Abstract

The influence mechanism of different geological parameters on the activation of small faults under mining in the deep coal face was investigated by numerical simulation. The study shows that (1) the degree of influence of six parameters including the fault lateral pressure coefficient λ, elastic modulus E, Poisson’s ratio μ, cohesion c, internal friction angle φ, and fault inclination angle θ on the activation of small faults was ranked in order as θ > λ > φ > μ > E > c. (2) The lateral pressure coefficient λ of the fault zone rock mass, the internal friction angle φ, and the fault inclination angle θ had a great influence on the fault activation. The larger the λ of the fault zone rock mass was, the smaller the φ was, the larger the subsidence amount drop of the rock layers on both sides of the fault was, and the greater the severity of the fault activation was. The fault activation degree decreased first, then increased, and then decreased with the increase of θ. When θ was 15 and 60°, there was relatively severe fault activation. When θ was 75°, the fault was not easy to activate. (3) Poisson’s ratio μ, elastic-modulus E, and cohesion c of the fault zone rock mass had little effect on the fault activation. The larger the E of the fault zone rock mass was, the larger the μ was, the smaller the c was, and the possibility of fault activation increased slightly. The research results can provide important theoretical support for the theoretical research on fault activation, on-site roof management, and mining schedule arrangement in the mining process of deep coal face.

1. Introduction

Underground coal mining faces have various geological structures. These geological structures create adverse effects on mining work to varying degrees. In particular, the special geological structures, such as fault, greatly affects mining activities. The widespread distribution of fault structures exerts a huge impact on the mining design of the working face, safe and efficient production, and mine production.1−3 As the mining depth increases, the overlying rock presents complex mining displacement characteristics, and some special joint structures such as folds and faults exert a very severe impact on the movement of overlying rock. Compared with some major coal-producing countries, such as the United States, Australia, and Russia, the occurrence conditions of our coal mines display the overall characteristics of high gas and multiple faults, which greatly hinder the development of our coal enterprises.4,5

In view of the unfavorable conditions of abundant underground faults and a wide distribution in some areas of China, experts and scholars have carried out a large number of relevant studies to ascertain the law of fault activity, so that precautions can be made in advance to reduce the impact on mining work. Li Shucai et al.6 established the damage evolution equation of discontinuous jointed rock mass in a complex stress state. Liu Chao et al.7 carried out all-side tracking and monitoring on the fault activation process and a development trend in excavation activities by establishing a microseismic monitoring system. The results demonstrated that the MS monitoring technology can detect small buried brittle faults ahead of the working face and is also an effective method to study the process and mechanism of brittle fault activation.8 Based on the “gradient plasticity theory”, Lin Yuandong et al.9 established a continuum strain gradient model to analyze the deformation and failure mechanism of the fault zone and proposed the “shear zone-out-of-band elastic rock system” as a criterion for fault activation. Zhao Yixin et al.10,11 used the Coulomb fracture stress increment as the activation criterion of the fault unit and introduced the damage factor to evaluate the activation-slip damage degree of the fault surface. Li Zhonghua et al.12 believed that with the increase of fault inclination angle, the normal stress and shear stress during fault activation decreased, while the horizontal thrust first increased and then decreased. Guo Shousong13 believed that when the near-field mining induces the activation of the fault structure, if the mining face is located in the fault foot wall, the upward and downward shear-slip instability of the fault rock block and the instability in fault rock block tension and separation are higher compared to the upper wall mining method. Yu Qiuge et al.14 concluded that when the lithological parameters of the fault surface are close, the normal stress and shear stress of the fault surface have an approximately linear relationship with the vertical distance to the fault outcrop. Ji Hongguang et al.15 introduced the Coulomb stress, analyzed the variation characteristics of the fault under mining disturbance stress, and compared the risk of slippage in the parallel fault and the vertical fault of the working face. Through numerical simulation software, Sainoki et al.16 analyzed the influence of fault properties on the activation slip and released energy during ore excavation, finding that the friction angle within the fault had the strongest influence. WANG Hongwei et al.17 used FLAC3D to simulate the slip of faults under different horizontal stresses and proposed that horizontal stress is the main driving force for the fault slip induced by coal seam mining. Wang Lianguo et al.18 used the numerical simulation software ANSYS to simulate the activation law of coal seam floor faults caused by coal mining. The results show that when the working face is located in the fault foot wall, there is a horizontal tensile stress zone in the upper wall of the fault.

