Abstract

The study aims to test if Ecuadorean coffee's symbolic and material contents agree with the instrumental analysis and grading protocols. We studied the relationship between the chemical composition and the organoleptic characteristics of eight non-specialty and six specialty coffee samples. Firstly, the study addresses the grading following the Specialty Coffee American Association (SCAA) method. The second stage focuses on the qualitative composition of the coffee brews employing GC-MS and caffeine concentrations using HPLC. Then, we employed statistical tools such as Cohen's concordance coefficients, dissimilarity dendrograms, and linear correlations between the chemical compounds in the beverage and the attributes' scores. The grading panel consisted of 6 semi-trained-testers who would assess if the primary cultural capital can provide a criterion to identify specialty coffee. The variety of compounds allowed the evaluators to distinguish between commercial and specialty coffees. However, the composition analysis identified molecules that would imply greater gradation in the tasting, a prevision that was not reflected in the results. Finally, we confirmed that basic training could create cultural capital to distinguish non-specialties from specialty coffees through their chemistry and organoleptic attributes.

Keywords: Ecuadorian coffee, Cultural capital, Sensory evaluation, Semi-trained testers, Statistical concordance correlation

Graphical abstract

Highlights

-

•

Specialty coffee showed more variety in chemical molecules than commercials.

-

•

The caffeine content is not different in commercial and specialty coffees.

-

•

Basic training does not allow for a correct evaluation of specialty coffees.

-

•

A semi-trained team distinguishes between specialty and commercial coffees.

-

•

The presence of lactones correlates negatively with scoring attributes.

1. Introduction

Ecuadorian coffee does not participate significantly in international markets like other exporting goods, such as bananas or flowers. However, according to the Central Bank of Ecuador (CBE), in 2019 (evaluated from January to November in FOB prices), the exportation of raw coffee reached 5,6 million USD and elaborated coffee at 64 million USD, which represents 0.03 and 0.31 percent of the total exportations, respectively (Central Bank of Ecuador, 2019). In addition, Ecuador exported 483 thousand 60 kg bags at the regional level in all forms, representing 0.39% of the worldwide market in 2018 (International Coffee Organization, 2020).

According to the Ecuadorian Socioeconomic Level Stratification Survey in 2012, 13.1 percent of the families were classified in stratum middle or upper-middle classes (National Institute for Statistics and Census, 2011). This fact implied increased demand for products with unusual tastes like gourmet coffee, tea, or chocolate served in fancy shops with refinement levels far from those traditionally consumed by Ecuadorians.

The fast-growing market could not always allow the consumers to acquire social capital to distinguish a coffee with a unique embedded taste. Here it is relevant to consider the general perception of Ecuadorians about the local coffee. The National Service for Intellectual Rights (SENADI), on its official website, indicates that “Ecuadorian coffee must be highly recognized worldwide for its high quality and magnificent flavors” (SENADI, 2017). Also, a report collects several pleasant insights like “juicy and complex, plenty of jam notes, sweetness, medium acidity, and yellow fruits. It is just a very well-balanced and satisfying coffee -when drinking-the best Ecuador offers” (Molina, 2018). Unfortunately, local people have assumed these claims from government institutions or specialists as absolute truth.

The economic boom suffered a setback in 2014; some preferences and habits related to coffee have settled for some years. Thus, by 2018 and 2019, the business continues thriving in coffee shops, mainly in Quito, Guayaquil, and Cuenca (Arciniegas, 2019). This phenomenon is known as the Ecuadorian third wave of coffee. It creates a new quality lexicon to describe a coffee cup among baristas, roasters, and traders (Fischer, 2017). In turn, that lexicon becomes more popular among consumers. However, it is not always wholly understood by consumers or farmers for the lack of social and cultural capital.

In this work, the concept of cultural capital does not include the commercialization of coffee but understanding the difference between commercial and specialty coffee. In this sense, cultural capital is a tool for evaluating the quality of coffee, which is not transmitted directly in the commercialization of coffee but in the application of acquired knowledge. Unfortunately, this issue ultimately leads to a mediocre stagnation of the local market, diminishing its international projection, where attributes rely on what Carlo Petrini in the 80's called Education of Taste (Lingle, 1984).

There are three ways of perceiving coffee quality based on its attributes: material, symbolic, and in-person service (Rosenberg et al., 2018) (Daviron and Ponte, 2005). The combination of these attributes directly affects coffee scores and prices. Material refers to chemical contents presented due to production processes; human senses usually measure material with a certain subjectivity level. Symbolic attributes represent an added value based on reputation, brands, origins, and even the level of strategic alignment with slow food movements. Finally, in-person describes material and symbolic directly to the consumers. Here, retailers explain how a coffee cup contains quality, authenticity, and connection with some farming practices carried out thousands of kilometers away, typically in an exotic location. As a result, consumers are usually willing to pay more for that cup of exceptional coffee (Daviron and Ponte, 2005).

Traore et al. (2018) developed a model to determine the influence of material attributes on coffee prices; nevertheless, they also found that symbolic factors like altitude, market size, and country of origin play a significant role in determining coffee quality. In Ecuador, the farmers have not understood the descriptive profile yet. Most of them produce coffee traditionally without being aware of their bean's actual material content and the symbolism of their processes. Therefore, they have not been able to use these hallmarks at their convenience to improve their quality of life (Perez et al., 2017). Something similar happens on the side of the final consumers; they do not own the knowledge to compare the material content with the organoleptic perception. This information asymmetry has provoked an unequal accumulation of the gain surplus by the symbolic stakeholders (roasters, baristas, and traders). Since they handle and sometimes can change the terms of coffee quality to raise prices; meanwhile producers take most of the material risks (Fischer, 2017) associated with labor, uncertainty, and climate issues.

This work aims to establish the relationship between chemical compounds and the valuation in cupping of commercial and specialty coffees from Ecuador and to provide elements of judgment to increase the cultural capital of this product so that it can be valued for export.

2. Methods

Fig. 1 shows coffee's complex pathway to develop the cup's desired chemical content. These inputs make each cup's chemistry unique and enable discrimination between excellent coffees and those with less desirable flavors (Mussatto et al., 2011) using instrumental techniques (Teranishi et al., 2012) and grading protocols.

