Abstract

Bioelectricity has been stated as a key factor in regulating cell activity and tissue function in electroactive tissues. Thus, various biomedical electronic constructs have been developed to interfere with cell behaviors to promote tissue regeneration, or to interface with cells or tissue/organ surfaces to acquire physiological status via electrical signals. Benefiting from the outstanding advantages of flexibility, structural diversity, customizable mechanical properties, and tunable distribution of conductive components, conductive fibers are able to avoid the damage-inducing mechanical mismatch between the construct and the biological environment, in return to ensure stable functioning of such constructs during physiological deformation. Herein, this review starts by presenting current fabrication technologies of conductive fibers including wet spinning, microfluidic spinning, electrospinning and 3D printing as well as surface modification on fibers and fiber assemblies. To provide an update on the biomedical applications of conductive fibers and fiber assemblies, we further elaborate conductive fibrous constructs utilized in tissue engineering and regeneration, implantable healthcare bioelectronics, and wearable healthcare bioelectronics. To conclude, current challenges and future perspectives of biomedical electronic constructs built by conductive fibers are discussed.

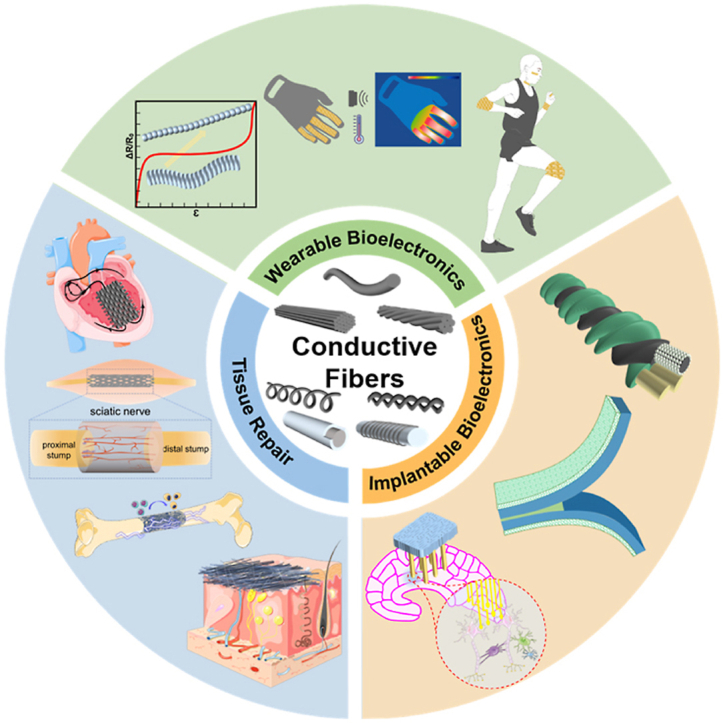

Keywords: Conductive fibers, Conductive biomaterials, Tissue repair, Implantable bioelectronics, Wearable bioelectronics

Graphical abstract

Highlights

-

•

Discussing the up-to-date constructing methods of flexible and biocompatible conductive fibers.

-

•

Underlining the significance of matrix conductivity for tissue repair and regeneration.

-

•

Introducing the advances on conductive fibers for implantable and wearable bioelectronics.

-

•

Presenting the challenges and emerging strategies for designing conductive fibers.

1. Introduction

Bioelectricity is recognized as a crucial instructive factor for human life activities and its regulative actions in cell behavior have been well documented although its action mechanism remains undefined [1]. Numerous in vitro and in vivo experiments have exerted electrical stimulation to living cells and tissues directly through electrodes or indirectly through bioelectronic devices based on conductive biomaterials, to trigger series of cell activities for tissue repair process in electroactive tissues, such as cardiac [[2], [3], [4], [5]], nerve [[6], [7], [8]], bone [[9], [10], [11], [12]] and skin [[13], [14], [15]]. Furthermore, sufficient evidence suggests that electrical signals can be transmitted by conductive biomaterial graft or bioelectronic devices implanted in or worn on human bodies to activate beneficial electrical response in processes of wound healing [14,15], drug delivery [16], sensing for biochemical factors and biophysical signals for tissue repair [17,18], and health monitoring [19,20]. In such context, conductive biomaterials are highly desirable for conductive scaffolds and bioelectronics.

Conductive biomaterials, the indispensable components of conductive scaffolds and bioelectronics, have been gaining growing attention and rapid development in recent years. Conductive biomaterials can be generally classified as five categories: (1) intrinsic conductive polymers (ICPs), such as polypyrrole (PPy) [21], polyaniline (PANi) [22], and poly (3,4-ethylenedioxythiophene) (PEDOT) [23]; (2) carbon nanomaterials, including one-dimensional single-walled carbon nanotubes (SWCNTs), multi-walled carbon nanotubes (MWCNTs) [24,25] and carbon nanofibers (CNFs) and two-dimensional graphene, graphene oxide (GO) and reduced graphene oxide (rGO) [[26], [27], [28]]; (3) metallic nanomaterials, such as silver nanoparticles (AgNPs), silver nanowires (AgNWs), gold nanoparticles (AuNPs) and gold nanorods (AuNRs); (4) MXenes, two-dimensional crystal nanomaterials of transition metal carbides, nitrides or carbonitrides, represented by Ti3C2Tx nanosheets; (5) liquid metals (LM), represented by eutectic-gallium-indium (EGaIn) [29,30]. Each type of conductive biomaterials possesses their own unique advantages applicable to biomedical constructs, yet at the same time, most of them also display an inevitable disadvantage, i.e., mismatched mechanical behaviors with the deformable tissues leading to severe inflammation and electronic failure [31,32]. Fortunately, as a special form of soft materials, fibers and fiber assemblies are equipped with lightweight, distinguished flexibility, tunable mechanical properties and structural diversity. Consequently, with reasonable composition and structure design of conductive fibers and mature weaving, knitting, braiding, embroidering, stitching, and nonwoven technologies, it is readily to meet the requirements of multidimensional deformation capacity under complex forces and biomimicking heterogenous structures for biomedical constructs [33,34]. In order to maximize the advantage of these conductive biomaterials in biomedical applications, great effort has been put in the researches of fabrication and applications of conductive fibers.

Herein, this review mainly focuses on flexible composite conductive fibers aimed at biomedical field. Fabrication methods of conductive fibers with enriched composition/structural designs are concluded as wet spinning, electrospinning, microfluidic fabrication, 3D printing, and surface modification on fibers, yarns or fabrics. Current advances of conductive fibers applied in tissue repair and regeneration for electroactive tissues, implantable bioelectronics and wearable bioelectronics for personal health monitoring are discussed separately. Finally, existing issues and prospects for further development of conductive fibers are provided as well.

2. Fabrication technologies for conductive fibers

Due to the inherent rigidity, insolubility and infusibility of most conductive biomaterials, preparation of composite conductive fibers is usually chosen for the feasibility, flexibility and convenience of processing [35]. The mechanical, electrical and biological properties can be fine-tuned by proper composition and structure designs of fibers to meet the requirements of tissue repair materials or bio electronics. Hence, various types of conductive fibers have been developed by the combination of fiber-forming polymers and conductive biomaterials through wet spinning, microfluidic spinning, electrospinning and 3D printing, as well as through surface modification on nonconductive fibers. Moreover, textile processing technologies are further adopted to enrich structure designs of conductive fibers to obtain biomimicking structures.

2.1. Fiber fabrication technology

2.1.1. Wet spinning

Wet spinning is a mature filament production technology for soluble/dispersible materials (Fig. 1A), in which homogenously dispersed spinning dope is continuously injected into a certain poor solvent of the solute through a syringe with a fine needle driven by an injection pump [19]. After the nonsolvent-induced phase separation, the thin flow is solidified and subjected to drying and/or stretching to obtain fibers. Among all the general spinning parameters of solvent, concentration and flow rate of the precursor solution, needle diameter, solvent, temperature and concentration of the coagulation bath, and solidification time, the used solvents crucially affect formation of stable spinning flow and smooth double diffusion process.

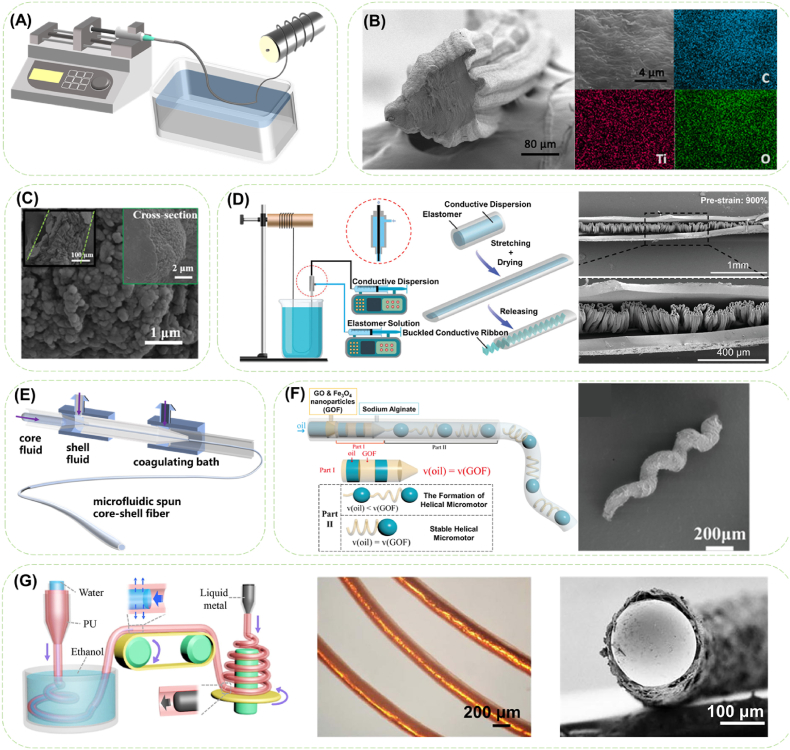

Fig. 1.

Diagrams of conductive fibers fabricated by wet spinning and microfluidic spinning. (A) Typical fabrication device for wet spinning process. (B) Cross-sectional SEM image and EDS mapping images of C, Ti, and O of the MXene/CNT/PU fiber. Reproduced with permission from Ref. [36]. Copyright 2021, Elsevier Ltd. (C) SEM image of corn-like PANi/regenerated cellulose fiber. Reproduced with permission from Ref. [37]. Copyright 2016, American Chemical Society. (D)The coaxial wet-spinning process for encapsulating the conductive dispersion in an elastic TPE channel and the pre-strain-then-buckling strategy and SEM image of the obtained fiber fabricated with 900% pre-strain. Reproduced with permission from Ref. [38]. Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (E) Schematic illustration of microfluidic spinning process. (F) Schematic diagram of the formation mechanism and the SEM image for the graphene oxide-based helical micromotors (GOFHMs). Reproduced with permission from Ref. [39]. Copyright 2020, American Chemical Society. (G) Schematic illustration of the generation device of the LM-encapsulated microfiber, and the bright-field microscopic image and the SEM image of the cross-section of LM-encapsulated microfibers. Reproduced with permission from Ref. [40]. Copyright 2020, Science China Press.

