Abstract

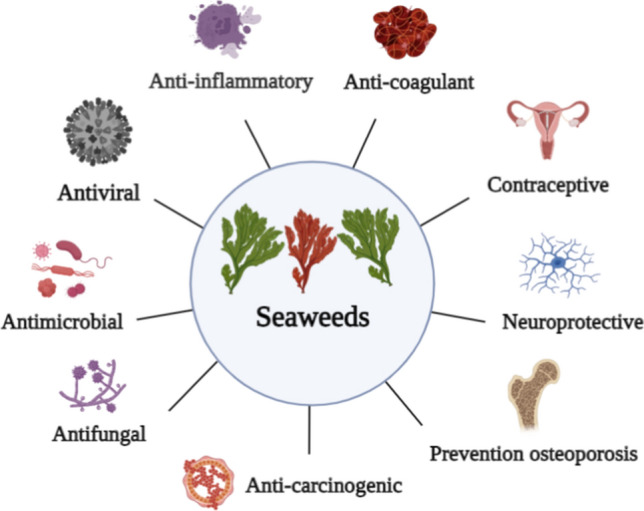

The development and recycling of biomass production can partly solve issues of energy, climate change, population growth, food and feed shortages, and environmental pollution. For instance, the use of seaweeds as feedstocks can reduce our reliance on fossil fuel resources, ensure the synthesis of cost-effective and eco-friendly products and biofuels, and develop sustainable biorefinery processes. Nonetheless, seaweeds use in several biorefineries is still in the infancy stage compared to terrestrial plants-based lignocellulosic biomass. Therefore, here we review seaweed biorefineries with focus on seaweed production, economical benefits, and seaweed use as feedstock for anaerobic digestion, biochar, bioplastics, crop health, food, livestock feed, pharmaceuticals and cosmetics. Globally, seaweeds could sequester between 61 and 268 megatonnes of carbon per year, with an average of 173 megatonnes. Nearly 90% of carbon is sequestered by exporting biomass to deep water, while the remaining 10% is buried in coastal sediments. 500 gigatonnes of seaweeds could replace nearly 40% of the current soy protein production. Seaweeds contain valuable bioactive molecules that could be applied as antimicrobial, antioxidant, antiviral, antifungal, anticancer, contraceptive, anti-inflammatory, anti-coagulants, and in other cosmetics and skincare products.

Keywords: Seaweeds, Seaweed biogas, Seaweed biochar, Seaweed food, Climate change mitigations, Seaweeds cosmetics, Seaweeds pharmaceuticals, Biorefineries

Introduction

Our planet faces several challenges, including climate change, rapid population growth, food shortages, and rising demand for bioactive compounds derived from nature in various aspects of life (Chen et al. 2022). To sustain these issues while simultaneously reducing negative effects on the ecosystem and preserving natural bioresources, deploying renewable biomass as a substitute for fossil fuels requires immediate and widespread adoption policies (Osman et al. 2021a). This may also involve the use of alternative renewable green energy sources.

Biomass biorefining for the production of diverse products, such as human food, animal feed, biochemicals, and bioenergy, through eco-innovative and sustainable bioprocess systems, is associated with sustainable development goals (Heimann 2019). Due to the biogenic origin of biomass, carbon dioxide emissions from bioprocesses do not contribute to a rise in atmospheric carbon dioxide levels (Tursi 2019; Osman et al. 2021b). Seaweeds are a rich source of unutilised biomass that can be used to address global challenges when cultivated using sustainable methods. As depicted in Fig. 1, seaweeds can address problems associated with climate change, bioenergy generation, agriculture, food consumption, animal and human health, useful chemicals, bioactive ingredients, and coastal management. In addition, if properly implemented, seaweeds could provide a sustainable circular bioeconomy strategy (Barbier et al. 2020).

Fig. 1.

Seaweed biorefineries. Seaweeds can be harvested either through cultivation or from a natural source. Cultivated seaweeds use carbon dioxides from other refinery sources and the sun to sequester carbon within their biomass and are therefore regarded as a carbon sequestration tool when converted into a stable form of carbon such as biochar. In addition, wild seaweeds can float and descend deeper into the ocean, where they can be buried and act as a carbon sink. On the other hand, seaweeds can be extracted to obtain bioactive molecules that can be used in various biorefineries, such as antimicrobials, antioxidants, food supplements, plant growth promoters, anti-inflammatory, anticancer, contraceptives, cosmetics, and skin care agents. As a climate change mitigation strategy, seaweed residues or biomass can be used as feedstocks for anaerobic digestion to produce biomethane, which can be used to replace fossil fuels as a bioenergy source. Bioplastic derived from seaweed is an innovative method to replace synthetic, non-biodegradable plastics and protect the environment. Conversion of seaweed biomass to biochar is another method for mitigating climate change

Compared to lignocellulosic biomass from terrestrial plants, seaweeds are more suitable for biorefinery applications due to their rapid growth rates, extremely large yields, and lack of planetary land required for cultivation (Rajak et al. 2020). In addition, the absence of recalcitrant lignocellulosic assembles suggests that less energy may be required to recover high-valued bio-products of commercial interest, which favours economic and life cycle analyses of any assumed biorefinery bioprocess that uses seaweed as feedstocks. In addition, the existence of unique inherited polysaccharides in various seaweed species presents unique characteristics for either direct application or as compounds for the bioeconomy. Thus, seaweeds are third- or even fourth-generation feedstocks (Gaurav et al. 2017; Del Rio et al. 2020). However, the potential applications of seaweeds in biorefineries are still in their infancy, with progress beyond the laboratory scale being slow. Figure 1 depicts the review's interest in utilising seaweed biomass in various novel biorefineries. Specifically, the use of seaweeds in climate change mitigation and environmental sustainability, food consumption, animal feed additives, fish diets, bioplastic production, biofertilisers, biochar production, carbon sequestration tools, crop enhancers, antimicrobials, anti-inflammatory, anticancer, contraceptive, cosmetics, and skin care agents were reviewed.

The integration of seaweeds and bioprocesses can undoubtedly result in the commercialisation of seaweed biorefineries and call attention to the significant need for cooperative funding in this extremely promising research area, as well as the need for ongoing seaweed projects around the globe. In addition, the challenges currently faced by seaweed biorefineries and the future research required for seaweed's industrial growth are addressed.

Worldwide seaweed production and seaweed types

Global seaweed productions

Seaweeds are marine photosynthetic organisms, also known as “macroalgae,” that provide the energy foundation for all aquatic organisms, thereby playing a crucial role in the aquatic ecosystem's equilibrium. Multiple environmental benefits are provided by seaweed, such as carbon sequestration or capture, eutrophication mitigation, ocean acidification modification, shoreline protection, and habitat provision.

Seaweeds are an essential component of global aquaculture. In 2019, seaweed cultivation accounted for approximately 30% (wet weight) of the 120 gigatonnes of global aquaculture production, with brown (Phaeophyceae) and red (Rhodophyta) seaweeds, respectively, being the third- and second-largest contributors to global aquaculture after barbels, carps, and other cyprinids (FAO 2021a). Asia produces more than 97% of the world’s seaweed, with eight genera accounting for 96.80% of global seaweed production (Chopin and Tacon 2021).

In 1969, the 2.2 gigatonnes of global seaweed production were contributed equally by wild collection and cultivation, according to statistics. In 2019, cultivation seaweed production accounted for more than 97% of the world's seaweed production, while wild seaweed production remained at 1.1 gigatonnes (Cai et al. 2021). In Asia, more than 99.1% of seaweed production originated from cultivation, accounting for 97.38% of global production, with seven leading seaweed-producing nations in South or Eastern Asia, as shown in Table 1. Europe and the Americas accounted for 0.80 and 1.36%, respectively, of the world's seaweed production, with wild seaweed collection dominating, while cultivation accounted for only 3.87 and 4.70%, respectively, of total seaweed production. Contrarily, seaweed farming was the primary source of African seaweed production, accounting for 81.30 and 84.94% from Africa and Oceania, respectively; however, wild seaweeds only account for 0.41 and 0.05% of global seaweed production, respectively (Table 1).

Table 1.

Global seaweed production

| Area | Overall seaweed production (cultivated and wild) | Seaweed cultivation | ||

|---|---|---|---|---|

| Wet weight (thousand tonnes) | Global share (%) | Wet weight (thousand tonnes) | Share in cultivated and wild production (%) | |

| World | 35,762.5 | 100 | 34,679.1 | 96.97 |

| Asia | 34,826.8 | 97.383 | 34,513.2 | 99.10 |

| China | 20,296.6 | 56.754 | 20,122.1 | 99.14 |

| Indonesia | 9962.9 | 27.859 | 9918.4 | 99.55 |

| Republic of Korea | 1821.5 | 5.093 | 1812.8 | 99.52 |

| Philippines | 1500.3 | 4.195 | 1499.9 | 99.97 |

| Japan | 412.3 | 1.153 | 345.5 | 83.80 |

| Korea | 603 | 1.686 | 603 | 100.00 |

| Malaysia | 188.1 | 0.526 | 188.1 | 100.00 |

| Rest of Asia | 42 | 0.118 | 23.3 | 55.48 |

| Americas | 487.2 | 1.362 | 22.9 | 4.70 |

| Chile | 426.6 | 1.193 | 21.7 | 5.09 |

| Peru | 36.3 | 0.102 | – | – |

| Canada | 12.7 | 0.035 | – | – |

| Mexico | 7.3 | 0.021 | 0.01 | 0.14 |

| USA | 3.4 | 0.009 | 0.3 | 8.82 |

| Rest of the Americas | 0.904 | 0.003 | 0.9 | 99.56 |

| Europe | 287 | 0.803 | 11.1 | 3.87 |

| Norway | 163.2 | 0.456 | 0.1 | 0.06 |

| France | 51.5 | 0.144 | 0.2 | 0.39 |

| Ireland | 29.5 | 0.083 | 0.04 | 0.14 |

| Russian Federation | 19.5 | 0.055 | 10.6 | 54.36 |

| Iceland | 17.5 | 0.049 | – | – |

| Rest of Europe | 5.7 | 0.016 | 0.2 | 3.51 |

| Africa | 144.9 | 0.405 | 117.8 | 81.30 |

| United Republic of Tanzania | 106.1 | 0.297 | 106.1 | 100.00 |

| Morocco | 17.6 | 0.049 | 0.3 | 1.70 |

| Madagascar | 9.7 | 0.027 | 8.9 | 91.75 |

| South Africa | 11.2 | 0.031 | 2.2 | 19.64 |

| Rest of Africa | .43 | 0.001 | 0.4 | 93.02 |

| Oceania | 16.6 | 0.046 | 14.1 | 84.94 |

| Papua New Guinea | 4.3 | 0.012 | 4.3 | 100.00 |

| Solomon Islands | 5.6 | 0.016 | 5.6 | 100.00 |

| Kiribati | 3.7 | 0.010 | 3.7 | 100.00 |

| Australia | 1.9 | 0.005 | – | – |

| Rest of Oceania | 1.1 | 0.003 | 0.6 | 54.55 |

There are 35.8 million metric tonnes of seaweed are produced worldwide. Around 97% of global seaweed production was originated from Asia. In Europe and the Americas, wild types of seaweed dominate production, whereas in Asia, Oceania, and Africa, cultivation dominates (Cai et al. 2021)

Even though seaweeds are generally low-value supplies, seaweed trades accounted for 5.4% of the $275 billion USA worth of world aquaculture production in 2019. This percentage was slightly lower than the other four groups, including cyprinids (carps and barbels), salmons, smelts, and trouts, marine prawns and shrimps, and crayfishes (Cai et al. 2021). The global market for commercial seaweed is anticipated to increase from $15.01 billion in 2021 to $24.92 billion in 2028. The global growth of the seaweed market can be attributed to the use of seaweed as a protective material against coronavirus, as highlighted by the World Health Organization, as well as the use of seaweeds in a variety of applications, including the food industry, livestock feed, agar, alginate, pharmaceutical, and others (Insights 2021).

