Abstract

This study investigated the optimization of pea protein (PP) and citrus fiber (CF) contents with the goal of producing a clean-label plant-based stirred soymilk yogurt that is free of additives. If CF is absent, a greater PP concentration tends to produce soymilk yogurt with improved physical properties (viscosity, flowability and water holding capacity). A CF concentration of 0.1% helped to improve the physical properties necessary in the production of stirred yogurt; however, an increase in CF concentration to 0.2% or higher would instead cause the physical properties to become unfavorable. The lactic acid bacteria (LAB) count was unaffected by CF content and increased proportionally with PP content. Response surface methodology was employed to investigate how the physical properties were affected by the mixing ratio, and an optimization technique was used to obtain the optimal yogurt mixing ratio. According to the optimization process, the optimal contents of 4% PP and 0.1% CF was obtained with a desirability of 87.1%. This result could provide the basic and fundamental information for developing clean-label plant-based stirred soymilk yogurt as a reference in the future.

Keywords: Soymilk yogurt, Pea protein, Citrus fiber, Optimization, Clean-label, Fermentation

Introduction

Sustainable development has recently become a growing trend of interest among consumers worldwide given the global concerns regarding climate change from environmental pollution. Therefore, consumers are more open to the idea of keeping development at a level that does not overwhelm nature. Plant-based food products, which originally was a niche product category popular among vegetarians in the past, are experiencing new growth fueled by great interest among environmentally conscious consumers. Additionally, the demand for clean-label plant-based foods that are free of additives is growing by the day. In 2020, the global plant-based food market was valued at $42,186.43 million, with 66% of products consisting of alternatives for dairy food products (GlobeNewswire, 2021). Following this plant-based food trend, the yogurt industry is also actively seeking to develop plant-based products that could potentially replace traditional dairy yogurt products.

Only one study reported that the heat treatment of raw soymilks affected physicochemical, textural, and volatile characteristics of soy yogurts (Zhou et al., 2019). The operations of microbials mask the beany flavor in soymilk (Hou et al., 2000). It has been reported that raffinose, which is the source of the unpleasant odors of soy beans, decomposes during the fermentation of soy milk (Li et al., 2012; Subrota et al., 2013). The effect of ultra-high-pressure homogenization conditions on the storage quality of soy yogurt was reported (Ferragut et al., 2009). Most research efforts are pointed towards studying the properties of soy yogurt according to the fermentation or treatment conditions. In contrast, there are very few studies on the properties of stirred soy yogurt. The most important characteristic of stirred yogurt is that it must have qualities that make it suitable for consumption using a spoon. Simply fermenting soy milk results in a yogurt with low viscosity, which is undesirable for stirred yogurt. Additives such as thickeners (hydrocolloids, emulsifiers, starch) are the simplest means of further enhancing the properties that make yogurts suitable for spoon consumption. However, the use of additives conflicts with the ideals of vegan and green dining, which leans towards the clean label movement. Therefore, through previous studies (Shin et al., 2021), this study identified suitable vegetable food materials for strengthening the physical properties of yogurt, and PP as protein and CF as dietary fiber were selected.

Related theories about the pea protein-based yogurt have been studied by several researchers in recent years (Klost and Drusch, 2019; Vogelsang-O’Dwyer et al., 2021). Multiple studies have focused on the fermentation characteristics of pea protein (PP) isolated and purified from peas. For example, it has been reported that PP can be subjected to lactic acid fermentation with L. plantarum to effectively reduce off-flavors (Shi et al., 2021). Additionally, the formation of gel networks during PP fermentation is due to interactions between the hydrophobic sections of proteins (Klost et al., 2020b). The protein solubility and emulsifying capacity decreased after PPI fermentation (Arteaga et al., 2021). Furthermore, the pre-treatment of PP at high pH has been reported to increase water-soluble components, which in turn improves the quality of the gel network (Klost et al., 2020a). Thus, the PP would be a potential ingredient to fortify the protein content, reduce the beany flavor, and enhance stabilization on the additional shear in the plant-based stirred soymilk yogurt.

Citrus fiber (CF) contains soluble and insoluble fibers: the former consists of pectin and hemicellulose, whereas the latter contains cellulose, hemicellulose, and lignin (Liu et al., 2012). Several research papers have focused on the fact that CF undergoes physical property and structural changes when treated via high pressure homogenization (HPH). The HPH process changes the granular structure of CF and creates a large number of small pores on the surface of citrus fibers (Zhu et al., 2018). The homogenization treatment results in a porous structure, citrus fibers of a significantly smaller particle size and lower crystallinity, and the fracturing of polysaccharides via a mechanical process (Huang et al., 2021). Furthermore, the HPH process changes shear behavior from shear-thinning to shear-thickening (Su et al., 2020). The average particle size decreases and that the particles are reshaped following high pressure heat treatment; specifically, the CF structure changes from particles to compact network structures (Hua et al., 2017).

In the present study, plant-based stirred soymilk yogurts were prepared using the mechanisms of the different gel networks formed via acidification during PP fermentation and the physical treatment of CF. The purpose is to derive the optimal mixing ratio value of PP and CF by investigating the changes in physical properties and structure according to the mixing ratio of vegetable soymilk yogurt and comparing it with the dairy yogurt.

Materials and methods

Materials

The commercial product of an additive-free soymilk (4.7% protein content) was obtained from Namyang Dairy Products Co. Ltd. (Cheonan, Korea). Empro E86 (Emsland-Starke GmbH, Emlichheim, Germany) pea protein (PP) with a protein content of 84% or higher, and Citri-Fi 100 (Fiberstar Co., Ltd., River Falls, Wisconsin, USA) with 90% or higher dietary fiber content were used in this study. The VEGE-033 (Lactobacillus delbrueckii subsp. bulgaricus, Streptococcus thermophilus) 50DCU strain (DuPont™ Danisco, København, Denmark) was the lactic acid bacteria (LAB) that is suitable for vegetarian food products by a supplier. Dextrose monohydrate (DAESANG Co., Incheon, Korea) was used to grow the lactic acid bacteria. Lactic acid (KANTO Chemical Co., Inc., Tokyo, Japan), 0.1 N sodium hydroxide standard solution (DAEJUNG Chemicals & Metals Co., Ltd., Siheung, Korea), and sodium chloride (Junsei Chemical Co., Ltd., Tokyo, Japan) were used. Distilled water was obtained from a water purification system (Barnstead diamond T2, Thermo Fisher Scientific, USA), and BCP Plate Count Agar (Eiken Chemical CO., LTD., Tochigi, Japan) was used for the analysis of lactic acid bacteria.

