Significance

Insect wings present striking examples of automatic shape morphing in both nature and technology, the mechanisms of which are not fully understood. Here, we present a new discovery from wings of a flying beetle that can shed light on wing shape changes in flight: an unusual bell-shaped structure, which is compliant in one direction and almost 10 times stiffer in the opposite direction. Our results show that the structure is an effective one-way hinge that achieves functionality using a single material with no extra mass. The use of the insect-inspired hinge in applications, including easily assemblable modular designs, adaptive airless tires, and metamaterials with zero Poisson’s ratio, suggests that the structure can have biomimetic applications over a considerable size range.

Keywords: wing, flight, flexion line, compliant joint, shape morphing

Abstract

Insect wings are deformable airfoils, in which deformations are mostly achieved by complicated interactions between their structural components. Due to the complexity of the wing design and technical challenges associated with testing the delicate wings, we know little about the properties of their components and how they determine wing response to flight forces. Here, we report an unusual structure from the hind-wing membrane of the beetle Pachnoda marginata. The structure, a transverse section of the claval flexion line, consists of two distinguishable layers: a bell-shaped upper layer and a straight lower layer. Our computational simulations showed that this is an effective one-way hinge, which is stiff in tension and upward bending but flexible in compression and downward bending. By systematically varying its design parameters in a computational model, we showed that the properties of the double-layer membrane hinge can be tuned over a wide range. This enabled us to develop a broad design space, which we later used for model selection. We used selected models in three distinct applications, which proved that the double-layer hinge represents a simple yet effective design strategy for controlling the mechanical response of structures using a single material and with no extra mass. The insect-inspired, one-way hinge is particularly useful for developing structures with asymmetric behavior, exhibiting different responses to the same load in two opposite directions. This multidisciplinary study not only advances our understanding of the biomechanics of complicated insect wings but also informs the design of easily tunable engineering hinges.

The wings of insects are remarkable examples of complex microengineering. Unlike those of birds, bats and the extinct pterosaurs, insect wings lack internal muscles. Hence, the aerodynamically essential cyclical changes in shape and orientation that they undergo in flapping flight are semiautomatic. These changes result from elastic interactions between the structure of the wings and the aerodynamic and inertial forces they receive and are modulated remotely by muscular action at the wing base (1–5).

In simplest terms, typical wings consist of membrane supported by a shallow three-dimensional framework of tubular veins. However, both the detailed structural geometry and material properties vary around the wing in ways that are often highly nonlinear, so that deformations in flight—bending, torsion, alteration in section, and reversible buckling—can be caused by local lines or areas of asymmetric flexibility, patches and pads of elastomeric cuticle (2, 6–13), and also by internal mechanisms, such as planar levers (14–16). Further, the hind wings of beetles (Coleoptera), earwigs (Dermaptera), and a few cockroaches (Blattodea) fold up under the protective forewings when at rest. The folding and unfolding, often highly complex processes, again involve a combination of internal planar levers, cuticle elasticity, and simple basal muscular action (17, 18). Such mechanisms are usually extremely simple but sometimes have unexpected—even counterintuitive—effects. Butterflies and dragonflies, for example, use the asymmetric twisting response of thin cambered cantilevered plates when loaded behind the torsional axis to allow passive supination for the upstroke but minimal passive pronation in the downstroke (4, 19, 20).

In this paper, inspired by a detail in an insect wing, we describe and analyze what may be another such simple, unexpected mechanism. We believe that the mechanism can have potential applications in the design of novel structures and metamaterials, and we give some examples of these.

An Asymmetric Hinge in a Double-Layer Membrane?

The wing membrane of adult insects is a double-layer structure. It is formed at the final molt by the juxtaposition, expansion, and toughening of the cuticle of the dorsal and ventral sides of the juvenile wing pads, with the elimination of the intervening hemolymph and cellular material. The membrane is continuous with the veins: hemolymph-filled tubes of variable cross-section with thickened walls that provide support for the wing (21, 22).

Fig. 1A is a transmission electron micrograph of a detail of the membrane of a hind wing of the scarabaeid beetle Pachnoda marginata (Drury 1773), a section of the claval flexion line, about which the wing profile changes cyclically in flight (1, 23) (see SI Appendix, Fig. S1 for magnified images and the position of the structure within the wing). The section is of a tube and is approximately triangular, with the ventral membrane forming a nearly straight lower side but the dorsal membrane forming an arch with a curved apex. The section has some similarity to those of the wing veins but is far smaller and differs from them in that the sides of the structure are structurally identical with the adjacent membrane, whereas wing veins normally have some parts of their walls thickened and stiffened by sclerotization. We believe it instead to be an asymmetric, linear hinge of a kind that seems not previously to have been analyzed. Three-dimensional (3D)-printed physical models show that such a structure distorts readily when bent downward but is resistant to upward bending (Fig. 1B and SI Appendix, Movie S1).

