Abstract

Potato fries, a relatively an untapped food matrix for fortification, was fortified with iron using vacuum impregnation technique and impact of this fortification on quality attributes (structure, color, texture, flavor, acrylamide, sensory characteristics) of the product was assessed. Further, to reduce the dietary restraints of consumers for fried fries, fat reduction was achieved using vacuum frying. Ferrous ammonium sulphate hexahydrate was used as a fortificant to yield 3.15 mg iron from 30 g fries (RACC for snacks- Recommended Amount Customarily Consumed). Effect of iron fortificant level, blanching, vacuum and restoration time (independent variable) were evaluated on responses (iron impregnation level and firmness) of fries using box-behnken design of response surface methodology. Results showed that blanching time was the most significant variable affecting iron impregnation followed by iron concentration and vacuum time. Ferrous ammonium sulphate hexahydrate was found to be the most appropriate fortificant since reflecting the least colour and sensory changes in fries. A fortified raw potato fries when fried under vacuum, provided better retention of colour and reduced fat absorption (by 17.72%) with comparable crispiness (0.37 kg/sec vs 0.35 kg/sec), firmness (0.39 kg/sec vs 0.38 kg/sec), color (ΔE = 1.39) and sensory score (7.9 vs 8.1 on 9-point scale) with control fries.

Keywords: Potato fries, Iron, Acrylamide, Vacuum impregnation, Fortification, Vacuum frying

Introduction

Iron deficiency, mainly due to low intake of bioavailable iron, lack of iron enriched processed foods, is the third greatest global health risk among pre-school and school going children (Boccio and Iyengar 2003). Thus Iron deficiency, affecting 34% of the world population especially in developing nations (Balcı et al. 2012). Additionally, anemia in adolescence leads to reduce resistance to infection, impair physical growth and mental development (Sen and Kanani 2006). These ill-effects are mainly related to low intake of bioavailable iron because Recommended Daily Allowances (RDAs) for iron rely upon the amount of absorbed iron from the diet that to be utilized for conducting normal body functions (Hurrell and Egli 2010).

Iron fortification of food is a key approach to counteract iron deficiency. Ideally, the food consumed by most population segments, should be chosen as a vehicle for fortification. Since, the prevalence of micro-nutrient deficiencies are generally greater in teenagers, the recognition of a friendly medium has become very important. Recent research indicates that the consumption of snack foods including biscuits, candies, chips and fries has mounted with time. Thus, potato-based snacks such as potato fries can be used as an ideal carrier for targeted nutrient’s delivery i.e. iron, because of porous matrix of potatoes and wide acceptability of fries in targeted group (among children and teenagers). At food matrix level, negative interaction between fat and iron absorption has reported (Nair 2012). Since, potato fries has low fat percentage in comparison with potato chips therefore it would be an effective carrier for fortification than chips, another popular potato based snack. Moreover, potatoes are rich in vitamin C and low in phytate, therefore, effective mineral absorption can be expected from potato and potato based product (Joshi et al. 2021).

Potato fries have a fat content ranging from 15 to 18 g/100 g (wet basis) and its acrylamide content ranging from 150 to 5000 µg/Kg, are major dietary restraints for fried products in today’s world (Dueik and Bouchon 2011). Therefore, vacuum frying as an option for frying of potatoes fries was used in this study. Low pressure ‘vacuum frying and oil separating’ technology was first patented by Yang (1989) to eliminate the disadvantages of conventional atmospheric frying method such as high fat absorption, calorific value, rancidity and acrylamide formation. Vacuum frying is similar to conventional frying, but it is carried out under low pressure (atleast 50 mm Hg lower than the atmosphere pressure: 760 mm Hg). In comparison to conventional frying, vacuum frying is considered superior in terms of lower oil intake, Maillard browning, acrylamide formation (potential A-2 carcinogen) with comparable sensory scores (Banerjee and Sahu 2017).

Now a day, various processing methods are available for fortification and among various fortification techniques, vacuum impregnation (VI) technique offers an effective way for incorporating desirable fortificant/s into porous food matrices such as fruit and vegetable tissues (Joshi et al. 2019). It is based on the application of a vacuum pressure which removes gases entrapped into the capillaries and to impregnate them with a desired external (fortificant) solution during the restoration period at atmospheric pressure (Tiwari et al. 2020). In nutshell, it consists of first evacuation of tissue pores under vacuum that further filled by dipping in fortificant solution.

Fortifying potato fries with iron using vacuum impregnation technique can be successfully done with a suitable iron fortificant, which least affects the sensory properties of the product. In this view, current study’s approach was to club the benefits of vacuum assisted impregnation and frying in developing reduced fat iron fortified potato fries. To the best of our knowledge, it is a first-time effort on fortification of potato fries with iron fortificants and its effect on quality characteristics of fries.