Experimental design

Thirteen experimental points containing five central points were constructed according to a central composite design (CCD, α = 1.414) using Design-Expert (version 8.0.7, Statease Inc., Minneapolis, MN, USA) to optimize the mixing ratio of PP and CF for the plant-based soymilk yogurt. The factors (independent variables) were the concentration of PP (A) and CF (B), and their levels (determined from the preliminary experiment) were 1–4% and 0.1–0.3%, respectively. The factors and levels with actual values were summarized in Table 1. The responses (dependent variables) were apparent viscosity, flowability, water holding capacity (WHC), pH, titratable acidity (TA), and lactic acid bacteria (LAB) concentration. The CCD matrix including factors (with actual levels) and responses was also shown in Table 2.

Table 1.

Factors and levels of the central composite design

| Normalized level | Factor | |

|---|---|---|

| A: Pea protein (%) | B: Citrus fiber (%) | |

| − 1.414 | 0.38 | 0.06 |

| − 1 | 1 | 0.1 |

| 0 | 2.5 | 0.2 |

| 1 | 4 | 0.3 |

| 1.414 | 4.62 | 0.34 |

Table 2.

Central composite design matrix and responsea for characteristics of plant-based soymilk yogurt

| Run | PP (%) | CF (%) | Response | |||||

|---|---|---|---|---|---|---|---|---|

| Viscosity (cP) | Flowability (cm) | WHC (%) | TA (%) | pH | LAB (× 109 CFU/g) | |||

| 1 | 1.00 | 0.10 | 2547 ± 177.76 | 11.3 ± 0.23 | 66.19 ± 1.52 | 0.524 ± 0.01 | 4.52 ± 0.01 | 1.9 ± 0.25 |

| 2 | 4.00 | 0.10 | 3167 ± 234.38 | 8.3 ± 0.30 | 68.92 ± 2.87 | 0.656 ± 0.01 | 4.71 ± 0.02 | 6.5 ± 0.35 |

| 3 | 1.00 | 0.30 | 707 ± 34.63 | 23.0 ± 0.21 | 40.79 ± 0.74 | 0.505 ± 0.01 | 4.42 ± 0.03 | 2.7 ± 0.10 |

| 4 | 4.00 | 0.30 | 720 ± 23.09 | 18.5 ± 0.58 | 44.23 ± 0.17 | 0.663 ± 0.01 | 4.48 ± 0.02 | 5.6 ± 0.23 |

| 5 | 0.38 | 0.20 | 1977 ± 57.74 | 12.4 ± 0.35 | 57.59 ± 0.59 | 0.460 ± 0.02 | 4.48 ± 0.02 | 1.6 ± 0.25 |

| 6 | 4.62 | 0.20 | 1767 ± 20.00 | 17.0 ± 0.61 | 60.13 ± 0.30 | 0.680 ± 0.01 | 4.64 ± 0.06 | 5.0 ± 0.78 |

| 7 | 2.50 | 0.06 | 2340 ± 61.10 | 11.3 ± 0.40 | 59.70 ± 0.65 | 0.665 ± 0.01 | 4.61 ± 0.04 | 6.1 ± 0.58 |

| 8 | 2.50 | 0.34 | 773 ± 23.09 | 18.4 ± 0.92 | 42.58 ± 0.49 | 0.649 ± 0.01 | 4.78 ± 0.02 | 4.9 ± 0.72 |

| 9 | 2.50 | 0.20 | 2083 ± 20.00 | 20.5 ± 0.20 | 60.41 ± 0.29 | 0.659 ± 0.01 | 4.45 ± 0.02 | 4.4 ± 0.20 |

| 10 | 2.50 | 0.20 | 2027 ± 18.97 | 13.5 ± 0.30 | 60.85 ± 0.17 | 0.650 ± 0.01 | 4.46 ± 0.01 | 4.9 ± 0.31 |

| 11 | 2.50 | 0.20 | 2063 ± 20.09 | 12.6 ± 0.26 | 60.89 ± 0.38 | 0.659 ± 0.2 | 4.42 ± 0.01 | 4.6 ± 0.20 |

| 12 | 2.50 | 0.20 | 2047 ± 18.87 | 14.1 ± 0.44 | 60.54 ± 0.41 | 0.661 ± 0.01 | 4.49 ± 0.02 | 4.8 ± 0.21 |

| 13 | 2.50 | 0.20 | 1920 ± 19.19 | 13.2 ± 0.32 | 61.12 ± 0.33 | 0.662 ± 0.01 | 4.51 ± 0.02 | 4.4 ± 0.10 |

PP pea protein, CF citrus fiber, WHC water holding capacity, TA titratable acidity, LAB lactic acid bacteria concentration

aMean values of three measurements

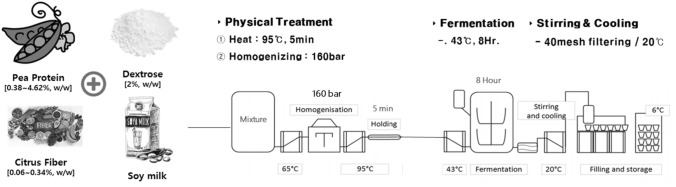

Preparation of plant-based soymilk yogurt

The process flow chart for experimental yogurt is presented in Fig. 1. PP (0.38–4.62%, w/w) and CF (0.06–0.34%, w/w) were added to soymilk heated at 65 °C depending on mixing ratios designed by CCD (Table 2), respectively, followed by addition of dextrose monohydrate (2%, w/w). The mixture was thoroughly blended with a hand mixer for 2 min, after which it was subjected to homogenization (APV-1000, APV Gaulin, Assen, Netherlands) under a first stage pressure of 140 bar and a second stage pressure of 20 bar (a total pressure of 160 bar). The homogenized suspension was then immediately sterilized at 95 °C for 5 min and subsequently cooled to 43 °C for LAB inoculation. The LAB strain, VEGE-033 was diluted 100-fold with sterilized 0.85% (w/v) NaCl solution, after which an aliquot (1 mL) of the diluted stater was added to the suspension (1 kg). The sample was then gently shaken to ensure the LAB and the ingredients were well mixed. Following inoculation, the sample was transferred to 1 L glass bottle and incubated in a 43 °C water bath (BS-21, Jeio Tech, Korea) for 8 h. The incubated broth was subsequently shaken to break down the curd and prevent the LAB from undergoing further fermentation, after which the curd was cooled to 20 °C. The cooled fermented broth was poured into several polystyrene cups through a 40-mesh filter to break the coarse curd pieces. After sealing the cups using a heat press sealing machine, the cups were stored in a refrigerator at 6 °C. For a control, a dairy milk-based yogurt was prepared with the mixture of dairy milk, whey protein concentrate (WPC), and milk protein concentrate (MPC) to the mixing ratio of 95:3:2 (w/w) under the preparation process identical to that of the plant-based soymilk yogurt (Abu-Jdayil and Mohameed, 2002; Serra et al., 2009).