Fig. 1.

Double-layer membrane; microscopy and basic physical testing. (A) Transmission electron micrograph of the double-layer membrane from the hind wing of the beetle Pachnoda marginata. (B) Physical testing of a 3D-printed, double-layer membrane. The structure is compliant in downward bending but stiff in upward bending. Scale bars: 5 μm (A) and 2 cm (B).

We have investigated and characterized the biomechanics of the structure using a combination of multidisciplinary approaches, including microscopy techniques, parametric modeling, computational simulations, 3D printing, and mechanical testing. We have studied the effects of the structural and material properties and have examined some possible biomimetic applications.

Results

The micrograph of the unusual double-layer structure is presented in Fig. 1A. The upper and lower layers separate for a linear distance of 20 µm, with one—the “upper” for reference—forming a bell-shaped curve of 36 µm length, while the lower component is nearly straight. Each layer is ∼1.37 µm thick. The upper layer shows creases at the vertex and one curved side. The creases, which may be the result of the sectioning, suggest that the walls are flexible and could crease during wing deformation.

To understand the potential biomechanical advantages of the double-layer membrane over the typical single-layer membrane, we performed a computational study. We developed two models with the same volume: a double-layer membrane model based on the microscopic observations described earlier and a single-layer membrane model, in which the two layers are merged. We subjected the models to an equal force in bending, both upward and downward, and in axial loading, both compression and tension (Fig. 2). We used the simulation data to compare the displacements of the models in each loading. We noticed that both the double-layer and single-layer models showed an asymmetric response to loads in two opposite directions (i.e., downward bending vs. upward bending and compression vs. tension) (Fig. 2A; see SI Appendix, Fig. S2 for the stresses developed within the models). Asymmetry was defined as the ratio of the displacement in downward bending to the displacement in upward bending and as the ratio of the displacement in compression to the displacement in tension. The strongest asymmetric response of both models was observed in axial loading, with displacements in compression being larger than those in tension. The asymmetric response was noticeably stronger in the double-layer membrane model; this model showed an asymmetry of 9.3 in axial loading and 2.2 in bending, in contrast to 2.1 times and 1.5 times asymmetry recorded for the single-layer model for the same comparisons, respectively.

Fig. 2.

Results of the computational study. (A and B) Quantitative (A) and qualitative (B) comparisons of the asymmetric response of the double-layer and single-layer membrane models (down/up asymmetry: displacement in downward bending to displacement in upward bending; compression/tension: displacement in compression to displacement in tension). The results are presented for both down/up and compression/tension asymmetric responses. (C) Influence of the design parameters on the asymmetric response of the double-layer membrane model. The Right panels show the design parameters and how they were varied among the models. The intensity of the colors in the lowermost row of the Right panels indicates the relative elastic modulus of the layers, with darker color (black) representing the highest elastic moduli and the brighter color (white) representing the lowest elastic modulus. For the sake of presentation, two outlier data points (from upper-layer width model 2 and lower-layer thickness model −2) have been removed from the plot in C.

Applying a load to the double-layer membrane model from below (i.e., upward bending) put the lower, nearly straight layer into tension. There was minimal distortion of the curved upper layer, so that the structure acted as a rigid tube. Loading from above (i.e., downward bending), however, caused the lower layer to bend into the lumen of the tube, pulling the sides together (Fig. 2B). Under tension, the double-layer membrane model underwent minor stretching with no noticeable shape change. In contrast, the deformations were notably larger in compression under the same force. This was caused by the collapse of both the upper and the lower layers under compression (Fig. 2B). The slight curvature of the lower layer gave a predisposition to downward buckling when the double-layer membrane was loaded in compression.

To characterize the influence of the structure and material of the double-layer structure on its asymmetric behavior, we performed a set of computational simulations. We varied the design parameters of our double-layer membrane model and developed 28 extra models with distinct structural/material properties (Fig. 2C). The design parameters varied among the models are shown in the right-hand side panel in Fig. 2C. The left-hand side panel presents the compression/tension asymmetry versus the downward/upward asymmetry for each model set. Here, for example, when the height of the upper layer was increased (triangle symbol), the downward/upward asymmetry decreased from 2.5 to 1.6, whereas the compression/tension asymmetry increased from 4.5 to 11.

The results showed the strong influence of the design parameters on the behavior of the model. The width of the bell-shaped curve, here referred to as “upper layer width”, and the thickness of the upper layer had the strongest influence on the downward/upward asymmetry of the models (i.e., displacement in downward bending in comparison to upward bending). Changing the width of the upper layer by ∼3.5 times resulted in approximately four times increase in the downward/upward asymmetry. Likewise, increasing the thickness of the upper layer by three times led to approximately three times increase in the downward/upward asymmetry. On the other hand, the strongest control over the compression/tension asymmetry of the models (i.e., displacement in compression to that in tension) was achieved through simultaneous manipulation of the thickness of both the upper and lower layers. Increasing the thickness of the two layers by three times reduced the compression/tension asymmetry by approximately five times.

