Abstract

Soymilk (SM) is nutritionally nearly equal to milk from cows and is free of cholesterol, gluten, and lactose. This study’s objective was to formulate a cholesterol-free soymilk dessert (SOD) and compare it’s to commercial desserts (CODs). Results indicated that the CODs contain substantial amounts of cholesterol while SOD does not. Soymilk dessert has more protein, and vitamin E than CODs, but less fat and calcium. In addition, the result also highlighted that SOD has higher number of amino acids compared to CODs. The total antioxidant, flavonoids and phenolics content of SOD were significantly higher than CODs. Furthermore, the in vitro antioxidant activity of SOD and CODs by DPPH and ABTS methods revealed that the IC50 of SODs significantly (p < 0.001) lower than CODs, and lower IC50 indicated the higher free radical scavenging power of SODs than CODs. These findings indicated that this non-dairy SOD may provide beneficial protein, as well as minerals, and antioxidants to support the body’s various physiological functions.

Keywords: Soymilk, Macronutrients, Cholesterol, Antioxidant, Phytochemicals

Soymilk,; Macronutrients; Cholesterol; Antioxidant; Phytochemicals.

1. Introduction

Consumers all across the world are constantly looking for products that are good for their health. This demand is met by milk and its fermented products, known as commercial desserts (COD). This is due to its great nutritional value and a plethora of health-promoting characteristics (Ali et al., 2022). Furthermore, animal milk and its products may have allergic potential and cause digestion problems in some people due to a lack of the lactase enzyme. Aside from this, animal milk products are abundant in cholesterol and fat (Punia et al., 2020). On the other hand, products based on plant-based milk are free of cholesterol, especially soymilk-based products.

For more than two decades, the health benefits of soy-based meals have been thoroughly examined. Soybeans are not only a good source of plant protein but are also associated with numerous health benefits. Besides protein, soybean contains other basic macro and micronutrients such as fat, carbohydrate, minerals, vitamins, and phytochemicals (Friedman and Brandon, 2001; Messina and Messina, 2010). At present, soybean products are becoming popular food item due to its rich nutrient composition.

In Asia, the most common soybean products are Soymilk (SM), Tofu, Natto and Soy sauce etc. Other fermented soy products like Sufu, Miso and Douchi have also been part of Asian diet (Cao et al., 2019; Jayachandran and Xu, 2019). Besides, animal milk based commercial dessert, SM features a balanced nutritional profile equivalent to that of regular milk, but is absent of lactose, gluten, and cholesterol, as well as rich in phytochemicals (Rathi et al., 2015).

To date, the majority of the underlying evidence suggests that soy product consumption improves bone health, lowers cancer risk, and progression of diabetes (Friedman and Brandon, 2001; Gobert and Duncan, 2009; Jayachandran and Xu, 2019; Morency et al., 2017). However, soy products also contain some anti-nutritional factors such as trypsin initiators and allergen proteins that could affect normal digestion and nutrient availability. There is emerging evidence that fermented soy products by Neurospora crassa and Saccharomyces cerevisiae contain high quality protein and that it could degrade allergens in soy meal (Dai et al., 2017; Li et al., 2019). However, this emerging evidence needs further validation.

Various soy products are readily available in the global market. However, there is limited literature on soy dessert preparation. Given the aforementioned beneficial effects of soy products, this study focuses on the use of SM to prepare a cholesterol-free dessert. The objectives include analyzing the nutrient composition and antioxidant activity of the SM dessert, and comparing its nutritional value with the commercially available cow milk-based desserts. The formulated soymilk-based dessert reported higher protein, lower fat, and zero cholesterol compared to the available milk based commercial desserts on the market. Additionally, soymilk desserts contain a significant number of antioxidants, phenolics, and flavonoids and show good in vitro antioxidant activity in DPPH and ABTS assays.

2. Methods and materials

In this present study, SM dessert was developed from soymilk and analyzed its nutritional value and antioxidant activity. Additionally, the available milk-based commercial desserts were collected from local market. The details about soymilk dessert are provided in the following section.

2.1. Chemicals and reagents

Sigma-Aldrich (USA) supplied the ascorbic acid, gallic acid, rutin hydrate, trypsin, folin-ciocalteu’s reagent, 2.2-azino-bis (3-ethylbenzothiazoline-6-sulphonic acid) (ABTS), 2,2-Diphenyl-1-picrylhydrazyl (DPPH), TPTZ, ferric chloride, sodium hydroxide and methanol. All additional compounds were obtained from BDH in the United Kingdom and were of analytical quality.

2.2. Preparation of SM dessert

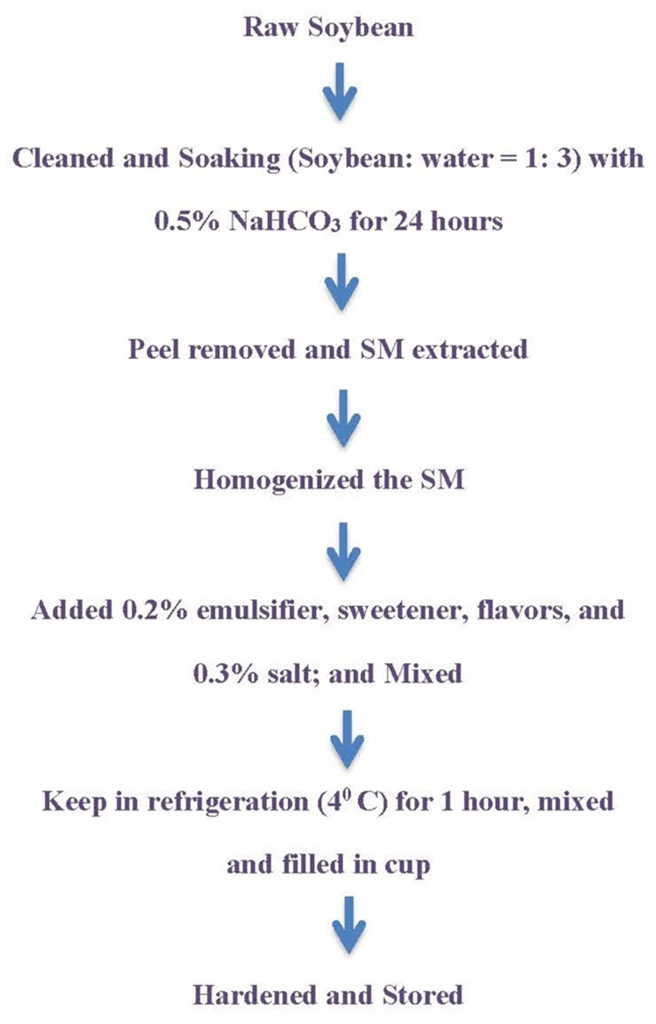

Figure 1 presents the flow chart for preparation of soy milk. Raw soybean (100 g = 5 BDT) was collected from local market of Dhanmondi, Dhaka. After cleaning, 100 g of raw soybean was soaked in 300 ml of water (soybean: water = 1: 3) and 0.5% sodium bi-carbonate for 24 h. After sorting, the outer layer of soybean was removed. This was followed by blending the soybean with mater to make soy milk (soybean: Water = 1:3). This blended solution (soy milk) was heated for 30–35 min and was allowed to cool at room temperature. This milk was homogenized for 10 min. Further, we used, 0.2 % emulsifier, 0.3 % salt, sweetener (zero calorie), food grade color and flavors for dessert preparation. The product was finally placed in refrigerator (0 °C) for hardening and storing. Commercial desserts (CODs) were collected from locale market that were formulated by commercial dessert manufacturing industry. The major ingredients of commercial desserts are summarizing in Table 1.