Fig. 1.

Process flow chart for experimental yogurt

Apparent viscosity and flowability

The apparent viscosities of the samples were measured using a Brookfield viscometer (DV2T, AMETEK Brookfield, Middleboro, MA, USA). A spindle (No. 63) was used for liquid viscosity measurement. Viscosity changes were measured as the spindles were rotated at 30 rpm for 1 min. The flowability of the samples was measured using a Bostwick consistometer (LD-BC-24, CSC Scientific Company, Inc., Fairfax, VA, USA) by measuring the distance that went by during 1 min (Abu-Jdayil and Mohameed, 2002).

Soluble content and water holding capacity (WHC)

Soluble content was measured using a digital refractometer (RX-500 α, ATAGO CO., LTD, Tokyo, JAPAN). To determine the WHC of the yogurt samples, 40 g of each sample was centrifuged at 4500 rpm for 30 min at 10 °C. The supernatant was isolated, and the precipitate was weighed (Ladjevardi et al., 2016). The WHC was calculated using the following equation:

| 1 |

pH and titratable acidity (TA)

The pH values of the samples were measured using a pH meter (Thermo Scientific Orion 3 Star, Thermo Electron Corporation, Beverly, MA, USA) (Ladjevardi et al., 2016). The lactic acid produced by fermentation was titrated using a 0.1 N sodium hydroxide solution (Serra et al., 2009). TA was calculated from the titration volume using the following equation:

| 2 |

where N is a normality of titrant and 90 is an equivalent weight for lactic acid.

Lactic acid bacteria (LAB) determination

LAB was determined using the following method. Samples (10 g) was added into 90 mL of sterilized saline solution and vortexed for 1 min. Samples were serial diluted up to 108. Diluted sample (1 mL) was mixed with sterilized MRS medium (20 g) and poured into disposable petri dish. Samples were incubated in 37 °C incubator (BF-18i, BNF Korea, Seoul, Korea) for 48 h and counted the colony number. Consequently, LAB was calculated using dilution factor (Ladjevardi et al., 2016).

Statistical analysis

The plant-based soymilk yogurt was prepared three times for each experimental condition, and the characteristics were measured at least once for each specimen. One-way analysis of variance (ANOVA) was conducted to estimate the significance of the regression model (p < 0.05). In addition, both response surface methodology (RSM) and statistical optimization were performed using mean values of three replicate measurements of each characteristic. These statistical analyses were conducted using the Design-Expert software (version 8.0.7, Statease Inc., Minneapolis, MN, USA). Meanwhile, a Tukey’s HSD multiple range test was performed using SAS (version 9.4, SAS Institute, Inc., Cary, NC, USA) at p < 0.05 to identify significance between predicted and actual values of characteristics of the optimal plant-based soymilk yogurt and to compare characteristics of the optimal plant-based soy milk to those of the milk-based yogurt (control).