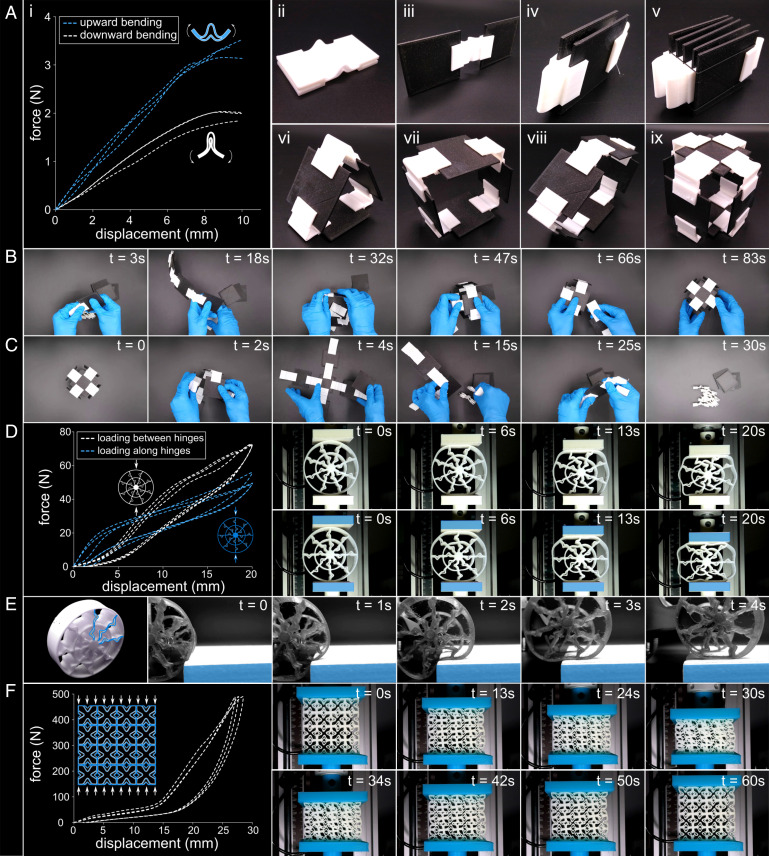

We also tested the performance of the double-layer hinge in application. The first application was a modular structure, in which double-layer membrane models were used as compliant one-way hinges. Considering that the hinges had to be bent in downward bending but resist upward bending, we could choose among many models in the upper half-plane of the graph shown in Fig. 2C. However, we decided to use a model with an increased lower-layer height, as we wanted to rely only on the structural strategies and minimize the use of material in our 3D-printed parts. We fabricated the selected model using 3D printing and characterized its performance under loading (Fig. 3A, i and ii and SI Appendix, Movie S2). The model appeared to be particularly suitable for this application, enabling us to easily assemble any number of modules, fold them on each other, and further form a variety of geometric shapes (Fig. 3A, iii–ix). This was facilitated by the flexibility of the hinges when bent downward, enabling them to remain in a deformed state with minimal forces. Fig. 3 B and C and SI Appendix, Movie S3 show the disassembly and assembly processes of the modular cube in Fig. 3A, ix.

Fig. 3.

Double-layer hinge in application. (A) Double-layer membrane as a compliant hinge in modular designs. The structure used in these examples exhibited a desirable bending asymmetry (A, i). Taking advantage of the asymmetric behavior of the double-layer membrane hinge, we used that to connect a series of square plates and fold them in various ways (A, ii–v) and also form a variety of geometric shapes (A, vi–ix). (B) Assembly of the modular design shown in A, ix. (C) Disassembly of the modular design shown in A, ix. (D and E) Using the double-layer hinge in an adaptive airless tire. The tire was tested in compression between two rigid plates (D). The loading was applied in two orientations: between the hinges (upper row) and along the hinges (lower row). (F) Using the double-layer hinge in a metamaterial with a zero Poisson’s ratio. The metamaterial was tested in compression, and the results were used to characterize its mechanical behavior in loading (Upper row) and unloading (Lower row).

In the second application, we implemented a double-layer hinge model in an airless tire (Fig. 3 D and E). We used a hinge with an increased lower-layer height in comparison to the reference model. This was because the deformations of the inner compliant hinges are caused by both axial forces and bending moments, depending on the direction of contact. Hence, we required hinges that could offer a compromise between load bearing and deformability in compression and downward bending but a reasonable resistance to upward bending. The hinges were radially oriented within an airless tire, which was fabricated using 3D printing and then tested in compression, both along the direction of the hinges and between them (Fig. 3D and SI Appendix, Movie S4). We also tested the tire in application; in contact with an obstacle, the tire underwent limited deformation and adapted to the obstacle (Fig. 3E), a process that can increase the stability and controllability of vehicles.

