Highlights

-

•

Ultrasonic technology (UT) is a pollution-free and green technology in solid food.

-

•

UT can accelerate lipid, protein, physicochemical and sensory changes in solid food.

-

•

Different frequencies of UT can improve ultrasonic utilization.

-

•

UT combined with other technologies can improve the desired quality of food.

-

•

Reducing UT energy consumption is the trend of future development.

Keywords: Freezing, Cooling, Thawing, Single/multi-frequency ultrasonic, Optimization, Application

Abstract

Solid foods include fish, shrimp, shellfish, and other aquatic products, fruits, and vegetables. These products are commonly used for food freezing, cooling, and thawing. However, traditional freezing, cooling, and thawing of solid food technologies have limitations in quality, such as protein denaturation and water loss in food. Ultrasound-assisted technology has become a useful method in solid food processing due to improved preservation quality of solid food. This paper comprehensively reviews the mechanism and application of ultrasonic in solid food processing technology. Although the application of ultrasound-assisted ultrasound in solid food processing is relatively comprehensive, the energy saving of food cold processing is essential for practical application. This paper analyzes the optimization of ultrasonic in solid food processing, including orthogonal/multi-frequency technology and the combination of ultrasonic and other technologies, which provides new ideas for freezing, cooling, and thawing of solid food processing.

1. Introduction

With the improvement of people’s quality of life, consumers’ requirements for food are increasing daily. Food freezing, cooling, and thawing are essential in solid food processing. Low temperature inhibits the growth of microorganisms, slows down the activity of enzymes, and preserves the original flavor and nutrients of food [1]. To prolong food preservation time, it is necessary to reduce the factors affecting food quality during solid food processing. For example, the formation and distribution of ice crystals have essential effects on food cells during freezing [2], [3] and the growth of ice crystals needs to be controlled [4]. During the thawing process, lipid oxidation is one of the critical indicators affecting quality, and it is necessary to consider how to improve lipid stability [5]. During the refrigeration process, the activities of microorganisms and enzymes accelerate the spoilage and deterioration of food. It is necessary to improve food quality by inactivating microorganisms and inhibiting the activity of enzymes [6].

Traditional food processing technologies have low freeze–thaw efficiency, are prone to lipid oxidation, and easily cause irreversible damage to food [7], [8], [9], [10], [11]. However, new solid food processing technologies, such as microwave-assisted freeze/cooling/thawing technology [3] and ultrasonic freeze/cooling/thawing dipping technology [12], can improve heat transfer rate and reduce the effects of ice crystals and microorganisms on food quality during solid food processing [13], [14]. Studies have shown that the increase in freezing speed reduces the effect of ice crystals on frozen food [15], and the increase in the thawing rate minimizes the impact of microorganisms on frozen food [16]. The cavitation and mechanical effects produced by ultrasonic can improve food's freezing rate and antibacterial effect. Its thermal effect helps improve solid food's thawing efficiency [17], [18]. In addition, additive-free ultrasonic treatment is a very promising application in the modern green food industry [19]. Among them, the selection and combination of ultrasonic frequency and power and the variety of ultrasonic and other technologies can improve the efficiency of ultrasonic technology in food processing [20], [21], [22]. This paper focuses on the research and application of the new ultrasonic processing technology, especially the application of single/multi-frequency ultrasonic and the combination of ultrasonic and other technologies in solid food processing.

2. Mechanism of ultrasonic processing

2.1. Freezing

Freezing solid foods, which involves freezing food to –18 °C to convert the free water into ice crystals, is a common and widely used preservation method [23]. During the freezing process, ice crystals' formation, distribution, and size play a crucial role in the quality of frozen food [24]. Kono et al.[25] studied the freezing rate and ice crystal size effect on the salmon fillet. The results showed that ice crystal diameter (20 ∼ 450 μm) decreased exponentially with the improvement of the freezing rate. To reduce the harm of ice crystals to food tissue, studies have shown that food quality can be improved by reducing the size of ice crystals and making them more uniform [26]. The slow freezing has large and uneven ice crystals inside food, destroying cell tissue and thus reducing food quality [27]. However, small, uniform ice crystals formed by rapid freezing reduce this damage [28]. Ultrasonic technology can effectively change the size of ice crystals and protect the microstructure of food [29].

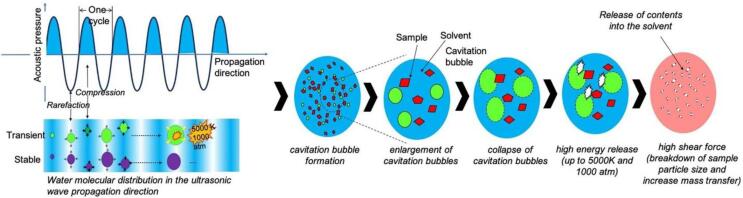

Ultrasonic impregnation freezing (UIF) is a method to improve the quality of frozen food by exposing food to a secondary refrigerant with a low temperature, such as –25 °C [30]. Fig. 1 shows the mechanism of ultrasonic freezing [31]. It mainly improves the frozen food quality by increasing the heat transfer rate and enhancing the nucleation probability of ice crystals, thereby shortening the freezing time and enabling the frozen food to form fine, uniform ice crystals [32], [33]. When ultrasonic is applied to a secondary refrigerant solution, cavitation, microflow, thermal, and mechanical effects are produced [34], [35]. In the cavitation effect, the resulting cavitation bubbles can effectively reduce the subcooling temperature required for ice crystal nucleation [36]. The cavitation effect can improve the heat transfer efficiency, and cavitation bubbles can effectively decrease the supercooling temperature required for ice crystal nucleation, thereby accelerating the formation of ice crystals [37] and contributing to the primary nucleation [38]. At the same time, cavitation bubbles turn large ice crystals into small ice crystals, which become new ice cores and form new ice crystals, thereby achieving secondary nucleation. The primary and secondary nucleation of ice crystals increases the freezing rate [39]. Besides, the increase of freezing rate by ultrasonic method can destroy large ice crystals and form small and uniform ice crystals, reduce the damage to food microstructure, improve the stability and microstructure of protein [40], [41]. The Microflow effect is closely related to the cavitation effect, depending on whether the cavitation bubbles collapse into steady-state cavitation or transient cavitation [12]. n the steady-state cavitation effect, the internal air is continuously exchanged with the loaded cooling medium under the action of ultrasonic cavitation bubbles, and the exchange can generate eddy currents around the cavitation bubbles, resulting in a microfluidic effect [42]; In transient cavitation, the generated cavitation bubble bursts and generates energy when its volume increases and reaches the critical size, resulting in turbulence and micro-flow effect and improving heat transfer efficiency [43]. In the thermal effect, the vibration energy generated when ultrasonic propagates in the secondary refrigerant is absorbed and converted into thermal energy [13]. Among the mechanical impact, the ultrasonic in the secondary refrigerant, as mechanical waves, generate vibrations, which enhance the transfer of energy [44]. Chen et al.[45] studied the effect of ultrasonic impregnation freezing with a frequency of 45 kHz and a power of 320 W on the frozen storage (0, 2, 4, 6, 8, and 10 weeks) of sea bass. The results showed that when the secondary refrigerant temperature is at –20 °C, the ice crystal diameter of UIF was reduced by 32 % compared with that of impregnation freezing. When the secondary refrigerant temperature is at –40 °C, the ice crystal diameter of UIF decreases by 21.5 % compared with that of impregnation freezing, indicating that ultrasonic can effectively increase the nucleation of ice crystals and reduce the size of ice crystals. Sun et al.[46] studied the influence of ultrasound impregnation freezing with a power of 175 W and a frequency of 30 kHz on the quality of frozen storage (0, 30, 60, 90, and 180 days) of carp. The results showed that compared with air freezing and UIF, the carbonyl content of carp was significantly reduced, the free amino acid content was increased, the oxidation of protein was inhibited, and the quality of carp was improved.

Fig. 1.

Diagram of ultrasonic action on ice crystals [48].

Therefore, it can be concluded that UIF has a faster freezing rate and better protein stability than traditional freezing techniques (air freezing and immersion freezing) and low-temperature quick-freezing. However, local high temperatures caused by ultrasonic cavitation and thermal effects lead to cell destruction [47], which in turn causes problems such as protein oxidation.[31] Therefore, it is an important criterion to select the appropriate ultrasonic power and frequency for different frozen products to solve the local high temperature and ultrasonic energy consumption caused by ultrasonic, to obtain the excellent freezing effect.

2.2. Cooling

Due to people's demand for fresh, nutritious, and convenient food, the application of fresh food has been dramatically expanded [49]. Microorganisms and enzymes are the main factors that cause food spoilage. The growth of microorganisms spoils food. Lipase in food decomposes fat, while protease decomposes protein [50], [51]. Ultrasound is a pollution-free technique for preserving solid food at 4 °C, which can inhibit the growth of microorganisms, thereby improving food quality [52].

