Abstract

Fused Deposition Modelling (FDM) is one of the additive manufacturing (AM) techniques that have emerged as the most feasible and prevalent approach for generating functional parts due to its ability to produce neat and intricate parts. FDM mainly utilises one of the widely used polymers, polylactic acid, also known as polylactide (PLA). It is an aliphatic polyester material and biocompatible thermoplastic, with the best design prospects due to its eco-friendly properties; when PLA degrades, it breaks down into water and carbon dioxide, neither of which are hazardous to the environment. However, PLA has its limitations of poor mechanical properties. Therefore, a filler reinforcement may enhance the characteristics of PLA and produce higher-quality FDM-printed parts. The processing parameters also play a significant role in the final result of the printed parts. This review aims to study and discover the properties of PLA and the optimum processing parameters. This review covers PLA in FDM, encompassing its mechanical properties, processing parameters, characterisation, and applications. A comprehensive description of FDM processing parameters is outlined as it plays a vital role in determining the quality of a printed product. In addition, PLA polymer is highly desirable for various field industrial applications such as in a medical, automobile, and electronic, given its excellent thermoplastic and biodegradability properties.

Keywords: FDM, PLA, 3D printing, Mechanical properties, Processing parameters, Applications

Introduction

The additive manufacturing (AM) concept, usually referred to as rapid prototyping (RP) and free-form fabrication, is governed by 3D printing (3DP), which describes a method of adding layers of material to create a finite object [1]. AM has recently gained attention due to its process description. In engineering, the AM technique is broadly utilised to fabricate their desired products, and any shapes could be established with Computer Aided Design (CAD) files [2]. Furthermore, biomechanical, construction, and prototyping industries use the AM concept [3, 4]. To achieve a competitive edge in the current global economic environment, designers and production engineers must deliver products rapidly to meet customer requirements. Since no tooling is required in AM, it is a highly effective way to design and construct complicated geometry while shortening the design and production cycle time at the lowest cost [5, 6]. Besides, high accuracy can be achieved in a short period by adjusting the printing process parameters [2].

Multiple AM technologies are employed for printing composites, polymers, metals and ceramics. These are powder bed fusion (PBF), binder jetting, directed energy deposition (DED), material extrusion, and material jetting [7–11], whereby all are dissimilar in terms of techniques and materials used [2, 12]. In the 1980s, the 3D printing method was mainly employed in AM, combined with different materials and applications such as mechanical engineering, computer engineering, and electronics. In addition to being one of the most influential techniques during the third industrial revolution, it is also considered a technique affecting our daily lives dramatically [13]. The reduced cost of developing a new product is an essential benefit of 3D printing. However, in the last few years, many industries have only fully utilised 3D printing for prototypes and production. Even though 3D printing entails many advantages, such as less waste, reduced costs, and automation, the uptake in the construction industry is slow and limited [3].

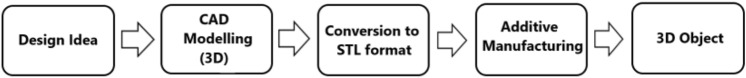

The goal of AM in today's market is to produce high-quality parts with minimal cost, high productivity, reduced lead times and safety [5]. In 3D printing, FDM is the second most popular technique after stereolithography [14]. Despite the options available for AM techniques, FDM, which builds components layer by layer using a thermoplastic filament [15], as shown in Fig. 1, has become the most practical method for producing functional parts due to its ability to create complex parts in a safe environment [4, 16, 17].

Fig. 1.

Additive manufacturing schematic diagram

This process has become a significant focus on 3D printing technology [13] due to its economical cost [4], better accuracy, dimensional stability [18], subtle fabrication method, and vast material customisation [17]. Researchers have experimented with a variety of thermoplastic filaments on the FDM platform for a variety of applications comprising acrylonitrile butadiene styrene (ABS) [19], biodegradable polylactic acid (PLA) [20], polyvinyl chloride (PVC) [21], polyamide (PA6) [15], polycarbonate (PC) [22], and many more. Amid these thermoplastic filaments, ABS and PLA are the preferred choices for FDM 3D-printed parts [23, 24]. FDM, however, offers substantial advantages over traditional manufacturing techniques because it enables rapid prototyping and on-demand production. Furthermore, FDM is the vanguard that enables redistributed production, which is crucial in lowering carbon emissions and leading to future innovative manufacturing techniques [14]. Through this method, parts made of porous materials are manufactured by layering materials [25]. The general idea behind FDM is to develop a digital design, followed by its subsequent slicing into a series of layers or laminations [14]. The filament is fed through a heated nozzle during the printing process, which squeezes out the melted material and falls onto a low-temperature printing platform. Therefore, the nozzle movements could be controlled to create the desired 3D structure by designing and programming a specific printing path. As the deposited material accumulates, a structure is built up layer by layer [26]. In addition, FDM is extensively used in various industries like aerospace [27, 28], stationary, training aid, construction [29], and medicine [14, 30, 31] due to its affordable price of printer devices and a wide variety of inexpensive filaments [13, 32].

In today's 3D printing technology (FDM), PLA is considered the most promising material and is commonly employed in many industries due to its unique properties and characteristics. As a result, most researchers have undertaken further research on the FDM 3D-printed parts, and PLA utilisation has increased yearly. This review aims to discuss the overview of PLA in FDM in terms of its properties, processing parameters, characterisation, and applications of FDM-PLA products in detail. In this paper, detailed literature research on FDM 3D-printed parts was carried out. This paper intends to provide some useful references and information for researchers in this field.

Polylactic acid thermoplastic

Plastics are classified as thermoplastics or thermosetting plastics according to their formability. As the Van der Waals forces predominantly bond polymer chains, it is possible to melt thermoplastics in more than one cycle to create the desired shapes. On the other hand, due to the crosslinking amongst chains of thermosetting plastics, they are 'set' once heated to the desired temperature, and re-heating will not restore their flow properties afterwards [33]. In addition, combining natural and synthetic polymers could produce plastics that meet the objective requirements for functional properties. Biodegradable natural plastics are partly made from renewable resources (such as starch) and could be produced either naturally or synthetically. It is primarily made up of polyester due to its potential to hydrolyse ester bonds. The polyester family is divided into two major groups: aliphatic (linear) polyesters and aromatic (aromatic rings) polyesters. In addition to PLA (polylactic acid), PCL (polycaprolactone), PHA (polyhydroxyalkanoates), PHB (polyhydroxybutyrate), PBAT (polybutylene adipate/terephthalate), PBS (polybutylene succinate), and PET (polyethene terephthalate), several biodegradable polyesters are being developed commercially [34].

Compared to other thermoplastics, PLA is low in impact toughness, decreased processing temperature, and has a relatively small processing window. The commercial PLA polymer blends generally consist predominantly of Poly(L-lactic acid) (PLLA). However, a small proportion of Poly(D-lactic acid) (PDLA) is added to lower the melting point to increase the processing window. This results in a significant reduction in crystallinity. Furthermore, PLA is also hydrophobic and has a slow decomposition rate. Due to its high strength, elastic modulus, and biodegradability, PLA is a commercially available bio-based polymer utilised in various applications [35]. PLA is used in commercial products not merely for its degradability nor because it is made from renewable resources; it is also used because it works effectively and provides excellent properties at a reasonable cost [36].

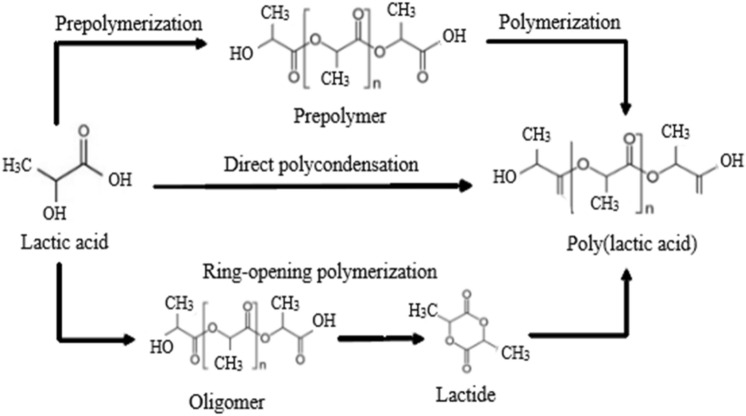

PLA is synthesised from lactic acid monomers via two distinct routes. Then, the polymer is synthesised via a direct polycondensation (DP) route or through the ring-opening polymerisation (ROP) route using a suitable catalyst [34, 35]. Figure 2 shows the two different routes for the synthesis of PLA. The direct polycondensation of lactic acid involves the dehydration of lactic acid, simultaneous esterification of the monomers, and the release of water for each added acid unit [37]. A high molar mass polymer is difficult to obtain due to the rapid reaction between water and the formed oligomers [38]. Therefore, lactide ring-opening polymerization (ROP) is widely used to synthesise PLA in the industrial sector. An ROP occurs when cyclic monomers are propagated by different types of ions [37]. Lactic acid is produced in the fermentation of corn, sugarcane, beets, and potatoes [35]. In addition, genetically modified lactic acid bacteria can produce lactic acid by fermenting glucose and sucrose [39]. Since the lactides from which PLA is ultimately derived are capable of being produced through microbial fermentation, it is a sustainable alternative to petrochemical products. Figure 3 shows the stereochemical forms of PLA in three different forms: poly (L-lactide) (PLLA), poly (D-lactide) (PDLA), and poly (DL-lactide) (PDLLA) [40].

Fig. 2.

Two different routes in the synthesis of PLA [37]

Fig. 3.