We also used a double-layer hinge model to develop a metamaterial with zero Poisson’s ratio. We developed metamaterials that consisted of unit cells in form of squares and used double-layer membrane models with increased lower-layer height at the edges of each square. This enabled us to develop a metamaterial that can collapse under compression with no or only minor transverse deformation (Fig. 3F and SI Appendix, Movie S5). As seen in Fig. 3F, the metamaterial exhibited two distinct stiffness regimes: a low-stiffness regime up to 15 mm displacement, during which the hinges collapsed under compression, and a high-stiffness regime just after that, during which the adjacent hinges interlocked. When the pressure was removed, the material returned to its initial state with no apparent plastic deformation.

Discussion

One-way hinges and asymmetric bending and twisting are widespread in insect wings (1, 2, 12, 19, 24–27). They operate in flight, allowing the wings to deform automatically and asymmetrically between the upstroke and the downstroke and also in controlling the precise, complex patterns of folding and unfolding in the hind wings of beetles (Coleoptera) and of earwigs (Dermaptera) (17, 18, 28, 29). The mechanisms often involve specific areas of elasticity within the wing cuticle, sometimes including lines or patches of the protein elastomer resilin (6, 30–34), but other examples depend on reversible thin-plate buckling, in which the shape and height as well as the elastic properties of the wing section are of major importance (1, 8, 15, 19). The double-layer membrane structure described here can fit into the latter category. Our real-scale computational simulations and up-scaled physical modeling confirmed the original hypothesis that the double-layer membrane can act as a one-way hinge, stiff in tension and upward bending but unstable in compression and downward bending. The structure is unique in its simplicity; the double-layer membrane can achieve functionality using a single material and requiring almost no extra mass.

The asymmetric response of the double-layer membrane is a geometric nonlinearity effect, which results from changes in the geometric configuration of the structure under loading. The reason for the stronger asymmetric response of the double-layer membrane in comparison with the single-layer membrane is that such configuration changes increase the resistance of the double-layer membrane to displacements in one direction but decrease the resistance to displacements in the opposite direction. This effect is noticeably smaller in the single-layer membrane. Considering that the geometric nonlinearity occurs under large deformations, it is likely that both the double- and single-layer membrane structures show symmetric behavior for small deformations.

Our computational analyses showed that the structural and material properties, here referred to as “design parameters”, have a strong influence on the mechanical behavior, particularly on the asymmetry, of the double-layer membrane hinge. This means that the design parameters can be used to tune the properties of the structure in a wide range. This characteristic enabled us to develop a broad design space, which later facilitated the process of model selection. Furthermore, the design parameters influenced the asymmetric response of the models to different extents. For example, the width of the upper membrane appeared to impact the down/up asymmetry more than any other design parameter. The design parameters also exhibited different impacts on the asymmetric response of the double-layer membrane in two orthogonal directions tested here, i.e., down/up versus compression/tension. Our findings, therefore, suggest that, to obtain desired properties in an application, the design parameters should be carefully chosen, as any design parameter allows tuning the properties within a certain range and in a specific direction.

An interesting observation is the formation of an interlocking effect in some double-layer membranes. This effect results from the physical contact between the upper and lower layers and can be seen mostly in models with small upper-layer heights. When the interlocking takes place, the hinge cannot be closed, and thereby its stiffness increases (SI Appendix, Fig. S3). This effect can be used, for example, to develop bioinspired compliant hinges with a “closing limit”. There are also a few other mechanisms for interlocking in insect wings, including joint-associated spikes (14, 31, 35) and nodus (12, 34, 36), which are situated on the wing and therefore can be more easily examined. These mechanisms prevent detrimental deformations in certain wing areas and by that play a key role in insect flight efficiency. The discovery of the double-layer membrane hinge suggests that there might be other, yet undiscovered mechanisms hidden in the wing design.

Double-layered membranes are not uncommon in nature. The phospholipid bilayers that surround all living cells are a particularly active area of study. Synthetic lipid bilayers have proven to be a useful tool in investigating their properties on the nanometer scale, and Lu et al. (37) have used these to model membranes whose layers have different properties. Double membranes also have technological applications. For example, Zuo et al. (38) have combined layers with different properties and dimensions to develop dual-membrane hollow fibers for vacuum membrane distillation in desalination processes.

Our manufactured models showed the effectiveness of the discovered double-layer hinge in applications. Generally, the double-layer membrane can be used where a structure should undergo large deformations only in a certain direction and/or when it should exhibit different but tunable stiffness levels in opposite directions. The deformability in combination with high tunability makes the double-layer hinge particularly interesting for designing adaptive structures, such as the airless tire developed here. The structure is also particularly suitable for providing asymmetric deformations, where properties in two opposite directions drastically differ. This is a desirable property for development of shape-morphing systems that should resist loads in a certain direction but need to be compliant in a different direction. In metamaterials, as shown here, the double-layer membrane can give rise to potentially unique properties, for example, by locally varying the stiffness of the material.

