Abstract

The collapse of a laser-induced vapor bubble near a solid boundary usually ends in a liquid jet. When the boundary is from a soft material the jetting may pierce the liquid-solid interface and result in the injection of liquid into it. A particular impulsive jet flow can be generated when a laser pulse is focused just below the free surface of a thin liquid layer covering a gelatin sample used as a surrogate of biological tissue. Here, a downwards jet forms from a liquid splash at the free surface and then penetrates through the liquid layer into the soft boundary. In the present manuscript we report on the use of this novel jet, termed “bullet” jet, to pierce soft materials and we explore its potential to become an optical needle-free injection platform. The dynamics and depth of the injection is studied as a function of the elasticity of the solid and the liquid properties. Injections of up to 4 mm deep into 4 %w/w gelatin within 0.5 ms are observed. The advantages of the bullet jet over other kinds of impulsively generated jets with lasers are discussed.

1. Introduction

In the last decade needle-free injection has received renewed interest [1] once it was realized that cavitation bubbles could be utilized as powerful on-demand micro-scale pumps and accelerate a liquid drug into the skin by forming fast liquid jets. In almost all implementations of cavitation based needle-free injection devices, the bubbles are generated with a laser that is absorbed in the liquid and through superheating causes an explosive phase change. In general, one can separate the designs in two classes: the ones with two compartments, one where the driving cavitation bubbles are nucleated and another one used as a reservoir containing the liquid with the drug [2,3]; or the ones having a single compartment, where the cavitation bubble is nucleated within the drug to be injected [4–13] and in some cases directly next to the targeted soft material [14,15].

In the literature, the generation of a thin liquid jet using a laser pulse is commonly referred to as LIFT (Laser-induced forward transfer) [16–18]. In this technique a laser induced bubble is nucleated close to the free boundary of a liquid pool, producing a fast jet which advances away from the liquid surface immediately after the bubble collapse. A jet may be also formed by a self-focusing mechanisms that utilizes a concave free surface that transforms into a thin needle through a pressure impulse [5]. Other implementations utilize the bubble expansion itself as a displacement pump and combine it with a converging nozzle [10,19]. In both cases a liquid jet with velocities of tens to hundreds of meters per second and sub-millimeter diameter is formed that after a short travel in air impacts onto soft matter (usually a gel used as a surrogate for skin and biological tissue). In those experiments the jets typically penetrate between 500 m and 1500 m, which is deep enough for some applications like needle-less micro-dose drug delivery or micro-drop printing [8,20,21].

Recently, an alternative technique to generate focused liquid jets was reported by the present authors [22]. There, the splash formed during laser ablation at a free interface closes and focuses a jet back downwards into the liquid pool. For this to occur the laser pulse must be focused at a very short distance (of the order of a hundred microns) below the free surface of the liquid. The resulting jet was termed “bullet jet” as its flow resembles the flow from a bullet impacting into a liquid pool. The typical velocities achieved by the bullet jet are several tens of meters per second while it penetrates several millimeters into the liquid. These properties made them an attractive transport phenomenon for the implementation in needle-free injection platforms. In the present work we report on utilizing the bullet jet to penetrate into a biological tissue mimicking elastic material by varying the liquid properties and the stiffness of the elastic solid. The advantage of the bullet jet over the self focusing impulsive flow or the use of a nozzle is its simpler geometry: any liquid pool with a planar or curved gas-liquid interfaces can be converted into a bullet jet.