Stereochemical forms of PLA [40]

The PLA's properties are influenced by its' component isomers, annealing time, processing temperature, and molecular weight (MW) [41]. It has a lower ductility but higher strength than ABS. The printing of PLA composites resulted in an increased void content and an increase in anisotropy, similar to FDMs of ABS composites [4]. The crystallinity of polymers is one of their most important properties, indicating how much crystalline material is in the polymer compared to amorphous material [41]. Crystallinity affects several polymer properties, including hardness, tensile strength, melting point, elastic modulus, crease, and stiffness. Therefore, the most crucial consideration in selecting a polymer is its' crystallinity [36]. The PLA’s crystallinity is directly influenced by the stereochemistry and thermal history, affecting its properties generally [41]. The properties of PLA may be altered with the use of specific catalysts. These catalysts might contain isotactic or syndiotactic components with enantiomeric units that are not the same. PLA with a PLLA concentration greater than 90% is crystalline, whereas PLA with a D-isomer content greater than 10% is amorphous [33, 42]. In 3D printing, semi-crystalline thermoplastics are employed [33]. Besides that, as the PLLA amount decreases, the melting temperature (Tm) and glass transition temperature (Tg) of PLA decreases. According to Auras et al. (2011), the amorphous and crystalline PLLA had densities of 1.248 g/ml, and 1.290 g/ml, respectively. In contrast, the solid PLA had densities of 1.36 g/cm3 for L-lactide, 1.33 g/cm3 for meso-lactide, 1.36 g/cm3, and 1.25 g/cm3, respectively for crystalline and amorphous PLA [42].

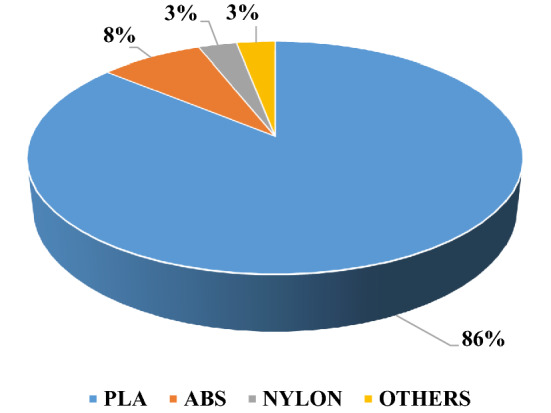

According to Fig. 4, FDM employs a variety of bases. PLA has a higher percentage (86%) than other plastics, followed by 8% for acrylonitrile butadiene styrene (ABS), nylon at 3%, and others at 3%. The others category comprises polycaprolactone (PCL), polyvinyl alcohol (PVA), and polyhydroxyalkanoates (PHA). However, due to its biocompatible and biodegradable properties, PLA often dominates all these materials as the primary base material for FDM.

Fig. 4.

Pie chart representation of the type of base materials for FDM

Benefits of PLA

PLA has several benefits. First, the material has good biocompatibility, is non-toxic and non-irritating, and could be broken down thermally by hydrolysis. Therefore, it is widely used in tissue engineering, medical sutures, and drug sustained-release materials and support [41]. The synthetic raw material is derived from renewable agricultural resources rather than petroleum. This has contributed to the improvement of the agricultural economy. It comes from harvestable crops and does not pollute the environment when it is degraded into water and carbon dioxide. Comparatively to petroleum-based commodity plastics, there is a reduction in carbon dioxide emissions due to their ability to fix considerable quantities of carbon dioxide. A key characteristic of PLA is that its physical properties can be tailored by modifying the material. The polymer is relatively stiff, with a glass transition temperature of 60–70 °C and a melting point of 170–180 °C. Therefore, in long-term use, there is no loss of plasticity or toughness [13, 43].

Properties of PLA

PLA polymers possess an essential property called crystallinity, representing the number of crystals in the polymer relative to the amorphous portions. Therefore, several properties of the polymer depend on their crystallinity, including the tensile strength, elastic modulus, creases stiffness, hardness, and melting points [44–46]. In addition, the PLA's rheological and mechanical properties are affected by its transition temperatures, which determine its density and heat capacity [47]. Table 1 shows the physical and mechanical properties of PLA. Therefore, the researchers studied the PLA properties quite extensively.

Table 1.

Physical and mechanical properties of PLA

| Characteristics | Value | Unit | References |

|---|---|---|---|

| Physical | |||

| Density | 1.21–1.25 | g/cm3 | |

| Molecular weight (Mw) | 66 | g/mol | [41, 185] |

| Glass transition temperature (Tg) | 45–60 | °C | |

| Melting temperature (Tm) | 150–162 | °C | |

| Specific gravity | 1.27 | ||

| Mechanical | |||

| Tensile strength | 28–50 | Mpa | |

| Elongation at break | 26 | % | [45, 195] |

| Young modulus | 1.2–3 | Gpa | |

| Yield strength | 70 | Mpa | [41] |

| Ultimate tensile strength | 73 | Mpa |

Several factors affect the PLA's properties, including component isomers, annealing time, processing temperature, and melting point. Stereochemistry, thermal history, and properties generally influence PLA's crystallinity. Hence, crystallinity is the most critical factor when selecting polymers for specific applications [36]. PLA that contains more than 90% PLLA is crystalline, while PLA with a lower optical purity is amorphous. Therefore, decreasing PLLA's concentration decreases PLA's melting and glass transition temperatures [48]. Generally, several chemicals, such as acetonitrile, chloroform, dioxane, dichloroacetic acid, and methylene chloride, 1,1,2-trichloroethane, are soluble in PLA products [44]. In addition to a range of alcohols such as methanol, ethanol, and propylene glycol, lactic acid-based polymers are also insoluble in unsubstituted hydrocarbons such as hexane or heptane. In ethyl acetate, acetone, and tetrahydrofuran, the crystalline PLLA is insoluble [49]. PLA could also be formulated by mixing lactide monomers with other lactone-type monomers, hydrophilic polymers such as polyethene glycol (PEG) or other monomers with functional groups of amino acids and carboxylic acids [50]. Mixed microstructure and phase interface and mechanical properties of the components are strongly correlated with the quality of the final product, which can be altered dramatically by the blending process [51].

Types of filler reinforced with PLA

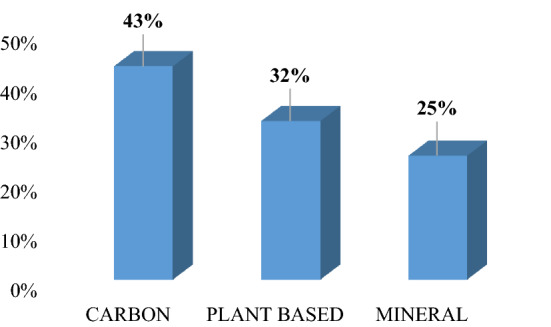

Fillers are generally mixed with polymers to reduce costs or alter the properties of polymeric compounds, such as their optical, physical, and rheological characteristics. Thus, fillers can be a cost-effective way to cut PLA costs while simultaneously improving the mechanical properties, such as the elastic modulus/stiffness at room temperature or high temperatures, particularly in PLA grades that permit high levels of crystallinity [52]. PLA-nanocomposites have been discussed and explored in a few recent publications by researchers; however, nanofillers will be referenced less frequently in the future, and the remarks will mainly focus on PLA composites, including micro fillers [53–55]. In 3D printing, filaments can be reinforced with various fillers, including carbon, plant, and mineral-based. Figure 5 shows the types of fillers that are reinforced with PLA. Based on an analysis of the three types of filler materials, the carbon-based filler has the highest percentage of being widely used by researchers at 43%, plant-based filler at 32%, and mineral-based filler at 25%. The plant-based fillers included wood particles, hydroxypropyl methylcellulose, hemp hurd, hemp fibres, carbonised cellulose nanofibers, microcrystalline cellulose (MCC), cellulose nanofibers (CNF), cellulose nanocrystal (CNC), and cork powder. Carbon-based fillers it comprised of continuous carbon fibre (CCF), short carbon fibre (SCF), carbon fibre (CF), continuous flax fibre (cFF), and carbon nanotube (CNT). Besides that, the mineral-based fillers also included hydroxyapatite, akermanite, and ceramics. Tables 2, 3, and 4 summarise the filament manufacturing method for PLA reinforced with various fillers, including plant-based fillers, carbon-based fillers, and mineral-based fillers in 3D printing.

Fig. 5.

Bar chart illustration of the type of fillers reinforced with PLA

Table 2.

Filament manufacturing method for PLA reinforced with plant-based fillers (3D printing)

| Thermoplastic | Grade | Types of filler | Material blending | Filler ratio | Filament production | Filament diameter (mm) | References |

|---|---|---|---|---|---|---|---|

| PLA | 2003D | Wood particles | Dried, compounded and pelletized | 0%, 10%, 20%, 30%, 40%, and 50% | Single screw filament Noztek-Pro Extruder | 1.75 | [23, 195, 196] |

| PLA | 4032D | Hydroxypropyl methylcellulose | Melt blending and extrusion | 1%, 3%, 5%, and 7% | Single screw extruder | 1.75 | [197] |

| PLA | – | Hemp fibres | 10% | Replicator 2 from MakerBot | 1.75 | [198–201] | |

| PLA | 4032D | Hemp hurd (HH) | Melt-compounding (13% PBAT as toughening agent) | – | Single screw extruder 3D da Vinci 1.0 Professional Printer | 1.75 | [202] |

| PLA | 4032D | Carbonized cellulose nanofibers (CCN) | CNF suspension was diluted down to 1 wt%, homogenized, spray drying | – | Single screw extruder (EX2, Filabot, Barre, VT) | 1.74 | [203–205] |

| PLA | 4043D | Microcrystalline cellulose (MCC) | Injection molding using a single-screw minijector | 5% | LulzBot TAZ 6 | – | [206–209] |

| PLA | 4032D | Cellulose nanofibers (CNF) | Solvent-mixed, thermal compounding, extrusion | 1%, 2%, and 3% | FlashForge Creator Pro (Flashforge USA) | – | [204, 210, 211] |

| PLA | 2003D | Cellulose nanocrystal (CNC) | Compounding, extrusion | 1%, 2%, 5%, and 10% | Single screw extruder Ultimaker 3.0 | 1.75 | [20, 212–215] |

| PLA | 4032D | Cork powder | Melt-mixing, compression molding (tributyl citrate (TBC) plasticizer) | 5%, 10%, 15%, 20%, 25%, 30%, and 50% | Makerbot Replicator 2 | 1.75 | [216] |

aPLA: Polylactic acid, the terms such as ‘4032D’ refers to the commercial grade of PLA

Table 3.

