Abstract

LIMKs are important regulators of actin and microtubule dynamics, and they play essential roles in many cellular processes. Deregulation of LIMKs has been linked to the development of diverse diseases, including cancers and cognitive disabilities, but well-characterized inhibitors known as chemical probes are still lacking. Here, we report the characterization of three highly selective LIMK1/2 inhibitors covering all canonical binding modes (type I/II/III) and the structure-based design of the type II/III inhibitors. Characterization of these chemical probes revealed a low nanomolar affinity for LIMK1/2, and all inhibitors 1 (LIMKi3; type I), 48 (TH470; type II), and 15 (TH257; type III) showed excellent selectivity in a comprehensive scanMAX kinase selectivity panel. Phosphoproteomics revealed remarkable differences between type I and type II inhibitors compared with the allosteric inhibitor 15. In phenotypic assays such as neurite outgrowth models of fragile X-chromosome, 15 showed promising activity, suggesting the potential application of allosteric LIMK inhibitors treating this orphan disease.

Graphical Abstract

INTRODUCTION

LIM kinases (LIMKs) 1 and 2 are two structurally conserved protein kinases that belong to the tyrosine kinase-like family (TKL). The LIMKs are dual specificity kinases recognizing serine/threonine as well as tyrosine-containing substrates and are represented in humans by two paralogues, LIMK1 and LIMK2. Both LIMKs share the same domain organization, which comprises two N-terminal LIM domains, a PDZ domain and a proline/serine-rich region followed by the C-terminal kinase domain. Human LIMK1 and LIMK2 share a high structural similarity, with >50% overall sequence conservation and >70% sequence similarity within the kinase domain. LIMKs show a distinct cell-type-specific expression pattern and subcellular localization.1 LIMKs have been reported to be activated by at least three different signaling pathways.2 The best-known pathway resulting in LIMK activation is via the small GTPases of the Rho family, such as RhoA, Rac, or CDC42, which activate Rho kinases (ROCK) or p21-activated kinases (PAKs). These kinases activate LIMKs by phosphorylating Thr508 in LIMK1 or Thr505 in LIMK2, located in the activation loop. In addition, Takemura et al. demonstrated that phosphorylation of Thr508 in LIMK1 by Ca2+/calmodulin-dependent protein kinase IV (CaMKIV) is critical for calcium-induced neurite outgrowth.3 LIMK1 has also been reported to be phosphorylated and activated by the MKK6/p38/MK-2 signaling cascade on Ser323, which is located between the PDZ and PK domains.4

Fragile X syndrome (FXS), a common inherited form of intellectual disability and autism, is characterized by abnormal synapse and dendritic spine development. FXS occurs because of genetic alterations, leading to an increased number of CGG trinucleotide repeats in the 5’ untranslated region of the RNA binding protein FMR1 (fragile X messenger ribonucleoprotein 1), resulting in methylation of the FMR1 locus and silencing of FMR1 transcripts. However, in some cases inactivating mutations of the FMR1 gene have been observed. FMR1 binds to and thereby represses the translation of a number of mRNAs including the mRNA encoding for the long isoform of bone morphogenetic protein type 2 receptor (BMPR2), resulting in the derepression of the full-length isoform of this kinase. This isoform interacts and strongly activates LIMK1, resulting in the stimulation of the noncanonical BMP signal transduction pathway, actin reorganization, and promotion of neurite outgrowth and synapse formation.5,6 Recently, it has been demonstrated that the pharmacological inhibition of LIMK1 ameliorates the aberrant spine development in FMR1-KO mice, suggesting LIMK1 as a potential target for the treatment of FXS (Figure 1).7

Figure 1.

(A) Activation of LIMK by different pathways (according to ref 2). (B) Downstream effects of LIM kinases. LIMK influences actin dynamics via phosphorylation and inactivation of cofilin (left) and microtubule disassembly (middle). In addition, other interaction partners that can be phosphorylated by LIMKs have been reported (right), but the phenotypic effects of these interaction partners are less well described.

