Abstract

The COVID-19 epidemic seriously threats the human society and provokes the panic of the public. Personal Protective Equipment (PPE) are widely utilized for frontline health workers to face the ongoing epidemic, especially disposable face masks (DFMs) to prevent airborne transmission of coronavirus. The overproduction and massive utilization of DFMs seriously challenge the management of plastic wastes. A huge amount of DFMs are discharged into environment, potentially induced the generation of microplastics (MPs) owing to physicochemical destruction. The MPs release will pose severe contamination burden on environment and human. In this review, environmental threats of DFMs regarding to DFMs fate in environment and DFMs threats to aquatic and terrestrial species were surveyed. A full summary of recent studies on MPs release from DFMs was provided. The knowledge of extraction and characterizations of MPs, the release behavior, and potential threats of MPs derived from DFMs was discussed. To confront the problem, feasible strategies for control DFMs pollution were analyzed from the perspective of source control and waste management. This review provides a better understanding the threats, fate, and management of DFMs linked to COVID-19 pandemic.

Keywords: Microplastics, COVID-19 pandemic, Disposable facemasks, Personal protective equipment, Plastic pollution

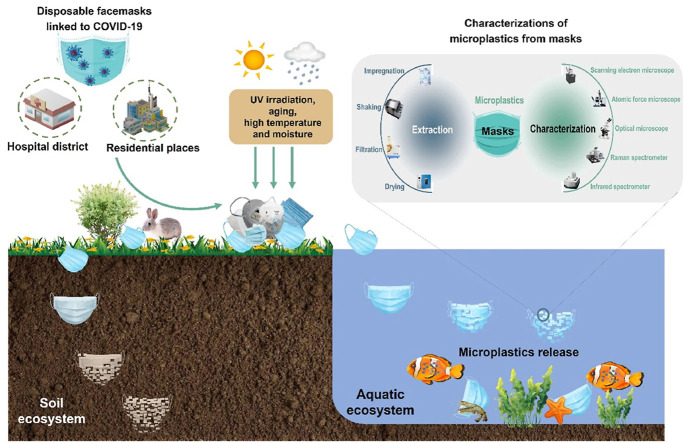

Graphical abstract

1. Introduction

The appearance of COVID-19 epidemic originated from novel SARS-CoV-2 coronavirus seriously threats human society worldwide. The severity and high infectiousness of the COVID-19 provoke the panic of the public. Preventive measures have been implemented to restrain the coronavirus spread, including lockdown of cities, social space, and isolation (Oraby et al., 2021). The transmission of SARS-CoV-2 coronavirus heavily relies on airborne transmission (Buonanno et al., 2020), and the Personal Protective Equipment (PPE) including facemasks, gloves, and protective suits are widely utilized for frontline health workers to face the ongoing epidemic (Kahlert and Bening, 2020). As to the public, facemasks has been made mandatory in most global regions.

Daily utilization of disposable face mask (DFMs) has become a universal prerequisite for preventing coronavirus transmission (Liao et al., 2021). The massive consumption of DFMs result in a deficiency of facemasks all over the world, inducing major production conversely. The global demand for surgical masks was estimated to be 89 million per month before the appearance of COVID-19 (World Health Organization, 2020), and the worldwide utilization of facemasks sharply reached 129 billion per month in 2020 (Prata et al., 2020a). The ubiquitous discard of used DFMs in the environment exacerbates the plastic contamination. An online survey manifested that 9% investigative people abandoned DFMs carelessly (Fadare and Okoffo, 2020). It was reported that approximate 10 million facemasks would be discharged per month because of improper disposal of facemasks (Kwak and An, 2021). Approximate 1.56 billion facemasks were discharge into the marine area in 2020 (Sun et al., 2021). DFMs are mainly consisted of polymers such as polypropylene, polyacrylonitrile, and polystyrene (Abbasi et al., 2020). DFMs undergo decomposition or degradation due to physical, chemical, or biochemical interactions in natural environment. The overproduction and massive utilization of DFMs seriously challenge the management of plastic wastes. Several papers have been reported on the plastic pollution caused by DFMs (Silva et al., 2021a, 2021b; Dharmaraj et al., 2021). COVID-19 pandemic aggravates global plastic pollution, and environmental sustainability request the straightened links between policy-industry-research associated with COVID-19 pandemic. Thousands of DFMs may be discarded into the environment daily, and contaminant release from DFMs results in the potential ecotoxicological threats, especially for the marine ecosystem. The ongoing epidemic exacerbates the environmental problem, posing serious threats to human health and ecosystems. It is suggested that researches on plastic mitigation and monitoring ecotoxicological impacts should be conducted to control plastic pollution derived from DFMs. With growing awareness of plastic pollution caused by DFMs, it is essential to deeply understand ecotoxicological threats and propose effectively management of DFMs.

In the past three years, DFMs gains sharply growing worldwide attention. Data from Web of Science core collection database manifest publications increase from 24 to 175 and citations significantly increase from 485 to 3481 from 2019 to 2021. Microplastics (MPs) as emerging pollutants have received global attention due to wide distribution, high abundance, enrichment of toxic species, and potential threats (Zhang et al., 2021a; Bian et al., 2022). Recently, MPs release from DFMs receives increasing attention and discussed by several studies. Aragaw (2020) reported a preliminary work about as a potential microplastic release from surgical face masks, and suggested that microplastic pollution raised environmental threats. Subsequently, some studies were implemented to qualitatively and quantitatively examine the microplastic release to environment (Chen et al., 2021; Shen et al., 2021; Wang et al., 2022a). Additionally, several reviews were reported on the topic. Shukla et al. (2022) reviewed MPs from facemasks as a potential risk after Covid-19 pandemic. Hu et al. (2022) summarized DFMs as new sources of microplastic pollution, and proposed the necessity of taking actions for prevention of microplastic problem derived from DFMs. Currently, rudimentary consensus is obtained about microplastic release from DFMs and potential environmental threat. The study is still in its infancy, and more studies are essential to deeply the problems caused by DFMs.

Although several reviews have been published, most of them are overview of current understanding. Considering research advances, it is imperative to survey recent studies and conduct a critical review to provide better understanding the problem. The objectives of this work are to (i) survey the environmental threats of DFMs; (ii) review the MPs release from DFMs; (iii) discuss source control of DFMs; (vi) introduce techniques for management of used DFMs. This review provides a systematical summary of the pollution, MPs release, and management of DFMs based on recent researches.

2. Environmental threats of DFMs

A great amount of plastic wastes is produced due to massive consumption and utilization of facemasks. The widely used facemasks by the public and healthcare workers include surgical masks, respirators, and cloth masks (Fig. S1). Surgical DFMs are mostly widely used because of low cost and high particle filtration efficiency. Surgical DFMs consist of an outer layer to repel fluids, (ii) a middle layer to prevent, and (iii) an inner layer. Discarding facemasks results in the release of plastic wastes in natural environment, posing environmental risks. Similar to general plastic wastes, DFMs may cause irreversible environment pollution owing to the accumulation in environment, and potential threats involve (i) habitat changes within aquatic, soils, and sediments ecosystems; (ii) alteration of carbon and nutrient cycles; (iii) ecotoxicity and biological threats to endangered species; and (iv) negative social influence (MacLeod et al., 2021). Moreover, the management of collected DFMs in disposal sites may consumes energy and discharge greenhouse gases. It was reported that the transportation of 10 tons of PPE wastes to the disposal site (10 km) led to global warming impact (2.76 kg CO2-eq) (Kumar et al., 2021). There exist distinct features of DFMs compared to general plastic wastes, (i) soaring consumption linked to the COVID-19 pandemic, (ii) potential risks of virus transmission, (iii) difficult management of post-consume DFMs, and (iv) unique structure and components. The adverse impacts of DFMs on environment are subsequently discussed.

2.1. The fate of DFMs in environment

DFMs are discarded or deposited in landfill or on land. Without proper management, DFMs can be released into environment, mostly land-river-ocean pathway. Spennemann (2022) reported that DFMs could be long-term source of MPs in recycled urban wastes. The lost or discarded DFMs on the lawn may suffer from fragmentation by lawn cutting equipment. The generated fragments are either wind-dispersed into urban environment, or collected by the leaf catcher of the equipment. The collected fragments will be disposed with the urban green wastes and then enter the municipal waste stream. MPs will be produced from the fragmented masks by mechanical, UV-induced, or weathering interactions.

