Abstract

Introducing new materials with low cost and superior solar harvesting efficiency requires urgent attention to solve energy and environmental challenges. Titanium carbide (Ti3C2Tx) MXene, a 2D layered material, is a promising solution to solve the issues of existing materials due to their promising conductivity with low cost to function as a cocatalyst/support. On the other hand, metal–organic frameworks (MOFs) are emerging materials due to their high surface area and semiconducting characteristics. Therefore, coupling them would be promising to form composites with higher solar harvesting efficiency. Thus, the main objective of this work to disclose recent development in Ti3C2Tx-based MOF nanocomposites for energy conversion applications to produce renewable fuels. MOFs can generate photoinduced electron/hole pairs, followed by transfer of electrons to MXenes through Schottky junctions for photoredox reactions. Currently, the principles, fundamentals, and mechanism of photocatalytic systems with construction of Schottky junctions are critically discussed. Then the basics of MOFs are discussed thoroughly in terms of their physical properties, morphologies, optical properties, and derivatives. The synthesis of Ti3C2Tx MXenes and their composites with the formation of surface functionals is systematically illustrated. Next, critical discussions are conducted on design considerations and strategies to engineer the morphology of Ti3C2Tx MXenes and MOFs. The interfacial/heterojunction modification strategies of Ti3C2Tx MXenes and MOFs are then deeply discussed to understand the roles of both materials. Following that, the applications of MXene-mediated MOF nanotextures in view of CO2 reduction and water splitting for solar fuel production are critically analyzed. Finally, the challenges and a perspective toward the future research of MXene-based MOF composites are disclosed.

1. Introduction

In the modern age, the major issues faced by mankind is the energy crisis and the rapid depletion of fossil fuels. There is a growing urgency to look for alternative fuels and energy sources to partially fulfill the increasing energy demand. Thus, researchers are devoted to discovering sustainable technologies to overcome the energy crisis.1,2 For instance, renewable energy production such as steam reforming for H2 energy production3 and CO2 hydrogenation reactions4 to produce fuels such as hydrocarbons or alcohols are mature technologies that have already reached commercial scale operations. However, these approaches are highly energy-intensive as they require high thermal energy input to initiate the reactions. In turn, photocatalytic H2 production and CO2 reduction are emerging as promising advances in generating fuels and energy as they rely solely on naturally available solar energy to drive the reactions.5−7 Not only that, abundantly available CO2 and H2O function as low-cost feed stocks for the photocatalytic reactions. Hence, solar-driven CO2 reduction and water splitting is an up-and-coming approach to generate renewable fuels due to their inexpensiveness and environmentally benign process.8−10

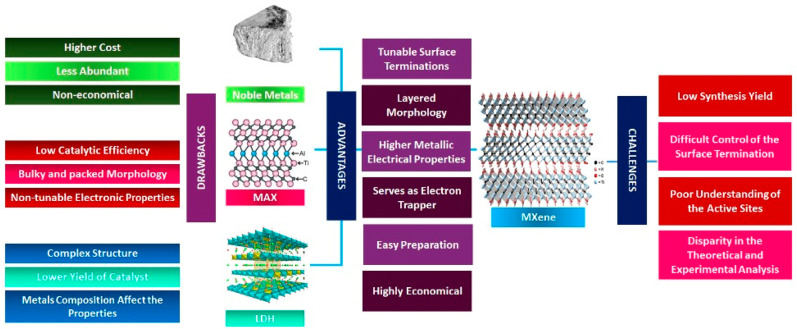

In 2011, MXenes were a class of novel materials first discovered by Gogotsi and co-workers.11 MXenes are promising photocatalytic materials that are derived from MAX via acid etching to remove the Al layers, leaving behind the M (transition metals) and X (C or N) with a general formula of Mn+1Xn. MXenes exist in either 0D quantum dots (QDs) or as 2D layered structures, which provides a higher specific surface area, reaction sites, ameliorated light harvesting, and electron acceptance capability as well as the prolonged lifetime of charge carriers.12,13 Additionally, they have good mechanical and chemical stability as well as easily tunable valence electrons via preparation using lighter and heavier transition metals.14 Due to its metallic properties, MXenes are able to act as a cocatalyst for photocatalytic reactions due to their ability to form a Schottky junction, which acts as an electron trap and mediator.15 By pairing the MXenes with other photoresponsive materials, a built-in internal electric field is induced, thus electron separation and migration are promoted.16 Also, several studies reported that some MXenes exhibit semiconducting properties with band gaps from 0.05 to 2.87 eV.17 Thus, MXenes are promising cocatalysts and can be coupled with semiconductors to boost reactivity.

Among the semiconductors, metal–organic frameworks (MOF) are a promising class of materials that have different morphologies and dimensionalities, ranging from 1D rods to 2D layered sheets and 3D network structures.18 Yaghi’s group pioneered the discovery and successful preparation of MOFs in 1999.19 The existence of highest occupied molecular orbitals (HOMOs) and lowest unoccupied molecular orbitals (LUMOs) separated by an energy band gap (Ebg) makes them suitable candidates as photocatalysts due to their ability to harvest solar energy. Not only that, MOFs also have various beneficial properties such as extremely large specific surface area,20 high porosity,21 and a tunable structure. The light harvesting capability of MOFs is augmented due to the large surface area, which increases the exposed surface area of the material to light irradiation. Moreover, the desirable porosity makes it an excellent CO2 adsorbent that eases the subsequent conversion to solar fuels.22

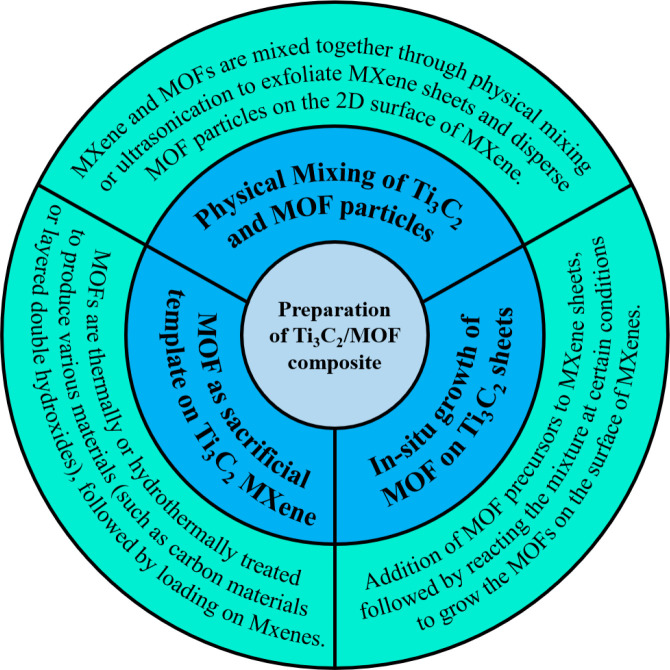

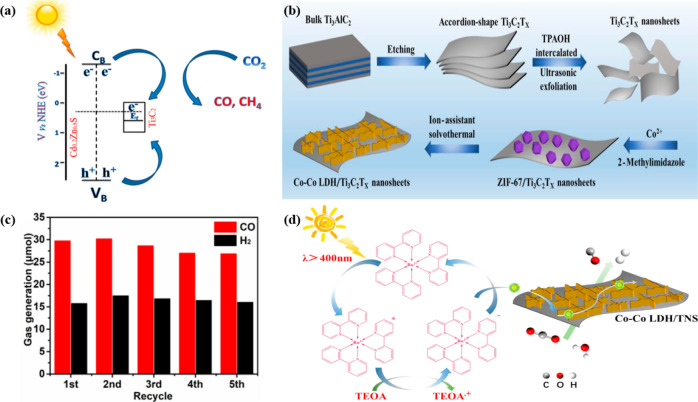

Researchers all around the world are devoted to discovering highly active catalysts for solar-energy-driven renewable energy evolution. Pristine Ti3C2Tx MXene alone cannot be utilized as a photocatalyst for either solar-driven H2 production or CO2 reduction due to its inability to generate electron/hole pairs for photoredox reactions. Conversely, they are effective as cocatalysts due to their blackbody, which facilitates light absorption and harvesting.23 Not only that, Ti3C2Tx MXenes are able to function as electron reservoirs, in which they can efficiently trap photogenerated electrons.24 Hence, Ti3C2Tx MXenes must be coupled with other photoresponsive materials to unleash their full potential as a cocatalyst. In the past, Ti3C2Tx-based composite photocatalysts have been prepared, in which Ti3C2-based semiconductor composites were widely employed. For instance, Li et al. paired Ti3C2 QDs with a g-C3N4 semiconductor as a photocatalyst for H2 production, where the MXene effectively trapped the photogenerated electrons from the g-C3N4 nanosheets.25 Similarly, a ternary semiconductor-based TiO2/C3N4/Ti3C2 composite was utilized for solar-driven CO2 reduction. An S-scheme heterojunction was first obtained between the TiO2/C3N4 interface due to formation of an internal electric field, band bending, and Coulomb force, where the electrons in TiO2 combined with the holes in the valence band (VB) of C3N4. Subsequently, the electrons produced in C3N4 were trapped by Ti3C2Tx MXenes.26 However, the composite pairing with semiconductors presents a glaring disadvantage, which is the fast recombination of charge carriers due to large energy band gaps. In efforts to overcome this shortcoming, Ti3C2Tx-based MOF nanotextures are gaining attention as photocatalysts for solar fuel production. To date, 90,000 different MOF structures have been discovered, each with their own unique properties and energy band gap. This means that the potential combinations of Ti3C2Tx/MOF composites are limitless, in turn presenting a huge potential and research interest in maximizing solar fuel generation.

Herein, we reviewed the various applications of Ti3C2Tx MXene-based MOF composites on the photocatalytic production of solar fuels. First, an in-depth discussion on the principles and mechanism of photocatalysis is conducted. Then the fundamentals of photocatalytic CO2 reduction and water splitting are discussed by understanding the various possible oxidation and reduction reactions involved. The various preparation method of Ti3C2Tx MXenes are thoroughly reviewed, which includes HF etching, acid-containing fluoride ions, water-free etching, alkali etching, electrochemical etching, and molten salt substitution. Then a comprehensive discussion on the preparation of Ti3C2Tx MXene-based MOF composites is conducted. Numerous applications of Ti3C2Tx MXene-based MOF composites are reviewed and discussed for the sustainable production of solar fuels. Finally, the challenges and comparative analysis of Ti3C2Tx MXenes are conducted over various materials. Despite limited studies conducted on the Ti3C2Tx–MOF composites, they are definitely promising photocatalysts for solar fuel production and should be further explored for various applications.

