Abstract

Titanium (Ti) has been widely used for manufacturing of bone implants because of its mechanical properties, biological compatibility, and favorable corrosion resistance in biological environments. However, Ti implants are prone to infection (peri-implantitis) by bacteria which in extreme cases necessitate painful and costly revision surgeries. An emerging, viable solution for this problem is to use copper (Cu) as an antibacterial agent in the alloying system of Ti. The addition of copper provides excellent antibacterial activities, but the underpinning mechanisms are still obscure. This review sheds light on such mechanisms and reviews how incorporation of Cu can render Ti–Cu implants with antibacterial activity. The review first discusses the fundamentals of interactions between bacteria and implanted surfaces followed by an overview of the most common engineering strategies utilized to endow an implant with antibacterial activity. The underlying mechanisms for antibacterial activity of Ti–Cu implants are then discussed in detail. Special attention is paid to contact killing mechanisms because the misinterpretation of this mechanism is the root of discrepancies in the literature.

Keywords: Antibacterial mechanisms, Ti–Cu implants, Contact killing, Ion releasing, Anti-infection, Biomaterials, Antimicrobial

Graphical abstract

List of abbreviations

- AFM

Atomic Force Microscopy

- AgNP

Silver nanoparticle

- AMP

Antimicrobial Peptide

- at. %

Atomic Percentage

- ATP

Adenosine Triphosphate

- ATPase

Adenosine Triphosphatase

- B. cereus

Bacillus cereus

- D. radiodurans

Deinococcus radiodurans

- DCMS

Direct Current Magnetron Sputtering

- DNA

Deoxyribonucleic Acid

- E. coli

Escherichia coli

- E. hirae

Enterococcus hirae

- EPA

Environmental Protection Agency

- EPS

Extracellular Polymeric Substance

- ETS

Electron Transport System

- HiPIMS

High Power Impulse Magnetron Sputtering

- K. pneumoniae

Klebsiella pneumoniae

- MAPD

Micro-area Potential Difference

- MIC

Minimum Inhibitory Concentration

- MRSA

Methicillin-Resistant Staphylococcus aureus

- MSC

Mesenchymal Stem Cell

- P. aeruginosa

Pseudomonas aeruginosa

- P. gingivalis

Porphyromonas gingivalis

- PEG

Polyethylene Glycol

- PEM

Polyelectrolyte Multilayers

- PIII

Plasma Immersion Ion Implantation

- PMF

Proton Motive Force

- PPO

Propylene Oxide

- RGD

Arginylglycylaspartic Acid

- RNA

Ribonucleic Acid

- ROS

Reactive Oxygen Species

- S. aureus

Staphylococcus aureus

- S. epidermidis

Staphylococcus epidermidis

- S. mutans

Streptococcus mutans

- SBMA

Sulfobetaine Methacrylate

- SEM

Scanning Electron Microscopy

- SLA

Sandblasting and Acid Etching

- SLE

Selective Acid Etching

- SLM

Selective Laser Melting

- TEM

Transmission Electron Microscopy

- TNT

Titanium Nano Tubes

- WHO

World Health Organization

- wt. %

Weight Percentage

1. Introduction

Once an implant is exerted in the human body, the pathogenic bacteria and the human host cells compete for the surface of the implant, as described by the term “race for the surface” [1]. If the bacteria possess the upper hand and adhere to the surface of the implant prior to the tissue cells, biofilm formation ensues, which brings about a precarious state in which the bacteria resist the attack from antibiotics and the host immune system. This process results in bacterial infection around the implant [2,3]. Consequently, the formation of new bone around the surgical implant is hindered, which is conducive to the biomedical implant loosening and several revision surgeries to constrain the infection [4].

The infection associated with implants is the second major cause for postoperative complaints in clinical practice [5]. The prevalence of infection after arthroplasty of the knee, hip, and ankle is estimated to be 0.5–2%, 0.3–1.7%, and 2–9%, respectively [[6], [7], [8]]. In the United States alone, for example, 4.3% of orthopedic implants fail every year due to bacterial infections [9]. In the case of dental implants, infection occurs with a rate of 9.3–12.8% at the implant level and 18.5–19.8% at the patient level [10,11]. In extreme cases, getting rid of such implant-related infections requires revision surgeries which are painful and bring an economic burden to patients and healthcare systems [12,13].

Titanium and its alloys have been extensively used in medical applications because of their high biocompatibility, excellent corrosion resistance, and favorable mechanical properties. Thus, titanium alloys are exploited as the favored materials to fabricate artificial joints (hip, knee, shoulder, ankle, elbow, wrist, knuckle, etc.), bone fixations (intramedullary nail, plate, screw, etc.), braces, and dental implants [[14], [15], [16], [17], [18]]. However, titanium implants are prone to bacterial invasion despite antibiotic administration and strict aseptic techniques, because they are bio-inert and do not resist bacterial adhesion and biofilm formation [19,20]. An effective approach to combat the incidence of bacterial infection on implants is to fabricate an implant with antibacterial activity to inhibit the initial bacterial adherence [19].

Copper has garnered growing interest in this area because of its excellent antibacterial activity and significant role in human metabolism. As such, Ti–Cu alloys with favorable antibacterial properties have been established as highly promising materials for fabricating implantable medical devices [21].

Although extensive efforts have been made to produce antibacterial Ti–Cu alloys, our understanding of why Ti–Cu demonstrates the antibacterial activity is still largely limited. The acquisition of this knowledge is crucial for designing Ti–Cu alloys with engineered microstructures to achieve enhanced antibacterial properties. Since we need to make links between different realms of knowledge, including microbiology, material science, chemistry, and even physics, to understand the multifaceted concepts of antibacterial mechanisms in the Ti–Cu implant, achieving this goal seems to be far-fetched, and also lack of it may be the root of a large body of contradictions found in the published literature [22]. Despite these complexities, deductive and comprehensive analysis of existing data can help us to determine the underlying mechanisms of action.

Here, we first briefly discuss the immediate interactions of bacteria with a surface implanted in the human body. According to these interactions, current stage-of-the-art strategies to prohibit bacterial infections on the implant surface are briefly reviewed. We then discuss the antibacterial behavior of copper and the underpinning mechanisms. Next, the mechanisms of antibacterial activity in Ti–Cu implants are discussed and delineated. Specifically, ion releasing and the contact killing mechanisms and various key factors affecting each are highlighted, because the lack of differentiation between these two mechanisms in the literature has sowed dissension among scholars. The paper finally concludes by providing suggestions for further investigations and possible future directions in the area of Ti–Cu implants. The mechanisms of action elucidated and discussed in this review open up new avenues for fundamental research on understanding the bacteria-surface interactions with important implications for a wide range of practical applications, including the fabrication of next-generation antimicrobial implantable devices.

2. Bacteria and their interactions with implant materials

Bacteria are classified as prokaryotes and can be found practically everywhere on Earth in many shapes and sizes [23]. Each bacterial cell is made of three main parts: cell envelope, cytoplasm, and the nucleoid. In most bacteria, the cell envelope is comprised of a capsule, cell wall, and cytoplasmic membrane, which protect the cytoplasm of the cell and defend the bacteria from external damages. An important component of the cell envelope is the cell wall which is mainly composed of peptidoglycan [24]. Although the cell wall of all bacteria has peptidoglycan, not all cells have the same overall structure of peptidoglycan. In fact, the thickness of peptidoglycan separates two important types of bacteria, namely Gram-negative and Gram-positive bacteria [25].

The Gram-negative cell wall is composed of a single layer of peptidoglycan surrounded by a membranous structure called the outer membrane and a periplasm. The cell wall in Gram-negative is thinner and less compact compared to that of Gram-positive bacteria. Generally, in Gram-positive bacteria, the cell wall is thick and consists of several layers of peptidoglycan. They lack the outer membrane envelope found in Gram-negative bacteria [26] (Scheme.1). Beneath the cell wall, a thin living membrane (cytoplasmic membrane) exists that is made of phospholipids and proteins. This membrane functions as a selective permeability barrier that regulates the passage of substances into and out of the cell and separates vital components of the cell from harmful components of the environment. The bacterial cell membrane has a variety of functions for energy production and biosynthesis in the cell. A membrane is a place where there is an electron transport system (ETS) that produces energy during respiration or photosynthesis, and it contains enzymes called ATP synthetase (ATPase) that convert energy into a useable state in a bacterial cell, so-called adenosine triphosphate (ATP). Other vital components of a bacteria cell are cytoplasm and nucleoid, where the DNA is located [23].

Scheme 1.

(a) General structure of a bacteria cell, and the cell wall structure in (b) Gram-negative bacteria, and (c) Gram-positive bacteria.

2.1. Biofilm formation

Bacteria that are capable of colonizing the human body are creative and adapt themselves against the defense system of the body [27]. One of the specific methods by which bacteria adapt themselves to environmental conditions is the ability to form biofilm as a strategy to deal with environmental hazards. Biofilm is defined as structured microbial communities embedded in a self-produced extracellular matrix that adheres to a susceptible surface [28]. Biofilm formation is a complex process that consists of several phases: growth, maturity, attachment, and dispersal (Scheme 2). In short, initial colonizers form biofilm by secretion of extracellular polymeric substances (EPS) containing molecules of glycoproteins and polysaccharides. This viscous substance makes thousands of bacteria join together. In the next phases, the secretion of this matrix is multiplied by different species of bacteria until it leads to the formation of a mature mixed-population biofilm [29,30]. Bacteria make up less than 1/3 of the total biofilm volume, and the rest of the volume in biofilm is occupied by the EPS.

