Abstract

Flexible piezoelectrics realise the conversion between mechanical movements and electrical power by conformally attaching onto curvilinear surfaces, which are promising for energy harvesting of biomedical devices due to their sustainable body movements and/or deformations. Developing secondary functions of flexible piezoelectric energy harvesters is becoming increasingly significant in recent years via aiming at issues that cannot be addressed or mitigated by merely increasing piezoelectric efficiencies. These issues include loose interfacial contact and pucker generation by stretching, power shortage or instability induced by inadequate mechanical energy, and premature function degeneration or failure caused by fatigue fracture after cyclic deformations. Herein, the expedient secondary functions of flexible piezoelectrics to mitigate above issues are reviewed, including stretchability, hybrid energy harvesting, and self-healing. Efforts have been devoted to understanding the state-of-the-art strategies and their mechanisms of achieving secondary functions based on piezoelectric fundamentals. The link between structural characteristic and function performance is unravelled by providing insights into carefully selected progresses. The remaining challenges of developing secondary functions are proposed in the end with corresponding outlooks. The current work hopes to help and inspire future research in this promising field focusing on developing the secondary functions of flexible piezoelectric energy harvesters.

Keywords: Flexible piezoelectrics, Stretchable, Hybrid energy harvesting, Self-healing

Graphical abstract

Highlights

-

•

Overview of expedient secondary functions of flexible piezoelectrics for biomedical energy harvesting.

-

•

Discussion on mechanisms of state-of-the-art strategies for function development.

-

•

Uncovering the link between structural characteristics and function performance.

-

•

Pointing out research directions for secondary functions development of biomedical piezoelectric energy harvesters.

1. Introduction

The increasingly aging world's population has stimulated the development of patient-centred healthcare over the conventional hospital-centred diagnosis. The Internet of Things (IoT) technology provides a viable solution by ubiquitously employing trillions of smart devices, sensors, and actuators to realise real-time patient-centred monitoring/diagnosis [1]. Despite the miniaturisation of electronics and ultra-low power communication techniques, the regular replacement or recharging of power devices such as batteries and supercapacitors is still required, which not only increases the cost but might induce complications for long-term implantable electronics at hard-to-reach sites. Piezoelectrics can scavenge and harvest mechanical energy from the human body and in turn generate electrical power, therefore acting as stable, eco-friendly, and maintenance-free energy sources to power biomedical sensors or actuators [2,3]. In addition, biomedical piezoelectrics have the advantages including superior biocompatibility, facile processability, high durability, reliability, and sensitivity [4], therefore serving as a promising solution for biomedical energy harvesting. Fig. 1(a) shows the past and the predicted global market of piezoelectric devices from 2017 to 2026 [5]. An enormous and steadily expanding market is witnessed, which is predicted to reach 27.5 billion US dollars in 2026. Particularly, lightweight flexible piezoelectric devices can conformally attach to curved human joints and organs, serving as biomedical sensors by harvesting mechanical energy. A flexible piezoelectric energy harvester typically contains a flexible piezoelectric thin film, as shown in Fig. 1(b). Two electrodes are attached on the top and bottom surfaces to form a sandwich like structure that is encapsulated by an outer flexible substrate. Fig. 1(c) exemplifies the wearable and implantable biomedical devices based on flexible piezoelectric energy harvesters [[6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18]]. These devices are found in diverse applications as energy generators or medical actuators, indicating the huge potential of flexible piezoelectrics in the biomedical field.

Fig. 1.

Backgrounds of flexible piezoelectric devices for biomedical applications. (a) The past and the predicted global market sizes of piezoelectric devices from 2017 to 2026 [5]. (b) The typical structure of flexible piezoelectric devices. (c) The diverse biomedical applications of flexible piezoelectric devices as wearable electronics (Reproduced with permission [8]. Copyright 2018, Royal Society of Chemistry), including pronunciation monitor [6] (Reproduced with permission [6]. Copyright 2017, American Chemical Society), artificial glove [7] (Reproduced with permission [7]. Copyright 2017, Institute of Physics), electricity generator [8] (Reproduced with permission [8]. Copyright 2018, Royal Society of Chemistry), e-tattoo [9] (Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [9]. Copyright 2019, The Authors, published by Wiley-VCH), movement sensor [10] (Reproduced with permission [10]. Copyright 2015, Elsevier), and energy harvesting shoe insole [11] (Reproduced with permission [11]. Copyright 2020, American Chemical Society); as implantable devices (Reproduced with permission [14]. Copyright 2015, Elsevier), including blood–brain barrier opener [12] (Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [12]. Copyright 2020, The Authors, published by United States National Academy of Sciences), bone tissue stimulator [13] (Reproduced with permission [13]. Copyright 2020, Elsevier), aorta electricity generator [14] (Reproduced with permission [14]. Copyright 2015, Elsevier), pacemaker [15] (Reproduced with permission [15]. Copyright 2021, Elsevier), abdomen pressure monitor [16] (Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [16]. Copyright 2018, The Authors, published by United States National Academy of Sciences), and neural stimulator [19] (Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [19]. Copyright 2020, The Authors, published by Springer Nature).

So far, flexible piezoelectric energy harvesters have been extensively reported to be fabricated from: (i) inorganic piezoelectric materials, including semiconducting nanowires (e.g., ZnO [3,20], GaN [21,22], CdS [23], InN [24], and ZnS [25]), lead-based (e.g., lead zirconate titanate (PZT) [26], PbZrO3 [27], and PbTiO3 [28]) and lead-free ceramics thin films (e.g., BaTiO3 [29], LiNbO3 [30], (K,Na)NbO3 (KNN) [31], and LiTaO3 [32]); (ii) organic piezoelectric materials including synthetic polymers (e.g., poly(vinylidene fluoride) (PVDF) [33,34], poly(vinylidene fluoride-co-tri-fluoroethylene) (PVDF–TrFE) [35], nylon-11 (PA-11) [36], polylactic acid (PLA) [37], poly(l-lactide) (PLLA) [38], and poly(d-lactide) (PDLA) [39]), natural organics (e.g., amino acid [40], peptide [41], protein [42], and virus [43,44]), and molecular ferroelectrics [45]; and (iii) piezoelectric composites composing of conductive fillers (e.g., graphene [46], carbon nanotubes [47], and silver [48]), or non-conductive fillers (e.g., PZT [49], BaTiO3 [50], KNN [51], ZnO [52], MgO [47], and TiO2 [47]), and matrix (e.g., PVDF [49], P(VDF-TrFE) [47], hydroxyapatite [53], PDMS [51], and polyvinylidene fluoride hexafluoropropylene (PVDF-HFP) [46]). Numerous studies have been dedicated to significantly improve the output power of flexible piezoelectric devices via materials engineering (e.g., texture/crystallinity enhancement [[54], [55], [56], [57]], dipole/polarisation alignment [41,58], doping engineering [[59], [60], [61]], surface micro-morphologies design [[62], [63], [64]], and nanocomposite [8,65,66]), and device design (e.g., Y-shaped attachment [67], operation mode adjustment [68], and gated-controlled piezotronics [69]). Reports on some impressive devices include a highly efficient PZT thin film nanogenerator that can light up 105 LEDs at the same time with an unbending motion [26], and a curved PVDF energy harvester able to light up 476 LEDs by a press-and-release motion [70].

Nevertheless, some issues that are irrelevant to output enhancement still hinder the practical applications of flexible piezoelectric devices. These issues include:

-

(i)

Stretching-induced loose interfacial contact, user discomfort, and pucker generation due to soft and curvilinear body surfaces;

-

(ii)

Power shortage or intermittency under working environments with inadequate mechanical energy;

-

(iii)

Premature degeneration or failure of device function due to fatigue fracture generation after cyclic mechanical loading and unloading.

The proposed solution to the above issues revolves around developing specific secondary functions in flexible piezoelectrics, including stretchability, hybrid energy harvesting, and self-healing.

Previously, several reviews have been reported providing excellent overviews of flexible and stretchable piezoelectric energy harvesters [[71], [72], [73], [74]]. However, a comprehensive and insightful review of multiple promising secondary functions of flexible piezoelectric energy harvesters that tackle issues irrelevant to improving piezoelectric output, including stretchability, hybrid energy harvesting, and self-healing, is still lacking. In this context, this review firstly introduced the fundamentals of piezoelectricity to provide a proper foundation for associated concepts and the development of secondary functions. Afterwards, backgrounds, mechanisms, and strategies to develop expedient secondary functions of stretchability, hybrid energy harvesting, and self-healing are respectively discussed by reviewing carefully selected progresses. In the end, the remaining challenges of the above secondary functions are respectively proposed with corresponding future outlooks. This paper hopes to provide a reference and inspire future research in this promising field focusing on developing the secondary functions of flexible piezoelectrics, which is of vital significance to advance their biomedical applications.