The existing research results mainly focus on the rock stress distribution or fault displacement before and after excavation,19−21 and the change process of rock layer displacement during the excavation and the influence of different small fault parameters on the rock layer displacement have not been fully revealed.22 Combining theoretical analysis and numerical simulation, this paper focuses on the variation law of overlying rock displacement caused by the change of small fault parameters under the influence of mining, so as to summarize the factors through which small faults affect overlying rock displacement under the influence of mining. The research results can provide important theoretical support for the theoretical research on fault activation, on-site roof management, and mining schedule arrangement in the mining process of deep coal face.

2. Methods

2.1. Fault Activation Mechanism under the Influence of Mining

The mining activities in the adjacent fault structure area often induce instability and activation of the weak surface of the fault, causing strong dynamic load disturbance and inducing rock burst disasters. The initial fault–coal–rock mass system is in a state of static equilibrium. When there are mining engineering activities nearby, according to the distance, there are far-field and near-field disturbance effects. The existence of such disturbances will break the initial stress equilibrium of the fault structure, which in turn leads to the activation-slip phenomenon of the originally stable fault structure.12,23 When the activation slip occurs in the fault structure, a high-energy earthquake origin will be generated near the weak surface of the fault. The existence of this earthquake origin will cause severe dynamic load disturbance on the coal face, which then induces rock burst.

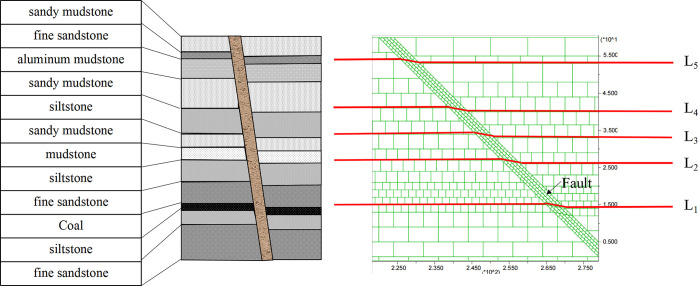

Because the strength of the fault zone rock mass is lower than that of the upper and lower wall rock mass, the original microfractures of the fault zone rock mass are damaged and expanded in the fault zone under the mining action. A fracture surface approximately parallel to the fault surface will be formed after the original microfracture of the fault zone is extended and connected. Under the influence of mining, the fault zone rock mass will slide down the fracture surface, causing a step drop on both sides of the fault. A section perpendicular to the fault strike is taken, and the triangular microelement body with a unit thickness on one side of the rock fracture surface of the fault zone is taken as the research object, and the mechanical model of the rock mass slip in the fault plane is established, as shown in Figure 1.14

Figure 1.

Mechanical model of rock mass slip in the fault plane.

Before the mining causes the rock mass slip in the fault plane, the microelement body is still, and the force analysis of the microelement body along the x and y directions shows that

|

1 |

where, ds is the contact area between the microelement body and the fracture surface; θ is the fault inclination angle, (°); and σ and τ are the normal stress and shear stress of the rock mass on the other side of the fracture surface with regard to the microelement body, MPa.

From the above formula, the normal stress σ and shear stress τ of the fracture surface can be obtained as

|

2 |

The mining of the working face destroys the original stress equilibrium of the coal and rock mass. When the working face approaches the geological structure of the fault, changes in the stress equilibrium state caused by the mining activity will generate the Coulomb stress f(σ, τ) on the fracture surface of the fault zone rock mass. When the Coulomb stress on the fracture surface reaches the ultimate shear strength τc of the fault zone rock mass, the fault zone rock mass will undergo relative frictional dislocation, causing a slip of the fault zone rock mass. That is, when the relative friction dislocation occurs in the fault zone rock mass, the Coulomb stress f(σ, τ) of the fracture surface must meet

| 3 |

where, ν is the friction factor of the fracture surface; τc is the ultimate shear strength of the fault zone rock mass, MPa; φ is the friction angle in the fault zone rock mass, (°); and c is the cohesion of the fault zone rock mass, MPa.

