Abstract

The cured place pipe (CIPP) manufacturing process is used to repair buried pipes, and its waste commonly discharged into the air can enter nearby buildings. Exposure can prompt illness and need for medical care. A mass balance model was applied to estimate indoor styrene concentrations due to intrusion of CIPP emissions through plumbing under different bathroom ventilation conditions. To better understand building contamination and recommend emergency response actions, calculations to estimate chemical intrusion through plumbing were developed. Field reports and study calculations showed that contractorapplied external pressures during plastic manufacture have and can displace plumbing trap water seals. Modeled styrene vapor concentrations that entered the building (1, 300, 1,000 ppm) were similar to CIPP worksites. Modeling revealed that in some cases, bathroom exhaust fan operation during a CIPP project may increase indoor styrene concentrations due to enhanced entrainment of styrene-laden air from the sink and toilet. However, styrene concentrations decreased with increasing air leakage across the bathroom door due to reduced suction from the plumbing system. CIPP waste discharges should be treated as hazardous material releases and can pose a threat to human health. Immediate building evacuation, respiratory protection, provision of medical assistance, source elimination, and building decontamination are recommended.

Keywords: Sewer repair, Plumbing, Vapor intrusion, Styrene, Volatile chemical products, Building ventilation

Graphical Abstract

1. Introduction

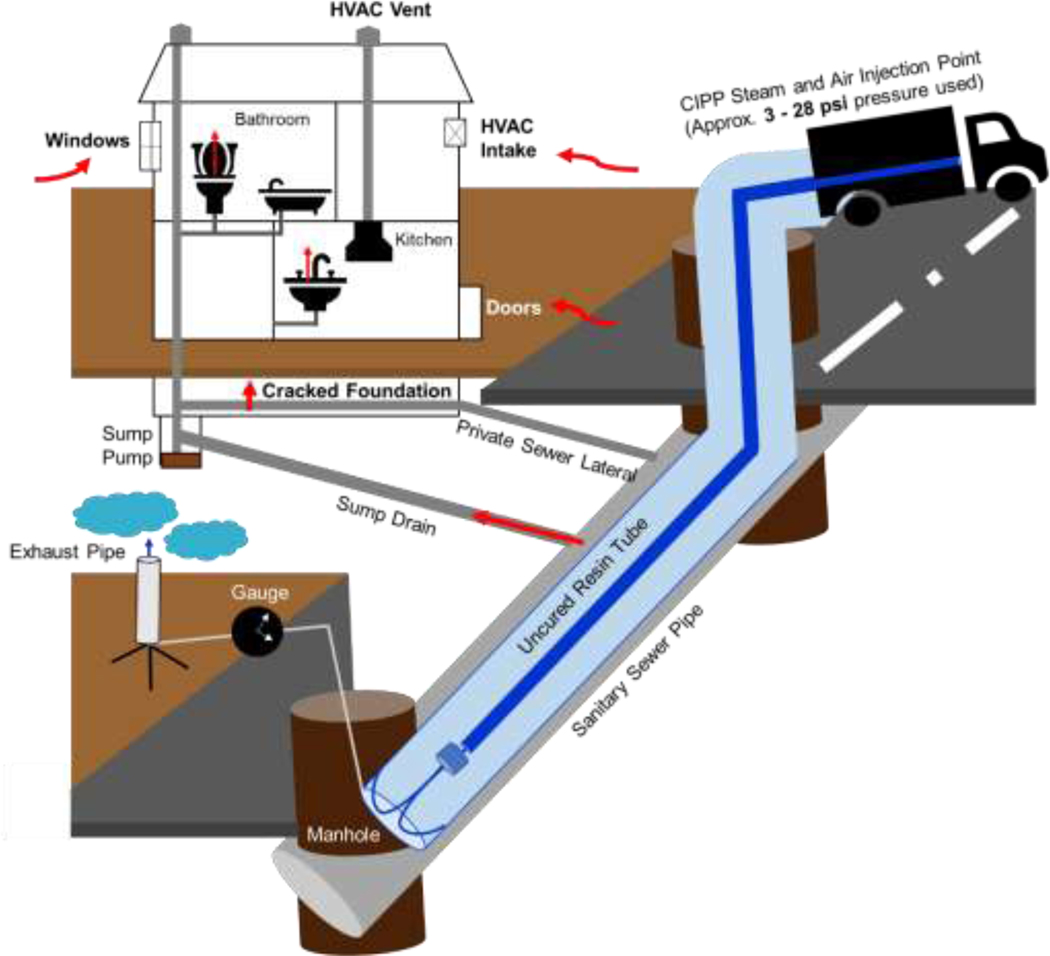

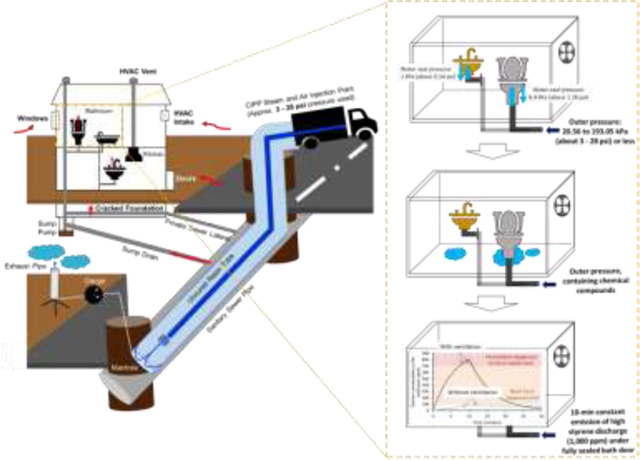

The cured place-pipe (CIPP) manufacturing process, where a new plastic liner is created inside a damaged sewer pipe, has been growing in popularity for more than 45 years. This practice is widely used in North America, along with Asia, Australia, Europe, Oceania, and South America. In some cases, the use of CIPP can be 60–80% less costly compared to removing and replacing a buried pipe. During liner manufacture, an uncured tube of styrene- or non-styrene resin is inserted into the buried pipe (Figure 1). Next, the resin is exposed to heat (steam or hot water), ultraviolet (UV) light, or ambient air to transform the resin into a plastic liner. Steam injection is the most popular curing method (Stratview Research, 2020) and pressures of 20.56 to 193.05 kPa [3 to 28 pounds per square inch (psi)] (Driver et al., 2010; Matthews, 2015; UFGS, 2010; City of Round Rock, 2017) have been applied. Once the liner is hardened, its ends are cut off, and water flow is reinstated to the now repaired pipe.

Figure 1.

Schematic of building intrusion pathways for CIPP waste products from a sewer liner manufacturing worksite. The CIPP worksite includes a pressure source at the truck, uncured resin tube, exhaust pipe, and the escape of exhaust and fugitive emissions into the air.

A challenge with the CIPP process is that industry practice encourages the discharge (not capture) of process waste containing hazardous substances into the air (Matthews, 2020; NASSCO, Inc. 2020a). Little is known about the composition and magnitude of chemicals discharged. Based on CIPP resin heating experiments, approximately 6 to 20 tons of volatile organic compounds (VOCs) were estimated to be discharged into the air during CIPP sewer lining projects (Sendesi et al., 2020). The limited CIPP worksite air testing data available indicate that at least 40 chemicals, including carcinogens, endocrine disrupting compounds, and respiratory irritants, can be present (Table S1) (AirZone, 2001; Ajdari, 2016; Dusseldorp, 2006; Matthews, 2020; NIOSH, 2019; Ra et al., 2019; Teimouri Sendesi et al., 2017). In recent years, some hazardous substances detected in various media, including the air, resin, plastic liner residuals, and others created by the manufacturing process were not listed on CIPP ingredient safety data sheets present at worksites (Li et al., 2019; Ra et al., 2019; Ra et al., 2018).

Emergency responders and public health officials have been called to investigate CIPP-initiated building chemical contamination incidents in at least 33 U.S. states and five countries (Ra et al., 2019; Sendesi et al., 2020; Teimouri Sendesi et al., 2017) (Table S2). Often, these incidents were first discovered by chemical odor or illness complaints, and several agencies have raised concerns (CDPH, 2017; CDPH, 2018; FDOH, 2020; The City of Burlington, 2020; Toronto Public Health, 2019; VDOH, 2020). Generally, respiratory problems are the most common emergency responder injury when responding to acute chemical incidents (Melnikova et al., 2018). In the U.S., acute exposure guideline levels (AEGLs) and acute reference exposure levels (ARELs) can be considered when investigating exposures for the public (Table S3). In 2018, the California Environmental Protection Agency (CalEPA) Office of Environmental Health Hazard Assessment (OEHHA) identified 4.9 ppm as the AREL for styrene exposure to the general public for CIPP projects (CDPH, 2018; OEHHA, 1999). Styrene is one of many compounds that can be emitted from CIPP worksites. In contrast, chemical exposures to CIPP workers, municipal workers providing construction oversight, health officials, and emergency responders should consider occupational exposure limits such as recommended exposure limits (RELs), permissible exposure limits (PELs), threshold limit value (TLVs), and immediately dangerous to life or health (IDLH) concentrations (Table S1 and Table S3).

CIPP waste has been documented to enter buildings through the floor, bathroom sink, and toilet drains (ARLNow, 2016; Braun, 2014; City of Arlington Fire Department, 2017; Dealer, 2010; Langhout, 2016; New York City Department of Environmental Protection, 2018; Salem Fire Department, 2018; Sedmihradsky, 2019). In an effort to prevent chemical entry, contractors, utilities, and emergency responders have advised building occupants to: (a) pour water into plumbing traps (p-trap), (b) put a wet rag or towel over or inside drains (Schmidt, 2016a; Schmidt, 2016b), and (c) cover basins and drains (CDPH, 2018; Quon, 2019; Times Union, 2016). P-traps with water seals are required on all fixtures, including the toilet, sink, bathtub, shower, and floor drains. These plumbing components help prevent transient gases, insects, and rodents from entering the room (Beckley, 2020; Gormley, 2017; Hansen, 1921; WHO, 2006). When used infrequently, p-traps can sometimes become dry and improper trap installation can lead to siphoning (WHO, 2006). Because artificial air or steam pressure for CIPP projects keeps the uncured resin tube pressed against the pipe wall during the curing and cool-down periods (Teimouri Sendesi et al., 2017), and waste (and pressure) are not prevented from leaving the tube, this contractor-applied pressure could push CIPP chemical waste through sewer lines and into the building. Vent stacks that can regulate the air pressure within building plumbing do not always exist, may be malfunctioning, or can be improperly designed (Miller, 2021; Reichman, Roghani, et al., 2017). Ultimately, this waste could encounter a p-trap water seal and water seal displacement may be possible. Waste may also escape the uncured resin tube by migrating through the CIPP’s reinforcement, a porous felt (Langhout, 2016), and permanent pinholes that form in the CIPP wall (Figure S1). While one health department has recommended that p-traps should have water seals and/or be plugged, towels should be inserted in the drains, and the sewer line should be vented (CDPH, 2018; CDPH, 2017), the air pressure required to displace a p-trap water seal has not been documented in the literature. CIPP construction standards do not address this topic (ASTM International, 2017a; ASTM International, 2017b).

