Abstract

The utilization of Fourier’s law of heat conduction provides the parabolic partial differential equation of thermal transport, which provides the information regarding thermal transport for the initial time, but during many practical applications, this theory is not applicable. Therefore, the utilization of modified heat flux model is to be used. This work discusses the utilization of non-Fourier heat flux model to investigate thermal performance of tri-hybrid nanoparticles mixture immersed in Carreau Yasuda material past over a Riga plate by using Hamilton Crosser and Yamada Ota models considering the variable thermos-physical characteristics. The phenomenon presenting the transport of momentum and energy are developed in the form of coupled partial differential equations, which are complex and then transformed into ordinary differential equations by using an appropriate transformation. The transformed equations have been tackled numerically via finite element scheme and the authenticity of obtained solution is shown with the help of comparative analysis of present results with those are available in open literature.

Subject terms: Mathematics and computing, Nanoscience and technology

Introduction

Industrial applications for hybrid nanofluids are still in the early stages of development. Hybrid nanofluids have only recently emerged as a new phenomenon, even though nanofluids have existed for decades. Hybrid nanofluids are expected to improve current application performance levels. A handful of hybrid nanofluid applications are currently being researched. They are expected to have the same density, heat capacity, and viscosity as their mono-component counterparts. The heat transfer coefficient can be significantly increased when two or more nanofluids are mixed. Researchers' interest in hybrid nanofluid applications has recently been piqued. Thermal storage, welding lubrication, transformer cooling, refrigeration, and biomedical and drug-reduction heat pipe cooling have many applications. The following are other potential uses: magnetic nanofluids have been used in various applications by researchers. Using a magnetic field can improve their ability to transfer heat.

It is possible to achieve thermal equilibrium with a wide variety of liquids. Fourier's law ignores the liquid's thermal relaxation characteristics when calculating heat transfer. The Fourier law makes it challenging to model heat transfer in fluids. These two scientists came up with a new heat conduction theory to solve this problem. Researchers came up with a new Fourier law for heat transfer in response to this new theory. Researchers frequently make use of these principles. Regardless of the outcome, our research is essential and must be completed. Reddy et al.1 estimated thermal enactment of hybrid nanoparticles in bio-magnetic pulsatile considering nanofluid in irregular channel. Xiu et al.3 discussed impacts of tri-hybrid nanoparticles in Reiner Philippoff liquid considering non-uniform Lorentz force past a stretching surface. They have adopted FEM to conduct numerical consequence and estimated comparison among hybrid nanoparticles and tri-hybrid nanoparticles. They have included that thermal enhancement for tri-hybrid nanofluid is better than thermal performance for hybrid nanoparticles. A study by Dogonchi and colleagues4 investigated the effect of nanoparticles on fluid heat transfer. They have used heat transfer theory to determine the thermal relaxation time. Al-Mdallal et al.5 visualized entropy optimization in pseudoplastic nano-polymer in occurrence of Lorentz force past a circular cylinder. Basha et al.6 utilized finite element method to obtain results of bio fluid associated with hybrid nanofluid in the presence of Lorentz force in stenosis artery. Reddy et al.7 performed role of entropy generation in peristaltic fluid considering nanofluid based on gold-blood in a microchannel. Basha and Sivaraj8 discussed results of entropy generation in Eyring–Powell fluid in the presence of biomedical applications in heated channel. In addition, it appears that numerous relevant works9–12 have been cited as well.

The heat transfer mechanisms are strikingly similar to those governing solute distribution in liquids. To incorporate the generalized Fourier heat transfer law into Fick's equations, scientists had to conduct prior research on the Fick law and the generalized Fourier heat transfer law. Fick's law of mass and heat transfer in Prandtl fluids is the focus of this study (non- Newtonian fluid). The current investigation will be better positioned if prior studies are reviewed. In the presence of nanoparticles, thermal transport is significantly accelerated. According to Haneef and colleagues13, the Cattaneo-Christov rheological fluid has heat and mass flux. Nawaz et al.14 studied the temperature-dependent coefficients of viscoelastic fluids using a theory other than the Fourier transform. The thermal act of a micro-polar fluid with monocity and hybridity was evaluated by Nawaz and his colleagues using a novel heat flux theory.

Recent years have seen a rise in interest in fluids that can be used in various industrial and domestic contexts. The list includes ink, nail polish, ketchup, and even wall paint. On the condiment bar, ketchup and whipped cream are included. Shear-thinning, pseudo-plastic, and plastic fluid are all terms that can be used interchangeably. As a result of the shear-thinning effect, fluids flow more easily under shear-thinning stresses. Oil paint, cream, and other mediums can benefit significantly from this feature. In a team led by Eberhard, The power law theory was used for the first time to calculate an effective shear rate. They went into the study assuming that the permeability would remain constant. Materials were subjected to shear thickening and thinning tests by Rosti and Takagi. A wide range of distinctive features was thus discovered. Gul et al.15 solved the thin-film power-law model for slip lifting and drainage. Sketches and various fluid velocity parameters were used to estimate the flow rate and coefficient of skin friction. The slip parameter was found to increase with a decrease in velocity. Hussein et al. investigated Brownian motion and thermophoresis in nanofluids in a vertical cylinder apparatus. Curvature calculations on the fluid and the model were used to determine the speed reductions. Abdelsalam and Sohail16 found that bioconvection affects the flow of nanofluids with varying viscosities over an elongated bidirectional surface. It was discovered that the motile density profile and the Peclet and Lewis indices were linked. Brownian motion and time-dependent thermophoresis can be used to study the thermal and concentration relaxation times of Sutterby flows. With the help of boundary layer theory and a suitable similarity transformation, they were able to turn the physical model into a coupled PDE system (PDEs). As a result of this update, the model can now be used to investigate a broader range of physical phenomena. After the ODEs had been converted, they were examined. The Prandtl number was used to gauge the temperature. The Schmidt number was increased by increasing the solution's concentration. In Chu and colleagues17, activation energy and chemical reactions significantly impact nanofluid flow. There was a decrease in fluid velocity when the Keller box scheme was implemented. Basha and Sivaraj18 evaluated features of entropy generation inserting -blood nanofluid in porous surface. In the case of pseudo-plastic drainage and lifting, the relationship between velocity decrease and Stokes number established by Alam et al.19 can be used to solve the problem. The pseudo-plastic model with variable viscosity showed flow. This paragraph necessitates citations. A perturbation technique was used to increase the magnetic parameter value and the velocity to solve the boundary value problem. New parameters have also been added to the studies conducted in20–22,29–31 and references therein.