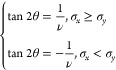

By substituting eq 2 into eq 3 and then taking the first derivative of θ, there is

|

4 |

It can be seen that the conditions for fault activation are mainly related to the fault inclination angle, the friction coefficient, and compressive stress of the fault zone rock mass. From a theoretical point of view, the influence of the friction coefficient of the fracture surface of rock mass in the fault zone on fault activation is as follows: with the increase of the friction coefficient of the fracture surface of rock mass in the fault zone, the possibility of fault activation decreases and influence of fault dip on fault activation: with the increase of fault dip, the possibility of fault activation increases. However, theory is not enough to prove everything, and it needs to be tested by practice. A large number of literature studies have pointed out that fault activation is related to factors, such as rock shear elastic modulus, Poisson’s ratio, fault inclination angle, and mine pressure distribution.

The main factors affecting fault activation include the lateral pressure coefficient λ, the elastic modulus E, the Poisson’s ratio μ, the internal friction angle φ, the cohesion c, and the fault inclination angle θ of the fault zone rock mass, and so forth. E, μ, φ, c, and θ are the properties of the fault zone rock mass. The lateral pressure coefficient λ of the fault zone rock mass is mainly affected by the original ground stress and the mining stress of the fault zone rock mass. The original ground stress includes the gravity of the overlying rock and the tectonic stress, and the size of the tectonic stress is closely related to the fault drop and the width of the fault zone. The mining stress of the fault zone rock mass is mainly affected by the relative position between the fault and the working face, the thickness of the mining coal seam, and the burial depth of the coal seam, overlying rock lithology, mining methods, and goaf treatment modes. In order to further analyze the specific influence of various factors, next, we use UDEC numerical simulation software to, respectively, study the influence of lateral pressure coefficient λ, elastic modulus E, Poisson’s ratio μ, cohesion c, internal friction angle φ, and fault inclination angle θ of the fault zone rock mass on the fault activation process, and analyze the mechanism by which these factors influence the activation of small faults under mining.

2.2. Numerical Model

The model herein takes the 25030 working face of a mine of Henan Shenhuo Coal & Power Co., Ltd. as the engineering background. The working face is located in mining area 25 in the east wing of the mine, with a horizontal elevation of −780 m, a ground elevation of +37.5 m, and a working face elevation of −725––635 m. The coal seam thickness of the working face is 0.5 – 3.2 m, the average thickness is 2.2 m, and the coal seam structure is simple. The coal seam inclination angle is 15° – 2°, with an average of 11°. Strike length is 1022 m, tilt length is 195 m, and the area is 174442 m2. There is magmatic rock intrusion near the cutting hole of the working face, resulting in thinning of the coal seam, which has a certain impact on the recovery. There are 2 faults exposed in the working face, of which F25030-1 has a greater impact on the recovery. The fault is a normal fault, with an inclination of 135°, an inclination angle of 42°, and a drop of 1 m.

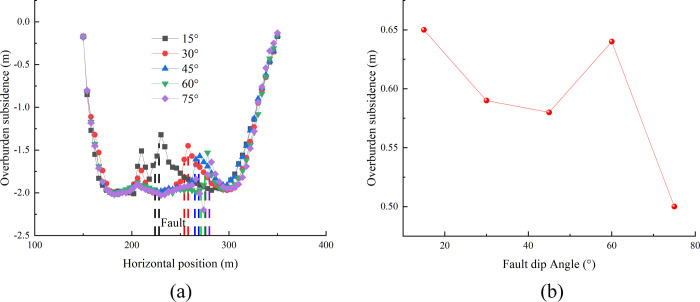

According to the actual situation of the site, the model establishes a 600 m (length) × 60 m (height) horizontal coal-rock layer. The boundary is fixed and constrained, the excavation position is at the horizontal coordinate of 150 m, and a 150 m coal pillar is reserved on the left boundary to eliminate the boundary effect. A 200 m long working face was excavated from 150 to 350 m, 10 m in each step, as shown in in Figure 2, the coal seam below L1 is 2 m thick, and the full height is mined at one time, and subsequent excavation was carried out after equilibrium. For the convenience of research, displacement monitoring lines L1∼L5 (Figure 2) were set at 2, 14, 21, 28, and 41 m away from the coal seam floor, a vertical downward pressure of 20.4 MPa was evenly applied to the upper boundary to simulate the ground stress, and a stress gradient is applied to the horizontal stress to simulate a linear increase with depth of the horizontal stress. The initial coal rock parameters are shown in Table 1.

Figure 2.

Schematic diagram of numerical simulation geological model.

