Abstract

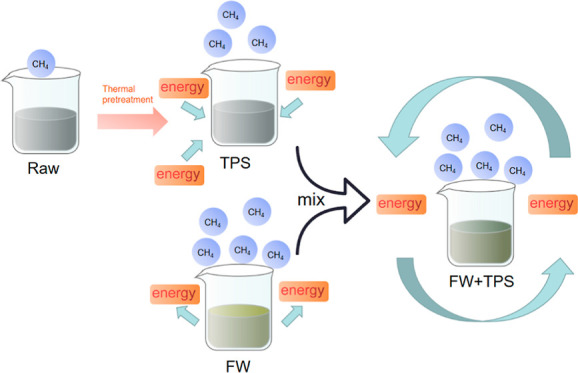

Thermal pretreatment (TP) was an effective method to improve the anaerobic digestion of waste-activated sludge. In order to balance the energy consumption of sludge TP integrated with anaerobic digestion, food waste was introduced as a co-substrate to achieve an energy self-sustainable sludge treatment system. An anaerobic biodegradability test was performed using thermal pretreated sludge and food waste in order to clarify the kinetics and mechanism of co-digestion, especially the synergetic effect on specific methane yield. The prominent synergetic effect was an initial acceleration of cumulative methane production by 20.7–23.8% observed during the first 15 days. The modified Gompertz model presented a better agreement of the experimental results, and it was a suitable tool for methane production prediction of mono- and co-digestion. The energy assessment showed that co-digestion with food waste was a sustainable solution. When the moisture content of the TP sludge was 80–90%, the energy compensation required was about 0.04–0.22 t VSFoodwaste/t VSSludge, which could maintain the integration of neutral or even positive energy between TP and anaerobic digestion.

1. Introduction

Nowadays, waste-activated sludge is globally recognized as a potential resource for renewable energy and nutrient recovery rather than an environmental liability.1 Anaerobic digestion has proven to be a reliable and economical technology of waste-activated sludge management and is considered as an essential part of modern municipal wastewater treatment plants (WWTPs) to reduce the amount of waste-activated sludge and to recover bioenergy.2,3

Hydrolysis of organic particulates known as the rate-limiting step in sludge anaerobic digestion is limited by cell wall rupture and extracellular polymeric substance degradation.4 To sidestep the bottleneck, various disintegration methods have been introduced prior to anaerobic digestion to release the readily biodegradable substrate contained in the cell.5,6 Thermal pretreatment (TP) is a temperature-dependent reaction, and the maximum methane production is reached at the reaction temperature ranging from 150 to 175 °C.7−9 Several commercial technologies, such as Cambi, Exelys (Veolia), and CTH (Aqualogy), state that TP can integrate in WWTPs with complete energy self-sufficiency.10

With the rapid industrialization and urbanization, at least 6.25 million tons of dry sludge is generated per year from over 3600 WWTPs in China, with a processing capacity of 49.43 billion m3/d, and the sludge production is expected to increase in the near future.11,12 However, the organic particulate in the sewage is removed using a septic tank and is further diluted by storm water or underground water in the pipeline. As a result, waste-activated sludge in China contains only 20–50% of organic content, much lower than that in developed countries, (70–80%).12 The shortage of organics leads directly to a low energy content in the sludge, which has a critical role in the energy generation as biogas produced in anaerobic digestion. In view of the energy balance, TP and anaerobic digestion of waste-activated sludge will stay at their infancy in China until a higher concentration of organic matter is available in the influent of WWTPs.

To solve this problem, anaerobic co-digestion (AcoD) of the high organic feedstock such as food waste (with a methane potential of 302–716 mL CH4/g VSin) is a feasible option to improve the digestion efficiency, stability, and energy benefit.13,14 Astals reported that the synergistic effect in co-digestion led to an acceleration of specific methane yield rather than a significant change in cumulative methane production. The results showed that the benefit of AcoD was enhancing not only methane production but also an acceleration of the degradation kinetics.15 The renewable energy systems (RESs) in Europe have set forward a fixed goal of supplying 20% of the European energy demands from RESs by 2020, and at least 25% of the bioenergy in the future can originate from biogas produced from wet organic materials such as animal manure, whole crop silages, wet food, feed wastes, and so on.16 America has also harnessed biogas from organic waste management since at least the 1920s, and feeding fat, oil, and grease to digesters presented better economic benefits.17

In practice, AcoD with food waste (FW) is a cost-effective alternative to improve the energy balance of sludge treatment systems. However, few studies have evaluated the synergetic effect and the energy balance of AcoD integrated with sludge TP. Liu et al. applied TP to accelerate FW solubilization before co-digestion with waste-activated sludge.18 However, Cano et al. suggested that TP had not showed remarkable effect on easily degradable substances rich in lipids and carbohydrates.19 Besides, Cuetos et al. reported the instability and inhibition in an mesophilic AcoD of thermal pretreated slaughterhouse waste (at 133 °C for 20 min) caused by long-chain fatty acid (LCFA) accumulation.20 Thus, TP of the easily biodegradable substrates prior to AcoD seems contradictory to its original intention.

Until now, the effects of TP of waste-activated sludge on methane production and kinetics parameters were widely studied,8,21−24 and the synergetic effects and mechanism of co-digestion were generally discussed.25,26 Nonetheless, the synergetic effects of co-digestion of thermal pretreated sludge (TPS) and FW need to be evaluated, and an available tool is required to assess the energy feasibility of full-scale applications and set the basis of process control.