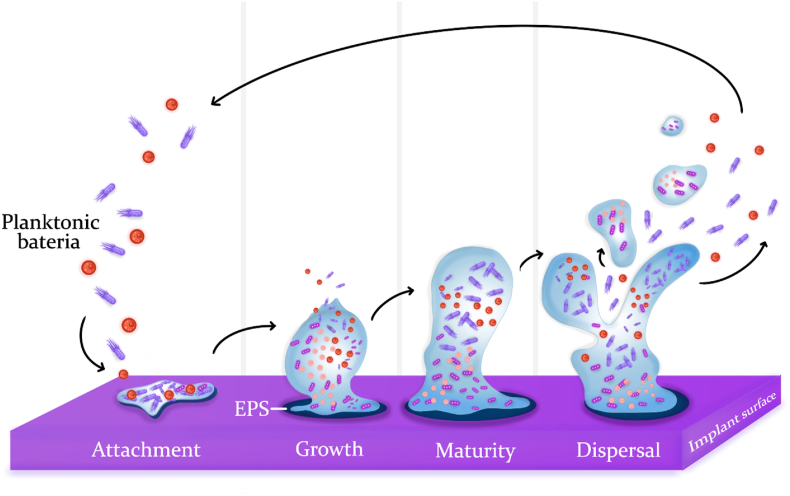

Scheme 2.

Different stages of biofilm formation and development on a susceptible surface. Attachment: Initial colonizers adhere to the implant surface due to van der Waals forces and reproduce, followed by secretion of a gel-like substance (extracellular polysaccharides). Growth: The substance tenaciously bounds with the surface and protects bacteria against external threats, providing them with a safe environment to reproduce. Maturity: The population of bacteria in EPS increases until a mature biofilm is formed. Dispersal: The biofilm is dispersed by releasing either a small part of it or planktonic bacteria to colonize other sites of the implant [27].

It has been estimated that about 65% of bacterial infections in the human body are associated with bacterial biofilm formation [31]. After biofilm formation, bacteria can tolerate antibiotics at concentrations of 10–1000 times more than their planktonic mode, making biofilms tremendously difficult to eliminate from living hosts [14,30]. Therefore, antibiotic administration to eliminate biofilm could be dangerous; since, in this state, the probability of the emergence of antibiotic resistance is too high.

3. Strategies to combat biofilm formation in implants

As discussed in the previous section, the bacterial biofilm formed on an implant surface is the main cause of implant-related infections [14]. The current therapy to combat bacterial biofilm on implants mainly relies on antibiotic therapy. However, bacteria in biofilm are more resistant to antibodies, phagocytes, and any antibacterial drugs than planktonic bacteria [32]. Further, the efficiency of antibiotic treatment is gradually reducing due to the abuse of antibiotics and the emergence of deadly superbugs [33,34].

Another noteworthy treatment to tackle biofilm formation, particularly in dental implants, is to mechanically clear the biofilm. The mechanical treatments, however, carry the risk of micromorphological changes in the implant's surface and surface roughness alterations [35]. The roughness of the implant surface is a vital feature for osseointegration [36]. Moreover, with the mechanical clearance procedure, the entire bacteria may not be removed from the implant surface [37,38]. Altogether, it can be concluded that combatting the bacteria only after biofilm formation is not much efficient [39]. Intervening before biofilm formation and preventing it at the early stages is thus a more viable strategy [40].

In this regard, various approaches have been developed by equipping the implants with remarkable characteristics by which the initial stages of biofilm formation could be prevented. Such implants, endowed with antibacterial properties, combat bacteria in three different ways: prohibition of bacterial adhesion, killing the bacteria which come in contact with the surface, and releasing antibacterial agents to kill planktonic bacteria [41]. An antibacterial implant may apply one, two, or all three anti-infection strategies against bacteria [42]. In this section, we briefly review these strategies. Scheme 3 illustrates the various strategies currently employed to combat bacterial infection and inhibit biofilm development on the implant surfaces.

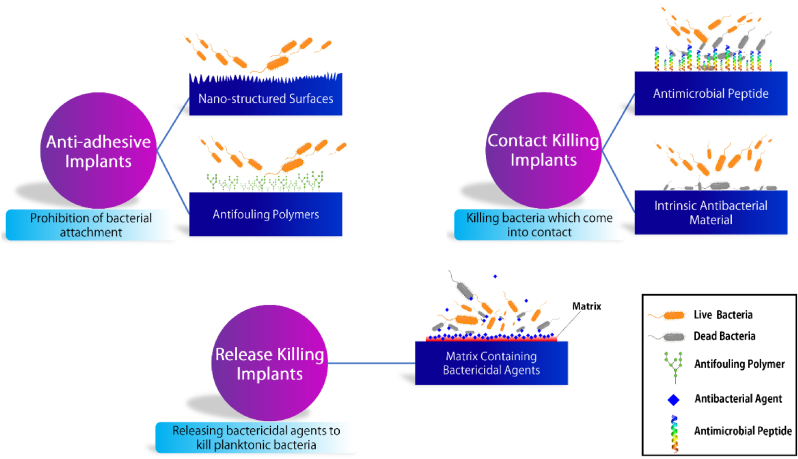

Scheme 3.

Various strategies to fabricate an antibacterial implant. Anti-adhesive implants are obtained through either changing the surface chemistry or morphology of the implants. Contact killing implants are fabricated by immobilizing antimicrobial peptides (AMP) on the surface or utilizing antimicrobial chemical compounds. Release-killing implants are acquired by equipping the surface with an antibacterial agent, which could be released from a matrix coated on the surface.

3.1. Anti-adhesion implants

One of the widely applied approaches to prevent biofilm formation on the implants is surface modification with an aim to prevent or reduce bacterial adhesion. Such surfaces possess antifouling or antiadhesive properties and do not allow bacterial adhesion; nonetheless, they may not kill the bacteria. They are classified as passive surfaces which just discourage bacterial adhesion and do not kill bacteria. The antiadhesive implants can be achieved through fabricating micro/nano-structured surfaces or via physically immobilizing antifouling polymers on the surface of implants [41,43]. The immobilization of antifouling polymers can also be applied by chemical grafting that is acquired by UV, plasma, or ozone activation [[44], [45], [46], [47]]. However, the chemistry involved in chemical grafting is often complex, difficult to scale up, and challenging to replicate [48].

In many studies, the antibacterial activity of surfaces with nanotopographic features have been investigated. Hue et al. [49], for example, reported the improvement in antiadhesion properties of selective laser melting (SLM)-modified titanium implants by coating titanium dioxide nanotubes on the SLMed titanium. Yi et al. [50] coated ZnO nanopillars on various surfaces and reported that the surfaces prohibit bacterial adhesion. Inspired by cicada and catkin, Ye and coworkers [51] fabricated a biomimetic nanostructured implant through a hydrothermal chemical reaction technique, and the achieved implants demonstrated remarkable bacterial antiadhesion. Although the exact mechanisms of antiadhesion properties observed in the nano-architecture surfaces have not been completely understood, it seems that the hydrophilicity of high-roughened surfaces combined with the physical electrostatic interactions between the nanoscale topography and the bacteria are conducive to the antiadhesion phenomenon [52,53].

Antifouling polymers have been extensively used for a wide variety of applications such as drug delivery, bioseparation, marine coating, and medical implants to prevent the adsorption of biomolecules and microorganisms on the surface [54]. An antibacterial implant, on which a specific type of antifouling polymer is immobilized, produces a hydrated surface layer that resists protein adhesion [41].

There are a relatively large number of polymers that can confer antifouling properties to an implant surface [54]. Polyethylene glycol (PEG) is the most prominent one among these polymers [[55], [56], [57]]. However, using PEG as an antiadhesion agent on an implant surface is associated with the problem of blocking the adhesion of eukaryotic cells. Such blockage is unwanted because the adhesion and proliferation of eukaryotic cells on the implanted material is an indispensable step for the integration of the implant with the surrounding tissues [58]. This issue can be tackled by immobilizing a cell adhesive sequence such as arginyl glycyl aspartic acid (RGD) to the PEG-containing surfaces to maintain the bioactivity of the implants [59]. In another approach, various surface topographies combined with suitable surface chemistries can be harnessed to achieve anti-adhesion surfaces for the modification of implants [60,61]. Hsiao et al. [48], for example, reported the improvement of resistance to bacterial adhesion on a convex surface compared with a smoother surface when modified with diblock copolymers (containing poly SBMA (poly sulfobetaine methacrylate) and PPO group (poly propylene oxide)).

To turn a passive coating into an active surface that dynamically kills the contaminating bacteria; bactericidal molecules, ions, or other agents can be incorporated with the antiadhesive polymers [62,63]. This incorporation is indeed essential since anti-adhesion surfaces do not necessarily prevent the adhesion of all species of bacteria. It is, thus, required to equip the surface with a bactericidal effect to enhance the antibacterial activity of implants [41].

3.2. Release-killing implants

Local delivery of antibacterial agents from the surfaces of implants is another strategy to actively kill planktonic bacteria around the implant [64]. In fact, the antibacterial agents are confronted with bacteria that surround the wound or those which do not come in contact with the implant and kill them actively. This encounter is of paramount importance because the planktonic bacteria can invade unhealed wounds and bring about infections around the wounds [65]. Importantly, the locally administered antibacterial therapy seems to be more efficient than conventional systemic administration of antibacterial agents because the former faces bacteria in the early stages of infections and before biofilm formation.