It should be noted that the commercialisation of biomedical piezoelectric energy generators should also consider their narrow bandwidth, and the scalable manufacturing of not only piezoelectric energy harvester but also its integrated circuit and energy storage device, as well as encapsulation. In addition, biomedical energy harvesters, especially bio-implantable energy harvesters, are required to be biocompatible, which necessitates biocompatible device components including piezoelectric material, electrode, substrate, and encapsulation [75]. For piezoelectric biomedical energy harvesters, electrode materials have been reported including Cr [76], Ag [77], Cu [78], Au [76], Al [79], graphene [80], and indium tin oxide (ITO) [81], substrate materials have been reported including plastic films (e.g., polyethylene terephthalate (PET) [82,83], and polyimide(PI) [84]) and metallic foils (e.g., Ni [85], Pt [86], and Ni–Cr alloy [87]), and encapsulation materials have been reported such as PI [84], PDMS [88], and PDMS/Parylene-C [89]. Initial studies have confirmed their biosafety [76,89], but long-term biocompatibility studies using large animal models or clinical studies are highly desired to conclude on their long-term biocompatibility. In terms of piezoelectric material, high-performance lead-free piezoelectric ceramics [90,91] and piezoelectric polymers [2] have been widely reported to be biocompatible, while lead-based ceramics may also be biocompatible in the crystalline state [92] or under proper encapsulation [84]. However, for bio-implantable energy harvesters, only lead-free piezoelectric ceramics and polymers are expected to be utilised, considering the wet and complex physiological environment-induced varying degrees of solubility and potential ion penetration/leakage, especially for long-term implantation applications.

2. Fundamentals of piezoelectricity in brief

The word “piezo” is a Greek word meaning “to press”, therefore piezoelectricity logically and appropriately depicts the generation of electricity by pressing. Piezoelectricity was firstly discovered by French physicist Pierre Curie and his older brother Jacques Curie in 1880 [93]. They found that mechanical stress can induce the production of surface charges in a range of crystals, such as tourmaline, quartz, and topaz. Subsequently, the converse piezoelectric effect, i.e., the generation of mechanical strain induced by electricity, was thermodynamically predicted by Franco-Luxembourgish physicist Gabriel Lippmann in 1881 [94], and later experimentally confirmed by the Curie brothers. Since then, investigations on understanding fundamentals and discovering applications of piezoelectricity have been exponentially grown [[95], [96], [97]].

2.1. Piezoelectricity mechanisms

The mechanisms of piezoelectricity are separately introduced for inorganic and organic piezoelectric materials. For inorganic piezoelectric materials, piezoelectricity requires a non-centrosymmetric crystal structure [2], or the symmetry breaking of some inorganic materials such as hydroxyapatite [98]. The piezoelectric voltage is engendered by a net mechanically induced polarisation in the crystal. Specifically, when mechanical strain is applied, the atomic structure is deformed and thus induces the displacement of ion balance, as exemplified in Fig. 2(a) for the case of PZT. The shift of ion balance leads to the formation of a dipole moment in the crystal unit. Adjoining dipoles tend to be aligned, forming a Weiss domain with a net dipole density or polarisation. Polarisation directions are random in the crystal. To form a net polarisation in the crystal upon mechanical stress, inorganic piezoelectric materials need to be poled under a high electric field at an elevated temperature to regulate polarisation along the direction of the poling electric field, as shown in Fig. 2(a). As a result, a net polarisation can be generated in the crystal under proper mechanical stress, leading to piezoelectric charges on the surface of inorganic piezoelectric materials. Conversely, piezoelectric materials can generate mechanical deformations by applying external electric fields, called the converse piezoelectric effect.

Fig. 2.

Piezoelectricity fundamentals. The piezoelectricity mechanisms of (a) inorganic PZT and (b) organic PVDF piezoelectric materials. (c) The three-axis coordinate system of piezoelectric directions and piezoelectric charge coefficient diagrams.

The piezoelectricity of organic piezoelectric materials can be understood as the reorientation of molecular dipoles induced by an intense electrical field or mechanical stretching [99]. Fig. 2(b) exemplifies the piezoelectricity mechanism of PVDF [100]. The different electronegativities between atoms, i.e., carbon-fluorine and carbon-hydrogen, lead to the formation of randomly distributed molecular dipoles in PVDF, pointing from negative (high electronegativity) to positive (low electronegativity) charges. For the phase in PVDF, the molecular dipoles are antiparallel, therefore the net dipole is close to zero and PVDF is unpolarised. By poling PVDF with a high electrical field and stretching, phase can be transformed into phase where molecular dipoles become mostly parallel, resulting in a polarised PVDF.

2.2. Piezoelectric coefficients

Piezoelectric coefficients depict the relationships between piezoelectric responses and the directions of applied external stimuli. Various piezoelectric coefficients can be used to depict the piezoelectric responses of interest, including the charge coefficient (, the response of polarisation charge, C N−1; or the response of strain, m V−1), the voltage coefficient (, the response of electric field, V m N−1), the permittivity coefficient (, the response of dielectric displacement, farad m−1), and electromechanical coupling coefficient (, the response of electromechanical coupling, dimensionless).

Considering the anisotropy of piezoelectric materials, the identification of directions in a piezoelectric element is important to characterise piezoelectric responses. Therefore, a three-axis coordinate system is utilised to define piezoelectric directions, as shown in Fig. 2(c). The three directions X, Y and Z in the classic orthogonal coordinate system are defined as the directions 1, 2 and 3 for the normal piezoelectricity, while their shear directions are defined as the directions 4, 5 and 6 for the shear piezoelectricity, respectively. On this basis, directions of piezoelectric coefficients can be described using two subscripts, i and j, where i represents the direction of generated electrical field or applied voltage, while j reflects the direction of applied mechanical stress or induced strain. Fig. 2(c) exemplifies the diagrams of , and , where the poling direction is considered as the “3” direction. As can be seen, surface charges and therefore electric fields can be generated in the “3” direction by mechanically deforming piezoelectric materials along the “3” () or the “1” direction () or applying shear stresses along the “4” direction (). By reversing the direction of deformation, for example, by applying mechanical tension rather than compression, an opposite electric field can be generated, as exemplified in the diagrams.

In addition to the subscripts, superscripts are also applied to further specify their mechanical or electrical boundary conditions of piezoelectric coefficients. For example, is the permittivity under a constant stress field. In this way, the piezoelectric effect and the converse piezoelectric effect can be described using the following two equations [101], respectively:

| (Eq. 2.1) |

| (Eq. 2.2) |

where D and E are respectively the electric displacements and electric field vectors, S and T are the strain and stress tensors, respectively, is the elastic compliance matrix under a constant electric field, while d and are the coefficient matrices for the piezoelectric effect and the converse piezoelectric effect ( is the transposition of d), respectively. Piezoelectricity therefore can be essentially understood as the generations of electric charges (D) or strains (S) by applying mechanical stress (T) and/or electric field (E), whose behaviours are unique to the direction and depend upon material-intrinsic parameters (, and ).

Based on above fundamentals, considerations are required when developing secondary functions to prevent undesirable function interference or counteraction. Firstly, since piezoelectric outputs are direction-dependent, structure manipulation, such as developing 3D stretchable structures, needs to be coupled with mechanics analysis (e.g., finite element analysis) to guide external forces preferentially loaded in directions with strong piezoelectric responses to prevent significant output deterioration. Secondly, microstructure engineering, such as engineering dynamic hydrogen bond networks and proton interactions for self-healing capacity, needs to consider the impact on material crystallinity or chain arrangement, which may lead to the counteraction of local dipole moments and degenerated piezoelectric performance. Thirdly, a portion of piezoelectric materials is also pyroelectric materials, whose dipole moments can be thermally induced to generate pyroelectric voltage and vice versa. Proper thermal management is necessary when developing hybrid energy harvesters to avoid unexpected conflicts between various energy harvesting systems.

3. Stretchability

Due to the soft and curvilinear surfaces of human limbs, joints, and organs, the practical applications of flexible piezoelectrics suffer from issues including user discomfort, loose interfacial contact, poor wrinkle resistance, and pucker or even breakage. To this end, developing stretchable flexible piezoelectrics is necessary, which affords the capacity to eliminate above issues by conformally attaching onto curvilinear and soft surfaces during stretching. It will also lead to smaller device size and greater design flexibility. The increase in allowable strain enabled by stretchability may also contribute to improved piezoelectric output and sensitivity.

Basically, the stretchability of flexible piezoelectrics can stem from four classes of strategies, including (i) nano/micro-structure design, (ii) morphology design, (iii) elastic piezoelectric or non-piezoelectric matrix, and (iv) stretchable interconnections and substrates for devices based on rigid piezoelectric arrays. In this section, state-of-the-art strategies to develop stretchable flexible piezoelectrics are classified based on the above criteria and discussed by understanding structural characteristics and material properties. The evolution of each class of strategies is reflected by highlighting the improved aspect of evolved strategies compared with earlier ones. The impacts of stretchability on piezoelectric behaviour are also discussed.

3.1. Microstructure design

Designing stretchable microstructures has been proven as an effective strategy to induce stretchability. Fig. 3(a) shows a wavy microstructure of PZT ribbons [102], formed by releasing pre-strained flat PZT ribbons (buckling process) [103]. The buckled PZT ribbons possess a wavy microstructure along the out-of-plane direction, enabling the crack-free tensile strain. The increased stretchability is attributed to the accommodation of in-plane deformations enabled by wavy microstructure by varying its wavelength and amplitude. The wavy microstructure also leads to significantly higher piezoelectric current density, for example, 250 μA cm−2 [102] than 4 μA cm−2 of non-stretchable PZT nanowires-based energy generator [104], due to the much higher strain gradients at buckled regions than flat regions and also the absence of the substrate clamping effect [105]. On top of which, Su et al. further stacked wavy microstructured PZT ribbons into a multilayered architecture for increased piezoelectric output, by which the peak voltage can increase from 3.7 V (single PZT ribbon) to 8.1 V by stacking 5 PZT ribbons [106]. The operation modes of stretchable wavy piezoelectric ribbons are limited by their simple geometries. Developing deterministic complex 3D microstructures [107] can extend their operation modes and provide the desired stretchability. It has been found that the motions of ribbons are dominated by out-of-plane bending and twisting deformations, and the bending and torsional degrees of freedom of ribbons are constrained by deformations' isometric nature (i.e., length invariant) [108]. By compressively buckling delicately designed 2D patterns, sophisticated 3D microstructures can be fabricated to enable a notably wider frequency range of vibrations and larger piezoelectric output than 2D serpentine, as shown in Fig. 3(b) [109].

