Abstract

One of the main causes of the significant commercial vehicle traffic in the city region is last-mile deliveries. Parcel lockers, which are one of the easiest and most environmentally friendly solutions for last-mile delivery, are one of the most studied subjects recently. The parcel locker ensures consumer privacy while being quick and efficient. Its full-time service can effectively address the issue of student and office worker pickup. In this paper, the location of a parcel locker intended to be established in the most convenient location in Beşiktaş district of İstanbul, Turkey has been determined. This problem can be solved using a multi-criteria decision-making (MCDM) structure due to the availability of numerous aspects that must be considered while choosing the optimum location. Additionally, the benefit of fuzzy logic is employed to translate expert opinions into mathematical expressions and incorporate them into decision-making processes. To choose the ideal location for the parcel locker, a novel model integrating the Bayesian Best Worst Method (B-BWM) and Pythagorean fuzzy Weighted Aggregated Sum Product Assessment (PF-WASPAS) approaches is proposed for the first time in the literature. Additionally, a sensitivity analysis is conducted to evaluate the model’s robustness. As a consequence, the suggested model effectively identifies the best location for a parcel locker in Istanbul.

Keywords: Bayesian best worst method, Location selection, Parcel locker, Pythagorean fuzzy numbers, WASPAS

Introduction

The development of technology, the growing online shopping industry during the coronavirus disease 2019 (COVID-19) period, and changing customer expectations have caused businesses to focus on last-mile delivery. Many countries have developed new ways to increase customer satisfaction, which has been frustrated by serious delivery problems and inadequate delivery service. Several systems, such as self-collection, are being developed for last-mile delivery.

Last-mile deliveries are often a reason for increasing traffic in densely populated areas. The number of delivery vehicles has increased with the growing interest in online shopping, which brings environmental damage in addition to traffic density. Re-delivery of vehicles, especially for undelivered cargo, troubles the environmental and financial losses for a single delivery. When delivery recipients are not at the address, not being able to receive their cargo within the desired time also affects customer satisfaction. Recently, parcel lockers have been used as last-mile delivery systems to prevent such reasons (Iwan et al. 2016).

Parcel lockers are unattended delivery machines located at selected locations (Fig. 1). A parcel locker is a locked storage container where items can be kept and held until picked up by a mailman, delivery service, locals, or clients. A parcel locker offers a quick, easy, and secure delivery method. These lockers allow both the receipt and delivery of parcels that 24 h a day, 7 days a week.

Fig. 1.

A parcel locker picture.

Source: Google

Parcel lockers make parcel deliveries more efficient. Since a package no longer needs to be personally picked up and signed, pickup and delivery can be performed at any time. The packages are securely stored in the package locker, which is only accessible to authorized persons such as the delivery person and the recipent. In this way, the delivery person does not need to make more than one attempt.

Although the type of cabinet varies, the overall delivery process follows three basic steps as delivery, notification, and collection. After the receiver places the order online, he/she chooses the option of picking up the parcel locker. When the order arrives, the delivery person must enter a unique code to unlock the locker. A notification is sent when the package is delivered to the parcel locker and receives the package. If the recipient wants to return the product, it will be sufficient to place the product in the cabinet with a different code produced by the delivery company.

The International Post Corporation (IPC) Cross-Border Electronic Commerce (E-Commerce) Customer Survey conducted in 2019 examined the delivery preferences and experiences of global consumers (Source and Corporation 2020). About 36,000 respondents in 41 countries were asked which delivery locations they used. The most frequently used location was home delivery (66%), followed by delivery to the post office (21%), delivery to the postal service point (14%), and delivery to the cargo locker (12%), followed by 65% of respondents who were extremely or very satisfied with delivery to parcel lockers. The countries that use the stations the most are Estonia, Finland, Poland, and Lithuania (Source and Corporation 2020).

Parcel lockers are currently being used in more than 20 countries, including the UK, Europe, the USA, and Canada (Deutsch and Golany 2018). In China, for example, the number of Internet of Things (IoT)-based parcel lockers increased from 15,000 to 406,000 from 2014 to 2019. Moreover, the market value of the IoT-based parcel locker is expected to reach 1438.9 million USD by 2027 due to the effect of the pandemic (State Post Bureau of the People’s Republic of China 2020). Peppel and Spinler (2021)‘s paper optimize stationary parcel locker locations and the ecological effect of stationary parcel lockers by minimizing emissions and costs simultaneously. To improve customers’ experiences with parcel lockers, Vakulenko et al. (2018) investigated the customer-parcel locker interaction experience in Sweden as well as consumers’ views and value of parcel lockers. Zhou et al. (2020) evaluated the impact of psychological characteristics and demographic data on behavioral intention to employ the locker service in a related empirical study.

Parcel lockers are usually located in easily accessible, frequently visited public places. They can be located in an office center area, parking area, public transportation stops, supermarkets, gas stations, or shopping malls, etc. Having so many options when choosing a location makes the problem challenging. It becomes imperative to make the most optimal choice, especially in terms of financial, environmental, and ease of use.

Customers find parcel lockers to be quick and convenient. They also believe that these lockers do an excellent job of protecting customers’ privacy. With the increasing use of parcel lockers recently, researchers have accelerated their studies on parcel lockers. To better understand Thai customers’ intentions to use smart lockers, Tsai and Tiwasing (2021) incorporate resource matching theory, innovation diffusion theory, and theory of planned behavior. Chen et al. (2018) use technology readiness, consumer coproduction theory, and resource matching theory to examine consumer intention in the parcel lockers in China. Mangiaracina et al. (2019) identify ten potential approaches, including parcel lockers, pickup locations, acceptance boxes, crowdsourced logistics, and drones by examining the novel last-mile delivery strategies. According to Pan et al. (2021)’s research, using a parcel locker can greatly improve the delivery efficiency, decrease delivery waiting times, and shorten communication times. González-Varona et al. (2020) analyze the effects of locker usage on CO2 emission. The implications of delivery trucks, drones, and their combined use on costs, CO2 emissions and traffic density are being studied by Di Puglia Pugliese et al. (2020). According to Figliozzi and Jennings (2020), autonomous ground vehicles (AGV) have an impact on how far they can travel, how much energy they use, and how much CO2 they emit. Halldórsson and Wehner (2020) investigate the impacts of click and collect, pay-per-place, parcel locker, in-car delivery, and home delivery options on energy efficiency. Ostermeier et al. (2022) examine the effects of the integrated usage of trucks and AGV on overall cost, distance and emission. While determining the criteria, two articles (Krstić et al. 2021; Simić et al. 2021) are mostly inspired. In these studies, similar main criteria are used as in our study. However, according to our study, the sub-criteria and the solution strategies vary. While Krstić et al. (2021) use a novel hybrid model that combines Delphi, Factor Relationship, and VIseKriterijumsa Optimizacija I Kompromisno Resenje (VIKOR), and Simić et al. (2021) use Weighted Aggregated Sum Product Assessment (WASPAS) WASPAS and Picture Fuzzy Sets; our study uses a different combination of multi-criteria decision-making (MCDM) methods. Our new model integrating the Bayesian Best Worst Method (B-BWM) and Pythagorean fuzzy WASPAS (PF-WASPAS) approaches proposes for the first time in the literature to select the ideal location.

In the literature, studies on the parcel lockers are generally examined in the form of innovations in the field of customer satisfaction or logistics. There is no known study on the parcel locker location selection. In particular, a new model integrating the B-BWM and PF-WASPAS approaches has been proposed for the first time in the literature to select the ideal location. The criteria weights are determined by B-BWM and the alternatives are ranked by PF-WASPAS.

Generally, decision-making can be defined as identifying and choosing an alternative among a series of alternatives. In most cases, various criteria are involved in the identification and selection process. Therefore, these problems are called MCDM problems. In MCDM problems, it is aimed to establish a criteria hierarchy by using a number of perspectives. MCDM is one of the decision methodologies frequently used in many fields in the scientific world. MCDM can help improve the quality of decisions by making the decision-making process clearer and more rational. The greatest strength of MCDM methods is that they handle problems that arise in many conflicting situations. MCDM methods, which guide the decision-making processes, are frequently used in the literature. The B-BWM and the PF-WASPAS Method are also included in this group of methods.

Especially, the B-BWM is a relatively new method in the literature. In order for the parcel locker location selection stage to yield accurate results, decision-makers must evaluate many criteria and sub-criteria and weight the criteria. With B-BWM, decision-makers do not need to make pairwise comparisons between all criteria. They just must define the most and least desirable criterion and then make pairwise comparisons between the best/worst criterion and other criteria. Additionally, the B-BWM method is used in the criterion weighting because of the probabilistic perspective it provides to group decision-making problems.

In the last stage of the proposed method, different locations are evaluated with the PF-WASPAS method using the weights obtained by the B-BWM method. WASPAS is a popular MCDM technique that combines two leading MCDM approaches, the weighted aggregate model (WSM) and the weighted product model (WPM). WASPAS was initially presented to the literature as an innovative approach based on utility theory. Later, it was greatly extended in various studies. In fact, WASPAS is much more than an integrated form of both the WSM method and the WPM method. This is because the method offers an optimal level of accuracy beyond combining the WSM and WPM methods. In this study, WASPAS is operated under a pythagorean fuzzy environment. Pythagorean fuzzy sets (PFSs) are extended when intuitionistic fuzzy sets cannot define uncertainty. This extension makes PFSs more powerful and flexible tools for solving problems involving uncertainty. Decision-makers used these clusters that could not be expressed with intuitionistic fuzzy sets. Obviously, PFSs are better suited for real life in complex decision-making problems.

