Summary

From flexible electronics and multifunctional textiles to artificial tissues, polymers penetrate nearly every aspect of modern technology. High thermal conductivity of polymers is often required in their applications, where heat dissipation is crucial to maintain product reliability and functionality. However, the intrinsic thermal conductivity of bulk polymers is largely hindered by the randomly coiled and entangled chain conformation. Here, we report a copolymerization strategy that can simultaneously manipulate the intrachain and interchain hopping and increase the thermal conductivity of linear copolymerized polyimide (PI) to three times higher than that of pure PI at a low-level introduction of 2,4,5,7-tetraamino-1,8-dihydroxyanthracene-9,10-dione (10%). In addition, the large-scale copolymerized PI films display thermal stability after annealing. These remarkable results allow bulk PI to be a potential candidate for thermal management, and this copolymerization method may benefit future synthesis of interfacial thermal materials.

Subject areas: Polymer chemistry, Thermal property, Polymers

Graphical abstract

Highlights

-

•

A copolymerization method to fabricate large-sized and thermally stable PI films

-

•

The intrachain and interchain hopping in the copolymer can be simultaneously enhanced

-

•

Thermal conductivity of copolymerized PI films is about 3x higher than that in pure PI

Polymer chemistry; Thermal property; Polymers

Introduction

Polymers are generally considered thermal insulators and have a low thermal conductivity in a narrow range of 0.1–0.3 W m−1K−1, which significantly limits their applications, for example, wearable sensors and electronic encapsulation.1,2,3 To improve their thermal conductivity, conventional methods usually focus on polymer-based composites, i.e., to use fillers with high thermal conductivity, such as graphene, metal particles, and carbon nanotubes to enhance the thermal transport.4 However, the phonon mismatch between the fillers and the polymer matrix leads to a non-negligible interfacial thermal resistance.5 A large amount of fillers is often required to achieve the desired thermal conductivity, yet it can sacrifice the electrical insulation.6 Meanwhile, the poor contact between the fillers and the polymer matrix along with filler aggregation may be confronted with the composites and can deteriorate the mechanical strength.5 Therefore, the previous study to enhance filler content and decrease the thermal boundary resistance with less concentration on the thermal conductivity of the polymer matrix proves to be insufficient for composites with high thermal conductivity.7

Instead, a pioneering study shows that a single extended polyethylene chain has an ultrahigh thermal conductivity of ∼350 W m−1K−1 (exceeds most metals), motivating current interest in thermal manipulation in pure polymers.1,8,9,10,11,12 While strong intrachain hopping can greatly enhance the thermal conductivity in stretched polymer fibers or films, the coiled chains in bulk polymers bring more scattering centers, resulting in inefficient thermal transport and, hence, low thermal conductivity.13,14,15,16 For example, conjugated polymers are expected to be thermally conductive among various polymers as they possess stiff backbones and intermolecular π-π interactions, with the latter being approximately 10–100 times stronger than the van der Waals force.17,18 However, they also possess low thermal conductivity (∼0.2 W m−1K−1) because of the strong phonon scattering by segmental random rotations, chain entanglements, side chains, and so on.17,18 Therefore, (1) improving the rigidity of main chains, (2) controlling the intermolecular interactions, and (3) inhibiting the aforementioned phonon scattering factors are the keys to achieve high thermal conductivity in conjugated polymers.

Efforts have been made to tune the chain structure and interchain bonds of conjugated polymers to explore their potential as good thermal conductors. Xu et al. reported an oxidative chemical vapor deposition method that could extend the conjugated length and stabilize the planar structure in poly(3-hexylthiophene) and increase the thermal conductivity to 2.2 W m−1K−1.17 More recently, researchers utilized light-triggered π-π interactions between the azobenzene groups to control the thermal conductivity in azobenzene. However, reliability and scalability in practical applications may be faced with these materials.19 Currently, polymers with increased thermal conductivity are still in the lab stage, and it remains a great challenge to fill the gap between lab-scale proof-of-concept and commercialization.

In this work, we report the enhanced thermal conductivity in linear copolymerized polyimide (PI) prepared by a common copolymerization method. We copolymerized 2,4,5,7-tetraamino-1,8-dihydroxyanthracene-9,10-dione monomers (4NADA, a sort of atypical anthraquinone-based monomer) into the backbone of PI (Kapton-type) and synthesized large-sized free-standing PI films. Taking advantage of the rigid π-conjugated bonds of 4NADA, the intramolecular thermal transport is improved. Moreover, the coplanar morphology of 4NADA can suppress chain distortions and simultaneously densely pack the chains and increase the thickness of π-stacking. In addition, the α-substituted groups in 4NADA spontaneously form intramolecular hydrogen bonds with carbonyl groups, avoiding excess phonon scattering in the copolymer. All these can facilitate thermal transport in the copolymerized PI, and the thermal conductivity reaches 0.58 ± 0.06 W m−1K−1 at only 10% loading of 4NADA. As a typical dielectric material, an enhanced thermal conductivity may provide new opportunities for PI as a potential candidate in thermal management.20