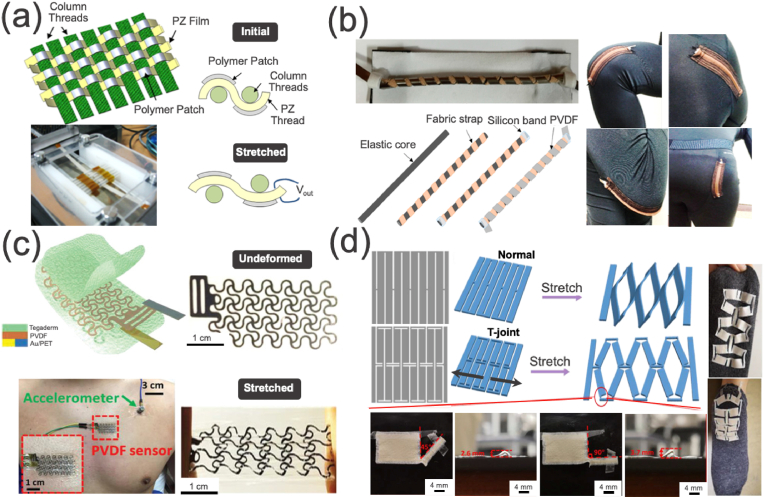

Fig. 3.

Microstructure design of stretchable flexible piezoelectrics. Stretchable microstructures including (a) buckled microstructure [102], (b) complex 3D microstructure [109], (c) wavy interfacial pattern [115], (d) microporosity [116], and (e) coiled microstructures [117]. (a) Reproduced with permission [102]. Copyright 2011, American Chemical Society. (b) Reproduced with permission [109]. Copyright 2019, Springer Nature. (c) Reproduced with permission [115]. Copyright 2013, Wiley-VCH. (d) Reproduced with permission [116]. Copyright 2014, Wiley-VCH. (e) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [117]. Copyright 2020, The Authors, published by Wiley-VCH.

Above out-of-plane wavy microstructure may suffer from thick encapsulation and poor pressing-mode () piezoelectric responses [110]. An in-plane wavy microstructure may prevent the above drawbacks while maintaining the desired stretchability. This was reported from stretchable PVDF nanoribbons [111,112], which was fabricated by printing straight PVDF nanofibers onto pre-strained PDMS substrate followed by releasing. The pre-strain and the space among printed nanofibers were simulated and designed to realise large scale in-plane wavy fibres with high uniformity and integration, which contribute to a much higher in-plane strain of 110% [111]. This strategy was later optimised by printing fractal PVDF nanofibers [113], i.e., a structure with a higher buckle density, combined with liquid metal interconnection electrodes. Consequently, an improved stretchability of 200% was achieved by Huang et al. [113]. By designing the pre-strain of PVDF nanofibers and optimising printing parameters, the same group later realised wavy serpentine PVDF nanofibers with a further improved stretchability of 300% [114].

Fig. 3(c) demonstrates a stretchable P(VDF-TrFE) film on a micro-patterned carbon nanotube (CNT)-PDMS electrode [115]. The stretchability was attributed to the wavy interfacial pattern between the film and electrode, which enables a strain of 30% without cracking [115]. Siddiqui et al. [80] applied the similar micro-pattering strategy but using stacked BaTiO3–P(VDF-TrFE) composite mats. Due to the stress-relieving effect induced by micropattern and the free-standing nature of stacked mats, increased stretchability of 40% was achieved with a peak open-circuit voltage of 10.1 V.

In addition, microporosity has been reported to enhance the stretchability of PVDF films [116], as shown in Fig. 3(c). Compared with rigid plastic films under low porosity, it was found high porosity (>40%) can lead to sponge-like soft and lossy PVDF films, yielding a considerably larger displacement and higher electrical output under the same external impact.

Overtwisting can produce stretchable microstructures for piezoelectric fibres [[117], [118], [119]]. A very high strain of 740% has been reported by twisting PVDF-TrFE nanofibers into yarns and then overtwisting yarns into a stretchable coiled structure [118]. The high stretchability was ascribed to the interaction forces between nanofibers, including friction, van der Waals, and electrostatic forces. To further enhance the output of piezoelectric fibres, polar phase stabilising fillers can be incorporated to develop composite fibres [120]. Mokhtari et al. [117] developed PVDF/BaTiO3/reduced graphene oxide (rGO) composite fibres with a coiled structure to fabricate a stretchable piezoelectric textile, as shown in Fig. 3(c). BaTiO3 nanoparticles present high dipole attractions and can stabilise the electroactive -phase by electrostatic interactions and hydrogen bonding with PVDF chains, while conductive rGO particles can provide free electronic charges to promote the formation of PVDF/BaTiO3 dipoles in the composite. The textile device generated a high voltage output of 1.2 V and presented a high strain of 100%. Despite the high stretchability, coiled stretchable fibres might suffer from poor piezoelectric regularity, especially under high strains, because the deformation tends to occur by micro-buckle unfolding rather than coil opening.

3.2. Morphology design

Stretchable morphologies have been reported including textile, filamentary serpentine (FS), and the kirigami structures.

Fig. 4(a) shows a typical stretchable textile based on piezoelectric PVDF threads [121]. Such a structure is fabricated by weaving silicon tube column threads with PVDF row threads into stitches. When the structure is stretched, PVDF threads undergo tensile stresses, while the alternately patterned elastic polyester patches on PVDF threads contribute to the thread contraction, generating piezoelectric voltages during continuous stretches and contractions. Based on that, Ahn et al. further used piezoelectric column straps weaved with piezoelectric row straps, separated by elastic hollow tubes [122]. In addition to enhanced piezoelectric output, as-fabricated stretchable textile can also serve as a tactile sensor, due to the distance change and thus the capacitance change between column and row threads enabled by the hollow tubes during stretching and compressing. Kim et al. reported a helical structure which might be used to significantly improve the stretchability of aforementioned piezoelectric thread/strap [123]. As shown in Fig. 4(b), the helical structure was formed by twinning PVDF strap and fabric band around an elastic core in the opposite direction, which enabled a high stretchability up to 158%. By stitching the helical piezoelectric harvester with clothes, piezoelectric voltages of 3.9 and 4.4 V can be generated during push-up and squatting motions, respectively. Above stretchable textiles may suffer from electrical shorting under wet environments. This can be prevented by introducing cotton threads as the insulating spacer between electrodes [124], or developing a core-shell structure where the inner electrode is fully shield and isolated from the outer electrode consisting of conductive yarn [125,126].

Fig. 4.

Morphology design of stretchable flexible piezoelectrics. Stretchable morphologies including (a) textile [121], (b) helical strap [123], (c) filamentary serpentine (FS) meshing [9], and (d) kirigami cutting [110]. (a) Reproduced with permission [121]. Copyright 2013, Wiley-VCH. (b) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [123]. Copyright 2017, The Authors, published by Multidisciplinary Digital Publishing Institute. (c) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [9]. Copyright 2019, The Authors, published by Wiley-VCH. (d) Reproduced with permission [110]. Copyright 2020, Elsevier.

The stretchable FS structure [9,127] is depicted in Fig. 4(c), which was applied to fabricate a PVDF-based piezoelectric e-tattoo for mechano-acoustic cardiovascular sensing [9]. The fabrication was realised by a cut-and-paste process, where the FS-structured PVDF was firstly patterned by a mechanical cutter plotter, whose pattern was subsequently pasted by Au electrodes on the top. The FS e-tattoo presents a good stretchability of 100% and compatible deformations with human skin. However, the serpentine pattern in the FS structure is stress-relieving, which compromises the piezoelectric output and sensitivity. The sensitivity after stress-relieving (0.4 mV per micro-strain) is only 3.6% of that in stretching straight PVDF ribbons [9].

The undesirable output degradation induced by stress-relieving can be mitigated by kirigami structures, which can achieve stretchability by creating out-of-plane deformations above 2D flat sheets and realising complex 3D geometries. The stretchability of kirigami structures has been witnessed in lithium-ion batteries [128], cellular metamaterials [129], solar tracking system [130], etc. Its application in piezoelectrics was reported in 2018, when Hu et al. [131] found that kirigami PVDF films exhibited 18% strain without fracture while generating a slightly degraded piezoelectric output of 132 mV, in contrast to the 160 mV output observed in uncut PVDF films under a 1% strain. By rationally designing kirigami parameters such as cut density and cut position [131], the stress aggregation at the sharp corners of cuts, which can limit stretchability, can be minimised and thus realising improved piezoelectric outputs and stretchability. Sun et al. [132] utilised finite element analysis (FEA) simulations and found that the conventional continuous electrode connection can lead to charge cancellation from opposite strains on the electrode, thereby deteriorating piezoelectric outputs. They reported a segmented electrode connection to address this issue, where electrodes were deposited only at regions of the highest strain. The output voltage of the kirigami-structured sensor was consequetly improved by 2.6 times and reached 1.63 V under a tensile strain of 10% [132]. The piezoelectric performance of kirigami structure can be further improved by controlling the cut shape, so that the optimal piezoelectric mode can be adopted [110]. Specifically, simple kirigami structures typically function by the out-of-plane tilting during stretching, which disables the most facile and common “3-3” mode to harvest energy by pressing. A T-joint-cut, as shown in Fig. 4(d), can overcome this issue by introducing a joint point to connect short and long cuttings, so that the out-of-plane tilting occurs only at the joint point during stretching, and other places are flat to enable “3-3” mode to harvest energy by pressing. The joint point also enables the rotation of other parts around during stretching, which leads to enhanced stretchability. As a result, the kirigami-structured sensor with a T-joint-cut presented an impressive strain of 300% with an open current voltage of 6 V [110].