In this approach, the surfaces of implants are coated with a matrix film in which antibacterial agents are loaded. The antimicrobial agents are released upon implant insertion into the body, thereby resulting in proficient localized drug delivery. The antibacterial agents that have been typically used in this area include metal ions such as silver (Ag+) [66,67], zinc (Zn2+) [68], and copper (Cu2+) [69], antibiotics like rifampin [70], bactericidal polymers such as polyelectrolyte multilayers [71] and chitosan [72], and antimicrobial peptides (AMP) like GL13K [73] and Mel4 [74].

Besides the type of antibacterial agents, the matrices or carriers on which the bactericides are coated define the releasing behavior of the system. The matrices can be chosen from a wide variety of options such as titanium nanotubes (TNTs) [75,76], mesoporous structures [42], hydroxyapatite [77], hydrogels [78,79], and other appropriate polymers such as chitosan [80], and polyelectrolyte multilayers (PEMs) [81]. Based on the chosen system (type of bactericide and matrix), the functional surface kills the planktonic bacteria through different approaches. For example, the metallic ions enter bacteria, interfere with their respiratory process, and induce reactive oxygen species (ROS) overproduction, which culminates in bacteria death [34].

There are numerous studies investigating the antibacterial properties of metallic ions implanted into various matrices such as titanium. Liu et al. [82], for example, doped Cu into Ti implants using the plasma immersion ion implantation technique (PIII) and reported an enhanced antimicrobial activity for the fabricated Cu-doped Ti. Wan et al. [83] also reported that the antibacterial ability of stainless steel, pure Ti and Ti alloys are enhanced by the implantation of Cu ions into these matrices. In addition, in the research of Hou et al. [84], the antibacterial effect of Ag-doped Ti was confirmed.

The releasing kinetics in release-killing implants is evidently crucial. In the initial period after implantation, the implant releases an inordinate number of bactericide agents known as the burst-release stage, followed by a slow-release stage [41]. At first glance, the burst release may be taken as a virtue because numerous antibacterial agents kill bacteria in a short time. However, it stimulates the cytotoxicity for surrounding tissues and cells and leads to short-term antibacterial activity. Thus, myriad techniques to control the speed and manner of agents’ release are well documented in the literature [80,[85], [86], [87], [88]]. In one of these techniques, the trigger-responsive antibacterial coatings can release the drugs only in the presence of bacteria, where changes in the local microenvironment, aroused by the bacterial infection, can trigger the operation of the drug delivery system [89,90]. As a case in point, Dong et al. [91] designed a pH-dependent silver nanoparticles (AgNPs) releasing titania nanotube arrays implant, in which the nanotube arrays were fabricated on the surface of titanium implant as carriers, and AgNPs were fixed on TNT implant surface via a low pH-sensitive acetal linker. As the pH level around the implant decreases to 5.5, AgNPs are released from the implant surface in high doses. Not only this technique prolongs the lifetime and enhance the efficacy of the antibacterial activity of the implant, but also it diminishes the risk of cytotoxicity of the antibacterial agents.

3.3. Contact-killing implants

Contact-killing implants are made of materials or covered with coatings that kill the bacteria on contact. Contact killing implants show a few advantages over the other two types of implants. First, contact-killing implants, unlike antiadhesion implants, actively kill the sessile bacteria [41]. Second, since the bactericide agents do not detach from the surface in contact with bactericidal implants, there is no risk of cytotoxicity to the surrounding tissues in comparison to the ion-releasing implants. Also, contact-killing implants often have a long-term bactericidal effect that makes them more efficient against bacterial infections [35,41].

Direct contact sterilization implants can be fabricated through various approaches. Implants with surfaces functionalized by AMP have been extensively reported to show antibacterial activity against a broad spectrum of bacteria [[92], [93], [94], [95], [96]]. In this type of implants, AMPs are immobilized on the surfaces through either non-covalent or covalent bonds and kill the adhered bacteria without the delivery of antibacterial agents [97,98]. In one work, as an example, the antibacterial behavior of Mel4, covalently bound to plasma polymer-coated Ti implants, was ascribed to the depolarization of bacterial cytoplasmic membrane by electrostatic interactions occurring between the membrane and Mel4 agents [99].

The other type of direct contact-killing implants are made from ceramics which inherently possess antibacterial activity. For example, zirconia implants prohibit bacteria adhesion and biofilm formation and consequently exhibit lower inflammation than titanium implants [100,101]. Another example is photoinduced titanium oxide (titania) that kills bacteria through photodecomposition and the production of ROS species [102,103].

Another strategy is to utilize the bactericidal activity of metals such as Ag and Cu to make antibacterial implants. Contact killing implants containing metals could be secured either by embedding them to the surface via surface modifications such as plasma activation strategies [104,105] or by intermingling them into the matrix during the fabricating process (alloying) [21,106]. For example, Chen et al. [107] endowed the surface of titanium implants with antibacterial properties via silver and reported that the surface-treated implants exhibited more than 90% antibacterial activity against Escherichia coli (E. coli), Pseudomonas aeruginosa (P. aeruginosa), and Staphylococcus aureus (S. aureus). Alternatively, Lei et al. [108] fabricated Ti–Ag alloys with different silver contents and noted that Ti–Ag with 3 weight percent (wt.%) and 5 wt.% Ag possessed prolonged antibacterial activities and good biocompatibility.

Numerous techniques, including ion implantation [83], oxidation [109], ion-beam assisted deposition [110], dip coating [111], plasma spraying [112,113], electroplating [114], magnetron sputtering [105,[115], [116], [117], [118], [119]], ion-assisted plasma polymerization [[120], [121], [122], [123], [124]] and plasma immersion ion implantation (PIII) [[125], [126], [127], [128], [129]] have been established to fabricate implant coatings and bioactive interfaces. In particular, a large body of works has been devoted to create contact killing surfaces that contain bactericidal agents such as F [130], Cu [83,131], Ag [108,109,132] and Zn [133]. Table 1 lists various techniques utilized to coat copper-containing surfaces and their antibacterial performance. Nevertheless, one important aspect that needs to be taken into consideration is that these types of coatings may lose their antibacterial effectiveness over time because ion-releasing is inevitable, and the antibacterial agents may run out over time. Moreover, surface coatings can be vulnerable to mechanical shear forces and may delaminate from the substrate under physiological environments [134]. Therefore, implant materials alloyed with antibacterial metals can present a more prudent course of action because the bulk of the material exhibits antibacterial activity rather than only the surface and for a long period.

Table 1.

Techniques used to fabricate antibacterial Ti–Cu coating and their antibacterial efficacy.

| Substrate | Antibacterial Agents | Fabricating Method | Description | Antibacterial Rate (%) | Ref. |

|---|---|---|---|---|---|

| Pure Titanium | Copper | Ion Implantation | The concentration of Cu was 4 × 1017 Cu ions/cm2 | 100% in plate count method test | [135] |

| Si wafer | Ti-xCu film | High power impulse magnetron sputtering (HiPIMS) and DC magnetron sputtering (DCMS) | A cuboid Ti target was used for DC magnetron sputtering (DCMS), and a Cu target was sputtered using high power pulsed magnetron sputtering (HPPMS) | The antibacterial activity of Ti-xCuO coatings, x = 3.1–33.9 at.% in plate count method was 99% | [116] |

| Pure Ti | Nitrogen (N) and copper (Cu) dual ions | plasma immersion ion implantation and deposition (PIII&D) | Titanium nitride (TiN) film was embedded with Cu nanoparticles (Cu NPs) | Cu–Ti and N/Cu–Ti samples showed nearly 100% antibacterial efficacy in bacterial counting method | [126] |

| 316L stainless steel and Si | Ti-xCu coating | Hybrid high power impulse magnetron sputtering (HiPIMS) and DC magnetron co-sputtering (DCMS) | Ti-xCu coatings were co-sputtered on silicon wafers and polished 316 L stainless steel substrates using DCMS and HiPIMS techniques | Pure Cu and Ti-xCu coatings with x = 55 and 65 at.% showed an antibacterial efficacy of 99.9% | [105] |

Alloys that are made with antibacterial elements have other merits over ion-releasing and anti-adhesion implants. First, antibacterial alloys are inherently equipped with the ion releasing mechanism, and the antibacterial elements are released in solution and kill bacteria. Secondly, the fabricating process of alloys can be simpler and with lower cost than complex immobilizing procedures to couple antibacterial agents to surfaces.

4. Antibacterial effects of copper

Since the down of civilization, copper and its compounds have been exploited for hygiene in general and as disinfectant agents to sterilize chest wounds and drinking water [22]. In the 19th century, scientists discovered the adverse effect of pathogens on everyday diseases, and since then, many studies have been carried out on antibacterial agents such as copper [136]. The use of copper as an antimicrobial agent proceeded until the advent of antibiotics in the 1930s, but the spread of antibiotic-resistant bacteria at the end of the 1980–1990s raised the need for different approaches to combat pathogens, one of which was to take advantage of copper surfaces in hygiene-sensitive areas. In 2008, the U.S. Environmental Protection Agency (EPA) officially recognized copper and its alloys as the first effective metallic antibacterial agents, and thenceforth, the research community quickly introduced copper into the research cycle of manufacturing disinfectant surfaces and implants [22]. In general, copper has been deployed as an antibacterial agent in various forms, such as thin films, ionic forms, and nanoparticles, depending on its end application in a biomedical device [[137], [138], [139], [140]]. Also, copper can be used either purely or as a component of a wide range of alloys, including those that are based on Ti [141,142].

