providing easier‐accessed imprinted cavities for recognition and binding kinetics of templates. Meanwhile, almost all binding sites of NMIPs show similar affinity and specific selection to target templates. Wang et al. proposed a surface monomer‐directing strategy for highly dense imprinting of 2,4,6‐trinitrotoluene (TNT) at the surface of silica nanoparticles based on molecular nanoimprinting technology.[ 84 ] They built models and analyzed the distribution of effective binding sites in bulk polymers and NMIPs respectively. It was demonstrated that nanostructured imprinted materials improved the binding capacity, kinetics, and site accessibility. In addition, MIP nanoparticles could keep stable in a certain solution, endowing them with precise manufacturing control ability, which showed a wide application prospect in drug delivery assay, capillary electrophoresis (CE), sensors, sample separation, and so on. Ciardelli and his colleagues fabricated imprinted P(MMA‐co‐MAA) nanospheres for biomedical applications such as drug release via precipitation from diluted monomer solutions.[ 131 ] These acrylic polymeric nanospheres showed a comparable superiority in stable release and recognition of molecules of clinical interest. However, the fabrication procedures of NMIPs are inconvenient due to the demand for precise shape, homogeneous size, degree of crosslinking, and stable template‐monomer interactions. Choosing suitable protocols is very important for the production of NMIPs with excellent performances. Commonly employed synthetic strategies mainly involve precipitation polymerization, mini‐/micro‐emulsion polymerization, thiol ligand capping method, atom transfer radical polymerization (ATRP), reversible addition‐fragmentation chain transfer polymerization (RAFT), etc.[ 132 , 133 , 134 ] These methods are demonstrated efficient to create NMIPs as substitute enzyme mimics and artificial antibodies. Sellergren and coworkers designed thin films composite beads of L‐phenylalanine anilide‐NMIPs by RAFT polymerization.[ 135 ] They used 2‐phenylprop‐2‐yl‐dithiobenzoate as a chain transfer agent and the RAFT mediation allowed efficient control of the grafting process while prohibiting the formation of visible gel. The resultant NMIPs were able to act as chiral stationary phases with high selectivity, which could be applied for the separation of template racemates and structurally analogous racemates.

Figure 9.

The applications of nanoimprinting technology. A) Scheme of the assembly of TNT on alumina pore walls modified with APTS, and the subsequent preparation of TNT‐imprinted nanowires with numerous imprinted sites. Reproduced with permission.[ 127 ] Copyright 2006, American Chemical Society. B) Preparation of peptide‐imprinted poly(hydroxy 3,4‐ethylenedioxythiophene)‐coated nanotubes for detection of α synuclein in human brain organoids. Reproduced with permission.[ 128 ] Copyright 2020, American Chemical Society. C) Scheme of fabrication of MIPs nanofibrous (poly(L‐lactide‐co‐D,L‐lactide)/poly(acrylic acid)) (PLDLLA/PAA) scaffolds integrated with dexamethasone‐loaded molecularly imprinted nanoparticles. Reproduced with permission.[ 129 ] Copyright 2020, Elsevier B.V.