Material and methods

Variety selection

Freshly harvested Kufri Frysona variety of Potatoes (Solanum tuberosum L.), were chosen and procured from CPRI Regional Station Modipurum, Uttar Pradesh, India for fortification purpose keeping its high ascorbate to phytate ratio (1.549) and suitability for French fries in view (Joshi et al. 2021). Potato tubers, after skin curing, were stored at elevated temperature (100C –120C) in storage chambers and using sprout suppressant Isopropyl N-(3-chlorophenyl) Carbonate (CIPC) or Chloropropham treatment until being utilized for study. Peeling and cutting of fries (~ 0.25 × 0.25 inch thick and ~ 5inch long) were done using commercial stainless-steel French fries cutter which is used only for potato processing in ICAR-CPRI, Shimla.

Fortificants and carrier

In current study through preliminary trials, out of five fortificants namely, ferric chloride hexa hydrate, ferrous ammonium sulphate hexahydrate, ferric ammonium citrate (green), ferrous gluconate, ferric ammonium citrate (brown) studied; ferrous ammonium sulphate hexahydrate was selected as fortificant. Compare to other fortificants, higher bioavailability and non-significant impact on appearance and other sensory properties and delayed oxidation responses of the product, ferrous ammonium sulphate hexahydrate had an additional edge and was used as fortificant in this study. The RDA values based on 2000 kcal intake (4–17 years of age) is 15 mg (https://www.nin.res.in/nutrition2020/RDA_short_report.pdf). Therefore, research work was planned in such a manner that the targeted level of iron (21% RDI for iron i.e.3.15 mg) can be achieved by consuming 30 g of serving of potato fries in accordance with Recommended Amount Customarily Consumed (RACC 2015). Ferrous ammonium sulphate hexahydrate (Food grade- E24863), was provided by Titen Biotech Limited, Delhi- 110,033.

Process optimization using vacuum impregnation technology

Experimental design for process optimization

To evaluate the effect of four independent variables e.g., blanching time (X1), iron content (X2), vacuum time (X3), and restoration time (X4) on response variables (iron content and firmness) of potato fries, a total of 27 runs (trials) were carried out and the responses were taken by repeating each trial thrice to see the changes in responses. The level of iron concentration, blanching, vacuum and restoration time were kept at 0.025, 0.0625, 0.1%; 0 (unblanched), 1, 2 min; 5, 10, 15 min; 10, 15, 20 min, respectively.

The response function was partitioned into linear, quadratic, and interactive components Eq. (1).

Where Y is the response; X1, X2, are input variables; β0 is the intercept; β1 are linear coefficient; βii are quadratic coefficients; βij are interaction coefficients.

| 1 |

Vacuum impregnation process

In desiccators, raw potato fries, after blanching at 720C for predefined time, were exposed to vacuum (30 mm Hg) for a predefined time. After that, the raw fries were dipped in impregnation (fortificant) solution (ferrous ammonium sulphate hexahydrate) of a particular concentration while keeping constant solid to solvent ratio 1:4 (w/v) for a particular restoration time as suggested by RSM design (Table 1).

Table 1.

The Box–Behnken Design and Experiment Data for Mineral Impregnation in Potato Fries

