Abstract

Wound healing is a complex process that is critical in restoring the skin's barrier function. This process can be interrupted by numerous diseases resulting in chronic wounds that represent a major medical burden. Such wounds fail to follow the stages of healing and are often complicated by a pro‐inflammatory milieu attributed to increased proteinases, hypoxia, and bacterial accumulation. The comprehensive treatment of chronic wounds is still regarded as a significant unmet medical need due to the complex symptoms caused by the metabolic disorder of the wound microenvironment. As a result, several advanced medical devices, such as wound dressings, wearable wound monitors, negative pressure wound therapy devices, and surgical sutures, have been developed to correct the chronic wound environment and achieve skin tissue regeneration. Most medical devices encompass a wide range of products containing natural (e.g., chitosan, keratin, casein, collagen, hyaluronic acid, alginate, and silk fibroin) and synthetic (e.g., polyvinyl alcohol, polyethylene glycol, poly[lactic‐co‐glycolic acid], polycaprolactone, polylactic acid) polymers, as well as bioactive molecules (e.g., chemical drugs, silver, growth factors, stem cells, and plant compounds). This review addresses these medical devices with a focus on biomaterials and applications, aiming to deliver a critical theoretical reference for further research on chronic wound healing.

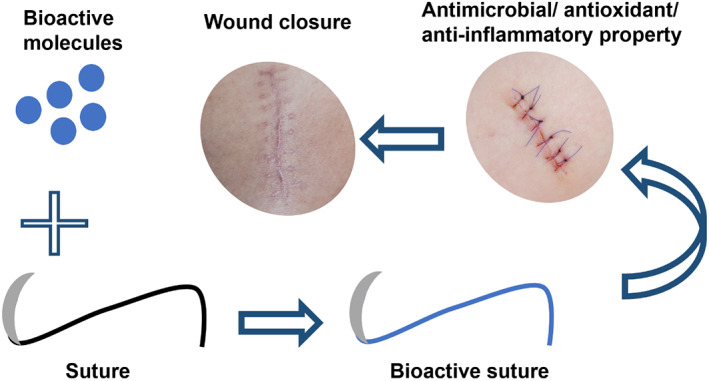

Keywords: biomaterial, biomedical device, chronic wound, wound healing

Abbreviations

- 3D

three‐dimensional

- ADSCs

adipose‐derived stem cells

- AgNPs

silver nanoparticles

- bFGF

basic fibroblast growth factor

- BG

bioactive glass

- BMSC

bone marrow‐derived mesenchymal stem cells

- Ca

calcium

- CPP

cell‐penetrating peptide

- ECM

extracellular matrix

- EEP

ethanolic extract of propolis

- EGF

epidermal growth factor

- EPC

endothelial progenitor cells

- ESBL

extended‐spectrum beta‐lactamase

- FDA

Food and Drug Administration

- GFs

Growth factors

- HUVECs

human umbilical vein endothelial cells

- MMP

matrix metalloproteinase

- MRSA

methicillin‐resistant Staphylococcus aureus

- MSCs

mesenchymal stem cells

- NF‐(κ) B

nuclear factor kappa‐light‐chain‐enhancer of activated B cells

- NPWT

negative pressure wound therapy

- NPWTci

NPWT continuous irrigation

- NPWTi

NPWT instillation

- Nrf2

nuclear factor erythroid 2‐related factor

- NSAID

non‐steroidal anti‐inflammatory drug

- P

phosphorus

- PANi‐EB

polyaniline emeraldine base

- PCL

polycaprolactone

- PDGF

platelet‐derived growth factor

- PDGF‐BB

platelet‐derived growth factor‐BB

- PEG

polyethylene glycol

- PEO

polyethylene oxide

- PL

platelet lysate

- PLA

polylactic acid

- PLGA

poly(lactic‐co‐glycolic acid)

- PLLA

polylactic‐co‐ε‐caprolactone

- PVA

polyvinyl alcohol

- PVP

polyvinylpyrrolidone

- rhEGF

recombinant human epidermal growth factor

- ROS

reactive oxygen species

- Si

silicon

- SSIs

surgical site infections

- TGF‐β

transforming growth factor‐beta

- VEGF

vascular endothelial growth factor

- ZnO

zinc oxide

1. INTRODUCTION

Wounding occurs when the epidermal layer of skin is ruptured and the underlying dermis is thus exposed to the air. Depending on the depth of the skin damage and the area of the skin affected, the tissues exposed to the air range from blood vessels to bone. Thus, wounds are generally classified into three categories. When only the epidermal skin surface is injured, it is regarded as a superficial wound. When the injury involves deeper dermal layers (e.g., blood vessels, sweat glands, and hair follicles), it is known as a partial‐thickness wound. In terms of a full‐thickness wound, this happens when the underlying subcutaneous fat or deeper tissues become ruptured. 1 Burns are common skin injuries that also present significant challenges in restoring functionality and preventing scarring. Burn injuries can be classified as first‐, second‐, and third‐degree, in accordance with superficial, partial‐thickness, full‐thickness wounds. For fourth‐degree burns, the nerve endings are ruptured and there is a loss of feeling in the wound area, and the damage involves underlying tissues, muscles, tendons, ligaments, and even bone. 1

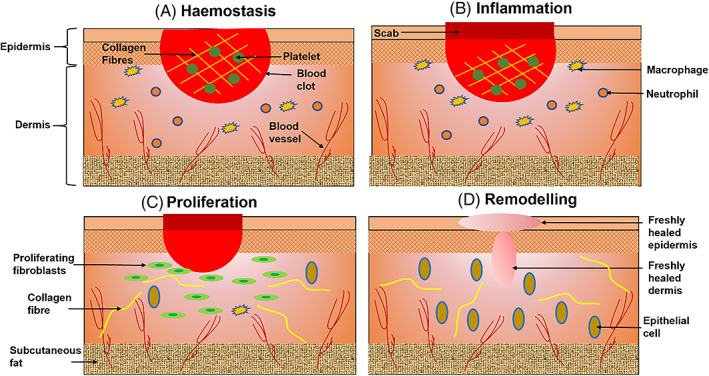

There are four distinct, yet overlapping phases for completing the wound healing process, including hemostasis, inflammation, proliferation, and remodeling (Figure 1). A variety of cell types, enzymes, cytokines, proteins, and hormones participate in the tissue repair processes. 2 Briefly, after an injury is created, in the normal healing process, hemostasis will be triggered to generate blood clots and blood vessels constrict to restrict the blood flow, followed by the secretion of proinflammatory cytokines and growth factors. 3 These growth factors, in turn, stimulate inflammation, facilitated by macrophages, neutrophils, and lymphocytes that are recruited by epithelial cells. Angiogenesis is then induced by growth factors, where reepithelization occurs due to the proliferation of fibroblasts and keratinocytes. The fibroblasts, at a later time point, will further differentiate into myofibroblasts leading to the deposition of extracellular matrix (ECM). 4

FIGURE 1.

Schematic representation of the cutaneous wound healing. (A) Hemostasis. A wound causes blood clot formation. (B) Inflammation. Recruitment of macrophages and neutrophils. (C) Proliferation. Fibroblast proliferation induces epithelial cell generation. (D) Remodeling. Wound closure

In order to pave the way for promoting wound healing, a comprehensive understanding of the healing process and the potential polymers and bioactive compounds, along with existing medical devices for wound management, are considered important requirements that physicians and technologists must be aware of, to benefit from biomaterial assisted wound healing. The aim of this review is to provide an updated overview of the potential of biomaterials and their applications in wound management and treatment and offer an organized framework for categorizing natural and synthetic polymers, as well as bioactive compounds, that will be useful in biomedical device manufacturing for addressing chronic wound healing. We chose to focus on both biomaterials and their applications because, with increased studies on wound dressings, there is still a lack of reviews updating the latest research findings. Particularly, sutures as the most popular surgical devices, their potential for facilitating wound healing is neglected. In our opinion, we need to be cognizant of wider fields to be able to develop new strategies to tackle the challenges presented by chronic wounds.

2. STUDY METHOD

Firstly, articles that address wound healing with a focus on biomaterials and biomedical devices were searched from the Web of Science, Google Scholar database and related websites for the years 2010 to 2022. Secondly, all search results were exported to a spreadsheet for organized review and the quality evaluation was performed by noting the study type. The relevant articles were identified based on the abstracts of the research. The full text of articles was obtained if they matched the criteria of desire. Search terms used included a combination of the following: chronic wound, wound healing, wound management, skin tissue engineering, biopolymer, phytomedicine, biomaterial application, wound dressing, growth factor, stem cell, silver, curcumin, honey, aloe vera, suture, nanofiber scaffold, hydrogel. During this process, 2940 articles were discovered, 957 articles were selected, and 289 of them were cited in this study.