For these reasons, B-BWM-integrated PF-WASPAS methodology is proposed to solve the parcel locker location selection problem.

The subject of parcel lockers is a current topic that has just started to be discussed in the literature. The parcel locker location problem has generally been studied by considering how it will contribute to the environment and economy as a last-mile delivery chain. Since it is a newly widespread technology, some studies have measured how its use in different countries will be met according to the classical delivery approach. Studies on the use of MCDM methods in location selection are limited.

In this study, we aim to find answers to various questions. How to choose a parcel locker location, which is the most environmentally friendly, least costly, and risk-free for people, according to certain criteria? Which factors are effective in people's use of the parcel locker and why? The relevant literature has been extensively studied to determine the criteria. Following observations from the literature review served as the inspiration for this paper. The primary contribution of this study mostly consists of methodological and application aspects:

-

i)

A unique MCDM framework is proposed from a methodological standpoint to address difficult decision-making problems under Pythagorean fuzzy environment. To the authors’ knowledge, no study in the recent literature on decision-making extends the PF-WASPAS with weight calculation via B-BWM.

-

ii)

Especially recently, Turkey has been making new breakthroughs for environmentally friendly cargo transportation and sustainable logistics solutions. Turkey’s largest postal distribution company and other cargo companies have started to install parcel lockers in accessible locations at less cost and in a greener environment. However, there are limited studies on determining the most suitable parcel locker location for companies. This study focuses on choosing locations for parcel locker stations, and criteria are established and examined with the station’s sustainability.

The present study aims to decide in which areas it would be more appropriate to place the parcel lockers. The rest of the paper is organized as follows. The main and sub-criteria are explained in in the “The criteria affecting parcel locking location decision” section. Research methodology is presented in the “The proposed methodology” section and followed by an application in the “Real case study in Istanbul” section. Finally, the “Discussion and implications” section concludes by summarizing the results, limitations, and research agenda.

The criteria affecting parcel locking location decision

Technological developments and the ongoing effects of the pandemic have changed people’s shopping habits and online shopping has becoming more popular day by day. Increasing customer expectations, fuel prices, and environmental concerns have forced service providers to consider alternative cargo delivery methods. The parcel locker stands as a promising solution for cargo delivery tasks, and many companies consider locating these parcel lockers to serve customers in different parts of cities. However, the success of this relatively new attempt requires authorities to consider many aspects, and one of the most crucial aspects is the location of the parcel lockers. This study investigates the location selection problem of the parcel lockers and presents a real-life case study. After extensive literature research and expert interviews, we identified six main criteria as physical characteristics, resilience, financial, social, convenience and proximity as given in Table 1. By evaluating a total of thirty-two sub-criteria, the most suitable parcel locker location is determined.

Table 1.

The parcel locker location selection criteria

| Main criteria | Sub-criteria |

|---|---|

| 1-Physical Characteristics |

1.1 Land size (Tu et al. 2010) 1.2 Parking area (Kuo et al. 2002; Tolga et al. 2013) 1.3 Infrastructure adequacy (Tu et al. 2010; Simić et al. 2021) 1.4 Possibility of expansion (Awasthi et al. 2011; Mirzaei et al. 2015) 1.5 Loading practicality (Svadlenka et al. 2020) 1.6 Visibility (Tolga et al. 2013) |

| 2-Resilience |

2.1 Theft risk (Expert view) 2.2 Natural disaster risks (Peker et al. 2016) 2.3 Accident risks (Expert view) 2.4 Climate conditions (Svadlenka et al. 2020) |

| 3-Financial |

3.1 Investment cost (Simić et al. 2021) 3.2 Operational and Maintenance Cost (Krstić et al. 2021; Simić et al. 2021) 3.3 Transportation costs (Wang et al. 2021) 3.4 Insurances-taxes (Svadlenka et al. 2020; Krstić et al. 2021) |

| 4-Social |

4.1 Number of people residing in the vicinity of the candidate location (Yildiz et al. 2020) 4.2 Income level (Yildiz et al. 2020) 4.3 Educational level (Roig-Tierno et al. 2013) 4.4 Average age of people residing in the vicinity of the candidate location (Expert view) 4.5 The average number of people passing by the candidate location on any day (Yildiz et al. 2020) 4.6 The attitude of residents/population shopkeepers (Tolga et al. 2013) |

| 5-Convenience |

5.1 Traffic intensity (Özdaǧoǧlu 2011; Bingqing and Liting 2020) 5.2 Closeness to public transportation) (Awasthi et al. 2011; Peker et al. 2016) 5.3 Pedestrian convenience (Kuo et al. 2002) 5.4 Multimodal transportation convenience (Awasthi et al. 2011) 5.5 Seasonality effect (Roig-Tierno et al. 2013) 5.6 Closeness to the major roads/highways (Tolga et al. 2013) |

| 6-Proximity |

6.1 Closeness to the residential area (Yildiz et al. 2020) 6.2 Closeness to main distribution centers (Expert view) 6.3 Distance to the nearest cargo branch (Expert view) 6.4 Distance to the nearest parcel lockers (Yildiz et al. 2020) 6.5 Closeness to shopping malls (Expert view) 6.6 Closeness to business centers (Singh et al. 2018) |

Physical characteristics

The performance of parcel lockers is affected by the physical conditions of the alternative locations, and decision-makers should consider them beforehand (Yildiz et al. 2020). The candidate location should be large enough for car parking, cargo collecting, and reloading operations. Additionally, the location should be suitable for potential future developments in terms of infrastructure features and expansion possibilities. However, the parcel lockers should be easily recognizable by the customers, so they should not be located off the beaten track (Tolga et al. 2013).

Resilience

The cargo should be secure until the customers pick them up, and many risk parameters must be considered for the alternative locations. Firstly, the delivery packages should be protected from thieves and the risk of robbery. They should not be placed in areas where high crime rates Yildiz et al. (2020). On the other hand, natural disasters and climate effects are other risk parameters. The parcel locker should not be located in a disadvantageous area in terms of weather conditions such as wind, and the earthquake or fire risks should be considered.

Financial

Setting up a new parcel locker includes expenses affected by the possible locations. For instance, the investment cost is probably high if the alternative location is in a vibrant area like the city center. However, the transportation expenses, maintenance costs, and taxes to be paid may differ for various location points (Wang et al. 2021).

Social

Demographic characteristics of the region play a crucial role in such decisions. The parcel locker should be close to the locations that people often use in their social lives so that they do not waste time. In this context, it is advantageous that the lockers are accessible both to those who live near the candidate site and to those who pass by the candidate locations. However, income, age, and education affect people’s shopping patterns and must be considered to define the optimum location. This is a relatively new implementation, and the people’s attitude is essential for adaptation (Tolga et al. 2013).

Convenience

The parcel locker should be in a place where pedestrians and drivers can easily access it, Özdaǧoǧlu (2011). Additionally, the alternative location can be integrated into multi-modal and public transportation networks. It should be close to the highways but where no serious traffic jams prevent collecting cargo from the parcel lockers (Bingqing and Liting 2020). There is a sensitive balance here; the location should be convenient to convince customers to collect their packages instead of selecting a home delivery option.

Proximity

While trying to find a location for a parcel locker, the decision-maker should look at some essential features such the location of cargo centers, central distribution warehouses and competitors. Additionally, the business centers and shopping malls are generally located in vibrant parts of the cities, and people often pass by these places. These crowded areas may be a good alternative for setting up a parcel locker. The decision-makers should also consider the nearest cargo machine, if applicable, to avoid unnecessary investments.

The proposed methodology

To determine the ideal parcel locker location for the Beşiktaş district in Istanbul, a fuzzy MCDM strategy is proposed in this research. For this purpose, the integrated methodology is discussed in this section. In this methodology, the PF-WASPAS approach is integrated with the B-BWM approach to obtain the best results in selection problems with conflicting criteria in an uncertain environment.

The B-BWM is used to generate the weights of the criteria, and the PF-WASPAS approach is used to rank the alternatives. The combination of these two methodologies is unique to this paper, making it a novel paper in the literature in terms of methodology. First, the B-BWM method is presented in the following sub-section. In the second sub-section, after introducing the preliminary concepts for Pythagorean fuzzy numbers, the WASPAS methodology in a Pythagorean fuzzy environment is presented. The proposed hybrid methodology’s steps are given in Fig. 2.

Fig. 2.