Figure 1.

Flow chart for preparation of soymilk dessert (SOD).

Table 1.

List of ingredients for making commercial desserts (CODs).

| COD-I | COD-II | COD-III |

|---|---|---|

| Milk solids | Full cream milk powder | Skim milk powder |

| Vegetable Fat | Skim milk powder | Milk Fat |

| Milk Fat | Vegetable Fat | Milk Protein |

| Glucose syrup | Glucose | Glucose Syrup |

| Sugar | Sugar | Purified sugar |

| Treated water | Treated water | Treated Water |

| Emulsifier (E471) | Emulsifier (INS471, 466, and 433) | Cocoa Powder |

| Stabilizer (E407, E412, and E65) | Stabilizer (INS407 and 412) | Emulsifier |

| Artificial Flavouring agent | Vanilla food flavour | Stabilizer |

| Permitted natural colour | Permitted food colour | Chocolate flavour |

2.3. Nutritional analysis

Proximate composition: Proximate analysis involved estimation of moisture, ash, protein, and fat content present in food. Moisture and ash content were determined using the American Oil Chemists' Society’s recognized techniques (AOAC, 2005). The estimation of milk fat was performed by Rose-Gottlieb method and the total protein concentration was calculated using the Kjeldahl method as described by the AOAC (2005).

Cholesterol: The total cholesterol content was determined by direct saponification and capillary gas chromatography methods previously described by Fletouris et al. (1998).

Minerals, vitamins and amino acids: Minerals (Iron, sodium, calcium, phosphorus and potassium) were analyzed following the methods described in the Manual of Laboratory Techniques (AOAC, 2005). For 6 h, a weighted sample (g) was held at 600 °C in a muffle furnace. After preparing the stock solution with 6M HCl, the minerals were identified by atomic absorption spectrometry (Spectrophotometermodel: Thermo scientific, ICE 3000 series). Both water and fat soluble vitamins were determined according to Chen (Chen and Wolf, 2007) by UPLC-MS-MS (model: Thermo scientific, ultimate 3000) methods. The amino acid analysis was conducted by the amino acid analysis system instruction manual described by AOAC (2000).

2.4. Sample preparation for antioxidant determination

3.16 g of SOD and 2.64 g of CODs dried extract was diluted in 50 mL of methanol in a falcon tube, resulting in a stock solution with a concentration of solution expressed as mg/ml. These solutions were vortexed and sonicated for 4–6 h. The stock precipitate was prepared through Whatman No. 1 filter paper and stored at 4 °C until needed

2.4.1. Total phenolic content

The total phenolic content was determined in accordance with standard procedures described before by (Zilic et al., 2012) with some changes. 0.5 ml of extract was measured from the stock solution and combined with 0.5 ml of Folin-Ciocalteu reagent (0.5 N) and incubated at room temperature for 5 min. After adding 2.0 ml of saturated sodium carbonate and incubating for an additional 30 min at room temperature, the absorbance at 765 nm was measured and the absorbance value computed using the gallic acid standard curve as a positive control.

2.4.2. Total flavonoid content

The aluminum chloride technique was used to determine the flavonoid content (Zilic et al., 2012) using rutin hydrate as a standard. One milliliter of sample was mixed with four milliliters of ultra-pure water. This was followed by the addition of 0.3 ml of 5% NaNO2 and a 5-minute incubation at room temperature (RT). Again, 0.3 ml of 10% AlCl3 solution was then added and kept for 6 min at room temperature. Following incubation, 2 ml of 1M NaOH solution was added and the mixture was brought to a final volume of 10 ml with double distil water. Finally, after allowing the combination to stand for 15 min, the absorbance at 510 nm was determined in comparison to a blank sample.

2.4.3. Total antioxidant capacity

Total antioxidant activity was evaluated using the previously established Phosphomolybdenum blue technique by (Dai et al., 2017). Take 1 ml of methanol extract in a test tube and add 3 ml of previously made reagent mixture and mix well. Then the mixture solutions were incubated at 950 C for 90 min, cooled and took absorbance at 695 nm against a blank (methanol and reagents). The total antioxidant was calculated using gallic acid equivalent as a standard.

2.4.4. Ferric reducing antioxidant power assay (FRAP)

The FRAP assay was carried out according to the method described by Ketnawa with some modifications (Ketnawa and Ogawa, 2019). The FRAP reagent was made in the following proportions: acetate buffer (1.6 g sodium acetate and 8 ml acetic acid to generate 500 ml) (pH 3.6), 10 mM TPTZ solution in 40 mM HCl, and 20 mM iron (III) chloride solution in a ratio of 10:1:1 (v/v). 0.5 ml of sample extract and 0.5 ml of distilled water were placed in a test tube. 4 ml of the FRAP reagent was added to this and thoroughly mixed. A UV-visible spectrophotometer was used to determine the absorbance at 593 nm, and water was utilized as a blank. Triplicate samples were taken. A similar process was used to construct a standard curve using gallic acid (0.2 ml, 0.4 ml, 0.6 ml, 0.8 ml, and 1 ml).

2.4.5. 2,2-Diphenyl-1-picrylhydrazyl (DPPH) radical scavenging ability

The DPPH radical scavenging ability was tested using the method proposed by (Chi and Cho, 2016) with some modifications. Two millilitres of samples at various concentrations were added to two millilitres of previously prepared DPPH methanol stock solution (0.004 percent) and incubated in the dark for 20 min. At 517 nm, the absorbance was determined using ascorbic acid as a reference. Evaluate the amount of inhibition by:

| Inhibition (%) = (A0 – A1/A0) × 100 |

where, A0 denotes the absorbance of the control sample and A1 denotes the absorbance of the test sample.