Uniform distribution of conductive components in fibers ensures the consistent mechanical and electrical properties in different segments along the fiber, and avoids severe interface issue due to the typical mechanical mismatch. Therefore, to weaken the strong interactions of the conductive nanoparticles, the solvent systems and mixing means are considered to form stable spinning solutions. Thorough stirring was adopted to mix CNTs and MXenes uniformly with polyurethane (PU)/dimethyl formamide solution, and after being injected into the coagulation bath, a stretchable conductive fiber was prepared [36]. With the MXene nanosheets serving as the connecting bridges among the CNT network (Fig. 1B), the composite fiber achieved an optimized conductivity of ∼6 S cm−1 under 200% strain with a combined CNT concentration of 4 wt% and MXene concentration of 0.5 wt%. In order to ensure the biocompatibility while overcoming the poor dispersion of graphene in aqueous system, a surfactant-free strategy was proposed by simple mechanical stirring graphene/cellulose aqueous solution with a mediation of inorganic alkali [41]. The steric hindrance effect between the inorganic metal-ions loaded on graphene and the cellulose chains could effectively prevent the π–π stacking of nanosheets leading to stable cellulose/graphene aqueous spinning dope. The densified hydrogen bonds between graphene and cellulose with a 5 wt% graphene granted the composite fiber ductile fracture behavior (fracture strain: 11.1 ± 0.6%, toughness: 17.9 ± 0.4 MJ/m3) and a conductivity of 0.51 × 10−2 S cm-1

The process of mutual diffusion, infiltration and exchange between the spinning solution and coagulation bath also matter to the properties of the obtained fibers. The tensile behavior of polystyrene sulfonic sodium (PSS) doped PEDOT (PEDOT:PSS)/polyvinyl alcohol (PVA) fiber was found to be affected by both the formation of stably entangled molecular chains and the phase transition process [42]. In this case, PVA could disrupt the electrostatic complexation between PEDOT and PSS molecular chains, and therefore the entangled PVA and PEDOT molecular chains can increase the breaking elongation. On the other hand, ethylene glycol could smooth the structure of the PEDOT molecular chains, rendering strengthened PEDOT fibers. Peak breaking strength and elongation (180 ± 6.1 MPa and 32 ± 1.7%, respectively) were reached at 20 wt% PVA and the addition of 10 wt% ethylene glycol in the PEDOT:PSS/PVA solution further increased the strength to 210 ± 5 MPa. Moreover, enhanced elongation and conductivity of wet spun fibers can be also effectuated by alteration in coagulation bath. With the assistance of the electrostatic complexation between PSS and metal ions, rapid gelation of PEDOT:PSS was enabled in an environment-friendly and low-cost coagulation bath of water-ethanol [43]. Pure PEDOT:PSS fiber prepared with 0.1 M Li+ in the water-ethanol bath achieved a maximal elongation (55%) and a highest conductivity (∼10 S cm−1) compared with addition of other metal ions with different valences.

Structure designs of wet spun fibers can be implemented by different means, such as in situ polymerization of ICPs in the coagulation bath, coaxial feeding of spinning solutions, and adjusting drawing speed of the spinning flow. Corn-like PANi/regenerated cellulose fiber was prepared by in situ polymerization of aniline in the oxidant-contained coagulation bath (Fig. 1C) [37]. Stretchable coaxial fiber with buckled PEDOT:PSS cores were prepared through coaxial wet spinning of thermoplastic elastomer (TPE) solution and PEDOT:PSS/polyethylene-block-poly (ethylene glycol) (PBP) solution while stretching the solidified TPE fiber before drying (Fig. 1D) [38].

Despite the relatively simple and industrially scalable process, it is difficult to realize precise regulation over the fluid and control over the fiber-forming process especially when it comes to multi-phase fluid. Besides, the decision and application of the spinning aid and the coagulation bath can cause worrisome biotoxicity, environmental pollution and waste. Although some concepts of green wet spinning have emerged, circumspect consideration should be put in the whole situation of such wet chemistry.

2.1.2. Microfluidic spinning

By precisely integrating multiphase concentric/laminar flows and regulating the flowing state of each phase in separate microchannels, well-defined microscale fibers can be fabricated by microfluidic devices [44]. The most basic form of microfluidic spinning consists of two fluid phases forming a coaxial configuration with a core fluid hydrodynamically focused by the sheath fluid in the channel (Fig. 1E). When the core flow is solidified in situ by ultraviolet (UV)-induced polymerization, phase inversion, ionic or chemical cross-linking, thermal curing, or solvent evaporation [45], fibers can be extruded through an outlet channel without clogging due to the lubrication action of the sheath flow.

Owing to the controllable adjustment of spinning parameters during microfluidic fabrication and easy modification of microfluidic devices, composite fibers with desired structure designs can be prepared. Wu et al. [46] prepared an oriented GO/polyacrylonitrile (PAN) composite fiber membrane by microfluidic spinning with a moving receiver using an orthogonally optimized parameter combination of the PAN concentration (15%), flow rate (0.5 mL/h), and rotation speed of the receiving frame (200 rpm). The degree of orientation of the composite membrane was further improved to 89.3% after stabilization and carbonization. Hollow fibers composed of alginate, polyacrylamide (PA), and PPy were prepared through Ca2+ ion crosslinking at the intersection of the microfluidic channels followed by UV crosslinking of PA [47]. The lumen size of the composite fiber could be regulated from ∼0.8 mm to ∼1.2 mm by varying external and internal nozzle diameter, while the wall thickness could be increased from ∼0.1 mm to ∼0.3 mm with varied external and internal flow rate. Such tunable lumen morphology and a biologically compatible conductivity of ∼3 × 10−3 S cm-1 provided both structural and characteristic basis for drug loading and bioelectrical signal transduction. Moreover, functionalized helical microfiber can also be fabricated by utilizing the unbalanced fluidic friction between the microfiber and its surrounding fluid, adjusting the flow rates of fluids or varying the structures of microfluidic devices [39,[48], [49], [50]]. Magnetic microscale coils were formed within the optimized concentration range of graphene oxide/Fe3O4 (GOF) solution (16–22 wt%) and sodium alginate (SA) solution (1.5–3.5 wt%), meanwhile the pitch (254.2–1107.7 μm), length, and linear diameter can be tailored by adjusting the flow velocity of GOF solution, the oil phase and the SA solution (Fig. 1F) [37].

Additionally, parameter adjusting and device modifying are in favor of optimizing fiber properties. LM-encapsulated PU microfibers with adjustable conductivity and good deformation ability (480%) were constructed by coaxially injecting PU (1–5 mL/h) and LM (0.1–0.5 mL/h) in the opposite direction with a speed difference in feeding flow (Fig. 1G) [40]. Lam et al. [51] designed a coaxial microfluidic device with an external Teflon tube for the water coagulant solution of calcium chloride and acetic acid, and an internal glass tube for the aqueous mixture of natural rubber, CNTs, and PEDOT:PSS. Upon neutralization of the negative charge of the rubber by Ca2+, continuous fibers with an elongation rate over 1500% were prepared. Due to the addition of PEDOT, the connection of CNTs can be strengthened, resulting in the improved electrical conductivity (33.4 kΩ), linearity (up to 1000%) and durability (200% over 2000 repetitive elongation cycles) of the fibers.

Microfluidic spinning shows obvious advantages of diverse structure designs, easy combination with different crosslinking forms, compatibility with most water-soluble natural polymers and thus reduced difficulty of post-processing and toxicity, which is of great significance to materials for regenerative medicine and tissue engineering. However, since the regulation over the fluid is completed in the confined microscale channels with enhanced surface effect, a noteworthy influence of the surface characteristics of the microchannels on the fluid behavior should be taken into concern. Besides, the difficulty in designing, manufacturing, using and maintaining the microfluidic devices and the relatively low production efficiency of microfluidic technology cannot be neglected.

2.1.3. Electrospinning

Solution electrospinning is a conventional manufacturing technology for micro/nanoscale fibers, the size, morphology and structure of which are comprehensively affected by multiple factors including solution parameters, device parameters and environmental parameters. Since nanomaterials tend to clog the syringe needle or reduce the solution homogeneity and destabilize the Taylor cone [52,53], electrospinning of conductive biomaterials is usually accomplished through mixed dispersion of spinnable polymers and conductive materials (Fig. 2A). By involving a sacrificial phase in the spinning solution, single-component electrospun conductive fibers could be obtained, but it always comes with the disadvantages of rigidity, brittleness and higher biological toxicity [54,55].

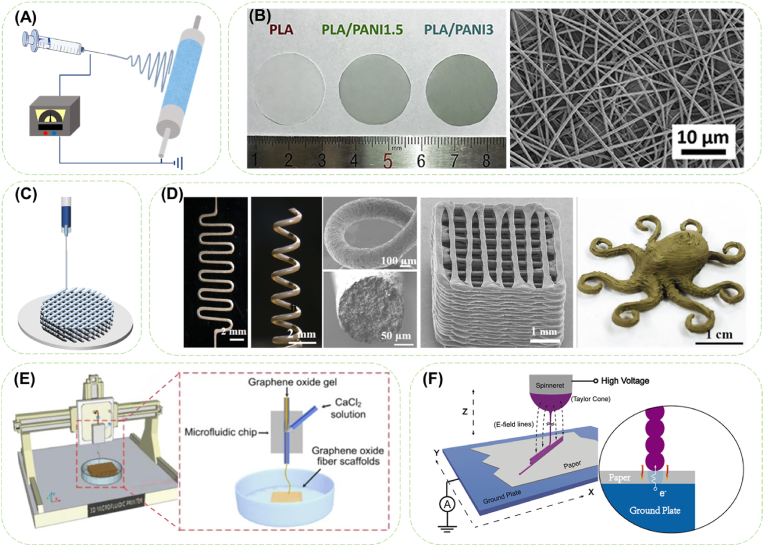

Fig. 2.

Diagrams of fabrication of conductive fibers assemblies. (A) Schematic illustration of electrospinning process. (B) Optical images of PLA/PANI nanofibrous sheets with PANI concentrations of 0 wt%, 1.5 wt%, and 3 wt%, and SEM image of PLA/PANI nanofibrous sheets with 3 wt% PANI. Reproduced with permission from Ref. [58] Copyright 2017, Acta Materialia Inc. (C) Schematic illustration of 3D printing process. (D) 3D-printed Ag@CNF/PLA conductive structures including planar zig-zag, freeform 3D spiral, simple layer-by-layer 3D cubic scaffold and complicated self-supported 3D octopus. Reproduced with permission from Ref. [59]. Copyright 2019, American Chemical Society. (E) Schematic setup of the near-field electrospinning process and a close-up schematic of stacked fibers. Reproduced with permission from Ref. [60]. Copyright 2015, American Chemical Society. (F) Schematic illustration of the M3DP for fabricating microfibrous scaffolds. Reproduced with permission from Ref. [61]. Copyright 2020, American Chemical Society.