The proposed hybrid methodology

Bayesian best–worst method

This section explains the steps of the B-BWM, which is an extended version of the original BWM for group decision-making problems. BWM is a relatively new MCDM method developed by Rezaei (2015), and it has many advantages over other comparison-based methods. BWM provide decision-makers with consistent and reliable results, although it requires less comparison data. Additionally, BWM includes fewer comparison steps, making it a time-efficient method. In BWM, firstly, the best (most desirable) and worst (least desirable) criteria are determined considering all criteria set and then pairwise comparisons are carried out. Despite all the advantages of the method, BWM cannot merge the preferences of multiple decision-makers and is convenient for only individual decision-making Mohammadi and Rezaei (2020). To avoid the adverse effects of conventional ways of aggregating the preferences (e.g., arithmetic or geometric means) in group decision-making problems, Mohammadi and Rezaei (2020) introduced the B-BMW. The B-BWM uses a probabilistic perspective and the creedal ranking to minimize information loss and pave the way for group decision-making Ak et al. (2022).

B-BWM is used in many studies with many purposes. Yang et al. (2020) use B-BWM to determine the weight of criteria to establish sustainable sport tourism in Taiwan. Guo et al. (2020) evaluate the business risk of an electricity retail company via B-BWM. Li et al. (2020) use B-BWM to prioritize the factors to solve energy storage planning program selection problem. Liu et al. (2021) employ B-BWM to rank the challenges for sustainable supply chain blockchain technology implementation. Huang et al. (2021) build an airport resilience assessment model based on B-BWM methodology. Ak et al. (2022) propose a risk assessment tool for occupational health, safety and environmental concerns in the textile production industry. Gul and Yucesan (2022) use B-BWM to determine the weight of performance criteria to evaluate the performance of Turkish universities. Ayyildiz and Erdogan (2022) prioritize the insulation material selection factors by B-BWM.

The calculation steps of B-BWM are as follows (Mohammadi and Rezaei 2020; Saner et al. 2022).

Step 1: The criteria set C= is established by literature review and expert evaluations.

Step 2: Each expert determines the most important (best) and the least important (worst) criterion from criteria set C. The best and the worst criteria for expert k are presented by and , respectively.

- Step 3: The best criterion is compared with other criteria using a scale between 1 and 9, and Best-to-Others vectors () are obtained for each decision-maker.

1

Here K is the number of experts, and presents the pairwise comparison between the best and other criteria by decision-maker k.

- Step 4: The worst criterion is compared with other criteria using a scale between 1 and 9, and Others-to-Worst vectors () are obtained for each decision-maker.

2

Here, K is the number of experts, and presents the pairwise comparison between the worst and other criteria by decision-maker k.

Step 5: and are used as input vectors for calculations from the probabilistic perspective proposed by Mohammadi and Rezaei (2020).

B-BWM has similar calculation steps to BWM, except that the criterion weights of the multiple decision-makers are aggregated using a probability perspective in B-BWM.

| 3 |

| 4 |

where multinomial is the multinomial distribution.

| 5 |

| 6 |

| 7 |

= is the aggregated weight matrix. Dir (1) and Gamma (0.1, 0.1) are the Dirichlet and Gamma distributions, respectively. This B-BWM model is solved by JAGS, one of the most preferred Monte Carlo methods and credal ordering is determined by the procedure proposed by Mohammadi and Rezaei (2020).

Pythagorean fuzzy WASPAS

Yager (2013) proposed PFSs, which are generalized version of intuitionistic fuzzy sets introduced by Atanassov (1999). As defined in Definition 1, PFSs differ from intuitionistic fuzzy sets in that the total of membership and non-membership degrees can exceed 1, but their squares cannot (Ilbahar et al. 2018; Karasan et al. 2018).

Definition 1: Let X be a fixed set. A Pythagorean fuzzy number is shown as :

| 8 |

If the degree of membership is described by the function and . For every , it holds X [0,1] defines the degree of non-membership of the element to P, respectively.

| 9 |

The indeterminacy ratio is obtained as in the following (Ayyildiz and Taskin Gumus 2021a):

| 10 |

Instead of providing precise numbers to highlight the ambiguity, experts can use interval numbers to better reflect the criteria and options under consideration. Interval fuzzy numbers are used in this work to better handle ambiguity. The following are the preliminary Pythagorean fuzzy numbers with interval values Ayyildiz et al. (2021).

Definition 2. An interval-valued Pythagorean fuzzy set (IVPFSs) A defined in X is given as Ayyildiz and Taskin Gumus (2021b):

| 11 |

where

| 12 |

The hesitation interval of PFSs relative to A, which is similar to PFSs and corresponds to interval-valued membership values, is given as

| 13 |

IVPFSs convert to PFSs if for every , and . The expression for an IVPFSs A is known as an interval-valued Pythagorean fuzzy number (IVPFN).

The score function of an IVPFN is defined as

| 14 |

where . However, it is occasionally noted that this function fails to rank the IVPFNs. Thus, it is unable to select the top candidate among them. The accuracy function for an IVPFN, which is defined as follows Garg (2017), is another function for resolving it.

| 15 |

The MCDM problem-solving method WASPAS is introduced by Zavadskas (Zavadskas et al. 2012, 2019). WASPAS combines the well-known MCDM approaches of weighted sum and weighted product Urosevic et al. (2017). To handle different MCDM problems, WASPAS methodology is extended with various fuzzy sets Lescauskiene et al. (2020).

WASPAS is built using two combined models. WSM: The main idea of this technique is to calculate the total score of the alternatives as the weighted sum of the attribute (criteria) values. WPM is designed to avoid the alternatives with subpar attribute values. Each alternative score is calculated by scaling each attribute’s importance to a power equal to its weight Gupta et al. (2019).

In this study, the interval valued Pythagorean fuzzy numbers are used to evaluate alternative locations. WASPAS is extended with PFSs with different goals. Ilbahar and Kahraman (2018) use PF-WASPAS to measure the performance of retail store. Kahraman et al. (2019) focus on Global System for Mobile communication (GSM) operator selection problem and solve the problem by PF-WASPAS. Ilbahar et al. (2019) use PF-WASPAS to perform a renewable energy alternative assessment for Turkey. Boltürk and Kahraman (2019) solve the Automated Storage and Retrieval Systems (AS/RS) technology selection problem by PF-WASPAS. Ayyildiz et al. (2021) integrate WASPAS with Analytical Hierarchy Process (AHP) using interval valued pythagorean fuzzy numbers to determine the best location for refugee camps in Istanbul, Turkey. Al-Barakati et al. (2022) use PF-WASPAS to evaluate the renewable energy sources. Alrasheedi et al. (2022) integrate WASPAS with stepwise weight assessment ratio analysis (SWARA) in a Pythagorean fuzzy environment to solve the sustainable supplier selection problem.

The steps PF-WASPAS are given below (Ayyildiz et al. 2021):

Step 1. Using the linguistic terms shown in Table 2 (Ayyildiz et al. 2021), construct a Pythagorean fuzzy evaluation matrix to evaluate options by criteria. Let be the pythagorean fuzzy evaluation value of alternative j according to criterion i by expert k.

- Step 2. Aggregate expert opinions using the weight of each expert via Eq. 16.

where denotes the weight of expert k and the number of experts is shown with k.16

| 19 |

Table 2.

Scale for the PF-WASPAS evaluations

| Interval valued fuzzy number | ||||

|---|---|---|---|---|

| Linguistic terms | ||||

| Very poor—VP | 0.12 | 0.27 | 0.66 | 0.81 |

| Poor—P | 0.21 | 0.36 | 0.57 | 0.72 |

| Medium poor—MP | 0.30 | 0.45 | 0.48 | 0.63 |

| Fair -F | 0.39 | 0.54 | 0.39 | 0.54 |

| Medium good—MG | 0.48 | 0.63 | 0.30 | 0.45 |

| God—G | 0.57 | 0.72 | 0.21 | 0.35 |

| Very good -VG | 0.66 | 0.81 | 0.12 | 0.27 |

- Step 5. Determine the threshold value . WSM and WPM are combined with .where λ takes values between 0 and 1.

23

- Step 6. Defuzzify the Phythagorean fuzzy number () to determine the final results of each alternative, via Eq. 24.

24 Step 7. Rank the alternatives with decreasing score.

Real case study in Istanbul

Parcel locker cargo distribution technology has started to become widespread in Turkey as well as in developed countries. This type of package delivery machines is installed in big cities, especially in Istanbul. It is very important where the parcel lockers will be installed in order to maximize the use of people. Therefore, in this study, possible parcel locker locations to be established in Beşiktaş, one of the most crowded regions in Istanbul, are determined. Besiktas district is selected as an application area within the scope of this study. The location, shopping malls, business centers, universities, schools, tourist destinations, and socio-economic structure of the Besiktas play a key role in the application area selection. A new combination of MCDM is used to determine which of these locations is better.

A novel decision-making application is presented using Bayesian and fuzzy logic together with MCDM approaches to select the best location for a parcel locker. For this purpose, firstly criteria are determined via literature review and expert interview, as explained before.

An expert team is essential to this study in order to determine the main and sub criteria, which is the most important element in the parcel locker location selection (see the “The criteria affecting parcel locking location decision” section); iii) evaluate the main and sub-criteria to determine their weights (see the “Determining criteria weights” section); and finally, iii) determine which of the alternative points considered in the location selection problem is the most appropriate (see the “Evaluating the alternative locations” section). Particularly, an expert group is formed which consists of four qualified experts to take their opinion. Various factors are taken into consideration while choosing experts, as i) extensive education (ideally post-graduate, but at least undergraduate) and familiarity with parcel lockers and/or location selection problems; ii) experience in the related fields (5 years as a minimum); iii) participation in MCDM research prior. Expert-1 is a Ph.D. student in Industrial Engineering and has 5 years of work experience in the related field. Expert-2 is a professor with 17 years of academic experience and numerous publications in the field of MCDM. Expert-3 is an academician with a Ph.D. in Industrial Engineering and 8 years of experience working in the field. Expert-4 is a manager with 13 years of experience working in the field of cargo transportation.