3.3. Elastic matrix and stretchable interconnections

For piezoelectric composites [133], both piezoelectric polymers and non-piezoelectric elastomers have been reported to contribute to stretchability as the elastic matrix. PVDF [79,134] and its copolymers such as P(VDF-TrFE) [135,136] and PVDF-HFP [137] are mostly used piezoelectric polymers, while PDMS [6,138] and silicone elastomer [77,139,140] are commonly applied as the elastomer.

Studies on piezoelectric polymer-based stretchable composites have been devoted to improving their piezoelectric output and mechanical properties. Among which, incorporating engineered fillers such as doped ZnO [137,141], surface charged Al2O3 [142], Ag nanoparticles [143,144], SnO2 nanosheet [145], and graphene [146] has been proven as an effective strategy to increase the composite's energy output, and potentially improve its mechanical properties. The reason for the enhanced output can be essentially attributed to the interaction between fillers and polymer matrix, by which the content of polymer's main electroactive phase can be improved for stronger piezoelectric responses. For example, the positive surface charges of Co-doped ZnO nanofillers were reported to interact with the molecular dipoles (CH2 or CF2) of PVDF-HFP to improve its β-phase content [137,147], while the incorporation of graphene filler can achieve similar benefit by forming micro-capacitors in PVDF and improving polarisation efficiency and orientation of dipole moments due to its good dielectric properties [146,148]. Fig. 5(a) shows the mechanism of increased β-phase in PVDF-HFP induced by surface-charged Al2O3 nanoparticles [142]. When Al2O3 nano-fillers are dispersed in the matrix, their high surface energy and positive surficial charges induce the Coulomb repulsion among fillers and thereby ensure uniform filler distribution. Meanwhile, the interfacial hydrogen bonding between charged filler surface and matrix orders PVDF-HFP chains to transform into crystallised β-phase, leading to a 5.6 times higher dielectric constant than pure PVDF-HFP polymer. On the other hand, the reason for filler incorporation to enhance the composite's mechanical properties may lie in the uniform filler distribution which can facilitate load transfer between filler-matrix interface [149]. Zhang et al. [79] reported eleven times and twice increase in the strength and stretchability of PVDF, respectively, after introducing uniformly distributed boron nitride nanosheets.

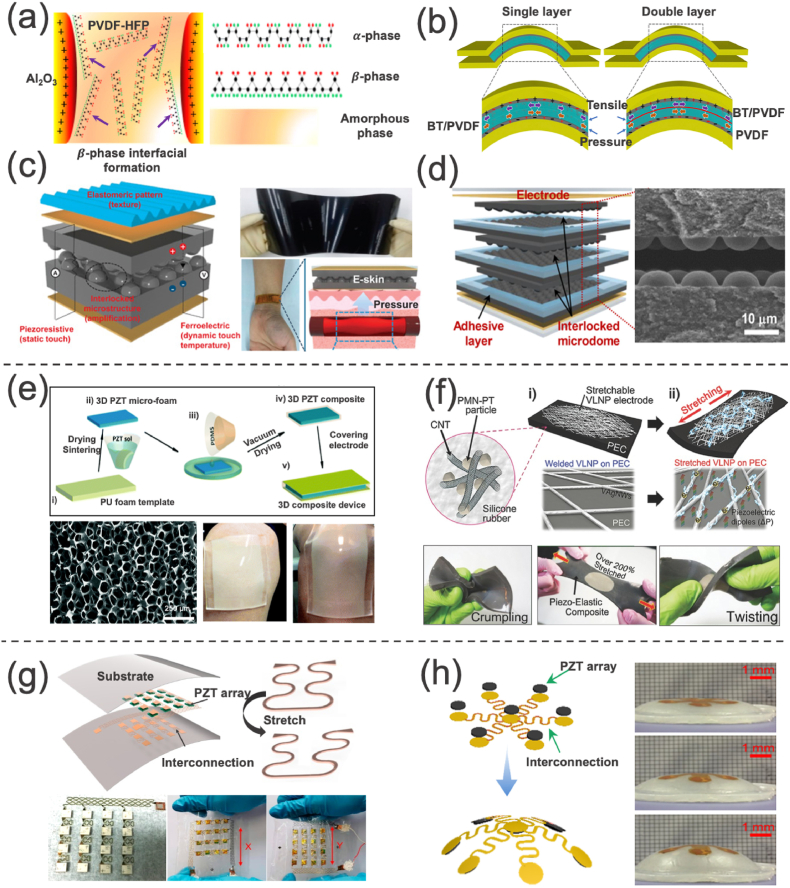

Fig. 5.

Elastic matrix and stretchable interconnection of stretchable flexible piezoelectrics. Piezoelectric polymer-based elastic matrix with (a) surface charged Al2O3 fillers [142], (b) double-layered structure [150], (c) fingertip skin-like interlocked structure [64], and (d) multi-layered interlocked structure [164]. Non-piezoelectric elastomer-based elastic matrix with (e) PZT ceramic foam [169], and (f) multiwalled carbon nanotubes as physical distribution disperser [77]. Stretchable (g) serpentine structured Cu interconnections [170], and (h) claw-shape interconnections [171]. (a) Reproduced with permission [142]. Copyright 2019, Wiley-VCH. (b) Reproduced with permission [150]. Copyright 2018, Elsevier. (c) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [64]. Copyright 2015, American Association for the Advancement of Science. (d) Reproduced with permission [164]. Copyright 2018, American Chemical Society. (e) Reproduced with permission [169]. Copyright 2018, Royal Society of Chemistry. (f) Reproduced with permission [77]. Copyright 2015, Wiley-VCH. (g) Reproduced with permission [170]. Copyright 2015, Wiley-VCH. (g) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [170]. Copyright 2019, The Authors, published by Multidisciplinary Digital Publishing Institute. (h) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0) [171]. Copyright 2021, The Authors, published by American Association for the Advancement of Science.

Structure engineering can also enhance the output of piezoelectric polymer-based stretchable composites. Fig. 5(b) shows a double-layered PVDF-based composite with barium titanate fillers embedded in the top PVDF layer and a pure PVDF layer at the bottom [150]. As shown, compared with single-layered structure which may degenerate piezo-response due to the counteraction of top and bottom opposite charges, the counteracting effect in double-layered structure is weak, and the additional charges accumulated at the heterointerface can induce higher composite's electric capacity. This structure can be further optimised by developing multi-layered piezoelectric composites [151,152], which can suppress the charge injection and migration at dielectric/electrode and dielectric/dielectric interfaces to significantly improve the breakdown strength and the charge density. Li et al. [153] investigated the influence of the number of layers on device performance and found that layer number higher than four will lead to an increased possibility of current leakage and piezoelectric electron-hole recombination, and overall deteriorated output performance. The optimal four-layered BaTiO3/PVDF film generated promising piezoelectric voltage and current of 14.22 V and 2.42 A, respectively [153].

Micro-patterning and nano-templating [154] may also enhance the output of piezoelectric polymers using methods including electron/ion beam writing [155], layer-by-layer assembly [156], nanoimprinting [157], soft lithography [158], and patterned electrohydrodynamic pulling [159]. Surmenev et al. [160,161] found imprinted PVDF micropillars possessed 1.85 times stronger piezoelectric response than flat PVDF film counterparts, from 40 to 74 p.m. V−1. This is because of the strain confinement effect of micropillars which can withstand a high strain upon applied loading. On the other hand, nano-templating using anodized aluminium oxide (AAO) template was found to possess a template confinement effect towards the alignment of polymer chain which can promote α-to-β phase transition in PVDF [162,163]. Fig. 5(c) [64], and (d) [164] show another novel micro-pattern inspired by fingertip skin. Compared with planar films, the interlocked micro-dome arrays possess a larger contact area and stress concentration effect between micro-domes, which can induce enhanced deformations and thus higher piezo-responses. Lee et al. [164] further increased the contact area by fabricating multi-layered e-skin with interlocked micro-dome arrays (Fig. 5(d)) and realised a high sensitivity of 47.7 kPa−1 with 1.3 Pa minimum detection.

Lastly, the output of ferroelectric and piezoelectric polymers may be significantly improved based on the cutting-edge discovery of the morphotropic phase boundary (MPB) [165] and the chirality-induced relaxor property [166] in P(VDF-TrFE). MPB used to be exclusive in the field of ferroelectric ceramics, whose composition enables the coexist of two or more competing phases (i.e., relaxor phase and normal ferroelectric phases), leading to more thermally dynamic ferroelectric dipoles, more facile polarisation reorientation, and therefore higher piezoelectric response [166,167]. The discovery of MPB in ferroelectric P(VDF-TrFE), and the origin of relaxor behaviours, provided the necessary fundamental knowledge to understand relaxor ferroelectric polymers and their composition design. Based on that, Park et al. [168] reported greatly improved piezoelectric voltage of 20 V and current of 210 nA from poled ferroelectric P(VDF-TrFE) nanofibers with 50% molar fraction of TrFE, compared with the 9.5 V and 110 nA obtained from normal poled P(VDF-TrFE) nanofibers with 30% molar fraction of TrFE. Such work may inspire future work to develop novel relaxor ferroelectric polymers serving as the promising matrix of high-performance stretchable piezoelectric composites.