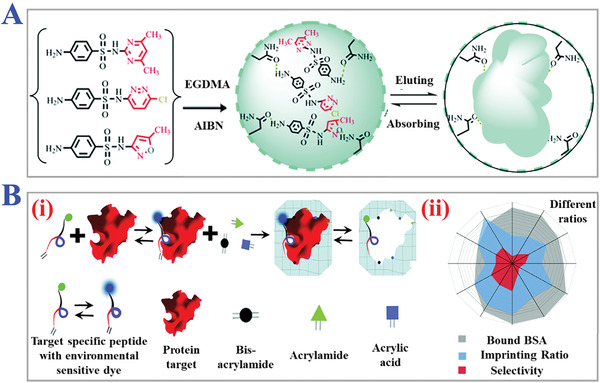

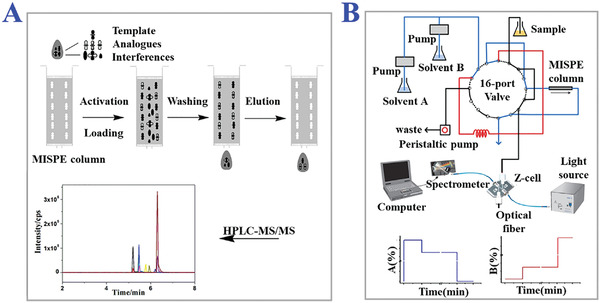

3.3. Multi‐Template Imprinting Technology

During traditional MIT procedures, single kind of template molecule is selected for the preparation of MIPs in most cases. In order to realize simultaneous recognition and rebinding of several targets, a feasible strategy is to prepare one MIP compound for each corresponding target template, which ensures the recognition specificity. However, different templates require individual polymerization protocols and reagents, so this strategy is relatively high‐cost and complex. Multi‐template imprinting technology, integrating binding sites of multiple templates in a single MIP, has been reported as a compositive strategy to widen the applications of MIPs, as presented in Figure 10A.[ 136 ] The concept of double‐template imprinting was first proposed by Screenivasan's group in 1999 to seek synthetic polymer with more than one component binding site and a high degree of selectivity to sensor elements.[ 137 ] They addressed 2‐hydroxy ethyl methacrylate (HEMA)‐based MIPs with two model templates namely salicylic acid and hydrocortisone. Through the study of the participation of hydrogen bonding and uptake amounts of templates, the feasibility of imparting multiple recognition sites in a single synthetic polymer was eventually proved. Recently, multiple‐template imprinting MIPs involving three or more templates have been developed. Krupadam et al. fabricated multi‐template MIPs simultaneously imprinted with three p‐type pharmaceutical chemicals (nicotine, epinephrine, and physostigmine) for selective adsorption of multiple targets from water and wastewaters.[ 138 ] The resultant MIP particles were optimized with sizes ranging from 25 to 40 µm, excellent adsorption efficiency in contrast to typical adsorbent like resin XAD and powdered activated carbon (PAC). Chen and coworkers proposed a multi‐template imprinting approach for up to sixteen polycylic aromatic hydrocarbons (PAHs) templates imprinted sol‐gel MIP adsorbent.[ 139 ] The SPE adsorbent was demonstrated to possess high rebinding affinity, detection sensitivity, and satisfactory reusability for the extraction of multiple PAHs for seawater samples. Actually, the selectivity of a single template among compounds of multiple targets would be inevitably weakened in comparison with MIPs imprinted with a single template, because the recognition sites of each template decreased with the increase of remixing multiple binding sites, and thus the final recognition efficiency is integrally comprised of rebinding sites of multiple templates indeed.

Figure 10.

The applications of multi‐reagents imprinting technology. A) Schematic diagram of ultra‐durable, multi‐template MIPs for ultrasensitive monitoring and multicomponent quantification of trace sulfa antibiotics. Reproduced with permission.[ 287 ] Copyright 2021, The Royal Society of Chemistry. B) Synthesis approach of hydro‐MIPs assembled with peptide multi‐functional monomers blocks (acrylamide, AA, and methylene bis‐acrylamide) for detection of protein (i), and the radar plot of the MIP parameters of hydro‐MIPs (ii). Reproduced with permission.[ 140 ] Copyright 2018, Royal Society of Chemistry, Creative Commons Attribution‐NonCommercial 3.0 Unported License.

3.4. Multi‐Functional Monomer Imprinting Technology

As we reviewed above, non‐covalent interactions between template molecules and functional monomers are relatively stable, contributing to rapid dissociating and rebinding during non‐covalent imprinting. These non‐covalent interactions like dipole‐dipole interactions, hydrogen‐bond formation, and electrostatic interactions can be enhanced by aggrandizing multiple interaction sites, which means introducing multiple functional monomers around template molecules. Afterwards, these multiple functional monomers provide different binding functional groups for complementary combination with different action regions or epitopes of template molecules (Figure 10B).[ 140 ] Mosbach's group first demonstrated the possibility of synchronously imprinting with multiple distinct functional monomers for non‐covalent imprinting in 1993.[ 141 ] They designed MIPs comprised of two functional monomers including MAA and 2‐vinlpyridine (2Vpy), which possessed carboxy and pyridinyl functionalities respectively. Such synthetic polymers were evaluated with better recognition capabilities as compared to MIPs with only a single MAA or 2Vpy, which confirmed the superiority of combining multiple functional monomers. Benefitting from the advantages of simultaneous targeting different moieties of template molecules, MIPs with more functionalities have been developed. Athikomrattanakul et al. fabricated MIPs with two complementary functional groups in parallel for thermometric sensor configuration of nitrofurantoin (NFT).[ 142 ] The specific tailor‐made functional monomers complex consisted of first monomer diaminopyridine derivative (BMP) as the receptor for imide residue together with three kinds of (thio)urea‐based derivatives (1‐(4‐vinylphenyl)‐3‐(3,5‐bis(trifluoromethyl)phenyl thiourea, urea) (VTU, VFU) and second monomer 1‐(4‐vinylphenyl)‐3‐(pentafluorophenyl)thiourea (PTU)) to interact with nitro groups of NFT. Apart from some organic template molecules, multi‐functional monomer imprinting technology has also been applied for imprinting ions. For example, Li and coworkers reported novel Pb2+ ion imprinted polymers via synergistic interaction of dual functional monomers for solid‐phase extraction of Pb2+ in water samples.[ 143 ] Two commonly used functional monomers like MAA and 4‐vinyl pyridine (4‐VP) were selected to form coordination complexes with Pb2+ ions. By virtue of the proton abstraction action of 4‐VP for proton acceptor MAA, Pb2+ ions could better bind with carboxyl groups, thus, these robust binding sites contributed to improving adsorption efficiency and selectivity. However, it is not so easy to discover reasonable multiple functional monomers which can interact with one template at different action sites. The synergetic binding sites should avoid mutual interference as far as possible and be able to keep stable under various polymerization reaction conditions or organic solutions. In addition, the explorations of new natural functional monomers or artificial monomer compounds also deserve more attention. And it remains a challenge for the further development of multi‐functional monomer imprinting technology to effectively utilize the collaborative rebinding sites of multifunctional monomers to enhance the final imprinting factor, binding affinity, recognition capability, and maximum rebinding efficiency.

