Abstract

An experimental research is assessed to examine the engine performance and exhaust emissions of direct injection (DI) and indirect injection diesel (IDI) engines fueled with petroleum diesel, biodiesel, and nanoemulsion fuel. The nanoemulsion fuel was produced using a hydrodynamic cavitation reactor. These three fuels were used to study the exhaust emissions, brake power, brake specific fuel consumption (BSFC), brake thermal efficiency (BTE), and exhaust gas temperature at engine speeds ranging from 1100, 1400, 1700, 2000, and 2300 rpm with engine loads of 25, 50, and 75%. Furthermore, three fuels were burned in two types of combustion engines such as DI and IDI diesel engines under identical conditions. The finding showed that using DI and IDI engines influenced the magnitude of emissions as well as the performance with different speeds and loads. By comparing the performance of DI and IDI engines at a maximum engine load of 75%, the most concerning parameter among the efficiency of an engine of BTE of diesel, biodiesel, and nanoemulsion fuel from the DI engine was higher at 24.19, 24.83, and 20.76%, respectively, than that of the IDI engine at 2300 rpm engine speed. At the maximum load and speed of engines, the BSFC of diesel, biodiesel, and nanoemulsion fuel in the DI engine were 4.44, 23.73, and 20% lower than in the IDI engine, respectively. Emission results of the DI and IDI engines were analyzed at 75% load and 2300 rpm speed. The results demonstrated that emissions of NOx from nanoemulsion fuel from the IDI engine was significantly reduced by 82.46% when the values were compared to the DI engine. In terms of CO emissions, the IDI engine emits significantly less than the DI diesel engine. The CO emissions of diesel, biodiesel, and nanoemulsion fuel in the IDI engine were 69.02, 28.95, and 48.75% lower than those in the DI engine, respectively. The studies conclude that the emissions from IDI engines clearly show that pollution from exhaust emissions can be reduced to a low level compared to the DI engine. However, when high-performance engines are considered, the DI engine is recommended rather than the IDI engine.

1. Introduction

The internal combustion diesel engine has acted as a dependable and efficient engine for a long time. Because of increased concern about energy sources and environmental impact, there has recently been a surge of interest in the study of diesel engine operation. For the vehicle population, the diesel engine is increasingly being considered a possible replacement for the spark ignition engine.1 The emissions of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM) are the most pollutants in diesel engines. Some researchers such as Landi et al.2 and Di Sarli et al.3 are trying to reduce such PM using advanced catalytic diesel particulate filters (DPFs).2,3 As soon as they exceeded the limits set by the European emission standards, those emissions become a topic of concern.4 Therefore, reducing emissions from the exhaust and supporting fuel economy have become major issues in combustion engines and environmental improvement through the transportation sector.5 Alternative fuel research should be expanded in both indirect injection (IDI) and direct injection (DI) diesel engines.6 In particular, indirect injection diesel engines with simple fuel injection and reduced injection pressure can perform with heavy and high-density biofuel.7 Furthermore, the IDI engine emits less NOx than the DI engine because there is no air mix in the secondary stage of a combustion chamber and the temperature in the primary combustion chamber is lower.8 For IDI diesel engines, a pre-combustion chamber, also known as a swirl chamber or a pre-chamber, was included. Pre-chamber injection of fuel ensures that the fuel swiftly mixes with air and auto-ignition.9 The DI diesel engines require a high injection pressure to inject fuel directly into a piston-cylinder combustion chamber. As a result of the complete atomization of fuels, these engines do not need a pre-chamber to ensure appropriate fuel diffusion into the air.10 For the usage of oil–diesel blends as an alternative fuel in a diesel engine, Rahman et al.11 studied the emission analysis using diesel blend with three essential oils including orange, eucalyptus oil, and tea tree oil blends (5 and 10% blended with diesel) in a six-cylinder, 5.9 L, turbocharged diesel engine at 1500 rpm engine speed with four different engine loads of 25, 50, 75, and 100%. The results were compared to petroleum diesel and diesel–10% biodiesel blends, wherein biodiesel was produced from waste cooking oils. The results showed that the lowest NOx and CO emission was found using a eucalyptus oil–diesel blend followed by orange and tea tree oil–diesel blend. Thus, the tea tree oil–diesel blend had the most CO and NOx emission among these three essential oil–diesel blends. Although all these essential oils consisted of oxygen content, the emission rate of each essential oil was different because of different chemical structures, for example, the dissimilar and complex bonding of oxygen molecules into the structures. However, NOx emission of all these essential oil–diesel blends was lower than that of diesel because all these essential oils had a lower cetane number than diesel, which causes shorter ignition delay and a better combustion process.11 The following are the important studies that have been undertaken in recent years on the influence of split injection on the combustion process and emission characteristics in diesel engines of DI and IDI. When compared to a single injection, Jafarmadar12 described split injection as an effective approach for lowering both NOx and soot emissions in the DI and IDI engines. They used simulation models to evaluate the effect of single and three different split injections at 10, 20, and 25% full fuel injected of the second pulse in DI and IDI engines to optimize the lowest NOx emissions and soot emission. For the IDI engine, the optimum case for NOx and soot emission was 75% first pulse injection, 20 °CA (crank angle) second pulse injection, and a 25% delay between injections (75%–20 °CA–25%). For the DI engine, the injection case of 75%–25 °CA–25% was the lowest for NOx and soot emissions. According to their results, the NOx and soot emissions were 302 and 1180 ppm for IDI and DI engines, respectively, in the case of 75%–25 °CA–25% injection. Therefore, the emissions of NOx and soot from the IDI engine were lower than those from the DI engine due to the high turbulence intensity of the IDI engine.12 For another research topic of the comparison of emissions and performance between DI and IDI diesel engines, Putrasari et al.13 tested the modified four-stroke diesel engine. For the modification of IDI to DI’s combustion chamber, the pre-chamber was enclosed in a cylinder head with a tin cast; the injector was replaced with another injector that was slightly higher and larger than the origin for injection capacity and other modifications such as ring groove, piston pinhole, and piston length. The engine was run at 1500 rpm engine speed by varying engine loads of 0, 10, 20, 30, 40, 50, and 60 Nm. For BSFC, the IDI engine’s BSFC was higher than that of the DI engine because the primary and secondary combustion processes took place in the IDI engine. The smoke emission percentage of the DI engine was significantly higher than that of the IDI engine. At the maximum load condition, the smoke emission percentage of the DI engine was approximately 99%, while the IDI engine was around 10%. For CO emission, the CO emission amount of the IDI engine was significantly smaller than that of the DI engine. At the maximum load case, the percentage of CO emission in the IDI engine was only around 0.1%, while the DI engine emitted approximately 1.2% of CO emission.13 Moreover, Huang et al.14 described the phenomenon of emissions and performance of the DI an IDI engine using diesel and diesel mixed with Chinese pistache biodiesel, which consisted of 70 wt % diesel and 30 wt % biodiesel. The testing process for the engine was run with two different engine speeds of 1500 and 2000 rpm. Their results showed that the NOx emission of the IDI engine was lower by 66% than the DI engine. The smoke emission of the IDI engine was reduced by 70% for diesel and by 60% for blended fuel compared to the DI engine. The BTE and BSFC of the IDI engine were around 10% lower and 9% higher, respectively, than those of the DI engine. In general, the emissions of blended fuel, especially NOx and CO, were less than diesel fuel in both DI and IDI engines. However, the BTE and BSFC of blended fuel were higher than those of diesel fuel.14 According to the research reports discussed above, the IDI engine contributes lower pollutant emissions than the DI engine. This is an important factor to consider for reducing environmental air pollution. In addition to providing a partial solution for reducing exhaust gas emissions, the biodiesel can be mixed with diesel to minimize CO, unburned hydrocarbon (HC), and toxic gas emissions15 because biodiesel is a highly oxygenated fuel that contains more oxygen atoms that can enhance the efficiency of combustion. The emissions analysis of diesel–biodiesel fuel blends, such as nitrogen dioxide (NO2) and NOx emission, as well as the NO2 to NOx ratio, were performed in a diesel engine with two different diesel–biodiesel blends of diesel blended with B10 and B20 at constant speed of 1500 rpm and constant load of 25%, where the biodiesel was produced from coconut oil. The results showed that NOx emissions during the cold-operation period were clearly higher than those during the hot-operation period by 31–60%. It was related to differences in combustion temperature and injection strategy. The cold operating phase resulted in 1.14–2.42 times higher NO2 emissions than the hot operation period. The NO2 emissions of diesel were much greater than those of B10 and B20 fuel blends.16 Moreover, water-in-oil emulsion fuel composed of a small droplet of water in diesel and biodiesel, known as diesel–biodiesel–water blends, can reduce the NOx emissions, carbon dioxide (CO2), and HC emissions.17 The water content is added as an internal phase emulsion to the diesel and biodiesel fuel blends. When the combustion process occurs inside the cylinder, the droplet of water first evaporates due to the fact that the boiling point of water is lower than that of oil and then explodes into tiny droplets of fuel due to a micro-explosion effect that lowers the temperature of the combustion chamber, which can improve combustion efficiency.18 Many researchers such as Alaa et al.,19 Najjar et al.,20 and Vellaiyan21,22 studied the water-in-oil emulsion fuel to reduce the emission gases. Only a few studies have been conducted on nanoemulsion fuel testing in DI and IDI engines to compare performances and emissions. Therefore, the current research will fulfill these critical knowledge gaps.

