Abstract

Working with expansive soil as pavement subgrade is not technically easy due its poor workability and insufficient capacity to support the imposed cyclic traffic loading. For satisfactory performance of the pavement structure constructed in such foundation hence the properties of the weak subgrade have to be modified. One of the ideal solutions to these problems might be looking towards naturally abundant and industrial waste materials that are produced in large quantities as stabilizing agent for clay subgrades so that the instability concerns can be alleviated. This study hence primarily aimed at experimentally scrutinizing the stabilizing potential of waste ceramic dust and natural lime in modifying geotechnical properties of the highly plastic subgrade material. Both the separate and combined effects of the two stabilizing agents were investigated with respect to mitigating the key parameters required for stable road construction. The degree of improvement for various mix ratios were compared with the design and requirements of Ethiopian roads authority specifications for road construction. Accordingly, the optimum dosage for natural lime was 6% whereas that of the waste ceramic is 20% for safe road subgrades. It was also indicated that natural lime is more powerful than the waste ceramic dust from effectiveness point of view. The conducted experimental test revealed that the response of soil parameters to variation in amount of stabilizers in the separate application method is more sensitive for natural lime than the waste ceramic dust. The improvement rate in magnitude of the required geotechnical parameters in the combined case is by far greater than the separate application of the additives.

Keywords: Expansive subgrade, Stabilization, Waste ceramic dust, Limestone

Expansive subgrade; Stabilization; Waste ceramic dust; Limestone.

1. Introduction

Expansive soils are commonly source of instability in construction of road foundation [1, 17]. Existence of weak subgrades in many cases is the root cause of road failures and damages [2, 11, 51]. The expansive behavior of highly plastic subgrades results in development of excessive and permanent deformation in the road structure during its service life [3, 22]. Likewise, roads built on this type of subgrade, unconditionally experiences premature failure and pavement distresses [4]. Due to its low consistency, expansive soil is proscribed as unsuitable material for construction of road pavement [5, 19, 39]. Therefore, weak subgrade soils are totally or partially removed through excavation before commencement of the actual construction work, in the conventional road construction trend [6, 16]. Removal of unsuitable soil through excavation is however practically not feasible in case thickness of the soil mass extends over larger depth [7, 15]. Hence, application of mechanical improvement methods by using any viable stabilizing agent could be a solution to overcome the feasibility related challenges [13].

In the stabilization of clayey soils not only the physical properties of the soil are affected but also its chemical properties are altered as a result of reactions taking place between the negatively charged clay particles and the cation from the stabilizers like limestone and waste ceramic dust [23, 26, 33]. Limestone is rich in calcium ion (Ca2+) and ceramic dust contains sodium ion (Na2+) which has paramount significance for effective cation exchange and development of flocculation-agglometration [28]. The addition of lime to clay initiates a two phase reactions with both immediate and long term benefits in improving properties of the clay soil. The short term process involves cation exchange between ions of clay particle and calcium ions of lime material resulting in suppression of diffuse water encircling the clay particles [31]. The suppression of pore water forms strong bond between particles of clay soil [32]. Similarly, its long term benefit comes from the pozzolanic reaction which occurs as a result of critical combination of liberated SiO2 and or Al2O3 to form cementing agents like calcium silica hydrate (CSH) and calcium aluminate hydrate (CAH). The pozzolanic reaction hence contributes to development of cementetious materials having strong bond [30]. Application of lime stabilization expedites constructions in clay soil even during rainy weather, due to proven drying action of lime material [33].

Many studies were conducted to investigate the critical performance of both limestone and waste ceramic in modifying the intrinsic engineering properties of highly plastic soils for subgrade use. The achieved degree of improvement in engineering properties of a stabilized soft soil highly depends on dosage of the stabilizer and gradation of the mix [9, 15]. According to Rakhil and Devi [21], ceramic waste can conveniently be used as stabilizing material that it is found effective in improving geotechnical properties of expansive clay soils. In using ceramic waste for weak soil stabilization, not only the properties of the soil are improved but also the disposal issue of the waste material can be settled [2]. Binici [9] stated that ceramic is known for its good stiffness, specific gravity and rigidity. Nifana and Palanikumar [18] investigated effect of ceramic dust on soil index properties, unconfined compressive strength, swelling potential and Californian Bearing Ratio and reported that significant improvement was achieved with addition of ceramic waste. Besides, it was concluded that ceramic dust up to 30% can be used for safe and economic stabilization of weak subgrade. Rakhil and Devi [21] reported that 30% addition of waste ceramic to soft subgrade led to reduction in plasticity index by 18.2% and rise in the Californian Bearing Ratio value by 29.4%. Besides, blending of the ceramic material with the subgrade reduced thickness of pavement by 45% which apparently contributed to 31% cost saving.

Lime is technically known for its fast hydrating characteristics which make it one of the well suited stabilizing agents to modify properties of problematic soils such as clay [19]. The strength gain arises chiefly from the chemical reaction taking place between lime and clay minerals [22, 24]. Jamal et al. [11] on the study on Lime Kiln Dust for Treated Subgrades found that addition of 5% lime reduced the plasticity index of compressible soil to the level its compressibility properties can be managed. Finding of the study also revealed that no significant difference between the degrees of improvement in swelling index of the subgrade was observed for 5% and 8% dosage of lime. Furthermore, finding of the study conducted by Prasad et al. [20] to stabilize weak subgrade using 1%–5% of lime and 0.5%–1.5% dosage of waste plastic fiber demonstrated that 4% is an ideal dosage for lime to desirably modify properties of soft subgrade. Besides, optimum moisture content of the soil got diminished with rise in dosage of lime. Meron and Samuel [15] analyzed stabilizing efficiency of lime and bagasse ash for 3% lime and 15% bagasse ash separately and in combination as well. In contrary to many previous works, finding of the study revealed that rise in magnitude of optimum moisture content were witnessed with a gradual increase in lime content. Despite the considerable number of studies conducted on application of lime as stabilizing material, limited information regarding the stabilizing capacity of waste ceramic has been documented in literatures. Besides, any form of comparative analysis was not conducted to compare performance of the two agents in stabilizing problematic subgrades. The previously conducted works mainly focused on the separate performance of the two additives and their joint effect on modifying properties of weak soils was not documented. In the current study hence, comparative study was conducted to judge the stabilizing potential and performance of waste ceramic dust and lime on highly plastic subgrade. The obtained degree of improvement for each parameter was compared with the Ethiopian Roads Authority specifications for construction of roads.

2. Materials and methods

2.1. Characterization of the materials used

The experimental analysis considered in the current study considered three different materials which include expansive clay soil, waste ceramic dust and limestone. The expansive clay is the material considered as weak subgrade which is incompetent in its performance as pavement foundation. Hence, it is unlikely to directly use it for construction purpose without application of any improvement mechanism. In relation to this, the waste ceramic dust and limestone are used as stabilizing agents through employing various proportions of mix. These two materials are separately mixed and blended with the weak subgrade with varying mix ratios and their effect is investigated. Eventually, the three materials are mixed up to assess joint performance of the additives in modifying properties of the clay subgrade.