Table 1. Mechanical Properties of Coal Seam and Rock.

| lithology | thickness/m | density/(kg m–3) | bulk modulus/GPa | shear modulus/GPa | cohesion/MPa | tensile strength/MPa | internal friction angle/(°) |

|---|---|---|---|---|---|---|---|

| sandy mudstone | 5 | 2500 | 66.62 | 26.35 | 18 | 3.8 | 39 |

| fine sandstone | 2 | 2700 | 78.84 | 24.44 | 25 | 3.2 | 43 |

| aluminum mudstone | 5 | 2500 | 70.62 | 28.35 | 16 | 3.8 | 37 |

| sandy mudstone | 8 | 2500 | 66.62 | 26.35 | 18 | 3.8 | 34 |

| siltstone | 7 | 2355 | 70.92 | 26.55 | 14 | 3.8 | 39 |

| sandy mudstone | 4 | 2500 | 66.62 | 26.35 | 16 | 3.1 | 34 |

| mudstone | 3 | 2250 | 54.39 | 22.27 | 19 | 3.8 | 30 |

| siltstone | 6 | 2700 | 78.84 | 24.44 | 25 | 3.2 | 41 |

| fine sandstone | 6 | 2355 | 62.92 | 26.55 | 1.04 | 1.1 | 27 |

| coal | 2 | 1450 | 10.55 | 10.54 | 0.8 | 0.8 | 16 |

| siltstone | 4 | 2355 | 62.92 | 26.55 | 1.24 | 1.1 | 35 |

| fine sandstone | 8 | 2700 | 78.84 | 24.44 | 25 | 1.2 | 41 |

| fault | 2000 | 2 | 2 | 0.5 | 0 | 18 |

3. Results and Discussion

3.1. Failure Characteristics of Fault-Bearing Overlying Rock under the Influence of Mining

A normal fault with an inclination angle of 45°, a horizontal fault distance of 4 m, and a drop of 1 m was selected, and the working face was mined from 150 m. The simulation displays the failure characteristics of the overlying rock when the working face is located at 70, 40, and 20 m before the fault and 10, 30, and 60 m across the fault, as shown in Figure 3.

Figure 3.

Failure characteristics of fault-bearing overlying rock under the influence of mining.

It can be seen from Figure 3 that.

-

1

When the coal face is far away from the fault (70 m and 40 m), the overlying rock in the goaf is not disturbed by the fault. When the coal face advances 50 m and is 70 m away from the fault, the first period of pressure is applied, and the top basically collapses to the goaf. The average subsidence of the rock layer above the basic roof is 1.53 m, and the average subsidence of the basic roof is 1.78 m.

-

2

As the coal face continues to advance, the coal face gradually approaches the fault. When it is 20 m away from the fault, the fault slips. It can be seen from Figure 3c that the location of the fault surface and the displacement vector nearby are not vertically downward, but an oblique downward trend is exhibited, and the foot wall obviously slips along the fault. Affected by the dislocation formed by the slip of the fault foot wall along the fault, the subsidence of upper wall near the fault surface is significantly lower than that of the foot wall.

-

3

When the coal face is 10 m across the fault, the displacement of the overlying rock above the goaf lags behind after excavation. That is, the overlying rock will not be displaced immediately after the coal is mined out, only sinking gradually after the goaf is advanced forward. Moreover, the subsidence of the upper wall is smaller than that of the foot wall. The average subsidence is 1.36 m for the upper wall and 1.89 m for the foot wall.

-

4

When the coal face is 60 m across the fault, the overlying rock receives gradually weakened influence from the fault, and the displacement gradually conforms to the movement law of the overlying rock during non-fault mining. At this time, the displacement of the rock layer above the goaf tends to stabilize, and the displacement of the overlying rock near the fault surface is smaller in the upper wall than in the foot wall. The average subsidence of the fault is 1.5 m in the upper wall and 1.89 m in the foot wall. The overlying rock displacement initially returns to normal when the coal face passes the fault by about 60 m, displaying the same displacement law as when it is not disturbed by the fault.

During the whole process, the subsidence displacement of the foot wall is dominated by subsidence, which is to slide down along the fault in the vicinity of the fault surface. The upper wall is affected by the fault. In particular, the rock mass at the top of the model near the fault is most obviously affected by the fault slip. The rock caving is insufficient, and the subsidence is less than that of foot wall.

3.2. Influence of Lateral Pressure Coefficient on Fault Activation

In order to study the influence of the lateral pressure coefficient of the fault zone rock mass on the fault activation, the failure characteristics of the overlying rock around the small fault under the influence of mining were, respectively, simulated when the lateral pressure coefficients of the fault zone rock mass were 0.5, 0.75, 1.0, 1.25, and 1.5 (Figure 4).