3.5. Stimuli‐Responsive MITs

Stimuli‐responsiveness, as known as environmental responsiveness or intelligent responsiveness, refers to the capability of responding to several external stimuli with remarkable changes in properties like volume sizes (swelling or shrinking), topological shape, molecular chain structure, elasticity, solubility and structure colors, etc.[ 144 , 145 ] Commonly external stimuli include temperature, pH value, electric field, magnetic field, photonic irradiation, and so on. Generally, stimuli‐responsive MITs impart MIPs materials with these intriguing responsive properties, resulting in precisely controlled recognition and rebinding process of target template molecules. Although the external stimuli will inevitably lead to loss of memory of template imprints to some extent, the imprinting sites can still remain stable in the 3D structures of MIPs, which ensures the specific selectivity with a slight sacrifice of efficiency. Therefore, stimuli‐responsive MITs as new smart techniques have been widely applied for drug delivery system, separation science, sensor technology, and other biomedical fields.[ 146 , 147 ] In this section, we will review the mechanisms, advantages, disadvantages, and practical examples of several following stimuli‐responsive MITs.

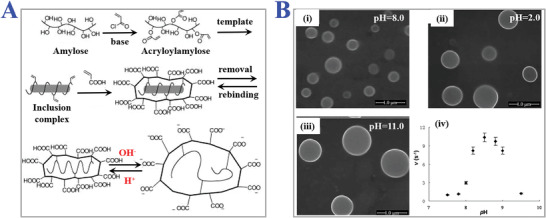

3.5.1. pH‐Responsive

The pH‐responsive functionality of MIPs mainly relies on the pH‐sensitive functional groups, namely cationic groups (pyridine groups, amino groups, imidazole, dibuthylamine groups, methacrylatge groups, etc.) and anionic groups (carboxyl groups, etc.).[ 148 ] When pH value of the external environment changed, these functional groups would undergo ionization and protonation process, destroying the cross‐linking degrees or stable interactions like hydrogen bonds between polymers’ skeletons, and eventually leading to the volume change of MIPs, as illustrated in Figure 11 .[ 149 , 150 , 151 , 152 ] Generally, under low pH condition, cationic groups tend to become protonated, and then the resultant increasing internal charge repulsions cause the swelling volume of MIPs (acid‐swelling). While under high pH conditions, with the decreasing of charge repulsions, cationic groups usually become less ionized, and other binding interactions within polymers themselves become tighter, finally causing the shrinking volume of MIPs (alkali‐shrinking). On the contrary, anionic groups will cause volume shrinking (acid‐shrinking) under low pH conditions, while causing volume swelling (alkali‐swelling) under high pH conditions.[ 151 ] During the swelling or shrinking process, the spatial cavities of template imprints or the pore sizes of MIPs can be adjusted, making it possible to externally control the target rebinding and recognition process. Zhao and coworkers designed an enzyme mimic of horseradish peroxidase catalytic system, which combined pH‐responsive hydrogel with molecularly imprinted catalyst, as presented in Figure 11B.[ 152 ] They fabricated tetrapolymer of NIPAM, 4‐VP, hemin, and acrylamide (AAm) to copolymerize with homovanillic acid (HVA) as template molecules based on precipitation polymerization. It was confirmed that this pH‐responsive MIP system possessed remarkable sensitivity under both acidic and alkaline conditions with obvious variations in volumes. The mechanism of swelling or shrinking was mainly attributed to the process of deprotonation and negative charge repulsion. When the repulsion overcame attractive forces, the MIPs could swell free under acidic conditions. This novel study indicated the feasibility of integrating stimuli‐sensitive monomers into MIP systems and explored the application of artificial enzymes or catalytic compounds.

Figure 11.