2.4.6. Free radical scavenging by 2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) method

The free radical scavenging activity was determined using the previously described enhanced ABTS radical cation decolorization method (Ketnawa and Ogawa, 2019). Put 0.2 ml, 0.4 ml, 0.6 ml, 0.8 ml, and 1.0 ml of methanol extract into different test tubes and make the volume up to 1.0 ml with water. Following that, 3.0 ml of ABTS reagent mixture was added, thoroughly mixed, and incubated for 10 min. As a blank, measure the absorbance at 670 nm against water and reagent mixture, and use rutin hydrate as a standard. The percent of inhibition was calculated by the following formula:

| Inhibition (%) = (A0 – A1/A0) × 100 |

where, A0 denotes the absorbance of the control sample and A1 denotes the absorbance of the test sample.

2.5. Sensory evaluation

A panel of 5 semi-trained judges assessed sensory qualities. The acceptance tests (taste, color, flavor, and consistency) were graded hedonically. The hedonic scale included three points: 0 = dislike, 5 = neutral, and 10 = like. Each product went through the same process. All members are willingly participating in the sensory evaluation test upon the request of the laboratory head, quality control research section, IFST, BCSIR. The head of quality control research section, IFST, BCSIR, has taken written consent from the participants.

2.6. Statistical analysis

All experiments were replicated three times. The data were expressed using the mean and standard deviation. Graphpad prism7.0 was used to determine the one-way ANOVA and t-test between the mean values of SOD and CODs (I, II, and III). A statistically significant level of probability was defined as ∗p < 0.05 and ∗∗p < 0.01. To further understand the general correlations between SOD and CODs, a cluster analysis (CA) with dendrogram was generated using Ward’s method in the SPSS package (SPSS 17.0, SPSS Inc., Chicago, IL, USA).

3. Results and discussion

3.1. Nutrient composition

The content of macronutrients in SOD and CODs are compared in Table 2. Overall, there is a significant difference in moisture, ash, fat, protein, and carbohydrates. Compared to CODs (I, II and III), SOD has more protein (∼1.5%), less fat (∼3.0%), less total sugar (∼10.7%), and less carbohydrate (∼4.3%). The moisture and protein content are significantly higher in SOD than in CODs. Protein percentage in SOD is about 1.5% higher than in CODs, with COD-I having the lowest protein percentage among the CODs. Previous studies revealed that the protein content of fermented soybean products was increased by about 2–2.8% compared with non-fermented soy products (Genevois et al., 2018; Li et al., 2019) and our results are in line with these findings. Another study reported that soya products contained 7–9.2% protein with essential amino acids except methionine (Friedman and Brandon, 2001). On the other hand, Table 2 presents a clear difference between fat, total sugar and carbohydrate percentages of SOD and CODs. In SOD, the fat percentage is 8.09 ± 0.07. Compared to CODs, the fat percentage is significantly (p < 0.05) lower (about ∼3%) in SOD than in CODs, where COD-III showed the highest percentage of fat. Table 2 also showed that COD-III contains higher total sugar percentages (about ∼10%) than SOD and also higher than COD-I and II. Similar to our findings, studies published in the past by Nande et al. (2008) reported that SM contains low fat content (1.9–5.3%) compared to cow milk. In our study, we used plant oil as an emulsifier, which might have added to the fat content in our dessert. Previously, some studies explained that compared to other dairy products, soy milk diets may have some positive effect on reducing body weight due to their low sugar and low carbohydrate content (Faghih et al., 2011; Genevois et al., 2018; Huang et al., 2019).

Table 2.

Nutritional analysis of developed SOD and CODs.

| Nutrients | SOD (% ± SD) | COD-I (% ± SD) | COD-II (% ± SD) | COD-III (% ± SD) |

|---|---|---|---|---|

| Moisture | 73.43 ± 1.16a,b,c | 60.43 ± 0.77a | 62.62 ± 0.45b | 62.68 ± 0.40c |

| Ash | 0.74 ± 0.005b,c | 0.72 ± 0.011 | 0.87 ± 0.02b | 0.85 ± 0.025c |

| Fat | 8.09 ± 0.07b,c | 10.86 ± 0.44 | 11.16 ± 0.45b | 14.24 ± 0.67c |

| Protein | 6.16 ± 0.07a | 4.45 ± 0.06a | 5.44 ± 0.28 | 5.41 ± 0.18 |

| Carbohydrate | 11.58 ± 0.31a,b,c | 23.54 ± 0.49a | 19.907 ± 0.23b | 16.81 ± 0.34c |

| mg/100 g | mg/100 g | mg/100 g | mg/100 g | |

| Cholesterol | 0.0 | 5.62 ± 0.19 mg | 4.46 ± 0.27 | 27.11 ± 0.11 |

Results are indicated as mean value ±standard deviation (SD).

a = indicates significant difference between SOD and COD-I, p value < 0.05.

b = indicates significant difference between SOD and COD-II, p value < 0.05.

c = indicates significant difference between SOD and COD-III, p value < 0.05.

3.2. Sensory evaluation

The present study examined the sensory properties of SODs in terms of flavor, taste, color and texture, and overall acceptability. Taste is the primary factor that determines a product’s acceptability, and so has the greatest impact on the product’s commercial success. The results shows that the sensory attributes and overall acceptability of SOD are higher on day 1 and slightly decreased on day 15 and day 30 (Figure S1). Moreover, it has been shown that SOD is safe to consume up to day 15. However, sensory evaluation on a broad scale is recommended for further experimentation.

3.3. Cholesterol content of desserts

Table 2 indicates the cholesterol content of SOD and CODs. The cholesterol content in SOD is absent but the CODs contain a significant amount of cholesterol (5.62 ± 0.19, 4.46 ± 0.27 and 27.11 ± 0.11 mg/100 g respectively). Soybeans and soymilk contain no cholesterol, and soya meals provide extra health benefits. On the other hand, studies also described that milk products from cows or goats contained a significant amount of cholesterol ranging from 4.9 to 23.5 mg/100 g (Talpur et al., 2006; Park, 2000). The newly developed SOD contains no cholesterol and that’s why the consumption of this dessert may help to prevent coronary heart diseases. Different human research has validated the animal results on soy proteins' hypocholesterolemia-lowering benefits. One putative reason for soy protein’s cholesterol-lowering action is its capacity to regulate the amounts of LDL receptors in the liver (Cao et al., 2019; Friedman and Brandon, 2001; Jayachandran and Xu, 2019). So, the newly formulated cholesterol-free dessert may be beneficial for people, especially the obese. This product may help to lower the LDL level in the blood and regulate good physiological functions of the body. Multiple lines of evidence indicate that soy protein may have a beneficial effect on insulin resistance, lipid absorption, fatty acid metabolism, and other hormonal, cellular, and molecular alterations linked with obesity (Eslami and Shidfar, 2019; Jayachandran and Xu, 2019).