2.1.1. Clay soil

The expansive soil considered to be improved in the study was sampled from outskirt of Asendabo town, Jimma Zone, Ethiopia. The soil samples were collected from a depth of 2 m below the natural ground surface near the damaged road segment connecting Asendabo town with Deneba town along the Addis Ababa-Jimma trunk road. The collected samples hence are part of the road subgrade and have same physical properties with foundation of the damaged pavement. The characteristics and nature of expansive soils are different which is highly affected by the constituent minerals [23]. Some of the physical properties of the soil were presented in Table 1. Clay soils categorically are moisture sensitive soils highly influenced by variation in water content that they heavily absorb water and hence abruptly undergoes swelling and lose strength [3, 14, 17, 51]. These expansive soils are easily compressible when wet and possess a tendency to heave during the wet conditions and shrink in volume during dry seasons [20, 22]. Expansive soils are also commonly known for the presence of large amount of clay minerals which absorb immense quantities of water after rainfall. Compressible soils whose free swell index exceeds 50% are considered as highly expansive and such soils undergo volumetric changes leading to pavement distortion [2, 6, 7, 8].

Table 1.

Some geotechnical properties of the expansive subgrade soil.

| SN | Soil properties | Values |

|---|---|---|

| 1 | Natural moisture content (%) | 44.18 |

| 2 | Liquid limit (%) | 79.60 |

| 3 | Plastic limit (%) | 31.41 |

| 4 | Plasticity index (%) | 48.19 |

| 5 | Maximum dry density (g/cm3) | 1.23 |

| 6 | Optimum moisture content (%) | 34.06 |

| 7 | Specific gravity | 2.70 |

| 8 | Free swell (%) | 74.00 |

| 9 | CBR (%) | 2.01 |

| 10 | Classification (USCS) | CH, Highly plastic inorganic clay |

| 11 | Classification (AASHTO) | A-7-6, Poor clay |

| 12 | Cohesion (kPa) | 40 |

| 13 | Internal friction angle (°) | 0 |

| 14 | Poison ratio | 0.40 |

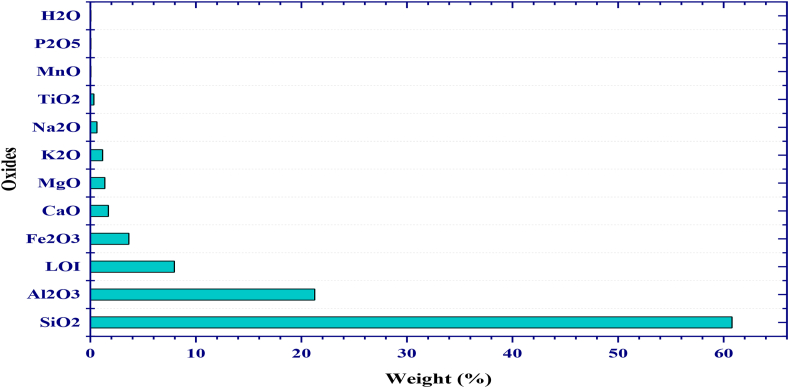

Figure 1 represents the Oxides compositions of the natural weak subgrade. As observed from figure, the dominant chemical predominantly found in the soil is Silicon Oxide (SiO2) followed by Aluminum Oxide (Al2O3) which accounts 60.8% and 21.26% by weight respectively. Contrarily, Manganese oxide (MnO), Phosphorus pent oxide (P2O5) and Water (H2O) are the least significant chemicals in composition wise. Hence, the intrinsic properties of the expansive soil are highly influenced by the typical properties of the dominant oxide which is silicon dioxide.

Figure 1.

Chemical composition of the expansive clay subgrade.

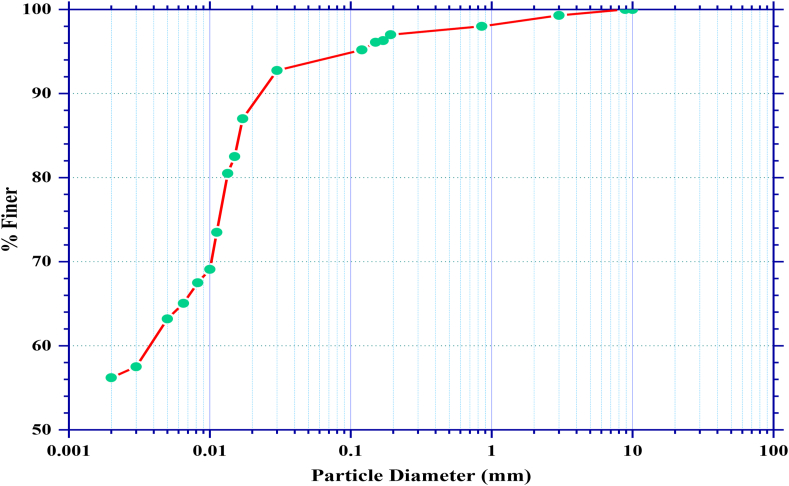

Texturally, the weak soil contains very small fraction of sand particles and chiefly composed of large pecentage of fines. Hence, the soil is overwhelmingly composed of fine grains (clay and silt) whose particle sizes are finer than the No 200 sieve. As observed from Figure 2, the gravel soil fraction is missing at all. The soil particle size distribution reveals that almost 94.2.0% of the particles passes the No 200 sieve and the sand fraction accounts 6.8% of the soil mass. The soil by its type is proscribed as a material with poor engineering property and it is not deemed to be directly considered for subgrade construction without employing any form of stablization. Besides, from gradation perspective, the soil is poorly graded (uniformly graded) type and its constituent particles are not well proportionated which limits its consideration for road construction.

Figure 2.

Particle size distribution of the clay subgrade.

2.1.2. Waste ceramic dust (WCD)

The ceramic dust was collected from locally available sources and ceramic factories. Direct use of industrial waste for stabilization purpose has contributes to reduction of environmental pollution [18]. In many areas, the disposal issue of waste ceramic is critical environmental concern. Hence, the idea of utilizing it as an admixture to stabilize weak ground is of paramount essence from both lessening pollution and strength improvement perspectives [9, 21]. In many cases, in order to achieve a desired degree of improvement, larger values of mix proportions are required. In some practical areas, however small content of ceramic blend (up to 5%) can potentially stand out to improve the load bearing and strength properties of compressible subgrade soils [2, 18]. Waste ceramic product is widely used for stabilization of compressible and weak soils due to its very good characteristic properties which such as high strength, long service life, chemical inertness, non-toxicity and specific porosity [25, 29]. Table 2 and Figure 3 represent some physical and chemical properties of the waste ceramic respectively.

Table 2.

Physical properties of the waste ceramic material.

| SN | Parameters | Values |

|---|---|---|

| 1 | Unit weight (kN/m3) | 22.6 |

| 2 | Liquid limit (%) | None |

| 3 | Plastic limit (%) | None |

| 4 | Plasticity index (%) | None |

| 5 | Free Swell | 0.5 |

| 6 | Specific gravity | 2.81 |

| 7 | Cohesion (kPa) | 6 |

| 8 | Internal friction angle (o) | 36 |

| 9 | Poison ratio | 0.26 |

Figure 3.

Chemical compositions of the waste ceramic material.

2.1.3. Natural lime (limestone)

The limestone material used as stabilization agent in the study was obtained from naturally existing lime sources situated near Ambo town. Lime in its processed or natural form can be used to improve bearing capacity and plasticity characteristics of weak soils [8]. In the current study, the limestone sample was directly collected from easily accessible deposits (limestone rock mass) without any processing. Limestone mostly consists of calcium carbonate in its chemical composition. Lime is calcium-containing inorganic material in which carbonates, oxides, and hydroxides predominate. To be strict, limestone is calcium oxide or calcium hydroxide whereas the natural limes are partly fossiliferous and contains abundant stylolite [7]. The properties of good quality lime, which makes it suitable for use as an engineering material are; easily workable, possesses good plasticity, offer good resistance to moisture, stiffens early, used for stabilizing the soils and an excellent cementation behavior [11, 16]. The physical properties of the limestone were summarized in Table 3. Another golden advantage of using lime for weak soil stabilization is its fast dehydrating characteristics, which is ideal for modifying fine-grained soils. Unlike ceramic dust, the dosage of natural lime required to meet road specifications and to achieve optimum improvement of weak soils is by far less than that of ceramic material. Even though the required percentage of mix is highly dependent on the intrinsic properties of weak soils, small amount of lime from 4 to 7% can be used to effectively modify compressible soil [10].