To the authors’ knowledge, indoor air pollutant accumulation due to CIPP waste entry via plumbing systems has not yet been evaluated, even though CIPP chemicals have been documented to enter buildings. Some building occupants have reported hearing “whistling” and “high roaring” sounds at drains where emissions entered the building, witnessed toilet seal ruptures, and a mist-like material filling affected rooms (City of Columbia Fire Department, 2017; Langhout, 2016; Linder, 2015; Sedmihradsky, 2019). Contractors have recommended “pour[ing] two or three cups of water into the sink and drain if the smell was severe” (Alani, 2020; ARLnow, 2010; Braun, 2014; The Times Herald, 2011; Mitchell, 2020; Proeber, 2020; Schmidt, 2016a; Schmidt, 2016b). Municipalities have sometimes claimed that pouring water down drains will prevent any odor from entering the building and that odor does not pose a health risk (City of Mishawaka, 2019a; City of Mishawaka, 2019b; Lake County, 2020). A police department claimed that CIPP fumes could not enter a home if the p-traps were full of water (City of Darlington Police Department, 2016a; City of Darlington Police Department, 2016b). In one case, contractors offered to pour an absorbent material down building drains (Landstra, 2018; Whelton, 2017). Ventilation by opening windows and doors was often recommended to help reduce indoor air concentrations of volatile chemicals (City of Darlington Police Department, 2016a; City of Darlington Police Department, 2016b; City of Effingham Fire Department, 2011; Effingham City Emergency Management Agency, 2011; Fili, 2015; NASSCO, 2020b; New York City Department of Environmental Protection, 2018; Landstra, 2017; Pittari, 2015; Sanitation District 1, 2016; Salem Fire Department, 2018; Schmidt, 2016b; Schmidt, 2016a; Tom, 2015; Whelton, 2017). Portable or installed ventilation fans have also been used.

The objective of this study is to better understand the factors that influence volatile chemical entry into buildings through plumbing during CIPP installations and recommend building contamination response actions for emergency responders and health officials. While more than forty contaminants have been found to be discharged into air at CIPP worksites, and manufacturing waste has entered buildings (Langhout, 2016), only styrene air concentration data were available to the degree necessary for indoor air modeling purposes. Specific objectives of this study are to: (1) determine the pressure needed to displace water seals in plumbing traps, (2) develop and apply a bathroom mass balance model for various chemical intrusion scenarios and ventilation conditions, and (3) provide recommendations to emergency responders and public health officials.

2. Materials and Methods

2.1. Calculating the Pressure Needed to Displace Water from the P-trap

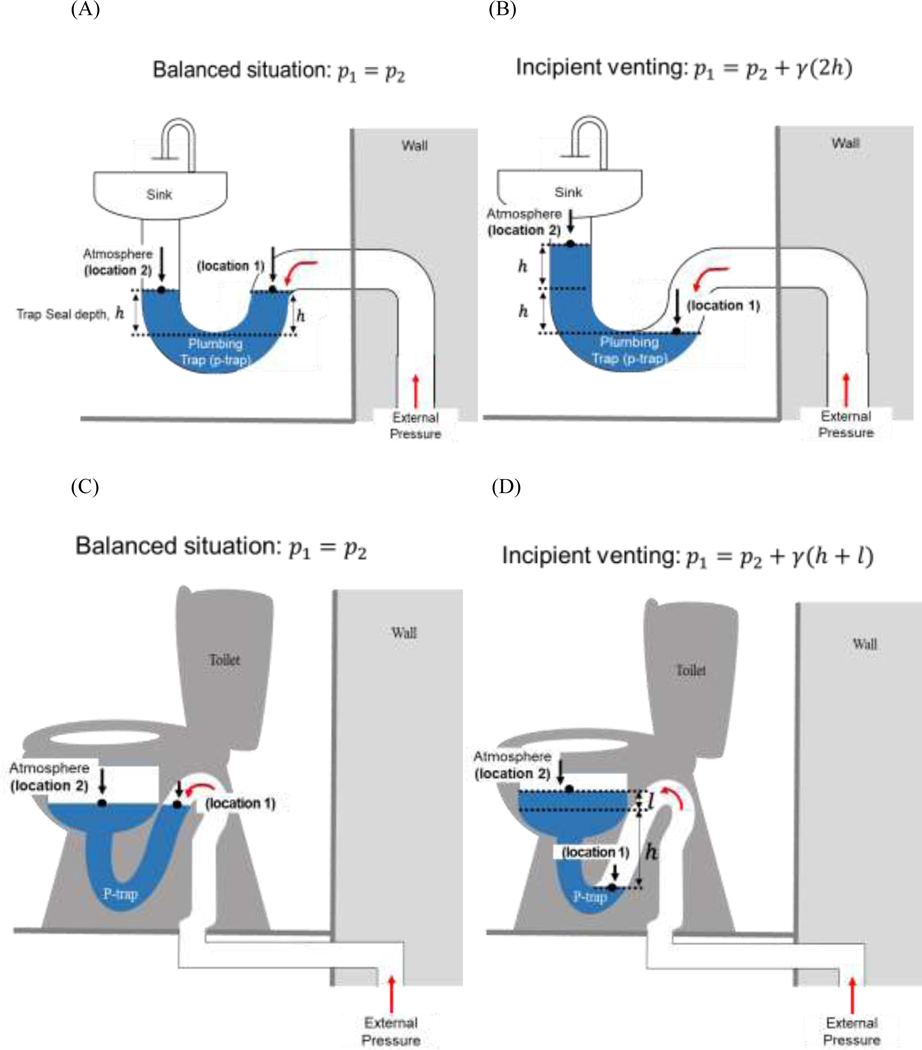

2.1.1. Sink Venting

To estimate the air pressure needed for water seal displacement, the dimensions of a standard sink p-trap in the U.S. were applied (Ripka, 1997). The sink drain is connected to a p-trap and then runs to the wall (Figure 2A, 2B). The trap depth is considered to range between h = 5.08 and 10.16 cm (about 2 and 4 in) (International Code Council, 2019; International association of Plumbing and mechanical officials, 2018). The relative (gauge) pressure needed to displace the water seal was calculated by assuming a hydrostatic pressure distribution in the water at the point of incipient venting and equating the volume of water between the balanced case and the moment of incipient venting, which will occur at the point shown in Figure 2B (this was verified with a simple laboratory experiment):

| (1) |

where the specific weight of water is denoted as γ (taken here as 9,790 N/m3 for freshwater at 20°C) (Gerhart et al., 2016).

Figure 2.

A sectional view of the sink (A, B) and toilet (C, D) in a typical bathroom.

Working in gauge pressures, and assuming that location 2 in the home is at local atmospheric pressure, 𝑝2 =0, the sewer gas gauge pressure that will cause venting if exceeded () can be estimated as:

| (2) |

2.1.2. Toilet Venting

The air pressure required to cause displacement of the toilet trap water seal was estimated in a similar manner to the sink (Figure 2C, 2D). As the excess sewer gas pressure pushes the trap water down, the water will rise slightly in the toilet, with the volume of water rising in the toilet balancing the water displaced from the trap seal. The authors assumed that the point shown in Figure 2D is the point of incipient venting and that the water has a hydrostatic pressure distribution at this point. The toilet trap seal depth is usually used as ℎ=10.16 cm (about 4 in) (International Code Council, 2019; International association of Plumbing and mechanical officials, 2018), and the p-trap pipe inner area estimated at 45.58 cm2 (about 3 in diameter) (Ripka, 1997; USEPA, 2015a). Equating the water volume displaced from the trap to the toilet bowl, and assuming a water surface area of 360 cm2 (determined by inspection of several toilet bowls in the U.S.), the bowl water deflection is estimated as . With these assumptions, the necessary sewer gas back pressure (gauge) for toilet venting becomes:

| (3) |

2.1. Bathroom Chemical Air Contamination and Decontamination Model

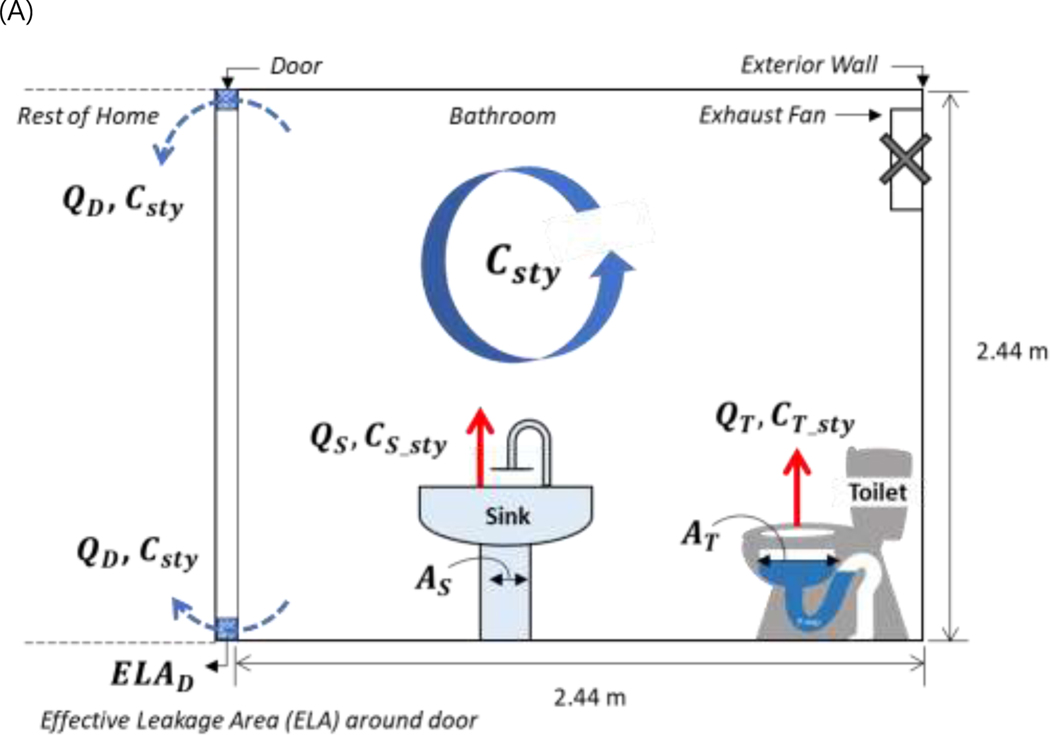

2.2.1. Mass Balance Model Derivation and Assumptions

Styrene transport was simulated with the mass conservation equation in MATLAB R2018b, treating styrene as incompressible over the range of pressures encountered. For the present study, an average size U.S. bathroom (2.44 m × 2.44 m × 2.44 m) was considered (US Census Bureau, 2017a; US Census Bureau, 2017b), with a toilet, sink, and bathroom exhaust fan (IRC, 2015; USEPA, 2010) (which is only activated under certain conditions) (Figure 3). The bathroom was treated as a single continuous stirred tank reactor (CSTR). The following assumptions were considered for the bathroom model: (1) the window was always closed (or there was no window), (2) airflow was affected by the operation of the exhaust fan, (3) the CIPP waste contamination source originated from the sink and toilet, (4) styrene concentrations in outdoor air and the rest of the home were negligible, (5) the p-trap water in the toilet and sink are completely blown off, (6) integration of a mechanical heating, ventilation, and air conditioning (HVAC) system with the bathroom was not considered, (7) adsorption and desorption of styrene with indoor surfaces were neglected, (8) styrene vapor did not react with other gas-phase species, and (9) styrene vapor did not interact with trap water or water bubbles. When CIPP intrusion incidents occur, occupants have been documented to close the bathroom door to help prevent the emissions from entering adjacent living areas. The bathroom and toilet spaces are not considered as habitable spaces under the old International Code Council (ICC) code, hence air conditioning and/or heating has not been installed or required in some of the bathrooms in older homes (International Code Council, 2003). For the short time duration modeled in this study, chemical loss due to ventilation was assumed to be greater than chemical loss due to surface adsorption (Jørgensen, 2007).

