Abstract

Thumba oil with a higher triglyceride content can be a promising feed for synthesizing a fatty acid alkyl ester as an alternative to pure diesel. The current study investigates the emission and performance characteristics of thumba methyl ester (TME) in compression ignition (CI) engines corresponding to variable loads and compression ratios (CRs), respectively. TME was prepared at an optimized pressure of 5 bar by hydrodynamic cavitation. The properties of TME–diesel blends with varied volume percentages of biodiesel, such as 5, 10, 15, 20, and 25, denoted B5, B10, B15, B20, and B25, respectively, were compared to pure TME (100% biodiesel) and pure diesel (100%). The B20 biodiesel blend has been observed as the optimal one based on the lower emission composition and higher brake thermal efficiency. For B20 fuel, injection at 23° before the top dead center (TDC) and a CR of 18 resulted in the lowest brake specific fuel consumption of 0.32 kg/kW h and a maximum brake thermal efficiency of 36.5%. Using titanium dioxide nanoparticles in the pre-stage of TME manufacturing has ultimately reduced the nitrogen oxide, hydrocarbon, and carbon monoxide emissions. At a CR of 18 and advanced injection 23° before TDC for a CI engine, TME derived from thumba oil has the potential to be a viable diesel substitute.

1. Introduction

The domestic, agriculture, transportation, commercial, and industrial sectors across the globe are primarily dependent on energy. The increased demand for energy has led to heavy dependency on fossil fuels because of reliability, adaptability, higher energy conversion efficiency, and accessible handling facilities. As fossil fuels are exhaustible and the consumption rate is too high, severe fossil fuel scarcity is inevitable.1 Second, the combustion of fossil fuels contributes mainly to the hazardous emission of particulate matter, hydrocarbons (HCs), nitrogen oxides (NOx), and carbon monoxide (CO). Therefore, an alternate source for fuel has become the demand of time to overcome the fast-approaching energy scarcity and hazards of environmental pollution. Because of its similar qualities to pure diesel, biodiesel is the most efficient and renewable fossil fuel substitute.2 Second, biodiesels may be used in diesel engines without major engine modifications. Hence, biodiesel has been considered to be a potential alternate fuel in the recent past due to its biodegradability, nontoxicity, nonflammability, and nonexplosive and environment-friendly nature with comparatively better combustion attributes than pure diesel. This has grabbed the attention of researchers as a sustainable substitute to fossil fuels.3,4

Biodiesels are sulfur-free, mono-alkyl esters of long-chain fatty acids obtained from edible and inedible oils and animal fats. The feedstock used for the generation of biodiesel includes oils derived from sunflower, cottonseed, soybean, rapeseed, Jatropha, and Karanja.5 The investigations of Sathiamoorthy et al.6 revealed that the unburnt HC, CO, NOx, and exhaust smoke emissions could be significantly reduced by blending palmarosa oil with diesel at different compositions. The biodiesel made from castor oil resulted in 10% reduction in HC and CO emissions, with a little rise in the brake-specific fuel consumption (BSFC).7 Ellappan and Rajendran8 provided a comprehensive review of eucalyptus oil-blended biodiesel. Sayyed et al.9 used 90% diesel and 10% biodiesel blends from different feedstocks such as Karanja, Jatropha, mahua, and neem oil to determine the parameters of a direct-injection compression ignition (CI) engine. Their experimental investigations revealed significantly reduced CO emission by around 47% with use of 5% Jatropha and 5% neem oil.9

Citrullus colocynthis, namely, thumba oil, has been considered the feedstock for biodiesel synthesis in the present work. It is abundantly available in the western regions of Rajasthan and Gujarat in India. Approximately 1 million tons of thumba seeds are harvested annually from the arid districts of Rajasthan. The thumba seeds contain as high as 50% of oil and gave a yield of 450 to 675 kg per hectare.10 Through a catalytic transesterification process, the fatty acid content of thumba oil can be used to produce biodiesel. However, the thumba oil, instead of having a pretty good composition of saturated and unsaturated fatty acids, has been one of the most underutilized biodiesel feedstock.11 Jain et al.12 used biodiesel with 20% thumba oil to achieve 1.27% higher brake thermal efficiency (BTE).

The performance and emissions of a CI engine running on various fuels are heavily influenced by combustion parameters. Among such parameters, the compression ratio (CR) is one of the most vital parameters which influences all characteristics of a fuel being used. With a higher CR, the cylinder temperature rises and ignition delay decreases, resulting in smaller BSFC and higher BTE. Because the fuel atomization process is accelerated at higher temperatures due to the higher CR, CO and HC emissions are reduced, while NOx emissions are increased. However, NOx emissions can be regulated by adopting various methods, such as exhaust gas recirculation. The combustion parameters revealed a longer combustion duration and a shorter ignition delay for the biodiesel blend at a greater CR.13

Due to the lower CR, the delay time lengthens and the peak cylinder pressure falls, while the exhaust gas temperature rises. Hence, the BTE can be improved with lower BSFC.14 Vijaykumar et al.15 investigated the behavior of a variable CR (VCR) engine with the CR varying from 17 to 18 at an increasing step of 0.5 using mahua oil-blended biodiesel at different proportions.15 The most favorable characteristics were noticed at a maximum CR of 18, which was not feasible to increase further due to vibration issues of the engine. With an increase in CR from 16:1 to 18:1 in a CI engine employing hydrogen-enriched biogas diesel, Rocha et al.16 found a decrease in HC, CO, and smoke opacity emissions, while increasing the BTE and ignition delay.16 In a CI engine fueled with palmyra oil methyl ester, Rao and Vara Prasad17 changed the CI from 16:1 to 20:1 to get a 6.91% higher BTE and a 10.2 % lower BSFC. The HC and CO emissions were lower at a higher CR with a higher NOx content, which was addressed by adopting the exhaust gas recirculation approach. Aside from the CR, the injection time of a diesel engine has a significant impact on the vehicle’s performance and emissions. The combustion duration is effectively reduced as the fuel injection is retarded, which leads to incomplete combustion. As a result, the performance suffers an adverse impact with lower BTE and higher BSFC. Simultaneously, the exhaust emissions get affected, resulting in higher HC and CO contents. A comprehensive review provided by Rahman et al.18 found that delaying the injection timing increased the HC and CO emissions, while decreasing NOx emissions in diesel engines. Injection timing and compression ratio have major role in reducing the emission with rise in BMEP.19

Shareef and Mohanty20 reported a reduction in HC and CO emissions by 26 and 35%, respectively, for a diesel engine working with dairy scum biodiesel when injected 26° before top dead center (TDC) compared to the conventional injection. Nayak et al.21 observed a significant improvement in efficiency and reduced pollutants when injected 25° before TDC. CakMak and Özcan22 experimented with biodiesel having 80% diesel and the remaining being different proportions of canola oil and tert-butyl ether mixture to study the emission and combustion behavior. Öztürk et al.23 discovered that the injection timing can be delayed to address the issue of high NOx emissions in a diesel engine running on canola-mixed biodiesel with 90% diesel content.

Refined (esterified) biodiesel, such as thumba methyl ester (TME), which is readily available in India, according to the literature, could be a potential alternative sustainable fuel24−26 to unrefined thumba oil16 for diesel engines. However, the consequences of combusting TME/diesel blends made with nanocatalysts in a diesel engine have yet to be described in the literature.27−29 So far, the effects of combusting blends of fatty acid methyl ester30−32 prepared using homogeneous catalysts like NaOH or KOH and diesel in the diesel engine have been reported.33−36 Therefore, the current study is “first of its kind,” which reports the effects of combusting blends of fatty acid alkyl ester prepared using a nanocatalyst and diesel in the diesel engine. However, there is currently no study to support the use of heterogeneous catalysts in the hydrodynamic cavitation method for biodiesel synthesis.37,38 The use of a photocatalyst in the synthesis of biodiesel has not yet been investigated.39 The current study is the first one which studies it utilizing an enhanced technology, hydrodynamic cavitation, which can produce biodiesel that is both cheaper and cleaner.40,41 There has not been much research done on using UV light and hydrodynamic cavitation to produce biodiesel,43−46 thus there are opportunities to experiment in this field.47

The present study is intended to investigate the suitability of TME as a potential blending element for use in CI engines. TME was synthesized by transesterifying thumba oil with methanol in a hydrodynamic cavitation reactor26 based on an earlier work.24,25 The impacts of CR and spill timing on the performance and emission parameters of a single-cylinder, four-stroke VCR diesel engine powered by thumba oil biodiesel were studied. The BTE, BSFC, and brake-specific energy consumption (BSEC) were used for performance evaluation. On the other hand, HC, CO, and NOx emissions have been considered when analyzing hazardous engine emissions. These results are compared to diesel to determine whether TME is a viable replacement for diesel fuel and engine parameters to achieve optimal performance and emission characteristics.