In Eastern Asia, seaweeds are commonly consumed as human foods; however, in other world regions, seaweeds are consumed only by coastal communities or by very small numbers of consumers for a variety of purposes, such as exotic dietary foods, nutritional supplements (micronutrients), food with a low environmental footprint, and animal feed. In contrast, seaweed is not well known in several world regions.

In biorefineries, seaweeds have many applications, including foods and food supplements, animal feed, cosmetics, nutraceuticals, pharmaceuticals, textiles, biofertilisers/plant enhancers, biofuel, and bioplastic packaging, among others (FAO 2018). However, the contributions of seaweed to these products are typically dependent on the scientific community and seaweed-associated industries. Due to numerous environmental, social, and economic benefits and share, seaweed has the potential to contribute to various sustainable development goals (SDGs) such as sustainable development goals 1–3, 8, 10, and goals 12–14 (Duarte et al. 2021). Today, there is a growing interest in seaweed production, focussing on seaweed as a food resource to feed a growing human population and as a source of eco-friendly biomass (Cai et al. 2021).

Seaweed types

In general, seaweeds are divided into three categories: brown seaweeds with over 2000 Phaeophyceae species, red seaweeds with over 7200 Rhodophyta species, and green seaweeds with over 1800 Chlorophyta species (Cai et al. 2021).

Brown seaweeds

The global cultivation of brown seaweed increased from 13 megatonnes in 1950 to 16.4 gigatonnes in 2019 at an average annual growth rate of 10.9%, which was higher than the global aquaculture growth rate (7.9%) for all species (Cai et al. 2021). In terms of tonnage and value, brown seaweeds accounted for 47.30 and 52.0%, respectively, of global seaweed cultivation in 2019, with Asia being the largest producer (99.93%). Kelp (Laminaria/Saccharina) and wakame (Undaria) are the most prevalent two genera of brown, cold-water seaweed worldwide. As shown in Table 2, seven nations supplied nearly 12.27 million tonnes of Laminaria/Saccharina in 2019, with 99.74% coming from four Asian nations and 0.27% coming from three European nations.

Table 2.

| Seaweed category | Seaweed family | Country/area | Production | |

|---|---|---|---|---|

| Tonnes (wet weight) | Share of the world (%) | |||

| Brown seaweeds | Laminaria/Saccharina | Worldwide | 12,273,748 | 100.00 |

| China | 10,978,362 | 89.45 | ||

| Republic of Korea | 662,557 | 5.40 | ||

| Korea | 600,000 | 4.89 | ||

| Japan | 32,600 | 0.27 | ||

| Faroe Islands | 156 | 0.00 | ||

| Norway | 73 | 0.00 | ||

| Spain | 0.14 | 0.00 | ||

| Undaria | Worldwide | 2,563,582 | 100.00 | |

| China | 2,023,930 | 78.95 | ||

| Republic of Korea | 494,947 | 19.31 | ||

| Japan | 44,600 | 1.74 | ||

| France | 105 | 0.00 | ||

| Unidentified brown seaweeds | Worldwide | 1,250,000 | 100.00 | |

| China | 1,240,000 | 99.20 | ||

| the Russian Federation | 11,000 | 0.88 | ||

| USA | 241 | 0.02 | ||

| Mexico | 10 | 0.00 | ||

| Sargassum (mainly S. fusiforme) | Worldwide | 304,000 | 24.32 | |

| China | 270,000 | 21.60 | ||

| Korea | 34,000 | 2.72 | ||

| Alaria esculenta | Worldwide | 105 | 0.01 | |

| Norway | 44 | 0.00 | ||

| Ireland | 42 | 0.00 | ||

| Faroe Islands | 19 | 0.00 | ||

| Cladosiphon okamuranus | Japan | 90 | 0.01 | |

| Macrocystis pyrifera | Chile | 2 | 0.00 | |

| Red seaweeds | Kappaphycus/Eucheuma | Worldwide | 11,622,213 | 100.00 |

| Asia | 11,491,956 | 98.88 | ||

| Indonesia | 9,795,400 | 84.28 | ||

| Philippines | 1,498,788 | 12.90 | ||

| Malaysia | 188,110 | 1.62 | ||

| China | 4200 | 0.04 | ||

| Cambodia | 2000 | 0.02 | ||

| Viet Nam | 1700 | 0.01 | ||

| Timor-Leste | 1500 | 0.01 | ||

| Sri Lanka | 247 | 0.00 | ||

| Myanmar | 11 | 0.00 | ||

| Africa | 115,334 | 0.99 | ||

| United Republic of Tanzania | 10,069 | 0.09 | ||

| Zanzibar | 104,620 | 0.90 | ||

| Tanzania (mainland) | 1449 | 0.01 | ||

| Madagascar | 8865 | 0.08 | ||

| Kenya | 400 | 0.00 | ||

| Oceania | 14,050 | 0.12 | ||

| Solomon Islands | 5600 | 0.05 | ||

| Papua New Guinea | 4300 | 0.04 | ||

| Kiribati | 3650 | 0.03 | ||

| Fiji | 500 | 0.00 | ||

| Latin America and the Caribbean | 874 | 0.01 | ||

| Brazil | 700 | 0.01 | ||

| Saint Lucia | 103 | 0.00 | ||

| Ecuador | 45 | 0.00 | ||

| Grenada | 20 | 0.00 | ||

| Belize | 3 | 0.00 | ||

| Venezuela | 3 | 0.00 | ||

| Gracilaria | Worldwide | 3,639,833 | 100.00 | |

| Asia | 3,617,828 | 99.40 | ||

| China | 3,480,850 | 95.63 | ||

| Indonesia | 123,000 | 3.38 | ||

| Viet Nam | 11,150 | 0.31 | ||

| Republic of Korea | 1769 | 0.05 | ||

| Taiwan | 976 | 0.03 | ||

| Philippines | 83 | 0.00 | ||

| Latin America and the Caribbean | 21,702 | 0.60 | ||

| Chile | 21,672 | 0.60 | ||

| Brazil | 30 | 0.00 | ||

| Africa | 303 | 0.01 | ||

| Morocco | 273 | 0.01 | ||

| Tunisia | 30 | 0.00 | ||

| Europe | 0.13 | 0.00 | ||

| Spain | 0.13 | 0.00 | ||

| Porphyra | Worldwide | 2,984,123 | 100.00 | |

| Asia | 2,984,123 | 100.00 | ||

| China | 2,123,040 | 71.14 | ||

| Republic of Korea | 606,873 | 20.34 | ||

| Japan | 251,200 | 8.42 | ||

| Korea | 3000 | 0.10 | ||

| Taiwan | 10 | 0.00 | ||

| Green seaweeds | Total 6 regions | 16,696 | 100.00 | |

| Caulerpa spp. | Philippines | 1090 | 6.53 | |

| Monostroma nitidum | Korea | 6321 | 37.86 | |

| Capsosiphon fulvescens | Korea | 3386 | 20.28 | |

| Ulva spp. | South Africa | 2155 | 12.91 | |

| Codium fragile | Republic of Korea | 3258 | 19.51 | |

| Green seaweeds nei | 92.62% Viet Nam, 7.2% Portugal, and 0.18% Spain | 486 | 2.91 | |

With 18.25 gigatonnes, red seaweeds are the most abundant type of seaweed produced globally, followed by brown seaweeds with 16.40 gigatonnes and green seaweeds with 16.70 megatonnes. Gracilaria, Eucheuma/Kappaphycus, Porphyra are the most common red seaweed genera, while Laminaria/Saccharina and Undaria are the most commonly brown seaweed genera globally. Asia is the leading global brown and red seaweed producer, accounting for 99.93 and 99.17%, respectively

The majority of the 2.56 gigatonnes of Undaria (primarily Undaria pinnatifida) farming (7.40% of total seaweeds) were supplied by three Eastern Asian countries and one European country (0.004%) (Table 2). Farmed brown seaweed is mostly used for human consumption (e.g., wakame salads and kombu soup) as well as abalone feeds. Additionally, cultivated brown seaweed is used as a feedstock to produce (i) animal feeds; (ii) hydrocolloid (e.g., alginate for several biorefineries); (iii) biofertiliser or bio-stimulants; (iv) cosmetic or pharmaceutical ingredients; and (v) biodegradable bioplastics (FAO 2018).

Red seaweeds

The cultivation of red seaweeds increased from 21 megatonnes in 1950 to 18.25 gigatonnes in 2019, a 10.3% average annual increase that is less than brown seaweed but greater than global aquaculture growth (7.9%). In 2019, red seaweeds accounted for 52.65% of global seaweed cultivation, of which 99.17% occurred in Asia. Red seaweed cultivation is primarily dependent on two warm-water genera (Gracilaria and Eucheuma/Kappaphycus) and one cold-water genus (Porphyra, commonly called nori) (Cai et al. 2021). The 11.62 gigatonnes of Eucheuma/Kappaphycus cultivation in 2019, accounting for 33.54% of total seaweeds, was supplied by 23 regions, including nine Asian countries (98.88%), four in East African countries, four Pacific Islands, and six Latin American territories and the Caribbean, as shown in Table 2.

In 2019, 99.40% of the 3.64 gigatonnes of cultivated Gracilaria (10.50% of total seaweed production) were produced by Eastern and South-eastern Asia (Table 2). The 2.98 gigatonnes cultivated Porphyra represented 8.61% of seaweed produced by five Eastern-Asian countries (Table 2). Gracilaria are typically used for agar generation and abalone feeds, whereas Eucheuma/Kappaphycus are mainly employed to isolate carrageenan (FAO 2018). In addition to alginate purified from brown seaweeds, carrageenan and agar are hydrocolloids derived from seaweed that are commonly used in food and/or non-food biorefineries. Eucheuma/Kappaphycus and Gracilaria are also used as human foods (such as pickles and salads), while Porphyra are primarily used in sushi wrap and as a soup ingredient.