Figure 3.

Schematic of bathroom model with the location of the sink, toilet, and bathroom exhaust fan noted: (A) non-ventilation condition (exhaust fan off) and (B) ventilation condition (exhaust fan on). The diagram is a single-cell CSTR model; the arrows represent the airflow pathways. Supply and return vents for a home mechanical HVAC system are not considered.

The indoor air model was limited to styrene in the bathroom only, and the vapor concentration was assumed to be significantly affected by the bathroom air exchange rate (AER, h−1) (Reichman, Shirazi, et al., 2017). Indoor AERs of 0.25 and 0.50 h−1 are commonly used in indoor air modeling analyses (Reichman, Shirazi, et al., 2017), and the U.S. EPA suggests a typical indoor AER value of 0.18 to 1.26 h−1 (USEPA, 2015b). In this study, 0.5 h−1 was selected as the AER value for the bathroom for the non-ventilation case (exhaust fan off, infiltration across closed door) (Table 1). An effective leakage area (ELA) can exist due to small cracks or gaps around doors and windows. Since the ELA for the exterior bathroom wall is small, any air entering through the sink or toilet would leave through the door as that is the only other opening (assuming the exhaust fan damper remains shut) (Figure 3). It also assumed that the air entering the bathroom from the sink and/or toilet causes the bathroom to be positively pressurized relative to an adjacent hallway or room (Equation 4):

| (4) |

where and = volumetric flowrate at which air enters the bathroom through toilet and sink, respectively (m3/min), = flowrate at which air is transported from the bathroom to the rest of house through the door gap (m3/min), and V= bathroom volume (m3). Here, the bathroom AER is defined as the AER induced by airflow through the toilet and sink during the CIPP installation process for the non-ventilation case (exhaust fan off).

Table 1.

Summary of bathroom ventilation conditions considered.

| Exhaust fan on; air exchange rate (AER) in the bathroom: 10 h−1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Toilet only | Toilet + Sink | Toilet only | Toilet + Sink | Toilet only | Toilet + Sink | Toilet only | Toilet + Sink | |

| Floor gap of bathroom door (Width × Height) | 81.28 cm × 0 cm (perfectly sealed door) | 81.28 cm × 2.54 cm | 81.28 cm × 5 cm | 81.28 cm × 2 m (door fully open) | ||||

| Adjustment factor for ELA (a) | 1 | 0.66 | 0.5 | 0.025 | ||||

| Exhaust Fan (QE, %) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Sink (a · Qs, %) | 0 | 11 | 0 | 7 | 0 | 5 | 0 | 0.003 |

| Toilet (a · QT, %) | 100 | 89 | 66 | 59 | 50 | 45 | 0.025 | 0.022 |

| ELA of door ((1 – a) · QD, %) | 0 | 0 | 34 | 34 | 50 | 50 | 0.975 | 0.975 |

| Exhaust fan off; AER in the bathroom: 0.5 h−1 | ||||||||

| Toilet only | Toilet + Sink | |||||||

| Sink (QS, %) | 0 | 11 | ||||||

| Toilet (QT, %) | 100 | 89 | ||||||

| ELA of door (QD, %) | 100 | 100 | ||||||

For ventilated bathroom environments (exhaust fan on), the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends a minimum of 25 to 50 cubic feet per min (CFM) (Dougan & Damiano, 2003), and other standards set the range for ventilation to 28.2 to 142.4 CFM (Sandberg & Blomqvist, 1985). Researchers used 6.5 to 24 h−1 as an experiment for a bathroom with air exchange to the outdoors (Tung et al., 2009) and other investigators recommended an AER of 10 h−1 for a ventilated bathroom (Yang, 2004). In the present study, 10 h−1 for the AER was applied for the bathroom with ventilation (exhaust fan on). According to Chan et al. (2005), the ELA may range from 0.04 m2 to 0.3 m2 for a general single-family house in the U.S., which involves air exfiltration. If the ELA in the door gap occupies the largest area, the exhaust fan creates a negative pressure in the bathroom, drawing air from the adjacent hallway or room across the door. The width of a typical interior door is 81.28 cm and door-to-floor gaps can vary, from less than 1.27 cm to 5 cm. This single-cell model considered ELA effects using four different floor gaps for the bathroom door (width x height): 81.28 cm × 0 cm (perfectly sealed door), 81.28 cm × 2.54 cm, 81.28 cm × 5 cm, and 81.28 cm × 2 m (door fully open) (Table 1). Considering the bathroom size used in this study and assuming the ELA is distributed evenly on a volumetric basis, each volumetric flowrate can be calculated in a simplified manner as:

| (5) |

where = volumetric flowrate from the bathroom to outdoors through the exhaust fan (m3/min); a= adjustment factor for ELA; and = surface area of toilet and sink, respectively (m2); and = effective leakage area due to the door gap (m2). Here, the bathroom AER is defined as the AER induced by airflow through the exhaust fan to the outdoors during operation (exhaust fan on). Leakage due to cracks along the window or exterior wall would modify the above ventilation conditions.

To set the bathroom’s AER to 0.5 h−1 and 10 h−1, respectively, under the non-ventilation and ventilation conditions, it was assumed that the airflow from the toilet and sink would persist at a constant level for up to 3 hours during a CIPP installation process. The styrene emission rate from the sink/toilet and transient CSTR mass balance were evaluated for a time range from 0 to 180 min. In the CSTR model, the emission equation and the mass balance equation were linked to solve the ordinary differential equation (ODE) simulation (Figure 3). Equations 6 and 7 represent the styrene concentration model for the non-ventilation and ventilation condition, separately:

| (6) |

| (7) |

where E = emission rate (mg/min) from the sink and toilet, respectively; V= volume of the bathroom (m3); and = influent concentration of styrene from the toilet and sink, respectively (mg/m3). Both styrene emissions from the toilet and sink were considered at three different levels: Ca, Cb, or Cc (see Section 2.2.2, Figure S2, and Table S4); and = concentration of styrene inside the bathroom and outside the bathroom (i.e., rest of home) (mg/m3).

2.2.2. Influent Concentration of Styrene from the Toilet and Sink

In this model, styrene vapor either entered the bathroom through the: (1) sink (‘single case’) and (2) the sink and toilet simultaneously (‘double case’). The styrene entry condition was considered either instantaneous (i.e., a single discharge) or constant release over a specified time interval, 10 min (Figure S2). The time interval was obtained from the literature (NOISH, 2019; Teimouri Sendesi el al., 2017). At the manhole surface of CIPP worksites, elevated styrene air concentrations have been observed for about 10 min in the Teimouri Sendesi et al. (2017) study and 20 minutes in the NIOSH (2019) study. Still, there is lack of information on how long volatile chemicals may be discharged into buildings (i.e., time-resolved styrene emissions study). As a result, this study considered either an instantaneous styrene emission or a 10 min constant emission to consider a range of indoor styrene intrusion scenarios. After the emission period, the styrene concentration in the make-up air from the toilet and sink was assumed to be zero (Figure S2 and Table S4).

Three representative entry concentrations were selected to represent a range of emission concentrations based on prior studies of styrene measured in manholes (Ajdari, 2016; Matthews, 2020; NIOSH, 2019) due to the limitation of representative indoor air testing results (Najafi et al., 2018). These included Ca = 1 ppm (4.26 mg/m3, ‘high styrene discharge case’), Cb = 300 ppm (1,278 mg/m3, ‘medium styrene discharge case’), and Cc = 1,000 ppm (4,260 mg/m3, ‘low styrene discharge case’). The selected representative concentrations were converted to levels with ‘mg/m3’ units under 1 atm at 25°C and simulated result levels were re-converted to ‘ppm’ units for the consistency of units. For the scenario that involved a styrene inflow from the sink and toilet at the same time, the influx from the toilet started 1 min after the sink inflow began, depending on the relative lower blowback probability of the toilet (see the Table S4).

3. Results and Discussion

3.1. Incident Review and Building Chemical Entry Pathways

More than 136 contamination incidents (Ra et al., 2019; Sendesi et al., 2020; Teimouri Sendesi et al., 2017), many involving multiple people, have been reported at residential (single-story, multi-story) and commercial buildings (Table S2). The number of incidents found likely underestimates the number that have occurred. A 2016 Freedom of Information Act request in the U.S. found multiple CIPP chemical exposure incidents in several municipalities that had not been publicly reported (Teimouri Sendesi et al., 2017). Evacuation of an animal shelter and purported CIPP waste-induced illness was reported in Florida, U.S. as far back as 1993. Commercial buildings impacted have included an animal shelter, cancer care center, daycare centers, dental center, hospitals, schools, restaurants, various office types, and local, county, state, and federal government buildings. Persons complaining of odor and adverse health impacts have lived on the ground floor to the tenth floor of an affected building. Exposed persons have included infants, children, pregnant women, and persons who have compromised immune systems (Ra et al., 2019; Sendesi et al., 2020; Teimouri Sendesi et al., 2017). Some information indicated that occupational exposure limits were inappropriately used by CIPP contractors and emergency responders to decide if a chemical exposure was safe for the general public (e.g., children and infants) (Georgia Department of Community Health, 2007). A greater frequency of publicly reported building contamination incidents was found in recent years (Figure S3).

Persons exposed to CIPP waste have complained of illness and evidence suggests they were often not directed to medical professionals. Complaints of “adhesive”, “glue”, “resin-like”, and “chemical” odors, as well as nausea, headache, vomiting, breathing difficulties, eye irritation, and nasal irritation symptoms were noted. Further incident examination revealed that some municipalities encouraged persons exposed to contact the contractor, not medical professionals or emergency responders (City of Columbia Fire Department, 2017; City of Midland, 2018; City of St. Louis Park Fire Department, 2016; Joosen, 2018). A 2020 CIPP industry information sheet recommends persons exposed should contact the CIPP contractor (NASSCO, 2020b), and does not mention medical professionals or emergency responders. The authors’ discussions with some CIPP contractors indicated companies did not report chemical exposure incidents to medical professionals, municipalities (whom they are paid by), or encourage people exposed to seek medical attention. The authors’ discussions with some municipalities also indicate that persons who complain of illness are not recommended to seek medical advice. No CIPP construction standards were found that recommended how to handle exposures to CIPP waste products (NASSCO, 2020a).

CIPP waste can enter buildings through multiple pathways (Figure 1). Waste material can be discharged into the air during the uncured resin tube insertion, curing, and cool-down processes. Waste can travel through sewer pipes directly to buildings, enter the building through foundation cracks, and exit the buried pipes through manholes and vents aboveground. Water seal blowback incidents for sinks and toilets have been reported, and sometimes buildings next to one another did not have the same indoor air contamination problems. This may be because of differences in sewer pipe characteristics (i.e., size, cracks, pipe roughness/friction loss, etc.), air pressure (i.e., applied pressure, existence of vent stacks, etc.), and plumbing characteristics. Styrene is the most commonly measured chemical, but one of a multitude of chemicals used for CIPP manufacture (Matthews, 2020; Teimouri Sendesi et al., 2017). The highest CIPP-induced styrene vapor concentration publicly reported (1,825 ppm) was found in the vicinity of the resin truck during the curing process, and 1,070 ppm was confirmed exiting a manhole during steam curing (Ajdari, 2016). When multi-phase waste was captured leaving the exhaust pipe at multiple CIPP steam curing projects, total styrene levels (not just styrene vapor) of 1,800 to 4,300 ppm were documented (Teimouri Sendesi et al., 2017). Styrene levels on the order of 10 to 100 ppm have been reported at worksites (AirZone, 2001; Bauer, 2012; CSHC, 2017; Dusseldorp and Schols, 2006; EHS-Alaska, 2018; Ganley, 2018; Londer, 2018; Matthews et al., 2020; Najafi et al., 2018; NIOSH, 2019; PBSUSA, 2018; Quantor, 2006; Ra et al., 2019; Ra et al., 2018; RIVM, 2006; Teimouri Sendesi et al., 2017). Waste discharged from the worksite has also been transported over the ground by wind, and entered buildings through windows, doors, or HVAC outdoor air intakes (such airflow pathways were not considered in the present model).