Figure 4.

Subsidence amount and drop variation of overlying rock under different lateral pressure coefficients of the fault zone rock mass.

It can be seen from Figure 4 that (1) the lateral pressure coefficient of the fault zone rock mass has a great influence on the fault activation. Before the coal face passes through the fault, the overlying rock subsidence decreases slightly with the increase of the lateral pressure coefficient, and the horizontal position when the goaf has the maximum subsidence is slightly delayed with the increase of the lateral pressure coefficient. (2) After the coal face passes through the fault, there is a significant difference in the subsidence of the rock layer above the fault. The larger the lateral pressure coefficient λ is (increased from 0.5 to 1.5), the smaller the overlying rock subsidence is (reduced from 1.54 to 1.38 m), and there is little difference in the displacement of the rock layer below the fault (reduced from 2.03 to 2.00 m), resulting in a greater drop in the subsidence formed at the fault. (3) As the lateral pressure coefficient λ increases, there is a greater displacement drop on both sides of the fault zone rock mass, which increases from 0.51 to 0.62 m, and the fault activation is all the more severe. For its reason, the increase in lateral pressure coefficient will make it less difficult for fracture development and expansion of fault zone rock mass, and the fault zone rock mass is more likely to slip along the fracture surface.

3.3. Influence of Elastic Modulus on Fault Activation

In order to study the influence of the elastic modulus of the fault zone rock mass on the fault activation, the failure characteristics of the surrounding overlying rock of small faults were respectively simulated under the influence of mining when the elastic modulus of the fault zone rock mass was 0.5, 1.0, 2.0, 4.0, 6.0, and 8.0 Gpa (Figure 5).

Figure 5.

Subsidence amount and drop variation of the overlying rock under different elastic moduli of the fault zone rock mass.

It can be seen from Figure 5 that (1) the elastic modulus of the fault zone rock mass has little effect on the fault activation. Before the coal face reaches the fault, the overlying rock is slightly affected by the fault, and the exhibited subsidence law is similar to the subsidence law of the overlying rock when there is no fault. (2) When the coal face is excavated to 30 m across the fault (Figure 4b), the overlying rock subsidence amount begins to differ due to the elastic modulus of the fault. As the elastic modulus increases (from 0.5 GPa to 8.0 GPa), the subsidence increases slightly (from 1.87 to 1.95 m). After the coal face is 80 m across the fault, the overlying rock is no longer affected by the fault, and the shape of the overlying rock in the goaf is basically fixed. (3) It can be seen from Figure 5d that, under a greater elastic modulus of the fault zone rock mass (increasing from 0.5 to 8.0 GPa), the overall drop in the subsidence of the overlying rock on both sides of the fault increases slightly (from 0.58 to 0.60 m).

3.4. Influence of Poisson’s Ratio on Fault Activation

In order to study the influence of the Poisson’s ratio of the fault zone rock mass on the fault activation, the failure characteristics of the overlying rock around the small fault under the influence of mining were, respectively, simulated when the Poisson’s ratios of the fault zone rock mass were 0.1, 0.2, 0.3, and 0.4 (Figure 6).

Figure 6.

Subsidence amount and drop variation of the overlying rock under different Poisson’s ratios of the fault zone rock mass.

It can be seen from Figure 6 that (1) the Poisson’s ratio of the fault zone rock mass has little effect on the fault activation. During the entire mining process, the subsidence process of the overlying rock in the goaf below the fault is almost the same as that under the condition of no fault. There is an obvious difference between the subsidence of the upper rock layer and that of the lower rock layer, but the subsidence is little affected by the Poisson’s ratio of the fault. (2) After the coal face passes through the fault, the overlying rock subsidence amount is slightly different under different Poisson’s ratios. With the increase of Poisson’s ratio, μ, the subsidence amount drop formed by the rock layers on both sides of the fault tends to gradually increase as a whole. As the Poisson’s ratio of the internal rock mass increases from 0.1 to 0.4, the displacement difference of the rock layers on both sides of the fault increases from 0.58 m to 0.61.(3) With the increase of the Poisson’s ratio of the fault zone rock mass, the lateral deformation of the rock mass increases, and the rock mass is more likely to slip along the fault zone fracture surface, leading to increased subsidence amount drop in the rock mass on both sides of the fault, so that the fault activation is more severe. When the coal face continues to advance through the fault, the larger the Poisson’s ratio of the fault zone rock mass is, and the greater the subsidence rate of the overlying rock on the fault upper wall is, but the displacement gap gradually narrows after the final stabilization.