The water-in-oil (W/O) emulsion fuels were the most economical approach and can be used to get better efficient combustion in the diesel engine without modifying any of the engine components. Another advantage was the considerable decrease in NOx emission caused by lowering the temperature of the combustion chamber by micro-explosion of small droplets of W/O emulsion fuel during the combustion process. Furthermore, the presence of water in emulsion fuel can also reduce the formation rate of soot or PM and support the burning process inside the cylinder due to its high oxidation concentration.23 A research contribution of employing water-in-diesel emulsion in a four-stroke single-cylinder diesel engine to reduce NOx and HC emissions was studied by Kannan and Udayakumar.24 The engine was tested under three types of fuel, namely, pure diesel, diesel with 10 vol % water (D10), and diesel with 20 vol % water (D20) at a fixed engine speed of 1500 rpm with varying engine loads of 1, 2, 3, 4, and 5 kW. Their results showed that BTE increased when the proportion of water presence increased in emulsion fuel because the water vapor expansion in the cylinder provides a downward force acting on the top of the piston, resulting in increased torque during the cycle. BSFC dropped across all engine loads as the water content in an emulsion fuel increased owing to lower heat losses and improved thermal efficiency. The lowest BSFC value of 0.2 kg/kW·h was found at a maximum load of 5 kW using D20 blended fuel. For the emission analysis, NOx and HC emissions of D20 were the lowest compared to the diesel and D10 fuels. The NOx reduction percentages for D10 and D20 were 10 and 20%. Because of the impact of water vaporization, the water phase in the emulsion fuel helps in lowering the flame temperature. For the HC emission, when the water amount in the emulsion increased, the HC emissions were decreased at all loads because of the phenomenon of micro-explosion in emulsion fuel resulting in the formation of fine droplet disintegration and the development of the fuel–air mixing in the combustion chamber.24 Another emulsion fuel testing was contributed by the research team of Khalife et al.25 who studied the mixing of water, biodiesel, and diesel blending. For blending conditions, the biodiesel from used frying oil was 5 wt % and the water content was 2, 4, and 6 wt %. Span80 and Tween80 surfactants were used in a mass ratio of 1:1. An ultrasonic homogenizer was utilized for the emulsion fuel formation. The ultrasonic bath process was used to prepare the emulsion within a mixing time of 10 min. The engine was run with diesel, biodiesel B5, and different water–biodiesel–diesel blended fuels of B5W2, B5W4, and B5W6 at 10 kW engine load and different engine speeds of 1000–2500 rpm. When the water content of the emulsion fuel was increased, the brake power (Pb) decreased. The BSFC increased under the emulsion fuels of B5W2 and B5W6, whereas it decreased in the B5W4 fuel. They found that this is due to the effect of water on fuel viscosity, the lower calorific value of the blended fuel, and the micro-explosion phenomena. The CO, NOx, and O2 emissions of all emulsion fuels were lower than diesel except for the HC and CO2 emissions at a maximum speed of 2500 rpm because the water in emulsion fuel could decrease the combustion temperature.25

In the earlier research of our team (Oo et al.),26 the diesel–biodiesel–water nanoemulsion fuel production using a 3D-printed rotor–stator hydrodynamic cavitation reactor was described in detail. In this research, the optimization of the rotor parameters in the stator such as the hole diameter and hole depth over the rotor surface, the rotor speed, and the coarse emulsion fuel flow rate was analyzed to produce nanoemulsion fuel. The optimized condition was a hole diameter of 5.8 mm, a hole depth of 6.4 mm, a rotor speed of 4011 rpm, and an 11.8 L/h emulsion flow rate. This optimized condition successfully produced 257.6 nm average droplet size nanoemulsion fuel. This nanoemulsion fuel was tested at different engine speeds without varying loads. The findings indicated that when compared to diesel and biodiesel, the NOx emissions from nanoemulsion fuel were reduced by 60.4 and 57.53%, respectively. With the maximum speed, the fuel consumption of nanoemulsion fuel was 3.32% inferior to the biodiesel and 18.18% superior to the diesel.26

According to the abovementioned research reports about the comparison of the performance and emission analysis between the DI and IDI engines, in terms of engine performance, the DI is better than the IDI. However, in terms of emission analysis, the IDI is better than the DI engines. In addition, to the best of our knowledge according to the summary reviews of engine testing for engine performances and emissions analysis as listed in Table 1, no published study has yet examined the D42B50W2S3T3 nanoemulsion fuel with diesel, biodiesel, water, Span80, and Tween80 compositions of 42, 50, 2, 3, and 3 vol %, respectively. Therefore, this nanoemulsion fuel, diesel, and biodiesel were examined for the gas emissions of NOx, CO, CO2, O2, HC, Pb, BSFC, and BTE in the IDI and DI diesel engines by ranging speeds of engine from 1100 to 2300 rpm and varying the engine loads of 25, 50, and 75% using a dynamometer to fill the knowledge gaps about applying nanoemulsion fuel in IDI and DI diesel engines.

Table 1. Summary Reviews of Engine Testing for Engine Performances and Emissions Analysis.

| reference | blended fuel | blending method | tested engine | engine speed (rpm) | engine load | engine performance | emissions analysis |

|---|---|---|---|---|---|---|---|

| Putrasari et al.13 | diesel | IDI and modified DI engine | 1500 | 0, 10, 20, 30, 40, 50, and 60 Nm | IMEPa and BSFC | smoke and CO | |

| Huang et al.14 | diesel mixed with Chinese pistache biodiesel | stirrer | IDI and DI engine | 1500 and 2000 | 1–10 kW | BSFC and BTE | NOx, smoke, CO, and HC |

| Kalam et al.27 | diesel mixed with coconut oil | stirrer | IDI engine | 800–3200 | 10–1000 Nm | BP and SFC | HC, smoke, EGT, CO, NOx, and CO2 |

| Ozsezen et al.28 | diesel mixed with biodiesel from used frying palm oil | stirrer | IDI engine | 1000–3000 | full load condition | BSFC, BP, and BTE | EGT |

| Kannan and Udayakumar24 | diesel–water | stirrer | DI engine | 1500 | 1, 2, 3, 4, and 5 kW | BTE and BSFC | NOx and HC |

| Rahman et al.11 | diesel–essential oils | stirrer | DI engine | 1500 | 25, 50, 75, and 100% | CO, NOx, and PM | |

| Khalife et al.25 | diesel–biodiesel–water | ultrasound homogenizer | DI engine | 1000, 1500, 2000, and 2500 | 10 kW | BP, BSFC, BTE, and BMEPb | NOx, CO, HC, CO2, and O2 |

| in this study | diesel–biodiesel–water nanoemulsion fuel | rotor–stator HCRc | IDI and DI engine | 1100, 1400, 1700, 2000, and 2300 | 25, 50, and 75% | Pb, BSFC, and BTE | EGT, NOx, CO, HC, CO2, and O2 |

IMEP is the indicated mean effective pressure.

BMEP is the brake mean effective pressure, and EGT is the exhaust gas temperature.

HCR is the hydrodynamic cavitation reactor.

2. Materials and Methods

2.1. Materials

Nanoemulsions are kinetically stable liquid-in-liquid dispersions emulsion within the droplet size ranges of 20–500 nm.29 Therefore, this study used diesel–biodiesel–water nanoemulsion fuel having a 257.6 nm mean droplet size, which was measured by a Zetasizer Nano ZS analyzer to investigate the engine performance and emission gas of DI and IDI diesel engines. The diesel (B7) is equivalent to 93 vol % petroleum diesel mixed with 7 vol % biodiesel, which is the primary raw material in the nanoemulsion fuel production process. The B100 biodiesel (100% biodiesel) was produced from the waste cooking oil using the base-catalyzed transesterification. The water was applied as a dispersed phase of the oil-based emulsion fuel and filtered through an ultrafiltration machine (UltraFlow, model: UB 6 SF). To keep the nanoemulsion fuel stable for a longer separation time, two kinds of emulsifiers, namely, Span80, which is a W/O surfactant occupying an HLB value of 4.3, and Tween80, which is an O/W surfactant with an HLB value of 15, were used. These emulsifiers were acquired from Namsiang Co., Ltd. (Bangkok, Thailand). The production process of D42B50W2S3T3 nanoemulsion fuel produced using a 3D printed rotor–stator hydrodynamic cavitation reactor was described in our previous paper.26 The properties of this nanoemulsion fuel are listed in Table 2. The organic elemental analysis of a CHNS-O elemental analyzer (CE Instruments Flash EA 1112 Series, Thermo Quest, Italy) was carried out to determine the nanoemulsion fuel’s low heating value (LHV). The density and viscosity of the nanoemulsion fuel were measured using a hydrometer (ASTM–1298 standard) and a Jubalo Visco Bath (ASTM–D445 standard), respectively. At 15 °C, the densities of diesel, biodiesel, and nanoemulsion fuel were 830, 865, and 870 kg/m3, respectively, achieving the diesel and biodiesel specifications for both commercial and community standards, as shown in Table 2. The viscosities of the diesel, biodiesel, and nanoemulsion fuel used in this study were 3.37, 5.76, and 5.4 cSt at 40 °C. The copper plate corrosion of nanoemulsion fuel was No. 1a, which was within the standards of biodiesel and diesel. The LHV of the nanoemulsion fuel was 38,169 kJ/kg, which was less than diesel’s LHV of 43,683 kJ/kg. Nevertheless, the nanoemulsion blend’s LHV value was greater than that of biodiesel, which had 37,463 kJ/kg of LHV. The prices of diesel (B7), biodiesel (B100), and D42B50W2S3T3 nanoemulsion fuel blend are 1.18, 1.79, and 1.95 USD based on the exchange rate on 8 July 2022 (exchange rate from 1 Thai baht = 0.028 USD)30, which are listed in Table 2. The price of the nanoemulsion fuel is quite expensive compared to diesel, in part because of the high cost of the emulsifiers.