Determining criteria weights

The priorities of the main and sub-criteria that affect the location of parcel lockers are evaluated by B-BWM methodology in this sub-section. B-BWM steps are applied to determine the weights of service dimensions. First, the weights of the main criteria are calculated. For this purpose, the following calculation procedure is applied. Four experts are consulted to express their opinions on the criteria importance. First, each expert determines the best (most important) and the worst (least important) main criteria, as shown in Table 3.

Table 3.

The best and worst criteria

| Best | Worst | |

|---|---|---|

| Expert-1 | C6.Proximity | C2.Resilience |

| Expert-2 | C5.Convenience | C1.Tangibles |

| Expert-3 | C5.Convenience | C4.Social |

| Expert-4 | C3.Financial | C4.Social |

C5.Convenience is determined as the most important main criterion by two experts, and C6.Proximity and C3.Financial are determined as the most important main criteria by one expert. C4.Social is determined as the least important criterion by two experts.

Then, Best-to-Others Vectors and Others-to-Worst Vectors are constructed based on expert opinions given in Table 4.

Table 4.

Best-to-Others and Others-to-Worst vectors

| Best-to-Others | Others-to-Worst | |

|---|---|---|

| Expert-1 | 7; 6; 8; 3; 4; 1 | 8; 1; 5; 5; 6; 6 |

| Expert-2 | 9; 5; 2; 2; 1; 2 | 1; 3; 4; 3; 9; 3 |

| Expert-3 | 3; 3; 2; 5; 1; 2 | 3; 4; 5; 1; 6; 4 |

| Expert-4 | 3; 2; 1; 6; 5; 4 | 3; 4; 6; 1; 4; 3 |

The vectors constructed based on expert opinions are used and the weights are calculated as given in Fig. 3.

Fig. 3.

Weights of main criteria

According to the weights presented in Fig. 3, “C5. Convenience” is the most important main criterion to determine the parcel locker locations. Therefore, it can be said that the convenience of the location for the customers plays a key role in improving the service level and customer satisfaction.

In most of the MCDM methodologies, the higher weights are determined as more important. Nevertheless, sometimes the weight differences can be insignificant and this can be a challenge when ranking the criteria. Especially, in group decision-making problems, the ranking must be handled more careful. At this point, the credal ranking plays an important role. This shows how much one criterion is superior to another. The credal ranking for the main criteria is presented in Fig. 4.

Fig. 4.

Credal ranking graph of the main criteria

The values written next to the arrows in Fig. 4 show that the factor of X is more important than the factor of Y in the reliability of r (i.e. ). The value of can take a value between and presents the probability value. For example, means that the C5. Convenience main criterion is absolutely more important than the C1. Tangibles main criterion, because the takes a value of 0.97. Again, in Fig. 4, shows the importance weight value of C3. Financial is greater than the weight of C6. Proximity with a reliability of 0.53. This means that the probability of absolute superiority of both criteria is weak.

After determining the main criteria weights, the sub-criteria weights are calculated by B-BWM again. The Best-to-Others Vectors and Others-to-Worst Vectors are constructed based on expert opinions for the sub-criteria of each main-criterion as presented in Table 5.

Table 5.

Best-to-Others and Others-to-Worst vectors for sub-criteria

| Best-to-Others | Others-to-Worst | Best-to-Others | Others-to-Worst |

|---|---|---|---|

| Sub criteria of C1.Tangibles | Sub criteria of C4.Social | ||

| 2; 1; 8; 6; 3; 2 | 7; 7; 1; 5; 7; 6 | 8; 3; 3; 6; 1; 3 | 1; 6; 6; 3; 8; 5 |

| 3; 1; 2; 7; 2; 6 | 5; 7; 4; 1; 1; 3 | 1; 3; 3; 2; 1; 7 | 7; 3; 3; 3; 5; 1 |

| 2; 4; 3; 5; 1; 2 | 4; 3; 4; 1; 6; 5 | 1; 3; 3; 6; 2; 1 | 6; 4; 4; 1; 5; 5 |

| 4; 3; 2; 6; 5; 1 | 4; 5; 4; 1; 3; 7 | 1; 2; 5; 6; 3; 4 | 6; 5; 4; 1; 3; 2 |

| Sub criteria of C2.Resilience | Sub criteria of C5.Convenience | ||

| 1; 7; 6; 8 | 8; 2; 3; 1 | 3; 1; 2; 3; 6; 9 | 6; 9; 7; 6; 3; 1 |

| 1; 3; 3; 5 | 5; 2; 3; 1 | 2; 1; 1; 1; 5; 2 | 3; 5; 3; 2; 1; 2 |

| 1; 4; 3; 5 | 5; 2; 3; 1 | 2; 2; 4; 1; 5; 3 | 3; 4; 3; 5; 1; 4 |

| 1; 3; 2; 4 | 4; 2; 3; 1 | 2; 3; 4; 1; 6; 5 | 5; 3; 3; 6; 1; 2 |

| Sub criteria of C3.Financial | Sub criteria of C6.Proximity | ||

| 5; 2; 8; 1 | 4; 7; 8; 1 | 1; 8; 4; 5; 3; 3 | 8; 1; 5; 5; 6; 6 |

| 1; 2; 1; 5 | 5; 4; 4; 1 | 1; 2; 3; 5; 2; 2 | 4; 5; 3; 1; 2; 2 |

| 3; 1; 2; 4 | 2; 4; 3; 1 | 1; 3; 3; 6; 2; 1 | 6; 4; 4; 1; 5; 4 |

| 3; 2; 1; 4 | 3; 2; 4; 1 | 5; 4; 6; 3; 1; 2 | 3; 4; 1; 3; 6; 5 |

Later, the sub-criteria weights of each main criterion are calculated by applying B-BWM. The sub-criteria weights are multiplied by related main criterion weight and the final weights of sub-criteria are determined as given in Table 6.

Table 6.

Final weights of sub-criteria

| Sub criteria | Local weight | Final weight | |

|---|---|---|---|

| C11 | Land Size | 0.194 | 0.023 |

| C12 | Parking area | 0.215 | 0.026 |

| C13 | Infrastructure adequacy | 0.135 | 0.016 |

| C14 | Possibility of expansion | 0.087 | 0.010 |

| C15 | Loading practicality | 0.173 | 0.021 |

| C16 | Visibility | 0.195 | 0.023 |

| C21 | Theft risk | 0.491 | 0.068 |

| C22 | Natural disaster risks | 0.167 | 0.023 |

| C23 | Accident risks | 0.223 | 0.031 |

| C24 | Climate condition | 0.119 | 0.016 |

| C31 | Investment cost | 0.240 | 0.047 |

| C32 | Operational cost | 0.323 | 0.063 |

| C33 | Delivery (transportation) cost | 0.294 | 0.057 |

| C34 | Insurances-taxes | 0.143 | 0.028 |

| C41 | Number of people residing in the vicinity of candidate locations | 0.195 | 0.024 |

| C42 | Income level | 0.185 | 0.023 |

| C43 | Educational level | 0.161 | 0.020 |

| C44 | Average age of people residing in the vicinity of the candidate location | 0.099 | 0.012 |

| C45 | Average number of people passing by the candidate location on any day | 0.229 | 0.028 |

| C46 | Attitude of residents/population shopkeepers | 0.132 | 0.016 |

| C51 | Traffic intensity | 0.191 | 0.045 |

| C52 | Closeness to public transportation | 0.235 | 0.056 |

| C53 | Pedestrian conveniency | 0.168 | 0.040 |

| C54 | Multimodal transportation conveniency | 0.230 | 0.054 |

| C55 | Seasonality effect | 0.077 | 0.018 |

| C56 | Closeness to the major roads/highways | 0.099 | 0.023 |

| C61 | Closeness to the residential area | 0.224 | 0.042 |

| C62 | Closeness to main distribution centers | 0.133 | 0.025 |

| C63 | Distance to the nearest cargo branch | 0.131 | 0.025 |

| C64 | Distance to the nearest parcel lockers | 0.103 | 0.019 |

| C65 | Closeness to shopping malls | 0.211 | 0.040 |

| C66 | Closeness to business centers | 0.198 | 0.037 |

Evaluating the alternative locations

Within the scope of the study, Istanbul/Besiktas region is chosen as a real-case study area for the parcel locker location selection problem. The location, socio-economic status, schools, universities, shopping centers, and business centers of the region play a key role in the selection process. A cargo distribution process, which is one of the most popular private logistics service providers, is discussed in this study. The process of cargo distribution operations in this region is handled. For this purpose, five alternative locations in Besiktas presented in Fig. 5 are evaluated by the proposed integrated Pythagorean fuzzy approach. The main reason for choosing these five locations is the proximity of each location to public transportation points and shopping centers. Most of the points were chosen because they are in a central location and on a route where many people come and go during the day. YTU is the largest university campus in the county; Zorlu is the biggest shopping center in the district, İskele is a point where sea and land public transportation intersect, Ortaköy is a historically visited center close to public transportation, and Ihlamur Kasrı is a historically visited point close to the center.