Fig. 1.

The process involved in the Arabica coffee pathway from farming to cupping.

The chemistry of coffee, which influences the brew's flavor at most, embraces two stages: the green bean and the roasting. Table 1 shows the main constituents of green beans, while Fig. 2 indicates the main reaction pathways during roasting.

Table 1.

Arabica green bean coffee components.

| Group | Compound | Farah, 2012 (Farah, 2012) | Barbosa et al., 2019 (Barbosa et al., 2019) | Kitzberger et al., 2013 (Kitzberger et al., 2013) | Poisson et al., 2017 (Poisson et al., 2017) |

|---|---|---|---|---|---|

| Sugars | Sucrose | 6.0–9.0 | 5.6–6.8 | 6.2–9.3 | 6.0–9.0 |

| Reducing sugars | 0.1–0.4 | – | 0.2–0.5 | 0.2–0.5 | |

| Nitrogenous | Protein/peptides | 10.0–11.0 | 13.6–15.2 | 16.1–18.0 | 8.5–12.0 |

| Free amino acids | 0.5 | – | – | 0.2–0.8 | |

| Caffeine | 0.9–1.3 | 1.2–1.3 | 1.3–1.5 | 0.8–1.4 | |

| Trigonelline | 0.6–2 | – | 1.0–1.2 | 0.6–1.2 | |

| Organic acids | Quinic acid | 0.4 | 0.29–0.33 | 0.3–0.6 | 2.0–2.9 |

| Malic acid | 1.0 | 0.3–0.5 | |||

| Citric acid | 0.9–1.3 | ||||

| Lipids | Coffee oil | 15.0–17.0 | 14.4–15.0 | 12.0–14.4 | 15–17.7 |

| Diterpenes | 0.5–1.2 | 1.2–1.5 | 0.6–1.5 | – | |

| Phenolics | Chlorogenic acids | 4.1–7.9 | 4.0–8.0 | 4.2–5.4 | 6.7–9.2 |

Fig. 2.

Main pathways of green coffee molecules during roasting. (For interpretation of the references to colour in this figure legend, the reader is referred to the Web version of this article.)

The main flavor precursors during roasting are sugars, proteins, free amino acids, trigonelline, and chlorogenic acids, as shown in Fig. 2.

As a result of these chemical reactions, aromatics, acids, and other flavor components are created to confer to the coffee a unique aroma and flavor in the cup. The main pathways are Maillard (150–200 °C), Caramelization (170–200 °C), Pyrolysis (>220 °C), First Crack (>205 °C), and the Second Crack (225–230 °C).

2.1. Methods description

We start determining the chemical composition of 14 coffee samples and compare their material content with a cup grading. The research's novelty is testing whether basic training can allow customers to discriminate between specialty and commercial coffees since evaluators are regular consumers with basic coffee cultural capital. A Q-grader -a trained and licensed coffee cupper that can evaluate coffees based on the expectations and Specialty Coffee Association (SCA) ‘s practices-monitors the entire tasting process to follow all protocols strictly.

The organoleptic evaluation follows the SCAA protocols, comprising several criteria to evaluate the primary flavor attributes (Lingle, 1984), (Lingle and Menon, 2017). These attributes determine the quality of coffee through all the production processes, e.g., farming, harvesting, and green bean processing, related to uniformity, clean cup, and sweetness (Kipkorir et al., 2015). Each panelist rates the holistic sensory perception of all attributes through grading (Malau et al., 2018).

The balance was the last criterion incorporated into the SCAA protocol (Lingle and Menon, 2017). Although it is not a primary attribute per se, it is considered an essential quality feature because a high score means flavor, aftertaste, acidity, body, and even aroma in the brew (Laukaleja and Kruma, 2018) coexist under desirable equilibrium. Furthermore, all the stages in the whole process influence the final cup scoring. Finally, we correlate the results with statistical analysis of concordance, dissimilarity, and correlation.

2.2. Grading protocol

2.2.1. Cupping team

The grading and coffe characterization took place at the Chemical Engineering Faculty of the Universidad Central del Ecuador. The team consisted of a Q grader and five locally trained graders who also are part of the research team. The 40-h training covers coffee genetics and origin generalities, nose profile, gradation, SCAA tasting protocol, and infusions.

2.2.2. Sample preparation

We selected coffee samples from renowned specialty suppliers in the country. We weighed 8.25 g of sample and placed it in a ceramic cup of 250 ml capacity and 80 mm in upper diameter. Then, for grinding, we calibrate the mill with a granulometry between 70 and 75% of the sample passing through the Mesh Sieve Series No. 20 (841 μm). The product is collected in the same cup and covered immediately to reduce volatilities. This process repeats for five cups previously labeled. Then we pour approximately 150 ml of water at 92 °C (the maximum temperature liquid water reaches at Quito altitude 2800 m.a.s.l.) in each cup over the milled coffee. The selection of water yields its TDS value of c.a. 65 mg/l. The controls of the coffee's times, temperatures, and tastings comply strictly with the SCAA protocol.

2.2.3. Grading model construction

Our evaluation took place in two groups. First, it consisted of 8 eight samples graded by four tasters. The second group included six samples graded by six tasters. The samples' codification corresponds to Ci for commercial (samples with 80 points or less) and Ei for specialty (samples with scores higher than 80 points). The sample details are shown in Table 2.

Table 2.

Coffee samples, origin, and crop altitude.

| Sample ID | Origin | Specie | Altitude (m.a.s.l.) |

|---|---|---|---|

| C1 | Loja | Arabica | 2093 |

| C2 | Amazon | – | 500 |

| C3 | Loja | Arabica | 2093 |

| C4 | Loja | Arabica | 2093 |

| C5 | Loja | Arabica | 2093 |

| C6 | Galápagos | Arabica | 4 |

| C7 | Zaruma | Arabica | 1317 |

| C8 | – | Arabica/Robusta | – |

| E1 | Pichincha | Arabica Sarchimore | 1181 |

| E2 | Pichincha | Arabica Sarchimore | 1181 |

| E3 | Pichincha | Arabica Sarchimore | 1181 |

| E4 | Íntag | Arabica Typica | 1914 |

| E5 | Morona Santago | Arabica Castillo | 1751 |

| E6 | Pichincha | Arabica Typica | 1251 |

The statistical model considers three types of variables:

-

⁃

Dependent: coffee quality score.