Well-known substrates for the LIMKs are actin-binding proteins, namely cofilin 1, cofilin 2, and destrin, also called actin-depolymerizing factors (ADFs). Cofilin/ADF is phosphorylated by LIMKs at Ser3, which results in its inactivation, and causes polymerization and stabilization of actin filaments and suppression of actin turnover. Thus, phosphorylation of cofilin by LIMKs plays a pivotal role in the actin cytoskeletal reorganization and many cellular activities such as cell migration or morphogenesis.2,8 Besides their central role in actin filament dynamics, it has been demonstrated that LIMKs are regulators of the microtubule disassembly, which is independent of the regulation of actin microfilament. It is believed that the LIMK1 PDZ domain interacts with tubulin, and overexpression of LIMK1 has been associated with microtubule destabilization9,10 as pharmacological inhibition of LIMKs leads to a microtubule stabilizing effect.11–14 Many additional macromolecular interaction partners of LIMKs have been identified; however, only a few small molecules have been identified inhibiting LIMK activity and their mode of action has been poorly characterized1,15–17 (Figure 2). One of the most studied LIMK inhibitors is the dual LIMK1/2 inhibitor compound 1 (BMS-5/LIMKi3), which has originally been developed by Bristol–Meyer–Squibbs. BMS-5 is known as an ATP competitive LIMK1/2 inhibitor with IC50 values in the low nanomolar range.18 Other inhibitors such as compound 2 (Damnacanthal)19 or 3 (Pyr1)12 have also been disclosed; however, no selectivity data have been reported. These compounds seem to be reactive or have a limited solubility, which makes them less attractive as starting compounds for the development of a chemical probe for LIMK1/2. More recently, compound 4 has been published as an allosteric type III inhibitor with preference for LIMK2 versus LIMK1, although no cellular data are available and only a limited selectivity screen has been reported.20 Some additional LIMK1/2 inhibitors have been published based on a pyrrolopyrimidine scaffold, which include SR7826 (5) or LX7101 (6). However, a significant number of off-targets have been reported for both of these inhibitors. LX7101, which has been investigated in phase 1/2a clinical trials for primary open-angle glaucoma or ocular hypertension,21 is known as a dual LIMK/ROCK inhibitor with off-target PKA activity.22–24 Thus, a more comprehensive evaluation of inhibitor selectivity and the development of selective LIMK inhibitors is needed for a mechanistic evaluation of LIMK1/2 roles in human pathology and physiology. Here, we describe the development of an allosteric dual LIMK1/2 inhibitor as well as a type II inhibitor together with a detailed characterization of the type I inhibitor LIMKi3. All inhibitors exhibited excellent selectivity for LIMK1/2, with no additional off-targets identified for the allosteric type III inhibitor (15) and only one and four additional off-targets identified for the type I (1) and type II (33) inhibitors, respectively. All three inhibitors showed submicromolar cellular on-target activity, making them suitable as chemical probes for LIMK1/2.

Figure 2.

Reported LIMK inhibitors in the literature.

RESULTS AND DISCUSSION

For our chemical probe development, we chose compound 4 as the starting point, as allosteric inhibitors have usually favorable properties in terms of selectivity profile.20,25 Therefore, we resynthesized 4 and modified this lead structure at three different positions. To understand the structure–activity relationship, modifications were introduced at the sulfonamide residue (R1) and at the amide nitrogen as well as the pending ring system (R2 and R3). Compounds 15–27 were synthesized in a two- or three-step synthesis using the previously reported synthetic strategy.20 The first step of the synthetic route consisted of the installation of the sulfonamide using aniline or benzylamine, and the sulfonamide intermediates were subsequently coupled by secondary amines to the corresponding amides (Scheme 1). The binding affinity of this first set of compounds to LIMK1 and LIMK2 was determined by differential scanning fluorimetry (DSF). Interestingly, only small modifications were tolerated on the sulfonamide moiety (R1; see Table 1). Introduction of chlorines, especially in para-position (23), led to strong reduction in Tm shifts in comparison to 4, as well as the introduction of an additional methylene group from the phenyl moiety in 4 to a benzyl moiety in 22 reduced binding. Surprisingly, the introduction of a chlorine in meta-position (19) led to a decrease in ΔTM in the DSF assay for LIMK1 but this modification had a lesser effect on LIMK2 Tm shifts compared to the lead structure 4. Likewise, it was impossible to replace the benzyl moiety on the tertiary amide in position R3 either by shortening (25) or by elongation (21) without losing activity. The largest impact of this SAR series with respect to ΔTM values was achieved in position R2 by elongation of the methyl group to ethyl (16), n-propyl (17), or an n-butyl (15) derivative. In turn, the reduction of the methyl group in this position to a secondary amide (24) nearly completely abrogated binding to both LIMK1 and LIMK2. To understand the binding affinity and to correlate ΔTM in the DSF assay into affinities, isothermal titration calorimetry (ITC) experiments were performed using recombinant LIMK1 kinase domain with compounds 15–18. These experiments revealed that KD values of compounds 15–17 were 64, 53, and 89 nM, respectively (Table 1). In addition, the combination of the propyl-residue in R2 with chlorine in meta-position on R1 (18) resulted in a significant decrease in ΔTM for LIMK1 and LIMK2; however, ITC revealed that 18 still had a KD of 386 nM (Table 1).