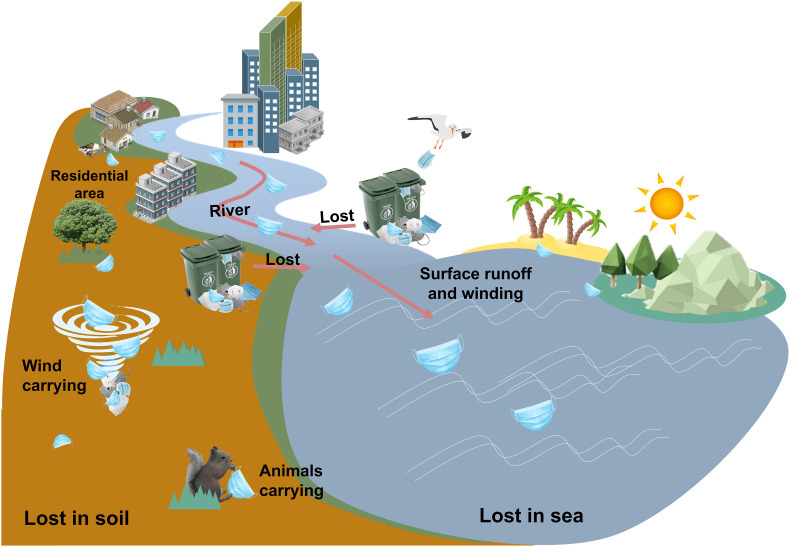

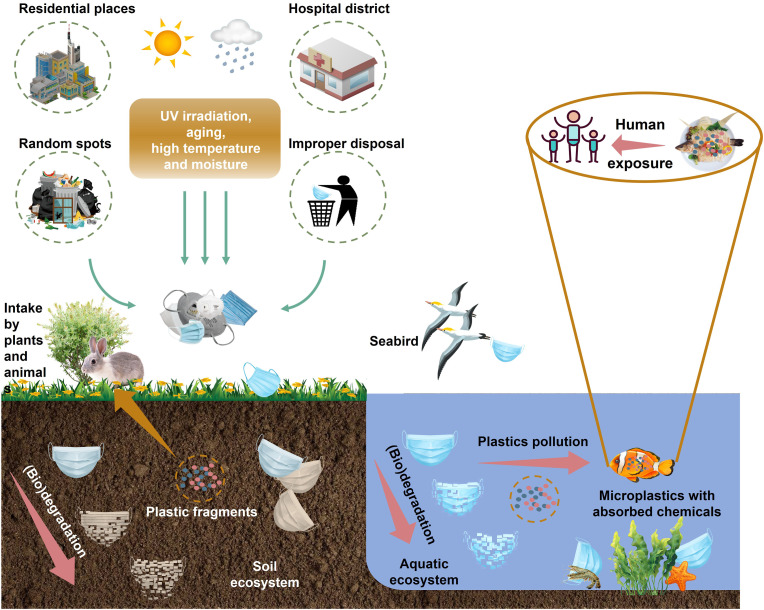

The used DFMs are fragmentated into small particles by physical or chemical interactions, and the terrestrial DFMs fragments are transported into the aquatic environment (Fig. 1 ) (Hu et al., 2022). DFMs in the aquatic environment cause greater problems compared to terrestrial environment. It was reported that plastics exposed in soil were easier to be decomposed than those in the aquatic environment (Chamas et al., 2020). The degradation of DFMs can be hampered in aquatic environment because of water submergence, and the accumulation of DFMs may pose serious threats to aquatic species.

Fig. 1.

The fate of DFMs in the environment. The image was redrawn from (Hu et al., 2022).

DFMs contain chemical compounds such as dyes, plasticizers, and flame retardants. On the one hand, the organic components in DFMs tends to be leached and released into environment, especially when fragmentation into small debris occurs. One other hand, the small debris derived from DFMs enables accumulation of organic pollutants on the surface. Anastopoulos and Pashalidis (2021) found that DFMs acted as dye carriers by adsorption in the aquatic environment. Organophosphate esters (OPEs) are widely used as flame retardants or plasticizers, and gains increasing attention as emerging pollutant. OPEs in DFMs reached 28 μg/mask, and among DFMs KN95 masks exhibited maximum OPE level (Fernández-Arribas et al., 2021). Microplastics have been proved as potential vehicle for accumulation and migration of organic contaminates (Fu et al., 2021). Plastic debris from DFMs may carry organic pollutants in environment, and this requires extensive studies.

2.2. The threats of DFMs to aquatic species

Plastic fragments from DFMs may pose threats to biodiversity. Small plastics can be ingested by aquatic organisms and induce entangling digestive system and physical harm such as internal blockages (Debroy et al., 2021). Some DFMs are colored with dyes, and the dye compounds are water-soluble and can be leached. The chromophoric dyes compete light with aquatic plants, hindering the photosynthesis and potentially destroying the ecosystem. Marine debris especially plastic litters ingested by marine megafauna such as seabirds, mammals, turtles, and fish are summarized, and 914 species are affected through entanglement while 701 species affected by ingestion (Kühn and Van Franeker, 2020). DFMs or their fragments can be ingested by marine megafauna, and the elastic cords of DFMs may entangle marine faunas. Plastic remnants derived from DFMs were discovered in the guts of sharks (Pullangott et al., 2021). Neto et al. (2021) reported the ingestion of DFMs and potentially induced death of a penguin. The ingestion of MPs released from DFMs significantly declined the fecundity of copepods (Sun et al., 2021).

2.3. The threats of DFMs to terrestrial species

Commonly, DFMs are discarded haphazardly or disposed as plastic wastes. The used DFMs as potential vector for SARS-CoV-2 virus should be strictly managed under the COVID-19 pandemic. However, the haphazard abandoning DFMs in environment has been found in many counties such as Canada (Prata et al., 2020b), Peruvian (Torres and De-la-Torre, 2021), Thailand (Tesfaldet et al., 2022), China (Shen et al., 2021), Portugal (Prata et al., 2021), Turkey (Akarsu et al., 2021), Australia (Spennemann, 2021), Ethiopia and France (Aragaw, 2020). The abandoned DFMs in the terrestrial system may block the urban wastewater system and influence the aeration and water percolation of agricultural soils (Silva et al., 2021a). Discarded DFMs in the soil can threat the fauna through entanglement or mistaken for food, and a bird tangled littered DFMs and died in Columbia was reported (Selvaranjan et al., 2021). In addition, small fragments from DFMs in soil can change the bulk density, soil structure, and water holding capacity, and negatively influence the activity of soil microbial and the cycle of plant nutrients (Zhou et al., 2020. Du et al., 2021). The accumulation and translocation of small plastic particles in plant tissues have been reported, which influence plant growth and agricultural productivity (Ullah et al., 2021). The impact of plastic fragments from DFMs has not been reported.

3. MPs released from DFMs

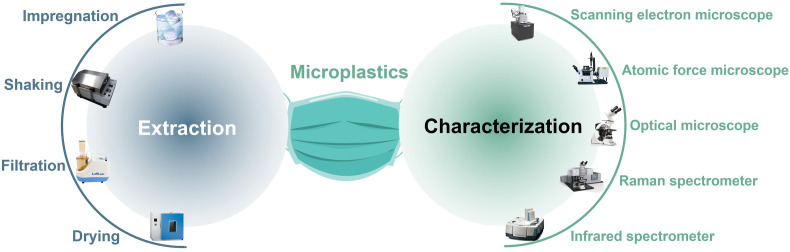

3.1. Extraction and characterizations of MPs

Recently, increasing attention was paid on MPs release from DFMs. Several researches were conducted to reveal MPs release in aquatic environment. The analysis of MPs from DFMs can be shown in Fig. 2 . Generally, extraction is performed to collect of MPs from DFMs, including impregnation, stirring/shaking, filtration, and drying steps. The target DFMs from different sources (types, brands, models, etc.) are pretreated to remove elastic ear loops and nose bridges (Wang et al., 2021a; Sullivan et al., 2021). The whole facemasks or cut pieces are used in extraction experiments. Some studies investigated MPs release from different layers of facemasks (Ma et al., 2021; Wang et al., 2021a). After impregnation facemasks into water, stirring or shaking is conducted to induce MPs release. Then, the water containing MPs is subjected to filtration to collect released MPs. After drying at room temperature or low temperature, the quantity, color, and morphology of collected MPs are analyzed. Details for MPs extraction from DFMs are listed in Table 1 .

Fig. 2.

Analysis of MPs released from DFMs.

Table 1.

Specific conditions for MPs extractions.

| Facemasks | Impregnation | Shaking | Filtration | Drying | MPs release | References |

|---|---|---|---|---|---|---|

| Surgical or N95 face mask | A whole facemask, 100 mL Milli-Q water in glass bottle | Shaking rigorously for 3 min | A total of 1000 mL leachate per facemask | 100 μL leachate dropped onto silicon wafer and dried at room temperature | Over one billion of MPs ranging from 5 nm to 600 μm | Ma et al. (2021) |

| Surgical, KF-AD, and KF94 facemasks | A whole facemask, 200 mL Milli-Q water in glass flask | 150 rpm for 24, 48, and 72 h | Whatman nitrocellulose filter (pore size 0.45 μm), vacuum filtration | Drying at room temperature for 24 h. | Over 47 microfibers per mask per day | Dissanayake et al. (2021) |

| Ecoparksg disposable masks | Mask strips (1.5 × 14 cm), 50 mL deionized water in absence and presence of 20 sand | Shaking at 300 rpm for 24 h | Without filtration | / | Over 1.5 million MPs per weathered mask | Wang et al. (2021a) |

| Surgical masks | A whole facemask, 1 L artificial seawater in glass bottle | Stirring at 4000 rpm for 24 h | Sieving through 500 μm mesh and vacuum filtration through a Whatman nitrocellulose filter (pore size 0.45 μm) | Drying for 24 h | 173,000 microfibers per surgical mask per day | Saliu et al. (2021) |

| Medical surgical facemasks, disposal medical facemasks, normal disposal facemasks and N95 facemasks | A whole facemask, 200 mL deionized water in glass flask | Shaking at 120 rpm for 24 h | Filtration through a Millipore mixed cellulose esters membrane filter (pore size 0.8 μm | Drying at room temperature | MPs 183.00 ± 78.42 pieces per new mask, 1246.62 ± 403.50 pieces per used mask | Chen et al. (2021) |

| Surgical masks | A whole facemask, 250 mL of artificial seawater in glass bottle | Shaking at 200 rpm for 9 days | Vacuum filtration through a membrane filter (0.45 μm) | Drying at room temperature | Estimated 396 billion MPs per day. | Sun et al. (2021) |

| Common masks, surgical masks, and face filtering piece masks | Facemask (1 × 1 cm), 15 mL deionized water or 6 g sand with 10 mL water in glass tubes | Rotating at 60 rpm for 240 h | Filtration through a 1 μm glass fiber filtrate | Oven-drying at 60 °C for 3 h | MPs 272 ± 12.49 items/cm2 mask after sediment abrasion | Wu et al. (2022) |

| Surgical facemasks | Cut facemask, 500 mL of Milli-Q water in a glass beaker. | Kitchen chopper with a rotating blender blade | / | / | MPs thousands of microfibers and up to 108 submicrometric particles per facemask | Morgana et al. (2021) |

| N95 masks, medical surgical masks, and normal medical masks | A whole mask in 200 mL deionized water in conical flask | Shaking at 220 rpm for 24 h | Filtration with a 0.45 μm cellulose ester membrane | Drying at room temperature | MPs: 801–2667 particles/(piece·d) for N95 mask, 1136–2343 particles/(piece·d) for medical surgical mask, and 1034 −2547 particles/(piece·d) for normal medical mask |