Fig. 5.

Alternative parcel locker locations

The alternative locations are evaluated with respect to the obtained criterion weights. Firstly, the same experts are asked to evaluate alternative locations considering the determined criteria by linguistic terms given in Table 2. By this way, an alternative evaluation matrix is constructed for each expert and is presented in Table 7.

Table 7.

Alternative evaluation matrix

| C11 | C12 | C13 | C14 | C15 | C16 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C41 | C42 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EXPERT-1 | A-1 | G | MG | G | G | G | MG | VG | G | G | MG | MG | G | F | MG | G | G |

| A-2 | VG | G | G | G | G | VG | VG | G | MG | MG | G | G | G | MG | G | G | |

| A-3 | G | MG | G | MG | G | VG | G | G | MG | MG | G | G | G | MG | G | VG | |

| A-4 | G | B | G | B | MB | VG | MG | MB | MG | F | MG | G | MG | MG | G | G | |

| A-5 | VG | F | G | B | MG | VG | G | MB | MG | F | MG | G | G | MG | G | G | |

| C43 | C44 | C45 | C46 | C51 | C52 | C53 | C54 | C55 | C56 | C61 | C62 | C63 | C64 | C65 | C66 | ||

| A-1 | G | MG | MG | G | G | MG | G | MG | G | MG | G | MG | G | G | MG | MG | |

| A-2 | G | G | VG | VG | MG | VG | VG | G | B | VG | G | MG | G | G | VG | G | |

| A-3 | VG | G | VG | VG | F | VG | VG | VG | MG | VG | MG | MG | G | G | VG | VG | |

| A-4 | MG | G | VG | MG | MB | G | MG | MG | MB | G | MG | MG | G | G | G | G | |

| A-5 | MG | G | VG | G | MB | VG | G | VG | B | VG | MG | MG | G | G | G | G | |

| C11 | C12 | C13 | C14 | C15 | C16 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C41 | C42 | ||

| EXPERT-2 | A-1 | MB | MG | B | MG | F | G | MG | F | G | F | F | G | MG | VB | F | VG |

| A-2 | VG | MG | MG | G | MG | G | F | F | MG | F | MG | G | G | MB | G | MG | |

| A-3 | G | VG | VG | MG | G | VG | VG | F | G | G | G | MB | G | B | VG | VG | |

| A-4 | B | VB | MG | VB | VB | VG | MG | MB | B | B | B | B | B | VB | G | G | |

| A-5 | B | VB | MB | VB | B | VG | F | B | B | B | MB | B | MB | MB | VG | MB | |

| C43 | C44 | C45 | C46 | C51 | C52 | C53 | C54 | C55 | C56 | C61 | C62 | C63 | C64 | C65 | C66 | ||

| A-1 | MG | B | F | MG | MB | MG | MG | F | G | MG | MG | B | F | F | MB | MG | |

| A-2 | G | VG | G | VG | MB | VG | MG | G | MB | G | G | MG | MG | MB | G | G | |

| A-3 | MG | MG | VG | VG | MB | VG | G | VG | MG | G | G | G | G | MB | VG | VG | |

| A-4 | MG | MG | G | G | VB | MG | MG | MB | G | G | MG | MG | F | G | MB | MB | |

| A-5 | F | G | VG | G | VB | VG | VG | VG | VG | G | F | F | G | F | MG | G | |

| C11 | C12 | C13 | C14 | C15 | C16 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C41 | C42 | ||

| EXPERT-3 | A-1 | G | G | F | MG | MG | MB | F | F | MB | G | G | F | F | F | G | G |

| A-2 | G | G | G | F | MG | F | MG | F | B | G | MG | MG | F | MB | F | B | |

| A-3 | F | VG | VG | MG | G | F | VG | VG | VG | VG | VB | B | MB | MG | MG | VG | |

| A-4 | MB | MB | MB | MB | F | G | F | MB | MB | F | MB | MB | F | F | MG | G | |

| A-5 | MG | VB | B | MB | MB | VG | MB | B | B | F | B | MB | F | F | MB | MB | |

| C43 | C44 | C45 | C46 | C51 | C52 | C53 | C54 | C55 | C56 | C61 | C62 | C63 | C64 | C65 | C66 | ||

| A-1 | G | B | MB | B | MB | MB | MG | MB | G | MB | G | MB | MG | MG | MB | MG | |

| A-2 | VG | VG | F | G | F | MG | G | MG | B | G | MG | MG | MB | MB | MG | G | |

| A-3 | G | G | G | F | B | VG | B | VG | MG | VG | MG | G | B | VB | VG | VG | |

| A-4 | F | F | G | MG | MB | F | F | F | MB | F | MG | F | MB | F | F | B | |

| A-5 | B | F | VG | MG | G | VG | G | VG | MG | VG | MB | F | F | MB | MG | MG | |

| C11 | C12 | C13 | C14 | C15 | C16 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C41 | C42 | ||

| EXPERT-4 | A-1 | F | MB | F | F | F | MB | G | G | MB | F | B | F | B | F | F | F |

| A-2 | VG | VG | VG | VG | VG | VG | VG | VG | VG | MG | G | G | G | VG | G | MB | |

| A-3 | G | G | MG | MG | MG | MG | MG | MG | MG | G | MG | MG | MG | MB | VG | MG | |

| A-4 | VB | VB | MB | MB | MB | F | MB | MB | F | MB | F | B | VB | MG | MG | VG | |

| A-5 | B | B | G | G | G | G | F | F | G | B | MB | MB | MB | G | MB | G | |

| C43 | C44 | C45 | C46 | C51 | C52 | C53 | C54 | C55 | C56 | C61 | C62 | C63 | C64 | C65 | C66 | ||

| A-1 | F | MG | MB | MB | MB | F | MB | F | MB | F | F | MB | MB | MB | MB | F | |

| A-2 | G | VG | G | MG | G | G | VG | G | F | G | G | G | G | G | G | VG | |

| A-3 | MG | G | VG | VG | MG | VG | G | VG | VG | VG | VG | VG | VG | VG | VG | G | |

| A-4 | MB | MB | MG | G | F | MB | MG | MB | MG | MB | MB | F | F | F | F | MB | |

| A-5 | B | F | F | F | B | MG | F | MG | G | MG | MG | MG | MG | MG | MG | MG |

So far, the criteria weights are calculated, and an alternative evaluation matrix is constructed, and then these weights and the matrix can be used to compare the alternative locations given in Fig. 6. For this purpose, the weighted sum model and the weighted product model are calculated for each alternative, as given in Table 8.

Fig. 6.

Final rankings of alternatives according to the sensitivity analysis

Table 8.

The weighted sum and product models for alternative locations

| Weighted sum model | Weighted product model | |||||||

|---|---|---|---|---|---|---|---|---|

| Alternative | ||||||||

| A-1: Ihlamur Kasrı | 0.318 | 0.437 | 0.586 | 0.703 | 0.428 | 0.579 | 0.595 | 0.710 |

| A-2: YTÜ | 0.397 | 0.525 | 0.490 | 0.627 | 0.528 | 0.679 | 0.508 | 0.637 |

| A-3: Zorlu | 0.410 | 0.542 | 0.471 | 0.615 | 0.532 | 0.684 | 0.509 | 0.636 |

| A-4: Ortaköy | 0.292 | 0.409 | 0.616 | 0.730 | 0.379 | 0.532 | 0.635 | 0.744 |

| A-5: İskele | 0.336 | 0.459 | 0.565 | 0.690 | 0.427 | 0.581 | 0.600 | 0.713 |

The λ is determined as 0.5 (Ayyildiz and Taskin Gumus 2020; Ayyildiz et al. 2021; Tumsekcali et al. 2021) to combine models fairly, and pythagorean fuzzy results presented in Table 9 are determined as alternatives.

Table 9.

Pythagorean fuzzy values of the results

| Alternative | ||||

|---|---|---|---|---|

| A-1: Ihlamur Kasrı | 0.515 | 0.68 | 0.348 | 0.499 |

| A-2: YTÜ | 0.626 | 0.781 | 0.249 | 0.399 |

| A-3: Zorlu | 0.635 | 0.79 | 0.24 | 0.392 |

| A-4: Ortaköy | 0.466 | 0.635 | 0.391 | 0.543 |

| A-5: İskele | 0.524 | 0.69 | 0.339 | 0.492 |

Then, the results are defuzzied via Eq. 24 to determine the final scores of the alternatives. Thereafter, alternatives are ranked in descending order with respect to the final scores as given in Table 10.

Table 10.