3. WOUND HEALING IN NORMAL AND CHRONIC WOUNDS

The initial repair of a wound is completed by the formation of a fibrin blood clot to reinforce the wound area and a haemostatic plug is formed to efficiently seal off the underlying tissues from any extended exposure to the air. 2 Serotonin to promote cell proliferation and migration of keratinocytes and fibroblasts, and histamine to accelerate angiogenesis are released by mast cells at the injury site. Furthermore, endothelial cells initiate the recruitment of neutrophils and monocytes for the formation of macrophages at a later stage. 2 Leukocytes are also encouraged to the wound site due to complement activation. Bacteria are phagocytosed by macrophages for eliminating microbes and removing dead cells. 5 Besides bacteria, foreign bodies, and endotoxins can also activate macrophages to release growth factors to contribute to the various cellular reactions. 5 Angiogenesis is a process initiated in the inflammation phase, that involves growing new blood vessels from existing ones. 6 Newly formed epithelial tissue can completely cover the wound site within the first 48 h due to the migration of basal cells from the edge of the wound.

After a few days, macrophages supersede the neutrophils to activate cytokines and produce growth factors. In the following week, transforming growth factor‐beta (TGF‐β) stimulates fibroblast proliferation to infiltrate the wound clot, increasing the number of single collagen fibers. At the initial stage, collagen fibers are soft gel‐like biomaterials that accumulate outside the cells. When the wound becomes mature, collagen fibers are remodeled into a strong fiber placed to cover the whole wound bed. At the same time, a certain number of fibroblasts transform into myofibroblasts for the sake of smooth muscle cell formation. 7 Subsequently, the wound area starts to contract with the help of myofibroblasts and is eventually closed by secondary determination. 7 The cytoplasmic actin filaments are the major components of the myofibroblast, which is the main cause of wound contraction. The wound remodeling phase is a continuous procedure that can progress throughout the lifetime of the patients. 8

Based on the method of wound formation and the duration of the wound healing process, there are typically two types of wounds, including acute and chronic. Amongst healthy patients, an acute wound can be healed completely within 2 to 3 weeks, followed by the remodeling phase with minimal scarring. 9 However, when a wound becomes stuck in one of the phases for a period of 6 to 8 weeks, then the wound is categorized as a chronic wound. 8 In a chronic wound, the site of damaged tissue is greater than the visible area. The tissues beneath and around the wound site are also affected which can further develop into an ulcer. 8

The main causes of acute wounds are ascribed to mechanical injuries (i.e., frictional contact between cutaneous and solid surfaces), which includes penetrating injuries such as surgical wounds caused by incisions. Other causes involve burns, electrical shock and chemical injuries. 10 Chronic wounds, on the other hand, are related to certain diseases, such as diabetes, and do not follow a logical progression. 11 A chronic wound is defined as a wound that fails to heal promptly or a set of healing phases, namely hemostasis, inflammation, proliferation, and remodeling, as in Figure 1. 6

In the early stages of wound repair, the lack of macrophages in the inflammation or proliferation phase results in a reduction of re‐epithelialization and granulation tissue formation or hemorrhage. 12 The M1 subset of macrophages facilitates the formation of pro‐inflammatory mediators and conducts the phagocytic activity. Whereas, the M2 subset of macrophages is associated with the production of the ECM and the formation of anti‐inflammatory mediators. 13 The failure of the transition between M1 and M2 results in chronic wounds (e.g., venous ulcers and diabetic wounds). 14 Chronic wounds frequently remain in the inflammation phase and the duration is dependent upon factors such as bacterial load and the presence of necrotic tissue in the wound site. 11 Additionally, most chronic wounds never heal, even the wounds that are able to heal may take several years. Moreover, there is a high risk for the wound to reappear after healing, unless the foundation issue is solved Ferreira et al., (2006) concluded that an acute or chronic wound that takes a long time to heal should be treated as a complex wound. This type of wound is characterized as having an extensive loss of integument (i.e., skin, hair, and glands), the presence of infection, tissue necrosis, and underlying pathology. 15

For patients with diabetes, the wound healing process halts at the inflammatory phase, which hinders the generation of cytokines, proteins and growth factors that are essential for completing the wound healing process. 16 A chronic wound often results in the formation of an ulcer that can be unhealing, and in the worst case, can lead to amputation. The mechanisms that cause the pathogenesis of chronic wound healing include the continued expression of inflammatory cytokines, nonresponding macrophages and polymorphonuclear leukocytes. 16 Furthermore, the reactive oxygen species become increased in the case of delayed wound healing, which stimulates pro‐apoptotic transcription and stimulates the executioner caspase‐3 to cause apoptosis that irretrievably eventually leads to cell death. 2

Impaired wound healing is a serious medical problem that may lead to increased health care expenses and poor quality of life for patients that may result in repeated re‐hospitalization. 17 Type‐2 diabetics, for example, can cause chronic unhealing wounds and foot ulcers. Chronic wounds are painful and take a long time to heal or fail to heal altogether. They can also cause further complications, including prolonged inflammation, and microbial infections. They may also inhibit angiogenesis and prevent wound closure. 16 In the worst cases, amputation of the affected limb or organ may be required when the available clinical methods have failed to produce the desired results. Thus, studies on wound dressings that have effective healing potential are essential.

4. WOUND INFECTION AND WOUND PAIN

4.1. Wound infection

The presence of micro‐organisms (e.g., bacteria and fungi) can weaken the natural immune system of the host and induce infection in the injured areas. Streptococcus pyogenes, Staphylococcus aureus, Pseudomonas aeruginosa, and some Clostridium species are common bacterial sources that cause delayed wound healing. Other wound infection factors include hypoxia, ischemia and immune deficiencies (e.g., virus and chemotherapy). 18

Additionally, neglected wound care can eventually lead to fatalities from bacteraemia and septicaemia. 10 In healthy individuals, micro‐organisms will multiply on the surface of a wound, but this does not trigger the host immune response or show any clinical symptoms. 19 Unfortunately, when the colonization of the wound invades the living tissues of the host, a series of local and systematic responses are triggered. This can consequently cause purulent discharge and symptomatic cellulitis, which further leads to soft tissue injury. 20 It has been reported that the formation of bacterial biofilms is responsible for the delay of wound healing caused by the high microbial load on the wound site. 19 In terms of burn wounds, roughly 75% of this type of wound are more predisposed to contamination, due to the presence of micro‐organisms already present in the hair follicles, sebaceous glands and the presence of Pseudomonas aeruginosa and Staphylococcus aureus. 21 Chronic wounds are more prone to infection in comparison to acute wounds. This is due to the impaired migration of leukocytes and weakened phagocytosis under the presence of high microbial bioburden. 16

4.2. Wound pain

Pain management is crucial to the recovery of injured patients. Excessive pain can hinder the healing process due to the anxiety‐induced accumulation of stress hormones, leading to prolonged physical and mental burden and extended hospital stays. 22 It is worth noting that the expression of pain from the patient needs to be addressed individually since the pain process largely depends on each patient's perception, not what clinicians believe it should be. There are two types of wound pain, including nociceptive pain and neuropathic pain. Nociceptive pain is a natural physiological response when encountering tissue damage. This type of pain generally lasts within a set period, but when the healing speed slows down, then the inflammatory response might extend. Under this circumstance, primary hyperalgesia (at the wound site) and secondary hyperalgesia (in the surrounding tissue) may experience intensified sensitivity. 23 Neuropathic pain is generated by nerve damage, which can be caused by a primary lesion. The development of neuropathic pain may be related to infection, cancer or metabolic disorders. This can lead to chronic pain over a long period. 24 For the sake of patient comfort and daily task performance, alleviation of pain is the priority for patients with chronic wounds. Efficient wound management can significantly promote a patient's quality of life. 25 Skin transplants, for instance, can cause extreme pain to the patient, due to the impact of the exposure of nerve endings during the skin harvest. Therefore, pain management is also necessary at the secondary wound site. 10

Primary hyperalgesia is a heightened sensitivity caused by a prolonged inflammation or repeated stimulus to the wound and surrounding area, which may be treated by the combination of a non‐steroidal anti‐inflammatory drugs (NSAIDs) combined with a mild opioid in the hospital, to decrease local inflammation and modulate pain at spinal cord level, respectively. 24 Wound dressings provide two basic functions. The first is to cover the wound, preventing infection. The second is to alleviate wound pain, by reducing the bacterial load and hence reducing the inflammatory reaction to the nervous system. Oral administration, on the other hand, can take up to a couple of days to have a significant impact on pain relief. Therefore, topical drug delivery to the wound site is the top choice for pain alleviation. Ibuprofen, in particular has been widely studied due to its excellent local pain reduction effects. 26 Arapoglou et al., (2011) designed a foam dressing loaded with ibuprofen and compared its effect with local best practices on various wound types. 27 They reported that ibuprofen‐loaded foam dressings were associated with significantly higher pain relief based on patient scores. Therefore, they believed that ibuprofen should be applied in chronic and acute wounds for efficient pain reduction, which also suggested that local pain relief by ibuprofen could be a safer alternative to systemic pain treatment. 27

5. POLYMERIC MATERIALS

5.1. Natural polymers

Natural polymers are generally biodegradable or bioabsorbable and biocompatible. Some also manifest antimicrobial or anti‐inflammatory properties such as chitosan and keratin. Hence, natural proteins (e.g., keratin, casein, collagen, and silk) and polysaccharides (e.g., chitosan, alginate, and hyaluronic acid) have received increased interest in wound dressing production, due to their similarity to macromolecules, which are recognized by the human body, achieving ECM biomimicry.