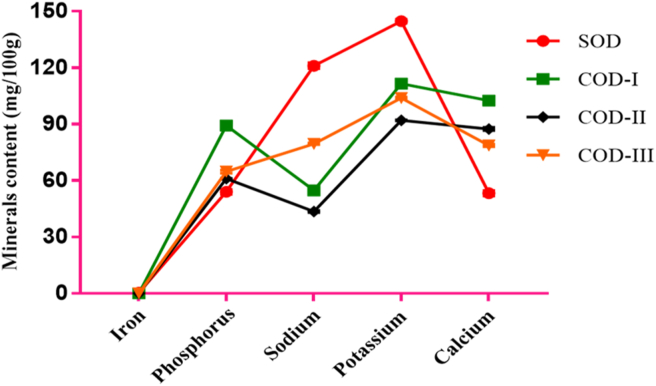

3.4. Minerals in desserts

The minerals content of the newly developed dessert is shown in Figure 2. There is substantial difference between minerals content of SOD and CODs. Compared to CODs (I, II and III), SOD has more sodium (∼40% higher), more potassium (∼31.23% higher), less phosphorus (∼6.0 % lower) and less calcium (∼20.75% lower). Additionally, only SOD contains significant amount of iron. Similar to iron, potassium and sodium content are significantly higher in SOD than CODs. However, this is not the case for calcium and phosphorus content. CODs contain higher calcium and phosphorus than SOD. Previous studies reported that soy milk or soy product contains iron 4.7–15.98 mg, potassium 292 mg, phosphorus 78 mg, calcium 301 mg and magnesium 39 mg (Reinwald and Weaver, 2010; Rizzo and Baroni, 2018). Previous data showed that milk or milk products are a rich source of minerals than other non-dairy products but not iron content (Ortega et al., 2019; Scholz-Ahrens et al., 2019). Comparing SOD with CODs, we can say that SOD may become a good source of some minerals like iron, potassium, sodium and phosphorus.

Figure 2.

Mineral content of SOD and CODs.

3.5. Vitamins in desserts

Table 3 indicates the vitamin content of SOD and CODs. SOD and CODs both have high levels of water-soluble and fat-soluble vitamins. The earlier study revealed that soya cheese contained vitamin B complex, biotin, and pantothenic acid (Chen and Wolf, 2007). In SOD, the amounts of vitamins E and B1, B2 and B6 are significantly higher than CODs (I, II and III). On the other hand, vitamin A, vitamin D, and niacin content are significantly lower in SODs than the CODs (I, II and III). Table 3 also shows that, in SOD, vitamin E content (0.66 mg/100 g) is higher and vitamin D (9.16 ug/100 g) content is lower. SOD contains a moderate amount of vitamin B complex vitamins, except niacin (B3). On the other hand, milk products are also rich in vitamins as well as minerals. A recent study found that milk and milk products have similar vitamin and mineral content, and our findings are consistent with previous findings (Górska-Warsewicz et al., 2019). Like other nutrients, vitamins are crucial for maintaining the body’s mechanism, growth, and disease prevention. Vitamin A is required for normal immune function, and a deficit can result in a decreased response to infection and night blindness (Oliveira et al., 2019).

Table 3.

Vitamin’s content of SOD and CODs.

| Name of vitamin | SOD (Amount/100 g) ± SD | COD-I (Amount/100 g) ± SD | COD-II (Amount/100 g) ± SD | COD-III (Amount/100 g) ± SD |

|---|---|---|---|---|

| Vitamin-A | 35.0 μg ± 1.11 | 33.12 mg ± 1.32 | 28.73 mg ± 1.01 | 23.72 mg ± 0.81 |

| Vitamin-D | 9.16 μg ± 0.82 | 1.77 mg ± 0.21 | 1.91 mg ± 0.77 | 1.49 mg ± 0.17 |

| Vitamin-E | 0.43 mg ± 0.21 | 0.13 mg ± 0.05 | 0.09 mg ± 0.1 | 0.10 mg ± 0.09 |

| Thiamin (B1) | 0.072 mg ± 0.19 | 0.05 mg ± 0.12 | 0.033 mg ± 0.66 | 0.057 mg ± 0.21 |

| Riboflavin (B2) | 0.05 mg ± 0.16 | 0.03 mg ± 0.13 | 0.07 mg ± 0.32 | 0.043 mg ± 0.15 |

| Niacin (B3) | - | 0.09 mg ± 0.11 | 0.10 mg ± 0.41 | 0.077 mg ± 0.10 |

| Vitamin B6 | 0.68 mg ± 1.01 | 0.38 mg ± 0.19 | 0.46 mg ± 0.10 | 0.26 mg ± 0.11 |

| Biotin | 234 μg ± 2.21 | 1.54 mg ± 0.12 | 1.10 mg ± 0.13 | 1.15 mg ± 0.19 |

Results are indicated as mean value ±standard deviation (SD).

3.6. Amino acids in developed dessert

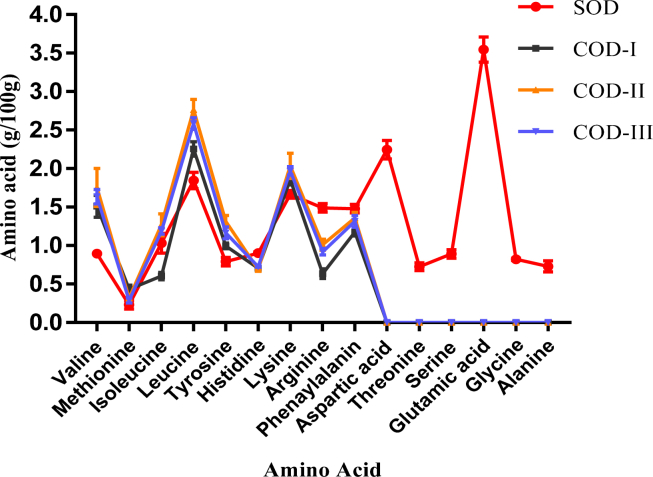

Soybean or soybean products are good sources of high-quality plant-based protein (Friedman and Brandon, 2001; Ketnawa and Ogawa, 2019; Li et al., 2019). Additionally, animal milk is also rich in protein as well as amino acids. The protein content of any food depends on its amino acid quantity. The analysis of amino acid content of SOD and CODs are presented in Figure 3. The amino acid content of SOD and CODs were determined on a dry basis. In comparison to CODs, we observed that the newly formulated SOD has a higher number of amino acids. The findings revealed that SOD has 15 amino acids, whereas CODs only have 9 amino acids. SOD contains a larger amount of glutamic acid (3.52 %) than the other amino acids. On the other hand, methionine (0.23 %) content is lower than other amino acids in SOD. Furthermore, in SOD, the percentages of histidine (0.90 %), arginine (1.49 %) and phenylalanine (1.48 %) are higher than CODs. Additionally, SOD contains six more amino acids (aspartic acid, threonine, serine, glutamic acid, glycine and alanine) than CODs. In contrast, the CODs contained higher percentages of valine, leucine, and isoleucine compared to SOD. Previously, it was described that soybean is a good source of protein containing all amino acids with methionine deficiency (Friedman and Brandon, 2001; Kudełka et al., 2021). However, soy dessert contains amino acids in a significant amount that are very important for vegetarians or individuals' diet. During processing, some nutrients might be lost (often known as post-harvest losses). As a result, while soya dessert contains fewer amino acids than raw soybeans, but it contains nearly all of the amino acids that are important for consumer health. Altogether, the evidence suggests that SOD has better amino acid quality than CODs.