Table 3.

Some physical properties of limestone material.

| SN | Parameters | Values |

|---|---|---|

| 1 | Unit weight (kN/m3) | 22.67 |

| 2 | Liquid limit (%) | 26.51 |

| 3 | Plastic limit (%) | None |

| 4 | Plastic index (%) | None |

| 5 | Free Swell | 1.32 |

| 6 | Specific gravity (Gs) | 2.66 |

| 7 | Cohesion (kPa) | 13 |

| 8 | Internal friction angle (o) | 34 |

| 9 | Poison ratio | 0.28 |

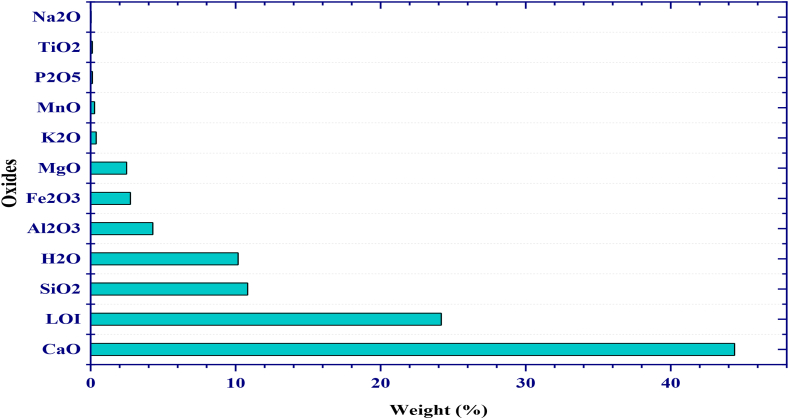

Figure 4 represents the chemical properties of the natural limestone. As observed from figure, the dominant chemical found in limestone is calcium oxide (CaO) followed by Loss on ignition (LOI) and Silcon Oxide (SiO2) accounting 44.4%, 24.18% and 10.83% by weight respectively. In relation to this, Sodium oxide (Na2O), Manganese oxide (MnO), Phosphorus pent oxide (P2O5) and Titanium oxide (TiO2) are the rare chemicals found in limestone.

Figure 4.

Chemical compositions of the natural lime.

2.2. The experimental tests

2.2.1. Sample preparation and blending

The weak and compressible clay samples were taken from the test pits excavated up to 2 m by using manual excavation tools. The collected samples were kept in sampling bags to avoid significant moisture loss and painstakingly brought to soil laboratory. The limestone mass collected from the natural source was manually crushed into finer pieces passing the 425 μ sieve and the experimental tests were carried out as per the recommendation of AASHTO M-145. Accordingly, five different mix proportions of natural lime ranging from 2 to 10% were considered to investigate the effect of variation in mix ratio on performance of the weak subgrade material. The two materials were mixed together by the use of mechanical mixer with the purpose of uniformly dispersing the stabilizer.

Similarly, blocks of ceramic waste obtained from the locally available factories were crushed into same dimension with that of limestone to make the mixing convenient and consistent with the weak soil. The ceramic was crushed manually by using hammer to make particles with different size uniformly distrusted in the mix. Likewise, the crushed ceramic waste constitutes particles of various diameters to purposely avoid dominance of some particles having same size. Accordingly, eight mix ratios varying from 2 to 25% were employed to mix the ceramic waste with the weak subgrade material. Mix of the materials was then directly used for different laboratory tests in order to determine compaction characteristics, Atterberg limits, unit weight, moisture content, California bearing ratio and swelling index.

2.2.2. The test design and considered case scenarios

The overall test process of the designed experimental test encompasses four different case scenarios for comparison purposes. The first case considers characterization of the sole weak subgrade material without blending with any stabilizing agent. In this case, the necessary physical properties of the compressible and weak subgrade were determined so as to characterize the material from suitability and workability perspectives. The second case is the case in which the critical effect of limestone is investigated by varying its dosage. Hence, the possible clear relationship between variation of the mix ratio and the achieved degree of improvement can be established for each determined parameter. Thirdly, the mixture of crushed waste ceramic and weak subgrade was used without inclusion of other ingredients so that the stabilizing performance of the waste ceramic dust (WCD) separately from the natural lime can be determined.

In the fourth case, the combined effect of waste ceramic and limestone on the subgrade properties was studied by using mixture of the three materials (waste ceramic, limestone and weak soil). To do so, various combinations of mix ratios of the waste ceramic and limestone were adopted. Likewise, five different combinations with varying amount of additives were considered. These combinations are 2% natural lime +15% WCD, 4% natural lime +15% WCD, 6% natural lime +15% WCD, 8% natural lime +15% WCD and 10% natural lime +15% WCD. Accordingly, the improvement potential of the stabilizing agents separately and in combination was scrutinized. Summary of the considered mix proportions for each case scenario was presented in Table 4.

Table 4.

Mix proportions required for the case scenarios.

| Scenario 2 (blending of limestone) |

Scenario 3 (blending of WCD) |

Scenario 4 (combined effect of limestone and WCD) |

||||

|---|---|---|---|---|---|---|

| (% of Limestone | % Soil | (% of WCD) | % Soil | (% of Limestone | (% of WCD) | % Soil |

| 2 | 98 | 2 | 98 | 2 | 15 | 83 |

| 4 | 96 | 4 | 96 | 4 | 15 | 81 |

| 6 | 94 | 6 | 94 | 6 | 15 | 79 |

| 8 | 92 | 8 | 92 | 8 | 15 | 77 |

| 10 | 90 | 10 | 90 | 10 | 15 | 75 |

| 15 | 85 | – | – | – | ||

| – | – | 20 | 80 | – | – | – |

| – | – | 25 | 75 | – | – | – |

| – | – | 30 | 70 | – | – | – |

The improvement performance of the last three cases (Case two through four) was then compared with specification of Ethiopian Road Authority for road construction. A systematic study on the separate impact of these stabilizing agents enables the effective comparative analysis to be made especially from economy and workability points of view. Eventually, the well performing and feasible option from the three cases was possibly selected for future applications of subgrade stabilization practices. The dosages of stabilizers considered in the current study were partly adopted from practical trends and previously documented literatures as well.

2.2.3. The subgrade tests and procedures

The soil parameters considered in the current study for attainment of the research objective include moisture content, compaction characteristics, Atterberg limits (Plastic limit, Liquid limit and Plastic index), California bearing ratio, Specific gravity, Swelling index and Soil particle distribution. Before all, moisture content of the naturally existing weak soil was determined according to AASHTO T-265 standard test method for laboratory determination of soil water content. Standard compaction test was conducted to determine the compaction characteristics (maximum dry density and optimum moisture content) of the natural and treated subgrade. Many engineering properties of soil, such as the strength, stiffness, resistance to shrinkage and imperviousness of the soil would be improved by increasing the soil density [16]. The test was conducted according to AASHTO T-99 procedures. This method is employed for the particles of the soil retained on the sieve No. 4 (4.75 mm).