When ultrasound acts on enzymes through thermal effect and cavitation effect, the released energy causes the structure change of enzymes, thereby affecting enzyme activity [53], [54], [55], thinning and rupture of cell membranes, inactivating microorganisms [56], [57] and achieving the purpose of sterilization [58]. The crumble of cavitation bubbles in the cavitation effect increases the temperature and pressure, thus promoting free water to generate free radicals [59]. Yeoh and Ali et al.[60] studied the effect of ultrasonic with a power of 29 W and a frequency of 37 kHz on the refrigerated quality of pineapple. The results showed that compared with the no-ultrasonic group, the ultrasonic group could effectively inhibit microbial metabolism and improve the antioxidant capacity of protein, which was conducive to preserving pineapples in cold storage. Franco et al.[61] studied the effect of ultrasonic with a power of 50 W and a frequency of 40 kHz on the quality of frozen bananas. The results showed that compared with the no-ultrasonic group, ultrasonic treatment could effectively retain the content of phenolic compounds and improve its antioxidant capacity, thus maintaining better color and nutrition. Compared with traditional refrigeration technology, ultrasonic cooling technology has a better antibacterial effect.

2.3. Thawing

Solid frozen foods usually require thawing. Enzyme and microbial activity are gradually restored during thawing, so rapid thawing is also needed [62]. Common thawing methods include air thawing [10], water thawing [63], etc. Among them, air thawing takes a long time, which is easy to cause lipid oxidation of food. Water thawing also leads to the loss of soluble substances in frozen food, which leads to a significant decrease in the quality of frozen food after thawing [64], [65]. Ultrasonic impregnation thawing (UIT) can significantly shorten the thawing time, reduce lipid oxidation, maintain meat quality, and increase meat tenderness [66], [67].

UIT is also based on the cavitation and mechanical and thermal effects of ultrasound on the medium [68]. In the cavitation effect, the volume of the cavitation bubble increases to a critical size and then bursts to generate energy [34]. In the mechanical impact, ultrasonic vibration acts on the medium to drive the medium to generate power, which helps improve food thawing efficiency [69]. In the thermal effect, ultrasonic energy is converted into heat energy. The liquid near the solid surface of the food forms an acoustic cavity, in which many cavitation bubbles will be generated. Ice-water conversion accelerates heat transfer efficiency and increases the rate of food thawing [70], [13]. Corina et al.[71] applied ultrasound (power of 0.6 W/cm2, a frequency of 25 kHz) and air thawing to the longissimus dorsi of pigs, respectively. The results showed that compared with air thawing, the time required by ultrasonic immersion thawing was reduced by 87 %, and the thawing rate was increased from 0.05 °C/min to 0.4 °C/min. There was no significant change in pork quality compared with fresh pork.

The thawing rate is an essential criterion for solid food thawing technology. Improving the utilization rate of ultrasonic waves in the thawing process, thereby improving the thawing rate, is significant to its application in the actual solid food industry.

3. Optimization and application of ultrasonic process

3.1. Optimization and application of ultrasonic impregnation freezing technology

3.1.1. Single-frequency ultrasonic impregnation freezing (SUIF)

First of all, it should be noted that the thermal effect of ultrasonic is different under different powers, and the protein denaturation caused by the local high temperature of ultrasonic must be considered [72]. The reason may be that shear forces in cavitation bubbles generated by ultrasound can break hydrogen bondings and electrostatic particles that affect protein stability. Selecting the appropriate ultrasonic power can enhance the repulsive force between electrostatic particles, thereby preventing the aggregation of protein molecules and improving the strength of protein molecules [73], [74]. Qiu et al.[75] investigated the effect of ultrasonic methods at a frequency of 25 kHz and power of 150 W, 200 W, and 250 W on the silver carp quality. The results showed that ultrasonic waves at a power of 250 W could promote protein oxidation, and ultrasonic waves at a power of 200 W had the better water-holding capacity and protein stability than other powers of ultrasound.

Secondly, to better form smaller and more uniform ice crystals in frozen food, the temperature of the secondary refrigerant can be set to –40 °C by increasing the freezing rate and temperature difference, and the food can be frozen to –18 °C by ultrasonic, which accelerate the freezing speed. Chen et al. [45] studied the effect of UIF with a power of 320 W and a frequency of 45 kHz on the quality of frozen sea bass at different secondary refrigerant temperatures of –20 °C and –40 °C. The results showed that compared with the ultrasonic group at –20℃, the ice crystals in the –40 °C ultrasound group were smaller, the water content was higher, and the protein structure was more stable. UIF at a lower temperature can effectively reduce the impact of freezing on food quality.

3.1.2. Multi-frequency ultrasonic impregnation freezing (MUIF)

There are two problems with the single-frequency ultrasonic impregnation freezing (SUIF) technology. One is that the cavitation effect caused by the propagation of ultrasonic waves in a single direction is limited to a limited volume range close to the ultrasonic and has significant inhomogeneity [76]. The second is the cavitation shield formed near the sonotrode port, a phenomenon that prevents the propagation of acoustic energy [76]. Multi-frequency ultrasonic impregnation freezing (MUIF) is proposed to address these two problems. There are two types of MUIF, one using multiple horizontal ultrasonic generators and the other using orthogonal ultrasonic generators [77]. On the premise that all samples were potatoes, compared with single-frequency and dual-frequency ultrasound, Zhu et al.[78] and Tian et al.[79] demonstrated that horizontal and vertical ultrasound could improve the potato freezing time and reduce potato juice loss, respectively.

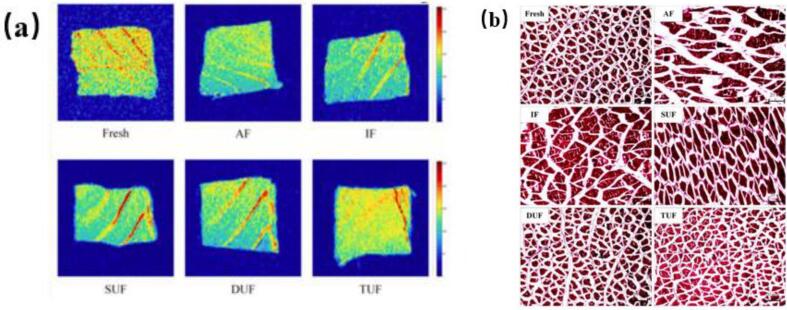

hese new ultrasonic freezing technologies increase the range of ultrasonic cavitation effect, avoid the problem of the uneven sound field when using single-frequency ultrasound, and significantly improve the cavitation effect and freezing efficiency [77], [80]. Ma et al.[81] investigated the effects of ultrasonic impregnation freezing on the quality of large yellow croaker under the same ultrasonic power (175 W), single frequency (20 kHz), double frequency (20 kHz and 28 kHz), and multi-frequency (20 kHz, 28 kHz, and 40 kHz). The results showed that compared with other freezing methods, MUIF could effectively reduce the accumulation of TVB-N, improve the water holding capacity (WHC) of large yellow croaker, and make the intracellular water distribution more uniform. Fig. 2 (a) represents the WHC imaging of large yellow croaker muscles. The moisture content of the NUIF sample group was closer to that of the fresh sample group. In addition, another way to assess the quality of the MUIF treatment is to observe the imaging using a light microscope, which can see the size of ice crystal interspaces from Fig. 2 (b). The large yellow croaker treated with MUIF has smaller voids and higher density, which proves that MUIF can effectively reduce the size of ice crystals.

Fig. 2.

(a) Water retention distribution of large yellow croaker at different frequencies; (b) Space size distribution of large yellow croaker with different frequencies caused by ice crystals under light microscopy observation [81].

3.1.3. Ultrasonic impregnation freezing (UIF) combined with other technologies

Based on UIF, combined with other technologies, the formation of large ice crystals in solid food can be more effectively reduced, and the loss of protein content and the retention capacity of cells can be improved [82]. When solid food is put into a pressure vessel, and gas such as CO2 is injected into the vessel to pressurize for some time, air bubbles will form in the food. These air bubbles can act as nuclei during the freezing process, promoting the nucleation of ice crystals and accelerating the freezing rate [83], [84]. Jiang et al.[85] studied the effect of UIF with a power of 300 W and a frequency of 20 kHz, combined with ultrasonic and CO2 (0.5 MPa), on cantaloupe quality. Combining ultrasonic and CO2 is to first extract the air from the cantaloupe in the container, then add CO2 for some time to the required pressure, and then perform UIF and freezing treatment. The results showed that the combination of ultrasonic and CO2 resulted in smaller and more uniform ice crystals, less vitamin C loss, better flavor index, and better protection of the cantaloupe microstructure compared to other technologies [86].

In conclusion, some food additives have the effect of maintaining protein stability and improving food water retention. These additives can effectively combine with ultrasonic technology to enhance food quality. For fruit and vegetable food, ultrasound can be combined with other technologies to maintain its hardness, crispness, and other indicators, thereby improving the quality of fruit and vegetable food. For meat, ultrasound can be combined with other technologies to maintain protein stability, water retention, and other indicators to improve meat quality. There are few studies on MUIF and combining ultrasonic and other technologies in food freezing.