Green seaweeds

Since 1990, green seaweed cultivation has been comparatively smaller and on a downward trend. The 16.70 megatonnes of global green seaweed farming in 2019 represented approximately 0.048% of total seaweed production, which was less than half of the maximum production in 1992 (38.6 megatonnes). This is in contrast to the rapid growth of brown seaweed cultivation (3-folds) and red seaweed cultivation (15-folds) over the same time period (Cai et al. 2021).

In 2019, six seaweed species cultivated an average of more than 500 kilograms of green seaweed. During 1950–2019, Caulerpa spp. was the most abundant green seaweed species, with an average annual production of 6.4 megatonnes; however, the Philippines’ contribution decreased from 28.7 megatonnes in 1998 to 1.09 megatonnes in 2019. In 2019, the total production of Monostroma nitidum was 6.3 megatonnes, which was lower than the maximum production of 17.7 megatonnes in 1992 (Cai et al. 2021).

In 2019, the Republic of Korea cultivated Capsosiphon fulvescens, Monostroma nitidum, and Codium fragile, which accounted for 12.97 megatonnes of the global green seaweed harvest and 78% of the global green seaweed total (see Table 2). Green seaweeds that have been cultivated can be used as vegetables in salads. Both Caulerpa lentillifera (green caviar or sea grape) and Monostroma nitidum (green laver) are considered delicacies in the marketplace. Other uses for green seaweeds include biofertiliser, animal feeds, bio-stimulants, cosmetics, pharmaceuticals, and wastewater treatment (FAO 2018).

Wild seaweeds harvest

From approximately 1.06 gigatonnes in 2006 to a maximum of 1.29 gigatonnes in 2013 and settling at approximately 1.09 gigatonnes (wet weight) in 2015, wild harvests have remained constant (FAO 2018). In 2015, Chile produced the most wild seaweed (345.704 megatonnes), followed by China (261.77 megatonnes), Norway (147.39 megatonnes), and Japan (93.3 megatonnes).

The dominant species harvested from the wild seaweeds are Chilean kelp (Lessonia nigrescens) with 22% of the total harvested species, followed by huiro palo (Lessonia trabeculata) with 7%, Gracilaria spp. with 5% and the rest-tangle (Laminaria digitata), luga negra (Sarcothalia crispata), kelp (Macrocystis spp.), Japanese kelp (Saccharina japonica), North Atlantic rockweed (Ascophyllum nodosum), and Gigartina skottsbergii—accounting for less than 5%. Farmed and wild Gracilaria species are a major source of agar for human consumption (FAO 2018).

Contamination by heavy metals such as mercury and arsenic is a significant concern with wild seaweed. These factors inhibit market expansion, particularly in nations prioritising food safety and sustainability. Consumers will be willing to pay more for seaweed from nations with a strict coastal zone management policy (FAO 2018).

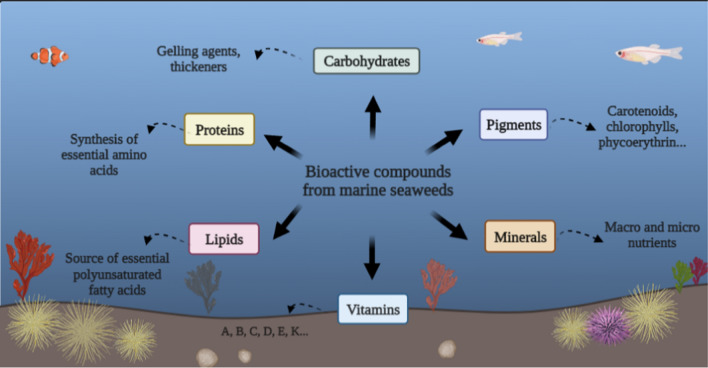

Chemical components of seaweed

The classification of seaweeds into three major taxonomic groups was made possible by morphological and pigment characteristics (red, brown, and green seaweed). Seasonally and geographically variable carbohydrates, lipids, proteins, minerals, and vitamins are present in seaweeds (Torres et al. 2019). Due to their complex composition, their hydrocolloids or polysaccharides, such as agars, alginates, and carrageenan, seaweeds can also be utilised in various biorefineries.

Seaweeds contain 70–90% water (fresh weight basis) and are primarily composed of 25–77% carbohydrates (dry matter basis), 5–43% proteins (dry matter basis), 9–50% ash content (dry matter basis), and 1–5% lipids (dry matter basis) (Del Rio et al. 2020; Praveen et al. 2019). The major carbohydrates presented in seaweed are cellulose, sucrose, starch, carrageenan, ulvan, laminarin, mannitol, agar, fucoidan, and alginate (Del Rio et al. 2020). The absence or low lignin content of seaweed, as low as 0.03 g/kg dry weight (Wang et al. 2020a; Ghadiryanfar et al. 2016), facilitates biofuel processing and degradation compared to the costly pretreatment required for traditional lignocelluloses biomass (Elsayed et al. 2019). In addition, the high carbohydrate and low lipid content of seaweeds make them ideal candidates for alcohol-based biofuels (Sirajunnisa and Surendhiran 2016). Table 3 shows the primary components of various seaweeds.

Table 3.

Chemical components of seaweeds

| Group | Seaweed species | Protein (dry weight%) | Carbohydrate (dry weight%) | Lipid (dry weight%) | Ash content (%) | References |

|---|---|---|---|---|---|---|

| Brown seaweed | Ascophyllum nodosum | 4.8–9.8 | 39.5–60.6 | 1.9–4.8 | 18–24 | Ghadiryanfar et al. (2016) |

| Fucus serratus | 9.6 | 26.4 | 2.8 | 18.8 | Kostas et al. (2016) | |

| Laminaria digitata | 26.8 | 21.7 | 1.9 | 24.3 | Kostas et al. (2016) | |

| Dictyopteris australis | 9.70 | 33.12 | 1.34 | 28.11 | Verma et al. (2017) | |

| Stoechospermum marginatum | 10.90 | 33.58 | 3.91 | 35.83 | Verma et al. (2017) | |

| Iyengaria stellata | 11.73 | 31.96 | 2.84 | 31.17 | Verma et al. (2017) | |

| Sargassum linearifolium | 8.93 | 29.82 | 1.93 | 31.5 | Verma et al. (2017) | |

| Laminaria digitata | 12.9 | 46.6 | 1.0 | 26.0 | Kostas et al. (2017) | |

| Saccharina japonica | 8 | 51 | 1 | Not mentioned | Jambo et al. (2016) | |

| Undaria pinnatifida | 24 | 43 | 4 | Not mentioned | Jambo et al. (2016) | |

| Stypopodium schimperi | 1.12–3.15 | Not mentioned | 2.48–11.53 | 3.88–17.98 | Lee et al. (2020) | |

| Sargassum thunbergii GEEL-15 | 7.14 | 37.0 | 7.88 | 20.84 | Yang et al. (2021a) | |

| Sargassum vulgare | 10.32 | 39.07 | 4.02 | 30.09 | de Melo et al. (2021) | |

| Red seaweed | Palmaria. palmata | 22.9 | 39.4 | 3.3 | 25.7 | Kostas et al. (2016) |

| Ulva lactuca | 16.4 | 23.8 | 1.0 | 21.5 | Kostas et al. (2016) | |

| Dictyota dichotoma | 9.52 | 35.11 | 2.67 | 40.13 | Dixit et al. (2018) | |

| Sciania fasciularis | 8.07 | 22.99 | 0.97 | 23.232 | Verma et al. (2017) | |

| Gelidium micropertum | 9.13 | 37.81 | 2.20 | 15.678 | Verma et al. (2017) | |

| Halymenia venusta | 14.13 | 34.81 | 1.43 | 17.123 | Verma et al. (2017) | |

| Rhodymenia dissecta | 9.84 | 33.87 | 1.45 | 21.163 | Verma et al. (2017) | |

| Haloplegma duperreyi | 9.33 | 30.50 | 0.55 | 17.12 | Lee et al. (2020) | |

| Halymenia venusta | 14.13 | 34.81 | 1.43 | 17.12 | Lee et al. (2020) | |

| Gracilaria gracilis | 13.70 | 28.6 | 1.70 | 36.00 | Lee et al. (2020) | |

| M. stellatus GEEL-16 | 9.14 | 35.08 | 4.63 | 28.17 | Yang et al. (2021a) | |

| Gracilaria corneus | 21.27 | 23.55 | 1.93 | 34.16 | de Melo et al. (2021) | |

| Hypnea valentiae | 4.56 | 30.10 | 0.73 | 32.88 | Dixit et al. (2018) | |

| Acanthophora spicifera | 6.55 | 48.51 | 1.40 | 47.04 | Dixit et al. (2018) | |

| Gracilaria corticata | 5.46 | 33.29 | 0.88 | 28.51 | Dixit et al. (2018) | |

| Corallina mediterranea | 10.7–20.6 (17.05) | 24.4–29.4 (26.6) | 1.49–2.55 (2.07) | 35.5–42.1 (39.0) | Mohy El-Din (2018a) | |

| Gracilaria gracilis | 13.7 | 28.6 | 1.7 | 36 | Parsa et al. (2018) | |

| Green seaweed | Ulva lactuca | 12.17 | 32.61 | 1.45 | 20.940 | Verma et al. (2017) |

| Acrosiphonia orientalis | 7.47 | 24.55 | 1.24 | 24.980 | Verma et al. (2017) | |

| Valonia utricularis | 9.03 | 12.80 | 3.69 | 20.317 | Verma et al. (2017) | |

| Ulva sp. GEEL-17 | 4.24 | 55.40 | 6.67 | 21.30 | Yang et al. (2021a) | |

| Ulva fasciata | 11.42 | 40.91 | 2.37 | 20.89 | de Melo et al. (2021) | |

| Ulva fasciata | 6.55 | 44.51 | 2.45 | 24.92 | Dixit et al. (2018) | |

| Caulerpa sertularioides | 9.44 | 44.7 | 1.88 | 31.24 | Dixit et al. (2018) | |

| Ulva lactuca | 15.65–23.2 (Average 19.34) | 17.2–19.5 (18.50) | 2.28–4.05 (3.46) | 21.5–28.33 (25.8) | Mohy El-Din (2018a) | |

| Cladophora glomerata | 13.70 | 34.70 | 2.40 | 26.10 | Parsa et al. (2018) | |

| Caulerpa macrodisca | 20.54 | 37.66 | 1.42 | 29.03 | Zuldin et al. (2021) |

Seaweeds pose unique structural properties in terms of carbohydrates, protein, and lipids. Seaweeds contain 12.8–60.6% carbohydrates (dry matter basis), 1.12–26.8% proteins (dry matter basis), 3.88–40.13% ash content (dry matter basis), and 0.55–11.53% lipids (dry matter basis). Variations in chemical components of seaweeds are attributed to different species, collection seasons, and growing environments

Brown seaweeds (Phaeophyceae) are olive-greenish to dark brownish due to the presence of fucoxanthin pigments, which mask the original chlorophyll colour. The brown seaweeds include kelp (Laminaria spp.), which can attain a maximum length of 100 m and a daily growth rate of 50 cm (Sudhakar et al. 2018; Wei et al. 2013). 55% (dry weight basis) of brown seaweeds are composed of laminin and mannitol as storing polysaccharides (Hreggviðsson et al. 2020). Laminarin is a polysaccharide that may be hydrolysed into glucose sugar monomer by laminarase (endo-1,3(4)-b-glucanase) (Del Rio et al. 2020). Mannitol can dehydrogenate into fructose, which can be further bio-converted into bioethanol (Wang et al. 2020a; Horn et al. 2000). In addition, brown seaweeds contain alginate and cellulose, which are fundamental polysaccharides that give the cell wall mechanical strength. Typically, high levels of total carbohydrates (up to 65%) make brown seaweeds attractive biomass for biofuel purposes (Del Rio et al. 2020).

