Abstract

Paper recycling is a viable option for wastepaper management. This study assessed the suitability of recycled papers as a food packaging material. Permanence and durability of three different recycled papers; R1:150 GSM, R2:120 GSM, and R3:100 GSM with aging were evaluated using standard methods. Eventhough opacity increased with aging grammage, burst strength, tensile strength, pH, brightness, and whiteness decreased. Recycled papers failed water absorptiveness test even before aging. Presence of heavy metals in recycled papers were compared with food packaging standards and migration of heavy metals from the packaging to different food types was assessed. Presence of Cu, Zn, Mn, Cr, Cd and Pb were below EC and EPA standards but only Pb and Cd exceeded the EU standard. Migration of Cu, Zn, Mn and Cr were within EPA, EU and EC standards except Pb and Cd with respect to EC standard. Highest migration is associated with foods contain more fatty acids; fast food, sausages and pizza.

Keywords: Food packaging, Durability, Permanence, Recycled papers, Heavy metals, Food packaging standards

Food packaging; Durability; Permanence; Recycled papers; Heavy metals; Food packaging standards.

1. Introduction

According to global statistics, 2.01 billion tons of Municipal Solid Waste (MSW) is generated annually with an average per capita waste generation of 0.74 kilograms (kg). Per capita waste generation is expected to increase by 19% in high income countries while 40% or more in low- and middle income countries. Waste accumulation is estimated to be increased up to 3.40 billion tons by 2050 (The World Bank records IBRD.IDA, 2022). Therefore, solid waste management has become an alarming problem in both the developed and developing world (Abdel and Mansour, 2018). Different nations in the world face many social, environmental, and economic problems due to solid waste generation. Major components of MSW are food, plastic, metal, paper and paper board, rubber, leather, textile, and hazardous compounds. Among MSW, paper and paper board accumulation is around 20%.

The recycled paper market in the world runs back to 30 years. Certain countries show promising recycling rates for paper and paper board waste as illustrated in Table 1. In the U.S., 46 million tons (68.2%) of paper and paper board are subjected to recycling compared to other components in MSW. Among the European Union countries in 2017, Austria, Belgium, Germany, and Finland reached 83.5%, 92.9%, 87.1%, and 100% of recycling of paper and cardboard (Tiseo, 2022). When it comes to Asia, China had reached 46.5% (54.93 Mmt) in 2020 (Statista Research Department).

Table 1.

Percentage of waste paper and board accumulation in different countries in the world.

| Country | Year | % of paper and paper board waste in MSW | Reference |

|---|---|---|---|

| Austria | 2004 | 22 | Karak et al. (2012) |

| France | 2005 | 23.3 | Bayard et al. (2010) |

| Germany | 2005 | 24 | Muhle et al. (2010) |

| United Kingdom | 2018 | 18 | Idumah and Nwuzor (2019) |

| Lithuania | 2010 | 15 | Miliute and Staniskis (2010) |

| Indonesia | 2009 | 10 | Shekdar (2009) |

| Malaysia | 2009 | 16 | Periathamby et al. (2009) |

| Philippines | 2009 | 19.5 | Shekdar (2009) |

| Singapore | 2008 | 21.2 | NEA Singapore (2009) |

| Thailand | 2007 | 20.7 | Chaya and Gheewala (2007) |

| Japan | 2015 | 46 | Niyati (2015) |

| India | 2019 | 13.8 | Sharma and Jain (2019) |

| Africa | 2019 | 9 | Solid Waste Management Data Book, Africa (2019) |

| United States | 2018 | 23.1 | Environmental Protection Agency, 2018 |

| Sri Lanka | 2019 | 7 | Central Environmental Authority |

Recycled papers can be made of a mixture of post-consumer papers, rejected papers from paper mills, pre consumer papers such as trims, and overs from printers that may contain virgin fibers. At present, 90% of the paper pulp is made of wood. Paper production is responsible for about 35% of clear-felled trees which is 1.2% of the earth's total commercial output (Kapse et al., 2018). One ton of newspaper recycling will save one ton of wood, while printing or copying paper recycling will result in saving more than 2 tons of wood (Soni et al., 2020). Also, virgin paper can be recycled up to 5 to 7 times (Soni et al., 2020). According to the EPA 2018 estimates, recycled paper production consumes 50% less water and reduces air pollution by 74% compared to virgin paper production. Therefore, it is very important to manage waste papers to conserve the environment to minimize obliteration and pollution due to the paper industry (Scott, 2019). However, poor fiber quality of recycled papers may result in problematic situations in different end uses of papers including printing, writing, and packing. Therefore, it is very important to evaluate the paper quality parameters of recycled papers to guarantee the satisfaction of different end users.

Most importantly, the permanence and durability of recycled papers should be measured to understand paper quality (Scott, 2019). Permanence is the ability to resist changes when not in use while durability is the ability to resist the changes when in use (Tumosa, 2008). Permanence is a measure of the chemical stability of papers and durability is a measure of the physical and mechanical stability of papers (Caulfield and Gunderson, 1988). Permanence and durability of recycled papers highly depend on the types of post consumer fibers. Papers that are made of different types of post consumer fibers will not age at a similar rate (Scott, 2019).

Low cost, light weight, availability, printability, and strength make paper and paper board products popular as food packaging materials around the world (Elmas and Cinar, 2018). However, the limitation of using paper and paper board as a food packaging material is the permeability to moisture which may facilitate the migration of unintended compounds from paper and board packaging into food items (Alamri et al., 2021). The migration of unintended chemicals from food packaging is affected by different parameters such as comparability and the nature of food, contact time, temperature, contacting layer of food packaging, food packaging compounds, food simulating liquids, and heating and storage conditions (Bhunia et al., 2013). It is necessary to avoid toxic materials and contaminants migration from paper or paper board food packaging or wrappings to food items as this may adversely influence consumer health (Elmas and Cinar, 2018; Biedermann et al.,2013). Paper manufacturing sector uses a variety of chemicals either directly in paper and pulp production or in the conversion processes which may lead recycled papers to be contaminated with certain chemical substances (Pivnenko et al., 2015). Papers with secondary fibers may contain additives, dyes, adhesive chemicals, pigments, and starch as such chemicals are added to color adjustment and improve opacity (Conti, 2007). Higher repetition of recycling will result in low-quality paper fractions leading to the accumulation of unintended chemical substances in recycled papers (Pivnenko et al., 2015). Additives such as zinc oxide and zinc sulfide are used as filling and coating materials and to increase the cohesive strength of paper and paper board production, cadmium metal had been used (Elmas and Cinar, 2018). In addition, calcium carbonate is added as a filler to avoid quality degradation with aging by adjusting pH. Therefore, zinc, lead, chromium, cadmium, etc. can be expected as contaminants in papers (Bilitewski et al., 2012). Heavy metals are considered as an important quality index for paper packaging (Conti, 2007). According to the European Council Standard, it is required to test paper food packaging for various contaminants such as aromatic amines, benzophenone, polyaromatic hydrocarbons, plasticizers, and heavy metals (Nerín and Asensio, 2007). Heavy metals are considered a primary parameter in rating paper packaging (Conti, 2007). European Union (EU) and United State (US) regulations on heavy metal limitations in food packaging provide guidelines to implement different packaging laws around the world (Conti, 2007). The Materials and Articles in Contact with Food Regulations (2012) implemented several EU regulations to avoid migration of toxic contaminants from food packaging. According to the Framework Regulation European council (EC) No. 1935/2004, it is required to label a food packaging with the logo to indicate that food contact materials are safer for human health.

The main objectives of this study are to evaluate the paper quality of three different types of recycled papers by assessing grammage, burst strength, tensile strength, water absorptiveness, pH, brightness, whiteness, and opacity, assess the presence of heavy metals; copper [Cu], manganese [Mn], chromium [Cr], nickel [Ni], zinc [Zn], cadmium [Cd], lead [Pb], in three types of recycled papers that can be used for food packaging and compare the presence of heavy metal contents with three different paper packaging standards; Environmental Protection Agency (EPA) standard/2012, EU standard and EC standard.