Further experimental studies are needed to obtain the best multi-frequency ultrasonic combination technologies and the commercial application of these technologies in the aquatic product processing industry. At present, there are many patents for the application of ultrasonic freezing in solid food. Although in the experimental stage, this step is beneficial to promote the application of ultrasonic in the actual food industry. Table 1 lists most of the research results and patents of the UIF for preserving solid food quality.

Table 1.

Some studies using different UIF treatments and patents in solid foods processing.

| Product/Patent No. | Method | Results/Description of invention | Reference |

|---|---|---|---|

| SUIF | |||

| Lotus root | Frequency of 30 kHz and a power of 90 W, 150 W and 210 W | The results showed that compared with ultrasonic waves with other powers, ultrasonic waves with 150 W had a rapid freezing rate, improved hardness, reduced drip loss and protected microstructure of lotus root. | [87] |

| Patent | |||

| EP2269474A2 | – | An apparatus for reducing a temperature of a product which can facilitate heat transfer at the surface of the product. | [109] |

| TW103207050 | – | A kind of impregnated freezing dedicated unit of lift of ultrasonic freezing. | [110] |

| CN111955535A | – | An invention discloses a processing method for ultrasonic-assisted oyster freezing which can reduce muscle tissue and nutrient loss of oyster. | [111] |

| CN:201310100237:A | – | A method for enhancing brine salting-process frozen fish fillets through ultrasonic. | [113] |

| CN103168828A | – | A method of improving the freezing speed and quality of litchi chinensis through variable frequency ultrasonic enhancement. | [114] |

| MUIF | |||

| Potato | The same ultrasonic power (270 W), single frequency (20 kHz), double frequency (20 kHz, 28 kHz) and multi-frequency (20 kHz, 28 kHz, 40 kHz) | The results showed that MUIF can cut down freezing time and reduce juice loss compared with SUIF and DUIF. | [78] |

| Potato | the same ultrasonic power (270 W), single frequency (respectively 20 kHz and 28 kHz), orthogonal (upper and lower 20 kHz, left and right 20 kHz) and orthogonal (upper and lower 20 kHz, left and right 28 kHz). | The experiment showed that, comparing with other freezing methods, orthogonal ultrasonic wave increased the freezing rate faster and reduced the juice loss rate more obviously, which was more beneficial to the freezing preservation of potatoes. | [79] |

| Patent | |||

| CN202110049445.9 | – | An ultrasonic freezing equipment which can quickly take away a heat of a food to be frozen, so as to efficiently freeze the food. | [108] |

| UIF combined with other technologies | |||

| Surimi of grass carp | Power of 300 W and frequency of 28 kHz combined with soluble soybean sugar | The results showed that compared with ultrasonic freezing, the new ultrasonic technology added SSPS effectively reduced the contents of sulfhydryl group, carbonyl group and fibrin protein, and maintained the quality of surimi. | [88] |

| Patent | |||

| CN107198149A | – | A method for freezing surimi by ultrasonic waves together with water-soluble soybean polysaccharide which can reduce ice crystals and improve the quality of surimi comparing with single using ultrasonic mechanism. | [112] |

3.2. Optimization and application of ultrasonic impregnation cooling technology

3.2.1. Single-frequency ultrasonic impregnation cooling (SUIC)

In ultrasonic thawing, the effects of ultrasonic intensity of different frequencies and powers on food quality are different. Antunes-Rohling et al. [68] used ultrasonic intensity at a frequency of 25 kHz and various powers of 29.4 W/kg, 14.7 W/kg, and 2.9 W/kg to thaw frozen cod fillets. The study showed that the ultrasonic treatment group at 2.9 W/kg had the best water holding capacity compared to other ultrasonic powers. Compared with the control group, ultrasound intensities of 2.9 W/kg resulted in the most weight gain (18.6 %) and a 33 % reduction in hydration time.

3.2.2. Multi-frequency ultrasonic impregnation cooling (MUIC)

Based on the ultrasound impregnation cooling technology, similar to UIF, the combination of different ultrasonic frequencies and powers can enhance the cavitation effect of ultrasonic, thereby improving the utilization rate of ultrasonic and enhancing the bacteriostatic impact [89], [90]. Zhao et al.[91] studied the effects of ultrasonic impregnation of a single frequency (20 kHz), double frequency (20 kHz and 28 kHz), and multi-frequency (20 kHz, 28 kHz, and 40 kHz) on refrigerated quality of large yellow croaker. In contrast, the water-holding capacity and texture of large yellow croaker treated with dual-frequency ultrasound were better than those treated with multi-frequency ultrasound.

3.2.3. Ultrasonic impregnation cooling (UIC) combined with other technologies

After perfecting the combination of ultrasonic frequency and power, combined with the technology of bacteriostatic effect, the food quality can be significantly improved. For example, slightly acidic electrolyzed water (SAEW) has potent antibacterial activity against various microorganisms. Hypochlorous acid, the main chlorine-containing compound in SAEW, inhibits bacterial activity by causing cell membrane damage [92]. Lan et al. [93] investigated the effects of the combination of the ultrasonic with the power of 600 W, frequency of 20 kHz, and SAEW on the refrigerated quality of sea bass at 4 °C. The results showed that this novel ultrasonic technology effectively inhibited protein degradation and microbial growth and extended the shelf life of sea bass by at least four days. Likewise, Li et al.[94] studied mirror carp with an ultrasonic frequency of 30 kHz and a power of 200 W in combination with SAEW. The results showed that compared with the US treatment, the US + SAEW treatment reduced the relative activities of 2,3,5-triphenyl tetrazolium chloride-dehydrogenase (TTC-dehydrogenase) by 65.89 % and ATP-ase by 10.26 % in Pseudomonas. Therefore, the US + SAEW treatment effectively inhibited the activities of antioxidant enzymes.

Many experiments have shown that multi-frequency ultrasonic and ultrasonic combined with other technologies have inhibitory effects on food microorganisms. However, there are currently few mathematical models on the mechanism of ultrasonic inhibition of microorganisms. Future research focuses on determining the optimal combination of ultrasonic frequency and power and how to apply it to food industrialization.

3.3. Optimization and application of ultrasonic impregnation thawing

3.3.1. Single-frequency ultrasonic impregnation thawing (SUIT)

Also, it should be noted that the magnitude of cavitation and thermal effects will vary with ultrasonic power during thawing. If the ultrasonic power is too high, many cavitation bubbles and vibrations can destroy the microstructure of the food [95], [96]. Moreover, the hyperthermic effect causes food to be locally overheated, thereby affecting the quality of food [97], [98]. Selecting usable ultrasonic power can effectively improve food's thawing rate, thereby improving food quality. Chu et al.[99] investigated the effect of UIT on the protein quality of large yellow croaker stored at − 18 °C at different powers (240, 280, and 320 W) at 20 ± 1 °C and a frequency of 40 kHz. When the ultrasonic energy is 320 W, the damage to the protein is most substantial, and the thawing rate is the slowest. When the ultrasonic power is 280 W, the protein stability can be increased, and the thawing rate is the fastest.

3.3.2. Multi-frequency ultrasonic impregnation thawing (MUIT)

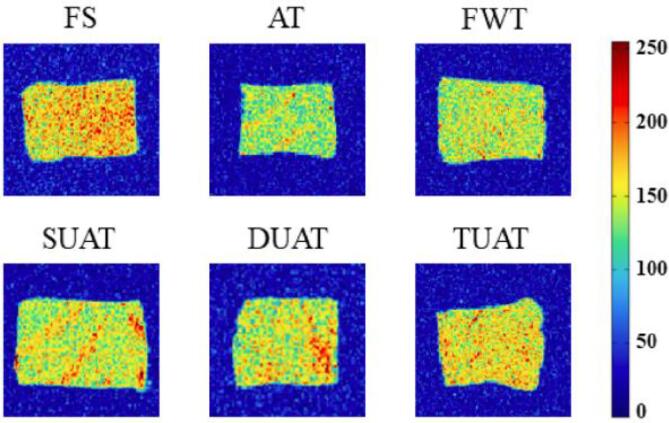

Based on SUIT, to further improve the thawing efficiency and maintain food quality, orthogonal/multi-frequency ultrasound impregnation thawing technology was proposed [100], which can effectively enhance thawing efficiency, water retention, hardness and reduce cooking loss [101]. Bian et al.[102] used ultrasonic thawing with a power of 180 W, single frequency (20 kHz), double frequency (20 and 28 kHz), and multi-frequency (20, 28, and 40 kHz). The results showed that compared with other thawing methods, under MUIT, the texture properties of the large yellow croaker were the best, the TVB-N was the lowest, and the protein damage during the thawing process was reduced, which was more conducive to maintaining the quality of large yellow croaker. In terms of water distribution and migration, as shown in Fig. 3, the triple ultrasound frequencies of the UAT (TUAT) sample are closer to that of the fresh samples, which can generate more cavitation nuclei and promote the cavitation effect to reduce the destruction of ice crystals.