2. Fundamentals and Principles

2.1. Principles of Photocatalysis

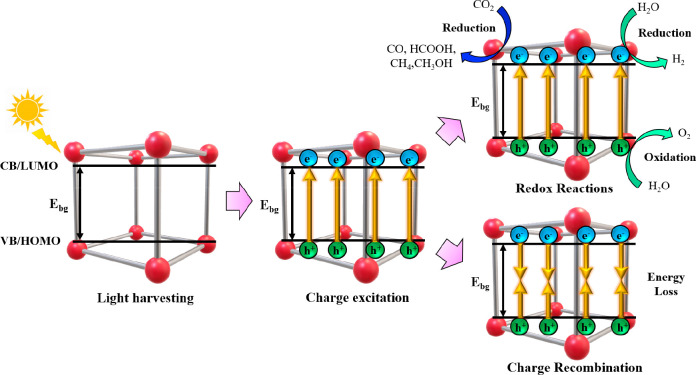

Photocatalysis is an up-and-coming sustainable approach to induce catalysis as it only utilizes naturally available solar energy as energy input to the reaction system. The photocatalysis pathway consists of four crucial steps, as shown in Figure 1. They are light harvesting, charge excitation, occurrence of redox reaction, and the recombination of charge carriers.27 Initially, the photoresponsive materials are exposed to light irradiation. There are three main radiations from solar energy, each with varying energy levels, with UV radiations having the highest energy, followed by visible light and infrared radiation. Hence, UV radiations show the highest efficiency in generating electron/hole pairs, whereas the infrared radiations only function to provide a heating effect.28 The light harvesting step can be further enhanced through multiple reflections and a light scattering effect over materials with rough surfaces as a result of meso- and macropores.29 Upon successful light harvesting, electrons are excited with sufficient energy to transverse the Ebg from the VB or HOMO to the conduction band (CB) or LUMO. On the other hand, the photogenerated holes are then left behind in the VB or HOMO.30 Following the charge excitation step where electron/hole pairs are formed, there are two possibilities that may occur, which is the favorable utilization of electron/hole pairs for redox reactions or the unfavorable recombination of charge carriers leading to loss of energy. The CO2 reduction reaction occurs on the CB/LUMO of the material, where the electrons are utilized to convert CO2 into solar fuels such as CO, HCOOH, CH4, and CH3OH, whereas the oxidation half-reaction occurs over the VB/HOMO.31 Similarly, photocatalytic water splitting reactions consist of two half-reactions, which is the reduction and oxidation of water to produce H2 and O2 gas, respectively. There are two types of recombinations that occur, namely, volume recombination where the charge carriers undergo recombination at the bulk of the material or surface recombination where the electron/hole pairs recombine on the surface of the material.32 The recombination of charge carriers will then lead to the loss of energy in the form of heat. Hence, the recombination should be prevented at all costs via different approaches, such as the formation of heterojunctions and surface sensitization, which can trap electrons and provide spatial separation, which prolongs the lifetime of the photogenerated electron/hole pairs.

Figure 1.

Schematic illustrating the overall mechanism for photocatalysis of CO2 reduction and hydrogen production. Adapted with permission from ref (30). Copyright 2022 Elsevier.

2.2. Fundamentals of Photocatalytic Solar Fuel Production

Recently, photocatalytic solar fuel production has been gaining traction due to its simplicity, cost-effectiveness, and environmentally benign process. There are two widely known and sustainable technologies to produce renewable fuels, namely, photocatalytic CO2 reduction and water splitting to produce H2. For photocatalytic reactions to occur, there are two main processes occurring, which is the reduction and oxidation half-reactions. For a particular reduction half-reaction to occur, the CB/LUMO of the material must be more negative compared to the redox potential. Conversely, the VB/HOMO of the photoresponsive material should be greater than that of the redox potential of the oxidation half-reaction for it to be feasible.33Equation 1 shows one electron reduction of CO2 to the CO2– radical.34 However, the reaction is deemed unfeasible due to it possessing a high redox potential. Not only that, it is impossible for a photocatalyst to supply enough potential to transfer a single electron to a CO2 molecule.35 Hence, reactions with low redox potentials are proton-assisted multielectron reactions, making them achievable over a wide range of materials.36 As shown in eqs 2–5, CO2 can be reduced to a wide variety of products, namely, CO, HCOOH, CH3OH, and CH4, respectively. The product selectivity depends on the amount of the number of electrons supplied to the CO2 molecule. For instance, photocatalytic CO2 reduction usually favors the production of CO and HCOOH due to it only requiring two electrons to initiate the reaction. On the other hand, the formation of CH3OH and CH4 requires more electrons and protons (6 and 8, respectively) to facilitate the reaction. For the photocatalytic water splitting to produce H2, it involves two crucial steps. The first step is shown in eq 6, where two holes are utilized to oxidize the water molecules to produce oxygen and two protons. Subsequently, the protons and electrons proceed via eq 7 to produce H2.37,38

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

| 6 |

| 7 |

2.3. Overview, Fundamentals, and Properties of MXenes

MXenes are a type of two-dimensional (2D) nanomaterial obtained through selective etching of MAX phases. The general formula of MXene is Mn+1XnTX, in which the M stands for the early transitional metal elements such as Sc, Ti, Hf, Mo, Ta, Nb, Cr, and so on. The acronym A represents the Al or Si layer, while X constitutes either C or N elements. The chemical exfoliation of the A element of MAX results in the termination of the M surface with abundant of functional groups, Tx such as −F, −OH, and −O. The first MXene material ever synthesized was in 2011 which is titanium carbide MXene (Ti3C2Tx) by Naguib and co-workers via chemical etching with hydrofluoric acid (HF).11 It was known that the mechanical method was not able to exfoliate the Mn+1Xn layers due to the strong metallic M–A bonds in MAX phase. Therefore, the selective etching is considered a preferable method to break the M–A bonds owing to the different chemical activities of M–A and M–X bonds in MAX.39 The n in the formula of MXene represents the atomic layer in a unit cell. A different compositional formula of MXene with different atomic layers can be obtained such as M2XTx, M3X2Tx, and M4X3Tx, as presented in Figure 2a. The typical structure of MXenes could be categorized as mono-M MXenes and double-M MXenes based on their compositional configurations.40 In mono-M MXenes, the compositional arrangement is distinguished by the position of an early transitional metal covering (M) the C or N (X) elements. On the other hand, double-M MXenes are subcategorized into solid solution and ordered type. In solid solution of double-M MXenes, two early transitional metals, M1 and M2, are randomly distributed into the MXenes, while for ordered type, one of the M metals is positioned between the second transition M metal.

Figure 2.

(a) Different compositional formula of Ti3C2Tx MXene with different atomic layers. Reprinted with permission from ref (40). Copyright 2019 Wiley. (b) Different electronic properties of Ti3C2Tx MXene. Reprinted from ref (15). Copyright 2021 American Chemical Society.

Typically, Ti3C2Tx MXenes are metallic materials that exhibit excellent electrical conductivity of 6000–8000 S cm–1, comparable to noble metal and graphene materials. This makes available as significant cocatalysts to promote the photocatalysis process. Additionally, the electrical properties of Ti3C2Tx MXenes can also be tailored through different M metal compositions, morphological modulation, and tuning the termination properties.15 For instance, delaminating the multilayer Ti3C2Tx MXene layers into their individual layer is reported to exhibit higher electrical conductivity up to 15000 S cm–1.41 The findings also suggested that the thickness of the Ti3C2Tx MXenes flakes is significantly linked to the electrical conductivity by which the monolayer Ti3C2Tx MXenes exhibited higher electrical conductivity compared to that of the bilayers and trilayers.42

In the perspective of electronic conductivity, Ti3C2Tx MXenes are metallic in nature and thus unable to generate electrons and holes. Therefore, they are typically used as a cocatalyst to assist photocatalytic activity due to the Schottky barrier effects. A higher work function is one of the distinct properties of Ti3C2Tx MXenes that give them a significant role as a photocatalytic enhancer and favorable as a noble metal substitution. A work function as high as 6.25 eV could be achieved, which is as high as other renowned metal cocatalysts such as Ag (∼4.5 eV), Au (∼5.38 eV), and Pt (∼6.10 eV).43−45 In the photocatalysis process, incorporating metal with a higher work function could improve the carrier dynamics and induce a stronger redox reaction.

Nevertheless, the work function of Ti3C2Tx MXenes can be varied depending on the tailored surface termination groups. This is because their work function is mainly controlled by the induced dipole moments arising from the transfer of charges between the termination group of Ti3C2Tx MXenes and the changes in the total surface dipole moments due to surface relaxation. In this context, the findings suggested that Ti3C2Tx MXenes with an −OH terminal group were observed to exhibit a work function of 1.6–2.8 eV. On the other hand, −O-terminated Ti3C2Tx MXenes displayed a higher work function between 5.75 and 6.25 eV.46 Furthermore, the termination of −OH groups caused the decrease of the work function compared to that with −O and −F termination, where the work function was shown to either increase or decrease depending on the M metal constituted.47 However, theoretical analysis through first-principles calculations indicated that some MXenes can exhibit semiconducting properties depending on the type of M metal constitution, surface terminating group, and the number of the MXene layers, such as that presented in Figure 2b. It was suggested that Ti3C2Tx manifests metallic properties regardless of any surface functionalization. The same findings were observed on the MXenes with thicker sheets and a large number of transition metals. Therefore, the probability of MXenes to undergo the shifting of the electronic properties into semiconducting is high in thinner MXenes, such as those with n = 2. Therefore, not all MXenes are metallic in nature, and some can exhibit semiconducting properties by configuring their termination groups, morphological structure, and types of metal composition. The feasibility of tailoring the electronic and electrical properties is one of the distinct properties of MXenes that favors them in a wide range of scientific applications.

2.4. Fundamental and Principles of Metal–Organic Frameworks

MOFs are a class of crystalline materials with metal nodes held together by organic linkers, forming highly sophisticated porous structures.48 Initially, MOFs were mainly used in the field of gas storage, but slowly their role expanded into various applications such as gas/liquid adsorption and separation,49 electrode development for supercapacitors,50,51 and batteries52 as well as heterogeneous catalysis.53−55 MOFs are able to be used in broad applications mainly due to their unique properties and characteristics, such as an unprecedented specific surface area, high porosity, and easily tunable chemistry.56 MOFs exists in a variety of morphology and dimensionality, from 1D rod structures to 2D layers and finally 3D network structures. Additionally, MOFs can also act as sacrificial templates to produce a different material such as porous metal oxides and layered double hydroxides. Similar to semiconductor materials, MOFs are also bestowed with impressive optical properties, making them able to induce electron/hole pairs upon irradiation with a light source. Table 1 summarizes the various MOFs discovered over the years with their respective metal nodes, linkers, and physical and optical properties.