The applications of pH‐responsive MIPs. A) Synthesis scheme of amylose‐based MIPs and their pH‐responsive structural change. Helical inclusion‐complex formation between acryloyl‐amylose and monomers with ionizable units could be reversibly tuned depending on pH of solution. Reproduced with permission.[ 149 ] Copyright 2003, Wiley‐VCH. B) SEM images of pH‐sensitive water‐soluble imprinted hydrogels under different pH value: i) 8.0, ii) 2.0, iii) and 11.0. iv) The catalytic efficiency of imprinted hydrogels in a buffer solution of different pH conditions. Reproduced with permission.[ 152 ] Copyright 2010, Wiley‐VCH.

Different from the component ratios during traditional MIPs procedures, the ratio of cross‐linkers to functional monomers is usually relatively lower to fabricate loose cross‐linked structures for better pH sensitivity, because highly cross‐linked structures of MIPs will hinder the slight changes caused by external pH conditions. Gong and his colleagues reported pH‐sensitive MIP nanospheres/hydrogel composites with controllable release capability of dexamethasone‐21 phosphate disodium (DXP) as a potential coating for better biocompatibility of implantable glucose biosensors.[ 153 ] They set the molar ratio of functional monomers (2‐hydroxyethyl methacrylate (HEMA) and 2‐(diethylamino) ethyl methacrylate (DEAEMA)) to cross‐linkers (EGDMA) as 1:20. The final spatial structure was actually lowly cross‐linked, and the resultant MIPs showed higher loading capacity with pH‐sensitive release in the range of pH from 6.0–7.4, which endowed this new pH‐sensitive system with potentials for prolonging the lifetime of in vivo sensors. As mentioned above, a common synthesis route for fabricating pH‐responsive MIPs is to introduce pH‐sensitive monomers as functional monomers to interact with templates. Tao et al. proposed a novel molecular imprinting strategy for the preparation of pH‐responsive MIPs.[ 149 ] They used amylose modified with acryloyl groups as host matrix, bisphenol A (BPA) as template molecule, and acrylic acid (AA) as functional monomers. Then the pH‐responsive MIPs were synthesized by typical radical polymerization in aqueous solution. They demonstrated that when the templates were copolymerized with functional monomers of ionizable units like carboxyl groups, the configurational structures of imprinted sites were reversibly changeable and well responsive to the pH value of the target solution. The resultant pH‐responsive MIPs system was expandable to other hydrophobic molecules as well as some metal ions due to the combination ability of abundant carboxylate groups.

3.5.2. Thermo‐Responsive

Similar to pH‐responsive MIPs, the thermo‐responsive functionality is also based on the integration of thermo‐sensitive functional monomers during copolymerization processes. The thermo‐sensitive functional monomers are mainly comprised of amphipathic components like hydrophilic and hydrophobic groups. Such amphipathic components can change their spatial structures in response to the change in environmental temperature according to the principles of chemical thermodynamics and kinetics. Under different temperature conditions, these thermo‐sensitive monomers tend to form the most stable 3D conformation and reach kinetic equilibrium, which provides potential for controlled manipulation of combination between functional monomers and template molecules, such as easier removal of templates, enhanced mass transfer, and higher rebinding percentage. Low‐critical solution temperature (LCST) refers to the boundary temperature which causes the structural changes of thermo‐sensitive monomers.[ 154 , 155 ] At a temperature lower than LCST, hydrogen bonds between polymers’ skeletons act as the main intermolecular forces and determine the structural states of polymers. When the temperature was higher than LCST, these hydrogen bonds would be destroyed, and the increased hydrophobic interactions eventually caused the shrinkage of MIPs networks, as schemed in Figure 12A.[ 156 ] NIPAM, a commonly used thermo‐sensitive polymer, possesses an LCST at approximately 32 °C with a unique phase transformation capability depending on environmental temperature (Figure 12B).[ 157 ] It could be anticipated that the weakened hydrogen bonds and increased hydrophobic interactions between the isopropyl groups of NIPAM could cause precipitation from aqueous solution at a temperature above LCST. Benefitting from the responsive abilities to thermal changes, NIPAM has been widely used as functional monomers for imprinting organic molecules, macromolecules, metal ions, biomolecules, etc. For instance, Zhao et al. proposed a thermo‐sensitive protein MIPs hydrogel for selective recognition of bovine serum albumin (BSA).[ 158 ] They used N‐(3‐(Dimethylamino)propyl)‐methacrylamide (DMAPMA) as the main functional monomers to self‐assemble onto template proteins by electrostatic interaction, and NIPAM was chosen as an assistant functional monomer to impart polymers with thermo sensitivities. The volume of the resultant MIPs could be adjusted by thermo stimuli to realize the controllable recognition of target BSA proteins with higher affinity and specificity. Apart from introducing thermo‐sensitive monomers to bind with template molecules, there also exists another strategy to endow MIPs with thermo sensitivity, that is to modify typically fabricated MIPs with one thermo‐sensitive layer. Zhang and coworkers designed an efficient approach to obtain water‐compatible and thermo‐sensitive MIPs with facile surface‐grafting polymer brushes via RAFT polymerization.[ 159 ] The NIPAM brushes were facilely grafted on MIP microspheres to improve dispersion stability in water and surface hydrophilicity. When the temperature exceeded 45 °C, the NIPAM brushes would collapse onto the MIP microspheres, decreasing the exposure of binding sites and hindering the rebinding efficiency, which realized the temperature gates for controlling target recognition. This route avoids adding other complicated functional monomers or polymerization methods, and enables molecular imprinting processes more flexible. Furthermore, such approaches would explore the applications of these intelligent thermo‐responsive MIPs for bioanalytical sensors, controllable drug delivery, molecular gating, and so on (Figure 12C).[ 160 ]