Due to the presence of phycoerythrin and phycocyanin pigments, red seaweed (Rhodophyceae) has a characteristic red/pink colour. These seaweeds can grow in depths ranging from 40 to 250 m (Wang et al. 2020a). 40–70% (dry weight basis) of red seaweeds are composed of carbohydrates, such as glucan, cellulose, and galactan (Praveen et al. 2019). The structural cell wall of red seaweeds contains carrageenan and agar, which are valuable long-chain polysaccharides for gel formation and thickening foods such as ice cream, yoghurt, and pudding (Samaraweera et al. 2012; Zhang et al. 2019a).

Green seaweeds (Chlorophyceae) typically grow as paper-thin sheets or filamentous springy fingers in shallow, near-surface water. Green seaweeds contain photosynthetic pigments, such as carotenoids and chlorophyll A and B. Chlorophyceae mainly consist of 40 and 60% dry matter polysaccharides, including starch, pectin, and cellulose (Praveen et al. 2019; Michalak 2018). Because of variations in environmental conditions, the chemical composition of seaweeds varies considerably between species and seasons. For instance, Ulva sp. contained the maximum carbohydrates contents in June (61% dry weight basis), while the same species exhibited a steady decline from 49 to 41 dry weight% throughout July to September, respectively (Wang et al. 2020a). Similarly, Ulva intestinalis presented a peak protein content of 27.7% in the winter, which dropped to 6.7% in the spring (Osman et al. 2020).

Furthermore, the extensive seasonal variation in water properties results in substantial variations in seaweed biomass yields. For instance, Ulva intestinalis had the maximum biomass yield of 61.5 g/square metre/year, while Ectocarpus siliculosus showed 1.3 g/square metre/year (Osman et al. 2020). In order to determine the optimal yield period for seaweeds, the variety of seaweed must be determined based on the season, the growth cycle, and the desired end products.

Economic benefits of the seaweed industry

The global cultivated seaweed production from the 34.7 gigatonnes for various biorefineries valued at 14.7 billion United States dollars, which mainly contributed to Laminaria/Saccharina (4.6 billion United States dollars), Porphyra (2.7 billion United States dollars), Kappaphycus/Eucheuma (2.4 billion United States dollars), Gracilaria (2 billion United States dollars) and Undaria (1.9 billion United States dollars). In 2019, average first-sale estimates were 0.47 United States dollars/kilogram (wet weight) for brown seaweeds, 0.39 United States dollars/kg for red seaweeds and 0.79 United States dollars/kg for green seaweeds (Cai et al. 2021).

Seaweed cultivation is usually a labour-intensive industry that employs a large number of people. Therefore, a substantial portion of a first-sale price’s $14.7 billion is converted into wages supporting various households' incomes in coastal areas. Additional downstream activities, such as postharvest handling, processing, distribution, and marketing, generate more jobs and income. Additionally, carrageenan extraction from seaweed created numerous administrative and support positions in government offices and laboratories (Cai et al. 2021).

According to United Nations Comtrade statistics, 98 nations earned 2.65 billion United States dollars of foreign exchange in 2019 through exporting seaweeds (909 million United States dollars) and seaweed-based hydrocolloids (1.74 billion United States dollars). For instance, China, Indonesia, the Republic of Korea, Philippines, Chile, Spain, France, the USA, Germany, and the UK have gained approximately 578, 329, 320, 252, 209, 145, 124, 102, 82, and 78 million United States dollars from exporting of seaweeds and seaweed-based hydrocolloids in 2019, respectively (Cai et al. 2021).

The protein content of seaweeds ranges from 10 to 30% (based on dry matter content), with red and green seaweeds typically containing more protein than brown seaweeds. The lipid content of seaweed ranges between 1 and 5% of seaweed’s dry matter. The levels of protein and lipids in seaweeds varied by harvest season. 500 gigatonnes of dry seaweed would yield 100 and 15 gigatonnes of seaweed protein and oil, respectively, assuming a lipid content of 3% and a protein content of 20% (Table 4). Comparable to soy protein when considering the amino acid content and anti-nutritional properties of both soy protein and seaweed. Taking into account the profile of long-chain omega-3 fatty acids makes seaweeds more advantageous than other soy proteins and comparable to the nutritional value of fish oils. Currently, about 250 gigatonnes of soy protein and 1 gigatonne of fish oil are produced annually. Consequently, 500 gigatonnes of seaweeds could replace nearly 40% of current soy protein production and represent a 750% increase over fish oil. Utilising seaweeds and seaweeds containing oils would provide long-chain omega-3 fatty acids that are beneficial to human health and could eliminate the need for fish oil in animal feeds and aquaculture.

Table 4.

Generalised services from 500 gigatonnes dry weight of seaweeds (World-Bank-Group 2016)

| Item | Service/production | Remarks |

|---|---|---|

| Ocean area required | 500,000 km2 (About 0.03% of the ocean surface areas) | Estimated from average annual production of 1000 dry tonnes/square kilometre |

| Protein yield | 100 gigatonnes | Based on the protein content of 20%/dry seaweed’s weight |

| Algal oil for people and animals | 15 gigatonnes |

Based on the lipid content of 3%/dry seaweed’s weight Provides 23 United States billion dollars that would completely substitute fish oil in animal diets |

| Nitrogen removal | 1 gigatonne |

Assumes nitrogen content of 0.2% of dry weight Represent 61% of the nitrogen input as fertiliser |

| Carbon removal | 135 gigatonnes | Based on seaweed’s carbon content of 27%/dry weight. Equivalent to 6% of the carbon input annually to oceans |

| Bioenergy potential | 1250 terawatt-hour | Based on 50% carbohydrate content, bio-converted to bioenergy. Equivalent 1% of annual world energy utilise |

| Land sparing | 1,000,000 square kilometres | Presumes five tonnes/hectare farm yields. Equivalent 6% of world cropland |

| Freshwater saving | 500 cubic kilometres | Presumes agricultural use about 1 cubic metre water/kilogram biomass. Equivalent 14% of annual world freshwater withdrawals |

Seaweeds have the potential to supply 500 gigatonnes of dry seaweed that would generate 100 and 15 gigatonnes of seaweed protein and oil, respectively. In addition, these quantities can eliminate 1 gigatonne of nitrogen, 135 gigatonnes of carbons, 1250 terawatt-hours of energy, and 500 cubic kilometres of fresh water

The prices of soy meal and fish oil are approximately $550 and $1500 per tonne, equating to approximately $28 and $15 billion for the protein and oil fractions of seaweed. Approximately one job per 10 tonnes of dry seaweed can be generated; therefore, the seaweed industry must generate approximately 50 million jobs in addition to the 100 million jobs generated by marine capture fisheries (World-Bank-Group 2016).

Summary

Nearly 34.65 gigatonnes, or approximately 30% of the 120 gigatonnes of global aquaculture production, come from seaweed cultivation. There are three types of seaweed: brown, red, and green. The first two types represent 16.40, and 18.25 gigatonnes, respectively. Asia produces approximately 97.4% of the world’s seaweed, of which 99.1% is cultivated. Europe and the Americas produced 0.80 and 1.36%, respectively, of the world's seaweed, with wild seaweed dominating.

In biorefineries, seaweeds have many applications, including foods and food supplements, animal feed, cosmetics, nutraceuticals, pharmaceuticals, textiles, biofertilisers/plant enhancers, biofuel, and bioplastic packaging, among others. Seaweed has the potential to contribute to several sustainable development goals, including goals 1–3, 8, 10, and 12–14. In general, seaweeds are comprised of 70–90% water, 25–77% carbohydrates (dry matter basis), 5–43% proteins (dry matter basis), 9–50% ash content (dry matter basis), and 1–5% lipids (dry matter basis). Seaweed contains cellulose, sucrose, starch, carrageenan, ulvan, laminarin, mannitol, agar, fucoidan, and alginate as seaweed’s primary carbohydrates. Compared to traditional lignocellulosic biomass, seaweed’s low lignin content makes biomass processing and degradation simpler from a biofuel standpoint.

Environmental benefits of seaweed cultivation

Role of seaweed in climate change mitigation

As a result of increased carbon dioxide emissions, global temperatures are increasing. Currently, the situation is deteriorating, particularly due to the rapid economic growth of developing nations whose carbon dioxide emissions are anticipated to rise in the near future. Therefore, taking all feasible measures to reduce atmospheric carbon dioxide load to prevent ecological damage is essential (Jhariya et al. 2021; Banerjee et al. 2021a, b). To replace fossil derivatives, climate change has prompted a blue carbon paradigm in which food and fuel can be obtained from aquatic environments through carbon harvesting, carbon sequestration, and carbon sinking (Yong et al. 2022). Seaweeds have the potential to serve as a renewable energy source and carbon sink; furthermore, seaweeds may play a significant role in climate change mitigation strategies, as shown in Figs. 2 and 3.