-

⁃

Independent: coffee variety and taster.

-

⁃

Blocking: taster experience.

2.3. Chemical compounds characterization

The chemical analysis was carried out using the HPLC and GC-MS instruments. Each sample was prepared with the procedure described in Fig. 3.

Fig. 3.

Sample preparation for instrumental analysis.

The compounds of the coffee infusions were identified employing a GC gas chromatography equipment Agilent Technologies 7820A-5977E with ionizing type EI (Electron Impact) 70 eV. For this purpose, a 3 ml sample of the infusion is dissolved in 6 ml methanol. This solution is placed using a syringe in the vials previously filtered (Titan 3 PVDF 0.45 mm). The running time is 38 min in a temperature range of 40–250 °C.

The splitless injector set-point temperature was 225 °C, column program 40 °C, 3 min and 5 °C/min ramp from 40 °C to 200 °C, hold time 3 min. The column used was a VF-5ht Utilmetal (30 m x 250 μm x 0.1 μm). Additional settings are as follows: 1 μL sample, 11.898 psi helium carrier gas, 1.5 ml/min flow rate, transfer line temperature 370 °C, quadrupole temperature 150 °C, ion source temperature 230 °C, mass scan range: 50–550. Compounds were identified by comparing m/z spectra with the NIST database in ChemStation Software. The percentage peaks areas correspond to the relative yields of molecules among all the identified ones.

The caffeine quantitation was carried out using an HPLC instrument. Agilent Infinity 1290 HPLC with a diode array detector set to 270 nm wavelength (Londoño-Larrea et al., 2018) The column temperature is 25 °C, Chromolith High-Resolution RP-18 uncapped 150–4.6 mm. The mobile phase (methanol: water, 25:75) was developed to 0.520 ml/min and 1.4 μl sample injection volume. Standard solutions were prepared at known concentrations of 200–1000 mg/l. The calibration curve was correlated with R2 = 0.96690.

3. Results

3.1. Chemical compound identification

Analyzing the samples through gas chromatography allowed the identification of about 52 components in all the coffees. These were grouped according to the organoleptic properties' chemical characteristics (Fig. 1). Each sample has a different composition according to the farming process and roasting conditions (Hu et al., 2020). However, in all the cases, we expect the presence of caffeine; for this reason, it was quantified by HPLC.

There are no significant differences in the caffeine range between commercial and specialty coffees (Table 3). Some studies indicate that caffeine content depends on the variety of coffee and not on the incidence of roasting (Hu et al., 2020). In this case, most samples are Arabica-type. Nevertheless, the extraction methods do affect the amount of caffeine in infusions; our results are comparable to those obtained for beverages prepared with V60 (0.74 g/ml), Aeropress (0.78 mg/ml), and French press (0.52 g/ml) (Angeloni et al., 2019). Identifying compounds relies on the peak area, retention time, molecular weight, and molecular formula, as shown in Table 4.

Table 3.

Content of caffeine identified by HPLC.

| Sample | Concentration (mg/ml) |

|---|---|

| C1 | 0.689 |

| C2 | 0.605 |

| C3 | 0.701 |

| C4 | 0.545 |

| C5 | 0.434 |

| C6 | 0.709 |

| C7 | 0.828 |

| C8 | 0.902 |

| E1 | 0.508 |

| E2 | 0.571 |

| E3 | 0.620 |

| E4 | 0.548 |

| E5 | 0.605 |

| E6 | 0.527 |

Table 4.

Chemical Components identified by GC-MS Chromatography.

| Code | Compound | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | E1 | E2 | E3 | E4 | E5 | E6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1,2-Cyclopentanedione | X | X | X | X | X | |||||||||

| 2 | 10,13-Octadecadiynoic acid, methyl ester | X | |||||||||||||

| 3 | 10-Octadecenoic acid, methyl ester | X | X | X | X | ||||||||||

| 4 | 11-Octadecenoic acid, methyl ester | X | X | X | X | X | |||||||||

| 5 | 12,15-Octadecadiynoic acid, methyl ester | X | |||||||||||||

| 6 | 1-methoxymethoxy-hexa-2,4-diene | X | |||||||||||||

| 7 | 2(3H)-Furanone, 3-butyldihydro- | X | |||||||||||||

| 8 | 2,5-Dimethylfuran-3,4(2H,5H)-dione | X | |||||||||||||

| 9 | 2-Cyclopenten-1-one, 2-hydroxy- | X | X | X | X | X | |||||||||

| 10 | 2-Cyclopenten-1-one, 2-hydroxy-3-methyl- | X | X | X | X | X | X | X | X | X | |||||

| 11 | 2-Furanmethanol | X | X | X | X | X | X | X | X | X | |||||

| 12 | 2-Hexadecanol | X | |||||||||||||

| 13 | 2-Hydroxy-gamma-butyrolactone | X | |||||||||||||

| 14 | 2-Methoxy-4-vinylphenol | X | |||||||||||||

| 15 | 2-Propanone, 1-hydroxy- | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| 16 | 3,5-Heptadienal, 2-ethylidene-6-methyl- | X | |||||||||||||

| 17 | 4,7-Octadecadiynoic acid, methyl ester | X | |||||||||||||

| 18 | 4-Acetamidobenzofuroxane | X | X | ||||||||||||

| 19 | 4H-Pyran-4-one, 2,3-dihydro-3,5-dihydroxy-6-methyl- | X | |||||||||||||

| 20 | 7,10-Octadecadienoic acid, methyl ester | X | |||||||||||||

| 21 | 8-Octadecenoic acid, methyl ester | X | |||||||||||||

| 22 | 9,12-Octadecadienoic acid (Z,Z)-, methyl ester | X | X | X | X | ||||||||||