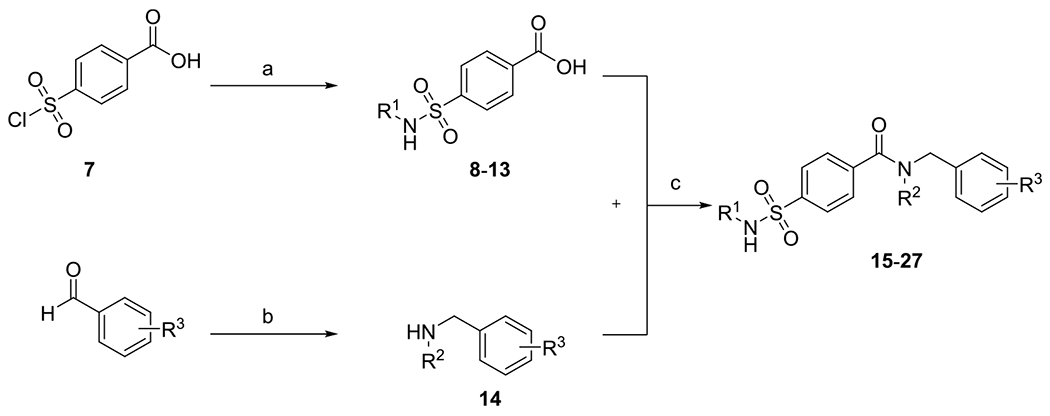

Scheme 1. Synthesis of Sulfamoylbenzamides (15–27)a.

aReagents and conditions: (a) substituted anilines or benzylamine (10 equiv), 4-(chlorosulfonyl)benzoic acid (1.00 equiv), THF, RT, 18 h; (b) primary amines (1.00 equiv), benzaldehyde (1.00 equiv), sodium triacetoxyborohydride (1.40 equiv), glacial acetic acid (2.00 equiv), DCE, RT, 20 h, 56%; and (c) EDC*HCl (1.20 equiv), HOBT (1.00 equiv), secondary amine (1.50 equiv), DCM, RT, 20 h, 45–86%.

Table 1.

Structure–Activity Relationship (SAR) on the 4-Sulfamoylbenzamide Moiety for the Allosteric Type III Inhibitorsa