Table 1. Various Classification of MOFs and Their Properties.

| MOF | metal node | linkers | dimension | surface area (m2/g) | HOMO (eV) | LUMO (eV) | Ebg (eV) | refs |

|---|---|---|---|---|---|---|---|---|

| ZIF-67 | Co | 2-methylimidazole | 3D | 1139.00 | 1.18 | –0.74 | 1.92 | (95,96) |

| Co-MOF-74 | Co | 2,5-dihydroxyterephthalic acid (H4DOBDC) | 1D | 1025.00 | (97) | |||

| MOF-71 | Co | terephthalate acid (H2BDC) | 2D | 56.50 | (98) | |||

| MOF-5 | Zn | terephthalic acid (H2BDC) | 3D | 1101.00 | 3.82 | (87) | ||

| ZIF-7 | Zn | benzimidazole | 3D | 167.00 | (99) | |||

| ZIF-7-NH2 | Zn | 2-aminobenzimidazole | 3D | 417.00 | (99) | |||

| ZIF-8 | Zn | dimethylimidazole | 3D | 1123.00 | 2.10 | –1.20 | 3.30 | (20,100) |

| HKUST-1 | Cu | 1,3,5-tricarboxylic acid (H3BTC) | 3D | 1143.06 | 2.01 | –0.58 | 2.59 | (101) |

| Cu-MOF | Cu | 1,3,5-trimesic acid | 3D | 19.00 | 1.64 | –0.80 | 2.44 | (102) |

| Cu3(L)2(4,4′-bipy) | Cu | 4,4′-bipyridine (4,4′-bipy) | 3D | 83.86 | 2.82 | (103) | ||

| UiO-66 | Zr | terephthalic acid (H2BDC) | 3D | 835.00 | 3.19 | –0.72 | 3.91 | (86) |

| UiO-66-NH2 | Zr | 2-aminoterephthalic acid (H2BDC-NH2) | 3D | 917.00 | 1.82 | –1.01 | 2.83 | (86) |

| UiO-67 | Zr | biphenyl-4,4′-dicarboxylate (H2BPDC) | 3D | 2500.00 | 2.43 | –1.20 | 3.63 | (63) |

| MIL-101 | Fe | 1,4-benzenedicarboxylic acid (H2BDC) | 3D | 1413.00 | 2.59 | (54,104) | ||

| NH2-MIL-101 | Fe | 2-aminoterephthalic acid (NH2-BDC) | 3D | 1237.40 | 0.97 | –1.75 | 2.72 | (105) |

| PCN-250 | Fe | 3,3′5,5′-azobenzene tetracarboxylic acid (H4abtc) | 3D | 1240.00 | 1.19 | –0.89 | 2.08 | (88) |

| MOF-901 | Ti | 4-aminobenzoid acid | 2D | 550.0 | 2.65 | (106) | ||

| NH2-MIL-125 | Ti | 2-aminoterephthalic acid (H2BDC-NH2) | 3D | 405.40 | 2.10 | –0.40 | 2.50 | (53) |

| MIL-125 | Ti | terephthalic acid | 3D | 1510.00 | 3.43 | 0.16 | 3.27 | (66,107) |

| NTU-9 | Ti | 2,5-dihydroxyterephthalic acid (H4DOBDC) | 2D | 1205.00 | 0.32 | –1.58 | 1.90 | (108,109) |

| PCN-415 | Ti | terephthalic acid | 3D | 1050.00 | 3.31 | (110) |

2.4.1. Chemistry of Metal–Organic Frameworks

MOFs are composed of two main building blocks, including metal nodes and the bridging organic linkers. More than 60,000 types of MOFs can be discovered due to the endless possibilities of combination between different metal precursors with organic linkers. Figure 3 summarizes the general chemistry of MOFs. One of the more straightforward ways to classify and identify MOFs is through their metal nodes. For instance, Co, Zn, Cu, Zr, Fe, and Ti are some of the typical metal nodes present in monometallic MOFs. Co-based MOFs are highly utilized due to their relatively low cost and simple preparation methods.57 In the field of catalysis, Co metals were reported to show impressive activity in renewable fuel production.58 Zn-based MOFs such as ZIF-7 and ZIF-8 are referred to as noble-metal-free systems due to Zn being a cheaper and abundant alternative to noble metals, as well as showing promising performance under light irradiation.59 Cu is another transition metal that has shown beneficial properties in promoting photocatalytic performance. A study reported that the doping of Cu can enhance the reception of visible light by 35% as well as reduce the energy band gap significantly.60 Zr-based MOFs possess great structural stability with a high specific surface area due to Zr-carboxylate coordination bonds.61 UiO-6662 and UiO-6763 are two examples of well-known Zr-based MOFs that have been utilized in various photocatalytic reactions. In the case of Fe-MOFs, oxo-iron clusters are present which makes them potential candidates as photocatalysts as they exhibit good visible light harvesting ability.64 Finally, Ti-based MOFs consist of tetravalent Ti4+ cations which can form tough frameworks due to strong metal–ligand bonding. The presence of Ti-oxo clusters contributes to the photocatalytic activity by enhancing the redox reactions.65

Figure 3.

Illustration of the chemistry of MOFs in terms of metal node classification and organic linkers.

The second building blocks that are used to prepare MOFs are organic linkers. The linkers are the bridges between metal nodes that originate from organic acids such as terephthalic acid or trimesic acid. Usually, functionality can be introduced to MOFs via the use of functionalized linkers or via postsynthetic modifications. Most notably, the Ti-based MIL-125 and NH2-MIL-125 have a relatively similar synthesis method with similar metal precursors and solvents used, in which only the organic acids deployed are different. In the case of preparing MIL-125, terephthalic acid is utilized, whereas amine-functionalized terephthalic acid (2-amino terephthalic acid) is used to prepare NH2-MIL-125.66 Hence, NH2-MIL-125 will have amine functional groups on the linkers of the MOF. Another way to induce functionalization is through the postsynthetic modification (PSM) of the linkers.67 Su’s group reported an improvement in water resistance of Mg-MOF-74 via PSM by functionalizing it with tetraethylenepentamine (TEPA). Hence, amine functional groups were introduced to Mg-MOF-74, which inhibits the damaging effects of water entering into the framework.68

2.4.2. Physical Property of Metal–Organic Frameworks

MOFs are materials that have been widely researched in various fields and applications due to their desirable and unique physical properties. Here, the physical properties of MOFs such as their surface area, porosity, and various synthesis methods are critically discussed, which is then summarized, as shown in Figure 4. First, MOFs tend to boast incredibly high specific surface area, usually in the range of hundreds if not thousands. Titanium-based MIL-125 has a surface area of 1510 m2/g,66 whereas its metal oxide counterpart TiO2 only has a mere surface area of 35 m2/g.69 Moreover, MOFs are also bestowed with numerous pores with large openings. These large pores are beneficial for enabling them to function as effective materials for gas adsorption and capture. A chromium-based MIL-101 features a high pore volume of 1.63 cm3/g, in turn promoting a huge N2 uptake capacity of 1003 cm3/g.70 Interestingly, the porosity of MOFs not only is limited to gas adsorption but also enables them to capture large heavy metal molecules, as well. Nimbalkar et al. noticed that UiO-66 with a free carboxylic group is riddled with micropores of 0.4–0.7 nm, in turn providing a high lead and methylene blue adsorption capacity of 100 and 169 mg/g, respectively.71 Hence, a large surface area and pore volume is a highly sought-after property as it opens doors to various applications such as catalysis and adsorption.

Figure 4.

Illustration of the physical properties and preparation method of MOFs.

Even though most of the MOFs exist as three-dimensional (3D) polyhedrons, there are also some MOFs exhibiting 1D rods and 2D sheet structures. Recently, a novel 1D chiral imine Zr-MOF (DUT-136) was synthesized via the use of Schiff base of (R,R)-1,2-diphenylethylenediamine and 4-formylbenzoic acid linkers.72 Similarly, a number of 2D MOFs have been discovered by researchers, such as NUS-173 and MIL-169.74 In the past, various preparation methods for MOFs have been discovered. The most common approach to prepare MOFs is through the solvothermal method. Here, the metal precursors and linkers were first dissolved in solvent, such as methanol and N,N-dimethylformamide (DMF). Then the mixture was placed in a Teflon-lined stainless-steel autoclave where heat was introduced to the system to initiate the chemical reaction. Finally, the obtained slurry was washed and dried to obtain the MOF crystals.75 The solvothermal synthesis step usually utilizes a reaction temperature of not more than 200 °C, with a reaction time ranging from 12 to 72 h. A titanium-based NH2-MIL-125 was prepared via a conventional solvothermal method with reaction conditions of 150 °C and 72 h.76 Correspondingly, an Fe-MOF was prepared by first dissolving FeCl3·6H2O and H2BDC precursors in DMF solvent, followed by reaction for 24 h at 110 °C.77 Despite the easy process of the solvothermal synthesis method, it is limited by various factors such as a long synthesis time and inhomogeneous heating of reactants.78

MOFs can also be prepared via a straightforward co-precipitation method where the reactants are mixed until precipitates are formed without involving external energy sources.79 Co-precipitation provides a uniform distribution of components. ZIF-67 is a prime example of a MOF prepared via the co-precipitation method. The synthesis step is relatively straightforward: Co precursors were mixed with linkers (2-methylimidazole) in methanol and stirred for 6 h. Then the resulting solution was washed and dried to obtain 3D purple dodecahedral crystals.80 However, to date, there is only a limited number of MOFs prepared using this method. MOFs are also prepared using an energy-free approach, which is the slow evaporation method. In this method, the solvent is gradually evaporated at room conditions, leaving behind the dried MOF powders. Even though this process does not consume any energy, the synthesis requires a long period of time. Ghosh and co-workers reported a preparation period of 1 week for the synthesis of an Fe-MOF ([C18H22FeN2O6]NO3) via the slow evaporation method.81 In another study, 2 weeks were consumed to prepare purple Co-MOF crystals via the slow evaporation approach.82 Finally, microwave-assisted synthesis was also employed to achieve rapid synthesis of MOFs. This technique utilizes microwaves to provide a heating effect to initiate the chemical reaction, in turn producing nanosized crystals.83 The microwave-assisted approach is almost similar to the conventional solvothermal method but provides additional benefits such as fast crystallization time and facile morphology control and produces MOFs with narrow particle size distribution.64 Most notably, Reza et al. discovered that using a microwave-assisted method to prepare UiO-67 required a much shorter preparation time (2.5 h) compared to that with the conventional solvothermal method (24 h). This is because the microwave heating couples directly with the solvent molecules, causing a rapid rise in temperature at the reaction media, which induces localized superheating. This provides a much more efficient heat transfer compared to conventional heating, resulting in a much shorter reaction time.84

2.4.3. Optical Property of Metal–Organic Frameworks

Solar energy is a renewable source of energy that can be easily accessed. To fully utilize this abundant source of energy, researchers have been devoted to discovering materials that can effectively harvest and adsorb solar energy. Solar energy mainly comprises three main irradiations, namely, infrared, visible light, and ultraviolet (UV) radiations. Here, UV radiation has the highest energy content (shortest wavelength), followed by visible light and infrared radiation. Only high energy UV and visible light can generate electron/hole pairs over photoresponsive materials. However, despite the highest energy content of UV radiation, it only accounts for less than 4% of the solar spectrum, whereas visible light and infrared radiation constitutes 43 and 53% of solar energy, respectively.85 Hence, to effectively utilize solar energy for photocatalysis, suitable materials must be explored to efficiently harvest visible light radiations.