Physical aspects of flow model

Two dimensional model regarding rheology of Carreau Yasuda martial is developed and flowing assumptions are observed as

Vertical Riga plate is considered;

Two dimensional and incompressible flow are assumed;

Heat generation and variable thermal conductivity are adopted;

The suspension of () in ethylene glycol is inserted;

Lorentz force and bouncy forces are addressed;

Two kinds of nanomaterial in EG (ethylene glycol) are imposed;

Non-Fourier’s law is utilized;

Hamilton Crosser and Yamada Ota models are imposed;

Variable fluidic properties are addressed;

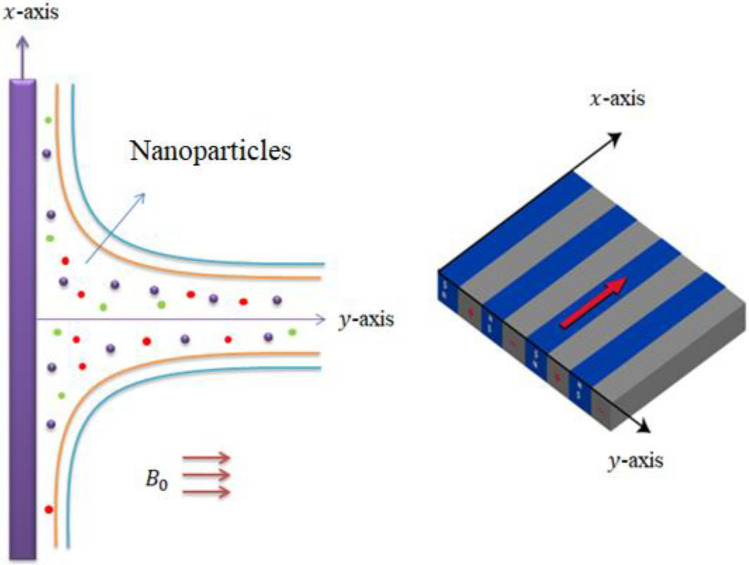

The graphical representations of geometry are mentioned by Fig. 1.

Figure 1.

Geometry and coordinates system.

Figure 1 shows a vertical surface and Riga plate. It is mentioned that y-axis is considered as horizontal and x-direction is assumed as a vertical direction. The constant magnetic field is inserted along y-direction whereas Riga plate is considered under electromagnetic force. Momentum and thermal boundary layers are generated. The motion of tri-hybrid nanoparticles is induced using wall velocity The desired PDEs23,24 are obtained as

| 1 |

| 2 |

| 3 |

| 4 |

The desire transformations23 are delivered as

| 5 |

Thermal condictivity in term of variable form2 which are

| 6 |

ODEs are achieved using Eq. (6) and obtained as

| 7 |

| 8 |

Using Eq. (6) in Eq. (5) and BCs are

| 9 |

The correlations between two kinds of hybrid nanomaterial models25 are given below and the relationship between the physical quantities is mentioned in Table 1.

| 10 |

| 11 |

| 12 |

| 13 |

Table 1.

Thermal properties17 of two kinds of nanofluid in EG (ethylene glycol).

| 0.253 | 2430 | 1113.5 | |

| 8.4 | 692 | 4230 | |

| 1.4013 | 2270 |

Parameters appeared in Eqs. (9)–(12) which are defined as

Shear stress is defined as

| 14 |

Skin friction coefficient and temeprature gradient23,24 is delievered as

| 15 |

| 16 |

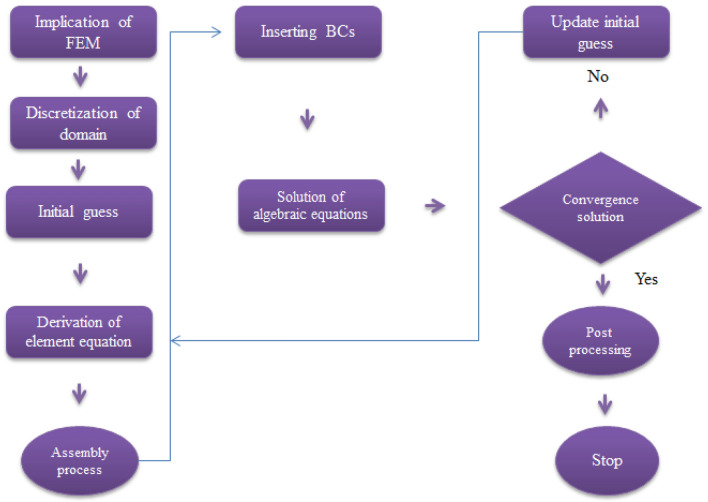

Numerical approach

Finite element apparoch is utlized to find numerical solution of resultant transformed ODEs (ordinary differential equations). Tables 2 and 3 are preapred to estimate grid size study and validation of problem. The proposed methodology is shown with the help of Fig. 2. Several advantages of finite element method are presecribed below.