Liao et al., 2021 |

| Surgical masks | A whole mask, 3 L of ultrapure water in a glass beaker | Stirring at 120 rpm for 24 h | Vacuum filtration through nitrocellulose membrane (pore size 0.45 μm) | Drying at 40 °C | MPs 360 items per mask in the static water | Shen et al. (2021) |

| Disposable face masks | 10 facemasks, 1.5 L deionized water | Gent stirring for 4 h | Vacuum filtration through a 0.1 μm Al2 O3 membrane filter | Drying for 2 h at 50 °C | / | Sullivan et al. (2021) |

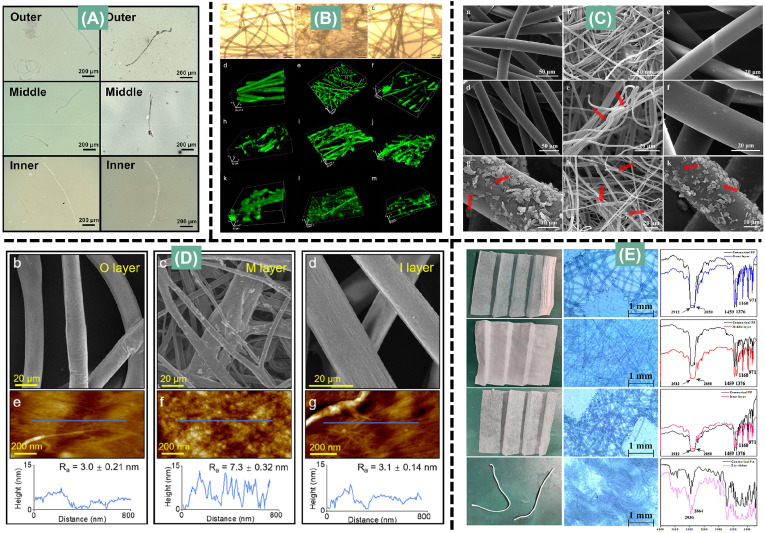

After extraction, characterizations are conducted to identify MPs. Various techniques are used to identify the MPs released from DFMs, such as optical microscope, scanning electron microscope (SEM), atomic force microscope (AFM), Fourier transform infrared spectroscopy (FTIR), and Raman spectroscopy (Fig. 3 ). Optical microscope, SEM, and AFM are mainly employed to reveal the morphology of MPs. Optical microscope can be easily used to examine the size, shape, color, and quantity of MPs, but it fails to observe small MPs especially at nano scale. SEM and AFM can clear observe MPs at micron to nano scale, and SEM enables identification of MPs composition associated with energy dispersive X-ray spectroscopy (Wu et al., 2022) while AFM is able to analysis surface roughness (Wang et al., 2021a). Quantitative identification is necessary to examine the release behavior of MPs from DFMs, but it is difficult for visual identification. Images obtained from microscope can be analyzed using specific software for quantitative identification (Ma et al., 2021; Liao et al., 2021; Shen et al., 2021). A laser in-situ scattering and transmissometry analyzer was reported to determine the particle size distribution of released MPs (Wang et al., 2021a). FTIR and Raman are commonly used to identify the polymer type of MPs (Ma et al., 2021; Chen et al., 2021). Raman spectroscopy is an advantage for MPs identification. FTIR spectra of DFMs suggested that all three layers were consisted of polypropylene (Wang et al., 2021a; Sun et al., 2021). Fadare and Okoffo (2020) suggested the inner layer to be PE and the outer layer to be PP determined by FTIR spectra. The existence of polystyrene in some facemasks was identified by FTIR (Dissanayake et al., 2021), while polyethylene terephthalate in DFMs determined by Raman spectrum (Chen et al., 2021). The difference in polymer composition of DFMs can be attributed to the sources, types, and determined position of facemasks.

Fig. 3.

(A) The images, (B) Florescentmicrocopy and the confocal 3D micrographs, (C) SEM images of released microfibers from different layers of surgical facemask (Wu et al., 2022); (D) SEM and AFM images of the fibers in the different layers of facemask (Ma et al., 2021); (E) pictures, fiber structure, and FTIR spectra of disposable surgical mask (Shen et al., 2021).

3.2. The release behavior of MPs

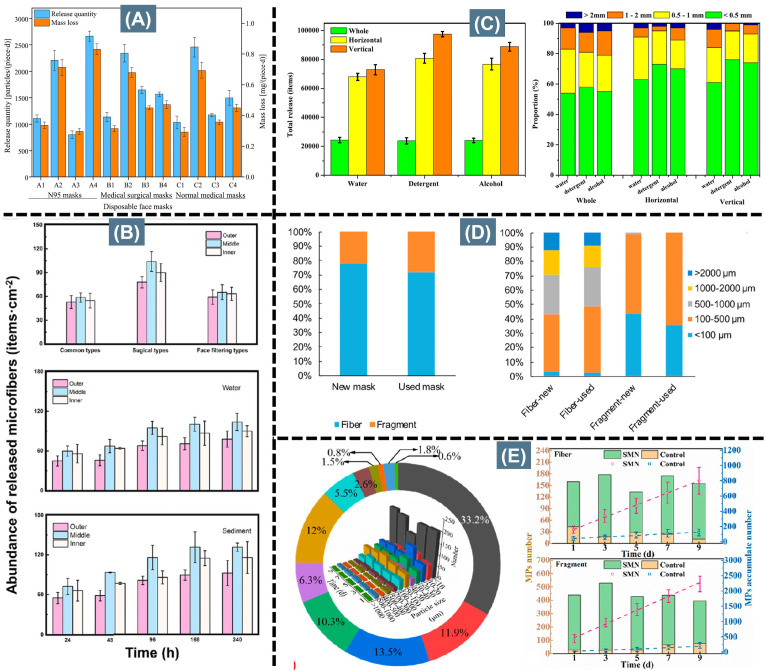

Currently, most researchers studied MPs release from DFMs in aquatic environment. Extraction is commonly conducted to examine the release of MPs from DFMs. MPs releases from different types of facemasks are studied employing diverse facemasks. MPs released from different DFMs (KF-AD, KF94, surgical facemasks) were reported by Dissanayake et al. (2021). The surgical and KF94 facemasks created the maximum quantity of microfibers. Each facemask released more than 47 fibers per day under experimental conditions, and the released MPs fibers significantly increased with increasing time. Microfibers released from DFMs were 50.33 ± 18.50 items/mask, remarkably higher than that from KN95 respirator (31.33 ± 0.57 items/mask) (Wang et al., 2022a). Small polymeric fibers, particles, siliceous fragments, and leachable chemicals were determined from all DFMs (Sullivan et al., 2021). Heavy metals and organic species derived from plastic additives and contaminants, such as polyamide-66, surfactants, dyes, and polyethylene glycol were identified. Liang et al. (2022) found that the quantities of MPs released from N95, surgical, and normal facemasks were 801–2667 particles/mask, 1136–2343 particles/mask, and 1034–2547 particles/mask, respectively (Fig. 4 A). The release kinetics over 7 days revealed that all DMFs released MPs rapidly in the initial stage and then the release slowed, and the release kinetics could be described by the Elovich equation. MPs with particle size of 100–500 μm and <100 μm underwent a rapid release, while most released MPs were fibers and transparent plastics.

Fig. 4.

(A) The release number of MPs and mass loss of facemasks (Liang et al., 2022); (B) the abundance of microfibers from the common, surgical and filtering masks (Wu et al., 2022); (C) the amount and length distribution of released microfibers from masks subjected to cutting (Shen et al., 2021); (D) shapes and sizes of MPs released from the new and used DFMs (Chen et al., 2021); (E) Size distribution and MPs fiber and fragment released from surgical masks (Sun et al., 2021).

Generally, DFMs consist of three layers with different function, structure, and chemical composition, and MPs release from different layers can be dissimilar. The quantification and characterization of MPs from DFMs were studied, and DFMs released large quantities of similar MPs (Ma et al., 2021). Each face mask released over one billion of MPs. The particles were irregularly-shaped with size from 5 nm to 600 μm, and most of them were nanoscale. It was found that the middle layers released more MPs than the inner and outer layers of facemasks. Kokalj et al. (2022) found that MPs released from each layer of DFMs differed significantly in size and shape (fibers of 45.1 ± 21.5 μm for inner layer, fragments of 55.6 ± 28.5 μm for middle layer, and fibers of 42.0 ± 17.8 μm for outer layer).

To simulate MPs release in real situation, some measures are employed in experiments, such as simulated artificial seawater, shaking or stirring, weathering DFMs, and sediment environment. From a study of microfibers release from surgical DFMs in the simulated marine environment, the release quantity was above 173,000 items/day for facemasks exposed to UV irradiation for 180 h or subjected to strong agitation in simulated seawater (Saliu et al., 2021). The impact of environmental conditions on microfiber release from different DFMs was examined under simulated conditions (Wu et al., 2022). The released microfibers from facemasks in water and sediment environments obeyed the sequence of surgical, common, and FFP (Fig. 4B). The quantity of microfibers was up to 272 items/cm2 after sediment abrasion. The length of released microfibers from surgical facemask changed from 47.78 μm to 3.93 mm with most microfibers to be 0.1–1 mm. More small fibers and increased roughness of microfibers were observed in sediment environment. The cracks and protrusions resulted from sediment abrasion may accelerate facemask decomposition and the release of inherent chemicals. The mechanical shear of DFMs was conducted using kitchen chopper with a rotating blender blade, and shear experiments were performed by changing time and energy density (Morgana et al., 2021). The exposure to different mechanical forces induced breaking and fragmenting DFMs into small plastic fragments. Each facemask released thousands of microfibers and up to 108 submicrometric particles in water even with slight fabric deterioration. A predominant release of MPs was nano-sized and readily taken in aquatic organisms.