2. Materials and methodology

2.1. Sample collection and preparation

To evaluate the quality of recycled papers for food packaging, three types of recycled papers; brown kraft papers (R1; 150 GSM), yellow kraft papers (R2; 100 GSM), and white papers (R3; 120 GSM), were selected. These recycled papers were made from papers subjected to one prior recycling. R1, R2, and R3 were evaluated for grammage, burst strength, tensile strength, water absorptiveness, pH, brightness, whiteness, and opacity. Following TAPPI T 400 standard, the 80 representative sample papers from each type was collected. TAPPI T 409 was followed in determining the machine direction of paper and paperboard, and TAPPI T 402 standard was followed in preconditioning, conditioning, and testing of paper and paper products.

Temporal variations of recycled papers were assessed to evaluate the durability and the permanence. ASTM D 4714 standard was followed for accelerated aging of papers (Kullman, 2009). The Perfect Arrhenius Relationship method was adopted for accelerated aging. The 80 papers from each type was placed in an accelerated aging chamber and the temperature increased from an ambient air Temperature of 27.5 °C to an experimental Temperature of 90 °C at the RH of 50%. It was assumed that the aging will be doubled in each 10 °C increment in Temperature. Ten sample papers from each paper type were removed as interval batches from the aging chamber at days 0, 3, 7, 10, 14, 21, and 28 equivalent to 0, 384 days, 2.5 yrs, 3.5 yrs, 4.9 yrs, 7.4 yrs and 9.8 yrs of natural aging time respectively. Day 0 was assumed as the date of initiation of the experiment with zero aging.

2.2. Paper quality assessment

Each paper quality parameter test was carried out according to the standard test methods of Technical Association of the Pulp and Paper Industry (TAPPI), American Society for Testing and Materials (ASTM), or International Organization for Standardization (ISO). For each parameter, ten replicates were tested from each accelerated aging interval.

2.2.1. Tensile strength

The tensile strength of recycled papers was estimated using ISO 2470:1999 method as in Eq. (1) (ISO 2470:1999). Tensile strength (kNm) was estimated by dividing the maximum load by the width of the paper specimen which is 15 mm. As fiber orientation in the paper is unequal between machine direction (MD) and cross direction (CD), tensile strength should be measured in both directions. Usually, MD is greater than the CD. MD is the direction of the paper web which is running on the machine. CD means the direction perpendicular to the paper sheet that is running on the machine during papermaking.

| (1) |

F = tensile force (kN)

W = standard width of paper (15 mm)

S = tensile strength (kNm)

2.2.2. Burst strength

Burst strength was tested using TAPPIT 403 method. The test specimen was held between the annular clamps of a burst strength testing machine and subjected to an increasing hydro statistic pressure using a rubber diaphragm until the test specimen ruptures. The maximum pressure reading at the rupture point is the burst strength which is measured in Kilo Pascals (kPa). Procedure was repeated for both sides of specimen papers.

2.2.3. Water absorptiveness

Water absorptiveness of the recycled papers was measured according to the Cobb60 Method (ISO 535:2014). Samples were collected according to the ISO 186 and conditioned following ISO 187 method. Samples were cut into 100 cm2 pieces and weighted to the nearest 0.01 g using an electronic balance. One sample was placed on the dry rubber mat at the metallic plate of the ISO 535 Cobb tester that was used to measure the water absorptiveness and laid a weighed specimen on it. After wiping the steel ring dry, placed it upon the specimen and fastened it firmly sufficient in the vicinity with the crossbar to save any leakages in the ring and specimens. Deionized water (100.00 ml) was poured into the ring as quickly as possible thus giving ahead of 1.0 ± 0.1cm. A standard test time of 60S was maintained for a single sheet. Cobb60, 45±1S at excess water was removed and 60±1S blotting was carried out. The sample was folded with the wet area inside and immediately reweighted near to 0.01g. The dry weight of the sample was subtracted from its wet weight. The expression of results was dependent on the time of the test. Water absorptiveness was calculated using Eq. (2) (ISO 535:2014).

| (2) |

Where;

A = water absorptiveness (g/m2)

m1 = dry mass in grams of test paper (g)

m2 = wet mass in grams of test paper (g)

F = test area (100 cm2)

2.2.4. Opacity, brightness, whiteness

A colorimeter was used to test opacity, brightness, and whiteness (ISO 2471:1998). Color tech software was used in the machine to test all the optical parameters. Reflectance factor, luminous reflectance factor, single-sheet luminous reflectance factor, and intrinsic luminous reflectance factor were used as the basis for the software. Opacity was considered as the ratio between the single-sheet luminous reflectance factor and intrinsic luminous reflectance factor of the same paper type. Brightness was recorded as a diffuse blue reflectance factor (ISO 2470). Ten sample papers from one paper type were placed on each other to make a test specimen. The test specimen was placed on the test piece pad of the colorimeter and measured at ten non-overlapping regular intervals in a raw at right angles to the machine direction of the paper. The test was repeated for each paper type. Average values of opacity, brightness, and whiteness were calculated at the end of the test.

2.2.5. pH

According to TAPPI T 428 method, samples were cut into 5–10 mm square pieces and kept separately. From each sample, 5.00 g was weighted using an electric balance. Samples were transferred into an Erlenmeyer flask of 500.00 ml and 250.00 ml of boiling water was added. Then it was attached to the condenser. The flask was placed on a hot plate and boiled gently at 60 ± 5 min with occasional shaking. At the end of the period, the sample was transferred into the Büchner funnel and suction was applied to complete the filtration and cooled the extract rapidly in the rubber stopped Erlenmeyer flask. As soon as the extract reached the room temperature, it was transferred into a beaker and tested using a pH meter while transferring N2 free air through the sample.

2.2.6. Grammage

According to the TAPPI T 400 standard method, the testing samples were prepared. The samples were cut into 100.00 cm2 pieces by using a cutting trim. Each sample was weighted by using a scientific digital balance. Mass per unit area was calculated using Eq. (3) (TAPPI T 400). Grammage is resulted in grams per square meter (g/m2).

| (3) |

Where;

G = grammage (g/m2)

M = mass of the test specimen (g)

A = area of the test specimen (m2)

2.3. Heavy metal assessment of recycled papers

In heavy metal analysis, the oven-dry method (ISO 287, 2009) was used to remove moisture content in sample papers. Samples were kept in an oven at 105 °C for 4h. Oven dry weights of samples were taken using a scientific digital balance (±0.01g). 1.00g of each oven-dried wastepaper sample was cut into small pieces with polyethylene gloves in hands (Elmas and Cinar, 2018). Five replicates from each sample type were tested. Strong oxidizing acids (nitric acid [HNO3], hydrogen peroxide [H2O2], hydrogen chloride [HCl]) were used to digest waste papers to dissolve heavy metals from the heaviest metal pollutants (Mantylahti and Laakso, 2002). The prepared samples were kept in 12.00 ml of concentrated HNO3, 4.00 ml of concentrated H2O2, and 2.00 ml of concentrated HCl at 50 °C hot water bath for 3h to extract heavy metal components into the solution (Elmas and Cinar, 2018). Then samples were kept at room temperature for 24h to complete the digestion. Each sample was filtered using 47μm filter paper to remove solid matters from the solution. Heavy metal measurements for Cu, Mn, Zn, Cr, Ni, Cd, and Pb were carried out using an Atomic absorption spectrometry (AAS) (Turek et al., 2019).

Five different food types; fast food, pizza, sausages, candy, and chocolates were selected to test the heavy metal migration. Selected food types (500.00g) were wrapped with 2.00m2 of the three different types of recycled papers separately and kept for 72h in normal laboratory conditions at T = 27 °C. Five replicates from each food type were tested for each paper type. After that, 2.00g from each food type was cut into pieces and kept in 100.00 ml of a 3% (v/v) metal-free solution of acetic acid for 24 h at 40 °C. At the end of this treatment, the contact liquid solution was analyzed by flame AAS to determine the heavy metals (Duran et al., 2013; Conti, 1997).

Analyzed heavy metal concentrations were compared with three international standards; food packaging standards by EPA, USA (2012), Article 5(1) of Regulation (EC) No 1935/2004, Commission Metal Content Directive 2002/72/EC (August 2002) and European Committee for Food Contact Materials and Articles (CD-P-MCA) provides standard for food packaging materials.

2.4. Statistical analysis

2.4.1. Paper quality

All the parameters observed for the three types of recycled papers were subjected to MANOVA to test whether there is any statistical difference between paper types and accelerated aging days. Day 0 results were subjected to cluster analysis to see the similarity between the three types of recycled papers followed by factor analysis to identify the most contributing parameters for clustering.