Table 2. Properties of Nanoemulsion Fuel (Diesel–Biodiesel–Water) Produced by 3D-Printed Rotor–Stator Hydrodynamic Cavitation.

| property | diesel (B7) | biodiesel (B100) | nanoemulsion fuel |

|---|---|---|---|

| density at 15 °C (kg/m3) | 830 | 865 | 870 |

| viscosity at 40 °C (cSt) | 3.37 | 5.76 | 5.4 |

| copper corrosion | No. 1 | No. 1 | No. 1a |

| LHV (kJ/kg) | 43,683 | 37,346 | 38,049 |

| HHV (kJ/kg) | 46,311 | 40,060 | 40,802 |

| cetane number | 50 min | 65.4 | |

| mean droplet size (nm) | 257.6 | ||

| price (USD/kg) | 1.18a | 1.79b | 1.95 |

2.2. Diesel Engine Performance and Emission Measurement

The analysis and comparison of the engine performance and emission gas between DI and IDI diesel engines with the diesel–biodiesel–water nanoemulsion fuel were performed in this study. In our previous study, the emission gas analysis of the nanoemulsion fuel (D42B50W2S3T3 blend) of the DI engine without varying the engine load was described. The specification of the DI diesel engine was the same as the mentioned detail in our previous study.26 Additional parts of investigations were conducted in this study, with the emphasis on the engine performance and emission gas analysis for both DI and IDI engines operating under different engine loads. The diesel engine test setup and dynamometer are shown in Figure 1. An eddy current dynamometer (DW 16, Jiangsu Lan Ling Test Equipment Co., Ltd.) was used to analyze variable engine loads. The details of the specification and function of the eddy current brake dynamometer used in our laboratory have been described in Thawornprasert et al.33 More details of the technical characteristics of the DI engine, IDI engine, and dynamometer are listed in Table 3. The emissions of NOx, CO, CO2, O2, and HC were analyzed using the exhaust gas analyzer (model: Testo 350 XL), and the performance of Pb, BSFC, and BTE of both DI and IDI diesel engines at different engine speeds, were performed using the rotary encoder (model: E6B2-CWZ6C, OMRON) to measure the engine speed. In this study, a load controller (model: SC-1D, 90 V 5A, Jiangsu Lan Ling Test Equipment Co., Ltd.) was utilized to operate a magnetic field in the dynamometer by adjusting the AC current. The encoder (model: E6B2-CWZ6C, OMRON) was used to observe the speed of the mechanical shaft, which was connected to the engine at a flywheel. The strain gauge load cell (model: RMS2, RUIMA) was applied to detect the force at the dynamometer’s arm, and the force data acquisition was calculated to torque data. All these equipment and steps are necessary to control the load for engine testing. During the operation of the diesel engine, a data logger (model: CFY-2S, Jiangsu Lan Ling Test Equipment Co., Ltd.) recorded the power, torque, speed, temperatures of the air, fuel, engine oil, exhaust, inlet, and outlet water (to determine engine performance), and NOx, CO, CO2, O2, and HC (to determine emissions). Moreover, the fuel consumption of all fuels was detected using a digital electronic weighing scale (model: AND EK-300i) in a unit of kg/h. When the engine setup was completed, the diesel engine was run at a constant engine speed of 1100 rpm without engine load for 30 min. This duration was regarded as the running-in period. Following the completion of the run-in time, the biodiesel and nanoemulsion fuel blends were replaced to operate the engine. After approximately 20 min of running the engine on biodiesel and fuel blends, the engine speed was gradually increased to engine speeds of 1100, 1400, 1700, 2000, and 2300 rpm with 25, 50, and 75% engine loads. For the emission analysis, the unit conversion of emission gas calculation from ppm to g/kW·h was calculated based on the following equations:34,35

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

Figure 1.

Diesel engine test rig and dynamometer: (1) exhaust gas valve, (2) emission gas analyzer, (3) fresh air temperature sensor, (4) diesel engine, (5) strain gauge load cell, (6) eddy current brake dynamometer, (7) computer display, (8) digital balancing scale, (9) fuel temperature sensor, (10) engine load controller, and (11) data logger.

Table 3. Specification of Diesel Engine and Dynamometer.

| characteristic of diesel engine | ||

| model | RT100 DI | RT100 IDI |

| type of combustion | direct injection | indirect injection |

| engine type | four-stroke | four-stroke |

| bore and stroke | 88 mm × 90 mm | 88 mm × 90 mm |

| displacement volume | 547 cm3 | 547 cm3 |

| max. power engine | 7.35/2400 (kW/rpm) | 7.35/2400 (kW/rpm) |

| max. torque engine | 6.62/2400 (kW/rpm) | 6.62/2400 (kW/rpm) |

| compression ratio | 18:1 | 22:1 |

| max. torque engine | 33.34 Nm at 1600 rpm | 33.34 Nm at 1600 rpm |

| cooling system | water cooling system | water cooling system |

| characteristic of dynamometer | ||

| model | DW 16 | |

| dynamometer type | eddy current brake | |

| max. power | 16 kW | |

| max. torque | 70 Nm | |

| max. speed | 13,000 rpm | |

| turning inertia | 0.02 kg.m2 | |

| max. voltage | 80 V | |

| max. current | 3.5 A | |

| cooling water pressure | 0.02–0.05 MPa | |

| flow of cooling water | 6.5 L/min |

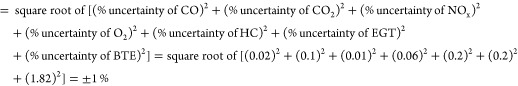

2.3. Uncertainty Analysis

The determination uncertainty analysis was executed to know the accuracy and error of the results obtained from the measuring instruments for the engine’s performance and emission gases analysis. The LHV value was analyzed using the CHNS/O analyzer. This LHV value will be applied to the calculation of BTE uncertainty. The percentage uncertainties occurrences for the Pb, fuel consumption, BSFC, and BTE were 0.21, 0.31, 0.52, and 1.82%, respectively. The details of the percentage uncertainties from the measuring devices for each test were described in Table 4. These percentage uncertainties results were obtained by recording the percentage uncertainties of different devices using many kinds of sensors such as CHNS/O analyzers, digital balance scales, temperature sensors, rotary encoder sensors, digital stopwatches, and strain gauge load cells. Then, the overall experimental uncertainty for the whole experimental analysis was calculated according to eq 6. According to the calculation result, the overall experimental uncertainty for this study was ±1%. For the calculation of error bar for each analysis, all the experimental results for each analysis were repeated three times to calculate the average value. The standard deviation (SD) and standard error (SE) were then calculated using the function of Microsoft Excel as shown in eqs 7 and 8.36

Table 4. Range of Measurements, Accuracy of Devices, and Percentage of Uncertainties.

| measurement | range | device | accuracy | % uncertainty |

|---|---|---|---|---|

| Measured Variable | ||||

| CO (ppm) | 0–1.0 × 104 | gas analyzer | ±5% | ±0.02 |

| CO2 (vol %) | 0–25 | gas analyzer | ±0.8% | ±0.1 |

| NOx (ppm) | 0–3000 | gas analyzer | ±5% | ±0.01 |

| O2 (vol %) | 0–25 | gas analyzer | ±0.8% | ±0.06 |

| HC (ppm) | 0–4.0 × 104 | gas analyzer | ±10% | ±0.2 |

| EGT (°C) | 0–1000 | temperature sensor | ±2.6 °C | ±0.2 |

| weight (g) | 0–300 | digital balance scale | ±0.02 g | ±0.01 |

| time (s) | digital stop watch | ±0.1 s | ±0.1 | |

| temperature of fuel (°C) | –250 to 1300 | temperature sensor | ±2.6 °C | ±0.2 |

| speed (rpm) | 0–6000 | rotary encoder | ±10 rpm | ±0.2 |

| load (Nm) | 0–70 Nm | strain gauge load cell | ±0.1% | ±0.01 |

| LHV (kJ/kg) | CHNS/O analyzer | ±1.3 | ||

| Calculated Parameter | ||||

| brake powera (W) | ±0.21 | |||

| fuel consumptionb (kg/h) | ±0.31 | |||

| BSFCc (kg/kW·h) | ±0.52 | |||

| BTEd (%) | ±1.82 | |||

The uncertainty of brake power is [(uncertainty of speed) + (uncertainty of load)], which is equal to [(0.2) + (0.01)] = ±0.21%.

The uncertainty of fuel consumption is [(uncertainty of weight) + (uncertainty of time) + (uncertainty of temperature of fuel)], which is equal to [(0.01) + (0.1) + (0.2)] = ±0.31%.

The uncertainty of BSFC is [(uncertainty of fuel consumption) + (uncertainty of brake power)], which is equal to [(0.31) + (0.21)] = ±0.52%.

The uncertainty of BTE is [(uncertainty of BSFC) + (uncertainty of LHV)], which is equal to [(0.52) + (1.3)] = ±1.82%.

The overall experimental uncertainty of performance and emission is as follows:

|

6 |

| 7 |

| 8 |

where X refers to the individual data point, M is the mean value, and n is the data point.

3. Result and Discussions

3.1. Engine Performance

3.1.1. Brake Power

The brake power (Pb) of an engine is the power available at the crankshaft and is usually measured using a brake mechanism. Figure 2 shows the Pb at various engine speeds for DI and IDI engines using diesel, biodiesel, and nanoemulsion fuel with varying loads. In the DI and IDI diesel engines, it steadily increased as the engine speed increased. Diesel had the most significant brake power at all engine speeds in both DI and IDI engines compared to other fuels. At 2300 rpm, the Pb of diesel in the DI engine was 6.93 kW, which is 1.75 and 3.82% higher than biodiesel and nanoemulsion fuel, respectively. For the IDI engine, the Pb of diesel fuel was greater than that of biodiesel and nanoemulsion fuel, with the percentage differences of 6.09 and 11.49%. This is due to the fact that diesel has a higher LHV value than biodiesel and nanoemulsion fuel, resulting in a higher combustion efficiency than those fuels.37 Another reason is that the viscosity and density of biodiesel and nanoemulsion fuel were higher than diesel, resulting in a longer ignition delay in the combustion process and reduced combustion efficiency.38 Comparing the Pb results from the DI and IDI engines, the Pb results of the IDI engine for biodiesel and nanoemulsion fuel were slightly lower than that of the DI engine by 0.44 and 2.89%, respectively, at the maximum load and speed. However, the Pb of the IDI for diesel was higher than that of the DI engine by 4.79% at the maximum load and speed.