2. Materials and methods

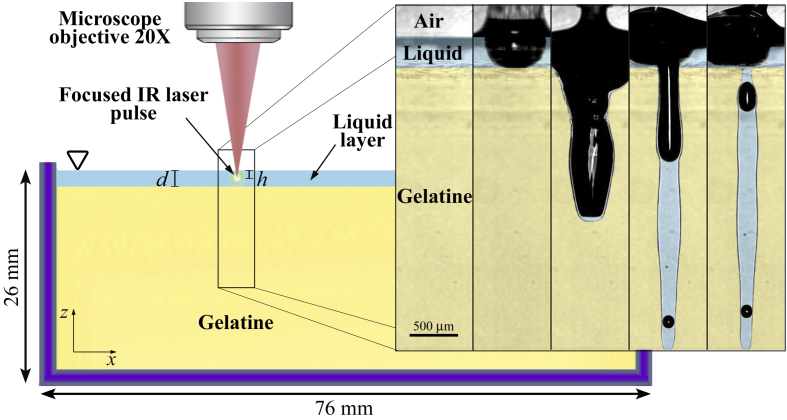

The liquid jets are produced by focusing an infrared laser pulse (Quantum Light Instruments Q2, wavelength nm, energy of J, 4 ns of duration) with a microscope objective (Zeiss LD Achroplan 20X, NA=0.4) close to the surface of a liquid layer sitting on top of a gelatin block (Yasin 250bloom). The liquid and the gelatin are contained in a slim rectangular glass cuvette (internal dimensions of 76 mm × 26 mm × 5 mm) as shown in Fig. 1. The cuvette is made from a 3D printed plastic frame that holds two standard microscope slides with a thickness of 1 mm. As demonstrated in the inset of Fig. 1, the laser pulse induces a gas cavity in the liquid layer, whose later dynamics results in the piercing of the gelatin surface and liquid injection into the soft matter block. High speed recordings of the process were taken using a 5× long distance microscope objective (Edmund Optics). The images were acquired simultaneously with two different cameras. The rather fast dynamics of bubble/splash generation on the liquid surface was captured with a Shimadzu XPV-X2 camera (maximum frame rate of 5 Mfps), while the slower jet penetration was recorded with a Photron AX-Mini 200 (maximum frame rate of 900 kfps). A femtosecond laser (Ekspla FemtoLux 3, 515 nm, 230 fs pulse duration, 5 MHz repetition rate) was used as a light source in the shadowgraphs. The use of a pulsed illumination system with those characteristics allowed us to capture the ejection of aerosol particles generated during the bubble/splash inception and also to obtain images with sharp edges.

Fig. 1.

Experimental setup. A laser induced bubble is produced at a distance below the surface of a static liquid layer of depth (coloured in light blue). The liquid is covering the flat surface of the gelatin block (in yellow) contained in the cuvette built. The inset details the liquid injection process. In short, the laser is focused at a distance of less than m, thereby type of splash which evolves into a bullet jet. This jet injects liquid and entrained air into the gelatin while reaching a depth of several millimeters. See Visualization 1 (5MB, mp4) .

After production, the gelatin samples are stored for around 20 h at C in a fridge, and then left at room temperature for 45 minutes prior to the experiments. We selected gelatin concentrations of 4%, 6% and 8% w/w to study the effect of Young’s modulus while matching some of the mechanical properties of human skin. An effective Young modulus of 10 kPa was reported in Ref. [23], yet its value fluctuates considerably depending on the methods and samples employed, see for example Refs. [2,4,9,23,24]. The strength and the Young modulus of the samples were measured [25,26] (detailed in the Supplemental document) and the values are reported in Table 1. There, the effect of a liquid diffusion into the gelatin surface was accounted for by depositing a layer of 1 mm in height of water on top of the gelatin for 30 min; i.e. the maximum time that the samples were used in the measurements.

Table 1. Mechanical properties of the gelatin samples measured at 22°C. For the “wet” samples the gelatin was kept for 30 min with a 1 mm water layer on top of it.

| Concentration (%) | Young Modulus (kPa) | Strength (g) | |

|---|---|---|---|

| Dry | Wet | ||

| 4 | 6.5 ± 1.5 | 61 ± 2 | 47 ± 2 |

| 6 | 10.7 ± 1.7 | 116 ± 3 | 100 ± 3 |

| 8 | 17 ± 0.5 | 200 ± 5 | 168 ± 5 |

3. Results and discussion

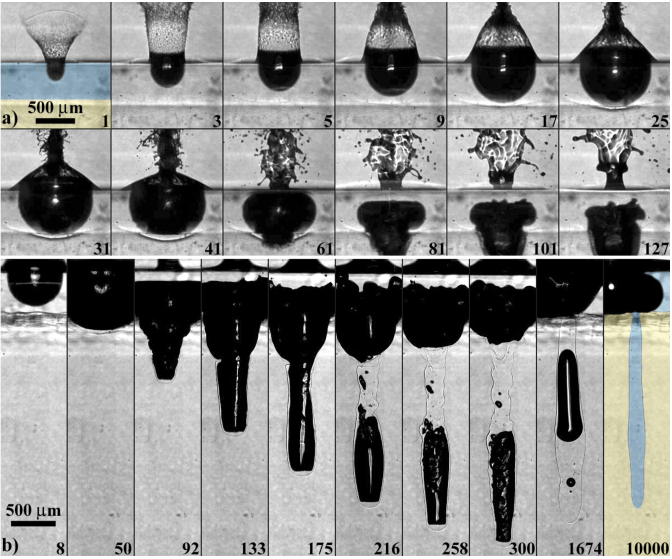

Figure 2 presents a detailed view of the formation process of a bullet jet and the piercing dynamics into the gelatin (4% w/w) covered with a thin layer of water. The laser energy deposition nucleates an open cavity and a splash, which expands as a liquid conical and thin curtain (see Fig. 2(a)). A few microseconds after the laser shot the rapid expansion of the submerged part of the cavity provokes a pressure drop in the gas/vapor inside it. At this point, the pressure gradient between the bubble interior and the atmospheric air above the splash forces the liquid curtain to close from its top shaping the liquid structure into a “water bell” [27,28]. The formation of the water bell implies also a closure of the volume defined by the expanding submerged cavity and the gas trapped in the liquid curtain, see s in Fig. 2(a)). While the submerged part of the cavity continues to expand (due to the liquid inertia) a stagnation point on the bell’s apex is formed and as a consequence two vertical and opposing jets are produced. Our interest lies in the downward jet that becomes visible for s in Fig. 2). A comprehensive explanation of this phenomenon with numerical simulations of the flow field are available in Ref. [22].