Filament manufacturing method for PLA reinforced with carbon-based fillers (3D printing)

| Thermoplastic | Grade | Types of filler | Material blending | Filler ratio | Filament production | Filament diameter (mm) | References |

|---|---|---|---|---|---|---|---|

| PLA | 3D850 | Continuous carbon fibre (CCF) | PLA dissolved in dichloromethane, fully dissolved using the magnetic stirrer | 20% | MeCreator 2 (Geeetech) 3D | 1.75 | [32, 217, 218] |

| PLA | 3D850 | Short carbon fibre (SCF) | PLA dissolved in dichloromethane using magnetic stirrer, impregnation process | 20% | Prusa i3 MK3S 3D printer | 1.75 | [203, 217, 219] |

| PLA | – | Carbon fibre (CF) | 15% | Ender-3 printer | 1.75 | [220–223] | |

| PLA | 3260HP | Continuous flax fibre (cFF) | extrusion, coating | – | Prusa i3 Printer | 1.75 | [224] |

| PLA | 3052D | Carbon nanotube (CNT) | Drying, double screw extruder, forming process | 2%, 4%, 6%, and 8% | Raise3D N2 Plus 3D printer | 1.75 | [115, 225, 226,] |

Table 4.

Filament manufacturing method for PLA reinforced with mineral-based fillers (3D printing)

| Thermoplastic | Grade | Types of filler | Material blending | Filler ratio | Filament production | Filament diameter (mm) | References |

|---|---|---|---|---|---|---|---|

| PLA | – | Hydroxyapatite (HA) | Solvent mixing, PLA and HA powders were dispersed in dichloromethane | 5%, 10%, and 15% | Single screw extrusion machine (Noztek Touch) | 2.85 mm | [24, 227–230] |

| PLA | 4043D | Ceramic | 40% | Creator Pro, Flashforge | 1.75 mm | [196, 231] | |

| PLA | – | Akermanite | Akermanite powder was synthesised by sol–gel method, micro-extruder | 10%, 20%, and 30% |

BORNA, DAYAN K36 P |

1.75 | [232, 233] |

Cellulose, a natural bio-based material, is abundant in nature. Their non-toxicity and eco-friendly nature have made them suitable for emerging fields such as automotive, biomedicine, electronic, structural engineering and drug delivery [56]. Numerous studies and extensive literature exist on cellulose nanofiber (CNF), microcrystalline cellulose (MCC), cellulose nanowhiskers (CNW), and cellulose nanocrystal (CNC) [57, 58] and to make PLA–cellulose nano and micro-composites, PLA is used as a matrix [59–65]. Due to their good structural reinforcement, such as lightweight, low cost, biodegradability, versatility, renewable nature, biocompatibility, excellent adaptability, and recyclable properties, the composites made of cellulose-reinforced polymers have received considerable attention [56, 66]. Using cellulose for PLA reinforcement (in the form of micro or nanofibres) is a new research field.

However, this topic has gained much attention in the past few years for its role in PLA–cellulose nanocomposites [67, 68]. The prospect of using natural fibres-reinforced polymeric materials instead of conventional fibres is capturing the attention of researchers and engineers due to its eco-friendly, low cost, and decomposability [69]. As plastics exhibit poor mechanical properties, high-strength materials (fibres) can improve their mechanical performance [69, 70]. From the industrial perspective, cellulosic fibres have the disadvantage of having a highly hydrophilic surface, which reduces the interfacial interaction of the polymer with the fibre, resulting in decreased mechanical properties [57]. PLA, however, can quickly degrade at high temperatures (300–372 °C). A study demonstrated that around 99.5% of cellulose fibres could reinforce PLA for possible applications in the automotive sector [52]. Due to its unique properties, such as high chemical and thermal stability, low density, high tensile strength, and high thermal and electrical conductivity, carbon fibres (CF) are considered reinforcing fibres for PLA [71]. In addition, PLA-reinforced CF composites are vital for applications in the biomedical field and specific engineering applications [52, 72].

Nevertheless, Thunga et al. [73] demonstrated the feasibility of converting bio-based fibres, for instance, the lignin/PLA blends, into carbon fibres (CF) [73]. Science and industry have drawn significant interest in using carbon nanotubes (CNT) and carbon black as fillers in polymer composites due to their high technological potential in many areas [74–76]. Because of their intrinsic properties, CNTs are one of the most commonly considered nanofillers for blending with many polymers, including PLA. Therefore, many reviews concerning CNTs' synthesis, structural and functional properties [76–78]. A polymeric matrix, PLA, was used to produce micro or nanocomposites containing different geometries of carbonaceous fillers [52, 55, 79]. These PLA–carbonaceous fillers exhibit enhanced nucleating, thermal, mechanical, electrical conductivity, and other properties [52, 80, 81]. Sensors that detect strain, temperature, and organic solvents could be made from electrically conductive composites [52]. Numerous studies have shown that combining different fillers can dramatically improve the PLA's specific properties. Wu et al. (2015) combined CNTs and CB to make the PLA foams more electrically conductive. Due to their higher aspect ratio, CNTs can act as 'bridges', connecting CB particles and creating a more effective network structure [80]. PLA-hydroxyapatite (HA) composites are of particular interest as they merge the osteoconductive and bone fusion properties of HA with the ease of processing and absorbability of PLA [52, 82–84]. According to Marius et al. (2016), PLA/HA composites exhibited enhanced mechanical properties and interfacial adhesion, and the bending strength was about 28%. Despite this, the mechanical strength is insufficient for the fixture of weight-bearing bones. However, carbon fibres were found to harm HA after implanting them into bone because of their outstanding biocompatibility and strength [52].

Degradation of PLA

A biodegradable polymer is a substance that, under typical environmental conditions, can be broken down by microorganisms into carbon dioxide and water [85]. Biodegradable materials, particularly polymer composites and blends, are being evaluated globally [86]. PLA is an aliphatic polyester that belongs to the class of biodegradable materials. Therefore, as PLA is hydrophilic, the degradation rate is slow [87]. In addition, different environmental conditions could cause unintended degradation of PLA-based materials [86, 88]. PLA can be broken down naturally by hydrolysing ester bonds [89]. The main benefit of using PLA is that it will decompose to water, carbon dioxide, and a small amount of non-toxic surplus material when exposed to conditions that include a combination of moisture, oxygen, and naturally existing microbes [90, 91]. PLA will deteriorate through a variety of different methods. These include photodegradation, hydrolytic, oxidative, thermal, microbiological, enzymatic, and oxidative processes [86]. PLA typically degrades via composting in 2 months at 50–60 °C [92]. Any polymer undergoing degradation will change its mechanical, optical, or electrical properties due to crazing, cracking, erosion, discolouration, or phase separation [93]. Khalid et al. (2022) investigated the degradation of recycled polymers using several recycling technology techniques. However, recycled polymers degrade and lose mechanical and thermal characteristics [94]. Additionally, by reducing the crystallinity by rapid cooling during melt processing, PLA's composting and biodegradation can be improved since enzymes can more readily target the amorphous components [95].

FDM's processing parameters for PLA (FDM-PLA)

Additive manufacturing's success depends on its ability to meet customer needs. Therefore, it is vital to select the correct parameters for the process [5]. The most researched aspects of the FDM 3D printing technique are the processing parameters [96]. Several parameters affect the mechanical performance of FDM 3D-printed parts in the design stage and during printing. For example, raster orientation and layer thickness are design parameters, whereas nozzle temperature, printing speed, filament diameter and bed temperature are process parameters [97, 98]. Kumar et al. (2020) highlighted that the FDM input parameters significantly influenced the mechanical performance of 3D-printed prototypes [23]. In addition, defects can occur during the fabrication of components using 3D printing technology, affecting the mechanical performance of the 3D-printed products [97, 99]. Therefore, a production engineer's primary concern is determining the optimal process conditions. This plays a significant role in ensuring quality, improving dimensional accuracy, avoiding unacceptable wastes, reducing scrap levels, enhancing production rates, and reducing cost and production time. However, FDM is a very complex process that poses great difficulty in determining necessary parameters because many conflicting parameters would affect the quality of the part and material properties [5]. Figure 6 shows the four parameters affecting the FDM-printed parts. According to Rahman et al. (2021), six variables might impact the quality of the FDM-printed parts nozzle temperature, print bed temperature, infill density, printing speed, and layer thickness. The experiment results indicated that the optimum value for the nozzle temperature, print bed temperature, infill density, printing speed, and layer thickness was 220 °C, 110 °C, 15%, 55 mm/s, and 0.2 mm, respectively [100].

Fig. 6.

Figurative illustration of the four parameters affecting the FDM-printed parts

Table 5 summarises the printing conditions of PLA reinforced with various types of fillers based on several findings that were conducted. The material volume printed on a specific component is the infill density. The infill density directly influenced the quality of the printed component. A less-density component has poor mechanical properties, while a denser component requires more time to produce but has superior mechanical properties [101]. It refers to printing the inner structure of the component being printed. Figure 7 shows the graphical representation of a layer height.

Table 5.

Printing conditions of PLA reinforced with various types of fillers

| Material | Layer height (mm) | Nozzle diameter (mm) | Nozzle temperature (°C) | Platform temperature (°C) | Infill density (%) | Printing speed | Raster angle (°) | infill pattern | References |

|---|---|---|---|---|---|---|---|---|---|

| PLA + Wood | 0.3 | 0.4 | 200 | 65 | 100 | 80 mm/min | 0,90,45,-45 | Linear | [195, 196, 234] |

| PLA + HPMC | 0.2 | – | 200 | 40 | 100 | 50 mm/s | 0 | Parallel | [235] |

| PLA/RPLA + MCC | 0.38 | – | 200 | 60 | 100 | 60 mm/s | 45/-45 | – | [23] |

| PLA + CCN | 0.2 | 0.4 | 220 | 70 | 100 | 2400 mm/min | 45/-45 | Rectilinear | [197] |

| PLA + CNF | 0.2 | 0.6 | 210 | 60 | 100 | 1800 mm/min | 45/-45 | Rectilinear | [236] |

| PLA + CNC | 0.2 | 0.35 | 230 | 60 | 100 | – | [212] | ||

| PLA + Cork powder | 0.4 | 0.8 | 230 | 60 | 100 | 30 mm/s | [216] | ||

| PLA + HA | 0.4 | 0.4 | 210 | 50 | – | 35/50 mm/s | – | – | [20, 203, 210, 227] |

| PLA + Akermanite | 0.4 | 0.4 | 210 | – | – | 10 mm/s | – | – | [232, 233] |

| PLA + PVC/Fe3O4 | 3.2 | – | 225 | 70 | 100 | 90 mm/s | 45 | – | [234] |

| PLA + Carbon | 0.1,0.2,0.3 | – | – | – | 65,75,85 | 60,80,100 mm/s | – | – | [237] |

| PLA + Carbon Black | 0.2 | 0.4 | 230 | 60 | 100 | 30 mm/s | 0/45/–45/90 | – | [226, 238, 239] |

| PLA + Carbon fibre | 0.1,0.2,0.3 | 0.4 | 205,215,225 | – | 40,60,80 | 60,80,100 mm/s | – | – | [240, 241] |

| PLA + CCF/SCF | 0.2,0.5 | 0.4,1.5 | 210,250 | 60,75,90 | 100 | 3.0,25 mm/s | – | Rectilinear | [218,242] |

Fig. 7.