In terms of non-piezoelectric elastomer-based stretchable composites, piezoelectric particles are dispersed in the matrix as fillers. Nevertheless, they may suffer from issues of (i) low piezoelectric output due to decreased content of effective piezoelectric materials and filler aggregation, (ii) unexpected fatigue failures due to poor filler dispersion in polymer matrix with high viscosity, and (iii) poor connection among piezoelectric fillers.

Efforts have been reported to address these tangled issues from filler's point of view, including (i) fabricating highly crystalline NWs as fillers (e.g., ZnO NWs [172], Li-doped ZnO NWs [173], and BaTiO3 NWs [174]) due to their high crystallinity and uniform alignment in the growth direction, (ii) using organic fillers such as P(VDF-TrFE) [135] due to their better dispersion than inorganic fillers within polymer matrix, and (iii) fabricating 3D cellular-structured filler network [169]. As shown in Fig. 5(e), by fabricating PZT fillers into a ceramic foam filled with elastic PDMS, the stretchable PZT-PDMS composite possesses a continuous pathway for high-efficiency load transfer, which results in a stable and superior piezoelectric voltage of more than 60 V under a tensile strain of 15% after 5000 cycles [169]. Efforts were also reported by introducing carbon nanotubes (CNTs) as the external physical distribution disperser [175] into composites to improve filler dispersion [77,134,174]. As shown in Fig. 5(f), incorporated multiwalled carbon nanotubes (MWCNTs) into (lead magnesio niobate-lead titanate) (PMN-PT)-silicon elastomer piezoelectric composites can act as a type of physical distribution disperser [175], mechanical reinforcer, and electrical bridging agent, leading to the increased piezoelectric voltage of 4 V and current of 500 nA and meanwhile good stretchability of up to 200% as assisted by stretchable Ag nanowires-based electrodes [77]. Lastly, an optimised fabrication method such as the shear dispersion method [139,140] can mitigate the filler propagation issue, where fillers are mixed with the matrix under laminar shear force and pressure contributed by two rollers with different rotational speeds. The improved filler homogeneity allows for higher filler proportions within elastic matrix. A high filler ratio of 92 wt% has been reported in a stretchable PZT-silicone elastomer piezoelectric composite, which generated an outstanding output power density of 81.25 μW cm−3 under 30% strain [140].

Lastly, stretchability of piezoelectric devices can be realised by fabricating rigid piezoelectric arrays on a stretchable substrate with stretchable interconnections [170,176]. Fig. 5(g) exemplifies a PZT-based stretchable piezoelectric transducer on a PDMS substrate [170], where the stretchable serpentine structured Cu interconnections can provide the device with 25% stretchability in binary directions. On top of that, the “claw-shape” interconnections have been reported in a PZT-based piezoelectric ultrasound transducer, enabling stretchability in multiple directions, as shown in Fig. 5(h) [171].

Table 1 summarises the fabrication method, piezoelectricity, and stretchability performances of different classes of stretchable flexible piezoelectrics.

Table 1.

Summary of fabrication method, piezoelectricity, and stretchability performances of stretchable flexible piezoelectrics.

| Strategy | Material | Fabrication | Piezoelectricity | Stretchability | Ref |

|---|---|---|---|---|---|

| Micro-structure design | PZT on PDMS substrate | Transfer printing PZT ribbons onto prestrained PDMS substrates and releasing strain for buckled PZT | Current density of 2.5 μA mm−2 under periodic strain of 8% | 8% | [102] |

| PZT and PI layers | Transfer printing, stacking buckled PZT and PI layers | Voltage of 8.1 V with 5 PZT layers | [106] | ||

| PVDF | Compressive buckling complex 3D microstructures | Voltage of 790 mV | ∼2.8% | [109] | |

| PVDF on PDMS substrate | Mechano-electrospinning, straight PDVF nanofibers on a prestrained PDMS substrate | Current of 1.2 nA and voltage of 40 mV with 120 PVDF fibers under 30% strain | 110% | [111] | |

| PVDF on PET substrate | Electrohydrodynamically printing, depositing poled nanofibers onto prestrained PET substrates | Current of 4 nA and voltage of 150 mV with 50 fibres at 2.3 Hz. | 100% | [112] | |

| PVDF on PDMS substrate with liquid metal electrode | helix electrohydrodynamic printing buckled and fractal PVDF fibres | Average maximum current of 20 nA with 120% strain | 200% | [113] | |

| PVDF on PDMS substrate with liquid metal electrode | helix electrohydrodynamic printing self-similar PVDF nanofibers | Current of ∼8 nA under 120% strain in bi-direction stretching | 300% | [114] | |

| P(VDF-TrFE) in between of PDMS-CNT substrate and graphene | Photolithography and etching enabled micro-patterning at the interface of P(VDF-TrFE) and PDMS-CNT | Voltage up to 1.4 V under simultaneous strain and thermal gradient | 30% | [115] | |

| P(VDF-TrFE), Ag coated nylon yarn, CNT sheets |

Electro-spinning P(VDF-TrFE) nanofibres, core-shell structure with inner and outer electrodes | Voltage of 2.6 V and current of 15 nA for a single 10 mm fiber compressed laterally under 160 kPa, output density of 50 μW cm−3 | 5% | [119] | |

| PVDF-TrFE nanofibers | Twisting electrospun yarns into ribbons and overtwisting into coiled structure | Voltage of 20 mV | 740% | [118] | |

| PVDF-rGO- BT piezoelectric fibres | Melt-spinning nanofibres, twisting and coiling fibres into coiled structure | Voltage of 1.3 V and power density of 3 W kg−1 | 100% | [117] | |

| Morphology design | PVDF on PET substrate | Stitching PVDF straps and weaving with elastic tubes | Voltage of 51 V and power of 850 μW by stretching in lateral direction | 6 mm for 9 × 9 cm2 device | [122] |

| PVDF straps | PVDF strap and fabric band twinning around elastic core forming helical structure | Voltage of 20 V at knee position | 158% | [123] | |

| BaTiO3-PVC threads | Weaving threads, Cu wires and cotton threads into fabric with interdigited electrodes | Voltage of 1.9 V and current of 24 nA at bending elbow | Arm bending | [124] | |

| PVDF thread | Band weaving core-shell structured PVDF thread with separated electrodes | Voltage of 3.5 V under axial strain of 0.25%, voltage of up to 8 V under wet conditions | ∼30% | [126] | |

| PVDF tattoo on Tegaderm substrate | Cut-and-paste fabrication PVDF sheets into a filamentary serpentine network | Voltage of 2.2 V with Tegaderm substrate, voltage of 2.74 V without substrate | 112.9% | [9] | |

| PLA-SWCNT composite film | Mechanical punching process for patterning, photolithography-etching-transfer printing for device | Current of 4 nA and voltage of 210 mV under 1% strain | 31% | [127] | |

| PVDF on Kapton substrate | Scalpel cutting for two patterns of centre cutting and edge cutting | Voltage of 299 mV at a strain level 5% for centre cutting pattern with dense spacing |

30% | [131] | |

| PVDF film on PET substrate | Linear cutting PVDF film with FEA-guided pattern and inter-segment electrode design | Voltage of 1.63 V under 10% strain | 10% | [132] | |

| BaTiO3–P(VDF-TrFE) composite with silver electrode | Direct-write 3D printing process with designed cut shape | Voltage of 6 V under 60 N compression force and 5 Hz for T-joint-cut kirigami structure | 300% | [110] | |

| Elastic matrix | PMN-PT/CNT/PVDF | Mixing, magnetic stirring, and heating | Voltage 4 V and current 30 nA for 30 vol%PMN-PT/CNT/PVDF composite, device size 1.5 cm × 1.5 cm | 6% | [134] |

| BaTiO3/PDMS composite with Ag NWs as electrode | Spin coating and curing | Voltage of 105 V, current density of 6.5 μA cm−2 and power density of 102 μW cm−2 for 5% filler content under 40 N periodic compression | 60% | [6] | |

| PZT/PDMS composite | Bath sonicating and curing |

d31 of 30 pC N−1 at 25% strain for 38 vol% PZT (20 μm particle size)/PDMS (Mw = 139 kg mol−1) |

254 ± 136% (breakage strain) | [138] | |

| Pb(Mg1/3Nb2/3)O3–PbTiO3 microparticles, CNTs, silicone rubber matrix, and very long Ag NW electrodes | Magnetic stirring, curing, and vacuum suction method to transfer Ag NWs electrode | Voltage of 4 V and current of 500 nA under 200% stretching motion | 200% | [77] | |

| PZT, Ag-coated glass microspheres, silicone rubber matrix. | Shear dispersion method for uniformly dispersed fillers in silicone rubber matrix | Voltage of 20 V and current of 0.55 μA with dimension of 5 cm * 4 cm under 50% strain and 0.7 Hz frequency | 100% | [139] | |

| PZT powders in rubber matrix | Mixing technology for uniformly dispersed high-content filler | Power density of 81.25 μW cm−3 under 30% strain | 30% | [140] | |

| Amino-functionalised boron nitride nanosheets/PVDF nanofibre membranes | Electrospinning and ultrasonic stirring | Voltage of 0.9 V and current of 0.85 μA for 1.5 wt% filler content | 110% | [79] | |

| 3D PZT microfoam/PDMS | PU foam template and sintering for 3D PZT microfoam, filled with PDMS | Voltage of 60 V under a tensile strain of 15% after 5000 cycles | 15% | [169] | |

| Stretchable interconnection | Bulk PZT arrays with serpentine structured Cu interconnections on PI substrate | electron beam evaporation, photolithography and etching for patterning electrode, low-temperature solder paste for connection | resonant frequency of 356.6 KHz | 25% in binary directions | [170] |

| PZT plate with fractal serpentine Cu interconnection | Reflow soldering for bonding, low-melting point solder paste, 3D printing | Response voltage of 4256 mV with excitation voltage of 18000 mV with 5-mm transmission distance | 20% | [171] |

4. Self-healing

The fatigue fracture of flexible piezoelectric materials induced by cyclic mechanical loading and unloading needs to be avoided to prevent premature device failure. It is thus desirable for piezoelectric devices to be self-healing, which serves as another beneficial secondary function to boost the durability of piezoelectric energy harvesters. Current studies on self-healing piezoelectrics are still in their infancy. Self-healing property can be found in piezoelectric composites [177,178], and piezoelectric molecular crystals [179].