Fig. 2.

Detailed view of the liquid injection mechanism: the bullet jet injects water into a block of gelatin (4 w/w, water depth m, and m). (a) High speed video taken with 1 Mfps depicting the temporal evolution of the splash that transforms into the bullet jet and pierces the gelatin s. (b) Dynamics of a bullet jet penetrating the gelatin block taken at 48 kfps. The jet has an initial speed of approximately 22 m/s. The water and the gelatin are transparent and the gas phase is dark in the images. The yellow and blue colour added to the last frame of the sequence indicates the space occupied by the gelatin and the liquid, respectively. The numbers indicate the elapsed time in microseconds following the laser pulse. See Visualization 2 (7.4MB, mp4) and Visualization 3 (5.2MB, mp4) .

The image sequence Fig. 2(a) reveals how the water-gelatin interface is deformed by the expanding bubble (starting from s) in a similar way as liquid would be displaced [29]. The tight focus of the high numerical aperture lens prevents any bubble nucleation within the gelatin, i.e. only the liquid flow is responsible for its deformation and the piercing starting from s.

Figure 2(b) shows the liquid (and gas) injection dynamics of a bullet jet generated as a result of the closing splash. The jet is faintly visible at s before it penetrates the gelatin between s and s with an initial velocity of approximately 22 m/s. The liquid jet is present along the whole length of the gaseous phase while it advances, acquiring a cylindrical shape after entering into the gelatin (see Fig. 9 in Ref. [22]). Maximum penetration depth is reached at s when it losses momentum due to viscous friction [5]. While the liquid jet is hidden by the gas bubble, there is a small fairly constant liquid volume in the tip of the jet flow driving the advance of the elongated bubble. After the jet and the gas phase surrounding it reach a maximum penetration depth of mm the conduit formed by the jet shrinks slowly. Subsequently, the gas bubble is pushed out (mainly by buoyancy) of the incision s, yet most of the liquid remains after 10 ms in the conduit, see last frame of Fig. 2(b). There, the conduits has thinned and reduced slightly in depth.

Overall the cavity expansion in the liquid layer and the penetration dynamics of the bullet jet into the gelatin resemble the dynamics previously observed for a deep liquid pool [22]. Particularly, the initial jet tip speed of about 20 m/s measured when it penetrates into the gelatin is similar to the speeds found for pure liquids. We explain this similarity with the fact that the jet is formed in the liquid above the gelatin due to the pressure gradient between the interior of the laser induced cavity and the atmosphere, thus the gelatin has not effect on the initial liquid flow prior contact with the soft matter. This dependence on the liquid only is advantageous for a laser based liquid injection system, i.e. the initial penetration velocity is independent on the material properties. Thus, the particular stiffness of the target material is not affecting the jetting mechanism.