Therefore, the primary objective of this study was to provide better insights into the synergetic effects of TPS and FW in anaerobic digestion. The modified Gompertz model and first-order model were used to analyze the experimental data and to predict the performance of co-digestion. From them, an energy assessment was performed by analysis energy consumption of the seven different solid contents of waste-activated sludge in TP to evaluate the feasibility to maintain an energy self-sustained AcoD system integrated with the sludge TP process.

2. Materials and Methods

2.1. Substrates and Inoculum

Press cake of wasted-activated sludge from the municipal WWTPs (Nanning, China), with a capacity of 4.8 × 105 m3/d using a reverse anoxic–anaerobic–aerobic process, was diluted to 10% of total solid (TS) with distilled water before homogenizing (WBL25B26, Midea Co., Ltd., China), and then the sludge slurry was stored at 4 °C.

FW from Guangxi University canteen was used in this study. Non-biodegradable material such as bones, plastic, and glass was removed manually before homogenization. FW slurry was packed in a plastic container and stored at 4 °C. FW slurry was thawed to ambient temperature before feeding.

Inoculum from a pilot-scale anaerobic digester fed with pretreated sludge was sieved through a 1 mm mesh to remove large particles Inoculum used in this test was degassed by incubation at 37 °C until no significant methane production was observed.24,26

2.2. Thermal Pretreatment

TP was conducted using an electric-heating reactor (HK-ZZ01, Hengke Instruments, China) equipped with four 1 L hydrothermal synthesis reactors inside the chamber. Homogenized sludge slurry was treated at 165 °C for 15 min. Pretreated sludge was stored at 4 °C for further analysis and tests.

2.3. Anaerobic Biodegradability Test

Anaerobic biodegradability tests were conducted to evaluate the biodegradability of the mono-substrates (pure sludge without thermal pretreatment and FW addition (WAS), TPS, and FW) and three mixtures (TPS/FW = 64%/36%, 37%/63%, and 17%/87%, named as AcoD-I, -II, and -III) in triplicate.

All the experiments were carried out with the feeding/inoculum ratio (0.5 g of VSFeed/g VSIno) suggested by Angelidaki.27 The head space of the 500 mL serum bottle, used as bench-scale digester, was flushed with nitrogen for 3 min before sealing with rubber stoppers. The digesters were immersed in a water batch at 37 ± 0.5 °C and manually mixed on a daily basis. Daily methane yield was measured by the liquid displacement method with 2% NaOH solution.28 All tests were performed in triplicate, and methane production was normalized to the volatile solid (VS) in the substrate.

Specific methane yield and cumulative methane production were calculated in VS-base. Although the so-called 1% criterion was adopted, the ultimate methane production obtained in this study was not equivalent to the biochemical methane potential of the substrate.29

2.4. Analytical Methods

In order to know the dilution factor of the sludge press cake and FW, TS and VS of all the samples were determined by heating at 105 °C for 24 h for TSs and 550 °C for 2 h for VSs. Soluble fractions of the sludge were defined by centrifuging at 8000 rpm for 20 min, and the supernatants were characterized by soluble chemical oxygen demand (SCOD), ammonia, alkalinity, and volatile fatty acids (VFAs) (Table 1). VFA was analyzed according to the five-point titration method.30 The content of ammonia nitrogen was determined by ultraviolet spectrophotometry with an NF reagent. SCOD, TS, VS, pH, and alkalinity were determined according to standard methods.31 All analyses were performed in triplicate and given as mean ± standard deviation.

Table 1. Characteristics of Raw Sludge, TPS, and FW.

| raw sludge | TPS | FW | |

|---|---|---|---|

| TS (%, ww) | 21.6 ± 0.2 | 10.0 ± 0.4 | 13.6 ± 0.2 |

| VS/TS (%) | 54.7 ± 0.3 | 52.4 ± 0.3 | 91.9 ± 0.2 |

| SCOD (mg/L) | 2870 ± 150 | 18830 ± 530 | 10750 ± 330 |

| pH | 8.2 ± 0.1 | 5.8 ± 0.1 | 4.8 ± 0.1 |

| VFA (mg/L) | 330 ± 14 | 2470 ± 210 | 1850 ± 170 |

| alkalinity (mg/L) | 645 ± 30 | 1250 ± 135 | 580 ± 23 |

| total ammonia nitrogen (mg/L) | 36 ± 7 | 415 ± 13 | 103 ± 17 |

2.5. Calculation

2.5.1. Modeling

The objective of introducing the simplified models was to obtain kinetics parameters, allowing us to compare the results and predict the methane production. The modified Gompertz model and first-order kinetics model were applied to estimate the kinetics parameter in this work, allowing reliable comparison between mono- and co-digestion. Nonlinear optimization by the least squares procedure was applied in the simulation using Matlab (R2014a).

The modified Gompertz model, next presented in eq 1, was used to describe the progression of cumulative methane production in the batch tests32

| 1 |

where M is the cumulative methane production (mL CH4/g VSin), M0 is the ultimate methane production (mL CH4/g VSin), Rmax is the ultimate specific methane production rate (mL CH4/g VSin·d), λ is the lag phase time (day), t is the digestion time (day), and e ≈ 2.718.

First-order kinetics is used to describe the hydrolysis of particulate organic matter. The progression of cumulative methane production can be described by the following equation.33

| 2 |

where M is the cumulative methane potential (mL CH4/g VSin) at digestion time t days, M0 is the ultimate methane potential of the substrate mL CH4/g VSin·d, kh is the first-order hydrolysis rate constant (d–1), and t is the digestion time (days).