For piezoelectric composites, their self-healing capacity is contributed by polymer matrices, including ionomers and elastomers. Ionomers are a group of polymers with ionic functional groups attached to the polymer backbone [180]. They have been reported to be self-healing, initiated by mild thermal treatments [181]. The self-healing of ionomers relies on the elasticity contributed by the attraction of ionic blocks, i.e., cross-linked plastics. When a fractured ionomer is heated, this elasticity can result in large-scale elongation at the fracture region to heal/close the crack, realising the self-healing function [180]. As the matrix of piezoelectric composites, ionomers are also flexible, mechanically robust, and possess good adhesion to ceramic piezoelectric fillers. James et al. [177] incorporated PZT powders into a Zn ionomer and reported excellent fatigue resistance at strain levels of 4%. For high strains of 6% and 8%, the loss of piezoelectric charge coefficient d33 due to fracture occurrence can be partially recovered under a thermal treatment at 70 °C for 40 min (roughly 92% and 73% at 6% and 8% strains, respectively).

Elastomers are another type of self-healing matrices of piezoelectric composites. Compared with the above ionomers, elastomers may self-heal without external stimulus at room temperature. The self-healing property of various elastomers stems from different mechanisms depending on their chemical structures and polymerisation processes. Yang et al. [178] reported a self-healing PDMS-4,4′-methylene bis phenyl urea (MPU)x-isofordone biuret (IU)1-x supramolecular elastomer as the matrix of piezoelectric PZT particles. Its self-healing property stems from a dynamic hydrogen bond network composed of alternating strong and weak hydrogen bonds, as shown in Fig. 6(a). The strong hydrogen bonding from MPU can provide a highly tensile property to improve the elasticity of the elastomer, while the weak hydrogen bonding from IU contributes to the self-healing of fractures at room temperature. By repeatably cutting the device, an almost full recovery of the device output was observed. At 70 wt% PZT content, the output voltage and current of the device reached peak values of 3.2 V and 56.1 nA, respectively [178].

Fig. 6.

The mechanisms of self-healing elastomers for piezoelectric composites. Self-healing (a) polydimethylsiloxane (PDMS)-4,4′-methylene bis phenyl urea (MPU)x-isofordone biuret (IU)1-x due to dynamic hydrogen bond network [178], (b) methyl thioglycolate–modified styrene–butadiene–styrene (MGSBS) due to proton interactions [182], and (c) lactate-based piezoelectric elastomer (LBPE) due to reduced crystallinity [183].

Methyl thioglycolate–modified styrene–butadiene–styrene (MGSBS) is another type of self-healing elastomer [182]. Unlike the above hydrogen bonding mechanism, its self-healing behaviour originates from the δ+ protons adjacent to the ester of methyl thioglycolate that electrostatically interact with the δ-aromatic centre of styrene, as shown in Fig. 6(b). MGSBS can withstand the damage of 18 mm cut line and be self-healed after 24 h. By integrating a piezoelectric macrofiber composite with MGSBS, a leaf-shape self-sensing piezoelectric actuator was fabricated with a high bandwidth up to 10 kHz, which is promising to be applied to novel soft robotics.

Self-healing property can also be realised by reducing the crystallinity of elastomers, and a self-healing lactate-based piezoelectric elastomer (LBPE) has been reported using this strategy [183]. As shown by the chemical structure of the elastomer in Fig. 6(c), the reduced crystallinity is attributed to butanediol (BDO) and sebacate (SA) as flexible chains and itaconate (IA) as a cross-linking agent. The reduced crystallinity enables larger lattice distortions and asymmetries and therefore reduced elastic modulus to withstand external forces. Meanwhile, its low glass transition temperature and long linear molecular nature enable self-healing capability from irregular scratches.

The above self-healing capacities are enabled by soft and amorphous polymers as matrices. Lately, self-healing behaviour was also observed in crystals. Bhunia et al. reported a self-healing piezoelectric bipyrazole organic single crystal [179], whose crystal structure is shown in Fig. 7. A 3D hydrogen-bonded network can be found between water and bipyrazole molecules, as well as the N–H···N interactions within the packing of bipyrazole molecules. This hydrogen-bonded network contains dispersive interactions, leading to highly elastic deformations at fractures. Meanwhile, breaking the polar molecular arrays generates opposite electrical charges on the fracture surfaces due to the formation of molecular dipoles, which act as a natural restoring force at the fracture area to drive the self-healing process. Although the flexibility of elastic molecular single crystals is inferior to other polymer-based self-healing piezoelectric composites, their high crystallinity is promising to generate high piezoelectric outputs. Moreover, their superior atomic-level self-healing may be favourable for flexible electronics with micro-components based on accurately oriented and highly crystalline piezoelectric materials.

Fig. 7.

Self-healing piezoelectric crystals. Piezoelectric bipyrazole organic crystals with an electrostatically driven self-healing capacity [179]. Reproduced with permission [179]. Copyright 2021, American Association for the Advancement of Science.

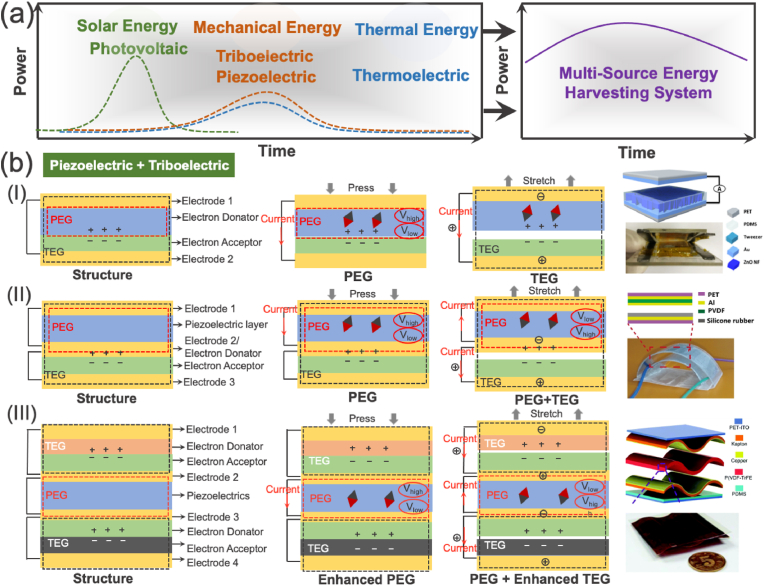

5. Hybrid energy harvesting

It is vital to ensure the continuous and stable energy generation of flexible piezoelectric devices under complex working environments, especially given conditions with inadequate mechanical energy supply. The solution may be obtained by considering the compensation effect of other types of energy harvesting to generate power collectively and possibly synergistically with piezoelectric systems. By integrating other energy harvesters into flexible piezoelectric devices, various energy sources can compensate each other to contribute to a continuous and stable energy output whenever at least one of them is available, as schematically shown in Fig. 8(a). In fact, apart from piezoelectric-responsive mechanical energy, other types of energy sources such as friction-related mechanical energy, thermal energy, and solar energy can also be harvested respectively by triboelectrics [184,185], thermoelectrics [[186], [187], [188]] or pyroelectrics [189,190], and photovoltaics [[191], [192], [193]], to generate electrical power. This section focuses on the fundamental mechanisms and structures to synergistically integrate flexible piezoelectric generators with other energy harvesting systems to develop the secondary function of hybrid energy harvesting.

Fig. 8.

Mechanisms and structures to integrate flexible piezoelectric and triboelectric energy generators. (a) The schematic of continuous energy harvesting by piezoelectrics and triboelectrics (mechanical energy), thermoelectrics and pyroelectrics (thermal energy), and photovoltaics (solar energy). (b) Three typical mechanisms and structures to synergistically integrate flexible piezoelectric and triboelectric generators. The example of Structure (I) is reproduced with permission [199]. Copyright 2018, American Chemical Society. The example of Structure (II) is reproduced with permission [202]. Copyright 2017, Elsevier. The example of Structure (III) is reproduced with permission [203]. Copyright 2017, Royal Society of Chemistry.

5.1. Comprehensive mechanical energy harvesting

Mechanical energy is abundant in our daily life, and the energy induced by pressing, bending, stretching, and twisting can be harvested by piezoelectric materials. In addition, other types of mechanical energy induced by rubbing different materials in contact can also be harvested by triboelectricity. Compared with piezoelectric materials, triboelectric materials do not have to be dielectric and have a much wider range of material choices, more diverse working modes (e.g., contact-separation mode, sliding mode, single-electrode mode, and freestanding mode) [194], and higher energy generation efficiencies under low-frequency motions [185]. By inducing synergistic integration, the hybrid generator can produce outputs beyond the linear summation of the outputs of the individual triboelectric and piezoelectric mechanisms [195], thereby realising a comprehensive mechanical energy harvester for continuous energy generation.