Fig 3.

Water retention distribution of large yellow croaker at different frequencies [102].

Ultrasonic impregnation thawing (UIT) combined with other technologies UIT in solid foods can be combined with different technologies to improve food quality according to the characteristics of different foods. Qian, etc.[103] used the power of 100 w ultrasonic combined with a plasma-activated waterway to thaw frozen chicken breasts. The results showed that this new composite thawing method did not change the quality of chicken breasts using an ultrasonic, including plasma-activated waterway and color, but reduced protein and lipid oxidation to better maintain the quality of the chicken breasts.

In conclusion, MUIT ultrasonic impregnation thawing combined with other technologies can speed up thawing efficiency and improve protein stability. Still, attention should be paid to the selection of ultrasonic power and frequency. For different frozen food thawing, the ultrasonic power and frequency are different, and its thawing effect is also different. Many experimental studies are needed to select the best-frozen food thawing power, frequency, and combination and apply it to food industrialization. Like freezing patents, there are many patents for ultrasonic thawing solid food. On the theoretical basis, it further provides the experimental basis for the application of ultrasonic in the food industry, which is conducive to the early realization of the application of ultrasonic thawing. Table 2 lists most of the research results and patents of the UIT in maintaining solid food quality.

Table 2.

Some studies using different UIT treatments and patents in solid foods processing.

| Product/Patent No. | Method | Results/Description of invention | Reference/Inventor (s) |

|---|---|---|---|

| SUIT | |||

| Tuna fibrin | Frequency of 40 kHz with different powers (160, 280 and 400 W) | The results showed that ultrasonic thawing at 280 W could better improve the stability of tuna fibrin. | [104] |

| Beef | Frequency of 20 kHz and different powers (200, 400 and 600 W) | The results showed that ultrasonic thawing with frequency of 400 W was the best for improving the stability of beef fibrin, which helped to avoid the loss of minerals and water-soluble vitamins in the thawing process. | [105] |

| Patent | |||

| CN202890408U | – | An ultrasonic defroster can be used for rapidly and uniformly defrosting the foods. | [115] |

| CN206808598U | – | The utility model discloses an ultrasonic wave unfreezes the method can be applied to thaw frozen food. | [116] |

| CN110393210A | – | An ultrasonic water water-flowing thawing device for squids and a method for thawing the squids which can improve the thawing quality of the squids. | [117] |

| CN207885597U | – | The utility thawing equipment can promote the effect of unfreezing, improves the work efficiency that unfreezes, guarantees food hygiene safety, reduces food nutrition and runs off. | [118] |

| CN205611648U | – | An ultrasonic wave sea water squid thawing apparatus with low costs, high efficient. | [119] |

| CN211268413U | – | An ultrasonic thawing equipment for aquatic products which can improve the uniform unfreezing efficiency of the aquatic products. | [120] |

| CN111096354A | – | A method for defrosting raw tuna with high-frequency ultrasonic wave which can enhance the defrosting speed of the tuna. | [122] |

| MUIT | |||

| Large yellow croaker | Power of 200 W, single frequency (28 kHz, 40 kHz) and dual frequency (28, 40 kHz) | The experiment showed that dual-frequency ultrasonic thawing availably improved the texture, water holding capacity and microstructure of large yellow croaker compared with other thawing methods. | [106] |

| Patent | |||

| CN109619370A | – | An ultrasonic thawing control method and a thawing device which can generate ultrasonic signals in multiple propagation directions. Compared with single-directional ultrasonic thawing of the to-be-treated object, the time required for thawing is shortened and the temperature uniformity of the to-be-treated object is improved. | [121] |

| UIT combined with other technologies | |||

| Sciaenops ocellatus (red drum) | The combination of ultrasound, infrared and microwave | The experiment showed that compared with the use of ultrasonic treatment alone, the combination of ultrasonic and infrared, The combination of ultrasound and microwave can improve the structural stability of sciaenops ocellatus (red drum) protein. | [107] |

| Patent | |||

| CN212325324U | – | an ultrasonic wave and microwave combined ice melting device, compared with a traditional food unfreezing mode, it can be better guaranteed that original taste and flavor of food lock nutritional ingredients in the food, the taste of the food is prevented from being damaged, and the food is restored to the position before freezing. | [123] |

4. Conclusion and future trends

This paper reviews the application of ultrasonic technology in freezing, cooling, and thawing of solid food processing. Among them, the multi-frequency ultrasound and the combination of ultrasound and other technologies are becoming the research hotspot, which improves the freezing or thawing rate, water retention, protein stability, food hardness, and brittleness.

Although ultrasonic technology has been widely used in solid food, it is essential to improve the internal quality of food. Ultrasound should be used to mitigate studies of lipid oxidation-related changes during freezing, refrigeration, and thawing. To understand how the new ultrasonic technology affects the composition of solid food, it is necessary to investigate the dynamics of protein–protein and protein-lipid interactions in solid foods after the new ultrasonic treatment. At the same time, regardless of freezing, cooling, and thawing, adequate energy consumption is far greater than total energy consumption. How to effectively improve the efficiency of ultrasonic and reduce energy consumption is also an important research direction in the future.

Moreover, determining the acoustic field distribution and the stability of ultrasonic power need to be further improved. Presently, ultrasonic processing technology in solid food processing is still in the laboratory research stage, and there is a lack of large-scale ultrasonic-assisted dipping equipment for actual production. It is believed that with a further understanding of the mechanism of ultrasonic-assisted heat and mass transfer technology, such equipment will gradually be industrialized.

5. Availability of data and materials

Not applicable as it is a review. Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

Funding

This paper is supported by China Agriculture Research System of MOF and MARA (CARS-47); Shanghai Professional Technology Service Platform on Cold Chain Equipment Performance and Energy Saving Testing Evaluation (20DZ2292200, 19DZ2284000).

Ethics approval and consent to participate

Not applicable as it is a review.

CRediT authorship contribution statement

Huan Yu: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Software, Writing – original draft. Jun Mei: Conceptualization, Data curation, Investigation, Methodology, Project administration, Validation, Writing – original draft, Writing – review & editing. Jing Xie: Funding acquisition, Methodology, Project administration, Validation, Writing – review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

The authors do not have permission to share data.

References

- 1.Zhang M.C., Xia X.F., Liu Q., Chen Q., Kong B.H. Changes in microstructure, quality and water distribution of porcine longissimus muscles subjected to ultrasound-assisted immersion freezing during frozen storage. Meat Sci. 2019;151:24–32. doi: 10.1016/j.meatsci.2019.01.002. [DOI] [PubMed] [Google Scholar]

- 2.Cheng L.N., Sun D.W., Zhu Z.W., Zhang Z. Emerging techniques for assisting and accelerating food freezing processes: a of recent research progresses. Crit. Rev. Food Sci. Nutr. 2017;57(4):769–781. doi: 10.1080/10408398.2015.1004569. [DOI] [PubMed] [Google Scholar]

- 3.Xanthakis E., Le-Bail A., Ramaswamy H. Development of an innovative microwave assisted food freezing process. Innovative Food Sci. Emerg. Technol. 2014;26:176–181. doi: 10.1016/j.ifset.2014.04.003. [DOI] [Google Scholar]

- 4.C. James, Graham Purnell, S.J. James, A Review of Novel and Innovative Food Freezing Technologies [J]. Food and Bioprocess Technology, 2015, 8: 1616-1634. https://doi.org/10.1007/s11947-015-1542-8.

- 5.Li B., Sun D.W. Novel methods for rapid freezing and thawing of foods – a review. J. Food Eng. 2002;54(3):175–182. doi: 10.1016/S0260-8774(01)00209-6. [DOI] [Google Scholar]

- 6.Wang G.T., Liu Y.P., Yong H.M., Zong S., Jin C.H., Liu J. Effect of ferulic acid-grafted-chitosan coating on the quality of pork during refrigerated storage. Foods. 2021;10(6):1374. doi: 10.3390/foods10061374. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Mohsen D.I., Nasser H., Epameinondas X., Alain L.B. Review on the control of ice nucleation by ultrasound waves, electric and magnetic fields. J. Food Eng. 2017;195:222–234. doi: 10.1016/j.jfoodeng.2016.10.001. [DOI] [Google Scholar]

- 8.Liang D.W., Lin F.Y., Yang G.M., Yue X.J., Zhang Q.K., Zhang Z.Q., Chen H.B. Advantages of immersion freezing for quality preservation of litchi fruit during frozen storage. LWT – Food Sci. Technol. 2015;60(2):948–956. doi: 10.1016/j.lwt.2014.10.034. [DOI] [Google Scholar]

- 9.Otero L., Pérez-Mateos M., López-Caballero M.E. Hyperbaric cold storage versus conventional refrigeration for extending the shelf-life of hake loins. Innovat. Food Sci. Emerg. Technol. 2017;41:19–25. doi: 10.1016/j.ifset.2017.01.003. [DOI] [Google Scholar]