Figure 2.

Effect of brake power on different engine speeds between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.1.2. Brake Specific Fuel Consumption

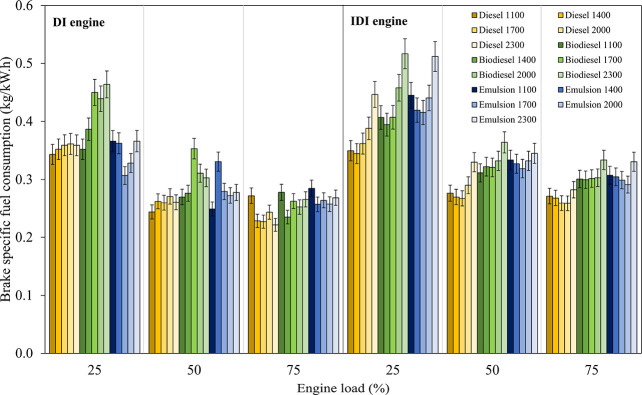

The quantity of fuel consumed per unit of time per engine braking power is called brake specific fuel consumption (BSFC).39 As illustrated in Figure 3, the BSFC was used to examine the performance characteristics of diesel, biodiesel, and nanoemulsion fuel at engine speeds ranging from 1100 to 2300 rpm and engine loads of 25, 50, and 75%. In both DI and IDI engines, the BSFC of all three fuels decreases as the engine load increases. The main reason for decreasing BSFC with engine load increment is due to the conversion efficiency of the fuel. At higher loads, a higher combustion efficiency can be achieved because the turbulence and in-cylinder temperature inside the combustion chamber were high, which help in the atomization and proper mixing of fuel. At the low load condition, the engine ran with a richer air fuel ratio compared to a full load condition. The similar results were reported by Shrivastava et al.40 and Yesilyurt et al.41 They found that the BSFC decreased when the engine load increased.40,41 By comparing the maximum engine load of the DI engine, the high BSFC of nanoemulsion fuel is slightly higher than those of diesel and biodiesel by 20.41 and 3.77%, respectively, at the highest speed of 2300 rpm. A related result was described by Shrivastava40 who studied diesel–biodiesel–water emulsion fuel to examine the performances and emissions of diesel engines. They found that increasing the engine load reduces BSFC and that the lowest BSFC of diesel was found, while the BSFC value of nanoemulsion fuel was the highest due to heat loss from the ignition and the water phase in the blended fuels.40 However, at the engine loads at 25 and 50%, the BSFC of biodiesel was the highest at all engine speeds. In the IDI engine, the BSFC of biodiesel was the highest among three different kinds of fuels for all engine loads and speeds. The highest BSFC of biodiesel was found with (0.52 kg/kW·h) at 25% load and 2300 rpm speed of engines. In part, due to the lower calorific value of biodiesel compared to diesel, more fuel is needed to achieve the same engine power as diesel. The caloric value is a crucial consideration when calculating and comparing BSFC. Furthermore, the biodiesel viscosity was higher than that of diesel and nanoemulsion fuel, causing a less effective intermixing of the fuel and air, and the heating value of biodiesel was lower than those of diesel and nanoemulsion fuel. As consistent research, Dhar and Agarwal42 studied diesel engine’s performance and exhaust emissions when blended with biodiesel produced from vegetable oil. The biodiesel contents of 5, 10, 20, and 50 vol % blended with pure diesel and B100 were used to examine the performance, emissions, and combustion characteristics at a brake mean effective pressure of 0.14–0.68 MPa and engine speeds of 1200, 1500, 1800, 2100, 2400, and 2600 rpm. They found that BSFC for a higher volumetric percentage of the biodiesel blends was greater than that of diesel fuel because the calorific value of biodiesel blends was always higher than diesel.42 By comparing the DI and IDI engines, the DI engine had a lower BSFC than the IDI engine at all engine loads and speeds. At 75% load at 2300 rpm speed of engines, the BSFC of diesel, biodiesel, and nanoemulsion fuel in the DI engine were 4.44, 23.73, and 20% lower than in the IDI engine, respectively.

Figure 3.

Effect of brake specific fuel consumption on different engine speeds and loads between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.1.3. Brake Thermal Efficiency

The brake thermal efficiency (BTE) expressed the efficiency of an engine capable of converting the heat received from combustion fuel into engine power.43 According to Figure 4, three fuel types were evaluated to determine BTE: diesel, biodiesel, and nanoemulsion fuels. The engine loads were 25, 50, and 75%, and the engine speeds were 1100, 1400, 1700, 2000, and 2300 rpm. When the engine ran under 25 and 50% load conditions, the BTE of nanoemulsion fuel was less than those of the diesel and biodiesel in the DI engine. However, at the maximum load, the BTE of the diesel was the highest when compared to biodiesel and diesel, with percentage differences of 0.4 and 5.46%, respectively, at 2300 rpm speed. The BTE results are indirectly proportional to the specific fuel consumption and fuel heating value. According to BSFC results, the BSFC value of the diesel was the lowest resulting in the highest BTE of diesel at the maximum load and 2300 rpm engine speed. In the IDI engine, the BTE results of diesel were almost the same as the biodiesel and nanoemulsion fuels. The BTE of diesel was lightly greater than those of biodiesel and nanoemulsified fuel by 1.03 and 1.97%, respectively. Shrivastava40 reported similar results when they studied the performance and exhaust gas emission analysis with the emulsion fuel, Karanja biodiesel, and diesel in a four-cylinder diesel engine with varying engine loads at a constant speed. Their BTE results for diesel were the highest compared to other fuels at the maximum load. The BTE of emulsion fuel was lower than biodiesel at a low load. In spite of this, when the engine load was increased, the BTE of emulsion fuel was higher than that of biodiesel. That is because of the lower micro-explosion of the aqueous phase in the combustion chamber at low loads. Nevertheless, the combustion efficiency of emulsion fuel is higher as the load increases, and the aqueous phase micro-explosion effect of the emulsion fuel improves the combustion process more completely than biodiesel.40 When considering the comparison of the DI and IDI engine, the BTE results from the DI engine were higher than that of the IDI engine. At the maximum load, the BTE of diesel, biodiesel, and emulsion fuel from the DI engine were higher by 24.19, 24.83, and 20.76%, respectively, than that of the IDI engine at a speed of 2300 rpm. A related result was described by Huang et al.14 who studied the engine performance and emission analysis between direct and indirect injection engines using the diesel and blended fuel (diesel with Chinese pistache biodiesel) at 1500 and 2000 pm. The BTE results for the blended fuel in the IDI engine were lower on average, 8.1 and 9.4%, than that of the DI engine at 1500 and 2000 rpm, respectively. For the diesel fuel, the BTE of the IDI engine was lower on average, 10 and 8.7%, than that of the DI engine at 1500 and 2000 rpm, respectively. The BTE value of the IDI engine was lower than the DI engine because the heat loss from the IDI engine was higher than that from the DI engine for the cooling system.14

Figure 4.

Effect of brake thermal efficiency on different engine speeds and loads between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.2. Emissions from Diesel, Biodiesel, and Nanoemulsion Fuel

3.2.1. Exhaust Gas Temperature

Figure 5 illustrates the exhaust gas temperature (EGT) of diesel, biodiesel, and nanoemulsion fuel at various engine loads and speeds in DI and IDI engines. The EGT of diesel and biodiesel in the DI engine gradually increases when the engine speed rises at all engine loads. The EGT of nanoemulsion fuel was steadily increased at engine speeds of 1100, 1400, 1700, and 2000 rpm; however, it dropped slightly at 2300 rpm maximum speed at all engine loads in the DI engine. The EGT of all fuel types increased steadily in the IDI engine as the engine speed increased at all loads. Because the LHV value of biodiesel was less than that of diesel, the EGT of biodiesel was 4.26 and 1.58% lower than that of diesel in both DI and IDI engines, respectively, at a maximum engine speed of 2300 rpm and an engine load of 75%. These results were the same as the finding of Tan et al.44 Their results mentioned that the EGT from biodiesel combustion was less than that of diesel fuel because the LHV and cetane number of these fuel are less than those of diesel. The EGT of nanoemulsion fuel was the lowest compared to diesel and biodiesel at all speeds and loads in DI and IDI engines because the heat release from combustion was sucked in the aqueous phase.44 Nanoemulsion fuel compositions with effectively dispersed water have the potential to absorb combustion heat, resulting in a decrease in flame temperature.45 With the maximum engine speed and load, the EGT of nanoemulsion fuel was 13.81 and 9.56% for the DI engine and 5.16 and 3.59% for the IDI engine, less than those of diesel and biodiesel, respectively. By comparing the DI and IDI engines, the EGT of diesel, biodiesel, and nanoemulsion fuel of the DI engine was less than that of the IDI engine at the maximum engine load and speed. The percentage differences of EGT between DI and IDI engines were 3.23, 5.91, and 11.88% for diesel, biodiesel, and nanoemulsion fuel, respectively. The IDI engine has a shorter ignition delay and faster combustion than the DI engine. The start of fuel injection time in the IDI engine is long ignition delayed, resulting in a higher temperature and pressure in a combustion chamber. As a result, the faster and stronger vaporization process, as well as the faster combustion process with higher fuel injection pressure, could enhance the cylinder pressure and heat release rate.46,47

Figure 5.