California bearing ratio is another important soil property used as improvement criteria. It is actually expressed by force exerted by a plunger and the depth of penetration into specimen and it is aimed at determining the relationship between force and penetration [10, 15]. The California bearing ratio test indirectly measures the shearing resistance of soil under controlled moisture and density conditions [23, 24]. It determines the strength and swelling potential of the subgrade soil. The test was carried out as per ((AASHTO T-193-93) test procedure. Furthermore, Atterberg limits (Liquid limit, plastic limit and plastic index) were determined for air-dried samples by using Casagrande apparatus. Standard reference of AASHTO T-89 and 90 were applied to execute the test. The same procedure was followed for the treated soil with varying contents of limestone and waste ceramic dust. In addition to the mentioned tests, specific gravity test was conducted according to AASHTO T 100-93 standard by using water pycnometer procedure. It is a measure of density of a soil with respect to density of water [12, 13]. Free swell test is the simplest but very important test conducted to study the swelling properties of the soil. The free swell index is the increase in the volume of soil, without any external constraints, on submergence in water [3, 5, 6]. For the current study, IS 2720(Part 40)1977 standard was used to check the swelling potential of the soil.

With regard to particle size distribution, grain size analysis was carried out in accordance with ASTM D422-63 test procedure. The mechanical analysis was used for the coarse grained soils by using a set of sieves whereas hydrometer analysis was used for fine grained soils. Both mechanical and hydrometer testing methods were performed for soils comprising both coarser and finer sizes. Lastly, classification of the natural weak soil by using unified and AASHTO soil classification systems were done.

2.2.4. Chemical analysis

Chemical analysis was made to characterize the materials considered in the study. X-ray diffraction (XRD) test was conducted to determine chemical properties of the clay soil, limestone and waste ceramic dust. X-ray diffraction analysis is basically carried out to determine the mineralogical phases present in different materials. The representative oven dried samples of the three materials were crushed until a powder passes the No. 200 (0.075 mm opening) sieve. The powder samples were step-scanned from 10° to 75° (2θ) with 1 s time step and under continuous scanning speed. Testing and analysis were conducted by setting voltage of 30 kV with 25 mA and the scanning time for XRD test was 0.02°/sec. Diffraction is associated with a phenomena that occur when a wave encounters an obstacle or opening. It is bending of waves around the corners of an obstacle or through an aperture into the region of geometrical shadow of the obstacle [26]. X-ray diffraction is basically employed to measure the average spacing and orientation between layers and crystals [27]. Besides, the size, shape, crystal structure and internal stress of small crystalline regions is investigated [28].

2.3. Clay soil stabilization and chemical reactions

Stabilizing agents when added to expansive clay soil play three pivotal roles in the process of improving properties of the soil. These are drying, modification and stabilization roles. During the first phase rapid fall in moisture content of the clay soil rapidly drops due to the chemical reaction taking place between water and the additives. The secondly, addition of stabilizing agents lessens in the plasticity, reduces swelling and shrinkage characteristics. In relation to this, addition of lime to clay soil increases optimum moisture content and decreases the maximum dry density of the clay. These mentioned modifications in properties of the soil takes place within short period of time after addition of lime. The third phase of improvement process is about bringing a long term impact on properties of clay soil. These improvements include long term strength, consistent reduction in plasticity, and permanent reduction in shrinkage, swelling and resistance to thawing and prolonged soaking [28].

A number of reactions take place when lime material is added to clay soils with high moisture content which leads to improvement in properties of the clay soil. These chemical reactions are mainly two types namely colloidal and pozzolanic. The immediate (colloidal) reactions include but not limited to cation exchange, flocculation and carbonation. The pozzolanic reaction takes place after sometime due to dissolution of alumina and silica sheets of clay particles. These reactions may occur immediately after blending the additives with clay soils or after a long period of time [26, 28]. Unlike the pozzolanic and other colloidal reactions, carbonation is an unwanted reaction that negatively influences the stabilization process. This reaction takes place in clay-lime mixtures. In this reaction, lime material reacts with carbon dioxide and results in formation of calcium carbonate instead of the important cementitous materials such as calcium silicate hydrate (CSH) and calcium aluminate hydrate (CAH) [31, 32].

2.3.1. Cation exchange

Cation exchange is one of the important reactions mainly contributing to changes in the plasticity characteristics of soil. Cations are positively charged ions such as calcium (Ca2+), magnesium (Mg2+), and potassium (K+), sodium (Na+) hydrogen (H+), aluminum (Al3+), iron (Fe2+), manganese (Mn2+), zinc (Zn2+) and copper (Cu2+) [28]. Clay soils have a cation exchange capacity primarily because clay particles tends to be negatively charged. Soil as a whole does not have electric charge. Hence, the negative charge of the clay particles is balanced by the positive charge of the cations in the limestone and waste ceramic dust. Fine-textured soils like clay have larger cation exchange capacity value than the coarse grained soils [28, 31]. Cation exchange capacity (CEC) is the potential of soil to hold on to cations. The cation exchange capacity of soil is also defined as the total number of inions per unit weight of the soil. It is expressed in Milliequivalents per 100 gm of soil [28, 35].

The cation exchange takes place in soil in order of the replacing power of the cations. Cations with lower valence are replaced by those having higher valence. In the case of cations with same valence, smaller cations are replaced by larger ones. For instance, both Magnesium (Mg2+) and Calcium (Ca2+) have the same valence. However, Mg2+ is replaced earlier than the Ca2+ since valence of the latter cation is larger than the former [28]. When adequate amount of lime material is added to expansive clays soil, calcium cation from the lime replaces the weaker cations found in the clay soil. Cation exchange lessens the thickness of diffuse water layer bounding the clay particles that makes the particles come closer to each other which leads to development of flocculation [36, 38]. Cation exchange of soil is affected by variety of factors such as soil texture, nature of clay minerals, PH value and organic content. The negatively charged clay colloids attract and hold positively charged cations carried by limestone and ceramic material. Soils with high clay content have high cation exchange capacity than soils with low content of clay. The calcium hydroxide formed due to reaction between quick and water increases the electrolytic concentration of soil and pH of the water continued between soil particles. As a result, the silicates (SiO2) and aluminates (Al2O3) from the clay particles are dissolved. The silicates get ionized with increase in PH of pore water which in turn raises the cation exchange capacity [33, 37].

2.3.2. Flocculation-agglomeration

Clay soil stabilization is the net result of cation exchange and flocculation-agglomeration processes. These two processes contributes to reduction in adsorbed water layer, rise in inter particle friction and increase in workability as the plastic soil texture through time changes to non-plastic materials. Flocculation-agglomeration is a process in which change in soil texture occurs as negatively charged clay particles bonded together and build large size particles. This happens when the pore water existing between the clay particles gets diminished because of the cation exchange [35, 37, 38]. The result of XRD test presented in Figures 3 and 4 revealed that calcium oxide and sodium oxide are the dominant chemicals found in waste ceramic dust and limestone respectively. Calcium oxide accounts 45% of the limestone sample used for chemical analysis. When clay soil is subjected to lime stabilization, calcium and magnesium atoms carried by lime material replaces sodium and hydrogen atoms carried by the clay and hence soil with very friable behavior is formed. The sodium ion (Na+) carried by the ceramic material is exchanged with calcium ions (Ca++) carried by the lime material. As a result, the plastic clay soil gains flocculated type of structure instead of the dispersed structural arrangement which improves its workability in general [30, 34].