It was found that MPs release from DFMs was influenced by natural weathering (Wang et al., 2021a). The transformation of chemical composition and chain structure of DFMs occurred, while the mechanical strength after UV weathering decreased. The middle layer of masks was mostly sensitive to UV irradiation. The release of above 1.5 million MPs per mask was observed into the aquatic environment. The enhancement of MPs release (16 million particles per weathered mask) was revealed by physical abrasion resulted from sand, indicating that the shorelines as the major acceptor of abandon DFMs exacerbates the transformation of masks to MPs.) Fig. 4C shows the effect of mechanical action, organic solvents, and natural weathering on MPs release from DFMs (Shen et al., 2021). Each facemask release 360 MPs in the static water, and it increased in water with increasing vibration rate. Organic solvents (detergent and alcohol) enhanced MPs release from facemasks. The release of microfibers from DFMs fragments was significantly improved due to large exposure area. After natural weathering for 60 days, the masks transformed into highly fragile debris. Several billions of MPs would be generated from a weathered facemask.

The release behavior of MPs from new and used DFMs is exhibited in Fig. 4D (Chen et al., 2021). MPs release from the used masks were 1246.62 items, significantly higher than 183.00 items for virgin facemasks. Most MPs released from DFMs were polypropylene fibers derived from the nonwoven fabrics. The abrasion during the utilization of DFMs accelerated MPs release. The used DFMs without proper disposal could be important source of MPs in the environment. The release quantity of MPs was 396 billion per day, and it was estimated that discarded DFMs in the whole year of 2020 produced over 1370 trillion MPs discharging into coastal ocean environment (Fig. 4E) (Sun et al., 2021). It was evaluated over 1381 million microfibers per day were released in South Korea based on the assumption of one facemask for 70% of urban people one day (Dissanayake et al., 2021).

The dry and wet state emission of MPs from DFMs was extensively investigated (Rathinamoorthy and Balasaraswathi, 2022). Dry abrasion simulating the situation of handling, usage, or open land disposal induced the release of 14,032–177,602 fibers/mask. Exposure of DFMs in seawater produced more microfibers compared to freshwater exposure, and MPs released was lower than the dry state. Moreover, the natural weathering caused significant effects on MPs release at both dry and wet states. Bio-fragmentation of MPs derived from facemasks occurred in soil in the presence of earthworm (Kwak and An, 2021). DFMs in organic fraction of municipal solid waste negatively influenced high-solids anaerobic digestion, and the undegraded facemasks might cause MPs pollution and promote transmission of antibiotic resistance genes (de Albuquerque et al., 2021). Currently, most researches focus on MPs release in aquatic environment. Environments such as atmosphere, soil, and sediment are important parts of the ecosystem that is susceptible to the negative impacts of waste DFMs. There is less available data about MPs release from DFMs in other environments. More efforts should be performed to explore MPs release from DFMs in different environments such as atmosphere, soil, sediments.

Current studies prove the release of MPs from DFMs in aquatic environment. As displayed in Table 1, the results of MPs release from different studies are highly different. The difference in MPs release from DFMs can be ascribed to several reasons. First, different DFMs (types, brands, models, etc.) are used for experiments, and the inherent variance of DFMs results in diversity of MPs release. Second, different experimental procedures, such as mask cut, pretreatment or weathering, shaking or stirring, induce the change of results of MPs release. Third, experimental conditions and used devices or apparatus are diverse, causing experimental variance. The quantitative methods for MPs identification are the most important reason. No standard methods are developed for identification of MPs quantity, and techniques used in previous studies are tentative and cause significant difference in MPs release.

Currently, most studies focus on evaluation of the potential sources of MPs from DFMs, as well as the negative impacts on environment. The study is still in its infancy. The reported data is different from different studies, and the used methods and devices for MPs identification are diverse. Nevertheless, numerous researches suggest that DFMs are remarkable sources of MPs, negatively influencing ecosystem and environment (Aragaw, 2020). Therefore, the impacts caused by MPs should be emphasized with suggestions on the mitigation methods to counter these impacts. Researches on mitigation of MPs release from DFMs are rarely reported. It has been proven that MPs release is influenced by intrinsic facemasks (types, sections, and brands), additional disposal (usage, destroy, and weathering), and environmental conditions (temperature, humidity, saline, etc.) (Liang et al., 2022; Wang et al., 2021a; Ma et al., 2021). Based on current understanding, several practices are suggested: i) reducing the generation of waste DFMs from sources, ii) hindering the migration of waste DFMs in environment, iii) improvement of official policy and publica awareness for disposal of waste DFMs. Studies have conducted to develop potential techniques of MPs removal, such as adsorption (Abuwatfa et al., 2021), coagulation (Wang et al., 2022b), magnetic separation (Shi et al., 2022), and froth flotation (Jiang et al., 2022a, 2022b; Zhang et al., 2021b) There are still requirements of more researches on the mitigation methods toward MPs release from DFMs.

3.3. Potential MPs threats

Discarded DFMs undergo the fragmentation through physical or chemical interactions, inducing the generation of MPs. For example, DFMs in water undergo the fragmentation and breakdown by means of aquatic corrosion and weathering. Studies have proved the release of MPs from DFMs. MPs as emerging pollutant have been widely investigated, and their toxicity and adverse impact on environment are revealed and summarized (Shi et al., 2021; Ge et al., 2021). The inherent toxicity of MPs can threat ecosystems, and the carriers of hazardous pollutants make MPs more dangerous. The released MPs in environment will accumulate in ecosystems, and potentially end up in human body through food chain (Du et al., 2022). Besides ingestion, MPs derived from DFMs can enter human body through inhalation. It was found that airborne microplastics could be inhaled and human lung tissue (Amato-Lourenço et al., 2021). Ma et al. (2021) detected MPs from DFMs in the nasal mucus, and discovered the inhalation of MPs by mask wearers (Fig. S2). MPs exposure manifests toxicity such as oxidative stress, inflammatory lesions, metabolic disturbances, and neurotoxicity (Rahman et al., 2021). The bioaccumulation of MPs occurs in the food chain and enhances human exposure to MPs, potentially inducing detrimental environmental, social, and economic impacts.

There are few available data on the ecotoxicological impacts of MPs generated from DFMs. MPs attached onto diatoms surface affected their photosynthesis ability, and ingested by marine organisms including rotifers, shrimps, copepods, groupers, and scallops after short-term exposure (Fig. S3), providing direct evidence of ingestion of released MPs from DFMs by marine organisms. An acute study with planktonic crustacean revealed that the adsorption and ingestion of released MPs from DFMs occurred, but not caused severe effects on the daphnids at relatively high concentrations (Jemec Kokalj et al., 2022). The impacts of MPs from DFMs on terrestrial invertebrates was investigated considering the survival, reproduction, and immune factors of woodlice, mealworm, and enchytraeids (Kokalj et al., 2022). The survival of terrestrial invertebrates and reproduction of enchytraeids were not affected by the MPs. A transient immune response of woodlice and a change of energy-related biomarkers of mealworm larvae were observed caused by MPs from DFMs. Further studies are imperative to quantify the impacts of MPs from DFMs on ecosystem and human health, especially for long-term evaluation.

COVID-19 pandemic causes severe threats to human society. Facemasks are widely used as effective strategy to hinder COVID-19 spread. In the post era of COVID-19 pandemic, DFMs as new sources of plastic pollution should be given concern. The special concerns of facemasks as emerging pollutants are highlighted by researchers (Aragaw, 2020; Dharmaraj et al., 2021; Mghili et al., 2022). Facemasks as emerging plastic pollution on beaches threatens the marine environment, and it is deduced that MPs pollution increases drastically in the Moroccan Mediterranean in the near future (Mghili et al., 2022). Based the survey of the extensive use of the face mask and how it affects human health, it was pointed out that COVID-19 pandemic could bring a new form of marine pollution as discarded PPE ended up in the ocean (Dharmaraj et al., 2021). The sharp increase in the use of DFMs during the pandemic posed significant threats to the wildlife, terrestrial ecosystem, and marine ecosystem (Silva et al., 2021b; Shukla et al., 2022). The MPs generation in environment and health influence of DFMs can be shown as Fig. 5 (Du et al., 2022). Microfiber pollution derived from DFMs is a huge environmental issue, and how to prevent discarded DFMs from entering the environment are an important issue all over the world. Appropriate regulations and measures should be devised to avoid any undesirable impacts derived from DFMs.

Fig. 5.

The health influence of DFMs and MPs generation in environment. The image was redrawn from (Du et al., 2022).

3.4. Source control of waste DFMs

Due to the potential threat to ecosystem and public health, it is imperative to decrease the utilization of DFMs. Currently, DFMs are imperative during the COVID-19 pandemic. Governmental regulation and public awareness should turn to the trade-off of epidemic control and environmental pollution, reducing the excessive utilization of DFMs. Strategies, such as reusable facemasks, bio-degradable facemasks, and reusing DFMs, are helpful for source control of DFMs. Facemasks are potentially contaminated materials, and should be treated with special disposal implementation, such as putting used facemasks in plastic bags. The implementation should be conducted for all types of facemasks.