Vast investigations have addressed the antibacterial activity of metallic copper and copper alloys over a broad spectrum of bacteria. Word Health Organization announced methicillin-resistant Staphylococcus aureus (MRSA) as a high-priority pathogen and a serious threat to public health [143]. However, it has been reported that pure copper kills the whole population (107 cfu/mL) of MRSA in only 45 min [144]. In another study, the results showed that after only 90 min exposure to a copper surface at 20 °C, a high concentration (107 cells) of E. coli vanished [145]. Additionally, it was demonstrated that copper alloys (>70% Cu) completely kill Clostridium difficile (C. difficile) after 24–48 h [146]. Souli et al. [147] investigated the antibacterial activity of copper surfaces on clinical isolates of E. coli, Enterobacter spp., Klebsiella pneumoniae (K. pneumoniae), P. aeruginosa and Acinetobacter baumannii (A. baumannii); and reported that copper surfaces destroyed all tested strains within a few hours.

4.1. The two modes of stress

When bacteria come in contact with a copper surface, a series of events causes the bacteria to be destroyed. In this regard, the main molecular target of copper, the nature of bacterial changes, and the sequence of events that lead to bacterial death have not yet been fully understood. This has been the subject of considerable debate among researchers for many years. In this section, we strived to point out the contradictions around the identification of cellular targets of copper toxicity in order to have a deeper understanding of the antibacterial activity of Ti–Cu alloys. Nonetheless, we emphasize that in works reviewed in this section, copper has been used either purely or with relatively high concentrations (copper coupon with 100 wt.% of copper or alloys with at least 50 wt.% of copper). Bacterial exposure to these forms of antibacterial metal is highly acute and is different from bacterial contact with Ti–Cu alloys with lower content of copper. In the former, cells face more challenging conditions which differ from the latter chronic case [148]. However, we tried to focus on results that can be achieved in both states of copper, namely pure copper or as a component of alloys.

In a controversial work, Airey and Verran [149] reported that the MRSA was not killed after exposure to the surfaces of copper coupons. This finding was based on the Live/Dead staining technique which is used to distinguish damaged cells from those left intact. The authors observed that MRSA cells were undamaged, therefore concluding that the copper surface is unable to kill MRSA. However, Weaver et al. [150] challenged these results by studying the antibacterial effect of copper surfaces against MRSA and analyzing DNA integrity and tracking respiring MRSA cells. Results indicated that although copper exposure does not affect the cell membrane integrity (Fig. 1), copper surfaces are able to kill bacteria by other mechanisms. DNA analysis showed that copper causes MRSA inactivation by inducing maximum damage to the genomic DNA. Also, no activity of respiring cells was found. Thus, the claim of MRSA viability upon copper exposure was refuted and instead, an alternative model was proposed. This model suggests that copper ions enter the cell and rapidly kill MRSA by applying detrimental effects on cellular respiration and DNA integrity without markedly effecting the integrity of the cell membrane.

Fig. 1.

An assessment to detect the cell membrane integrity of MRSA bacteria inoculated with copper surfaces. Bacteria were stained with Backlight™, Systo 9 (a), and propidium iodide (b). Cells with undamaged membranes fluoresce green (a), while bacteria with damaged membranes fluoresce red (b). This assessment shows that copper exposure does not disrupt the cell membrane integrity of MRSA. However, other analyses reported in this work confirmed that bacteria were killed as a result of damages to their DNA and respiratory system [150].

Understanding the damage delivered to the DNA of bacteria upon exposure to a copper-containing surface, or any antibacterial agent in general, is of great importance because otherwise (in the case of intact DNA), there is the possibility of emergence and spread of resistant organisms [151]. Warnes et al. [152] investigated the antibacterial effect of copper surfaces against pathogenic enterococci, a type of bacteria with a high propensity for genetic transfer. The authors reported that copper and copper alloys resulted in the disintegration of Gram-positive enterococci DNA into fairly small fragments and inhibition of respiration, while just little damage to the cell membrane was observed. This finding suggests that the development of copper resistance is unlikely. Warnes et al. confirmed their previous results in other works and added that the membrane depolarization occurs after cell death [153,154].

Nevertheless, Espírito Santo et al. [148] were uncertain about whether DNA damage is causative for or subsequent to cell death and conducted an experiment to investigate the primary target of copper in both Gram-positive [(Bacillus cereus (B. cereus), and Deinococcus radiodurans (D. radiodurans)] and Gram-negative (E. coli) bacteria. Their study showed strong evidence that death in both Gram-negative and Gram-positive cells after contact to copper surface coincided with membrane damage which are combined with the cellular accumulation of copper. Indeed, they suggested that lethality is not caused by DNA damage, and instead, DNA damage is a secondary event ensuing the cell death. Various studies on the different types of bacteria confirm the results reported by Espírito Santo et al. [22,141,[155], [156], [157], [158]]. Grass et al. [22] believed that bacteria-killing proceeds by the following steps: membrane disintegration, copper accumulation in cells, oxidative damage, cell death, and DNA degradation.

Therefore, based on the argument mentioned above, there are generally two competing hypotheses as the two modes of stress about the antibacterial characteristic of copper surfaces:

-

1

The cell membrane is the primary target of copper surface-induced lethality, and DNA damage occurs after cell death.

-

2

The genotoxicity of copper and damage to cellular DNA is the underlying cause of bacteria death, and cell membrane damage occurs after cell death.

There is a possibility that the difference in the cell wall structure, which determines the type of bacteria (Gram-positive and Gram-negative), determines the effective mode of stress. The lack of the outer membrane and periplasmic space in the cell wall of Gram-positive bacteria can make DNA accessible to copper ions and their damage. Thus, the latter hypothesis is the controlling mechanism. In contrast, in Gram-negative bacteria, due to the protection of nucleic acid by the periplasm, the access of copper ions to DNA is restricted until the cytoplasmic membrane becomes disintegrated. As such, the first hypothesis is more likely in this case [153]. Nevertheless, Santo et al. [155] reported that the antibacterial mode of stress for copper is not dependent on the structural difference in the cell wall, and all bacteria are killed as a result of extensive membrane damage. However, the kinetics of killing (time needed to kill bacteria) can be affected by the morphology of the cells [141,155].

Regardless, Vincent et al. [139], in their review paper, have considered this discrepancy inevitable as a result of different protocols and assays, and various types and strands of bacteria used with varying forms of copper (coupons, alloys, and particles) across different works published in the literature. In another review paper, Grass et al. [22] suggested that there is no risk of developing bacterial resistance to copper because copper exposure completely degrades plasmid DNA, which is responsible for the transfer of resistance genes between organisms. Another reason is that copper surfaces kill bacteria rapidly, leaving no time for bacteria to divide and thus preventing the development of resistance genes. The fact that copper has been utilized by humans since the dawn of humanity, yet no bacteria resistant to copper have been detected, supports the claim of no bacterial resistance to copper. Taken together, future studies should be concentrated specifically on this subject by deploying pre-arranged protocols and investigations in a systematic manner to be able to compare determinant factors between studies.

The noteworthy point to bear in mind is that the two modes of stress are inseparably interwoven with the two antibacterial mechanisms discussed above, namely ion releasing and contact killing. It is suggested that during the contact of bacteria with the Cu-containing metal, the metal-bacterial contact damages the cell envelope of the bacteria and, subsequently, makes the cells susceptible to further damage by copper ions [157]. Thus, the contact killing mechanism results in the cell membrane rapture, and the damage to DNA stems from the accumulation of copper ions into the bacteria cells. Therefore, a distinction should be drawn between these two concepts. In a recent publication, for example, the authors incorrectly considered these two concepts identical and used them interchangeably [159].

Using a specific engineering design, Mathews et al. [160] well discriminated the ion releasing mechanism from the contact killing mechanism. They designed a system named contact arrays in which the surface of a copper coupon was coated with an inert polymer so that it prevented contact of the Enterococcus hirae (E. hirae) bacteria with the metal surface (Fig. 2). It was observed that although the quantity of released ion in the sample coated with contact arrays was preserved in comparison to the non-polymeric sample, the antibacterial characteristic of the modified surface was significantly attenuated, indicating the importance of the contact killing mechanism.

Fig. 2.

Scanning electron microscope (SEM) images of the contact array system designed by Mathews et al. [160] This system was used to show the significant role of the contact-killing mechanism in the antibacterial ability of a copper surface. The surface of the copper coupon was coated with an inert polymer to prevent contact of the E. hirae bacteria with the metal surface. The SEM images of the honeycomb-like structure of inert polymer coated on the surface of the copper coupon at relatively low (a) and high (b and c) magnifications. The size of the holes was designed to be smaller than that of bacteria to prevent the contact of bacteria with the copper surface. The red arrows point to E. hirae bacteria.

5. Ti–Cu antibacterial implants

Among the metallic alloys employed for implants, such as stainless steel, cobalt-chromium, niobium, and tantalum, titanium and its alloys have been widely used in the preparation of orthopedic and dental implants because of their superior mechanical properties, high fatigue limit, corrosion resistance, bioactivity, as well as biocompatibility [161]. The mechanical properties of the material and the loading conditions in the host have, conventionally, influenced material selection for different clinical applications. For example, Ti–6Al–4V is commonly used in orthopedics, while commercially pure titanium is utilized in dentistry [162]. However, due to the cytotoxicity and neurotoxic effects of aluminum and vanadium, Ti–6Al–4V alloys should be cautiously and carefully used in biomedical applications [163,164].