3.5. Influence of Cohesion on Fault Activation

In order to study the effect of rock mass cohesion in the fault zone on fault activation, the failure characteristics of overlying rock around small faults under the influence of mining were, respectively, simulated when the cohesions of fault zone rock mass were 0.005, 0.1, 0.2, and 0.3 Mpa (Figure 7).

Figure 7.

Subsidence amount and drop variation of the overlying rock under different cohesions of the fault zone rock mass.

It can be seen from Figure 7 that the cohesion of the fault zone rock mass has very little effect on the fault activation. When the mining face does not reach the fault, the overlying rock subsidence amount is basically not affected by the cohesion of the fault zone rock mass. After the coal face passes through the fault, the overlying rock receives a small influence from the cohesion of the fault zone rock mass. As the cohesion increases (from 0.005 to 0.3 MPa), the subsidence amount of the rock mass above the fault increases slightly (from 1.40 to 1.42 m), and the subsidence amount of the rock layer below the fault also increases slightly (from 2.01 to 2.02 m). The rock masses on both sides of the fault have a similar subsidence amount, and the subsidence amount drop is almost unchanged (from 0.61 to 0.60 m). As the cohesion of the fault zone rock mass increases, the shear strength increases, the possibility of sliding along the fault fracture decreases, and the severity of fault activation also decreases slightly.

3.6. Influence of Internal Friction Angle on Fault Activation

In order to study the effect of the internal friction angle of the fault on the fault activation, the failure characteristics of the overlying rock around the small fault under the influence of mining were, respectively, simulated when the internal friction angles of the fault zone rock mass were8, 13, and 18°(Figure 8).

Figure 8.

Subsidence amount and drop variation of the overlying rock under different internal friction angles of the fault zone rock mass.

It can be seen from Figure 8 that, (1) the internal friction angle of the fault zone rock mass has a great influence on the fault activation. When the coal face is 20 m away from the fault, the overlying rock subsidence amount near the fault begins to be affected by the internal friction angle of the fault. The larger the internal friction angle is, the smaller the overlying rock subsidence amount is. (2) After the coal face passes through the fault, under a greater internal friction angle of the fault (increasing from 8 to 18°), the subsidence amount of the rock layer below the fault is closer (increasing from 2.02 to 2.03 m), and the rock layer subsidence amount above the fault is greater (increasing from 1.42 to 1.5 m). As a result, there is a smaller subsidence amount drop formed by the overlying rocks on both sides of the fault, which decreases from 0.60 to 0.53 m, and the fault activation is less severe. (3) Under a greater internal friction angle, the fault zone rock mass is less likely to slip along the fault surface, so the fault activation is less severe accordingly. That is, as the friction angle in the fault zone rock mass increases, the fault activation is less severe.

3.7. Influence of Fault Inclination Angle on Fault Activation

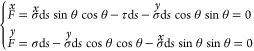

In order to study the effect of fault inclination angle on fault activation, the failure characteristics of overlying rocks around small faults under the influence of mining were, respectively, simulated when fault inclination angles were 15, 30, 45, 60, and 75°(Figure 9).

Figure 9.

Subsidence amount and drop variation of the overlying rock under different inclination angles of the fault zone rock mass.

It can be seen from Figure 9 that (1) the fault inclination angle has a great influence on the fault activation, and the fault activation degree first decreases, then increases, and then decreases with the increase of the fault inclination angle. When the fault inclination angles are 15 and 60°, after the coal face passes through the fault, there is a relatively great displacement difference between the rock mass on both sides of the fault, 0.65 and 0.64 m, respectively, and the fault activation is relatively severe. (2) There are various opinions on the influence of fault inclination angle on fault activation at this stage. Ref (24) believes that when the fault inclination angle is small, the fault internal stress changes more violently with the mining stress compared to the case when the fault inclination angle is greater, so activation is easier. Ref (25) also believes that when the fault inclination angle is close to 45° + 1/2 internal friction angle, fault activation requires minimum stress critical value, and activation is the easiest at this time. It can be seen from Figure 9b that the subsidence amount difference between the two sides of the fault reaches the maximum under fault inclination angles of 15 and 60°, and activation is most likely to occur at this time. The fault zone rock mass slides along the fault surface more easily and fault activation is the most intense then. The numerical simulation results coincide with viewpoints of ref (24)(25), respectively. (3) When the fault inclination angle is 75°, there is a small subsidence amount drop in the overlying rock on both sides of the fault, which is 0.50 m. Slip is the least likely to occur, the internal stress changes are relatively small, and the activation degree is small.