| Treatments | Independent variables (Coded level) | Dependent variables | ||||

|---|---|---|---|---|---|---|

|

X1 blanching time (min) |

X2 iron (%) |

X3 vacuum time (min) |

X4 restoration period (min) |

Iron (mg/100 g) | Firmness (kg/sec) |

|

| 1 | 0 (-1) | 0.025 (-1) | 10 (0) | 15 (0) | 5.4 | 0.27 |

| 2 | 0(-1) | 0.1 (+ 1) | 10 (0) | 15 (0) | 11.5 | 0.27 |

| 3 | 2 (+ 1) | 0.025 (-1) | 10 (0) | 15 (0) | 6.9 | 0.32 |

| 4 | 2(+ 1) | 0.1 (+ 1) | 10 (0) | 15 (0) | 11.7 | 0.33 |

| 5 | 1 (0) | 0.0625 (0) | 5 (-1) | 10 (-1) | 9.5 | 0.37 |

| 6 | 1(0) | 0.0625 (0) | 15 (+ 1) | 10 (-1) | 10.5 | 0.38 |

| 7 | 1 (0) | 0.0625 (0) | 5 (-1) | 20 (+ 1) | 9.5 | 0.37 |

| 8 | 1 (0) | 0.0625 (0) | 15 (+ 1) | 20 (+ 1) | 10.5 | 0.38 |

| 9 | 1 (0) | 0.025 (-1) | 10 (0) | 10 (-1) | 6.5 | 0.36 |

| 10 | 1 (0) | 0.1 (+ 1) | 10 (0) | 10 (-1) | 12.3 | 0.38 |

| 11 | 1 (0) | 0.025 (-1) | 10 (0) | 20 (+ 1) | 6.6 | 0.35 |

| 12 | 1 (0) | 0.1 (+ 1) | 10 (0) | 20 (+ 1) | 12.4 | 0.36 |

| 13 | 0(-1) | 0.0625 (0) | 5 (-1) | 15 (0) | 7.6 | 0.24 |

| 14 | 2(+ 1) | 0.0625 (0) | 5 (-1) | 15 (0) | 8.9 | 0.33 |

| 15 | 0(-1) | 0.0625 (0) | 15 (+ 1) | 15 (0) | 8.2 | 0.26 |

| 16 | 2(+ 1) | 0.0625 (0) | 15 (+ 1) | 15 (0) | 9.1 | 0.32 |

| 17 | 1 (0) | 0.025 (-1) | 5 (-1) | 15 (0) | 5.9 | 0.36 |

| 18 | 1 (0) | 0.1 (+ 1) | 5 (-1) | 15 (0) | 11.9 | 0.37 |

| 19 | 1 (0) | 0.025 (-1) | 15 (+ 1) | 15 (0) | 7.1 | 0.36 |

| 20 | 1 (0) | 0.1 (+ 1) | 15 (+ 1) | 15 (0) | 12.7 | 0.38 |

| 21 | 0(-1) | 0.0625 (0) | 10 (0) | 10 (-1) | 7.8 | 0.26 |

| 22 | 2(+ 1) | 0.0625 (0) | 10 (0) | 10 (-1) | 9.3 | 0.32 |

| 23 | 0(-1) | 0.0625 (0) | 10 (0) | 20 (+ 1) | 7.9 | 0.25 |

| 24 | 2(+ 1) | 0.0625 (0) | 10 (0) | 20 (+ 1) | 9.3 | 0.32 |

| 25 | 1 (0) | 0.0625 (0) | 10 (0) | 15 (0) | 10.7 | 0.37 |

| 26 | 1 (0) | 0.0625 (0) | 10 (0) | 15 (0) | 10.5 | 0.36 |

| 27 | 1 (0) | 0.0625 (0) | 10 (0) | 15 (0) | 10.7 | 0.36 |

Vacuum fried fries preparation

The vacuum fryer with 2.5 kg capacity of raw fries and 80 L of Rice bran oil was used in this study. Frying was done for 30–45 min at vaccum pressure 650 mm Hg and 90 °C till bubbles in oil get disappeared. De-oiling was done at 55–60 rpm. Whole cycle of operation was completed in 50 min which also included heating of oil. The potato fries were allowed to cool down at ambient temperature before storing them in polyethylene bags inside of desiccators for further examination. However, for control preparation, potato sticks of same dimensions were blanched at 720C for 2 to 3 min followed by partial frying in atmospheric pressure. The partial fried fries were stored in frozen storage (-18º C) till consumed while consuming finish frying of frozen fries need to be done.

Quality characterization of optimized product

Oil content

With the use of soxhlet method, oil content was estimated for control, and fortified potato fries (Ranganna 2007).

Mineral content estimation

Iron content of control, and experimental potato fries from 17 runs were estimated by atomic absorption spectrophotometer (ShimadzuAA700) using wet ashing procedure (Raghuramulu et al. 2003).

Colorimetric measurements

To investigate the color changes of potato fries as affected by different iron fortificant concentration, methodology reported by Joshi et al. (2018) was used. Total color change was calculated using the formula given below.

Texture profile analysis

French fries were known for its unique texture such as crispy from periphery and mealiness- floury in core. In order to evaluate the effect of process parameters on textural properties of fortified potato fries, the texture analysis was done by texture analyser as well as by sensory method. Fortified potato fries were taken and analyzed for texture characteristics, using a texture analyzer (Model TA-XT2, Texture Technologies Corp., Scarsdale, N.Y., U.S.A.) containing a 3.3-mm-wide rectangular flat probe. The texture analyzer settings were as follows: pretest speed, 2 mm/s; test speed, l mm/s; distance as 30% strain; time, l s; trigger force, 20 g; contact area, 33 mm2 and threshold, 25 g. The software calculated hardness, fracturability, brittleness, springiness, cohesiveness, gumminess, chewiness, and resilience of the potato fries.

Structural changes through SEM

Optimized fortified potato fries and control samples were evaluated for their structural differences through SEM (Scanning Electron microscopy—EVO 18, Zeiss model) as per the method described by Tiwari et al. (2018).

Flavour analysis

Flavour analysis was performed to evaluate the effect of iron fortification on the flavour compound of potato fries as the method given by Raigond et al (2015).

Acrylamide content analysis

Concerning negative impacts of fried potato fries such as acrylamide formation (class 2 carcinogen), fortified fries were evaluated for their acrylamide content according to the methods reported by Andrzejewski et al (2004).