2.4.2. Heavy metals analysis in different paper types

Copper (Cu), manganese (Mn), zinc (Zn), chromium (Cr), cadmium (Cd), and lead (Pb) levels found in recycled papers were compared with EPA standard (2012), EC standard, and EU standard using one-sample t-test. Heavy metal migration test results were subjected to MANOVA analysis to check the significant difference in heavy metal concentrations concerning food type and recycled paper type. All the statistical analyses were done using MINITAB 17 version.

3. Results and discussion

3.1. Paper quality testing: mechanical, chemical, and optical parameters

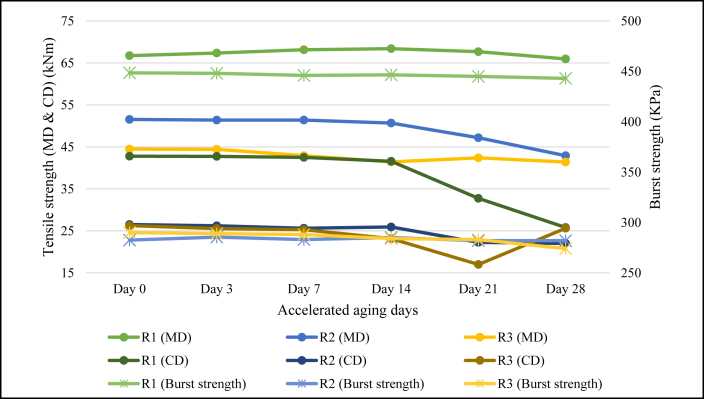

Recycled papers showed significantly different Machine Direction (MD) and Cross Direction (CD) tensile strength values of three different recycled papers with accelerated aging. The highest tensile strength value was recorded in R1 (MD: 66.73 kNm; CD:42.78kNm) while the lowest tensile strength value was recorded in R3 (MD: 44.49 kNm; CD:26.26 kNm). Figure 1 shows the temporal variations of the tensile strength (MD & CD) and burst strength along with accelerated aging in three types of recycled papers. Mechanical and energy properties of papers specify the chemistry, morphology, and shape of the character fiber as well as the fiber network structure of the paper. Those properties additionally imitate chemical properties that affect the paper to fail its durability or permanence with aging. Strength properties can oblige as signs of the permanence of papers (Caulfield and Gunderson, 1988).

Figure 1.

Variation of tensile strength (MD & CD) and burst strength along with accelerated aging (T = 90 °C RH = 50%) in recycled papers.

Consistent with (Kullman, 2009), papers made of recycled papers no longer display any considerable distinction between MD and CD tensile strength values with accelerated aging days. This could be due to the variations and the quality degradation of the recycled fibers over the virgin fibers. While papers are recycled, in the very first cycle of recycling, the resulted fibers' tensile strength values alternate by almost 50% from the virgin papers (Brancato, 2008). As tensile strength is one of the great signs of fiber strength, fiber length, and fiber bonding, tensile strength entirely defines the structure of the paper and also the properties of its individual fibers (Kullman, 2009). Usually, papers that are made of long fibers have higher tensile power values as compared to short fibers (Caulfield and Gunderson, 1988). Therefore, the R1 recycled papers with the highest tensile strength value were made using long fibers compared to R2 and R3 recycled papers. To maximize the paper-making properties, paper and pulp enterprises tend to carry out mechanical treatments such as pulp refining (Bajpai, 2018). Utilization of the pulp refining in paper production resulted in the reduction of tensile strength. This could happen due to the mechanical fragmentation of long fibers in recycled papers into short fibers (Soltani et al., 2013). Burst strength of recycled papers showed a significant difference along with aging. R1 paper type showed the highest burst strength value (448.50 kPa) while R2 (282 kPa) and R3 (290 kPa) paper types showed the values in the range of 280–300 kPa. However, burst strength values of all the three types of papers decreased with aging. Unlike tensile strength, burst strength is strained equally in both MD and CD directions. However, due to the nature of the rupture pattern of the papers, there might be different burst strength values between MD and CD (Caulfield and Gunderson, 1988). Similar findings were obtained by the study conducted by Caulfield, and Gunderson (1988) and Karlsson (2010). Strength property changes of papers may due to the reduction of wet flexibility and the changes in bonding properties of fibers which is called hornification. Irreversible hydrogen bonding is the most applicable method to overcome the hornification process of fibers (Miao et al., 2018). Figure 2 shows the variations of the pH values along with accelerated aging (T = 90 °C RH = 50%) in recycled papers.

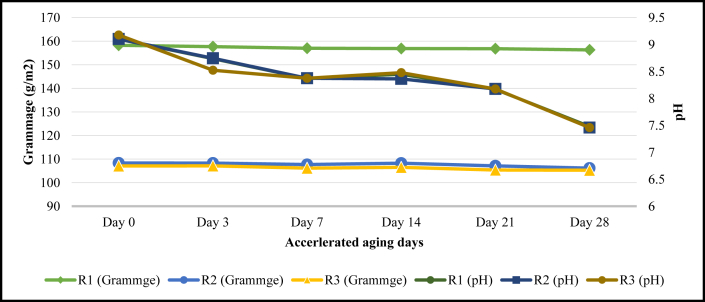

Figure 2.

Variation of grammage and pH values along with accelerated aging (T = 90 °C RH = 50%) in recycled papers.

Assessing of the pH value with aging will help to discover the deterioration within the quality of the paper fiber whilst the paper becomes low in acidic fiber (Kullman, 2009). R1, R2 and R3 varieties of recycled papers displayed high pH values ranging from 9.1 to 9.10 indicating the alkaline state of the papers. The variation of pH pattern varied from alkaline to neutral with aging this could be due to the addition of calcium carbonate as a filler in paper manufacturing (Kullman, 2009).

All the types of recycled papers failed the water absorptiveness test (Cobb60) even before aging. This has happened as recycling cause less accessibility of fibers to hydroxyl functional groups (Soltani et al., 2013). If any paper material fails Cobb60 proves the unsuitability of the material neither for printing and writing nor food packaging. In food packaging, moisture absorption will spoil the food (ISO 535:2014). Failing Cobb60 test causes problematic situations due to moisture reabsorption (Scribner and Carr, 1935; Noriyuki and Tatsuo, 2013). Also, in recycled papers, not adding enough filling materials may result in poor performance in the water absorptiveness test (Kullman, 2009). According to the several research studies that have been carried out to increase the water resistance of paper products, anionic resins as dimethyl dihydroxyethylene urea (DMDHEU) and Topsize RD44 were used in the paper and pulp industry as a sizing agent. Chemicals which are more resistant to water improve the water-resistant capacity of papers ((Tutus et al., 2016).

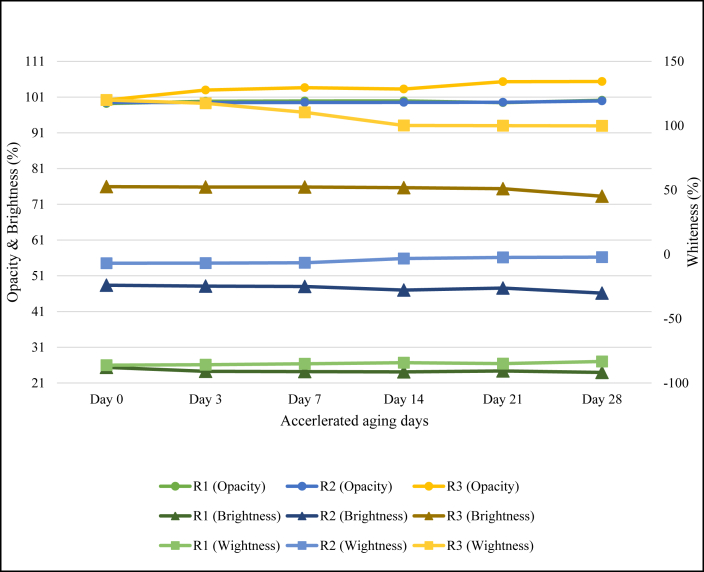

Opacity is the capability of a paper to cover or mask the color or object within the lower back of it. High opacity allows one to read the front facet of the page without being distracted with the aid of print photographs on the opposite facet of that page. Consequently, opacity may be identified as a completely vital parameter in checking the suitability of papers for printing. For an instance, bulky sheets have higher opacity than dense sheets. However, bulky sheets are less robust than dense sheets as bonding within the fibers is poorer in bulky sheets (Bajpai, 2018). Opacity values of recycled papers improved with aging from 98% to 100%. Consistent with Yousaf et al. (2016), opacity value extended with the most effective recycling and remained consistent in the course of further recycling. According to (Kullman, 2009), opacity values of recycled papers extended with aging. Current findings are also inline with (Kullman, 2009) findings. R1, R2, and R3 papers showed an increasing trend of opacity values with aging. This difference resulted due to the fiber-matrix variations in papers take place in specific manufacturing methods adopted by different manufacturers (Kullman, 2009). Following Figure 3 shows the temporal variations of opacity, brightness and whiteness with accelerated aging (T = 90 °C RH = 50%) in recycled papers.