| 23 | 9-Hexadecenoic acid | X | |||||||||||||

| 24 | 9-Octadecen-12-ynoic acid, methyl ester | X | |||||||||||||

| 25 | 9-Octadecenoic acid, methyl ester, (E)- | X | X | X | X | X | X | ||||||||

| 26 | Acetic acid | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| 27 | Butanoic acid, 4-hydroxy- | X | X | X | X | X | X | X | X | ||||||

| 28 | Butyrolactone | X | X | X | X | X | X | X | X | X | X | ||||

| 29 | Caffeine | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| 30 | Catechol | X | |||||||||||||

| 31 | cis-13-Octadecenoic acid | X | |||||||||||||

| 32 | cis-3-Dodecene | X | |||||||||||||

| 33 | cis-Vaccenic acid | X | X | X | X | X | |||||||||

| 34 | Cyclopropyl carbinol | X | X | X | X | X | X | X | X | X | X | ||||

| 35 | Ethyl iso-allocholate | X | X | X | X | ||||||||||

| 36 | Furaneol | X | X | ||||||||||||

| 37 | Furfural | X | X | X | X | X | X | X | X | X | |||||

| 38 | Hexadecanoic acid, methyl ester | X | X | X | X | X | X | ||||||||

| 39 | Linalool | ||||||||||||||

| 40 | Methyl 10-trans,12-cis-octadecadienoate | X | X | ||||||||||||

| 41 | Methyl 9-cis,11-trans-octadecadienoate | X | X | X | X | ||||||||||

| 42 | Methyl octadec-6,9-dien-12-ynoate | X | X | X | |||||||||||

| 43 | Methyl stearate | X | X | X | X | X | |||||||||

| 44 | Nonanoic acid, 9-(o-propylphenyl)-, methyl ester | X | X | X | X | ||||||||||

| 45 | Oleic Acid | X | X | ||||||||||||

| 46 | Oxime-, methoxy-phenyl- | X | X | X | X | X | X | X | X | X | X | X | X | X | |

| 47 | Phenethylamine, p,α-dimethyl- | X | X | ||||||||||||

| 48 | Phenol, 4-ethyl-2-methoxy- | ||||||||||||||

| 49 | p-Mentha-1,5-dien-7-ol | X | X | X | X | X | X | X | X | X | |||||

| 50 | Pyridine | X | X | X | X | X | X | X | X | X | X | X | X | ||

| 51 | Terpinen-4-ol | X | X | X | X | X | X | ||||||||

| 52 | trans-13-Octadecenoic acid, methyl ester | X | X | X | X |

Commercial coffees have fewer compounds than specialties. For example, coffee C4 has the least number of compounds: 10 out of 52 (19.2%). In contrast, E3 has 28 of the 52 components (53.8%). Moreover, 27 are presented only in specialty coffees, of which 28 appear only in one. On the other hand, we found only 23 compounds in commercial coffees, and 14 do so in only one coffee. Nevertheless, some components are common to both types of coffee, as Fig. 4 shows.

Fig. 4.

Compounds identified in each coffee sample.

Among the commercial coffees, C2, C3, and C5 have the most considerable proportion of compounds (34.6%). Conversely, this proportion is higher in specialty coffees, with a maximum of E3 28 (53.8%). However, for each type of coffee, the 95% confidence interval (CI) analysis indicates no statistically significant difference in the proportions of the compounds. Under the same criteria, coffees C4, C6, C7, and C8 differ significantly from coffee E3.

For data handling, we group the compounds into 15 categories (Fig. 5). An analysis within each group indicates that the fatty acids present a greater variety of molecules and that, unlike the commercial ones, all of these are found in specialty coffees. For example, only in E3 were there 15 fatty acids. By contrast, commercial coffees present a higher number of ethers and ketones; this is the case of C2, C3, and C5, which show four different molecules. Similarly, C2 stands out for presenting the highest number of furan derivatives (Fig. 6).

Fig. 5.

Relation between groups and number of compounds of each coffee sample.

Fig. 6.

Cohen's concordance coefficients between coffee samples.

Cohen's concordance coefficient between all the samples was applied to relate the compounds identified in each sample. The fourth quadrant indicates low discordance between specialty and commercial coffees, the most discordant are C5 and E4. On the other hand, the highest concordance is between coffees C7 and E5. As expected, the concordance values are higher between commercial coffees (third quadrant) and specialty coffees (first quadrant). However, there is more concordance between commercial coffees.

The analysis of dissimilarity ratifies what was mentioned in the study of Cohen's concordance (Fig. 7); there is a clear difference between commercial and specialty coffees. The formation of 2 clusters can be appreciated, whose dissimilarity index is close to 50%, and each cluster is exclusive for commercial and specialty coffees. C4 and C6 have the most remarkable similarity, and C5 is the commercial coffee that presents the most significant difference from the rest of the commercial coffees, despite having the same number of components as C2 and C3.

Fig. 7.

Dendogram of dissimilarity analysis between commercial and specialty coffees.

The height in the specialty coffee cluster reflects less similarity among them, which suggests a more significant variety of compounds. E2 and E4 present the most remarkable similarity, while E3 is highly different among specialty and commercial coffees for its number and type of components.

3.2. Sensory analysis results

In Table 5, we present the grading summary sorted by attribute with the average of each component and the final score that determines the specialty or commercial condition.

Table 5.