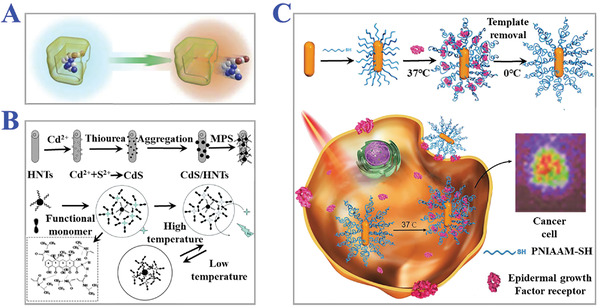

Figure 12.

The applications of thermo‐responsive MIPs. A) The principle of thermo‐responsive release process of template molecules. Reproduced with permission.[ 156 ] Copyright 2015, Elsevier Inc. B) Fabrication of CdS/halloysite nanotubes modified with thermal‐responsive MIPs layers as core‐shell photocatalysts for selective photo‐degradation of target tetracycline. Reproduced with permission.[ 157 ] Copyright 2013, Royal Society of Chemistry. C) Thermal‐stimuli responsive MIPs nanoprobes for intracellular Raman imaging and visualization. The gold nanorods coated with MIPs layer could combine epidermal growth factor receptor (EGFR) under the temperature variation from 0 to 37 °C. Reproduced with permission.[ 160 ] Copyright 2018, Wiley‐VCH.

3.5.3. Photo‐Responsive

Photonic irradiation is another conventional external stimulus including ultraviolet light, visible light, near‐infrared and infrared light, etc. Generally, under irradiation of such photonic stimulus, the isomerization of molecular chains or dissociation of functional groups would cause the changes in chemical or physical properties of polymers, which can be classified into four categories, including shift of hydrophilic‐hydrophobic balance, break of polymer junction, degradation of molecular chains and reversible cross‐linking.[ 161 , 162 , 163 ] To prepare photo‐responsive MIPs, a feasible strategy is to introduce photo‐sensitive functional monomers which are comprised of three functional components involving photo‐sensitive segment, recognition segment, and polymerizable segment. Owing to their reversible photoisomerization features, azobenzene and its derivatives have been commonly applied in the synthesis of photo‐responsive MIPs. When exposed under ultraviolet light, the molecular conformation of azobenzene changed from stable trans‐isomer to cis‐isomer, with the reverse transformation to the original state occurring by irradiation of visible light. During the above processes, the recognition sites of MIPs tend to undergo changes in dipole moments and configuration geometry. Taking advantage of this, the controllable release of template molecules and uptake of targets can be achieved based on the reversible changes of internal imprints cavities (size, shapes, charges, chemical functionality) of MIPs through easy switches of ultraviolet light and visible light. Thus, integrating azobenzene and its derivatives into typically used functional monomers is a promising fabrication route for photo‐responsive MIPs (Figure 13 ).[ 164 , 165 , 166 ] Lam et al. designed water‐soluble 4‐[(4‐methacryloyloxy) phenylazo] benzenesulfonic acid (MAPASA) as azobenzene‐like functional monomers for the preparation of photo‐responsive MIP hydrogels to function in biocompatible aqueous media.[ 167 ] Due to the reversible trans‐cis isomerization of MAPASA, such MIP hydrogels were demonstrated with high substrate affinity and the capacity to realize photo‐regulated release and uptake of paracetamol (N‐(4‐hydroxyphenyl) acetamide). The excellent properties imparted this photo‐responsive MIP hydrogel material with great potential for pharmaceutical separation and drug delivery systems.

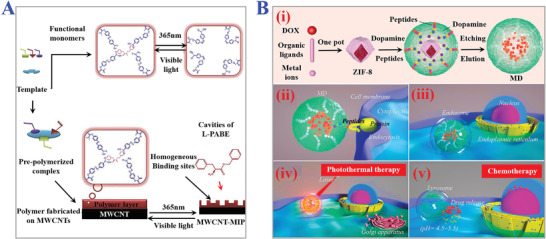

Figure 13.