2. Materials and Methods

2.1. Materials

The titanium dioxide (TiO2) nanocatalyst was synthesized by hydrolysis of titanium isopropoxide with water as a solvent by the power ultrasound method. Thumba oil was first extracted from seeds using hexane as the solvent. Its free use fatty acid content was measured using gas chromatography with flame -ionization detection (GC-FID) and automatic injection. Thumba oil’s high fatty acid (FFA) content suggests that it could be used as an alternative fuel.

2.2. Initial Pretreatment of Thumba Oil and Its Characterization

It is essential to remove suspended particles from the raw oil before being used in the operation. The raw oil was first filtered before being heated to 373 K for 20 to 30 min to allow the anhydrous oil to undergo alcoholysis. The initial FFA content was calculated using 0.1 N KOH and was found to be 1.6 mg KOH/g of raw oil.8 The estimated thermo-physical properties of the raw thumba oil by following appropriate ASTM standards were found to be as follows: a specific gravity of 0.918, a cetane number of 45, a flashpoint of 188 °C, a cloud point of 6 °C, a heating value of 42,780 kJ/kg, and a kinematic viscosity of 1.4 cSt at 15 °C. GC shows that thumba oil contains 67.43% unsaturated fatty acids and 22.57% saturated fatty acids. Oleic and linoleic acids are the most common unsaturated fatty acids, while myristic, palmitic, and stearic acids are the most common saturated fatty acids in thumba oil. The acid content of thumba oil is summarized in Table 1.

Table 1. Fatty Acid Content.

| fatty acids | wt % |

|---|---|

| palmitic acid (C16H34) | 9.55 |

| stearic acid(C18H38) | 7.70 |

| oleic acid (C18H36) | 18.26 |

| linoleic acid (C18H34) | 62.06 |

| behenic acid (C21H43) | 2.43 |

2.3. Methods

2.3.1. Alcoholysis for the Synthesis of TME

Alcoholysis is a chemical reaction that produces fatty acid alkyl esters by combining oil’s triglycerides with suitable alcohol in the presence of a catalyst. Among the different heterogeneous catalysts, TiO2 has been considered in the present work because it reduces emissions due to its higher oxidation capacity and thermal conductivity, which renders an ecological advantage.24 TiO2 can hold the energy and supply it to other reacting components.25 Similarly, methanol is the considered alcohol because of its quick reaction ability with triglycerides.20

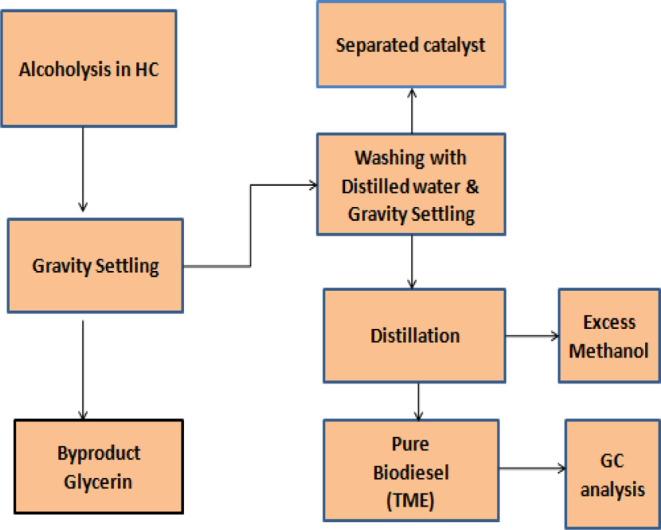

TME was prepared by alcoholizing oil with methanol using TiO2 nanoparticles as catalysts in the hydrodynamic cavitation system. The experimental design of the hydrodynamic cavitation apparatus is shown in Figure 1b. Innocenzi and Prisciandaro,28 Ghayal et al.,26 and Bargole et al.27 investigated the alcoholysis of waste cooking oils in the hydrodynamic cavitation system using NaOH or KOH catalysts. Figure 2 depicts a block diagram of the entire procedure. Steps were carried out as shown in Figure 2 under optimized process conditions (reaction time of 1 h) as stated in our earlier work.25,26 Considering the objective for maximum conversion of triglyceride, the molar ratio of methanol and oil has been maintained at 1:6, which is 100% above the stiochiometric ratio. For optimum yielding of the TME, suitable TiO2 catalyst concentration (1.2 wt % in oil), temperature (60 °C), and inlet pressure (5 bar) have been calculated.25,26 Finally, the products were washed with deionized H2O at 323 K following gravity settling to separate the TiO2 and solid impurities. TME was thoroughly investigated using the EN 14103 standard procedure.

Figure 1.

(a) Hydrodynamic cavitation setup for biodiesel synthesis.

Figure 2.

Steps in TME synthesis.

2.3.2. Characteristics of TME (Biodiesel)

The current research was carried out to investigate pure diesel (D100), TME (B100), and biodiesel blends with 5, 10, 15, 20, and 25% of biodiesel. The biodiesels were named B5, B10, B15, B20, and B25 based on the content of TME. A proper mixture of the respective blends was developed by magnetic stirring at around 700 to 850 rpm. Further, complete mixing was achieved with the help of a probe-type ultrasonicator. The physicochemical parameters of various blends were calculated using ASTM criteria. Table 2 summarizes the physical features of the blends in more detail.

Table 2. Physicochemical Properties of Prepared Blends.

| properties | B100 | B5 | B10 | B15 | B20 | B25 | diesel | ASTM standard |

|---|---|---|---|---|---|---|---|---|

| density (kg/m3) | 863 | 831 | 833 | 837 | 838 | 842 | 831 | ASTM D4052 |

| viscosity @ 40 °C (cSt) | 3.49 | 2.75 | 2.78 | 2.95 | 3.12 | 3.21 | 2.6 | ASTM D445 |

| heating value (kJ/kg) | 30,772 | 42,492 | 41,620 | 41,418 | 41,265 | 41,025 | 43,185 | ASTM D5865 |

| flash point (°C) | 141 | 54 | 56 | 60 | 62 | 63 | 53 | ASTM D93 |

| fire point (°C) | 168 | 64 | 69 | 70 | 73 | 77 | 62 | ASTM D93 |

| flow rates (kg/h) at 100% load | 1.23 | 1.40 | 1.42 | 1.45 | 1.55 | 1.62 | 1.15 |

2.3.3. Engine Configuration and Operating Conditions

The research was aided by a single-cylinder, four-stroke, VCR diesel engine that ran on pure diesel and thumba oil biodiesel mixtures. The complete test engine setup schematic diagram is depicted in Figure 3. The engine is from Kirloskar with a CR of 16, which can be varied from 9 to 18. The engine capacity is 3.7 kW at a rate of speed of 1500 rpm. The detailed specifications of the test engine setup are summarized in Table 3. To analyze and record the different performance and combustion parameters, the IC Enginesoft 9.0 software is installed. The exhaust gas emissions for unburned HC, CO, and NOx were measured using an AVL Digas 444 Exhaust Gas Analyzer (NOx). To meet baseline characteristics, the engine was also given the ability to perform with pure diesel at rated speed. Afterwards, the readings were taken and recorded for various planned fuels corresponding to various brake powers by varying the engine load at an increasing step of 25% through the dynamometer.

Figure 3.

Schematic diagram of the engine setup. (1) Diesel tank, (2) fuel control valve, (3) exhaust gas silencer, (4) air filter, (5) airflow indicator, (6) inlet valve, (7) exhaust valve, (8) charge amplifier, (9) airflow meter, (10) diesel injector, (11) in-cylinder pressure transducer, (12) crank angle encoder, (13) high-speed combustion data acquisition system, (14) computer, (15) VCR test engine, (16) coupling, (17) exhaust gas analyzer, (18) exhaust gas probe, (19) dynamometer, and (20) control panel.