Final ranking of the alternatives

| Ranking | Alternative | Final score |

|---|---|---|

| 1 | A-3: Zorlu | 0.718 |

| 2 | A-2: YTÜ | 0.710 |

| 3 | A-5: İskele | 0.621 |

| 4 | A-1: Ihlamur Kasrı | 0.612 |

| 5 | A-4: Ortaköy | 0.569 |

A3-Zorlu is the best alternative location to locate the parcel locker machine according to PF-WASPAS as given in Table 10. This point can be reached by many different modes of transportation, such as Subway, Metrobus, and Public Bus. There is also a shopping mall here and there are many business centers around it. Therefore, it is a frequent destination for people. This point, which is close to many universities, is frequently visited at almost every hour of the day. A-2: YTÜ is determined as the second best alternative and A-4:Ortaköy is the worst option among the five alternatives to locate a parcel locker. The main reason why Ortaköy location is the worst: it is a bit farther than other alternatives and because it is a historical region, it is visited by more tourists than locals in daily life.

Sensitivity analysis

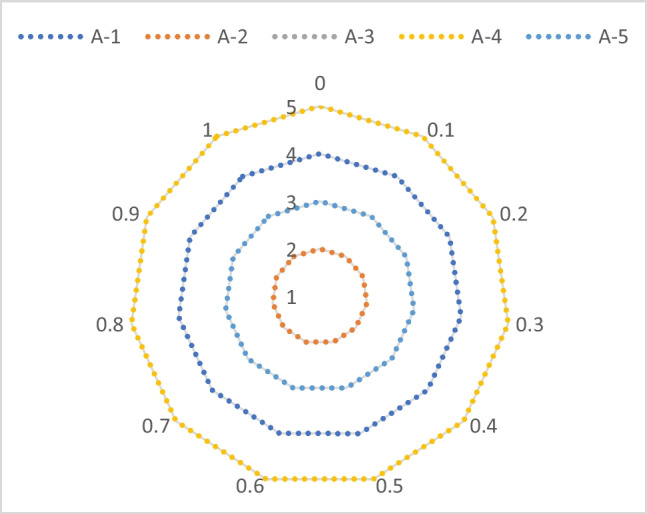

A sensitivity analysis is performed to test the applicability and effectiveness of the proposed methodology. An analysis is conducted by changing the threshold value (λ). For this purpose, the threshold value is increased by 0.1 starting from 0 and till 1. It emphasizes the parcel locker location selection decision’s robustness. The final scores of the alternatives are presented in Table 11 as results of the sensitivity analysis.

Table 11.

The final scores of alternative locations

| 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A-1:Ihlamur Kasrı | 0.539 | 0.555 | 0.571 | 0.585 | 0.599 | 0.612 | 0.625 | 0.637 | 0.648 | 0.659 | 0.669 |

| A-2: YTÜ | 0.626 | 0.645 | 0.663 | 0.680 | 0.695 | 0.710 | 0.723 | 0.736 | 0.748 | 0.760 | 0.771 |

| A-3: Zorlu | 0.630 | 0.650 | 0.669 | 0.687 | 0.703 | 0.718 | 0.732 | 0.746 | 0.758 | 0.770 | 0.781 |

| A-4: Ortaköy | 0.497 | 0.513 | 0.528 | 0.543 | 0.556 | 0.569 | 0.582 | 0.594 | 0.605 | 0.616 | 0.626 |

| A-5: İskele | 0.538 | 0.557 | 0.574 | 0.591 | 0.606 | 0.621 | 0.635 | 0.648 | 0.660 | 0.672 | 0.684 |

After this, alternatives are ordered according to their final scores to determine the best option for each scenario. Figure 6 shows the final rankings of the alternatives for each scenario.

As seen in Fig. 6, the final rankings of alternatives are never changing according to results of the sensitivity analysis. Therefore, it can be said that A-3: Zorlu is always the best option to locate the parcel locker. Therefore, the proposed methodology provides a robust decision for the parcel locker location selection problem.

Discussion and implications

The volume of electronic commerce is growing day by day with technological development. With the development of internet-based technology and tools in commercial services, two basic constraints such as time and space have disappeared, and e-commerce activities have undoubtedly accelerated. In other words, people have started to evaluate digital options instead of physical stores while shopping. In addition, with the dynamic life, people started to move more often. New solutions are emerging at the point of the final delivery of digital shopping to the buyer. At this point, both the continuation of trade activities and the parcel lockers that all stakeholders in the supply chain can benefit from gain great importance. Logistics service providers should make more careful and strong decisions and fulfill the demands of stakeholders in different roles in the supply chain. Especially in the delivery process, which is the last stage of e-commerce, the operational service quality of transportation and logistics enterprises is of great importance for retailers and logistics service providers who aim to deliver the products subject to shopping to the end consumer as soon as possible and without any problems. Cargo transportation service is critical for both logistics service providers and retailers within the scope of ensuring economic sustainability.

Parcel lockers are an electronic locker system that creates an order pick-up point, where usually small-volume cargoes are placed and each customer is served by generating a unique cargo delivery code. The system, which is called self-service because it includes the process of receiving the cargoes with the effort of the customer, prevents operational inefficiencies arising from transportation with partial cargo in the delivery process to the end consumer (Boysen et al. 2020). It also offers customer flexibility in terms of time so that cargoes can be received 24/7. In addition to the positive aspects of the system, it is striking that there are some limitations in terms of creating perceived benefits regarding meeting customer expectations Although parcel lockers provide great convenience for customers to receive their cargo 24/7, they are not in the first place among customers' delivery preferences Joerss et al. (2016). However, if the home delivery option is significantly higher than the delivery fee to the parcel lockers, then it is concluded that most of the customers are willing to use the parcel lockers.

With the use of parcel lockers, distribution operations can also be carried out at night. Shifting the logistics operations for urban distribution activities from daytime hours to night hours can also ensure that the density of commercial vehicles on the roads is avoided. Logistics service providers can achieve a more successful operational planning for the next day with night distribution. Additionally, night logistics is emerging as a great solution strategy for logistics service providers by overcoming obstacles such as wasting time in traffic jams, consuming too much fuel due to stop/go crossings and road bans applied during daylight hours. In this context, logistics service providers have the opportunity to operate with faster delivery and higher efficiency, while minimizing the damage they cause to society and the environment (Ljubičić and Pavlović 2015).

“Convenience” is determined as the most important criterion as a result of MCDM analysis. The parcel locker should be located in a location where customers can easily reach. People use major roads and multi-modal transport options to travel to or from work. In this context, when determining the parcel locker location, the places where people visit frequently should be preferred. Customers expect solutions that are suitable for them. Logistics service providers can increase customer loyalty and develop more sustainable strategies in the market by locating parcel lockers with “convenient” approaches to customers.

Theft risk is determined as the most important sub-criterion among thirty-two sub criteria. Therefore, decision makers should make various procedural decisions and support security measures using technology to increase cargo security and prevent theft threats to this type of transportation. For example, the known shipper application can be used, which allows registered or designated shippers to ship the cargo. Physical security measures on parcel lockers can be increased. Operational and delivery costs are also important sub-criteria for parcel locker location decisions. As a result of the global economic environment, constantly changing competitive conditions have shortened product life cycles, increased R&D expenses, increased marketing, sales and distribution expenses, increased use of new technology and therefore decreased industry resources. Thus, with all these changes, the costs of products and services increase. In this context, supply chains must perform transportation services at minimum cost to survive.

Conclusions and further research

Eventually, this study introduces a hybrid fuzzy decision-making methodology for evaluating alternative locations of parcel lockers to ensure the most effective transportation operations for supply chains. In this study, we handle the parcel locker location selection problem and investigate which criteria should be considered while making parcel locker location decisions. A real-life study in Istanbul is conducted to show the solution procedure of the problem. For this purpose, firstly the problem is modeled as a decision-making problem and the criteria are determined based on the literature review and expert opinions. The criteria weights are determined by B-BWM methodology, then the most appropriate location is determined via PF-WASPAS with respect to predetermined weights. The most important main criterion is determined as “Convenience” and the least important main criterion is determined as “Tangibles” among the six main criteria.

In the decision-making analysis carried out for Istanbul, which is the biggest city of Turkey, it is concluded that the most appropriate location is determined as the region marked with A-3: Zorlu with 0.723 final score value and this alternative is followed by A-2: YTÜ with a score value of 0.713. When a detailed and comprehensive evaluation and examination are conducted with respect to considered main and sub criteria and the final results are analyzed with multiple experts, it can be interpreted that the use of the first-ranked area, namely, A-3: Zorlu, as a parcel locker location is a very reasonable result, due to its proximity, ease of transportation and many people visiting it during the day. A sensitivity analysis is performed to observe the effect of the threshold value on the final ranking in the decision process. According to the results, it is seen that the best alternative never changes. Thus, it can be said that the proposed hybrid methodology is stable to the changes in decision parameters.

This study introduces the B-BWM integrated PF-WASPAS methodology to the literature to solve complex decision-making problems. The contributions of this study to the literature can be specified as follows: i) The parcel locker location selection problem is introduced to the literature and handled as a MCDM problem; ii) The most detailed criteria structure is constructed to evaluate alternative locations based on sustainable supply chain management perspective; iii) B-BWM is integrated into PF-WASPAS methodology for the first time in the literature to make a more robust and accurate group decision analysis; iv) The most important criteria in the parcel locker location selection decision process are determined as a result of B-BWM; v) A five alternatives in Istanbul are evaluated and the best alternative is determined as a real-life study to show the applicability of the proposed hybrid methodology.