Figure 3.

The amino acid content of SOD and CODs.

3.7. Phytochemicals and antioxidants content of SOD

Health promoting properties ascribed to soy drinks and products have been associated, among other bioactivities, with their antioxidant properties. SOD contains a considerable number of phytochemicals and antioxidants. The results indicated that SOD contains a significant amount of antioxidant phenolic and flavonoids compounds. The phenolic and antioxidant content were calculated to be equivalent to gallic acid and our study found that SOD contain significantly (p < 0.001) higher phenolics (77.77 ± 1.05 mg/100 g) and antioxidant (449.24 ± 1.19 mg/100 g) content compared to COD-I, COD-II, and COD-III (Table 4). On the other hand, the flavonoids were determined by aluminum chloride method and found that the flavonoid was absent in CODs and but present in SOD (392.44 ± 1.38 mg/100 g) and equivalent to rutin hydrate. In our study, we didn’t found flavonoids in CODs according to AlCl3 method, but it might be detectable to other flavonoids determination methods. According to previous research, soya products are an excellent source of bioactive chemicals such as phenolics (3.0 ± 0.272 mg/g) and flavonoids (1.5 ± 0.085 mg/g) and these compounds significantly increased in fermented soy products (Chi and Cho, 2016). Research also suggested that soy products contain good quality protein and are rich in antioxidants, and our results are also consistent with these results (Hu et al., 2019; Huang et al., 2019; Li et al., 2019).

Table 4.

Phytochemicals and antioxidant content of different dessert equivalent to different standard.

| Parameters | Linear regression equation | Standard | SOD (mg/100 g) | COD-I (mg/100 g) | COD-II (mg/100 g) | COD-III (mg/100 g) |

|---|---|---|---|---|---|---|

| Phenolic content | y = 98.419x - 0.7443 R2 = 0.9857 |

Gallic acid | 77.77 ± 1.05a,b,c | 33.60 ± 0.98a | 53.18 ± 0.34b | 39.8 ± 0.66c |

| Flavonoid’s content | y = 638.95x + 9.8716 R2 = 0.9899 |

Rutin hydrate | 392.44 ± 1.38 | ND | ND | ND |

| Antioxidant content | y = 256.11x - 12.645 R2 = 0.9974 |

Gallic acid | 449.24 ± 1.19a,b,c | 344 ± 4.24a | 397 ± 5.65b | 371.5 ± 4.94c |

| Antioxidant activity by FRAP | y = 5.2877x + 0.137 R2 = 0.9973 |

Gallic acid | 16.70 ± 0.39a,b | 22.76 ± 0.50a | 11.02 ± 0.84b | 15.92 ± 0.44 |

| IC50of SOD (mg/mL) | IC50of COD-I (mg/mL) | IC50of COD-II (mg/mL) | IC50of COD-III (mg/mL) | |||

| DPPH assay | y = 45.648x + 5.345 R2 = 0.9832 |

Ascorbic acid | 122.7 ± 1.0a,b,c | 323.89 ± 4.10a | 198.44 ± 2.65b | 979.78 ± 13.5c |

| ABTS assay | y = 9.457x - 4.219 R2 = 0.9906 |

Rutin Hydrate | 27.7 ± 0.15 | ND | ND | ND |

Results are indicated as mean value ±standard deviation (SD). ND = Not detected in those methods.

a = indicates significant difference between SOD and COD-I, p value < 0.001.

b = indicates significant difference between SOD and COD-II, p value < 0.001.

c = indicates significant difference between SOD and COD-III, p value < 0.001.

Phenolic compounds have been shown to protect against the development of a variety of chronic diseases, including diabetes, atherosclerosis, and cancer. This protective impact of phenolics is likely due to their antioxidant and free radical scavenging capabilities (Sanjukta and Rai, 2016; Santos et al., 2017; Takagi et al., 2015; Vieira et al., 2018). Furthermore, even if antioxidants are beneficial, it is unknown which antioxidants are required in excess of average dietary intake. While some academics oppose the concept that antioxidants can help avoid chronic diseases, others feel that such a possibility is unproven and erroneous from the start (Eslami and Shidfar, 2019; Gobert and Duncan, 2009).

The FRAP method was used to determine the ability of this compound to decrease Fe (III). This could be due to hydrogen donation by phenolic compounds, which is also associated with the presence of a reductant agent. The result (Table 4) indicates that the developed product SOD contains considerable power to reduce the free radical (16.70 ± 0.39 mg/100 g) compared to CODs. In FRAP assay, the COD-I exhibited highest reducing activity (22.76 ± 0.50 mg/100 g) compared to SOD, COD-II and CO-III The reaction mixture’s increased absorbance suggested that it has stronger reducing power. Generally, reducing characteristics are connected with the presence of certain reductants (Chi and Cho, 2016; Ketnawa and Ogawa, 2019; Li et al., 2019; Sanjukta and Rai, 2016). The result indicates the formulated soya dessert (SOD) can be a considerable source of phytochemicals and antioxidants which may protect the body from free radicals while providing some anti-disease functions.

3.8. Analysis of free radical scavenging power by DPPH and ABTS assay

Scavenging activities for free radicals are critical due to the harmful effects of free radicals in dietary and biological systems. Table 4 (lower part) represents the IC50 of the SOD and CODs by DPPH and ABTS assay. The in vitro DPPH assay reported that SOD and CODs exhibited free radical scavenging activity. The IC50 of SOD (122.74 ± 1.07 mg/ml) is significantly lower (p < 0.001) compared to CODs. On the other hand, in ABTS assay, only SOD exhibited free radical scavenging power (IC50 = 27.79 ± 0.15 mg/ml) equivalent to rutin hydrate standard. The IC50 value denotes the smallest amount of antioxidant required to reduce half of the total free radicals in the body. Lower IC50 indicates good reducing power of free radicals. In this study, the result indicates the lower IC50 for SOD compared to CODs in DPPH and ABTS assay equivalent with ascorbic acid and rutin hydrate standard respectively. Previously, study described that the soybeans have good free radical scavenging power after fermentation by Neurospora crassa and Bacillus subtilis, and the IC50 for DPPH was 1.84 mg/ml and 13.33 mg/ml respectively. On the other hand, IC50 for ABTS was 10.78 mg/ml (Dai et al., 2017; Li et al., 2019).