Complex geometric problems can be handled by FEM;

Most of arising problems in applied science are resolved by FEM;

It deals with different types of boundary conditions;

Relatively required low investment, time and resources;

It behaves significantly well in view of discretization of derivatives.

Table 2.

Grid size study of concentration, teeprature and velocity for 300 elements when

| 30 | 0.5721974488 | 0.3921033142 |

| 60 | 0.5460428484 | 0.3836649886 |

| 90 | 0.5373843928 | 0.3808296144 |

| 120 | 0.5330677499 | 0.5076407203 |

| 150 | 0.5304818169 | 0.5059713564 |

| 180 | 0.5287599374 | 0.5048579897 |

| 210 | 0.5275304862 | 0.3775697622 |

| 240 | 0.5266088495 | 0.5034653655 |

| 270 | 0.5258925734 | 0.5030028093 |

| 300 | 0.5253200716 | 0.5026336120 |

Table 3.

Figure 2.

Flow chart of FEM.

Residuals

The resiudulas2 of desired problem are

| 17 |

| 18 |

| 19 |

Weak forms

The weak forms are developed using residual method. Shape function2 is

| 20 |

Approximations of Galerkin

Stiffness matrices2 are

| 21 |

| 22 |

| 23 |

| 24 |

Computational tolerance

The computational tolerance is delivered as

| 25 |

Estimation of error

Several methods are availbale t define error estimation. Residual based estimation26 is well known method for total energy norm which can be defined as

| 26 |

where and reveals individual element. Energy norm can be delivered as

| 27 |

Results and its outcomes

The development of flow model regarding rheology of Carreau liquid over Riga heated plated is addressed in the presence of magnetic induction. Heat energy and heat transfer rate are visualized involving non-Fourier’s law inserting chemical reaction and heat absorption/heat generation. Three kinds of nanomaterial are inserted in EG. ODEs are simulated by FEM. Graphical results associated with heat energy against various parameters are mentioned below.