5.1.1. Chitosan

Chitosan is one of the most widely used ligands. It has been reported to have a positive charge and can improve the absorption of metal anion drugs. 28 Owning to its cationic charge, chitosan has been applied as a coating layer on negatively charged particle surfaces via electrostatic adsorption. 29 Chitosan has also shown its potential for the modulation of drug release behavior. 30 The nanoparticles that are coated by positively charged chitosan attract the negatively charged cell membrane, which enhances the permeation of poorly water‐soluble drugs. 31

The functional versatility of chitosan makes it a popular natural cationic polymer in the production of hydrogels, membranes, and electrospun nanofibers for wound healing. 17 , 32 , 33 Furthermore, chitosan dressings have been selected to treat injured tissues due to their antibacterial properties. 34 Chitosan/alginate hydrogels were produced and loaded with different concentrations of hesperidin. 35 These hydrogel products were evaluated in the full‐thickness dermal wound in a rodent model. The results indicated that the chitosan/alginate hydrogels had a better wound closure rate than the control group of gauze‐treated wounds. 35 In another study, a nanofiber mat that contained chitosan, PVA and zinc oxide (ZnO) demonstrated high antibacterial and antioxidant activities, suggesting its potential for the faster healing of diabetic wounds. 17

5.1.2. Keratin

Keratin is one of the most abundant protein sources found in human or animal parts, such as hair, wool, nails, and feathers. Keratins can be divided into two categories, including epithelial keratins and trichocyte keratins. Epithelial keratins are soft keratins, which contain low sulfur (~1%) and cysteine (<3%). They are the main component in the stratum corneum of the skin and play an important role in stabilizing the cells in epithelia. Trichocyte keratins, as hard keratins, have a higher sulfur (~5%) and cysteine (4%–17%) percentage. They act as structural scaffolds in the areas connecting to the epidermis. 36 Keratin materials have been widely applied in tissue regeneration ascribed to their biocompatibility, biodegradability and structural support. These properties make it possible to produce various wound dressings, such as films, hydrogels and scaffolds, to facilitate the chronic wound healing process. 37

Keratin and HA‐based PCL/PEO fibers can be produced via emulsion and coaxial electrospinning techniques. The results showed that the incorporation of natural polymers promote cell viability and has the potential for wound dressing applications. 38 Keratin (5% w/v) and chitosan (2% w/v)‐based PVA nanofibrous scaffolds have been reported to exhibit desirable tensile strength, swelling ratio, and porosity. These properties were enhanced with the addition of keratin and chitosan. 39 The same research group also utilized the keratin/chitosan (50:50 w/w) blend to produce surgical sutures with anti‐inflammatory properties. The scratch assay showed improved cell proliferation and migration in the presence of the sutures, which indicated the potential of the sutures to be used for facilitating wound healing. 40

5.1.3. Casein

Casein is derived from cow milk makes up 80% of the protein in milk. It has received increasing attention due to its biocompatible, biodegradable, self‐assembling properties. More than half of casein (~55%) contains polar amino acid groups, which benefits hydrogen bond formation to produce films. 41 However, this property also makes it impossible to electrospun casein alone. Therefore, synthetic polymers (e.g., PEG, PVA) have been added to facilitate the casein‐based electrospinning process. 42 , 43 Moreover, cross‐linking agents (e.g., glutaraldehyde and silane) are required during the casein‐based product process, due to the low water stability and mechanical strength of casein caused by its high hydrophilicity. 41

Casein/PVA electrospun nanofibrous mats were successfully fabricated to promote haemostatic activity via thrombin generation. The addition of casein enhanced epithelial proliferation and restitution. 42 Casein/cellulose/chitosan scaffolds have been developed to facilitate wound healing. The presence of casein exposed nucleation sites to bind blood clotting ions, which is essential for hemostasis. 44 A study on casein/alginate‐based injectable hydrogel production was reported. The hydrogels consist of casein, alginate, iron nanoparticles, and bacterial cellulose. The swelling studies revealed a 4000% water uptake of the hydrogels, which indicated its wound dressing potential. Additionally, the porous structure of the hydrogel improved cell viability, suggesting the use of this hydrogel product in wound management. 45

5.1.4. Collagen

Collagen is a biodegradable natural tissue matrix, which provides tensile strength for the skin. It is one of the most important components involved in wound healing and tissue regeneration, which makes collagen a popular choice in the terms of selecting biocompatible and nontoxic materials. 46 Moreover, collagen can facilitate the hemostasis process and has antibacterial properties. 46 Collagen has also been reported to have the ability to enhance dermal and epidermal wound repairs by stimulating granulation tissue formation and activating angiogenesis and the deposition of collagen fibers. 10

As the main component of the ECM and the most abundant protein in the human body, collagen is widely used to produce wound healing biomedical devices. A collagen/chitosan gel was developed and incorporated with a cell‐penetrating peptide (CPP). 47 The authors reported that this collagen/chitosan/CPP gel could retard S. aureus proliferation and showed good wound healing capacity. This result was further confirmed by in vivo study in the mouse where the treatment of collagen/chitosan/CPP gel was compared with a collagen/chitosan gel and a chitosan gel. Amongst all the treatments, collagen/chitosan gel contained CPP demonstrated the highest healing rate and fastest healing speed. 47 In another study, type I collagen was electrospun with PLA and loaded with a drug compound (either triclosan or levofloxacin). 48 This product demonstrated good antimicrobial activities for both E. coli and S. aureus. In addition, an initial burst release was observed due to the presence of the drug at the surface. Furthermore, a controlled drug dissolution profile was achieved after the burst release, which was attributed to the addition of collagen to the fibers that helped shift drug release behavior. 48 Zhou et al. (2017) successfully electrospun bioactive glass and fish collagen to produce nanofiber mats. 49 The mats possessed improved tensile strength and had a certain level of antibacterial activity. Furthermore, the collagen/bioglass mats facilitated the secretion of type I collagen and vascular endothelial growth factor in human dermal fibroblasts, which indicated its potential for effectively inducing skin regeneration. 49

5.1.5. Hyaluronic acid

Hyaluronic acid is a glycosaminoglycan that is one of the components of connective tissues. It is the main integrant of ECM in the skin, which also plays an important role in the tissue regeneration process. 50 Hyaluronic acid maintains structures to support the biological function of organs and it has a high capacity to retain water on the wound surface, which can prevent the injured sites from dryness and promote healing speed. 51 Hyaluronic acid can be easily incorporated into foams or cream to achieve topical drug delivery. Some commercial products contain Hyaluronic acid, including the commercial products Hyalofill® and Hyalomatrix® exhibited positive outcomes in wound repair and pain management. 52

One of the disadvantages of applying hyaluronic acid solutions in the electrospinning process is their very high viscosity even at low concentrations. Despite these limitations, El‐Aassar et al. (2020) fabricated Hyaluronic acid/polygalacturonic acid nanofibrous mats embedded with silver nanoparticles, 53 an in vivo study demonstrated that maximum wound epithelization and collagen deposition was achieved after 14 days, indicating its efficient use for the quick healing of wound infections. 53 In another study, Eskandarinia et al. (2020) designed polyurethane/hyaluronic acid nanofibrous mats enriched with three different concentrations of ethanolic extract of propolis (EEP). 54 The results showed that polyurethane/hyaluronic acid nanofibrous mats with 1% EEP exhibited higher antibacterial activity and higher biocompatibility, as well as an accelerated wound healing process in the animal model in comparison with mats that contained 2% EEP, which promoted their use for further biomedical applications. 54 Hyaluronic acid‐based hydrogels are another focused research topic. Dopamine‐functionalized hyaluronic acid hydrogels incorporated with arginine derivatives were developed with improved antioxidant activity. 55 Enhanced tissue re‐epithelialization and accelerated wound closure were observed in a murine model, suggesting its potential to be used for wound skin repair and regeneration in human patients. 55 The design of photo‐responsive supramolecular hyaluronic acid hydrogels was reported by Zhao et al. in 2020. 56 This hydrogel product displayed excellent biocompatibility and cell viability. Furthermore, a full‐thickness skin defect model revealed superior wound healing efficiency with controlled epidermal growth factor (EGF) release properties, which indicated that it could be a promising wound dressing for clinical treatment. 56

5.1.6. Alginate

Sodium alginate is a natural polysaccharide extracted from brown algae, which has many biological properties that favor wound management. 57 Sodium alginate is widely used in biomedical applications due to its biocompatibility, bio‐absorbability, and ability to form gels. Its high‐water absorption property removes secretions from the injured sites and hence, controls bacterial growth. It is generally utilized in a hydrogel form for facilitating wound healing and tissue engineering. 57 The common way to prepare hydrogel from alginate solution is to add an ionic crosslinking agent. An “egg‐box” shape forms between guluronic acid and adjacent polymer chains due to the interactions between the molecules. 10 The molecular weight ratio of combined mannuronic and guluronic, and the cross‐link extensions have a significant impact on the matrix formation. The amount of α‐l‐guluronic acid that residues in a hydrogel determine the characteristics of the gels (i.e., rigid gels contain high guluronic acid, whereas elastic gels contain low guluronic acid). 58