3.2. Pressure Needed to Prompt Plumbing Trap Blowback and Styrene Emission

For sinks, the minimum pressure needed to displace the p-trap water seal was calculated to be 0.995 kPa (about 0.14 psi). For a toilet, 8.85 kPa (about 1.28 psi) was needed for water seal displacement. These pressures were much less than the reported pressure applied by contractors during sewer lining, 20.56 to 193.05 kPa (about 3 to 28 psi). Limited publicly available information was found regarding maximum and average pressures by contractors used during lining or pressure differentials at indoor sewer plumbing fixtures. No studies were found that had previously examined external pressure-induced water seal blowback. Since head loss may occur due to fluid friction with the pipe wall and elevation, and pressures may change as gases expand into connected pipes, specific information such as the proximity of the CIPP worksite to the building sewer lateral and plumbing characteristics would influence whether water seal displacement occurs. Approximately 0.5 to 43% of the total pressure applied by the contractor would be needed to prompt water seal displacement. The reviewed incidents showed blowback has previously occurred in buildings, suggesting such pressures may be achieved in residential plumbing systems.

When p-traps lack water, vapors can migrate into the building either by direct pressure applied by the contractors or pressure differentials previously known to occur as documented by sewer vapor studies not associated with CIPP (Beckley & McHugh, 2020; Gormley et al., 2017; Kang et al., 2020; Nielsen & Hvidberg, 2017; Pennell et al., 2013). The water seal of floor drains can also be absent (Kang et al., 2020), especially under infrequent use conditions. Another situation where CIPP waste may enter the building could be volatile chemical partitioning from sewer air into the p-trap water, and further partitioning into indoor air (Pankow, 1994). This may occur when concentration differences exist, driving mass transfer through the trap water and into buildings. It is also possible that if air flow resistance is artificially increased at the exhaust stack by the addition of a physical restriction (i.e., the small diameter exhaust pipe itself and waste collection/treatment device which contractors do not currently use), this added resistance may cause increased chemical discharge into nearby buildings if pressure relief is not considered.

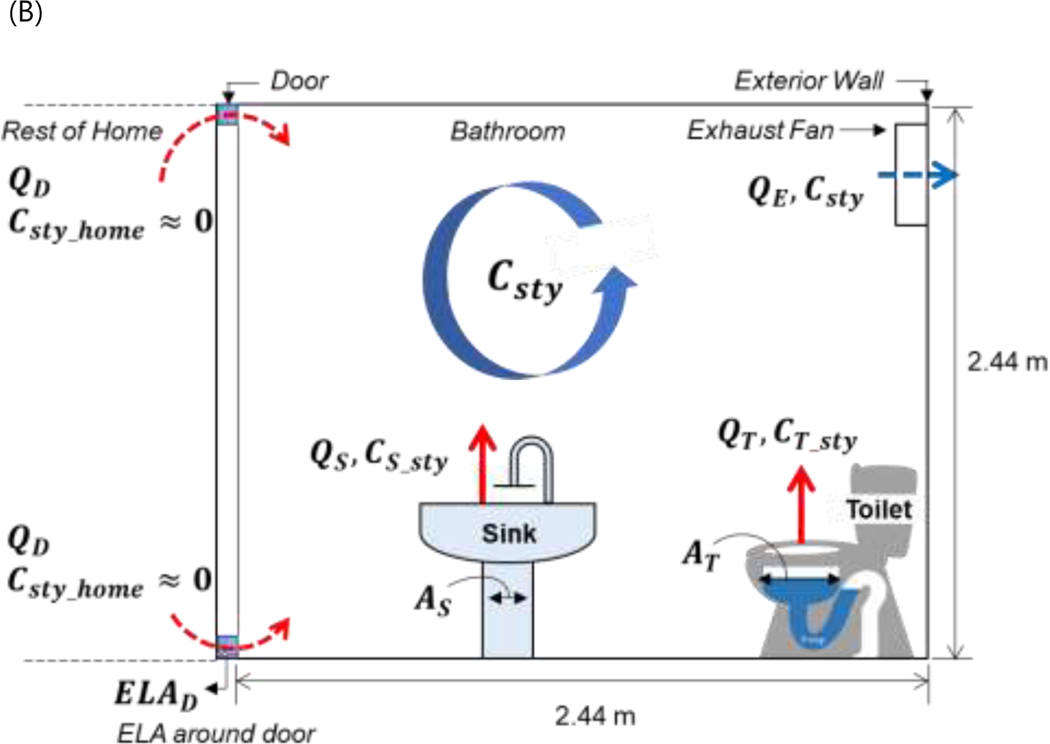

3.3. Bathroom Simulation of Styrene Exposure and Decontamination

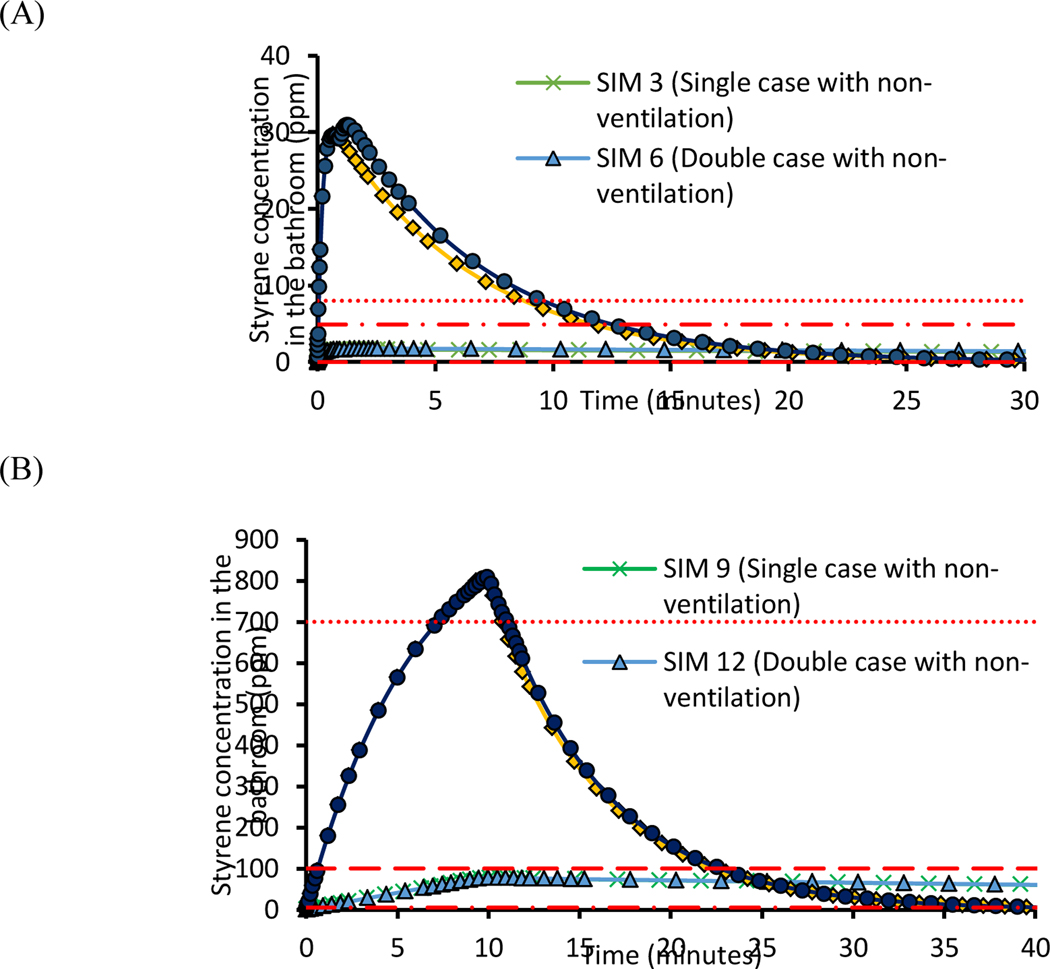

The predicted bathroom air styrene concentration was influenced by bathroom exhaust fan operation and certain conditions prompted exceedance of the styrene IDLH concentration. Figure 4 shows the time-dependent change in indoor styrene concentration according to the Cc emission scenario ( = 1,000 ppm) from the sink and/or toilet under perfectly sealed door condition. For both the instantaneous inflow (Figure 4A) and the 10 min constant inflow conditions (Figure 4B), the greatest styrene concentrations were found when the exhaust fan was on (AER 10 h−1), followed by the non-ventilation condition (AER 0.5 h−1 with a perfectly sealed door). This was due to the bathroom exhaust fan entraining more contaminated styrene-laden air through the p-trap of the sink and toilet during its operation.

Figure 4.

Time-series of the estimated indoor styrene vapor concentration after inflow ( = 1,000 ppm) into the bathroom for the: (A) instantaneous inflow cases and (B) constant inflow cases. The ventilation level was simulated for a perfectly sealed door. For information on the type of styrene influx and its intrusion condition, see Table S4 and Table 1, respectively.

When the exhaust fan was on for the high styrene discharge case ( =1,000 ppm) with instantaneous emissions for the single case (i.e., sink emission only) and double case (i.e., sink and toilet emission) (Figure 4A), the indoor styrene concentrations reached 30 and 31 ppm, respectively. These levels exceeded the styrene occupational exposure limit [ACGIH TWA: 20 ppm] and the value used by California for the general public [CalEPA OEHHA AREL 4.9 ppm]. After styrene discharge was completely halted, bathroom ventilation via the exhaust fan decreased the styrene concentrations, but at least 13 min was needed to reach the AREL and an additional 42 min was required to reduce the concentration below the odor threshold (0.0028 ppm). In contrast, when the exhaust fan was off as chemicals entered the bathroom, styrene exposure limits were not exceeded for either population (1.7 ppm and 1.8 ppm). This was due to less efficient entrainment of styrene-laden air from the plumbing system when the exhaust fan was off. During a 60 min period, the total amount of styrene inside the room, under the double case discharge condition, was 14 kg (with ventilation) and 5.58 kg (for non-ventilation case) (Figure S4).

When the exhaust fan was operated at a constant toilet/sink emission, styrene concentrations of 802 ppm and 806 ppm were reached in under 10 min (Figure 4B). These levels far exceeded a variety of worker exposure limits, including the OSHA ceiling limit (200 ppm) (OSHA, 2020) and NIOSH IDLH concentration (700 ppm) (NIOSH, 2020). NIOSH recommends that workers should wear an organic vapor cartridge respirator when 500 ppm styrene concentrations or higher are possible, and a self-contained breathing apparatus (SCBA) with a full face piece when levels are 700 ppm or higher (NIOSH, 2020). Once the emission ceased, the exhaust fan on scenario showed 45 min was needed for styrene levels to decrease below the AREL, and 85 min was needed to reach the odor threshold concentration. When the exhaust fan was off under the high discharge case, the maximum styrene concentration was 77 ppm. The levels also exceeded recommended occupational short-term exposure limit (STEL; 15-min); 40 ppm of ACGIH (40 ppm) (ACGIH, 1999). During a 60 min period, the total amount of styrene that passed through the bathroom, under the double discharge condition, was 625 kg (with ventilation) and 300 kg (for non-ventilation case) (Figure S4).