2.3.3. Pozzolanic reaction

Hydrated lime via its reaction with particles of clay soil permanently transforms into a strong cementitious material. Hydrated lime is the product of chemical reaction between water and quicklime. For effective treatment of clay soil, lime material with high content of calcium and not more than 5 percent magnesium is preferred [28]. Upon mixing lime with clay soils, calcium ions are combined initially with or adsorbed by clay minerals, which significantly mitigates workability of the compressible clay soil. In process of lime stabilization, pozzolans play critical long term role especially in generating cementitious bonds [33, 38]. Pozzolanic materials are known for their cementing characteristics and hence good bonding performance. Due to their bonding nature and cementation characteristics, their reaction and action in expansive clay soils build up firmly bonded particles which directly contributes to reduction in swelling tendency and improvement in strength properties of the clay soil [40].

These pozzolans naturally exist in clay soils. Pozzolans such as silica and alumina react with calcium found in lime, and water to form calcium-silicate-hydrates (C–S–H) and calcium-aluminate-hydrates (C–A–H) respectively [34]. The aluminum and silicon are common to clay minerals but vary in proportions following their specific structure [26]. Pozzolanic reactions involving clay soil minerals and lime result from the addition of lime to clay in the presence of water. Calcium cations combine with liberated Silicon dioxide (SiO2) and or Aluminum oxide (Al2O3) to form cementing agents; calcium silicate hydrate (CSH–3CaO2SiO2 3H2O) and calcium aluminate hydrate (CAH—3CaOAl2O3 Ca(OH)2 12H2O), which alter the soil structure, reduces plasticity and improves its workability [41]. The reactivity of lime is influenced by various properties of clay soil such as soil pH, organic carbon content, presence of carbonates, natural drainage, degree of weathering, and excessive quantities of exchangeable sodium, clay mineralogy, extractable iron, and silica-alumina ratio [33, 34].

2.4. Specifications and standards used

The stabilizing potential of the additives and their combination was compared with the existing and applicable road construction specifications. Accordingly, the obtained degrees of improvements were compared with Ethiopian Roads Authority (ERA) 2013 specification for road construction and Indian standard. The Liquid Limit (LL), Plastic Index (PI) and California Bearing Ratio (CBR) of the improved soil was compared with ERA 2013 specification whereas Indian Standard specification was used to reflect on swelling potential of the soil (Table 5). Ethiopian Roads Authority (ERA) 2013 Specification for road construction primarily gives due emphasis to limited soil parameters such as California Bearing Ratio, Plastic Index, Liquid Limit, Particle size distribution and Degree of compaction. Besides, the manual has no limiting recommendation for swelling potential of subgrade materials.

Table 5.

The ERA 2013 and IS specifications for road construction (subgrade).

| SN | Subgrade Properties | Recommendation of ERA 2013 Specifcation | IS: 2911 Part III- 1980 |

|---|---|---|---|

| 1 | Liquid Limit (PL) (%) | <30 | |

| 2 | Plastic Limit (LL) (%) | <60 | |

| 3 | California Bearing Capacity (CBR) | >3 | |

| 4 | CBR Swell (%) | <2 | |

| 5 | Free Swell (%) | - | <20 |

3. Results and discussions

3.1. Effect of natural lime and WCD on compaction characteristics of the clay

The compaction properties of the expansive clay subgrade were influenced by blending of the additives considered in this study. It was indicated that variation in dosage of the stabilizers has critical impact on compaction properties of the clay subgrade. The gradual increment in dosage of waste ceramic dust (WCD) resulted in almost linear rise in magnitude of maximum dry density (MDD) of the expansive clay whereas an increment in amount of natural lime sharply reduced the resulting maximum dry density (Figure 5(a)). Likewise, addition of 10% and 30% WCD improved the maximum dry density by 12.4% and 30.6% respectively.

Figure 5.

Effect of additives' dosage on; (a) Maximum dry density, (b) optimum moisture content.

With regard to the optimum moisture content, the value goes increasing with addition of waste ceramic dust whereas it undergoes decrement with rise in amount of added natural lime (Figure 5(b)). With blending of 10% WCD, the optimum moisture content got reduced from 34.06% to 24.38%. Addition of 30% dosage of waste ceramic dust similarly reduced the optimum moisture content by 44.6%. The reduction in optimum moisture content might be due to attraction of water by the dry fine dusts of crushed ceramic which eventually leads to fall in water content of the mix [15]. Contrarily, addition of the 10% of natural lime further increased optimum moisture content (OMC) of the soil from 34.06% to 42.86% which is 25.84% increment. The rate of change in magnitude of the optimum moisture content was faster with fluctuation in amount of natural lime than the waste ceramic dust. Hence, the small variation in amount of the natural lime leads to considerable change in optimum moisture content of the expansive subgrade soil than the waste ceramic dust does. The study conducted by [23] to investigate the effect of cement and lime on geotechnical properties of clay soil concluded that as lime content increase from 2% to 10%, both the maximum dry density and optimum moisture content rise. However [42], reported that maximum dry density of the treated clay decreases whereas its optimum moisture content goes increasing with increase in lime content.

The combined effect of waste ceramic dust and natural lime on maximum dry density and optimum moisture content of the clay soil was indicated by the green curve in Figure 5(a) and (b) respectively. As observed from the graphs, the maximum dry density goes rising with increase in amount of limestone with constant amount of waste ceramic dust (15%) whereas optimum moisture content of the clay radically reduced. The joint performance of 4% natural lime and 15% WCD in lessening optimum moisture content is almost equivalent with separate application of the 30% WCD. The optimum moisture content of the clay subgrade undergoes visible increment with addition and increase in dosage of natural lime for the second case scenario (separate application of natural lime in complete absence of any other additive). However, when it is used in combination with specified amount of waste ceramic dust, the resulting optimum moisture content got reduced. In relation to this, Rakhil and Devi [21], Nifana and Palanikumar [50] posit that the MDD increased whereas OMC reduced with gradual increase in content of WCD. The rate of change in magnitude of the parameters however is lower than the rate of change observed in the current study.

3.2. Effect of natural lime and waste ceramic dust on CBR and CBR swell of the clay soil

Figure 6(a) represents effect of waste ceramic dust and natural lime dosage on California bearing ratio (CBR) of the clay soil. As shown in the Figure, the uncured California bearing ratio value increased for all mixes starting from 2% to 10% for the natural lime and from 2% to 30% for the waste ceramic dust. Likewise, the separate application of 6% WCD and natural lime resulted in 54.73% and 87.24% rise in magnitude of California bearing ratio respectively. The experimental test revealed that the 3% natural lime equivalently performs with 10% WCD in modifying California bearing ratio of the soil. Hence, it can be inferred that change in California bearing ratio of the expansive soil is more sensitive to dosage of limestone than the waste ceramic dust. Improvement in strength of clay soil is not fully achieved over short time duration that strength gain is directly associated to the pozzolanic reactions [43]. The strength and load bearing capacity of clayey soils is a result of formation of cementitious materials like calcium silicate hydrate and calcium aluminate hydrate [44]. Gradual increment in dosage of lime material apparently improves the strength properties of expansive clay soil. However, further addition of lime beyond some limit reduces the strength due to formation of excess silica which increases porosity of the clay material [45]. The resulting improvement pattern in the values of CBR in the current study has good agreement with Meron W, Samuel T [15]. It was concluded in the study that CBR value of clay soil rose from 0.91% to 9.73% by addition of 3% lime material. Similarly, Akshaya KS [2] reported that addition of 30% ceramic material to clay soil gave rise to increment in the soaked CBR value from 1.6 to 4.1%. In the current study however the improvement observed was from 2% to 8.13% for the 30% WCD.