Effect of exhaust gas temperature on various speeds and loads of engines between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.2.2. Nitrogen Oxide Emission

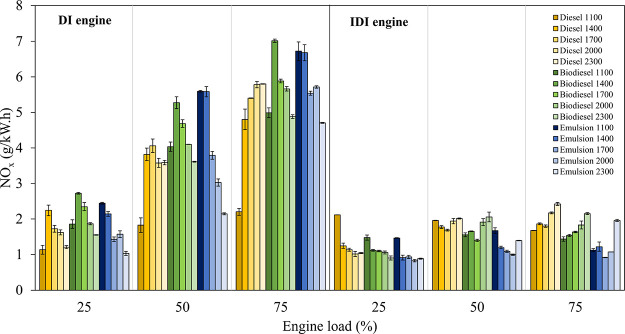

The NOx emissions occur when the fuel combusts with air in the combustion chamber. NOx emissions were produced during the processes in the combustion chamber as a result of the reactions of nitrogen and oxygen in the air. High NOx emissions were emitted by many industries, particularly electrical power plant boilers, and were also produced by the combustion in transportation system engines due to the high-temperature combustion of several types of fuels.48,49 NOx emissions are a significant air pollutant that may cause ozone depletion and acid rain when they react in the atmosphere.50 The influence of NOx emissions at 25, 50, and 75% engine loads of the three types of fuels, diesel, biodiesel, and nanoemulsion fuels, in DI and IDI engines were studied in this work, as shown in Figure 6. In the DI engine, the NOx emissions of diesel fuel steadily increased as the speed increased when considering the maximum engine load under a 75% condition. NOx emissions from biodiesel and nanoemulsion fuel tended to increase at 1100 and 1400 rpm of engine speeds when compared to diesel fuel because biodiesel has a larger O2 content than diesel fuel, which may result in higher NOx emissions than diesel and due to the volume of water in the nanoemulsion fuel contributing to the drainage.51 At 2300 rpm speed, the NOx emissions from the combustion of nanoemulsion fuel were less than those of diesel and biodiesel at 20.74 and 3.55%, respectively. Considering the IDI engine’s maximum engine load of 75%, the NOx emissions progressively arose as the speed increased. At all engine speeds, the NOx emissions of nanoemulsion fuel were less than those of diesel and biodiesel. At 2300 rpm for IDI engine, the NOx emission from nanoemulsion was 21.41 and 9.25% less than that of biodiesel and diesel, respectively. Because the water was the internal phase particle of the nanoemulsion fuel, the combustion chamber temperature was lower, affecting the decrease in NOx content.52 The water-based nanoemulsion fuel was able to decrease the temperature of the combustion chamber.52 It can be proved with the EGT results as discussed in the above section. At the maximum speed, the EGT of nanoemulsion fuel was less than those of diesel and biodiesel in DI and IDI engines. As supporting results for this issue, Maawa et al.53 observed the engine performances and exhaust emission with different water amounts in B20-blended fuel (diesel mixed with 20 vol % palm oil methyl ester) in the diesel engine. The water-in-oil emulsified fuels such as B20E5 (5 vol % of water), B20E10 (10 vol % of water), and B20E20 (20 vol % of water) were prepared using a stirrer at 800 rpm for 15 min. The engine was run under different engine loads, namely, 20, 40, and 60%, at a fixed engine speed of 2500 rpm. The results showed that a significant reduction of NOx emission has occurred in water-in-oil emulsion fuel at all loads. The NOx emission decreased when the proportion of water increased in the emulsion. The emulsion fuel that contains the most water content (B20E20) reduced the NOx emission by 26.17% compared to diesel fuel because of the heat sink effect, and the caloric value of the emulsion was partially absorbed by the water, resulting in decreasing the flame temperature and limiting the NOx formation.53 When the NOx emissions of combustions from DI and IDI diesel engines were compared, a significant reduction of NOx emissions was found in the IDI engine compared to the DI engine at all speeds and loads. The NOx emissions of diesel, biodiesel, and nanoemulsion fuel in the IDI engine were 81.89, 77.67, and 82.46% lower than that of the DI engine, respectively, at 75% maximum engine load at 2300 rpm speed. Likewise, Ozsezen et al.54 described the HC, CO, and NOx emissions of combustions from DI and IDI diesel engines. According to their results, the IDI engine emits less NOx, HC, and CO than the DI engine. Because of the high turbulence intensity, the exhaust of IDI diesel engines has less smoke than that of DI diesel engines.54 The combustion chamber of an IDI diesel engine is separated into two sections, a pre-chamber and a primary chamber, which are connected by a throat.55 As the combustion process progresses, a higher pressure exists in the swirl chamber than in the main combustion chamber. The swirl chamber’s turbulence and the flow into the main combustion chamber help with improved mixing and combustion efficiency. Combustion was carried out in the pre-chamber, and then the pre-chamber gases mixed with the air in the main chamber to create exhaust emissions. As a result, the air in the main chamber had a low rate of reaction between nitrogen and oxygen gases.46,47

Figure 6.

Effect of NOx emission on various speeds and loads of engines between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.2.3. Carbon Monoxide Emission

CO emissions are toxic, colorless, odorless gases produced in engines with incomplete combustion or insufficient O2 gas to produce CO2 emissions.56 The diesel, biodiesel, and nanoemulsion fuels were tested to analyze the CO emissions at 25, 50, and 75% of engine loads and 1100, 1400, 1700, 2000, and 2300 rpm of engine speeds for DI and IDI diesel engines, as shown in Figure 7. At the maximum load in the DI engine, CO emissions from nanoemulsion fuel were greater than the other two fuels at all engine speeds. At 2300 rpm, the CO emission from nanoemulsion fuel was the highest with 26.78% followed by biodiesel with 11.18% compared to diesel fuel at a maximum load condition in the DI engine. This is due to the water involvement in the nanoemulsion fuel, which contains a high concentration of OH– resulting in higher oxidation of carbon to form CO.57 Mazlan et al.58 studied the emission characteristics of non-surfactant emulsion fuel in a commercial vehicle at 32, 40, 48, 56, and 64 km/h. The compositions of emulsified diesel fuel included different amounts of water of 5, 6.5, 10.8, and 30 vol %. With 64 km/h maximum speed, CO emissions from nanoemulsion fuel increased because more water was used in the emulsion fuel, which decreases the combustion temperature and increases CO emissions.58 For CO results from the IDI engine, CO emission at 25% was higher than 50% of engine load because of the low gas temperature and less duration of oxidation reaction.59 At all engine speeds, the CO emission of nanoemulsion fuel was greater than diesel fuel at the maximum engine load. With 2300 rpm speed and 75% load, the CO emission of biodiesel was the highest at 1.27 g/kW·h. The second-highest CO emission was found in a nanoemulsion fuel with 1.21 g/kW·h, whereas the CO emission of diesel was emitted at 0.74 g/kW·h. In terms of percentage difference, biodiesel had 52.74% higher CO emissions than diesel, whereas nanoemulsion fuel had 48.21% higher CO emissions than diesel. The nanoemulsions had higher CO emissions than diesel due to the water phase absorbing heat, which lowers the ignition timing temperature.52 By comparing the CO emission of DI and IDI engines, the IDI engine emitted less CO than the IDI engine for all speeds and loads. Considering the results at 75% maximum engine load and 2300 rpm speed, the CO emissions of diesel, biodiesel, and nanoemulsion fuel in the IDI engine were 69.02, 28.95, and 48.75% lower than that of the DI engine, respectively. A related result was mentioned in the article of Putrasari et al.,13 who reported the performance and emission analysis of modified DI and IDI engines with the diesel fuel varying the engine loads at a constant engine speed. The CO emission from the IDI engine was significantly less than that from the DI engine. They reported that the combustion process in the IDI engine was more completed than that in the DI engine due to an erroneous spray pattern from the injector into the top of piston in the DI engine, causing excess fuel supplement to the chamber.13

Figure 7.

Effect of CO emission on different engine speeds and loads between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.2.4. Carbon Dioxide Emission

The CO2 emissions of diesel, biodiesel, and nanoemulsion fuels at 25, 50, and 75% loads were tested at engine speeds of 1100, 1400, 1700, 2000, and 2300 rpm in DI and IDI engines, as shown in Figure 8. For the DI engine, the CO2 emissions from three different types of fuels increased as the engine loads increased. From engine testing results at a maximum speed of 2300 rpm, the CO2 emission of nanoemulsion fuel was less than that of diesel and biodiesel by 1.91 and 5.41% for 50% engine load and 3.39 and 1.42% for 75% engine load. Because of its water-based composition, nanoemulsion fuel reduces the heat generated by combustion.52 However, the CO2 emissions from nanoemulsion fuel were 11.59 and 1.99%, slightly superior to those of the biodiesel and diesel at a low engine load of 25%. Because the engine starts up with fuel-rich conditions in the combustion chamber, CO2 is produced. It might be related to the subsequent reaction with excess oxygen.59 In the IDI engine, the CO2 emissions of three different fuels increased the proportion to the engine load. According to CO2 results at a maximum speed of 2300 rpm, the CO2 emission of nanoemulsion fuel was the lowest with 6.94 and 3.65% for 25% load, 5.76 and 8.58% for 50% load, and 22.53 and 19.74% for 75% engine load compared to biodiesel and diesel, respectively. Diesel seemed to have the highest CO2 emissions followed by biodiesel, while the lowest CO2 emissions were emitted by nanoemulsion fuels when run under maximum engine load conditions. When compared to the CO2 emission in DI and IDI engines at a maximum load of 75% and 2300 rpm speed, the CO2 emissions of diesel, biodiesel, and nanoemulsion fuel in the IDI engine were 9.85, 10.69, and 28.88% lower than that of the DI engine, respectively.

Figure 8.