Table 3. Details of the Engine Setup.

| name | single-cylinder, four-stroke VCR diesel engine with a dynamometer, |

| supplier | Kirloskar oil engine LTD, Sangli |

| type of Engine | single-cylinder vertical, four-stroke cycle |

| direction of rotation | clockwise/anticlockwise |

| bore | 0.080 m |

| stroke | 0.11 m |

| cubic capacity | 0.5 × 10–3 m3 |

| nominal CR | 10 to 18 |

| fuel timing by the spill | 23° BTDC |

| the exhaust valve closes (ATDC) | 4.5° |

| exhaust valve opens (BBDC) | 35.5° |

| inlet valve closes (ABDC) | 35.5° |

| inlet valve opens (BTDC) | 4.5° |

2.3.4. Performance Characteristic Calculations

Performance characteristics were evaluated as

| 1 |

where BMEP is the brake mean effective pressure. A strain-gauge-type load cell sensor was used for load sensation, and a digital load indication was used.

| 2 |

| 3 |

2.4. Uncertainty Analysis

The uncertainty analysis can demonstrate the accuracy of an experimental examination. Uncertainties can occur due to experimental conditions, improper calibration, and the environment.20 The % uncertainties of BSFC, BTE, and BP were estimated using the linearized approximation method.20 The typical uncertainty values are summarized in Table 4.

Table 4. Accuracy and Uncertainty.

| parameter | accuracy | uncertainty |

|---|---|---|

| NOx | ±12 ppm | ±0.25 |

| CO | ±0.03% | ±0.25 |

| HC | ±12 ppm | ±0.25 |

| BTE | ±0.4 | ±1.2 |

| BSFC | ±4 g/kW h | ±1.2 |

| BP | ±0.04 kW | ±0.4 |

By employing the error propagation principle

|

3. Results and Discussion

Laboratory-scale studies were carried out to investigate the appropriateness of TME as a diesel alternative and the impacts of CR and injection timing on emission characteristics to arrive at the best possible result. The tests were carried out in two stages. The first phase of studies was used to identify the ideal blend, while the second phase was used to determine performance characteristics by adjusting load and emission characteristics at different CRs and injection timings.

3.1. TiO2 Synthesis and Characterization

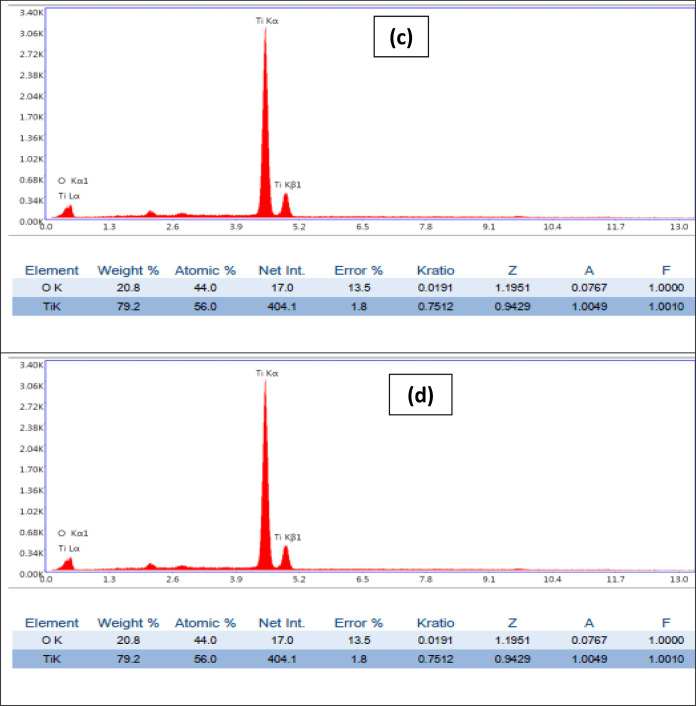

With static suspension, the smallest crystalline size of 8 nm was produced at pH = 2. The amount of H2O and calcination temperature employed significantly impact the TiO2 nanocatalyst shape.5Figure 4a,b depicts the SEM examination of nanocatalysts generated at various precursor to solvent ratios, and EDAX analysis, as shown in Figure 4c,d, showed the existence of Ti and O as important elemental components.

Figure 4.

SEM images of TiO2 nanoparticles at solvent to precursor ratios of (a) 40 and (b) 60; EDAX plots at solvent to precursor ratios of (c) 40 and (d) 60.

3.2. Determination of the Optimal Blend

The studies’ early stages were examined to determine the best TME blend in terms of emission and performance. The studies were conducted with a VCR engine at 1500 rpm and a fixed CR of 18 for diesel and TME blends with TME compositions ranging from 5 to 25% and 100% by volume. The investigation was carried out with a load varying from 0 to 100%, with an interval of 25%. Various TME blends, such as B5, B10, B15, B20, B25, and B100, and D100 were synthesized, and their effects on different engine characteristics were studied to obtain an optimized blend ratio. Finally, their experimental performances are compared with that of the diesel.