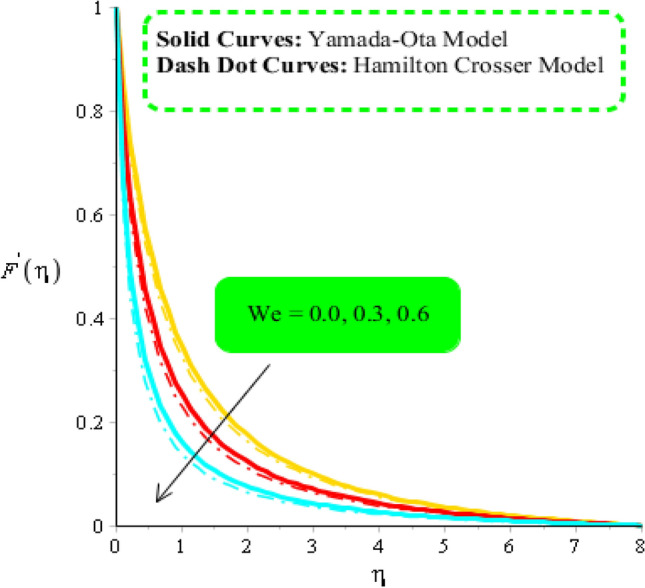

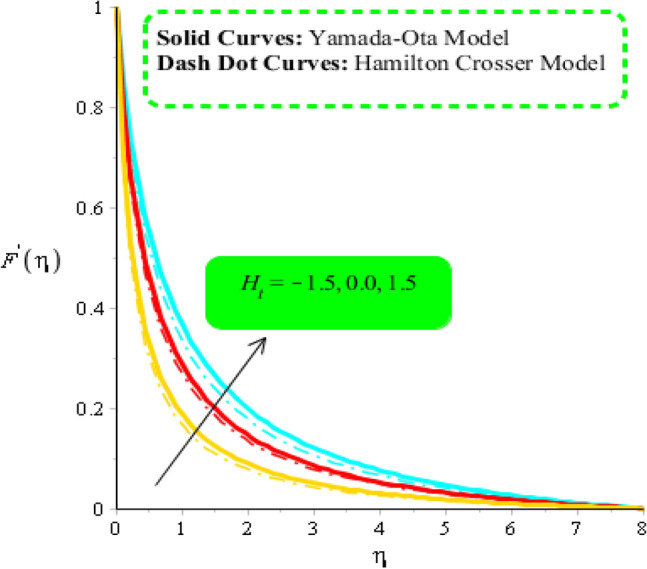

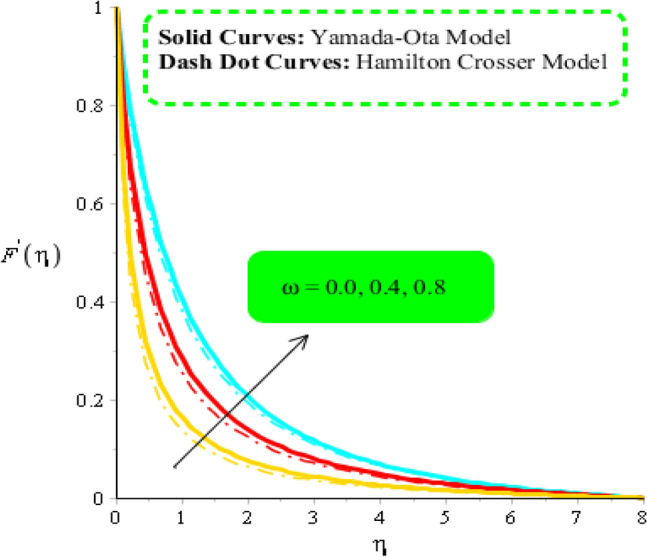

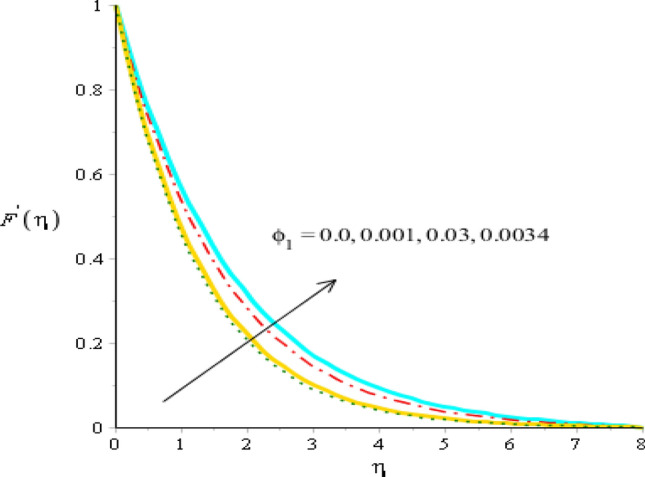

Comparative outcomes regarding velocity field

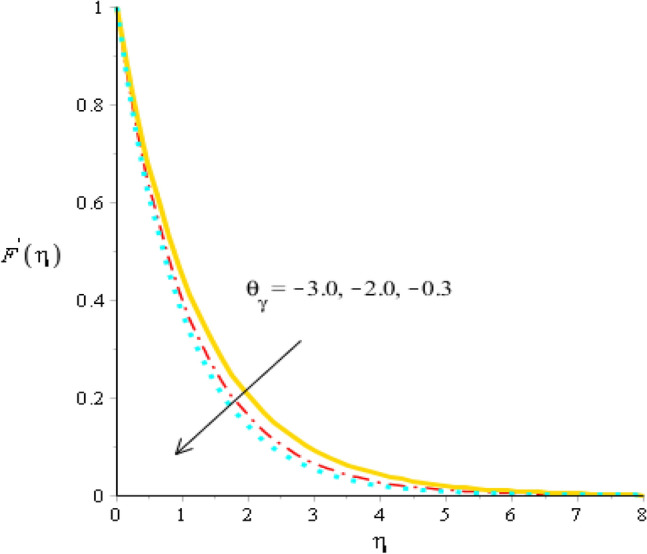

Figures 3, 4 and 5 are plotted to measure comparative acceleration among two hybrid fluid models against change in several parameters. It is noticed that model-I is associated with Yamada-Ota hybrid model whereas model-II is considered by Hamilton Crosser hybrid model. Figure 3 is developed to notice relationship between velocity field and It predicted that acceleration is decreased slowly when is enhanced. Physically, it is ratio between viscous force and frictional force. So, fluid becomes significantly viscous due to inverse proportional relation between and velocity distribution. It is noticed that appearance of is formulated using rheology of Carreau Yasuda in momentum equations. An inverse relation is visualized among flow and variation of Therefore, it can be investigated that fluid becomes thinning when is enhanced. Further, flow for is higher than flow for . Flow is induced for case of hybrid nanofluid model-I is higher than flow for hybrid nanofluid model-II. An influence of on velocity distribution is carried out by Fig. 4. An implication heat source parameter accelerates maximum heat energy. In this, two types of behavior are addressed in term of heat generation and heat absorption. It is mentioned that heat generation process is occurred for and heat absorption process is occurred for . Therefore, flow for is greater than flow for Moreover, fluidic temperature is enhanced when heat generation process is occurred. Physically, an external heat source is utilized to control thickness of momentum boundary layers. MBLTs (momentum boundary layer thicknesses) for hybrid nanofluid-I is greater than MBLTs for the case of hybrid nanofluid-II. The role of on velocity distribution is carried out by Fig. 5. An acceleration into fluidic particles is augmented when is increased. The concept of is utilized during process of applying electromagnetic force in Riga plate. It can be noticed that appearance of is developed in last term of momentum equation An electromagnetic force is utilized to enhancement flow when is increased. Figure 6 reveals effect of on velocity profile. It is numerically included that motion into particles is enhanced when is increased. The directly proportional impact for on flow is investigated in ethylene glycol. Behavior of is carried out by Fig. 7. A decreasing trend is visualized on flow behavior when is enhanced. It is studied that formulation of is established when variable viscosity is addressed in present problem. Higher values of are made declination into flow.

Figure 3.

Comparison in velocity field against when

Figure 4.

Comparison in velocity field against when

Figure 5.

Comparison in velocity field against when

Figure 6.

Behavior of velocity field against when

Figure 7.