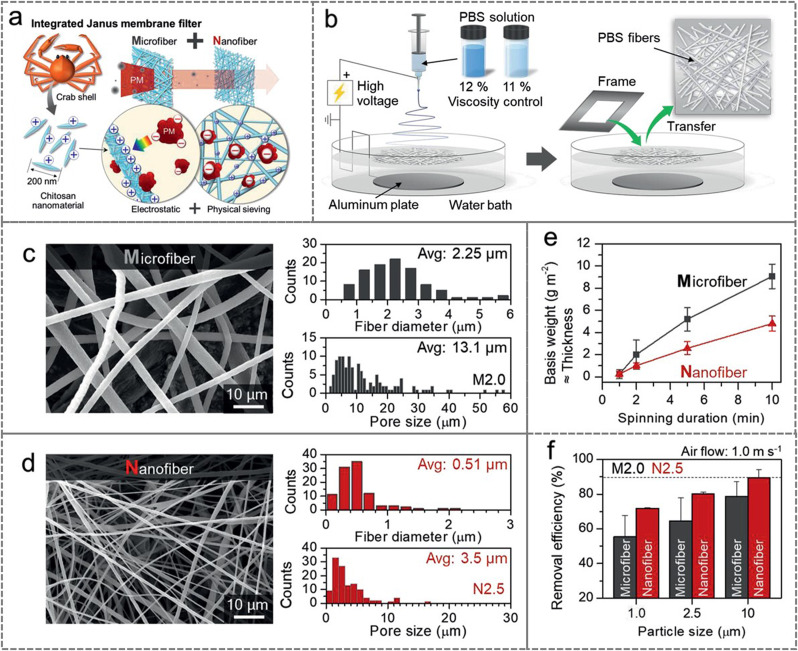

3.5. Bio-degradable facemasks

Biopolymers as green materials receive great interest because of eco-friendliness. It is essential to change towards biopolymers for PPE (Silva et al., 2021a). The working mechanism of facemasks involves electrostatic attraction or physical sieving. As to the former, filters are consisted of charged products for retaining particles with reverse charge. For the latter, it involves the interception, inertial impaction, and diffusion mechanisms (Tebyetekerwa et al., 2020). A fibrous mask filter using polybutylene succinate was fabricated (Choi et al., 2021). The microfiber and nanofiber mats were consolidated into a Janus membrane filter and coated by chitosan nanowhiskers (Fig. 6 a and b). The average fiber diameter of micro and nanofiber mats was 2.25 and 0.51 μm (Fig. 6c and d). The thickness of microfiber and nanofiber mats increased with the spinning duration (Fig. 6e). The removal efficiency of N2.5 was higher than that of M2.0 because of smaller pores. The as-prepared filter removed 98.3% PM2.5 that was comparable to the commercial N95 filter (Fig. 6f).

Fig. 6.

(a) Filtration mechanisms of chitosan-coated PBS fibers combined Janus membrane filter; (b) schematical fabrication process of PBS fiber mat; SEM image and its average fiber diameter and pore size of (c) microfiber mat and (d) nanofiber mat; (e) basis weight ≈ thickness of PBS microfiber and nanofiber mats; (f) PM removal efficiency of the microfiber and nanofiber mats with similar basis weights (Choi et al., 2021).

Wheat gluten biopolymer, a by-product of cereal industries, was electrospun into nanofiber membranes and prepared as the filter media of facemasks (Das et al., 2020). Chowdhury et al. (2021) developed an air-permeable mask using electrospun licorice roots. He's group (2020) conducted electrospinning polylactic acid and 3D printing the material on top for fabricating biodegradable mask filter. The materials could filter 79% of air at MMAD 500–600 nm, which was larger than that of standard facemasks (55% at MMAD 700 nm). Polylactic acid was suggested as an appropriate substance for producing reusable respirator (Vaňková et al., 2020). The microstructure of the 3D printed polylactic acid was examined after disinfection. Polylactic acid structures were not compromised apart from efficient elimination of various bacterial, fungus, and viruses.

Since polylactic acid is mainly generated using starch-rich crops, and mass production using polylactic acid poses high pressures on the agricultural production. It is a sustainable way to utilize bio-materials especially agricultural or industrial by-products to fabricate facemasks. Moreover, common bio-based polymers are generally expensive, notably surpassing conventional plastics (Shogren et al., 2019), while the market for bio-based facemasks remains dubious.

3.6. Reusing DFMs after decontamination

Reusing DFMs after decontamination is a strategy to diminish the utilization and discarding of DFMs. Efforts have been made to decontaminate and reuse DFMs to solve the facemask shortage and the produced environmental burden. Various methods such as ultraviolet germicidal irradiation, dry and moist heat treatment, vaporized hydrogen peroxide, and ethanol treatment have been developed for mask decontamination, and the main characteristics of these methods are summarized in Table S1 (Ju et al., 2021). Most decontamination methods are tested and proposed for reusing N95 masks.

Several decontamination methods were suggested because they could disinfect virus, retain the filtration efficiency, and maintain the physical structure of masks (Seresirikachorn et al., 2021). The effects of ultraviolet germicidal irradiation, ethanol treatment, and dry and moist heat on the particle filtration efficiency (PFE) of N95 masks was reported by Liao et al. (2020). Among all tested methods, moist heat at 85 °C and 30% relative humidity manifested the least effect on the PFE. Moist heat treatment up to 50 cycles caused minor change in the PFE, ultraviolet germicidal irradiation caused small degradation after 20 cycles, and ethanol treatment remarkable declined the PFE of filter fabrics. Ultraviolet germicidal irradiation, isopropanol treatment, and dry and moist heat for decontamination of N95 masks was compared (Ou et al., 2020). Ultraviolet germicidal irradiation maintained the PFE for 10 cycles, dry heat sustained the PFE, but isopropanol treatment was not recommended for mask decontamination due to significant decline of the PFE of electret filter.

The decontamination methods are imperative to meet several necessities: (i) effective decontamination of masks and inactivation of all pathogens; (ii) no deterioration of the masks, especially microscopic structure; (iii) no residual chemicals or by-products; (vi) low cost and wide accessibility of required equipment or resources; (v) easy operation and safety (Ju et al., 2021). Additionally, the scalability of the methods should all be taken into consideration. The decontamination methods may compromise PPE and mask integrity, but no one-size-fits-all methods are applicable to for different facemasks. The design of favorable procedures for different DFMs should be taken into consideration to ensure consistency and reliability in decontamination processes.

3.7. Reusable facemasks

DFMs or reusable facemasks are compulsory or voluntarily used by the public during the COVID-19 pandemic. Reusable facemasks are very accessible due to low price, but varying significantly in quality. The disparity in protection efficiency is the major concern of people for using reusable masks due to different production standard. Reusable masks are more porous and breathable but less protective than surgical masks (Konda et al., 2020). Reusable facemasks subjected to standardized production exhibits protection efficiency larger than 90% comparable to DFMs, and they should be (Prata et al., 2021). From environmental perspectives, reusable masks generate lower carbon footprint than surgical masks, and the life cycle effect of reusable masks account for only 5% of disposable masks (Ray et al., 2022). Reusable masks are recommended to be used in lower-risk situations. Moreover, antiviral materials capable of eliminating surface virus can be applied to improve the protection efficiency of reusable masks (Ji et al., 2020).

4. Management of waste DFMs

Even though some measures discussed above enable source control of DFMs, a great amount of DFMs are still consumed and discarded, causing potential threat to environment. Suitable management of used DFMs is imperative to decrease MPs release into environment. The used DFMs is inevitable to enter waste stream. Traditional landfill or incineration can be applied for management of PPE (Torkashvand et al., 2021). Additionally, plastics in DFMs may be recycled by mechanical recycling. A recycling method for plastic litters, potentially fitting PPE recycling, was proposed by Pietrelli et al. (2017). The process included collection, rinsing, and density separation from polyvinyl chloride and sand, and extrusion at 150–160 °C with the addition of plasticizers. Based on morphological, chemical, physical, and thermal analysis, the recycling route of mechanical recycle DFMs was studied by Battegazzore et al. (2020). Direct recycling of facemasks could be achieved through injection molding or improving mechanical performance with additives from industrial wastes. Recently, some researches on conversion of DFMs into value-added products for specific applications are reported, offering some insights into management of waste DFMs. The conversion of the DFMs should consider the pre-processing due to the existence of hazardous bacteria.

4.1. Pyrolysis of DFMs

There are many technologies such as pyrolysis, gasification, hydrogen technologies, and chemolysis for converting plastic wastes into value-added substances. Pyrolysis is one of the common techniques for thermal conversion of plastic wastes. Pyrolysis is thermal decomposition of plastics at elevated temperature, producing gas (fuels), liquids (biofuel), and solids (carbon materials). Although research on conversion of plastic wastes into gaseous or liquid fuels are widely explored, studies on PPE plastics linked to COVID-19 epidemic are rarely reported. Owing to the massive generation of PPE wastes, especially DFMs, it is imperative for developing novel approaches to recycle the plastics (Zand and Heir, 2021). Because of high polypropylene content, the creation of biofuels from medical PPE through pyrolysis was a promising way (Jain et al., 2020). Pyrolysis of medical gloves and facemasks at 400 °C for 1 h was conducted, yielding ∼75% crude oil and 10% char (Aragaw and Mekonnen, 2021).

A few researches related to pyrolysis of DFMs have been conducted. Pyrolysis of DFMs generated hydrocarbons such as CH4, C2H4, and C2H6 without production of solid char (Park et al., 2021a). Catalytic pyrolysis of DFMs produced aromatics, and the yield and constituent of produced gases and oils were related to pyrolysis temperature and zeolite catalysts (Lee et al., 2021). Maximum oil yield (80.7 wt%) occurred at 550 °C in the non-catalytic pyrolysis process, and the temperature was catalytic pyrolysis temperature to produce benzene, toluene, ethylbenzene, and xylene. The zeolite catalyst of HY and HBeta induced 67% and 134% higher aromatics than HZSM-5 catalyst owing to large pores, high surface area and acid site density. The employment of catalysts changed the chemical structure and molecular weight (Park et al., 2021b). Catalytic pyrolysis improved the aromatic concentration of pyrolysis oil via decarboxylation, deoxygenation, and dehydration reactions. The thermochemical transformation COVID-19 masks into gaseous fuels was reported by Jung et al. (2021). Multi-step pyrolysis was able to induce C–H and C–C bonds scissions of DFMs and promoted the formation of syngas and C1-2 hydrocarbons. H2 and CH4 generation was enhanced by catalytic pyrolysis over Ni/SiO2 catalyst owing to the capability for dehydrogenation. Additionally, CO2-assisted pyrolysis produced more CO and benefited to thermo-chemical process. The thermochemical transformation of DFMs is an environmentally friendly approach to reduce DFMs discharge and produce value-added products. The valorization of COVID-19 masks was conducted through gasification over Ni-loaded ZSM-5 zeolite catalysts (Farooq et al., 2022). The 25% Ni was found as an optimal loading on ZSM-5 due to the highest H2 selectivity (45.04%). Using steam as gasifying agent induced lower content of N-containing species in the gasification products. The Ni-loaded zeolite catalyst improved hydrogen production and lowered the formation of hazardous substances.