3.3. TME, TME–Diesel Blends, and Diesel Performance

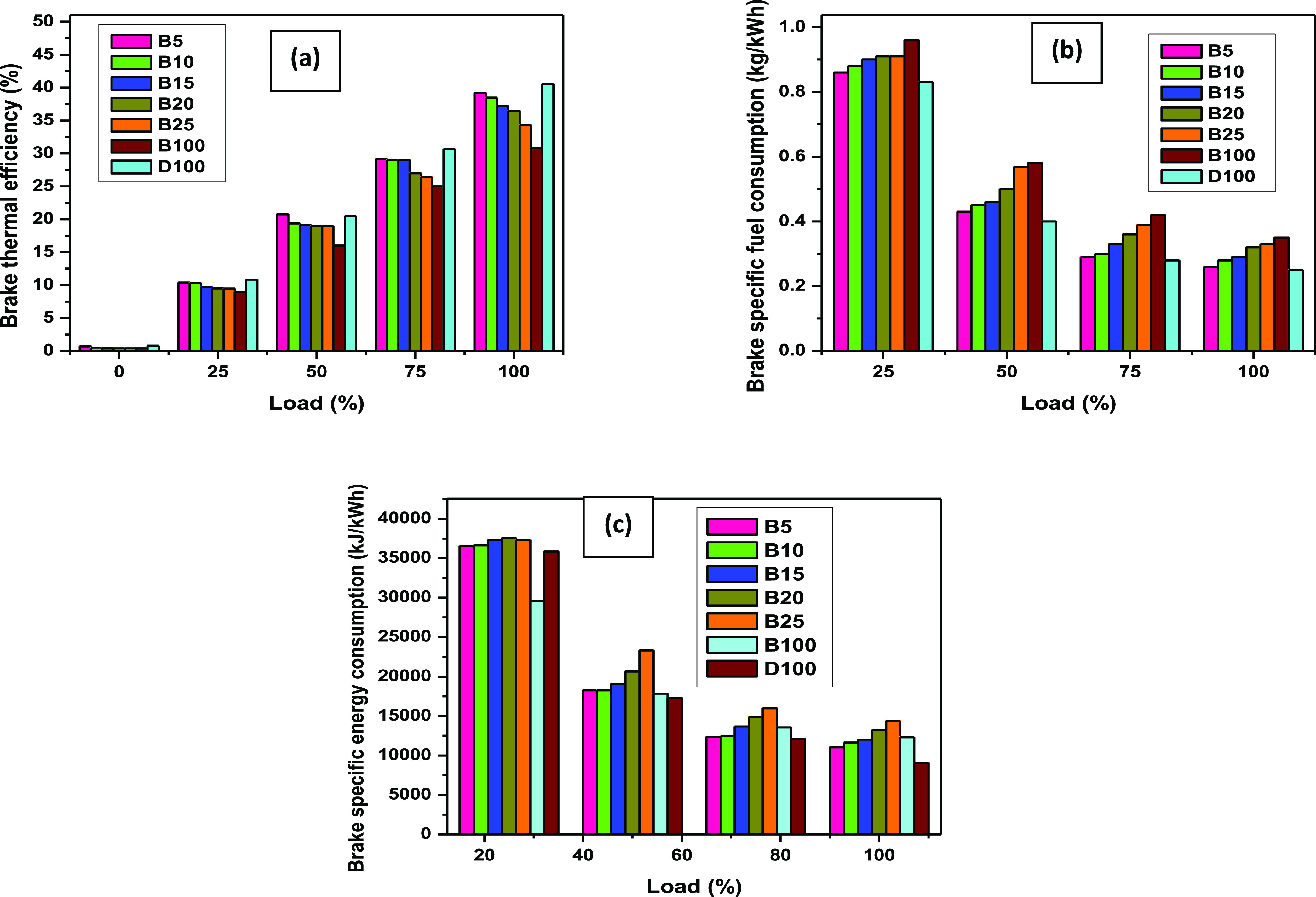

3.3.1. Brake Thermal Efficiency

The BTE is a measure of the ability of an engine to convert the chemical energy content of the fuel into useful mechanical work available at the crankshaft. Under normal operating circumstances, the BTE of an automotive engine primarily depends on the amount of fuel consumed and the heating value of the corresponding fuel. As depicted in Figure 5a, BTE is increased with the rise in load on the diesel engine for pure TME, TME–diesel blends, and diesel. At full load, the brake power developed by all fuels was approximately identical. Table 2 illustrates the heating values. The flow rates to the engine cylinder at 100 % load were 1.15 kg/h for diesel, 1.23 kg/h for TME, 1.40 kg/h for B5 blend, 1.42 kg/h for B10 blend, 1.45 kg/h for B15 blend, 1.55 kg/h for B20, and 1.621 kg/h for B25 blend. As a result, at 100% load, BTE for pure TME blends is lower than diesel.

Figure 5.

(a) BTE with load; (b) BSFC with load; and (c) BSEC with load.

According to the performance tests implemented, it is discerned that BTE for TME blends is less than that of pure diesel at 100% load. The experimental performance indicates that BTE is 40.5% for pure diesel, corresponding to the 100% load engine operating conditions. In comparison, it varies from 39.2 to 34.3% for B5 to B25, respectively, which indicates a slight decrease in BTE with an increase in TME %. On the other hand, The BTE for 100% biodiesel is 30%, which shows a decrease in BTE with a rise in TME %.

The BTE of the diesel engine increases with the engine load irrespective of the fuel. Simultaneously, the BTE was observed to be decreasing with the increase in the content of TME in the biodiesel blend. The primary reason behind the decrease in BTE with the increase in thumba oil content is the higher density and viscosity and lower heating value and adiabatic flame temperature of the biodiesel blend than pure diesel. The combustion process becomes improper, leading to lower output power with the increase in viscosity of the fuel. Simultaneously, the lower heating value of the oxygenated biofuel blend reduces the BTE, resulting in a lower BTE with the increase in thumba oil content. However, there was a very small reduction in BTE by 0.7% as the thumba oil content increased from 15 to 20% in the biodiesel blend. Almost similar behavior of BTE for all the fuel blends was observed at other loads. Similar trends in the variation of BTE have been reported in the literature by different researchers for other kinds of biodiesels.

Shareef and Mohanty20 reported a drop in BTE with the rise in dairy scum biodiesel from 10 to 30% at all load conditions. Patil et al.1 observed exactly similar experimental conditions to the current study of BTE and reported the same BTE considerations for neat rubber oil methyl ester at full load conditions, injected 23° before TDC. Patil and Patil32 observed similar effects and reported them. The brake thermal efficiency is shown to improve as the load on the diesel engine increases for pure sunflower oil methyl ester at 100% load, injected 23° before TDC. Chako et al.34 reported that multiple injections for both diesel and biodiesel blends that exhibit a decrease in BTE. The current study’s experimental results are consistent with those reported by many other researchers.30−32

3.3.2. Brake Specific Fuel Consumption

BSFC variation with load for pure TME, TME–diesel blends, and diesel is depicted in Figure 5b. The BSFC of pure diesel (0.25 kg/kW h) was found to be somewhat smaller than that of pure TME (0.35 kg/kW h) and TME blends (0.26 to 0.33 kg/kW h) at 100% load engine running circumstances. This is because, at a constant speed of 1500 rpm at 100% load, pure diesel had a lower mass flow rate than all other mixtures. Because the brake power generated at zero loads was smaller, the BSFC for all fuels drops as the engine load increases. However, as load rises from 25 to 100%, brake power rises faster than the amount of fuel burned per unit hour.

BSFC increases with a rise in percentage composition from 5 to 25% of TME in the diesel. The current study performance has the same considerations as reported by many researchers.12−15 This is because brake power for TME, TME–diesel blends, and diesel is almost the same at any load condition. The diesel’s lower density, viscosity, and higher heating value give 100% combustion with low BSFC, compared to the TME blends. Due to the increased density, viscosity, and decreased heating value with increased TME, complete agitation of fuel and air is not possible.15,16 The start of the combustion of TME–TME diesel blends occurred very close to TDC because of the addition of comparatively low cetane number (25) fuel. This indicates that the ignition delay period was lower for neat diesel (cetane number 50). Due to the increased ignition delay period, the possibility of knocking has increased.

According to Shareef and Mohanty,20 BSFC increases as the quantity of dairy scum methyl ester in the diesel increases. Patil and Patil31 observed exactly similar experimental conditions to the current study and reported the same BSFC considerations for neat rubber oil methyl ester at full load conditions, injected 23° before TDC. Patil and Patil32 found comparable results, reporting that BSFC rose from 5 to 20% when butanol was added to SOME-butanol blends. Chako et al.34 observed that at 1100 bar, the BSFC decreased by 21.5% for B20 with a single injection, whereas with multiple injections, it gave a 34.7% reduction. This variation is induced by the improved combustion of the pilot fuel at higher FIP, thus generating higher in-cylinder pressure. The current study’s experimental results are consistent with those reported by many other researchers15,16

3.3.3. Brake Specific Energy Consumption

BSEC is the product of BSFC (kg/kW h) to the heating value ((kJ/kg)) of the fuel. BSEC variation with a load for pure TME, TME–diesel blends, and diesel is depicted in Figure 5c. At 100% load engine operating conditions, the BSEC of pure diesel (9069 kJ/kW h) was found to be lower than that of pure TME (12309 kJ/kW h) and TME blends (11,048 to 14,359 kJ/kW h). This is because, at a speed of 1500 rpm and 100% load, the flow rate of pure diesel was found to be lower than that of all other mixtures. Because the brake power generated at zero loads was smaller, BSEC for all fuels diminishes as the load on the engine increases. However, as load grows from 25 to 100%, brake power increases faster than the increasing quantity of gasoline consumed per unit hour. Chako et al.35 reported that B20 possessed lower BSEC than D100.

BSEC nearly increases with an increase in the proportion from 5% to 20% of TME. The experimental performances have similar considerations as reported by many researchers.17,18 This is because the brake power for TME, TME–diesel blends, and diesel is almost the same at any load condition. The diesel’s lower density and viscosity and higher heating value give 100% combustion, resulting in lower BSEC compared to the TME blends.

From the current section of performance characteristics, it may be concluded that the brake power developed by all the blends was discovered to be almost nearly equal. The BTE of pure TME was higher than that of TME–diesel blends and diesel at 100% load under engine operating circumstances. However, at the full load, BSFC was shown to be lower for pure diesel than for pure TME and other mixtures. Also, the BSEC of pure diesel was less than that of pure TME and TME blends. As a result, running the VCR diesel engine at full load with either pure diesel or pure TME will be beneficial. However, this can be finalized after analyzing the emission characteristics in Sections 2.4 and 3.5.

3.4. Impact of Injection Timing

The retarded injection timing gives away a minor ignition delay and lowers the fuel burning rate. As a result, the temperature and pressure in the cylinder are observed to be relatively high.12 The injection of fuel between 19 and 27° before TDC at an interval of 2° and standard injection timing of 23° before TDC have been considered to study the impact of injection timing.