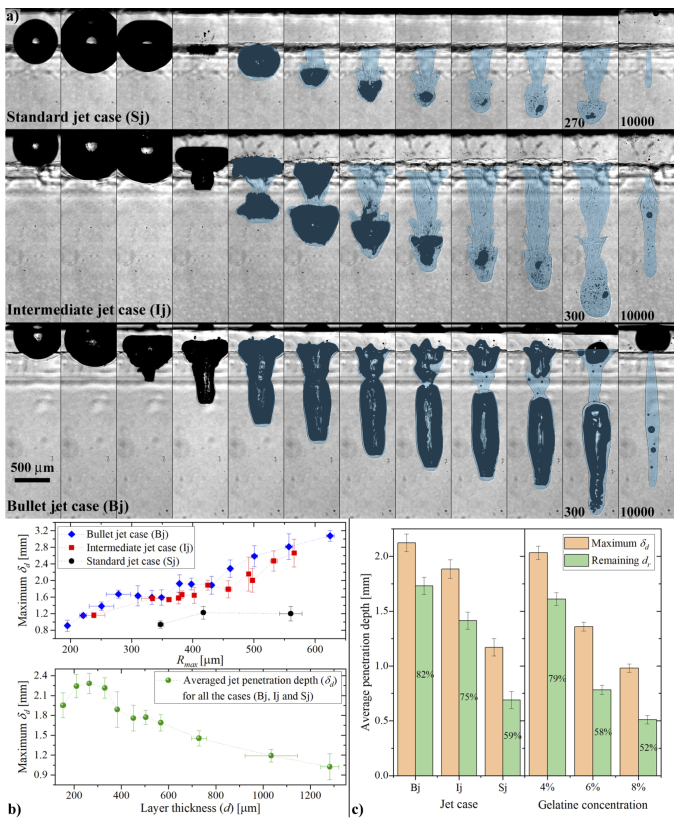

3.1. Evaluation of different types of jet to produce an effective liquid deposition

Besides the bullet jet, also other conventional types of jets may be generated [22,30–33], depending on the location of the laser focus from the free interface, , and the bubble/cavity maximum radius, , computed as the average radius of the hemispherical cavity measured in the vertical and horizontal directions. Here, we classify the measured jets into three different cases according to their stand-off distance [34] ( ) and their temporal evolution. For simplicity, we will call these three regimes: standard jet, intermediate jet and bullet jet. One example of the penetration dynamics of each one of these jets is presented in Fig. 3(a). For the largest distances the standard jetting regime is observed. Here the bubble acquires a “meniscus” shape [22] during its collapse and the jet formed within the bubble impacts onto the lower bubble wall along a rather broad region. It continues to flow into the gelatin producing a mushroom-shaped liquid indentation. When the distance is reduced the width of the jet piercing the bubble from the top becomes thinner. This results in a longer and also thinner mushroom shape of the injected liquid, see intermediate jet in Fig. 3(a). When is further reduced to around one hundred microns the bullet jet regime is found. Its narrower tip and smoother shape may be responsible for the piercing of the elastic boundary and deeper penetration into the gelatin [21]. While not studied in greater detail, the bullet jet seemingly produces lesser deformation of the surrounding media when looking at the displacement of visible impurities in the gelatin. Overall the amount of liquid retained in the gelatin is highest for the bullet jet regime, see last frame of each image sequence in Fig. 3(a), i.e. at t=10 ms.

Fig. 3.

Comparison between three different jetting regimes produced by varying the depth of the laser focus from the free surface . (a) Prototypical examples of the penetration dynamics for cases with m, m and m, respectively. Here, m and the gelatin concentration is 4 % w/w. The videos were recorded at 48 kfps. The numbers indicate the time in microseconds after the bubble/splash inception. See Visualization 4 (5.8MB, mp4) , Visualization 5 (5.9MB, mp4) , and Visualization 6 (3MB, mp4) . (b) Maximum penetration depth ( ) averaged over 150 individual measurements taken with a liquid thickness ( ) between 150 m and 1300 m. The upper subplot gives account of the strong correlation between and . The lower subplot reveals the existence of an optimum value of around 275 m. (c) Statistics on for different jet cases and gelatin concentrations. The percentage value on the columns represent / . The subplot on the right does not include measurements of the standard jet case.

The upper panel of Fig. 3(b) plots the maximum penetration depth for the three regimes as a function of the bubble/cavity maximum radius. Overall larger bubbles/cavities produce deeper penetrating jets. Interestingly, the maximum penetration depth of the jet in the intermediate regime are similar to the bullet jet regime. Yet when comparing the remaining depth after ms with the maximum depth , liquid is deposited deeper by the bullet jet, see also Fig. 3(c). It is worth noticing that is not only depending on the laser pulse energy but also connected to the depth . This is because, in the cases with an open cavity, part of the initial bubble vapor is expelled to the atmosphere immediately after the laser shot, and consequently the pressure inside the cavity decays much faster than in the cases with a closed cavity. Therefore, the parameter that defines the type of jetting regime is the stand-off distance ( ).

The lower panel of Fig. 3(b) plots the maximum penetration depth, , as a function of the thickness of the liquid layer. A maximum is obtained for a layer thickness of m. The occurrence of a maximum may be explained considering that for a too shallow layer a smaller amount of fluid feeds the jet, while for a very large the jet looses momentum by viscous dissipation before impacting onto the gelatin interface [4].