Results and discussions

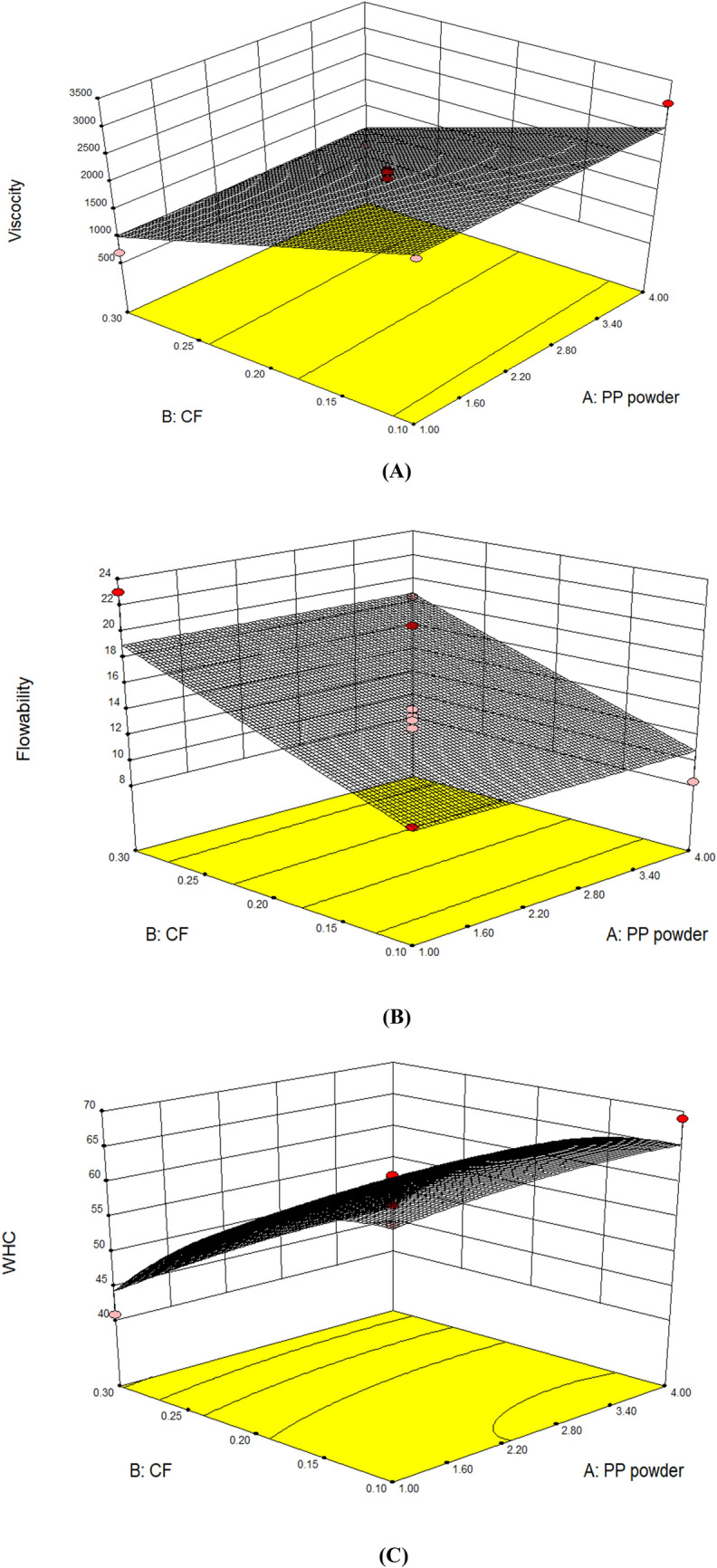

Viscosity and flowability

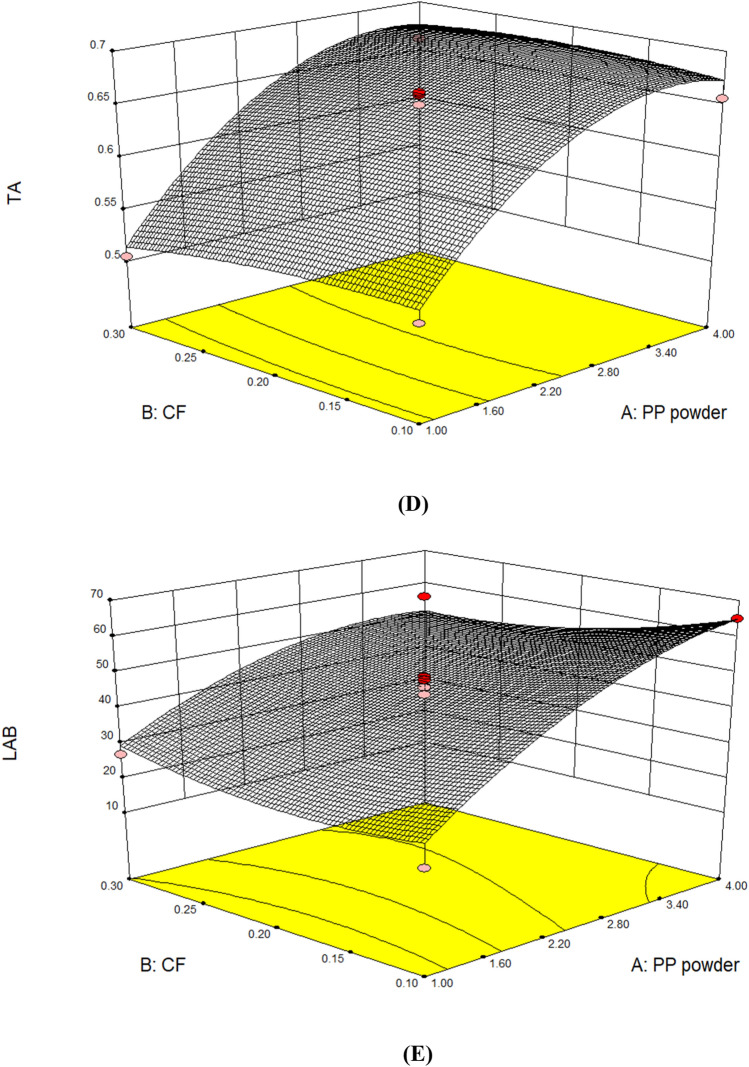

Viscosity and flowability of the plant-based soymilk yogurts prepared depending on experimental points were 700–3100 cP and 8.3–23.0 cm, respectively (Table 2). A linear regression model is fitted to describe the effects of PP and CF contents on viscosity and flowability of the plant-based soymilk yogurt (Table 3). Significance of both viscosity (p < 0.01) and flowability (p < 0.01) was found only in the CF content (Table 3). As PP increased, viscosity increased, and flowability tended to decrease (Fig. 2A, B). Through this, it was confirmed that when the PP content in plant based stirred soymilk yogurt is increased, its consistency is enhanced. Given a fixed PP mixing ratio of 4%, the viscosity decreased from 3100 cP with 0.1% CF content to 720 cP with 0.3% CF content (Table 2). This phenomenon is also reflected in the flowability results, as the flowability increased from 8.3 cm with 0.1% CF content to 23.0 cm with 0.3% CF content (with a fixed PP content of 4%) (Table 2; Fig. 2B). The aforementioned viscosity and flowability observations in the present study are believed to be due to the following reasons. Following the primary physical treatment processes (sterilization and homogenization) during the production of plant-based yogurt, CF absorbs water and fat (Su et al., 2019). As a result, CF combines with the water-soluble parts of the PP and the fat in soy milk to form the primary pectin gel network structure of CF (Hua et al., 2017). This network structure is broken down along with fermented coagulants that are formed during the fermentation process (due to the acid coagulation properties of PP protein) by additional secondary physical treatment processes, which includes passing through a 40-mesh filter. When the yogurt is placed in cold storage, gel reorganization interferes with the restructuring process, during which viscosity is normally restored (Abu-Jdayil and Mohameed, 2002; Renan et al., 2008; Serra et al., 2009).

Table 3.

Significance of the regression models (F values) and the effects of variables on characteristics of the plant-based soymilk yogurt

| Source | Viscosity | Flowability | WHC | TA | pH | LAB |

|---|---|---|---|---|---|---|

| Regression | 23.28**a | 7.47* | 14.24** | 56.70** | 2.02 | 23.04** |

| Ab | 0.10 | 0.014 | 0.98 | 202.01** | 3.12 | 86.43** |

| Bb | 46.46** | 14.93** | 56.92** | 0.67 | 0.11 | 1.84 |

| A × B | – | – | 0.01 | 0.76 | 0.46 | 3.30 |

| A2 | – | – | 0.51 | 80.05** | 0.41 | 16.29** |

| B2 | – | – | 13.24** | 1.62 | 6.29 | 4.68 |

| Lack of Fit | 46.22** | 7.23 | 346.34** | 21.65** | 15.93* | 8.50* |

|

r2 (Adjusted r2) |

0.8232 (0.7879) |

0.5991 (0.5189) |

0.9105 (0.8466) |

0.9759 (0.9587) |

0.5903 (0.2976) |

0.9427 (0.9018) |

WHC water holding capacity, TA titratable acidity, LAB lactic acid bacteria concentration

a*p < 0.05; **, p < 0.01

bA, pea protein (PP); B, citrus fiber (CF)

Fig. 2.