Figure 6.

Effect of stabilizers' dosage on; (a) Californian bearing ratio (CBR), (b) CBR Swell.

Furthermore, addition and increase in amount of the stabilizers reduced CBR Swell of the clay soil. As indicated in Figure 6 (b), CBR Swell of the natural soil was significantly lowered upon addition of both limestone and waste ceramic dust. With application 6% natural lime, the CBR Swell got reduced from 6.08 to 4.91. Similarly, a considerable reduction from 6.08 to 4.81 was observed with application of same amount of waste ceramic dust. The conducted experimental study also revealed that the performance of limestone for dosages less than 6% was categorically less significant than that of same amount of waste ceramic dust. For the dosages greater than 6% however the application of limestone remained better than the waste ceramic dust. In relation to this, for the separate application of 10% natural lime and waste ceramic dust, the resulting CBR Swell decreased by 49% and 40.5% respectively. As observed from Figure 6 (b), the slope of Dosage Vs CBR Swell graph is relatively higher for limestone stabilization (Case scenario 2). It is good instrument to reflect on the clear extent to which CBR Swell of the natural clay soil is sensitive to variation in dosage of the additives. Development of cementitious materials like calcium silicate hydrate, calcium aluminum silicate and gyrolite due to pozzolanic reaction, reduces the moisture sensitivity of clay which in turn reduces swelling characteristics of clay [46]. In relation to this, Nifana S, Palanikumar M [50] pointed out that the dosage of ceramic material and CBR Swell of clayey soils are inversely related to each other.

Like maximum dry density, California bearing ratio of the soil sharply increased with rise in dosage of limestone. As indicated in Figure 6(a) and (b), the rate of rise in California bearing ratio was very fast. The California bearing ratio increases from 30% to 20% when the mix combination shifts from 15% WCD +2% Limestone to 15% WCD +6% Limestone is increased from 0 to 30% respectively. Furthermore, the CBR Swell got diminished with increase in dosage of stabilizers in each combination. Accordingly, the free swell fell from 4.36% to 3.64% as the amount of natural lime in the combination rise from 2% to 4% which is 16.1% reduction. As dosage of lime increase, the strength and frictional resistance of the clay soil also increase [39].

3.3. Effect of natural lime and waste ceramic dust on LL and PI of the clay soil

With respect to Atterberg limits, both liquid limit and plastic index of the soil goes decreasing with addition of the stabilizers. Figure 7(a) represents the graphical illustration of effect of mix dosage on liquid limit of the clay soil. Blending of 2%, 6% and 10% limestone with the clay soil decreased value of the liquid limit from 79.6% to 71.45%, 58.27% and 29.4% respectively. The 10% limestone almost equally performs with 30% WCD in reducing liquid limit of the clay which implies that like in the case of CBR, response of the clay soil to dosage of natural lime is more sensitive than that of the waste ceramic dust. Hence, for waste ceramic dust to achieve similar degree of improvement in reducing liquid limit with any arbitrary amount of natural lime, about 200% more dosage is required.

Figure 7.

Effect of additives' dosage on; (a) Liquid limit (LL), (b) Plastic index (PI).

Similarly, plastic index which is another important index property of the expansive subgrade got reduced with increase in amount of both stabilizers. In natural state the intact plastic index of the soil was 50.32%. With addition of 6% and 10% limestone however the resulting plastic index value fell to 14.14% and 7.15% respectively. Likewise, application of the same amount of waste ceramic dust decreased magnitude of the stated parameter by 3.8% and 10.64% respectively. The cation exchange taking place between the additives and the clay material eventually results in development of flocculation which is the process in which clay particles come close to each other to form strong bond due to suppression of pore water [43]. Subhashree [28] and Bell [47] reported that flocculation is an important process which reduces the plastic behavior of clay soil thus, reduces plasticity index and liquid limit. Hence, the clay material gains strength since its frictional resistance is improved. According to Rakhil and Devi [21], an increase in ceramic content of the clay-WCD mixture gives rise to decrease in both plasticity index and liquid limit of clay soil. Finding of the study also revealed that the decrement rate of liquid limit is by far less than that of the plasticity index. Furthermore, Nifana and Palanikumar [50] found out that addition of 30% ceramic material to clay soil lessened the liquid limit from 42% to 33% which is 21.4% reduction. Similar decrement trend in the magnitude of liquid limit was observed in the current study. However, the degree of improvement in the latter study is greater than the former one that the stated parameter reduced by 65%.

In the combination of limestone and waste ceramic dust, the magnitude of both liquid limit and plastic index goes decreasing with rise in amount of limestone on the 15% WCD. The combined effect of limestone and waste ceramic dust on liquid limit and plastic index of the clay soil was depicted in Figure 7(a) and (b) respectively. Liquid limit and plastic index of the natural (non-stabilized) expansive clay was 79.6% and 50.32% respectively. The post stabilization values however were lowered to 46.83% and 9.88% for the combination of 15% WCD and 6% natural lime. Similarly, the plastic index value was lowered to 10.2% upon blending the 15% WCD and 4% natural lime with the expansive subgrade. Among all available combinations of the stabilizers’ dosage, the 4% and 15% combination was found to be the most economical alternative to modify properties of the clay.

The partial replacement of some portion of the plastic clay particles with the non-plastic waste ceramic dust and less plastic limestone material considerably reduced the plastic index of the stabilized clay subgrade. The reduction in magnitude of the plasticity index is mainly due to availability of calcium in limestone and silicate in clay soil which is very important for effective cation exchange to take place [15]. Besides, the ionic exchange of lime and clay minerals of the soil led to agglomeration and flocculation of clay particle which in turn result in reduction of plasticity of the soil [22]. Meron , Samuel [15] and Rakhil and Devi [21] pointed out that the liquid limit and plasticity reduces as dosage of lime material increases. Besides, the swelling and shrinkage characteristics drop with increase in content of lime material.

3.4. Effect of natural lime and waste ceramic dust on free swell of the clay soil

The variation of free swell with change in dosage of the stabilizers (WCD and limestone) was presented in Figure 8. Like other geotechnical properties, free swell of the soil was influenced by the stabilizers. As it can be observed from the Figure, addition and increment in amount of both natural lime and waste ceramic dust resulted in decrease in free swell. Addition of the additives to the clay soil significantly altered its expansive characteristics. After employment of stabilization to the soil, the clay did not experience exaggerated volume change upon addition of water. Accordingly, upon separate application of 6% and 10% natural lime, the free swell decreased from 74% to 25.59% and 13.65% respectively. Similarly, value of the stated parameter got diminished to 66% and 46.44% for the same dosage of waste ceramic dust. The colloidal reactions occurring right after addition of lime material, considerably lowers the plasticity and swelling properties of clay thus, mitigates its workability [48].

Figure 8.

Effect of additives' dosage on free swell of the clay subgrade.