Despite the advantages of Ti-based implants, they are susceptible to bacterial adhesion and colonization which leads to biofilm formation and implantation failure in the later stages [40,165]. The bacterial infection caused by biofilm formation upon implantation is one of the most considerable complications in orthopedic surgery and dental implantation. As explained above, the biofilm formation protects the bacteria enmeshed in EPS against environmental dangers such as antibiotic treatment and the immune system [30]. Thus, the most effective approach to prevent biofilm formation on implants is to provide them with an antibacterial surface that discourages the first phase of biofilm formation. This can be achieved through introducing antibacterial elements such as Cu, Ag, and Zn into the Ti-based alloy system [166]. A quick survey of the literature reveals that among these elements, vast investigations have been dedicated to the Ti–Ag implants. However, Ti–Ag implants suffer from a serious drawback: formation of silver salts that may be absorbed into the circulatory system and become deposited in various body tissues, leading to some major medical problems [167]. In addition, the antibacterial activity of Ag is more pH-, humidity-, and temperature-dependent compared to that of Cu, which may restrict its applications [[168], [169], [170]].

These drawbacks encouraged researchers to focus on other alternatives, including titanium-copper alloys [171]. Considering the antimicrobial efficiency, economic cost, and cytotoxicity, the copper element can be a promising agent [164,172]. In an investigation, among 21 metallic elements tested, silver and copper presented similar rates of bacteria-killing, which was 5- to 10-fold higher than that of other elements [173]. In addition, unlike silver element, copper as an essential trace metal, has biological applications in the body and is an important member of several enzymes in the cell and contributes to the formation of red blood cells in the body [174,175]. Copper also endows the alloy with satisfactory strength, ductility and corrosion resistance [165,[176], [177], [178], [179], [180]]. In addition, copper triggers the proliferation and osteogenic differentiation of mesenchymal stem cells (MSCs), and brings about angiogenesis and collagen deposition [181,182].

The appropriate amount of copper added into Ti should be carefully considered since a small amount of copper brings nearly non-antibacterial ability, whilst excess concentrations of copper would cause cytotoxicity. The adequate daily intake of copper for each adult is in the range of 2–3 mg, and the World Health Organization (WHO) recommends the tolerable upper intake level (UL) of approximately 10 mg/day for adults as the excessive amount of Cu is highly toxic for cell, though other ions such as silver are harmful to biological cells even in small quantities [[183], [184], [185]]. Therefore, the development of Ti–Cu alloys with suitable balance among antibacterial properties, cytotoxicity, and formability has important implications for developing dental and orthopedic implants. Considering that excessive copper intake can cause metal toxicity, titanium alloys with a copper content lower than 10 wt.% have been extensively investigated in the literature [172].

Although initially, copper was added to titanium implants in order to improve their mechanical properties and also to increase the casting ability [[186], [187], [188]], Shirai et al. [21] firstly reported the antibacterial properties of a Ti–Cu implant in 2009. In this research, the antibacterial properties of Ti-1 wt.% Cu, and Ti-5 wt.%Cu (hereafter referred to as Ti–1Cu and Ti–5Cu) implants were investigated. All the Cu-containing samples were “antibacterial” according to the GB4789.2–2010 Food Safety Standard, which considered materials with antibacterial efficacy of higher than 90% as “antibacterial” [163]. This research was a distinguished turning point for the development of antibacterial Ti–Cu implants and showed the great potential of the copper element in the fabrication of anti-infection biomaterials. Since then, considerable efforts have been made to further develop this alloy system in order to improve its antibacterial activity, cell biocompatibility, mechanical properties, and anticorrosion behavior.

The two most common bacteria that in most cases cause implant-associated infections are S. aureus (Gram-positive) and E. coli (Gram-negative). It has been well documented in the literature that Ti–Cu alloys effectively kill both of these bacteria [176,[189], [190], [191], [192], [193], [194], [195], [196], [197]]. For example, Zhang et al. [19] reported that the Ti–10Cu alloy removed more than 99% of S. aureus and E. coli bacterial colonies in the plate-count method assay even after several times of polishing (Fig. 3). This experiment confirms that antibacterial properties in Ti–Cu alloys exist in the entire materials, including their bulk and surfaces, compared to Cu-coated surfaces, which show antibacterial effect only on the surface. In another study, the antibacterial rates of Ti–3Cu alloy and Ti–4Cu alloy reached 90.33% and 92.57%, respectively [198]. The in vitro results in Lui and co-workers’ study [199] showed that sandblasted and acid etched Ti–5Cu (SLAed alloy) kills at least 90% of Streptococcus mutans (S. mutans) and Porphyromonas gingivalis (P. gingivalis) -two significant oral bacteria-compared to SLAed Ti, and also significantly inhibits biofilm formation. Also, the outstanding antibacterial effects and favorable biocompatibility of the sintered Ti–10Cu alloy have been proved through in vivo rabbit muscle infection model in another study [200].

Fig. 3.

Typical S. aureus and E. coli colonization images of (a)–(b) negative samples, (c)–(d) control samples (cp-Ti), and (e)–(f) Ti–10Cu samples after incubation for 24 h in the plate counting test method. A large number of bacteria were detected on the negative and cp-Ti samples, indicating that cp-Ti does not show antibacterial activity. However, the copper-containing sample (Ti–10Cu) killed nearly all S. aureus and E. coli bacteria, indicating that Ti–10Cu implants exhibit a strong antibacterial activity [19].

Besides the significant antibacterial performance, Ti–Cu alloys can present desirable biocompatibility with bioactivity behavior. Research showed that the Cu-containing antibacterial Ti alloys exert favorable cell spreading behavior with no cytotoxicity to a range of cell types such as rBMSCs, MG63, and MC3T3-E1 [137,178,[201], [202], [203], [204], [205]]. As an example, the study of Zhang et al. [204] demonstrated great cell adhesion and spreading of MG63 cells on Ti–Cu alloys with outstanding cell viability. In another study, it was reported that the Ti–Cu alloys can further encourage cell differentiation in comparison with cp-Ti. Moniri et al. [203] reported that Ti–Cu alloys trigger osteoblast formation due to the release of Cu ions. In vivo investigations also confirmed the favorable potential of Ti–Cu alloys in promoting osteogenesis [206,207].

5.1. Mechanisms of action in Ti–Cu implants

Researchers have not yet reached a general agreement on the mechanisms of copper-induced antibacterial effect, i. e contact-killing or ion-releasing. However, it is clear that copper causes “multiple-hit damage” in bacteria cells by various pathways, including oxidative stress and leakage of essential nutrients; disrupting the structure of enzymes and their functions; damaging the DNA; and oxidation of cell proteins, nucleic acids and lipids [134,136,[208], [209], [210]]. Recently, it was reported that upon the contact of S. mutans with the surface of a Cu-bearing Ti implant, the pathogenicity of bacteria diminished and the biofilm formation was prevented [211]. This activity was explained by down-regulation of the gene expressions related to the bacterial adhesion and acid production. In early articles in the field, the release of copper ions was considered the underlying mechanism of such antimicrobial activity [[212], [213], [214]]. Wang et al. [165] reported that high copper contents in an Ti–Cu alloy result in the release of higher concentrations of Cu ions which yields stronger antibacterial ability. Eriksson [215] believed that continuous release of copper ions from the Ti–Cu alloys surface kills the bacteria by preventing biofilm formation. Liu et al. [202] argued that with the increase in incubation time, the number of ions released from the Ti–Cu alloy is enhanced, and consequently, the antibacterial performance improves. In the research of Cao et al. [216], the antibacterial effect of the surface-oxidized Ti–Cu alloy was attributed to the formation of Cu2O and CuO and release of Cu+ and Cu2+ from the coating.

In other research as well, the antibacterial properties of the Ti-Cu alloys have been attributed to the release of copper ions. Nevertheless, we could trace contradictions in the results. As a case in point, the minimum inhibitory concentration (MIC) of copper ions for the E. coli and S. aureus is determined to be 256 μg/mL and 448 μg/mL, respectively [[217], [218], [219]]. However, the measured amount of released copper ions per day from Ti–5Cu alloy in the research of Lui et al. was 0.003 μg/mL which was considerably lower than the MIC values reported for the two mentioned bacteria [39]. Nevertheless, the antibacterial rate in this alloy was more than 90%. In the research of Zhang et al. [19] the concentration of copper released from the Ti–10Cu was 0.34 mg/L, while zero S. aureus bacterial survival was recorded. Once again, the concentration of released copper ions from the surface was insufficient to generate such a substantial antibacterial effect. Fowler et al. [169] reported that a solution with the copper concentration of 9 × 10−5 g/mL actively killed more than 90% of Staphylococcus epidermidis (S. epidermidis) bacteria. Nonetheless, in their previous study, they showed that the Ti–10Cu with the ion releasing amount of 9 × 10−8 g/mL exhibits a much larger antibacterial effect [171]. From these works, it is clear that the concentration of copper ions released from the surface of Cu-containing materials is far less than the MIC. This implies that considering the release of Cu ions as the main mechanism of antimicrobial activity may not be precisely correct. In summary, for all bacteria to be killed solely through the ion releasing mechanism, the concentration of released copper ions must be equal or greater than the MIC value [220]; otherwise, another mechanism must be playing a role [207].

5.1.1. Contact-killing mechanism

In the previous sections, the two modes of stress exerted by copper on bacteria were described, and it was discussed that membrane damage could occur. However, several researchers believe that this may not be the primary target of copper [150,[152], [153], [154]].