Graphical representation of layer height [101]

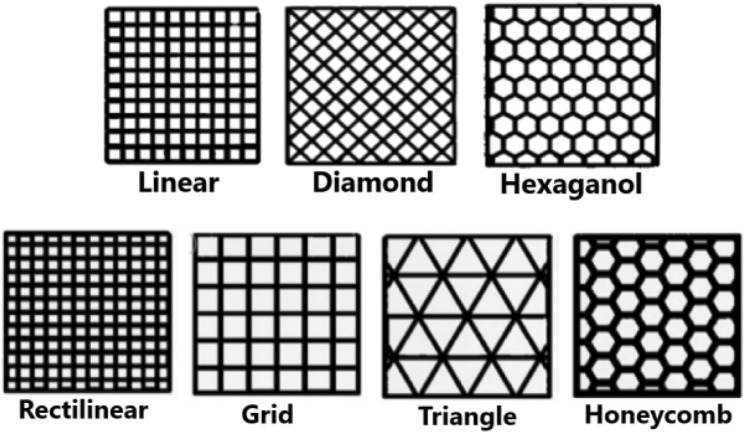

Numerous filling patterns, including hexagonal, linear, rectilinear, and diamond shapes, as shown in Fig. 8 [102].

Fig. 8.

Examples of infill patterns for FDM-printed parts [101, 103]

In FDM, the hexagonal pattern is the most widely used infill design [104]. Liseli et al. (2021) showed the importance of correlating the effect of infill patterns on mechanical properties in their experimental study. As a result, the different patterns might produce superior results concerning compressive or tensile properties. However, similar patterns might not respond the same to other types of stresses. Therefore, linking the laying pattern to the components' mechanical properties seems relevant. Hence, it might play an essential role in defining the properties of fabricated components [105]. The raster angle specifies the x-axis material deposition direction in the FDM machine along the build area, and the angle varies from 0° to 90° [106]. An experiment conducted by Wu et al. (2015) to determine the effects of raster angle (45°, 30°, and 0°) and layer thickness (40 μm, 30 μm, and 20 μm) on the mechanical properties of 3D-printed parts [107].

Nozzle temperature (°C)

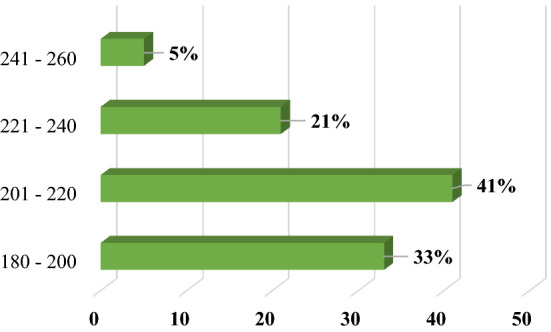

Various nozzle temperature level for printing PLA is shown in Fig. 9. The range of 201–220 °C shows the highest percentage, followed by 180–200 °C. The nozzle temperature must be higher than the melting point of the thermoplastic in order for it to flow. PLA's melting temperature and glass transition were affected by the amount of PDLA content in PLLA. The melting temperature (Tm) of PLA is 150–165 °C, the glass transition temperature (Tg) is 55–65 °C, and printing using PLA can be printed at 190–230 °C. Several factors affected the optimum printing temperature, such as the bed temperature, the surrounding temperature, printing speed and the plastic's crystallinity, and thermal properties. In a recent optimisation study, pure PLA prints were found to have the best properties at a temperature of 215 °C [100]. The influence of nozzle temperature on mechanical characteristics was investigated by Behzadnasab et al. (2016). For 3D-printed parts using a set of nozzle temperatures which were 180 °C, 200 °C, 220 °C, and 240 °C. The researchers discovered that increasing nozzle temperature to 240 °C made the PLA 3D-printed parts more durable. A typical upper-temperature limitation for 3D printing polymer materials is 240 °C. The polymer suffered degradation when the nozzle temperature exceeded this limit [108].

Fig. 9.

Bar chart representation of the various nozzle temperature level for printing PLA in which the optimal temperature recommendation is at 201–220 °C

Printing speed (mm/s)

The mechanical properties of printed objects are influenced by printing speed. Printing at high speeds can result in poor layer bonding and weaken the part's mechanical properties. Printing speed can substantially impact material cooling and melting rates, resulting in poor layer bonding [100]. Figure 10 illustrates the printing speed range recommended for PLA printing used by researchers. The highest percentage of printing speed is found between 46 and 65 mm/s, with 32%, followed by 22% between 26 and 45 mm/s. Approximately 19% lie between 5 and 25% mm/s, 12% between 66 and 85 mm/s, 11% between 86 and 105 mm/s, and 4% lie between 106 and 165 mm/s. Print speed has little impact on tensile strength but substantially impacts production costs; a low feed rate aids interlamellar bonding but reduces productivity and raises production costs. Raster angle, or the angle at which a raster or bead is deposited about the horizontal, has been shown to have a greater impact on toughness, tensile strength, and ductility [96].

Fig. 10.

Printing speed range recommended for PLA printing

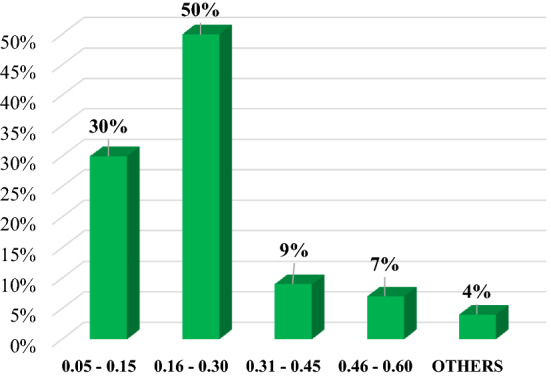

Layer height (mm)

During a single pass along the vertical axis of a FDM machine, the amount of material deposited is called layer height. Material deposition heights are always less than the diameter of the extruder's nozzle. This value solely depends on the diameter of the extruder tip [101]. Figure 11 illustrates the appropriate layer height for PLA printing that is commonly used in FDM. The graph shows that approximately 50% of the data lies between 0.16 and 0.30 mm. Around 30% range from 0.05 to 0.15 mm followed by 0.31 and 0.45 mm (9%) and 0.46–0.69 mm (7%), while the others consists of 0.61–0.9 mm (4%). In their research, Elena et al. (2019) demonstrated that layer height had an unavoidable impact on the components' bending and impact properties. They recommended a minimum layer thickness for improved bending capabilities and increasing layer thickness for better impact qualities [109]. Furthermore, to reduce the angle of a slide and surface roughness in FDM-printed components, Barrios et al. (2019) developed an orthogonal experimental design to determine suitable processing parameters such as layer height [110].

Fig. 11.

Bar chart illustration of the appropriate layer height (mm) for printing PLA

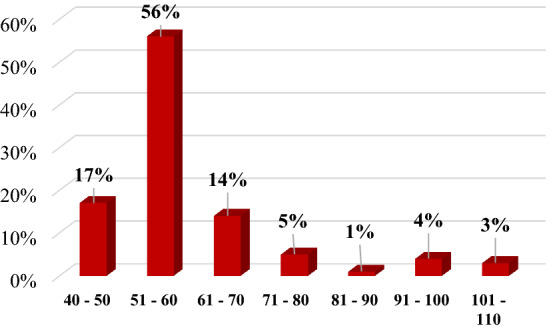

Bed temperature (°C)

For 3D printing, heated beds are required. While not all printers have them, those that do must be adjusted to a specific temperature. The ideal temperature range, for example, is 55° C to 70° C [111]. Research shows from Fig. 12 that 56% ranges from 51 to 60 °C, which is the most suitable temperature for experiments. Approximately 17% range from 40 to 50 °C is the second-highest temperature, followed by 61–70 °C (14%), 71–80 °C (5%), 91–100 °C (4%), 101–110 °C (3%) and the least is from 81 to 90 °C (1%). To prevent warping, it is vital to set the temperature of the heated bed. Heated beds improve the printing quality since they keep the plastic warm and prevent warping.

Fig. 12.

Analysis of the range of optimal bed temperature (°C) for PLA printing

Nozzle diameter (mm)

Figure 13 illustrates the ideal nozzle diameter that are frequently used for the FDM process. The top nozzle diameter range is between 0.4 mm and 0.6 mm (88%) followed by 0.7 mm to 0.9 mm (7%), and 1.0 mm to 3.0 mm (5%). There is a direct correlation between the nozzle diameter and broad width. As a result, the nozzle diameter directly impacted the liquefier's pressure drop [107]. Urner et al. (2020) established that the nozzle's length to diameter (L/D) ratio affected the pressure drop fluctuation. There is an increase in pressure drop if D (diameter) is small. It is vital to choose an optimum nozzle diameter to maintain a constant extruded material flow. Furthermore, the nozzle's diameter is shown to significantly impact the time of extrusion. The larger the diameter of the nozzle, the shorter the time it would take to complete the extrusion. In addition, it has been shown that the diameter of the nozzle greatly influenced the geometric error [16].

Fig. 13.