Results and discussion

Molecular design

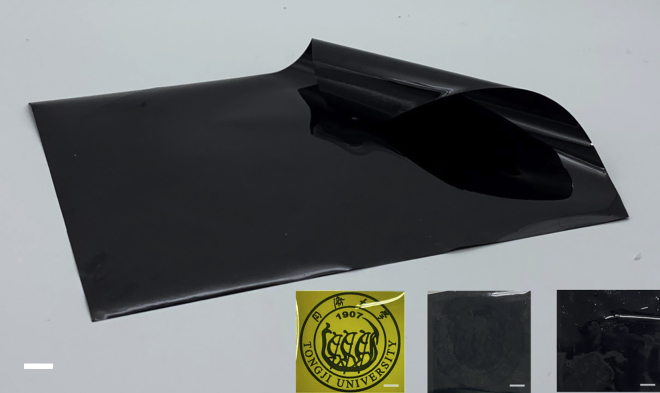

4NADA was synthesized from 1,8-dihydroxyanthracene-9,10-dione via nitrification and subsequent reduction, following the route mentioned in our previous work.21 The obtained diamine monomer was copolymerized with 4,4′-diaminodiphenyl ether (ODA) and 1,2,4,5-benzenetetracarboxylic dianhydride to afford a viscous polyamic acid (PAA) solution. After vacuum defoaming, the PAA solution was coated onto a glass substrate and subsequently cured by a thermal annealing process to obtain corresponding PI films. The samples are labeled as PIx, where x being the molar proportion of 4NADA among the diamines, φ4NADA. The chemical structure of the copolymerized PI is depicted (Figure 1B). The 4NADA monomer shows a full domain absorption biased toward red light and, therefore, exhibits a bluish-black color. Figure 2 is a photograph of PI10%, and the insets are images of pure PI, PI2%, and PI10%, where the transparency of the films decreases with the increase of φ4NADA. It is worth noting that black PI would not hamper the intrinsic thermal properties of PI but can extend its applications in many areas, such as optical fixed attenuators and optical terminators.21

Figure 1.

Design concept for thermally conducted copolymerized polyimide (PI)

(A) Left: a scheme of pure PI film, where the molecular chains (indicated by the orange curves) are highly entangled (middle panel). The main thermal pathways are the weak interchain interactions, through which the thermal transport is inefficient. Right: Chemical structure for pure PI. One can see that the benzene rings in 4,4′-diaminodiphenyl ether (ODA) are randomly rotated.

(B) Left: a scheme of PI10%. Middle: The short blue lines represent the integrated 2,4,5,7-tetraamino-1,8-dihydroxyanthracene-9,10-dione (4NADA) monomers in the PI chains. Right: Chemical structure for the copolymerized PI. The introduction of 4NADA can enhance the main chain rigidity, as 4NADA is stiffer than ODA. Besides, its coplanar structure provides more opportunities for interchain π-stacking. Thus, more efficient thermal channels are formed in the copolymerized PI (indicated by the yellow bold lines in the middle panel). n and m are the mole numbers of ODA and 4NADA.

Figure 2.

A representative image of PI10%

The scale bar is 1 cm. Insets: Photographs of pure PI, PI2%, and PI10%, respectively (from left to right). The color changes from yellow to black as the molar proportion of 4NADA increases. The scale bars are 2 cm.

The design concept for the copolymerized PI is illustrated in Figure 1. 4NADA is a rigid molecule with a coplanar structure (Figure 1B). Copolymerizing 4NADA into the backbone of PI can improve the stiffness of the main chains. Compared to ODA, which has a rotatable C-O-C bond between the benzene rings (Figure 1A), 4NADA can suppress segmental rotation. Molecular chains with fewer distortions can be formed by the substitution of 4NADA for ODA, which may offer more chances for the formation of densely-packed intermolecular stacking. In other words, stiffer, extended, and more densely-packed molecular chains (Figure 1B, right panel) may be developed by copolymerization, which can effectively improve intrachain and interchain thermal transport in the obtained PI films.17

Thermal measurement and sample characterization

At the low-level introduction of 4NADA, the thermal conductivity increases as a function of φ4NADA and reaches the maximum of 0.58 ± 0.06 W m−1K−1 at φ4NADA = 10%, almost three times larger than that of the pure PI (0.21 ± 0.02 W m−1K−1) (Figure 3B). Rigid polymer chains are generally better thermal conductors since their high bond-stretching energy corresponds to strong intramolecular hopping.18,22,23 Therefore, the integrated 4NADA segments in the backbones can enhance the intrachain interactions and contribute to the thermal transport network.