Optimized composition formula presents a convenient solution to improve the spinnability and reduce the brittleness of the composite fibers. Liang et al. [56] successfully prepared PPy-loaded electrospun silk fibroin (SF) fibers through electrostatic interaction between the negative charged amorphous region of SF and positively charged doped PPy. The addition of PPy reduced the average fiber diameter to 0.375 ± 0.077 μm, since conductive jet flows are subjected to stronger drafting force in high-voltage electric field than nonconducting ones. Meanwhile, the existence of 7% SF in the solution granted the fiber mats more uniform distribution of PPy and a reduced Young's modulus (1.437 ± 0.044 MPa). Nazari et al. [57] synthesized rGO/Ag nanocomposites and mixed them with PU solution for electrospinning. The existence of AgNPs in electrospun fibers could lead to a lower level of cytotoxicity while rGO could inhibit the agglomeration of AgNPs.

The shapes, diameters and aggregation forms of the conductive fibers can be easily adjusted through altering electrospinning parameters [62,63]. Aligned fibers with anisotropic mechanical properties can be collected from a disc collector rotating at a speed of 1000 rpm [64]. Fiber sheets with electrical conductivity and nanofibrous structure for cardiac tissue engineering (CTE) were obtained by electrospinning mixture of poly (l-lactide) (PLLA) and PANi (Fig. 2B) [58]. In order to simulate the nanofiber structure of myocardial extracellular matrix (ECM), the diameters of these nanofiber sheets were controlled in the same range about 500 nm by adjusting the electrospinning voltage of 12–16 kV.

Despite the advantages of wide adaptability of materials, tunable fiber fineness, and simple and adjustable device construction, electrospinning still puts up with challenges of susceptibility to environment change and toxic solvent involvement. On the other hand, the distinguished fiber-forming process of electrospinning also decides that fibers are deposited into compact 2D membranes/mats instead of treatable single fibers. Accurately constructing fiber assemblies with designated complex structures remains as a challenge and warrants further research for electrospinning.

2.1.4. 3D printing

3D printing is an attractive strategy for customizing 3D constructs by extruding melt or solution from the nozzle according to the program-established action trajectory [65,66] (Fig. 2C). Because of the programmability of the additive manufacturing method, it has also been widely used to customize fine-shaped fibers [67,68]. When it comes to fabricating conductive constructs with 3D printed fibers for biomedical applications, the conductive ink has to meet the requirements of certain fluidity (i.e. shear thinning rheological properties) [65], and rapid curing performance [69] to achieve printability, as well as relatively small shear stress for preventing cell damage when extruding cell-laden conductive fibers [70].

Ink components and shear force are both significant to the rheological behavior of conductive ink. In order to prepare elastic conductive fibers, suitable rheological behavior of conductive ink for direct ink writing was obtained by mixing PTFE powder with polydimethylsiloxane (PDMS) prepolymer to overcome the low viscosity of PDMS [71]. Based on this, coaxial stretchable graphene fibers were successfully prepared with an improved tensile modulus of 120 kPa, a tensile strength of 220 kPa and a length at break of 350%. By introducing amphiphilic nanofibrillated cellulose (NFC), agglomeration of CNTs caused by strong van der Waals force can be overcome in aqueous solution (Fig. 2D) [59]. Obvious shear-thinning behavior of the CNT/NFC solution can therefore be attained, and under the shear force during extrusion and the tension applied during drying, highly arranged conductive microfibers were prepared [72].

To further widen the applicability in heterogenous bionic structure design, 3D printing has been combined with other spinning methods. Near-field electrospinning (NFES, Fig. 2E), as a combination of 3D printing and solution electrospinning, was established to obtain direct, continuous, and controllable fibers with a minimal line width of 50–500 nm by shortening the distance between needle and collector to 500 μm to 3 mm [[73], [74], [75]]. Melt electrowriting (MEW) is another thriving direct writing technology based on melt-extrusion 3D printing and melt electrospinning, with a fiber diameter ranging from ∼2 μm to ∼50 μm [76,77]. Since MEW requires fusible and thermally stable materials like polycaprolactone (PCL) and high amount of additives leads to poor spinnability or morphology, it remains challengeable for fabricating composite conductive fibers. In Chung's research [78], although composite graphene/PCL fiber was fabricated through MEW, the compromises in printing parameters (printing temperature of 100 °C and minimum printing speed of 30 mm/s) made due to the addition of graphene resulted into extended cooling time and indistinct layer formation. By combining microfluidic spinning with programmable 3D printing platform, microfluidic 3D printing (M3DP) (Fig. 2F) was developed to fabricate a 3D GO microfibrous scaffold [61]. After hydrothermal reduction, rGO scaffolds with a conductivity of 2 × 10−3 S cm-1 and adjustable fiber structure can be used for electroactive tissue regeneration. Wei et al. [79] designed a bionic microfluidic printer head to alleviate the problem of gel curing at the nozzle, so that hydrogels can be continuously printed into fibers, two-dimensional networks, and even three-dimensional structures.

3D printing can realize precise control of fiber shapes and especially stack patterns of conductive fibers [80], but it is only available for the polymers with low melting-point or photocuring feature. This restriction on raw materials makes it difficult to meet large-scale industrial production. In addition, it is difficult to accurately control the parameters such as material hydrodynamics and curing time.

The as-mentioned fiber-forming methods are all widely applied in fabricating composite fibers in recent biomedical researches with respective characteristics. On the one hand, wet-spun fibers and electrospun membranes are equipped with tunable structures, predictable mechanical and electrical properties, simple and easily maintainable manufacturing devices, and high preparation efficiency, which are applicable for conforming with the complex deformation of human bodies as components of scaffolds and bioelectronics. On the other hand, microfluidic spinning and 3D printing possess outstanding advantages of precise control over multi-phase fluid and fiber deposition, which is practically useful for constructing multiscale and heterogenous biomimicking structures as integrated multifunctional materials for electroactive tissues.

2.2. Surface modification on fibers

Different from the above-mentioned blending preparation methods, surface modification is a relatively simple and versatile approach for fabricating conductive fibers (Fig. 3A), which can be easily accomplished by modifying process and equipment for dyeing and finishing [33].

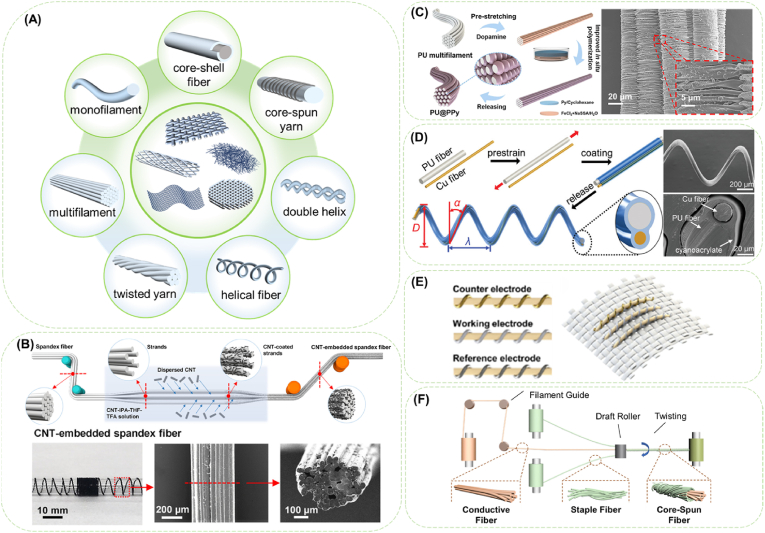

Fig. 3.

Diagrams of surface modification for conductive fibers. (A) Different forms of fibers and fiber assemblies. (B) Schematic diagram of the fabrication process of CNT-embedded spandex fiber and photograph and SEM images of the obtained fibers. Reproduced with permission from Ref. [81]. Copyright 2021, American Chemical Society. (C) Schematic diagram of preparing worm-shaped graphene-coated filaments and SEM images of the fiber. Reproduced with permission from Ref. [82]. Copyright 2022, The Authors. Creative Commons Attribution 4.0 International License. (D) Schematic illustration of fabricating helical PU/Cu fibers by fixing a pre-stretched PU fiber and a paralleled Cu fiber and SEM images of the obtained fiber. Reproduced with permission from Ref. [83]. Copyright 2020, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (E) Schematic illustration of the fiber-shaped three-electrode glucose sensor integrated into an elastic textile. Reproduced with permission from Ref. [84]. Copyright 2019, American Chemical Society. (F) Fabrication method of core-spun yarn. Reproduced with permission from Ref. [85]. Copyright 2021, American Chemical Society.

Dip coating, spray coating and in situ chemical deposition [86,87] are widely applied to simply grant fibers conductivity [88]. Interconnected conductive network of CNTs can form on the fiber surface after immersion in well dispersed CNTs solution (Fig. 3B) [89]. In situ polymerization of ICPs can be directly carried out on the surface of fiber substrates to achieve a tight and effective bonding between the conductive layer and the substrate, which is mostly suitable for preparation of conductive fibers with ICPs [62,[90], [91], [92], [93]]. Fibers soaked in pyrrole and p-toluene sulfonate solution can be deposited with a 150 nm-thick PPy layer after adding ferric chloride solution for oxidation polymerization [94]. Besides the dispersion status and deposition form of the conductive components, functional groups were introduced on utilized to promote the formation of a continuous conductive layer. For chemically inert raw materials, pre-treatment of surface activation such as amino-silanization treatment [95] or polydopamine (PDA) modification [88] is required for fixed deposition of conductive materials.

Even though effective bonding between the conductive components and the fiber surface can be realized by as-stated modification methods, the huge difference in mechanical properties (especially tensile elongation) will inevitably deactivate the conductive element under physiological deformation. Therefore, serpentine structures, mesh structures, pre-strained wavy structures, and buckling structures have been involved in structure designs of conductive fibers [96], with the same principle of reserving extra length/volume for the intrinsically rigid conductive components when the elastic matrix is undeformed [38,83,97]. Deposition of conductive components on pre-stretched substrates or constructing helix-structured conductive fibers turn out to be the easiest and most useful approach to develop elastic conductive fibers. By wrapping oriented CNT sheets on the stretched styrene (ethylene-butylene)-styrene (SEBS) rubber fiber cores, Liu et al. [98] created highly stretchable (up to 1320%) core-sheath conductive fibers. Muscle fiber bundles-inspired parallel conductive monofilaments were designed by in situ polymerization of PPy on pre-stretched PU multifilament, which attained a flexible conductive layer by doping PPy with plasticizer (Fig. 3C) [82]. Differentiated process of strain relaxation of the elastic PU fiber and plastic Cu fiber was utilized to fabricate helical PU/Cu fibers by fixing the pre-stretched PU fiber and a paralleled Cu fiber with cyanoacrylate coating (Fig. 3D) [83]. Similarly, pre-stretching can be implemented on fiber mats by depositing elastic fibers on a sacrificial inelastic matrix with a subsequential removal process of the matrix. Following the strategy, a stretchable Au-deposited fiber mat was developed by electrospinning fluorine rubber on a PSS layer followed by gold sputtering, which can maintain conductive under 170% strain and gas-permeable after an isotropic shrinkage in area of 35–40% on removal of the PSS layer [99].