Scores of SCAA gradation of the coffee samples.

| Code | Fragrance/Aroma | Flavor | Aftertaste | Acidity | Body | Uniformity | Balance | Clean cup | Sweetness | Overall | Total. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 7.19 | 6.63 | 6.50 | 6.50 | 6.50 | 10.00 | 6.88 | 10.00 | 10.00 | 7.06 | 77.25 |

| C2 | 7.38 | 7.38 | 7.19 | 7.25 | 6.81 | 10.00 | 7.13 | 10.00 | 10.00 | 7.25 | 80.38 |

| C3 | 6.50 | 6.75 | 7.06 | 6.63 | 6.63 | 10.00 | 6.25 | 10.00 | 10.00 | 6.94 | 76.75 |

| C4 | 6.13 | 6.13 | 6.19 | 6.19 | 6.38 | 10.00 | 6.13 | 10.00 | 10.00 | 6.19 | 73.31 |

| C5 | 6.44 | 6.50 | 6.31 | 6.19 | 6.38 | 8.50 | 6.56 | 8.50 | 8.50 | 6.31 | 70.19 |

| C6 | 6.56 | 6.25 | 6.13 | 6.06 | 6.50 | 8.00 | 6.06 | 8.00 | 8.00 | 6.19 | 67.75 |

| C7 | 6.31 | 6.31 | 6.31 | 6.06 | 6.56 | 10.00 | 6.31 | 10.00 | 10.00 | 6.13 | 74.00 |

| C8 | 6.19 | 6.75 | 6.19 | 6.38 | 6.06 | 10.00 | 6.13 | 10.00 | 10.00 | 6.19 | 73.88 |

| E1 | 7.79 | 7.71 | 8.04 | 7.92 | 7.71 | 10.00 | 7.58 | 10.00 | 10.00 | 7.79 | 84.54 |

| E2 | 7.67 | 8.08 | 7.83 | 7.83 | 7.67 | 10.00 | 8.17 | 10.00 | 10.00 | 7.88 | 85.13 |

| E3 | 7.67 | 7.33 | 7.38 | 7.96 | 7.63 | 10.00 | 7.29 | 10.00 | 10.00 | 7.38 | 82.63 |

| E4 | 7.71 | 7.79 | 8.17 | 7.83 | 7.71 | 10.00 | 7.79 | 10.00 | 10.00 | 7.88 | 84.88 |

| E5 | 7.33 | 7.58 | 7.42 | 7.50 | 7.50 | 10.00 | 7.67 | 10.00 | 10.00 | 7.83 | 82.83 |

| E6 | 7.95 | 7.90 | 8.05 | 7.55 | 8.15 | 10.00 | 8.50 | 10.00 | 10.00 | 7.85 | 85.95 |

C2 exceeds 80 points due to the uniformity, clean cup, and sweetness components. It is worth noting that these three criteria scored 10 points in 12 of the 14 coffees. Therefore, certain quality cannot be asserted and deserves further analysis. We employed descriptive statistics for tabulating the data and measures of central tendency and dispersion, such as the arithmetic mean, the median, and the standard deviation, in the program R version 3.5.2 (Mendenhall et al., 2015). The researchers selected all the coffees based on knowledge of coffee production and marketing dynamics.

The total scores of commercial coffees are lower than those of specialty coffees. The maximum score corresponds to E6 (86), and the minimum to C6 (68). The range of scores for specialty coffees is from 83 to 86, while for commercial coffees, it is between 68 and 80, which confirms that they cannot be considered specialty coffees. The size of the 95% CI reflects more significant variability in the ratings of the commercial coffees, an effect that tends to occur when the tasters are not experts. The results of the grading of each of the coffees are shown in Supplementary Fig. S1.

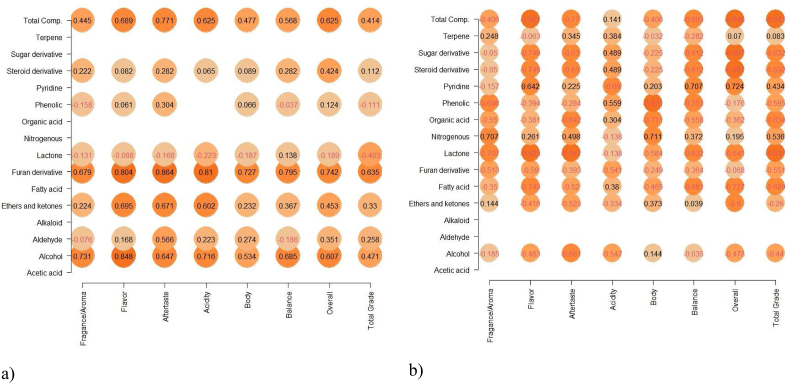

To analyze the incidence of the group of compounds in the cup rating, we carried out a correlation analysis between both variables, Fig. 9a for commercial and Fig. 9b for specialty coffees. The positive correlation implies that the presence of a specific group of compounds enhances the coffee tasting rating.

Fig. 9.

Correlation analysis between the chemical groups and the grading atributes.

In commercial coffees, alcohols and furan derivatives present a high positive correlation with the rating. In contrast, lactone -with which the rating has a low negative correlation-has a weak negative incidence on the rating. In addition, the similar values of the correlation coefficients allow for categorizing a coffee type since none stands out during the tasting.

Specialty coffees do not show this homogeneous behavior; however, it is evident that lactones have a higher negative correlation with the rating. Their presence penalizes the score, especially in taste and aftertaste. Similar behavior repeats in the groups of phenols, organic acids, fatty acids, and derivatives of furans, although with lower negative correlation values. In addition, it is possible to identify (to a lesser extent than in commercial coffees) groups of compounds that have a positive correlation with the tasting assessment, for instance, nitrogenous (positive correlation with body and fragrance/aroma) and pyridines (positive correlation with the balance and taste).

When analyzing the correlation from the tasting criteria, terpenes, nitrogenous and ethers, and ketones have a positive correlation with the fragrance/aroma. In contrast, the flavor has a positive correlation with nitrogenous and pyridines. Furthermore, acidity correlates positively with five of the groups, including organic and fatty acids and the presence of nitrogenous. Finally, pyridines and terpenes enhance the total rating, while lactones and fatty acids mirror a negative correlation.

We performed regression analysis relating the number of compounds and the tasting rating as indicated in Fig. 10.

Fig. 10.

Grouping of the coffee samples in the function of the number of compounds and grading.

Based on the total number of compounds and the complete tasting assessment, we distinguish three groupings by a linear trend (Fig. 10). The red line represents the commercial with a positive slope. The black line has the highest correlation coefficient and is parallel to the red line. It groups commercial coffees with a rating greater than 75. In this grouping, C2 is very close to specialty coffees, which indicates that, of the commercial coffees, it is the one with a score most relative to specialty coffees. The trend of specialty coffees (green line) shows that E5 and E3, with a more significant number of compounds, have a tasting evaluation similar to commercials. On the other hand, E1, E2, E4, and E6 would be the most similar specialty coffees with the highest tasting graduation, even though they do not have the highest number of compounds.