Two directions for future research are particularly worth following. First, studies should test the scalability of the double-layer membrane hinge. Scalability is a reasonable concern when translating small-scale biological strategies into engineering applications. Recent studies have tested and verified the scalability of some of the wing-derived strategies. A few examples include the development of durable kites, stiffness-varying splints, insect-inspired wings for medium-sized flapping-wing drones, airplane wing models and origami arms that resist collisions by undergoing reversible buckling, extensible robotic arms, confined-space crawling robots, and unlockable revolute joints (27, 39–46). Based on our results, the double-layer membrane can work at different scales, but its effectiveness will clearly depend on overall size, relative wall thickness and section shape, and the properties of the material. It is necessary to understand whether and how the relationship between the geometry and functionality of the double-layer membrane would change by changing the scale. It is possible that, for larger objects, the problem of strength may arise, while using stronger materials can be limited by required large deformations. Second, future research should focus on identifying other factors that might influence the behavior of the double-layer membrane. For example, in real insect wings, there might be a hydraulic dimension involved. If this is the case, any fluid in the double-layer membrane would strongly influence the operation of the system, particularly in downward bending, during which the internal volume would be reduced. Future works will shed more light on both the functionality and biomimetic applications of the double-layer membrane hinge and its presence in other insect wings.

SI Appendix, Video S6 summarizes our study in a short video.

Conclusion

In this paper, we reported a double-layer membrane structure in the wings of Pachnoda beetles. Despite its remarkable simplicity, we cannot find that it has previously been described. We showed that the structure works as a one-way hinge, the functionality of which may rely on reversable buckling of thin sheets and plates that insects use very effectively.

This study is important for two distinct reasons. First, the results advance our understanding of the biomechanics of insect wings. The previously undescribed structure potentially contributes to automatic shape changes of insect wings in flight, although the extent of the contribution still needs further evaluation. Second, the biological one-way hinge described here offers biomimetic inspiration for the design and development of engineering structures that exhibit asymmetric responses to equal forces applied in different directions. This is particularly interesting because the double-layer membrane offers a simple, inexpensive way of making a one-way hinge without increasing the mass.

Methods

Microscopic Analysis of the Wing Membrane.

The detail illustrated in Fig. 1A was discovered in the course of an unpublished investigation into the microstructure and ultrastructure of the hind wing of the beetle Pachnoda marginata. Elements of the wing were fixed in 3% glutaraldehyde in sodium cacodylate buffer, embedded in Spurr’s resin (Sigma-Aldrich), sectioned with a diamond knife, and examined and photographed with a JEOL 100S transmission electron microscope.

Investigation of the Structure-Material Mechanics of the Double-Layer Hinge.

We used computational modeling to investigate the mechanical behavior of the double-layer membrane structure in its original scale. A computational approach was chosen, as it enabled us to systematically alter the structural and material properties of the double-layer membrane and test their influence on its response to applied loads. The models were developed using the state-of-the-art parametric modeling tool Grasshopper 3D (Rhino). First, we developed a model inspired by the double-layer hinge shown in Fig. 1. Next, to assess the advantage of the double-layer membrane over the typical single-layer membrane structure, we developed a second model in which we shifted the upper and lower layers toward the midline of the double-layer membrane model and merged them together. Both the “double-layer membrane model” and the “single-layer membrane model” had the same volume. We have added both the models as the SI Appendix.

We then systematically changed the design parameters of the double-layer model, including the height, thickness, and width of the upper layer; the height and thickness of the lower layer; and the thickness of the upper and lower layers at the same time. We also changed the material properties of the upper and lower layers. This enabled us to develop 28 extra models, which we used to establish a link between the design and performance of the double-layer membrane structure. See SI Appendix for the individual models (SI Appendix, Dataset S1) and the full parametric model (SI Appendix, Dataset S2).

After modeling, we then exported the models to the commercial finite-element software package ABAQUS (Simulia) for the analysis. We assigned the same properties to the models, except for the models that were designed to test the effect of the material properties. Assigning the same properties to the models enabled us to obtain results that were only influenced by the geometry of the models. For our models, we used the same material properties as those reported for the wing membrane of the desert locust (47, 48). These included an elastic modulus of 1.86 GPa, a density of 1,200 kg/m3, and a Poisson’s ratio of 0.3. The models were assumed to be homogeneous and isotropic. The same approach was applied to the models with altered material properties. The only difference was that, in these models, we once reduced the elastic modulus of the upper layer and then that of the lower layer each in two steps from 1.86 GPa to 0.93 GPa and then to 0.47 GPa.