Bar chart showing the ideal nozzle diameter used for the FDM process

Properties of PLA–FDM

As composites are exposed to heat, it has the potential to alter the physical and chemical properties of composites dramatically. This is because the material would go through evaporation, sublimation, water absorption, and other processes affected by temperature and time. This would result in electrical, thermal, magnetic, and mechanical changes [112].

Thermal properties

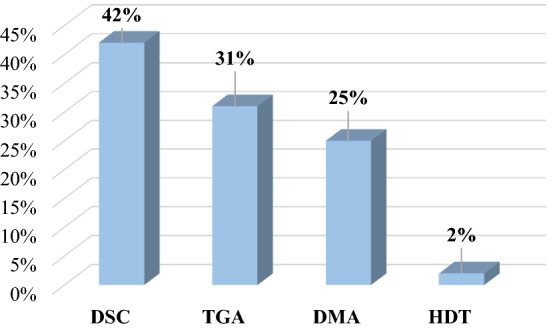

The thermal properties of PLA played a vital role in specific applications. For example, semi-crystalline or amorphous PLAs have glass transition temperatures (Tg) and melting temperatures (TMs) of about 55 °C and 180 °C, respectively. In addition, PLA might have different thermal properties depending on its composition and molecular weight (stereoisomer content) [113]. Figure 14 shows the various methods used to determine the thermal properties of PLA over the past few decades. There are several types of thermal properties analyses, such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), dynamic mechanical analysis (DMA), and heat deflection temperature (HDT). In addition, the most widely used method for analysing the thermal properties of PLA is DSC, followed by TGA, DMA and HDT.

Fig. 14.

Various methods used to determine the thermal properties of PLA

Differential scanning calorimetry (DSC)

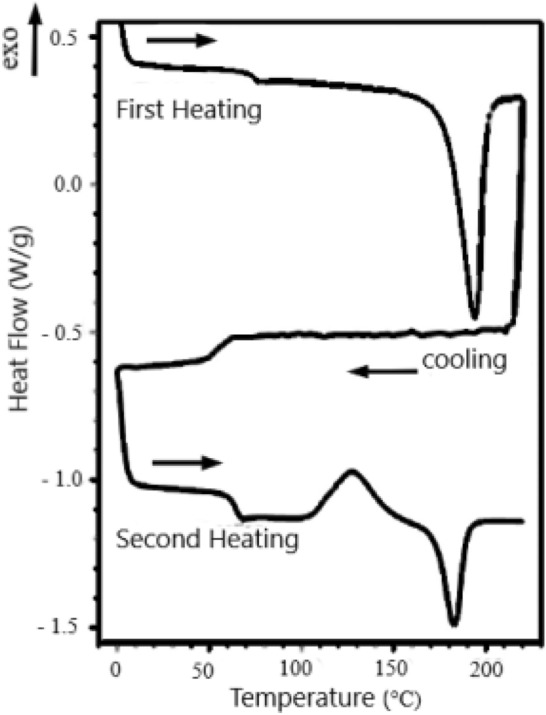

The differential scanning calorimetry (DSC) method is typically used to determine the thermal properties of polymer materials [114]. A DSC curve can quickly reveal the glass transition temperature (Tg), cold crystallisation temperature (Tcc), and melting temperature (Tm) of various samples [115]. During FDM printing, heat is transferred and is cooled several times. Therefore, knowledge of heat transfer and rheology is necessary.

Figure 15 shows thermal analysis (DSC) of PLLA. The graph explains the heat–cool–heat cycle from below glass transition temperature to the above melting point. The preparation of the material determines the temperature in the first heating range. In the second cycle, which is cooling, the material did not have sufficient time to crystallise. Therefore, its thermal history is erased. The second heating cycle depends upon the polymer's chemical structure [33]. As PLLA has a stereotypical orientation, molecular chains go through an orderly process that leads to crystallinity. The thermoplastic polymers, PLLA, exhibited extreme enthalpy with increasing temperature at glass transition, cold crystallisation, and melting. Calorimetry displayed a noticeable shift in the enthalpic baseline with increasing heat absorption. The glass transition temperature was reached when the polymer chains obtained sufficient energy to experience heightened local motion, which was manifested physically as a substantial easing in stress-induced material distortion. The second extreme was cold crystallinity when the new mobile chains were reordered, releasing heat into the environment. As the temperature was raised further, melting (third stage) occurred when the crystalline order of material was eroded by chain slippage, resulting in 100% amorphous material [107].

Fig. 15.

Thermal analysis (DSC) of PLLA [33]

The following Eq. (1) can be used to compute crystallinity (c):

| 1 |

where = percentage of crystallinity,

= the melting enthalpy,

= enthalpy of crystallisation during DSC heating test,

= weight percentage of PLA in the composite,

= melting enthalpy of 100% crystalline PLA (93.7 J/g) [104].

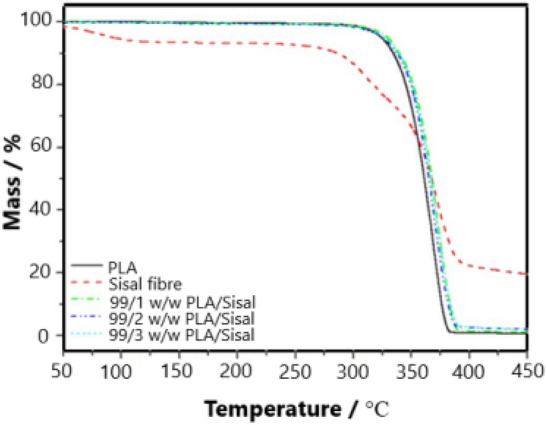

Thermogravimetric analysis (TGA)

TGA (thermogravimetric analysis) was used to study the composites' thermal stability [116, 117]. The mass of a sample was monitored while its temperature was raised in TGA. A thermogravimetric analyser conducted TGA by placing a sample on a pan. The sample's temperature was monitored by a thermocouple adjacent to it. This setup used heating coils and cooling elements in an enclosure similar to a furnace. The protective tubing prevented the sample from coming into contact with the heating coils. Gases such as nitrogen or argon, used as purge gases, flow across the sample at a specified rate. The sample mass decreased as the temperature rose, yielding a thermogram showing the sample mass change versus temperature as the sample decomposed [118]. A 3D-printed PLA-reinforced fibre can be tested for thermal stability at high temperatures using weight loss following heating in nitrogen or air. PLLA degraded at a rate of 10 °C/min to 25 °C/min in nitrogen environments with a peak degradation temperature between 340 and 360 °C. In the process of mass and heat transfer from the solid phase boundary to the interior of the material, the temperature degradation increased in proportion to the heating rate (338 °C at 10 °C/min to 357 °C at 25 °C/min) [106]. Figure 16 shows the thermogravimetric analysis of pure PLA and PLA/sisal fibre. As a result of the low fibre contents in the composites and the excellent interaction between the fibre and PLA, there was no degradation of the sisal composite [119]

Fig. 16.

TGA analysis of PLA and PLA/sisal fibre [119]

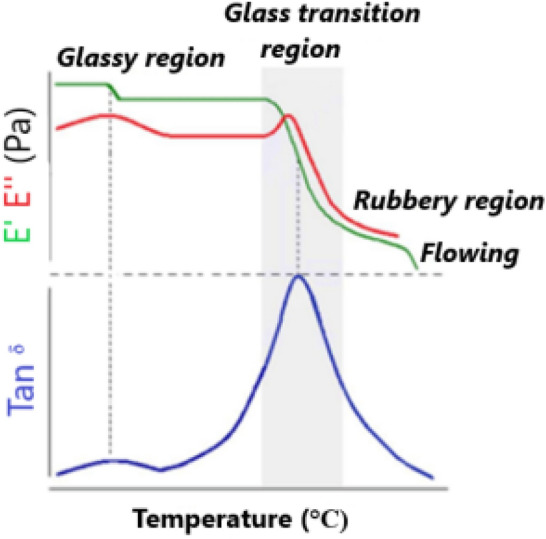

Dynamic mechanical analysis (DMA)

Dynamic mechanical analysis is a practical approach for assessing the morphology and viscoelastic properties of crystalline polymers and composite materials, as well as other vital parameters, including crosslinking density and primary relaxations [120], dynamic fragility [121], variation of viscosity with dynamic and complex properties, storage and loss compliance, creep compliance, and stress relaxation modulus with temperature [122]. A dynamic mechanical property consists of three significant properties: damping factor, loss modulus, and storage modulus. A material's storage modulus (Eʹ) measures its rigidity and energy storage capability. This method could evaluate the stiffness of composites, the degree of crosslinking, and the degree of bonding between fibres and matrix [123]. The fibre length, matrix material, matrix and fibre bonding, and loading on the fibres are all factors affecting the strength of fibres [124]. When a material is subjected to cyclic loading, its loss modulus (Eʺ) indicates how much energy dissipates. A material's loss modulus, also known as a viscous response, is in contrast to the storage modulus or called elastic response [125]. Figure 17 represents a polymer with a well-behaved pattern. This schematic diagram illustrates the viscoelastic behaviour of a thermoplastic elastomer: elastic modulus (E'), viscous modulus (E"), and loss factor (tan*) vs temperature. Viscoelastic properties could exhibit intricate patterns as a function of temperature when overlapping events occur. It is possible that PLA-derived materials were in this category significantly when PLA was modified or combined with additives to eliminate its drawbacks [126].

Fig. 17.

Diagram of viscoelastic behaviour of thermoplastic elastomer [126]

Heat deflection temperature (HDT)

In polymeric materials, heat deflection temperature is essential since it determines maximum operating temperatures. High HDT polymers can be used in fields requiring high-temperature stability, such as automotive and electrical boards [127]. According to reports, PLA's HDT is just 55 °C, significantly lower than the current petroleum-based plastics like acrylonitrile–butadiene–styrene (ABS), poly(methyl methacrylate), and others [128]. Polylactide (PLA)'s low heat deflection temperature has significantly restricted its use in high-temperature applications [129]. Benwood et al. investigated the impact strength and thermomechanical properties of PLA in FDM. It was discovered that raising the bed temperature led to a considerable rise in crystallinity, which substantially increased the thermal resistance (HDT) [130].