The expansive behavior of the clay subgrade was considerably minimized with rise in amount of limestone material. As observed from Figure 8, the graph, magnitude of the free swell fell from 74% to 20% and 10% upon addition of 4% and 8% natural lime to the waste ceramic dust respectively. Besides, the decrement rate in free swell for the joint consideration of additives was faster than the separate blends. Likewise, the resulting degree of improvement in reducing free swell for the identified optimum dosage of limestone and waste ceramic dust is less than that of the joint action. In the case of separate application, the 10% limestone resulted in 81.5% reduction in magnitude of the free swell whereas the free swell reduced by 88.3% with combination of 4% limestone and 15% waste ceramic dust. The study conducted by [49] indicated that blending quicklime (CaO) or hydrated lime (Ca (OH)2) with clayey and expansive soils lessens the swelling and swelling pressure and hence reduces the sensitivity of clay soil to moisture variation. Likewise, Nifana and Palanikumar [50] reported that linear shrinkage of clayey soil decreased by an average of approximately 4–7% with addition of 5% lime.

3.5. Combined effect of the additives on geotechnical properties of the cay

The experimental analysis revealed that the separate application 6% natural lime in absence of the waste ceramic dust met all the requirements of ERA 2013 specification for road construction. For the 4% natural lime however not magnitude of all parameters were above the minimum requirement. Similarly, the minimum waste ceramic dust dosage required to let all parameters fall above the lowest safe margin of ERA specification is 20%. Hence, the 6% and the 20% WCD can be considered as the optimum dosages identified for separate application of the materials. To obtain further improvement in performance of the clay soil however joint influence of the two additives was investigated. It is the case in which various amount of natural lime is mixed with the 15% of waste ceramic dust in order to compare the degree of improvement achieved in the separate (case 2 and 3) and combined (case 4) application of the additives. Accordingly, the natural lime with dosages ranging from 2% to 10% was blended with 15% WCD to have an alternative optimum dosage in addition to the amounts identified for the separate employment of the stabilizers. The second alternative might be effective option incase availability of one of the materials matters. Besides, the combined application of the stabilizers is of paramount importance especially not to miss advantage of the better performing material [4]. Furthermore, combined stabilization approach in many cases is more effective than the separate consideration of stabilizers not only from degree of improvement view point but also with respect to having variety of chemical compositions within the blend [22]. Existence of various oxides and chemicals having different properties in the mix facilitates the cat ion exchange between the clay particles and the stabilizing agents which is vital for attainment of the anticipated degree of improvement [22, 23].

4. Conclusion

Application of the industrial waste ceramic dust and natural limestone considerably modified the geotechnical properties of the expansive subgrade. The achieved degree of improvement in properties of the stabilized soil highly depends on dosage of the stabilizers. Accordingly, both California bearing ratio and Maximum dry density of the clay goes increasing with addition of waste ceramic dust. Contrarily, with rise in amount of natural lime, the value of Maximum dry density got reduced whereas increment in value of California bearing ratio was witnessed. In the combined application of the additives however both parameters increased with increase in dosage of additives. The conducted experimental test revealed that the response of soil parameters to variation in amount of stabilizers is more sensitive for natural lime than the waste ceramic dust. It was also observed that the amount of natural lime required to meet road specifications and to achieve optimum improvement in properties of the soil was by far less than that of ceramic dust. Likewise, extra amount up to 150% of ceramic dust is obviously required to come up with similar degree of improvement with any arbitrary dosage of limestone. Accordingly, the 4% lime performed equivalently with the separate application of 15% waste ceramic dust in altering magnitude of the considered soil parameters. Small amount of limestone can hence possibly make a difference in altering magnitude of the parameters. Hence, from effectiveness point of view, natural lime is more powerful than the waste ceramic dust. For the separate application of additives, 20% waste ceramic and 6% natural lime was identified as optimum dosage for case 3 and case 2 respectively. For the combined case (case 3) however the combination of 15% WCD + 4% natural lime was identified to be the viable optimum amount. In relation to this, the rate of improvement in magnitude of the required parameters in the combined case (case 4) was by far greater than the separate application of the additives (case 2 and 3). Lastly, the three identified optimum dosages successfully fulfilled requirements of ERA 2013 specification for road construction.

Declarations

Author contribution statement

Adamu Beyene: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote paper.

Yada Tesfaye: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data.

Damtew Tsige; Alemineh Sorsa; Teyba Wedajo: Analyzed and interpreted the data.

Narobika Tesema: Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Getnet Mekuria: Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interest’s statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.AI-Azzo S.I. Treatment of Expansive clayey soil in AL-Wahda district at Mosul city with crushed lime stone. INJES. 2009;9(2):1–10. https://www.researchgate.net/publication/289650896_Stabilization_of_expansive_soil_using_waste_ceramic_dust [Google Scholar]

- 2.Akshaya K.S. Stabilization of expansive soil using waste ceramic dust. EJGE. 2012;17 https://pdfcoffee.com/stabilization-of-expansive-soil-using-waste-ceramic-dust-akshaya-kumar-sabat-pdf-free.html [Google Scholar]

- 3.Al-Sharif M.M., Attom M.F. A geo-environmental application of burned wastewater sludge ash in soil stabilization. Environ. Earth Sci. 2014;71(5):2453–2463. [Google Scholar]

- 4.Amakye S.Y., et al. Enhancing the engineering properties of subgrade materials using processed waste: a Review. Geotechnics. 2021;1:307–329. [Google Scholar]

- 5.Arif ur R., et al. Stabilization of subgrade by using additives (cement, lime) GSJ. 2019;7(4) https://www.globalscientificjournal.com/researchpaper/stabilization_of_sub_grade_by_using_additives_cement_lime_.pdf [Google Scholar]

- 6.Ayothiraman R., et al. Evaluation of liquefaction potential of guwahati gateway city to North-Eastern India. Nat. Hazards. 2012;63:449–460. [Google Scholar]

- 7.Bantayehu U. Expansive soil in Ethiopia: review. IJRET. 2007;6(5) https://www.ijsret.org/pdf/121824.pdf [Google Scholar]

- 8.Bhengu P.H., Allopi D. Influence of lime on lime soil stabilization on natural occurring acidic soil engineering properties. ASRJETS. 2017;30(1):57–69. https://asrjetsjournal.org/index.php/American_Scientific_Journal/article/view/2618/1097 [Google Scholar]

- 9.Binici H. Effect of crushed ceramic and basalt pumice as fine aggregates on concrete on mortars properties. Construct. Build. Mater. 2007;21(6):1191–1197. [Google Scholar]

- 10.Chulmin J., Antonio B. Purdue University; 2008. Post-construction Evaluation of Lime-treated Soils. Joint Transportation Research Program.https://rosap.ntl.bts.gov/view/dot/50908/dot_50908_DS1.pdf [Google Scholar]

- 11.Jamal K., et al. University of Kansas; 2017. Lime kiln Dust for Treated Subgrades.https://rosap.ntl.bts.gov/view/dot/35064/dot_35064_DS1.pdf Technical Report. [Google Scholar]

- 12.Kassahun A. Engineered soil and the need for lime-natural pozzolan mixture percentage approximation. Ethiop. J. Sci. 2018;41(2):70–79. https://www.ajol.info/index.php/sinet/article/download/198297/186988 [Google Scholar]

- 13.Kumar B.S., Preethi T.V. Behavior of clayey soil stabilized with rice husk ash & lime. IJETT. 2014;11 http://businessdocbox.com/Green_Solutions/94110833-An-experimental-investigation-on-stabilizing-the-soil-using-rice-husk-ash-with-lime-as-admixture.html [Google Scholar]

- 14.Maureen A.K. U S Department of Agriculture; 2009. Stabilization Selection Guide for Aggregate- and Native-Surfaced Low- Volume Roads.https://www.fs.fed.us/t-d/pubs/pdf/08771805.pdf Technical Report. [Google Scholar]