The high acceptance of alginate in biomedical applications is related to its positive clinical research results. For instance, a group of patients with full‐thickness pressure ulcers were randomized with alginate wound dressing or dextranomer paste treatment for the wounds. It was reported that patients who were treated with alginate wound dressings had relatively better outcomes. 10 Sodium alginate solutions are commonly mixed with PVA to produce hydrogels or nanofibers. An alginate/PVA hydrogel was designed and encapsulated with synthesized green tea polyphenols, 59 which were characterized and applied in a diabetic rat model for regulating the immune response and enhancing wound closure. The results demonstrated that this hydrogel product promoted chronic wound healing by regulating the PI3K/AKT signaling pathway. 59 In another study, a sodium alginate/PVA hydrogel incorporated with PCL microspheres was introduced by Bahadoran et al. (2020) for facilitating wound healing. 60 In vitro results indicated that the increased concentration of alginate was associated with higher porosity and elasticity, but also related to decreased strength and elongation at break. Moreover, the in vivo burn wound rat model showed potential for achieving cell‐induced tissue regeneration and burn wound healing. 60 An alginate/PVA‐based nanofibrous membrane produced via the electrospinning method and incorporated with honey. 61 The results showed that the increased honey content led to improved antioxidant properties, and the alginate/PVA‐based nanofibers did not reveal any cytotoxicity. This study exhibited the biomedical potential of honey loaded alginate/PVA membrane. 61 However, an in vivo animal study needs to be conducted to confirm its clinical safety.

5.1.7. Silk fibroin

Silk fibroin derived from various insects has good biocompatibility, biodegradability, and mechanical properties. 62 Silk fibroin has been widely studied as a biomedical material for regeneration in a wide range of tissues, such as skin, vascular, cartilage, bone, tendon, and ligament. 63 , 64 , 65 , 66 , 67 One type of silk fibroin extracted from silkworm cocoons contains amino acid residues. It has been used in a variety of forms (e.g., hydrogels, films, fibers, and sponges) to enhance collagen synthesis and re‐epithelialisation, which in turn promotes wound healing.

A biopolymer dressing capable of temperature sensing and wound healing was fabricated through electrospinning silk fibroin and nanodiamond. 72 Nanodiamonds are nanoparticles, which are non‐toxic and have a high specific surface area and tunable surface chemistry. 68 According to the authors, the presence of the nanodiamond improved the thermal stability of the silk fibroin‐based membranes. High biocompatibility and rapid wound closure rates were observed in the animal study. Interestingly, this silk fibroin/nanodiamond dressing selectively exhibited antibacterial properties toward gram‐negative bacteria but showed no effect on gram‐positive bacteria. 69 Therefore, its usefulness as a wound dressing is debatable as most gram‐positive bacteria are pathogenic. In another study, a multilayer membrane (silk fibroin/chitosan/alginate) with controlled drug release properties was reported by Pacheco et al. in 2020. 70 Silk fibroin provided excellent mechanical properties for this wound dressing product. It is worth noting that in this study, the authors reported that the incorporation of the drug into the membrane did not weaken its mechanical strength indicating the high performance of the dressings. 70

5.2. Synthetic polymers

Numerous synthetic polymers are used in wound dressings. Amongst the synthetic polymers, aliphatic polyesters, in particular, are well studied, including polyvinyl alcohol (PVA), polyethylene glycol (PEG), polylactic acid (PLA), poly(lactic‐co‐glycolic acid) (PLGA), and polycaprolactone (PCL). 40 , 71 , 72 , 73 , 74 The main properties that these synthetic polymers have in common are high biocompatibility and hydrophilicity, which provides a moist environment and inhibits the accumulation of excess exudates at the wound site, and these polymers generate nontoxic products during the degradation process. 10 In addition, the degradation rate of synthetic polymers can be modulated by adjusting the polymeric composition and the molecular weight. Another common property is that synthetic polymeric materials are adhesive, which renders them with stable mechanical strength and allows them to reside in the tissue for an extended time. 75 The most important reason for them to be chosen in wound care management is not only due to their ability to maintain a moist environment, control the release of various bioactive molecules, resemble skin tissue structures, but importantly these polyesters have approval from the Food and Drug Administration (FDA). 75

5.2.1. Polyvinyl alcohol

PVA exhibits excellent biocompatibility, especially PVA at pharmaceutical grade. PVA is a macromolecular organic substance that has no side effects on the human body, it has been used in various biomedical applications, including artificial joints, 76 contact lenses, 77 cardiovascular devices, 78 and wound dressing. 61 Because of the linear structure of PVA, it can be crosslinked by strategies such as irradiation and chemical agents. Venkataprasanna et al. (2020) applied the chemical glutaraldehyde to crosslink the PVA‐based solutions to increase their mechanical strength and stability. 73

In recent publications, the combination of PVA, chitosan and starch has been a popular topic in the research of wound healing. In one of the studies, PVA/chitosan/starch was electrospun to produce nanofibrous mats, 79 and it was reported that these mats had high cell viability and antibacterial properties. Even though this investigation lacked the in vivo studies necessary to confirm its biological safety, the in vitro scratch assay proved its ability to accelerate wound healing. 79 PVA/chitosan nanofibers that contained the silk protein sericin were fabricated by the electrospinning technique. 80 The low sericin content of the PVA/chitosan nanofibers exhibited higher cell proliferation than PVA/chitosan nanofiber alone. Moreover, the animal study further confirmed their wound repair capability. 80 In another study, PVA/starch was used to make hydrogel membranes. 81 Three different essential oils (clove, oregano, or tea tree oil) were incorporated into the hydrogel membranes. According to the authors, PVA/Starch hydrogels produced with 0.1 ml clove oil in 7% (w/v) starch solution exhibited better antibacterial efficacy compared to the other essential oils, and it was suggested for use as a wound dressing for burn wounds. 81

5.2.2. Polyethylene glycol

PEG is a water‐soluble amphiphilic polymer. It has been approved for use in human intravenous, oral and dermal applications by the FDA, due to its nontoxicity. 82 PEG incorporated with PLA modified the unwanted drawbacks of PLA (e.g., brittleness and low hydrophilicity), to produce PEG‐ and PLA‐based alternating block and random block polyurethane dressings for wound healing. 83 An in vivo rat skin model showed that the dressings demonstrated anti‐inflammatory properties and had a better healing effect than gauze alone. 83 PEG/chitosan hydrogels loaded with silver nanoparticles were reported to be able to accelerate wound healing in diabetic patients. 74 The antimicrobial and antioxidant properties, as well as the wound healing capacity, were shown in both in vitro and the in vivo diabetic rabbit model, 74 which indicated that it can be a promising material for chronic diabetic wound healing.

5.2.3. Polycaprolactone

PCL has good biocompatibility and biodegradability, as well as excellent mechanical strength. It has been widely used in tissue engineering applications. 84 PCL can be electrospun at low voltages to produce scaffolds with good mechanical resistance. 85 PCL/chitosan/curcumin nanofibers fabricated via the electrospinning method were then electro‐sprayed with curcumin‐loaded chitosan nanoparticles. 86 The existence of PCL improved the spinnability of the chitosan and the strength of the electrospun nanofibers. PCL/chitosan/curcumin nanofibers showed antibacterial, antioxidant, and cell proliferation efficiencies, which were confirmed by an in vivo study, indicating that these nanofibers enhanced the wound healing process. 86 Ehterami et al. (2018) electrospun PCL/collagen nanofibers that were then coated with insulin delivering chitosan nanoparticles and tested on a rat model. 87 Compared with sterile gauze, PCL/collagen‐based dressings provided nearly full wound closure within 14 days, which suggested its potential to be applied in clinical practice for wound repair.

5.2.4. Polylactic acid

PLA is an aliphatic polyester directly obtained by the condensation polymerization of lactic acid monomers or the ring‐opening polymerization of the cyclic lactide dimers. 88 PLA is biocompatible, biodegradable and has high versatility. It has been used in tissue engineering, suture production and other biomedical applications. 89 The limitations of PLA, such as its slow degradation rate and low mechanical strength, can be regulated by blending it with other polymers or additives to improve its biological and mechanical properties. 90

In one of the studies, PLA was blended with PCL and loaded with herbal extracts, 91 using the double‐nozzle electrospinning method to produce wound dressings. The optimum scaffold had an average fiber diameter of 638 ± 69 nm and was effective against gram‐positive and gram‐negative bacteria. 91 However, the authors only conducted a proliferation MTT assay to show that although the higher herbal extract led to higher cell viability, there was no in vitro scratch assay or in vivo animal study was done to investigate the effects of the PLA/PCL/herbal extract nanofibers on the wound healing process. Therefore, a further study that can prove its wound healing capacity needs to be included.

In another study, nanofibers of PLA and Poly(γ‐glutamic acid) (γ‐PGA) were fabricated with a core‐shell structure via the coaxial electrospinning method. 92 The authors optimized the electrospinning parameters and demonstrated the biocompatibility and non‐cytotoxicity of the nanofibers. Furthermore, the proliferation of dermal fibroblasts and keratinocytes improved, and re‐epithelialization occurred after 14 days of wound creation in the rat model, which indicated the potential of the core‐shell structured nanofiber for clinical wound repair.