Figure 3.

Thermal measurement results

All data are represented as mean ± SEM.

(A) The thermal conductivity of the samples as a function of molar proportion of 4NADA, φ4NADA.

(B) High-temperature stability of the copolymerized PI films. After annealing, the thermal conductivity of PI10% maintains nearly the same as before.

Furthermore, the coplanar structure of 4NADA constrains the atoms to be in the same atomic plane, thus greatly increasing the stiffness of segmental rotation and facilitating the interchain π-stacking.23 We employed UV-vis spectroscopy and X-ray diffraction (XRD) pattern to characterize the π-π interactions in the films. The UV cutoff wavelength in Figure 4A corresponds to the energy gap of electronic transfer between π-orbitals.24,25 From PI to PI10%, the red shift of it indicates stronger π-electrons transfer with increasing 4NADA. This is interpreted not only by the electron-donating ability of the substituents on the anthraquinone but also by the longer conjugation length in the copolymer.21,26

Figure 4.

Sample characterization

(A) UV-vis transmission spectra for the pure and copolymerized PI films. The colored curves with a different cutoff wavelength from left to right indicate the PI films with increasing φ4NADA.

(B) Exemplary cross-plane XRD profiles for the pure and the copolymerized PI films, which are represented by multiple Lorentzian peaks.

Figure 4B shows the cross-plane XRD profiles of the three exemplary films. Due to the wide full width at half maximum (FWHM) and low intensity of the single peaks, the XRD pattern shows a broad shoulder for pure PI, which can be represented by three single Lorentz peaks at 19.8° (interspacing of 4.5 Å), 23.4° (interspacing of 3.8 Å), and 29.7° (interspacing of 3 Å). The coherence length (Lc) of an ordered region is defined by the Scherrer equation27,28 and equals 0.89λ/(FWHM cosθ), where λ is the wavelength of the X-ray in radian. After the introduction of 4NADA, these Lorentz peaks shift to higher diffraction angles, indicating the formation of more densely-packed chains. For PI10%., the peak positions are 21.1°, 25.0°, and 30.8°. Meanwhile, the last two peaks, corresponding to the ordered structures in PI films, display narrower FWHM as φ4NADA increases, indicating the ordered region transferred to a larger one with densely-packed chains (Table 1).29,30 However, even for PI10%, these peaks are dispersive. Thereby, the corresponding short Lc is unlikely to form a long-range ordered structure. Although no intense peak assignable to the large crystalline region is observed, the gradually elongated Lc confirms the formation of partially ordered structures with an increase of φ4NADA.23

Table 1.

XRD analysis for the samples

| Sample | Peak position (°) | FWHM | Coherence length (Å) |

|---|---|---|---|

| PI | 23.7 | 8.7 | 9.6 |

| 29.7 | 12.9 | 6.3 | |

| PI2% | 24.3 | 8.4 | 9.6 |

| 30.7 | 9.3 | 8.3 | |

| PI10% | 25 | 7.6 | 10.6 |

| 30.8 | 8.4 | 9.7 |

Data are represented as mean ± SEM.

FWHM, full width at half maximum.

With the introduction of 4NADA, the interchain π-stacking becomes more densely-packed, and its thickness is extended. First, ordered regions themselves have higher thermal conductivity than entangled chains.10 Second, larger ordered regions can reduce the interfaces between the ordered and disordered regions.31 Practically, the phonon-boundary scattering takes place if the size of the sample is smaller than the phonon mean free path, causing a size-dependent or thickness-dependent thermal conductivity.32,33 A larger-sized sample usually has higher thermal conductivity, in which phonons process less boundary scattering.31,32,33 In this case, regarding the entire film that contains both the ordered and disordered regions, larger thicknesses of π-stacking can reduce the ordered-disordered interfaces and, therefore, contribute to the enhanced thermal conductivity. Moreover, π-stacking has significant implication on ordering and stretching the polymer chains and, thus, indirectly enhances thermal transport along the chain via the intrachain covalent bonding.