The reduction of DPPH and radicals indicates that the extracts studied contain radical inhibitors or scavengers capable of serving as main antioxidants. They may react with free radicals, notably peroxy radicals, which are the primary propagators of the fat auto-oxidation chain, bringing the chain reaction to a halt (Ketnawa and Ogawa, 2019; Li et al., 2019; Sanjukta and Rai, 2016). According to the findings, the anti-oxidative action of formulated dessert extracts may be attributed in part to their radical scavenging activities.

In this study, we used three CODs and SOD. The major ingredients of CODs are described in Table 1. The commercial manufacturer used milk solids, vegetable fat, milk fat, glucose syrup, sugar, treated water, emulsifier, stabilizer, artificial flavoring agent, permitted natural color, cocoa powder, and chocolate flavor. On the other hand, glucose syrup, sugar, cocoa powder, chocolate flavor, and traditional milk were not used in our formulated SOD. However, the nutritional analysis of the newly developed SM dessert shows a significant nutritional content. Macronutrient analysis has shown that SOD contains significantly (p < 0.05) higher protein content than CODs. On the other hand, SOD contains a significantly lower amount of fat and carbohydrate content than CODs (Table 2). According to recent research, soy milk and other soy products contain significant amount of protein, fewer carbohydrates, and less fat (Rizzo and Baroni, 2018). Additionally, a study also reported that soy-based protein contains a good amount of essential amino acids compared to other plant proteins (Kudełka et al., 2021; Gorissen et al., 2018). The newly formulated SOD reported a higher number of amino acids compared to CODs (Figure 3). In our study, the CODs showed only 9 amino acids, and SOD had 15 amino acids. It may have some reason for the lower amino acid content in CODs compared to SOD. Firstly, there is some post-harvest loss of amino acids during COD preparation in industry. Secondly, the manufacturer may use less milk for preparing CODs. On the other hand, SOD contains all essential amino acids, but the percentages of amino acids are lower than in raw soybeans (Kudełka et al., 2021), and it may happen due to post-harvest loss during dessert preparation. Soy’s high protein level, along with its low carbohydrate level, distinguishes it as a unique source of vegetable protein when compared to other plant-based milk. Furthermore, nutritional analysis of SOD has shown that it has contained sodium, phosphorus, potassium, calcium and iron and also free of cholesterol (Figure 2 and Table 2) and the reported results are closely related to previous results (Andrés et al., 2015).

Apart from macro and micronutrients, soy milk includes significant number of phytochemicals (Leksawasdi et al., 2022) as well as phytoestrogens, which are polyphenols with a similar chemical structure to endogenous estrogens, which raises concerns regarding their safety, particularly at high doses. Tofu can be made by pureeing and cooking soy beans to obtain soy milk, which can then be curdled with magnesium chloride or calcium sulphate. Additionally, other fermentation procedures are advantageous for soy sauce, sufu, natto, and tempeh production (Zaheer and Humayoun Akhtar, 2017). Phytochemicals have been regarded as a miraculous natural component capable of preventing several significant health conditions and SOD has reported significant phytochemicals and antioxidant content compared to CODs and also shown their in-vitro free radical scavenging power (Table 4). Several studies have found that soy milk and soy products are high in phytochemicals or bioactive compounds, which have a variety of health benefits (Takagi et al., 2015; Tezuka and Imai, 2015). Furthermore, research also described that the milk from oil seeds provides antioxidant and metal chelating activities (Ramesh et al., 2022; Huang et al., 2022). In contrast, compared to SOD, the CODs have shown higher IC50 in DPPH methods but didn’t show activity in ABTS methods. Study revealed that milk and milk products show antioxidant properties due to presence of vitamins and some compounds (Punia et al., 2020; Kim et al., 2019). The nutrients presences in animal milk constantly decreases due to milk processing or improper post-harvest technologies.

However, during the last two decades, substantial attempts have been made to include soy products into western diets for their health advantages, with varying degrees of success. Consumption of soy products has been associated with a decrease in the incidence or severity of chronic illnesses such as cardiovascular, breast, and prostate malignancies, menopausal symptoms, and bone loss, to name a few. In general, moderate consumption of traditionally cooked and lightly processed soy products may provide small health advantages while decreasing the risk of undesirable health impacts (Daily et al., 2019; Kim et al., 2021; Zaheer and Humayoun Akhtar, 2017). Aside from cholesterol, phytochemicals, and antioxidants, this study discovered that newly formulated SOD contains a significant amount of macro- and micronutrients. However, more deep studies are needed to reveal the clear health benefits of SOD.

4. Conclusion

In this study, we formulated a soya milk-based dessert (SOD) and analyzed the nutritional value, in-vitro antioxidant content, and free radical scavenging activity. The formulated SOD contained no cholesterol, low sugar, low carbohydrate, good quality protein, low fat, and high mineral and vitamin content. The results also suggested that SOD contains more protein than CODs, as well as vitamin E, B2 and B6. In addition, the SOD also exhibited a significant number of amino acids, antioxidants, and phytochemicals compared to CODs. The DPPH and ABTS assays reported good free radical scavenging power of SODs compared to CODs. From our research, we may say that soybean products are one of the best sources of good quality protein, antioxidants, and phytochemicals. Thus, it was established that the absence of cholesterol and lactose, as well as the low-fat content of this non-dairy soya product may deliver beneficial protein, micronutrients, flavonoids, and antioxidants for the human body’s various physiological functions.

Declarations

Author contribution statement

Md. Munnaf Hossen; Md. Nazim Uddin: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

Md. Shafiqul Islam Khan; Kanika Mitra: Conceived and designed the experiments; Wrote the paper.

S. M. Hedaytul Islam; Ummey Hafsa Bithi; Rahat Bin Robbani: Performed the experiments.

Md. Hasanuzzaman; Md. Abu Tareq; Md. Nazmul Hassan; Abu Sayeed: Analyzed and interpreted the data.

Funding statement

Kanika Mitra was supported by Bangladesh Council of Scientific and Industrial Research [F-11, 2016].

Data availability statement

Data will be made available on request.

Declaration of interest’s statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The authors thank the staff of Institute of Food Science and Technology, Bangladesh Council of Scientific and Industrial Research, Dhanmodi, Dhaka, Bangladesh for their cordial support during research period. Moreover, we thank the Central Analytical and Research Facilities laboratories, BCSIR for analyzing the amino acid profiles of our samples. Also, we expressed gratitude to the quality control research section, IFST, BCSIR, for conducting the sensory evaluation test.