- 15.Meron W., Samuel T. Stabilization of expansive soil using bagasse ash & lime. EEA. 2014;32 https://www.ajol.info/index.php/zj/article/download/142172/131911 [Google Scholar]

- 16.Mostafa E., Nirmal D. Louisiana State University; 2017. Lime Utilization in the Laboratory, Field, and Design of Pavement Layers.https://www.ltrc.lsu.edu/pdf/2017/FR_575.pdf Technical Report. [Google Scholar]

- 17.Mukesh A.P., Patel H.S. A Review on effects of stabilizing agents for stabilization of weak soil. IISTE. 2012;2(6) https://www.iiste.org/Journals/index.php/CER/article/viewFile/2432/2455 [Google Scholar]

- 18.Nifana S., Palanikumar M. Mechanical stabilization of subgrade soil using ceramic powder. IJME. 2021;6(3) https://kalaharijournals.com/resources/IJME2021Dec21-40/DEC_29.pdf [Google Scholar]

- 19.Paul L.W. University of Southern Queensland; 2011. Effectiveness of Lime Stabilisation on Reactive Soils for Main Roads.https://core.ac.uk/download/pdf/11049943.pdf Dissertation. [Google Scholar]

- 20.Prasad R.R., et al. Use of lime and waste plastic fibers for subgrade stabilization. IJEAT. 2018;8(2C2) https://www.ijeat.org/wp-content/uploads/papers/v8i2c2/B10091282C218.pdf [Google Scholar]

- 21.Rakhil K.R., Devi K. Review on the effect of waste ceramic dust on the geotechnical properties of expansive soils. IRJET. 2016;3(12) https://www.irjet.net/archives/V3/i12/IRJET-V3I12298.pdf [Google Scholar]

- 22.Sankar B., et al. Research and Development Information, PCA; 2003. Stabilization of Clay Soils by Portland Cement or Lime: A Critical Review of Literature.https://www.cement.org/docs/default-source/cement-concrete-applications/sn2066.pdf?sfvrsn=5f54fdbf_2 [Google Scholar]

- 23.Sanjay K.D. Louisiana State University; 2012. Stabilization of Very Weak Subgrade Soil with Stabilizers.https://digitalcommons.lsu.edu/cgi/viewcontent.cgi?article=1066&context=gradschool_theses Dissertation. [Google Scholar]

- 24.Seco A., et al. Stabilization of expansive soils for use in construction. Appl. Clay Sci. 2011;51(3):348–352. [Google Scholar]

- 25.Torgal Jalali. Reusing ceramic wastes in concrete. Construct. Build. Mater. 2010;24(5):832–838. [Google Scholar]

- 26.Mutaz M., Muawia D. Chemical analysis and X-ray diffraction assessment of stabilized expansive soils. Bull. Eng. Geol. Environ. 2014;73:1063–1072. [Google Scholar]

- 27.Abdullahi S.L., Audu A.A. Comparative analysis on chemical composition of bentonite clays obtained from Ashaka and Tango deposits in gombe state, Nigeria. Chem. Search J. 2017;8(2):35–40. [Google Scholar]

- 28.Subhashree S. National Institute of Technology Rourkela; Rourkela-769008, Orissa, India: 2014. Geo-Engineering Properties of Lime Treated Plastic Soils. Thesis. [Google Scholar]

- 29.Oleng M. Physical and chemical properties of crushed ceramic and porcelain clay tile powder. IJIEASR. 2018;7(7) [Google Scholar]

- 30.Laurent de W., et al. Kinetics of lime/bentonite pozzolanic reactions at 20 and 50 °C: batch tests and modeling. Cement Concr. Res. 2014;59:34–42. https://hal-mines-paristech.archives-ouvertes.fr/hal-00958128 [Google Scholar]

- 31.Gissele S.R. Effect of lime on the mechanical response of a soil for use in unpaved forest roads. Acta Sci. Technol. 2020;42 [Google Scholar]

- 32.Pavan A., Dallas N.L. 2020. Analytical Tests to Evaluate Pozzolanic Reaction in Lime Stabilized Soils. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Araújo R.A. Evaluation of the pozzolanic activity of red ceramic waste usingmechanical and physicochemical methods. Cerâmica. 2019;65:461–469. [Google Scholar]

- 34.Mertens G. Pozzolanic reactions of common natural zeolites with lime and parameters affecting their reactivity. Cem. Concr. Res. 2009;39:233–240. [Google Scholar]

- 35.Amadi A.A., Okeiyi A. Use of quick and hydrated lime in stabilization of lateritic soil: comparative analysis of laboratory data. Geo-Engineering. 2017;8:3. [Google Scholar]

- 36.Edmeades D.C. Effects of lime on effective cation exchange capacity and exchangeable cations on a range of New Zealand soils. N. Z. J. Agric. Res. 1982;25(1):27–33. [Google Scholar]

- 37.Khan M.A. National Institute of Technology; Rourkela, Odisha-769008: 2015. Effect of Lime and Fly Ash on Cation Exchange Capacity (CEC) and Unconfined Compressive Strength (UCS) of Soils. Thesis. [Google Scholar]

- 38.Ellina B. Effective cation exchange capacity of calcium silicate hydrates (C-S-H) Cem. Concr. Res. 2021;143 [Google Scholar]

- 39.Adamu B.N. Settlement analysis of pipe culvert situated in soft clay treated with prefabricated vertical drain. Adv. Civil Eng. 2022 [Google Scholar]

- 40.Mohamed A.M.O., Al-Hosani K.I. International Conference on Geo-environment. 2000. Waste utilization from cement industry for modification of soil properties in Physicoarid lands. Muscat, 1–12. [Google Scholar]

- 41.Raymond N.Y., Ouhadi V.R. Experimental study on instability of bases on natural and lime/cement stabilized clayey soils. Appl. Clay Sci. 2006;35(3–4):238–249. [Google Scholar]

- 42.Arvind K., et al. Influence of fly ash, lime, and polyster fibres on compaction and strength properties of expansive soil. ASCE. 2007 [Google Scholar]

- 43.Mathew P.K., Rao S.N. Effect of lime on cation exchange capacity of marine clay. J. Geotech. Geoenviron. Eng. 1997;123(2):183–185. [Google Scholar]

- 44.Narasimha R.S., Rajesekaran G. Reaction products for medin lime-stabilized marine clays. J. Geotech. Eng. Geotech. Div. ASCE. 1996;122(5):329–336. [Google Scholar]

- 45.Dash S.K., Hussain M. ASCE; 2012. Lime Stabilization of Soils: Reappraisal. [Google Scholar]

- 46.Mateous M. Soil lime research at iow a state University. J. Soil Mech. and Found. Eng. Div. ASCE. 1964;90(2):127–153. [Google Scholar]

- 47.Bell F.G. Chapman and Hall; London: 1993. Engineering Treatment of Soils. [Google Scholar]

- 48.Thompson M.R. Lime-treated soils for pavement construction. ASCE. 1968;94(2) 1991-217. [Google Scholar]

- 49.Kate J.M., et al. IGC; Delhi: 2009. Influence of Bentonite Proportions on Swelling Characteristics of clay Mixes. [Google Scholar]

- 50.Russell L., et al. New Peaks in Geotechnics, Denver; Geo-Denvar: 2007. Stabilization of Oklahoma Expansive Soils using Lime and Class C fly Ash. [Google Scholar]

- 51.Damtew T., et al. Deformation analysis of cement modified soft clay soil using finite element method (FEM) Heliyon. 2022;8 doi: 10.1016/j.heliyon.2022.e09613. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.