We meshed the models using the general-purpose, eight-node brick elements with reduced integration (C3D8R) with second-order accuracy. A reduced integration scheme was used to reduce the computational runtime. Using the hourglass control and distortion control prevented detrimental mesh distortions. We then subjected the models to four loading scenarios: tension, compression, upward bending, and downward bending. In all scenarios, the displacements and rotations of the models were fixed at the uppermost point of their axis of symmetry. The models were subjected to an equal force (2.4 mN) at their free ends. We then measured the displacements of the models and recorded their deformation patterns. We used the results to investigate the mechanical behavior of the models under each loading scenario and compare among them.

Using the Double-Layer Hinge in Applications.

To test the performance of the double-layer hinge models in application, we used them in three distinct designs. First, we used a set of similar double-layer membrane models as compliant joints in a modular design, where they were used to connect a series of stiff, flat plates together at their edges. In this application, the models were used as one-way hinges by which we could fold the flat plates on each other and further form a variety of geometric shapes. Second, we combined the double-layer hinge models in an airless tire. The models were situated along the radius of the tire. The double-layer membranes were intended to enable the tire to deform and adapt to uneven surfaces. In the third application, we employed a combination of the double-layer membrane models to develop a two-dimensional metamaterial. The metamaterial consisted of square-shaped unit cells, where each edge of the squares is formed by a double-layer hinge model. The metamaterial was intended to collapse under compression in one direction without being deformed in the perpendicular direction, i.e., behaving as a zero Poisson’s ratio material.

The models for the applications were developed using Rhino and manufactured by 3D printing. We used 3D printing, because it is a cost- and time-efficient prototyping method that allows manufacturing of complicated models as those developed here. We used a Raise3D E2 3D printer, as this is a high-precision 3D printer that is compatible with the thermoplastic polyurethane (TPU) used for manufacturing of the models. The TPU (Sunlu filament, 1.75-mm diameter) was selected as the building material, because of its high elasticity and toughness, which enabled us to develop deformable parts.

Prior to 3D printing, the stl./obj. files of the models (available as SI Appendix, Dataset S3) were exported to the 3D slicing software IdeaMaker (Raise3D), where they were prepared for manufacturing. Here, the models were rescaled and reoriented. Considering the geometry of the models and their relatively thin walls, no support or infill was added. After slicing the models, the gcodes were extracted and prints were done at a layer height of 0.2 mm, nozzle temperature of 200 °C, bed temperature of 60 °C, and print speed of 40 mm/s. No postprocessing was performed on the 3D-printed parts.

To characterize the mechanical performance of the manufactured parts, we tested them under loading. Mechanical tests were performed using a universal testing machine (1ST, Tinius Olsen) equipped with a 500N loadcell. Specifically, we tested the hinge used in the modular designs in three-point bending (SI Appendix, Movie S2) and both the airless tire and the metamaterial in compression between two flat plates (SI Appendix, Movies S4 and S5). The hinge and the tire were subjected to 10-mm and 20-mm displacements, respectively. The displacement on the metamaterial was continued until the maximum capacity of the loadcell was reached. We tested at least three specimens of each part. All experiments were performed at an increasing displacement of 1 mm/s. The data from the experiments, including force, displacement, and time, were continuously recorded using the software Horizon (Tinius Olsen) and are available as SI Appendix (SI Appendix, Dataset S4). We also recorded the tests using a digital camera (SONY RX100vi).

Supplementary Material

Acknowledgments

The authors would like to thank Mr. Shayan Ramzanpour for his support with computational analysis. We are grateful to our three anonymous reviewers for their insightful suggestions and invaluable comments. This project was partially supported by the London South Bank University Mechanical Engineering and Design’s Seed Funding to A.K.

Footnotes

The authors declare no competing interest.

This article is a PNAS Direct Submission.

This article contains supporting information online at https://www.pnas.org/lookup/suppl/doi:10.1073/pnas.2211861119/-/DCSupplemental.

Data, Materials, and Software Availability

The authors declare that the data supporting the findings of this study are available within the paper and its SI Appendix files. SI Appendix are additionally available via the following link: https://figshare.com/s/bb7ba43b371cfb7aaf63.

[Supplemental Datasets] data have been deposited in [Figshare] (https://figshare.com/s/bb7ba43b371cfb7aaf63) (49). All other data are included in the manuscript and/or supporting information.

References

- 1.Wootton R. J., Support and deformability in insect wings. J. Zool. 193, 447–468 (1981). [Google Scholar]

- 2.Wootton R. J., Functional morphology of insect wings. Annu. Rev. Entomol. 37, 113–140 (1992). [Google Scholar]

- 3.Brodsky A. K., The Evolution of Insect Flight (Oxford University Press, 1994). [Google Scholar]

- 4.Wootton R. J., Newman D. J., Dragonflies & Damselflies: Model Organisms for Ecological and Evolutionary Research, Córdoba-Aguilar A., Ed. (Oxford University Press, 2008), pp. 261–274. [Google Scholar]

- 5.Rajabi H., Gorb H. S. N., How do dragonfly wings work? A brief guide to functional roles of wing structural components. Int. J. Odonatol. 23, 23–30 (2020). [Google Scholar]