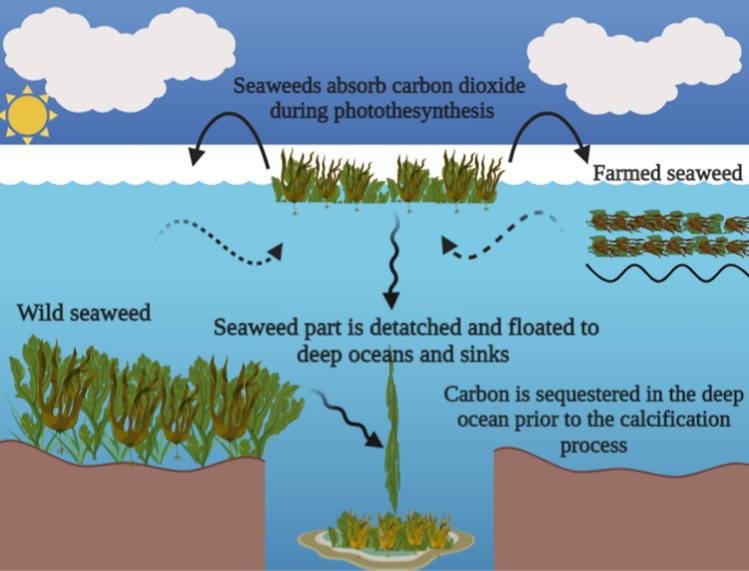

Fig. 2.

Seaweed’s role in deep ocean carbon sequestration, which is an effective carbon sequestration strategy. Seaweeds have the capacity to remove carbon dioxide from the atmosphere. Then, there are two modes for transporting seaweeds to the sediment and depths of the ocean: the drift of seaweed particles through marine canyons and the sinking of negatively floating seaweed detritus. Overall, seaweeds can store 173 teragrams of carbon per year on average

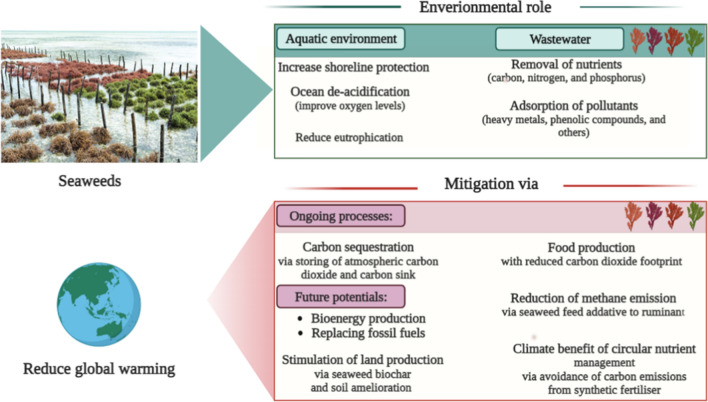

Fig. 3.

Beneficial functions of seaweeds in environmental restoration and climate change mitigation. Therefore, seaweeds can be viewed as carbon sequestration tools due to their ability to reduce carbon footprint. Seaweeds have the capacity to restore water pH, oxygen levels, and shoreline protection against wave energy dissipation. In addition, using seaweed biomass as feedstocks for biogas production is a promising area of research that can be utilised to replace fossil fuels. Utilising seaweeds for biochar production is also a promising area of research for the environmental sequestration of carbon and the benefit of plants

Blue carbon emphasises the capture and storage of organic carbon by the oceans and coastal environments, with coastal vegetated ecosystems contributing significantly to global carbon sequestration (Macreadie et al. 2019). Particularly, seaweed may absorb a significant amount of carbon dioxide from the aquatic ecosystem and support a variety of ecological benefits, such as remediation of shore contaminants and habitat for other aquatic organisms (Macreadie et al. 2019; Duarte et al. 2017a). Yong et al. (2022) recently reported on the potential contribution of seaweed to the newly emerging blue carbon strategy and seaweed's role in mitigating climate change over the long term. The authors reported that seaweed possessed all the necessary characteristics for classification as a blue carbon reservoir with a substantial carbon sink potential, in addition the role of seaweed in climate change mitigation, bio-economy enhancement via fossil fuel substitution, human food, biofuels, renewable biomass, and animal feed. About 50% of the world's carbon could be sequestered by seaweed (Chung et al. 2011; Jagtap and Meena 2022). In addition, seaweed can offset half of the world's bioenergy, making seaweed a potential means of reducing greenhouse gas emissions (Duarte et al. 2017b).

Numerous studies have highlighted seaweed’s capacity as a carbon sink (Yong et al. 2022; Macreadie et al. 2019; Moreira and Pires 2016; Krause-Jensen and Duarte 2016). Krause-Jensen and Duarte (2016) stated that seaweeds grown in coastal zones are effectively sequestered carbon dioxides from the atmosphere and act as a carbon sink organism in deep oceans and marine sediments. Globally, they estimated that seaweeds could sequester between 61 and 268 megatonnes of carbon per year, with an average of 173 megatonnes. Nearly 90% of carbon was sequestered by exporting biomass to deep water, while the remaining 10% was buried in coastal sediments. The 173 megatonnes of carbon per year sequestered by wild seaweeds are dispersed throughout the deep ocean, where the carbon supplying this flux is produced over 3.5 million square kilometres inhabited by seaweed (Krause-Jensen and Duarte 2016). Aquaculture of seaweed has the potential to sequester approximately 1500 tonnes of carbon dioxide per square kilometre, which is equivalent to the annual carbon dioxide emissions of approximately 300 Chinese individuals (Duarte et al. 2017a). Lehahn et al. (2016) demonstrated that the cultivation of seaweeds could completely replace the reliance on fossil fuels for transportation, meet 100% of the future demand for acetone, ethanol, and butanol, provide 5–24% of the demand for proteins and produce biogas that could mitigate 5.1 × 107–5.6 × 1010 tonnes of carbon dioxide emissions from natural gas use.

Jagtap and Meena (2022) reported the carbon sequestration potential of certain seaweeds as follows: Eucheuma spp. can sequester 68.43 tonnes carbon/hectare/year, Kappaphycus striatum can sequester 125.51 tonnes carbon/hectare/year, Laminaria spp. can sequester 1156 tonnes carbon/hectare/year, Ecklonia spp. can sequester 562 tonnes carbon/hectare /year, Sargassum spp. can sequester 346 tonnes carbon/hectare/year, and Gelidium spp. can sequester 17 tonnes carbon/hectare/year. The authors reported that the overall carbon sequestration by seaweed cultivation in Indonesia was 621,377 tonnes of carbon/year and 2.66 million tonnes of carbon/year from the pond and marine culture, respectively. Thus, seaweed can sequester carbon and reduce atmospheric carbon dioxide levels, thereby mitigating the effects of global warming. In addition to carbon sequestration, seaweed acquires nutrients from water bodies, where seaweed uses nitrogen and phosphorus and fixes carbon in the water through photosynthesis, which has multiple benefits, including reducing carbon and nitrogen concentrations in the water, mitigating ocean acidification, and increasing oxygen levels to revitalise and restore water habitats (Yong et al. 2022).

The major limitations of this claim stem from the notion that a carbon sink concept should be provided by carbon buildup in seaweed's biomass; however, seaweed's carbon consumed as human food or fed to livestock enters the carbon cycle and provides no carbon sink meaning (Troell et al. 2022). Therefore, when seaweeds are transferred to the deep ocean and sediments, they are considered a carbon sink or converted into biochar. Optimising the blue carbon role of seaweeds necessitates the management of the seaweed’s fate, whether seaweed originated from aquaculture or was harvested in the wild, in order to address this issue. One option is to replace fossil fuels with biofuels produced from seaweed biomass (Chen et al. 2015; Farghali et al. 2021; Ap et al. 2021) or substitute food/feed production practices of intensive carbon dioxide footprints with seaweed-established food/feed means, which has much lower life-cycle carbon dioxide emissions (Duarte et al. 2017a; Troell et al. 2022). Another decarbonisation pathway uses seaweed to reduce enteric methane emissions from ruminants (Troell et al. 2022).

In addition to acting as a carbon sink, seaweed is an excellent candidate for removing carbon dioxides from the atmosphere due to seaweed’s rapid growth rate and high photosynthetic efficiency (Sondak et al. 2017). The carbon dioxides emitted from the carbon-based power plant's combustion may be injected into closed or open seaweed systems in order to increase seaweed growth rate and carbon sequestration (Cole et al. 2014). During cultivation, one tonne of dry seaweed biomass can absorb nearly 960 kilograms of carbon dioxide. Additionally, seaweed has additional eco-benefits, such as reducing global warming, eutrophication, and acidification. Seaweed can also be used to fixate phosphorus, potassium, and nitrogen (Duarte et al. 2017b).

Seaweed as a potential wastewater treatment tool

Industrial effluents and aquaculture farms typically cause severe environmental issues, such as intense pollution and ecological degradation. The presence of significant nutrients in water bodies, such as nitrogen and phosphorus, frequently results in water eutrophication, which results in hypoxia and the prevalence of harmful microalgal blooms (Arumugam et al. 2018).

The most effective way to reduce pollution is to treat wastewater at the pollution’s source; however, most industries and aquacultures lack on-site treatment technologies (Wang et al. 2020a). In most cases, chemical, physical, and biological methods are used to treat wastewater (Tawfik et al. 2022a). Biological processes are superior to other treatment methods due to their straightforward operation, low cost, and eco-friendliness. Seaweeds can be used for the biological removal of phosphorus and nitrogen from wastewater (Fig. 3). Seaweeds can utilise ammonia–nitrogen and nitrate, two common nitrogen compounds found in agricultural, industrial, and sewage water discharges (Wang et al. 2020a). Xiao et al. (2017) estimated the role of large-scale seaweed farms in removing nutrients and mitigating coastal water eutrophication in China. They found that seaweed farming removed approximately 75 and 9.5 megatonnes of nitrogen and phosphorus, respectively, in China. The authors projected that the seaweed industry would eliminate 100% of the total phosphorus feed into Chinese coastline waters by 2026. The World Bank estimates that a global seaweed harvest of 500 million tonnes by 2050 will be achieved, which will utilise approximately 10 million tonnes of water nitrogen, which represents 30% of the nitrogen that reaches the seas, and 15 million tonnes of phosphorus, which is about 33% of the phosphorus generated from dung and fertilisers (Jagtap and Meena 2022). Duan et al. (2019) showed that Gracilaria lemaneiformis cultivation could sequester 1192.03 tonnes of carbon, 15.89 tonnes of phosphorus, and 128.10 tonnes of nitrogen from the Yantian Bay seawater.

Utilising fungi and bacteria for bioremediation has been intensively studied and is currently attracting significant interest. However, growing microorganisms require external carbon sources for optimal growth (Wang et al. 2020a). Due to their autotrophic growth, seaweeds are promising bioremediation agents. The cell walls of seaweed are composed of multiple polymers, including cellulose, pectin, hemicellulose, and arabino-galactan proteins. The predominant functional groups consisting of carboxyl, amines, and phosphoryl provide negative charges to the cell walls of the seaweed, thereby attracting pollutants with cationic groups to the seaweed's surface and initiating the sorption process (Wang et al. 2020a). Bioaccumulation was primarily responsible for the seaweed's uptake of organic contaminants and other growth supplements. Table 5 details the ability of seaweed to absorb certain heavy metals from bodies of water.

Table 5 .