For the medium styrene discharge case ( = 300 ppm), the maximum indoor concentrations for both the exhaust fan on and off scenarios were less than the NIOSH IDLH (Table 2). However, most concentrations were greater than the AREL. When the styrene discharged constantly for about 10 min, the styrene indoor concentrations exceeded EPA AEGL-1 (20 ppm,) even under the non-ventilation condition. After the emission was halted and the exhaust fan was on, approximately 1 hour was needed to reduce the styrene concentration below its odor threshold concentration (AIHA, 2013). When the low styrene discharge concentrations entered the bathroom ( = 1 ppm), most of the maximum styrene concentrations were less than the AREL or the U.S. EPA Reference concentration (Rfc, 0.23 ppm) (USEPA, 1992). However, these levels still exceeded the odor threshold concentration, which is sufficient for occupants to detect the odor.

Table 2.

Indoor air styrene concentrations were compared against exposure levels for the general public and workers: (left) Public health and regulatory levels for exposure and the corresponding defined color indices, (right) The simulated peak styrene concentration and corresponding time to reach that concentration with the exhaust fan on and off.

| COMPARISON LEVELS: Public Health and Regulatory Levels for Exposure and Color Indices | |||

|---|---|---|---|

| Color | Concentration (ppm) | Public Exposure Level | Worker Exposure Level |

| < 0.0028 | - | - | |

| 0.0028 – 0.23 | Odor Threshold (AIHA, 2013) (min 0.0028 ppm) | ||

| 0.23 – 4.9 |

USEPA Rfc (ATSDR, 1992)

(0.23 ppm) |

- | |

| 4.9 – 8 | Cal EPA OEHHA AREL (OEHHA, 1999) (4.9 ppm) | - | |

| 8 – 20 | USEPA NOAEL (USEPA, 1999) (8 ppm) | - | |

| 20 – 40 | USEPA, AEGL-1 (USEPA, 2020a) (20 ppm) | ACGIH TWA (ACGIH, 1999) (20 ppm) | |

| 40 – 50 | - | ACGIH STEL (ACGIH, 1999) (40 ppm) | |

| 50 – 100 | - | NIOSH TWA (NIOSH, 2020); AIHA ERPG-1 (AIHA, 1998) (50 ppm) | |

| 100 – 200 | - |

OSHA TWA (OSHA, 2020); NIOSH STEL (NIOSH, 2020) (100 ppm) |

|

| 200 −250 | - | OSHA C (OSHA, 2020) (200 ppm) | |

| 250 – 700 | - | AIHA ERPG-2 (AIHA, 1998) (250 ppm); USEPA AEGL-2 (USEPA, 2020a) (230 ppm) |

|

| > 700 | - |

NIOSH IDLH (NIOSH, 2020)

(700 ppm) |

|

| RESULTS: Peak Concentration and Corresponding Time to Reach that Level | |||||

|---|---|---|---|---|---|

| Scenario | Observed Concentration (corresponding time) [unit: ppm (min)] |

||||

| Exhaust Fan On | Exhaust Fan Off | ||||

| Floor gap: 81.28 cm × 0 cm |

81.28 cm × 2.54 cm |

81.28 cm × 0 cm | 81.28 cm × 2 m | ||

| SIM 1 | 0.03 (0.79) | 0.02 (0.65) | 0.01 (0.64) | 0.0007 (0.70) | 0.002 (1.33) |

| SIM 2 | 8.90 (0.66) | 5.88 (0.67) | 4.45 (0.74) | 0.22 (0.68) | 0.50 (1.31) |

| SIM 3 | 29.68 (0.66) | 19.56 (0.78) | 14.84 (0.70) | 0.74 (0.63) | 1.65 (1.37) |

| SIM 4 | 0.03 (1.26) | 0.02 (0.65) | 0.01 (1.34) | 0.0008 (1.46) | 0.002 (1.75) |

| SIM 5 | 8.90 (0.66) | 6.08 (1.25) | 4.70 (1.26) | 0.23 (1.25) | 0.51 (1.80) |

| SIM 6 | 30.97 (1.24) | 20.07 (1.28) | 14.84 (0.70) | 0.76 (1.30) | 1.78 (1.58) |

| SIM 7 | 0.80 (9.72) | 0.53 (9.84) | 0.40 (9.71) | 0.02 (9.66) | 0.08 (10.04) |

| SIM 8 | 6.08 (10.07) | 23.71 (10.13) |

|||

| SIM 9 | 19.98 (9.72) | 77.23 (10.08) |

|||

| SIM 10 | 0.80 (9.75) | 0.54 (10.18) | 0.40 (9.80) | 0.02 (9.66) | 0.08 (10.11) |

| SIM 11 | 6.03 (9.82) | 21.90 (10.34) |

|||

| SIM 12 | 20.01 (9.75) | 77.08 (10.00) |

|||

Abbreviations: ACGIH=American Conference of Governmental Industrial Hygienists, AEGL=Acute Exposure Guideline Level, AIHA=American Industrial Hygiene Association, AREL=Acute Reference Exposure Level, C=Ceiling, USEPA=US Environmental Protection Agency, ERPG=Emergency Response Planning Guidelines, IDLH=Immediately dangerous to life or health, NIOSH=National Institute for Occupational Safety and Health, NOAEL=No observed effect level, OEHHA=Office of Environmental Health Hazard Assessment, OSHA=Occupational Safety and Health Administration, Rfc=Reference concentration, STEL=Short Term Exposure Limit, and TWA=Time-weighted Average

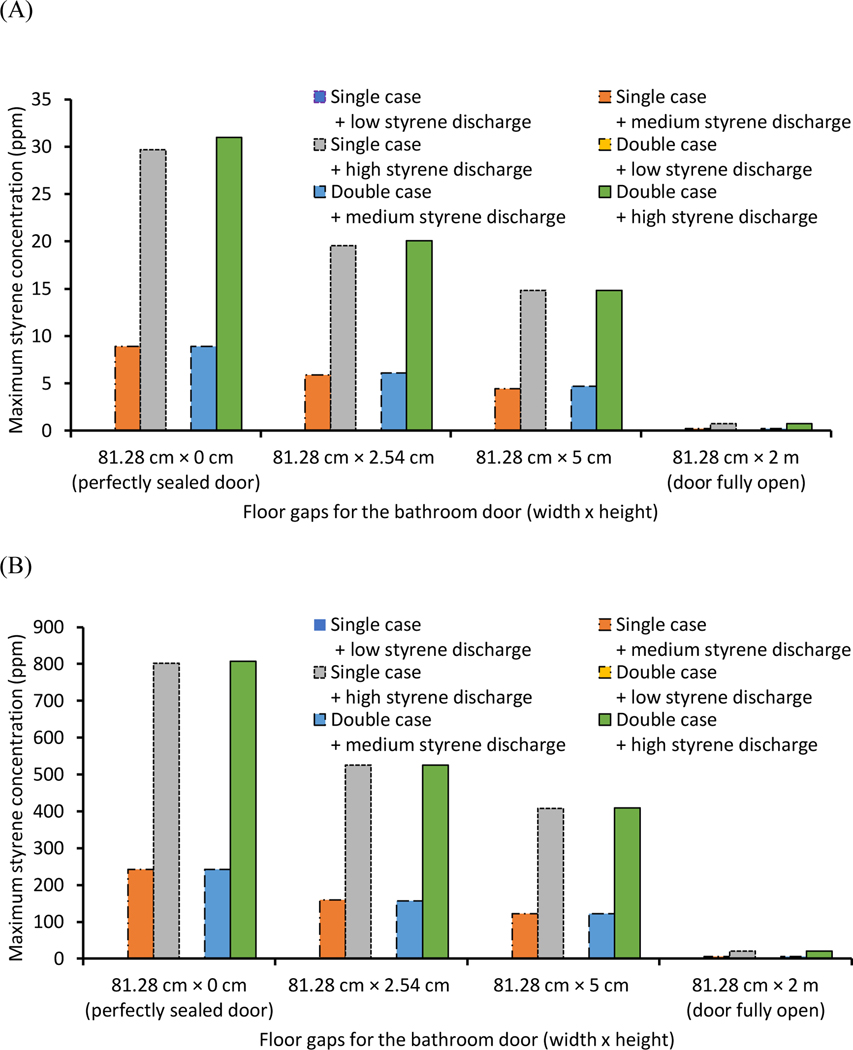

Figure 5 illustrates the bathroom air styrene concentrations as a function of the ELA of the bathroom door (for ventilation cases only). An increase in the gap between the bathroom door and the floor (i.e., door ELA) decreased the maximum value of the styrene concentration reached in the bathroom (Table 2 and Figure 5). The presence of door ELA (completely sealed door vs. door with 5 cm of floor gap) reduced the styrene concentration in the bathroom by up to 65 %. As the floor-to-door gap area was doubled (206.5 m2 to 406.4 m2), the maximum styrene concentration decreased by 23 to 50 %. When the bathroom door was fully opened, the styrene concentration decreased significantly, from about 30 ppm to 0.8 ppm (instantaneous release) and from about 805 ppm to 20 ppm (constant release) under the high discharge cases. As more makeup air (i.e., from adjacent hallway or room) was induced with increasing door ELA due to entrainment by the exhaust fan, there was less intrusion of air containing styrene from the toilet or sink. This suggests that bathroom exhaust fan operation needs to be accompanied by the dilution of styrene-free air from adjacent indoor spaces to minimize suction from the plumbing system when the p-traps are blown out. However, it is noted that this is still not a guaranteed prevention method of styrene inflow from the sink or toilet, as the styrene concentration still exceeds the AREL under both medium and high discharge cases (constant release).

Figure 5.

Maximum styrene concentrations for each bathroom door ELA condition for the: (A) instantaneous emission cases and (B) constant emission cases.

3.4. Implications to Emergency Responders and Public Health Officials

Emergency responders and health officials should approach each CIPP project as a potential hazardous materials incident. This recommendation is based on recorded worker and public health impacts associated with CIPP waste exposures, limited available chemical testing and exposure data, and indoor air modeling results from the present study (USEPA, 2020b). Multiple field studies have shown that CIPP manufacturing activities generated styrene levels that have exceeded the IDLH concentration and created hazardous atmospheres. The degree this phenomenon is widespread remains unclear. Very limited chemical air testing results were found for buildings contaminated by CIPP waste. Where testing was conducted the investigators did not document the factors that controlled air transport through the sewers and affected plumbing or condition of the plumbing (i.e., roughness, lengths, elevation, etc.).

Material safety data sheets for CIPP worksites do not to describe all hazardous chemicals that responders may encounter (Li et al., 2019), and in addition to styrene, multiple other VOCs, materials, and water vapor can be discharged into the air (AirZone, 2001; ATSDR, 2005; Li et al., 2019; Matthews, 2020; NIOSH, 2019; Ra et al., 2019; Ra et al., 2018; Teimouri Sendesi et al., 2017; Willett, 2017). Thus, responders should consider that chemicals not on the CIPP resin and initiator material safety data sheets at the worksite may also be present in the building (i.e., acetone, methylene chloride, benzene, etc.). With firefighters having a recommended 320 sec (i.e. 5 min and 20 sec) response time (National Fire Protection Association, 2020), they may quickly find themselves surveying an active hazardous materials release.