The mechanism of the triboelectric effect lies in the coupling effects of contact-electrification and electrostatic induction, by which certain materials will be charged by contact-electrification charges after contacting a different material, and then being separated [196]. The charges on the contact-separation surface tend to subsequently induce an equal number of opposite charges on the surface away from the contact-separation surface by electrostatic induction. In this way, if the electrostatically induced surfaces of the two materials are connected, triboelectric currents will be driven to flow externally. The triboelectric potential and current can be derived by the following two equations:

| (Eq. 5.1) |

| (Eq. 5.2) |

where and are triboelectric voltage and current, respectively, is the triboelectric charge density, is the vacuum permittivity, and d is the distance between two triboelectric materials.

The outputs of piezoelectricity and triboelectricity are related, i.e., piezoelectric voltage and triboelectric charges, respectively. Their integration can be simply realised by replacing the triboelectric layer of a triboelectric energy generator (TEG) with a piezoelectric material, or a tribo-piezoelectric composite (piezoelectric fillers within a triboelectric matrix) [197]. The typical structure of tribo-piezoelectric hybrid energy generators can be understood as the structure (I) of Fig. 8(b), where electron donator and accepter depict the positively and negatively charged materials of TEG after a contact-separation motion, respectively. When the hybrid device is pressed, the piezoelectric energy generator (PEG) will be firstly triggered, generating a piezoelectric voltage and thus a piezoelectric current flowing from electrode 1 to 2. Meanwhile, the contact-electrification charges appear at the contact interface of TEG. Afterwards, the separation of TEG contact surfaces induced by stretching or rubbing leads to electrostatically induced charges on the surfaces of electrodes 1 and 2. By externally connecting the two electrodes, a triboelectric current can flow from electrode 1 to 2. As a result, by cyclically pressing and stretching the hybrid device, the PEG and the TEG can work collectively to harvest comprehensive mechanical energy. Chowdhury et al. [197] utilised this structure to fabricate a Li-doped ZnO-PDMS-based flexible piezoelectric-triboelectric hybrid energy generator, and realised a continuous electricity generation of 60.0 V potential (compared with 10.1 V from sole Li-doped ZnO-PDMS-based PEG [198]) and 75 μA current without electrical poling. Similarly, He et al. [199] fabricated a ZnO-PDMS-based piezoelectric-triboelectric hybrid energy generator with Structure (I), but the piezoelectric ZnO layer is encapsulated with Au to realise pronounced triboelectrification of Au–PDMS contact, as shown on the right of Structure (I). The hybrid generator can produce a peak output voltage of ∼470 V and a current density of ∼60 μA cm−2, lighting up 180 commercial light-emitting diodes through periodic hand compression. In contrast, the output voltage and current density of sole Zn-PDMS-based PEG is only 130V and 37 μA cm−2 under the same testing condition (i.e., 7 N periodic compression under a frequency of 10 Hz).

It can be noted that stretching processes in structure (I) only output triboelectric currents, while the as-induced piezoelectric voltage is wasted due to the absence of an electrode in PEG. The structure (II) shown in Fig. 8(b) can harvest both triboelectric and piezoelectric currents during stretching processes by adding one electrode (electrode 2 in yellow colour) in between that of the electron donator and the electron acceptor of the above-described structure (I). In this way, PEG and TEG are connected in parallel. When the hybrid device is pressed, piezoelectric current can still be generated as discussed above, flowing from electrode 1 to 2. But when the device is stretched, electrode 2 can both act as an electron donator in TEG leading to a triboelectric current flowing from electrode 2 to 3, and also as an electrode of PEG to output a piezoelectric current from electrode 2 to 1, resulting in an increased overall power output. Jung et al. [200] applied Structure (II) to fabricate a PVDF (piezoelectric)-PTFE (triboelectric) hybrid energy which can light 600 LED bulbs with 0.2 N pressing force. The high output can be attributed to the designed arc-shaped PEG in this hybrid system to induce higher levels of strain and drive PEG to contract. Under the same testing condition and device size (7 × 3 cm2), great enhancements of output voltage and current density were observed from the hybrid device (370 V and 12 μA cm−2) than sole PEG (80 V and 7.62 μA cm−2). Wang et al. [201] tried to optimised the hybrid system from TEG point of view, by which they introduced pillar micro-patterns onto the surface of triboelectric MWCNT- PDMS membrane in order to increase the surface roughness to improve the triboelectric output. The TEG output was reported to be improved from 20.08 V to 30.06 V after patterns introduction. Zhu et al. [202] combined the above two strategies and further optimised the arc structure to a double-arched structure, where both PEG and TEG were designed to be arc-shaped, to develop a piezo-tribo hybrid sensor, as shown on the right of Structure (II). The d-arched sensor with middle shared electrode (the electrode 2 in Structure (II) schematic) can increase sensitivity and deformation range, while micro-patterns on the surface of silicon rubber can benefit TEG with improved output. Consequently, the d-arched hybrid sensor was able to present output voltage of 34.6 V and current of 6.6 μA under the vibration amplitude of 6 mm. Correspondingly, the output of sole PEG was observed to be 24.2 V and 5.3 μA.

The above two structures both require the incorporation of one dielectric piezoelectric material into TEG. Structure (III) in Fig. 8(b) can overcome this restriction by alternatingly connecting PEGs and TEGs, where the top and bottom TEGs are connected with one PEG in the middle. Different with the independent working mechanisms of PEG and TEG in the above two structures, this structure allows a mutual output reinforcement. Specifically, when the hybrid is pressed, the materials adjacent to PEG (highlighted as green) are designed to be an electron acceptor and an electron donator of the top and bottom TEGs, respectively, to possess opposite contact-electrification charges. This, in turn, poses an electrical field to the middle PEG. If the direction of piezoelectric voltage upon pressing is the same as this electrical field, a TEG-reinforced piezoelectric output can be achieved for the PEG. On the other hand, when the hybrid is stretched, the piezoelectric voltage of PEG can impose a high/low electric potential to the adjacent triboelectric layers (highlighted as green), which can strengthen the electrostatic induction of TEG and leading to PEG-enhanced triboelectric currents. Chen et al. [203] employed Structure (III) and adopted a wave-shaped structure to fabricate a piezo-triboelectric hybrid generator based on P(VDF-TrFE) nanofibers, as shown on the right of Structure (III). Such a wavy structure has the advantages of built-in space and self-recovery characteristics. The peak hyrid output and current were observed to be 96 V and 3.8 μA respectively, showing around two times improvement than its initial piezoelectric output. Meanwhile, due to the reinforcement effect of piezoelectric potential towards TEG, as described above, the output of TEG was observed to increase by 16 V.

5.2. Mechanical and thermal energy harvesting

The human body can provide continuous and stable thermal energy to be harvested for power generation. So far, pyroelectrics and thermoelectrics have been reported as two types of thermal energy harvesters. Pyroelectric materials are a group of piezoelectric materials (dielectrics) that can generate a voltage across the material in the presence of a thermal fluctuation. The mechanism of pyroelectricity is similar to piezoelectricity. However, rather than mechanically induced, dipole moments and polarisation are thermally induced, causing atoms to oscillate beyond their neutral positions under a temperature fluctuation [204]. Since all pyroelectric materials are also piezoelectric, their integration can be essentially understood as fabricating “piezoelectric” generators using pyroelectric materials [87,115,[205], [206], [207]]. For example, Lee et al. [115] fabricated a pyro-piezoelectric hybrid generator with a typical sandwich structure, i.e., piezoelectric and pyroelectric P(VDF-TrFE) film in the middle of two stretchable electrodes. By simultaneously applying stretching and heating, increased output of 1.1 V was observed, in contrast to that of 0.7 V and 0.4 V under only stretching and heating conditions, respectively.

Thermoelectric materials can realise the reliable and direct conversion between heat and electricity through the Seebeck effect (power generation) and the Peltier effect (refrigeration) [208]. The mechanism of thermoelectric materials can be understood by the diffusion of charge carriers from the hot end to the cold end in the presence of a temperature difference, which forms an electric voltage between two ends of the thermoelectric material, and vice versa [186,[208], [209], [210]]. The performance of a given thermoelectric material is governed by the dimensionless figure of merit (zT), which is expressed as:

| (Eq. 5.3) |

where S, σ, κ, and T are the Seebeck coefficient, electrical conductivity (σ = nμe, where n, μ, and e are the carrier concentration, carrier mobility, and electron charge, respectively), total thermal conductivity, and absolute temperature, respectively.

The efficiency of a given thermoelectric energy generator, on the other hand, can be evaluated by:

| (Eq. 5.4) |

where , , and are the power-generation efficiency, and the temperatures at the hot and cold ends, respectively; and is the average dimensionless figure of merit (zT) which is calculated by:

| (Eq. 5.5) |

The uncoupled working mechanisms of thermoelectric and piezoelectric materials favour their facile integration for continuous energy generation. Additionally, thermoelectric materials enable precious temperature control, including cooling effect below ambient temperature by controlling external voltage input, which is promising for a medical cooling blanket and may benefit biomedical technologies such as polymerase chain reaction (PCR) [211]. Therefore, integrating thermoelectric energy harvesters with flexible PEGs holds promises to not only realise continuous energy outputs by simultaneously harvesting the thermal and mechanical energy of the human body, but also enable novel applications of PEGs in biomedical settings.