It is a simple and efficient method to obtain conductive fiber by surface coating, and the surface conductivity of the fiber can be realized by changing the coating parameters. Faced with the possible wet condition and repetitive external force in diverse practical application scenarios, the bonding firmness between the fiber and conductive coating and the conductive stability should be paid more attention. The combined strategy of surface modification and structure design surfaces as a potential solution for preserving conductivity in a larger strain range.

2.3. Assembly technologies of conductive fibers

Taken the axial directions and axial length of fiber assemblies into concern, filaments/fibers/yarns with length of meters to kilometers and nano/microscale diameter can be classified as 1D materials [33], while 2D fiber assemblies mainly refer to electrospun fibrous networks with negligible thickness in this review and 3D fiber assemblies refer to woven fabrics, knitted fabrics, braided wires, tubular braid, and multilayered 3D printed constructs which contains fiber interlacing or loop intermeshing. Benefitting from the distinctive deformability and combination diversity of 1D fibers, customized conductive fiber assemblies can be fabricated by weaving, knitting, braiding or simply sewing (Fig. 3E) [84] in accordance with the application scenarios and functional requirements.

Yarns possess better loading capacity of conductive components, and the directional arrangement of the fibers in the yarn allows for enhanced mechanical strength and ease of handling. Core-spun yarns stand for a special form of fiber assemblies with the structure of sheath fibers entangled on elastic core filament. Through a proper design of the core filaments and sheath fibers, the properties of obtained core-spun yarns, including high strength, multifunction and wearing comfort can be optimized, meanwhile the high compatibility and strong liquid adsorption capacity can be maintained. Yang et al. [85] wrapped cotton fibers on Ag yarn to form a core-spun yarn (Fig. 3F) and dip-coated with PDMS afterwards to obtain a conductive composite fiber. The composite fiber was able to be further woven into a flexible 3D sensing fabric.

According to the physiological and biophysical principles, conductive fiber-based biomaterials with 2D topography and 3D geometry have been developed to modulate cell behaviors and tissue/organ functions [100]. For bioelectronics, sufficient contact area and deformation conformability between surfaces of the electronic device and the applied tissue/organ are vital for its function implementation. The stretchability of bioelectronics could be realized by adopting either intrinsically stretchable electrode materials or extrinsically stretchable structures, in order to alleviate the strain-related changes in conductivity and active surface of the electrodes. Gao et al. [42] choose nylon coated spandex and PEDOT:PSS/PVA fibers as common and inductive zone yarns respectively to fabricate weft knitted fabrics. The PEDOT:PSS/PVA fibers survived repeated exposure to friction and tensile/bending strain in the knitting process without damage. MXene-coated PU fibers can be knitted into a single elbow sleeve by commercial-scale knitting machines for tracking various movements of the wearer's elbow in real time [101]. Both woven fabrics with vertical warp and weft yarns and knitted fabrics with crisscross loops can provide unique topographic clues for native anisotropic tissues [102,103]. Distributing conductive fibers in hydrogels or coating conductive fabrics with hydrogels can be seemed as feasible assembly methods for attenuating the interfacial problem between fiber assemblies and the targeted tissues, except that the isotropic hydrogel encapsulation will wipe off the structural feature of fiber assemblies especially anisotropy.

Textile technologies possess the advantages over other biofabrication technologies in controlling geometric structures, mechanical properties, pore structures and distribution of the loading molecules [104]. Besides, the processing parameters in this mature and controllable technology can be easily adjusted to achieve required properties.

3. Electrical signal transmitting for tissue repair

With the consensus on material-guided cell behaviors [105,106], great efforts have been put in geometrical cues (topographical structure) [107] and physical cues (mechanical, electrical, thermal and magnetic stimuli) transmitted by biomaterials [108]. Fiber manufacturing techniques offer unique advantages to construct biomimicking structures [34]. Moreover, with the involvement of conductivity into fibers, delivery of internal/external electrical signals can be facilitated for improving cell adhesion, differentiation, and proliferation for tissue regeneration [100,105]. Hence, conductive fibers have been variously applied in regenerative medicine and tissue engineering for cardiac, nerves, bones and skins [109].

3.1. Cardiac tissue engineering

Myocardial ECM exhibits as an anisotropic, interwoven fibrous network that enables mechanical and electrical coupling between cardiomyocytes resulting in synchronous cardiac contraction [110,111]. After myocardial infarction (MI), the electroactive myocardium will be replaced by nonfunctional scar tissue, which inhibits coupled cellular communication [104]. Fortunately, the disconnected current path can be restored by a conductive patch attached to the myocardium, and the thinned ventricular wall, meanwhile, can be mechanically supported. Nevertheless, due to the lack of self-repair and renewal ability of the heart, CTE is expected to repair the heart by creating functional myocardium in vitro [112]. Cardiomyocytes rely heavily upon electrical signaling transmitted throughout the natural heart for tissue homeostasis and regular beating rhythms [113]. Hence, conductive fibers, in the form of cardiac patches and CTE scaffolds, have shown tremendous potentials in featuring biomimetic structural complexities [104].

3.1.1. Conductive cardiac patches

Upon being sutured or adhered on the epicardium, conductive cardiac patches are enabled to play the electrically restoring and mechanically supporting part for improving heart function after MI (Fig. 4A) [[114], [115], [116]].

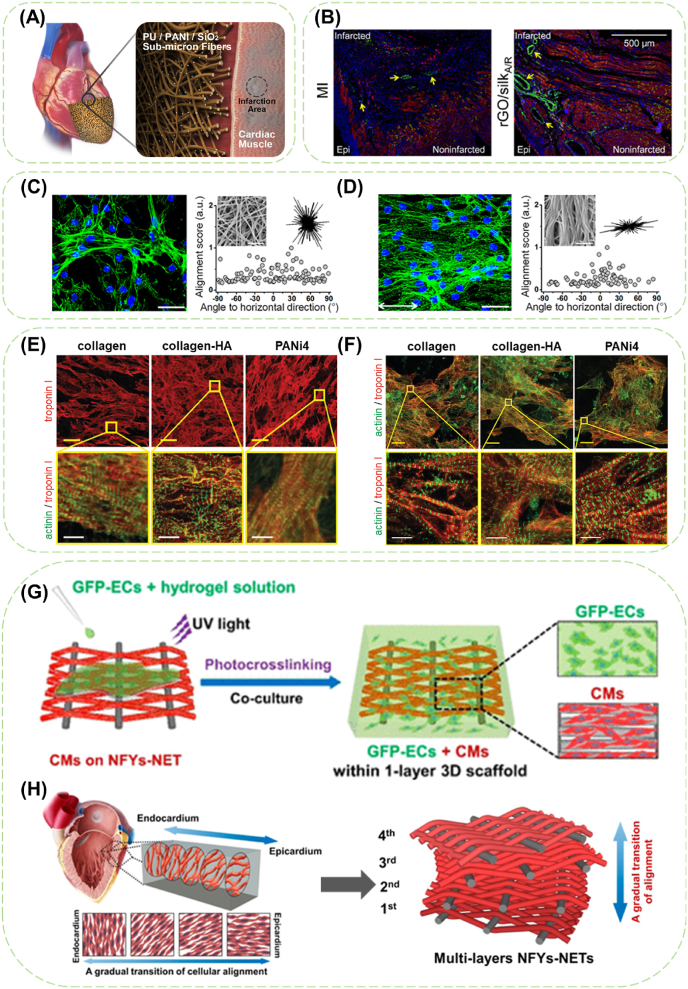

Fig. 4.

The application of conductive fibers in cardiac patches and CTE scaffolds. (A) Representative treatment of a conductive sub-micron fiber cardiac patch to promote the electrical signal transduction. Reproduced with permission from Ref. [63] Copyright 2021, American Chemical Society. (B) Immunofluorescence images stained with cTnT and Cx-43 for the infarcted-noninfarcted transition areas. The yellow arrows indicate the microvascular structures strained by Cx-43. Reproduced with permission from Ref. [64] Copyright 2021, Acta Materialia Inc. F-actin staining images (scale bar: 20 μm) and nucleus alignment analysis of cardiomyocytes on (C) random and (D) aligned CNT/silk fibrous scaffolds at day 7. Inset in the corner is the corresponding scanning electron microscope (SEM) image of the fibrous membrane (scale bar: 5 μm). Reproduced with permission from Ref. [117] Copyright 2020, American Chemical Society. Confocal images of (E) NRCMs and (F)human induced pluripotent stem cells derived cardiomyocytes (hiPSC-CMs) cultured on electrospun fiber mats at day 5 stained for the cardiomyocyte-specific markers troponin I and/or sarcomeric-α-actinin. (Scale bars: (E): yellow: 25 μm, white: 4 μm; (F): yellow: 10 μm, white: 4 μm) Reproduced with permission from Ref. [118] Copyright 2019, The Authors. Creative Commons Attribution 4.0 International License. (G) Schematics showing the coculture procedure that cardiomyocytes were cultured on the NFYs-NET layer while green fluorescent protein-positive endothelial cells (GFP-ECs) were encapsulated within hydrogel shell. (H) Myocardium showing a gradual transition of aligned cell layers from endocardium to epicardium and schematics of multiple layers of fabrics assembled with the gradual transition of orientation. Reproduced with permission from Ref. [103] Copyright 2017, American Chemical Society.

An electrospun sub-micron fiber patch composed of shape memorable PU/PANi/silicon oxide (PU/PANi/SiO2) was developed, which integrated 3D porous structure, specific thickness, elastic deformation, conductive stability, and self-adhesion property, and effectively reduced the infarction area after implantation [63]. The infarcted myocardium treated with aligned rGO/silk patches showed significant improvement on left ventricular (LV) pumping function including enhanced ejection fraction (EF), LV fractional shortening (LVFS), and ventricular fibrillation threshold compared with MI group [64]. Positive effect of the rGO/silk patch on alleviating the adverse myocardial remodeling was also displayed by preserving the LV wall thickness, reducing scar size and improving cardiomyocyte survival (Fig. 4B).