Considering the studies in which transition electron microscopy (TEM) and atomic force microscopy (AFM) analyses were used to monitor the bacteria, it seems that cell envelop rupture plays a significant role and cannot be neglected [39,207,[221], [222], [223]]. Using AFM, Nan et al. [221] demonstrated that after contact of E. coli bacteria with the surface of copper-bearing stainless steel, the cell wall of E. coli is disintegrated. In the research of Liu et al. [39], TEM images of examined bacteria (Fig. 4) indicated that after contact with a copper-bearing alloy, the peptidoglycan layer of bacteria is disappeared (e), the cell membrane is separated from the cell wall (f), and the cellular contents release out of the bacteria (h). In a similar study, E. coli and S. aureus bacteria were exposed to Ti–5Cu alloy, and analogous observations were reported [207]. Furthermore, Li et al. [224] reported S. aureus bacteria were killed when they were exposed to Ti6Al4V5Cu alloy. However, the genomic integrity of bacteria in contact with the copper-containing alloy was not damaged, but the gene replication process was disrupted. The vital point to bear in mind is that it seems the membrane disintegration is not due to the attack of copper ions. Instead, the contact of bacteria with the copper-containing surface may be a key, defining factor [139,160,177,190,225,226].

Fig. 4.

TEM images of S. mutans and P. gingivalis bacteria. (a) S. mutans bacteria exposed to Ti. (b) P. gingivalis bacteria exposed to Ti. (c) S. mutans bacteria exposed to Ti–Cu alloy. (d) P. gingivalis bacteria exposed to Ti–Cu alloy. White and black arrows show the peptidoglycan layer and the cell membrane, respectively. The red arrow determines the separation of the cytoplasmic membrane from the cell wall and expels the contents of the cell. The bacteria exposed to the Cu-containing surfaces exhibit shriveled or cracked morphologies [39].

What is the unique characteristic of a copper-containing surface which is conducive to membrane disintegration? This question cannot yet be answered clearly and confidently because there is no striking information available on the processes involved. It is known that the initial attachment of bacteria on a surface is governed by physical and electrostatic forces such as van der Waals force and hydrophobic interactions [221]. Therefore, the hydrophilicity of the implant surface and the surface charge of bacteria influence the adhesion forces [220]. Nan et al. [221] proved that the adhesion force of “bacteria cell-antibacterial stainless steel” (Cu-containing stainless steel) is more than that of “cell-stainless steel” and even “cell-cell”. These finding provide evidence that bacteria are more strongly absorbed onto the antibacterial surface. To justify the cell envelop rapture due to the contact of bacteria with the copper surface, we suggest that the electrostatic interactions of the Cu-containing phase disrupt the balance in the internal-external osmotic pressure of the cell which is conducive to the disintegration of the cell envelope. It is reported that the concentration of K+ (which plays a significant role in the regulation of cellular osmotic pressure [24]) in the bacterial solution after the contact of bacteria with antibacterial stainless steel tremendously increased, indicative of the disorder in the osmotic pressure of the bacterial cell [221]. In addition, Shi et al. [220] claimed that under the contact killing mechanism, the Cu- or Ag-containing particles cause physiological metabolic disorders of bacteria by disrupting the normal functions of membrane proteins and ion channels on the bacterial cell membrane. This eventually results in the leakage of cytoplasm, as observed in Fig. 4. In another study, it was confirmed that leakage of reducing sugars and proteins from the cells occurs when the S. aureus bacteria come in contact with the Ti6Al4V5Cu alloy [224].

A few recent studies attributed the contact killing mechanism to the galvanic cells generated as a result of the potential difference between the matrix (Ti phase) and the Cu-containing phase (such as Ti2Cu and Cu-rich phase) on the surface [132,[227], [228], [229], [230], [231]]. In the Ti–Cu implants, the intermetallic phase of Ti2Cu owns a nobler standard of electrode potential than the titanium matrix. Therefore, the intermetallic phase appears as an anode, and the matrix acts as a cathode in the Ti–Ti2Cu micro galvanic couple (or micro-electric couple), in the presence of solution [231]. Zhang et al. [227] estimated the potential difference between the Cu-rich phase and stainless-steel matrix is around 40 mV, creating a charge transfer between anode and cathode in the mentioned micro electric couple near the Cu-rich phase.

On the other hand, various respiratory chains embedded in the cell membrane of bacteria generate energy (synthesize adenosine triphosphate (ATP)) for bacterial survival through successive electron transfer reactions. During the release of ATP, the ATP synthetase (ATPase) pushes H+ to the outside of the membrane by dissociation of H2O and leaves OH− within bacteria, which leads to an electrochemical gradient of protons, known as the proton motive force (PMF). Based on the chemiosmotic model, the PMF, the difference in free energy of inside and outside of the bacteria, pumps protons from outside into the cell, facilitating the ATP synthesis. The electrochemical potential also creates a membrane potential (Δψ). Therefore, the PMF is essential for bacteria to grow and remain viable [[232], [233], [234], [235]]. When the bacteria are in contact with the material surface, the potential difference between the Cu-containing phase and the matrix consumes H+ ions. This in turn disrupts the PMF activity of bacteria, resulting in the reduction of ATP production. In addition, electron transfers induced from the potential difference of microdomains (Cu-containing phase and matrix) interfere with the normal respiration of bacteria and hasten the production of intracellular ROS, which in turn trigger the bacteria death.

In the study of Fu et al. [236], this phenomenon was well demonstrated. Knowing that pure Au, Ta, and Zr show no antibacterial activity against S. aureus and E. coli, Fu et al. selected these elements rather than Cu and Ag to prepare Ti–Au, Ti–Ta, and Ti–Zr alloys. The authors found that only the Ti–Au alloy shows significant antibacterial effect due to the presence of intermetallic phase Ti3Au (only Ti–Au had secondary phase). It was reported that the micro-area potential difference (MAPD) between the second phase and the matrix induces electron transfer between them which interferes with the ETS of bacteria and ultimately leads to bacterial death. Moreover, Xie et al. [237] confirmed that the existence of MAPD between Ti2Cu and the matrix results in the antibacterial effect of the Ti–Cu alloy. Thus, the formation of Ti2Cu phase plays a pivotal role in the antibacterial behavior of Ti–Cu alloys [238]. Scheme 4 illustrates how the presence of Ti2Cu in the microstructure of Ti-Cu alloy can actively kill bacteria through the contact killing mechanism.

Scheme 4.

Schematic of contact killing mechanism of Ti–Cu implants containing the intermetallic phase of Ti2Cu in their microstructure. (a) The planktonic bacteria adhere to the surface of the implant. (b) After contact with the implant surface, the cell wall of bacteria is disintegrated and the cellular content leaks out. (c) The potential difference between Ti2Cu and Ti matrix results in the formation of micro-galvanic cell and the generated electron transport between the anode and the cathode of the cell is conducive to the interfering of normal cell function such as ATP synthesis and disturbing the potential membrane. Another suggested mechanism is the disruption of balance in the internal-external osmotic pressure of the cell due to the excessive accumulation of K+ outside the bacteria which is culminated in the disintegration of the cell.

5.1.2. Ion-releasing mechanism

Although our understanding of the contact killing mechanism is still limited, the ion releasing mechanism that encompasses all interactions of copper ions with the internal components of bacteria cells is almost fully known.

Copper ions within the bacteria facilitate the production of ROS [136,239]. Hydrogen peroxide (), superoxide anion (), and hydroxyl radical () are the three common types of ROS [240]. Inside the bacteria, ROS is created as a byproduct of natural metabolism, but it can also be produced in the presence of copper ions, during the Fenton-type reaction and Haber-Weiss cycle [241], and in some cases during the non-Fenton reactions [242]. Oxidative stress is referred to a condition where the balance between environmental ROS production and the ability of a biological system to detoxify them is disturbed. Such condition leads to extreme ROS production and consequently to loss of normal cell function and, ultimately, cell death [160,243,244]. Generally, free radicals attack their nearest molecules to steal their electrons. Thus, the attacked molecule becomes a free radical itself and thereby a chain reaction commences. These radicals spread like an avalanche through the entire bacteria cell, oxidize lipids, amino acids, carbohydrates, and ribonucleic acid (RNA) and also cause DNA mutation [40,158,175,[239], [240], [241],[244], [245], [246], [247], [248]]. Also, free radicals can directly attack the polyunsaturated fatty acid in the cell membrane and initiate lipid peroxidation (cell membrane disruption) [190,224]. Li et al. [224] investigated the effect of copper addition to Ti6Al4V alloy on the ROS production and the killing ability of this alloy in S. aureus. The authors reported that the antibacterial alloy produces a large concentration of ROS in the bacterial cell. Also, Grass et al. [22] discussed that the redox cycling between different copper species, Cu, Cu+, and Cu2+ is the reason for ROS production and showed that the absence of oxygen in this cycle doubles the time required for the complete killing of bacteria. Furthermore, Mathews et al. [160] reported the reduction potential of Cu/Cu+, Cu+/Cu2+, and Ag/Ag+ are in the range of biological reduction potentials which results in the production of ROS species.

In addition to such ROS-regulated damages to critical bacteria components, the copper ion itself also has destructive interactions with components within the bacteria. These interactions have important implications, including a negative impact on the ETS and hence energy production [139,150], an adverse effect on gene expression such as the expression of genes related to the formation of biofilm [245], reducing the amount of protein and polysaccharide in the biofilm [39], effects on Fe–S protein clusters [246,249], damage to the cell membrane by electrostatic reactions [249,250], disturbance of metal/metal ion homeostasis, genotoxicity, photo-cleaning, and protein and enzyme dysfunction [249].

5.2. Aspects affecting the measured antibacterial activity of Ti–Cu implants

Reviewing the literature reveals that a few experimental factors greatly influence the data obtained on the antibacterial performance of Ti–Cu implants. These factors should be carefully considered when evaluating the experimental results, as they can be the underlying reason of the contradictions among different works reported in the literature.