Behavior of velocity field against when

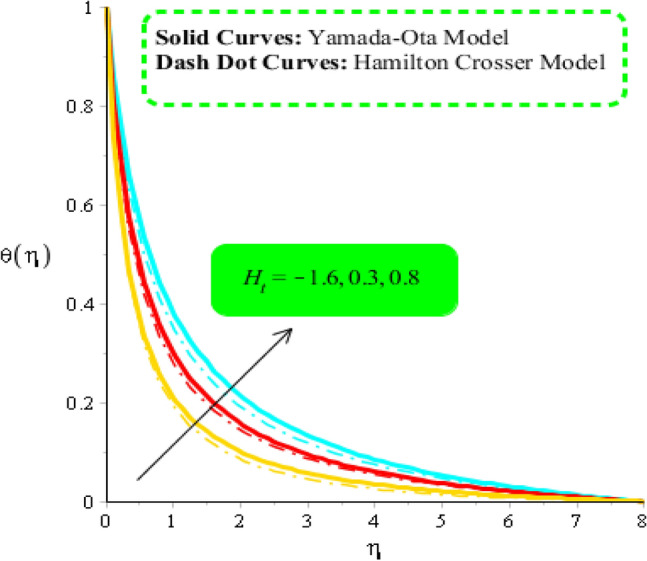

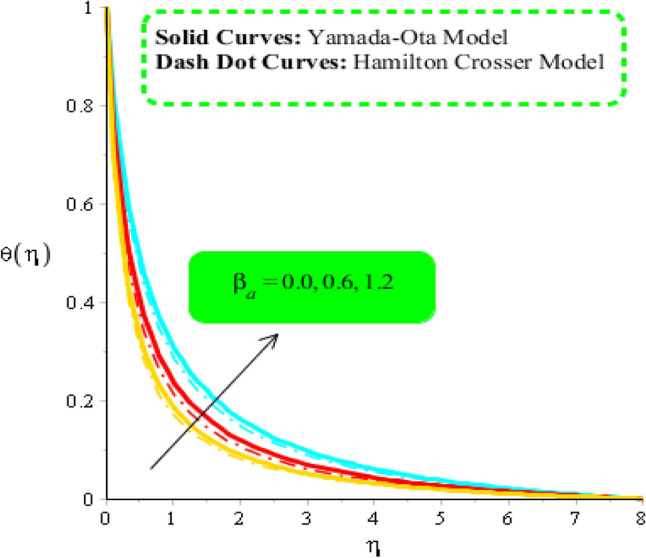

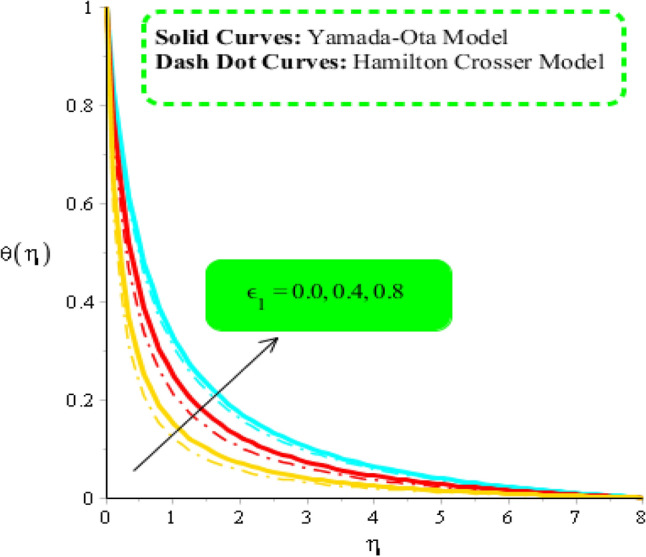

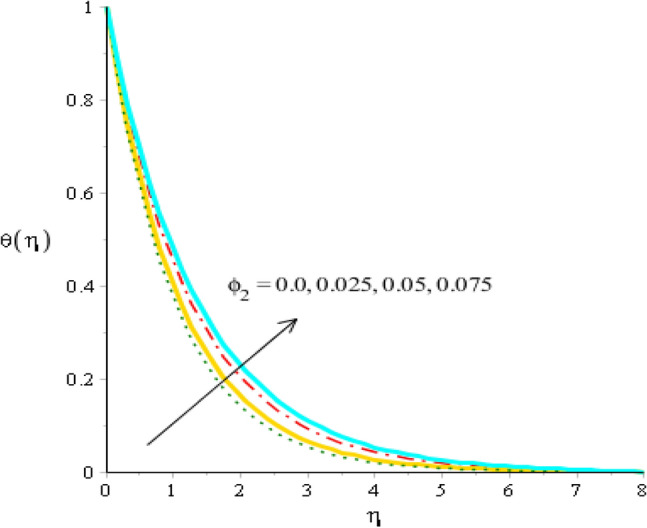

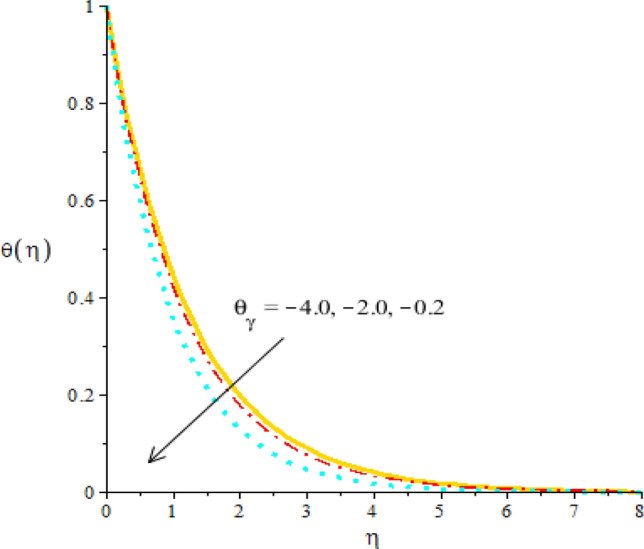

Comparative outcomes regarding temperature field

Figures 8, 9 and 10 are developed to estimate variation in temperature field against heat source, and . Figure 8 reveals increasing behavior of heat energy against change in Heat energy was enhanced against increment in This is happened when external heat source is utilized. It is noticed that heat generation process is occurred for and heat absorption process is occurred for . Therefore, flow for is greater than flow for Moreover, fluidic temperature is enhanced when heat generation process is occurred. Thermal performance for Yamada Ota model is greater than thermal performance for Hamilton Crosser model. Thermal layer thickness is also increasing function when is enhanced. Figure 9 captures an estimation of heat energy against variation in It is investigated that is developed using concept of CCHFM (Cattaneo-Christov heat flux model) in energy and concentration equations. Time relaxation parameter restores maximum heat energy among fluidic particles. Therefore, heat energy is enhanced when is increased. The concept of is produced conspiring non-Fourier’s procedure in energy equation as well as in concentration equation. It is utilized to visualized thermal flux among wall and fluid. An enhancement into fluidic temperature is occurred because of direct proportional relation among thermal layers and Fig. 10 reveals an impact of on temperature distribution. It is addressed that heat energy is increased against change in Mathematically, has directly proportional relation versus mass diffusion rate. From Eq. (7), is existed in such function (function has domain of temperature). Mass diffusion rate is boosted when is enhanced. Mass diffusion for is less than for the case of . Basically, Therefore, heat energy is inclined. TBLT (thermal boundary layer thickness) for Yamada Ota model is higher than TBLT for the case Hamilton Crosser model. Figure 11 is plotted to measure heat energy versus impact of It is visualized that heat energy is boosted when is increased. This is because is appeared due to occurrence of hybrid nanoparticles () in base fluid named as ethylene glycol. Thermal energy can be boosted by adding an increment of into particles. Figure 12 reveals effect of on temperature profile. Reduction into fluidic heat energy is investigated by considering higher values of It is happened due to appearance of variable viscosity.

Figure 8.

Comparison in temperature field against when

Figure 9.

Comparison in temperature field against when

Figure 10.

Comparison in temperature field against when

Figure 11.

Comparison in temperature field against when

Figure 12.

Behavior of temperature field against when

An estimation regarding wall stress and temperature gradient

Table 4 is prepared to measure consequences of and on wall stress and heat energy rate. It is estimated that divergent velocity and heat energy rate are declined versus the change in But divergent velocity is enhanced versus the change in . These outcomes are recorded in Table 4. Table 5 demonstrates impact of heat transfer rate against variation in and From Table 5, it is included that thermal performance of heat transfer rate is significantly decreased when and are enhanced. The outcomes regarding heat transfer rate are recommended in Table 5.