Sensory evaluation

Sensory evaluation was conducted to compare analytical texture with the respective organoleptic results. The sensory analysis was carried out with two groups of panelists. One panel group of 30 semi -trained panelists from the host organizations were requested for fortified potato fries evaluation in comparison with control. Panelist scored the samples on color, crispness, blisters, flavor and, done-ness attribute. The panel referred a structured scale of 9-point hedonic scale for examining the intensity of all sensory parameters.

Another panel was consumer representative, selected from nearby areas of Noida, Uttar Pradesh, India. This group consisted of 75 persons with age from 12–57 years and various socioeconomic backgrounds. Members were requested to rate the sample based on 9 points hedonic scale for its color, taste, flavor and overall acceptability in comparison with control (Larmond 1977). Samples scoring 7.5 and above were considered acceptable (Sethi et al. 2022). Observation of both the groups was clubbed together by taking average of the readings (Table 2).

Table 2.

Characteristics of Optimized Potato Fries

| Attributes | Control Fries | Iron Fortified Fries | Significance |

|---|---|---|---|

| Proximate Composition | |||

| Moisture (%) | 4.48 ± 0.2 | 2.71 ± 0.1 | s |

| Protein (%) | 4.1 ± 0.3 | 4.2 ± 0.2 | ns |

| Fat (%) | 18.4 ± 1.1 | 12.3 ± 1.5 | s |

| Ash (%) | 1.98 ± 0.1 | 3.1 ± 0.2 | s |

| Carbohydrates (%) | 71.04 ± 1.7 | 77.69 ± 2.0 | s |

| Minerals | |||

| Iron (mg/100 g) | 0.6 ± 0.2 | 16.37 ± 0.4 | s |

| Sensory Evaluation | |||

| Color | 7.95 ± 1.31 | 7.89 ± 1.05 | ns |

| Taste | 7.96 ± 1.09 | 7.76 ± 1.14 | ns |

| Flavour | 8.07 ± 1.11 | 7.62 ± 1.10 | s |

| Overall acceptability | 8.2 ± .32 | 7.9 ± 0.23 | s |

| Acrylamide content (µg/kg) | 50.34 ± 0.42 | 45.13 ± 0.27 | ns |

| Flavour (Umami Compounds) ( μg/g) | 5.8 ± 0.23 | 2.38 ± 0.54 | s |

| Texture (Instrumental) | |||

| Firmness (kg/sec) | 0.38 ± 0.02 | 0.39 ± 0.03 | ns |

| Brittleness (mm) | 0.20 ± 0.12 | 0.19 ± 0.01 | ns |

| Fracturability (N) | 0.37 ± 0.14 | 0.37 ± 0.02 | ns |

| Springiness (N) | 0.96 ± 0.03 | 0.94 ± 0.04 | ns |

| Cohesiveness (N) | 0.58 ± 0.04 | 0.58 ± 0.02 | ns |

| Gumminess (N) | 0.22 ± 0.03 | 0.22 ± 0.01 | ns |

| Chewiness (N) | 0.22 ± 0.03 | 0.21 ± 0.01 | ns |

| Resilience (N) | 0.29 ± 0.05 | 0.27 ± 0.02 | ns |

| Texture (Sensory) | |||

| Crispiness | 7.96 ± 1.09 | 7.90 ± 1.14 | ns |

| Hardness | 7.98 ± 1.02 | 7.92 ± 1.22 | ns |

| Doneness | 8.20 ± 1.17 | 7.79 ± 1.07 | ns |

| Blisters | 8.10 ± 1.15 | 7.48 ± 1.07 | ns |

Significant at 1% level of significance, ns: non-significant

Statistical analysis

Replicated data obtained for different treatments were subjected to statistical analysis. For comparison of quality attributes of iron enriched fries with control at 1% level of significance, two-tailed t-test assuming unequal variances was carried out using MS Excel 2007. The central points (coded as 0) for each independent variable were 0.0625% of ferrous ammonium sulphate hexahydrate, 1 min of blanching time, 10 min of vacuum time and 15 min of restoration time. Surface plots were derived from STATISTICA Version 5.0 software.