Figure 3.

Variation of opacity, brightness and whiteness with accelerated aging (T = 90 °C RH = 50%) in recycled papers.

The brightness of recycled papers can be decreased due to aging processes (Borch et al., 2001). According to the results of this study, the highest brightness value was recorded in R3; 75.94% while the lowest in R1; 25.37%. When it comes to the whiteness, the highest was recorded in R3; 119.94, and the lowest was recorded in R1: 86.16%.

Altogether, grammage, burst strength, tensile strength, water absorptiveness, pH, brightness whiteness, and opacity showed a significant difference among accelerated aging days (P < 0.05; MANOVA). There is a significant difference between paper types before aging with respect to all the parameters tested (P < 0.05; MANOVA). The interaction between paper types and accelerated aging days is statistically significant for all the parameters (P < 0.05; MANOVA). Therefore, the paper quality depends on aging days and the paper type. Due to significant differences between aging days and paper types, cluster analysis was carried out to check the similarity between the three different recycled paper types. Two clusters resulted. R1 and R2 paper types clustered together while leaving R3 in a different cluster at 99.27% similarity.

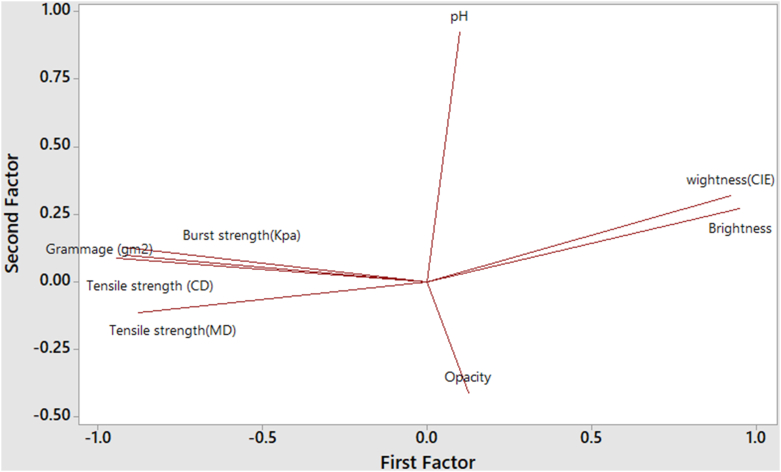

According to the analysis of the rotated loading plot, mechanical parameters (grammage, tensile strength MD & CD, burst strength) are loaded into one dimension, chemical parameter (pH) is loaded into another dimension and optical parameters (opacity, brightness, whiteness) of three different recycled papers are loaded into the third dimension. Following Figure 4 illustrate the Rotated Loading plot of the Grammage, Tensile strength (CD & MD), Burst strength, Opacity, Brightness, Whiteness, and pH.

Figure 4.

Rotated Loading plot of the Grammage, Tensile strength (CD & MD), Burst strength, Opacity, Brightness, Whiteness, and pH.

According to the factor analysis with respect to rotated loading, grammage (0.945), burst strength (0.926) and brightness (0.949) had large positive loadings in factor 1, therefore, this factor is described by the strength and optical properties of the paper. pH has a large positive loading (0.924) in factor 2 thereby this factor is described by the pH. Factor 3 is described by the opacity with a large positive loading (0.901). All the three factors explained 0.946% of the variance of the data. Figure 4 shows the rotated loading plot of all the parameters tested in this study. Due to the results of the statistical analysis, mechanical parameters (grammage and burst strength) and optical parameters (brightness and opacity) directly affect the paper quality.

3.2. Heavy metal existence and migration to food

The presence of heavy metals; copper (Cu), manganese (Mn), zinc (Zn), chromium (Cr), nickel (Ni), cadmium (Cd), and lead (Pb) in three different recycled papers was evaluated. There was no any Ni concentrations exist in three different recycled papers. The variation of mean ± Standard Error of the Mean (SEM) of different heavy metals presented in each paper type and safety limit values set by different standards are listed in Table 2.

Table 2.

Variation of heavy metal concentrations among three different types of recycled papers (mg/Kg).

| Heavy metal | EPA, 2012 paper-based food packaging regulations | Metal Content Directive 2002/72/EC limited values | Council of Europe specific release limits (SRLs) for food packaging | R1 (Mean ± SEM) | R2 (Mean ± SEM) | R3 (Mean ± SEM) |

|---|---|---|---|---|---|---|

| Cu | 25 | 25 | 4 | 0.0095 ± 0.0105b | 1.940 ± 0.0195a | 0.976 ± 0.018a |

| Mn | DC | DC | 1.8 | 0.0134 ± 0.0017 | 0.0156 ± 0.0006 | 0.0150 ± 0.0013 |

| Zn | 50 | 100 | 5 | 0.4573 ± 0.0179 | 0.4520 ± 0.03 | 0.4521 ± 0.004 |

| Cr | 3.05 | 1 | 0.250 | 0.1963 ± 0.026 | 0.0264 ± 0.0019 | 0.1463 ± 0.002 |

| Cd | 0.5 | 1 | 0.005 | 0.0185 ± 0.0009 | 0.0253 ± 0.0003 | 0.0249 ± 0.0004 |

| Pb | 3 | 2 | 0.01 | 0.2618 ± 0.017 | 0.1974 ± 0.001 | 0.1255 ± 0.115 |

Note: N = 5, p < 0.05, one-sample t-test, n.d = non detective.

Apart from Pd and Cd concentrations of R1, R2, and R3 which were significantly higher than the EU standard (P < 0.05, one-sample t-test), all the other heavy metal concentrations were significantly lower than the EPA, EU and EC standards. When comparing the amount of heavy metals presence in three different types of recycled papers, Cu, Cr, Pd, and Cd are significantly different among paper types and there is no difference with respect to Zn and Mn.

Heavy metal migration from R1, R2, and R3 types of papers to all the four types of food used was recorded. It is noteworthy to mention that the Pb concentrations migrated from food to R1, R2, and R3 papers arestatistically higher than the EU standard (P < 0.05, one-sample t-test). Migrated concentration values of other heavy metals are within the EPA, EC, and EU standards (Table 3).

Table 3.