Seaweed’s role in removing heavy metals, phosphorus, and nitrogen from wastewater

| Category | Seaweed type | Wastewater source | Treatment conditions | Contaminants | Treatment efficacy | References |

|---|---|---|---|---|---|---|

| Red seaweed | Gracilaria lemaneiformis | Aquaculture |

Cage co-culturing seaweed with the fish Pseudosciaena crocea Water salinity: 26–29 pH: 7.43–7.83 Temperature:18.4–26.0 °C Time: 20 days |

Phosphate and nitrogen |

Nitrogen: 21.0% Phosphate: 28.6% |

Wei et al. (2017) |

| Gracilaria chouae | Aquaculture |

Co-culturing seaweed with Sparus macrocephalus (black sea bream) Temperature: 16.61–22.68 °C Water salinity: 28.33–31.07 Time: 28 days pH: 8.16–8.2 |

Phosphate and nitrogen |

Nitrogen: 41.2% (nitrate-nitrogen: 37.76%, nitrite-nitrogen: 36.99%, ammonia–nitrogen: 29.27%) Phosphorus: 46.2% (Phosphate–phosphorus: 40.64%) |

Wu et al. (2015) | |

| Gracilaria tikvahiae | Shrimp wastewater |

Co-culturing seaweed with Litopenaeus vannamei (Pacific white shrimp) Temperature: 18–33 °C Salinity: 30.4–34.8 g/kg Time: 18 days pH: 7.4–7.9 |

Nitrogen | Nitrogen: 35% | Samocha et al. (2015) | |

|

Agarophyton tenuistipitatum Hydropuntia edulis |

Brackish water |

Temperature: 27–30 °C Salinity: 20% Seaweed biomass density: 0–4.5 g/litres pH:7.75–8.19 Time: 0-2 h hours |

Nitrogen and Phosphorus |

Optimal removal at 3.5 g/litres (ammonia–nitrogen > 80% Phosphate phosphorus removal > 20%) |

Sarkar et al. (2020) | |

| Gracilaria lemaneiformis | Seawater | Temperature: 20 ± 2 ℃, salinity: 30 ± 0.2, irradiance: 80 micromole/(cubic metre/second) with a photoperiod of 12-h light: 12-h dark. Time: 3 days | Nitrogen and Phosphorus | Ammonia–nitrogen (45.99–59.79%, nitrate-nitrogen (13.10–30.21%), nitrite-nitrogen (12.88–14.11%), and phosphate-phosphorus (27.07–31.49%) | Duan et al. (2019) | |

| Gracilariacorticata | Aqueous solution | Metal concentration: 50 mg/l, pH 5, adsorbent dosage: 104 g/l, temperature: 29.9 °C | Cobalt | Cobalt: 87.8% | Raju et al. (2021) | |

| Brown seaweed | Turbinaria ornata | Municipal wastewater | Metal concentration: 99.8 mg/l, mixing speed: 250 rounds per minute, adsorbent dosage: 16.2 g/l | Lead | 99.80% | Al-Dhabi and Arasu (2022) |

| Sargassum sp. | Simulated wastewater |

Biomass size: 2.2 millimetre Dosage: 0.1 g Temperature: 30 °C pH: 5 Time: 4-h (nickel (ii) ion) and 6-h (copper (ii) ion |

Nickel (ii) ion and copper (ii) ion | Copper (ii) ion: 2.06 mmol/gram nickel (ii) ion: 1.69 mmol/gram | Barquilha et al. (2017) | |

| Sargassum sp. | Synthetic wastewater |

Time: 60 min Temperature: 25 °C cadmium (ii) ion Seaweed: 0.5 g Rounds per minute: 150 pH: 4 Metal concentration: 5 mg/l zinc (ii) ion Biomass: 1 g pH: 3 Rounds per minute: 200 Ions concentration: 5 mg/l |

Cadmium (ii) ion and zinc (ii) ion | Cadmium (ii) ion: 95.3% zinc (ii) ion: 90.3% | Mahmood et al. (2017) | |

| Sargassum filipendula | Simulated wastewater | Sorbent size: 0.737 mm Sorbent: 2 mg/l Temperature: 25 °C Rounds per minute: 180 Time: 24 h pH: 3.5 Metal concentration: 1 mmol/l | Silver, cadmium, chromium, copper, nickel, lead, and zinc ions | Silver: 33.62% Cadmium: 78.03% Chromium: 72.8% Copper: 69.05% Nickel: 32.74% Lead: 56.19% Zinc: 44.21% | Cardoso et al. (2017) | |

| Sargassum dentifolium | Simulated wastewater | Sorbent dosage: 1.5 g/ 100 ml, Ion concentration: 100 parts per million, the flocculation contact time was 1 h followed by 12 h static, temperature: 50 °C, pH: 7 | Chromium | Chromium (VI): 99.68% | Husien et al. (2019) | |

| Cystoseira crinite and Cystoseira barbata | Aqueous and wastewater solutions | Chromium (III): Dosage: 100 parts per million, pH 4.5, contact time: 120 min, adsorbent dosage: 0.1 g/50 ml. Chromium (VI): Ion concentration: 100 parts per million, adsorbent dosage: 100 mg/50 ml, contact time: 24-h, pH: 2.0 | Chromium (III) and Chromium (VI) | Chromium (III): 73.34% (Cystoseira crinite), 70.70% (Cystoseira barbata) Chromium (VI): 28% (Cystoseira crinite) 35%, (Cystoseira barbata) | Yalcin and Ozyurek (2018) | |

|

Seaweeds Ulva intestinalis, Gracilaria sp., Fucus spiralis, Osmundea pinnatifida, Ulva lactuca, Fucus vesiculosus |

Synthetic seawater | Metal concentration: 1 micromole per cubic decimetre, 72 h contact time, temperature: 22 °C, pH: 8.5, salinity of 30 g per cubic decimetre | Mercury |

95% 90% 85% 80% 90% 80% |

Fabre et al. (2020) | |

| Sargassum muticum | Mining-influenced water | Metal dosage: 2.5 mg/l, temperature: 293 Kelvin, pH: 7 | Arsenic | Almost 100% | Vieira et al. (2017) | |

| Caulerpa scalpelliformis | industrial wastewater |

Adsorbent dosage: 1.5 g/litre, temperature: 30 °C contact time: 1 h, pH: 5.7 Agitation: 150 rounds per minute |

Zinc | 83.3 mg/gram | Jayakumar et al. (2021) | |

| Sargassum polycystum | Simulated water | Cadmium: Adsorbent dosage: 1.8 g/l, pH: 4.65, agitation speed: 76 rounds per minute Zinc: pH: 5.7, agitation speed: 125 rounds per minute. adsorbent dosage: 1.2 g/l | Multi-metals | Cadmium: 86.20 Zinc: 92.90% | Jayakumar et al. (2022) | |

| Sargassum filipendula | Real and synthetic effluents |

Metal concentration: 1 mmol/l (19.56 mg/l of nickel; 17.33 mg/l of chromium; and 21.79 mg/l of zinc) Temperature: 50 °C |

Multi-metals | Chromium: 0.864 mol/g Zinc: 0.302 mmol/g Nickel: 0.347 mmol/g | Costa et al. (2020) | |

| Green seaweed | Ulva rigida | Simulated wastewater | Temperature: 20 °C Sorbent: 0.5 g Sorbent size: 0.5 cm Time: 5 h Rounds per minute: 180 Metals concentration: 25 mg/l | arsenic cation (3 +), arsenic cation (5 +), antimony (3 +) selenium (4 +) ions and selenium (6 +) ions | Selenium: (4 +) ions: 0.5 mg/g (pH: 2–4) Selenium: (6 +) ions: 0.2 mg/gram (pH: 2–3) Limited removal efficiency towards arsenic but was effective for antimony and selenium | Filote et al. (2017) |

Seaweeds demonstrated a great capacity for removing nutrients from wastewater. For instance, seaweeds can absorb over 41% of nitrogen and phosphorus. In addition to nitrate-nitrogen, ammonia–nitrogen, and nitrite-nitrogen, seaweeds can also remove other nitrogen forms. Similarly, seaweeds can absorb a variety of heavy metals, including copper, cobalt, iron, zinc, lead, nickel, cadmium, silver, chromium, arsenic, antimony, and mercury. This makes seaweeds a very promising option for wastewater treatment on a large scale

In addition to heavy metals and nutrients, seaweeds can absorb other pollutants. For instance, Navarro et al. (2008) examined the sorption of phenol compounds by the Macrocystis integrifolia and Lessonia nigrescens seaweeds. Findings revealed the highest sorption efficacy of 35% at pH 10 by Macrocystis integrifolia due to a completely polar sorption pathway alongside an electrostatic sorption process. This study emphasised that phenol adsorption onto the seaweed’s surface has occurred through the interaction of hydrogen bonds with the hydroxyl groups of the seaweed’s polysaccharides, such as alginates. Common aromatic hydrocarbons were studied by applying red, green, brown, and seaweed biomass to toluene and benzene biosorption (Flores-Chaparro et al. 2017). Results demonstrated that Phaeophytes could remove toluene and benzene by 28 and 112 mg/gram, respectively. The sorption process was ascribed to hydrophobic interaction mostly with lipids and, to some extent, with carbohydrates and proteins through nonspecific Van der Waals relations.

In addition, the bioaccumulation of micropollutants by freshwater seaweed has been demonstrated to be a crucial method for removing sulfamethoxazole, triclosan, and trimethoprim (Bai and Acharya 2017). The intracellular seaweed biodegradation is found to be the most useful biosorption approach by which seaweed cells may remove chemical contaminants from the environment (Xiong et al. 2018). In this context, nearly 30–80% of hazardous chemicals, including ibuprofen, tris(2-chloroethyl) phosphate, carbamazepine, and caffeine in wastewater, were biodegraded within the seaweed’s cells (Matamoros et al. 2016; Hom-Diaz et al. 2017; Ding et al. 2017). Thus, the sorbent properties of seaweeds can be viewed as a viable option for reducing the toxic impact of multiple contaminants in aquatic environments, which is favourable for combined energy production.

Summary

Seaweed can act as a carbon sink by storing seaweed particles in the deep ocean or drifting them in sediments. In addition, other carbon sequestration pathways of seaweeds farming, such as biofuel production that mitigates carbon dioxide emissions and replaces fossil fuels, acting as biofertilisers that replace synthetic fertiliser, lowering methane emissions when used as cattle feed, inhibiting water wave energy, and protecting shorelines that mitigate climate change, increasing water pH and providing oxygen to the waters that decrease ocean deoxygenation and acidification. Consequently, seaweeds contribute to carbon sequestration, coastal safety, carbon sink, food security, and the control of ocean deoxygenation and acidification; therefore, seaweed is remarkably regarded as a promising blue carbon adaptation and climate change mitigation strategy.