- 10.Creed P.G., Bailey C., James S.J., Harding C.D. Air thawing of lamb carcasses. Int. J. Food Sci. Technol. 1979;14(2):181–191. doi: 10.1111/j.1365-2621.1979.tb00862.x. [DOI] [Google Scholar]

- 11.Chen C., Mei J., Xie J. Impact of thawing methods on physico-chemical properties and microstructural characteristics of concentrated milk. J. Food Process. Preserv. 2021;45(9):e15642. [Google Scholar]

- 12.Zheng L.Y., Sun D.W. Innovative applications of power ultrasound during food freezing processes—a review. Trends Food Sci. Technol. 2006;17(1):16–23. doi: 10.1016/j.tifs.2005.08.010. [DOI] [Google Scholar]

- 13.Qiu L.Q., Zhang M., Chitrakar B., Bhandari B. Application of power ultrasound in freezing and thawing Processes: effect on process efficiency and product quality. Ultrason Sonochem. 2020;68 doi: 10.1016/j.ultsonch.2020.105230. [DOI] [PubMed] [Google Scholar]

- 14.Nowak K.W., Zielinska M., Waszkielis K.M. The effect of ultrasound and freezing/thawing treatment on the physical properties of blueberries. Food Sci. Biotechnol. 2018;08(28):741–749. doi: 10.1007/s10068-018-0528-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Sanz P.D., Elvira C.D., Martino M., Zaritzky N., Otero L., Carrasco J.A. Freezing rate simulation as an aid to reducing crystallization damage in foods. Meat Sci. 1999;52(3):275–278. doi: 10.1016/S0309-1740(99)00002-9. [DOI] [PubMed] [Google Scholar]

- 16.Wu X.F., Zhang M., Adhikari B., Sun J.C. Recent developments in novel freezing and thawing technologies applied to foods. Crit. Rev. Food Sci. Nutr. 2017;57(17):3620–3631. doi: 10.1080/10408398.2015.1132670. [DOI] [PubMed] [Google Scholar]

- 17.Leygonie C., Britz T.J., Hoffman L.C. Impact of freezing and thawing on the quality of meat: review. Meat Sci. 2012;91(2):93–98. doi: 10.1016/j.meatsci.2012.01.013. [DOI] [PubMed] [Google Scholar]

- 18.Körzendörfer A. Vibrations and ultrasound in food processing – sources of vibrations, adverse effects, and beneficial applications – An overview. J. Food Eng. 2022;324 doi: 10.1016/j.jfoodeng.2021.110875. [DOI] [Google Scholar]

- 19.Saclier M., Peczalski R., Andrieu J. A theoretical model for ice primary nucleation induced by acoustic cavitation. Ultrason. Sonochem. 2010;17(1):98–105. doi: 10.1016/j.ultsonch.2009.04.008. [DOI] [PubMed] [Google Scholar]

- 20.Guiné R.P.F., Florença S.G., Barroca M.J., Anjos O. The duality of innovation and food development versus purely traditional foods. Trends Food Sci. Technol. 2021;109:16–24. doi: 10.1016/j.tifs.2021.01.010. [DOI] [Google Scholar]

- 21.Bhargava N., Mor R.S., Kumar K., Sharanagat V.S. Advances in application of ultrasound in food processing: a review. Ultrason. Sonochem. 2021;70 doi: 10.1016/j.ultsonch.2020.105293. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Li S.Y., Zhang R., Lei D., Huang Y.Q., Cheng S.Y., Zhu Z.Z., Wu Z.L., Cravotto G. Impact of ultrasound, microwaves and high-pressure processing on food components and their interactions. Trends Food Sci. Technol. 2021;109:1–15. doi: 10.1016/j.tifs.2021.01.017. [DOI] [Google Scholar]

- 23.Svendsen E.S., Widell K.N., Tveit G.M., Nordtvedt T.S., Uglem S., Standal I., Greiff K. Industrial methods of freezing, thawing and subsequent chilled storage of whitefish. J. Food Eng. 2022;315 doi: 10.1016/j.jfoodeng.2021.110803. [DOI] [Google Scholar]

- 24.McDonald K., Sun D.W. Vacuum cooling technology for the food processing industry: a review. J. Food Eng. 2000;45(2):55–65. doi: 10.1016/S0260-8774(00)00041-8. [DOI] [Google Scholar]

- 25.Kono S.J., Kon M., Araki T., Sagara Y. Effects of relationships among freezing rate, ice crystal size and color on surface color of frozen salmon fillet. J. Food Eng. 2017;214:158–165. doi: 10.1016/j.jfoodeng.2017.06.023. [DOI] [Google Scholar]

- 26.Tan M., Ding Z., Xie J. Freezing-induced myofibrillar protein denaturation: Contributions of freeze-concentration and role of cellobiose. J. Food Eng. 2022;329:111076. [Google Scholar]

- 27.Zhou P.C., Chu Y.M., Lv Y., Xie J. Quality of frozen mackerel during storage as processed by different freezing methods. Int. J. Food Prop. 2022;25(1):593–607. doi: 10.1080/10942912.2022.2053154. [DOI] [Google Scholar]

- 28.Ren W.Y., Yuan G.Q., Lin X.E., Guo X.H., Wang Z.L. Comparison of the immersion chilling and freezing and traditional air freezing on the quality of beef during storage. Food Science & Nutrition. 2021;9(12):6653–6661. doi: 10.1002/fsn3.2613. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Xu B.G., Azam S.M.R., Feng M., Wu B.G., Yan W.Q., Zhou C.S., Ma H.L. Application of multi-frequency power ultrasound in selected food processing using large-scale reactors: a review. Ultrason. Sonochem. 2021;81 doi: 10.1016/j.ultsonch.2021.105855. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Das K., Zhang M., Bhandari B., Chen H.Z., Bai B.S., Roy M.C. Ultrasound generation and ultrasonic application on fresh food freezing: Effects on freezing parameters, physicochemical properties and final quality of frozen foods. Food Rev. Int. 2022:1–31. doi: 10.1080/87559129.2022.2027436. [DOI] [Google Scholar]

- 31.Fu X., Belwal T., Cravotto G., Luo Z. Sono-physical and sono-chemical effects of ultrasound: primary applications in extraction and freezing operations and influence on food components. Ultrason. Sonochem. 2020;60:104726. doi: 10.1016/j.ultsonch.2019.104726. [DOI] [PubMed] [Google Scholar]

- 32.Zhang P.Z., Zhu Z.W., Sun D.W. Using power ultrasound to accelerate food freezing processes: effects on freezing efficiency and food microstructure. Crit. Rev. Food Sci. Nutr. 2018;58(16):2842–2853. doi: 10.1080/10408398.2018.1482528. [DOI] [PubMed] [Google Scholar]

- 33.Ma X., Mei J., Xie J. Mechanism of ultrasound assisted nucleation during freezing and its application in food freezing process. Int. J. Food Prop. 2021;24(1):68–88. doi: 10.1080/10942912.2020.1858862. [DOI] [Google Scholar]

- 34.Gao S.P., Hemar Y.a., Ashokkumar M., Paturel S., Lewis G.D. Inactivation of bacteria and yeast using high-frequency ultrasound treatment. Water Res. 2014;60(sep.1):93–104. doi: 10.1016/j.watres.2014.04.038. [DOI] [PubMed] [Google Scholar]

- 35.Wen C.T., Zhang J.X., Zhang H.H., Dzah C.S., Zandile M., Duan Y.Q., Ma H.L., Luo X.P. Advances in ultrasound assisted extraction of bioactive compounds from cash crops – A review. Ultrason. Sonochem. 2018;48:538–549. doi: 10.1016/j.ultsonch.2018.07.018. [DOI] [PubMed] [Google Scholar]

- 36.Chew S.C., Ali M.A. Recent advances in ultrasound technology applications of vegetable oil refining. Trends Food Sci. Technol. 2021;116:468–479. doi: 10.1016/j.tifs.2021.08.001. [DOI] [Google Scholar]

- 37.Patrick M., Blindt R., Janssen J. The effect of ultrasonic intensity on the crystal structure of palm oil. Ultrason. Sonochem. 2004;11(3):251–255. doi: 10.1016/j.ultsonch.2004.01.017. [DOI] [PubMed] [Google Scholar]

- 38.Xu X., Zhang L., Feng Y.B., Zhou C.S., Yagoub A.E.A., Wahia H., Ma H.L., Zhang J., Sun Y.H. Ultrasound freeze-thawing style pretreatment to improve the efficiency of the vacuum freeze-drying of okra (Abelmoschus esculentus (L.) Moench) and the quality characteristics of the dried product. Ultrason. Sonochem. 2021;70 doi: 10.1016/j.ultsonch.2020.105300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Chow R., Blindt R., Kamp A., Grocutt P., Chivers R. The microscopic visualisation of the sonocrystallisation of ice using a novel ultrasonic cold stage. Ultrason. Sonochem. 2004;11(3):245–250. doi: 10.1016/j.ultsonch.2004.01.018. [DOI] [PubMed] [Google Scholar]