4.2. Conversion of DFMs into functional materials

Direct conversion of DFMs into functional materials mainly carbon-based materials is alternative strategy of management of DFMs. Because of unique fibrous structure and simple composition, discarded DFMs are good feedstocks for fabricating carbon materials for various applications (Emenike et al., 2022; Wang et al., 2022c). A study reported the fabrication of microporous supercapacitor electrode employing the triple networks of DFMs (Jiao et al., 2019). A 3D hybrid was prepared by loading of ferroferric oxide and carbon nanotubes on facemask fabric and subsequent polymerization of polypyrrole. The supercapacitor electrode using the as-prepared hybrid showed high specific capacity (221.7 F/g at 50 mV/s) and long-life cycling stability (88.2% after 10,000 cycles). Hu and Lin (2021) explored the transformation of facemasks to into cathode materials of supercapacitors. Collected facemasks were autoclaved at 110 °C with sulfuric acid and then subjected to alkaline activation at 750 °C for 2 h in a tubular furnace. The obtained material with large surface area of 2220 m2/g demonstrated excellent specific capacity (328.9 F/g), power density (300 W/kg), and energy density (11.2 W h/kg). Novel cathodes and anodes were fabricated using facemask-derived carbon (Zhu et al., 2021). Nickel oxide loaded carbon electrodes showed high specific capacitances and excellent rate capability. In addition, the assembled asymmetric supercapacitors manifested a high energy density (57 Wh/kg) with superior cycling stability (98.5% after 10,000 cycles). DFMs have been utilized as nitrogen-doping agents for carbon-based adsorbents through thermal carbonization of plant biomass using K2CO3 as activator, and effective adsorption of Cr(VI) was obtained due to large surface area and diversified surface groups (Bumajdad and Khan, 2021). In addition, Wang's group reported synthesis of carbon-based catalysts derived from MPs for Fenton-like degradation of organic pollutants in wastewater (Wang et al., 2021b; Sun et al., 2022), which can be considered for sustainable disposal of DFMs.

DFMs has great potential to be applied to the embankment construction of road and railway, backfill or reclamation construction. The feasibility of recycling the discarded DFMs was examined for road base and subbase applications (Saberian et al., 2021). The properties of concretes were remarkably improved such as tensile strength (12.2%), compressive strength (17.1%), and ultrasonic pulse velocity (4.1%) after adding 0.2% polypropylene fibers (Kilmartin-Lynch et al., 2021).

The potential of using facemask chips was evaluated as reinforcement in granular soil (Zhang et al., 2022). The addition of facemask chips increased shear strength, decreased shear induced volumetric dilation, and declined stiffness of granular soil. Also, it induced an improvement of energy absorption and minor change of the cumulative strain. The facemasks mixed in concretes possibly suffer thermal decomposition and the exposure of hazardous produced MPs my threat people health in the building employing the concretes (Khoo et al., 2021).

The unique structure and abundant carbon source make DFMs attractive alternative for fabricating carbon materials with large surface area for functional applications. Conversion of DFMs into functional carbon-based materials reduces MPs release and negative impacts of DFMs on environment. Thermal transformation of DFMs is still poorly understood, and more studies are required to develop green processes. Additionally, innovative methods are essential to convert DFMs into functional materials for various applications.

5. Conclusions

The COVID-19 pandemic has been continuously causing heavy damage to human around the world. DFMs are widely used for the control of the virus spreading. DFMs produced from non-degradable petrochemicals are hazardous medical wastes. The alarming rise in facemask usage causes a huge task for disposal this wastes. Recent studies prove the release of MPs from DFMs in aquatic environment, which will induce severe threats and pollution. The release behavior of MPs is still poorly understood due to limited extraction and identification methods, and more researches are necessary on MPs release from DFMs in different environment. Appropriate regulations and measures should be implemented to avoid any undesirable impacts derived from DFMs. Sources control of DFMs can be conducted through reusable facemasks, bio-degradable facemasks, and reusing DFMs. Pyrolysis and fabrication functional materials are sustainable management of used or discarded DFMs. If DFMs are not properly disposed, their impacts will be extended in the future and potentially cause deleterious pollution and threats to ecosystem and human. More extensive researches should be carried out to obtain in-depth understanding the transformation of DFMs in environment and induced threats.

Author statement

Chongqing Wang led the literature collection, analysis of results, and writing of the manuscript; Hongru Jiang contributed to the analysis of results and manuscript revisions; Dan Luo and Luyao Wang contributed to figure preparation; Yingshuang Zhang and Hui Wang contributed to the writing of the manuscript.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51804276 and 21878343).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.chemosphere.2022.137178.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

Data availability

No data was used for the research described in the article.

References

- Abbasi S.A., Khalil A.B., Arslan M. Extensive use of face masks during COVID-19 pandemic:(micro-) plastic pollution and potential health concerns in the Arabian Peninsula. Saudi J. Biol. Sci. 2020;27(12):3181–3186. doi: 10.1016/j.sjbs.2020.09.054. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Abuwatfa W.H., Al-Muqbel D., Al-Othman A., Halalsheh N., Tawalbeh M. Insights into the removal of microplastics from water using biochar in the era of COVID-19: a mini review. Case Studies in Chemical and Environmental Engineering. 2021;4 [Google Scholar]

- Akarsu C., MADENLİ Ö., DEVECİ E.Ü. 2021. Potential Microplastic Threat: Environmental Assessment of the Face Mask Pollution. [Google Scholar]

- Amato-Lourenço L.F., Carvalho-Oliveira R., Júnior G.R., dos Santos Galvão L., Ando R.A., Mauad T. Presence of airborne microplastics in human lung tissue. J. Hazard Mater. 2021;416 doi: 10.1016/j.jhazmat.2021.126124. [DOI] [PubMed] [Google Scholar]

- Anastopoulos I., Pashalidis I. Single-use surgical face masks, as a potential source of microplastics: do they act as pollutant carriers? J. Mol. Liq. 2021;326 doi: 10.1016/j.molliq.2020.115247. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A., Mekonnen B.A. Current plastics pollution threats due to COVID-19 and its possible mitigation techniques: a waste-to-energy conversion via Pyrolysis. Environmental Systems Research. 2021;10(1):1–11. doi: 10.1186/s40068-020-00217-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Battegazzore D., Cravero F., Frache A. Is it possible to mechanical recycle the materials of the disposable filtering masks? Polymers. 2020;12(11):2726. doi: 10.3390/polym12112726. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bian K., Hu B., Jiang H., Zhang Y., Wang H., Wang C. Science of The Total Environment; 2022. Is the Presence of Cu (II) and P-Benzoquinone a Challenge for the Removal of Microplastics from Landfill Leachate? [DOI] [PubMed] [Google Scholar]

- Bumajdad A., Khan M.J.H. The reuse of disposable COVID-19 surgical masks as a nitrogen-enrichment agent and structure promotor for a wild plant-derived sorbent. J. Ind. Eng. Chem. 2021;102:163–176. [Google Scholar]

- Buonanno G., Stabile L., Morawska L. Estimation of airborne viral emission: quanta emission rate of SARS-CoV-2 for infection risk assessment. Environ. Int. 2020;141 doi: 10.1016/j.envint.2020.105794. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chamas A., Moon H., Zheng J., Qiu Y., Tabassum T., Jang J.H., et al. Degradation rates of plastics in the environment. ACS Sustain. Chem. Eng. 2020;8(9):3494–3511. [Google Scholar]

- Chen X., Chen X., Liu Q., Zhao Q., Xiong X., Wu C. Used disposable face masks are significant sources of microplastics to environment. Environ. Pollut. 2021;285 doi: 10.1016/j.envpol.2021.117485. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Choi S., Jeon H., Jang M., Kim H., Shin G., Koo J.M., et al. Biodegradable, efficient, and breathable multi‐use face mask filter. Adv. Sci. 2021;8(6) doi: 10.1002/advs.202003155. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chowdhury M.A., Shuvho M.B.A., Shahid M.A., Haque A.M., Kashem M.A., Lam S.S., et al. Prospect of biobased antiviral face mask to limit the coronavirus outbreak. Environ. Res. 2021;192 doi: 10.1016/j.envres.2020.110294. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Das O., Neisiany R.E., Capezza A.J., Hedenqvist M.S., Försth M., Xu Q., et al. The need for fully bio-based facemasks to counter coronavirus outbreaks: a perspective. Sci. Total Environ. 2020;736 doi: 10.1016/j.scitotenv.2020.139611. [DOI] [PMC free article] [PubMed] [Google Scholar]

- de Albuquerque F.P., Dhadwal M., Dastyar W., Azizi S.M.M., Karidio I., Zaman H., Dhar B.R. Fate of disposable face masks in high-solids anaerobic digestion: experimental observations and review of potential environmental implications. Case Studies in Chemical and Environmental Engineering. 2021;3 doi: 10.1016/j.cscee.2021.100082. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Debroy A., George N., Mukherjee G. Role of biofilms in the degradation of microplastics in aquatic environments. J. Chem. Technol. Biotechnol. 2021;97:1–12. doi: 10.1002/jctb.6978. [DOI] [Google Scholar]

- Dharmaraj S., Ashokkumar V., Hariharan S., Manibharathi A., Show P.L., Chong C.T., Ngamcharussrivichai C. The COVID-19 pandemic face mask waste: a blooming threat to the marine environment. Chemosphere. 2021;272 doi: 10.1016/j.chemosphere.2021.129601. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dissanayake J., Torres-Quiroz C., Mahato J., Park J. Facemasks: a looming microplastic crisis. Int. J. Environ. Res. Publ. Health. 2021;18(13):7068. doi: 10.3390/ijerph18137068. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Du H., Xie Y., Wang J. Environmental impacts of microplastics on fishery products: an overview. Gondwana Res. 2021;108:213–220. [Google Scholar]