Seaweeds can remove pollutants and nutrients from wastewater, transforming waste into valuable commodities. Currently, seaweed cultivation is used for plutonium/uranium removal and refining wastewater runoff. Pollutants can be mitigated by growing seaweed on industrial discharges.

Seaweed as a feedstock for the anaerobic digestion process

Increasing global energy demands and the negative environmental impacts of fossil fuels increase the need for sustainable and eco-friendly biofuels. Seaweeds can be converted into high-value products, such as biofuels; consequently, they are considered promising third-generation feedstocks in bioremediation (Wang et al. 2020a). By 2054, biofuels derived from seaweed can replace the demand for fossil fuels in the transportation sector, thereby reducing greenhouse gas emissions (Lehahn et al. 2016). As previously discussed in Sect. 2.2, the ability of seaweeds to produce biogas can be attributed to their overall structure.

Utilising thermochemical conversion, anaerobic digestion, and fermentation, seaweed feedstocks were converted into biofuels (Rajak et al. 2020; Wang et al. 2021a). Thermochemical conversion and fermentation are energy-intensive processes that necessitate dehydration and dewatering (Wang et al. 2020a). However, by utilising seaweed for biogas production, all seaweed components, including carbohydrates, lipids, and protein, can be utilised without dehydration, thereby avoiding energy need (Thakur et al. 2022). Due to seaweed’s inexpensive polysaccharides and low lignin content, seaweed is promising biomass for the anaerobic digestion (Farghali et al. 2021). In addition, growing concerns about the depletion of fossil fuels and the increase in greenhouse gas emissions have necessitated the investigation of alternative resources for bioenergy production (Rajak et al. 2020). In this context, seaweed is considered third-generation biomass for bioenergy generation via anaerobic digestion, and seaweed can overcome the inherent limitations of using first- and second-generation feedstock (Ap et al. 2021).

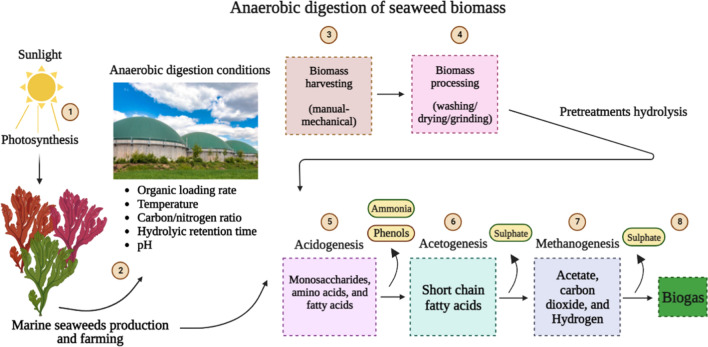

Hydrolysis of seaweed biomass generates volatile fatty acids and promotes the production of methane (Fig. 4). The generation of biogas from seaweed has not been thoroughly evaluated. The available reviews lack an understanding of the primary obstacles that limit methane production from seaweed feedstock, as well as the various methods that have been implemented to increase the biogas yield and suggest full utilisation of biomass.

Fig. 4.

Biogas production from seaweed resources: the mass of wild seaweed grown in aquatic water or farmed seaweed can be gathered manually or mechanically. After assembly, the seaweeds are managed, including rinsing with water, and then the dried or wet biomass is utilised for methane production. In the biogas digester, biomass undergoes four phases of anaerobic digestion, namely hydrolysis, acetogenesis, acidogenesis, and methanogenesis, in order to produce methane and carbon dioxides as end products. Diverse inhibitors and process parameters, such as ammonia, sulphates, phenols, organic loading rates, hydraulic retention time, and other factors, may affect the biogas yields from seaweed feedstocks

Diverse biogas yields have resulted from the anaerobic digestion of seaweed due to species diversity and seasonal variation in the chemical characteristics of the biomass (Milledge et al. 2019), with brown seaweed digestion yielding comparatively larger methane than that from green seaweeds (Sutherland and Varela, 2014). Even though biochemical batch tests demonstrate inconsistency in reported biogas yields, seaweed as biomass for biogas production has the potential to be an economically viable marine biomass when considered in the context of the circular economy (Milledge et al. 2019). Baltrenas and Misevicius (2015) examined the biogas potential of three seaweeds, Cladophora glomerata, Chara globularis, and Spirogyra neglecta, under mesophilic conditions (35 ± 1 °C). The results illustrated that Spirogyra neglecta and Cladophora glomerata produced 0.23 and 0.20 cubic metres of biogas per cubic metre of biomass per day, respectively, with biomethane contents exceeding 60%.

Biomethane production from green seaweed Ulva lactuca was evaluated in batch experiments after ulvan, protein, and sap extraction with individual and sequential extraction methods. Both treatments enhanced methane yields with the highest biomethane yield of 408-ml methane/gram volatile solids added from sap and ulvan residues (Mhatre et al. 2019). Anaerobic co-digestion of Mediterranean Sea Ulva rigida generated 408 ml of biogas when mixed with anaerobic sludge (Karray et al. 2017a). Allen et al. (2015) reported that the biomethane potential of cast brown seaweed was 342 and 166 L methane per kilogram of volatile solid for Saccharina latissimi and Ascophyllum nodosum, respectively. Nearly 30 megatonnes of wet shore seaweed are collected annually in Ireland, referred to as the wild harvest. Compared to the average biomethane price of 0.2 € per cubic metre, the anaerobic digestion of Irish seaweed resources combined with cattle slurry, food waste, and grass resulted in a financial incentive of 0.85–1.17 € per cubic metre (Rajendran et al. 2019). Washed and macerated Gracilaria vermiculophylla was anaerobically co-digested with 2% glycerol and 85% sewage sludge and produced 599 and 605 L of methane per kilogram volatile solid, respectively (Oliveira et al. 2014). Under mesophilic batch anaerobic digestion (38 °C), Ap et al. (2021) found that the biomethane yield of Sargassum fulvellum seaweed was 142.91-ml methane per gram volatile solid for macerated biomass (75–850 µm) compared to 68.11-ml methane per gram volatile solid for the raw biomass (106 µm–4.75 mm). However, under thermophilic batch digestion mode (55 °C), Farghali et al. (2021) found that the same untreated raw seaweed produced 145.69 ml of methane per gram of volatile solid. Nevertheless, the operational conditions, such as temperature and pretreatment method before anaerobic digestion, have the potential to influence biogas production. Consequently, the subsequent section discusses the difficulties of biogas production from seaweed and the potential solutions.

Challenges of biogas production from seaweed

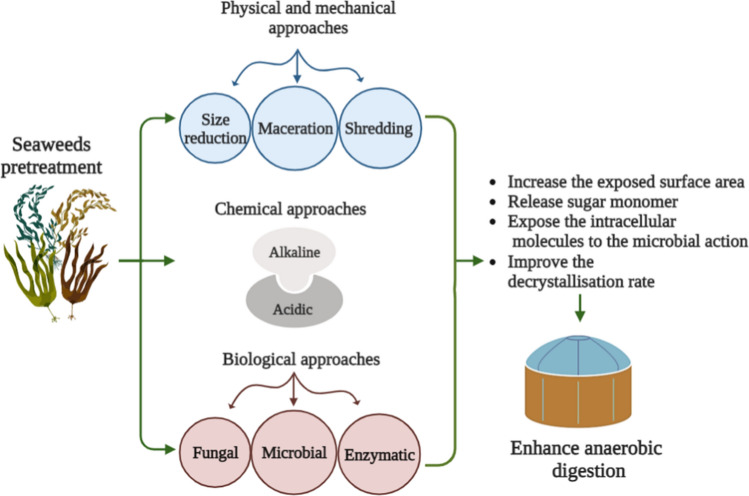

Seaweed cell wall rigidity

The anaerobic digestion of seaweed is limited by the firmness of the cell wall and the complexity of the biomolecular organic structures in seaweeds, which inhibits the fragmentation of the recalcitrant cell wall during hydrolysis and prolongs the anaerobic fermentation time (McKennedy and Sherlock 2015). The primary structural cell wall component in brown seaweed is cellulose, while in red and green seaweed, the primary structural cell wall component is cellulose, xylan, mannan, and xylan. These polysaccharides form various configurational microfibril structures, including flat ribbons in the case of cellulose and mannans and a helix configuration in the case of xylans (Maneein et al. 2018). Depending on the species, microfibrils with variable orientations are typically linked to polysaccharides matrix to form various carboxylic or sulphated polysaccharides (Synytsya et al. 2015). For example, sulphated fucans extracted from brown seaweed Himanthalia elongate have been suggested to interlock the cellulosic structure, whereas alginate–phenol bonds are the primary linkage governing the rigidity of seaweed cell walls (Deniaud-Bouet et al. 2014; Tiwari and Troy 2015). The association between protein in brown seaweed and phenols and sulphated fucans was observed (Deniaud-Bouet et al. 2014).

Moreover, phenols may have inhibitory effects on the anaerobic microorganisms (Maneein et al. 2018). Ulvans present in green seaweeds, including xylose, galactose, uronic, and rhamnose acid, are comparatively resistant to biodegradation and might constrain access to the disintegration of other polysaccharides, particularly starch and cellulose (Maneein et al. 2018). Therefore, the structural rigidity of seaweed's cell wall architecture, which is dominated by alginates and sulphated fucans in brown seaweeds, agar and carrageenans in red seaweed, and ulvans in green seaweed, prevents seaweed from being hydrolysed by microbes to monomers (glucose) (Maneein et al. 2018). Ometto et al. (2018) ascribed the low specific methane yield of Saccharina latissima seaweed to the high contents of alginate and lower level of readily biodegradable laminarin and mannitol. The rate-limiting phase of the anaerobic digestion of seaweed is considered to be the hydrolysis of complex polysaccharides. Therefore, partial removal of complex polysaccharides enhanced the biodegradability of seaweed in the actual fermentation reactor (Tedesco and Daniels 2018). Polyphenols and insoluble fibres have also been identified as hardly biodegradable and potential anaerobic digestion inhibitors (Jard et al. 2013). In addition, seaweed’s crystalline structure, surface properties, cellulosic polymers, lignin content, fibre strength, and the presence of hemicellulose materials are listed as other factors that influence the biodegradability of seaweed (Tedesco and Daniels 2018).

The biodegradability index quantifies the methane potential of biomass in relation to biomass’s theoretical biomethane yield. The obtained value indicates the degree of substrate biodegradation and biomethane yield relative to the theoretical yield of methane (Allen et al. 2015). Table 6 shows various biodegradability indexes for some seaweeds. Saccharina latissima showed the highest degradability index of 0.81. Anaerobically biodegradability index of Fucus serratus and Ascophyllum nodosum is 0.19–0.34 for 30 days; in addition, 66–81% of their volatile solid contents were not biodegraded due to high lignocellulose content (Lin et al. 2019). Overall, Sargassum brown seaweed is less biodegradable by anaerobic digestion than Ulva green seaweed and Gracilaria red seaweed (Maneein et al. 2018). Higher insoluble fibre values can support this in brown seaweed (10–75%) compared to green seaweed (29–67%) or red seaweed (10–59%) (Maneein et al. 2018; Cabrita et al. 2017). Accordingly, pre-treatment techniques have been suggested based on the type and structural composition of the seaweed, as described in the following section.