- 40.Kawai K., Hagiwara T. Control of physical changes in food products. Adv. Exp. Med. Biol. 2018;1081:385–399. doi: 10.1007/978-981-13-1244-1_21. [DOI] [PubMed] [Google Scholar]

- 41.Bian C.H., Yu H.J., Yang K., Mei J., Xie J. Effects of single-, dual-, and multi-frequency ultrasound-assisted freezing on the muscle quality and myofibrillar protein structure in large yellow croaker (Larimichthys crocea) Food Chemistry: X. 2022;15 doi: 10.1016/j.fochx.2022.100362. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Zhang Z., Sun D.W., Zhu Z.W., Cheng L. Enhancement of crystallization processes by power ultrasound: current state-of-the-art and research advances. Compr. Rev. Food Sci. Food Saf. 2015;14(4):303–316. doi: 10.1111/1541-4337.12132. [DOI] [Google Scholar]

- 43.Li H.Z., Pordesimo L., Weiss J. High intensity ultrasound-assisted extraction of oil from soybeans. Food Res. Int. 2004;37(7):731–738. doi: 10.1016/j.foodres.2004.02.016. [DOI] [Google Scholar]

- 44.Thompson L.H., Doraiswamy L.K. Sonochemistry: science and engineering. Ind. Eng. Chem. Res. 1999;38(4):1215–1249. doi: 10.1021/ie9804172. [DOI] [Google Scholar]

- 45.Chen X.Q., Liu H.Y., Li X.X., Wei Y.J., Li J.R. Effect of ultrasonic-assisted immersion freezing and quick-freezing on quality of sea bass during frozen storage. LWT. 2022;154 doi: 10.1016/j.lwt.2021.112737. [DOI] [Google Scholar]

- 46.Sun Q.X., Kong B.H., Liu S.C., Zheng O.Y., Zhang C. Ultrasonic freezing reduces protein oxidation and myofibrillar gel quality loss of common carp (Cyprinus carpio) during long-time frozen storage. Foods. 2021;10(3):629. doi: 10.3390/foods10030629. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.L.Z. Ye, X.J. Zhu, Y. Liu, Numerical study on dual-frequency ultrasonic enhancing cavitation effect based on bubble dynamic evolution [J]. Ultrasonics Sonochemistry, 2019, 59: https://104744. 10.1016/j.ultsonch.2019.104744. [DOI] [PubMed]

- 48.Fu X.Z., Belwal T., Cravotto G., Luo Z.S. Sono-physical and sono-chemical effects of ultrasound: primary applications in extraction and freezing operations and influence on food components. Ultrason. Sonochem. 2020;60 doi: 10.1016/j.ultsonch.2019.104726. [DOI] [PubMed] [Google Scholar]

- 49.Shen X., Zhang M., Devahastin S., Guo Z.M. Effects of pressurized argon and nitrogen treatments in combination with modified atmosphere on quality characteristics of fresh-cut potatoes. Postharvest Biol. Technol. 2019;149:159–165. https://10.1016/j.postharvbio.2018.11.023 [Google Scholar]

- 50.Chemat F., Huma Z.E., Khan M.K. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011;18(4):813–835. doi: 10.1016/j.ultsonch.2010.11.023. https://10.1016/j.ultsonch.2010.11.023 [DOI] [PubMed] [Google Scholar]

- 51.Khadhraoui B., Fabiano-Tixier A.-S., Robinet P., Imbert R., Chemat F. Green Food Processing Techniques. Elsevier; 2019. 2 - Ultrasound technology for food processing, preservation, and extraction [M]//CHEMAT F, VOROBIEV E; pp. 23–56. [Google Scholar]

- 52.Hashemi S.M.B., Abhari K., Khaneghah A.M. The combined effects of ultrasound and lactic acid in inactivating microorganisms on fresh radish (Raphanus raphanistrum subsp. sativus): microbiological and quality changes. Food Science & Nutrition. 2020;8(1):162–169. doi: 10.1002/fsn3.1287. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Pagnossa J.P., Rocchetti G., Ribeiro A.C., Piccoli R.H., Lucini L. Ultrasound: beneficial biotechnological aspects on microorganisms-mediated processes. Curr. Opin. Food Sci. 2020;31:24–30. doi: 10.1016/j.cofs.2019.10.006. [DOI] [Google Scholar]

- 54.Yu X.J., Bao X.J., Zhou C.S., Zhang L., Yagoub A.E., Yang H.P., Ma H.L. Ultrasound-ionic liquid enhanced enzymatic and acid hydrolysis of biomass cellulose. Ultrason. Sonochem. 2018;41:410–418. doi: 10.1016/j.ultsonch.2017.09.003. [DOI] [PubMed] [Google Scholar]

- 55.Wang D.L., Yan L.F., Ma X.B., Wang W.J., Zou M.M., Zhong J.J., Ding T., Ye X.Q., Liu D.H. Ultrasound promotes enzymatic reactions by acting on different targets: Enzymes, substrates and enzymatic reaction systems. Int. J. Biol. Macromol. 2018:453-461. doi: 10.1016/j.ijbiomac.2018.07.133. [DOI] [PubMed] [Google Scholar]

- 56.E.A. Alenyorege, H.L. Ma, I. Ayim, F. Lu, Cunshan Zhou, Efficacy of sweep ultrasound on natural microbiota reduction and quality preservation of Chinese cabbage during storage [J]. Ultrasonics Sonochemistry, 2019, 59: 104712. https://doi.org/10.1016/j.ultsonch.2019.104712. [DOI] [PubMed]

- 57.Beydokhti S.A., Rajabi M., Asghari A. Coupling of two centrifugeless ultrasound-assisted dispersive solid/liquid phase microextractions as a highly selective, clean, and efficient method for determination of ultra-trace amounts of non-steroidal anti-inflammatory drugs in complicated matrices. Anal. Chim. Acta. 2018;997:67–79. doi: 10.1016/j.aca.2017.10.005. [DOI] [PubMed] [Google Scholar]

- 58.Roohinejad S., Koubaa M., Sant'Ana A.D.S., Greiner R. Mechanisms of microbial inactivation by emerging technologies. Innovat. Technol. Food Preservat. 2018:111–132. doi: 10.1016/B978-0-12-811031-7.00004-2. [DOI] [Google Scholar]

- 59.Islam M.N., Zhang M., Adhikari B. The inactivation of enzymes by ultrasound—A review of potential mechanisms. Food Reviews International. 2014;30(1):1–21. doi: 10.1080/87559129.2013.853772. [DOI] [Google Scholar]

- 60.Yeoh W.K., Ali A. Ultrasound treatment on phenolic metabolism and antioxidant capacity of fresh-cut pineapple during cold storage. Food Chem. 2017;216:247–253. doi: 10.1016/j.foodchem.2016.07.074. [DOI] [PubMed] [Google Scholar]

- 61.Franco R.R., Ojeda G.A., Rompato K.M., Sgroppo S.C. Effects of short-wave ultraviolet light, ultrasonic and microwave treatments on banana puree during refrigerated storage. Food Sci. Technol. Int. 2021 doi: 10.1177/10820132211058444. 10820132211058444. [DOI] [PubMed] [Google Scholar]

- 62.Nowak K.W., Zielinska M., Waszkielis K.M. The effect of ultrasound and freezing/thawing treatment on the physical properties of blueberries. Food Sci. Biotechnol. 2019;28(3):741–749. doi: 10.1007/s10068-018-0528-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Li D.N., Zhao H.H., Muhammad A.I., Song L.Y., Guo M.M., Liu D.H. The comparison of ultrasound-assisted thawing, air thawing and water immersion thawing on the quality of slow/fast freezing bighead carp (Aristichthys nobilis) fillets. Food Chem. 2020;320 doi: 10.1016/j.foodchem.2020.126614. [DOI] [PubMed] [Google Scholar]

- 64.Cai L.Y., Cao M.J., Cao A.L., Regenstein J., Li J.R., Guan R.F. Ultrasound or microwave vacuum thawing of red seabream (Pagrus major) fillets. Ultrason. Sonochem. 2018;47:122–132. doi: 10.1016/j.ultsonch.2018.05.001. [DOI] [PubMed] [Google Scholar]

- 65.Farahnak R., Nourani M., Riahi E. Ultrasound thawing of mushroom (Agaricus bisporus): effects on thawing rate, protein denaturation and some physical properties. LWT. 2021;151 doi: 10.1016/j.lwt.2021.112150. [DOI] [Google Scholar]

- 66.Kissam A.D., Nelson R.W., Ngao J., Hunter P. Water-thawing of fish using low frequency acoustics. J. Food Sci. 1982;47(1):71–75. doi: 10.1111/j.1365-2621.1982.tb11029.x. [DOI] [Google Scholar]