Effect of CO2 emission on different engine speeds and loads between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

3.2.5. Hydrocarbon Emission

HC emissions are molecules that are either fully unburned or partly burned due to heterogeneous combustion in the combustion chamber.60 The HC emissions from diesel, biodiesel, and nanoemulsion fuel, were evaluated with DI and IDI engines at varied engine loads and speeds, as shown in Figure 9. The HC emissions increased with the engine load increases in both DI and IDI engines. At a low engine load, a lower fuel–air mixture can be found inside the combustion chamber and a low amount of fuel was injected into the chamber compared to the conditions at high engine loads.41 Therefore, the unburned HC emission was low at load engine load. However, at a high engine load, fuel dispersion in the spray, the amount of fuel placed on the walls, cylinder gas pressure and temperature, and injection duration were increased, which caused increasing HC emission.47 Similar research was reported by Yesilyurt et al.,41 Maroa and Inambao,61 and Mehta et al.62 who found that HC emissions decreased at a low engine load and HC emissions increased when the engine load increased. In the research of Yesilyurt et al.,41 they studied the performance and emission analysis in diesel engines using the blend of pentanol/safflower oil biodiesel/diesel fuel by varying the engine loads such as 500, 750, 1000, and 1250 engine load/W. Their results showed that HC emissions of diesel and biodiesel at a low engine load were approximately 0.62 and 0.602 g/kW·h, respectively. At the highest engine load, HC emissions of diesel and biodiesel were around 1.16 and 1.14 g/kW·h, respectively. The percentage differences of HC emission between the lowest and highest engine loads for diesel and biodiesel were 60.67 and 61.77%, respectively.41 For DI diesel engine at an engine load of 25%, HC emissions from nanoemulsion fuel were greater than those from diesel and biodiesel by 26.08 and 8% at the maximum speed, respectively, because the temperature in the combustion chamber was low when the water-in-oil emulsion fuel was used, resulting in incomplete combustion in the combustion chamber. The water involved in the nanoemulsion fuel and the temperature of the combustion chamber were relatively low under the conditions of a low engine load.59 However, when considering the 75% maximum load and 2300 rpm speed, the HC emission from nanoemulsion fuel was the lowest, with percentage differences of 4.65 and 9.09% compared to diesel and biodiesel, respectively. A constituted result was reviewed in Hasannuddin et al.,59 who reported the W/O emulsion fuels at 0, 5, 10, 15, and 20 vol % water contents in a DI engine, the engine speed ranging from 1500 to 2700 rpm. EGT results decreased while increasing water content was added to the fuel. The lowest EGT, CO, CO2, NOx, and HC emissions were found in the emulsion with 20 vol % water compared to the other conditions.59 Another research by Ghojel et al.63 showed the performance and emission phenomena of diesel and emulsified diesel and water fuel in the DI diesel engine. The emulsified fuel was composed of 13 vol % of water and 2 vol % of surfactant. Their research indicated that emulsified fuel reduced HC emissions by 60–90% when compared to diesel because of the lower combustion temperature and shorter combustion duration.63 Considering the HC emission for biodiesel, it was the highest HC emission at maximum engine load because the density and viscosity of biodiesel are higher than those of other fuels. Another reason was the longer injection period of the biodiesel compared to the other fuels.

Figure 9.

Effect of HC emission on different engine speeds and loads between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

Under the maximum load condition for the IDI engine, the HC emission of diesel fuel was lower than others at speeds of 1100, 1400, 1700, and 2000 rpm. However, at 2300 rpm speed and 75% of the highest engine load, the HC emission of emulsion fuel was the lowest at 15.38 and 8%, respectively, when compared to diesel and biodiesel, respectively. The water phase in the emulsion fuel could be changed to a small droplet during the combustion process in the chamber.59 As a result, the fuel in the involvement of the water breaks into smaller droplets. It increases the air-to-fuel ratio, resulting in complete combustion and decreased HC emissions at the ignition timing.64 This agrees with the results of Kumar et al.,65 who examined the performance and emissions of CO, HC, NOx, and soot in a single-cylinder, four-stroke diesel engine using diesel and emulsion fuel composed of a water ratio of 10 and 20 vol %. They found that while the engine was running at high speeds, emulsion fuels released less HC than diesel fuel.65 When comparing DI and IDI engines, the emissions of HC in IDI engines were clearly lower than those in diesel engines at all engine loads and speeds. The percentage differences in HC emissions from diesel, biodiesel, and nanoemulsion fuel between DI and IDI engines were 44.44, 55.55, and 54.54%, respectively, at 75% load and 2300 rpm speed of engines.

3.2.6. Oxygen Gas

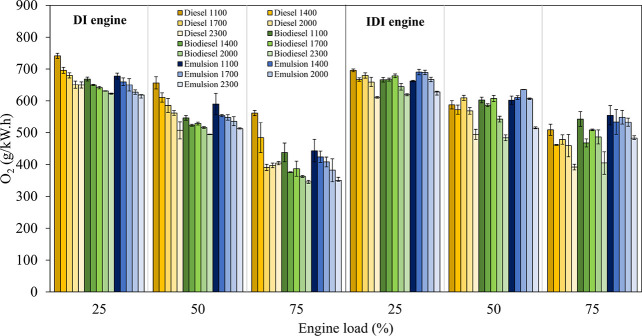

The excess oxygen from the exhaust means that the combustion process is incomplete in the chamber.66Figure 10 shows the O2 gas of diesel, biodiesel, and nanoemulsion fuel at engine speeds from 1100 to 2300 rpm under 25, 50, and 75% loads of in both the DI and IDI engines. For the DI engine, at the maximum speed and engine load, the O2 gas of nanoemulsion was 14.3% lower than that of diesel. This is because the boiling point of water in the blended fuel was less than that of diesel. As a consequence, water is an internal phase nanoemulsion fuel that is dispersed in the oil phase and evaporates first before being burned during the combustion period.17 Because the nanoemulsion fuel contains higher oxygen atoms than petroleum diesel, the fuel-to-O2 gas contact area increases, leading to completed fuel combustion.59 With 2300 rpm and an engine load of 75%, the O2 gas of biodiesel was the lowest with 15.64 and 1.34% compared to the diesel and nanoemulsion fuel, respectively. In the IDI engine, when comparing the O2 emissions produced by nanoemulsion fuel with diesel and biodiesel at various engine loads, the IDI engine’s O2 gas was the highest at 2300 rpm. In terms of O2 emissions, nanoemulsions were 20.82 and 17.56% higher than diesel and biodiesel, respectively, at the maximum load and speed of engines. By comparing the O2 gas of DI and IDI engines, the O2 gas of the IDI engine seemed greater than that of the DI engine at all speeds and loads. At 2300 rpm and 75% engine load, the O2 gas of the IDI engine for biodiesel and nanoemulsion fuel was 15.77 and 31.83% greater than that of the DI engine, respectively.

Figure 10.

Effect of O2 emission on different engine speeds and loads between DI and IDI engines with diesel, biodiesel, and emulsion fuel.

4. Conclusions

An experimental study of the performance and emission characteristics of the DI and IDI diesel engines using diesel–biodiesel–water nanoemulsion fuel produced by a hydrodynamic cavitation reactor was conducted at speeds between 1100 and 2300 rpm with engine loads of 25, 50, and 75% using a dynamometer. There are two main categories of conclusions for experiments with DI and IDI engines running on diesel, biodiesel, and nanoemulsion fuel (D42B50W2S3T3 blend), namely, (1) engine performance and (2) emissions, which are described as follows:

-

1.

Comparing the Pb results from the DI and IDI engines, the Pb results of the IDI engine for biodiesel and nanoemulsion fuel were slightly lower than that of the DI engine by 0.44 and 2.89%, respectively, at the maximum load and speed. For BSFC results, the DI engine had a lower BSFC than the IDI engine at all engine loads and speeds. At 75% load at 2300 rpm speed, the BSFC of diesel, biodiesel, and nanoemulsion fuel in the DI engine were 4.44, 23.73, and 20% lower than in the IDI engine, respectively. In terms of BTE, when comparing the BTE results from DI and IDI engines, the BTE values from the DI engine were greater than those from the IDI engine. At the maximum load and speed, the BTE of diesel, biodiesel, and nanoemulsion fuel from the DI engine were higher by 24.19, 24.83, and 20.76%, respectively, than that from the IDI engine.

-

2.

For comparison of emission results between DI and IDI engines, the EGT of diesel, biodiesel, and nanoemulsion fuel of the DI engine was less than that of the IDI engine at the maximum load and speed of engines. The percentage differences in EGT between DI and IDI engines were 3.23, 5.91, and 11.88% using diesel, biodiesel, and nanoemulsion fuel, respectively. For the NOx emissions, the NOx emissions of nanoemulsion fuel were less than two fuels of diesel and biodiesel at all speeds. When the NOx emissions of DI and IDI diesel engines were compared, the NOx emissions of the IDI engine were significantly less than that of the DI engine at all speeds and loads. At the maximum load and speed, the NOx emissions from diesel, biodiesel, and nanoemulsion fuel in the IDI engine were 81.89, 77.67, and 82.46% lower than those of the DI engine, respectively. For CO emissions, the IDI engine emitted less CO than the IDI engine for all engine speeds and loads. In terms of CO2 emissions, when compared to the CO2 emission in DI and IDI engines at the maximum load of speed, CO2 emissions of diesel, biodiesel, and nanoemulsion fuel in the IDI engine were 9.85, 10.69, and 28.88% lower than that of the DI engine, respectively. For HC emissions, the emission of HC in IDI engines was outstandingly reduced compared to that in the DI engine at all engine loads and speeds. For O2 exhaust gas, the IDI engine emitted O2 gas greater than that of the DI engine at all speeds and loads. At the maximum load and speed, the O2 gas of the IDI engine for biodiesel and nanoemulsion fuel was 15.77 and 31.83% greater than that of the DI engine, respectively.

According to the objective of this study, a comparison of the engine performance and emission analysis between the DI and IDI engines using three different fuel types was performed to determine exactly which type of engine has fewer emissions for better environmental impact and which one has high performance. As a practical implementation, this determination can be helpful in designing the preheating of the engine before the combustion process of the boiler to consider minimizing NOx emissions and improving energy savings in the industrial boilers. In summary from this study, the DI engine’s engine performances, such as Pb, BSFC, and BTE, were superior to the IDI engine. However, NOx, CO, CO2, and HC emissions from the IDI engine were lower than those from the DI engine. This is an important aspect of the application of the IDI diesel engine combustion system in industrial plants and power generators to reduce air pollution in the environment, especially for NOx emissions. Furthermore, applying W/O nanoemulsion fuels in the IDI engine can minimize emissions to a low level, particularly for NOx, CO2, and HC, when compared to diesel and biodiesel. Therefore, integrating an IDI diesel engine’s combustion system with nanoemulsion fuel can partially reduce air pollution and minimize the environmental impact of high-emission industries. As an outlook on future research from this study, these three types of fuels will be tested for evaluating long-term endurance engine tests because their fuel blends in diesel engines might cause wear in various parts of engine components for long-term engine running. The engine optimization analysis with this fuel blend for long-term engine running will be performed. In addition, the effect of droplet size in emulsion on the combustion process will be studied by adding or varying the percentage volume of water in the fuel blend.