Heavy metal migration from food wrappings made out of R1, R2, and R3 recycled papers to different types of food types (3%, v/v, acetic acid) (μg/L).

| Sample type | Cu | Mn | Zn | Cr | Cd | Pd | |

|---|---|---|---|---|---|---|---|

| R1 | Fast food | 0.748 ± 0.025 | 0.0065 ± 0.003 | 0.316 ± 0.006 | 0.135 ± 0.03 | 0.0068 ± 0.002 | 0.073 ± 0.01 |

| Pizza | 0.64 ± 0.005 | 0. 007 ± 0.0004 | 0.356 ± 0.021 | 0.126 ± 0.03 | 0.0031 ± 0.001 | 0.126 ± 0.02 | |

| Sausage | 0.538 ± 0.02 | 0.0045 ± 0.005 | 0.31 ± 0.012 | 0.206 ± 0.096 | 0.0018 ± 0.004 | 0.014 ± 0.005 | |

| Candy | 0.72 ± 0.02 | 0.0013 ± 0.0003 | 0.36 ± 0.02 | 0.148 ± 0.02 | 0.0026 ± 0.001 | 0.022 ± 0.02 | |

| Chocolate | 0.262 ± 0.04 | 0.0056 ± 0.002 | 0.344 ± 0.018 | 0.102 ± 0.009 | 0.0046 ± 0.001 | 0.06 ± 0.023 | |

| R2 | Fast food | 0.902 ± 0.08 | 0.014 ± 0.003 | 0.033 ± 0.001 | 0.023 ± 0.002 | 0.0022 ± 0.0001 | 0.072 ± 0.019 |

| Pizza | 0.84 ± 0.008 | 0.014 ± 0.003 | 0.035 ± 0.009 | 0.019 ± 0.001 | 0.0034 ± 0.001 | 0.044 ± 0.002 | |

| Sausage | 0.98 ± 0.05 | 0.056 ± 0.002 | 0.43 ± 0.02 | 0.022 ± 0.002 | 0.0017 ± 0.0002 | 0.0812 ± 0.0018 | |

| Candy | 0.55 ± 0.03 | 0.001 ± 0.0005 | 0.024 ± 0.01 | 0.014 ± 0.0008 | 0.004 ± 0.0008 | 0.0072 ± 0.01 | |

| Chocolate | 0.73 ± 0.013 | 0.008 ± 0.0008 | 0.33 ± 0.023 | 0.015 ± 0.003 | 0.0012 ± 0.0002 | 0.095 ± 0.004 | |

| R3 | Fast food | 0.64 ± 0.018 | 0.012 ± 0.001 | 0.14 ± 0.002 | 0.08 ± 0.007 | 0.001 ± 0.0005 | 0.066 ± 0.052 |

| Pizza | 0.63 ± 0.01 | 0.013 ± 0.001 | 0.45 ± 0.02 | 0.04 ± 0.006d | 0.011 ± 0.005 | 0.08 ± 04 | |

| Sausage | 0.62 ± 0.03 | 0.008 ± 0.0004 | 0.23 ± 0.02b | 0.017 ± 0.005 | 0.001 ± 0.0007 | 0.09 ± 0.004 | |

| Candy | 0.54 ± 0.02 | 0.001 ± 0.002 | 0.195 ± 0.051 | 0.0069 ± 0.006 | 0.002 ± 0.004 | 0.013 ± 0.003 | |

| Chocolate | 0.73 ± 0.008 | 0.0015 ± 0.0003 | 0.25 ± 0.008 | 0.014 ± 0.001 | 0.001 ± 0.0004 | 0.062 ± 0.04 |

Note - All data are stated together as μg of heavy metal per g of sample (food item) and μg of heavy metal per dm2 of the paper sample. (N = 5, p < 0.05, MANOVA; one-sample t-test).

According to the univariate results of MANOVA, Mn, Zn, Cr, Pb concentrations are significantly different (P < 0.05), while Cu and Cd concentrations are not significantly different among R1, R2, and R3 papers. Mn, Zn, Cr, and Cd concentrations are statistically different with respect to five different food types, while Cu and Pd concentrations are not statistically different among five different food types. Cu recorded the highest migration compared to other metals.

Among the harmful contaminants in papers, heavy metals are considered as a primary contaminant (Khan et al., 2013). Heavy metals show toxicological effects in the biological systems as they do not undergo biodegradation and tend to accumulate in body tissues even with low levels of exposure (Tangahu et al., 2011). Accumulation of heavy metals to a significant level would happen with repeated recycling of papers. If deinking of papers before recycling is not done, repeated recycling will enhance the accumulation of heavy metals as most of the paper printing inks consist of heavy metals. According to Cieplinski (2004) who tested polish paper packaging samples made out of recycled fiber pulp, concentration of heavy metals is positively related with number of cycles.

3.2.1. Copper (Cu)

The Cu concentrations of R1, R2, and R3 papers ranged from 1.94 mg/Kg to 0.95 mg/Kg. The highest concentration of Cu was recorded in R2 (1.94 ± 0.0105 mg/Kg) while the lowest concentration of Cu was recorded in R1 (0.095 ± 0.019 mg/Kg). These results did not exceed the migration permissible levels as per the EPA standard (25.00 mg/Kg), EC standard (25.00 mg/Kg), and the safety limit of EU standard (4.00 mg/Kg). Also, these values are well below the values obtained in different studies carried out on heavy metal contents in paper food packaging (Elmas and Cinar, 2018; Sood and Sharma, 2019). According to Isabell (1978), which was the first comprehensive study carried out in the UK on white-lined chipboard made with the highest percentage of wastepaper content had 50 mg/Kg of copper concentrations. Parry (2012) recorded 40.9 mg/Kg of copper in pizza packaging. According to Onyango et al. (1998), newspapers in Scotland were analyzed and the copper concentration was recorded as 20–30 mg/Kg. There was a research study carried out in Paris on heavy metal analysis in recycled paper pastry packaging and the Cu concentration recorded was within the range of 0.076–0.637 mg/Kg (Mohammadpour et al., 2016). The current study reported Cu concentrations as in the lower range of Mohammadpour et al. (2016) study. However, FAO/WHO (1999) has recommended 3mg per day as the maximum daily intake of copper for an adult. Therefore, the migration of Cu from paper packaging made of recycled papers is safe in terms of health (Duran et al., 2013; Conti, 2007). Primarily the blue color ink and pigments may result from copper. Compared to other heavy metal levels in paper packaging literature revealed lower levels of copper concentrations. Unless the dense use of blue colorant pigments or ink probably carries Cu for paper printing (Elmas and Cinar, 2018).

When considering the migration test, the highest Cu concentration was detected in Sausage wrapped in R2 papers which was 0.98 ± 0.05 μg/L while the lowest concentration was detected in chocolate wrapped in R1 (0.262 ± 0.04 μg/L). According to the Duran et al. (2013), highest Cu concentration was detected in pizza as 29.8 μg/L and the lowest in fast food as 0.02 μg/L. A Higher Cu concentration value was recorded in paperboard food packaging (14.1 μg/L) and Cu was not detected in paper and corrugated paperboard food packaging (Elmas and Cinar, 2018). All these values recorded in the literature were higher than the current study findings.

3.2.2. Manganese (Mn)

As recommended by the EU standard, the maximum migration permissible value for Mn is 1.8 mg/Kg. Mn concentration values resulted from this study vary between 0.0013 ± 0.0017–0.073 ± 0.0006 mg/kg which is within the permissible limit of the EU. Public concern on Mn levels in paper and board food packaging is considerably low due to less toxicity. Mn concentration of the study by Duran et al. (2013) was recorded in the range of 0.05–101.9 mg/Kg. Duran's study was done in Turkey and considered 39 different types of paper food packaging. A similar study was carried out by Mohammadpour et al., in 2016 and it recorded Mn concentrations in the range of 0.143–0.483 mg/Kg in pastry packaging made of recycled papers. Also, according to a research study conducted in India using different pizza packaging made from recycled papers, Mn concentration was recorded as 0.54 mg/Kg (Sood and Sharma, 2019) while Parry (2012) reported 0.006 mg/Kg of Mn concentration in his study on paper food packaging. Therefore, the current study's value of Mn concentration is similar to the Parry (2012) but lower than other literature cited.

According to the migration results, the lowest Mn concentration was detected as 0.001 ± 0.002 μg/L in candy wrapped by R3 type while the highest in pizza (0.013 ± 0.001 μg/L) wrapped by R2 type. With respect to the results of Duran et al. (2013) candy and milk sweets wrapped in recycled paper packaging recorded the lowest manganese values with a mean value of 0.01 μg/L while the highest manganese values were recorded in meat (36.1 μg/L).

3.2.3. Zinc (Zn)

Among all the heavy metal types, Zn showed significantly higher concentrations than the other heavy metals in recycled papers. Zn concentrations of R1, R2, and R3 recycled papers were in the same range, and on average it was around 0.45mg/Kg. According to the WHO, 40 mg of Zn per day is the safety limit for adults and it is considered an essential human nutrient for body functions. It acts as a co-factor for over 300 enzymes and is found in all body tissues (Schroeder et al., 1967). To increase the quality of papers, Zn-related compounds, such as zinc sulfide, zinc oxide, lithopone, etc. are used in paper production (Elmas and Cinar, 2018). According to the results of the study carried out using three different food packagings with 18 samples of food items by Elmas and Cinar (2018), Zn concentrations recorded exceeded the current study findings of 0.45mg/Kg. Current study findings do not exceed the maximum permissible values of the EC standard (100 mg/Kg) as well as the EPA standard (50 mg/Kg) and EU standard (5 mg/Kg).