Response surface plots of physical property changes in (A) viscosity, (B) flowability, (C) WHC, (D) TA, and (E) LAB according to the concentrations of PP and CF

Such results are the opposite of what normally takes place during the manufacturing of dairy milk-based yogurt. It has been previously reported that the addition of CF to milk-based mixtures results in stronger casein networks under higher pectin concentrations (Kieserling et al., 2019). This restructuring process may be due to the strong attraction of CF to calcium ions deposited on casein micelles (Kieserling et al., 2019). Under acidic conditions (as in the case of yogurt), it is known that the negatively charged carboxylic group of pectin (the main component of CF) is adsorbed and stabilized due to interfacial interactions with casein proteins, which have net positive charges (Jensen et al., 2010). However, it has been reported that an increase in pectin concentration to excessive levels causes casein micelles to be completely covered by a layer of pectin even in milk-based mixtures, thereby lowering the electrostatic interactions between particles (Liang and Luo, 2020; Srisuvor et al., 2013). Furthermore, excessive pectin concentrations can cause thermodynamic incompatibility, resulting in depletion flocculation (Maroziene and De Kruif, 2000). Likewise in the interaction between pectin and casein in an acidic condition, the physical properties of plant-based yogurts may be also influenced by the CF concentration, due to the electrostatic interaction between CF and weakly positive-charged soymilk and pea proteins and the depletion flocculation of the plant proteins under pH (caused from fermentation) closed to their isoelectric point.

Water holding capacity (WHC)

WHC of the plant-based soymilk yogurts ranged from 40.79 to 68.92% (Table 2). A quadratic regression model was appropriate to explain the impact of PP and CF concentrations on WHC of the plant-based soymilk yogurt (Table 3). The WHC was significantly influenced by linear (p < 0.01) and quadratic (p < 0.01) terms of CF, although PP concentration and mutual interaction between PP and CF concentrations were not significant (Table 3). The highest WHC (68.92%) was found in the plant-based soymilk yogurt containing 4% PP and 0.1% CF (Table 2). Given the fixed PP concentration, WHC decreased with increasing the CF concentration (Fig. 2C). CF is capable of absorbing more than 10 times its weight of water due to the inherent properties of the raw material itself (Huang et al., 2018). Furthermore, it has been reported that the WHC of CF treated by high pressure homogenization (HPH) is higher compared to untreated CF (Su et al., 2019). An explanation has been provided for this result in that the CF particles change from a spherical structure to a multi-branched flake-like structure due to physical impact, resulting in the exposure of the hydrophilic group and greatly increasing the contact area with water following HPH treatment (Dickinson, 2018). In this study, most of the WHC tended to be lower when the CF content was 0.2% or higher (Fig. 2C). When the number of anionic polysaccharides such as pectin is high, gel formation of the protein is hindered. As a result, the structural integrity of gel was reduced and the serum phase increased (Lucey and Singh, 1997). Such results are believed to be due to the aforementioned breakdown of the CF gel network structure that forms during the HPH treatment process when the sample is passed through a 40-mesh filter for additional physical treatment. In addition, as explained in the previous section, anionic CF electrostatically binds with weakly cationic soymilk and pea proteins under acidic pH. This phenomenon may limit the WHC of CF, resulting in reduction of the WHC in the plant-based soymilk yogurt.

Titratable acidity (TA), pH, and Lactic acid bacteria (LAB) count

Yogurts were produced by inoculating each sample with LAB and incubating for 8 h and the amount of lactic acid generated by LAB fermentation was determined via titration with 0.1 N NaOH. TA and pH of the plant-based soymilk yogurts were 0.46–0.68% and 4.42–4.78, respectively (Table 2). TA was fitted to the quadratic regression model (p < 0.01) in which linear (p < 0.01) and quadratic (p < 0.01) terms of PP with no mutual interaction (p > 0.05) between PP and CF (Table 3). The titration amount of lactic acid increased with increasing PP concentration (Fig. 2D). This shows that a significant amount of lactic acid was produced by fermentation, indicating active LAB growth. Conversely, if the PP concentration is fixed, the variations in TA are minimal with increasing CF concentration. This highlights how PP concentration is a greater determining factor of TA than CF concentration. Meanwhile, pH associated with TA was not interpreted even by any regression models (Table 3). This may be due to the relatively narrower pH range and interference of anionic CF in pH. Even with the same protein content, the pH decreased when the CF content increased (Table 2). This result may be due to the destruction of the CF gel network structure as mentioned above. The microstructure of stirred fermented dairy products is often described as a “suspension” of microgels (weakly interconnected) into serum (Gilbert et al., 2020; Moussier et al., 2019a; 2019b). Microgels are generally defined as individual or aggregated fragments of set gel that were not destroyed during shearing (Gilbert et al., 2020; Mellema et al., 2002, 2019b; Weidendorfer et al., 2008). At this time, the serum exists in a structure trapped in a porous protein network (Lucey, 2004; Tamime et al., 2007). The pH is basically a measure of the activity of hydrogen ions (H+) in the solution (Robinson and Wilbey, 1998). If the viscosity is high, restructuring can effectively occur and much of the total acid volume generated by fermentation ends up being in the coagulum. For this reason, it has been ended up with higher pH measurements as the volume of acid in the serum was low. In a similar manner, when cutting curds produced with rennet in cheese production processes, the pH of the resulting whey is lower than the pH of the curd by about 0.2. This is due to the presence of casein proteins, which have buffering capacity, inside the elastic networks that constitute curds; as a result, less of the total acid volume is exposed to the whey (Scott et al., 1998). Consequently, the plant-based soy yogurt investigated in this study exhibited a similar behavior: as the yogurt became more viscous, the total volume of acid in the serum ended up being lower. As a result, the relatively more viscous mixture with 4.0% PP content and 0.1% CF content produced the highest pH result. Taking the TA and pH results together, a higher protein content resulted in a greater amount of total lactic acid production (Fig. 2D). However, as the amount of dissociated H+ ions in the serum was low, the pH result was relatively high at near-neutral levels. It has been reported that greater amounts of lactic acid are required to change the pH of suspensions with greater amounts of vegetable proteins (like PP); moreover, physical treatment processes like sterilization and homogenization in yogurt manufacturing processes have been reported to increase the buffering capacities of vegetable proteins against lactic acid (Shin et al., 2021).