Table 6.

Biomethane potential and biodegradability index of some seaweeds (Allen et al. 2015; Tabassum et al. 2017a)

| Seaweed biomass | Methane production (litre methane/kilogram volatile solid) | Theoretical biomethane yield (litre methane/kilogram volatile solid) | Biodegradability index | Methane potential (cubic metre methane/tonne of wet weight) |

|---|---|---|---|---|

| Saccharina latissima | 342 | 422 | 0.81 | 34.5 |

| Fucus spiralis | 235 | 540 | 0.44 | 32.7 |

| Saccorhiza polyschides | 263 | 386 | 0.68 | 34.5 |

| Alaria esculenta | 226 | 474 | 0.48 | 26.9 |

| Ascophyllum nodosum | 166 | 488 | 0.34 | 32.3 |

| Himanthalia elongate | 260 | 334 | 0.78 | 21.1 |

| Ulva lactuca | 190 | 465 | 0.41 | 20.9 |

| Laminaria digitata | 218 | 479 | 0.46 | 22.5 |

| Fucus serratus | 101 | 532 | 0.19 | 13.5 |

| Fucus vesiclosus | 126 | 249 | 0.51 | 19.4 |

The biodegradability indices of seaweeds ranged from 0.19 to 0.81. The presence of recalcitrant components that are difficult for anaerobic microbes to digest is responsible for these wide variations. The presence of recalcitrant substance within the structure of seaweed resulted in methane production ranging from 101 to 342 L/kg of volatile solid, whereas the theoretical methane potential ranges from 249 to 540 L/kg of volatile solid

Effect of seasonal variations

Seasonal and geographical variations in the carbohydrate composition of seaweeds reduce the methane recovery from seaweed (i Losada et al. 2020). For instance, harvesting Irish seaweed during different seasons altered the seaweed's physicochemical properties, chemical composition, and subsequent methane yield. Tabassum et al. (2016a) found that Laminaria digitata seaweed biomass harvest was 4.5 folds higher in August compared to that in December, with biomethane production 1.4 times higher in August (327 L methane per kilogram of volatile solid). Additionally, Tabassum et al. (2016b) found that Ascophyllum nodosum Irish seaweed collected in the summer season had a higher polyphenolic value than that harvested in October. Therefore, specific methane yield was 2.9 times (47 cubic metres of methane per tonne wet weight) higher in October compared to the seaweed collected in December.

The Laminaria spp. seaweed harvested in November produced 342 L of methane per kilogram of volatile solid, whereas the same seaweed collected in March produced 163 L of methane per kilogram of volatile solid (Montingelli et al. 2016a). Maneein et al. (2021) examined the biogas production from Sargassum muticum. They found a high methane yield from Sargassum muticum collected in spring with a value of 19.7 L methane per kilogram wet weight over those harvested in summer, which showed 13.0 L methane per kilogram wet weight. The rapid methane production rate from spring-harvested seaweed was attributed to the increased availability of biodegradable carbohydrates, such as mannitol, which were readily bioconverted to methane. In addition, this variation was attributed to the fact that summer-harvested seaweed contained polyphenolics that were 3.8 times higher than spring-harvested seaweed.

The seasonal variation effects on the seaweed’s heavy metals content were analysed in Fucus vesiculosus, Ascophyllum nodosum, Alaria esculenta, and Saccharina latissima, which were collected in four various seasons (summer, spring, winter, and autumn). Generally, the contents of phosphorus, potassium, sodium, calcium, aluminium, magnesium, iron, and sulphur were higher during summer and spring. During the winter and autumn, however, only arsenic levels were higher (Ometto et al. 2018). Table 7 outlines the effects of different seaweed harvesting seasons on biomethane yield.

Table 7 .

Seasonal influence on the chemical composition and methane production of seaweed

| Seaweeds | Harvesting month | Total solid (%) | Volatile solids (%) | Carbon content (%) | Nitrogen (%) | Hydrogen (%) | Carbon/nitrogen ratio | Ash (%) | Theoretical biomethane potential (litres methane per kilogram volatile solid) | Biomethane potential (litres methane per kilogram volatile solid) | Biomass conversion (%) | Remarks | References |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laminaria digitata | August | 19.72 | 16.12 | 36.76 | 1.14 | 5.54 | 32.24 | 18.28 | 452 | 327 | 72.34 | High carbon content and biomethanation were observed in August | Tabassum et al. (2016a) |

| January | 11.43 | 7 | 26.06 | 3.95 | 3.38 | 6.59 | 38.82 | 421 | 237 | 56.29 | |||

| Ascophyllum nodosum | April | 20.99 | 15.94 | 36.14 | 2.47 | 5.03 | 14.63 | 24.06 | 497 | 217 | 43.66 | High polyphenolic compounds resulted in a low methane production | Tabassum et al. (2016b) |

| October | 28.52 | 22.01 | 40.67 | 0.89 | 5.11 | 46.75 | 22.83 | 543 | 215 | 38.59 | |||

| Laminaria digitata (dry biomass) | July | 93.7 | 65 | 30.8 | 1.4 | 5 | 22 | Not mentioned | 366 | 293 | 80.05 | High biomethane production resulted from high organic content | Membere and Sallis (2018) |

| Saccharina latissima | |||||||||||||

| (dry biomass) | June | 99.9 | 66 | 31.5 | 2.2 | 4 | 14.3 | Not mentioned | 443.9 | 281.4 | 63.3 | Low carbon/nitrogen ratio lowered the methane yield | Lin et al. (2019) |

| Ulva lactuca | July | 18.03 | 10.88 | 30 | 3.5 | 4.4 | 8.5 | 39.7 | 465 | 190.1 | 40.88 | Reduced methane was noted owing to elevated salinity | Tabassum et al. (2017a) |

| Fucus vesiculosus | July | 21.28 | 16.11 | 26.8 | 1.5 | 3.2 | 17.6 | 24 | 249 | 126.3 | 50.7 | Less methane yields due to the occurrence of inhibitors | Allen et al. (2015) |

| Saccorhiza polyschides | July | 15.25 | 13.11 | 36.1 | 1.6 | 5 | 23.2 | 14 | 386 | 263.3 | 68.21 | High carbon quantity improved methanation | |

| Fucus spiralis | July | 19.72 | 13.92 | 36.1 | 2.1 | 4.7 | 17.3 | 29.4 | 540 | 235 | 43.51 | High recalcitrant components reduced the methane generation | Tabassum et al. (2017a) |

| Laminaria digitata | March | 9.74 | 6.49 | 30.41 | 3.70 | 3.97 | 8.22 | 33.33 | 469 | 245 | 52.23 | Low carbon/nitrogen ratio reduced the methane generation | Tabassum et al. (2017b) |

| Ulva intestinalis | Summer | 18.2 | 14.2 | 31.5 | 2.88 | 4.29 | 10.9 | Not mentioned | 598 | 447.8 | 74.88 | Less sulphate content increased biomethanation | Romagnoli et al. (2019) |

| Ulva lactuca | June | 19.12 | 11.24 | 25.4 | 3.3 | 3.7 | 7.7 | Not mentioned | 431 | 250 | 58.01 | High salinity reduced the biogas yield | Allen et al. (2013) |

In terms of carbon, nitrogen, hydrogen, solids, and ash content, seaweeds exhibit seasonal variations in their chemical compositions. Generally, seaweed harvested between September and March (autumn) and July and August (end of summer) is richer in carbohydrates and nutrients, making seaweed more suitable for anaerobic digestion

Existence of inhibitory materials

Anaerobic digestion relies on microbial activity to convert complex compounds to monomers, which the microorganisms then consume to produce biomethane (Tawfik et al. 2022b). Typically, seaweed contains polyphenols, sulphated polysaccharides, and halogenated compounds, which inhibit anaerobic microorganisms (Tabassum et al. 2017a). The presence of sulphur-rich biomass in anaerobic digestion led to hydrogen sulphide production by sulphate-reducing bacteria (Farghali et al. 2019). The formation of hydrogen sulphide alongside methane indicates a competition between sulphate-reducing bacteria and methanogens for acetate, resulting in a decrease in methane production (Jung et al. 2022). In addition, the high salt content of seaweed biomass, which included sodium, calcium, potassium, and magnesium salts, led to the accumulation of salts in the anaerobic digestion systems, thereby inhibiting all microbes in anaerobic bioreactors (Maneein et al. 2018). High salinity shifted methanogens from the acetoclastic (Methanosaeta) to the hydrogenotrophic methanogens (Methanocorpusculum and Methanobrevibacter) (De Vrieze et al. 2017). Zhang et al. (2017) found that hydrogenotrophic methanogens (Methanobacterium) tolerated salinity up to 85 g/l, whereas acetoclastic methanogens (Methanosarcina and Methanosaeta) were inhibited at salinity more than 65 g/l during the anaerobic digestion of Laminaria japonica seaweed.

In addition, the inhibition of methanogen lowers the pH, leading to the accumulation of volatile fatty acids and the subsequent suppression of the anaerobic digestion process. As part of their chemical defence systems, seaweed also produces a variety of halogenated secondary metabolites, particularly chlorinated and brominated compounds (Nielsen et al. 2020). In 90% of red seaweed and 7% of green seaweed, chlorinated and brominated metabolites predominate, whereas iodine-containing metabolites predominate in brown seaweeds (Nielsen et al. 2020). Some brown seaweed types can build up to 1.2% of the iodine per seaweed dry weight. Halogens are well-known inhibitors of biomethane production from anaerobic digesters (Nielsen et al. 2020). Halogenated compounds inhibited the growth of anaerobic microorganisms. Specifically, halogenated aliphatics inhibited methanogenesis (Czatzkowska et al. 2020), which is frequently produced by seaweed (Leri et al. 2019). Saccharina latissima may generate up to 120–630 mg of organochlorine and aliphatic organobromine per kilogram dry weight of seaweed (Czatzkowska et al. 2020).

Algae and marine and terrestrial organisms collectively contain more than 8000 phenolic compounds (Perez et al. 2016). Particularly brown seaweeds contain substantial amounts of phenolics (about 14% dry weight). In many seaweeds, phlorotannins predominate among various polyphenols (Milledge et al. 2019; Montero et al. 2016). Seaweed polyphenol inhibits anaerobic digestion microbiota and reduces biogas production (Milledge et al. 2018; Tabassum et al. 2016c).

Insufficient trials and cost