Results and discussion

Effect of process variables on Iron content of fortified fries

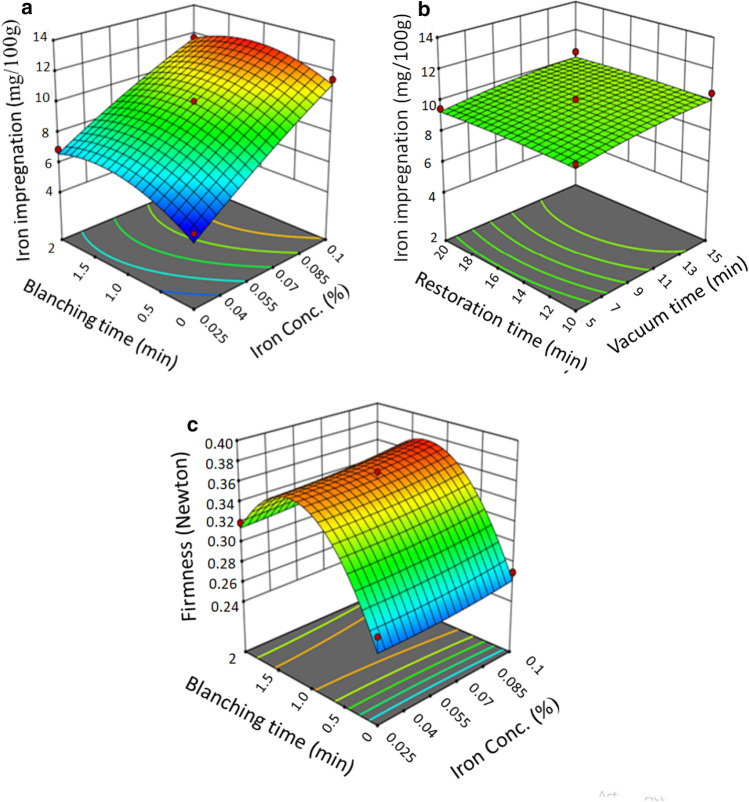

Among both the process variables, it is evident from statistical analysis and Fig. 1a, with increase in blanching time the iron content increased initially. After 1.5 min of blanching, blanched potato fries had 18.14 times higher iron content than control potato fries and contained 10.56 mg iron content per 100 g. Even for 1 min blanched vacuum impregnated potato fries could achieve targeted level of iron (15 mg/100 g). Present findings corresponded well with the earlier report of Alzamora et al. (2005). The blanching treatment resulted in profound structural modification (swelling of cell walls, disruption of membranes, etc.) that accelerates mass transport phenomena, resulting in the extensive uptake of solute inside the cytoplasm of parenchyma cells (Tiwari et al. 2018).

Fig. 1.

(a) Effect of Blanching Time and Iron concentration on iron impregnation in Potato Fries (b) Effect of Vacuum time and restoration time on iron impregnation in Potato Fries (c) Effect of Blanching Time and iron concentration on firmness of iron fortified Potato Fries

It was reflected from Fig. 1b that vacuum time within the range from 5 to 15 min used in the present study, did not show any significant effect on impregnation process in potato fries. Similarly, restoration time also had the positive effect on impregnation process however, it was statistically non-significant (p ≤ 0.05).

Effect of process variable on firmness of fortified fries

Figure 1c shows that among all the variables studied for impregnation, blanching had shown significant quadratic effect on potato fries firmness. Firmness scores were initially increased with increase in blanching time and decreased thereafter. Acceptable firmness which corresponded to instrumentation value (0.39 kg/sec) could be achieved at 1.5 min of blanching (70°C). These findings were in agreement with the reports of Aseidu-Larbi (2010) stated that blanching causes starch gelatinization while frying increases the dry matter content which results in loss of non-fiber substances from plant tissues and thereby leading to firmness of the product. However, prolonged blanching i.e. ≥ 1.5 min gave cooking effect and led to decrease in firmness.

Level optimization and validation

Mean optimized values for iron (fortificant) concentration, blanching time, vacuum time and restoration time obtained were 0.062%, 1.21 min, 8.1 min, and 10.01 min, respectively with 95% level of confidence limit. Potato fries were developed again by using above mentioned optimize condition for validation and the targeted iron content evaluation. Results reflected that iron content in developed fortified fries (16.37 mg/100 g) were close to targeted value (15.0 mg/100 g) showing appropriateness of the model for targeted fortification of potato fries. Figure 2(a) and (b) showed the comparison between control and fortified potato fries in terms of appearance. Unaffected aesthetic value of iron fortified fries (comparable with control) was achieved in this study that otherwise a major limitation of iron fortification.

Fig. 2.

(a) Control French fries (b) Iron Fortified fries

Quality evaluation of fries

To access the effect of fortification on fries, both the control and fortified fries were analysed for following quality characteristics.

Fat and mineral estimation

Results showed that oil uptake for vacuum fried fries was low (12.3%) compared to atmospheric frying (18.4%) (Table 2). Su et al. (2021) reported that because of the low pressure, air may diffuse faster into the porous space of matrix and thus hampering oil passage and therefore, leading to a reduction in fat absorption in vacuum fried snacks as compared to atmospheric fried ones. Thus, developed product can be treated as a nutritious alternative for commercial fries.

Mineral estimation reflected that the set target level (21% RDI) for school aged children could be achieved at 0.062% iron concentration and optimized condition used, which is 15 and 13.12 times higher than its control (0.7 mg/100 g) and commercial (0.8 mg/100 g) counterparts. (Table 2).