- 6.Gorb S. N., Serial elastic elements in the damselfly wing: Mobile vein joints contain resilin. Naturwissenschaften 86, 552–555 (1999). [DOI] [PubMed] [Google Scholar]

- 7.Wootton R. J., “Wings” in Encyclopedia of Insects, Resh V. H., Cardé R. T., Eds. (Academic Press, 2009), pp. 1055–1061. [Google Scholar]

- 8.Wootton R., The geometry and mechanics of insect wing deformations in flight: A modelling approach. Insects 11, 446 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Appel E., Gorb S. N., Comparative Functional Morphology of Vein Joints in Odonata (Schweizerbart Science Publishers, 2014). [Google Scholar]

- 10.Fauziyah S., Alam C., Soesilohadi R. C. H., Retnoaji B., Alam P., Morphological and mechanical characterisation of the hindwing nodus from the Libellulidae family of dragonfly (Indonesia). Arthropod Struct. Dev. 43, 415–422 (2014). [DOI] [PubMed] [Google Scholar]

- 11.Rajabi H., Ghoroubi N., Darvizeh A., Appel E., Gorb S. N., Effects of multiple vein microjoints on the mechanical behaviour of dragonfly wings: Numerical modelling. R. Soc. Open Sci. 3, 150610 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Rajabi H., Ghoroubi N., Stamm K., Appel E., Gorb S. N., Dragonfly wing nodus: A one-way hinge contributing to the asymmetric wing deformation. Acta Biomater. 60, 330–338 (2017). [DOI] [PubMed] [Google Scholar]

- 13.Mamat-Noorhidayah, Yazawa K., Numata K., Norma-Rashid Y., Morphological and mechanical properties of flexible resilin joints on damselfly wings (Rhinocypha spp.). PLoS One 13, e0193147 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Newman D. J., The functional wing morphology of some Odonata (Doctoral dissertation, University of Exeter, Exeter (1982).

- 15.Ennos A. R., A comparative study of the flight mechanism of Diptera. J. Exp. Biol. 127, 355–372 (1987). [Google Scholar]

- 16.Ennos A. R., The importance of torsion in the design of insect wings. J. Exp. Biol. 140, 137–160 (1988). [Google Scholar]

- 17.Haas F., Wootton R. J., Two basic mechanisms in insect wing folding. Proc. Biol. Sci. 263, 1651–1658 (1996). [Google Scholar]

- 18.Haas F., Gorb S., Wootton R. J., Elastic joints in dermapteran hind wings: Materials and wing folding. Arthropod Struct. Dev. 29, 137–146 (2000). [DOI] [PubMed] [Google Scholar]

- 19.Wootton R. J., Leading edge section and asymmetric twisting in the wings of flying butterflies (Insecta, Papilionoidea). J. Exp. Biol. 180, 105–119 (1993). [Google Scholar]

- 20.Ennos A. R., Mechanical behaviour in torsion of insect wings, blades of grass, and other cambered structures. Proc. Biol. Sci. 259, 15–18 (1995). [Google Scholar]

- 21.Pass G., Beyond aerodynamics: The critical roles of the circulatory and tracheal systems in maintaining insect wing functionality. Arthropod Struct. Dev. 47, 391–407 (2018). [DOI] [PubMed] [Google Scholar]

- 22.Salcedo M. K., Socha J. J., Circulation in insect wings. Integr. Comp. Biol. 60, 1208–1220 (2020). [DOI] [PubMed] [Google Scholar]

- 23.Wootton R. J., Function, homology and terminology in insect wings. Syst. Entomol. 4, 81–93 (1979). [Google Scholar]

- 24.Wootton R. J., Ennos A. R., The implications of function on the origin and homologies of the dipterous wing. Syst. Entomol. 14, 507–520 (1989). [Google Scholar]

- 25.Combes S. A., Daniel T. L., Flexural stiffness in insect wings. I. Scaling and the influence of wing venation. J. Exp. Biol. 206, 2979–2987 (2003). [DOI] [PubMed] [Google Scholar]

- 26.Toofani A., et al. , Biomechanical strategies underlying the durability of a wing-to-wing coupling mechanism. Acta Biomater. 110, 188–195 (2020). [DOI] [PubMed] [Google Scholar]

- 27.Eraghi S. H., et al. , Wing coupling in bees and wasps: From the underlying science to bioinspired engineering. Adv. Sci. (Weinh.) 8, e2004383 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Haas F., Beutel R. G., Wing folding and the functional morphology of the wing base in Coleoptera. Zoology (Jena) 104, 123–141 (2001). [DOI] [PubMed] [Google Scholar]