2.5.2. Theoretical Methane Production

The term “methane production” can refer to cumulative methane production (mL CH4/g VSin) or specific methane yield (mL CH4/g VSin·d) in this study. If the type and the composition of the substrate are known and all the materials are converted to biogas, the theoretical methane production of the substrate can be calculated from the following equation15,34

| 3 |

where MT(t) is the theoretical methane production of the mixture fed in AcoD, MTPS and MFW are the methane production of TPS and FW in mono-substrate digestion, and p (%) is the organic fraction of pretreated sludge in the mixture.

2.5.3. Relative Deviation

The synergistic effect during co-digestion was expressed as the relative deviation of theoretical production to quantify the difference between mono-substrate digestion and co-digestion from the following equation

| 4 |

where RD (%) is the relative deviation of the experimental data and the theoretical estimation of cumulative methane production, M (mL CH4/g VSin) is the cumulative methane production of co-digestion, or its fitted value of the kinetics model, and MT (mL CH4/g VSin) is its theoretical cumulative methane production calculated by eq 3.

2.6. Energy Assessment

The cumulative methane production and specific methane yield of the substrate in a specified period were recorded by sequential batch anaerobic fermentation. The average temperature and time of TP is 170 °C and 30 min, and dehydrated sludge (TS, 16%) is added.21 The thermal hydrolysis time starts from the time when the temperature in the cooking pot reaches the predetermined temperature. Methane production expressed per ton of VS feed was used for energy assessment. The activated sludge has different moisture contents by using belt filter press and folding screw dehydrator. Seven kinds of TP sludge with different moisture contents were used to evaluate the energy gap, and the amount of kitchen waste needed to fill the energy gap was calculated. For the simplest TP scheme, the steam required for heating is generated in a boiler supplied with biogas. The energy requirement per ton of sludge (by wet weight) is 18.7 Nm3 natural gas for steam boilers, equivalent to 14.6 Nm3 methane.19 In this study, the methane consumption in the pretreatment was 16.1 Nm3 methane per ton of substrate because the direct combustion of biogas without upgrading resulted in a 10% loss of thermal efficiency.

3. Results and Discussion

3.1. Anaerobic Biodegradability Test

3.1.1. Cumulative Methane Production

Cumulative methane production of waste-activated sludge increased by 57% after pretreatment, from 197 mL of CH4/g VSin to 310 mL of CH4/g VSin. It was evidenced that TP improved the biodegradability of waste-activated sludge and unlocked its potential, unable to release in anaerobic digestion without pretreatment. Cano reported a similar result that methane production increased from 184 mL of CH4/g VSin for raw sludge to 278 mL of CH4/g VSin for the treated sludge.19 The maximum cumulative methane production (819 mL of CH4/g VSin) was obtained from FW, which was 1.64 and 3.16 times that of raw sludge and treated sludge. Considering the organic content (92.0% for FW and only 54.7% for RS), the actual multiples of cumulative methane production of FW calculated on TS basis would stretch to 7.49 and 4.95 times that for raw sludge and treated sludge, in accordance with El-Mashad35 and Zhang.36 This result suggested that FW is a reasonable co-substrate to improve the energy balance of the anaerobic digestion process integrated with TP and/or a combined heat and power system.