Acknowledgments

This research was supported by the Postdoctoral Fellowship from Prince of Songkla University, National Science, Research and Innovation Fund (NSRF); Prince of Songkla University, grant no. ENG6505015M; and National Research Council of Thailand (NRCT), grant no. NRCT5-RSA63022-04.

Glossary

Nomenclature

- DI

direct injection

- IDI

indirect direct injection

- DPFs

diesel particulate filters

- Pb

brake power

- BSFC

brake specific fuel consumption

- BTE

brake thermal efficiency

- EGT

exhaust gas temperature

- NOx

nitrogen oxide

- CO

carbon monoxide

- CO2

carbon dioxide

- HC

hydrocarbon

- PM

particulate matter

- O2

oxygen

- IMEP

indicated mean effective pressure

- BMEP

brake mean effective pressure

- HCR

hydrodynamic cavitation reactor

- W/O

water in oil

- D42B50W2S3T3

42 vol % diesel +50 wt % biodiesel +2 vol % water +3 vol % Span80 + 3 vol % Tween80

- HLB

hydrophilic–lipophilic balance

- LHV

low heating value

- CHNS/O

carbon, hydrogen, nitrogen, sulfur, and oxygen

- SD

standard deviation

- SE

standard error

The authors declare no competing financial interest.

References

- Zhen X.; Wang Y.; Liu D. Bio–butanol as a new generation of clean alternative fuel for SI (spark ignition) and CI (compression ignition) engines. Renewable Energy 2020, 147, 2494–2521. 10.1016/j.renene.2019.10.119. [DOI] [Google Scholar]

- Landi G.; Di Sarli V.; Lisi L. A numerical investigation of the combined effects of initial temperature and catalyst activity on the dynamics of soot combustion in a catalytic diesel particulate filter. Top. Catal. 2021, 64, 270–287. 10.1007/s11244-020-01386-w. [DOI] [Google Scholar]

- Di Sarli V.; Landi G.; Di Benedetto A.; Lisi L. Synergy between ceria and metals (Ag or Cu) in catalytic diesel particulate filters: Effect of the metal content and of the preparation method on the regeneration performance. Top. Catal. 2021, 64, 256–269. 10.1007/s11244-020-01384-y. [DOI] [Google Scholar]

- Ghaffarpasand O.; Beddows D. C. S.; Ropkins K.; Pope F. D. Real–world assessment of vehicle air pollutant emissions subset by vehicle type, fuel and EURO class: New findings from the recent UK EDAR field campaigns, and implications for emissions restricted zones. Sci. Total Environ. 2020, 734, 139416 10.1016/j.scitotenv.2020.139416. [DOI] [PubMed] [Google Scholar]

- Duarte Souza Alvarenga Santos N.; Rückert Roso V.; Teixeira Malaquias A. C.; Coelho Baêta J. G. Internal combustion engines and biofuels: Examining why this robust combination should not be ignored for future sustainable transportation. Renewable Sustainable Energy Rev. 2021, 148, 111292 10.1016/j.rser.2021.111292. [DOI] [Google Scholar]

- Erdiwansyah Mamat R.; Sani M. S. M.; Sudhakar K.; Kadarohman A.; Sardjono R. E. An overview of higher alcohol and biodiesel as alternative fuels in engines. Energy Rep. 2019, 5, 467–479. 10.1016/j.egyr.2019.04.009. [DOI] [Google Scholar]

- Yadav P.; Kumar N.; Gautam R. Improvement in performance of CI engine using various techniques with alternative fuel. Energy Sources, Part A 2021, 1–27. 10.1080/15567036.2020.1864517. [DOI] [Google Scholar]

- Manjunath S.; Hegde R. N. Investigation on the performance of an IDI engine using a novel dual swirl combustor. Mater. Today: Proc. 2022, 52, 1361–1367. 10.1016/j.matpr.2021.11.090. [DOI] [Google Scholar]

- Barzegar R.; Shafee S.; Khalilarya S. Computational fluid dynamics simulation of the combustion process, emission formation and the flow field in an in–direct injection diesel engine. Therm. sci. 2013, 17, 11–23. 10.2298/TSCI111218108B. [DOI] [Google Scholar]

- Sener R.; Yangaz M. U.; Gul M. Z. Effects of injection strategy and combustion chamber modification on a single–cylinder diesel engine. Fuel 2020, 266, 117122 10.1016/j.fuel.2020.117122. [DOI] [Google Scholar]

- Rahman S. A.; Van T. C.; Hossain F. M.; Jafari M.; Dowell A.; Islam M. A.; Nabi M. N.; Marchese A. J.; Tryner J.; Rainey T.; Ristovski Z. D.; Brown R. J. Fuel properties and emission characteristics of essential oil blends in a compression ignition engine. Fuel 2019, 238, 440–453. 10.1016/j.fuel.2018.10.136. [DOI] [Google Scholar]

- Jafarmadar S.The Effect of Split Injection on the Combustion and Emissions in DI and IDI Diesel Engines, in: Bari S. (Ed.), Diesel Engine - Combustion, Emissions and Condition Monitoring. InTech. 2013, pp. 1–32. [Google Scholar]

- Putrasari Y.; Nur A.; Muharam A. The influence of two cylinder diesel engine modification (IDI to DI) on its performance and emission. J. Mechatron. Electr. Power Veh. Technol. 2013, 4, 17–24. 10.14203/j.mev.2013.v4.17-24. [DOI] [Google Scholar]

- Huang J.; Lin L.; Wang Y.; Qin J.; Roskilly A. P.; Li L.; Ouyang T.; Yu Y. Experimental study of the performance and emission characteristics of diesel engine using direct and indirect injection systems and different fuels. Fuel Process. Technol. 2011, 92, 1380–1386. 10.1016/j.fuproc.2011.03.001. [DOI] [Google Scholar]

- Singh A.; Sinha S.; Choudhary A. K.; Sharma D.; Panchal H.; Sadasivuni K. K. An experimental investigation of emission performance of heterogenous catalyst jatropha biodiesel using RSM. Case Stud. Therm. Eng. 2021, 25, 100876 10.1016/j.csite.2021.100876. [DOI] [Google Scholar]

- Zare A.; Stevanovic S.; Jafari M.; Verma P.; Babaie M.; Yang L.; Rahman M. M.; Ristovski Z. D.; Brown R. J.; Bodisco T. A. Analysis of cold–start NO2 and NOx emissions, and NO2/NOx ratio in a diesel engine powered with different diesel–biodiesel blends. Environ. Pollut. 2021, 290, 118052 10.1016/j.envpol.2021.118052. [DOI] [PubMed] [Google Scholar]

- Abdollahi M.; Ghobadian B.; Najafi G.; Hoseini S. S.; Mofijur M.; Mazlan M. Impact of water–biodiesel–diesel nano–emulsion fuel on performance parameters and diesel engine emission. Fuel 2020, 280, 118576 10.1016/j.fuel.2020.118576. [DOI] [Google Scholar]

- Shen S.; Sun K.; Che Z.; Wang T.; Jia M.; Cai J. Mechanism of micro–explosion of water–in–oil emulsified fuel droplet and its effect on soot generation. Energy 2020, 191, 116488 10.1016/j.energy.2019.116488. [DOI] [Google Scholar]

- Alaa M.; Soulayman S.; Abdelkarim T.; Walid Z. Water/heavy fuel oil emulsion production, characterization and combustion. Int. J. Renewable Energy Dev. 2021, 10, 597–605. 10.14710/ijred.2021.34873. [DOI] [Google Scholar]

- Najjar R.; Zarei-Gharehbaba L.; Tazerout M. The exhaust emission characteristics of a water–emulsified diesel/sunflower oil blend fuel by ionic liquid surfactants. Int. J. Environ. Sci. Technol. 2022, 19, 1175–1184. 10.1007/s13762-021-03191-8. [DOI] [Google Scholar]

- Vellaiyan S. Enhancement in combustion, performance, and emission characteristics of a biodiesel–fueled diesel engine by using water emulsion and nanoadditive. Renewable Energy 2020, 145, 2108–2120. 10.1016/j.renene.2019.07.140. [DOI] [Google Scholar]

- Vellaiyan S. Combustion, performance and emission evaluation of a diesel engine fueled with soybean biodiesel and its water blends. Energy 2020, 201, 117633 10.1016/j.energy.2020.117633. [DOI] [Google Scholar]

- Hossain A. K.; Refahtalab P.; Omran A.; Smith D. I.; Davies P. A. An experimental study on performance and emission characteristics of an IDI diesel engine operating with neat oil–diesel blend emulsion. Renewable Energy 2020, 146, 1041–1050. 10.1016/j.renene.2019.06.162. [DOI] [Google Scholar]

- Kannan K.; Udayakumar M. NOx and HC emission control using water emulsified diesel in single cylinder diesel engine. ARPN J. Eng. Appl. Sci. 2009, 4, 59–62. [Google Scholar]

- Khalife E.; Kazerooni H.; Mirsalim M.; Roodbar Shojaei T.; Mohammadi P.; Salleh A. M.; Najafi B.; Tabatabaei M. Experimental investigation of low–level water in waste–oil produced biodiesel–diesel fuel blend. Energy 2017, 121, 331–340. 10.1016/j.energy.2017.01.003. [DOI] [Google Scholar]

- Oo Y. M.; Legwiriyakul A.; Thawornprasert J.; Somnuk K. Production of diesel–biodiesel–water fuel nanoemulsions using three-dimensional printed rotor–stator hydrodynamic cavitation. Fuel 2022, 317, 123445 10.1016/j.fuel.2022.123445. [DOI] [Google Scholar]

- Kalam M. A.; Husnawan M.; Masjuki H. H. Exhaust emission and combustion evaluation of coconut oil–powered indirect injection diesel engine. Renewable Energy 2003, 28, 2405–2415. 10.1016/S0960-1481(03)00136-8. [DOI] [Google Scholar]

- Ozsezen A. N.; Canakci M.; Sayin C. Effect of biodiesel from used frying palm oil on the performance injection, and combustion characteristics of an indirect injection diesel engine. Energy Fuels 2008, 22, 1297–1305. 10.1021/ef700447z. [DOI] [Google Scholar]

- Gupta A.; Eral H. B.; Hatton T. A.; Doyle P. S. Nanoemulsions: formation, properties and applications. Soft Matter 2016, 12, 2826–2841. 10.1039/C5SM02958A. [DOI] [PubMed] [Google Scholar]

- Xe Currency Converter . Thai Baht to US Dollars exchange rate. https://www.xe.com/currencyconverter/convert/?Amount=1.7&From=USD&To=THB (assessed 2022-07-08).