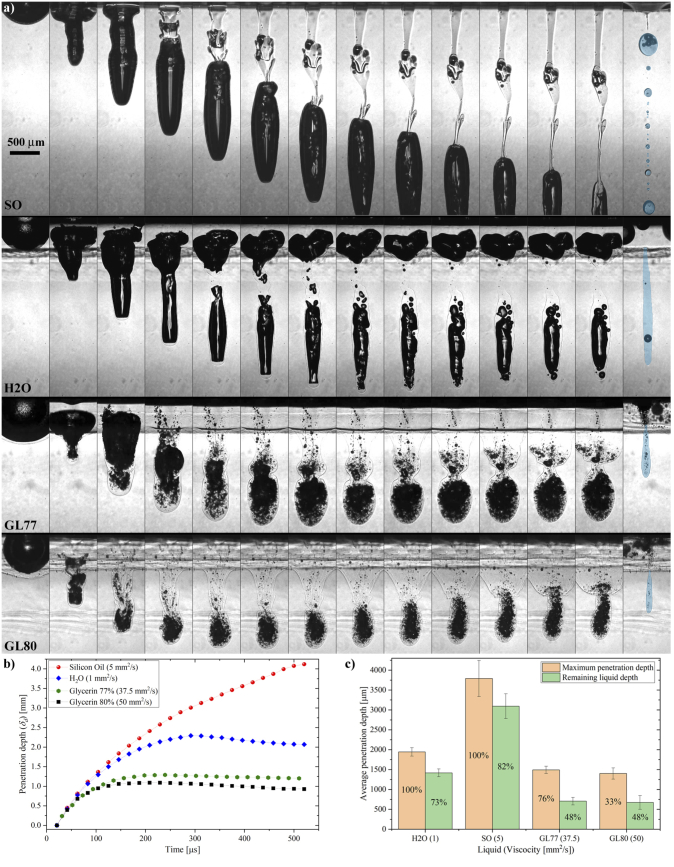

3.2. Influence of the liquid properties

We also investigated the influence of the properties of the liquid covering the gelatin layer. Therefore, the jet dynamics, and were evaluated for silicon oil (SO), water (H2O) and two aqueous solutions of glycerin with concentrations of 77% and 80% w/w (GL77 and GL80, respectively). The dynamic viscosities and the surface tension, of the liquids are: /s and mN/m for water, /s and mN/m for the silicon oil, /s and mN/m for GL77 and /s and mN/m for GL80 [35].

Generally speaking, we have not observed significant changes in the bubble/splash dynamics for the different liquids, at least for the range of viscosities used. However, the splashes produced from liquids with lower viscosities present a higher degree of atomization. As for the jet piercing dynamics, Fig. 4(a) shows a qualitative comparison of the jet advance for the four liquids. All cases present similar initial penetration velocities (see slopes in Fig. 4(b)). The glycerine solutions GL77 and GL80 reveal a considerably shorter penetration depth in contrast to H20 and SO cases. Likely the higher viscosities result in a higher deceleration of the piercing jet tip [9,12], see also Fig. 4(b). The jets produced from silicon oil in the top row of Fig. 4(a) reveal a remarkably reduced deceleration rate even as compared to water although the viscosity is about 5 times higher.

Fig. 4.

Jet piercing dynamics for different liquids covering the gelatin with a concentration of 4 % w/w. (a) Measurements taken with 24 kfps using silicon oil (SO), water (H2O) and glycerin aqueous solutions with a concentration of 77% and 80% w/w (GL77 and GL80, respectively). Here, m and varies between 420 m and 500 m. The last frame of each sequence, recorded 10 ms after the bubble/splash inception, shows in false color the remaining liquid after the jet stagnation. See Visualization 7 (5.8MB, mp4) , Visualization 8 (5.2MB, mp4) , Visualization 9 (9MB, mp4) , and Visualization 10 (9.1MB, mp4) . (b) Trajectory of the jet for the examples presented in (a). (c) Statistics on for different liquids with a viscosity ranging from 1 /s to 50 /s. The percentage value on the left column indicate the number of shots that effectively pierced the gelatin interface, while the number on the right column gives / .

The explanation for this could reside in how the reduced surface tension of the SO affects the specific dynamics of the jet tip and how this affects the rupture process of the gelatin as the liquid advances. More experiments are needed to shed some light on this matter.

The images in Fig. 4(a) also show that less liquid is retained inside the gelatin for the two high viscosity liquids, GL77 and GL80. This observation is verified from the averaged values plotted in Fig. 4(c). Additionally, the percentage of jets which effectively pierce the gelatin surface was significantly lower when the injected liquid was glycerin.