Additionally, as denoted by the nuclear magnetic resonance results in our previous study, the side groups of 4NADA manifest different nucleophilic activities due to the formation of intramolecular hydrogen bonds, leading to the linear conformation of the copolymer.21 In this case, no extra phonon scattering would be introduced by side groups in the copolymerization process.34

However, with the addition of 4NADA, the thermal conductivity slowly decreases. The reduced thermal conductivity is rationalized by the stacking of polymer chains at the high molar proportion of 4NADA. The possible increasing of the free volume in the random copolymer with φ4NADA may increase the difficulty in the formation of intermolecular hydrogen bond and hence lead to a nonuniform PI film, demonstrated by the reduced glass transition temperature (Tg) at φ4NADA of 15% (Figure S2).21 Another justification is the breaking strain of the films, which decreases as φ4NADA increases (Figure 4B) and becomes too fragile to measure when φ4NADA exceeds 15%. As a result, the thermal conductivity drops with further addition of 4NADA and to 0.41 ± 0.04 W m−1K−1 at φ4NADA of 20%.

Our previous study suggests several thermal physical properties (other than thermal conductivity) of the copolymerized films.21 From φ4NADA = 0 to 10%, the glass transition temperature (Tg) slightly increases from the initial 421°C to 434°C (Figure S2), and the temperature of 5% weight loss (Td5%) remains nearly constant, both indicate good thermal stability properties. Such improvement of Tg is influenced by the coplanar structure and rigid bonding of 4NADA, as the backbone of copolymerized PI became more rigid and more difficult to rotate with the increasing 4NADA content.21,35 To prove the stability of thermal conductivity, we placed the T-bridge sensor carrying a PI10% film into a chamber and annealed it at T = 200°C for 1 hour. After this process, the whole device was cooled down to room temperature, and then the thermal conductivity of PI10% was measured again. We find that after annealing, the change of the thermal conductivity is within the experimental errors (Figure 3B). This is comprehensible as 200°C is far below their Tg, the copolymerized films are still in the glassy state, and the chains would not be softened due to the temperature rise. Although we did not test the thermal conductivity at a temperature higher than 200°C, the thermal conductivity stability at T = 200°C can satisfy the needs of thermal management in many cases, like chip cooling.

Physical variables contributing to the enhanced thermal conductivity

In the previous paragraphs, we discussed the molecular interactions (both intrachain and interchain) and heat-carrier scattering effects that can impact the thermal conductivity. How the chain structure and conformation affect the physical variables contributing to the thermal conductivity has been proposed and is quite important to know.7 Due to the lack of periodic lattice in amorphous polymers, atomic vibrations described by the phonon picture are always a settlement. Allen et al. proposed that the vibration modes in amorphous polymers are categorized as propagons, diffusons, and locons, where diffusons, neither fully localized nor propagating, are the main heat carriers.36 However, recent works show that disordered materials can have a phonon-like mode which can propagate hundreds of nanometers, supporting the phonon picture.37,38 Moreover, the PI studied in this work is not fully amorphous but with ordered structures, which can be reflected by XRD patterns and the changes in FWMH and Lc, due to the extended and more densely-packed molecular chains. Therefore, the concept of “mean free path” is still usable to describe the average length for vibration modes here.2 To provide a straightforward picture and for convenience, the kinetic theory is used here. According to the kinetic theory, the thermal conductivity is described as κ ∼ cvl, where c, v, and l are, respectively, the specific heat, phonon group velocity, and phonon mean free path. To resolve this, we measured the density and Young’s modulus of the films. The density of the copolymerized films remains nearly constant as x varies (Figure 5A). The specific heat is measured by using a differential scanning calorimeter, and the results are shown in Figure 5B, which decreases from and by 22% for PI10%. Young’s moduli (E) of the films are determined by tensile tests. E ∼ ρv2, where ρ and v are density and average sound velocity, respectively, increases from 1.5 ± 0.2 to 2.2 ± 0.2 GPa with φ4NADA increasing from 0 to 10% (Figure 5C).21 Thus, the average sound velocity is increased by 20% for PI10%. Therefore, we conclude that the enhanced thermal conductivity of copolymerized PI is mainly due to the improved phonon mean free path, consistent with the picture of extended and more densely-packed molecular chains.

Figure 5.

Physical variables contributing to the enhanced thermal conductivity

Data are represented as mean ± SEM.

(A) Density of the pure and the copolymerized PI films.

(B) Specific heat of the samples.

(C) Young’s modulus and breaking strain of the pure and the copolymerized PI films.

In conventional bulk polymers, the phonon localization and phonon scattering lead to a relatively low phonon mean free path. By introducing 4NADA in the main chains, the structure order has been improved, and a longer phonon mean free path must underpin the higher thermal conductivity than the bulk value.

Conclusion

In this article, we report a copolymerization method that can enhance the thermal conductivity of PI films. The integration of the 4NADA in the backbone of PI improves the intramolecular interactions and the degree of structural order, and the observed thermal conductivity is three times higher than that of bulk PI at 10% loading of 4NADA. With this common and easily achieved technology, it is now possible to synthesize large-scale thermally conductive PI that also has good electrical insulation, high mechanical strength, and high-temperature stability.