3.1.2. CTE scaffolds

CTE established upon 3D fibrous conductive scaffolds has become a potential strategy for regenerating heart tissues over the last decade [109,119]. The fibrous morphology of electrospun fiber mats mimics the structure of ECM, allows gas and nutrient exchange and provides directional guidance for cell alignment [120]. Compared to random CNT/silk scaffolds, aligned CNT/silk scaffolds were capable of promoting spreading and organization of cardiomyocytes, implicated by the improved formation of sarcomeres and gap junctions (Fig. 4C and D) [117]. Except for improved cell structure development (Fig. 4E and F), neonatal rat cardiomyocytes (NRCMs) cultured on PANi-contained fiber scaffold also exhibited favorable beating behaviors with longer contraction time, higher contractile amplitude, and lower beating rates [118]. PPy-encapsulated SF electrospun fiber mat was reported to enhance cardiac-specific protein expression, promote cell-cell couplings, and induce strong contractions [56]. The external electrical stimulus and the conductive fiber mat synergistically improved the cell alignment and contraction synchrony as well as increasing the beating frequency to 60 ± 8 bpm. These electrospun scaffolds coupling conductivity and fibrous structures may provide optimal stimuli to foster cell morphology and functions for myocardial regeneration or establishment of in vitro cardiomyocyte culture platform. A 3D printed-fibrous scaffold with controllable hexagonal microstructure was also prepared for myocardial regeneration [121]. And the in vitro studies confirmed the ability of the scaffold in promoting cell arrangement, sarcomere formation, and the expression of markers related with cardiac maturation.

Yarn and weaving technology have also been applied to the preparation of cardiac scaffolds. Wu et al. [103] fabricated a 3D hybrid scaffold based on nanofiber yarns network (NFYs-NET) layers within a photocurable methacrylated gelatin (GelMA) hydrogel shell to accommodate cardiomyocytes and endothelial cells (ECs). The NFYs-NET was woven with conductive nanofiber yarns as wefts and surgical sutures as warps (Fig. 4G). The 3D hybrid scaffolds consisting of NFYs-NET layers were expected to induce aligned and elongated cardiomyocytes and to mimic the gradual transition of aligned cell layers from endocardium to epicardium (Fig. 4H), while the GelMA hydrogel shell were meant to provide a suitable 3D environment for mechanical protection and endothelialization. All the results showed the potential of conductive fabrics in myocardium regeneration.

3.2. Neural tissue engineering

Natural nerve tissue is composed of nerve bundles with multiple aligned assemblies, and transmits information mainly through action potential generated by synapses [122,123]. Hence, the orientation and electroconductivity of the matrix are of great benefits for guiding neuron alignment and transmission of electrical signals [124]. In results, conductive scaffolds and nerve conduits has shown remarkable effects in promoting nerve regeneration through cell proliferation and neural differentiation.

3.2.1. Conductive scaffolds

Geometry designs of nerve scaffolds have attracted serious attention due to the reports on electrical signals-assisted neural growth [125]. Composite fibrous scaffolds based on conductive materials and biopolymers have been developed for promoting neurogenic differentiation of stem cells and cell behaviors of neurons [8,75,122,124].

Electrospun MWCNTs/PCL/gelatin nanofibers [8] were prepared to explore the synergistic effect of conductivity and fiber alignment on the differentiation of bone marrow mesenchymal stem cells (BMSCs) into Schwann cells (SCs). The BMSCs extended along the aligned fibers, while they distributed randomly on unoriented scaffolds as on the tissue culture plate. Moreover, the disparity in expression levels of S100 and GFAP indicated that the aligned nanofibers could promote the differentiation of BMSCs into SCs, and that the conductivity can further enhance the differentiation efficiency. Wu et al. [122] fabricated cell-laden PPy/collagen hydrogel microfibers with highly oriented microstructures to serve as nerve scaffolds. Cell spreading and elongating along the microfibers, formation of cell-cell contact networks, activation of voltage-gated calcium ion channels (crucial marker in early neurogenesis) were observed as well as enhanced expression of neurogenesis marker tubulin-β3 and neurofilament protein. Additionally, the external electrical stimulation further promoted the neuronal functional expression. It shows the potential of conductive fiber scaffolds in constructing biomimetic microenvironment for neurogenesis. Wang's group [75] devised 3D conductive scaffolds with various microfiber patterns by NFES of poly (l-lactic acid-co-caprolactone) (PLCL), followed by GO coating of PLCL microfibers and in situ reduction of GO. The obtained scaffold with 25–50 layers of rGO exhibited superior conductivity (∼0.95 S cm−1) and capability of inducing neuronal-like network formation along the conductive microfibers under electrical stimulation (Fig. 5A–C). Overall, present studies have demonstrated that aligned conductive fibers play significant roles in cell differentiation and they can be used as a promising scaffold for nerve tissue engineering.

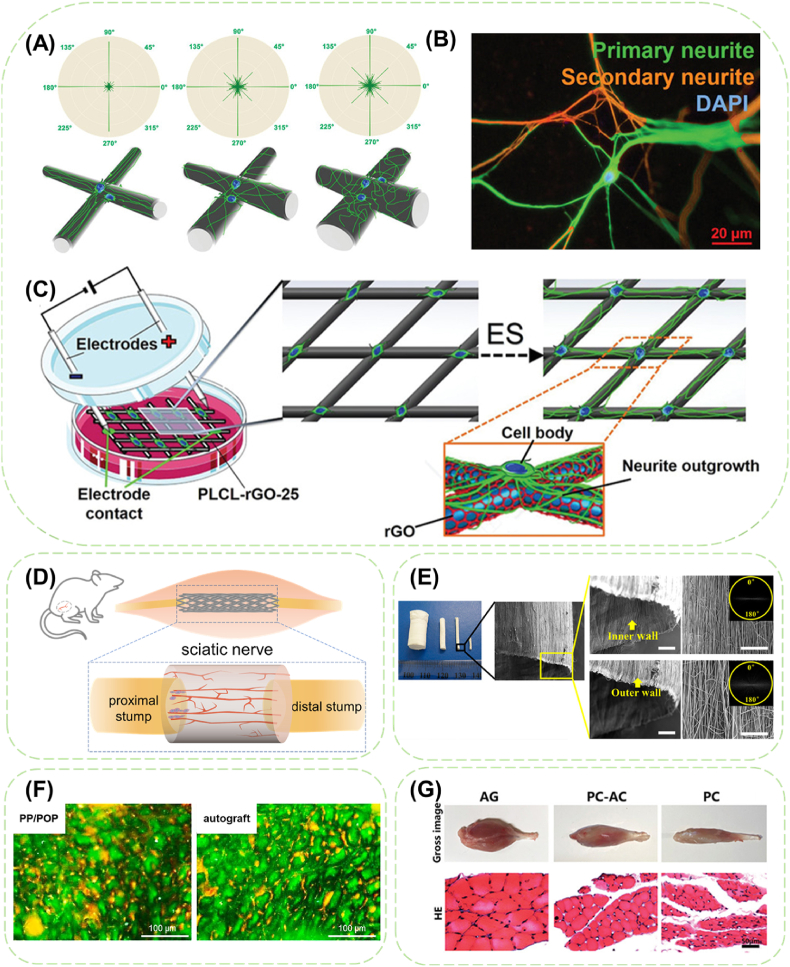

Fig. 5.

The application of conductive fibers in nerve regeneration and repair. (A) Semiquantitative analysis of the orientations of neurites of PC-12 cells on different diameter microfibers based on a python analysis. (B) Representative immunofluorescence image of the neurite outgrowth patterns, comprising primary (green) and secondary (orange) neurites, from a single PC-12 cell. (C) Schematic illustration of the culture setup with electrical stimulation to regulate the neurite outgrowth of PC-12 cells on rGO/PLCL conductive fiber scaffold. Reproduced with permission from Ref. [75] Copyright 2020, Wiley-VCH GmbH. (D) Schematic illustration of fibrous nerve conduit applied in rat sciatic nerve defect model. (E) Digital photo and SEM images of cellulose acetate butyrate nanofibrous conduits. (Scale bars: 100 μm) Reproduced with permission from Ref. [126]. Copyright 2015, American Chemical Society. (F) Immunofluorescence staining of the distal segments of the regenerated nerves repaired PP/POP conduits and autograft at 12 weeks post-operation. Reproduced with permission from Ref. [94]. Copyright 2018, Elsevier B.V. (G) Histomorphology and quantification of the gastrocnemius muscle in rats with sciatic nerve transection following nerve conduit implantation. HE staining showed the morphology of the myofibers of autograft (AG), PCL conduits containing aligned and conductivity nanofibers pre-seeded with BMSCs (PC-AC), and empty PCL conduits pre-seeded with BMSCs (PC) groups. Reproduced with permission from Ref. [8] Copyright 2020, The Authors. Creative Commons Attribution 4.0 International License.

3.2.2. Nerve conduits

Apart from constructing engineered nerve tissue in vitro, nerve conduits stand for another approach especially applicable for treating nerve injuries over short distances (<4 cm) [127]. Proximal and distal nerve stumps are inserted into the two ends of the conduit, and axons start regenerating from the proximal end and gradually growing into the distal ends (Fig. 5D) [128]. Currently, nerve autografts remain as the most popular clinical approach for nerve reconstruction despite the disadvantages of insufficient tissue availability, mismatch in tissue size and structure, and donor site morbidity [129].

Conduits composed of well-arranged nanofibers have showed effectively promotion effect in sciatic nerve regeneration and thus been widely adopted in nerve conduit design (Fig. 5E) [126]. Jing et al. [94] developed a nerve conduit by filling PPy-coated aligned poly (lactic co glycolic acid) (PLGA) fibrous mesh into the lumen of the casted PPy/PLGA conduit (PP/POP) to verify the synergistic effects of combined stimuli of axially aligned fibers and conductive materials in nerve recovery. In comparison with rats treated with the non-conductive conduit or the non-filled conduit, the PP/POP-treated group showed significantly shorter latency period in compound muscle action potential (CMAP), higher peak CMAP value, and higher density of nerve axons, dictating raised nerve conduction velocity and better nerve regeneration.

Even though, such conductive nerve conduits are still inferior to autografts in terms of other recovery evaluations (Fig. 5F), which results in the involvement of biochemicals [130] and electrical stimulus. Scrolled CNTs/PCL composite fiber mat was combined with external pulsed current for neural repair [124]. Results of walking track analysis, electrophysiological analysis and H&E staining revealed that the oriented structure provided a favorable platform for remyelination and axonal regeneration and prevention of gastrocnemius muscle atrophy. Rat BMSCs were seeded on MWCNTs/PCL/gelatin nanofiber membranes and induced in vitro for 2 weeks, and then the membrane was rolled up and inserted into a PCL conduit [8]. The transplanted cells differentiated into mature SCs and participated in the formation of myelin sheath on MWCNTs-contained nanofibers. Furthermore, compared to PCL conduit, MWCNTs-contained conduit significantly improved the number of regenerated axons at middle and distal sites of the conduit, as well as the number of remyelinated axons at middle sites of the conduit, while showed no significant difference with the autograft. Moreover, the wet weight and myofiber area ratio of the gastrocnemius muscle treated with MWCNTs-contained conduit were considerably ameliorated, revealing the inhibitory action of myoatrophy after sciatic nerve injury (Fig. 5G).