4. Conclusions

-

1

According to the microelement model of the fault zone rock mass slipping along the weak fracture surface, a mechanical model of the fault zone rock mass slip was established, and the main influencing factors of fault activation (lateral pressure coefficient λ, elastic modulus E, Poisson’s ratio μ, internal friction angle φ, cohesion c, and fault inclination angle θ of fault zone rock mass etc.) were analyzed. The mechanism by which various factors, such as the lateral pressure coefficient, affect the activation of small faults was numerically analyzed.

-

2

The fault activation generally begins when the coal face is 20 m away from the fault and ends when the coal face crosses the fault by 80 m. The fault top began activation first, and the subsidence amount of the rock layer above the fault was generally smaller compared to the rock layer below the fault. Due to the fault activation, an apparent drop appeared in the overlying rock subsidence amount on both sides of the fault. The various factors such as the lateral pressure coefficient of the fault zone rock mass exerted varying degrees of influence on the activation of small faults, and the order was as follows: that of fault inclination angle > lateral pressure coefficient > internal friction angle > Poisson’s ratio > elastic modulus > cohesion.

-

3

The lateral pressure coefficient, the internal friction angle and the fault inclination angle of the fault zone rock mass had a great influence on the fault activation. With the increase of the lateral pressure coefficient λ of the fault zone rock mass, the internal friction angle φ decreased, the subsidence amount drop of the rock layers on both sides of the fault increased, and the severity of the fault activation aggravated. The fault activation degree decreased first, then increased, and then decreased with the increase of the fault inclination angle. When the fault inclination angles were 15 and 60°, the fault activation was relatively severe. When the fault inclination angle was 75°, the fault was not easy to activate. The Poisson’s ratio μ, elastic modulus E, and cohesion c of the fault zone rock mass had little effect on the fault activation. The larger the elastic modulus E of the fault zone rock mass was, the larger the Poisson’s ratio μ was, the smaller the cohesion c was, and the possibility of fault activation increased slightly.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (grants no.51734007, 51704099, and 52074106), the Program for Innovative Research Team in University of Ministry of Education of China (grant no. IRT_16R22), the Key R&D and Promotion Projects in Henan Province (grant no.212102310105), and the Doctoral Fund of Henan Polytechnic University (grant no. B2019-56).

The authors declare no competing financial interest.

References

- Zuo J.-P.; Chen Z. H.; Wang H.-W.; Liu X.-P.; Wu Z.-P. Experimental investigation on fault activation pattern under deep mining. J. China Coal Soc. 2009, 34, 305–309. [Google Scholar]

- Li Z.-H.; Dou L.-M.; Chen G.-X.; Jiang H.; Du T. The risk of fault induced rockburst during mining. J. China Inst. Min. Technol. 2010, 39, 490–495. [Google Scholar]

- Zhang K.; He M.; Jiang Y. Mechanism research of roadway pressure bump induced by fault slip and activation. Coal Sci. Technol. 2017, 45, 12–20+64. [Google Scholar]

- Yin G.; Li X.; Guo W. Photo-elastic experimental and field measurement study of ground pressure of surrounding rock of large dip Angle working coalface. J. Rock Mech. Geotech. Eng. 2010, 29, 3336–3343. [Google Scholar]

- Peng S.; Meng Z.; Li Y. Influence of faults on coal roof stability by physical modeling study. Coal Gelogy & Exploration 2001, 29, 1–4. [Google Scholar]

- Li S.; Zhu W. Fracture damage mechanism of discontinuous jointed rockmass under the stage of complex stress and its application. Chin. J. Rock Mech. Eng. 1999, 18, 24–28. [Google Scholar]

- Liu C.; Li S.; Cheng C.; Xue J. Activation characteristics analysis on concealed fault in the excavating coal roadway based on microseismic monitoring technique. Int. J. Rock Mech. Min. Sci. 2019, 123, 104096. [Google Scholar]

- Cheng G.; Li L.; Zhu W.; Yang T.; Tang C.; Zheng Y.; Wang Y. Microseismic investigation of mining-induced brittle fault activation in a Chinese coal mine. Int. J. Min. Sci. Technol. 2017, 27, 883–887. [Google Scholar]