Limitation of this study

In this study, we propose a copolymerization method enabling the fabrication of large-sized free-standing PI films. In comparison to conventional bulk polymers, the copolymerized PI films have an enhanced thermal conductivity owing to the simultaneously improved intramolecular and intramolecular interactions. The thermal conductivity reaches its maximum at 10% loading of 4NADA and decreases with the addition of the rigid monomer. Here, we only use Kapton-type PI for copolymerization. Other configurations of PI are not synthesized and tested.

STAR★Methods

Key resources table

| REAGENT or RESOURCE | SOURCE | IDENTIFIER |

|---|---|---|

| Chemicals, peptides, and recombinant proteins | ||

| 1,8-Dihydroxyanthracene-9,10-dione | Tokyo Chemical Industry | CAS:117-10-2 |

| Concentrated sulfuric acid | Sinopharm Chemical Reagent Co., Ltd. | CAS:7664-93-9 |

| Concentrated nitric acid | Sinopharm Chemical Reagent Co., Ltd. | CAS:7697-37-2 |

| 1,2,4,5-benzenetetracarboxylic dianhydride | ChinaTech Chemical Co., Ltd. | CAS:89-32-7 |

| 4,4′-diaminodiphenyl ether | ChinaTech Chemical Co., Ltd. | CAS:101-80-4 |

| N,N-dimethylacetamide | J&K Scientific | CAS:127-19-5 |

| Software | ||

| Origin 8.5 | OriginLab Corporation | https://www.originlab.com/ |

| PowerPoint 2019 | Microsoft Corporation | https://www.microsoft.com/ |

| LabVIEW 2018 | National Instrument Corporation | https://www.ni.com/ |

| Measurement and characterization | ||

| UV-vis spectroscopy | Shimadzu | UV2600 |

| X-ray diffraction | Bruker | D8 Discover diffractometer |

| Current Source | Keithley | 6221 |

| Lock-in Amplifier | Stanford | SR830 |

Resource availability

Lead contact

Further information and requests for resources should be directed to and will be fulfilled by the lead contact, Prof. Qinghua Lu (qhlu@sjtu.edu.cn) and Prof. Xiangfan Xu (xuxiangfan@tongji.edu.cn).

Materials availability

All materials generated in this study are available from the lead contact upon request.

Experimental model and subject details

Our study does not use experimental models typical in the life sciences.

Method details

Sample preparations

PAAs (PAAx, where subscript x represents the molar proportion of 4NADA among all diamines), the precursor of PIs, were first synthesized by copolymerization of two diamines ODA and 4NADA with dianhydride PMDA in anhydrous DMAC (Dimethylacetamide). A black viscous solution was obtained with a solid content of 15 wt % (Figure S3). As a representative, PAA10% was synthesized guided by the route in Figure S3. 4NADA (0.18 g, 0.6 mmol) and ODA (1.08 g, 5.4 mmol) were added into a 250 mL three-necked flask, equipped with a mechanical stirrer and a nitrogen inlet, which contained anhydrous DMAC (15 mL). After both diamines had entirely dissolved, PMDA (1.31 g, 6.0 mmol) was slowly added to the mixture and then stirred for about 16 h to yield a viscous bluish-black PAA solution.

The solution was placed under a vacuum to remove bubbles produced by stirring and then slowly cast on flat glass with a 400 μm-depth blade at room temperature. Next, these films were vacuum-treated for 2 h in an oven and subsequently cured through an annealing procedure (115°C/15 min, 140°C/15 min, 200°C/30 min, 250°C/5 min, and 300°C/90 min). After cooling to room temperature, PIx% films (thickness about 25 μm) were peeled from the glass substrates in hot water and dried for 2 h at 80°C.

T-bridge method

The T-bridge method was performed to investigate the in-plane thermal conductivity of these films.39,40 As shown in the inset of Figure S1, an aluminum (Al) wire with a radius of rh and a length of lh was suspended between two heat sinks, serving as heater and temperature sensor; a sample was then bridged between the middle point of the heater and a third heat sink. Application of a DC current to the Al wire leads to a temperature rise of ΔTv = (R-R0)/βR0, where R is the electric resistance, R0 is the electric resistance at T = 300K, I = 0, and β is the temperature resistance coefficient of the Al wire at T = 300K, respectively. Two sets of measurements, i.e., with and without the sample, were performed, and the corresponding temperature rise on the Al wire is ΔTv’ and ΔTv, respectively. Figure S1 shows the representative temperature changes on the Al wire. The measured thermal conductivity of Al wire can be written as κh = lh2qv/12ΔTv, with qv = Q/V = I2R/πrh2lh being the volumetric heating joule. The thermal conductivity of the tested sample can be calculated as κf = πlflh2κhrh2(qvlh3 - 12lhκhΔTv’)/lh1lh2Af [12lhκhΔTv’ - qv (lh13 + lh23)], where the subscript f corresponds to the parameters of the tested sample. The whole measurement was performed at room temperature and under a high vacuum condition (better than 1 × 10−4 Pa) to reduce the impact from thermal convection. The thermal conductivity uncertainties are from the temperature drift in the cryostat chamber and errors in size measurement of the samples, which can be calculated following the same routine in our previous work.39