By analyzing the number of the compounds in each coffee and their relation with the scores (Fig. 8), we observe that in commercial coffees, despite having lactones, the predominance of furan derivatives, ethers and ketones, and alcohols grant a higher tasting score among non-experts. Conversely, in specialty coffees, a higher presence of fatty acids and the presence of lactones penalized the E3 coffee score.

Fig. 8.

Results of sensory analysis for each coffee sample.

4. Discussion

The chromatographic analysis identifies six compounds presented in most commercial and specialty coffees no matter their origin: (1) 2-Propanone, 1-hydroxy-, (2) Acetic acid, (3) Caffeine, (4) Oxime-, methoxy-phenyl-, (5) Pyridine, and (6) Butyrolactone. We infer that these compounds constitute the baseline of the chemical structure of coffee in Ecuador. These compounds contribute to different features. For example, the degradation of various sugars usually produces the number (1) during the Maillard reactions (Bressanello et al., 2017). Depending on the samples' aromatic complexity, it could contribute to the infusion's aroma with sweetish or ethereal (Sarghini et al., 2019), (Gonzalez-Rios et al., 2007) in Arabica coffees. The number (2) originates during the coffee and roasting processes. Although not as punchy or noticeable as citric or malic acid, it contributes to a rounded, clean-tasting cup. An acetic acid dash can create great complexity, mainly in specialty coffees. Still, saturation can provoke a vinegar sensation, which is usually penalized during grading. The number (3) is a bitter alkaloid that produces important aroma compounds (Al-Tameme et al., 2015) (Lopes et al., 2020). Caffeine is the most widely consumed psychoactive agent (van Dam et al., 2020). Various plants contain caffeine in their seeds, fruits, and leaves. Generally, caffeine is a bitter taste stimulant (Poole and Tordoff, 2017). During the roasting, (4) is degraded. It belongs to the heterocyclic compounds, acids, and phenols and is a source of phenolic compounds affecting coffee aroma like freshly baked bread (Zawirska-Wojtasiak et al., 2014). The numbers (5) and (6) usually appear in the volatile compounds among the essential contributors to the ground coffee flavor and espresso coffee; their odor descriptors are burnt/smoky and creamy, respectively (Amanpour and Selli, 2016). Finally, butyrolactone (6) has been reported only in sour beans (Amanpour and Selli, 2016). It is worth mentioning the furan derivatives presented in nine coffees, they generally found as furan methanol or furan methanol acetate, suspected to be mainly responsible for coffee aroma: smoky, oily, burnt, cooked sugar, caramel (Giacalone et al., 2019) (Chin et al., 2011), (Caporaso et al., 2014).

Because they scored below 80 points in the coffee tasting, commercial coffees showed mostly bitter and low acid flavors. They obtained an average of 6 points out of 10 in this attribute. The over-roasting possibly destroyed most organic acids. The gas chromatography corroborated this premise since the diagrams did not show acid-promoting compounds massively. Similarly, the characteristics of aftertaste and body, usually evaluated together, show a significant difference between the two types of coffee. The average difference is 1.33 and 1.25, respectively, regarding specialty. The balance rating reflects the synergistic combination between flavor, aftertaste, acidity, and body; therefore, we expected a low value in commercial coffees, and it concurs with an average grading of 6.43. Specialty coffees presented a higher number of compounds belonging to the groups of pyridines, phenols, organic acids, lactones, furane derivatives, fatty acids, and ethers and ketones. These compounds would foster a high rating in the flavor and odor attributes because of their flowers, fruity, and caramel aromas. The 21 fatty acids identified in the chromatography appear only in specialty coffees since overroast possibly destroys them in commercial coffees. However, Fig. 11 shows that the coffees with the widest variety of acids did not always obtain the highest rating. The excess of these acids is difficult to grade for a panel of inexperienced tasters, given the difficulty in assessing the types of acidity in coffee.

Fig. 11.

Relation between groups and number and percentage of compounds of each coffee sample.

Fig. 7 indicates the difference in coffee's chemical composition between specialties and commercials. For example, the cluster of specialty coffees shows more significant dissimilarity due to the greater number and variety of molecules, mainly fatty acids. E3 has 15 of the 21 identified acids and contains a derived sugar (4H-Pyran-4-one, 2,3-dihydro-3,5-dihydroxy-6-methyl-), which is not present in any other coffee. Therefore, it is the last to join the cluster with a dissimilarity close to 0.5. The dendrogram also shows consistency between the scores and the chemical similarity in coffees E1, E2, and E4 since they were rated very close (84.54–85.13). The dissimilarity value is the lowest in the specialty coffee analysis at < 0.2.

Regarding the connections between attributes and groups, we observe that commercial coffees show a high positive relationship between alcohols (fermentation) and furan derivatives (seasoning). This behavior is because the organoleptic attributes of these groups and their high sensory significance could mask more serious overroast defects. On the other hand, we observe that lactone has a low negative consequence with the evaluation attributes due to its bitter taste, generally penalized in the tasting.

In specialty coffees, alcohols and furans have a low negative correlation, while lactone shows a stronger negative correlation than commercial coffees. In addition, in all the attributes, except for acidity, the presence of fatty acids generates a negative correlation. Only nitrogenous compounds and pyridines positively correlate with most of the features. In the same way, the terpenes have a positive correlation with 4 of the seven attributes, such as fragrance/aroma, aftertaste, acidity, and overall, and the presence of most of the chemical groups generates high positive correlations with acidity. The highest correlation values suggest that the presence of lactones strongly penalizes the flavor rating and the aftertaste due to their bitter nature. The same happens with the phenols and the body rating. The presence of caffeine and derivative strongly penalizes the overall criteria; this effect is caused by the low evaluation of the taste and aftertaste criteria. The pyridines have a high positive confirmation with the balance and overall, while the nitrogenous ones (Phenethylamine, p,α-dimethyl-) positively affect the aroma and body.