The LAB count was 1.6 × 109–6.5 × 109 CFU/g over experimental points (Table 2) and followed the quadratic regression model (p < 0.01) with significant linear (p < 0.01) and quadratic (p < 0.01) terms of PP and no mutual interaction (p > 0.05) between PP and CF (Table 3). The LAB count was not significantly affected by the CF concentration but increased with the PP concentration in a near-proportional manner (Fig. 2E). This indicates that LAB growth is not affected by the properties of the plant-based soy yogurt medium. In other words, the LAB results confirm that the physical properties of the stirred soymilk yogurt investigated in this study were determined by the restructuring process after the coagulum was broken down by the 40-mesh sieve and not by the degree of LAB fermentation.

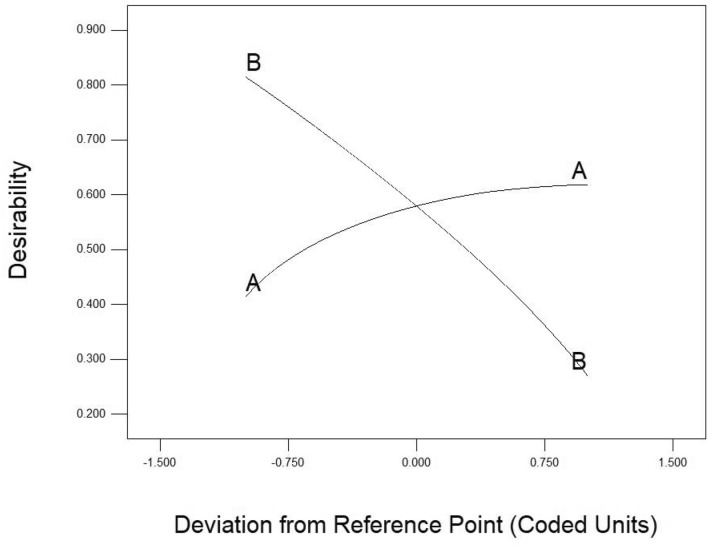

Optimization

A central composite design was used to determine the mixing amounts of PP powder and CF that resulted in a plant-based soymilk yogurt with optimal properties. Using overall responses, except for pH (not significant), and the numerical optimization based on a canonical model, the optimal point was derived as 4.0% PP and 0.1% CF with 87.1% desirability for the plant-based soymilk yogurt (Table 4). The predicted values of the plant-based soymilk yogurt characteristics under the derived optimal concentration of PP and CF were depicted in Table 4. In addition, a perturbation plot of the desirability indicates that the plant-based soymilk yogurt properties become improved with increasing PP content, whereas became worse with increasing CF content (Fig. 3).

Table 4.

Optimal values of factors and predicted values of the plant-based soymilk yogurt characteristics derived from numerical optimization based on a canonical model

| Source | Goal | Importance | Optimization |

|---|---|---|---|

| Pea protein (PP) | In range | 3 | 4.0 |

| Citrus fiber (CF) | In range | 3 | 0.1 |

| pH | None | – | – |

| Titratable acidity (TA) | Maximize | 1 | 0.67 |

| Water holding capacity (WHC) | Maximize | 3 | 65.35 |

| Viscosity | Maximize | 5 | 2,681.04 |

| Flowability | Minimize | 5 | 10.81 |

| Lactic acid bacteria (LAB) count | Maximize | 3 | 64.76 |

| Desirability | 0.871 |

Fig. 3.

Perturbation plot of desirability (A: pea protein, B: citrus fiber)

Verification

In order to verify the physical properties of the plant-based soymilk yogurt with the optimal mixing ratio (as predicted by the statistical design of experiments and RSM analysis), a yogurt was prepared with the optimal mixing ratio of 4% PP content and 0.1% CF content, and the physical properties were measured. A dairy milk-based sugar-free stirred yogurt (95% dairy milk, 3% WPC, and 2% MPC) that is similar with commercial sample was used as the control group for comparison (Table 5). The plant-based soymilk yogurt was determined to have a viscosity of 3,367 cP, flowability of 8.30 cm, TA of 0.66%, and LAB of 55.33 × 108 CFU/g, which are results that exhibit no significant differences compared to the control. Conversely, 65.80% WHC and pH 4.60 of the plant-based soymilk yogurt showed significant differences compared to 57.87% WHC and pH 4.43 of control. It has been confirmed that the results were similar to the predicted results corresponding to the optimal mixing ratio (as determined by RSM analysis) of 10.81 cm flowability, 65.35% WHC, 0.67% TA, and pH 4.54. Furthermore, the reliability of the values predicted by the experimental model, which was obtained using a central composite design, was acceptable. The viscosity and LAB results were relatively higher than the values predicted by the experimental model. However, since the viscosity of plant-based stirred soymilk yogurt was not significantly different from the viscosity of the milk-based control, it is clear that the optimal mixing ratio results in a yogurt with desirable properties.

Table 5.

Comparison in properties of the optimal plant-based soymilk yogurt (4% PP and 0.1% CF) and control (dairy milk-based yogurt)

| Response | Plant-based soymilk yogurt | Control | |

|---|---|---|---|

| Predicted value | Observed value | ||

| Viscosity (cP) | 2681.04 | 3367 ± 134.38A | 3443 ± 55.73A |

| Flowability (cm) | 10.81 | 8.30 ± 0.30A | 8.57 ± 0.31A |

| Water holding capacity (WHC, %) | 65.35 | 65.80 ± 2.87A | 47.87 ± 0.34B |

| Titratable acidity (TA, %) | 0.67 | 0.66 ± 0.01A | 0.65 ± 0.01A |

| pHa | 4.54a | 4.60 ± 0.04A | 4.43 ± 0.10B |

| Lactic acid bacteria (LAB) count (× 108 CFU/g) | 64.76 | 55.33 ± 8.50A | 63.67 ± 4.51A |

*Values sharing the same uppercase letter in row are not significantly different at p < 0.05

aMean value of pH values measured in 13 experimental points (Table 2)