| ||||||

|---|---|---|---|---|---|---|

|

| ||||||

| compound | R1 | R2 | R3 | LIMK1 ΔTm [°C] | LIMK2 ΔTm [°C] | LIMK1 KD [nM] |

| 15 | Ph | n-butyl | Bn | 5.6 ± 2.0 | 12.8 ± 0.1 | 64 ± 21 |

| 16 | Ph | ethyl | Bn | 6.7 ± 0.9 | 12.4 ± 0.1 | 53 ± 9 |

| 17 | Ph | n-propyl | Bn | 6.2 ± 0.9 | 12.2 ± 0.3 | 89 ± 18 |

| 4 | Ph | methyl | Bn | 4.5 ± 0.7 | 9.3 ± 0.1 | |

| 18 | 3-Cl-Ph | n-propyl | Bn | 2.9 ± 0.4 | 7.3 ± 2.4 | 386 ± 55 |

| 19 | 3-Cl-Ph | methyl | Bn | 0.9 ± 1.6 | 7.1 ± 0.2 | |

| 20 | 2-Cl-Ph | methyl | Bn | 1.5 ± 1.2 | 5.1 ± 0.0 | |

| 21 | Ph | methyl | (CH2)2-Ph | 1.3 ± 0.3 | 3.2 ± 1.3 | |

| 22 | Bn | methyl | Bn | 1.6 ± 0.7 | 2.6 ± 0.3 | |

| 23 | 4-Cl-Ph | methyl | Bn | −1.0 ± 2.3 | 2.2 ± 0.4 | |

| 24 | Ph | H | Bn | 0.4 ± 1.7 | 1.7 ± 0.1 | |

| 25 | Ph | methyl | Ph | 0.2 ± 0.1 | 1.7 ± 0.1 | |

| 26 | Bn | H | Bn | 1.2 ± 1.0 | 0.7 ± 0.1 | |

| 27 | (CH2)2-Ph | methyl | Bn | 0.9 ± 0.6 | 0.1 ± 0.2 | |

Binding of the substituted sulfamoylbenzamide derivatives (compounds 4 and 15–27) to LIMK1/2, as determined by DSF. ΔTm shifts are reported as means ± SD of three independent experiments. KD values for LIMK1 were determined by isothermal titration calorimetry (ITC). Errors were determined based on the nonlinear least-squares fit of the isotherms using a single binding site model.

Cocrystallization of 18 with LIMK2 Guided the SAR-Driven Back-to-Front-Pocket Optimization.

After our initial TM screen, we chose 18 for cocrystallization experiment because the ΔTm for LIMK1 was lower compared to the ΔTm for LIMK2, indicating possible isoform selectivity. However, ITC experiments reveal that 18 is still a submicromolar binder to LIMK1 (Table 1). The structure of the complex revealed the anticipated type III binding mode of 18 inducing an “αC-out” and “DFG-out” conformations (Figure 3A). This allosteric binding mode induced a strong rearrangement of the αC-helix resulting in a displacement of about 11.8 Å compared to the position of the αC-helix in the AMP–PNP complex (PDB-ID: 5HVJ).26 In addition, a large shift in the position of the P-loop and the DFG motif was observed, indicating that these three structural elements are highly flexible in unphosphorylated LIMK2 (Figure 3B). These findings were in agreement with the binding mode of the closely related derivative of the lead structure 4 (PDB-ID: 4TPT;20 Figure 3C). The most striking feature of the structure of 18 with LIMK2 was a strong distortion of the P-loop compared to the binding mode of 4, as well as a flip of F470 of the DFG motif. While in the parental compound 4, the access to the hinge was blocked by three phenylalanine residues (F341, F342, F470), the elongation of the alkyl chain causes a rearrangement of these flexible regions and opened access to the ATP-binding pocket (Figure 3D).

Figure 3.

(A) Cocrystal structure of the allosteric inhibitor 18 with LIMK2 (PDB-ID: 5NXD). (B) Superimposition of AMP–PNP bound to LIMK1 (PDB-ID: 5HVJ26) and 18 bound to LIMK2 (PDB-ID: 5NXD) revealed three flexible regions that led to the formation of the allosteric binding site. (C). Superimposition of the lead structure bound to LIMK2 (PDB-ID: 4TPT20) and 18 bound to LIMK2 (PDB-ID: 5NXD) revealed the distortion of the P-loop. (D) Superimposition of PDB-ID: 4TPT and PDB-ID: 5NXD revealed that access to the ATP-binding pocket was blocked by three phenylalanine residues. Structural rearrangement upon type III inhibitor binding opens access to the ATP pocket allowing the development of type II inhibitors.

These findings encouraged us to continue the SAR mainly in position R2 to increase the potency of the sulfamoylbenzamide moiety in a back-to-front-pocket optimization. In a first attempt, we tried to replace the n-butyl chain in 15 by terminal alkynes with different carbon chains (29, 31, 32) with a nitrile (28) or by a phenethyl moiety (30) to explore the space in this position (Table 2). In particular, 30–32 showed comparable TM shifts on LIMK2 and slightly superior TM shifts on LIMK1. All of these agents were still effective in a cellular system showing two- to three-digit nanomolar IC50 values in a NanoBRET assay for LIMK1 and LIMK2. The functional groups employed should be used as a bridging unit for the implementation of various potential hinge-binders to develop a highly potent and selective type II inhibitor. The terminal alkynes in 31 and 32 were used for click chemistry with benzyl azide to grow the inhibitor toward the ATP pocket, resulting in 33 and 34, with 33 showing a slightly better stabilization in TM shifts as well as better inhibition in the cellular assay system. For this reason, we kept the same linker in 33 and used different azides to study the ATP-binding pocket. Introduction of one chlorine in the ortho-position in 35 showed little lower IC50 values for both LIMK1/2 compared with 33, whereas the introduction of two chlorines in the meta- and para-positions in 37 displayed the same IC50 value for LIMK2 but was slightly worse for LIMK1. In the next step, we introduced more heterocycles in this position, aiming to achieve a possible polar interaction within the ATP-binding pocket. Introduction of a 4-pyridinyl residue in 36 still showed a good inhibition of LIMK2 (IC50: 118 nM) but was worse in LIMK1 (IC50: 540 nM). The imidazopyrimidine residue in 38 and the 2-methylthiazole in 39 were even slightly worse for both LIMK1/2, while the oxazolidinone in 40 completely abolished the activity for both (Table 3). The synthesis of these compounds (28–40) is described in Schemes 2 and 3, starting with the 4-chlorosulfonylbenzoic acid, which was coupled to various anilines. The corresponding carboxylic acids were then coupled to various secondary amines using EDC*HCl and HOBT to obtain the corresponding benzenesulfonamide derivatives. Alkynes 31 and 32 were then used for a CuAAC (“click-reaction”) to give triazoles 33–40 (Scheme 3).