Mechanical properties

The mechanical properties of materials define how it behaves when subjected to various loading modes such as tensile, shear, impact, and pressure. The material properties and structural parameters include infill density, raster angle, stacking sequence, and printing orientation. Also, the manufacturing variables, for example, the extrusion temperature, nozzle speed, bed temperature, and printing speed, would determine the mechanical properties of FDM parts [14].

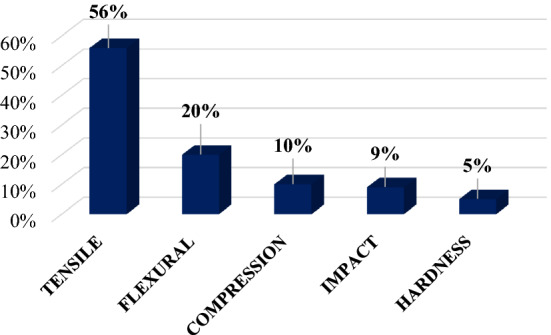

The mechanical properties of PLA for FDM are illustrated in Fig. 18. According to Fig. 18, 56% of researchers used tensile testing as the most common mechanical test. The flexural test involved bending, the second most common mechanical test (20%). The compression test was 10%, the impact test was 9%, and the toughness test was 5%. PLA outperformed the typical polymers, including polypropylene (PP), polyethene (PE), and polystyrene (PS), in terms of mechanical properties, predominantly in tensile strength, flexural strength and tensile Young's modulus.

Fig. 18.

Mechanical properties of PLA for FDM

On the other hand, PLA had lower impact strength and elongation than polyamide (PA), PE, PP, and PET. The PLA's Young's modulus and tensile strength (excellent stiffness) were equivalent to PET's. However, its poor toughness prevented its use in applications requiring plastic deformation at greater stress levels, prompting a surge of interest in PLA toughening over the last 5 years [131–133]. Oyama (2009) investigated the effects of agent content, annealing, and PLA molecular weights; high and low molecular weights on impact strength using poly (ethylene-glycidyl methacrylate) (EGMA) as a toughening agent for PLA. The PLA's impact strength might be increased by adding the agent (20%) and annealing it for 2.5 h at 90 °C [134, 135].

The characteristics of AM polymers were tested using the ASTM and ISO testing procedures. Specimens in the shape of dumbbells and flat and straight bars can be tested for tensile strength. The impact tests can be performed both on the notch and un-notch specimens. However, it is unclear whether the notch should be formed during or after printing [136]. The PLA composites reinforced with 6.6% CCF (continuous carbon fibre) outperformed pure PLA in tensile modulus and strength by 599% and 435%, respectively [137]. By varying the PLA and carbon fibre layers, Li et al. [138] synthesised composites containing short carbon fibres (100 μm–150 μm). The composite material consisting of a layer of PLA and one layer of PLA-CF (carbon fibre) exhibited the highest tensile strength of 56 MPa, which is 1.16 times greater than pure PLA [138]. Magri et al. (2021) examined the effects of FDM printing settings on the tensile characteristics of PLA composites with short fibres [107, 139]. The composite printed at 230 °C with infill lines-oriented angles of 0°/15°/−15° demonstrated the tensile strength of 36 MPa at the nozzle. This study examined the infill line orientation and the nozzle temperature for their influence. The above parameters have not been optimised for maximum tensile modulus and tensile strength.

Other factors, such as raster angle, layer thickness, and infill density, were likely to impact the tensile properties substantially [139]. Abeykoon et al. (2020) demonstrated that increasing the infill density would increase the tensile modulus of PLA material [100]. According to Cabreira et al. (2020), the 3D printing specimen's tensile strength depended greatly on the mass of the specimen. A lower infill density could make a model lighter and more effective under specific conditions. The fill pattern variables controlled the pattern filling, a printed solid made up of complicated 3D patterns [140]. The concentric pattern results in more significant tensile strengths than other patterns, regardless of the filling percentage, as studied by Akhoundi and Behravesh [141]. Because of the FDM method's fundamental nature, yield strength and Young's modulus might vary depending on the printing orientation, build plane, and layer thickness [142]. According to C. Abeykoon et al. (2020), Young's modulus for parts printed with 100% infill density was the highest. The study discovered that when the infill density dropped, the strength of the printed specimen reduced [100]. Narang et al. (2017) noted that 0° orientation gave maximum flexural and impact strength [143]. With a rise in bed temperature, Chadha et al. (2019) discovered that flexural and tensile strength increased and then declined. In addition, when layer thickness increased, the flexural and tensile strength improved [144]. Table 6 shows the effects of different types of filler on mechanical properties.

Table 6.

Effects of different types of filler on mechanical properties

| Materials | Study | Mechanical testing | Standard | Remarks | ||||

|---|---|---|---|---|---|---|---|---|

| Tensile | Flexural | Impact | Hardness | Compression | ||||

| PLA + Copper [243] | To study effect of process parameter | Flexural, Compression | ASTM D790 | ASTM D695 |

Flexural strength increases with increase of nozzle temperature As the nozzle temperature increase, there is an enhancement in the compression strength of the composite |

|||

| PLA + CCF [218] | To develop a novel extruder | Tensile, Flexural | ASTM D638, ASTM D3039 | ASTM D790 |

Increase in tensile modulus of elasticity and ultimate tensile strength about 208% and 36% compared to pure PLA Bending modulus and maximum bending strength improved about 367% and 109% |

|||

| PLA + Wood/Ceramic/Metal/Carbon Fibre [196] | To study the effects of different PLA composites | Tensile, Flexural | ASTM D638 | ASTM D790 |

Tensile and flexural properties are sensitive to filler materials Tensile and flexural modulus increased compared to virgin PLA |

|||

| PLA + HPMC [235] | Analysis of microstructure and properties of composite containing HPMC | Tensile, Flexural | GB/T1040–200 | GB/T1043–200 |

Tensile strength decrease as HPMC content increase Reduced impact strength |

|||

| PLA [218] | Investigation on mechanical properties | Tensile, Flexural, Impact, Hardness | ASTM D638 | ASTM D5943 | ASTM D256 | ASTM D785 | Hardness, ultimate tensile, impact and flexural increases at 100% infill density | |

| PLA + CF [244] | To investigate thermos-mechanical properties | Tensile, Flexural, Hardness, Impact | ASTM D638 | ASTM D790 | ASTM D256 | ASTM E384 | Tensile, flexural, hardness and impact strength increase with the increase of carbon fibre at 10%, 12% | |

Applications of FDMed-PLA

A growing number of innovative applications and innovations demonstrating FDM's great potential have emerged in recent years, illustrating enormous potential in AM's technology. FDM was recently employed as an alternative production process for manufacturing personal protective equipment (PPE), for instance, face shield and masks, during the COVID-19 pandemic [145–147]. Due to its unique ability to be a bioresorbable polymer, PLA can be used to create a wide variety of materials with biocompatible, biodegradable, and environmentally friendly properties that offer unique potential in various applications as in biomedical, packaging, medical, electronic, aerospace, and automobile sector [148]. Figure 19 shows that PLA is used mainly in medical and biomedical industries at 63%. Following this are electronic industries (16%), aerospace (8%), automobile (7%), and packaging industries (6%). In addition to serving as a surgical implant material and a drug delivery system, PLA has also been utilised to create porous scaffolds that promote tissue growth [149, 150]. PLA polymers have a wide variety of applications due to the simplicity of modifying their chemical and physical properties. A polymer can often be blended or copolymerise with other polymers and non-polymers to achieve the desired behaviour [50, 149]. Material surface properties are vital to their applications, especially in biomaterials. To create desirable surface properties on PLA biomaterials, different approaches have been developed for surface modification, including physical, chemical, plasma, and radiation-induced methods [44].

Fig. 19.

Applications of PLA in various industries

Biomedical

The study of biodegradable materials has been actively explored for medical applications during the last 2 decades due to their benefits over non-degradable biomaterials, including eliminating the need to remove implants and providing long-term biocompatibility [44]. PLA is an ideal material in biomedical applications where it can meet complex criteria, for example, biocompatibility and biodegradability [16]. PLA's employment in these applications is not exclusively due to its biodegradability or the fact that it is derived from renewable resources. However, PLA is utilised because it performs effectively and has outstanding qualities at a reasonable cost [151].

Pharmaceutical goods are frequently printed using 3D printers. Various PLA variants have been utilised to make biodegradable sutures, microparticles, nanoparticles, and scaffolds for cellular applications [44]. The low cost and free form of 3D printing make it a critical tool for individualised dose medicine. It can produce scaffolds with precise micro/nanostructures and custom shapes that are finely controlled [152–156]. 3D polymeric scaffolds as options for tissue regeneration should have hierarchical architectures and appropriate mechanical and biological qualities [157–159]. The fundamental problem of 3D printing scaffolds is increasing their mechanical characteristics while maintaining their porosity.

Furthermore, 3D printing often cannot create items with microporosity smaller than 10 μm [154]. Biodegradable polymer implants are helpful in the medical profession because they stay in the body for a short time and then degrade, requiring no additional surgery after the defect location has been fixed. In contrast, PLA fibres are preferred for long-term strength preservation applications, like ligament and tendon reconstruction and stents for vascular and urological operations [160].

Various cell types can be cultured on three-dimensional porous PLA scaffolds to treat cardiovascular disorders, muscle regeneration, bone regeneration, and other cardiovascular, neurological, and orthopaedic ailments [161–163]. Embedded embryonic stem cells mimic intramembranous and endochondral ossification when sown on scaffolds made from PLA material [164, 165]. Because of the high strength of PLLA mesh, 3D structures, for example, cages and trays, can be created [166]. Bone fixation devices are an intriguing application for which the PLA has considerable potential, as metallic fixations have significant drawbacks. Biodegradable materials have recently been used to replace metallic materials to fix shattered bones, such as plates, pins, screws, and wires. PLA has excellent applicability in this industry because bone fixation materials require high strength, like bone [44]. PLLA is used for temporary fillings in facial reconstruction surgery as injectable microspheres. In addition, PLLA microspheres have been used as an embolic material in transcatheter arterial embolization, a successful treatment for arteriovenous fistulas, malformations, severe bleeding, and malignancies [167, 168]. Figure 20 shows the tibia and femur parts printed using the FDM method.