5.2.1. Methods for in vitro evaluating the antimicrobial activity

In an early work, Zhang et al. [19] investigated the antibacterial performance of Ti–10Cu. The antibacterial activity of this alloy was measured through two approaches: plate-counting method and agar diffusion assay with the presence of S. aureus and E. coli bacteria. According to the obtained results, Ti–10Cu alloy showed no antibacterial characteristics in the agar diffusion test, but this alloy removed more than 99% of bacterial colonies in the plate-count method assay. This research clearly shows that the assay might influence the observed antibacterial activity of the alloy. Generally, the various parameters in the established antibacterial measurement method, such as incubation condition (time [202] and temperature [139]), culture media [251], the size of alloy, the number of bacteria, and the type of bacteria [172] may impact the results. For example, it was reported that the antibacterial activity of a Ti–Cu alloy was enhanced from 90% to 100% by prolonging the incubation time from 7 h to 24 h [202]. In addition, the condition of the implant surface in terms of whether it is dry or wet (inoculation methods) simulates the contact distance between bacteria and the implant. Thus, the applied inoculation method also influences the antibacterial behavior of the implant. It is established that in the dry inoculation, when bacteria are in full contact with the implant, the maximum antibacterial efficacy is observed [227,252]. Table 2 shows the impact of experimental parameters on the observed antibacterial performance of alloys.

Table 2.

The effect of experimental conditions on the antibacterial performance of various Ti–Cu alloys.

| Alloy (Ti- wt.%Cu) | Conducted Method | Bacteria | Experimental Condition | R % (antibacterial efficacy) | Ref. |

|---|---|---|---|---|---|

| Ti–10Cu | Agar diffusion assay | S. aureus | Incubation at 37 °C for 24 h under a humidity of 80% | No inhibition zone | [19] |

| E. coli | No inhibition zone | ||||

| Plate-count method | S. aureus | Incubation at 37 °C for 24 h under a humidity of 90% | >99.6 | ||

| E. coli | >99.2 | ||||

| Ti–5Cu | Biofilm-based gene expression | S. mutans | Incubation for 24 h | Only 43.37% of gene expression | [39] |

| P. gingivalis | Only 26.91% of gene expression | ||||

| Ti–3Cu | Plate-count method | S. aureus | Incubation at 37 °C for 24 h | Not identified but killed all bacteria after 24 h | [177] |

| Ti–5Cu | Quantitative antibacterial test | S. aureus & E. coli | Incubation at 37 °C and 90% humidity for 24 h | ≥99% | [207] |

| Ti–5Cu | Plate-count method | S. aureus & E. coli | Incubation at 37 °C and 90% humidity for 24 h | 92.7% and 96%, respectively | [178] |

| Ti–5Cu | Plate-count method | P. gingivalis | Anaerobic incubation at 37 °C for 18 h | 36% | [142] |

| BHI–S blood agar diffusion assay | No inhibition zone | ||||

| Ti–10Cu | Plate-count method | 68% | |||

| BHI–S blood agar diffusion assay | No inhibition zone | ||||

| Ti–1Cu | Bacteria direct contact test | S. epidermidis | 6 h direct contact, 24 h for growing bacteria followed by direct contact, incubation at 37 °C | 4% | [171] |

| Ti-2.5Cu | 13% | ||||

| Ti–3Cu | 16% | ||||

| Ti–10Cu | 24% |

5.2.2. Concentration of copper in the Ti–Cu alloy

The concentration of copper in the alloy can highly regulates the measured antibacterial properties. Fig. 5 presents the influence of copper content on the antibacterial efficacy of Ti–Cu alloys. Liu et al. [208] proved that the copper concentration in a Ti–Cu alloy improves the intensity of antibacterial activity; and they measured the critical amount of copper for a satisfactory and stable antibacterial performance (more than 90%), to be at least 5 wt.% Cu in a sintered alloy.

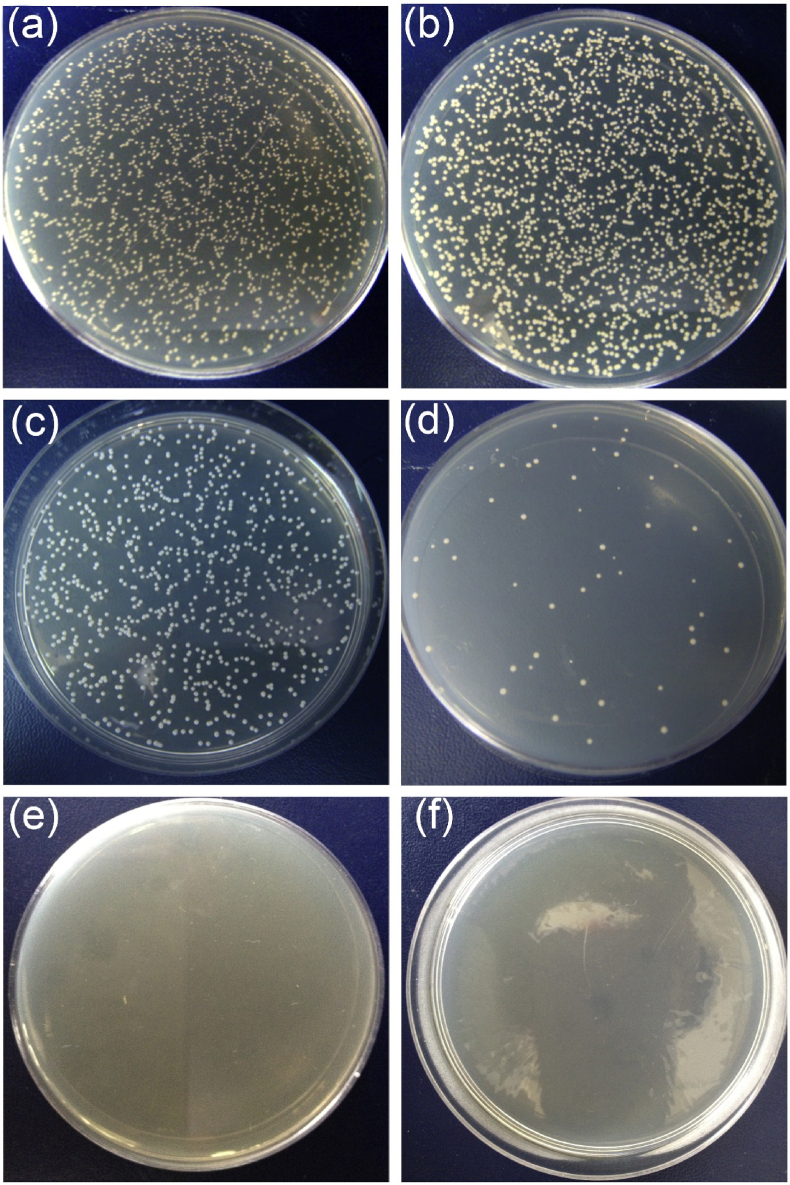

Fig. 5.

The effect of copper concentration present in the Ti-x wt.% Cu alloys on the S. aureus bacterial colonies in the plate counting test method. (a) Negative sample, (b) cp-Ti sample (c) Ti–2Cu sample, (d) Ti–5Cu sample, (e) Ti–10Cu sample, and (f) Ti–25Cu sample. While colonies excited in the case of Ti-2.5Cu and Ti–5Cu alloys, by increasing the copper content in the alloys, the bacterial colonies decreased, and alloys that contained more than 10 wt.% copper killed almost all bacteria [208].

There are significant discrepancies in the literature regarding the critical amount of copper needed to achieve effective antibacterial performance. We recognized that these discrepancies are as a result of different experimental conditions used for identifying the antibacterial activity of Ti–Cu alloy (Table 2). For instance, Bao et al. [176] used 36 h incubation time and reported an antibacterial rate of 99.3% for a typical Ti–3Cu alloy against S. aureus. However, in another research, Fowler et al. [171] employed 6 h of direct contact and reported the antibacterial rate of 16% for Ti–3Cu alloys against S. epidermidis. Rui Liu et al. [207] acquired the antibacterial rates of 96% and 80% for the Ti–5Cu alloy against E. coli and S. aureus in 12 h incubation, respectively; and for Ti–10Cu, Jie Liu et al. [202] reported the antibacterial rates of 36% and 43% against E. coli and S. aureus in 3 h incubation, respectively.

5.2.3. Microstructure of Ti–Cu alloy and the role of Ti2Cu phase

The microstructure of Ti–Cu implants, including the existing state of copper (such as Ti2Cu and Cu-rich phase) and its distribution in the alloy, exert a great influence on their antibacterial performance. In regards to the ion-releasing and contact-killing mechanisms, the microstructure of an alloy affects the release behavior of metal ions and determines the quality and the quantity of the contact surface between bacteria and implant surface. Hence, the understanding of Ti–Cu microstructure is essential to predict the antibacterial behavior of a system.

Based on the Ti–Cu binary phase diagram, the solid solubility of copper in α-Ti and β-Ti phase is about 2.1 wt.% at 790 °C and 18 wt.% at 1005 °C, respectively. The eutectoid reaction occurring at Ti-rich side of the diagram is β-Ti → α-Ti + Ti2Cu at the copper concentration of 7 wt.% (Table 3) [253,254]. Therefore, copper can exist in three different states at room temperature in the Ti–Cu alloys, which are ordinarily designed for implants applications (copper concentration less than 10 wt.%): interstitial solid solution in the α-Ti phase or unstable β-Ti phase, precipitated intermetallic Ti2Cu compound [40,226], and unstable copper-rich phases [171,208].