- Lin Y.; Tu M.; Liu W.; Wu J. Faults activation mechanism based on gradient-dependent plasticity. J. China Coal Soc. 2012, 37, 2060–2064. [Google Scholar]

- Lu Z.; Ju W.; Zhao Y.; Wang H.; Zheng J.; Liu A. Analysis of the mining induced stress rotation influence on fault stability. Rock Soil Mech 2019, 40, 4459–4466. [Google Scholar]

- Zhao Y.; Lu Z.; Zhu G.; Jiao Z.; Wang H.; Gao N. Fault reactive induced by the principal stress rotation for the underground coal mining. J. China Univ. Min. Technol. 2018, 47, 73–80. [Google Scholar]

- Li Z.; Bao S.; Yin W.; Liang Y.; Sun S. Study on the activation condition of giant thrust fault under mining disturbance. Journal of Mining & Safety Engineering 2019, 36, 762–767. [Google Scholar]

- Guo S. Study on the Mechanism of Fault Activation Induced by Mining near Fault Zone. Coal Engineering 2019, 51, 93–97. [Google Scholar]

- Yu Q.; Zhang H.; Zhang Y.; Deng W.; Zhang G. Analysis of fault activation mechanism and influencing factors caused by mining. J. China Coal Soc. 2019, 44, 18–30. [Google Scholar]

- Ji H.; Ma H.; Wang J.; Zhang Y.; Cao H. Mining disturbance effect and mining arrangements analysis of near-fault mining in high tectonic stress region. Saf. Sci. 2012, 50, 649–654. 10.1016/j.ssci.2011.08.062. [DOI] [Google Scholar]

- Sainoki A.; Mitri H. S. Dynamic behaviour of mining-induced fault slip. International. J. Rock Mech. Min. Sci. 2014, 66, 19–29. 10.1016/j.ijrmms.2013.12.003. [DOI] [Google Scholar]

- Wang H.; Shi R.; Deng D.; Jiang Y.; Wang G.; Gong W. Characteristic of stress evolution on fault surface and coal bursts mechanism during the extraction of longwall face in Yima mining area. J. Struct. Geol. 2020, 136, 104071. [Google Scholar]

- Wang L.; Miao X. Numerical simulation of coal floor fault activation influenced by mining. Int. J. Min. Sci. Technol. 2006, 16, 385–388. 10.1016/s1006-1266(07)60031-5. [DOI] [Google Scholar]

- Zhou X. M.; Wang S.; Li X. L. Research on theory and technology of floor heave control in semicoal rock roadway: Taking longhu coal mine in Qitaihe mining area as an Example. Lithosphere 2022, 2022, 3810988. 10.2113/2022/3810988. [DOI] [Google Scholar]

- Li X. L.; Chen S. J.; Liu S. M.; Li Z. H. AE waveform characteristics of rock mass under uniaxial loading based on Hilbert-Huang transform. J. Cent. S. Univ. 2021, 28, 1843–1856. 10.1007/s11771-021-4734-6. [DOI] [Google Scholar]

- Li X. L.; Chen S. J.; Wang S. Study on in situ stress distribution law of the deep mine taking Linyi Mining area as an example. Adv. Mater. Sci. Eng. 2021, 9, 5594181. 10.1155/2021/5594181. [DOI] [Google Scholar]

- Liu H. Y.; Zhang B. Y.; Li X. L.; Liu C.; Wang C.; Wang F.; Chen D. Research on roof damage mechanism and control technology of gob-side entry retaining under close distance gob. Eng. Fail. Anal. 2022, 138, 106331. 10.1016/j.engfailanal.2022.106331. [DOI] [Google Scholar]

- Liu S. M.; Li X. L.; Wang D. K.; et al. Investigations on the mechanism of the microstructural evolution of different coal ranks under liquid nitrogen cold soaking. Energy Sources, Part A Recovery, Util. Environ. Eff. 2020, 1, 1–17. 10.1080/15567036.2020.1841856. [DOI] [Google Scholar]

- Bu W.; Mao X. Research on effect of fault dip on fault activation and water inrush of coal floor. Chin. J. Rock Mech. Eng. 2009, 28, 386–394. [Google Scholar]

- Cai W.; Dou L.; Wang G.; Hu Y. Mechanism of fault reactivation and its induced coal burst caused by coal mining activities. Journal of Mining & Safety Engineering 2019, 36, 1193–1202. [Google Scholar]