3.3. Bone tissue engineering

Fibrous scaffolds have also been used for bone tissue repair due to their resemblance to native ECM and convenient fabrication [131]. In addition, enhanced osteogenic differentiation of stem cells under electrical stimulus aids to the growing applications of conductive scaffolds in bone tissue engineering [132,133].

The effects of scaffold porosity and conductivity on promoting osteogenic phenotype expression of osteoblast-like cells (MC3T3-E1) have been reported [134]. Yet, as scaffolds for bone tissue engineering, the structures, mechanical properties, biocompatibility and osteogenic bioactivity should be further improved. Electrospun GO/SF fibers showed ameliorated hydrophobicity and Young's modulus to support the growth and expansion of rat BMSCs [135]. The cytocompatibility and retention of exuberant cell proliferating effect of AuNPs/CNFs scaffold were confirmed via both indirect and direct activity assay of osteosarcoma cells [136]. Current-induced substrates as cellulose nanocrystal/PCL electrospun fiber scaffold coated with GO [137], PANi-deposited PLLA nanofibrous film [138], 3D-printed CNT-encapsulated scaffolds [139] have been reported to enhance cell viability and osteogenesis. The PANi/PLLA scaffold exhibited good cell adhesion and cytocompatibility of BMSCs, and provided better promotion of cell proliferation, osteogenic differentiation and in situ biomineralization than that of the PLLA scaffolds [138]. The combination with water-soluble single-stranded deoxyribonucleic acid (ssDNA) presented a possible solution to the inherent cytotoxicity of CNT-based materials, and the homogenous distributed ssDNA@CNT nano-complex assisted excellent electrical field distribution surrounding the scaffold (Fig. 6A and B) [139]. Huang et al. [140] combined aligned MWCNTs, nano-hydroxyapatite and PCL by 3D printing to mimic the native fibrillar proteins and apatite in the human skeleton, in which cells spread on the filament surface indicated by extended and elongated actin filaments, and migrated and proliferated throughout the scaffold indicated by the well-distributed nuclei (Fig. 6C). Similarly, electrical microenvironment can be established by immobilization of PPy nanoparticles on the surface of PCL nanofibrous scaffolds, and enhanced calcium-phosphate crystal deposition was observed on the scaffold after electrical stimulation [141]. Moreover, the 3D printed-PCL/MWCNTs scaffolds could significantly promote angiogenesis and new bone formation with the assistant of electrical stimulation (Fig. 6D) [142]. The implanted scaffolds contribute to the recruitment of osteoclasts, and although the addition of MWCNTs seems to inhibit osteoclastogenesis, electrical stimulation appeared to be the dominant factor to promote osteoclast formation and functionality in the bone remodeling prevailing process. The complex and changeable combination of various fibers, metal ions, conductive polymers and ceramics shows great potential in the treatment of bone, cartilage and osteochondral defects.

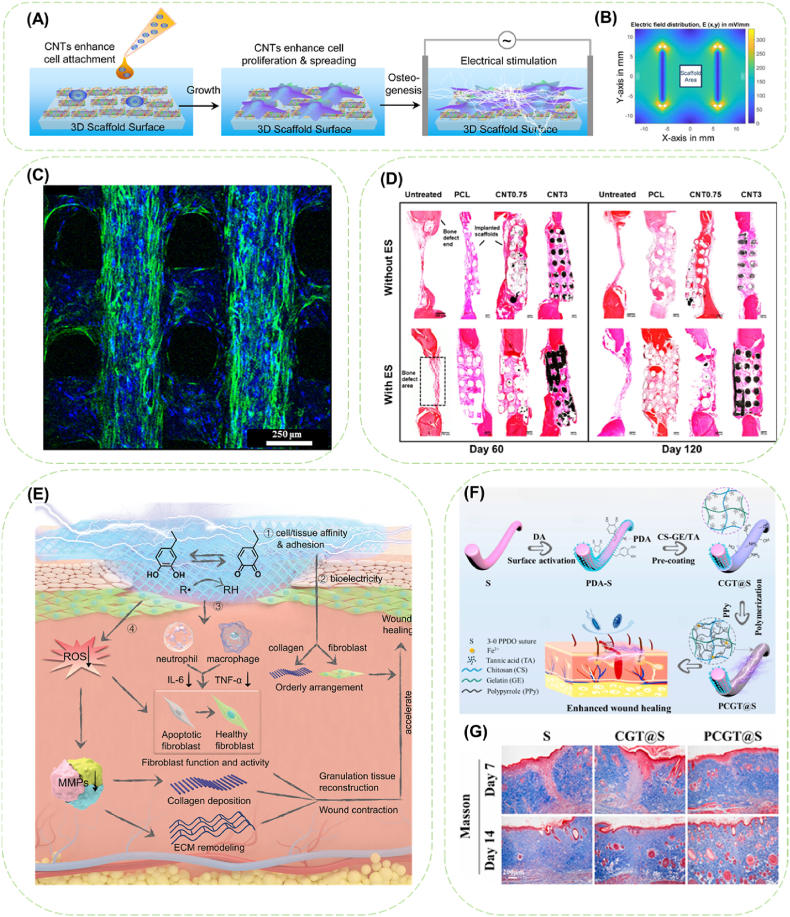

Fig. 6.

Conductive fibers applied in bone tissue engineering and wound healing. (A) Schematic illustration of conductive scaffold guiding osteoblast growth and osteogenic differentiation of BMSCs in electrical microenvironment. (B) Electrical field distribution surrounding the scaffold area. Reproduced with permission from Ref. [139]. Copyright 2020, Acta Materialia Inc. (C) Confocal image showing cell distribution on the PCL/HA/MWCNTs scaffold. Reproduced with permission from Ref. [140].Copyright 2019 Elsevier B.V. (D) The cross sections of bone tissue regeneration at the bone defect for PCL or PCL/MWCNTs scaffolds treated groups after 60 days and 120 days. Reproduced with permission from Ref. [142]. Copyright 2021, The Authors. Creative Commons Attribution 4.0 International License. (E) Schematic illustration of the mechanism of PEDOT-PDA-mSF patch in accelerated diabetic wound healing. 1) PDA promoted the cell adhesion and migration due to its cell/tissue affinity. (2) The conductive patch facilitated bioelectricity transmission. 3) The patch alleviated inflammation and 4) relieved oxidative stress. Reproduced with permission from Ref. [143]. Copyright 2021, Wiley-VCH GmbH. (F) Schematic fabrication process of the electroactive and antibacterial sutures. (G) The collagen deposition of PPDO suture (S), chitosan/gelatin/tannic acid coated-suture (CGT@S), and PCGT@S at day 7 and 14 post-operation. Reproduced with permission from Ref. [93]. Copyright 2021, Elsevier Ltd.

3.4. Wound closure

Skin is another typical electroactive tissue where changes in epithelial potential indicates the destruction of skin structure caused by trauma, surgery, burns or chronic diseases [144]. Thus, conductive dressings and multifunctional sutures have been proposed and proven to accelerate wound healing through resetting the electrical field in the damaged area to restore, imitate or replace the function of the skin [[145], [146], [147], [148]].

3.4.1. Wound dressings

Insufficient bioactivity and biodegradability of traditional wound dressings, as well as secondary injuries during replacement, would postpone the healing process. Hence, functional wound dressings with antibacterial activity, anti-inflammatory ability and proliferation promotion are strongly propelled.

Biocompatible and biodegradable SF is popular in wound dressings despite the demand of chemical modification against brittleness. PDA-assisted extraction process of silk fiber and deposition of PEDOT were combined to fabricate conductive silk-based microfibers (mSFs) [143]. PDA was adopted to protect the mSFs from excessive exposure to the corrosive alkaline solution, enhanced PEDOT assembling on the mSFs, and to promote the energy dissipation along the conductive mSFs, resulting in a good mechanical performance of the silk fiber-based patch embedded with the conductive mSFs. Owing to the combined effects of antioxidant PDA and conductive PEDOT, an accelerated healing process of diabetic wound was achieved (Fig. 6E), evidenced by the increased wound closed area, reduced epidermal gap and regenerated epidermal thickness, tight and uniform collagen deposition, reduced inflammatory response and controlled oxidative stress, all leading to the improved activity of fibroblasts and ECM reconstruction. Quaternized chitosan-graft-polyaniline (QCSP) modified PCL nanofiber membrane (PCL/QCSP) was fabricated to obtain a comprehensive performance of electroactivity, antioxidant and antibacterial ability for treating infection-susceptible chronic skin wounds [149]. The positively charged amino groups and quaternary ammonium groups in QCSP are effective for killing bacteria via electrostatic adherence. Consequently, PCL/QCSP showed better bacteria-killing behavior to E. coli compared to S. aureus, possibly because the down-regulated expression of genes vital to gram-negative bacteria occurs with the existence of PANi [150]. In the mouse full-thickness wounds defect model, after treatment with the PCL/QCSP, an ameliorated wound healing performance was confirmed by the enlarged wound contraction area, suppressed inflammatory cells infiltration, improved fibroblast immigration, regularized regenerated connective tissue and epithelium layer, increased thickness of granulation tissue, raised collagen deposition was observed all indicating ameliorated wound healing performance. Moreover, the immunohistochemical staining of vascular endothelial growth factor also revealed vascular angiogenesis which could further accelerate the wound healing process.

3.4.2. Conductive sutures

Sutures are common surgical instruments to facilitate wound closure by sealing the wound after incision or laceration. Nevertheless, lack of bioactivity and mismatched mechanical property of traditional sutures could result in delayed wound healing process and further cause acute wound failure or enlarged scar tissue.

With the as-mentioned promoting effect in wound healing, functional conductive sutures have become another rising interest in wound healing [[151], [152], [153]]. Our research group constructed an electrically responsive and antibacterial suture (PCGT@S) with PPy in situ deposited on a polydioxanone suture pre-coated with chitosan/gelatin/tannic acid (CS-GE/TA) (Fig. 6F) [93]. The pre-coating of CS-GE/TA guarantees the adaptability between the brittle PPy and the flexible suture, and ensures the stable electrical signal conduction of PCGT@S even in knotted state. In addition, additive antibacterial effects of chitosan, tannic acid and PPy rendered a high bacteriostatic rate of 99%. Immunohistochemical results of PCGT@S treatment in the full-thickness skin defect showed obviously promoted skin wound healing and tissue regeneration (Fig. 6G).