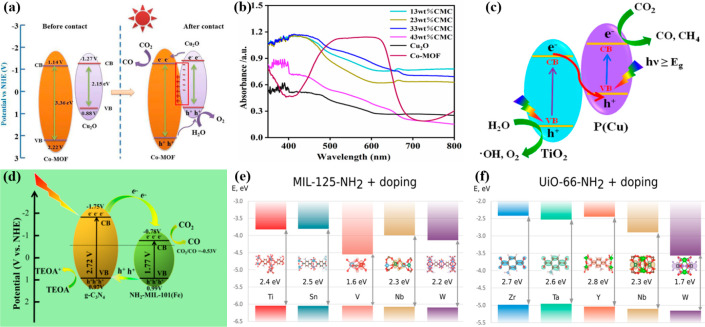

In this context, MOFs are highly sought-after materials due to their desirable optical properties, which makes them photoresponsive materials. To address the energy crisis, MOFs are employed as photocatalysts to harvest solar energy to generate renewable fuels. First, MOFs have a narrow energy band gap (Ebg) which allows electron to migrate over from the VB/HOMO to the CB/LUMO. The migration of charge carriers is only possible when photons with energy equal to or greater than Ebg strikes the surface of the MOF.64 Second, there has been a lot of MOFs discovered over the years, each with their own unique Ebg, as shown in Figure 5a. Some MOFs tend to have a wider band gap, such as UiO-6686 and MOF-587 with Ebg of 3.91 and 3.82 eV, respectively. However, there are also MOFs with narrow band gaps, such as PCN-25088 (2.08 eV) and NTU-9102 (1.90 eV). A narrow Ebg means that photons with lower energy are required to induce charge carrier formation. This means that visible light irradiation is sufficient to facilitate the photocatalytic reaction. Inversely, a wide Ebg requires more energy to generate electron/hole pairs, implying that UV irradiation will be more effective compared to visible light to drive photocatalysis. The relationship between the Ebg, the solar spectrum, and light wavelengths is illustrated in Figure 5b.

Figure 5.

(a) Band structures of various metal–organic frameworks. (b) Relationship between Ebg of photoresponsive materials (eV), solar spectrum, and light wavelength. Reprinted with permission from ref (64). Copyright 2021 Elsevier.

2.4.4. Metal–Organic Frameworks as Sacrificial Templates

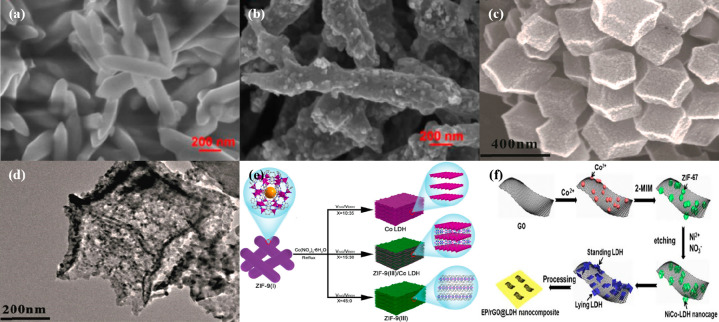

MOFs in their original form are proper candidates as photocatalysts but can also serve as sacrificial templates to produce other materials. One of the more common MOF derivatives is metal oxides, which are obtainable by simple thermal annealing of MOFs. By calcinating the MOF at elevated temperature, the organic linkers will be removed, leaving behind the metal nodes which are then oxidized, producing metal oxides which inherit the morphology, porosity, and surface area of the parent MOF.89 An Fe-MOF was synthesized via a solvothermal method with FeCl3·6H2O as the precursor and 1,4-benzenedicarboxylic acid linkers. The as-prepared MOF showed a well-defined nanospindle structure with a smooth surface, as illustrated in Figure 6a. Upon annealing the Fe-MOF in a N2 atmosphere, Fe2O3 was obtained while retaining the spindle structure of the parent MOF. From Figure 6b, it was noticed that the surface of the Fe-MOF-derived Fe2O3 was rougher with nanoparticles on the surface.90 Similarly, a Co-based MOF ZIF-67 was successfully converted into Co3O4 hollow polyhedrons via calcination treatment at 300 °C for 3 h. From the SEM image in Figure 6c, ZIF-67 particles have well-defined polyhedral shapes with a width of around 200 nm. After thermal treatment, the Co3O4 retained a similar polyhedral morphology with a specific surface area of 44.28 m2/g but had a hollow structure which is clearly observed in the TEM image in Figure 6d.91 Recently, there have been numerous reports on MOFs as templates to produce layered double hydroxides (LDHs). One study conducted by Chen et al. successfully converted 3D ZIF-9 into 2D Co LDH by varying the water/ethanol solvent volume ratio. According to the scheme in Figure 6e, when a 45:0 water/ethanol ratio was used, pure ZIF-9 with a 3D structure was obtained. However, as the ethanol amount increased from 15:30 to 10:35, ZIF-9 changed to ZIF-9/Co LDH and finally to pure 2D Co LDH.92 A bimetallic Ni–Co LDH-grown reduced graphene oxide (rGO) was also prepared via the etching of ZIF-67 by H+ upon the hydrolysis of nickel nitrate. As depicted in Figure 6f, ZIF-67 was first grown on GO. After successfully growing the ZIF-67 particles, the addition of nickel nitrate caused the framework of ZIF-67 to collapse into LDH platelets, resulting in the platelets inheriting a 3D structure of the parent MOF, forming standing and lying LDH on the GO.93 Another study reported an almost similar procedure to prepare Ni–Co LDH nanosheets, in which Co-MOF nanosheets were gradually decomposed and transformed into LDH via a hydrolyzed etching step.94 Thus, MOF templating is a useful way to produce other materials such as metal oxides and LDHs as the derivatives tend to retain the beneficial properties of the parent MOF, in turn promoting an enhanced photocatalytic activity.

Figure 6.

SEM images of (a) Fe-MOF and (b) Fe2O3 derived from Fe-MOF. Reprinted from ref (90). Copyright 2020 American Chemical Society. (c) SEM image of ZIF-67 and (d) TEM image of Co3O4 hollow polyhedrons. Reprinted with permission from ref (91). Copyright 2018 Elsevier. (e) Scheme of solvent ratio influence on formation of ZIF-9, ZIF-9/Co LDH, and Co LDH. Reprinted with permission from ref (92). Copyright 2021 Elsevier. (f) Preparation scheme of Ni–Co LDH on reduced graphene oxide. Reprinted with permission from ref (93). Copyright 2017 Elsevier.

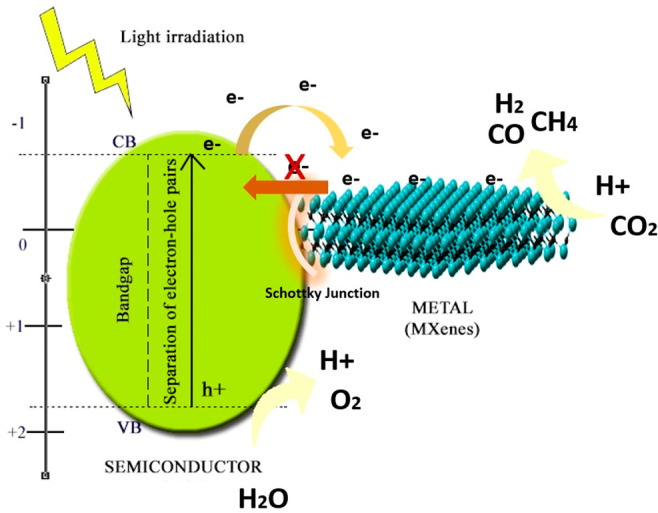

2.5. Fabrication of a MXene-Based Schottky Junction

The performance efficiency of single semiconductor materials such as MOFs in photocatalytic solar fuel conversion can be enhanced through engineering modifications such as hybridization with other semiconductor materials, forming heterojunction composites. Other modifications included engineering the morphology of the semiconductor into different dimensions, defect engineering, and creation of vacancies.27 However, one of the techniques that has been proven effective in creating higher-performance semiconductor materials is by the addition of metallic material. In this regard, the performance efficiency can be enhanced through an improvement in the carriers’ dynamics. This indicates that Ti3C2Tx MXene possesses a higher metallic electrical conductivity, which provides them with the ability to form a potential barrier at the metal–semiconductor interfaces, known as the Schottky junction.111 Ti3C2Tx MXenes are, in general, unable to generate electrons and holes as they are naturally a metallic material. Therefore, they are mostly employed as a cocatalyst and paired with other semiconductor materials such as MOFs to promote the photoactivity through the synergy of a metal–semiconductor junction. The role of adding Ti3C2Tx MXene material is to improve the separation efficiency and promote the transfer of electrons in single semiconductor materials.