Several compounds identified in the analysis depend on the roasting process, which is determined by the experience of roasters. In smaller batch roasters, the operator will utilize his eyes, ears, and nose to achieve the roasting desired. In more technical processes, batch roasters' weight loss or final bean temperature indicates the degree of roast (Parliment, 2000). The specialty coffees showed peaks in the chromatograph after the residence time of caffeine. These compounds belong mainly to fatty acids, terpenes, and esters. It could be because the specialty coffees analyzed had a medium roast (from City Roast and City + roast ∼ 420–430 °F, 219–221 °C, to Full City Roast and Full City + roast ∼ 430–440 °F, 221–226 °C) and commercial coffees had darker roast levels. In the local market, the roasting level is often an indicator of the green bean's quality, as the roaster uses an over-roast to cover errors such as underripe or rotten beans. Caffeine generally resists roasting, so the HPLC analysis results mainly depend on each sample's origin or species. For example, sample C8 corresponds to a Robusta/Arabica blend with the highest value of 901,939 mg/l. In the second place, we had a commercial coffee from Zaruma with 827,873 mg/l. Loja samples (C4 and C5) and Pichincha (E1 and E6) showed lower caffeine values, from 434,054 to 545,482 mg/l, corresponding to the Andean highlands.

The third wave of coffee should emerge as the instrument that allows consumers to acquire a cultural capital good enough to distinguish the general terms of commercial and specialty coffees. However, in Ecuador, its application has been limited to developing the symbolic component and in-person service, leaving aside the background material. In this sense, we observed how the coffees marketed as specials (C1, C3, C4, C5, C6, C7, and C8) do not meet a score expected by the tasters. For example, sample C6 originating from Galapagos, a natural paradise known worldwide, is marketed as an exceptional coffee. However, its organoleptic properties have assigned it a score of 67, and the material content indicates that it is one of the coffees with less chemical complexity, only surpassed by sample C4.

5. Conclusion

We carried out a study that relates the tasting score of 14 coffees from Ecuador, all marketed as specialty coffees, with the organic molecules that contribute to specific organoleptic attributes. Also, we tested the hypothesis that basic coffee tasting and infusion training can generate a level of cultural capital robust enough to identify characteristics consistent with chemical analysis.

The general outcome suggests that basic training in coffee extraction processes and attributes would be sufficient to differentiate commercial and specialty coffee. However, the proper gradation of specialty coffees requires a more profound knowledge of some features within a criterion; for example, the acidity is categorized as grapefruit, orange, lime, and apple in the flavor wheel.

Further research is necessary to relate each functional group to the value and origin of each coffee. We consider that cultural capital can force the domestic market to produce better quality, which would be essential to project Ecuadorian coffee in international markets where the material component is a priority.

Funding

This study was entirely supported by the Research Direction of the Universidad Central del Ecuador within the framework of Proyectos Semilla Fase 4- PS4: N°.cif4-ce-fiq-3.

CRediT authorship contribution statement

Gonzalo Chiriboga: Conceptualization, Methodology, Supervision, Project administration, Funding acquisition, Writing – review & editing. Sophía Peñaherrera: Investigation, Data curation, Formal analysis. Pablo Londoño-Larrea: Data curation, Formal analysis, Methodology. Luis Castillo: Data curation, Software, Validation, Visualization. Ghem Carvajal C: Resources, Methodology, Data curation, Writing – original draft, Writing – review & editing. Carolina Montero-Calderón: Conceptualization, Methodology, Data curation, Writing – original draft, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

We thank Barista Training Center (Quito, Ecuador) and Norberto Vázquez for collaborating in the grading phase.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.crfs.2022.10.023.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

Data availability

Data will be made available on request.

References

- Al-Tameme H.J., Hadi M.Y., Hameed I.H. Phytochemical analysis of Urtica dioica leaves by fourier-transform infrared spectroscopy and gas chromatography-mass spectrometry. J. Pharmacogn. Phyther. 2015;7(10):238–252. [Google Scholar]

- Amanpour A., Selli S. Differentiation of volatile profiles and odor activity values of Turkish coffee and French press coffee. J. Food Process. Preserv. 2016;40(5):1116–1124. [Google Scholar]

- Angeloni G., et al. What kind of coffee do you drink? An investigation on effects of eight different extraction methods. Food Res. Int. 2019;116:1327–1335. doi: 10.1016/j.foodres.2018.10.022. [DOI] [PubMed] [Google Scholar]

- Arciniegas A.F. Universidad Cooperativa de Colombia; 2019. La Cultura Del Café En Colombia Y Ecuador En Permanente Desarrollo. [Google Scholar]

- Barbosa M. de S.G., dos M.B., Scholz S., Kitzberger C.S.G., Benassi M. de T. Correlation between the composition of green Arabica coffee beans and the sensory quality of coffee brews. Food Chem. 2019;292:275–280. doi: 10.1016/j.foodchem.2019.04.072. April. [DOI] [PubMed] [Google Scholar]

- Bressanello D., et al. Coffee aroma: chemometric comparison of the chemical information provided by three different samplings combined with GC–MS to describe the sensory properties in cup. Food Chem. 2017;214:218–226. doi: 10.1016/j.foodchem.2016.07.088. [DOI] [PubMed] [Google Scholar]

- Caporaso N., Genovese A., Canela M.D., Civitella A., Sacchi R. Neapolitan coffee brew chemical analysis in comparison to espresso, moka and American brews. Food Res. Int. 2014;61:152–160. [Google Scholar]

- Central Bank of Ecuador . 2019. Información Estadística Mensual No. 2014 - Diciembre 2019.https://contenido.bce.fin.ec/home1/estadisticas/bolmensual/IEMensual.jsp Estadísticas Monetarias y Financieras. [Online]. Available: [Google Scholar]

- Chin S.T., Eyres G.T., Marriott P.J. Identification of potent odourants in wine and brewed coffee using gas chromatography-olfactometry and comprehensive two-dimensional gas chromatography. J. Chromatogr. A. 2011;1218(42):7487–7498. doi: 10.1016/j.chroma.2011.06.039. [DOI] [PubMed] [Google Scholar]