Fig. 20.

Parts of tibia and femur printed using FDM [169]

Tissue engineering

In tissue engineering, engineering ideas and life sciences are combined to improve damaged tissues' function. An engineered tissue relies on a scaffold that can facilitate cell migration and proliferation. After scaffold disintegration, porous scaffolds directed the implanted cells to form new tissue with a well-integrated structure [170]. Therefore, scaffolds are critical components of tissue engineering [171]. The application of tissue engineering in regenerative medicine is promising. For example, in cases of critical-sized defects, bone tissue cannot regrow on its own. These significant defects can be repaired through tissue engineering, and new cells can be grown to regenerate damaged tissues [172, 173]. This is the present method of restoring the damaged bone and potentially treating certain diseases in the future [171, 174]. For example, new treatments for congenital disorders, infections, and cancer are being tested using new tissue engineering technologies [175]. Biomaterials should be cytocompatible, not elicit cytotoxic, immunogenic, or inflammatory responses [173].

Furthermore, biodegradability is essential for removing substitutes after tissue healing [176]. The most common materials used in tissue engineering are polylactic acid (PLA), polyglycolic acid (PGA), polycaprolactone (PCL), polyhydroxyalkanoates (PHA), polyhydroxybutyrate (PHB), and polyetheretherketone (PEEK) [170]. Its excellent tensile strength and melting point make PGA one of the most widely used suture materials. However, due to high hydrolysis, it was not easy to process. In addition, it may not be possible for specific tissues to regenerate properly in PGA because of their lack of mechanical strength [177]. The solubility of PCL in organic solvents makes it an ideal scaffolding material. Since PCL does not degrade as rapidly as PLA and PGA, it is suitable for long-term in-vivo experiments [178–180]. PHB is a biocompatible and non-toxic degradation product, making it an ideal scaffold material.

In contrast to other biopolymers, it is brittle, hydrophobic, has poor stiffness, and is slow to degrade [181]. The mechanical, chemical, and radiolucent properties of PEEK make it ideal as a material for orthopaedic use, as its properties closely match those of bone. However, its chemical inertness makes it challenging to attach to native tissue [182]. Therefore, soft tissue engineering uses PGA since it is entirely bioresorbable but can produce a local acidic environment [177, 181]. Compared to other biopolymers, such as PCL, PLA, and PHA have superior thermal processing capabilities [41]. Therefore, this material can be used in both in-vitro and in-vivo applications when long-term mechanical integrity is critical. However, despite PLA's benefits, it is brittle, and its implementation depends on mechanical integrity, processing capability, and controlled surface properties. Therefore, PLA is engineered to be tough, degradation resistant, hydrophilic, and chemically inert [177, 181]. Figure 21 shows the hybrid bone scaffold using FDM.

Fig. 21.

Hybrid bone scaffold using FDM process [183]

Packaging

The PLA's market continues to expand due to its use in 3D printing and existing applications in food packaging [40]. Fresh products and those whose quality is not harmed by PLA's oxygen permeability are appropriate for food packaging applications. PLA is becoming more popular as a "green" food packaging material. According to new claims, in the sphere of fresh items, thermoformed PLA containers are employed in retail marketplaces for fruits, vegetables, and salads. These PLA-packaged products have infinite commercial potential. PLA has a variable molecular weight, and in the packaging sector, only the high molecular weight polymer is used [17]. Packaging materials must prolong the product's shelf life by preventing deterioration owing to physicochemical or biological factors and maintaining or improving overall quality and safety during storage and handling.

Furthermore, the materials should biodegrade in a fair amount of time after their useful life to avoid environmental waste disposal issues. As a result, there is a growing need for biodegradable polymers derived from renewable sources as an alternative to petroleum-based polymers in packaging materials, as they can reduce pollution. For example, Fig. 22 shows the PLA bottle composting. As a result, PLA is one of the most commonly used biopolymers in the industry [184, 185].

Fig. 22.

PLA bottle composting [186]

Textile

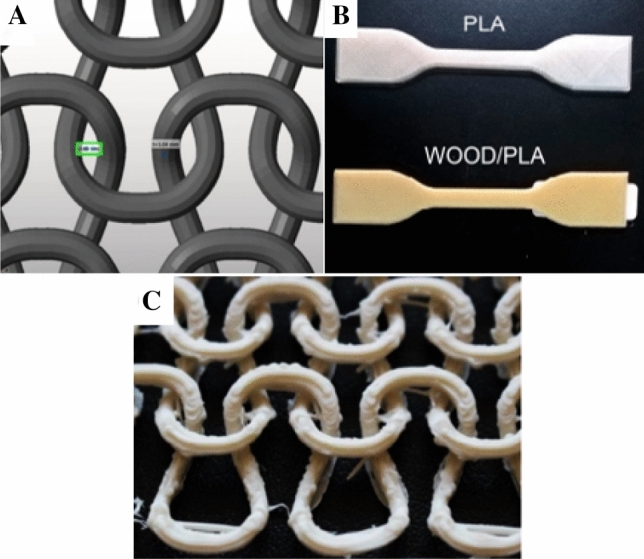

The popularity of 3D printing in the textile industry is increasing [187], whereby it is being used to fabricate a variety of gowns, shoes and other accessories [188]. In material creation in the textile sector, qualities like adhesion and stability are crucial [189]. The adhesive qualities of FDM prints on polyester fabrics and cotton exhibited outstanding properties [187]. Furthermore, the PLA composite filaments filled with wood flour were recently developed to fabricate ornaments by FDM printing [190]. Figure 23 demonstrates the single-face wet knitted fabric using the FDM method. This study demonstrated that adding WF to PLA filament improved its deformation resistance at initial deformation and reduced its degradation temperature. However, it did not affect the melting temperature.

Fig. 23.

Single-face wet knitted fabric (FDM): (A) CAD model; (B) PLA reinforced with wood flour composite; (C) Soft PLA printed using FDM [188, 190]

Current trend of polymer in FDMed-PLA

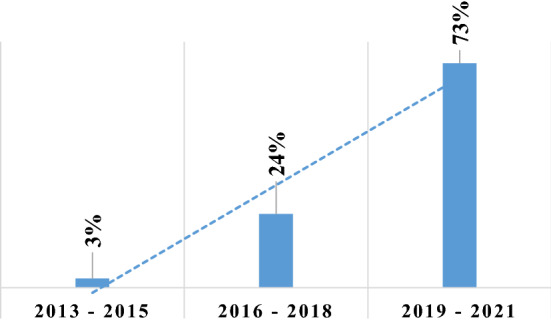

Generally, polymers are not considered the initial material types employed for fast prototyping using layer-by-layer manufacturing techniques. However, they are the most preferred and regularly utilised materials in the AM industry. This is due to the wide range of polymer-based composites available and the ease with which they may be adapted to various AM techniques. Therefore, the rise of PLA in FDM technology is expected to continue in the future years. The researchers' findings show that this AM-FDM technology continues to evolve, broaden its applications and remain affordable. Therefore, it is believed that AM-FDM would be increasingly integrated into the industrial processes and human livelihood. As shown in Fig. 24, it can be seen that the trend of PLA in FDM has been increasing from the year 2013 to 2021. The utilisation of PLA in FDM has been used by researchers widely in their studies due to its extensive and beneficial properties, especially its biodegradability, thus creating a functional application for many industries. In addition, 3D printing advances to a new level known as 4-dimensional printing (4DP) by creating "smart" materials. 4DP technology produces universal products with transformable shapes and material characteristics, recently gaining attention in the biomedical field [191–193].

Fig. 24.

Analysis of PLA usage in FDM from 2013 to 2021

Summary

The enormous potential of additive manufacturing (AM) technology has resulted in significant growth in numerous applications. Amongst the types of AM, FDM has received more attention than the other types due to its immense benefits, such as cost-effectiveness and the ability to fabricate complex geometry parts. This method uses low-cost materials and allows for the manufacture of complex patterns with high reproducibility, making it suitable for a broad range of colours, shapes, sizes, types, styles, materials, and functions. The future industrial revolution has been anticipated to be 3D printing. This review covered the current state of the art and the properties of PLA, types of fillers reinforced with PLA, printing conditions of PLA reinforced with different types of fillers, thermal and mechanical properties, and a wide range of applications. It can be stated from this study that processing parameters played an important role in deciding the end product of 3D-printed components, with variations in processing parameters causing variances in the final product's features:

-

i

Several factors contribute to the mechanical properties of 3D-printed products, including layer thickness, extruder temperature, raster angle, nozzle diameter, infill pattern, and nozzle temperature.

-

ii

Infill and nozzle diameter are crucial characteristics to consider, whereby these variables affect the porosity and pore size of FDM-printed items.

-

iii

It has been observed that FDM-printed parts significantly impact surface roughness and tensile strength depending on the infill density.

PLA's popularity in FDM technology is projected to grow exponentially in the coming years due to its unique characteristics of biodegradability, biocompatibility, and being environmentally friendly. As a result, it continues to expand its application in various fields, such as the biomedical, textile, and packaging industries. In addition, PLA composites are believed to be promising materials for bone tissue engineering and carriers capable of delivering drugs precisely where needed. In the future, PLA's functionality and physicochemical properties will be enhanced by combining fabrication technologies and composites, as well as expanding PLA as a scaffold for bone tissue engineering and drug delivery.