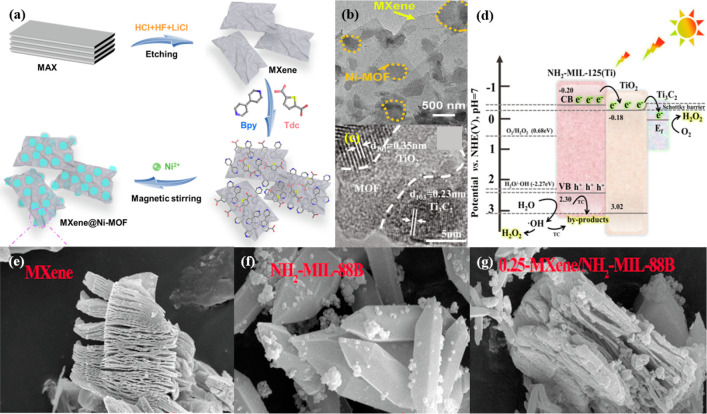

Fundamentally, the charge transfer mechanism in Ti3C2Tx MXene-based composites was achieved through the difference in the work function between Ti3C2Tx MXene and the semiconductor materials.112 The built-in internal electric field at the metal–semiconductor junction called Schottky barrier was formed through the band alignment when both the semiconductor and Ti3C2Tx MXene are in contact with each other. The Ti3C2Tx MXenes normally serve as electron acceptors due to their large metal work function. Typically, the electrons will migrate from higher Fermi level to lower Fermi level materials, which is the case for MOF-Ti3C2Tx MXene composites, where the electrons will migrate from a higher Fermi level of the MOF to a lower Fermi level for Ti3C2Tx MXene.113 Note that the metal work function value (ϕ) is defined as the energy required to transfer an electron from the Fermi level to the vacuum level, where the vacuum level is the reference level at which the electrons possess an energy level outside of the metal with zero kinetic energy. It is worth mentioning that the larger the difference of the work function between the two hybrid materials, the stronger the Schottky barrier that offers excellent separation of the photocarriers. Therefore, metal with a higher work function value such as noble metals and Ti3C2Tx MXene are highly sought after to optimize the solar to fuel conversion.114Figure 7 illustrates the electron transfer mechanism in Schottky junction composite materials. It can be observed that the electrons migrated to the surfaces of the Ti3C2Tx MXene are trapped and unable to return back to the semiconductor MOF; therefore, they reserve more electrons to undergo the redox reaction. The creation of a Schottky junction between MOF-Ti3C2Tx MXene interfaces prevents the reverse injection of electrons, hastens the electrons transfer to the Ti3C2Tx MXene surfaces, and inhibits the recombination of photogenerated charges.115

Figure 7.

Construction of a Schottky junction and electron transfer mechanism.

3. Different Synthesis Techniques of MXene

In general, several different techniques are available to synthesize Ti3C2Tx MXene. One of the common and most applied techniques for synthesizing Ti3C2Tx MXene is HF etching, which utilizes hydrofluoric acid as a primary etchant. The utilization of an etchant is significant, especially in breaking the Ti–Al bond in Ti3AlC2 MAX, as the mechanical method cannot exfoliate the Al layer. Since the pioneering study of Ti3C2Tx MXene synthesis through HF etching, several other techniques have been developed to combat the utilization of concentrated HF acid, which is non-ecological, especially in wide-scale industrial production. Therefore, safer routes such as acid-containing fluoride etchant, alkali etching, electrochemical etching, halogen etching, water-free etching, and molten salt substitution techniques are among the alternatives to synthesize Ti3C2Tx MXene. Among them, the etching process through the utilization of acid-containing fluoride etchant, known as the in situ HF technique, has been broadly employed after the HF etching technique, unlike other newly developed techniques that have not been deeply researched.116Figure 8 summarizes the various preparation methods together with their reaction conditions for the synthesis of Ti3C2Tx MXenes, and Table 2 provides the reaction parameters for the different Ti3C2Tx synthesis methods.

Figure 8.

Different synthesis techniques of Ti3C2Tx MXenes. Reprinted from ref (117). Copyright 2022 American Chemical Society.

Table 2. Summary of Preparation Methods and Parameters of Ti3C2 MXenes.

| synthesis method | catalyst | etching agents | termination group | synthesis parameters | comments | refs |

|---|---|---|---|---|---|---|

| HF etching | TiO2/Ti3C2 | HF | O, OH, F | 20 mL of 48% HF, 15 h etching time | multilayer MXene produced with lower photocatalytic efficiency compared to monolayer counterpart | (138) |

| 2D/2D HCN/MXene | HF | 39% HF, 24 h etching time | high purity of MXene was produced with well-defined multilayer structure | (139) | ||

| 39% HF, 48 h etching time | the growth of anatase TiO2 on exfoliated multilayers MXene | |||||

| 39% HF, 96 h etching time | the growth of anatase and rutile TiO2 was observed on MXene layer; more exfoliated layer and increase in the growth of TiO2 NP with increasing etching time | |||||

| TiO2/Ti3C2 | HF | O, OH, F | 49% HF, 24 h etching time (35 °C); ethyl alcohol as a washing agent; hydrothermally treated at 450 °C | the formation of TiO2/Ti3C2 safflower-like morphology with ∼1 μm safflower size and shorter nanorods formation | (140) | |

| 49% HF, 24 h etching time (35 °C); ethyl alcohol as a washing agent; hydrothermally treated at 550 °C | average safflower size ∼2 μm upon heat increase heat treatment; well-formed safflower morphology | |||||

| 49% HF, 24 h etching time (35 °C); ethyl alcohol as a washing agent; hydrothermally treated at 650 °C | average safflower size ∼2 μm with lower spatial density of TiO2/Ti3C2 nanorods compared to at 550 °C heat treatment; the safflower morphology slightly deformed at higher temperature | |||||

| BQ/TiC/UCN | HF | 40% HF, 72 h etching time, 20 mL DMSO, 24 h intercalation time | ultrathin MXene sheet is produced, effectively function as the electron mediator | (141) | ||

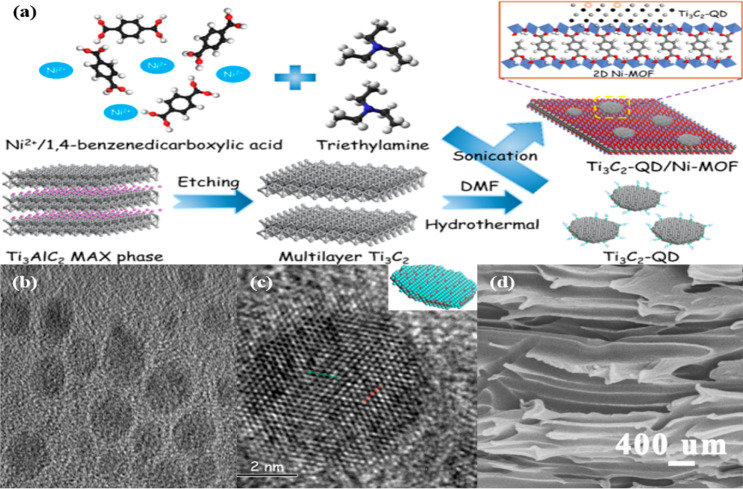

| Ti3C2-QD/Ni-MOF | HF | 20 mL HF, 24 h etching time, DMF intercalating agent | MXene QD constructed with enhance charge transfer and higher separation capabilities of the photocarriers | (142) | ||

| 2D/2D g-C3N4/Ti3C2TA/R (CN/TCT) MXene | HF | 39% HF, 24 h etching time | less distribution of TiO2 NPs on the surface of MXene | (121) | ||

| 39% HF, 96 h etching time | higher amount of TiO2 growth/conversion with more of rutile phase compared to anatase | |||||

| 49% HF, 24 h etching time | higher distribution of TiO2 on the MXene surface when employing more concentrated etchants | |||||

| 49% HF, 96 h etching time | both TiO2 (rutile) and TiO2 (anatase) having higher concentration due to more oxidation | |||||

| acid-containing fluoride ions | TiO2/Ti3C2 | LiF + HCl | O, OH, F | LiF with 6 M HCl, 24 h etching time | MXene flakes exhibit excellent hydrophilicity and dispersity with flakes size range of 10–100 nm | (138) |

| ZnCdS/TiO2/Na-MXene | LiF + HCl | LiF with 9 M of HCl, 24 h etching time (35 °C) | the preintercalation of Na+ and attachment of ZnCdS nanoparticles on the MXene flakes improve the oxidation stability and slowing the oxidation to TiO2 | (143) | ||

| 2D-Bi2MoO6@2D MXene | LiF + HCl | O, OH | LiF with 9 M of 20 mL HCl, 24 h etching time (35 °C) | 2D MXene serves as effective platform for impeding the agglomeration and support the growth of Bi2MoO6 constructing a hierarchical composite structure | (144) | |

| Ti3AlC2/Ti3C2Tx | LiF + HCl | 3.08 M LiF/HCl, 6 h etching time; 1, 3, 6, 24, and 36 h | delaminated MXene with more conversion to Ti3C2Tx than 1 h etched | (145) | ||

| 3.08 M LiF/HCl, 24 h etching time | delaminated MXene are formed with residual of Ti3AlC2 was observed | |||||

| 3.08 M LiF/HCl, 36 h etching time | delaminated MXene with residual of Ti3AlC2 was observed; partial delamination occurs even at 36 h etched time | |||||

| Ti3C2Tx | LiF + HCl | O, OH, F | LiF with 9 M HCl, 24 h etching time (30 °C) | c-lattice parameter of 25.75 Å | (146) | |

| LiF with 9 M HCl, 24 h etching time (35 °C), ethanol as washing agent | the highest c-lattice parameter of 30.99 Å obtained with ethanol as washing agent with improved delamination ratio | |||||

| alkaline etching | Ti3C2Tx | KOH | O, OH | 5 M KOH, 120 °C hydrothermal treatment | less developed of accordion-like structure of MXene; more exposed of Ti-OH sites with with alkali etching | (147) |

| Ti3C2Tx | NaOH | O, OH | 27.5 M NaOH treatment at 270 °C | higher purity (92%) of multilayer MXene produced with removal of −F termination group | (129) | |

| 27.5 M NaOH treatment at 250 °C | Ti3C2Tx yield decrease with reaction temperature | |||||

| 5–10 M NaOH treatment at 270 °C | formation of Na/K–Ti–O compounds (NTOs) due to lower concentration of NaOH, increasing the water content and facilitate oxidation | |||||

| NaOH treatment at 100–220 °C | no formation of MXene as reation cannot happen at lower temperature regardless of any concentration | |||||

| electrochemical etching | Ti3C2Tx | NH4Cl, TMAOH | O, OH | 1 M NH4Cl, 0.2 M TMAOH | higher yield of single or bilayer (>90%) with larger average dimension | (126) |

| Ti2C | HCl | –Cl, −O, −OH | 1 M HCl, 0.6 V, 1 day etching | less conversion of MXene sheets. | (128) | |

| 2 M HCl, 0.6 V, 5 days etching | the formation of carbon-derived-carbide (CDC) as the results of overetching | |||||

| molten salt substitution | Ti3C2Tx | CuCl2 | –Cl, −O | Ti3SiC2 in CuCl2 molten salt (750 °C) | delamination of the layer proceed with the aid of SiCl4 gas molecules produced through etching process | (136) |

| Ti3C2Tx | ZnCl2 | –Cl, −O | Ti3ZnC2 + ZnCl2 (annealed time: 0.5 h, 1 h, 1.5 h, 3.0 h) | the increasing of the ratio of molten salt, ZnCl2 in the starting precursor, a gradual conversion to Ti3C2Cl2 can be observed | (134) | |

| Ti3C2Tx | NaCl2, KCl, CuCl2 | –I, −Br, −Cl | NaCl2, KCl, CuCl2 (mixed ratio of 1:2:2:3), 10 h annealed time in Ar (700 °C) | well-configured Lewis acidic etching route could tailored the surface chemistry of MXene | (148) |