Table 2.

Structure–Activity Relationship (SAR) on the 4-Sulfamoylbenzamide Moiety with the Main Focus on Position R2 to Enter the ATP-Binding Pocket. Binding of the substituted sulfamoylbenzamide derivatives (compounds 28–32) to LIMK1/2 as determined by DSF and NanoBRETa

|

ΔTm shifts are reported as means of three independent experiments. IC50 values for LIMK1 and LIMK2 were determined in a cellular assay system using NanoBRET. IC50 values are reported as means ± SD of three independent experiments.

Table 3.

Structure–Activity Relationship (SAR) on the 4-Sulfamoylbenzamide Moiety with the Implementation of Various Potential Hinge-Binders for the Development of Type II Inhibitorsa

|

Binding of the substituted sulfamoylbenzamide derivatives (compounds 33–40 and 48) to LIMK1/2 as determined by DSF. ΔTm shifts are reported as means of three independent experiments. IC50 values for LIMK1 and LIMK2 were determined in a cellular assay system using NanoBRET. IC50 values are reported as means ± SD of three independent experiments.

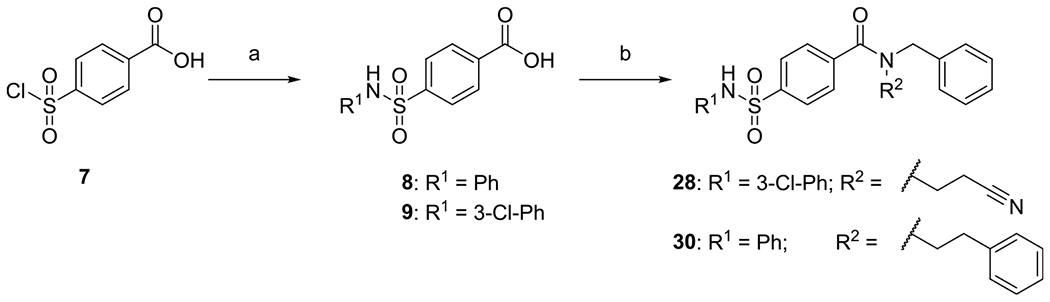

Scheme 2. Synthesis of Sulfamoylbenzamides (28, 30)a.

aReagents and conditions: (a) substituted anilines (10 equiv), 4-(chlorosulfonyl)benzoic acid (1.00 equiv), THF, RT, 18 h; and (b) EDC*HCl (1.20 equiv), HOBT (1.00 equiv), secondary amine (1.50 equiv), CH2Cl2, RT, 20 h.