Quantification and statistical analysis

The uncertainties of κ are introduced by measurements of dimensions, and temperature drifting in the vacuum chamber, which can be calculated as

Where wf and tf are respectively the width and thickness of the sample. The temperature drift in the cryostat chamber is 50 mK in this experiment.

The errors in the density come from the size measurement.

Young’s modulus of the films is the mean value from multiple measurements, the error of which is calculated by the limit value minus the mean one.

Additional resources

We have no relevant resources.

Acknowledgments

The authors would like to acknowledge the financial support from the Key Area Research and Development Program of Guangdong Province (no.: 2020B010190004), the National Natural Science Foundation of China (no.: 11890703, 11935010, 12004242, 12174286, and 51733007 [Key Program]), Shanghai Rising-Star Program (no.: 21QA1403300), and Shanghai Key Projects of Basic Research (16JC1403900).

Author contributions

B.L. and X.X. conceived the idea. Y.Z. synthesized the PI films. B.L., Y.Z., and L.D. performed the experiment. Authors discussed the results and contributed to the manuscript.

Declaration of interests

The authors declare no competing interests.

Published: November 18, 2022

Footnotes

Supplemental information can be found online at https://doi.org/10.1016/j.isci.2022.105451.

Contributor Information

Qinghua Lu, Email: qhlu@sjtu.edu.cn.

Xiangfan Xu, Email: xuxiangfan@tongji.edu.cn.

Supplemental information

Data and code availability

Original data reported in this paper will be shared by the lead contact upon request.

This paper does not report original code.

Any additional information required to reanalyze the data reported in this paper is available from the lead contact upon request.

References

- 1.Shrestha R., Li P., Chatterjee B., Zheng T., Wu X., Liu Z., Luo T., Choi S., Hippalgaonkar K., de Boer M.P., Shen S. Crystalline polymer nanofibers with ultra-high strength and thermal conductivity. Nat. Commun. 2018;9:1664. doi: 10.1038/s41467-018-03978-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Xu X., Zhou J., Chen J. Thermal transport in conductive polymer–based materials. Adv. Funct. Mater. 2020;30:1904704. doi: 10.1002/adfm.201904704. [DOI] [Google Scholar]

- 3.Xu X., Chen J., Zhou J., Li B. Thermal conductivity of polymers and their nanocomposites. Adv. Mater. 2018;30:1705544. doi: 10.1002/adma.201705544. [DOI] [PubMed] [Google Scholar]

- 4.Chen H., Ginzburg V.V., Yang J., Yang Y., Liu W., Huang Y., Du L., Chen B. Thermal conductivity of polymer-based composites: fundamentals and applications. Prog. Polym. Sci. 2016;59:41–85. doi: 10.1016/j.progpolymsci.2016.03.001. [DOI] [Google Scholar]

- 5.Huang X., Zhi C., Lin Y., Bao H., Wu G., Jiang P., Mai Y.-W. Thermal conductivity of graphene-based polymer nanocomposites. Mater. Sci. Eng. R Rep. 2020;142:100577. doi: 10.1016/j.mser.2020.100577. [DOI] [Google Scholar]

- 6.Kuilla T., Bhadra S., Yao D., Kim N.H., Bose S., Lee J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010;35:1350–1375. doi: 10.1016/j.progpolymsci.2010.07.005. [DOI] [Google Scholar]

- 7.Wei X., Wang Z., Tian Z., Luo T. Thermal transport in polymers: a review. J. Heat Transfer. 2021;143 doi: 10.1115/1.4050557. [DOI] [Google Scholar]

- 8.Henry A., Chen G. High thermal conductivity of single polyethylene chains using molecular dynamics simulations. Phys. Rev. Lett. 2008;101:235502. doi: 10.1103/PhysRevLett.101.235502. [DOI] [PubMed] [Google Scholar]

- 9.Shen S., Henry A., Tong J., Zheng R., Chen G. Polyethylene nanofibres with very high thermal conductivities. Nat. Nanotechnol. 2010;5:251–255. doi: 10.1038/nnano.2010.27. [DOI] [PubMed] [Google Scholar]