- Retail prices in Bangkok and its vicinity for the year 2022, Oil prices. https://www.pttor.com/th/oil_price (assessed 2022-07-08).

- Biofuel price situation 20–26 June 2022, Policy office and power plan, Ministry of Energy, Thailand. http://www.eppo.go.th/index.php/th/petroleum/itemlist/category/951-pricebiofuel (assessed 2022-07-08).

- Thawornprasert J.; Sopajarn A.; Niseng S.; Suybangdum P.; Duangsuwan W.; Somnuk K. Effect of diesel–palm fatty acid distillate ethyl ester–hydrous ethanol blend on the performance, emissions, and long–term endurance test on an unmodified DI diesel engine. ACS Omega 2022, 7, 5894–5907. 10.1021/acsomega.1c06082. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pilusa T. J.; Mollagee M. M.; Muzenda E. Reduction of vehicle exhaust emissions fom diesel engines using the whale concept filter. Aerosol Air Qual. Res. 2012, 12, 994–1006. 10.4209/aaqr.2012.04.0100. [DOI] [Google Scholar]

- Ağbulut Ü.; Sarıdemir S.; Albayrak S. Experimental investigation of combustion, performance and emission characteristics of diesel engine fuelled with diesel– biodiesel– alcohol blends. J. Braz. Soc. Mech. Sci. 2019, 41, 389. 10.1007/s40430-019-1891-8. [DOI] [Google Scholar]

- Cumming G.; Fidler F.; Vaux D. L. Error bars in experimental biology. J. Cell Biol. 2007, 177, 7–11. 10.1083/jcb.200611141. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Elkelawy M.; Etaiw S. E. H.; Alm-Eldin Bastawissi H.; Ayad M. I.; Radwan A. M.; Dawood M. M. Diesel/ biodiesel /silver thiocyanate nanoparticles/hydrogen peroxide blends as new fuel for enhancement of performance, combustion, and emission characteristics of a diesel engine. Energy 2021, 216, 119284 10.1016/j.energy.2020.119284. [DOI] [Google Scholar]

- Kumar A. M.; Kannan M.; Nataraj G. A study on performance, emission and combustion characteristics of diesel engine powered by nano–emulsion of waste orange peel oil biodiesel. Renewable Energy 2020, 146, 1781–1795. 10.1016/j.renene.2019.06.168. [DOI] [Google Scholar]

- Nayak S. K.; Hoang A. T.; Nižetić S.; Nguyen X. P.; Le T. H. Effects of advanced injection timing and inducted gaseous fuel on performance, combustion and emission characteristics of a diesel engine operated in dual–fuel mode. Fuel 2022, 310, 122232 10.1016/j.fuel.2021.122232. [DOI] [Google Scholar]

- Shrivastava N. Experimental investigation of performance, emission, and noise parameters of water–emulsified Karanja biodiesel: a prospective Indian fuel. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 1009–1017. 10.1007/s40430-016-0581-z. [DOI] [Google Scholar]

- Yesilyurt M. K.; Yilbasi Z.; Aydin M. The performance, emissions and combustion characteristics of an unmodified diesel engine running on the ternary blends of pentanol/safflower oil biodiesel/diesel fuel. J. Therm. Anal. Calorim. 2020, 140, 2903–2942. 10.1007/s10973-020-09376-6. [DOI] [Google Scholar]

- Dhar A.; Agarwal A. K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. 10.1016/j.fuel.2013.11.002. [DOI] [Google Scholar]

- Uyumaz A. Combustion, performance and emission characteristics of a DI diesel engine fueled with mustard oil biodiesel fuel blends at different engine loads. Fuel 2018, 212, 256–267. 10.1016/j.fuel.2017.09.005. [DOI] [Google Scholar]

- Tan Y. H.; Abdullah M. O.; Nolasco-Hipolito C.; Zauzi N. S. A.; Abdullah G. W. Engine performance and emissions characteristics of a diesel engine fueled with diesel–biodiesel–bioethanol emulsions. Energy Convers. Manage. 2017, 132, 54–64. 10.1016/j.enconman.2016.11.013. [DOI] [Google Scholar]

- Vellaiyan S.; Amirthagadeswaran K. S. The role of water–in–diesel emulsion and its additives on diesel engine performance and emission levels: A retrospective review. Alex. Eng. J. 2016, 55, 2463–2472. 10.1016/j.aej.2016.07.021. [DOI] [Google Scholar]

- Bui V. G.; Bui T. M. T.; Hoang A. T.; Nižetić S.; Nguyen Thi T. X.; Vo A. V.. Hydrogen–enriched biogas premixed charge combustion and emissions in direct injection and indirect injection diesel dual fueled engines: A comparative study. J. Energy Resour. Technol. 2021, 143, 10.1115/1.4051574. [DOI] [Google Scholar]

- Henein N. A.Analysis of Pollutant Formation and Control and Fuel Economy in Diesel Engines. In: Energy and Combustion Science; Elsevier, 1979, pp. 283–325. [Google Scholar]

- Wang C.; Liu Y.; Zheng S.; Jiang A. Optimizing combustion of coal fired boilers for reducing NOx emission using Gaussian Process. Energy 2018, 153, 149–158. 10.1016/j.energy.2018.01.003. [DOI] [Google Scholar]

- Chen Z.; Wu Z.; Liu J.; Lee C. Combustion and emissions characteristics of high n–butanol/diesel ratio blend in a heavy–duty diesel engine and EGR impact. Energy Convers. Manage. 2014, 78, 787–795. 10.1016/j.enconman.2013.11.037. [DOI] [Google Scholar]

- Siddiqi S. A.; Farsi B. A. The contribution of greenhouse gas emissions on future acid rain in States of Gulf cooperation council: Measures to adopt. J. Geosci. Environ. Protect. 2019, 07, 82–98. 10.4236/gep.2019.74006. [DOI] [Google Scholar]

- Goga G.; Chauhan B. S.; Mahla S. K.; Cho H. M. Performance and emission characteristics of diesel engine fueled with rice bran biodiesel and n–butanol. Energy Rep. 2019, 5, 78–83. 10.1016/j.egyr.2018.12.002. [DOI] [Google Scholar]

- Ithnin A. M.; Ahmad M. A.; Bakar M. A. A.; Rajoo S.; Yahya W. J. Combustion performance and emission analysis of diesel engine fuelled with water–in–diesel emulsion fuel made from low–grade diesel fuel. Energy Convers. Manage. 2015, 90, 375–382. 10.1016/j.enconman.2014.11.025. [DOI] [Google Scholar]

- Maawa W. N.; Mamat R.; Najafi G.; De Goey L. P. H. Performance, combustion, and emission characteristics of a CI engine fueled with emulsified diesel–biodiesel blends at different water contents. Fuel 2020, 267, 117265 10.1016/j.fuel.2020.117265. [DOI] [Google Scholar]

- Ozsezen A. N.; Canakci M.; Sayin C. Effects of biodiesel from used frying palm oil on the exhaust emissions of an indirect injection (IDI) diesel engine. Energy Fuels 2008, 22, 2796–2804. 10.1021/ef800174p. [DOI] [Google Scholar]

- Jafarmadar S. Three–dimensional modeling and exergy analysis in combustion chambers of an indirect injection diesel engine. Fuel 2013, 107, 439–447. 10.1016/j.fuel.2012.12.001. [DOI] [Google Scholar]

- Silitonga A. S.; Masjuki H. H.; Ong H. C.; Sebayang A. H.; Dharma S.; Kusumo F.; Siswantoro J.; Milano J.; Daud K.; Mahlia T. M. I.; Chen W.-H.; Sugiyanto B. Evaluation of the engine performance and exhaust emissions of biodiesel–bioethanol–diesel blends using kernel–based extreme learning machine. Energy 2018, 159, 1075–1087. 10.1016/j.energy.2018.06.202. [DOI] [Google Scholar]

- Koc A. B.; Abdullah M. Performance and NOx emissions of a diesel engine fueled with biodiesel–diesel–water nanoemulsions. Fuel Process. Technol. 2013, 109, 70–77. 10.1016/j.fuproc.2012.09.039. [DOI] [Google Scholar]

- Mazlan N. A.; Yahya W. J.; Ithnin A. M.; Hasannuddin A. K.; Ramlan N. A.; Sugeng D. A.; Muhammad Adib A. R.; Koga T.; Mamat R.; Sidik N. A. C. Effects of different water percentages in non–surfactant emulsion fuel on performance and exhaust emissions of a light–duty truck. J. Cleaner Prod. 2018, 179, 559–566. 10.1016/j.jclepro.2018.01.143. [DOI] [Google Scholar]