5.2.5. Poly(lactic‐co‐glycolic acid)

PLGA is a biocompatible and biodegradable copolymer polymerized from lactic acid and glycolic acid that has been approved for versatile clinical applications. The ratio of the two monomers determines the mechanical, physicochemical properties, and the degradation time of PLGA. 93 Porporato et al. (2012) utilized PLGA to promote the activity of exogenous lactate to accelerate angiogenesis for wound healing. The results showed that after 10 days of injury, the healing area achieved with the addition of PLGA was 60% greater when compared with the control. 94 Another study of PLGA/gelatine at ratios of 9:1, 7:3, or 5:5 (v/v) was electrospun to fabricate scaffolds. 95 The physical, chemical and biological properties of the scaffolds were investigated by the authors. They reported that the 7:3 (v/v) PLGA/gelatine ratio was the most suitable candidate for chronic wound treatment due to high cell proliferation and the lack of an inflammatory response. 95 However, from our point of view, their research was not robust enough to conclude the suitability of the PLGA/gelatine nanofiber scaffolds in the application of chronic wound healing. Further studies such as scratch assay and animal studies need to be conducted as well.

A novel study was conducted by Gao and his colleagues in 2020. 96 They designed a bilayer PLGA/PVA dressing, which contained silver nanoparticles in the PLGA electrospun film, and the stem cells were seeded into the gelatine modified side of PVA hydrogel. Interestingly, the addition of silver loaded PLGA films improved both the mechanical strength and moisture content of PLGA/PVA dressings. Moreover, the seeded stem cells were able to secrete bioactive growth factors through the dressing to facilitate cell growth and wound healing. 96 This wound dressing has a great potential for skin tissue engineering.

6. BIOACTIVE MOLECULES

The application of bioactive molecules in wound dressing manufacturing brings benefits in accelerating wound healing rate and inhibiting wound infections.

6.1. Chemical drugs

Drugs like NSAIDs are often prescribed to treat the pain that is generated from wounds like mechanical injuries or surgical wounds. Nevertheless, to limit systemic exposure to the drugs, they cannot be given throughout the entire healing process. Therefore, a better way to introduce anti‐inflammatory drugs into a wound healing process is to produce anti‐inflammatory wound dressings or sutures, which enable target drug release to achieve localized pain relief. The common strategies include electrospinning, suture coating and hydrogel production (the details of which are discussed in section 6).

Antibiotic drugs for topical delivery to the wound sites have received increased attention mostly due to the small volumes of drugs required by the local wound treatment compared to systemic administration. Topical application provides high and sustained concentrations of antibiotics to the wound site, which requires a low quantity of drugs compared with systemic therapy. 97 Combining antibiotics with other methods such as adequate nutrition, proper dressing, and elimination of dead tissues can reduce the exogenous microbial infection. 98 However, the unnecessary exposure of the resident microflora to excessive antibiotics can lead to the formation of antibiotic‐resistant strains. 99 Moreover, the antibiotic effect on pre‐existing normal bacterial flora is difficult to control. 100 Apart from the development of resistance, the administration of topical antibiotics may delay hypersensitivity reactions and cause superinfections. 97 Therefore, topical delivery systems need to be designed that can control antibiotic release, this can be achieved by applying polymers to engineer stimuli‐responsive systems, able to trigger antibiotic release under specific changes in physiological conditions (e.g., pH and temperature). 99

Even though the incorporation of chemical drugs into biomedical devices can assist wound repair to some degree, this method is still limited by the inefficient regulation of the initial burst drug release, particularly in relation to the wound healing process. Moreover, antibiotic resistance has become more common within pathogens, and this together with the decreased rate of new antibiotic production has resulted in the search for alternative strategies. Non‐antibiotic components such as silver and plant products have received increased attention for controlling antimicrobial activities in the wound healing process. 101 In addition, combining growth factors and stem cells into biomedical devices, on the other hand, could provide a more bioactive strategy to facilitate wound healing. 102 , 103

6.2. Silver

Silver and its nanoparticles (AgNPs) have been reported as ideal candidates for inhibiting pathogens due to their broad‐spectrum antimicrobial characteristics. The main mechanism behind its antimicrobial properties is due to the binding of thiol groups, which deactivates the enzyme proteins in the cell membrane of bacteria. These proteins are responsible for the transportation of ions and the production of membrane energy. 104 Silver has also been reported to involve catalytic oxidation reactions. Silver catalyzes the oxygen in the cell and the hydrogen from thiol groups forms disulphide bonds, which changes the protein structure of the cell, leading to cell dysfunction. 104

In the past, despite the antimicrobial properties of silver, its use was limited due to the belief that the toxic ions might affect patient health, even though silver is not known to cause cancer or have neurological or reproductive effects. AgNPs with a higher area‐to‐volume ratio have been developed to produce wound dressings, which have higher efficacy of bacterial inhibition and are significantly less toxic to humans. 104 They have been proven to have the ability to inhibit infections on the wound site caused by both gram‐positive and gram‐negative bacteria. Silver has also been found to be toxic against nonbacterial targets such as fungi. Nanofiber dressing loaded with 1% silver is used to treat fungi‐contaminated burn wounds. 105 However, the results were not statistically significant, authors presumed that it was due to the low concentration of silver loaded in the dressing compared with commercial products in the market.

A research study aimed at developing silver‐containing activated carbon fibers was compared with commercial silver dressings to determine their dressing efficacies. 106 The authors found that the silver‐containing activated carbon fibers showed antibacterial properties and the concentration of silver had little effect on cell viability. They concluded that their products could promote wound healing in the early stage, as compared with commercial products. Another study incorporated silver oxide with chitosan and PVP to produce an antibacterial film. 107 The researchers compared this product with other reported chitosan‐based dressings aimed toward wound healing applications, they found that the silver oxide‐loaded chitosan/PVP dressings had good antibacterial activities and healing capacity. Moreover, the transparency of the films enabled wound examination without removing the dressings, which could eliminate patient discomfort.

6.3. Growth factors

Growth factors (GFs) are essential for ECM formation and remodeling in the wound healing process, and they also play a pivotal role in promoting granulation tissue formation and regulating inflammatory responses. 6 GFs are considered ideal candidates for chronic wound treatment. They are secreted by the ECM and have the ability to transfer signals between cells and regulate proliferation, migration, and differentiation of the cells. The lack of interaction amongst GFs, ECM and cells generally lead to chronic wounds. 108 The deficiency of GFs, such as vascular endothelial growth factor (VEGF), basic fibroblast growth factor (bFGF), platelet‐derived growth factor (PDGF), EGF, and TGF‐β, can result in chronic pressure ulcers. 108 Additionally, the generation of PDGF was observed to be very low in chronic dermal ulcers compared with acute wounds. 6 This suggests that the deficiency of growth factors during the wound healing process is responsible for chronic wounds and that the incorporation of growth factors into wound dressings might slow or prevent the progression from acute to chronic wounds.

However, in nature, GFs have a short in vivo half‐life, they degrade rapidly under normal physiological conditions. 109 When applied to the wound surface, GFs have difficulties in absorbing through the skin around the wound lesions, and they may also be extruded before reaching the wound area, which limits GFs use in chronic wound applications. 6 Therefore, to extend the effectiveness of GFs, a sustained delivery system, such as the incorporation of GFs into scaffolds, is desired. 109 GFs that are embedded inside scaffolds are protected from wound proteases during the early phase of implantation, but also delayed initial release of the GFs may be achieved. 110 Additionally, microencapsulation and nanoencapsulation techniques have been used to protect the GFs during manufacturing to achieve long‐term exposure for the treatment of chronic wounds. La and Yang et al., (2015) incorporated platelet‐derived growth factor‐BB (PDGF‐BB) into a PLGA‐based wound healing dressing. The results showed that GFs had a prolonged release from the nanosphere form compared to the free form, indicating that the nanoparticles might be ideal to treat chronic wounds. 111

The local application of GFs is important to achieve a therapeutic effect on the wound site. However, continuous injection of GFs is difficult to apply in a clinical setting. Therefore, a topical delivery system, such as gel, cream or ointment, renders direct administration of GFs to the injured site could fulfill the requirements of clinical management. Nevertheless, to date, there is only one gel product (REGRANEX® Gel, becaplermin 0.01%) that has been approved by the FDA for patients with diabetic foot ulcers. 10 Even though the evidence has shown the benefit of becaplermin to chronic wounds is beneficial, the high cost and frequent dressing change requirement limits its use.

Biopolymeric wound dressings have been successfully produced with the incorporation of GFs into commonly utilized biomaterials including gelatine, 112 , 113 collagen, 114 , 115 and chitosan. 116 , 117 Electrospinning is a popular technique to produce nanofibers with controlled‐release GFs. GF‐loaded electrospun fibers can be achieved by incorporating GFs into the polymeric nanofibers 118 or conjugating them onto the surface. 119 The difference in the GF loading strategies determines a variation in GF release profiles. There was a novel approach proposed by Kulkarni et al. in 2014. 120 They utilized a layer‐by‐layer assembly method to encapsulate EGF on the surface of poly(acrylic acid)‐modified polyurethane nanofibers. This method successfully prolonged EGF release, which was regulated by adjusting the number of layers deposited onto the surface.