Acknowledgements

The authors thank Universiti Malaysia Pahang for offering laboratory facilities and financial support under the Fundamental Research Grant Scheme FRGS/1/2019/TK03/UMP/02/15 PGRS210377, PGRS210367.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Daminabo SC et al (2020) Fused deposition modeling-based additive manufacturing (3D printing): techniques for polymer material systems. Mater Today Chem 16:100248 [Google Scholar]

- 2.Dhinakaran V et al (2020) A review on recent advancements in fused deposition modeling. Mater Today 27:752–756 [Google Scholar]

- 3.Ngo TD et al (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos B 143:172–196 [Google Scholar]

- 4.Penumakala PK, Santo J, Thomas A (2020) A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos Part B 201:108336 [Google Scholar]

- 5.Mohamed OA, Masood SH, Bhowmik JL (2015) Optimization of fused deposition modeling process parameters: a review of current research and future prospects. Adv Manuf 3(1):42–53 [Google Scholar]

- 6.Mogan J et al (2021) A review of FDM and graphene-based polymer composite. IOP conference series: materials science and engineering. IOP Publishing, London [Google Scholar]

- 7.Arif ZU, Khalid MY, Rehman EU (2022) Laser-aided additive manufacturing of high entropy alloys: processes, properties, and emerging applications. J Manuf Processes 78:131–171 [Google Scholar]

- 8.Arif ZU et al (2022) Laser deposition of high-entropy alloys: a comprehensive review. Opt Laser Technol 145:107447 [Google Scholar]

- 9.Harun W et al (2018) A review of powdered additive manufacturing techniques for Ti-6al-4v biomedical applications. Powder Technol 331:74–97 [Google Scholar]

- 10.Dutta B et al (2011) Direct metal deposition. Advanced materials and processes. Springer, Berlin, p 33 [Google Scholar]

- 11.Idris MH, Sharif S, Harun WSW (2022) Evaluation of ABS patterns produced from FDM for investment casting process. WIT Trans Eng Sci 64:319–328 [Google Scholar]

- 12.Harun W et al (2009) Characteristic studies of collapsibility of ABS patterns produced from FDM for investment casting. Mater Res Innov 13(3):340–343 [Google Scholar]

- 13.Liu Z et al (2019) A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int J Adv Manuf Technol 102(9–12):2877–2889 [Google Scholar]

- 14.Cano-Vicent A et al (2021) Fused deposition modelling: current status, methodology, applications and future prospects. Addit Manuf 47:102378 [Google Scholar]

- 15.Arockiam AJ et al (2021) A review on PLA with different fillers used as a filament in 3D printing. Mater Today 50:2057–2064 [Google Scholar]

- 16.Solomon IJ, Sevvel P, Gunasekaran J (2020) A review on the various processing parameters in FDM. Mater Today 37:509–514 [Google Scholar]

- 17.Mohd-Puad NAS et al (2020) Review on the fabrication of fused deposition modelling (FDM) composite filament for biomedical applications. Mater Today 29:228–232 [Google Scholar]

- 18.Mohan N et al (2017) A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys Prototyp 12(1):47–59 [Google Scholar]

- 19.Postiglione G et al (2015) Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos A 76:110–114 [Google Scholar]

- 20.Kumar SD, Venkadeshwaran K, Aravindan M (2020) Fused deposition modelling of PLA reinforced with cellulose nano-crystals. Mater Today 33:868–875 [Google Scholar]

- 21.Sharma R (2018) Investigations for mechanical properties of Hap, PVC and PP based 3D porous structures obtained through biocompatible FDM filaments. Compos Part B

- 22.Yang J-U, Cho JH, Yoo MJ (2017) Selective metallization on copper aluminate composite via laser direct structuring technology. Compos B 110:361–367 [Google Scholar]

- 23.Kumar S et al (2021) 3D printed tensile and flexural prototypes of thermoplastic matrix reinforced with multi-materials: a statistical analysis. Mater Today 44:79–85 [Google Scholar]

- 24.Contreras-Naranjo JE et al (2021) 3D-printed hybrid-carbon-based electrodes for electroanalytical sensing applications. Electrochem Commun 130:107098 [Google Scholar]

- 25.Nkomo N et al (2017) A study of applications of 3D printing technology and potential applications in the plastic thermoforming industry. IOSR J Eng 7:16–22 [Google Scholar]

- 26.Yu Y et al (2020) Material characterization and precise finite element analysis of fiber reinforced thermoplastic composites for 4D printing. Comput Aided Des 122:102817 [Google Scholar]

- 27.Mohanavel V et al (2021) The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater Today 47:405–409 [Google Scholar]

- 28.Wickramasinghe S, Do T, Tran P (2020) FDM-based 3D printing of polymer and associated composite: a review on mechanical properties, defects and treatments. Polymers 12(7):1529 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Al-Ghamdi KA (2019) Sustainable FDM additive manufacturing of ABS components with emphasis on energy minimized and time efficient lightweight construction. Int J Lightweight Mater Manuf 2(4):338–345 [Google Scholar]

- 30.Cailleaux S et al (2021) Fused Deposition Modeling (FDM), the new asset for the production of tailored medicines. J Control Release 330:821–841 [DOI] [PubMed] [Google Scholar]

- 31.Obeid S et al (2021) Predicting drug release from diazepam FDM printed tablets using deep learning approach: Influence of process parameters and tablet surface/volume ratio. Int J Pharm 601:120507 [DOI] [PubMed] [Google Scholar]

- 32.Heidari-Rarani M, Rafiee-Afarani M, Zahedi A (2019) Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos B Eng 175:107147 [Google Scholar]

- 33.Bhagia S et al (2021) Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Appl Mater 24:101078 [Google Scholar]

- 34.Rahman MH, Bhoi PR (2021) An overview of non-biodegradable bioplastics. J Clean Prod 294:126218 [Google Scholar]

- 35.Saini P, Arora M, Kumar M (2016) Poly(lactic acid) blends in biomedical applications. Adv Drug Deliv Rev 107:47–59 [DOI] [PubMed] [Google Scholar]

- 36.Jamshidian M et al (2010) Poly-lactic acid: production, applications, nanocomposites, and release studies. Compr Rev Food Sci Food Saf 9(5):552–571 [DOI] [PubMed] [Google Scholar]

- 37.Hu Y et al (2016) Newly developed techniques on polycondensation, ring-opening polymerization and polymer modification: Focus on poly (lactic acid). Materials 9(3):133 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.de França JOC et al (2022) Polymers based on PLA from synthesis using D, L-lactic acid (or racemic lactide) and some biomedical applications: a short review. Polymers 14(12):2317 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6(25):4497–4559 [Google Scholar]

- 40.Madhavan Nampoothiri K, Nair NR, John RP (2010) An overview of the recent developments in polylactide (PLA) research. Bioresour Technol 101(22):8493–8501 [DOI] [PubMed] [Google Scholar]

- 41.Farah S, Anderson DG, Langer R (2016) Physical and mechanical properties of PLA, and their functions in widespread applications : a comprehensive review. Adv Drug Deliv Rev 107:367–392 [DOI] [PubMed] [Google Scholar]

- 42.Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4(9):835–864 [DOI] [PubMed] [Google Scholar]

- 43.Gupta B, Revagade N, Hilborn J (2007) Poly(lactic acid) fiber: an overview. Prog Polym Sci 32(4):455–482 [Google Scholar]

- 44.Lasprilla AJ et al (2012) Poly-lactic acid synthesis for application in biomedical devices - a review. Biotechnol Adv 30(1):321–328 [DOI] [PubMed] [Google Scholar]

- 45.Lopes MS, Jardini AL, Filho RM (2012) Poly (lactic acid) production for tissue engineering applications. Proced Eng 42:1402–1413 [Google Scholar]

- 46.Fraschini C et al (2005) Cracking in polylactide spherulites. J Polym Sci, Part B 43(22):3308–3315 [Google Scholar]

- 47.Henton DE et al (2005) Polylactic acid technology. Natl Fibers Biopolym Biocompos 16:527–577 [Google Scholar]

- 48.Auras RA et al (2011) Poly (lactic acid): synthesis, structures, properties, processing, and applications, 10th edn. John Wiley and Sons, London [Google Scholar]

- 49.Nampoothiri KM, Nair NR, John RP (2010) An overview of the recent developments in polylactide (PLA) research. Bioresour Technol 101(22):8493–8501 [DOI] [PubMed] [Google Scholar]

- 50.Cheng Y et al (2009) Polylactic acid (PLA) synthesis and modifications: a review. Front Chem China 4(3):259–264 [Google Scholar]

- 51.Broz M, VanderHart DL, Washburn N (2003) Structure and mechanical properties of poly (D, L-lactic acid)/poly (ε-caprolactone) blends. Biomaterials 24(23):4181–4190 [DOI] [PubMed] [Google Scholar]

- 52.Murariu M, Dubois P (2016) PLA composites: from production to properties. Adv Drug Deliv Rev 107:17–46 [DOI] [PubMed] [Google Scholar]

- 53.Bordes P, Pollet E, Averous L (2009) Nano-biocomposites: biodegradable polyester/nanoclay systems. Prog Polym Sci 34(2):125–155 [Google Scholar]

- 54.Ray SS, Okamoto M (2003) Biodegradable polylactide and its nanocomposites: opening a new dimension for plastics and composites. Macromol Rapid Commun 24(14):815–840 [Google Scholar]

- 55.Brzeziński M, Biela T (2014) Polylactide nanocomposites with functionalized carbon nanotubes and their stereocomplexes: a focused review. Mater Lett 121:244–250 [Google Scholar]

- 56.Khalid MY et al (2021) Recent advances in nanocellulose-based different biomaterials: types, properties, and emerging applications. J Market Res 14:2601–2623 [Google Scholar]

- 57.Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers 2(4):728–765 [Google Scholar]

- 58.Kalia S et al (2011) Cellulose-based bio-and nanocomposites: a review. Int J Polym Sci. 10.1155/2011/837875 [Google Scholar]

- 59.Ambrosio-Martín J et al (2015) Melt polycondensation to improve the dispersion of bacterial cellulose into polylactide via melt compounding: enhanced barrier and mechanical properties. Cellulose 22(2):1201–1226 [Google Scholar]

- 60.Jaszkiewicz A, Bledzki AK, Franciszczak P (2013) Improving the mechanical performance of PLA composites with natural, man-made cellulose and glass fibers- a comparison to PP counterparts. Polimery 58(6):435–442 [Google Scholar]

- 61.Graupner N et al (2016) Procedural influences on compression and injection moulded cellulose fibre-reinforced polylactide (PLA) composites: Influence of fibre loading, fibre length, fibre orientation and voids. Compos A 81:158–171 [Google Scholar]

- 62.Graupner N, Herrmann AS, Müssig J (2009) Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: an overview about mechanical characteristics and application areas. Compos 40(6–7):810–821 [Google Scholar]