The applications of photo‐responsive MIPs. A) Synthesis process of multiwalled carbon nanotubes‐based MIPs for enantioselective recognition of L‐phenylalanine benzyl ester (L‐PABE) via integrating photo‐responsive functional monomer. Reproduced with permission.[ 165 ] Copyright 2019, Elsevier Ltd. B) Preparation procedure of MIPs nanoparticles as photo‐thermal drug assays (i). The specific recognition and endocytosis process of capsule‐like MIPs nanoparticles for anti‐cancer therapy (ii–v). Reproduced with permission.[ 166 ] Copyright 2021, Elsevier B.V.

Sol‐gel polymerization process has been considered an effective method for fabricating photo‐responsive MIPs. The resultant sol‐gel MIPs possess the advantages of thorough removal of template, stability under extreme conditions (strong acid, strong base, combustion, etc.), and the convenience of adjusting porosity and thickness.[ 168 , 169 ] These above advantages made photo‐responsive sol‐gel MIPs ideal candidates for more complicated applications. For example, Zhong and his coworkers developed organic‐inorganic MIP hybrid azobenzene materials through sol‐gel process for photoinduced recognition of 2,4‐dichlorophenoxyacetic acid.[ 170 ] Similarly, they synthesized 4‐((4‐(3‐(trimethoxysilyl) propoxy) phenyl) diazenyl) phenyl 2‐(2,4‐dichlorophenoxy) acetate as azobenzene‐containing monomers according to Williamson etherification. The sol‐gel procedure contributed to building the silicate frameworks and unoccupied cavities of MIPs with organic moieties integrated. The resultant photo‐responsive MIPs were endowed with photo‐switchable and selectivity of target molecules upon irradiation at 360 nm and 440 nm, which could be applied for smart chemical sensors. However, the practical applications of photo‐responsive MIPs still faced challenges. The relatively slow transformation time of trans‐cis isomerization of photo‐sensitive functional monomers restricted the development of MIPs for rapid analysis and dynamic sensing. Besides, the irradiation conditions like limited wavelength and intensity could also cause inevitable and metamorphic damages to some targets or substrates. Therefore, more research emphasis should be put on synthesizing suitable photo‐sensitive functional monomers for MIPs to meet the flexible acquirements of diverse applications.