Acrylamide content

Acrylamide content in both potato fries, iron fortified (45.13 µg/kg) and control fries (50.34 µg/kg) was far below than the benchmark level set by European Union in 2017 for French fries i.e. 500 µg/kg. Reasons for this almost nil traces of acrylamide include utilization of low reducing sugar variety (Kufri Frysona-1), storage at elevated temperature (100C to 120C) using sprout suppressant (CIPC), blanching prior to frying and medium temperature frying (900C) etc. (Pedreschi et al. 2004). Study confirmed that iron fortification did not affect any acrylamide formation as evident from current experimental study. For this reason, the developed potato fries will be a healthier alternative for consumption due to high iron content and nil traces of acrylamide.

Color estimation

Table 2 showed an optimized condition, where developed product was similar in lightness parameter (L: 76.39) in comparison with control (L: 75.99). In colour analysis, parameter ‘a’ indicated the redness of the sample that non-significantly affected by iron fortification since ‘a’ value of fortified and control fries was -5.98 and -6.21, respectively. It has been reported that redness is linearly correlated with the acrylamide formation (R2 = 0.9569). Since low acrylamide content was found for both control and fortified and hence low ‘a’ values obtained in these samples. The yellowness of food product is specified by the parameter ‘b’ in color measurement. In general, higher ‘b’ parameter values show more yellowness to the product (Krokida et al. 2001). Yellowness of fries was found to be 23.20 (control) and 24.52 (Iron fortified). These findings showed that iron fortification also did not affect yellowness of the product. Thus, total color of fortified potato fries can be described as light yellow (L: 76.39; a: -5.98; b: 24.52) which was quite similar with control fries (L: 75.99; a: -6.21; b: 23.20) and thus resulted in very less total colour change (∆E = 1.39).

Texture analysis

The TPA values of experimental fortified fries samples are represented in Table 2. Value of firmness was 0.37 kg/sec for iron fortified and 0.35 kg/sec for control potato fries. The crispy structure of the fortified potato fries related to brittleness was 0.19 mm and found close to control fries (0.20 mm). Similarly, for other parameters like fructurability, springiness, cohesiveness, gumminess, chewiness, resilience, there were no significant difference observed (p ≤ 0.01) between control and fortified fries (Table 2). Results reflected that iron fortification did not affect the texture characteristics. Current finding of similar textural attributes of fries is in the line with the report of Zhao and Xie (2004) and Aseidu-Larbi (2010).

Structural effect of Iron impregnation

Figure 3(a) and (b), displayed that at 100x magnification, there were no significant differences observed in cell structure of fortified potato fries in comparison to control. To observe the changes more evidently SEM images were further taken at 500x. Under magnified view (Fig. 3(c) and (d)), it was observed that some deposition of iron was found at fortified fries cell periphery but granule appearance remained the same. Current result reflected that ferrous ammonium sulphate hexahydrate can be effectively used for iron fortification process with unaltered organoleptic properties.

Fig. 3.

Structural Change of Iron Impregnation in Comparison with Control Fries. (a) Control Fries (100x); (b) Fortified Fries (100x); (c) Control Fries (500x); (d) Fortified Fries (500x)

It is important to report that there was little discoloration was found in fries at higher salt concentration level (≥ 0.1%). Since, the targeted value of iron in fries could been achieved at 0.062% salt solution therefore, among all combinations of process variables for desirable output (iron content 15 mg/100 g in fries), only combination having lowest iron fortificant (0.062%) was selected for product development which was quite lower than objectionable dose (≥ 0.1%) for colour defect.

Flavor compounds

Potato fries flavor perception is due to both volatile and non-volatile compounds. Among non-volatile compounds, umami compounds (Glutamate + GMP) are the significant contributor to cooked and processed potato flavor (Raigond et al. 2014). The flavor compound (Umami 5’ nucleotide) was found to be 5.8 μg/g FW and 2.38 μg/g FW in control and iron fortified potato fries, respectively. This represents that iron impregnation adversely affect the umami flavor of potato fries. This reduction in natural umami compounds can be restored with the addition of umami-based flavor ready to use spice premixes.

Sensory evaluation

From data in Table (2), it could be observed that iron fortified fries had acceptable color (7.9) as that of control (8.2) potato fries. In addition, there were no significant differences among texture and taste characters. Overall acceptability of developed product was slightly lower than control may be attributed due to flavor masking effect of iron fortificant, though the fortified product was acceptable with appreciable sensory scores (7.8 on 9point hedonic scale).