3.4.1. Impact on HC Emissions

Because of the higher oxygen concentration, TME and TME mix fuel emit less HC due to inefficient combustion and a shorter ignition delay. During the delay interval, the injector’s incorrectly matched fuel–air combination contributes to HC emissions from the engine.13 The HC emissions with diesel at baseline injection timing and various blends at the injection of 19 to 27° before TDC are depicted in Figure 6a. HC emissions at full load conditions for B 25 were 16, 17.5, 15, 20, and 30 ppm at injection timings of 19, 21, 23, 25, and 27° before the TDC, respectively. HC emissions were observed to increase after standard injection timing of 23° before TDC. Similar observations were made for all the blends.

Figure 6.

(a) Impact of injection timing (spill timing) on HC emissions; (b) CO emissions; (c) NOx emissions; and (d) CO2 emissions.

For forwarded injection, the extended ignition delay improves the turbulence intensity, fuel spray atomization, and combustion temperature and lowers HC emissions. The longer ignition delay follows better spray penetration and fuel–air mixing before the ignition phase. This faster combustion rate in the premixed region increases the combustion temperature and reduces HC emissions.12 The retardation in injection follows a rise in HC emissions due to poor combustion diffusion. However, the HC emission at injection 23° before TDC is the lowest and is about 13.5% less than that of pure diesel. Shareef and Mohanty20 found that the emission and combustion parameters of DSB20 with injection at 26° before TDC were better than the diesel with injection at 23° before TDC. Similar experimental results were reported by Patil and Patil31 Chako et al.34 reported on unburned HC with engine load and FIP. B20 shows 26.3% lower HC emissions than diesel with a single injection at 4.15 bar BMEP.

3.4.2. Impact on CO Emissions

Figure 6b depicts the effect of injection timing on CO emissions from the VCR engine for various blends. The experimental investigation indicates that the CO emission for diesel at an injection timing of 23° before TDC is around 12% higher than the B25 blend. The CO emission for blend B25 was found to be 0.06% at 23° before TDC, while the same was found to be 0.059, 0.06, 0.085, and 0.11% for injections at 19, 21, 25, and 27° before TDC, respectively. CO emissions were observed to be increased after the standard injection timing of 23° before TDC. Similar observations were made for all the blends. Because of the increased cylinder temperature and more CO to CO2 with the lower oxygen content in B20 fuel, higher CO emissions are emitted when injected 23° before TDC for all blends.29

The advanced injection incorporates proper fuel–air mixing, protracts the physical delay period, and enhances the oxidation process. The retarded injection generates inactive combustion as the delay period lowers and simultaneously increases CO emissions.20 Because of the increased cylinder temperature and more CO to CO2 with the higher oxygen content in B25 fuel, lower CO emissions are emitted when injected 23° before TDC for all blends.29 Shareef and Mohanty et al.20 studied reported CO emissions for dairy scum oil biodiesel-20 when injected 26° before TDC. At full load conditions when injected 23° before TDC, Patil and Patil31 studied comparable experimental results and observed that neat rubber oil methyl ester-15 emits less CO than neat diesel and specific butanol blends. The use of TiO2 in the pre-stage has wholly eliminated the post-step of adding nanofluid combined with different blends that aim to reduce HC and CO emissions. Chako et al.34 observed that for D100, CO was reduced by up to 12.1%, whereas with B20, a 26.8% reduction was obtained. Since the post fuel itself needs sufficient oxygen for proper combustion, the B20 has the upper hand over feed D100 when it comes to the utilization of postinjection.

3.4.3. Impact on NOx Emissions

The oxygenated methyl esters give off higher NOx emissions compared to diesel. Proper monitoring of the spill timing should be implemented to control NOx emissions. The impact of spill timing on NOx emissions of the VCR engine for the various blends is depicted in Figure 6c. The cylinder temperature and pressure reach a high value near the TDC, giving NOx formation due to 100% complete combustion. The NOx emissions for B25 increased from 1175 to 1280 and 1320 ppm as the injection timing was increased from 19 to 23 and 27° before TDC, respectively. NOx emissions were observed to be decreased to 1080 ppm for retarded injection at 25° before TDC. However, NOx emissions were again increased to 1320 ppm as the timing was increased from 25 to 27°.

The fuel spray gets slowed down due to retarded fuel injection and generates incomplete combustion. As injection timing is forged ahead from 23 to 25° before TDC, the NOx emission decreases by around 15.6%, while upon forging ahead the injection timing from 25 to 27°, the NOx emission increases significantly by 20%. Hence, injection timing beyond 25° is not addressable concerning NOx emission. Patil and Patil31 observed similar conditions in the case of NOx emitted by burning neat rubber oil methyl ester-15 and selected butanol blends at full load conditions injected 25° before TDC. Shareef and Mohanty20 also reported that beyond injection at 26° before TDC, it is not advisable concerning NOx emissions for the dairy scum biodiesel-20 case, and delayed combustion decreases the cylinder temperature and pressure, resulting in a lower output power.13 Chako et al.34 reported that the B20 blend of waste cooking biodiesel exhibited a maximum increase of 10% in NO emissions with a single injection, whereas the introduction of pilot fuel in the multiple injection strategy has significantly reduced (25%) the NOx emissions for both D100 and B20.

3.4.4. Impact on CO2 Emissions

The impact of injection timing on CO2 emissions of the VCR engine for various blends is depicted in Figure 6d. The experimental investigation indicates that the CO2 emission for diesel at an injection timing of 23° before TDC is around 7.3% lower than that of the B25 blend. The CO2 emission for blend B25 was found to be 4.1% at an injection timing of 23° before TDC, while the same was found to be 4, 4.12, 4.2, and 4.1% for injection timings of 19, 21, 25, and 27° before TDC, respectively. CO2 emissions were observed to be increased after the standard injection timing of 23° before TDC. Similar observations were made for all the blends.

3.5. Combined Impact of Variable CRs and Injection Timings

3.5.1. Impact on HC Emissions

The unburnt HCs due to incomplete combustion are the main cause of greenhouse effects. Figure 7I–VII depicts the HC emissions from the CI engine fueled with B5, B10, B15, B20, and B25 at various CRs. Lower emissions were attained with the B20-fueled CI engine. Similarly, for CR 17 and 18, the HC emissions increase from 16 to 24 ppm and 17 to 23 ppm for the same B25 fuel over the same range of BMEP. Figure 7I–VII also depicts HC emissions decreasing with increased CR for all the fuels corresponding to the same BMEP. The experimental analysis indicates that 29, 20, and 16 ppm of HC emissions were obtained for B20 at 5 bar BMEP, corresponding to CR values of 16, 17, and 18, respectively, at a specific injection timing of 23° before TDC. Similar observations were made for all the blends The oxygen-rich content of TME leads to smooth and improved combustion, resulting in reduced HC emissions Figure 7I–VII also depicts the HC emissions from the CI engine fueled with TME(B100) and diesel(D100) at various CRs. In the case of B20 and B100, respectively, the results reveal a notable reduction in HC emissions of 15 and 29% when CR 18 is used instead of diesel. Figure 7I–VII also depicts the utilization of TiO2 nanoparticles as a catalyst in the pre-stage of TME synthesis, which has significantly reduced HC emissions compared to diesel. These findings show that using TiO2 reduces HC emissions in the long run due to its increased oxidation capacity, giving it an environmental advantage over alternative catalysts.5 The use of TiO2 in the pre-stage has wholly eliminated the post step of adding nanofluid combined with different blends that aim to reduce emissions. Based on HC emissions, a CR of 18 was the optimum one.

Figure 7.

(I–VII) Effects of CR on HC emissions for various blends.

Patil and Patil32 reported decreased HC emissions while using sunflower oil methyl ester with an optimum CR of 18 compared to a 20 %butanol blend. Similar effects were seen by Patil and Patil,31 who found that HC emissions increase as the proportion of butanol in the blend increases from 5 to 20% at any load state, with a drop in the Cetane number and the air-fuel ratio. Furthermore, Patil and Patil32 discovered the likelihood of an increase in affluent local areas of a blend–air mixture in the combustion chamber.