Calculations from the present study showed that p-trap water seals should not be solely relied upon to prevent CIPP waste from entering buildings and both exhaust fans and open areas could influence contaminant intrusion when the source may or is discharging CIPP waste into the building. P-traps may be effective if pressure at the fixture remains extremely low, but CIPP projects by design artificially apply much greater pressures. Prior CIPP building contamination reports that involved water being blown out of p-traps support calculations in the present study (ARLNow, 2016; Braun, 2014; City of Arlington Fire Department, 2017; Dealer, 2010; Langhout, 2016; Marquand, 2019; New York City Department of Environmental Protection, 2018; Salem Fire Department, 2018; Sedmihradsky, 2019). Odors and water blowback detections at a bathroom sink, toilet, floor drain, and the observation of bubbles may indicate contractors failed to contain their CIPP waste. When a CIPP sewer pipe project was planned, some contractors and municipalities have recommended building owners and occupants close and seal the building windows, doors, and vents. Public incident reports (Ra et al., 2019; Sendesi et al., 2020; Teimouri Sendesi et al., 2017) also showed that generated chemicals can spread in the atmosphere from the worksite to nearby buildings. Building occupants may consider: (1) to have their bathroom doors fully closed/sealed without operating exhaust fans to prevent additional entrainment from the plumbing system due to the high negative pressures created, or (2) to turn on bathroom exhaust fans while providing sufficient styrene-free air (such as through a fully open bathroom door) before emergency responders arrive. Operating a system that exhausts bathroom air, such as an exhaust fan, induces negative pressures that can entrain styreneladen air into the bathroom from a toilet and sink with a blown out p-trap. This action could increase the likelihood external air or external chemicals entering the building through the plumbing. Because real-time chemical measurement cannot be conducted in all buildings at all entry points before, during, and after CIPP manufacturing projects, when either odors, airflow from drains, or water seal blowback occurs, occupants should immediately evacuate their building and call emergency services and public health officials for help.

Because chemical exposure conditions have been confirmed at CIPP manufacturing sites and hazardous atmospheres may be caused inside affected buildings, responders should recommend building evacuations. A recommended action sheet for CIPP incidents for firefighters and health officials described in Table S6 includes topics such as considerations for: (a) analyzing the incident, (b) emergency procedures and decontamination, as well as (c) PPE and respiratory protection. Special consideration should be given to vulnerable groups such as children, infants, the elderly, and persons who are immunocompromised as they may be more susceptible to chemical exposure. Pets may also need to be evacuated. Building ventilation by occupants or contractors before emergency services arrives can reduce the ability of responders from confirming the initial chemical exposure conditions. Styrene air concentration data from the field and this study indicates respiratory protection (vapor cartridge or SCBA) could be necessary to enter the building. Eliminating the chemical source is an important step to gaining control of the incident. Standard multi-gas detectors (O2, H2S, CO, combustible gases) carried by emergency responders are not capable of detecting the contaminants of concern at CIPP worksites. Prior testing has revealed that handheld organic vapor photoionization detector (PID) instruments under- and overestimated styrene exposure by 10- to 1,000-fold (Ra et al., 2019), so emergency responders should not rely on these devices for CIPP hazardous atmosphere investigations. Sorbent tubes and canisters can be used for VOC air sample collection (NIOSH, 2019; NIOSH, 2018b; OSHA, 1991) and analysis (Table S5), but these are not real-time air testing instruments and require hours to days to obtain results.

Once the source of CIPP waste has been eliminated, building decontamination by ventilation could be helpful and its effectiveness will depend on several factors. These factors include the AER, air temperature, the degree chemicals absorbed onto or into materials (i.e., carpets, plastics, paints, wall, furniture, etc.), the chemical concentration, type of waste materials blown into the building (i.e. vapor, particulates, water vapor saturated with organics) (An et al., 1999; Herkert et al., 2018; Meininghaus et al., 2000; Zhao et al., 2004), and if there is a continued source (uncured resin, partially polymerized resin, or condensed materials blown into the plumbing or at the sewer lateral vs. the liner is not fully cured and volatilizes VOCs over extended periods). According to an ATSDR investigation, styrene levels were found in a contaminated office building four weeks after a CIPP incident (ATSDR, 2005). Other long duration exposures have also been reported in incidents reviewed by others (Dealer, 2010; Ra et al., 2019; Teimouri Sendesi et al., 2017). Certain parts of a building may have greater chemical air concentration than others (i.e., bathroom vs. bedroom vs. basement). Chemical air testing should be conducted to determine whether the chemical air concentrations pose a risk to the inhabitants. Testing should also be conducted after the building is closed allowing for any chemicals to volatilize into indoor air thereby helping to maximize the chance of finding residual contamination if it is present.

To lessen the chance building contamination incidents and chemical exposures, public health authorities and project funding agencies could encourage the infrastructure owners, who hire CIPP contractors, to contractually require that CIPP waste not be discharged into the air or use an alternative pipe repair method. By definition, a building would become contaminated when CIPP waste has left the infrastructure worksite and entered (private) property and plumbing. While an odor may pose a nuisance, the odor would indicate a failure to take proper care to contain the hazardous material. Plastic manufacturing waste capture and treatment controls have long been used in the composite manufacturing industry where hazardous conditions are well-known (USEPA, 2020c; USEPA, 2020d). If CIPP waste is not captured or the capture/treatment system fails, indoor air contamination may exceed styrene concentrations deemed unacceptable for the public and emergency responders, acute adverse health effects and injuries may occur, and emergency responders may need respiratory protection to enter and decontaminate the building.

To better understand occupational and public health risks and improve emergency response decisions, additional work is recommended. In the U.S., free health hazard evaluations of CIPP worksites by NIOSH (NIOSH, 2018a) may indirectly help document waste composition and chemical magnitudes if testing is conducted as waste exits the discharge points. More detailed characterization of the CIPP waste being discharged is needed. Waste composition may differ across resins, curing methods, and installation conditions, and some materials may be more likely to enter or travel deeper into buildings compared to other materials.

This study evaluated plastic manufacturing emissions and subsequent indoor intrusion via plumbing systems. However, as the bathroom mass balance model was established through various assumptions, additional experimental verification studies are recommended. In this study, the bathroom was considered as an ideal single-cell CSTR. However, spatial variations in indoor styrene concentrations may exist within the bathroom due to various factors (i.e., bathroom airflow distribution), especially for larger bathrooms (Breen et al., 2014; Méndez et al., 2008; Yang & Chen, 2001). This model did not consider an HVAC system connected to the bathroom. As ASHRAE recommends additional ventilation requirements for new homes (ASHRAE, 2019), it may be necessary to evaluate the impact of HVAC system operation on bathroom styrene concentrations during CIPP intrusion incidents. Additional studies of sewer pipe, plumbing integrity, airflow conditions, inflow pressure, the duration of waste entry, and indoor air testing should be considered.

To more accurately predict indoor air concentrations of volatile CIPP waste products, chemical intrusion through windows or other traps (i.e., bathtub, shower, and floor drains) should be considered. Chemical adsorption and desorption to indoor surfaces (Wang et al., 2020; Won et al., 2000, 2001), furniture, and personal effects were not considered in the present study, and these phenomena may extend the time needed for decontamination (e.g., creation of a surface reservoir of styrene). Conditions should be considered where the source is uncured resin left at the end of a sewer lateral or blown into plumbing, thereby volatilizes over longer time-scales into the building. For example, it is accepted CIPP construction practice that 5 to 10% v/v resin be squeezed out of the uncured resin tube and may move to nearby pipe cracks and joints (ASTM international, 2016). To obtain additional relevant indoor air data some or all of the numerous challenges reported should be addressed: (a) nearby buildings not being accessible and plumbing issues, (b) concerns about who is liable if chemical exposure/safety problems occur, (c) projects being scheduled right before the contractor appears without adequate time for planning, (d) building use and ventilation during air sampling, and (e) sewer lateral and building characteristics (i.e., plumbing type and other conditions). To assist emergency responders and health officials better understand the environments they encounter, a reliability assessment of real-time organic vapor testing devices for characterizing complex and CIPP project caused hazardous atmospheres should be conducted.

4. Conclusions

This study was conducted to better understand chemical ingress and potential exposure inside residential or commercial buildings due to CIPP-related chemical incidents. Previous investigators have detected chemical substances released to the outdoor environment from CIPP manufacture, but systematic indoor air evaluations for the general public have not been carried out. Results of the present study provide a baseline understanding for emergency responders and public health officials who respond to CIPP caused building contamination incidents.

While more than 40 volatile chemical compounds are known to be generated or released into the air at CIPP worksites, only styrene air concentration data was in enough abundance for indoor air modeling. For the limited data available, hazardous atmospheres that contain styrene have been confirmed at worksites (i.e., 1,825 ppm exiting a CIPP resin truck), 1,070 ppm exiting a downstream sewer pipe manhole during steam CIPP curing, and numerous studies indicating 10s to 100s of ppm at the worksite. The present study showed that the air and steam pressure currently used for CIPP manufacture could induce sink and toilet water blowback. According to building contamination incident reports, chemical odors as well as sink and toilet p-trap water seal blowbacks have been reported. The CIPP contractor, municipality, and emergency responder recommendation that building occupants pour water into their p-traps will not guarantee CIPP waste will be prevented from entering buildings. Responders should approach a suspected or confirmed CIPP caused building contamination incident as a hazardous materials release. Indoor air modeling revealed that bathroom exhaust fan operation and door air leakage strongly influenced indoor air styrene concentrations. Thus, different decontamination methods should be used depending on the characteristics of each residential building bathroom (such as the presence of a ventilation system). It is also recommended is that buildings should be evacuated out of an abundance of caution if chemical entry is suspected or confirmed, including detection of an odor. Responders should anticipate that CIPP construction projects generate hazardous atmospheres both outdoors and indoors and can require personal protective equipment such as vapor cartridge and SCBA respirators. Evacuating the impacted building is recommended with specific attention to populations more susceptible to chemical exposure (i.e., children, infants, and immunocompromised). Halting the CIPP manufacturing process can help reduce the source and provide responders better control of the incident. When buildings are ventilated before responders arrive, the magnitude of indoor chemical exposures inhabitants experienced may go undocumented.

While not all chemical exposures may pose a health risk, evidence shows immediately dangerous hazardous atmospheres have and can be created by CIPP projects in buried pipes directly connected to nearby buildings. Incident reports indicate hazardous atmospheres can be caused inside nearby buildings and public spaces. Additional work is needed to better understand conditions where CIPP waste can enter buildings, what chemicals and concentrations are possible, the scope of medical care and rapid chemical air testing needed, and which building decontamination procedures work best. Study results provide new insights into indoor air contamination caused by CIPP manufacturing projects. If effective CIPP waste capture and/or treatment methods were adopted instead of directly discharging process waste to the air, the number of people exposed to CIPP chemicals, and thus number of emergency response incidents, would likely decrease. Emergency responders and health officials should be trained about the acute chemical exposure risks associated with this plastic manufacturing process.

Supplementary Material

Highlights.

More than 136 exposure events due to CIPP installations have been reported

CIPP pressure makes blowback from sinks and toilets in nearby buildings possible

A mass-transfer model was developed to predict chemical fate in bathrooms

Some simulations showed that indoor styrene levels exceeded IDLH levels

Exposed occupants should evacuate and seek advice from medical professionals

Acknowledgement

This work was supported by National Institute of Environmental Health Sciences (NIE HS) R03/ES030783, National Science Foundation CBET award 2129166, and the Purd ue University Ross Graduate Fellowship program.