Contributor Information

Md. Nazim Uddin, Email: nazimbio@yahoo.com.

Kanika Mitra, Email: mitra.kanika@gmail.com.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- Ali M.A., Kamal M.M., Rahman M.H., Siddiqui M.N., Haque M.A., Saha K.K., Rahman M.A. Functional dairy products as a source of bioactive peptides and probiotics: current trends and future prospectives. J. Food Sci. Technol. 2022;59(4):1263–1279. doi: 10.1007/s13197-021-05091-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Andrés V., Tenorio M.D., Villanueva M.J. Sensory profile, soluble sugars, organic acids, and mineral content in milk- and soy-juice based beverages. Food Chem. 2015;173:1100–1106. doi: 10.1016/j.foodchem.2014.10.136. [DOI] [PubMed] [Google Scholar]

- AOAC . fifteenth ed. Association of Official Analytical Chemists; Arlington: 2005. Official Methods of Analysis. [Google Scholar]

- AOAC . Association of Official Analytical Chemists; Arlington: 2000. Official Methods of Analysis. [Google Scholar]

- Cao Z.-H., Green-Johnson J.M., Buckley N.D., Lin Q.-Y. Bioactivity of soy-based fermented foods: a review. Biotechnol. Adv. 2019;37(1):223–238. doi: 10.1016/j.biotechadv.2018.12.001. [DOI] [PubMed] [Google Scholar]

- Chen P., Wolf W.R. LC/UV/MS-MRM for the simultaneous determination of water-soluble vitamins in multi-vitamin dietary supplements. Anal. Bioanal. Chem. 2007;387(7):2441–2448. doi: 10.1007/s00216-006-0615-y. [DOI] [PubMed] [Google Scholar]

- Chi C.-H., Cho S.-J. Improvement of bioactivity of soybean meal by solid-state fermentation with Bacillus amyloliquefaciens versus Lactobacillus spp. and Saccharomyces cerevisiae. LWT - Food Sci. Technol. 2016;68:619–625. [Google Scholar]

- Dai C., Ma H., He R., Huang L., Zhu S., Ding Q., Luo L. Improvement of nutritional value and bioactivity of soybean meal by solid-state fermentation with Bacillus subtilis. LWT (Lebensm.-Wiss. & Technol.) 2017;86:1–7. [Google Scholar]

- Daily J.W., Ko B.S., Ryuk J., Liu M., Zhang W., Park S. Equol decreases hot flashes in postmenopausal women: a systematic review and meta-analysis of randomized clinical trials. J. Med. Food. 2019;22(2):127–139. doi: 10.1089/jmf.2018.4265. [DOI] [PubMed] [Google Scholar]

- Eslami O., Shidfar F. Soy milk: a functional beverage with hypocholesterolemic effects? A systematic review of randomized controlled trials. Compl. Ther. Med. 2019;42:82–88. doi: 10.1016/j.ctim.2018.11.001. [DOI] [PubMed] [Google Scholar]

- Faghih S., Abadi A.R., Hedayati M., Kimiagar S.M. Comparison of the effects of cows' milk, fortified soy milk, and calcium supplement on weight and fat loss in premenopausal overweight and obese women. Nutr. Metabol. Cardiovasc. Dis. 2011;21(7):499–503. doi: 10.1016/j.numecd.2009.11.013. [DOI] [PubMed] [Google Scholar]

- Fletouris DJ, Botsoglou NA, Psomas IE, Mantis AI. Rapid determination of cholesterol in milk and milk products by direct saponification and capillary gas chromatography. J Dairy Sci. 1998;81(11):2833–2840. doi: 10.3168/jds.S0022-0302(98)75842-4. [DOI] [PubMed] [Google Scholar]

- Friedman M., Brandon D.L. Nutritional and health benefits of soy proteins. J. Agric. Food Chem. 2001;49(3):1069–1086. doi: 10.1021/jf0009246. [DOI] [PubMed] [Google Scholar]

- Genevois C.E., Castellanos Fuentes A.P., Flores S.K., de Escalada Pla M.F. The functional and organoleptic characterization of a dairy-free dessert containing a novel probiotic food ingredient. Food Funct. 2018;9(11):5697–5706. doi: 10.1039/c8fo00805a. [DOI] [PubMed] [Google Scholar]

- Gobert C.P., Duncan A.M. Consumption, perceptions and knowledge of soy among adults with type 2 diabetes. J. Am. Coll. Nutr. 2009;28(2):203–218. doi: 10.1080/07315724.2009.10719772. [DOI] [PubMed] [Google Scholar]

- Gorissen S.H.M., Crombag J.J.R., Senden J.M.G., Waterval W.A.H., Bierau J., Verdijk L.B., van Loon L.J.C. Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids. 2018;50(12):1685–1695. doi: 10.1007/s00726-018-2640-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Górska-Warsewicz H., Rejman K., Laskowski W., Czeczotko M. Milk and Dairy Products and Their Nutritional Contribution to the Average Polish Diet. Nutrients. 2019;11(8):1771. doi: 10.3390/nu11081771. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hu C., Wong W.T., Wu R., Lai W.F. Biochemistry and use of soybean isoflavones in functional food development. Crit. Rev. Food Sci. Nutr. 2019:1–15. doi: 10.1080/10408398.2019.1630598. [DOI] [PubMed] [Google Scholar]

- Huang M.L., Huang J.Y., Kao C.Y., Fang T.J. Fermented soymilk and soy and cow milk mixture, supplemented with orange peel fiber or Tremella flava fermented powder as prebiotics for high exopolysaccharide-producing Lactobacillus pentosus SLC 13. J. Sci. Food Agric. 2019;99(9):4373–4382. doi: 10.1002/jsfa.9671. [DOI] [PubMed] [Google Scholar]

- Huang J., Qian J., Wang S., Li Y., Zhai X., Olajide T.M., Shen G.X., Liao X. Effect of selenium biofortification on bioactive compounds and antioxidant activity in germinated black soybean. J. Food Sci. 2022;87(3):1009–1019. doi: 10.1111/1750-3841.16014. [DOI] [PubMed] [Google Scholar]

- Jayachandran M., Xu B. An insight into the health benefits of fermented soy products. Food Chem. 2019;271:362–371. doi: 10.1016/j.foodchem.2018.07.158. [DOI] [PubMed] [Google Scholar]

- Ketnawa S., Ogawa Y. Evaluation of protein digestibility of fermented soybeans and changes in biochemical characteristics of digested fractions. J. Funct.Foods. 2019;52:640–647. [Google Scholar]