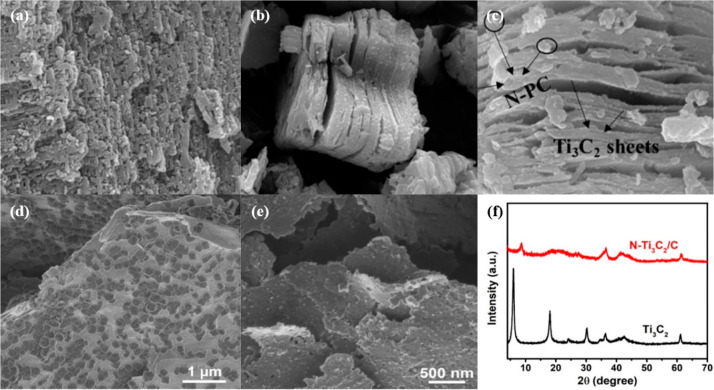

3.1. HF Etching

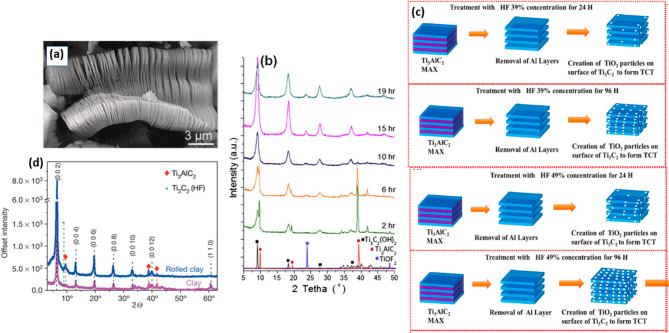

The HF etching technique is considered to be a pioneering technique and is an extensively used method to synthesize Ti3C2Tx MXene. HF was initially chosen as the primary etching agent due to its ability to break the large particle of MAX into smaller grains and its distinct properties to be one of the few selected etchants that can etch the titanium oxide layer typically present as a protective layer of Ti3C2Tx MAX.118 It was suggested that Ti3C2Tx MXene could be formed by treating the Ti3AlC2 MAX with 50% of HF acid under continuous stirring at room temperature.11,119 From the morphological perspectives, as presented in Figure 9a, the SEM image reveals an accordion-like structure, suggesting that the 2D structures of Ti3C2Tx MXene are formed after 2 h etching with HF. Studies also suggested that different morphologies of Ti3C2Tx MXene such as rolls, nanotubes, and multilayers were obtained after sonication. Moreover, the X-ray diffraction (XRD) pattern in Figure 9b shows that other parameters such as etching time could affect the removal of the Al layer of MAX. In this regard, the (104) peak at 2θ = 39, subjected to the MAX phase, was observed to slowly diminish with increasing etching time and was shown to completely disappear after 15 h of etching. This further revealed that increasing the etching time could assist the removal of the Al layer and the formation of Ti3C2Tx MXene. Further details on the mechanism of the Ti–Al bond breaking and the formation of Ti3C2Tx MXene is presented in eqs 8–10.120

| 8 |

| 9 |

| 10 |

Figure 9.

(a) SEM image of the 2D structure of Ti3C2Tx MXene after 2 h etching with HF. Reprinted from ref (119). Copyright 2012 American Chemical Society. (b) XRD analysis on Ti3C2Tx MXene at different etching times. Reprinted with permission from ref (125). Copyright 2013 Elsevier. (c) Formation of TiO2 on the Ti3C2Tx MXene sheets at different etching times. Reprinted with permission from ref (121). Copyright 2021 Elsevier. (d) XRD analysis on the formation of Ti3C2Tx MXene through reaction with LiF with HCl solution. Reprinted with permission from ref (122). Copyright 2014 Springer.

Generally, Ti3C2Tx MXene is formed by removing the Al layer sandwiched between the individual layer of Ti3C2Tx. As presented in eq 8, Ti3AlC2 MAX will react with three molecules of HF to form white small solid particles of AlF3 with the generation of H2 gas. The loss of the metallic bonding leads to the formation of layered Ti3C2Tx MXene, where the surface of Ti is terminated with functional groups such as −F and −OH such as that shown in eqs 9 and 10. It has been noted that the termination groups present are dependent on the type of etchants utilized. Therefore, the utilization of HF as a primary etching agent successfully etched away the Al layer of MAX. This technique has been favored due to the cost-effective and straightforward procedures. However, our research group found that the etching time could affect the creation of TiO2 on the Ti3C2Tx MXene surfaces.121 In this context, the etching of Ti3C2Tx MXene was carried out by utilizing 39 and 49% HF concentration, and both were etched at 24 and 96 h. It was suggested that increasing etching time with HF assisted the formation of TiO2 nanoparticles (NPs) on the surfaces of Ti3C2Tx MXene, as represented in Figure 9c. In this regard, the increasing number of active TiO2 semiconductor formation suggests a robust photocatalytic activity due to metal–semiconductor synergy. Even though the HF etching technique is highly utilized, the synthesis parameters, such as the concentration of HF and the etching time, are significant to ensure the purity of the produced Ti3C2Tx MXene. Moreover, controlling the synthesis parameters could essentially affect the photocatalytic activity of the Ti3C2Tx MXene-based materials.

3.2. Acid-Containing Fluoride Ions

Another synthesis technique that garnered scientific attention for the synthesis of Ti3C2Tx MXene is the acid-containing fluoride ion method. In order to minimize the use of concentrated HF acid, researchers have sought a new environmentally safe technique to synthesize Ti3C2Tx MXene. In this context, acid-containing fluoride ion etchants have been utilized to etch Al layers of Ti3AlC2 MAX, which at the same time delaminates their multilayer structure into the individual compartment.122 In this regard, the synthesis and delamination of Ti3C2Tx MXene can be achieved in a single step, unlike those by HF etching which requires intercalating agents to delaminate the multilayered structure of Ti3C2Tx MXene. The pioneering study reported that the single-step preparation method could be achieved by reacting Ti3C2Tx MXene with 6 M HCl with LiF at 45 °C for 45 h. Further analysis by powder XRD observed the removal of the Al layer from the Ti3AlC2 MAX, where the disappearance of Ti3AlC2 can be seen from Figure 9d. In this method, different types of acid and fluoride ions can be utilized, such as using sulfuric acid (H2SO4) containing NaF, KF, NH3F, CsF, and tetrabutylammonium fluoride.123 However, each combination might affect the properties of the synthesized Ti3C2Tx MXene. For instance, a study found that utilizing HCl might improve the electrochemical capacity of Ti3C2Tx MXene compared to those by HF.124 Additionally, each fluoride salt utilized might require different synthesis parameters such as the reaction temperatures and etching time. It has been suggested that utilizing fluoride salts such as NaF and KF might require 48 h etching time at 40 °C to ensure a complete etching process. However, acid-containing NH4F shows complete delamination after 24 h at 30 °C. A similar morphology can be observed in all synthesized Ti3C2Tx MXenes regardless of any types of fluoride ions. In this regard, the accordion-like structure is present, suggesting that different acid-containing fluoride ions successfully form the Ti3C2Tx MXene.

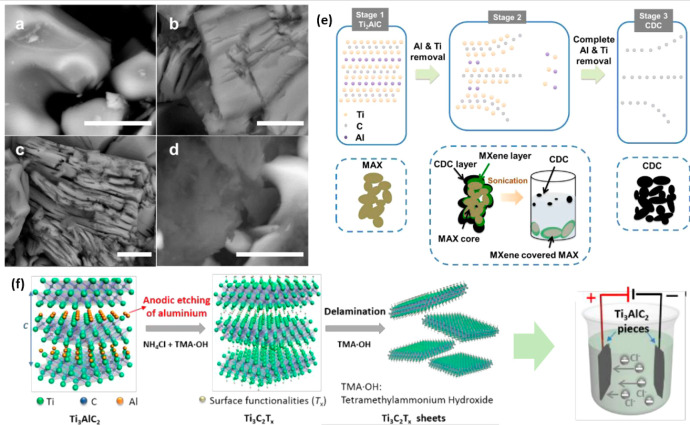

3.3. Electrochemical Etching

One of the newly developed techniques in synthesizing Ti3C2Tx MXene is the electrochemical etching by which the fluoride-based etchant can be eliminated. In this synthesized process, the electrode and electrolytes are required for the reaction to occur. The Al layer will be selectively etched with the assistance of electrolytes through anodic etching.126 In general, the Ti3AlC2 MAX will serve as a working electrode where the etching reaction will take place. Particularly, chemical and electrochemical etching is part of the surface reaction involving electron transfer, suggesting the possibility of forming Ti3C2Tx MXene by electrochemically etching the MAX phase. A study found that the Ti2AlC MAX can be electrochemically etched to form Ti2CTx MXene by utilizing an aqueous HCl (2 M) electrolyte. The absence of fluoride ions significantly yields fluoride-free terminated Ti2CTx MXene with the presence of −Cl, −O, and −OH terminal groups. In this approach, a three-layered structure of Ti2CTx MXene is formed, consisting of carbon-derived carbide (CDC), Ti2CTx MXene, and unetched MAX. Parameter study such as voltage, etching time, and electrolyte concentration was observed to affect the morphology and properties of Ti2CTx MXene, such as that shown in Figure 10a–d. In particular, increasing the concentration of the HCl and etching time shows pronounced delamination surfaces. However, overetching of Ti2CTx MXene might lead to the formation of CDC. Even though the three-layered structures consisting of CDC, MXene, and MAX are formed, bath sonication could separate the layered structure to obtain Ti2CTx MXene. The synthesis process of Ti2CTx MXene through this electrochemical etching is demonstrated in Figure 10e.