Footnotes

Credit author statement

This manuscript includes multiple authors and each contributed to this manuscript and its content and roles are described in accordance with the journals topics. YN, AW, and BB contributed to all aspects of the Conceptualization, Data Curation, Formal Analysis, Investigation, and Methodology. YN and AW contributed to Writing - original draft as well as Writing - review and editing. All other coauthors contributed to writing review and editing. JS, CJ, and CT contributed to Conceptualization, Methodology, and Formal Analysis and provided input to data as it was generated. YN, AW and JS contributed to funding acquisition. AW contributed to supervision.

Declaration of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

5. References

- Agency for Toxic Substances and Disease Registry (ATSDR). Toxicological Profile for Styrene. US Public Health Service, US Department of Health and Human Services, Atlanta, GA. 1992. [Google Scholar]

- Agency for Toxic Substances and Disease Registry (ATSDR). Division of Health Assessment and Consultation. Health Consultation, Schlitz Park Office Building, Milwaukee, WI. 2005. [Google Scholar]

- AirZone Inc. A Report on the Monitoring of Styrene in Toronto Homes During the Cured in Place Pipe (CIPP) Process for Sewer Pipe Rehabilitation by Insituform. Project 041–6742. Toronto, CN. 2001. [Google Scholar]

- Alani H. Do The Drains In Your Wicker Park Home Smell? Don’t Worry, It’s Just Sewer Work. https://blockclubchicago.org/2020/02/18/do-the-drains-in-your-wicker-park-homesmell-dont-worry-its-just-sewer-work/Feb. 18, 2020; (accessible at September 2020).

- American Conference of Governmental Industrial Hygienists (ACGIH). 1999 TLVs and BEIs. Threshold Limit Values for Chemical Substances and Physical Agents Biological Exposure Indices. Cincinnati, OH. 1999. [Google Scholar]

- American Industrial Hygiene Association (AIHA). The AIHA 1998 Emergency Response Planning Guidelines and Workplace Environmental Exposure Level Guides Handbook. Fairfax, VA. 1998. [Google Scholar]

- American Industrial Hygiene Association (AIHA). Odor Thresholds for Chemicals with Established Health Standards, 2nd Edition. Fairfax, VA. 2013. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ANSI/ASHRAE Standard 62.2–2019: Ventilation and Acceptable Indoor Air Quality in Residential Buildings. Atlanta, GA. 2019; Available at https://www.ashrae.org/technical-resources/bookstore/standards-62-1-62-2. [Google Scholar]

- American Society for Testing and Materials International (ASTM International). F1216–16 Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube. West Conshohocken, PA. 2016. [Google Scholar]

- American Society for Testing and Materials International (ASTM International). ASTM D790–17 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. West Conshohocken, PA. 2017a. [Google Scholar]

- American Society for Testing and Materials international (ASTM International). ASTM D2990–17 Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics. West Conshohocken, PA. 2017b. [Google Scholar]

- An Y, Zhang J, Shaw C. Measurements of VOC adsorption/desorption characteristics of typical interior building materials. HVAC&R Res. 1999; 5 (4): 297–316. doi: 10.1080/10789669.1999.10391240. [DOI] [Google Scholar]

- ARLnow. Sewer Work Prompts Numerous Fire Department Calls. Local News Now, LLC. https://www.arlnow.com/2010/11/23/sewer-workprompts-numerous-fire-departmentcalls/ (Accessed July 1, 2017). November 23, 2010. Arlington, VA. [Google Scholar]

- ARLNow. Hazmat Team Investigating ‘Unusual Odor in the Bathroom’ of Chinese Restaurant. https://www.arlnow.com/2016/05/05/hazmat-team-investigating-unusual-odor-in-thebathroom-of-chinese-restaurant/ May 5, 2016. [Google Scholar]

- Ajdari EB. Volatile organic compound (VOC) emission during cured-in-place-pipe (CIPP) sewer pipe rehabilitation. University of New Orleans, New Orleans, LA, 2016. [Google Scholar]

- Bauer G. Styrene: An overview—An awareness. Underground Infrastructure Research International Conference and Trenchless Technology Road Show. Waterloo, ON, CAN, 2012. [Google Scholar]

- Beckley L, McHugh T. A conceptual model for vapor intrusion from groundwater through sewer lines. Science of The Total Environment 2020; 698: 134283. [DOI] [PubMed] [Google Scholar]

- Braun SJ. CIPP Fumes Enter Homes; Personal Communication: Prairie Village, KS. 2014. [Google Scholar]

- California Department of Public Health (CDPH). Cured-In-Place-Pipe (CIPP) Additional Consideration for Municipalities. Sacramento, CA. 2017. [Google Scholar]

- California Department of Public Health (CDPH). CIPP Safety Alert. Sacramento, CA. 2018. [Google Scholar]

- Chan WR, Nazaroff WW, Price PN, Sohn MD, & Gadgil AJ. Analyzing a database of residential air leakage in the United States. Atmos. Environ, 2005; 39 (19), 3445–3455. doi: 10.1016/j.atmosenv.2005.01.062. [DOI] [Google Scholar]

- Circle Safety and Health Consultants, LLC. (CSHC). Industrial Hygiene Evaluation: CIPP – Styrene Exposure. Prince William County Service Authority. Woodbridge, VA, 2017. [Google Scholar]

- City of Arlington Fire Department. Incident #2150087, Report Type 671: Hazmat investigation w/no hazmat, odor of gas with no leak. Arlington, VA. August 3, 2017. [Google Scholar]

- City of Burlington Department of Public Works. CIPP Fact Sheet. Access on August 2020. Burlington, VT: https://www.burlingtonvt.gov/DPW/CIPPFactSheet. [Google Scholar]

- City of Columbia Fire Department. Incident #17–0009226, 671 Hazmat Release Investigation. Columbia, MO. April 25, 2017. [Google Scholar]

- City of Darlington Police Department. Assist Fire Department. Case number 2016–2610. December 20, 2016a. [Google Scholar]

- City of Darlington Police Department. ** NOXIOUS ODOR IN HOMES **. Facebook post. December 20, 2016b. [Google Scholar]

- City of Effingham Fire Department. Incident Report Type 86: Investigate. 8:14am. Effingham, IL. November 17, 2011. [Google Scholar]

- City of Midland Fire Department. Incident Report 2018–8002946. Type 671: Hazmat release investigation w/no hazmat. Midland, MI: July 18, 2018. [Google Scholar]

- City of Mishawaka. Municipal Government Public Notice on Facebook. Mishawaka, IN. August 12, 2019a. [Google Scholar]

- City of Mishawaka. 2019 CIPP Sewer Rehabilitation Information. Available at http://www.mishawaka.in.gov/city-news-20190812a. Mishawaka, IN. December 09, 2019b. [Google Scholar]

- City of Round Rock Department of Public Works. CIPP Specifications, Wastewater Rehabilitation 2017: CIPP & Pipe Bursting. Round Rock, TX, 2017. [Google Scholar]

- City of St. Louis Park Fire Department. Incident Report Type 421: Chemical Hazard. St. Louis Park, MN. June 28, 2016. [Google Scholar]

- Dealer TP. Some in Lorain County lake community complain of chemical odors from sewer rehab work. Scott M. Cleveland, OH: September 28, 2010; http://blog.cleveland.com/metro/2010/09/some_in_lorain_county_lake_com.html. [Google Scholar]

- Department of Defense and Unified Facilities Guide Specifications (UFGS). UFGS 22 05 83.63 Cured-In Place Pipe (CIPP) Lining. Available at https://www.wbdg.org/ffc/dod/unified-facilities-guide-specifications-ufgs/ufgs-22-05-83-63. Arlington, VA. August 2010. [Google Scholar]

- Dougan DS, Damiano L. ASHRAE Standard 62, Ventilation for Acceptable Indoor Air Quality, Analysis and Recommendations. AutomatedBuildings. 2003; Available at http://www.automatedbuildings.com/news/jan03/articles/ebtron/ebt.htm [Google Scholar]

- Driver FT, Wang W, Coyne JM. Installation of cured in place liners with air and flow-through steam to cure, Paten # US7766048B2. US Patent and Trade Office; Washington, D.C., 2010. [Google Scholar]

- Dusseldorp AaS E. Rioolrenovatie met kousmethoden-Achtergronden bij het informatieblad. RIVM rapport 609021038/2006, Bilthoven, RIVM-Rijksinstituut voor Volksgezondheid en Milieu. 2006. [Google Scholar]

- EHS-Alaska I. Styrene Exposure During Hot Water Cured-in-Place Pipe Lining; Eagle River, AK. Anchorage Water and Wastewater Utility, Anchorage, AK, March 2018. [Google Scholar]

- Effingham City Emergency Management Agency. Sewer Odor Press Release, Effingham, IL. November 17, 2011. [Google Scholar]

- Fili SL NB. Homeowners evacuated after chemical leak. KLKN-TV. June 6, 2015; Available at http://www.klkntv.com/story/29486797/homeowners-evacuated-after-chemical-leak. [Google Scholar]

- Florida Department of Public Health (FDOH). Cured-In-Place-Pipe [CIPP]. http://www.floridahealth.gov/environmental-health/hazardous-waste-sites/_documents/final_fdoh_cipp.pdf. Marriottsville, MD. 2020. [Google Scholar]

- Ganley S. Subject: RE: Question about your Styrene Air Testing Data, Email from PipeWorks (Simon Ganley) to Purdue University (Andrew Whelton). November 18, 2018. [Google Scholar]

- Georgia Depertment of Community Health. Technical Assistance, Gwinnett County Styrene Inhalation. GDCH, Chemical Hazards Program, Environmental Branch; Atlanta, GA. March 29, 2007. [Google Scholar]

- Gerhart PM, Gerhart AL, Hochstein JI. Munson, Young and Okiishi’s Fundamentals of Fluid Mechanics: John Wiley & Sons, 2016. [Google Scholar]

- Gormley M, Aspray TJ, Kelly DA, Rodriguez-Gil C. Pathogen cross-transmission via building sanitary plumbing systems in a full scale pilot test-rig. PloS one. 2017; 12 (2): e0171556. doi: 10.1371/journal.pone.0171556. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hansen AE. Plumbing fixture traps: an historical, statistical and experimental engineering research on vented and unvented traps. New York, NY: Harper & Brothers; 1921. [Google Scholar]

- Herkert NJ, Jahnke JC, Hornbuckle KC. Emissions of tetrachlorobiphenyls (PCBs 47, 51, and 68) from polymer resin on kitchen cabinets as a non-Aroclor source to residential air.Environ. Sci. Technol. 2018; 52 (9): 5154–5160. doi: 10.1021/acs.est.8b00966. [DOI] [PMC free article] [PubMed] [Google Scholar]

- International Association of Plumbing and Mechanical Officials. 2018 Uniform Plumbing Code, UPC 1005.0. Ontario, CA. January 2018. [Google Scholar]

- International Code Council Inc. (ICC). International Residential Code, Chapter 32 Traps, IRC 3201.2. Washington, DC. September 2019; Available at https://codes.iccsafe.org/content/IRC2018P3/copyright. [Google Scholar]

- International Code Council Inc. (ICC). 2003 International Residential Code (IRC): R303-Light, Ventilation and Heating. Washington, DC. 2003; Available at https://codes.iccsafe.org/content/document/728. [Google Scholar]