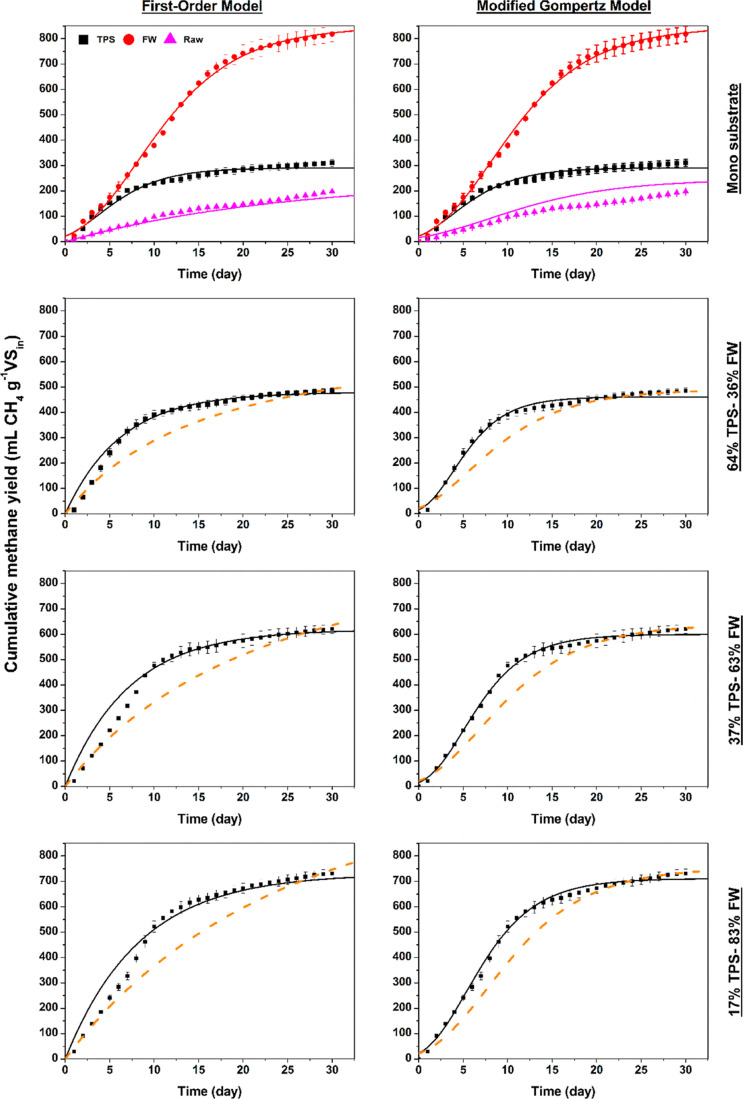

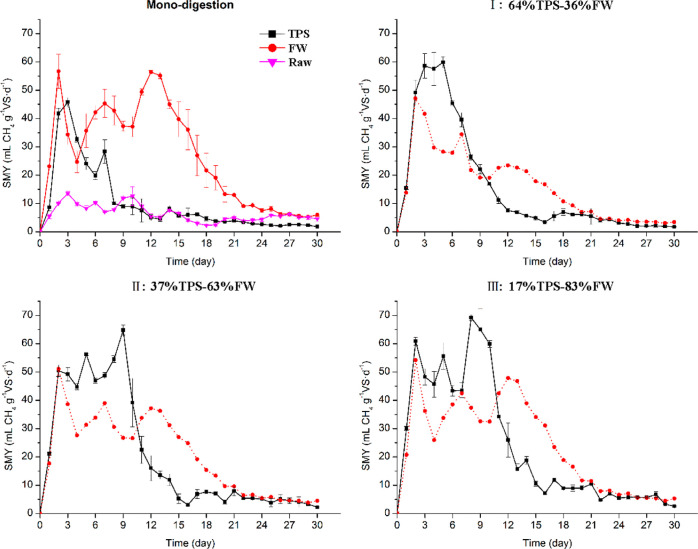

As shown in Figures 1 and 2, co-digestion exerted a greater effect on the maximum specific methane yield than cumulative methane production. Theoretical cumulative methane production of co-digestion calculated from eq 3 agreed with the experimental results (485, 621, and 731 mL of CH4/g VSin for AcoD-I, -II, and -II, respectively) at the end of the experiment. Different methane production profiles were observed; however, the deviation of the theoretical calculations in all tests fell below 10% after 15 days, the suggested solid retention time for completely mixed mesophilic digesters.37 In the end, the relative deviation was down to 1.5%, indicating that the ultimate cumulative methane production of the substrates was conserved and determined by the substrate composition. Astals also reported that the synergistic effect in co-digestion led to an acceleration of specific methane yield rather than a significant change in cumulative methane production.15

Figure 1.

Cumulative methane production in the anaerobic biodegradability tests using mono- and co-substrates. Experimental data (dotted line), model fit (solid line), and two model-base estimation (dashed line).

Figure 2.

Specific methane yield of raw sludge (Raw), TPS, and FW (experimental data, black solid line; and theoretical estimation, red dotted line).

3.1.2. Specific Methane Yield

Specific methane yield of mono-substrates (FW, TPS, and raw sludge) demonstrated the different degradation kinetics in anaerobic digestion (Figure 2). Pretreated sludge started with a rapid spike of 46 mL of CH4/g VSin·d at day 3, followed by a moderate decrease since day 8, whereas that of raw sludge remained fairly constant below 15 mL of CH4/g VSin·d throughout the experiment. The rapid methane production observed in the early phase was attributed to the liberation of the intra-cellular content from waste-activated sludge, thus providing more accessible soluble and micro-particle organics for the anaerobic microorganism. This assumption was supported by the remarkable enhancement of SCOD and VFAs due to the cell breakage and intercellular substrate leakage in accordance with Mottet et al.22 Besides the solubilization, the deflocculation of the macro-flocs structure in pretreatment provided extra surface area for microorganisms.23 The specific methane yield of FW fitted a sawtooth profile with three major peaks of 57, 45, and 56 mL of CH4/g VSin·d, at days 2, 7, and 12, suggesting that as a mixture of multi-substrate, FW would show a complex degradation behavior as the result of the combined effect of particle size distribution and chemical composition.23,38

Specific methane yields in co-digestions (solid line, black) along with their theoretical estimations (dotted line, red) calculated according to eq 3 are shown in Figure 2. By summing the specific methane yield of each substrate, the superposition of the signature curve shape was obtained. As expected, the signature three-peak curve of FW observed in mono-substrate digestion reappeared in AcoD-II and AcoD-III, which had higher weight of FW in the mixture.

However, the prominent feature of the synergistic effect of co-digestion was the acceleration of specific methane yield observed in the first 10 days for all co-digestion tests. This difference between experimental data and theoretical prediction might be associated with the inhibitory compound’s dilution. For example, LCFAs, the intermediates of lipid degradation, were known as an inhibitor for Gram-positive bacteria even at low concentrations. The toxicity of LCFAs was caused by the surface adsorption on the cell wall or cell membrane, which resulted in the malfunction of mass transfer and/or cell protection.39 In the test, the addition of TPS diluted the LCFA concentration in the digester, thus reducing the probability of inhibition, and improved the digestion efficiency.15 Due to the conservation of methane potential in co-digestion, the specific methane yield recorded in the experiment inevitably fell below its theoretical estimation after the initial quick methane production, indicating the rapid depletion of organic material.

3.2. Modeling

The results obtained in anaerobic biodegradability tests with the modified Gompertz model and first-order kinetics fine-tuning for FW, raw sludge, pretreated sludge, and the mixture are presented in Table.2 and the cumulative methane yield curves are shown in Figure 1. Parameters obtained by both models with a degree of accuracy (R2 over 0.974) enable a quantification of these kinetics improvements (Table.2).