- Daviron B., Ponte S. The Coffee Paradox: Global Markets, Commodity Trade and the Elusive Promise of Development. CTA Technical Publications; London: 2005. Overall introduction to the Coffee industry. [Google Scholar]

- Farah A. Coffee: Emerging Health Effects and Disease Prevention. 2012. Coffee constituents; pp. 21–58. [Google Scholar]

- Fischer E.F. MPIfG Discussion Paper. Max Planck Institute for the Study of Societies; Cologne: 2017. Quality and inequality: taste, value, and power in the third wave coffee market. [Google Scholar]

- Giacalone D., Degn T.K., Yang N., Liu C., Fisk I., Münchow M. Common roasting defects in coffee: aroma composition, sensory characterization and consumer perception. Food Qual. Prefer. 2019;71:463–474. March. [Google Scholar]

- Gonzalez-Rios O., et al. Impact of 'ecological' post-harvest processing on coffee aroma: II. Roasted coffee. J. Food Compos. Anal. 2007;20(3–4):297–307. [Google Scholar]

- Hu G., et al. Effect of roasting degree of coffee beans on sensory evaluation: research from the perspective of major chemical ingredients. Food Chem. 2020;331 doi: 10.1016/j.foodchem.2020.127329. May. [DOI] [PubMed] [Google Scholar]

- International Coffee Organization . 2020. Trade Statistics Tables Crop Year Production by Country.http://www.ico.org/trade_statistics.asp?section=Statistics Trade Statistics Tables. [Online]. Available: [Google Scholar]

- Kipkorir R.K., Muliro P., Muhoho S. Effects of coffee processing technologies on physico-chemical properties and sensory qualities of coffee. Afr. J. Food Sci. 2015;9(4):230–236. [Google Scholar]

- Kitzberger C.S.G., dos M.B., Scholz S., Pereira L.F.P., Benassi M. de T. Composição química de cafés árabica de cultivares tradicionais e modernas. Pesqui. Agropecu. Bras. 2013;48(11):1498–1506. [Google Scholar]

- Laukaleja I., Kruma Z. Quality of Specialty Coffee: balance between aroma, flavour and biologically active compound composition: Review. Res. Rural Dev. 2018;1:240–247. [Google Scholar]

- Lingle T.R. fourth ed. Coffee Development Group; Washington DC: 1984. Coffee Cuppers' Handbook, the Specialty Coffee Association of America. [Google Scholar]

- Lingle T.R., Menon S.N. The Craft and Science of Coffee. 2017. Cupping and grading-discovering character and quality; pp. 181–203. [Google Scholar]

- Londoño-Larrea P., Zapata S., Lara-López M., Villamarín-Barriga E. 2018. Preliminary Study of Caffeine Extraction from <em>Ilex Guayusa</em> L. Leaves Using Supercritical Carbon Dioxide; p. 5297. June. [Google Scholar]

- Lopes G.R., Passos C.P., Petronilho S., Rodrigues C., Teixeira J.A., Coimbra M.A. Carbohydrates as targeting compounds to produce infusions resembling espresso coffee brews using quality by design approach. Food Chem. 2020 doi: 10.1016/j.foodchem.2020.128613. August. [DOI] [PubMed] [Google Scholar]

- Malau S., Albiner S., Bilter S. Variability of organoleptic quality of Arabica coffee. Anadolu J. Agric. Sci. 2018;33:241–245. [Google Scholar]

- Mendenhall W., Beaver R.J., Beaver B.M. 14 th. Cengage Learning; México: 2015. Introducción a la Probabilidad Estadística. [Google Scholar]

- Molina A. 2018. Origin Spotlight: Exploring Ecuador's Specialty Coffee - Perfect Daily Grind. [Google Scholar]

- Mussatto S.I., Machado E.M.S., Martins S., Teixeira J.A. Production, composition, and application of coffee and its industrial residues. Food Bioprocess Technol. 2011;4(5):661–672. [Google Scholar]

- National Institute for Statistics and Census . 2011. Survey for Stratification of Socioeconomical Level. Quito. [Google Scholar]

- Parliment T.H. An overview of coffee roasting. ACS Symp. Ser. 2000;754:188–201. [Google Scholar]

- Perez J., et al. Economic sustainability-price, cost, and value. Cr. Sci. Coffee. 2017:133–160. [Google Scholar]

- Poisson L., Blank I., Dunkel A., Hofmann T. Elsevier Inc.; 2017. The Chemistry of Roasting-Decoding Flavor Formation. [Google Scholar]

- Poole R.L., Tordoff M.G. The taste of caffeine. J. Caffeine Res. 2017;7(2):39–52. doi: 10.1089/jcr.2016.0030. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rosenberg L., Swilling M., Vermeulen W.J.V. Practices of third wave coffee: a Burundian producer's perspective. Bus. Strat. Environ. 2018;27(2):199–214. [Google Scholar]

- Sarghini F., Fasano E., De Vivo A., Tricarico M.C. Influence of roasting process in six coffee Arabica cultivars: analysis of volatile components profiles. Chem. Eng. Trans. 2019;75:295–300. September 2018. [Google Scholar]

- SENADI . 2017. Ecuador con aroma de café – Servicios. [Google Scholar]

- Teranishi R., Wick E., Hornstein I. vol. 53. Springer Science; New York: 2012. Flavor Chemistry Thirty Years of Progress. 9. [Google Scholar]

- Traore T.M., Wilson N.L.W., Fields D. What explains specialty coffee quality scores and prices: a case study from the cup of excellence program. J. Agric. Appl. Econ. 2018;50(3):349–368. [Google Scholar]

- van Dam R.M., Hu F.B., Willett W.C. vol. 383. 2020. Coffee, caffeine, and health; pp. 369–378. (New England Journal of Medicine). 4. [DOI] [PubMed] [Google Scholar]

- Zawirska-Wojtasiak R., Wojtowicz E., Przygoński K., Olkowicz M. Chlorogenic acid in raw materials for the production of chicory coffee. J. Sci. Food Agric. 2014;94(10):2118–2123. doi: 10.1002/jsfa.6532. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.