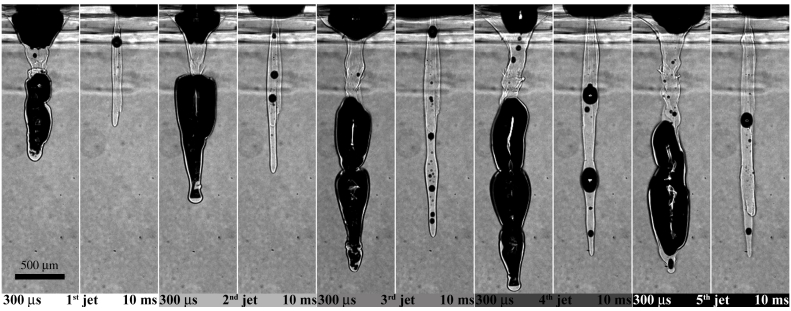

3.3. Effect of producing successive jets on the same spot

A further feature of the micro-injection method in the bullet jet regime is that for successive applications at the same spot the maximum penetration grows on every shot until it stagnates at a limit depth, as previously observed for regular jet injectors [20,36]. The experiments suggest that this limit depth is a function of elastic and liquid properties. Figure 5 shows an image sequence corresponding to 4 successive shots represented with 2 frames each. The first frame of the pair presents the instant where the bullet jet reaches its maximum transient depth (i.e. , approximately 300 s after the bubble inception). The second frame of each shot displays the deposited liquid once most of the injected gas has left the liquid filled cavity. From Fig. 5 it is evident that the jet penetrates deeper into the gelatin with every successive shot until it reaches a limit typically after 3 or 4 shots. This feature was observed for all the cases analysed in this work, and can be particularly useful for hard materials or when highly viscous liquids are used. The limiting number of shots producing the maximum effective penetration of the liquid could vary depending on the liquid characteristics and the specific mechanical properties of the sample. For instance, higher injection depths were achieved after multiple shots in the cases with 8%w/w gelatin or GL80, compared with cases where the laser was fired just once at a given point. As discussed early in the text, the final value of is directly related to the specific properties of the jet, which in turn depend on , and .

Fig. 5.

Multiple bullet jets produced in a consecutive way at the same location. Here the gelatin concentration was 4% w/w and the height of the water layer was m. The image sequence presents 2 different frames for each one of the 5 consecutive shots displayed. The first frame shows the moment when the liquid jet reaches a maximum penetration depth (approximately 300 s after the bubble inception) while the second frame shows the remaining liquid at a later instance 10 ms after the jet is produced. The effective penetration depth of the piercing jets when fired in this way is increased with each successive shot until it reaches a maximum, typically after 3 or 4 shots.

4. Conclusion

We have reported on the suitability of different jetting phenomenon for the injection of liquid into a soft elastic solid and demonstrated the advantages of the bullet-jet regime for that particular application. For instance, this regime presented an increased penetration depth and a higher ratio of injected liquid ( / ) for all the cases studied. Bullet jets can conveniently be created close to the surface of rather thin liquid layers, i.e. of more than m. Then the jet formation dynamics is independent of the underlying elastic material properties. As a result bullet jets sufficiently fast to penetrate 8% w/w gelatin are formed. This technique may be suitable for needle-free drug or ink delivery into the skin and similar soft materials. The relatively low pulse energies used to produce the bullet jets would require minimum protective measures (e.g. using special googles). An advantage of the present technique is its simplicity: the only requirement is that the pulsed laser is focused just below the surface of a thin layer of liquid covering the target solid. The injection depth of the jet can be controlled by changing the bullet jet dimensions by tuning the laser energy, yet it also depends on the solid and liquid properties (e.g. viscosity or surface tension). More experimental work is necessary to study the robustness of the bullet jet for industrial and medical applications.

Acknowledgments

J.M.R. acknowledges support by the Alexander von Humboldt Foundation (Germany) through the Georg Forster Research Fellowship. We acknowledge support for the publication fees by the Open Access Publication Fund of Magdeburg University.

Funding

Alexander von Humboldt-Stiftung10.13039/100005156 (Georg Forster Research Fellowship); Magdeburg University10.13039/501100012320 Open Access Fund.

Disclosures

The authors have no conflicts to disclose.

Data availability

Data underlying the results presented in this paper are not publicly available at this time but may be obtained from the authors upon reasonable request.

Supplemental document

See Supplement 1 (3.2MB, pdf) for supporting content.

References

- 1.Schoppink J., Fernandez Rivas D., “Jet injectors: perspectives for small volume delivery with lasers,” Adv. Drug Delivery Rev. 182, 114109 (2022). 10.1016/j.addr.2021.114109 [DOI] [PubMed] [Google Scholar]

- 2.Stachowiak J. C., Li T. H., Arora A., Mitragotri S., Fletcher D. A., “Dynamic control of needle-free jet injection,” J. Controlled Release 135(2), 104–112 (2009). 10.1016/j.jconrel.2009.01.003 [DOI] [PubMed] [Google Scholar]

- 3.Jang H.-J., Yu H., Lee S., Hur E., Kim Y., Lee S.-H., Kang N., Yoh J. J., “Towards clinical use of a laser-induced microjet system aimed at reliable and safe drug delivery,” J. Biomed. Opt. 19(5), 058001 (2014). 10.1117/1.JBO.19.5.058001 [DOI] [PubMed] [Google Scholar]