Table 4.

Simulations of divergent velocity (wall stress), Nusselt number and mass diffusion rate against and

| Variation in parameters | ||

|---|---|---|

| WE | ||

| 0.0 | 0.04083083709 | 0.8718781018 |

| 0.4 | 0.04115641821 | 0.7608320013 |

| 0.8 | 0.04548199932 | 0.5334280014 |

| − 1.5 | 0.05842070236 | 0.6865965216 |

| 0.0 | 0.02884959667 | 1.023554468 |

| 0.5 | 0.01075945969 | 1.268425453 |

| 0.0 | 0.02606740874 | 2.133026234 |

| 0.3 | 0.03568914202 | 0.687196814 |

| 0.5 | 0.1784160787 | 0.169312154 |

Table 5.

Simulations of Nusselt number rate against and when

| Variation in parameters | |

|---|---|

| 203 | 0.37123950368 |

| 205 | 0.33066012203 |

| 206 | 0.31062012239 |

| 0.0 | 0.96120133102 |

| 0.6 | 0.81663202181 |

| 0.9 | 0.76023217182 |

| 0.0 | 0.52322106912 |

| 2.0 | 0.42205522643 |

| 3.0 | 0.2245533610 |

Main findings

The numerical investigation has been performed to discuss the contribution of nanoparticles for the thermal enhancement in Carreau Yasuda liquid past over a Riga plate in the presence of variable properties. The derived equations are tackled numerically and important findings are reported as

Augmenting values of increase the dimensionless stress at boundary but depreciate the mass and heat transfer rates;

Maximum performance of heat energy rate can be achieved with source of hybrid nanoparticles as applicable in coolants related to automobiles, dynamics of fuel, pharmaceutical processes, vehicle thermal adjustment, cooling process, microelectronics, temperature enhancement and temperature reduction;

Comparative study have been performed to ensure the authenticity of solution;

Convergence analysis has been shown through grid independent analysis and three hundred elements are taken to establish the convergence;

The present problem related to electro-magneto-hydrodynamic has applicable in micro coolers, fluidic network flow, fluidic chromatography and thermal reactors.

Abbreviations

Velocity components

Gravitational acceleration

Fluid density

Fluid number

Specific heat

Ambient temperature

Fluid number

Stretching number

Wall velocity

Wall temperature

- ODEs

Ordinary differential equation

Hybrid nanofluid

Base fluid and fluid

Heat source number

Reynolds number

Wall heat flux and wall mass flux

Time relaxation parameter

Infinity

Dimensionless velocity

Solid particles

Weight functions

Independent variable

Energy and variable viscosity parameter

Silicon dioxide

Length of cylindrical particles

Space coordinates

Coefficient of thermal and solute concentration

Electromagnetic force components

Heat source

Fluid temperature

Thermal conductivity

Chemical reaction

Independent parameter

Kinematic viscosity from away of surface

Thermal conductivity and mass diffusion coefficients

Wiesenberger number

Bouncy parameters

Dimensionless temperature

Volume fractions

Prandtl number

Skin friction coefficient

Nusselt number

Kinematic viscosity

- FEM

Finite element method

- BCs

Boundary conditions

Electromagnetic magnetic force parameter

- PDEs

Partial differential equations

Shape function

Titanium dioxide

Ethylene glycol

Diameter of cylindrical particles

Author contributions

All the authors reviewed the manuscript and approved the submission.