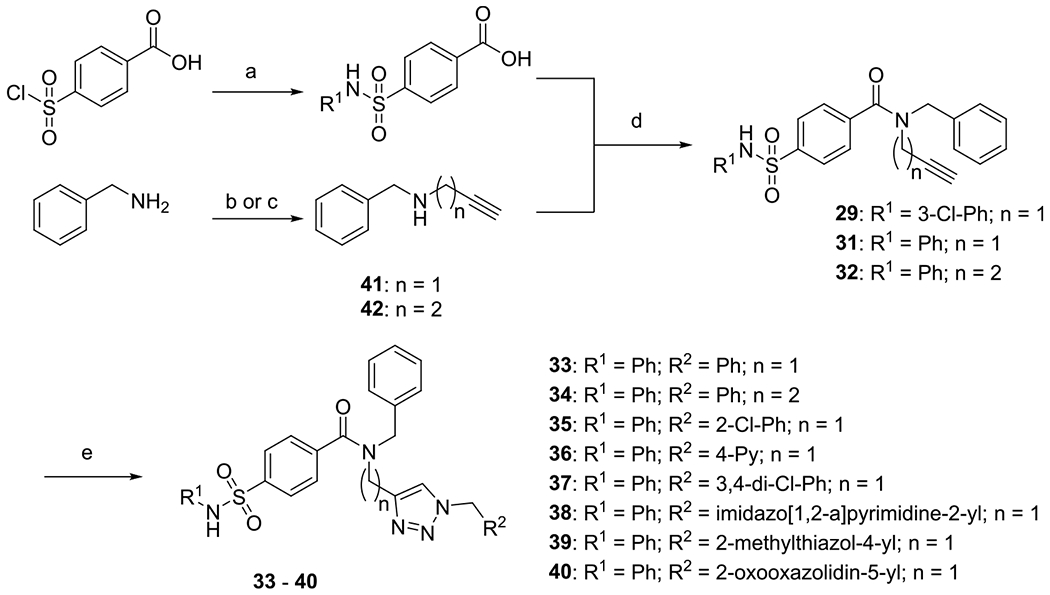

Scheme 3. Synthesis of Sulfamoylbenzamides (29, 31, 32) and Potential Type II Inhibitors (33–40)a.

aReagents and conditions: (a) substituted anilines (10 equiv), 4-(chlorosulfonyl)benzoic acid (1.00 equiv), THF, RT, 18 h; (b) 3-bromoprop-1-yne (1 equiv), benzylamine (6 equiv), RT, 72 h; (c) benzylamine (1.00 equiv), but-3-yn-1-yl 4-methylbenzene-1-sulfonate (1 equiv), K2CO3 (2 equiv), MeCN, reflux, 16 h; (d) EDC*HCl (1.20 equiv), HOBT (1.00 equiv), secondary amine (1.50 equiv), CH2Cl2, RT, 20 h; and (e) alkyne (1 equiv), azide (1 equiv), NaAsc (0.1 equiv), CuSO4*5H2O (0.01 equiv), H2O/t-BuOH, RT, 24–120 h.

Structural Insights Facilitated the Rational Design of a Highly Potent Type II Inhibitor.

Simultaneously, cocrystallization experiments of compound 1 with LIMK1 were performed. LIMKi3 has been reported as an ATP competitive inhibitor although no crystal structure of this compound in complex with LIMK1 or 2 has been published so far. The structure of the LIMKi3 complex revealed a canonical type I binding mode with “DFG-in” conformation (Figures 4 and S3). The aminothiazole moiety acted as an ATP mimetic hinge-binding moiety, forming two hydrogen bonds with Ile416 of the hinge backbone (Figure 4). In addition, the 2,6-dichlorophenyl residue was perpendicular to the pyrazole ring of 1, efficiently occupying the binding pocket (Figure 4). The combined insights of these two crystal structures were the basis for the rationale design of a type II inhibitor by maintaining the hinge-binder moiety of 1 and combining it with the N-phenylsulfonamide, which targeted the DFG- and αC-out-pocket, and the N-benzylamide of 18, which was oriented toward the P-loop pocket (Figure 4).

Figure 4.

(A) Cocrystal of 1 (salmon) bound to LIMK1 (marine blue), PDB-ID: 8AAU; 18 (slate blue) bound to LIMK2 (yellow orange), PDB-ID: 5NXD; alignment of 1 and 18 reveals an intersection point; cocrystal of 48 (orange) bound to LIMK2 (lime), PDB-ID: 7QHG. (B) Rational design of a type II inhibitor by combining types I (1) and III (18).

The synthesis of this compound is described in Scheme 4. The “allosteric” binding motif was synthesized as described above; the sulfonamide 8 was linked to the BOC-protected secondary amine to obtain the tertiary amide 46, and finally, the BOC-protecting group was cleaved using TFA in dichloromethane to obtain the primary amine 47. For the synthesis of the “hinge” binding motif, ethyl 2-amino-1,3-thiazole-5-carboxylate (43) was coupled to isobutyryl chloride to obtain the corresponding secondary amide (44) and afterward, the ester was cleaved to obtain the carboxylic acid 45. In the last step, the primary amine 47 and the carboxylic acid 45 were coupled using EDC*HCl and HOBT to obtain 48. The potency of this potential type II inhibitor was evaluated using DSF assay, and the ΔTM was about a magnitude higher both for LIMK1 (ΔTM = 17.8 °C) and for LIMK2 (ΔTM = 20.6 °C) (Table 3).