In addition, raised tissue regeneration efficiency and continuously monitoring of suture integrity are of assistance to reduce wound failure and scar tissue formation. Therefore, efforts have also been devoted in electrically driven drug-eluting sutures and electronic sutures sensing physiological variations of wound sites. Lee and coworkers [152] developed a drug release electronic suture system (DRESS) to monitor suture integrity in real time and to achieve on-demand drug release. The DRESS was composed of a AgNPs-embedded PU multifilament core and a drug-containing thermosensitive polymer shell. The conductive core plays a role of a highly sensitive and mechanical durable strain sensor while the thermoresponsive shell promotes the on-demand drug release by Joule heating under a 130 mV-voltage. Stable mechanical property, resistive response and temperature response were maintained when repeated stretch-release cycles were applied to the DRESS-sutured injured porcine skin. Moreover, monitoring the physicochemical states of deep surgical sites post-operatively is necessary to prevent infection, dehiscence and other complications. Wireless sensing (WiSe) sutures were prepared by PEDOT:PSS-functionalized silk sutures encapsulated in biocompatible parylene-C [153]. Functioning as a dipole antenna, the WiSe suture can be assembled with an electronic pledget consisting of a Schottky diode, a capacitive sensor and a tuning inductor, and this completes the construct of a wireless sensing system. The wireless sensing system enables transducing changes due to infection or leakage in the deep surgical site into shifts in the resonant dip of the harmonic signal spectrum. Monitoring of the wound integrity, gastric leakage and tissue fretting in porcine and the healing outcomes in rat model comparable to medical-grade sutures showed the ability of battery-free wireless detection of post-surgical complications and wound closure.

4. Conductive fibers in implantable bioelectronics

Next generation of implantable or wearable bioelectronics for single-point health monitoring requires the introduction of new features including flexibility, large area and facile processing of 1D or 2D materials, controlled biological properties, and mixed electronic and ionic conductivity [154], which just right falls into the advantages of textile technology and fiber materials. Therefore, conductive fiber-based implantable devices including signal capture devices, biosensors and implantable supercapacitors have been widely studied.

4.1. Biopotential acquiring electrodes

Electroencephalogram, electrocardiograph, and electromyography have been utilized in amplifying and recording spontaneous biological potential in human brain, heart and neural muscle in order to detect disease-related abnormal electrical activity and track disease recovery process. But aimed at avoiding severe inflammatory response caused by rigid electrode materials [155] and realizing real-time monitoring of internal electrical signals, conductive fibers as flexible electrode materials have received a deserved welcome in nerve probes and temporary pacing wires [156].

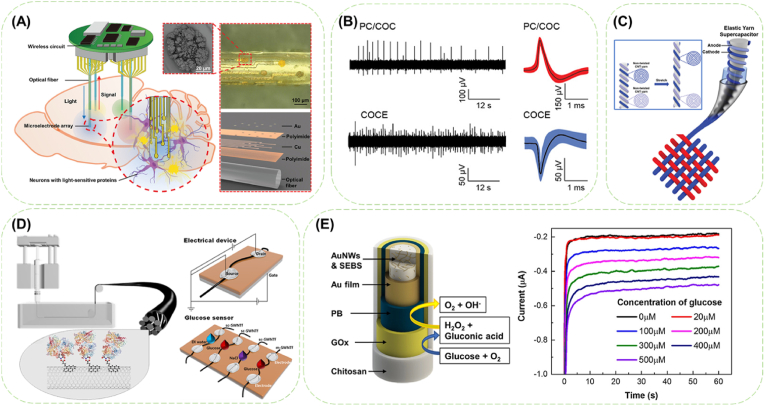

Nerve probe is a powerful tool to simultaneous probing and manipulating the electrophysiological activities of specific neurons (Fig. 7A) [157,158], in order to restore motion and sensory dysfunction by reconstituting the disconnected bundled axons. High signal to noise ratio (SNR), low impedance and stiffness (Young's modulus ∼580 kPa), and long-term biocompatibility are considered as necessary properties for a optimized interface between the electrode and the neural tissue [11,159,160]. By the extrusion and moisture curing of composite blend of silicone, polyethylene glycol end-capped PEDOT (PEDOT-PEG) and CNTs, a soft and elastomeric wire electrode with ∼500 kPa modulus was prepared [161]. The soft wire electrode was capable of acute nerve stimulation and evaluating the evoke force and CMAP upon stimulation in a rat model with mild inflammatory response and reduced axonal loss and deformation after one month implantation, despite that a hypodermic needle shuttle and vacuumizing were required for insertion. To avoid the complicated devices for auxiliary implantation of flexible neural probes, Tang et al. [157] proposed a microfiber-shaped neural probe (MFNP) with an elastic modulus changing from ∼10 GPa to ∼10 kPa before and after implantation. In this case, the CNT fiber core insulated by poly-p-xylene was wrapped in Ca2+-crosslinked alginate, composing a three-layer coaxial core-shell structure. The variable modulus was accomplished by the swelling of alginate contributed by the diffusion of water molecules and the relaxation of polymer chains in aqueous environment. Real time neuronal signal recording and single unit neuronal signal recording were achieved due to the same size of CNT fiber as neuron after the implantation of the dry MFNP into the cerebral cortex of adult mice. Besides an outperforming SNR (>5), stable electrochemical performance and limited inflammatory response ensured stable neural recording for 4 weeks post implantation. Conductive fiber is also composable with optoelectronic probes for realizing simultaneously electrophysiological recording and optical neuromodulation of spinal cord. The resilient concentric electrode composed of AgNWs mesh-deposited elastomer fibers can maintain low impedance at strain up to ∼100% and record spontaneous neural activity and sensory-evoked potentials after implantation (Fig. 7B) [162]. As a composite electrode, the aligned CNF deposited with alternate Au and Ag nano layers had a significantly decreased impedance and could maintain a relatively stable impedance at 1 kHz [163]. The integrated nanostructured electrode arrays provided continuous electrophysiology measurements up to 28 weeks post-implantation without concerning tissue response.

Fig. 7.

Conductive fibers acting as a component in implantable bioelectronics. (A) Schematic of the device implanted into different areas of the rat brain. An image and an exploded view (right) of a flexible optoelectronic fiber that consists of an optical fiber and eight microelectrodes whose surface has been coated with AuNPs (inset). Reproduced with permission from Ref. [158]. Copyright 2021, Wiley-VCH GmbH. (B) Spontaneous activity recorded in acute conditions with AgNW concentric mesh electrodes deposited onto two different core fibers (PC/COC: cyclic olefin copolymer (COC) wrapped-polycarbonate fiber; COCE: thermally drawn-COC elastomer fiber) in mice spinal cord and corresponding action potentials isolated from the recording. Reproduced with permission from Ref. [162]. Copyright 2017, The Authors. Creative Commons Attribution 4.0 International License. (C) Scheme and principle of supercapacitor based on CNT yarn twist. Supercapacitor consists of two non-twisted CNT yarns for anode and cathode. When stretching the supercapacitor, both non-twisted CNT yarns are constant. Reproduced with permission from Ref. [164]. Copyright 2020, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (D) Wet spinning of separated SWCNTs and enzyme immobilization, and characterizations of m- and sc-SWCNT fibers (gate effect and glucose sensing). Reproduced with permission from Ref. [165]. Copyright 2020, The Authors. Creative Commons Attribution 4.0 International License. (E) Schematic illustration of the fiber working electrode and the chronoamperometric responses of the fiber-based glucose sensor to the increasing glucose concentrations from 0 to 500 μM. Reproduced with permission from Ref. [84]. Copyright 2019, American Chemical Society.

Besides signal acquisition, conductive fibers can also be used as temporary pacing wires for correcting abnormal heart rates. Zhou et al. [166] attempted to improve the existing carbon-fiber-based temporary transvenous cardiac pacing metal leads by using carbon-fiber-graphene-woven leads or conductive cloth. The results showed that the carbon fiber bundle was stable and easily deformed under lower stress to reduce the damage to the myocardium, which demonstrates excellent clinical application value. Hang et al. [167] proposed an absorbable temporary epicardial pacing wire (TPW) based on screen-printed EGaIn circuits on PLCL membranes. The as-prepared TPW displayed excellent conductivity, flexibility, cycling stability (>100000 cycles), minor inflammatory response and 13% degradation during two-month subcutaneous implantation, avoiding secondary injuries of removal surgery and migration of the remaining wires.

4.2. Fiber-based supercapacitors

For implantable electronic devices, supercapacitors appear to be more ideal as power supply due to their high energy and power density, high capacity, and long life cycle, as long as the issues of conventional supercapacitors including rigidity, heavy weight, unstable electrolytes and degradation are solved [168]. Fiber-based supercapacitors are characterized by lightweight, flexibility, bendability, braidability and scalability [169].

Conductive fibers are enabled to integrate the electrodes and insulation layer of supercapacitors by partial modification on the fiber. Region-specific reduction of GO fiber enabled integrating rGO layer as electrodes with GO fiber as the separator into one single fiber to function as a flexible fiber supercapacitor without extra bonding agent or assembly process [170]. CNT yarns insulated by PU coating were wound around a pre-stretched rubber mandrel and packed in a silicone rubber tube, which was assembled as an elastic yarn supercapacitor after injecting solid electrolyte into the rubber tube (Fig. 7C) [164]. The elastic yarn supercapacitor exhibited a constant capacitance (capacitance change <3%) within 70% strain and a stable electrochemical storage capacity with dynamic sinusoidal stretching of 70% and 180° bending deformation during 1000 cycles. Although the electrolyte was separated from outer environment, the limited wettability of CNTs to the typical hydrophilic electrolyte always led to a relatively low energy density in CNT-based supercapacitors.

In order to resolve the biotoxicity issue of electrode materials, biomodification on electrodes emerges as possible strategies to evade the influence on cell activity. Kim's group dip-coated MWCNTs with biocompatible PEDOT:PSS/ferritin nanoclusters and fabricated PEDOT:PSS/ferritin/MWCNTs (PFM) fiber supercapacitor by a bi-scrolling process [171]. Capacitance of the PFM supercapacitor was enhanced by the support of PEDOT:PSS for charge transport between ferritin and MWCNTs, and by the increased loading of high capacitance-PEDOT:PSS on MWCNTs through reducing electrostatic repulsion. Meanwhile, the PFM fiber showed 90% remained capacitance eight days after stitched in mouse abdominal muscle and minimized restriction on motion besides good biocompatibility.