Funding

This research has received funding support from the NSRF via the Program Management Unit for Human Resources & Institutional Development, Research and Innovation [grant number B05F640204]. Also, this research was supported by the Postdoctoral Researchers Fellowship Training Program from Khon Kaen University, Khon Kaen 40002, Thailand.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Competing interests

The authors declare no competing interests.

Footnotes

The original online version of this Article was revised: The original version of this Article contained an error in Affiliation 5, which was incorrectly given as ‘Faculty of Engineering and Technology, Future University, Cario, Egypt’. The correct affiliation is: Faculty of Engineering and Technology, Future University in Egypt, New Cairo, 11835, Egypt. In addition, the original version of this Article omitted an affiliation for Mohamed R. Ali. Full information regarding the corrections made can be found in the correction notice for this Article.

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Change history

3/27/2023

A Correction to this paper has been published: 10.1038/s41598-023-32048-y

Contributor Information

Muhammad Sohail, Email: muhammad_sohail111@yahoo.com.

Kanit Mukdasai, Email: kanit@kku.ac.th.

Mohamed R. Ali, Email: mohamed.reda@fue.edu.eg

References

- 1.Reddy SRR, Raju CSK, Gunakala SR, Basha HT, Yook SJ. Bio-magnetic pulsatile CuO−Fe3O4 hybrid nanofluid flow in a vertical irregular channel in a suspension of body acceleration. Int. Commun. Heat Mass Transfer. 2022;135:106151. doi: 10.1016/j.icheatmasstransfer.2022.106151. [DOI] [Google Scholar]

- 2.Nazir U, Saleem S, Nawaz M, Sadiq MA, Alderremy AA. Study of transport phenomenon in Carreau fluid using Cattaneo-Christov heat flux model with temperature dependent diffusion coefficients. Phys. A. 2020;554:123921. doi: 10.1016/j.physa.2019.123921. [DOI] [Google Scholar]

- 3.Xiu, W., Saleem, S., Weera, W., & Nazir, U. Cattaneo-Christove thermal flux in Reiner Philippoff martial under action of variable Lorentz force employing tri-hybrid nanomaterial approach. Case Stud. Therm. Eng. 102267 (2022).

- 4.Dogonchi AS, Waqas M, Ganji DD. Shape effects of Copper-Oxide (CuO) nanoparticles to determine the heat transfer filled in a partially heated rhombus enclosure: CVFEM approach. Int. Commun. Heat Mass Transfer. 2019;107:14–23. doi: 10.1016/j.icheatmasstransfer.2019.05.014. [DOI] [Google Scholar]

- 5.Al-Mdallal Q, Prasad VR, Basha HT, Sarris I, Akkurt N. Keller box simulation of magnetic pseudoplastic nano-polymer coating flow over a circular cylinder with entropy optimisation. Comput. Math. Appl. 2022;118:132–158. doi: 10.1016/j.camwa.2022.05.013. [DOI] [Google Scholar]

- 6.Basha, H.T., Rajagopal, K., Ahammad, N.A., Sathish, S., & Gunakala, S.R. Finite Difference computation of Au-Cu/magneto-bio-hybrid nanofluid flow in an inclined uneven stenosis artery. Complexity (2022).

- 7.Reddy, S.R.R., Basha, H.T., & Duraisamy, P. Entropy generation for peristaltic flow of gold-blood nanofluid driven by electrokinetic force in a microchannel. Eur. Phys. J. Spec. Top. 1–15 (2022).

- 8.Basha HT, Sivaraj R. Entropy generation of peristaltic Eyring-Powell nanofluid flow in a vertical divergent channel for biomedical applications. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021;235(5):1575–1586. doi: 10.1177/09544089211013926. [DOI] [Google Scholar]

- 9.Anantha Kumar K, Sugunamma V, Sandeep N. Influence of viscous dissipation on MHD flow of micropolar fluid over a slendering stretching surface with modified heat flux model. J. Therm. Anal. Calorim. 2020;139(6):3661–3674. doi: 10.1007/s10973-019-08694-8. [DOI] [Google Scholar]

- 10.Anantha Kumar K, Sugunamma V, Sandeep N. Effect of thermal radiation on MHD Casson fluid flow over an exponentially stretching curved sheet. J. Therm. Anal. Calorim. 2020;140(5):2377–2385. doi: 10.1007/s10973-019-08977-0. [DOI] [Google Scholar]

- 11.Kumar A, Sugunamma V, Sandeep N. Impact of non-linear radiation on MHD non-aligned stagnation point flow of micropolar fluid over a convective surface. J. Non-Equilib. Thermodyn. 2018;43(4):327–345. doi: 10.1515/jnet-2018-0022. [DOI] [Google Scholar]

- 12.Sankar M, Park Y, Lopez JM, Do Y. Numerical study of natural convection in a vertical porous annulus with discrete heating. Int. J. Heat Mass Transf. 2011;54(7–8):1493–1505. doi: 10.1016/j.ijheatmasstransfer.2010.11.043. [DOI] [Google Scholar]

- 13.Haneef M, Nawaz M, Alharbi SO, Elmasry Y. Cattaneo-Christov heat flux theory and thermal enhancement in hybrid nano Oldroyd-B rheological fluid in the presence of mass transfer. Int. Commun. Heat Mass Transfer. 2021;126:105344. doi: 10.1016/j.icheatmasstransfer.2021.105344. [DOI] [Google Scholar]