- 4.Baxter J., Mitragotri S., “Jet-induced skin puncture and its impact on needle-free jet injections: experimental studies and a predictive model,” J. Controlled Release 106(3), 361–373 (2005). 10.1016/j.jconrel.2005.05.023 [DOI] [PubMed] [Google Scholar]

- 5.Tagawa Y., Oudalov N., Ghalbzouri A. E., Sun C., Lohse D., “Needle-free injection into skin and soft matter with highly focused microjets,” Lab Chip 13(7), 1357 (2013). 10.1039/c2lc41204g [DOI] [PubMed] [Google Scholar]

- 6.Gonzalez Avila S. R., Song C., Ohl C. D., “Fast transient microjets induced by hemispherical cavitation bubbles,” J. Fluid Mech. 767, 31–51 (2015). 10.1017/jfm.2015.33 [DOI] [Google Scholar]

- 7.Moradiafrapoli M., Marston J., “High-speed video investigation of jet dynamics from narrow orifices for needle-free injection,” Chem. Eng. Res. Des. 117, 110–121 (2017). 10.1016/j.cherd.2016.10.023 [DOI] [Google Scholar]

- 8.Berrospe Rodríguez C., Visser C. W., Schlautmann S., Rivas D. F., Ramos-García R., “Toward jet injection by continuous-wave laser cavitation,” J. Biomed. Opt. 22(10), 1 (2017). 10.1117/1.JBO.22.10.105003 [DOI] [PubMed] [Google Scholar]

- 9.Cu K., Bansal R., Mitragotri S., Fernandez Rivas D., “Delivery strategies for skin: comparison of nanoliter jets, needles and topical solutions,” Ann. Biomed. Eng. 48(7), 2028–2039 (2020). 10.1007/s10439-019-02383-1 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Oyarte Gálvez L., Fraters A., Offerhaus H. L., Versluis M., Hunter I. W., Fernández Rivas D., “Microfluidics control the ballistic energy of thermocavitation liquid jets for needle-free injections,” J. Appl. Phys. 127(10), 104901 (2020). 10.1063/1.5140264 [DOI] [Google Scholar]

- 11.Robles V., Gutierrez-Herrera E., Devia-Cruz L. F., Banks D., Camacho-Lopez S., Aguilar G., “Soft material perforation via double-bubble laser-induced cavitation microjets,” Phys. Fluids 32(4), 042005 (2020). 10.1063/5.0007164 [DOI] [Google Scholar]

- 12.Rohilla P., Marston J., “Feasibility of laser induced jets in needle free jet injections,” Int. J. Pharm. 589, 119714 (2020). 10.1016/j.ijpharm.2020.119714 [DOI] [PubMed] [Google Scholar]

- 13.Krizek J., Lavickova B., Moser C., “Degradation study on molecules released from laser-based jet injector,” Int. J. Pharm. 602, 120664 (2021). 10.1016/j.ijpharm.2021.120664 [DOI] [PubMed] [Google Scholar]

- 14.Ohl C.-D., Arora M., Ikink R., de Jong N., Versluis M., Delius M., Lohse D., “Sonoporation from jetting cavitation bubbles,” Biophys. J. 91(11), 4285–4295 (2006). 10.1529/biophysj.105.075366 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Mur J., Agrež V., Petelin J., Petkovšek R., “Microbubble dynamics and jetting near tissue-phantom biointerfaces,” Biomed. Opt. Express 13(2), 1061 (2022). 10.1364/BOE.449814 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Patrascioiu A., Fernández-Pradas J. M., Palla-Papavlu A., Morenza J. L., Serra P., “Laser-generated liquid microjets: correlation between bubble dynamics and liquid ejection,” Microfluid. Nanofluid. 16(1-2), 55–63 (2014). 10.1007/s10404-013-1218-5 [DOI] [Google Scholar]

- 17.Jalaal M., Li S., Klein Schaarsberg M., Qin Y., Lohse D., “Destructive mechanisms in laser induced forward transfer,” Appl. Phys. Lett. 114(21), 213703 (2019). 10.1063/1.5095520 [DOI] [Google Scholar]

- 18.Mahravan E., Kim D., “Bubble collapse and jet formation inside a liquid film,” Phys. Fluids 33(11), 112102 (2021). 10.1063/5.0060422 [DOI] [Google Scholar]

- 19.Ebrahimi Orimi H., Narayanswamy S., Boutopoulos C., “Hybrid analytical/numerical modeling of nanosecond laser-induced micro-jets generated by liquid confining devices,” Journal of Fluids and Structures 98, 103079 (2020). 10.1016/j.jfluidstructs.2020.103079 [DOI] [Google Scholar]

- 20.Oyarte Gálvez L., Brió Pérez M., Fernández Rivas D., “High speed imaging of solid needle and liquid micro-jet injections,” J. Appl. Phys. 125(14), 144504 (2019). 10.1063/1.5074176 [DOI] [Google Scholar]