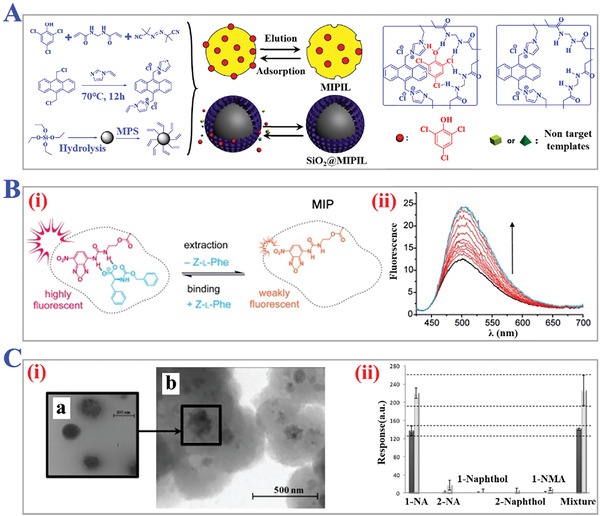

3.5.4. Magnetic‐Responsive

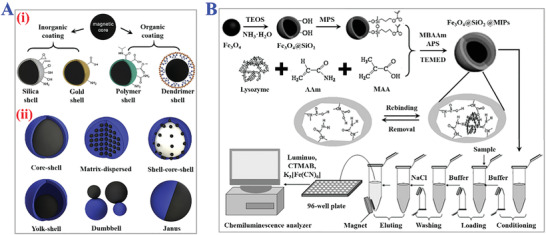

A typical strategy for the fabrication of magnetic‐responsive MIPs is to adopt magnetic materials as supporting substrates or functional components into polymers (Figure 14A).[ 171 ] Benefitting from the excellent magnetic responsiveness and easy operation of performing magnetic control, these magnetic components can be directionally removed from the MIPs upon external magnetic or electric fields. Such advantage provides feasible routes for efficient removal of template molecules during the fabrication step and effective purification of resultant polymers from compounds or medium solution, which avoids complex centrifugation or filtration processes and ensures the purity of polymers with stable recognition specificity. Hence, magnetic‐responsive MIPs have been widely applied in sample preparation, magnetic‐basic solid‐phase separation, controllable drug delivery, enzyme immobilization, cell sorting, and so on (Figure 14B).[ 172 ] Mosbach first proposed the concept of magnetic MIP beads for drug radioligand binding assay in 1998.[ 173 ] The superparamagnetic molecularly imprinted copolymer beads comprising of MAA and 1,1,1‐trimethylolpropane trimethacrylate (TRIM) were confirmed with capacity of easy separation from solution by the inclusion of magnetic iron oxide and high binding affinity to target (S)‐propranolol. With the development of magnetic materials for MIPs, Fe3O4 nanoparticles have been considered as a commonly used affording substrate, which is conventionally synthesized by coprecipitation method or solvothermal reduction method, followed by the modification with functional groups on their surfaces. Then several polymerization methods like surface imprinting, precipitation imprinting, or grafting methods are widely chosen to prepare magnetic‐responsive MIPs with spherical shape, particle, or core‐shell structure. For instance, Mei and his coworkers designed magnetic molecularly imprinted Fe3O4@SiO2 nanoparticles for specific recognition of lysozyme.[ 172 ] They transformed the surface of Fe3O4 nanoparticles to silica shells with tetraethyl orthosilicate (TEOS) by sol‐gel process, and then the γ‐methacryloxypropyltrimethoxysilane (MPS) was used to attach the surface with abundant double bond for growth of MIP film. The modification of functional groups aimed at enhancing the following covalent attachment of specific ligands including template lysozyme, AAm, and MAA. It was demonstrated that sufficient magnetic components were encapsulated in the resultant MIPs for an easy magnetic separation process. Such magnetic‐responsive Fe3O4@SiO2 MIPs showed excellent template recognition properties and high adsorption capacity. And all the characterization indicated that these multifunctional magnetic materials would explore the potential applications in bio‐separation, cell labeling, or bioimaging fields.

Figure 14.

The applications of magnetic‐responsive MIPs. A) (i) MIPs comprising of magnetic core and organic or inorganic shells. (ii) Different constructions of magnetic MIPs. Black part is the magnetic component and blue part is MIPs part. Reproduced with permission.[ 171 ] Copyright 2019, Elsevier B.V. B) Scheme of the lysozyme detection system based on Fe3O4@SiO2@MIPs. The magnetic responsiveness could realize easy separation of target lysozyme for sensitive CL. Reproduced with permission.[ 172 ] Copyright 2010, Elsevier B.V.

Suspension polymerization is another simple and suitable method for the preparation of magnetic‐responsive MIPs, which avoids disadvantages like excessive remnants, low extraction capacity, and laborious surface modification compared with other polymerization methods. Li et al. developed a novel microwave heating method for the preparation of magnetic‐responsive MIP beads for trace triazines analysis in complicated samples.[ 174 ] They used polyethylene glycol (PEG) modified Fe3O4 as magnetic cores, and then template atrazine and monomer MAA were self‐assembled by microwave heating during suspension polymerization. The porous magnetic beads with spherical shape were characterized by a narrow diameter distribution (80–250 µm), magnetic property (Ms = 0.491 emu g−1), and thermal stability under 260 °C. Apart from Fe3O4 and its derivatives, some other magnetic substrates like azide‐functionalized nanoparticles, titanium dioxide (TiO2), and QDs have also been investigated for further development of magnetic‐responsive MIPs‐based sensors or artificial antibody synthetic fields.

3.6. Other Novel Technologies

Above several MITs are widely used techniques in typical preparation processes of MIPs. These methods have been applied to fabricate diverse molecular imprinted materials in scientific fields of practical chemical and biomedical engineering. With the development of characterization methods and synthesis strategies, some other novel MITs have also been proposed to meet the requirements of some particular applications.