Table 2. Experimental Data and the Kinetic Parameters Obtained with the Evaluated Models.

| experimental |

modified

Gompertz model |

first-order kinetics |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| M | Rmax | M0 | Rmax | Λ | R2 | M0 | kh | R2 | |

| substrate | mL CH4/g VSin | mL CH4/g VSin·d | mL CH4/g VSin | mL CH4/g VSin·d | D | mL CH4/g VSin | d–1 | ||

| raw sludge | 197 | 13.6 | 194 | 9.03 | 0.01 | 0.985 | 259 | 0.04 | 0.990 |

| TPS | 310 | 45.8 | 293 | 27.43 | 0.00 | 0.974 | 305 | 0.14 | 0.996 |

| 64%TPS-36%FW | 485 | 59.9 | 463 | 51.97 | 0.64 | 0.988 | 479 | 0.16 | 0.995 |

| 37%TPS-64%FW | 621 | 64.8 | 601 | 56.94 | 1.13 | 0.995 | 619 | 0.14 | 0.995 |

| 17%TPS-83%FW | 731 | 69.2 | 711 | 61.12 | 1.24 | 0.997 | 742 | 0.12 | 0.997 |

| FW | 819 | 56.7 | 846 | 50.69 | 1.86 | 0.999 | 1195 | 0.04 | 0.974 |

The modified Gompertz model uses three parameters to describe cumulative methane production: ultimate methane production (M0), ultimate specific methane yield (Rmax), and lag phase time (λ). The ultimate methane potential (M0) estimated by the modified Gompertz model generally agreed with the experimental results with a negative deviation of 1.5–6.0%. Rmax indicates the initial slope of the curve, describing the maximum daily methane production. Waste-activated sludge suffered an increase of Rmax by 204% after pretreatment, from 9.03 to 27.43 mL of CH4/g VSin·d, pointing to the deflocculation and the solubilization of sludge flocs.40 The Rmax of AcoD-II and AcoD-III were higher than that of FW, which has the highest biochemical methane potential in the test. This result could be explained by two synergetic effects as the result of the TPS addition: (1) supplying extra buffer capacity of VFAs formed in acidogenesis and acetogenesis;25 (2) the dilution of LCFAs generated in lipid degradation to reduce the risk of inoculum deactivation caused by surface absorption.41

The negligible lag time (λ) of raw sludge and TPS indicated that no significant incubation time was needed for the inoculum to start the digestion process. It is worth considering the potential inhibition caused by the metabolites of protein, grease, and lipid of FW, characterized as a readily biodegradable substrate with high methane potential.42 As shown in Table 2, a high proportion of FW in the feed would exert a negative impact on lag time, which could be explained by the depression of inoculum bioactivity caused by LCFAs even in low concentrations.39

For the first-order model, the apparent hydrolysis constant (kh) is the reciprocal of time when half of the ultimate methane production was achieved. In the case of the TP effect, the initial kinetics acceleration of waste-activated sludge (kh increased from 0.04 d–1 to 0.14 d–1) demonstrated the different degradation kinetics of the particulate organic matter and the soluble organic matter, which coincided with the increment of SCOD and VFAs. The hydrolysis constant did not show a clear correlation with the substrate composition like it did with cumulative methane production. However, the comparison between the hydrolysis constant of FW and AcoD-III (17%TPS-83%FW) highlighted the synergetic effect of AcoD, wherein the degradation rate of FW was apparently enhanced by the addition of pretreated sludge (Table 2). As previously discussed, the high proportion of FW fed in the co-digestion would cause temporary inhibitory effects by LCFA absorption and/or VFA accumulation, thus suppressing the bioactivity of the inoculum and slowing down the specific methane yield.

According to the square deviation (Table 2), both models seemed to give a better estimation of cumulative methane production in most cases, and similar results were obtained by Donoso-Bravo;43 however, the cumulative methane productions of raw sludge and FW were obviously distorted by first-order kinetics in this study. Referring to the lag phase in the modified Gompertz model, the both substrates were slowly biodegradable, which means that they required a longer digestion period to obtain a satisfactory estimation by first-order kinetics. Besides, the modified Gompertz model was superior to the first-order model in describing the curve shape of cumulative methane production, as it can be seen in Figure 1 (solid, line). Up to this point, the comparison between the models was still inconclusive, and more quantitative evidence was necessary to preform further assessment.

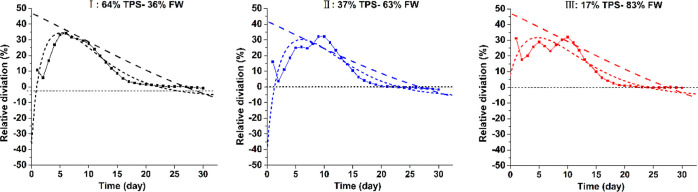

3.3. Synergetic Effect Assessment

Supposing there was no interaction between TPS and FW, the RD value shall be null in co-digestion tests. However, before the materials were fully converted, the deviation on the prediction of cumulative methane production reflects the interaction between pretreated sludge and FW in co-digestion. Therefore, the relative deviation of the theoretical estimation was used to quantify the synergetic effect between the co-substrates. According to the experimental results, the synergic effects was 10.7, 16.0, and 31.2% of improvement for AcoD-I, -II, and -III at the very beginning (Figure 3, solid line). During the first 15 days, the AcoD tests obtained a remarkable increment of cumulative methane production from 20.7 to 23.8%. However, with the depletion of the substrate, the synergetic effect faded away as the co-digestion proceeded, declining from approximately 10% at day 15 to below 1.5% by the end of the experiment. It was interesting to highlight that a small amount of thermal pretreat sludge in AcoD-III would remarkably improve the performance of FW digestion, which might relate to the dilution of the inhabitant previously discussed. In addition, no antagonistic effect was detected in trails of all tested blending ratios.

Figure 3.