Conclusion

Process parameters such as iron fortificant concentration, blanching, vacuum, and restoration time were optimized in vacuum impregnation process in order to fortify potato fries to fulfill 21% RDI of iron in 4–17 age population. Ferrous ammonium sulphate hexahydrate was found the most effective fortificant exerted the least change in colour and flavor of fries. Results showed that blanching time was the major governing factor in impregnation phenomenon followed by iron concentration and vacuum time. Except nutritional quality, iron fortification did not affect other quality parameter of fries including texture, colour, acrylamide content etc. Vacuum frying successfully helped in the reduction of fat and thus the dietary restraints of the consumers. Due to iron enrichment and fat reduction with nil traces of acrylamide, the developed iron fortified potato fries would be a nutritious alternative of commercial French fries. Unaffected aesthetic value of iron fortified fries (comparable with control) was achieved in this study that otherwise a major limitation of iron fortification. This is one of the key findings of current study that can carry forward for iron fortification research work.

Acknowledgements

The authors gratefully acknowledge the support provided by Dr. Brajesh Singh, Head Division of CPB & PHT, ICAR-CPRI, Shimla, Himachal Pradesh, India and Titen Biotech Limited, Delhi, India for providing fortificant

Authors’ contributions

PRATIBHA TIWARI– Analysis and writing of original draft.

MONIKA THAKUR–Concept, Writing and editing of original draft.

ALKA JOSHI: Methodology, Concept and Execution of work, editing of revised draft.

PINKY RAIGOND: Flavour compound analysis, Execution of work.

BINDVI ARORA: Statistical Analysis.

Funding

A funding declaration is mandatory for publication in this journal. Please confirm that this declaration is accurate, or provide an alternative.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

NA.

The work described has not been published before neither it is under consideration for publication elsewhere. Its submission to JFST publication has been approved by all authors as well as the responsible authorities- tacitly or explicitly- at (Amity Institute of Food Technology & CPRI SHIMLA) where the work has been carried out. If accepted, it will not be published elsewhere in the same form, in English or in any other language, including electronically without the written consent of the copyright holder. JFST will not be responsible should there be any claims for compensation or dispute on authorship.

Declarations

Conflicts of interest

The authors have not disclosed any competing interests.

Ethics approval

NA

Consent to participate

NA

Consent for publication

NA

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alzamora SM, Salvatori D, Tapia MS, Lopez-Malo A, Welti-Chanes J, Fito P. Novel Functional Foods from vegetable matrices impregnated with biologically active compounds. J Food Eng. 2005;67:205–214. doi: 10.1016/j.jfoodeng.2004.05.067. [DOI] [Google Scholar]

- Andrés-Bello A, García-Segovia P, MartínezMonzó J. Vacuum frying process of gilthead sea bream (Sparus aurata) fillets. Innov Food Sci Emerg Technol (IFSET) 2010;11:630–633. doi: 10.1016/j.ifset.2010.06.002. [DOI] [Google Scholar]

- Andrzejewski D, Roach JAG, Gay ML, Musser SM. Analysis of coffee for the presence of acrylamide by LC/MS/MS. J Agri Food Chem. 2004;52:1996–2002. doi: 10.1021/jf0349634. [DOI] [PubMed] [Google Scholar]

- Aseidu-Larbi AB (2010) Production and storage of minimally processed chips from water yam (Discoreaalata). M.Sc. Thesis; 121, Kwame Nkrumah University of Science and Technology, Ghana

- Balci YI, Karabulut A, Gürse D. Prevalence and risk factors of anemia among adolescents in Denizli, Turkey. Iran J Pediatrics. 2012;22(1):77–81. [PMC free article] [PubMed] [Google Scholar]

- Banerjee S, Sahu CK. A short review on vacuum frying-a promising technology for healthier and better fried foods. Int J Nutr Health Sci. 2017;2(2):68–71. [Google Scholar]

- Boccio JR, Iyengar V. Iron deficiency causes, consequences and stratification to overcome the nutritional problem. Biol Trace Elem Res. 2003;94(1):1–31. doi: 10.1385/BTER:94:1:1. [DOI] [PubMed] [Google Scholar]

- Bourne MC. Food Texture and Viscosity – Concept and Measurement. 2. New York: Academic Press; 2002. p. 427. [Google Scholar]

- Dueik V, Bouchon P. Vacuum frying as a route to produce novel snacks with desired according to quality attributes Available on-line at http://dse.usab-tm.ro Banat′s Journal of Biotechnology 2012, III (5), 30 according to new health trends. J Food Sci. 2011;76:188–195. doi: 10.1111/j.1750-3841.2010.01976.x. [DOI] [PubMed] [Google Scholar]

- Hurrell R, Egli I. Iron bioavailability and dietary reference values. Am J Clin Nutr. 2010;91:1461S–1467S. doi: 10.3945/ajcn.2010.28674F. [DOI] [PubMed] [Google Scholar]

- Joshi A, Sagar VR, Sharma S, Singh B. Potentiality of potato flour as humectants (anti-staling agent) in bakery product: Muffin. Potato Res. 2018;61(3):1–17. [Google Scholar]