Wound healing involves many complex mechanisms, which sometimes require more than one GF delivery to provide sufficient support. Studies have shown that a combination of different GFs can improve delayed wound repair in diabetes compared with a single GF treatment. 121 Moreover, the spatio‐temporal gradients can also have a considerable impact on treatment efficacy. Lai et al. (2014) either embedded bFGF, EGF, VEGF, and PDGF into collagen/hyaluronic acid‐based electrospun nanofibers or encapsulated them into gelatine nanoparticles. 122 Degradation lasted for a month simulating the temporal release of the normal wound healing process in the human body environment. EGF and bFGF were released in the initial stage mimicking the early phase of angiogenesis of wound repair. The sequent controlled release of VEGF and PDGF imitated the new skin reconstruction phase which was confirmed by an in vivo diabetic rat study.

Platelets are natural sources of multi‐GFs and proteins, which takes part in tissue regeneration. Additionally, platelet derivatives have been reported to facilitate wound healing and accelerate tissue repair. 123 Platelet lysate (PL) is obtained from blood platelets after freezing/thawing cycles. It has been reported that PL can activate various cell types during the wound healing process. 123 In comparison with platelet‐rich plasma or platelet‐rich fibrin, PL has the advantage of limiting the variability of individuals. It has been used to produce sponge‐like dressings, 124 scaffolds, 125 bioactive gels, 126 , 127 and eye drops. 128 , 129 Recently, a core‐shell structure particle‐based dressing was designed with a calcium alginate shell and embedded in an alginate matrix. 130 PL and an antibiotic were loaded in the external matrix as active components for the treatment of chronic skin ulcers. Based on the in vitro and ex vivo studies, the dressings were found to have excellent mechanical properties to handle stress and were able to absorb a high amount of wound extrudate. 130

6.4. Stem cells

Due to complex pre‐existing conditions such as diabetes and ischemia, chronic wounds often appear alongside complications of prolonged inflammation and impaired angiogenesis. 131 The conventional methods for facilitating wound healing such as autograft, xenograft, and allograft have inherent drawbacks of secondary surgeries, the risk of pathogen transfer and limited availability. Cell therapy has been introduced to overcome these difficulties. 132 Stem cells (e.g., mesenchymal stem cells, endothelial progenitor cells [EPC], and epithelial stem cells) have been utilized in wound treatment and their potential discovered for enhancing angiogenesis and tissue regeneration. 133 , 134 , 135 Even though the existing problems such as the high rate of cell death might decrease the treatment efficiency, cells therapy is still a promising strategy, since it integrates environmental signals and transforms them into bio‐factors in the wound sites. 136

For instance, EPCs are bone marrow mononuclear progenitor cells that secret growth factors and cytokines in the wound site to facilitate vascularization and increase angiogenesis. However, previous research on in situ or intravenous injection failed to achieve the target delivery. 132 Hence, Wang and co‐workers developed a bioactive glass (BG) nanoparticle‐based scaffold able to render high biocompatibility and prolong the viability of EPC for promoting wound healing. BGs have received considerable attention on both hard and soft tissue repair due to their unique biocompatibility. 137 Studies have reported that BG nanoparticles can release silicon (Si), Calcium (Ca), and phosphorus (P) ions to provide increased cell response. 138 , 139 It can also improve angiogenesis of human umbilical vein endothelial cells (HUVECs) by regulating growth factors such as VEGF and bFGF, resulting in an improvement in wound healing. 138

Evidence has shown the paracrine effect of stem cells on modulating the level of cytokines and GFs around the wound site. 132 Different from other differentiated cells, stem cells are involved in both acute and chronic wound healing processes, regulating the healing response and synthesizing multiple GFs until the skin is reconstructed. The topical delivery of GFs can be achieved by loading stem cells into scaffolds, which provide robust mechanical strength to sustain stem cell actions and enhance cell proliferation. Various stem cells and techniques can be used for wound healing applications. Amongst them, mesenchymal stem cells (MSCs) especially adipose‐derived stem cells (ADSCs) are probably the most studied stem cells in cutaneous wound healing in the past 5 years. 140 , 141 , 142 , 143 For further reading, Mazini and co‐workers have provided a detailed review of ADSCs in wound healing management. 144

Bone marrow‐derived mesenchymal stem cells (BMSC) are an old fashioned method for facilitating chronic wound healing that has been well studied. 145 , 146 , 147 Guo et al. (2018) recently reported on enhanced diabetic wound healing using ADSC with similar results to BMSC, 148 which was confirmed by conducting an in vivo study on full‐thickness wounds in diabetic mice. Moreover, cell migration and viability of ADSC and BMSC within the biomimetic‐collagen scaffolds were similar. 148 The main challenge of utilizing MSCs in wound management was to maintain their viability and adherence to the wound bed. In situ‐forming injectable hydrogel dressings have been developed to secure a large number of cells at the wound infection site. In addition, the relatively easier “living cell” loading method makes hydrogels a popular choice for implanting cells into complex tissue shapes. 149

6.5. Natural compounds

The development of alternative wound healing products has been a popular topic in recent years. Natural sources, in particular have received increased attention. Natural compounds, such as honey, aloe vera, curcumin and essential oils, have been applied in wound management. 150 , 151 Nevertheless, there is still a lack of standardization methods for the evaluation of the composition of natural products, which makes it difficult to estimate the efficacy of these compounds in wound management.

6.5.1. Curcumin

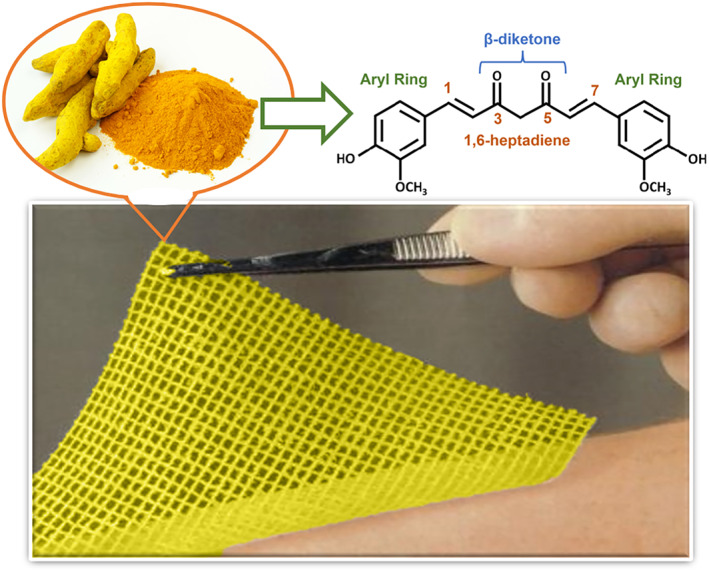

Curcumin is a natural polyphenolic molecule extracted from the Curcuma longa rhizome widely used in both normal and chronic wound repair. It is a wound‐healing agent and has anti‐inflammatory, anti‐infection, and anti‐oxidant effects. 152 Curcumin can stimulate granulation tissue proliferation and facilitate the transformation of TGF‐β1and proteins into ECM. 153 It acts as an antioxidant to scavenge free radicals since free radicals are considered the major cause of inflammation by activating the downregulation of the PI3K/AKT/NFκB pathway. 154 Studies have shown that the topical application of curcumin on wounds enhanced fibroblast proliferation and vascular density, which in turn promoted epithelial regeneration. 152

One of the major factors that cause chronic wounds involves oxidative stress. Antioxidant therapy focuses on encapsulating antioxidant agents into a wound dressing to eradicate reactive oxygen species (ROS), to promote the healing rate of chronic wounds. 155 Curcumin has been reported to have the potential to decrease ROS and increase healing speed, 152 which can be attributed to the phenolic hydroxyl groups and the diketone structure of curcumin (Figure 2). Its antioxidant efficacy is ascribed to the nuclear factor erythroid 2‐related factor (Nrf2) pathway, which activates the cytoprotective signaling constituents. 154

FIGURE 2.