- Kim I.S., Kim C.H., Yang W.S. Physiologically active molecules and functional properties of soybeans in human health-A current perspective. Int. J. Mol. Sci. 2021;22(8) doi: 10.3390/ijms22084054. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim Y.E., Kim J.W., Cheon S., Nam M.S., Kim K.K. Alpha-casein and beta-lactoglobulin from cow milk exhibit antioxidant activity: a plausible link to antiaging effects. J. Food Sci. 2019;84(11):3083–3090. doi: 10.1111/1750-3841.14812. [DOI] [PubMed] [Google Scholar]

- Kudełka W., Kowalska M., Popis M. Quality of soybean products in terms of essential amino acids composition. Molecules. 2021;26(16):5071. doi: 10.3390/molecules26165071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leksawasdi N., Taesuwan S., Prommajak T., Techapun C., Khonchaisri R., Sittilop N., Halee A., Jantanasakulwong K., Phongthai S., Nunta R., Kiadtiyot M., Saefung A., Khemacheewakul J. Ultrasonic extraction of bioactive compounds from green soybean pods and application in green soybean milk antioxidants fortification. Foods. 2022;11(4):588. doi: 10.3390/foods11040588. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li J., Zhou R.-l., Ren Z.-q., Fan Y.-w., Hu S.-b., Zhuo C.-f., Deng Z.-y. Improvement of protein quality and degradation of allergen in soybean meal fermented by Neurospora crassa. LWT. 2019;101:220–228. [Google Scholar]

- Messina M., Messina V. The role of soy in vegetarian diets. Nutrients. 2010;2(8):855–888. doi: 10.3390/nu2080855. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Morency M.E., Birken C.S., Lebovic G., Chen Y., L'Abbe M., Lee G.J., Maguire J.L. Association between noncow milk beverage consumption and childhood height. Am. J. Clin. Nutr. 2017;106(2):597–602. doi: 10.3945/ajcn.117.156877. [DOI] [PubMed] [Google Scholar]

- Nande P., Tapadia P., Jain K., Lodhaya F., Vali S.A. A study on soymilk as a substitute for animal milk. J Dairy Foods Home Sci. 2008;27(1):1–10. [Google Scholar]

- Oliveira S., Costa J., Faria I., Guerreiro S.G., Fernandes R. Vitamin A Enhances Macrophages Activity Against B16-F10 Malignant Melanocytes: A New Player for Cancer Immunotherapy? Medicina. 2019;55(9):604. doi: 10.3390/medicina55090604. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ortega R.M., Jimenez Ortega A.I., Perea Sanchez J.M., Cuadrado Soto E., Aparicio Vizuete A., Lopez-Sobaler A.M. [Nutritional value of dairy products and recommended daily consumption] Nutr. Hosp. 2019;36(Spec No3):25–29. doi: 10.20960/nh.02803. [DOI] [PubMed] [Google Scholar]

- Park Y.W. Comparison of mineral and cholesterol composition of different commercial goat milk products manufactured in USA. Small Rumin Res. 2000;37(1–2):115–124. doi: 10.1016/s0921-4488(99)00144-3. [DOI] [PubMed] [Google Scholar]

- Punia H., Tokas J., Malik A., Sangwan S., Baloda S., Singh N., Singh S., Bhuker A., Singh P., Yashveer S., Agarwal S., Mor V.S. Identification and detection of bioactive peptides in milk and dairy products: remarks about agro-foods. Molecules (Basel, Switzerland) 2020;25(15):3328. doi: 10.3390/molecules25153328. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ramesh L., B V Latha L., Kumar Mukunda C. Identification and characterization of metal-chelating bioenhancer peptide derived from fermented Citrullus lanatus seed milk. J. Food Biochem. 2022 doi: 10.1111/jfbc.14102. Advance online publication. [DOI] [PubMed] [Google Scholar]

- Rathi M., Upadhyay N., Dabur R.S., Goyal A. Formulation and physico-chemical analysis of whey-soymilk dahi. J Food Sci Technol. 2015;52(2):968–975. doi: 10.1007/s13197-013-1074-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reinwald S., Weaver C.M. Soy components vs. Whole soy: are we betting our bones on a long shot? J. Nutr. 2010;140(12):2312S–2317S. doi: 10.3945/jn.110.124008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rizzo G., Baroni L. Soy, soy foods and their role in vegetarian diets. Nutrients. 2018;10(1) doi: 10.3390/nu10010043. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sanjukta S., Rai A.K. Production of bioactive peptides during soybean fermentation and their potential health benefits. Trends Food Sci. Technol. 2016;50:1–10. [Google Scholar]

- Santos L., Davel A.P., Almeida T.I., Almeida M.R., Soares E.A., Fernandes G.J., et al. Soy milk versus simvastatin for preventing atherosclerosis and left ventricle remodeling in LDL receptor knockout mice. Braz. J. Med. Biol. Res. 2017;50(3) doi: 10.1590/1414-431X20165854. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Scholz-Ahrens K.E., Ahrens F., Barth C.A. Nutritional and health attributes of milk and milk imitations. Eur. J. Nutr. 2019;59:19–34. doi: 10.1007/s00394-019-01936-3. [DOI] [PubMed] [Google Scholar]

- Takagi A., Kano M., Kaga C. Possibility of breast cancer prevention: use of soy isoflavones and fermented soy beverage produced using probiotics. Int. J. Mol. Sci. 2015;16(5):10907–10920. doi: 10.3390/ijms160510907. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Talpur F.N., Bhanger M.I., Khuhawar M.Y. Comparison of fatty acids and cholesterol content in the milk of Pakistani cow breeds. J. Food Comp. Anal. 2006;19(6–7):698–703. [Google Scholar]

- Tezuka H., Imai S. Immunomodulatory effects of soybeans and processed soy food compounds. Recent Pat. Food, Nutr. Agric. 2015;7(2):92–99. doi: 10.2174/2212798407666150629123957. [DOI] [PubMed] [Google Scholar]

- Vieira A.M., de Almeida Brasiel P.G., Ferreira M.S., Mateus K., Figueiredo M.S., Lisboa P.C., et al. Maternal soybean diet during lactation alters breast milk composition and programs the lipid profile in adult male rat offspring. Endocrine. 2018;60(2):272–281. doi: 10.1007/s12020-018-1572-x. [DOI] [PubMed] [Google Scholar]

- Zaheer K., Humayoun Akhtar M. An updated review of dietary isoflavones: nutrition, processing, bioavailability and impacts on human health. Crit. Rev. Food Sci. Nutr. 2017;57(6):1280–1293. doi: 10.1080/10408398.2014.989958. [DOI] [PubMed] [Google Scholar]

- Zilic S., Serpen A., Akillioglu G., Gokmen V., Vancetovic J. Phenolic compounds, carotenoids, anthocyanins, and antioxidant capacity of colored maize (Zea mays L.) kernels. J. Agric. Food Chem. 2012;60(5):1224–1231. doi: 10.1021/jf204367z. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.