- 67.Li X.X., Ma Y.Y., Sun P., Liu H.Y., Cai L.Y., Li J.R. Effect of ultrasonic thawing on protein properties and muscle quality of Bonito. J. Food Process. Preserv. 2020;45(1):e14930. [Google Scholar]

- 68.Antunes-Rohling A., Astráin-Redín L., Calanche-Morales J.B., Marquina P., Beltrán J.A., Raso J., Cebrián G., Álvarez I. Eco-innovative possibilities for improving the quality of thawed cod fillets using high-power ultrasound. Food Control. 2021;121 doi: 10.1016/j.foodcont.2020.107606. [DOI] [Google Scholar]

- 69.Gan S.L., Zhang M., Mujumdar A.S., Jiang Q.Y. Effects of different thawing methods on quality of unfrozen meats. Int. J. Refrig. 2022;134:168–175. doi: 10.1016/j.ijrefrig.2021.11.030. [DOI] [Google Scholar]

- 70.Li X.X., Sun P., Jia J.Z., Cai L.Y., Li J.R., Lv Y.F. Effect of low frequency ultrasound thawing method on the quality characteristics of Peru squid (Dosidicus gigas) Food Sci. Technol. Int. 2018;25(2):171–181. doi: 10.1177/1082013218809556. [DOI] [PubMed] [Google Scholar]

- 71.Gambuteanu C., Alexe P. Comparison of thawing assisted by low-intensity ultrasound on technological properties of pork Longissimus dorsi muscle. J. Food Sci. Technol. 2013;52(4):2130–2138. doi: 10.1007/s13197-013-1204-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 72.Li J.G., Ma X.Y., Wang Y., Du M.T., Wang Y.T., Du J., Li K., Bai Y.H. Effects of immersion freezing on the conformational changes of myofibrillar proteins in pork under ultrasonic power densities of 0, 15, 30 and 45 W/L. Int. J. Food Sci. Technol. 2022;57(5):1896–2905. doi: 10.1111/ijfs.15596. [DOI] [Google Scholar]

- 73.Sun Q.X., Zhang C., Li Q.X., Xia X.F., Kong B.H. Changes in functional properties of common carp (Cyprinus carpio) myofibrillar protein as affected by ultrasound-assisted freezing. J. Food Sci. 2020;85(9):2879–2888. doi: 10.1111/1750-3841.15386. [DOI] [PubMed] [Google Scholar]

- 74.Firouz M.S., Sardari H., Chamgordani P.A., Behjati M. Power ultrasound in the meat industry (freezing, cooking and fermentation): mechanisms, advances and challenges. Ultrason. Sonochem. 2022;86 doi: 10.1016/j.ultsonch.2022.106027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 75.Qiu S., Cui F.C., Wang J.X., Zhu W.H., Xu Y.X., Yi S.M., Li X.P., Li J.R. Effects of ultrasound-assisted immersion freezing on the muscle quality and myofibrillar protein oxidation and denaturation in Sciaenops ocellatus. Food Chem. 2022;377 doi: 10.1016/j.foodchem.2021.131949. [DOI] [PubMed] [Google Scholar]

- 76.Chen X.H., Wang Z.R., Kan J.Q. Polysaccharides from ginger stems and leaves: effects of dual and triple frequency ultrasound assisted extraction on structural characteristics and biological activities. Food Bioscience. 2021;42(4) doi: 10.1016/j.fbio.2021.101166. [DOI] [Google Scholar]

- 77.Zhai W., Liu H.M., Hong Z.Y., Xie W.J., Wei B. A numerical simulation of acoustic field within liquids subject to three orthogonal ultrasounds. Ultrason. Sonochem. 2017;34:130–135. doi: 10.1016/j.ultsonch.2016.05.025. [DOI] [PubMed] [Google Scholar]

- 78.Zhu Z.W., Zhang P.Z., Sun D.W. Effects of multi-frequency ultrasound on freezing rates and quality attributes of potatoes. Ultrason. Sonochem. 2020;60 doi: 10.1016/j.ultsonch.2019.104733. https://10.1016/j.ultsonch.2019.104733 [DOI] [PubMed] [Google Scholar]

- 79.Y. Tian, P.Z. Zhang, Z.W. Zhu, D.W. Sun, H.H. Xu, B.H. Kong, Development of a single/dual-frequency orthogonal ultrasound-assisted rapid freezing technique and its effects on quality attributes of frozen potatoes [J]. Journal of Food Engineering, 2020: 110112. https://doi.org/10.1016/j.jfoodeng.2020.110112https://doi.org/10.1016/j.ultsonch.2018.10.006.

- 80.Sun Q.X., Sun F.D., Xia X.F., Xu H.H., Kong B.H. The comparison of ultrasound-assisted immersion freezing, air freezing and immersion freezing on the muscle quality and physicochemical properties of common carp (Cyprinus carpio) during freezing storage - ScienceDirect. Ultrason. Sonochem. 2019;51:281–291. doi: 10.1016/j.ultsonch.2018.10.006. [DOI] [PubMed] [Google Scholar]

- 81.Ma X., Yang D.Z., Qiu W.Q., Mei J., Xie J. Influence of multifrequency ultrasound-assisted freezing on the flavour attributes and myofibrillar protein characteristics of cultured large yellow croaker (larimichthys crocea) Front. Nutr. 2021;8 doi: 10.3389/fnut.2021.779546. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 82.Nobuhara T., Matsumiya K., Nambu Y., Nakamura A., Fujii N., Matsumura Y. Stabilization of milk protein dispersion by soybean soluble polysaccharide under acidic pH conditions. Food Hydrocolloids. 2014;34(1):39–45. doi: 10.1016/j.foodhyd.2013.01.022. [DOI] [Google Scholar]

- 83.Hu F., Sun D.W., Gao W.H., Zhang Z.H., Zeng X.A., Han Z. Effects of pre-existing bubbles on ice nucleation and crystallization during ultrasound-assisted freezing of water and sucrose solution. Innovative Food Sci. Emerg. Technol. 2013;20:161–166. doi: 10.1016/j.ifset.2013.08.002. [DOI] [Google Scholar]

- 84.Xu B.G., Zhang M., Bhandari B., Sun J.C., Gao Z.X. Infusion of CO2 in a solid food: a novel method to enhance the low-frequency ultrasound effect on immersion freezing process. Innovat. Food Sci. Emerg. Technol. 2016;35:194–203. doi: 10.1016/j.ifset.2016.04.011. [DOI] [Google Scholar]

- 85.Jiang Q.Y., Zhang M., Mujumdar A.S., Hu R. Combination strategy of CO2 pressurization and ultrasound: to improve the freezing quality of fresh-cut honeydew melon. Food Chem. 2022;383 doi: 10.1016/j.foodchem.2022.132327. [DOI] [PubMed] [Google Scholar]

- 86.Jiang Q.Y., Zhang M., Mujumdar A.S., Qu P., Hu R. Pressurized carbon dioxide combined with ultrasound-assisted immersion freezing: effects on microstructure and nucleation of honeydew melon. Int. J. Refrig. 2022;137:212–219. doi: 10.1016/j.ijrefrig.2022.01.031. [DOI] [Google Scholar]

- 87.Tu J., Zhang M., Xu B.G., Liu H.H. Effects of different freezing methods on the quality and microstructure of Lotus (Nelumbo nucifera) root. Int. J. Refrig. 2015;52:59–65. https://10.1016/j.ijrefrig.2014.12.015 [Google Scholar]

- 88.Gao W., Hou R., Zeng X.-a. Synergistic effects of ultrasound and soluble soybean polysaccharide on frozen surimi from grass carp. J. Food Eng. 2019;240:1–8. [Google Scholar]

- 89.T.S. Huang, C.L. Xu, K. Walker, P. West, S.Q. Zhang, J. Weese, Decontamination Efficacy of Combined Chlorine Dioxide with Ultrasonication on Apples and Lettuce [J]. Journal of Food Science, 2010, 71(4): M134-M139. https://doi.org/10.1111/j.1750-3841.2006.00015.x.