- Du H., Huang S., Wang J. Science of The Total Environment; 2022. Environmental Risks of Polymer Materials from Disposable Face Masks Linked to the COVID-19 Pandemic. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Emenike E.C., Iwuozor K.O., Agbana S.A., Otoikhian K.S., Adeniyi A.G. Efficient recycling of disposable face masks via co-carbonization with waste biomass: a pathway to a cleaner environment. Cleaner Environmental Systems. 2022:100094. [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Farooq A., Lee J., Song H., Ko C.H., Lee I.H., Kim Y.M., et al. Valorization of hazardous COVID-19 mask waste while minimizing hazardous byproducts using catalytic gasification. J. Hazard Mater. 2022;423 doi: 10.1016/j.jhazmat.2021.127222. [DOI] [PubMed] [Google Scholar]

- Fernández-Arribas J., Moreno T., Bartrolí R., Eljarrat E. COVID-19 face masks: a new source of human and environmental exposure to organophosphate esters. Environ. Int. 2021;154 doi: 10.1016/j.envint.2021.106654. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fu L., Li J., Wang G., Luan Y., Dai W. Adsorption behavior of organic pollutants on microplastics. Ecotoxicol. Environ. Saf. 2021;217 doi: 10.1016/j.ecoenv.2021.112207. [DOI] [PubMed] [Google Scholar]

- Ge J., Li H., Liu P., Zhang Z., Ouyang Z., Guo X. Review of the toxic effect of microplastics on terrestrial and aquatic plants. Sci. Total Environ. 2021;791 doi: 10.1016/j.scitotenv.2021.148333. [DOI] [PubMed] [Google Scholar]

- Hu X., Lin Z. Transforming waste polypropylene face masks into S-doped porous carbon as the cathode electrode for supercapacitors. Ionics. 2021;27(5):2169–2179. doi: 10.1007/s11581-021-03949-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hu T., Shen M., Tang W. Wet wipes and disposable surgical masks are becoming new sources of fiber microplastic pollution during global COVID-19. Environ. Sci. Pollut. Control Ser. 2022;29(1):284–292. doi: 10.1007/s11356-021-17408-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jain S., Yadav Lamba B., Kumar S., Singh D. Strategy for repurposing of disposed PPE kits by production of biofuel: pressing priority amidst COVID-19 pandemic. Biofuels. 2020:1–5. [Google Scholar]

- Jemec Kokalj A., Dolar A., Drobne D., Marinšek M., Dolenec M., Škrlep L., et al. Environmental hazard of polypropylene microplastics from disposable medical masks: acute toxicity towards Daphnia magna and current knowledge on other polypropylene microplastics. Microplastics and Nanoplastics. 2022;2(1):1–15. doi: 10.1186/s43591-021-00020-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ji D., Fan L., Li X., Ramakrishna S. Addressing the worldwide shortages of face masks. BMC Materials. 2020;2(1):1–11. doi: 10.1186/s42833-020-00015-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jiang H., Zhang Y., Bian K., Wang H., Wang C. Insight into the effect of aqueous species on microplastics removal by froth flotation: kinetics and mechanism. J. Environ. Chem. Eng. 2022;10(3) [Google Scholar]

- Jiang H., Zhang Y., Bian K., Wang C., Xie X., Wang H., Zhao H. Is it possible to efficiently and sustainably remove microplastics from sediments using froth flotation? Chem. Eng. J. 2022;448 [Google Scholar]

- Jiao S., Li T., Xiong C., Tang C., Dang A., Li H., Zhao T. Preparation of microporous supercapacitor electrode based on the triple networks of disposable sheet mask. Nano. 2019;14(12) [Google Scholar]

- Ju J.T., Boisvert L.N., Zuo Y.Y. Face masks against COVID-19: standards, efficacy, testing and decontamination methods. Adv. Colloid Interface Sci. 2021;292 doi: 10.1016/j.cis.2021.102435. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jung S., Lee S., Dou X., Kwon E.E. Valorization of disposable COVID-19 mask through the thermo-chemical process. Chem. Eng. J. 2021;405 doi: 10.1016/j.cej.2020.126658. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kahlert S., Bening C.R. Plastics recycling after the global pandemic: resurgence or regression? Resour. Conserv. Recycl. 2020;160 doi: 10.1016/j.resconrec.2020.104948. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Khoo K.S., Ho L.Y., Lim H.R., Leong H.Y., Chew K.W. Plastic waste associated with the COVID-19 pandemic: crisis or opportunity? J. Hazard Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.126108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kilmartin-Lynch S., Saberian M., Li J., Roychand R., Zhang G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021;296 doi: 10.1016/j.jclepro.2021.126460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kokalj A.J., Dolar A., Drobne D., Škrlep L., Škapin A.S., Marolt G., et al. Effects of microplastics from disposable medical masks on terrestrial invertebrates. J. Hazard Mater. 2022 doi: 10.1016/j.jhazmat.2022.129440. [DOI] [PubMed] [Google Scholar]

- Konda A., Prakash A., Moss G.A., Schmoldt M., Grant G.D., Guha S. Aerosol filtration efficiency of common fabrics used in respiratory cloth masks. ACS Nano. 2020;14(5):6339–6347. doi: 10.1021/acsnano.0c03252. [DOI] [PubMed] [Google Scholar]

- Kühn S., Van Franeker J.A. Quantitative overview of marine debris ingested by marine megafauna. Mar. Pollut. Bull. 2020;151 doi: 10.1016/j.marpolbul.2019.110858. [DOI] [PubMed] [Google Scholar]

- Kumar H., Azad A., Gupta A., Sharma J., Bherwani H., Labhsetwar N.K., Kumar R. COVID-19 Creating another problem? Sustainable solution for PPE disposal through LCA approach. Environ. Dev. Sustain. 2021;23(6):9418–9432. doi: 10.1007/s10668-020-01033-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kwak J.I., An Y.J. Post COVID-19 pandemic: biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J. Hazard Mater. 2021;416 doi: 10.1016/j.jhazmat.2021.126169. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee S.B., Lee J., Tsang Y.F., Kim Y.M., Jae J., Jung S.C., Park Y.K. Production of value-added aromatics from wasted COVID-19 mask via catalytic pyrolysis. Environ. Pollut. 2021;283 doi: 10.1016/j.envpol.2021.117060. [DOI] [PubMed] [Google Scholar]

- Liang H., Ji Y., Ge W., Wu J., Song N., Yin Z., Chai C. Science of The Total Environment; 2022. Release Kinetics of Microplastics from Disposable Face Masks into the Aqueous Environment. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liao L., Xiao W., Zhao M., Yu X., Wang H., Wang Q., et al. Can N95 respirators be reused after disinfection? How many times? ACS Nano. 2020;14(5):6348–6356. doi: 10.1021/acsnano.0c03597. [DOI] [PubMed] [Google Scholar]

- Liao M., Liu H., Wang X., Hu X., Huang Y., Liu X., et al. A technical review of face mask wearing in preventing respiratory COVID-19 transmission. Curr. Opin. Colloid Interface Sci. 2021;52 doi: 10.1016/j.cocis.2021.101417. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ma J., Chen F., Xu H., Jiang H., Liu J., Li P., et al. Face masks as a source of nanoplastics and microplastics in the environment: quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021;288 doi: 10.1016/j.envpol.2021.117748. [DOI] [PubMed] [Google Scholar]

- MacLeod M., Arp H.P.H., Tekman M.B., Jahnke A. The global threat from plastic pollution. Science. 2021;373(6550):61–65. doi: 10.1126/science.abg5433. [DOI] [PubMed] [Google Scholar]

- Mghili B., Analla M., Aksissou M. Face masks related to COVID-19 in the beaches of the Moroccan Mediterranean: an emerging source of plastic pollution. Mar. Pollut. Bull. 2022;174 doi: 10.1016/j.marpolbul.2021.113181. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Morgana S., Casentini B., Amalfitano S. Uncovering the release of micro/nanoplastics from disposable face masks at times of COVID-19. J. Hazard Mater. 2021;419 doi: 10.1016/j.jhazmat.2021.126507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Neto H.G., Bantel C.G., Browning J., Della Fina N., Ballabio T.A., de Santana F.T., et al. Mortality of a juvenile Magellanic penguin (Spheniscus magellanicus, Spheniscidae) associated with the ingestion of a PFF-2 protective mask during the Covid-19 pandemic. Mar. Pollut. Bull. 2021;166 doi: 10.1016/j.marpolbul.2021.112232. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oraby T., Tyshenko M.G., Maldonado J.C., Vatcheva K., Elsaadany S., Alali W.Q., et al. Modeling the effect of lockdown timing as a COVID-19 control measure in countries with differing social contacts. Sci. Rep. 2021;11(1):1–13. doi: 10.1038/s41598-021-82873-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ou Q., Pei C., Kim S.C., Abell E., Pui D.Y. Evaluation of decontamination methods for commercial and alternative respirator and mask materials–view from filtration aspect. J. Aerosol Sci. 2020;150 doi: 10.1016/j.jaerosci.2020.105609. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Park C., Choi H., Lin K.Y.A., Kwon E.E., Lee J. COVID-19 mask waste to energy via thermochemical pathway: effect of co-feeding food waste. Energy. 2021;230 doi: 10.1016/j.energy.2021.120876. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Park Y.K., Ha J.M., Oh S., Lee J. Bio-oil upgrading through hydrogen transfer reactions in supercritical solvents. Chem. Eng. J. 2021;404 [Google Scholar]

- Pietrelli L., Poeta G., Battisti C., Sighicelli M. Characterization of plastic beach debris finalized to its removal: a proposal for a recycling scheme. Environ. Sci. Pollut. Control Ser. 2017;24(19):16536–16542. doi: 10.1007/s11356-017-9440-4. [DOI] [PubMed] [Google Scholar]

- Prata J.C., Paço A., Reis V., da Costa J.P., Fernandes A.J.S., da Costa F.M., et al. Identification of microplastics in white wines capped with polyethylene stoppers using micro-Raman spectroscopy. Food Chem. 2020;331 doi: 10.1016/j.foodchem.2020.127323. [DOI] [PubMed] [Google Scholar]