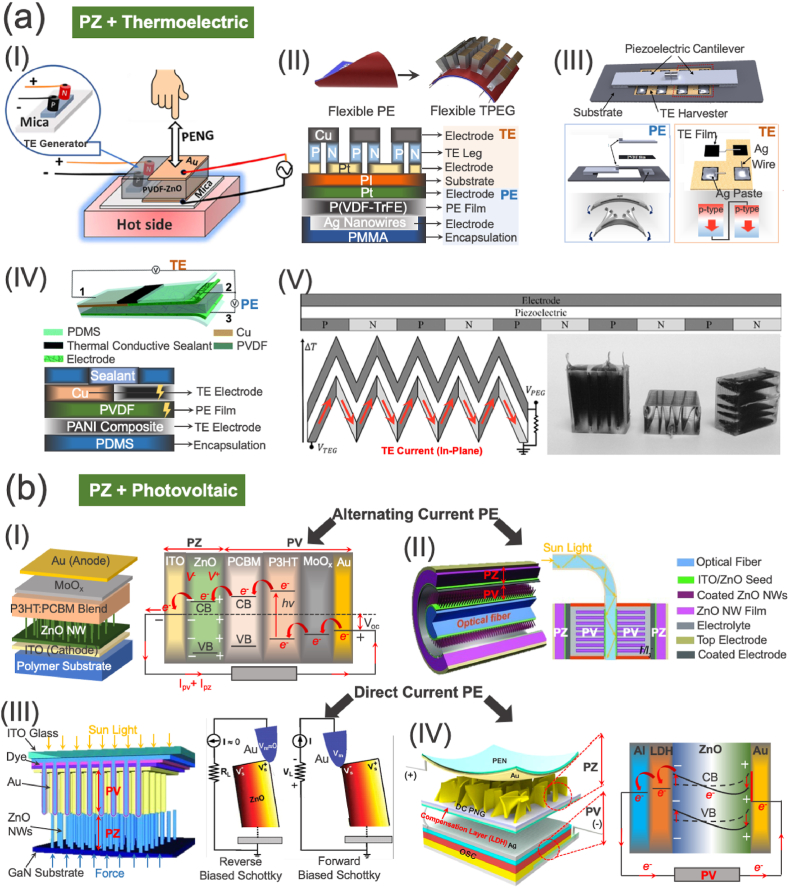

Current high-performance inorganic thermoelectric materials for room-temperature energy harvesting, e.g., Bi2Te3-based thermoelectric materials [212,213], are toxic and too rigid to be integrated with flexible PEGs. To overcome the above issues, a biocompatible encapsulation layer is required, and miniatured thermoelectric blocks are preferred to alleviate their geometrical incompatibility with flexible PEGs. Kumar et al. [214] integrated thermoelectric and piezoelectric generators by embedding miniatured Bi2Te3 and Sb2Te3-based thermoelectric blocks into a piezoelectric PVDF-ZnO encapsulation, as shown in structure (I) in Fig. 9(a). By hand tapping the hybrid generator under a temperature difference of 4 K, the thermoelectric and piezoelectric generators can output power of ∼1.8 nW and ∼1.2 μW, respectively. The low thermoelectric output may be associated with the PVDF-ZnO encapsulation, due to its adverse effect on heat transfer that prevents the maintenance of the necessary temperature difference for thermoelectric power generation.

Fig. 9.

Mechanisms and structures to integrate flexible piezoelectric generators with thermoelectric or photovoltaic generators. (a) Integrating piezoelectric and thermoelectric generators with structures (I) [214], (II) [216], (III) [220], (IV) [223], and (V) [222]. (I) Reproduced with permission [214]. Copyright 2019, Elsevier. (II) Reproduced with permission [216]. Copyright 2021, Elsevier. (III) Reproduced with permission [220]. Copyright 2019, Springer Nature. (IV) Reproduced with permission [223]. Copyright 2019, Royal Society of Chemistry. (V) Reproduced with permission [222]. Copyright 2016, American Institute of Physics. (b) Integrating photovoltaic cells with alternating current (AC)-type piezoelectric generators with structures (I) [224] and (II) [225], and with direct current (DC)-type piezoelectric generators with structures (III) [226] and (IV) [227]. (I) Reproduced with permission [224]. Copyright 2011, Royal Society of Chemistry. (II) Reproduced with permission [225]. Copyright 2012, Wiley-VCH. (III) Reproduced with permission [226]. Copyright 2011, Wiley-VCH. (IV) Reproduced with permission [227]. Copyright 2015, Elsevier.

Optimised structures were reported by Lee et al. [215] and Kim et al. [216] by stacking flexible inorganic thermoelectric generators with PEGs. Their structures can be understood by structure (II) in Fig. 9(a), where miniatured Bi2Te3-based thermoelectric blocks were fabricated on a flexible polyimide (PI) substrate and integrated with a P(VDF-TrFE) film-based PEG underneath [216]. By optimising the surficial properties of thermoelectric and piezoelectric components, a hybrid current of 3.8 μA was generated under a temperature difference of 3 K and periodic bending, compared with that of 1.5 μA contributed by only PEG. However, the flexibility of this structure is still restricted by the rigid thermoelectric generator and the contact between the thermoelectric blocks and flexible substrate.

More flexible thermo-piezoelectric hybrid generators can be achieved by utilising thermoelectric thin films [[217], [218], [219]]. Structure (III) in Fig. 9(a) depicts a novel structure to realise this goal [220]. Basically, two PVDF-based piezoelectric cantilevers are combined with flexible Sb2Te3-PEDOT:PSS thermoelectric paste on a flexible substrate. Without mechanical loadings, the two cantilevers are magnetically attracted by permanent magnets. When a mechanical bending is applied and its force is larger than the magnetic force, the two cantilevers can be separated and rapidly vibrate at their natural frequencies. Meanwhile, the underlying thermoelectric generator can harvest thermal energy without being interfered. The average power densities of piezoelectric and thermoelectric generators were 28.57 and 0.64 μW cm−2 (given a 9.2 K temperature difference), respectively. Although the thermoelectric output is much lower than that of the piezoelectric generator, the thermoelectric energy output was continuous, contributing to an uninterrupted total energy output [220]. The drawback of this structure, however, can be traced in its cantilever design that limits the mechanical energy harvesting of low-frequency motions.

The utilisation of thermoelectric thin films suffers from concerns of poor thermoelectric performances [221] and inferior temperature differences maintained in the out-of-plane direction, which restrict their energy harvesting. To address the above concerns, novel structures were proposed by Montgomery et al. [222] and Zhu et al. [223] to take advantage of the superior in-plane thermoelectric properties of thin films to fabricate thermo-piezoelectric hybrid energy generators. These structures, as shown in structures (IV) and (V) in Fig. 9(a), use thermoelectric materials as the electrodes of PEG. For structure (IV), a three-phase Te-MWCNT/polyaniline (PANI) thermoelectric composite with a relatively good electrical conductivity of 196 S cm−1 and a thermopower of 66.4 mV K−1 was applied as the electrode of PVDF-based PEG [223]. As shown, when the heat was transferred to the top thermoelectric electrode through the black thermal conductive sealant, it flows in a horizontal/in-plane rather than an out-of-plane manner in the material. A temperature difference will thus exist at the two ends of the electrode, generating electricity conducted by copper wires 1 and 2 attached by silver paste. If vertical mechanical stress is further applied to the device, PVDF film can output piezoelectric power through copper wires 2 and 3, realising the hybrid energy harvesting of thermal and mechanical energy. By approaching a warm heat block of 37.8 °C to the hybrid device, a thermoelectric voltage of 0.45 mV was generated to compensate the piezoelectric voltage of 1.35 V under a periodic compression force of 5 N [223].

The scale of thermoelectric thin films in Structure (IV) is constrained as an electrode, which directly causes its low output. Structure (V) is suitable for applications requiring a larger usage of thermoelectric thin films, where zigzag structured thermoelectric electrode has been designed [222]. One end of the thermoelectric thin film (CNT-PVDF) is connected in series to the piezoelectric film (PVDF) as the bottom electrode of the top PEG, while the other end is connected to the bottom of the hybrid device, forming the zigzag design. The temperature difference is forced along the in-plane direction to achieve a larger thermoelectric output. The device was observed to generate additional ∼3 mV thermoelectric voltage under a 10 K temperature difference on top of piezoelectric voltage. The hybrid system can generate 5.3 times higher voltage (28 μV Pa−1) than a conventional flat structure under an out-of-plane pressing condition and a 10 °C temperature difference [222].

5.3. Mechanical and solar energy harvesting

The sun is the most abundant renewable energy in the world; the solar energy which the earth receives in an hour is more than the energy consumed in a year [228]. Photovoltaic cells have long found success in harvesting abundant solar energy with relatively higher energy efficiency than other energy harvesting systems [[229], [230], [231], [232]], and their applications in biomedical settings have been reported to produce substantial energy to power most wearable biomedical devices [233]. In terms of biomedical implants, biocompatible and even bioresorbable photovoltaic cells [234] can serve as implantable subdermal energy generators producing higher output than PEG (100–200 μW mm−2 than PEG's 0.4–30 μW mm−2 [235]). Therefore, integrating photovoltaic materials with PEG is promising to compensate for the low and unstable power output from solely PEG, while PEG can compensate for solar cell's energy shortage under poorly light-accessible conditions (e.g., rainy days or dark environments) by harvesting mechanical energy, which collectively contribute to the continuous energy output of hybrid energy harvester.