Functional group of curcumin structure in wound management

Additionally, curcumin has also been reported to hinder transcription factor nuclear factor kappa‐light‐chain‐enhancer of activated B cells (NF‐(κ) B), which modulates the genes involved in the inflammatory response. 152 Kinases, including AKT, PI3K, and IKK, regulate the activity of NF‐(κ) B, and curcumin has an impact on these pathways. 152 Mohanty et al. (2012) designed an oleic acid‐based polymeric bandage loaded with curcumin that was placed on the dorsum of injured rats. The addition of curcumin had a downregulation effect on the expression of kinases in the PI3K/AKT/ NF‐(κ)B pathway. 156

Nguyen et al. (2013) designed curcumin‐loaded PLA nanofibers to function as wound‐healing patches. The result showed that the addition of curcumin had a significant impact on the tensile stress of the nanofibers (that increased up to 3.5 MPa), which indicated its suitability as a wound dressing. In the in vivo study, the dorsal wounds on the rats achieved 87% and 99% of wound closure rates on days 7 and 15, respectively. 157

Ranjbar‐Mohammadi et al. (2016) developed a curcumin‐loaded PCL/gum tragacanth nanofiber. The nanofibers were reported to be 85.14% and 99% antibacterial against extended‐spectrum beta‐lactamase (ESBL) and methicillin‐resistant Staphylococcus aureus (MRSA), respectively, with a curcumin content of 3 wt% revealing its potential for treating wounds infected with antibiotic‐resistant organisms. 158

A curcumin‐loaded mat produced by Zahiri et al. (2020) was electrospun with PCL‐gelatine. Sustained release of curcumin was observed from the electrospun mats, and the in vivo study revealed the significant wound closure achievement of curcumin‐loaded nanofiber mats on day 14 (82%), in comparison to the plain nanofibrous mats (73.4%). 159

6.5.2. Honey

Honey is derived from nectar by industrious honeybees and recently has been valued for its biomedical properties in treating diabetic ulcers, burns, and various skin wounds. 160 Instead of being treated as an “alternative medicine” as previous considerations, honey has become one of the main focuses in the terms of wound healing, since the advent of antibiotic resistance to the majority of modern medications. 161 Amongst the different honey types, Medihoney and Manuka honey were studied and showed similar healing properties. 162

Honey is known for its antimicrobial, anti‐inflammatory and antioxidant properties that accelerate wound healing rates. Many studies have shown its use in prohibiting challenging wound infections with its excellent antimicrobial activities. 163 Honey, in nature, contains major (macroelements) and minor (trace elements) ingredients that can perform biomedical activities in various wound healing settings. 163 However, the concentrations of these ingredients vary between different plant species where bees feed and are also influenced by environmental pollution. 164 The main ingredients are sugar (glucose and fructose, 65%) and water (18%) as well as minimal protein and lipid contents. 164 The minerals and heavy metals that honey contains have a significant influence on determining honey qualities. For instance, pale honey only holds 0.04% mineral content, however, it can reach 0.20% in darker honey products. 164 Another important component group of honey are polyphenols (e.g., catechin, quercetin, and taxifolin), which are known for their antioxidant properties. 162

Honey has antimicrobial efficiency against more than 60 bacterial species, including aerobic/anaerobic bacteria, gram‐negative/gram‐positive bacteria, and some fungi. 165 Honey plays an important role in inhibiting biofilm formation, which can be ascribed to its osmotic effect. The osmotic action is the result of the high sugar content in honey, depleting water from the bacterial cells, leading to dehydration and cell death. 166 Unexpectedly, researchers found that diluting honey in the water further increased its antimicrobial properties, they identified that hydrogen peroxide was the key antimicrobial agent in most honey. 167 Moreover, freshly collected honey was reported to have a high level of lysozyme (usually 5–10 mg/ml, occasionally 35–100 mg/ml), which is much higher than extractions from older honey samples. 168

Manuka honey is well known for its use in manufacturing wound dressings. It is produced in New Zealand and Australia from the nectar of the Mānuka tree, and it contains methylglyoxal which is a bioactive molecule that can kill bacteria and reduce the infection rate in biomaterials. 169 Notably, Manuka honey does not contain the hydrogen peroxide found in most other kinds of honey, but rather the methylglyoxal provides the antibacterial effect. Medihoney® dressing was designed for wound healing and used Manuka honey as an active agent. It was the first honey‐based dressing approved by FDA for clinical use. It was accepted for its excellent wound healing for light to moderate wounds such as diabetic foot ulcers, partial/full‐thickness pressure ulcers, and first/second partial‐thickness burns. 160 Moreover, literature has reported that Manuka honey can reduce inflammation and promote fibroblast migration, which provides the potential to enhance the wound healing rate. 162 Additionally, a study by Watanabe et al. (2014) showed that Manuka honey retarded the duplication of influenza virus and improved the effects of antiviral drugs, indicating a potential for the incorporation of honey with an antiviral drug in the future. 170

Surgihoney® is another commercial wound dressing product based on various honey sources. This highly standardized honey has a precise antimicrobial activity level and can steadily deliver oxygen‐free radicals. 171 Its antimicrobial activities own to hydrogen peroxide, which helps the dressing to fight against bacteria at a very low concentration. 162

Even though honey is a natural product and it has high purity, patients who are allergic to honey or bee venom still need to be aware of using honey dressings. Moreover, patients with diabetes need their blood sugar levels to be monitored to avoid putting them at risk of hyperglycaemia. 10

6.5.3. Aloe vera

Aloe vera is a tropical herb that grows in a relatively hot and dry environment. 172 Aloe vera gel extracted from the mucilaginous part of the leaf has been applied in various wound care for centuries. Aloe vera has antioxidant, antibacterial and anti‐inflammatory properties and it stimulates FGF to promote collagen production and secretion. 173 In addition, Aloe vera contains vitamins A, B, C, E, amino acids, enzymes, polysaccharides, and anthraquinones. 173 The glycoprotein fraction isolated from aloe vera was reported to be a bioactive component for wound healing. 174 Aloe vera gel was utilized on sutured incisions in the Wistar rat to study its topical efficacy. 175 It was reported that aloe vera gel had notable wound‐healing effects, which were confirmed by the observation of increased mean numbers of fibroblast proliferation and the mean thickness of the regenerating epithelium after 4 days of surgery. 175

A research group developed nanofibrous scaffolds with a combination of PCL/ aloe vera, PCL/silk fibroin, PCL/aloe vera/silk fibroin, and PCL/aloe vera/silk fibroin/curcumin. 176 These scaffolds successfully mimicked the natural environment of ECM. The total content of aloe vera was 16.6% (w/w), and the scaffolds that contained aloe vera had the best results in terms of porosity and mechanical properties, which indicated their suitability to be used as wound dressings. Aloe vera (25% w/w) was electrospun with silk fibroin and polylactic‐co‐ε‐caprolactone (PLLA) to produce dermal substitutes. 177 The final wound dressing product demonstrated both high wound healing activity and elastic strength, which was a combination of the unique properties of aloe vera and silk fibroin. Another study also used both aloe vera and silk fibroin to produce nanofibers, 178 and the aloe vera content was 10–20% w/w. In that study, vitamin E loaded starch nanoparticles were fabricated and then incorporated into aloe vera/silk fibroin/PVA nanofibers. The addition of aloe vera and vitamin E was ascribed to the largely enhanced cell viability. 178

Garcia‐Orue et al. (2017) developed a PLGA nanofibrous membrane that contained recombinant human epidermal growth factor (rhEGF) and aloe vera extract. 179 The authors reported that this was the first study that used a high proportion of aloe vera (aloe vera/PLGA/rhEGF at a ratio of 1:1:0.4). The addition of aloe vera promoted the proliferation of fibroblasts, which in turn facilitated wound healing. 179 Abdel‐Mohsen et al. (2020) proposed a novel wound dressing that consisted of collagen, chitosan‐glucan complex hollow fibers and aloe vera. This wound dressing was fabricated using a freeze‐drying technique and it demonstrated excellent blood clotting efficiency and wound healing characteristics, which suggests its application in soft tissue engineering. 180

6.5.4. Other phytomedicines

Other plant products, such as green tea, essential oils and grapevine are also used as bioactive molecules for facilitating wound healing. 181 , 182 , 183 Green tea contains high amounts of polyphenols, accounting for nearly 30% of the dry weight of the green tea leaves, which are potently antibacterial, anti‐carcinogenic, and anti‐inflammatory components. 182 There are also catechins within the green tea extract, which inhibit the growth of gram‐positive and gram‐negative bacteria causing damage to the cell wall. 182 All those features suggest that green tea may enhance the wound healing process. An antibacterial microneedle consisting of green tea extract and hyaluronic acid was designed to efficiently deliver green tea extract for facilitating wound healing. 184 In this system, researchers were able to regulate the degradation rate of green tea by modulating hyaluronic acid ratios. Additionally, this delivery system had a high loading capacity, as a 70% green tea load achieved sustained release within 72 h. 184

Essential oils are the largest group of secondary metabolites of plants. 185 They have been used for a variety of medical applications for centuries. 186 Essential oils can be extracted by steam distillation or cold pressing. Their use in cosmetic products and natural medicine products has been increasing. 187 Moreover, due to the anti‐inflammatory, antioxidant, and antibacterial characteristics of essentials oils, they play an important role in dermatological treatment for chronic wounds. 188 García‐Salinas et al. (2020) developed various PCL‐based electrospun patches and loaded them with essential oils thymol and tyrosol to reduce inflammation during wound healing. 181 They showed that essential oil‐loaded PCL patches reduced the size of inflamed cells in immunofluorescence assays, which indicated the alleviation of the inflammatory response, and their potential use for wound healing.

Tea tree oil is one of the most commonly studied essential oils. It is steam‐distilled from Melaleuca alternifolia, which is an Australian native plant. The major component of tea tree oil, which is Terpinen‐4‐ol, has excellent antimicrobial and anti‐inflammatory properties, however, the existence of 1,8‐cineole is a known potential allergic trigger in tea tree oil products. 181 Zhang et al. (2017) developed PLA‐based electrospun nanofibers and encapsulated them with tea tree and manuka essential oils. 189 They observed that tea tree oil worked as a plasticizer for PLA during the manufacturing procedure, which improved the mechanical properties of the PLA‐based electrospun nanofibers.