- Joshi A, Kaundal B, Raigond P, Singh B, Sethi S, Bhowmik A, Kumar R. Low-volume procedure to determine phytate and ascorbic acid in potatoes: standardization and analysis of Indian cultivars. J. Food Compos Anal. 2021;102:103998. doi: 10.1016/j.jfca.2021.103998. [DOI] [Google Scholar]

- Joshi A, Prajapati U, Sethi S, Arora B, Sharma RR (2019) Fortification in fresh and fresh-cut horticultural products, Chapter IX, In Fresh-Cut Fruits and Vegetables Technologies and Mechanisms for Safety Control Edited by Siddiqui MW, Academic Press, Elsevier, pp 183–203 (ISBN 978–0–12–816184–5).

- Krokida MK, Oreopoulou V, Maroulis ZB, MarinosKouris D. Color changes during deep frying. J Food Eng. 2001;49:219–225. doi: 10.1016/S0260-8774(00)00161-8. [DOI] [Google Scholar]

- Larmond E. Laboratory methods for sensory evaluation of foods. Ottawa: Department of Agriculture Ottawa; 1977. p. 637. [Google Scholar]

- Nair KM (2012) Fortification of bakery products. NIN (ICMR), PPT available at: http://www.ilsiindia.org/FortificationFoods/FortificationofBakeryProducts. Accessed 22 Jan 2012

- Pedreschi F, Kaack K, Granby K. Reduction of acrylamide formation in potato slices during frying. LWT-Food Sci Technol. 2004;37:679–685. doi: 10.1016/j.lwt.2004.03.001. [DOI] [Google Scholar]

- Raghuramulu N, Nair KM, Kalyanasundaram S. A manual of laboratory techniques. 2. Hyderabad: National Institute of Nutrition, ICMR; 2003. [Google Scholar]

- Raigond P, Singh B, Gupta VK, Singh BP. Potato flavour: Profiling of umami 5′-nucleotides from Indian potato cultivars. Indian J Plant Physiol. 2014;19(4):338–344. doi: 10.1007/s40502-014-0117-4. [DOI] [Google Scholar]

- Raigond P, Singh B, Dhulia A, Chopra S, Dutt S. Flavoring compounds in Indian potato snacks. J Food Sci Technol. 2015;52:8308–8314. doi: 10.1007/s13197-015-1888-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2. New Delhi: Tata McGraw-Hill; 2007. [Google Scholar]

- Recommended Amount Customarily Consumed (RACC) (2015) Recommended daily intake of vitamins and minerals. http://www.lenntech.com/recommended-daily-intake.html. Accessed 4 Mar 2015

- Sen A, Kanani SJ. Deleterious functional impact of anemia on young adolescent school girls. Indian Ped. 2006;43(3):219–226. [PubMed] [Google Scholar]

- Sethi S, Joshi A, SethK Bhardwaj R, Yadav A, Grover M. Phytonutrient content, antioxidant potential and acceptability of muffinsfunctionalized with soy and citrus industry waste. J Food Process Preserv. 2022 doi: 10.1111/jfpp.16606. [DOI] [Google Scholar]

- Su Y, Zhang M, Chitrakar B, Zhang W. Reduction of oil uptake with osmotic dehydration and coating pre-treatment in microwave-assisted vacuum fried potato chips. Food Biosci. 2021;39:100825. doi: 10.1016/j.fbio.2020.100825. [DOI] [Google Scholar]

- Tiwari P, Joshi A, Varghese E, Thakur M. Process standardization and storability of calcium fortified potato chips through vacuum impregnation. J Food Sci Technol. 2018;55(8):3221–3231. doi: 10.1007/s13197-018-3254-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tiwari P, Joshi A, Thakur M. Vacuum impregnation: A novel nondestructive technique for the development of functional foods. In: Thakur M, Modi V, editors. Emerging Technologies in Food Science. Singapore: Springer Nature; 2020. pp. 187–200. [Google Scholar]

- Yang CS (1989) Vacuum frying and oil separating device. US. Patent No. 4,873,920. Washington, DC: U.S. Patent and Trade-mark Office

- Zhao Y, Xie J. Practical applications of vacuum impregnation in fruit and vegetable processing. Trends Food Sci Technol. 2004;15:434–451. doi: 10.1016/j.tifs.2004.01.008. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

NA.

The work described has not been published before neither it is under consideration for publication elsewhere. Its submission to JFST publication has been approved by all authors as well as the responsible authorities- tacitly or explicitly- at (Amity Institute of Food Technology & CPRI SHIMLA) where the work has been carried out. If accepted, it will not be published elsewhere in the same form, in English or in any other language, including electronically without the written consent of the copyright holder. JFST will not be responsible should there be any claims for compensation or dispute on authorship.