Table 3.

The information related to the Ti–Cu binary system at lower temperature and lower copper content.

| Solid Solubility |

Eutectoid Reaction |

Ti2Cu Phase | ||

|---|---|---|---|---|

| α-Ti | β-Ti | β-Ti → α-Ti + Ti2Cu | ||

| Cu Concentration (wt.%) | 2.1 | 18 | 7 | 40 |

| Temperature (◦C) | 790 | 1005 | 790 | 1005 |

The α-Ti phase is formed during the equilibrium cooling processes, and the microstructures containing β-Ti are fabricated due to the fast cooling of alloys from the eutectoid temperature. The intermetallic phase of Ti2Cu precipitates within the Ti–Cu alloy under equilibrium solidification conditions when the copper content is less than 40 wt.% Cu [226]. In addition, the Cu-rich phase is a result of an incomplete solid-state reaction during the cooling in the sintering process and does not have a specific stoichiometric composition. Therefore, this phase is not an equilibrium phase and occurs under certain sintering conditions [208,255]. As such, the processing methods, heat treatment conditions, and surface modification procedures greatly influence the antibacterial efficacy of Ti–Cu implants. As a case in point, Liu et al. [208] recognized 5 wt.% of copper as the minimum copper concentration for effective antibacterial performance in Ti–Cu made by conventional sintering process, while Ji et al. [256] identified the Ti–3Cu alloy fabricated by selective laser melting process with a stable, highly-effective antibacterial performance of 99%. Table 3 summarizes the critical copper concertation and temperature in the Ti–Cu binary system at low copper contents and temperatures.

As discussed above, the earlier studies proposed that the ions released from the surface of Ti–Cu implants are responsible for killing bacteria. In fact, researchers held two misconceptions in justifying the antibacterial mechanisms of Ti–Cu implants by considering the ion-releasing mechanism as the only mechanism for the antibacterial properties of Ti–Cu alloy. The first group suggested that the ions released from the solid solution phases [165,212,213,215] are responsible for antibacterial activity. It means a microstructure containing a high ratio of solid solution can release more copper ions than a microstructure comprising a high ratio of intermetallic phases, and consequently, it is expected that the former possesses a stronger antibacterial activity than the latter. However, this was not observed in the inspiring research of Zhang et al. [190], and the sample with less ion release showed greater antibacterial activity. In this research, the influence of various forms of copper on the properties of Ti–Cu implant was investigated by fabricating different microstructures (copper existing forms) in the Ti–Cu alloys via various manufacturing processes and several heat-treatment processes (Table 4). Results showed that the Ti–Cu(S) alloy, which holds a higher percentage of Ti2Cu phase and a lower ratio of the solid solution, presented stronger antibacterial activity than the Ti–Cu (T4) alloy, which contains a large amount of solid solution in its microstructure. The data shown in Fig. 6 indicate that ion-releasing cannot be the only factor defining the efficacy of antibacterial properties in Ti–Cu alloys.

Table 4.

The effect of processing methods and the microstructure of Ti–Cu alloys on their antibacterial efficacy.

| Alloy (Ti- wt.% of Cu) | Processing Method | Microstructure | R % (antibacterial efficacy) | Mentioned Mechanism | Ref. |

|---|---|---|---|---|---|

| Ti–1Cu | Ingot melting and heat treatment of 900 °C for 18 h followed by 798 °C for 24 h and finally water quench | Solid solution of Cu in Ti | 4% after 6 h of contact with the alloy | Cu ion releasing | [171] |

| Ti-2.5Cu | Solid solution of Cu in Ti, Cu-rich phase | 13% after 6 h of contact with the alloy | |||

| Ti–3Cu | Solid solution of Cu in Ti, Ti2Cu | 16% after 6 h of contact with the alloy | |||

| Ti–10Cu | Solid solution of Cu in Ti, Ti2Cu | 24% after 6 h of contact with the alloy | |||

| Ti–3Cu | Ti–3Cu wrought bar and solid solution treated (900 °C for 5 h + 400 °C for 16 h) | Solid solution of Cu in Ti, and nano-scale of Ti2Cu | ≥99% | Disrupting the proton motive force and resisting the production of ATP by the nano-scale galvanic cells on the surface of Ti–Cu alloy | [177] |

| Ti–2Cu | Powder metallurgy | Solid solution of Cu in Ti, Ti2Cu | ≤79% | Cu ion releasing | [208] |

| Ti–5Cu | Solid solution of Cu in Ti, Ti2Cu, Cu-rich phase | ≤99.2% | |||

| Ti–10Cu | Solid solution of Cu in Ti, Ti2Cu, Cu-rich phase | 99.99% | |||

| Ti–25Cu | Solid solution of Cu in Ti, Ti2Cu, Cu-rich phase | 99.99% | |||

| Ti–5Cu (S) | Powder metallurgy | α-Ti phase and a small amount of Ti2Cu phases | 99.3% | Cu ion releasing and contact with the Ti2Cu phase | [257] |

| Ti–5Cu(E) | Extrusion process (sintered alloys were extruded at 800 °C at a rate of 10 mm/s) | α-Ti phase and a small amount of Ti2Cu phases, phases are smaller and more homogenized | 99.4% | ||

| Ti–10Cu(S) | Powder metallurgy | α-Ti phase and more Ti2Cu phases | 99.9% | ||

| Ti–10Cu(E) | Extrusion process (sintered alloys were extruded at 800 °C at a rate of 10 mm/s) | α-Ti phase and more Ti2Cu phases with flake shapes, phases are smaller and more homogenized | 99.8% | ||

| Ti–5Cu | Ingot melting followed by heat treatment at 850 °C for 2 h and cooling in the furnace | α -Ti (HCP) matrix and Ti2Cu precipitation | ≥99% | Contacting sterilization of Ti2Cu and Cu ion releasing | [207] |

| Ti–5Cu | Ingot melting followed by heat treatment at 900 °C for 2 h, and air cooling | Ti2Cu phase in the α -Ti matrix | ≤96%, | Cu ion releasing | [178] |

| Ti–5Cu (I) | Alloys were melted and casted in ingot (casting) | Nano-scale Ti2Cu, a relatively high amount of Cu in a solid solution state | 51% | Contact sterilization and Cu ion releasing | [190] |

| Ti–10Cu (I) | More nano-scale Ti2Cu, relatively high amount of Cu in solid solution state | 64% | |||

| Ti–5Cu (T4) | As-cast alloys were heat-treated at 900 °C for 2 h (T4) and quenched in room temperature water | Complete solid solution | <55%a | ||

| Ti–10Cu (T4) | A large amount of solid solution and a small amount of Ti2Cu phase | <70%a | |||

| Ti–5Cu (T6) | As-cast alloys were heat-treated at 900 °C for 2 h and quenched in water, and then at 400 °C for 12 h (T6) | Nano-scale Ti2Cu, a small amount of solid solution | >90%a | ||

| Ti–10Cu (T6) | Nano-scale Ti2Cu phase, a small amount of solid solution | <95%a | |||

| Ti–5Cu (S) | Ti and Cu powders were sintered (sintering) | Micro-scale Ti2Cu, a minimal amount of solid solution | >99%a | ||

| Ti–10Cu (S) | More micro-scale Ti2Cu, very small amount of solid solution | >99%a |

Data were derived from the graphs presented in the referenced paper.

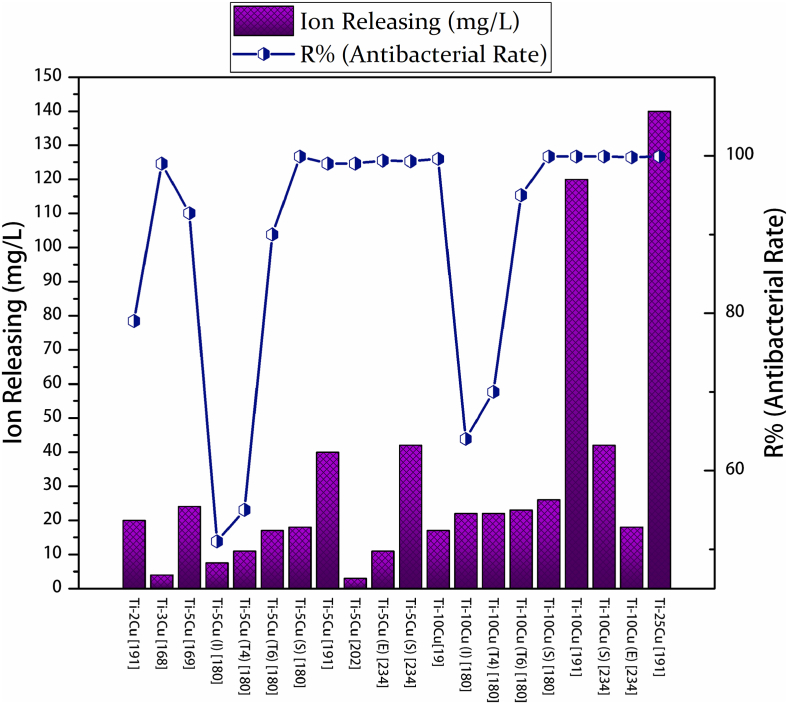

Fig. 6.

The relationship between ion releasing of an alloy and its antibacterial performance estimated in various publications [19,39,177,178,190,207,208,257]. These data well show that the ion-releasing characteristic is not the only factor determining the antibacterial performance. For example, the ion releasing amount of Ti–10Cu(I) alloy [180] is more than that of Ti–5Cu(S) [180], however, the antibacterial rate of the latter is much higher than the former.