- 14.Nawaz M, Arif U, Qureshi IH. Impact of temperature dependent diffusion coefficients on heat and mass transport in viscoelastic liquid using generalized Fourier theory. Phys. Scr. 2019;94(11):115206. doi: 10.1088/1402-4896/ab1cec. [DOI] [Google Scholar]

- 15.Gul T, Shah RA, Islam S, Ullah M, Khan MA, Zaman A, Haq Z. Exact solution of the two thin film non-Newtonian immiscible fluids on a vertical belt. J. Basic. Appl. Sci. Res. 2014;4(6):283–288. [Google Scholar]

- 16.Abdelsalam SI, Sohail M. Numerical approach of variable thermophysical features of dissipated viscous nanofluid comprising gyrotactic micro-organisms. Pramana. 2020;94(1):1–12. doi: 10.1007/s12043-020-1933-x. [DOI] [Google Scholar]

- 17.Chu YM, Nazir U, Sohail M, Selim MM, Lee JR. Enhancement in thermal energy and solute particles using hybrid nanoparticles by engaging activation energy and chemical reaction over a parabolic surface via finite element approach. Fract. Fract. 2021;5(3):119. doi: 10.3390/fractalfract5030119. [DOI] [Google Scholar]

- 18.Basha HT, Sivaraj R. Exploring the heat transfer and entropy generation of Ag/Fe3O4-blood nanofluid flow in a porous tube: a collocation solution. Eur. Phys. J. E. 2021;44(3):1–24. doi: 10.1140/epje/s10189-021-00024-x. [DOI] [PubMed] [Google Scholar]

- 19.Alam MK, Siddiqui AM, Rahim MT, Islam S, Avital EJ, Williams JJR. Thin film flow of magnetohydrodynamic (MHD) pseudo-plastic fluid on vertical wall. Appl. Math. Comput. 2014;245:544–556. [Google Scholar]

- 20.Sohail M, Ali U, Zohra FT, Al-Kouz W, Chu YM, Thounthong P. Utilization of updated version of heat flux model for the radiative flow of a non-Newtonian material under Joule heating: OHAM application. Open Phys. 2021;19(1):100–110. doi: 10.1515/phys-2021-0010. [DOI] [Google Scholar]

- 21.Sohail, M., & Raza, R. Analysis of radiative magneto nano pseudo-plastic material over three dimensional nonlinear stretched surface with passive control of mass flux and chemically responsive species. Multidiscip. Model. Mater. Struct. (2020).

- 22.Shafiq A, Khan I, Rasool G, Sherif ESM, Sheikh AH. Influence of single-and multi-wall carbon nanotubes on magnetohydrodynamic stagnation point nanofluid flow over variable thicker surface with concave and convex effects. Mathematics. 2020;8(1):104. doi: 10.3390/math8010104. [DOI] [Google Scholar]

- 23.Madhukesh JK, Varun Kumar RS, Punith Gowda RJ, Prasannakumara BC, Shehzad SA. Thermophoretic particle deposition and heat generation analysis of Newtonian nanofluid flow through magnetized Riga plate. Heat Transfer. 2022;51(4):3082–3098. doi: 10.1002/htj.22438. [DOI] [Google Scholar]

- 24.Sohail M, Nazir U, Chu YM, Al-Kouz W, Thounthong P. Bioconvection phenomenon for the boundary layer flow of magnetohydrodynamic Carreau liquid over a heated disk. Sci. Iran. 2021;28(3):1896–1907. [Google Scholar]

- 25.Gul H, Ramzan M, Nisar KS, Mohamed RN, Ghazwani HAS. Performance-based comparison of Yamada-Ota and Hamilton-Crosser hybrid nanofluid flow models with magnetic dipole impact past a stretched surface. Sci. Rep. 2022;12(1):1–11. doi: 10.1038/s41598-021-04019-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Brenner, S.C., Scott, L.R., & Scott, L.R., The mathematical theory of finite element methods (Vol. 3, pp. 263–291) (Springer, New York, 2008).

- 27.Akbar NS, Khan ZH, Haq RU, Nadeem S. Dual solutions in MHD stagnation-point flow of Prandtl fluid impinging on shrinking sheet. Appl. Math. Mech. 2014;35(7):813–820. doi: 10.1007/s10483-014-1836-9. [DOI] [Google Scholar]

- 28.Bilal S, Rehman KU, Malik MY, Hussain A, Awais M. Effect logs of double diffusion on MHD Prandtl nano fluid adjacent to stretching surface by way of numerical approach. Res. Phys. 2017;7:470–479. [Google Scholar]

- 29.Wakif, A., Boulahia, Z., Amine, A., Animasaun, I.L., Afridi, M.I., Qasimd, M. & Sehaqui, R. Magneto-convection of alumina-water nanofluid within thin horizontal layers using the revised generalized Buongiorno's model. Front. Heat Mass Transfer (FHMT), 12 (2018).

- 30.Rasool G, Shafiq A, Alqarni MS, Wakif A, Khan I, Bhutta MS. Numerical scrutinization of Darcy-Forchheimer relation in convective magnetohydrodynamic nanofluid flow bounded by nonlinear stretching surface in the perspective of heat and mass transfer. Micromachines. 2021;12(4):374. doi: 10.3390/mi12040374. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Rasool G, Shafiq A, Hussain S, Zaydan M, Wakif A, Chamkha AJ, Bhutta MS. Significance of Rosseland’s radiative process on reactive Maxwell nanofluid flows over an isothermally heated stretching sheet in the presence of Darcy-Forchheimer and Lorentz forces: Towards a new perspective on Buongiorno’s model. Micromachines. 2022;13(3):368. doi: 10.3390/mi13030368. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.