Scheme 4. Synthesis of Type II Binder (33)a.

aReagents and conditions: (a) amine (1.00 equiv), 2-methylpropanoyl chloride (1.20 equiv), pyridine (1.50 equiv), CH2Cl2, RT, 20 h, 87%; (b) LiOH*H2O (5.00 equiv), THF/H2O, 30 °C, 72 h, quant.; (c) EDC*HCl (1.20 equiv), HOBT (1.00 equiv), secondary amine (1.50 equiv), CH2Cl2, RT, 20 h, 83%; (d) TFA, CH2Cl2, RT, 2 h, quant.; and (e) EDC*HCl (1.20 equiv), HOBT (1.00 equiv), secondary amine (1.50 equiv), CH2Cl2, RT, 20 h, 66%.

In agreement with the significant increase in temperature shift data, the KD value for 48 for LIMK1 was determined using ITC and was found to be lower (KD = 7 nM) compared to the allosteric inhibitors (15–8). We also obtained the cocrystal structure of 48 with LIMK2. The structure confirmed that 48 bound as a type II inhibitor with the 2-aminothiazole moiety as a hinge-binder and the phenylsulfamoyl moiety in the DFG-out pocket, as expected (Figures 4 and S4). An additional hydrogen bond to the gatekeeper T405 was observed, engaging the nitrogen of the secondary amide. To determine the activity of the most interesting inhibitors, enzyme kinetic data (IC50) were measured using a RapidFire mass spectrometry (RF-MS) assay with the endogenous substrate cofilin. Both the type I inhibitor 1 (LIMKi3) and compound 15 (TH257), the developed allosteric inhibitor (type III), revealed low nanomolar activity in the RF-MS assay. For the type II inhibitor 48, potency was increased to 7 and 20 nM for LIMK1 and LIMK2, respectively. Compound 26 (TH263) had IC50 values >50 μM for LIMK1 and LIMK2, which was in agreement with the ΔTM in the DSF assay (Table 4), identifying 26 as a negative control compound. To evaluate the potential in vivo use of these new type II (48) and type III inhibitors (15), we evaluated the pharmacokinetic properties of 15, 18, and 48. It has been shown that attachment of the hinge-binding moiety to the allosteric part has not only an impact on the potency of these compounds but also an increased solubility and metabolic stability (Table S12).

Table 4.

Summary and Comparative Analysis of the Biological Activity of Type I (1), Type II (48), and Type III (15) Inhibitors and the Negative Control Compound 26 on LIMK1 and LIMK2 in Thermal Shift Assay (DSF), In Vitro Activity by RapidFire MS, and Cellular Activity by NanoBRET

| DSF ΔTm [°C] |

RapidFire MS IC50 [nM] |

NanoBRET IC50 [nM] |

||||

|---|---|---|---|---|---|---|

| compound | LIMK1 | LIMK2 | LIMK1 | LIMK2 | LIMK1 | LIMK2 |

| Type I 1 (LIMKi3) |

6.7 ± 0.3 | 3.7 ± 0.3 | 16.6 ± 4 | 11.6 ± 3 | 62 ± 19 | 17 ± 3.9 |

| Type II 48 (TH470) |

17.8 ± 0.4 | 20.6 ± 4 | 7 ± 2 | 20 ± 3 | 9.8 ± 1.7 | 13 ± 4.3 |

| Type III 15 (TH257) |

5.6 ± 2.0 | 12.8 ± 0.1 | 83.8 ± 14 | 15.5 ± 2 | 238 ± 97 | 91 ± 34 |

| neg. control 26 (TH263) |

1.2 ± 1.0 | 0.7 ± 0.1 | >50,000 | >50,000 | >25,000 | >25,000 |

KINOMEscan and Kinobead PD Assay Revealed Excellent Selectivity for All Types (I–III).