7. DEVICES FOR WOUND MANAGEMENT

7.1. Wound dressings

Advanced wound dressings are designed to maintain the wound microenvironment, facilitating re‐epithelialization and preventing further skin damage. It is crucial for wound dressings to be porous and breathable, which allows the gaseous exchange to protect the tissues from maceration and promote autolytic debridement. Moreover, the dressings must be able to provide thermal insulation, against infections, and balance the moisture of the wound environment. Furthermore, advanced wound dressings should facilitate wound healing in a way that promotes the natural healing process, including the enhancement of angiogenesis in an ischemic wound, and the acceleration of fibroblasts and keratinocytes migration rate. 190

Wound dressings can be classified as biological dressings, conventional dressings, biosynthetic dressings, and antimicrobial dressings. Amongst them, biological dressings (e.g., cadaver allograft skin, xenograft, and human amnion) and conventional dressings (e.g., Vaseline gauze and silicone sheets) are only used temporarily and cannot be utilized as a permanent skin replacement. 10 Biosynthetic dressings can mimic the natural skin function and replace the epidermis or dermis. For instance, Biobrane® is a biosynthetic skin dressing used on superficial and partial‐thickness wounds, and it has been proven to significantly reduce the healing time of superficial and mid dermal partial‐thickness burns within 12 h. 191 Antimicrobial dressings may contain silver, cadexomer iodine, or honey to prevent wound infection and inflammation. Especially the incorporation of silver compounds in burn wound treatment was a successful case, which effectively reduced the chances of burn‐induced sepsis and possible death. 22

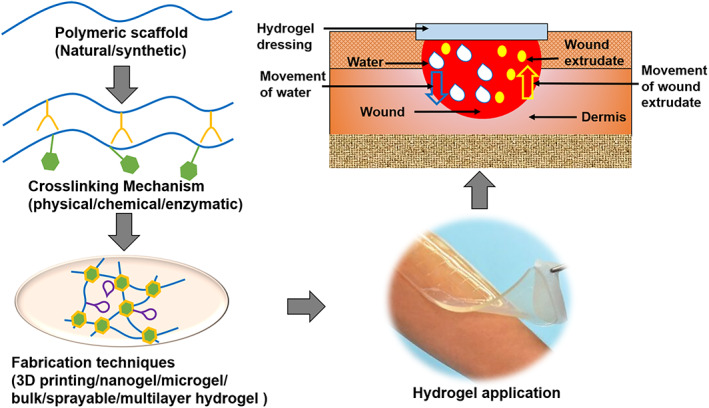

7.1.1. Hydrogels

Hydrogels are swellable dressings made from biocompatible and biodegradable materials such as polyvinylpyrrolidone (PVP) and methacrylate. 192 , 193 Hydrogels contain 80%–90% water molecules and provide a moist environment for the wound site through the release of water molecules. Hydrogels are 3D networks formed by hydrophilic water‐soluble polymers that have a wide range of physicochemical properties. 194 The hydrophilic chains within the hydrogel structure grant it the ability to absorb a large volume of water without changing its gelatinous nature. 193 Hydrogels are nontoxic and nonadherent, and their jelly‐like texture makes hydrogel dressings a common use in wounds with unusual shapes and edges. 195 Recent studies on hydrogel fabrication for wound healing have been summarized in Table 1.

TABLE 1.

Hydrogels in wound management

| Materials | Crosslinking engine | Bioassay | Wound healing assay | Properties/results | References |

|---|---|---|---|---|---|

| GelMA | Chemical | — | In vitro | The cells were able to grow in each layer, which rendered epidermis‐like thin cell layers for keratin/chitosan nanofibers, and dermis‐like cell‐laden for the GelMA hydrogel. | [200] |

| Sodium alginate/ gelatine/ AgNPs | Physical | Pseudomonas aeruginosa/ Staphylococcus aureus | In vitro/in vivo | AgNPs loaded sodium alginate/gelatine hydrogels accelerate skin tissue formation and stimulate early collagen scar generation in 14 days. | [201] |

| Chitosan/ PEG/ AgNPs | Chemical | Pseudomonas aeruginosa/ Escherichia coli/ Staphylococcus aureus/ Bacillus subtilis/ Bacillus pumilus | In vivo | AgNPs incorporated chitosan/PEG hydrogels exhibited sustained AgNPs release and achieved fast healing in the diabetic rabbit study. | [74] |

| PEG/PAH/gold nanoparticles/poloxamer® 407 | — | Staphylococcus aureus/Pseudomonas aeruginosa | In vivo | AuNPs with different shapes and surface modifications were loaded into PEG or PAH blended poloxamer® 407 hydrogels. AuNPs demonstrated slow release over 48 h. Hydrogels promoted skin re‐epithelization and achieved almost complete wound healing in 14 days. | [202] |

| BAPEG/DCS/VEGF | Hybrid | Staphylococcus aureus/Escherichia coli | In vitro/in vivo | BAPEG/DCS hybrid hydrogel repaired acute tissue immediately, due to adhesion and hemostasis of the hydrogel. Chronic wound healing could be achieved by VEGF‐loaded hydrogel. | [197] |

| QCS‐C/PLEL | Physical | Staphylococcus aureus/Escherichia coli | In vivo | An injectable adhesive thermo‐sensitive hydrogel was fabricated. In vivo study displayed superior ability to heal complicated skin defects compared with the suture and fibrin glue within 7 days. | [203] |

| Chitosan/PVA/AgNPs | Physical | Pseudomonas aeruginosa/Staphylococcus aureus | In vivo | AgNPs loaded chitosan/PVA hydrogel achieved 98 ± 4 to 99 ± 1% wound closure on day 12. | [204] |

| Gelatine/quercetin/Carbopol® | — | — | In vivo | Quercetin loaded liposomal hydrogel showed a wound reduction of 98.93% on day 12. Whereas, simple liposome‐hydrogel achieved 52.26% wound closure on day 4. | [205] |

| Chitosan/PLGA/PDGF/β‐glycerophosphate | — | — | In vivo | PDGF/PLGA hydrogel demonstrated better performance than PDGF alone in wound closure and granulation tissue formation. Moreover, autophagy levels were decreased in the PDGF/PLGA hydrogel group in comparison with control groups at day 8. | [206] |

| Quaternized chitosan (QCS)/polydopamine‐coated reduction graphene oxide (rGO‐PDA)/ poly(N‐isopropylacrylamide) (PNIPAm) | Chemical | Staphylococcus aureus/Escherichia coli | In vitro/in vivo | Self‐healing QCS/rGO3‐PDA/PNIPAm hydrogel with thermo‐responsive properties was successfully fabricated. The increased content of rGO‐PDA led to reduced drug release within 10 days, due to the decrease of swelling ratios. However, more drug (about 40%) were released in initial stage (8.5 h) with high rGO‐PDA loading. | [207] |

| Ag/Ag@AgCl/ ZnO | Hybrid | Staphylococcus aureus/Escherichia coli | In vivo | Ag/ Ag@AgCl/ ZnO hybrid hydrogel killed 95.95% E. coli and 98.49% S. aureus within 20 min. A sustained release of silver and zinc ions was observed in 21 days. Moreover, 90% Zn2+ was released in acidic conditions after 3 days, whereas, only 10% was released after 21 days in neutral conditions. | [208] |

| PH/PVA | Physical | — | In vitro | PH/PVA hydrogel demonstrated higher swelling and cell proliferation rate compared to the PVA hydrogel after 1 and 5 days. | [209] |

| BG/OSA | Chemical | — | In vivo | BG/OSA hydrogel completed the healing process on day 21 in a rat model. The presence of BG imparted tissue adhesiveness to the OSA hydrogel, due to alkaline ion release. | [210] |

| PDA/PUE/PEG‐DA | Hybrid | — | In vivo | PEG‐DA/PDA/PUE hydrogel absorbed 2000 times more solution than its own weight and completed wound healing in a rat model in 20 days. | [211] |

Abbreviations: AgNPs, silver nanoparticles; AuNPs, gold nanoparticles; BAPEG, benzaldehyde‐terminated PEG; BG, bioglass; DCS, dodecyl‐modified chitosan; GelMA, gelatine methacrylate; OSA, oxidized sodium alginate; PAH, polyallylamine hydrochloride; PDA, polydopamine; PDGF, platelet‐derived growth factor receptor; PEG, polyethylene glycol; PEG‐DA, polyethylene glycol diacrylate; PH, phlorotannins; PLEL, poly(d,l‐lactide)‐poly(ethylene glycol)‐poly(d,l‐lactide); PNIPAm, poly(N‐isopropylacrylamide; PUE, puerarin; PVA, Polyvinyl alcohol; QCS, quaternized chitosan; QCS‐C, catechol modified quaternized chitosan; rGO‐PDA, polydopamine‐coated reduction graphene oxide; VEGF, vascular endothelial growth factor.