In the decision-making model, the weight matrix is obtained by B-BWM. The effects of different strategies on the solution can be analyzed by adding new criteria. Therefore, a different weighting-based MCDM methodologies, such as AHP, Analytic Network Process (ANP), SWARA, classical BWM can be used to determine the weights of criteria in future studies. Additionally, Decision Making Trial and Evaluation Laboratory (DEMATEL) can also be used to analyze the interaction between the considered criteria. The evaluation criteria set can be extended or modified considering different scenarios. In this context, the pandemic effect on the logistics service providers can be included in the evaluation criteria set. Considering the location selection process, different decision-making models can be used to evaluate alternatives.

Author contribution

Bahar Yalcin Kavus and Ertugrul Ayyildiz developed the theoretical formulation and performed the analytic calculations and numerical analysis. Ertugrul Ayyildiz and Alev Taskin contributed to the sensitivity analysis and final version of the manuscript. Bahar Yalcin Kavus and Pelin Gulum Tas drafted the manuscript. Alev Taskin supervised the work.

Data availability

Not applicable.

Code availability

Not applicable.

Declarations

Ethical approval

Ethics committee approval is not required.

Consent to participate

Not applicable.

Consent for publication

The author confirms that the final version of the manuscript has been reviewed, approved, and consented for publication.

Conflict of interest

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Bahar Yalcin Kavus, Email: bahar.yalcin@nisantasi.edu.tr.

Ertugrul Ayyildiz, Email: ertugrulayyildiz@ktu.edu.tr.

Pelin Gulum Tas, Email: p.gulumtas@tudelft.nl.

Alev Taskin, Email: ataskin@yildiz.edu.tr.

References

- Ak MF, Yucesan M, Gul M. Occupational health, safety and environmental risk assessment in textile production industry through a Bayesian BWM-VIKOR approach. Stoch Env Res Risk Assess. 2022;36:629–642. doi: 10.1007/s00477-021-02069-y. [DOI] [Google Scholar]

- Al-Barakati A, Mishra AR, Mardani A, Rani P (2022) An extended interval-valued Pythagorean fuzzy WASPAS method based on new similarity measures to evaluate the renewable energy sources. Appl Soft Comput 120108689-S1568494622001557 108689. 10.1016/j.asoc.2022.108689

- Alrasheedi M, Mardani A, Mishra AR, Rani P, Loganathan N (2021) (2022) An extended framework to evaluate sustainable suppliers in manufacturing companies using a new Pythagorean fuzzy entropy-SWARA-WASPAS decision-making approach. J Enterp Inf Manag 35(2):333–357. 10.1108/JEIM-07-2020-0263

- Atanassov KT (1999) Interval Valued Intuitionistic Fuzzy Sets. 139–177. 10.1007/978-3-7908-1870-3_2

- Awasthi A, Chauhan SS, Goyal SK. A multi-criteria decision-making approach for location planning for urban distribution centers under uncertainty. Math Compute Model. 2011;53:98–109. doi: 10.1016/J.MCM.2010.07.023. [DOI] [Google Scholar]

- Ayyildiz E, Erdogan M (2022) Identifying and prioritizing the factors to determine best insulation material using Bayesian best worst method. Proceedings of the Institution of Mechanical Engineers Part E: Journal of Process Mechanical Engineering. 10.1177/09544089221111586

- Ayyildiz E, Taskin Gumus A (2021a) Pythagorean fuzzy AHP based risk assessment methodology for hazardous material transportation: an application in Istanbul. Environmental Science and Pollution Research 1–13.10.1007/s11356-021-13223-y [DOI] [PubMed]

- Ayyildiz E, Erdogan M, Taskin Gumus A (2021) A Pythagorean fuzzy number-based integration of AHP and WASPAS methods for refugee camp location selection problem: a real case study for Istanbul, Turkey. Neural Compute Appl 1–18.10.1007/s00521-021-06195-0

- Ayyildiz E, Taskin Gumus A. A novel spherical fuzzy AHP-integrated spherical WASPAS methodology for petrol station location selection problem: a real case study for İstanbul. Environ Sci Pollut Res. 2020;27:36109–36120. doi: 10.1007/s11356-020-09640-0. [DOI] [PubMed] [Google Scholar]

- Ayyildiz E, Taskin Gumus A. Interval-valued Pythagorean fuzzy AHP method-based supply chain performance evaluation by a new extension of SCOR model: SCOR 4.0. Complex & Intelligent Systems. 2021;7:559–576. doi: 10.1007/s40747-020-00221-9. [DOI] [Google Scholar]

- Bingqing F, Liting C (2020) Study on warehouse site selection based on AHP. In: Proceedings - 2020 5th International Conference on Information Science, Computer Technology and Transportation, ISCTT 2020. pp 276–280

- Bolturk E, Kahraman C (2019) As/RS technology selection using interval-valued pythagorean fuzzy WASPAS. In: International conference on intelligent and fuzzy systems. Springer, Cham, pp 867–875

- Boysen N, Fedtke S, Schwerdfeger S (2020) Last-mile delivery concepts: a survey from an operational research perspective. OR Spectrum 2020 43:1 43:1–58. 10.1007/S00291-020-00607-8

- Chen Y, Yu J, Yang S, Wei J. Consumer’s intention to use self-service parcel delivery service in online retailing: An empirical study. Internet Res. 2018;28:500–519. doi: 10.1108/IntR-11-2016-0334. [DOI] [Google Scholar]

- Deutsch Y, Golany B. A parcel locker network as a solution to the logistics last mile problem. Int J Prod Res. 2018;56:251–261. doi: 10.1080/00207543.2017.1395490. [DOI] [Google Scholar]

- Di Puglia Pugliese L, Guerriero F, Macrina G. Using drones for parcels delivery process. Procedia Manuf. 2020;42:488–497. doi: 10.1016/J.PROMFG.2020.02.043. [DOI] [Google Scholar]

- Figliozzi M, Jennings D. Autonomous delivery robots and their potential impacts on urban freight energy consumption and emissions. Transportation Research Procedia. 2020;46:21–28. doi: 10.1016/J.TRPRO.2020.03.159. [DOI] [Google Scholar]

- Garg H. Novel intuitionistic fuzzy decision-making method based on an improved operation laws and its application. Eng Appl Artif Intell. 2017;60:164–174. doi: 10.1016/J.ENGAPPAI.2017.02.008. [DOI] [Google Scholar]

- González-Varona JM, Villafáñez F, Acebes F, et al. Reusing newspaper kiosks for last-mile delivery in urban areas. Sustainability. 2020;12:9770. doi: 10.3390/SU12229770. [DOI] [Google Scholar]

- Gul M, Yucesan M (2022) Performance evaluation of Turkish Universities by an integrated Bayesian BWM-TOPSIS model. Socio-Economic Planning Sciences 80101173-S0038012121001658 101173. 10.1016/j.seps.2021.101173

- Guo S, Zhang W, Gao X (2020) Business risk evaluation of electricity retail company in China using a hybrid MCDM method. Sustainability 12(5):2040. 10.3390/su12052040

- Gupta S, Soni U, Kumar G. Green supplier selection using multi-criterion decision making under fuzzy environment: a case study in automotive industry. Comput Ind Eng. 2019;136:663–680. doi: 10.1016/J.CIE.2019.07.038. [DOI] [Google Scholar]

- Halldórsson Á, Wehner J. Last-mile logistics fulfilment: a framework for energy efficiency. Res Transp Bus Manag. 2020;37:100481. doi: 10.1016/J.RTBM.2020.100481. [DOI] [Google Scholar]

- Huang CN, Liou JJH, Lo HW, Chang FJ (2021) Building an assessment model for measuring airport resilience. Journal of Air Transport Management 95102101-S0969699721000843 102101. 10.1016/j.jairtraman.2021.102101

- Ilbahar E, Kahraman C (2018) Retail store performance measurement using a novel interval-valued Pythagorean fuzzy WASPAS method. Journal of Intelligent & Fuzzy Systems 35(3)3835–3846. 10.3233/JIFS-18730

- İlbahar E, Cebi S, Kahraman C (2019) Assessment of renewable energy alternatives with pythagorean fuzzy WASPAS method: a case study of Turkey. In: International conference on intelligent and fuzzy systems. Springer, Cham, pp 888–895

- Ilbahar E, Karaşan A, Cebi S, Kahraman C. A novel approach to risk assessment for occupational health and safety using Pythagorean fuzzy AHP & fuzzy inference system. Saf Sci. 2018;103:124–136. doi: 10.1016/j.ssci.2017.10.025. [DOI] [Google Scholar]

- Iwan S, Kijewska K, Lemke J. Analysis of parcel lockers’ efficiency as the last mile delivery solution – the results of the research in Poland. Transportation Research Procedia. 2016;12:644–655. doi: 10.1016/J.TRPRO.2016.02.018. [DOI] [Google Scholar]

- Joerss M, Neuhaus F, Schröder J. How customer demands are reshaping last-mile delivery. McKinsey Q. 2016;17:1–5. [Google Scholar]

- Kahraman C, Onar SC, Oztaysi B, Ilbahar E (2019) Selection among GSM operators using pythagorean fuzzy WASPAS method. Journal of Multiple-Valued Logic & Soft Computing 33