3.5.2. Impact on CO Emissions

CO emissions occur in CI engines due to poor fuel combustion inside the chamber. Figure 8I–VII: depicts the CO emissions from the CI engine fueled with B5, B10, B15, B20, and B25 at various CRs. Lower emissions were attained using the B20-fueled CI engine. The air–fuel mixture subjected to combustion is inadequate for lower BMEP (low engine load conditions), resulting in lower CO emissions. At higher BMEP values, the air–fuel mixture subjected to combustion is adequate and restricts the oxidation of CO to CO2 by engendering more CO emissions.20 As the CR increases, complete combustion occurs at a higher cylinder pressure and temperature and reduces CO emissions. Simultaneously, the rise in combustion temperature causes rapid oxidation of CO to CO2, resulting in significantly reduced CO formation. Similar observations were made for all the blends.

Figure 8.

(I–VII) Effects of CR on CO emissions for various blends.

Figure 8I–VII: also depicts that CO emissions decrease with increased CR for all the fuels corresponding to the same BMEP. At maximum load, The CO emissions for the B20 biodiesel blend were 0.13, 0.09, and 0.056 at CR 16, 17, and 18, respectively, at a specific injection timing of 23° before TDC. Compared to diesel, the CO emissions are reduced by 2.3% for CR 16 and by 15% for CR 18 with B25 biodiesel. The results show an illustrious fall in CO emissions by 15 and 22% in the case of B25 and B100, respectively, with CR 18 compared to diesel. Figure 8I–VII also depicts that the use of TiO2 nanocatalyst in the pre-stage of TME synthesis has significantly reduced CO emissions compared to diesel due to its improved oxidation capability. It seems the use of TiO2 in the pre-stage has completely eliminated the post-step of the addition of nanofluid combined with different blends, which aims to reduce emissions. The low cylinder temperature and more dilution of residual gases with oxygen cause improper air–fuel mixing, causing increased CO emissions at lower CR. The exact reverse phenomenon was observed with higher CR. Based on CO emissions, a CR of 18 was the optimum one.

Patil and Patil31 studied similar experimental results with an ideal value of CR of 18 with sunflower oil methyl ester and observed increased CO emissions in the case of a 20% butanol blend because the mass flow rate was higher than plain diesel and other selected fuels. Yuvarajan et al.30 investigated the use of TiO2 nanofluid in mustard oil methyl ester mixing, which resulted in lower CO emissions.

3.5.3. Impact on NOx Emissions

N2 becomes chemically reactive, and the probability of the formation of NOx increases rapidly as the in-cylinder temperature increases beyond 1473 K. Figure 9I–VII depicts the NOx emissions in the exhaust of the VCR engine fueled with B5, B10, B15, B20, and B25 at various CRs. Generally, the NOx emissions increase with the CR due to more fuel consumption and high temperatures inside the cylinder, leading to increased NOx emissions. The NOx emissions rise with an increase in CR for all fuels corresponding to the same BMEP, as shown in Figure 9I–VII. The experimental analysis indicates that NOx emissions increased from 680 to 1200 ppm for B20 as the CR increased from 16 to 18 at 5 bar BMEP at a specific injection timing of 23° before TDC. Similar observations were made for all the blends. The increased BMEP is primarily responsible for increasing the NOx emissions at higher CR. The increased combustion temperature drives forward the oxidation reaction rapidly to form NOx. Besides, the higher retention time for the exhaust gases inside the chamber and prolonged combustion lead to increased NOx emissions. The higher oxygen content of biodiesel, with cylinder pressure, temperature, and the entire oxidation reaction, results in increased NOx for all blends at higher CRs. Even though NOx emissions are higher for TME, they can be reduced by an exergy mechanism.20

Figure 9.

(I–VII) Effects of CR on NOx emissions for various blends.

Yuvarajan et al.30 investigated using TiO2 nanofluid in conjunction with mustard oil methyl ester to minimize NOx emissions. Patil and Patil32 investigated comparable experimental results with a CR of 18 using sunflower oil methyl ester and found that neat diesel had higher volumetric efficiency than other fuels, resulting in increased NOx generation with diesel combustion at higher loading circumstances. Similar effects were seen by Patil and Patil,31 who found that HC emissions increase as the proportion of butanol in the blend increases from 5 to 20% at any load state, whereas cetane number and air-fuel ratio decrease. Patil and Patil32 found that pure diesel burned more efficiently than sunflower oil methyl ester and butanol-sunflower oil methyl ester mixtures. As a result, when diesel fuel was burned, more diatomic nitrogen was dissociated to monoatomic nitrogen (N), resulting in more NOx than when butanol–sunflower oil methyl ester blends were burned.

3.5.4. Impact on CO2 Emissions

Figure 10I–VII depicts the CO2 emissions from the CI engine fueled with B5, B10, B15, B20, and B25 at various CRs. Lower emissions were attained with the B20-fueled CI engine. The presence of CO up to 0.15% in the exhaust gas, which was a clear indicator of complete combustion of all fuels at roughly 100%, backs up this theory. At the full load and higher CR, CO2 emissions from neat TME were lower than those of pure diesel and all blends. B25 had higher CO2 emissions than neat TME and neat diesel. According to Patil and Patil,32 increasing butanol from 5 to 20% in the butanol–SOME blend increased CO2 emissions. In the current investigation, no similar phenomenon was discovered. At the full load, Patil and Patil31 found that neat rubber oil methyl ester emits less CO2 than neat diesel and selected butanol blends.

Figure 10.

(I–VII) Effects of CR on CO2 emissions for various blends.

Low CO, HC, and particle matter emissions were caused by biodiesel’s high cetane number, but NOx emissions increased when compared to conventional diesel. The low degree of unsaturation of the fatty acid in the biodiesel feedstock and the long, straight carbon chain were the causes of the high CN. It was also noted that high CN in the biodiesel shortened the ignition delay and increased the residence duration of the combustion process, leading to incomplete combustion and low emissions as a result. Table 5 shows comparative performance with other studies.

Table 5. Comparative Performance with Other Studies.

| Sr No | parameters | current study | Shareef and Mohanty20 | Patil and Patil31 | Chacko et al.34 |

|---|---|---|---|---|---|

| 1 | type of oil | thumba oil | waste dairy scum oil | rubber seed oil | waste cooking oil |

| 2 | blends | B5, B10, B15, B20, B25, B100, D100 | DSB10, DSB20, DSB30, DSB100, D100 | B5, B10, B15, B20, B100, D100 | B20, B100, D100 |

| 3 | system of ester synthesis | hydrodynamic cavitation | BR | BR | BR |

| 4 | BTE | 30% for B100 | 31.87% for B30 | 25% for B20 | 24% for B20, |

| 5 | BSFC | 12,309 kJ/kW h | 0.341 kg/kW h | 0.28 kg/kW h for B20 | 11,395 kJ/kW h |

| 6 | CR | 18 | 18 | 17 | 18 |

| 7 | HC | 13.5% for B20 (33 PPM) | 38 ppm for DSB 20 | 13.5% for B20 | 20% for B20 |

| 8 | CO | 12% for B20 (31 PPM) | 6.9% for DSB20 | 11% for B20 | 10% for B20 |

| 9 | NOx | 1200 ppm for B20 | 988 PPM for B20 | 870 PPM for B20 | |

| 10 | optimized blends | B20 | DSB 20 | B 20 | B 20 |

3.5.5. Role of TiO2 in Performance and Emission Characteristics

When compared to diesel, biodiesel made with a TiO2 nanocatalyst had a lower CO emission of 0.06%. Compared to diesel, biodiesel had roughly 35% lower HC emissions. When compared to diesel, the SOx and NOx emissions have been significantly reduced because of the usage of the TiO2 nanocatalyst. The emission data indicate that TiO2 is ultimately more effective at reducing HC, SOx, and NOx emissions than other catalysts because of its improved oxidation capability and improved thermal conductivity.5s the process progresses, TiO2 binds the energy inside it and delivers it to the reaction mixture, which improves the reaction’s oxidation potential, thermal conductivity, and conversion. TiO2 nanoparticles were used in the pre-stage biodiesel synthesis, resulting in lower HC, CO, and NOx emissions and providing an ecological advantage over conventional catalysts. Thus, the post-step of the addition of nanofluid to various biodiesel blends in the VCR diesel engine has been eliminated.