Relative deviation of theoretical methane production obtained with experimental data (solid line), reaction curve model (dotted line), and the first-order kinetics (dashed line).

For a full-scale biogas plant, it is essential to predict the cumulative methane production based on the amount and the composition of the substrates. Theoretically, this estimation could be calculated from eq 3 based on the kinetics model of each substrate. In this case, the accuracy of the estimation depends on the kinetic models. Owing to the fact that the first-order model overestimated the cumulative methane production of FW by 46%, its model-based predictions generated non-negligible relative deviations of 29, 39, and 43% for AcoD-I, -II, and -III, respectively. On the contrary, the relative deviation of the prediction of the modified Gompertz model was below 3%. That is to say that the modified Gompertz model was superior to the first-order model in predicting the cumulative methane production in co-digestion.

On the other hand, the progress of substrate degradation shall be predicted to reckon the response of the digester to the feeding regime, including the amount and composition of feedstock. Thus, a reasonable model would not merely give the result of the process but also depict the progress of the process. According to this criterion, a comparison was conducted as shown in Figure 3 to quantify the ability of the models on the prediction of AcoD progress. The relative deviation of the modified Gompertz model (dotted line) was in line with the curve of the experimental data (solid line), sketching out the rapid growth and the gradual decline of the relative deviation. However, the first-order model (dashed line) cannot describe the progress of the synergetic effect in co-digestion. Thus, the modified Gompertz model is superior to the first-order model to express the interaction of the substrates in the co-digestion process.

3.4. Energy Assessment

Energy requirement for TP expressed per ton of substrate is converted to per ton of VS in this assessment. Table 3 shows the main results for raw sludge with different solid contents. First, it was remarkable that the performance of sludge dewatering greatly played a crucial role in reducing the overall energy cost, and the net benefit of TP in methane production was a constant for a certain substrate. From the findings presented, it was obvious that incorporating TP resulted in a loss of net energy output, which was an undesirable result for the waste management enterprise relying on the energy revenues. However, TP could only balance its energy cost with a solid content of 26%, beyond the range in any full-scale system.44 This conclusion indicated that other feedstock shall be introduced in this system to improve its energy balance. Therefore, FW was introduced as a co-substrate to enhance the energy production and economic performances of the waste-activated sludge management system, and the results were optimistic that a small fraction of FW in feedstock would neutralize the extra energy demand of TP.

Table 3. Energy Assessment of Anaerobic Co-Digestion Integrated with Sludge TP.

| TS

of feeding sludge, % |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| process | parameter | unit | 10% | 12% | 14% | 16% | 18% | 20% | 26% |

| TP | energy demand | Nm3/t VSFeed | 294.3 | 245.3 | 210.2 | 184.0 | 163.5 | 147.2 | 113.0 |

| anaerobic digestion | net benefita | Nm3/t VSFeed | 113 | 113 | 113 | 113 | 113 | 113 | 113 |

| energy gap | Nm3/t VSFeed | –181.3 | –132.3 | –97.2 | –71.0 | –50.5 | –34.2 | 0.0 | |

| AcoD | FW | Nm3/t VSFeed | 819 | 819 | 819 | 819 | 819 | 819 | 819 |

| blend ratio | t VSFoodwaste/t VSSludge | 0.22 | 0.16 | 0.12 | 0.09 | 0.06 | 0.04 | ||

The extrapolation from the batch tests and the theoretical balance describes the prospect of a sustainable organic solid waste management system by upgrading the existing sludge digestion facilities or the new designed plants integrated with TP process.

4. Conclusions

TP led to an increase of cumulative methane production by 57%, equivalent to a net energy benefit of 113 Nm3/t VSFeed and kinetics acceleration. The dominant synergetic effect of co-digestion was the acceleration of methane production observed at the early phase, measured with relative deviation by up to 20.7–23.8%.

Both the modified Gompertz model and the first-order kinetics model were capable of evaluating the ultimate cumulative methane production according to the composition of the feedstock. However, the modified Gompertz model provided a more reliable prediction of methane production throughout AcoD owing to its kinetics parameters (lag phase, λ) that enable to fine tune the fitting of the lag phase and synergetic effect witnessed at the start.

The energy balance of the integration of TP and anaerobic digestion was dependent on the methane production of the substrates and the performance of sludge dewatering. FW was highlighted in the energy assessment as an appropriate cosubstrate in co-digestion to improve the energy benefit, especially to neutralize the energy demand in TP. The conclusions in this study shall be verified in continuous experiments before using as a reference in full-scale application to identify the long-term effects of FW on digestion stability.

Acknowledgments

The authors want to thank China Postdoctoral Science Foundation (2019M663869XB), Guangxi Ba-Gui Scholars Program (2019A33), and Guangxi Natural Science Foundation (2019GXNSFAA185019) for the financial support to this research.

The authors declare no competing financial interest.