During the migration test, the highest Zn value was recorded in pizza in R3 as 0.45 ± 0.02 μg/L and the lowest in candy wrapped in R2 paper type as 0.024 ± 0.02 μg/L. A similar migration test was done by Elmas and Cinar (2018) using three fluting recycled papers, papers made of different types of recycled papers including the intermediate layer of corrugated paper and two test liner papers, fluting recycled paper type (140 GSM) had the highest Zn concentration as 3.8mg/Kg while fluting recycled paper type (100 GSM) had the lowest as 2.3mg/Kg. However, the Zn migration concentration of Elmas and Cinar (2018)'s study is lower than the current study.

3.2.4. Chromium (Cr)

The permissible daily intake of Cr varies between 50-200 mg (WHO, 1996; Bratakos et al., 2002). Although Cr is an essential element for certain body functions excessive intake may cause some toxicological effects such as chrome ulcers, corrosive reactions on the nasal septum, acute irritative dermatitis, allergic eczematous dermatitis, etc. (Air quality guidelines, 2000). In this study, the highest Cr concentration value was recorded as 0.1963 ± 0.0026 mg/Kg in R1 and the lowest was recorded in R2 as 0.026 ± 0.00019 mg/Kg. These values were well below the EPA standard, 2012 3.05 mg/Kg, the EC standard's limit value of 1 mg/Kg, and the EU standard limit of 0.250 mg/Kg. Current study findings are lower than the values, 0.02–2.1 mg/Kg, obtained by Sood and Sharma (2019) who examined different types of pizza packaging made of recycled papers, and also the values obtained by Elmas and Cinar(2018),0.51–6.16 mg/Kg, which was carried out in Istanbul fast food restaurant's paper related food packagings. One of the research conducted in Italy by (Conti, 1997) on fifteen different types of food packaging prepared by paper boards recorded Cr (III) as 7μgL-1 and Cr (IV) as 10.47μgL-1. Compared to the above research studies, the current study's highest recorded Cr value of 0.1963 ± 0.0026 mg/Kg is relatively lower.

Sausage wrapped in R1 had the highest Cr concentration (0.206 ± 0.09 μg/L) while the candy wrapped in R3 had the lowest concentration (0.0069 ± 0.006 μg/L) in migration testing. According to studies carried out by (Conti, 1997) and Duran et al. (2013) using corrugated paperboard food packaging, Cr values were recorded as 0.51 mg/kg and 6.61 mg/kg respectively. With respect to (Ali, 2012) the highest Cr was recorded in fast food (2.02 μg/L) while the lowest was recorded in milk sweets (0.30 μg/L). According to the study carried out by Skrzydlewska et al. (2003), Cr concentrations varied between 0.25-0.64 mg/kg. Therefore current study findings are lower than that of the above literature cited.

3.2.5. Lead (Pb)

WHO and Joint Expert Committee for Food Additives (JECFA) suggested the provisional tolerable weekly intake (PTWI) of Pb as 0.025 mg/Kg body weight. The highest concentration of Pb was recorded in R1 (0.26181 ± 0.008 mg/Kg) and the lowest concentration of Pb was recorded in R3 (0.125 ± 0.05 mg/kg). As suggested by the EU standard, the maximum permissible limit of Pb in food packaging materials is 0.01 mg/Kg. However, as recommended by the EPA standard, the maximum permissible limit of Pb in paper-based food packaging is 3.0 mg/Kg and the EC standard is 2mg/Kg. Mohammadpour et al. (2016) which related to the pastry recycled paper packaging recorded Pb concentrations as 0.037 mg/Kg while (Nowacka et al., 2018) which determined the heavy metals in the white top test liner and fluting paper, detected all the samples values lower than 0.002 mg/Kg. Therefore, the above study findings are lower than the current study findings. However, according to (Conti, 1997) in Italy who tested food packaging made out of brown and white bread bags, brown and white bakery paper, white bakery bags, butcher's paper, and salami paper, average Pb concentration value was recorded as 10mg/Kg while Duran et al. (2013) who tested 39 different food packaging products in Turkey, Pd concentrations recorded as 0.42–22.1 mg/Kg. A study from India on recycled pizza packaging recorded Pb values as 0.38 mg/kg (Sood and Sharma, 2019). According to the research conducted in South Korea using recycled paper packagings, Pd concentrations were detected between 0.4μg/L- 6.88 μg/L (Jo and Jeong, 2006). Recorded values in the literature are higher than the current study findings. It is necessary to test the relative humidity values maintained in the food packaging as well as the fatty acid content in the food to avoid transferring toxins from the packaging ink to food. Up-taking degraded paper waste for paper recycling will facilitate Pb migrations from the packaging to the food (Conti, 2007).

When studying the migration concentration of Pb, the highest was recorded in pizza wrapped with R1 (0.126 ± 0.001 μg/L) while the lowest in candy wrapped in R2 (0.0072 ± 0.001 μg/L). According to (Conti, 1997), Pb concentration values varied between non-detectives to 7.95 μg/L Duran et al. (2013) reported the highest Pb migration value in fast food as 5.75 μg/L and the lowest in coffee and milk sweets as 0.41 μg/L. It is noteworthy to mention that the migration value of Pb concentrations in the current study exceeded the maximum permissible level of the EU standard (0.01mg/Kg).

3.2.6. Cadmium (Cd)

Cd concentrations of the recycled papers ranged from 0.0.5 ± 0.0003 mg/Kg to 0.018 ± 0.0009 mg/Kg whilst the highest in R2 and lowest in R1. Consistent with the similar research carried out in Iran for pastry meals packaging, the Cd concentration mean value was recorded as 0.00115mg/Kg (Mohammadpour et al., 2016). Elmas and Cinar (2018) determined the heavy metals contained in one of the Istanbul fast food restaurant's papers associated food packaging, Cd concentration values varied from 0.04 mg/Kg- 0.18 mg/Kg at the same time as Jamnicki et al. (2012) who tested heavy metals in white top test liner and fluting papers cadmium concentration was recorded as 0.002 mg/Kg. One of the research accomplished in Denmark on recycled papers, Cd concentration was detected as 66 mg/Kg and 14 mg/Kg (Storr-Hansen and Rastogi, 1988). All the above comparable research values are greater than the current examination findings. Red and yellow are widely utilized in fine arts and printing processes may contain Cd (Zalewski, 1994). EPA has been classified cadmium as feasible human carcinogen (Group B1) while International Agency for Research on Cancer (IARC) classifies cadmium as a known human carcinogen. Apart from the EPA, EU and EC standards, there are more common standards and regulations associated with Cd. According to the National Institute of Occupational Safety and Health (NIOSH), cadium's Immediately Dangerous to Life and Health level (IDLH) is 9 mg/m3 (NIOSH 2006; NTP 2004). WHO reports tolerable weekly intake for cadmium as 7 μg/kg/body weight/week. Apart from above, ATSDR emphasizes chronic durational oral minimal risk level (MRL) of 0.1 μg/kg/day of cadmium founded on its renal effects. MRL standard describes how much cadmium can be taken orally without risk of adverse health effects (ATSDR 1999).

Cd migration concentrations were varied between 0.011 ± 0.0.5 μg/L (R3; pizza) and 0.001 ± 0.0004 μg/L (R3; chocolate). In line with the EPA and the EC standards, all the heavy metals discovered in studied 3 extraordinary recycled papers did not exceed the standard limits.

Consistent with the heavy metal migration test results, most heavy metal migration was detected in certain food types such as fast food, sausage, and pizza while the least migration was detected in chocolate or candy. When meal types with more fatty acids like fast food, sausage, and pizza are subjected to distinct environmental situations, fatty acid melts and penetrates paper packaging and facilitates migration of heavy metals into food. These findings can be supports through the research performed based totally on food packaging with recycled papers (Triantafyllou et al., 2002, 2007).

4. Conclusion

Brown craft papers (R1;150 GSM), Yellow craft papers (R2;100 GSM), and White papers (120 GSM) perform better in terms of the tensile strength (CD and MD) and burst strength up to the accelerated aging of 28 days equivalent to 9.8 years. Tensile strength and burst strength values of recycled papers are within the ISO and TAAPI standard values for food packaging. The brightness and whiteness of the three types of recycled papers showed a decreasing trend over aging while opacity values showed an increasing trend. pH values of all the papers changed from alkaline to neutral confirming the chemical stability of the papers over aging of 9.8years.