Conclusions

In the presented study, plant-based soymilk yogurts with various mixing ratios were prepared by taking advantage of gel networks that are formed due to acidification during pea protein fermentation as well as gel networks formed due to the physical treatment of CF. The physical properties of each mixing ratio sample were evaluated to determine the optimal mixing ratio of the two ingredients. Viscosity, flowability, WHC, and pH are properties that are linked to the fermentation broth and thus higher values are more suitable for stirred yogurt. In the absence of CF, such responses improved with increasing PP concentration, improving the physical properties of the soymilk yogurt. A CF concentration of around 0.1% aided in improving the necessary physical properties for the manufacturing of plant-based stirred soymilk yogurt (viscosity, flowability, WHC). However, the physical properties deteriorated when the concentration of CF increased to 0.2% or higher. Meanwhile, TA and LAB count were not affected by the CF concentration as both were shown to be unrelated to the physical properties. In contrast, both TA and LAB count increased in a proportional manner with the PP powder concentration. Using an optimization program, the optimal mixing ratio with 87.1% desirability was determined as 4% PP and 0.1% CF. This study could be used as a reference for developing commercial plant-based stirred soymilk yogurt products in the future.

Acknowledgements

This work was supported by the Foundation of Agri. Tech. Commercialization & Transfer, Republic of Korea (SA00016446).

Declarations

Conflict of interest

The authors and Pulmuone Corp. declare no conflict of interest. Pulmuone Corp. supported the research without any beneficial purposes.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Jae-Sung Shin, Email: drumlover@naver.com.

Beom-Hee Kim, Email: qjagml5567@naver.com.

Hyun-Seok Kim, Email: khstone@kyonggi.ac.kr.

Moo-Yeol Baik, Email: mooyeol@khu.ac.kr.

References

- Abu-Jdayil B, Mohameed H. Experimental and modelling studies of the flow properties of concentrated yogurt as affected by the storage time. Journal of Food Engineering. 2002;52:359–365. doi: 10.1016/S0260-8774(01)00127-3. [DOI] [Google Scholar]

- Arteaga VG, Leffler S, Muranyi I, Eisner P, Schweiggert-Weisz U. Sensory profile, functional properties and molecular weight distribution of fermented pea protein isolate. Current Research in Food Science. 2021;4:1–10. doi: 10.1016/j.crfs.2020.12.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dickinson E. Hydrocolloids acting as emulsifying agents–How do they do it? Food Hydrocolloids. 2018;78:2–14. doi: 10.1016/j.foodhyd.2017.01.025. [DOI] [Google Scholar]

- Ferragut V, Cruz N, Trujillo A, Guamis B, Capellas M. Physical characteristics during storage of soy yogurt made from ultra-high pressure homogenized soymilk. Journal of Food Engineering. 2009;92:63–69. doi: 10.1016/j.jfoodeng.2008.10.026. [DOI] [Google Scholar]

- Gilbert A, Rioux LE, St. Gelais D, Turgeon S. Studying stirred yogurt microstructure using optical microscopy: how smoothing temperature and storage time affect microgel size related to syneresis. Journal of Dairy Science. 2020;103:2139–2152. doi: 10.3168/jds.2019-16787. [DOI] [PubMed] [Google Scholar]

- GlobeNewswire. Available online: https://www.globenewswire.com/news-release/2021/07/20/2265395/0/en/Global-plant-based-food-and-beverage-market-size-to-expand-at-annual-rate-of-8-71-over-2021-2028.html (accessed on 20 July 2021).

- Hou JW, Yu RC, Chou CC. Changes in some components of soymilk during fermentation with bifidobacteria. Food Research International. 2000;33:393–397. doi: 10.1016/S0963-9969(00)00061-2. [DOI] [Google Scholar]

- Hua X, Xu S, Wang M, Chen Y, Yang H, Yang R. Effects of high-speed homogenization and high-pressure homogenization on structure of tomato residue fibers. Food Chemistry. 2017;232:443–449. doi: 10.1016/j.foodchem.2017.04.003. [DOI] [PubMed] [Google Scholar]

- Huang X, Dou JY, Li D, Wang LJ. Effects of superfine grinding on properties of sugar beet pulp powders. LWT. 2018;87:203–209. doi: 10.1016/j.lwt.2017.08.067. [DOI] [Google Scholar]

- Huang JY, Liao JS, Qi JR, Jiang WX, Yang XQ. Structural and physicochemical properties of pectin-rich dietary fiber prepared from citrus peel. Food Hydrocolloids. 2021;110:106140. doi: 10.1016/j.foodhyd.2020.106140. [DOI] [Google Scholar]

- Jensen S, Rolin C, Ipsen R. Stabilisation of acidified skimmed milk with HM pectin. Food Hydrocolloids. 2010;24:291–299. doi: 10.1016/j.foodhyd.2009.10.004. [DOI] [Google Scholar]

- Kieserling K, Vu TM, Drusch S, Schalow S. Impact of pectin-rich orange fibre on gel characteristics and sensory properties in lactic acid fermented yoghurt. Food Hydrocolloids. 2019;94:152–163. doi: 10.1016/j.foodhyd.2019.02.051. [DOI] [Google Scholar]

- Klost M, Drusch S. Structure formation and rheological properties of pea protein-based gels. Food Hydrocolloids. 2019;94:622–630. doi: 10.1016/j.foodhyd.2019.03.030. [DOI] [Google Scholar]

- Klost M, Brzeski C, Drusch S. Effect of protein aggregation on rheological properties of pea protein gels. Food Hydrocolloids. 2020;108:106036. doi: 10.1016/j.foodhyd.2020.106036. [DOI] [Google Scholar]

- Klost M, Giménez-Ribes G, Drusch S. Enzymatic hydrolysis of pea protein: interactions and protein fractions involved in fermentation induced gels and their influence on rheological properties. Food Hydrocolloids. 2020;105:105793. doi: 10.1016/j.foodhyd.2020.105793. [DOI] [Google Scholar]

- Ladjevardi ZS, Yarmand M, Emam-Djomeh Z, Niasari-Naslaji A. Physicochemical properties and viability of probiotic bacteria of functional synbiotic camel yogurt affected by oat β-glucan during storage. Journal of Agricultural Science and Technology. 2016;18:1233–1246. [Google Scholar]

- Li H, Yan L, Wang J, Zhang Q, Zhou Q, Sun T, Chen W, Zhang H. Fermentation characteristics of six probiotic strains in soymilk. Annals of Microbiology. 2012;62:1473–1483. doi: 10.1007/s13213-011-0401-8. [DOI] [Google Scholar]