- 10.Xu Y., Kraemer D., Song B., Jiang Z., Zhou J., Loomis J., Wang J., Li M., Ghasemi H., Huang X., et al. Nanostructured polymer films with metal-like thermal conductivity. Nat. Commun. 2019;10:1771. doi: 10.1038/s41467-019-09697-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Dong L., Xi Q., Chen D., Guo J., Nakayama T., Li Y., Liang Z., Zhou J., Xu X., Li B. Dimensional crossover of heat conduction in amorphous polyimide nanofibers. Natl. Sci. Rev. 2018;5:500–506. doi: 10.1093/nsr/nwy004. [DOI] [Google Scholar]

- 12.Singh V., Bougher T.L., Weathers A., Cai Y., Bi K., Pettes M.T., McMenamin S.A., Lv W., Resler D.P., Gattuso T.R., et al. High thermal conductivity of chain-oriented amorphous polythiophene. Nat. Nanotechnol. 2014;9:384–390. doi: 10.1038/nnano.2014.44. [DOI] [PubMed] [Google Scholar]

- 13.Kim G.-H., Lee D., Shanker A., Shao L., Kwon M.S., Gidley D., Kim J., Pipe K.P. High thermal conductivity in amorphous polymer blends by engineered interchain interactions. Nat. Mater. 2015;14:295–300. doi: 10.1038/nmat4141. [DOI] [PubMed] [Google Scholar]

- 14.Zhou J., Xi Q., He J., Xu X., Nakayama T., Wang Y., Liu J. Thermal resistance network model for heat conduction of amorphous polymers. Phys. Rev. Mater. 2020;4:015601. doi: 10.1103/PhysRevMaterials.4.015601. [DOI] [Google Scholar]

- 15.Shanker A., Li C., Kim G.-H., Gidley D., Pipe K.P., Kim J. High thermal conductivity in electrostatically engineered amorphous polymers. Sci. Adv. 2017;3:e1700342. doi: 10.1126/sciadv.1700342. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Zhang T., Luo T. Role of chain morphology and stiffness in thermal conductivity of amorphous polymers. J. Phys. Chem. B. 2016;120:803–812. doi: 10.1021/acs.jpcb.5b09955. [DOI] [PubMed] [Google Scholar]

- 17.Xu Y., Wang X., Zhou J., Song B., Jiang Z., Lee E.M.Y., Huberman S., Gleason K.K., Chen G. Molecular engineered conjugated polymer with high thermal conductivity. Sci. Adv. 2018;4:eaar3031. doi: 10.1126/sciadv.aar3031. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Zhang T., Wu X., Luo T. Polymer nanofibers with outstanding thermal conductivity and thermal stability: fundamental linkage between molecular characteristics and macroscopic thermal properties. J. Phys. Chem. C. 2014;118:21148–21159. doi: 10.1021/jp5051639. [DOI] [Google Scholar]

- 19.Shin J., Sung J., Kang M., Xie X., Lee B., Lee K.M., White T.J., Leal C., Sottos N.R., Braun P.V., Cahill D.G. Light-triggered thermal conductivity switching in azobenzene polymers. Proc. Natl. Acad. Sci. USA. 2019;116:5973–5978. doi: 10.1073/pnas.1817082116. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Dong L., Xu X., Li B. High thermal conductivity and superior thermal stability of amorphous PMDA/ODA nanofiber. Appl. Phys. Lett. 2018;112:221904. doi: 10.1063/1.5031216. [DOI] [Google Scholar]

- 21.Zhou Y., Zhang S., Zheng F., Lu Q. Intrinsically black polyimide with retained insulation and thermal properties: a black anthraquinone derivative capable of linear copolymerization. Macromolecules. 2021;54:9307–9318. doi: 10.1021/acs.macromol.1c01422. [DOI] [Google Scholar]

- 22.Liu J., Yang R. Length-dependent thermal conductivity of single extended polymer chains. Phys. Rev. B. 2012;86:104307. doi: 10.1103/PhysRevB.86.104307. [DOI] [Google Scholar]

- 23.Huang C., Qian X., Yang R. Thermal conductivity of polymers and polymer nanocomposites. Mater. Sci. Eng. R Rep. 2018;132:1–22. doi: 10.1016/j.mser.2018.06.002. [DOI] [Google Scholar]

- 24.Wang Q., Bai Y., Chen Y., Ju J., Zheng F., Wang T. High performance shape memory polyimides based on π–π interactions. J. Mater. Chem. A Mater. 2015;3:352–359. doi: 10.1039/C4TA05058D. [DOI] [Google Scholar]

- 25.Feng Y., Luo L.B., Huang J., Li K., Li B., Wang H., Liu X. Effect of molecular rigidity and hydrogen bond interaction on mechanical properties of polyimide fibers. J. Appl. Polym. Sci. 2016;133 doi: 10.1002/app.43677. [DOI] [Google Scholar]