4. Conclusions

TME biodiesel has been studied for its performance and emission characteristics. In the four-stroke VCR diesel engine, seven fuels have been tested under similar operating conditions, including pure TME, five TME–diesel blends, and pure diesel. Diesel possessed low BSFC at 100% load conditions, while the BTE of B20 has been found to be more promising than the other examined six fuels. However, the NOx emissions were observed to increase by 9.23% compared to diesel. The injection timing of 23° before TDC and a CR of 18 were observed to be the most optimal in performance and emission studies. When compared to diesel, B20’s HC and CO emissions were 13.5 and 12% lower, respectively, with a CR of 18 and injection timing of 23° before TDC. Based on the performance and emission characteristics, B20 is the optimal biodiesel composition compared to B5, B10, B15, B20, B100, and D100. Because of its better oxidation capability and improved thermal conductivity, TiO2 nanoparticles were used in the pre-stage biodiesel synthesis, resulting in lower HC, CO, and NOx emissions and providing an ecological advantage over conventional catalysts. Thus, the post-step of the addition of a nanofluid to various biodiesel blends in a VCR diesel engine has been eliminated.

Acknowledgments

The authors are thankful to Apex Innovation Lab, Sangli, India, for providing access to institutional facilities and support. There was no funding support for this research work. The authors also thank the Director of BITS Pilani, K K Birla Goa campus for his kind support for the publication.

The authors declare no competing financial interest.

References

- Singh D.; Sharma D.; Soni S. L.; Sharma S.; Kumar Sharma P.; Jhalani A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. 10.1016/j.fuel.2019.116553. [DOI] [Google Scholar]

- Anwar M.; Rasul M. G.; Ashwath N. A pragmatic and critical analysis of engine emissions for biodiesel blended fuels. Fuel 2020, 270, 117513. 10.1016/j.fuel.2020.117513. [DOI] [Google Scholar]

- Mofijur M.; Masjuki H. H.; Kalam M. A.; Atabani A. E.; Fattah I. M. R.; Mobarak H. M. Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 2014, 53, 78–84. 10.1016/j.indcrop.2013.12.011. [DOI] [Google Scholar]

- Vellaiyan S. Combustion, performance and emission evaluation of a diesel engine fueled with soybean biodiesel and its water blends. Energy 2020, 201, 117633. 10.1016/j.energy.2020.117633. [DOI] [Google Scholar]

- Patil A.; Baral S.; Dhanke P. Hydrodynamic cavitation for process intensification of biodiesel synthesis—a review. Curr. Res. Green Sustainable Chem. 2021, 4, 100144. 10.1016/j.crgsc.2021.100144. [DOI] [Google Scholar]

- Sathiyamoorthi R.; Sankaranarayanan G.; Adhith kumaar S. B.; Chiranjeevi T.; Dilip Kumar D. Experimental investigation on performance, combustion and emission characteristics of a single cylinder diesel engine fuelled by biodiesel derived from Cymbopogon Martinii. Renewable Energy 2019, 132, 394–415. 10.1016/j.renene.2018.08.001. [DOI] [Google Scholar]

- Arunkumar M.; Kannan M.; Murali G. Experimental studies on engine performance and emission characteristics using castor biodiesel as fuel in CI engine. Renewable Energy 2019, 131, 737–744. 10.1016/j.renene.2018.07.096. [DOI] [Google Scholar]

- Ellappan S.; Rajendran S. A comparative review of performance and emission characteristics of diesel engine using eucalyptus-biodiesel blend. Fuel 2021, 284, 118925. 10.1016/j.fuel.2020.118925. [DOI] [Google Scholar]

- Sayyed S.; Das R. K.; Kulkarni K. Experimental investigation for evaluating the performance and emission characteristics of DICI engine fueled with dual biodiesel-diesel blends of Jatropha, Karanja, Mahua, and Neem. Energy 2022, 238, 121787. 10.1016/j.energy.2021.121787. [DOI] [Google Scholar]

- Patil A. D.; Baral S. S.; Dhanke P. B.; Madankar C. S.; Patil U. S.; Kore V. S. Parametric studies of methyl esters synthesis from Thumba seed oil using heterogeneous catalyst under conventional stirring and ultrasonic cavitation. Mater. Sci. Energy Technol. 2018, 1, 106–116. 10.1016/j.mset.2018.06.004. [DOI] [Google Scholar]

- Pal A.; Verma A.; Kachhwaha S. S.; Maji S. Biodiesel production through hydrodynamic cavitation and performance testing. Renewable Energy 2010, 35, 619–624. 10.1016/j.renene.2009.08.027. [DOI] [Google Scholar]

- Jain N. L.; Soni S. L.; Poonia M. P.; Sharma D.; Srivastava A. K.; Jain H. Performance and emission characteristics of preheated and blended thumba vegetable oil in a compression ignition engine. Appl. Therm. Eng. 2017, 113, 970–979. 10.1016/j.applthermaleng.2016.10.186. [DOI] [Google Scholar]

- Nayak S. K.; Nayak S. K.; Mishra P. C.; Tripathy S. Influence of compression ratio on combustion characteristics of a VCR engine using Calophyllum inophyllum biodiesel and diesel blends. J. Mech. Sci. Technol. 2015, 29, 4047–4052. 10.1007/s12206-015-0850-2. [DOI] [Google Scholar]

- Hariram V.; Vagesh Shangar R. Influence of compression ratio on combustion and performance characteristics of direct injection compression ignition engine. Alexandria Eng. J. 2015, 54, 807–814. 10.1016/j.aej.2015.06.007. [DOI] [Google Scholar]

- Vijayakumar S. J. D.; Paulisingarayar S.; Anbarasu A.; Vetrivelkumar K.; Silambarasan R. Impact of compression ratio and effect of biodiesel blends in performance, combustion and emission characteristics of VCR DI diesel engine. Mater. Today: Proc. 2021, 37, 967–974. 10.1016/j.matpr.2020.06.182. [DOI] [Google Scholar]

- Rosha P.; Kumar S.; Senthil Kumar P.; Kowthaman C. N.; Kumar Mohapatra S. K.; Dhir A. Impact of compression ratio on combustion behavior of hydrogen enriched biogas-diesel operated CI engine. Fuel 2022, 310, 122321. 10.1016/j.fuel.2021.122321. [DOI] [Google Scholar]

- Rao G. P.; Vara Prasad L. S. Combined influence of compression ratio and exhaust gas recirculation on the diverse characteristics of the diesel engine fueled with novel palmyra biodiesel blend. Energy Convers. Manage.: X 2022, 14, 100185. 10.1016/j.ecmx.2022.100185. [DOI] [Google Scholar]

- Rahman S. M. A.; Masjuki H. H.; Kalam M. A.; Sanjid A.; Abedin M. J. Assessment of emission and performance of compression ignition engine with varying injection timing. Renewable Sustainable Energy Rev. 2014, 35, 221–230. 10.1016/j.rser.2014.03.049. [DOI] [Google Scholar]

- Panneerselvam N.; Murugesan A.; Vijayakumar C.; Kumaravel A.; Subramaniam D.; Avinash A. Effects of injection timing on bio-diesel fuelled engine characteristics—An overview. Renewable Sustainable Energy Rev. 2015, 50, 17–31. 10.1016/j.rser.2015.04.157. [DOI] [Google Scholar]

- Shareef S. M.; Mohanty D. K. Experimental investigations of dairy scum biodiesel in a diesel engine with variable injection timing for performance, emission and combustion. Fuel 2020, 280, 118647. 10.1016/j.fuel.2020.118647. [DOI] [Google Scholar]

- Nayak S. K.; Nižetić Ś.; Pham V.; Huang H.; Ölçer I. Ö.; Bui G. B.; Wattanavichien W.; Hoang T. H. Influence of injection timing on performance and combustion characteristics of compression ignition engine working on quaternary blends of diesel fuel, mixed biodiesel, and t-butyl peroxide. J. Cleaner Prod. 2022, 333, 130160. 10.1016/j.jclepro.2021.130160. [DOI] [Google Scholar]

- Çakmak A.; Özcan H. Analysis of combustion and emissions characteristics of a DI diesel engine fuelled with diesel/biodiesel/glycerol tert-butyl ethers mixture by altering compression ratio and injection timing. Fuel 2022, 315, 123200. 10.1016/j.fuel.2022.123200. [DOI] [Google Scholar]