- 29.Saito K., Nomura S., Yamamoto S., Niiyama R., Okabe Y., Investigation of hindwing folding in ladybird beetles by artificial elytron transplantation and microcomputed tomography. Proc. Natl. Acad. Sci. U.S.A. 114, 5624–5628 (2017). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Haas F., Gorb S., Blickhan R., The function of resilin in beetle wings. Proc. Biol. Sci. 267, 1375–1381 (2000). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Donoughe S., Crall J. D., Merz R. A., Combes S. A., Resilin in dragonfly and damselfly wings and its implications for wing flexibility. J. Morphol. 272, 1409–1421 (2011). [DOI] [PubMed] [Google Scholar]

- 32.Mountcastle A. M., Combes S. A., Biomechanical strategies for mitigating collision damage in insect wings: Structural design versus embedded elastic materials. J. Exp. Biol. 217, 1108–1115 (2014). [DOI] [PubMed] [Google Scholar]

- 33.Rajabi H., Shafiei A., Darvizeh A., Gorb S. N., Resilin microjoints: A smart design strategy to avoid failure in dragonfly wings. Sci. Rep. 6, 39039 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Rajabi H., Stamm K., Appel E., Gorb S. N., Micro-morphological adaptations of the wing nodus to flight behaviour in four dragonfly species from the family Libellulidae (Odonata: Anisoptera). Arthropod Struct. Dev. 47, 442–448 (2018). [DOI] [PubMed] [Google Scholar]

- 35.Rajabi H., et al. , A comparative study of the effects of vein-joints on the mechanical behaviour of insect wings: I. Single joints. Bioinspir. Biomim. 10, 056003 (2015). [DOI] [PubMed] [Google Scholar]

- 36.Chen Y. H., Skote M., Zhao Y., Huang W. M., Dragonfly (Sympetrum flaveolum) flight: Kinematic measurement and modelling. J. Fluids Structures 40, 115–126 (2013). [Google Scholar]

- 37.Lu L., Doak W. J., Schertzer J. W., Chiarot P. R., Membrane mechanical properties of synthetic asymmetric phospholipid vesicles. Soft Matter 12, 7521–7528 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Zuo J., Chung T. S., O’Brien G. S., Kosar W., Hydrophobic/hydrophilic PVDF/Ultem dual-layer hollow fiber membranes with enhanced mechanical properties for vacuum membrane distillation. J. Membr. Sci. 523, 103–110 (2017). [Google Scholar]

- 39.Jayaram K., Full R. J., Cockroaches traverse crevices, crawl rapidly in confined spaces, and inspire a soft, legged robot. Proc. Natl. Acad. Sci. U.S.A. 113, E950–E957 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Mintchev S., Shintake J., Floreano D., Bioinspired dual-stiffness origami. Sci. Robot. 3, eaau0275 (2018). [DOI] [PubMed] [Google Scholar]

- 41.Phan H. V., Park H. C., Mechanisms of collision recovery in flying beetles and flapping-wing robots. Science 370, 1214–1219 (2020). [DOI] [PubMed] [Google Scholar]

- 42.Büsse S., Koehnsen A., Rajabi H., Gorb S. N., A controllable dual-catapult system inspired by the biomechanics of the dragonfly larvae’s predatory strike. Sci. Robot. 6, eabc8170 (2021). [DOI] [PubMed] [Google Scholar]

- 43.Khaheshi A., Tramsen H. T., Gorb S. N., Rajabi H., Against the wind: A load-bearing, yet durable, kite inspired by insect wings. Mater. Des. 198, 109354 (2021). [Google Scholar]

- 44.Khaheshi A., Gorb S. N., Rajabi H., Spiky-joint: A bioinspired solution to combine mobility and support. Appl. Phys. (Berl.) 127, 1–7 (2021). [Google Scholar]

- 45.Khaheshi A., Gorb S., Rajabi H., Triple stiffness: A bioinspired strategy to combine load-bearing, durability, and impact-resistance. Adv. Sci. (Weinh.) 8, e2004338 (2021c). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Saito K., et al. , Insect wing 3D printing. Sci. Rep. 11, 18631 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Dirks J. H., Taylor D., Veins improve fracture toughness of insect wings. PLoS One 7, e43411 (2012). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Rajabi H., Darvizeh A., Shafiei A., Taylor D., Dirks J. H., Numerical investigation of insect wing fracture behaviour. J. Biomech. 48, 89–94 (2015). [DOI] [PubMed] [Google Scholar]

- 49.H. Rajabi et al., An insect-inspired asymmetric hinge in a double-layer membrane. Figshare. https://figshare.com/s/bb7ba43b371cfb7aaf63. Deposited 10 July 2022. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The authors declare that the data supporting the findings of this study are available within the paper and its SI Appendix files. SI Appendix are additionally available via the following link: https://figshare.com/s/bb7ba43b371cfb7aaf63.

[Supplemental Datasets] data have been deposited in [Figshare] (https://figshare.com/s/bb7ba43b371cfb7aaf63) (49). All other data are included in the manuscript and/or supporting information.