Figure 10.

(a) SEM images MAX, (b) Ti2CTx MXene etched with 1 M of HCl at 0.6 V for 1 day, (c) 2 M of HCl at 0.6 V for 5 days, (d) 2 M of HCl at 0.6 V for 14 days. (e) Synthesis illustration of the Al removal from MAX phase and formation of three-layered Ti2CTx MXene structure. Reprinted with permission from ref (128). Copyright 2017 Royal Society of Chemistry. (f) Synthesis process of electrochemical etching of Ti2CTx MXene in two-electrode system. Reprinted with permission from ref (126). Copyright 2018 Wiley.

Another study revealed that Ti3C2Tx MXene was successfully formed by utilizing binary aqueous electrolytes in a two-electrode system, such as that present in Figure 6f.126 In this method, the electrolyte consisting of 1 M NH4Cl and 0.2 M tetramethylammonium hydroxide (TMAOH) at pH >9 was employed for a 5 h reaction time to etch the Al layer and undergo intercalation to extract the carbide flakes. The presence of a Cl ion in the electrolyte expedites the anodic Al etching and breaks the Ti–Al bond. Intercalation by the ammonium hydroxide (NH4OH) promotes the etching underlying the surfaces. This approach successfully yields 90% of single and double Ti3C2Tx MXene layers with flakes larger than those in the conventional HF technique. On the other hand, the fluoride-free Ti3C2Tx MXene offers better capacitance (220 mF cm–2) than those conventionally prepared. Even though this synthesis method is shown to offer Ti3C2Tx MXene with Cl termination and successfully eliminate the −F functional, the formation of CDC required much attention. As mentioned, overetching the MAX phase in dilute HF, HCl, and NaCl electrolytes might lead to the removal of both Al and Ti layers.127 Moreover, the newly developed technique requires in-depth scientific study to ensure a successful formation of Ti3C2Tx MXene with excellent catalytic properties.

3.4. Alkali Etching

Aside from acid utilization as the etching agent, the study has found that alkali can also be employed to eliminate the Al layer of Ti3AlC2 MAX.129 A study on alkali etching revealed that the hydrothermal-assisted technique utilizing NaOH as the etching agent successfully etched the Al layer of Ti3AlC2 MAX to form Ti3C2Tx MXene. Alkali etching is one of the techniques to synthesize a fluorine-free Ti3C2Tx MXene as it does not utilize any fluoride-containing chemicals. Additionally, this newly developed preparation method was also revealed to yield high-purity (∼92%) Ti3C2Tx MXene with a multilayered structure. The strong binding ability of the NaOH with the Al element assists the etching process, thus making it possible. It has been noted that the synthesis parameters such as the reaction temperature and etching concentration are significant to ensure successful elimination of the Al layer. This is because, as demonstrated in Figure 11a, the low temperature might prevent the Al extraction process by the Al (oxide) hydroxides. Moreover, the inability to form Al4(OH)− due to lattice confinement from the Ti layer, known as the “jamming effect”, blocks formation of Ti3C2Tx MXene. On the other hand, utilizing a higher concentration of NaOH at a higher temperature leads to the oxidation of Ti3C2Tx MXene and the formation of NTOs such as Na2Ti3O7 and Na2Ti5O11. Higher water content promotes the oxidation of Ti to form NTOs. Therefore, a suitable reaction temperature and alkali concentration are required to ensure a complete formation of Ti3C2Tx MXene. The hydrothermal reaction at 270 °C with 27.5 M NaOH concentration successfully yielded Ti3C2Tx MXene with high purity compared to HF-etched MXene. In this hydrothermal-assisted NaOH etching method, controlling the temperature is essential to ensure a complete formation of Ti3C2Tx MXene, while the optimum concentration of Ti3C2Tx MXene controlled the purity of the produced Ti3C2Tx MXene. Even though the alkali-assisted, hydrothermal synthesis method has been shown to successfully generate Ti3C2Tx MXene, preventing the Ti3C2Tx MXene from overetching to form NTOs is one of the challenges and requires extra attention. In addition, this method needs in-depth research to confirm the successful formation of fluoride-free Ti3C2Tx MXene. Through this technique, −O and −OH terminal groups can be formed, and their role in stimulating photocatalytic activity and fuel conversion can be further extended.

Figure 11.

(a) Synthesis process of Ti3C2Tx MXene through alkali etching. Reproduced with permission from ref (129). Copyright 2018 Wiley. (b) Schematic representation of water-free etching of MXene by utilizing propylene carbonate. Reproduced with permission from ref (137). Copyright 2020 Elsevier. (c) SEM image of Ti3C2Tx MXene prepared through molten salt substitution. Reproduced from ref (134). Copyright 2019 American Chemical Society. (d–f) SEM image of Ti3C2Tx MXene by utilizing different types of MAX with chloride molten salts. Reproduced with permission from ref (136). Copyright 2020 Springer.

3.5. Water-Free Etching

Water-free etching is another alternative in producing Ti3C2Tx MXene with outstanding oxidation stability.130 In this synthesis process, the employment of water as a primary solvent is replaced by the polar organic solvent to ensure no presence of water. The exceptional potential of Ti3C2Tx MXenes in a wide array of applications indicates that they are one of the most favored materials. However, their hydrophilicity and tendency to oxidize limit their potential in applications requiring a longer storage period. Therefore, water-free etching was found to improve oxidation stability and broadened their role in any water-sensitive applications. In this preparation method, ammonium dihydrogen fluoride was utilized as the etching agent due to its capability to dissociate into NH4F and HF when dissolved in the polar solvents. Three reaction steps are required: etching, washing, and delamination. Specifically, as presented in Figure 11b, the etching process occurred at which Ti3AlC2 MAX underwent a reaction with NH4HF2, where the Al layer was etched out in the form of AlF3 and (NH4)3Al6. Reaction with propylene carbonate (PC) promotes delamination into single-layer Ti3C2Tx MXene. It has also been suggested that higher interlayer spacing of Ti3C2Tx MXene is obtained compared to water-etched Ti3C2Tx MXene.131 Controlling the termination groups are favorable as it has been revealed that, through this technique, approximately 70% of −F and −30% of −O/–OH containing MXene was obtained.132 In short, this method utilizes polar organic solvent, PC to replace water which was found to reduce the presence of the −OH terminating group. The control of the terminating group significantly enhances the oxidation stability, which raises Ti3C2Tx MXene potential in the water-sensitive applications as the finding suggested that more exposure of the Ti–OH species of Ti3C2Tx MXene expedites the oxidation process.133

3.6. Molten Salt Substitution

Another alternative in producing −Cl-terminated Ti3C2Tx MXene is through molten salt substitution.134 This method utilizes molten salts such as ZnCl2 and CuCl2 to undergo a substitution reaction with Ti3AlC2 MAX for the removal of the Al layer. This reaction process significantly produces nanolaminated Ti3C2Tx MXene with −Cl termination, which was found to be more stable than −F-terminated Ti3C2Tx MXene.135 The reaction mechanism is presented in eqs 11–13, which generally involves the replacement of the A element of MAX with the metal salts.

| 11 |

| 12 |

| 13 |

In eqs 11–13, the Zn2+ from the molten salts undergoes elemental replacement with the Al3+ from the Ti3AlC2 MAX. Stronger Lewis acidity by ZnCl2 promotes the substitution of Zn2+ with Al3+, forming Ti3ZnC2 MAX. Additionally, Zn2+ acts as a Lewis acid in the molten salt as it is a stronger Cl– and electron acceptor. Specifically, molten salt of ZnCl2 was ionized into Zn2+ and ZnCl42– in its molten state, while Al from Ti3AlC2 MAX undergoes redox conversion into Al3+. The formation of AlCl3 occurred through the bonding of ionic Al3+ with Cl–, where it will be evaporated. Rapid evaporation of AlCl3 facilitates the outward diffusion of the Al atom to undergo a substitution reaction. The elemental replacement further takes place when the reduced Zn atoms intercalate into the Al layer in the MAX phase, forming Ti3ZnC2, which is further exfoliated into Ti3C2–Cl2 MXene. The SEM image in Figure 11c reveals the morphology of the Cl-terminated MXene, where it shows a more compact structure with a less distinct accordion sheet compared to other conventional preparation techniques. Another study by Li et al. revealed that the synthesis of Ti3C2Tx MXene from different types of MAX phases could be achieved by employing different types of chloride molten salts such as CuCl2, FeCl2, NiCl2, and AgCl.136 Different morphology of MXenes etched by different chloride molten salts can be observed in Figure 11d–f, by which most of them show a prominent accordion-like structure of MXene.

4. Design Principles and Considerations for Ti3C2Tx MXene-Based MOF Composite

4.1. Morphological Design and Engineering of Ti3C2Tx MXenes and MOFs

In the context of morphological development, Ti3C2Tx MXenes intrinsically manifest a unique accordion-like multilayer structure. However, their morphology can be modified into different dimensional structures, such as 0D quantum dots, 2D delaminated flakes, and 3D hierarchical/multidimensional structures. Delaminating Ti3C2Tx MXenes into single flakes was shown to supply more exposed catalytic active sites and was observed to be highly efficient in driving the redox reaction compared to their multilayer morphology.149 Typically, delaminating of Ti3C2Tx MXene can be mainly performed through direct delamination or a two-step delaminating process. It has to depend on the preparation method of the Ti3C2Tx MXene itself. Direct delamination can be achieved via an acid-containing fluoride ion etching technique.150 In this regard, no intercalating agents are required to separate the layer as the fluoride ions can serve as intercalants to aid in the delamination process. On the other hand, the HF etching technique is regarded as a two-step process, requiring intercalating agents to assist the layer separation. Commonly used intercalating agents include dimethyl sulfoxide (DMSO), dimethylformamide (DMF), tetrabutylammonium hydroxide (TBAOH), and tetramethylammonium hydroxide (TMAOH).151−153 Interestingly, a comparison study by Su et al. shows that monolayer Ti3C2Tx MXene is more reactive toward the photoredox reaction due to its thinner sheet structure.138 This is because the size and structure of Ti3C2Tx MXenes distinctly affect their photocatalytic property and are correlated with their Fermi level energy. Hydrogen yield with 2.5 times enhancement was disclosed by employing monolayer Ti3C2Tx MXene compared to their multilayer counterpart. Even though the precise location of active sites in Ti3C2Tx MXenes is yet to be confirmed, through structural analysis, it was inferred to be positioned at the edge of the monolayer flakes. This corroborates with the experimental study where Ti3C2Tx MXenes with smaller flake sizes were observed to have an exceptional catalytic activity compared to that of a denser multilayer structure. More exposure of the catalytic active sites due to size effects and exposed flake edges supports the conjecture. Correspondingly, delaminated Ti3C2Tx MXenes through intercalation with TMAOH were revealed to have an apparent effect on the photocatalytic activity with 1.49 times activity improvement over that of the standard HF-etched multilayered Ti3C2Tx MXene.154 Moreover, the 2D geometry of monolayer Ti3C2Tx MXene offers excellent support for other semiconductor photocatalysts, especially for nanoparticle materials from agglomeration, providing uniform dispersion. Therefore, the solar absorption performance can be augmented owing to a larger light receiving area.155