- 26.Brédas J.L. Relationship between band gap and bond length alternation in organic conjugated polymers. J. Chem. Phys. 1985;82:3808–3811. doi: 10.1063/1.448868. [DOI] [Google Scholar]

- 27.Scherrer P. Mathematisch-Physikalische Klasse; 1918. Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen. [Google Scholar]

- 28.Ree M., Kim K., Woo S.H., Chang H. Structure, chain orientation, and properties in thin films of aromatic polyimides with various chain rigidities. J. Appl. Phys. 1997;81:698–708. doi: 10.1063/1.364210. [DOI] [Google Scholar]

- 29.Ree M., Nunes T.L., Czornyj G., Volksen W. Residual stress behaviour of isomeric PMDA-ODA polyimides. Polymer. 1992;33:1228–1236. doi: 10.1016/0032-3861(92)90768-R. [DOI] [Google Scholar]

- 30.Zhong D.H., Sano H., Kobayashi K., Uchiyama Y. A study of film thickness dependence of the graphitizability of PMDA–ODA polyimide-derived carbon film. Carbon. 2000;38:2161–2165. doi: 10.1016/S0008-6223(00)00075-0. [DOI] [Google Scholar]

- 31.Yang J., Yang Y., Waltermire S.W., Wu X., Zhang H., Gutu T., Jiang Y., Chen Y., Zinn A.A., Prasher R., et al. Enhanced and switchable nanoscale thermal conduction due to van der Waals interfaces. Nat. Nanotechnol. 2012;7:91–95. doi: 10.1038/nnano.2011.216. [DOI] [PubMed] [Google Scholar]

- 32.Guo J., Huang Y., Wu X., Wang Q., Zhou X., Xu X., Li B. Thickness-dependent in-plane thermal conductivity and enhanced thermoelectric performance in p-type ZrTe5 nanoribbons. Phys. Status Solidi RRL. 2019;13:1800529. doi: 10.1002/pssr.201800529. [DOI] [Google Scholar]

- 33.Wu X., Tao Q., Li D., Wang Q., Zhang X., Jin H., Li J., Wang S., Xu X. Unprecedently low thermal conductivity of unique tellurium nanoribbons. Nano Res. 2021;14:4725–4731. doi: 10.1007/s12274-021-3414-7. [DOI] [Google Scholar]

- 34.Luo D., Huang C., Huang Z. Decreased thermal conductivity of polyethylene chain influenced by short chain branching. J. Heat Transfer. 2018;140:031302. [Google Scholar]

- 35.Sazanov Y., Florinsky F.S., Koton M.M. Investigation of thermal and thermooxidative degradation of some polyimides containing oxyphenylene groups in the main chain. Eur. Polym. J. 1979;15:781–786. doi: 10.1016/0014-3057(79)90032-6. [DOI] [Google Scholar]

- 36.Allen P.B., Feldman J.L., Fabian J., Wooten F. Diffusons, locons and propagons: character of atomie yibrations in amorphous Si. Phil. Mag. B. 1999;79:1715–1731. doi: 10.1080/13642819908223054. [DOI] [Google Scholar]

- 37.Liu X., Feldman J.L., Cahill D.G., Crandall R.S., Bernstein N., Photiadis D.M., Mehl M.J., Papaconstantopoulos D.A. High thermal conductivity of a hydrogenated amorphous silicon film. Phys. Rev. Lett. 2009;102:035901. doi: 10.1103/PhysRevLett.102.035901. [DOI] [PubMed] [Google Scholar]

- 38.Regner K.T., Sellan D.P., Su Z., Amon C.H., McGaughey A.J.H., Malen J.A. Broadband phonon mean free path contributions to thermal conductivity measured using frequency domain thermoreflectance. Nat. Commun. 2013;4:1640. doi: 10.1038/ncomms2630. [DOI] [PubMed] [Google Scholar]

- 39.Cang Y., Liu B., Das S., Xu X., Xie J., Deng X., Fytas G. Surface contacts strongly influence the elasticity and thermal conductivity of silica nanoparticle fibers. Phys. Chem. Chem. Phys. 2021;23:3707–3715. doi: 10.1039/D0CP05377E. [DOI] [PubMed] [Google Scholar]

- 40.Fujii M., Zhang X., Xie H., Ago H., Takahashi K., Ikuta T., Abe H., Shimizu T. Measuring the thermal conductivity of a single carbon nanotube. Phys. Rev. Lett. 2005;95:065502. doi: 10.1103/PhysRevLett.95.065502. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Original data reported in this paper will be shared by the lead contact upon request.

This paper does not report original code.

Any additional information required to reanalyze the data reported in this paper is available from the lead contact upon request.