- Öztürk E.; Can Ö.; Usta N.; Yücesu H. S. Effects of retarded fuel injection timing on combustion and emissions of a diesel engine fueled with canola biodiesel. Eng. Sci. Technol. Int. J. 2020, 23, 1466–1475. 10.1016/j.jestch.2020.06.008. [DOI] [Google Scholar]

- Patil A. D.; Baral S.; Dhanke P. B.; Dharaskar S. A. Cleaner production of catalytic thumba methyl ester (Biodiesel) from thumba seed oil (Citrullus Colocyntis) using TiO2 nanoparticles under intensified hydrodynamic cavitation. Fuel 2022, 313, 123021. 10.1016/j.fuel.2021.123021. [DOI] [Google Scholar]

- Patil A. D.; Baral S. S. Process intensification of thumba methyl ester (Biodiesel) production using hydrodynamic cavitation. Chem. Eng. Res. Des. 2021, 171, 277–292. 10.1016/j.cherd.2021.05.007. [DOI] [Google Scholar]

- Ghayal D.; Pandit A. B.; Rathod V. K. Optimization of biodiesel production in a hydrodynamic cavitation reactor using used frying oil. Ultrason. Sonochem. 2013, 20, 322–328. 10.1016/j.ultsonch.2012.07.009. [DOI] [PubMed] [Google Scholar]

- Bargole S.; George S.; Kumar Saharan V. Improved rate of transesterification reaction in biodiesel synthesis using hydrodynamic cavitating devices of high throat perimeter to flow area ratios. Chem. Eng. Process. 2019, 139, 1–13. 10.1016/j.cep.2019.03.012. [DOI] [Google Scholar]

- Innocenzi V.; Prisciandaro M. Technical feasibility of biodiesel production from virgin oil and waste cooking oil: Comparison between traditional and innovative process based on hydrodynamic cavitation. Waste Manage. 2021, 122, 15–25. 10.1016/j.wasman.2020.12.034. [DOI] [PubMed] [Google Scholar]

- Bethi B.; Sonawane S. H.; Rohit G. S.; Holkar C. R.; Pinjari D. V.; Bhanvase B. A. Investigation of TiO2 photocatalyst performance for decolourisation in the presence of Hydrodynamic cavitation as hybrid AOP. Ultrason. Sonochem. 2016, 28, 150–160. 10.1016/j.ultsonch.2015.07.008. [DOI] [PubMed] [Google Scholar]

- Yuvarajan D.; Dinesh Babu M. D.; BeemKumar N.; Amith Kishore P. A. Experimental investigation on the influence of titanium dioxide nanofluid on emission pattern of biodiesel in a diesel engine. Atm. Poll. Res. 2018, 9, 47–52. 10.1016/j.apr.2017.06.003. [DOI] [Google Scholar]

- Patil V. V.; Patil R. S. Effects of partial addition of n-butanol in rubber seed oil methyl ester powered diesel engine. Proc. Inst. Mech. Eng., Part A 2017, 231, 607–617. 10.1177/0957650917708695. [DOI] [Google Scholar]

- Patil V. V.; Patil R. S. Investigations on Partial Addition of n-Butanol in Sunflower Oil Methyl Ester Powered Diesel Engine. J. Energy Resour. Technol. 2018, 140, 012205. 10.1115/1.4037372. [DOI] [Google Scholar]

- Loyte A.; Suryawanshi J.; Bhiogade G.; Devarajan Y.; Subbiah G. Recent developments in utilizing hydrous ethanol for diverse engine technologies. Chem. Eng. Process. 2022, 177, 108985. 10.1016/j.cep.2022.108985. [DOI] [Google Scholar]

- Chacko N. J. T. Effect of pilot and post fueling on the combustion and emission characteristics of a light-duty diesel engine powered with diesel and waste cooking biodiesel blend. Energy Sources, Part A 2020, 1–24. 10.1080/15567036.2020.1791285. [DOI] [Google Scholar]

- Vijayaragavan M.; Subramanian B.; Sudhakar S.; Natrayan L. Effect of induction on exhaust gas recirculation and hydrogen gas in compression ignition engine with simarouba oil in dual fuel mode. Int. J. Hydrogen Energy 2021, 47 (88), 37635–37647. 10.1016/j.ijhydene.2021.11.201. [DOI] [Google Scholar]

- Jayabal R.; Subramani S.; Dillikannan D.; Devarajan Y.; Thangavelu L.; Nedunchezhiyan M.; kaliyapermual G.; De P.; Melvin P. Multi-objective optimization of performance and emission characteristics of a CRDI diesel engine fueled with sapota methyl ester/diesel blends. Energy 2022, 250, 123709. 10.1016/j.energy.2022.123709. [DOI] [Google Scholar]

- Devarajan Y.; Jayabal R.; Munuswamy D. B.; Ganesan S.; Varuvel E. G. Biofuel from leather waste fat to lower diesel engine emissions: Valuable solution for lowering fossil fuel usage and perception on waste management. Process Saf. Environ. Prot. 2022, 165, 374–379. 10.1016/j.psep.2022.07.001. [DOI] [Google Scholar]

- Arulprakasajothi M.; Beemkumar N.; Parthipan J.; Battu B. N. Investigating the Physio-chemical Properties of Densified Biomass Pellet Fuels from Fruit and Vegetable Market Waste. Arabian J. Sci. Eng. 2020, 45, 563–574. 10.1007/s13369-019-04294-8. [DOI] [Google Scholar]

- Raja K. S.; Srinivasan S. K.; Yoganandam K.; Ravi M. Emissions and Performance Investigation on the Effect of Dual Fuel Injection in Biodiesel Driven Diesel Engine. Energy Sources, Part A 2021, 10.1080/15567036.2021.1877372. [DOI] [Google Scholar]

- Devarajan Y.; Choubey G.; Mehar K. Ignition analysis on neat alcohols and biodiesel blends propelled research compression ignition engine. Energy Sources, Part A 2020, 42, 2911–2922. 10.1080/15567036.2019.1618998. [DOI] [Google Scholar]

- Subramanian B.; Lakshmaiya N.; Ramasamy D.; Devarajan Y. Detailed analysis on engine operating in dual fuel mode with different energy fractions of sustainable HHO gas. Environ. Prog. Sustainable Energy 2022, 41, e145456 10.1002/ep.13850. [DOI] [Google Scholar]

- Munuswamy D. B.; Yuvarajan D. Critical Review on Effects of Alcohols and Nano-additives on Performance and Emission in Low-Temperature Combustion Engines: Advances and Perspectives. Energy Fuels 2022, 36, 7245–7268. 10.1021/acs.energyfuels.2c00930. [DOI] [Google Scholar]

- Devarajan Y.; Choubey G.; Mehar K.; Munuswamy D. B. Ignition analysis on neat alcohols and biodiesel blends propelled research compression ignition engine. Energy Sources, Part A 2020, 42, 2911–2922. 10.1080/15567036.2019.1618998. [DOI] [Google Scholar]

- Ganesan S.; Munuswamy D.; Subbiah G.; Yuvarajan D.; Mishra R.; Thangraja J. Experimental research on waste and inedible feedstock as a partial alternate fuel: environmental protection and energy-saving initiative. Biomass Convers. Biorefin. 2022, 10.1007/s13399-022-02799-1. [DOI] [Google Scholar]

- Banerji C.; Roji S. S. S.; Suresh V.; Yuvarajan D. Detailed analysis on exploiting the low viscous waste orange peel oil and improving its usability by adding renewable additive: waste to energy initiative. Biomass Convers. Biorefin. 2022, 10.1007/s13399-022-02870-x. [DOI] [Google Scholar]

- Muthiya S. J.; Natrayan L.; Kaliappan S.; Patil P. P.; Naveena B. E.; Dhanraj J. A.; Subramaniam M.; Paramasivam P. Experimental Investigation to Utilize Adsorption and Absorption Technique to Reduce CO2 Emissions in Diesel Engine Exhaust Using Amine Solutions. Adsorpt. Sci. Technol. 2022, 2022, 9621423. 10.1155/2022/9621423. [DOI] [Google Scholar]