Additionally, the tunability of their morphology indicates that they are a highly selective cocatalyst for photocatalytic enhancement. For instance, quantum dot Ti3C2Tx MXene can be constructed through layer cutting by DMSO intercalant and thermal treatment with PEI.25,156 Another study reported the preparation of Ti3C2Tx MXene QD through an ammonia-assisted hydrothermal reaction.157 Moreover, hydrothermal intercalation with DMF was also found to convert the nanosheets into QD structures.142 A benefit in converting into smaller nanosize QDs is to offer better solvent solubility and to expose more active edge sites. As mentioned, dimensional size has a great impact on the photoreaction activity, which highlights the significance of well-controlled morphology. The smaller dimensional size of the Ti3C2Tx MXene QD is shown to provide an effective coating for stabilizing the oxidation of other semiconductor materials. For instance, the Ti3C2Tx MXene QD was found to cover the porous surface of Cu2O NWs by coating them and hindering the easy oxidation of the NWs.25 In this regard, the photoreaction stability was observed to maintain up to six long cycles and retain as high as 86% methanol yield. The relevance of morphologically tuning the Ti3C2Tx MXene into a QD structure can prevail with their outstanding photoreaction activity for hydrogen generation, successfully obtaining their 2D nanosheet structure. A study found that the Ti3C2Tx MXene QD successfully produced solar hydrogen generation with as high as 10 times enhancement than that of Ti3C2Tx MXene nanosheets and 3 times higher than that incorporated with Pt, disclosing the novelty of the Ti3C2Tx MXene QD as a noble metal replacement.25

Aside from morphologically constructing Ti3C2Tx MXene into single flakes and quantum dots, hierarchical and multidimensional Ti3C2Tx MXene constructed through the combination of different dimensional domains was observed to benefit them through a supportive platform. Typically, multidimensional Ti3C2Tx MXene can be constructed by hybridizing them with other dimensional photocatalysts. For instance, the Ti3C2Tx MXene safflower shape was successfully generated by hydrothermal oxidation followed by ion exchange to form TiO2/Ti3C2Tx MXene with a 3D porous framework.140 Thermally oxidized Ti3C2Tx MXene could support the formation of TiO2 nanoparticles and, through the ionic exchange process, form the safflower-like-shaped TiO2–Ti3C2Tx. The merit of having a 3D structure framework could hinder the agglomeration of the nanoparticles and sheet aggregation, which could reduce the absorption efficiency. Thinner and smaller sizes of Ti3C2Tx MXene are highly beneficial for the carrier’s transmission where shorter distances are required to carry out the redox reaction, but the implication of agglomerated sheets is one of the serious drawbacks.158 The creation of a multidimensional structure of a Ti3C2Tx MXene-based composite with a 1D/2D structure highly benefits the carrier dynamics as different dimensional domains have an individual contribution for photocatalytic enhancement. For instance, 1D/2D CdS/Ti3C2Tx MXene constructed through in situ assembly and solvothermal treatment was found to give an eminent improvement in the photocatalytic activity compared to that of their intrinsic counterpart.149 The effective platform of 2D Ti3C2Tx MXene sheets for CdS nanorod growth provides intimate contact and aids in the separation of charges. For instance, the longitudinal oriented charge transmission with high length-to-diameter ratio semiconductors could improve the separation efficiency as a longer time is needed for the charges to travel back and recombine. On the other hand, hierarchical nanoflower-like core–shell morphology is constructed by in situ hydrothermal LDH on Ti3C2Tx MXene.159 The growth of smaller LDH nanoflakes creates a Ti3C2Tx MXene with abundant active sites for photocatalytic CO2 reduction. The well-dispersed LDH nanoflakes covering the Ti3C2Tx MXene surfaces in the core–shell-like shape improve the light absorption and hinder the serious agglomeration typically observed in LDH nanoflakes. Therefore, designing Ti3C2Tx MXene into different morphological structures is one of the promising engineering considerations for producing a very efficient photocatalyst for solar fuel conversion. Figure 12 summarizes the development of Ti3C2Tx MXene into different morphological structures.

Figure 12.

Morphological development of Ti3C2Tx MXene into monolayer, quantum dots, and hierarchical/multidimensional structure.

As mentioned previously, MOFs tend to naturally occur in 1D rods, 2D sheets, or 3D polyhedrons, in which the latter tend to be the more common morphology. 1D MOFs are usually identified by their nanometric diameter together with an extended length, adopting chains or rod structures. On the other hand, 2D MOFs exist as sheets or layers that have a nanoscale thickness. 2D MOFs have a few beneficial properties as an efficient photocatalyst, such as high exposed surface area to light irradiation and reactants, as well as excellent electron transferability.160,161 Finally, 3D MOFs are held together by strong chemical bonds, which come together to form a highly complicated network structure. These polyhedrons boast an extremely high surface area, with uniform pore size distributed all over the surface of the MOF.30 Nevertheless, the morphology and dimensions of MOFs can be further regulated via two main approaches which is (1) modification of synthesis parameters and (2) introduction of additives. First, various synthesis parameters were reported to modify the morphology of MOFs, such as temperature, reaction time, and solvent ratio. Yuan et al. noticed that the structure of Ni-MOF alters according to the solvothermal synthesis temperature. At room temperature and 60 °C, the Ni-MOF exhibits an urchin-like structure with a diameter of approximately 200 nm. As the temperature increased to 100 °C, one-dimensional nanowires with 10 nm diameter were obtained. The change in morphology was mainly due to the dynamic viscosity of 2-methylimidazole linkers, which limits the mass transfer through the temperature change.162 In another study, the effects of reaction temperature and time were studied with a Co-MOF. The original 2D nanoplates of Co-MOF were transformed into 1D layered microrods as both the reaction temperature (120 to 160 °C) and time (5 to 30 min) increased.163 The solvent ratio can also effectively alter the structure of the MOF due to the role of solvent as a directing agent as well as ligands, where they can be incorporated onto the lattice of the MOF. It was previously reported that by manipulating the DMF/ethanol solvent ratio from 3 to 1, the 3D structure of the MOF was converted into 2D nanosheets.164

Second, the use of additives such as modulators and surfactants is effective at tuning the morphology of MOFs. For example, a 3D hollow porous concave octahedral bimetallic Fe–Zn MOF was prepared via a conventional solvothermal method using FeCl3·6H2O, Zn(NO3)2·6H2O, and terephthalic acid as linkers, with DMF and C2H5OH alcohol as solvent. Upon introduction of polyvinylpyrrolidone (PVP), the morphology of the MOF showed a drastic change, from 3D octahedrons to 1D hollow porous nanorods.165 Additionally, Sarawade et al. investigated the effect of various surfactants on the morphology on a Co-MOF with linkers of 2,6-naphthalenedicarboxylic acid (H2ndc) and trans-1,2-bis(4-pyridyl)ethylene (bipyen). Without the use of surfactant, the Co-MOF exhibited a spindle-like microrod structure. However, upon the use of cetyltrimethylammonium bromide, sodium dodecyl sulfate (SDS), and Pluronic triblock copolymer (P123) surfactants, the original morphology was converted into 2D nanoplates, nanosheets, and 1D nanorods, respectively.163 The morphology engineering of MOFs was then summarized, as shown in Figure 13. MOFs tend to exist mainly in 3D structures, with some MOFs naturally existing in 1D rods or 2D sheets. However, the morphology and dimensions of MOFs can be further engineered either by varying the synthesis parameters or by using additives.

Figure 13.

Scheme illustrating the general morphology and morphological engineering of MOFs.

4.2. Active Sites over Ti3C2Tx MXene-Based MOF Composite

Active sites are the locations or specific sites where a certain reaction has the highest activity. It is of utmost importance to identify the active sites over photocatalysts to gain a deeper understanding of how to quantify and optimize the active sites with respect to a specific chemical reaction. This is because the types of active sites present on the surface of the catalyst can influence the overall selectivity of the products. The role of active sites is especially evident in thermal and photothermal catalysis. For example, the utilization of Ni166 and Co80 metals tends to yield a higher production of CH4 from the CO2 hydrogenation reaction. However, the use of Fe promotes the Fischer–Tropsch reaction, in turn exhibiting a higher C2+ hydrocarbon evolution.167,168 From these examples, we can get a general idea on the active sites of MOFs. MOFs are made up of a variety of metal nodes, such as Co, Zr, and Ti and can be regarded as isolated quantum dots that can be excited upon light irradiation.169 Second, the organic linkers can also function as active sites or be functionalized to anchor active sites. Most notably, UiO-66 linkers modified with Cu(II) porphyrins not only enhanced the overall photocatalytic activity but also boosted the light adsorption of the photocatalyst.170 Similarly, MOF-525, which consists of porphyrin linkers anchored Co metal, successfully incorporated the Co active sites onto the framework of the MOF. The introduction of CO active sites to the framework prolonged the lifetime of charge carriers and improved the CH4 production from photocatalytic CO2 reduction.171 Lastly, the huge cavity of MOFs is a suitable host for encapsulating photoactive metal nanoparticles. Zhao’s group successfully encapsulated Ni nanoparticles within the pores of UiO-66, which limited the growth of Ni via agglomeration.172 Interestingly, the encapsulation is not limited to only metals. Li et al. reportedly boosted the photocatalytic CO2 reduction by embedding carbon dots inside NH2–UiO-66 particles. These carbon dots function as electron receptors and photosensitizers, which promote charge separation and transfer.173 The discussion on the active sites of MOFs are summarized in Figure 14, where they exist either at the metal nodes, organic linkers, or within the cavity of MOFs.

Figure 14.

Overview of the active sites present over metal–organic frameworks.