However, all the three types of recycled papers failed the water absorptiveness test even before aging, therefore, R1, R2, and R3 paper types can be recommended as food packaging material only after improving the fiber quality at the production to meet the standards. Pb and Cd can be found in higher concentrations than EU standards in R1, R2 and R3 recycled papers. Heavy metals such as Cu, Zn, Mn, Cr are within the EU, EC, and EPA food packaging standards. Ni was not detected in R1, R2 and R3 recycled papers.

When considering the migration of heavy metals from recycled papers into food, R1, R2, and R3 recycled papers can be recommended for food packaging as per the EPA and EC standards. However, according to EU standards, it needs to pretreat recycled papers to remove Cd and Pd.

Food items with high levels of fatty acids facilitate migration of heavy metals relative to food items with lower fatty acid levels.

5. Recommendations

It is recommended to carry out heavy metal extraction and migration test for different paper and paper board food packaging available in the market and it is recommended to use different suitable chemicals that will make recycled papers more resistant to moisture absorption in order to use them as an alternative food packaging material.

Declarations

Author contribution statement

Rangika Bandara: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

G.M. Indunil: Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by the University of Kelaniya.

Data availability statement

Data will be made available on request.

Declaration of interest's statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

We would like to express our special thanks to the State Printing Cooperation, Sri Lanka, who helped us to initiate our research at their premises. We would also like to convey our sincere gratitude to the Material Division of the Industrial Technology Institute, Sri Lanka (ITI) which allowed us to do the laboratory experiments and our sincere thanks goes to the Department of Zoology and Environmental Management and the Department of Chemistry, University of Kelaniya, for helping us with the laboratory testings.

References

- Abdel-Shafy H.I., Mansour M.S. Solid waste issue: sources, composition, disposal, recycling, and valorization. Egypt. J. Petrol. 2018;27(4):1275–1290. [Google Scholar]

- Alamri M.S., Qasem A.A., Mohamed A.A., Hussain S., Ibraheem M.A., Shamlan G.…Qasha A.S. Food packaging’s materials: a food safety perspective. Saudi J. Biol. Sci. 2021;28(8):4490–4499. doi: 10.1016/j.sjbs.2021.04.047. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ali I. 2012. Study of the mechanical behavior of recycled fibers. Applications to papers and paperboards (Doctoral dissertation, Université de Grenoble) [Google Scholar]

- Bajpai P. Elsevier; 2018. Biermann's Handbook of Pulp and Paper: Volume 1: Raw Material and Pulp Making. [Google Scholar]

- Bayard R., de Araújo Morais J., Ducom G., Achour F., Rouez M., Gourdon R. Assessment of the effectiveness of an industrial unit of mechanical–biological treatment of municipal solid waste. J. Hazard Mater. 2010;175(1-3):23–32. doi: 10.1016/j.jhazmat.2009.10.049. [DOI] [PubMed] [Google Scholar]

- Bhunia K., Sablani S.S., Tang J., Rasco B. Migration of chemical compounds from packaging polymers during microwave, conventional heat treatment, and storage. Compr. Rev. Food Sci. Food Saf. 2013;12(5):523–545. doi: 10.1111/1541-4337.12028. [DOI] [PubMed] [Google Scholar]

- Biedermann M., Ingenhoff J.E., Zurfluh M., Richter L., Simat T., Harling A.…Grob K. Migration of mineral oil, photoinitiators and plasticisers from recycled paperboard into dry foods: a study under controlled conditions. Food Addit. Contam. 2013;30(5):885–898. doi: 10.1080/19440049.2013.786189. [DOI] [PubMed] [Google Scholar]

- Bilitewski B., Darbra R.M., Barceló D., editors. Global Risk-Based Management of Chemical Additives I: Production, Usage and Environmental Occurrence. Vol. 18. Springer Science & Business Media; 2012. [Google Scholar]

- Borch J., Lyne M.B., Mark R.E., Habeger C. vol. 2. CRC Press; 2001. Handbook of Physical Testing of Paper. [Google Scholar]

- Brancato A.A. Georgia Institute of Technology; 2008. Effect of Progressive Recycling on Cellulose Fiber Surface Properties.http://hdl.handle.net/1853/26504 [Google Scholar]

- Bratakos M.S., Lazos E.S., Bratakos S.M. Chromium content of selected Greek foods. Sci. Total Environ. 2002;290(1-3):47–58. doi: 10.1016/s0048-9697(01)01057-9. [DOI] [PubMed] [Google Scholar]

- Caulfield D.F., Gunderson D.E. 1988 Paper Preservation Symposium: Capital Hilton, Washington, DC. 1988, October. Paper testing and strength characteristics; pp. 31–40. October 19-21. [Google Scholar]

- Central Environmental Authority, Sri Lanka. http://www.cea.lk/web/index.php/en

- Chaya W., Gheewala S.H. Life cycle assessment of MSW-to-energy schemes in Thailand. J. Clean. Prod. 2007;15(15):1463–1468. [Google Scholar]

- Ciepliński M. Oznaczanie zawartości metali ciężkich w papierowych opakowaniach. Przeglad Pap. 2004;60(9):525–527. [Google Scholar]

- Conti M.E. The content of heavy metals in food packaging paper boards: an atomic absorption spectroscopy investigation. Food Res. Int. 1997;30(5):343–348. [Google Scholar]

- Conti M.E. CRC Press; Boca Raton, FL, USA: 2007. Heavy Metals in Food Packagings; pp. 339–362. [Google Scholar]

- Duran A., Tuzen M., Soylak M. Evaluation of metal concentrations in food packaging materials: relation to human health. Atom. Spectros. 2013;34(3):99–103. [Google Scholar]

- Elmas G.M., Çınar G. Toxic metals in paper and paperboard food packagings. Bioresources. 2018;13(4):7560–7580. [Google Scholar]

- Environmental Protection Agency. 2018. https://www.epa.gov/data [Google Scholar]

- Idumah C.I., Nwuzor I.C. Novel trends in plastic waste management. SN Appl. Sci. 2019;1(11):1–14. https://link.springer.com/article/10.1007/s42452-019-1468-2 [Google Scholar]

- Isabell R.D. PIRA; Leatherhead: 1978. The Total and Extractable Heavy Metal Content of Paper and Board, PB12 (R)/1978. [Google Scholar]

- Jamnicki S., Lozo B., Rutar V., Barušić L. A study on the food contact suitablity of recycled paper and board. Papíripar. 2012;54(4):14–20. http://epa.niif.hu/00800/00863/00046/pdf/EPA00863_papiripar_2012_04_14-20.pdf [Google Scholar]

- Jo B.M., Jeong M.J. Proceedings of the Korea Technical Association of the Pulp and Paper Industry Conference. Korea Technical Association of the Pulp and Paper Industry; 2006. Effect of Pre-treatments on the content of heavy metals in packaging paper; pp. 465–469. [Google Scholar]

- Kapse S., Meshram A., Dhundele D. International journal of advance scientific research and engineering trends. Int. J. 2018;3(11) [Google Scholar]

- Karak T., Bhagat R.M., Bhattacharyya P. Municipal solid waste generation, composition, and management: the world scenario. Crit. Rev. Environ. Sci. Technol. 2012;42(15):1509–1630. [Google Scholar]

- Karlsson H. 2010. Strength Properties Of Paper Produced from Softwood Kraft Pulp: Pulp Mixture, Reinforcement And Sheet Stratification (Doctoral Dissertation, Karlstads Universitet)https://www.diva-portal.org/smash/get/diva2:317178/FULLTEXT01.pdf [Google Scholar]

- Khan R., Srivastava R., Abdin M.Z., Manzoor N. Effect of soil contamination with heavy metals on soybean seed oil quality. Eur. Food Res. Technol. 2013;236(4):707–714. [Google Scholar]

- Kullman M. Recycled paper research at the library of congress. Int. Preserv. News. 2009;48(10) [Google Scholar]

- Mäntylahti V., Laakso P. 2002. Arsenic and Heavy Metal Concentrations in Agricultural Soils in South Savo Province. [Google Scholar]