References

- Cieślik B. M.; Namieśnik J.; Konieczka P. Review of sewage sludge management: standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. 10.1016/j.jclepro.2014.11.031. [DOI] [Google Scholar]

- Appels L.; Baeyens J.; Degrève J.; Dewil R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. 10.1016/j.pecs.2008.06.002. [DOI] [Google Scholar]

- Kelessidis A.; Stasinakis A. S. Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag. 2012, 32, 1186–1195. 10.1016/j.wasman.2012.01.012. [DOI] [PubMed] [Google Scholar]

- Eastman J. A.; Ferguson J. F. Solubilization of particulate organic carbon during the acid phase of anaerobic digestion. J. Water Pollut. Control Fed. 1981, 53, 352–366. [Google Scholar]

- Camacho P.; Deleris S.; Geaugey V.; Ginestet P.; Paul E. A comparative study between mechanical, thermal and oxidative disintegration techniques of waste activated sludge. Water Sci. Technol. 2002, 46, 79–87. 10.2166/wst.2002.0295. [DOI] [PubMed] [Google Scholar]

- Carrère H.; Dumas C.; Battimelli A.; Batstone D. J.; Delgenès J. P.; Steyer J.-P.; Ferrer I. Pretreatment methods to improve sludge anaerobic degradability: a review. J. Hazard. Mater. 2010, 183, 1–15. 10.1016/j.jhazmat.2010.06.129. [DOI] [PubMed] [Google Scholar]

- Bougrier C.; Delgenès J. P.; Carrère H. Effects of thermal treatments on five different waste activated sludge samples solubilisation, physical properties and anaerobic digestion. Chem. Eng. J. 2008, 139, 236–244. 10.1016/j.cej.2007.07.099. [DOI] [Google Scholar]

- Haug R. T.; Stuckey D. C.; Gossett J. M.; McCarty P. L. Effect of thermal pretreatment on digestibility and dewaterability of organic sludges. J. Water Pollut. Control Fed. 1978, 50, 73–85. [Google Scholar]

- Li Y.-Y.; Noike T. Upgrading of anaerobic digestion of waste activated sludge by thermal pretreatment. Water Sci. Technol. 1992, 26, 857–866. 10.2166/wst.1992.0466. [DOI] [Google Scholar]

- Cano R.; Pérez-Elvira S. I.; Fdz-Polanco F. Energy feasibility study of sludge pretreatments: A review. Appl. Energy 2015, 149, 176–185. 10.1016/j.apenergy.2015.03.132. [DOI] [Google Scholar]

- PRC MEP . National Bulletin of Environment Statistics (2014): Beijing, PR China, 2015.

- Yang G.; Zhang G.; Wang H. Current state of sludge production, management, treatment and disposal in China. Water Res. 2015, 78, 60–73. 10.1016/j.watres.2015.04.002. [DOI] [PubMed] [Google Scholar]

- Koch K.; Helmreich B.; Drewes J. E. Co-digestion of food waste in municipal wastewater treatment plants: effect of different mixtures on methane yield and hydrolysis rate constant. Appl. Energy 2015, 137, 250–255. 10.1016/j.apenergy.2014.10.025. [DOI] [Google Scholar]

- Kondusamy D.; Kalamdhad A. S. Pre-treatment and anaerobic digestion of food waste for high rate methane production - A review. J. Environ. Chem. Eng. 2014, 2, 1821–1830. 10.1016/j.jece.2014.07.024. [DOI] [Google Scholar]

- Astals S.; Batstone D. J.; Mata-Alvarez J.; Jensen P. D. Identification of synergistic impacts during anaerobic co-digestion of organic wastes. Bioresour. Technol. 2014, 169, 421–427. 10.1016/j.biortech.2014.07.024. [DOI] [PubMed] [Google Scholar]

- Holm-Nielsen J. B.; Al Seadi T.; Oleskowicz-Popiel P. The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 2009, 100, 5478–5484. 10.1016/j.biortech.2008.12.046. [DOI] [PubMed] [Google Scholar]

- EPA . Food Waste to Energy How Six Water Resource Recovery Facilities are Boosting Biogas Production and the Bottom Line, 2014; p 51. [Google Scholar]

- Liu Y.; Li X.; Kang X. Effect of volume ratio on anaerobic co-digestion of thermal hydrolysis of food waste with activated sludge. Int. Biodeterior. Biodegrad. 2015, 102, 154–158. 10.1016/j.ibiod.2015.02.015. [DOI] [Google Scholar]

- Cano R.; Nielfa A.; Fdz-Polanco M. Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: Energy and economic feasibility study. Bioresour. Technol. 2014, 168, 14–22. 10.1016/j.biortech.2014.02.007. [DOI] [PubMed] [Google Scholar]

- Cuetos M. J.; Gómez X.; Otero M.; Morán A. Anaerobic digestion and co-digestion of slaughterhouse waste (SHW): Influence of heat and pressure pre-treatment in biogas yield. Waste Manag. 2010, 30, 1780–1789. 10.1016/j.wasman.2010.01.034. [DOI] [PubMed] [Google Scholar]

- Kepp U.; Machenbach I.; Weisz N.; Solheim O. E. Enhanced stabilisation of sewage sludge through thermal hydrolysis - three years of experience with full scale plant. Water Sci. Technol. 2000, 42, 89–96. 10.2166/wst.2000.0178. [DOI] [Google Scholar]

- Mottet A.; Steyer J.-P.; Déléris S.; Vedrenne F.; Chauzy J.; Carrère H. Kinetics of thermophilic batch anaerobic digestion of thermal hydrolysed waste activated sludge. Biochem. Eng. J. 2009, 46, 169–175. 10.1016/j.bej.2009.05.003. [DOI] [Google Scholar]

- Prorot A.; Julien L.; Christophe D.; Patrick L. Sludge disintegration during heat treatment at low temperature: A better understanding of involved mechanisms with a multiparametric approach. Biochem. Eng. J. 2011, 54, 178–184. 10.1016/j.bej.2011.02.016. [DOI] [Google Scholar]

- Shiguang L.; Jian Z.; Shuangfei W.; Huan Z.; Yiming H.; Yongxin Z. Pilot-scale study on thermal hydrolysis and anaerobic digestion of excess sludge. Chin. J. Environ. Eng. 2015, 9, 431–435. 10.12030/j.cjee.20150171. [DOI] [Google Scholar]