- 21.Kiyama A., Endo N., Kawamoto S., Katsuta C., Oida K., Tanaka A., Tagawa Y., “Visualization of penetration of a high-speed focused microjet into gel and animal skin,” J. Visualization 22(3), 449–457 (2019). 10.1007/s12650-019-00547-8 [DOI] [Google Scholar]

- 22.Rosselló J. M., Reese H., Ohl C.-D., “Dynamics of pulsed laser-induced cavities on a liquid–gas interface: from a conical splash to a ‘bullet’ jet,” J. Fluid Mech. 939, A35 (2022). 10.1017/jfm.2022.223 [DOI] [Google Scholar]

- 23.Van Kuilenburg J., Masen M. A., Van Der Heide E., “Contact modelling of human skin: What value to use for the modulus of elasticity?” Proc. Inst. Mech. Eng., Part J 227(4), 349–361 (2013). 10.1177/1350650112463307 [DOI] [Google Scholar]

- 24.Diridollou S., Patat F., Gens F., Vaillant L., Black D., Lagarde J. M., Gall Y., Berson M., “In vivo model of the mechanical properties of the human skin under suction,” Skin Research and Technology 6(4), 214–221 (2000). 10.1034/j.1600-0846.2000.006004214.x [DOI] [PubMed] [Google Scholar]

- 25.Kavanagh J., Menand T., Daniels K., “Gelatine as a crustal analogue: determining elastic properties for modelling magmatic intrusions,” Tectonophysics 582, 101–111 (2013). 10.1016/j.tecto.2012.09.032 [DOI] [Google Scholar]

- 26.Phillips G., Williams P., Handbook of Hydrocolloids (Elsevier Science, 2020). [Google Scholar]

- 27.Clanet C., “Waterbells and liquid sheets,” Annu. Rev. Fluid Mech. 39(1), 469–496 (2007). 10.1146/annurev.fluid.39.050905.110317 [DOI] [Google Scholar]

- 28.Aristoff J. M., Bush J. W. M., “Water entry of small hydrophobic spheres,” J. Fluid Mech. 619, 45–78 (2009). 10.1017/S0022112008004382 [DOI] [Google Scholar]

- 29.Brujan E., Nahen K., Schmidt P., Vogel A., “Dynamics of laser-induced cavitation bubbles near elastic boundaries: influence of the elastic modulus,” J. Fluid Mech. 433, 283–314 (2001). 10.1017/S0022112000003335 [DOI] [Google Scholar]

- 30.Chen R. C. C., Yu Y. T., Su K. W., Chen J. F., Chen Y. F., “Exploration of water jet generated by q-switched laser induced water breakdown with different depths beneath a flat free surface,” Opt. Express 21(1), 445–453 (2013). 10.1364/OE.21.000445 [DOI] [PubMed] [Google Scholar]

- 31.Koukouvinis P., Gavaises M., Supponen O., Farhat M., “Simulation of bubble expansion and collapse in the vicinity of a free surface,” Phys. Fluids 28(5), 052103 (2016). 10.1063/1.4949354 [DOI] [Google Scholar]

- 32.Supponen O., Obreschkow D., Tinguely M., Kobel P., Dorsaz N., Farhat M., “Scaling laws for jets of single cavitation bubbles,” J. Fluid Mech. 802, 263–293 (2016). 10.1017/jfm.2016.463 [DOI] [Google Scholar]

- 33.Bempedelis N., Zhou J., Andersson M., Ventikos Y., “Numerical and experimental investigation into the dynamics of a bubble-free-surface system,” Phys. Rev. Fluids 6(1), 013606 (2021). 10.1103/PhysRevFluids.6.013606 [DOI] [Google Scholar]

- 34.Ohl C.-D., Kurz T., Geisler R., Lindau O., Lauterborn W., “Bubble dynamics, shock waves and sonoluminescence,” Philos. Trans. R. Soc., A 357(1751), 269–294 (1999). 10.1098/rsta.1999.0327 [DOI] [Google Scholar]

- 35.Takamura K., Fischer H., Morrow N. R., “Physical properties of aqueous glycerol solutions,” J. Pet. Sci. Eng. 98-99, 50–60 (2012). 10.1016/j.petrol.2012.09.003 [DOI] [Google Scholar]

- 36.Kato T., Arafune T., Washio T., Nakagawa A., Ogawa Y., Tominaga T., Sakuma I., Kobayashi E., “Mechanics of the injected pulsejet into gelatin gel and evaluation of the effect by puncture and crack generation and growth,” J. Appl. Phys. 116(7), 074901 (2014). 10.1063/1.4893175 [DOI] [Google Scholar]