- Miao Y., Zhi Y., Zhang H., Chen Y., Shan S., Jia Q., Ni Y. Recycled fiber treated with NaOH/urea aqueous solution: effects on physical properties of paper sheets and on hornification. Nord. Pulp Pap Res. J. 2018;33(4):651–660. [Google Scholar]

- Miliūte J., Kazimieras Staniškis J. Application of life-cycle assessment in optimisation of municipal waste management systems: the case of Lithuania. Waste Manag. Res. 2010;28(4):298–308. doi: 10.1177/0734242X09342149. [DOI] [PubMed] [Google Scholar]

- Mohammadpour I., Ahmadkhaniha R., Zare Jeddi M., Rastkari N. Heavy metals in recycled pastry packages and pastries. Acta Aliment. 2016;45(4):509–514. [Google Scholar]

- Mühle S., Balsam I., Cheeseman C.R. Comparison of carbon emissions associated with municipal solid waste management in Germany and the UK. Resour. Conserv. Recycl. 2010;54(11):793–801. [Google Scholar]

- National Environmental Agency. 2009. https://www.nea.gov.sg/our-services/waste-management/waste-statistics-and-overall-recycling Singapore. [Google Scholar]

- Nerín C., Asensio E. Migration of organic compounds from a multilayer plastic–paper material intended for food packaging. Anal. Bioanal. Chem. 2007;389(2):589–596. doi: 10.1007/s00216-007-1462-1. [DOI] [PubMed] [Google Scholar]

- Niyati M. A comparative study of municipal solid waste management in India and Japan. J. Soc. Stu. 2015;25:48–61. https://core.ac.uk/download/pdf/144446327.pdf [Google Scholar]

- Noriyuki T., Tatsuo Y. An examination of various evaluation tests for paper sizing—a proposal to use the klemm test for sizing evaluation. 繊維学会誌. 2013;69(5):96–99. [Google Scholar]

- Nowacka M., Rybak K., Wiktor A., Mika A., Boruszewski P., Woch J.…Witrowa-Rajchert D. The quality and safety of food contact materials–paper and cardboard coated with paraffin emulsion. Food Control. 2018;93:183–190. [Google Scholar]

- Onyango A., Koski K.G., Tucker K.L. Food diversity versus breastfeeding choice in determining anthropometric status in rural Kenyan toddlers. Int. J. Epidemiol. 1998;27(3):484–489. doi: 10.1093/ije/27.3.484. [DOI] [PubMed] [Google Scholar]

- Paper and cardboard recycling rate in China 2009-2020, Dec 15, 2021. https://www.statista.com/statistics/1076772/china-paper-recycling-rate/

- Parry R.T., editor. Principles and Applications of Modified Atmosphere Packaging of Foods. Springer Science & Business Media; 2012. [Google Scholar]

- Periathamby A., Hamid F.S., Khidzir K. Evolution of solid waste management in Malaysia: impacts and implications of the solid waste bill, 2007. J. Mater. Cycles Waste Manag. 2009;11(2):96–103. [Google Scholar]

- Pivnenko K., Eriksson E., Astrup T.F. Waste paper for recycling: overview and identification of potentially critical substances. Waste Manag. 2015;45:134–142. doi: 10.1016/j.wasman.2015.02.028. [DOI] [PubMed] [Google Scholar]

- Schroeder H.A., Nason A.P., Tipton I.H., Balassa J.J. Essential trace metals in man: zinc. Relation to environmental cadmium. J. Chronic Dis. 1967;20(4):179–210. doi: 10.1016/0021-9681(67)90002-1. [DOI] [PubMed] [Google Scholar]

- Scott G.M. Waste. Academic Press; 2019, January. Recovered paper; pp. 291–305. [Google Scholar]

- Scribner B.W., Carr R.W. Vol. 407. US Government Printing Office; 1935. http://nvlpubs.nist.gov/nistpubs/Legacy/circ/nbscircular407.pdf (Standards for Paper Towels). [Google Scholar]

- Sharma K.D., Jain S. Overview of municipal solid waste generation, composition, and management in India. J. Environ. Eng. 2019;3:145. [Google Scholar]

- Shekdar A.V. Sustainable solid waste management: an integrated approach for Asian countries. Waste Manag. 2009;29(4):1438–1448. doi: 10.1016/j.wasman.2008.08.025. [DOI] [PubMed] [Google Scholar]

- Skrzydlewska E., Balcerzak M., Vanhaecke F. Determination of chromium, cadmium and lead in food-packaging materials by axial inductively coupled plasma time-of-flight mass spectrometry. Anal. Chim. Acta. 2003;479(2):191–202. [Google Scholar]

- Solid Waste Management Data Book Africa. 2019. https://africancleancities.org/data/D2_S3_Jica_Databook.pdf [Google Scholar]

- Soltani M., Andalib M., Ravanbakhsh M. Some physical and mechanical properties of uncatalysed acetylated paper. Bioresources. 2013;8(1):1274–1282. https://link.springer.com/article/10.1007/s00226-019-01115-x [Google Scholar]

- Soni R., Suryawanshi N., Khidkikar P., Thakur S., Kshtriya S., Gajbhiye R., Wadbudhe R. 2020. Paper Recycling and Paper Plate Forming Machine. [Google Scholar]

- Sood S., Sharma C. Levels of selected heavy metals in food packaging papers and paperboards used in India. J. Environ. Protect. 2019;10(3):360–368. [Google Scholar]

- Storr-Hansen E., Rastogi S.C. Polychlorinated biphenyls and heavy metal levels in recycled paper for household use. Bull. Environ. Contam. Toxicol. 1988;40(3):451–456. doi: 10.1007/BF01689106. [DOI] [PubMed] [Google Scholar]

- Tangahu B.V., Sheikh Abdullah S.R., Basri H., Idris M., Anuar N., Mukhlisin M. A review on heavy metals (As, Pb, and Hg) uptake by plants through phytoremediation. Int. J. Chem. Eng. 2011;2011 [Google Scholar]

- The World Bank Records IBRD.IDA. 2022. https://www.worldbank.org/en/archive/home [Google Scholar]

- Triantafyllou V.I., Akrida-Demertzi K., Demertzis P.G. Migration studies from recycled paper packaging materials: development of an analytical method for rapid testing. Anal. Chim. Acta. 2002;467(1-2):253–260. [Google Scholar]

- Triantafyllou V.I., Akrida-Demertzi K., Demertzis P.G. A study on the migration of organic pollutants from recycled paperboard packaging materials to solid food matrices. Food Chem. 2007;101(4):1759–1768. [Google Scholar]

- Tumosa C.S., Erhardt D., Hufford K., Quasney E. The deterioration of newsprint and implications for its preservation. WAAC Newslett. 2008;30(3):21–24. [Google Scholar]

- Turek A., Wieczorek K., Wolf W.M. Digestion procedure and determination of heavy metals in sewage sludge—an analytical problem. Sustainability. 2019;11(6):1753. [Google Scholar]

- Tiseo Ian. 2022 (Jun 24). Recycling rate of paper and cardboard packaging waste in the EU.https://www.statista.com/statistics/1033512/recycling-rate-of-paper-and-cardboard-packaging-waste-in-the-eu-by-country/ [Google Scholar]

- Tutus A., Gultekin S., Cicekler M. 1st International Conference on Engineering Technology and Applied Sciences. 2016. Effects of using starch at size press on physical and optical properties of some packing papers; pp. 111–115. [Google Scholar]

- WHO and Joint Expert Committee for Food Additives (JECFA), by https://www.who.int/groups/joint-fao-who-expert-committee-on-food-additives-(jecfa)/about#:∼:text=The%20Joint%20FAO%2FWHO%20Expert,World%20Health%20Organization%20(WHO). (Assesed by March 16, 2022).

- Yousaf B., Liu G., Wang R., Imtiaz M., Zia-ur-Rehman M., Munir M.A.M., Niu Z. Bioavailability evaluation, uptake of heavy metals and potential health risks via dietary exposure in urban-industrial areas. Environ. Sci. Pollut. Control Ser. 2016;23(22):22443–22453. doi: 10.1007/s11356-016-7449-8. [DOI] [PubMed] [Google Scholar]

- Zalewski S. 1994. Design, Graphic Arts, and Environment. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.