- Angelidaki I.; Ahring B. K. Codigestion of olive oil mill wastewaters with manure, household waste or sewage sludge. Biodegradation 1997, 8, 221–226. 10.1023/a:1008284527096. [DOI] [Google Scholar]

- Elbeshbishy E.; Nakhla G.; Hafez H. Biochemical methane potential (BMP) of food waste and primary sludge: influence of inoculum pre-incubation and inoculum source. Bioresour. Technol. 2012, 110, 18–25. 10.1016/j.biortech.2012.01.025. [DOI] [PubMed] [Google Scholar]

- Angelidaki I.; Alves M.; Bolzonella D.; Borzacconi L.; Campos J.; Guwy A.; Kalyuzhnyi S.; Jenicek P.; van Lier J. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934. 10.2166/wst.2009.040. [DOI] [PubMed] [Google Scholar]

- Esposito G.; Frunzo L.; Liotta F.; Panico A.; Pirozzi F. Bio-methane potential tests to measure the biogas production from the digestion and co-digestion of complex organic substrates. Open Environ. Eng. J. 2012, 5, 1. 10.2174/1874829501205010001. [DOI] [Google Scholar]

- VDI . 4630: Fermentation of organic materials, characterisation of the substrate, sampling, collection of material data, fermentation tests. VDI Handbuch Energietechnik; Verein Deutscher Ingenieure (VDI). Berlin: Beuth Verlag GmbH, 2006; pp 44–59. [Google Scholar]

- Lahav O.; Morgan B. Titration methodologies for monitoring of anaerobic digestion in developing countries?a review. J. Chem. Technol. Biotechnol. 2004, 79, 1331–1341. 10.1002/jctb.1143. [DOI] [Google Scholar]

- APHA . Standard Methods for the Examination of Water and Wastewater, 18th ed.: Washington, DC, USA, 1998. [Google Scholar]

- Lay J.-J.; Li Y.-Y.; Noike T. Influences of pH and moisture content on the methane production in high-solids sludge digestion. Water Res. 1997, 31, 1518–1524. 10.1016/s0043-1354(96)00413-7. [DOI] [Google Scholar]

- Veeken A.; Hamelers B. Effect of temperature on hydrolysis rates of selected biowaste components. Bioresour. Technol. 1999, 69, 249–254. 10.1016/s0960-8524(98)00188-6. [DOI] [Google Scholar]

- Angelidaki I.; Sanders W. Assessment of the anaerobic biodegradability of macropollutants. Rev. Environ. Sci. Biotechnol. 2004, 3, 117–129. 10.1007/s11157-004-2502-3. [DOI] [Google Scholar]

- El-Mashad H. M.; Zhang R. Biogas production from co-digestion of dairy manure and food waste. Bioresour. Technol. 2010, 101, 4021–4028. 10.1016/j.biortech.2010.01.027. [DOI] [PubMed] [Google Scholar]

- Zhang C.; Su H.; Tan T. Batch and semi-continuous anaerobic digestion of food waste in a dual solid–liquid system. Bioresour. Technol. 2013, 145, 10. 10.1016/j.biortech.2013.03.030. [DOI] [PubMed] [Google Scholar]

- Bolzonella D.; Pavan P.; Battistoni P.; Cecchi F. Mesophilic anaerobic digestion of waste activated sludge: influence of the solid retention time in the wastewater treatment process. Process Biochem. 2005, 40, 1453–1460. 10.1016/j.procbio.2004.06.036. [DOI] [Google Scholar]

- Pavlostathis S.; Giraldo-Gomez E. Kinetics of anaerobic treatment: a critical review. Crit. Rev. Environ. Sci. Technol. 1991, 21, 411–490. 10.1080/10643389109388424. [DOI] [Google Scholar]

- Chen Y.; Cheng J. J.; Creamer K. S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. 10.1016/j.biortech.2007.01.057. [DOI] [PubMed] [Google Scholar]

- Donoso-Bravo A.; Pérez-Elvira S.; Aymerich E.; Fdz-Polanco F. Assessment of the influence of thermal pre-treatment time on the macromolecular composition and anaerobic biodegradability of sewage sludge. Bioresour. Technol. 2011, 102, 660–666. 10.1016/j.biortech.2010.08.035. [DOI] [PubMed] [Google Scholar]

- Palatsi J.; Laureni M.; Andrés M. V.; Flotats X.; Nielsen H. B.; Angelidaki I. Strategies for recovering inhibition caused by long chain fatty acids on anaerobic thermophilic biogas reactors. Bioresour. Technol. 2009, 100, 4588–4596. 10.1016/j.biortech.2009.04.046. [DOI] [PubMed] [Google Scholar]

- Alves M.; Mota Vieira J. M.; Álvares Pereira R. Á.; Pereira M.; Mota M. Effects of lipids and oleic acid on biomass development in anaerobic fixed-bed reactors. Part II: Oleic acid toxicity and biodegradability. Water Res. 2001, 35, 264–270. 10.1016/s0043-1354(00)00242-6. [DOI] [PubMed] [Google Scholar]

- Donoso-Bravo A.; Pérez-Elvira S. I.; Fdz-Polanco F. Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem. Eng. J. 2010, 160, 607–614. 10.1016/j.cej.2010.03.082. [DOI] [Google Scholar]

- Abu-Orf M.; Goss T. Comparing Thermal Hydrolysis Processes (CAMBI and EXELYS) For Solids Pretreatmet Prior To Anaerobic Digestion. Proc. Water Environ. Fed. 2012, 2012, 1024–1036. 10.2175/193864712811693272. [DOI] [Google Scholar]