- International Residential Code (IRC). Chapter 15 Exhaust Systems (M1501). Washington, D.C. 2015. [Google Scholar]

- Joosen C. Email to Andrew Whelton (Purdue University). SUBJECT: CIPP Styrene Exposure. US Forest Service. Bend, OR. November 15, 2018. [Google Scholar]

- Jørgensen R. Sorption of VOCs on material surfaces as the deciding factor when choosing a ventilation strategy. Build. Environ. 2007; 42 (5): 1913–1920. doi: 10.1016/j.buildenv.2006.03.003. [DOI] [Google Scholar]

- Kang M, Wei J, Yuan J, et al. Probable evidence of fecal aerosol transmission of SARS-CoV2 in a high-rise building. Ann. Intern. Med. 2020. doi: 10.7326/M20-0928. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lake County Public Works. Public Notice Your Sewer is Being Repaired. Lake County, IL. Access on. December 2020; Available at https://www.lakecountyil.gov/DocumentCenter/View/13497/Sample-Sewer-LiningRepair-Notice?bidId=. [Google Scholar]

- Landstra M. LS Water Utilities Releases Statement on Market Street Sewer Lining Project. Lee’s Summit Tribune. 2017; Available at https://lstribune.net/index.php/2017/08/26/ls-water-utilities-releases-statement-onmarket-street-sewer-lining-project/. [Google Scholar]

- Landstra M. LS Water Utilities Releases Statement on Market Street Sewer Lining Project. Lee’s Summit, MO. August 26, 2018; Accessed at https://lstribune.net/index.php/2017/08/26/ls-water-utilities-releases-statement-on-market-street-sewer-lining-project/. [Google Scholar]

- Langhout M. Good Hope overcoming recent water/sewer issues. The VOICE. Macomb, IL. June 16, 2016; http://www.mcdonoughvoice.com/news/20160616/good-hopeovercoming-recent-watersewer-issues. [Google Scholar]

- Linder L. Antigo family says nearby sewer repair is making them ill. WSAW-TV. Wausau, WI. October 21, 2015. [Google Scholar]

- Li X, Ra K, Nuruddin M, Sendesi SMT, Howarter JA, Youngblood JP, et al. Outdoor manufacture of UV-Cured plastic linings for storm water culvert repair: Chemical emissions and residual. Environ. Pollut. 2019; 245: 1031–1040. doi: 10.1016/j.envpol.2018.10.080. [DOI] [PubMed] [Google Scholar]

- Londer D. How to successfully install cured in place pipe (CIPP) lining. Proceedings for the Institute for Public Works Engineering Australiasa (IPWEA) Conference 2018, June 20–22. Rotorua, NZL. [Google Scholar]

- Marquand CL. Smell complaints over sewer relining work. Guernsey Press. Le Grand Bouet, St. Peter Port, GGY, September 10, 2019; Available at https://guernseypress.com/news/2019/09/10/smell-complaints-over-sewer-relining-work/. [Google Scholar]

- Matthews E, Matthews J, Alam S, Eklund S. NASSCO CIPP Emissions Phase 2: Evaluation of Air Emissions from Polyester Resin CIPP with Steam Cure. Final Report for National Association of Sewer Service Companies, Inc. (NASSCO, Inc.) Louisiana Tech University, Ruston, LA. 2020. [Google Scholar]

- Matthews JC. Large-diameter sewer rehabilitation using a fiber-reinforced cured-in-place pipe. Pract. Period. Struct. Des. Const. 2015; 20 (2): 04014031. doi: 10.1061/(ASCE)SC.1943-5576.0000231. [DOI] [Google Scholar]

- Meininghaus R, Gunnarsen L, Knudsen HN. Diffusion and sorption of volatile organic compounds in building materials− Impact on indoor air quality. Environ. Sci. Technol. 2000; 34 (15): 3101–3108. doi: 10.1021/es991291i. [DOI] [Google Scholar]

- Melnikova N, Wu J, Yang A, Orr M. Acute chemical incidents with injured first responders, 2002–2012. Disaster Med. Public Health Prep. 2018; 12 (2): 211–221. doi: 10.1017/dmp.2017.50. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Méndez C, San José J, Villafruela J, Castro F. Optimization of a hospital room by means of CFD for more efficient ventilation. Energy and Buildings 2008; 40: 849–854 [Google Scholar]

- Mitchell M. SUBJECT: FW: Hamilton Park Pavonia Street Odor, Electronic mail from Michael Mitchell to Andrew Whelton, Jersey City, NJ. August, 2020. [Google Scholar]

- Miller T. In-Field Analysis Provides Insights into the Sanitary Sewer Vapor Intrusion Pathway. Entanglement Technologies, Inc. 2021; Available at https://entanglementtech.com/wpcontent/uploads/2021/03/Entanglement_Tech-Identifying_the_Sewer_Pathway_with_AROMA-VOC.pdf. [Google Scholar]

- NASSCO, Inc. Guideline for the Safe Use and Handling of Styrene-Based Resins in Curedin-Place Pipe. Marriottsville, MD. 2020a. [Google Scholar]

- NASSCO, Inc. What’s that odor? Available at https://www.nassco.org/sites/default/files/Styrene%20Odor%20Information%20Document%2010%2022%202020.pdf. Marriottsville, MD. 2020b. [Google Scholar]

- National Fire Protection Association (NFPA). NFPA 1710. Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Career Fire Departments. Quincy, MA. 2020. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). Health Hazard Evaluations (HHEs). Washington, D.C. 2018a, Available at https://www.cdc.gov/niosh/hhe/request.html. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). Volatile organic compounds, C1 to C10, Canister method: Method 3900. In Ashley K, O’Connor PF, eds. NIOSH manual of analytical methods (NMAM®). 5th ed. Available at https://www.cdc.gov/niosh/nmam/pdf/3900.pdf. Washington, DC. 2018b. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). Health hazard evaluation report: evaluation of exposures to styrene during ultraviolet cured-in-place-pipe installation. LeBouf RF, Burns DA. Morgantown, WV: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, NIOSH HHE; Report No. 2018–0009-3334. 2019. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). NIOSH Pocket Guide to Chemical Hazards. Available at https://www.cdc.gov/niosh/npg/npgsyn-a.html. Washington, D.C. 2020. [Google Scholar]

- Najafi M, Sattler M, Schug K, Kaushal V, Iyer G. Evaluation of Potential Release of Organic Chemicals in the Steam Exhaust and Other Release Points during Pipe Rehabilitation Using the Trenchless Cured-In-Place Pipe (CIPP) Method, Final Report. Prepared for NASSCO, Inc. Marriottsville, MD. 2018. [Google Scholar]

- New York City Department of Environmental Protection. Emergency Notice to Residents. RE: W84th St – W. New York, NY. March 7, 2018. [Google Scholar]

- Nielsen KB, Hvidberg B. Remediation techniques for mitigating vapor intrusion from sewer systems to indoor air. Remed. J. 2017; 27 (3): 67–73. doi: 10.1002/rem.21520. [DOI] [Google Scholar]

- Office of Environmental Health Hazard Assessment (OEHHA). Air Toxics Hot Spots Program Risk Assessment Guidelines Part III: Technical Support Document for the Determination of Noncancer Chronic Reference Exposure Levels to solicit public comment. https://oehha.ca.gov/air/crnr/air-toxics-hot-spots-program-risk-assessment-guidelines-part-iii-1999. Sacramento, CA. 1999. [Google Scholar]

- Occupational Safety and Health Administration (OSHA). OSHA Sampling and Analytical Methods. US Department of Labor, Occupational Safety and Health Administration. Washington, DC. 1991; Available at http://www.osha.gov/dts/sltc/methods/index.html. [Google Scholar]

- Occupational Safety and Health Administration (OSHA). Permissible Exposure Limits-OSHA Annotated Table Z-2. Washington, D.C. Access on August 2020. Available at https://www.osha.gov/dsg/annotated-pels/tablez-2.html. [Google Scholar]

- Pankow JF. (1994). An absorption model of gas/particle partitioning of organic compounds in the atmosphere. Atmospheric Environment, 28(2), 185–188. doi: 10.1016/13522310(94)90093-0. [DOI] [Google Scholar]

- PBSUSA, Air Quality Summary Report Styrene Exposure Monitoring, Portland, Oregon, PBS Project 25024.006, Phase 0001. Portland, OR, August 28, 2018. [Google Scholar]

- Pennell KG, Scammell MK, McClean MD, Ames J, Weldon B, Friguglietti L, et al. Sewer gas: an indoor air source of PCE to consider during vapor intrusion investigations. Ground. Water Monit. Remed. 2013; 33 (3): 119–126. doi: 10.1111/gwmr.12021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Perera M, Walker R, Oglesby V. Ventilation rates and intercell airflow rates in a naturally ventilated office building. Proceedings of the 4th AIVC Conference Air Infiltration Reduction in Existing Buildings, 1983. [Google Scholar]

- Pittari J. Work to line old wastewater lines creates smell, but is considered safe. Picayune Item. Picayune, MS. June 2, 2015. [Google Scholar]

- Proeber D. Odors from sewer project raise concern in Bloomington neighborhood. The Pantagraph. Bloomington, IL. March 31, 2020. https://www.pantagraph.com/news/local/odors-from-sewer-project-raise-concern-in-bloomington-neighborhood/article_4129566d-a546-58be-a17d-ac569b102a37.html. [Google Scholar]

- Quantor. Development of styrene vapour during the renovation of sewer pipes, Report AK-06–006. RIVM. Amsterdam, NED, January 2006. [Google Scholar]

- Quon A. City blames smell permeating Moncton’s north end on sewer project. Global News. New Brunswick, CN. January 30, 2019. [Google Scholar]

- Ra K, Teimouri Sendesi SM, Howarter JA, Jafvert CT, Donaldson BM, Whelton AJ. Critical Review: Surface Water and Stormwater Quality Impacts of Cured In Place Pipe Repairs. J. Am. Water Works Ass. 2018; 110 (5): 15–32. doi: 10.1002/awwa.1042. [DOI] [Google Scholar]

- Ra K, Sendesi SMT, Nuruddin M, Zyaykina NN, Conkling EN, Boor BE, et al. Considerations for emission monitoring and liner analysis of thermally manufactured sewer cured-in-place-pipes (CIPP). J. Hazard. Mater. 2019; 371: 540–549. doi: 10.1016/j.jhazmat.2019.02.097. [DOI] [PubMed] [Google Scholar]

- Reichman R, Roghani M, Willett EJ, Shirazi E, Pennell KG. Air exchange rates and alternative vapor entry pathways to inform vapor intrusion exposure risk assessments. Reviews on environmental health 2017a; 32: 27–33. doi: 10.1515/reveh-2016-0039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reichman R, Shirazi E, Colliver DG, Pennell KG. US residential building air exchange rates: new perspectives to improve decision making at vapor intrusion sites. Environ. Sci. Process. Impacts. 2017b; 19 (2): 87–100. doi: 10.1039/C6EM00504G. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ripka LV. Plumbing Design and Installation. 1997; (Chapter 9): 259–275. [Google Scholar]

- Rijksinstituut voor Volksgezondheid en Milie, Netherlands National Institute for Public Health and the Environment (RIVM). Sewer renovation with stocking methods: backgrounds in the information sheet, Report Number 609021038/2006. 2006. Amsterdam, NED. [Google Scholar]

- Rulison L. Bethlehem installing new sewer lines without digging. Times Union. Albany, NY. 2016. [Google Scholar]