- 90.Jang J.H., Moon K.D. Inhibition of polyphenol oxidase and peroxidase activities on fresh-cut apple by simultaneous treatment of ultrasound and ascorbic acid. Food Chem. 2011;124(2):444–449. doi: 10.1016/j.foodchem.2010.06.052. [DOI] [Google Scholar]

- 91.Zhao X.Y., Lan W.Q., Zhai Y.T., Xie J. Multi-frequency ultrasound: a potential method to improve the effects of surface decontamination and structural characteristics on large yellow croaker (Pseudosciaena crocea) during refrigerated storage. Ultrason Sonochem. 2021;79 doi: 10.1016/j.ultsonch.2021.105787. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 92.Yoon S.R., Lee J.Y., Yang J.S., Ha J.H. Bactericidal effects of diluted slightly acidic electrolyzed water in quantitative suspension and cabbage tests. LWT. 2021;152 doi: 10.1016/j.lwt.2021.112291. [DOI] [Google Scholar]

- 93.Lan W.Q., Lang A., Zhou D.P., Xie J. Combined effects of ultrasound and slightly acidic electrolyzed water on quality of sea bass (Lateolabrax Japonicus) fillets during refrigerated storage. Soc. Sci. Electron. Publish. 2021;81 doi: 10.1016/j.ultsonch.2021.105854. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 94.Li F.F., Zhong Q., Kong B.H., Pan N., Xia X.F., Bao Y.H. Synergistic effect and disinfection mechanism of combined treatment with ultrasound and slightly acidic electrolyzed water and associated preservation of mirror carp (Cyprinus carpio L.) during refrigeration storage. Food Chem. 2022;386 doi: 10.1016/j.foodchem.2022.132858. [DOI] [PubMed] [Google Scholar]

- 95.Zhou P.C., Xie J. Effect of different thawing methods on the quality of mackerel (Pneumatophorus japonicus) Food Sci. Biotechnol. 2021;30(9):1213–1223. doi: 10.1007/s10068-021-00966-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 96.Wu B.G., Qiu C.C., Guo Y.T., Zhang C.H., Guo X.Y., Bouhile Y., Ma H.L. Ultrasonic-assisted flowing water thawing of frozen beef with different frequency modes: effects on thawing efficiency, quality characteristics and microstructure. Food Res. Int. 2022;157 doi: 10.1016/j.foodres.2022.111484. [DOI] [PubMed] [Google Scholar]

- 97.Li X.X., Sun P., Ma Y.Y., Cai L.Y., Li J.R. Effect of ultrasonic thawing on the water-holding capacity, physicochemical properties and structure of frozen tuna (Thunnus tonggol) myofibrillar proteins. J. Sci. Food Agric. 2019;99(11):5083–5091. doi: 10.1002/jsfa.9752. [DOI] [PubMed] [Google Scholar]

- 98.F.F. Li, B. Wang, B.H. Kong, X.F. Xia, Y.H. Bao, Impact of Ultrasound-assisted Saline Thawing on the Technological Properties of mirror carp (Cyprinus carpio L.) [J]. Ultrasonics Sonochemistry, 2022, 86: 106014. https://doi.org/10.1016/j.ultsonch.2022.106014. [DOI] [PMC free article] [PubMed]

- 99.Chu Y.M., Tan M.T., Bian C.H., Xie J. Effect of ultrasonic thawing on the physicochemical properties, freshness, and protein-related properties of frozen large yellow croaker (Pseudosciaena crocea) J. Food Sci. 2022;87(1):52–67. doi: 10.1111/1750-3841.15983. [DOI] [PubMed] [Google Scholar]

- 100.Wang Y.Y., Yan J.K., Ding Y.H., Ma H.L. Effects of ultrasound on the thawing of quick-frozen small yellow croaker (Larimichthys polyactis) based on TMT-labeled quantitative proteomic. Food Chem. 2022;366(1) doi: 10.1016/j.foodchem.2021.130600. [DOI] [PubMed] [Google Scholar]

- 101.Wang Y.Y., Yan J.K., Rashid M.T., Ding Y.H., Chikari F., Huang S.F., Ma H.L. Dual-frequency sequential ultrasound thawing for improving the quality of quick-frozen small yellow croaker and its possible mechanisms. Innovative Food Sci. Emerg. Technol. 2021;68(3) doi: 10.1016/j.ifset.2021.102614. [DOI] [Google Scholar]

- 102.Bian C.H., Cheng H., Yu H.J., Mei J., Xie J. Effect of multi-frequency ultrasound assisted thawing on the quality of large yellow croaker (Larimichthys crocea) Ultrason. Sonochem. 2022;82 doi: 10.1016/j.ultsonch.2021.105907. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 103.Qian J., Yan L.F., Ying K.Q., Luo J., Zhuang H., Yan W.J., Zhang J.H., Zhao Y. Plasma-activated water: a novel frozen meat thawing media for reducing microbial contamination on chicken and improving the characteristics of protein. Food Chem. 2022;375 doi: 10.1016/j.foodchem.2021.131661. [DOI] [PubMed] [Google Scholar]

- 104.Ma Y.Y., Li X.X., Sun P., Li J.R. Effect of ultrasonic thawing on gel properties of tuna myofibrillar proteins. J. Food Process. Preserv. 2022;46(2):e16268. [Google Scholar]

- 105.Guo Z.L., Ge X.Z., Yang L.H., Ma G.Y., Ma J.B., Yu Q.L., Han L. Ultrasound-assisted thawing of frozen white yak meat: effects on thawing rate, meat quality, nutrients, and microstructure. Ultrason. Sonochem. 2021;70 doi: 10.1016/j.ultsonch.2020.105345. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 106.Cheng H., Bian C.H., Chu Y.M., Mei J., Xie J. Effects of dual-frequency ultrasound-assisted thawing technology on thawing rate, quality properties, and microstructure of large yellow croaker (Pseudosciaena crocea) Foods. 2022;11(2):226. doi: 10.3390/foods11020226. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 107.Cai L.Y., Zhang W.D., Cao A.L., Cao M.J., Li J.R. Effects of ultrasonics combined with far infrared or microwave thawing on protein denaturation and moisture migration of Sciaenops ocellatus (red drum) Ultrason. Sonochem. 2019;55:96–104. doi: 10.1016/j.ultsonch.2019.03.017. [DOI] [PubMed] [Google Scholar]

- 108.Xie, J.;Xu, Q.J.; Wang, J.F. & Sun Y.Y. (2021). Ultrasound freezing equipment and freezing method using same. Patent No. CN202110049445.9. Published on 14 January 2021.

- 109.Linde, A. (2011). Method and apparatus for ultrasonic freezing. Patent No. EP2269474A2. Published on 5 May 2011.

- 110.Chen, L.D. (2014). Ultrasonic freezing immersion type freezing liftable dedicated machine set. Patent No. TW103207050. Published on 21 September 2014.

- 111.Cao, X.H.; Bai, G.; Wang; Z.N.; L, J.R.; Zhu, D.S.; Guo; X.H. & Mou, W.L. (2020). Ultrasonic-assisted oyster freezing method. Patent No. CN111955535A. Published on 20 November 2020.

- 112.Gao, W.H.; Hou, R.; Sun, D.W. & Zeng, X.A. (2017). Method for freezing surimi by ultrasonic waves together with water-soluble soybean polysaccharide. Patent No. CN107198149A. Published on 26 September 2017.

- 113.Sun, D.W.; Hu, F.; Zeng, X.A.; Wang, Q.J. & Gao, W.H. (2013). Method for improving brine salting-process frozen fish fillets through variable-power ultrasonic wave. Patent No. CN:201310100237:A. Published on 26 June 2013.

- 114.Sun, D.W.; Hu, F.; Zeng, X.A.; Wang, Q.J. & Gao, W.H. (2013). Method for improving the freezing speed and quality of litchi chinensis through variable-frequency ultrasonic enhancement. Patent No. CN103168828A. Published on 26 March 2013.

- 115.Mao, Y.D. (2013). Ultrasonic defroster. Patent No. CN202890408U. Published on 24 April 2013.

- 116.Zeng, Z.S.; J, Y. & X, B. (2017). Ultrasonic wave thawing equipment. Patent No. CN206808598U. Published on 29 December 2017.

- 117.Xie, J.; Tan, M.T.; Yu, W.H.; Wang, J.F.; Wang, X.S. & Li, J.R. (2019). Ultrasonic water water-flowing thawing device for squids and method for thawing squids. Patent No. CN110393210A. Published on 1 November 2019.

- 118.Du, H.D.; Xu, B.D.; Xie H.R. & Zhang, J.Z. (2018). Ultrasonic wave thawing equipment and refrigerator. Patent No. CN207885597U. Published on 21 September 2018.

- 119.Lin, X.L. (2016). Ultrasonic wave sea water squid thawing apparatus. Patent No. CN205611648U. Published on 5 October 2016.

- 120.You, X.L. & You, X.Z. (2020). Ultrasonic thawing equipment for aquatic products. Patent No. CN211268413U. Published on 18 August 2020.

- 121.Li, J.; Liang, J.N.; Zhang, B. & Jiao, J.S. (2019). Ultrasonic thawing control method and thawing device. Patent No. CN109619370A. Published on 16 April 2019.

- 122.Sun, X.J.; Li, X.X.; Liu, X.F.; Zhang, D.F.; Li, J.R.; Guo, X.H. & Mou, W.L. (2020). Method for defrosting raw tuna with high-frequency ultrasonic wave. Patent No. CN111096354A. Published on 5 May 2020.

- 123.Cui, H.J.; Wang, X.Q.; Zhang, Y.; Zhang, Y.H.; Xu, F.F.; Guo, J.H. & Liu, W.B. (2021). Ice melting device combining ultrasonic waves and microwaves. Patent No. CN212325324U. Published on 12 January 2021.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable as it is a review. Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

The authors do not have permission to share data.