- Prata J.C., Silva A.L., Walker T.R., Duarte A.C., Rocha-Santos T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020;54(13):7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- Prata J.C., Silva A.L.P., Duarte A.C., Rocha-Santos T. Disposable over reusable face masks: public safety or environmental disaster? Environments. 2021;8(4):31. [Google Scholar]

- Pullangott G., Kannan U., Gayathri S., Kiran D.V., Maliyekkal S.M. A comprehensive review on antimicrobial face masks: an emerging weapon in fighting pandemics. RSC Adv. 2021;11(12):6544–6576. doi: 10.1039/d0ra10009a. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rahman A., Sarkar A., Yadav O.P., Achari G., Slobodnik J. Potential human health risks due to environmental exposure to nano-and microplastics and knowledge gaps: a scoping review. Sci. Total Environ. 2021;757 doi: 10.1016/j.scitotenv.2020.143872. [DOI] [PubMed] [Google Scholar]

- Rathinamoorthy R., Balasaraswathi S.R. Disposable tri-layer masks and microfiber pollution–an experimental analysis on dry and wet state emission. Sci. Total Environ. 2022;816 doi: 10.1016/j.scitotenv.2021.151562. [DOI] [PubMed] [Google Scholar]

- Ray S.S., Lee H.K., Huyen D.T.T., Chen S.S., Kwon Y.N. Environmental Technology & Innovation; 2022. Microplastics Waste in Environment: A Perspective on Recycling Issues from PPE Kits and Face Masks during the COVID-19 Pandemic. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saberian M., Li J., Kilmartin-Lynch S., Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021;769 doi: 10.1016/j.scitotenv.2021.145527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saliu F., Veronelli M., Raguso C., Barana D., Galli P., Lasagni M. The release process of microfibers: from surgical face masks into the marine environment. Environmental Advances. 2021;4 [Google Scholar]

- Selvaranjan K., Navaratnam S., Rajeev P., Ravintherakumaran N. Environmental challenges induced by extensive use of face masks during COVID-19: a review and potential solutions. Environmental Challenges. 2021;3 doi: 10.1016/j.envc.2021.100039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Seresirikachorn K., Phoophiboon V., Chobarporn T., Tiankanon K., Aeumjaturapat S., Chusakul S., Snidvongs K. Decontamination and reuse of surgical masks and N95 filtering facepiece respirators during the COVID-19 pandemic: a systematic review. Infect. Control Hosp. Epidemiol. 2021;42(1):25–30. doi: 10.1017/ice.2020.379. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen M., Zeng Z., Song B., Yi H., Hu T., Zhang Y., et al. Neglected microplastics pollution in global COVID-19: disposable surgical masks. Sci. Total Environ. 2021;790 doi: 10.1016/j.scitotenv.2021.148130. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shi Q., Tang J., Liu R., Wang L. Toxicity in vitro reveals potential impacts of microplastics and nanoplastics on human health: a review. Crit. Rev. Environ. Sci. Technol. 2021:1–33. [Google Scholar]

- Shi C., Zhang S., Zhao J., Ma J., Wu H., Sun H., Cheng S. Separation and Purification Technology; 2022. Experimental Study on Removal of Microplastics from Aqueous Solution by Magnetic Force Effect on the Magnetic Sepiolite; p. 120564. [Google Scholar]

- Shogren R., Wood D., Orts W., Glenn G. Plant-based materials and transitioning to a circular economy. Sustain. Prod. Consum. 2019;19:194–215. [Google Scholar]

- Shukla S., Khan R., Saxena A., Sekar S. Microplastics from face masks: a potential hazard post Covid-19 pandemic. Chemosphere. 2022;302 doi: 10.1016/j.chemosphere.2022.134805. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silva A.L.P., Prata J.C., Walker T.R., Duarte A.C., Ouyang W., Barcelò D., Rocha-Santos T. Increased plastic pollution due to COVID-19 pandemic: challenges and recommendations. Chem. Eng. J. 2021;405 doi: 10.1016/j.cej.2020.126683. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silva A.L.P., Prata J.C., Mouneyrac C., Barcelò D., Duarte A.C., Rocha-Santos T. Risks of Covid-19 face masks to wildlife: present and future research needs. Sci. Total Environ. 2021;792 doi: 10.1016/j.scitotenv.2021.148505. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Spennemann D.H. COVID face masks: policy shift results in increased littering. Sustainability. 2021;13(17):9875. [Google Scholar]

- Spennemann D.H. COVID-19 face masks as a long-term source of microplastics in recycled urban green waste. Sustainability. 2022;14(1):207. [Google Scholar]

- Sullivan G.L., Delgado-Gallardo J., Watson T.M., Sarp S. An investigation into the leaching of micro and nano particles and chemical pollutants from disposable face masks-linked to the COVID-19 pandemic. Water Res. 2021;196 doi: 10.1016/j.watres.2021.117033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun J., Yang S., Zhou G.J., Zhang K., Lu Y., Jin Q., et al. Release of microplastics from discarded surgical masks and their adverse impacts on the marine copepod Tigriopus japonicus. Environ. Sci. Technol. Lett. 2021;8(12):1065–1070. [Google Scholar]

- Sun R., Yang J., Huang R., Wang C. Controlled carbonization of microplastics loaded nano zero-valent iron for catalytic degradation of tetracycline. Chemosphere. 2022 doi: 10.1016/j.chemosphere.2022.135123. [DOI] [PubMed] [Google Scholar]

- Tebyetekerwa M., Xu Z., Yang S., Ramakrishna S. Electrospun nanofibers-based face masks. Advanced Fiber Materials. 2020;2(3):161–166. doi: 10.1007/s42765-020-00049-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tesfaldet Y.T., Ndeh N.T., Budnard J., Treeson P. Assessing face mask littering in urban environments and policy implications: the case of Bangkok. Sci. Total Environ. 2022;806 doi: 10.1016/j.scitotenv.2021.150952. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Torkashvand J., Jonidi Jafari A., Godini K., Kazemi Z., Kazemi Z., Farzadkia M. Municipal solid waste management during COVID-19 pandemic: a comparison between the current activities and guidelines. Journal of Environmental Health Science and Engineering. 2021;19(1):173–179. doi: 10.1007/s40201-020-00591-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Torres F.G., De-la-Torre G.E. Face mask waste generation and management during the COVID-19 pandemic: an overview and the Peruvian case. Sci. Total Environ. 2021;786 [Google Scholar]

- Ullah R., Tsui M.T.K., Chen H., Chow A., Williams C., Ligaba‐Osena A. Microplastics interaction with terrestrial plants and their impacts on agriculture. J. Environ. Qual. 2021;50(5):1024–1041. doi: 10.1002/jeq2.20264. [DOI] [PubMed] [Google Scholar]

- Vaňková E., Kašparová P., Khun J., Machková A., Julák J., Sláma M., et al. Polylactic acid as a suitable material for 3D printing of protective masks in times of COVID-19 pandemic. PeerJ. 2020;8 doi: 10.7717/peerj.10259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang Z., An C., Chen X., Lee K., Zhang B., Feng Q. Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. J. Hazard Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.126036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang C., Sun R., Huang R., Wang H. Superior fenton-like degradation of tetracycline by iron loaded graphitic carbon derived from microplastics: synthesis, catalytic performance, and mechanism. Separ. Purif. Technol. 2021;270 [Google Scholar]

- Wang F., Wu H., Li J., Liu J., Xu Q., An L. Microfiber releasing into urban rivers from face masks during COVID-19. J. Environ. Manag. 2022 doi: 10.1016/j.jenvman.2022.115741. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang C., Huang R., Sun R., Yang J., Dionysiou D.D. Microplastics separation and subsequent carbonization: synthesis, characterization, and catalytic performance of iron/carbon nanocomposite. J. Clean. Prod. 2022;330 [Google Scholar]

- Wang C., Luo D., Zhang X., Huang R., Cao Y., Liu G., et al. Environmental Science and Ecotechnology; 2022. Biochar-based Slow-Release of Fertilizers for Sustainable Agriculture: A Mini Review; p. 100167. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wu P., Li J., Lu X., Tang Y., Cai Z. Release of tens of thousands of microfibers from discarded face masks under simulated environmental conditions. Sci. Total Environ. 2022;806 doi: 10.1016/j.scitotenv.2021.150458. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zand A.D., Heir A.V. Emanating challenges in urban and healthcare waste management in Isfahan, Iran after the outbreak of COVID-19. Environ. Technol. 2021;42(2):329–336. doi: 10.1080/09593330.2020.1866082. [DOI] [PubMed] [Google Scholar]

- Zhang Y., Jiang H., Bian K., Wang H., Wang C. A critical review of control and removal strategies for microplastics from aquatic environments. J. Environ. Chem. Eng. 2021;9(4) [Google Scholar]

- Zhang Y., Jiang H., Bian K., Wang H., Wang C. Is froth flotation a potential scheme for microplastics removal? Analysis on flotation kinetics and surface characteristics. Sci. Total Environ. 2021;792 doi: 10.1016/j.scitotenv.2021.148345. [DOI] [PubMed] [Google Scholar]

- Zhang J.Q., Wang X., Yin Z.Y., Yang N. Static and dynamic behaviors of granular soil reinforced by disposable face-mask chips. J. Clean. Prod. 2022;331 doi: 10.1016/j.jclepro.2022.131528. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhou Y., Wang J., Zou M., Jia Z., Zhou S., Li Y. Microplastics in soils: a review of methods, occurrence, fate, transport, ecological and environmental risks. Sci. Total Environ. 2020;748 doi: 10.1016/j.scitotenv.2020.141368. [DOI] [PubMed] [Google Scholar]

- Zhu Z., Gao F., Zhang Z., Zhuang Q., Yu H., Huang Y., et al. Synthesis of the cathode and anode materials from discarded surgical masks for high-performance asymmetric supercapacitors. J. Colloid Interface Sci. 2021;603:157–164. doi: 10.1016/j.jcis.2021.06.075. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

No data was used for the research described in the article.