- Liang L, Luo Y. Casein and pectin: structures, interactions, and applications. Trends in Food Science & Technology. 2020;97:391–403. doi: 10.1016/j.tifs.2020.01.027. [DOI] [Google Scholar]

- Liu Y, Heying E, Tanumihardjo SA. History, global distribution, and nutritional importance of citrus fruits. Comprehensive Reviews in Food Science and Food Safety. 2012;11:530–545. doi: 10.1111/j.1541-4337.2012.00201.x. [DOI] [Google Scholar]

- Lucey JA. Cultured dairy products: an overview of their gelation and texture properties. International Journal of Dairy Technology. 2004;57:77–84. doi: 10.1111/j.1471-0307.2004.00142.x. [DOI] [Google Scholar]

- Lucey J, Singh H. Formation and physical properties of acid milk gels: a review. Food Research International. 1997;30:529–542. doi: 10.1016/S0963-9969(98)00015-5. [DOI] [Google Scholar]

- Maroziene A, De Kruif C. Interaction of pectin and casein micelles. Food Hydrocolloids. 2000;14:391–394. doi: 10.1016/S0268-005X(00)00019-9. [DOI] [Google Scholar]

- Mellema M, Walstra P, Van Opheusden J, Van Vliet T. Effects of structural rearrangements on the rheology of rennet-induced casein particle gels. Advances in Colloid and Interface Science. 2002;98:25–50. doi: 10.1016/S0001-8686(01)00089-6. [DOI] [PubMed] [Google Scholar]

- Moussier M, Guénard-Lampron V, Lachin K, Moulin G, Turgeon SL, Michon C, Huc-Mathis D, Bosc V. What do stirred yogurt microgels look like? Comparison of laser diffraction, 2D dynamic image analysis and 3D reconstruction. Food Structure. 2019;20:100107. doi: 10.1016/j.foostr.2019.100107. [DOI] [Google Scholar]

- Moussier M, Huc-Mathis D, Michon C, Bosc V. Rational design of a versatile lab-scale stirred milk gel using a reverse engineering logic based on microstructure and textural properties. Journal of Food Engineering. 2019;249:1–8. doi: 10.1016/j.jfoodeng.2018.12.018. [DOI] [Google Scholar]

- Renan M, Guyomarc'h F, Arnoult-Delest V, Pâquet D, Brulé G, Famelart MH. The rebodying of stirred yoghurt: interactions between proteins. Journal of Dairy Research. 2008;75:450–456. doi: 10.1017/S002202990800352X. [DOI] [PubMed] [Google Scholar]

- Robinson RK, Wilbey RA. Tests for acidity and chemical analysis in process control. In: Scott R, Robinson RK, Wilbey RA, editors. Cheesemaking practice. Boston, MA, USA: Springer; 1998. pp. 81–97. [Google Scholar]

- Scott R, Scott J, Robinson RK, Wilbey RA. Cheesemaking practice. 3. New York, USA: Kluwer Acsdemic; 1998. pp. 271–273. [Google Scholar]

- Serra M, Trujillo A, Guamis B, Ferragut V. Evaluation of physical properties during storage of set and stirred yogurts made from ultra-high pressure homogenization-treated milk. Food Hydrocolloids. 2009;23:82–91. doi: 10.1016/j.foodhyd.2007.11.015. [DOI] [Google Scholar]

- Shi Y, Singh A, Kitts D, Pratap-Singh A. Lactic acid fermentation: a novel approach to eliminate unpleasant aroma in pea protein isolates. LWT. 2021;150:111927. doi: 10.1016/j.lwt.2021.111927. [DOI] [Google Scholar]

- Shin JS, Kim BH, Baik MY. Applicable plant proteins and dietary fibers for simulate plant-based yogurts. Foods. 2021;10:2305. doi: 10.3390/foods10102305. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Srisuvor N, Chinprahast N, Prakitchaiwattana C, Subhimaros S. Effects of inulin and polydextrose on physicochemical and sensory properties of low-fat set yoghurt with probiotic-cultured banana purée. LWT. 2013;51:30–36. doi: 10.1016/j.lwt.2012.10.018. [DOI] [Google Scholar]

- Su D, Zhu X, Wang Y, Li D, Wang L. Effects of high-pressure homogenization on physical and thermal properties of citrus fiber. LWT. 2019;116:108573. doi: 10.1016/j.lwt.2019.108573. [DOI] [Google Scholar]

- Su D, Zhu X, Wang Y, Li D, Wang L. Effect of high-pressure homogenization on rheological properties of citrus fiber. LWT. 2020;127:109366. doi: 10.1016/j.lwt.2020.109366. [DOI] [Google Scholar]

- Subrota H, Shilpa V, Brij S, Vandna K, Surajit M. Antioxidative activity and polyphenol content in fermented soy milk supplemented with WPC-70 by probiotic Lactobacilli. International Food Research Journal. 2013;20:2125. [Google Scholar]

- Tamime A, Hassan A, Farnworth E, Toba T. Structure of fermented milks. Oxford,UK: Blackwell Publishing; 2007. pp. 134–169. [Google Scholar]

- Vogelsang-O’Dwyer M, Zannini E, Arendt EK. Production of pulse protein ingredients and their application in plant-based milk alternatives. Trends in Food Science & Technology. 2021;110:364–374. doi: 10.1016/j.tifs.2021.01.090. [DOI] [Google Scholar]

- Weidendorfer K, Bienias A, Hinrichs J. Investigation of the effects of mechanical post-processing with a colloid mill on the texture properties of stirred yogurt. International Journal of Dairy Technology. 2008;61:379–384. doi: 10.1111/j.1471-0307.2008.00425.x. [DOI] [Google Scholar]

- Zhou Y, Li X, Hua Y, Kong X, Zhang C, Chen Y, Wang S. The absence of lipoxygenase and 7S globulin of soybeans and heating temperatures on the properties of soymilks and soy yogurts. LWT. 2019;115:108431. doi: 10.1016/j.lwt.2019.108431. [DOI] [Google Scholar]

- Zhu X, Lundberg B, Cheng Y, Shan L, Xing J, Peng P, Chen P, Huang X, Li D, Ruan R. Effect of high-pressure homogenization on the flow properties of citrus peel fibers. Journal of Food Process Engineering. 2018;41:e12659. doi: 10.1111/jfpe.12659. [DOI] [Google Scholar]