- Karasan A, Ilbahar E, Cebi S, Kahraman C. A new risk assessment approach: Safety and Critical Effect Analysis (SCEA) and its extension with Pythagorean fuzzy sets. Saf Sci. 2018;108:173–187. doi: 10.1016/j.ssci.2018.04.031. [DOI] [Google Scholar]

- Krstić M, Tadić S, Kovač M et al (2021) A novel hybrid MCDM model for the evaluation of sustainable last mile solutions. Math Probl Eng 2021.10.1155/2021/5969788

- Kuo RJ, Chi SC, Kao SS. A decision support system for selecting convenience store location through integration of fuzzy AHP and artificial neural network. Comput Ind. 2002;47:199–214. doi: 10.1016/S0166-3615(01)00147-6. [DOI] [Google Scholar]

- Lescauskiene I, Bausys R, Zavadskas EK, Juodagalviene B. VASMA weighting: survey-based criteria weighting methodology that combines ENTROPY and WASPAS-SVNS to reflect the psychometric features of the VAS scales. Symmetry (basel) 2020;12:1641. doi: 10.3390/sym12101641. [DOI] [Google Scholar]

- Li N, Zhang H, Zhang X, Ma X, Guo S (2020) How to select the optimal electrochemical energy storage planning program? A hybrid MCDM method. Energies 13(4):931. 10.3390/en13040931

- Liu P, Hendalianpour A, Hamzehlou M, Feylizadeh MR, Razmi J (2021) Identify and rank the challenges of implementing sustainable supply chain blockchain technology using the Bayesian best worst method. Technol Econ Dev Econ 27(3):656–680. 10.3846/tede.2021.14421

- Ljubičić H, Pavlović J (2015) Urban logistics systems and night goods delivery. In: 2nd Logistics International Conference. p 321

- Mangiaracina R, Perego A, Seghezzi A, Tumino A. Innovative solutions to increase last-mile delivery efficiency in B2C e-commerce: a literature review. Int J Phys Distrib Logist Manag. 2019;49:901–920. doi: 10.1108/IJPDLM-02-2019-0048/FULL/PDF. [DOI] [Google Scholar]

- Mirzaei E, Minatour Y, Bonakdari H, Javadi AA. Application of interval-valued fuzzy analytic hierarchy process approach in selection cargo terminals, a case study. Int J Eng Trans A. 2015;28:387–395. doi: 10.5829/IDOSI.IJE.2015.28.03C.07. [DOI] [Google Scholar]

- Mohammadi M, Rezaei J. Bayesian best-worst method: a probabilistic group decision making model. Omega (westport) 2020;96:102075. doi: 10.1016/J.OMEGA.2019.06.001. [DOI] [Google Scholar]

- Ostermeier M, Heimfarth A, Hübner A. Cost-optimal truck-and-robot routing for last-mile delivery. Networks. 2022;79:364–389. doi: 10.1002/NET.22030. [DOI] [Google Scholar]

- Özdaǧoǧlu A (2011) A multi-criteria decision-making methodology on the selection of facility location: fuzzy ANP. The International Journal of Advanced Manufacturing Technology 2011 59:5 59:787–803. 10.1007/S00170-011-3505-1

- Pan S, Zhang L, Thompson RG, Ghaderi H. A parcel network flow approach for joint delivery networks using parcel lockers. Int J Prod Res. 2021;59:2090–2115. doi: 10.1080/00207543.2020.1856440. [DOI] [Google Scholar]

- Peker I, Baki B, Tanyas M, Murat Ar I. Logistics center site selection by ANP/BOCR analysis: a case study of Turkey. Journal of Intelligent & Fuzzy Systems. 2016;30:2383–2396. doi: 10.3233/IFS-152007. [DOI] [Google Scholar]

- Peppel M, Spinler S (2021) The impact of optimal parcel locker locations on costs and the environment. 10.1108/IJPDLM-07-2021-0287

- Rezaei J. Best-worst multi-criteria decision-making method. Omega (westport) 2015;53:49–57. [Google Scholar]

- Roig-Tierno N, Baviera-Puig A, Buitrago-Vera J, Mas-Verdu F. The retail site location decision process using GIS and the analytical hierarchy process. Appl Geogr. 2013;40:191–198. doi: 10.1016/J.APGEOG.2013.03.005. [DOI] [Google Scholar]

- Saner HS, Yucesan M, Gul M. A Bayesian BWM and VIKOR-based model for assessing hospital preparedness in the face of disasters. Nat Hazards. 2022;111:1603–1635. doi: 10.1007/s11069-021-05108-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Simić V, Lazarević D, Dobrodolac M. Picture fuzzy WASPAS method for selecting last-mile delivery mode: a case study of Belgrade. Eur Transp Res Rev. 2021;13:1–22. doi: 10.1186/S12544-021-00501-6/TABLES/4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh RK, Chaudhary N, Saxena N. Selection of warehouse location for a global supply chain: A case study. IIMB Manag Rev. 2018;30:343–356. doi: 10.1016/J.IIMB.2018.08.009. [DOI] [Google Scholar]

- Source I, Corporation IP (2020) International Post Corporation : E-Commerce & Parcel Lockers

- State Post Bureau of the People’s Republic of China (2020) Statistical Bulletin on the Development of the Postal Industry in PRC in 2019

- Svadlenka L, Simic V, Dobrodolac M, et al. Picture Fuzzy Decision-Making Approach for Sustainable Last-Mile Delivery. IEEE Access. 2020;8:209393–209414. doi: 10.1109/ACCESS.2020.3039010. [DOI] [Google Scholar]

- Tolga CA, Tuysuz F, Kahraman C. A fuzzy multi-criteria decision analysis approach for retail location selection. Int J Inf Technol Decis Mak. 2013;12:729–755. doi: 10.1142/S0219622013500272. [DOI] [Google Scholar]

- Tsai YT, Tiwasing P. Customers’ intention to adopt smart lockers in last-mile delivery service: A multi-theory perspective. Journal of Retailing and Consumer Services. 2021;61:102514. doi: 10.1016/J.JRETCONSER.2021.102514. [DOI] [Google Scholar]

- Tu CS, Chen KK, Ter CC, Lu HA. Applying an AHP - QFD conceptual model and zero-one goal programming to requirement-based site selection for an airport cargo logistics center. Int J Inf Manage Sci. 2010;21:407–430. [Google Scholar]

- Tumsekcali E, Ayyildiz E, Taskin A. Interval valued intuitionistic fuzzy AHP-WASPAS based public transportation service quality evaluation by a new extension of SERVQUAL Model: P-SERVQUAL 4.0. Expert Syst Appl. 2021;186:115757. doi: 10.1016/J.ESWA.2021.115757. [DOI] [Google Scholar]

- Urosevic S, Karabasevic D, Stanujkic D, Maksimovic M (2017) An approach to personnel selection in the tourism industry based on the SWARA and the WASPAS methods. Econ Comput Econ Cybern Stud Res 51:

- Vakulenko Y, Hellström D, Hjort K. What's in the parcel locker? Exploring customer value in e-commerce last mile delivery. J Bus Res. 2018;88:421–427. doi: 10.1016/j.jbusres.2017.11.033. [DOI] [Google Scholar]

- Wang CN, Nguyen NAT, Dang TT, Hsu HP. Evaluating sustainable last-mile delivery (LMD) in B2C e-commerce using two-stage fuzzy MCDM approach: a case study from Vietnam. IEEE Access. 2021;9:146050–146067. doi: 10.1109/ACCESS.2021.3121607. [DOI] [Google Scholar]

- Yager RR (2013) Pythagorean fuzzy subsets. In: Proceedings of the 2013 Joint IFSA World Congress and NAFIPS Annual Meeting, IFSA/NAFIPS 2013. pp 57–61

- Yang JJ, Lo HW, Chao CS, Shen CC, Yang CC (2020) Establishing a sustainable sports tourism evaluation framework with a hybrid multi-criteria decision-making model to explore potential sports tourism attractions in Taiwan. Sustainability 12(4):1673. 10.3390/su12041673

- Yildiz A, Ayyildiz E, Gumus AT, Ozkan C. A modified balanced scorecard based hybrid pythagorean fuzzy AHP-Topsis methodology for ATM site selection problem. Int J Inf Technol Decis Mak. 2020;19:365–384. doi: 10.1142/S0219622020500017. [DOI] [Google Scholar]

- Zavadskas EK, Turskis Z, Antucheviciene J, Zakarevicius A. Optimization of weighted aggregated sum product assessment. Elektronika Ir Elektrotechnika. 2012;122:3–6. doi: 10.5755/j01.eee.122.6.1810. [DOI] [Google Scholar]

- Zavadskas EK, Bausys R, Mazonaviciute I. Safety evaluation methodology of urban public parks by multi-criteria decision making. Landsc Urban Plan. 2019;189:372–381. doi: 10.1016/j.landurbplan.2019.05.014. [DOI] [Google Scholar]

- Zhou M, Zhao L, Kong N, Campy KS, Xu G, Zhu G, ..., Wang S (2020) Understanding consumers’ behavior to adopt self-service parcel services for last-mile delivery. Journal of Retailing and Consumer Services, 52, 101911

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.

Not applicable.