The leak issue of electrolytes in fiber supercapacitors brings challenges in electrolyte encapsulation and is partially conquered by utilizing body fluid directly as an electrolyte. The supercapacitor formed by hydrophilic aligned CNTs fibers twisting into a double-helix, was able to work in physiological fluid with an enhanced energy storage capability due to the high pseudocapacitance introduced by the oxygen-containing groups [172]. Without additional packaging, the specific capacitance of the CNT fiber supercapacitor reached 11.4 F/g and 13 F/g in serum and blood, respectively, as well as a stable specific capacitance after 10000 cycles in phosphate buffered saline (PBS). Jang et al. [173] reported an implantable CNT yarn supercapacitor based on the redox system of Nicotinamide adenine dinucleotide (NAD) in living cells. The CNT yarn electrodes exhibited a maximum area capacitance (55.73 mF/cm2) in PBS and serum, and a negligible loss of capacitance after 10000 repeated charge/discharge cycles and bending/knotting deformation. More importantly, the CNT yarn electrodes implanted into the abdominal cavity of a rat skin revealed a stable electrical performance in vivo.

It is highly desirable to design and fabricate biodegradable energy storage devices with high energy/power densities and long cycling life for implanted bioelectronics. The most straightforward and feasible strategy is to utilize a series and parallel connection to construct energy storage devices arrays, which require biodegradable/bioabsorbable conducting wires [174]. Another promising strategy is to construct battery-supercapacitor hybrid system made of a high-capacity battery electrode and a high-rate capacitive electrode [175]. Besides in vivo applications, conductive fibers-based supercapacitors can also be used in intelligent wearable electronic devices [[176], [177], [178], [179]] which is more mature in fabrication due to lower requirements in flexibility, size and biocompatibility and resultingly not covered in this review.

4.3. Biosensors

Early detection and continuous monitoring of disease markers play a key role in disease diagnosis and treatment. Conductive fibers have also emerged as a possible strategy to improve the performance of biosensor devices.

The use of carbon nanomaterials, metallic nanoparticles, nano-structured conductive polymers and MXenes as electroactive medium has improved the performance of bio/chemical sensors. Co3O4 nanoparticles-doped carbon nanofibers prepared by electrospinning and carbonization combined high electrochemical conductivity and good biocompatibility and synergistically enhanced the immobilization of redox protein [180]. MWCNTs-functionalized electrospun nanofibers were reported as electrodes in an electrochemical sensor to detect the neurotransmitter dopamine, whose abnormal level is associated with various diseases such as schizophrenia and Parkinson's disease [181]. The as-prepared electrode displayed a limit of detection (LOD) of 0.15 μmol/L within the linear range of 1–70 μmol/L despite existence of interfering molecules. However, 82% remaining of the initial current value after 100 cycles indicated the insufficient stability. CNT fibers twisted into helical bundles showed bending stiffness close to soft tissue and injectability, enabling spatially resolved and real-time monitoring of H2O2 when implanted in mice tumours, and monitoring Ca2+ and glucose in cat's venous blood in vivo when integrated with a wireless transmission system [182]. PEDOT-embedded electrospun rubber nanofiber pre-attached with ssDNA probe sequence achieved electrochemical sensing of non-Hodgkin lymphoma gene with an ultra-low LOD of 1 aM (1 × 10−18 mol/L) [183]. The 400-fold improvement in LOD compared to a thin-film sensor analogue was realized by the improved hydrophilicity and high surface area brought by electrochemically polymerization of functionalized EDOT and sequentially grafting of poly (acrylic acid) brushes on the fibers surface. Such specific gene sensor helps to develop quick, accurate “liquid biopsies” for early disease detection meanwhile avoiding tissue biopsies.

Enzyme immobilization on conductive fibers is also adopted to achieve accurate sensing of biomolecules. Purified SWCNTs were wet spun into microfibers followed by glucose oxidase fixation as biosensor platform for glucose (Fig. 7D) [165]. Gold-sputtered PCL nanofibrous membranes exhibited higher sensitivity of hydrogen peroxide detection compared to similar Au layer-deposited Si/SiO2 wafers due to their higher surface area [184]. Upon immobilizing of superoxide dismutase by chemically crosslinked cysteine, the PCL/Au fiber presented a sensitivity of 16.1 μA mM−1 cm−2, a LOD of 1.9 μM detecting H2O2 and recoverable determination of superoxide in cell culture media. Different methods of enzyme immobilization affect the electron transfer process between the fibers and the enzyme active site and the encapsulation amount of enzymes, thus limiting the saturation levels upon enzyme immobilization and availability. Hence, new-generation biosensors are requiring enzyme-free biosensing for low-cost and easy fabrication.

In addition to biocompatibility, biodegradability is also considered in biosensors for both immunity and operation concerns. Wet-spun PEDOT:PSS fiber was coated with optically transparent, photo-crosslinkable SF sheath for insulation and protection, and the obtained core-sheath fiber worked as a fully organic and free-standing flexible biosensor of ascorbic acid which can be proteolytically biodegraded in a few weeks [185]. On the other hand, noninvasive wearable electrochemical biosensors built upon conductive fiber-based three-electrode systems have also drawn great attention for sensing electrophysiological and biochemical signals, or delivering drugs, which are very useful for patients in detecting diseases at an early stage. Stretchable Au/SEBS fiber sequentially modified with Prussian blue, glucose enzyme and chitosan to complete the design of fiber working electrode, which demonstrated clear and quantitative response with a sensitivity of 11.7 μA mM−1 cm−2 toward glucose in the range of glucose level in the sweat (from 0 to 500 μM) (Fig. 7E) [84]. Along with reduced requirement in biocompatibility comes with the leveled-up requirement in conformability, air permeability and stretchability between the fiber-based bioelectronics and the wearing site and the cycling performance of wearable fiber-based bioelectronics under frequented deformation.

5. Conductive fibers in wearable bioelectronics

The distinguished characteristics of fiber-based conductive materials over thermoplastic polymers, thermosetting polymers or hydrogels as wearable bioelectronics are usually manifested as their durability and wearing comfortability. The former originates from mechanically compliance and resistance to friction and washing, while the latter bases on flexibility as in recoverable folding, bending, stretching, and compressing deformations and breathability resulting from appropriate heat and moisture management. Typical applications of conductive fibers in wearable bioelectronics are categorized as conductors, electrical resistors for electrothermal therapy, and strain/pressure sensors for monitoring pulses, breaths and blood pressure.

5.1. Stretchable conductors

For wearable electronic devices, stretchability is indispensable for proper functioning during inevitable limb activity (Table 1). Researchers first focused on improving the elasticity of conductive fibers, mostly through compositing with elastomers commonly seen in the form of conductive coating on elastic fibers. However, the poor interaction and the huge differences in mechanical properties between elastomers and conductive coatings require the participation of soft adhesives to fix conductive components as well as avoid instant mechanical failure. A conductive fiber with a 500% elasticity formed by EGaIn coating on PU fiber via the hydrogen bonds from the intermediate polymethacrylate (PMA) layer, which can serve as a stable conductor for ECG electrodes when stretched to 100% [186]. Unfortunately, owing to the smooth and less elastic outer conductive layer, the conductivity of the fiber still showed an inevitable 40% decrease when stretched from 0% to 500%.

Table 1.

Conductive fibers applied as stretchable conductors.

| components | structure | Conductivity (S cm-1) | breaking strain | maximum operating strain | QF | cycling performance |

|---|---|---|---|---|---|---|

| PU@PMA@EGaIn [186] | smooth core-sheath fiber | >103 | ∼600% | 523% | N/A | 8000; 40% (8000 cycles under 40% strain) |

| PU@(Graphene/PU) [97] | worm-shaped buckled fiber | 1.24 | 1010% | 815% | 11.26 | 4000; 10% |

| PU@PDA@PPy [82] | buckled filaments in parallel | 2.38 | >1000% | >900% | 10.9 | 1500; 20% |

| (PEDOT:PSS/PBP)@TPE [38] | buckled ribbons in channels | ∼90 | ∼675% | 500% | ∼193 | 1800; 300% |

| (PU/Cu)@cyanoacrylate [83] | 3D helical fiber | >104 | ∼400% | 300% | N/A | 10000; 30% |

| SEBS@CNT fiber [98] | buckled core-sheath fiber | ∼18 | 1350% | 1000% | ∼222 | N/A |

| EGaIn/fluoroelastomer [187] | smooth core-sheath fiber | 4.35 × 104 | 1170% | 650% | 50 | 600; 100% |

| Au/fluorine rubber [99] | wrinkled fiber mat | ∼101 | 1000% | 170% | 0.75 | 500 cycles each under 30% and 60% strain respectively |

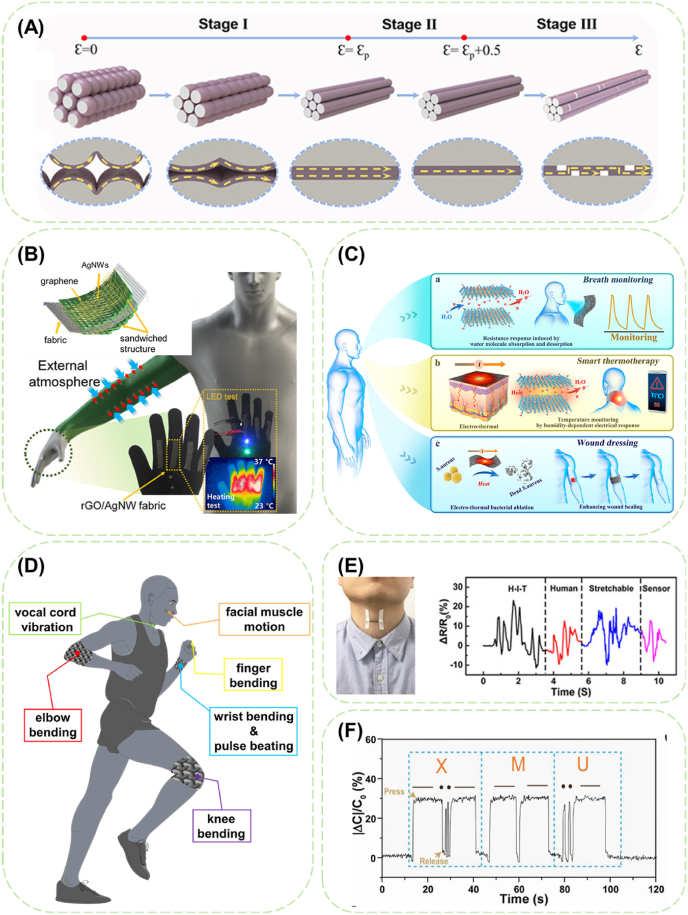

The pre-stretching method can easily improve the strain-insensitive performance of conductive fibers besides their tensile elongation. The strain-insensitive range and the quality factor (QF, defined as the percentage of strain divided by the percentage of resistance change) of CNT/SEBS core-sheath fibers can be further enlarged by overcoating a SEBS layer outside the CNT layer to reduce the contact between CNT buckles under low strain, and even further by winding the buckled fiber into coils [98]. Worm-shaped graphene/PU fiber could attain a strain-insensitive range up to 220% [97].