3.6.1. Controlled/Living Free Radical Polymerization (CLFRP)

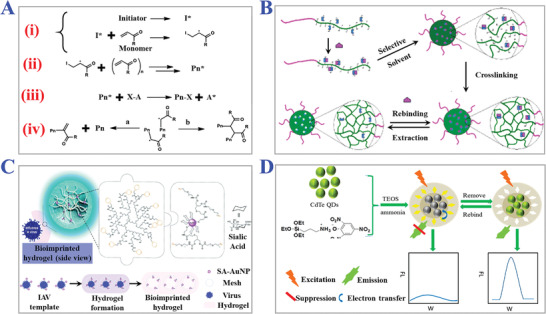

To obtain MIPs with well‐defined molecular weight, topological structure, low dispersity, precise composition, and exact functionality, controlled/living free radical polymerization (CLFRP) methods have been thoroughly investigated, including RAFT, ATRP, nitroxide‐mediated polymerization (NMP), initiating transfer terminator method and nitrogen oxides‐controlled stable free radical polymerization (SFRP).[ 175 , 176 , 177 ] The growth processes of polymer molecular chains during polymerization tend to be slower via thermodynamic control. Thus, the rates of chain growth and chain relaxation can reach a better balance. The resultant network of MIPs will be more homogeneous within a narrow range of molecular chain length. Generally, free radical polymerization involves a chain transfer reaction and a chain termination reaction. The critical feature of CLFRP is to reduce the concentration of active free radicals and the rate of chain termination. RAFT is a typical CLFRP method due to its tolerance for amounts of functional monomers and flexibility for diverse designs. During RAFT procedure, special agents with high chain transfer constant like double sulfur ester and its ramifications are usually used to enhance degradation transfer of free radical, as shown in Figure 15A.[ 178 , 179 ] Similarly, ATRP procedure, another new class of CLFRP, tends to use transition metal catalysts as halogen atom transfer assays for mediating the propagation and constructing reversible “promoting‐inactivation” reaction to minimize chain termination rates under relatively mild reaction conditions. Yang and his coworkers developed β‐estradiol imprinted nanotubes within a porous anodic alumina oxide (AAO) membranes for the chemical separation of target molecules by surface‐initiated ATRP route.[ 180 ] They grafted 2‐bromo‐2‐methylpropionyl bromide as ATRP initiator on the silanized AAO membranes to induce the following copolymerization of β‐estradiol, 4‐VP, and EGDMA. CuBr and 1,4,8,11‐tetraazacyclotetradecane (Me4Cyclam) acted as halogen atom transfer assays to control the growth of polymer chains onto the nanotubes. The final MIPs were tailored with uniform pores and adjustable thickness, and the binding affinity to targets was confirmed 11‐fold higher than common bulk MIPs. However, there still exist some challenges limiting the further development of CLFRP, such as realizing polymerization within the water or other liquid medium, complete elution of transition metal catalysts from MIPs, complex synthesis of initiators or iniferter, and so on. Therefore, researchers should pay more attention to the above problems to explore wider applications of CLFRP.

Figure 15.

The applications of other novel MITs. A) The mechanism of reversible addition‐fragmentation chain transfer polymerization (RAFT). i) Initiation. ii) Propagation. iii) Chain transfer. iv) Termination by disproportionation and combination. Reproduced with permission.[ 178 ] Copyright 2016, Elsevier Ltd. B) Synthesis procedure of MIPs nanospheres via self‐assembly of deblock copolymers. Reproduced with permission.[ 183 ] Copyright 2006, American Chemical Society. C) Construction of bio‐imprinted (influenza A virus) MIPs hydrogel with dual responsiveness including volume (swelling and shrinking) and color changing (purple to pink). Reproduced with permission.[ 185 ] Copyright 2020, Royal Society of Chemistry. D) Schematic illustration of the dummy MIPs‐capped CdTe QDs for fluorescent sensing of TNT. Reproduced with permission.[ 192 ] Copyright 2013, American Chemical Society.

3.6.2. Self‐Assembly of Block Copolymer

To prepare MIPs with core‐shell structures, self‐assembly of block copolymers has been adopted as a superior method in recent years.[ 181 , 182 ] Block copolymers tend to remain in micelles states based on the different solubility among selective solvents. Insoluble blocks can act as solid core or supporting substrates for anchoring soluble blocks which act as compositions of shell layer. During the typical self‐assembly procedure of MIPs block copolymers, first, the block copolymers with sectional block, which loaded combining sites to corresponding templates, were synthesized. Then the block copolymers combined templates based on interactions like hydrogen‐bonding, covalent interactions, etc. After transferring to selective solvents, the block copolymers would self‐assemble towards spherical core micelles with soluble block forming shell micelles. Subsequently, the micelles with core‐shell structure gradually became highly cross‐linked during polymerization processes. Finally, the template molecules were removed in such polymerized core‐shell micelles to construct desired MIPs. Compared with the methods which establish core‐shell MIPs by integrating with supporting substrates like Fe3O4 or QDs, the overriding advantage of this self‐assembly strategy is to avoid the modification or pretreatment process of core materials and reduce the complexity of interactions between core, shell, and template materials. The different block sequences within one block copolymer make up the functional components of final MIPs synergistically (Figure 15B).[ 183 ] Wooley et al. proposed a method to realize sequence control of triblock copolymers with unique toroidal morphology.[ 184 ] They synthesized poly[(tert‐butylmethacrylate)‐block‐(2‐hydroxylethylmethacrylate)], which was modified with 2‐acrylamide‐6‐carboxylbutyl amidopyridine and methacryloyl side group as cross‐linkable functional groups. 1‐alkyluracil and 1‐alkylthymine derivatives were selected as templates to form complexes with block copolymers by hydrogen bonding. Then the precursor complexes were self‐assembled in cyclohexane to form core‐shell nanostructures. The resultant MIPs exhibited high rebinding affinity to targets with better dispersibility due to the self‐assembly process of micelles. Furthermore, attributed to the self‐assembly of block copolymers approach, the performance of MIPs could be further adjusted by changing the block length, sequence arrangement, and group polarity.

3.6.3. Dual/Multi Responsive MIPs