To determine the selectivity of these different types of inhibitors, we chose compound 1 as type I inhibitor, 48 as our newly designed type II inhibitor, and compound 15 as the allosteric type III inhibitor, since 15 has the highest TM shift on LIMK2 for the allosteric compounds (Table 1). Compounds 1, 48, and 15 were evaluated in a comprehensive selectivity panel KINOMEscan (scanMAX, DiscoverX). The allosteric inhibitor 15 showed excellent selectivity when screened at 1 μM with KD values of 120 nM for LIMK1 and 64 nM for LIMK2, respectively (determined by DiscoverX; Tables S6 and S8). No significant interaction with other kinases of the 468 kinases was detected. Also the inactive control, 26, was evaluated in the KINOMEscan selectivity panel and revealed no interacting kinase (Tables S7 and S9). The type I 1 and the type II inhibitor 48 were less selective in the KINOMEscan panel when screened at 1 μM (Tables S2 and S4). However, as 1 and 48 had low nM potencies, we concluded that the concentration used for the selectivity assessment was too high. Both inhibitors were re-evaluated in the KINOMEscan panel at a concentration of 100 nM (Tables S3 and S5). The selectivity screen revealed an S(35)-score ranging from 0.01 to 0.02 (Figure 5). Recently, Klaeger et al. have shown that some compounds, which had been designated as chemical probes, were not selective in kinobead pulldown assays.27 Thus, all four compounds (1, 15, 48, and 26) were evaluated in a dose–response (30 μM to 1 nM) in the kinobead assay. In this assay, typically more than 200 full-length kinases were detected in cellular lysate. No other hits except LIMK1 and LIMK2 were identified, highlighting the specificity of these compounds. However, the IC50 values determined by the kinobead assay were slightly higher than those determined by RapidFire MS, which is likely due to the different readout, as the RapidFire MS is performed in an in vitro activity assay, whereas the kinobead PD assay determined the binding affinity in lysates (Figure 6C, D). Other potential reasons leading to differences in these two binding assays have been discussed elsewhere.27

Figure 5.

Comparison of types I, II, and III and the negative control compound. (A) Chemical structure of 1 (LIMKi3 = type I inhibitor), 48 (TH470 = type II inhibitor), 15 (TH257 = type III inhibitor), and 26 (TH263 = neg. control compound for TH257). (B) Selectivity profile using the scanMAX kinome wide selectivity assay (Eurofins) of 1, 48, 15, and 26. Data are illustrated using the TREEspot analysis (DiscoverX).

Figure 6.

Cellular target engagement for type I (LIMKi3, 1), type II (TH470, 48), type III (TH257, 15), and negative control compound (TH263, 26). (A) Results from NanoBRET assay on LIMK1. (B) Results from NanoBRET assay on LIMK2. (C) Results from kinobead pulldown (PD) assays. The kinobead pulldown assay covered around 300 kinases. Radar plots of each inhibitor (LIMKi3 (1), TH257 (15), TH263 (26), and TH470 (48)) showing all identified targets. The bars represent the pKD app for all identified targets. (D) A table that summarizes all IC50s and KD apps for the four ligands (LIMKi3 (1), TH257 (15), TH263 (26), and TH470 (48)) on LIMK1 and LIMK2 determined in cellular lysates by the kinobead pulldown assay.

To determine the cellular activity of these compounds, NanoBRET assays28–31 were performed, demonstrating one to two-digit nanomolar IC50 values for the type I (1) and type II (48) inhibitor: also, the allosteric inhibitor (15) had an IC50 of 238 nM for LIMK1 and 91 nM for LIMK2. Again, compound 26 had IC50 values higher than 25 μM on both LIMK1 and LIMK2, confirming its usefulness as a negative control (Table 4 and Figure 6). To assess all possible off-targets detected in kinome-wide screening, we performed nanoBRET assays on the off-targets detected for 1 and 48, which showed binding of less than 50% in scanMAX KINOMEscan assays (Eurofins). Dose–response titrations confirmed excellent selectivity in cells. Titration curves of all LIMK chemical probes are shown in Figure 6A,B and off-target activities are shown in Figure S1. In addition, temperature shift data measured on more than 100 human kinase domains as well as common off-targets of kinase inhibitors showed no significant temperature shifts (Table S11). Thus, the set of developed LIMK inhibitors (1, 15, and 48) together with the negative control 26 represent an excellent toolbox of three chemical probes with diverse binding modes covering all canonical binding modes.

Phosphoproteomic Approach Displays Remarkable Differences between Types I/II and III.

LIMKs are known as macromolecules with many different interaction partners.1 The best-known substrate of LIMKs to date is cofilin, although other phosphorylation substrates have been described (Figure 1), and therefore, LIMKs are fundamental for various cellular functions through regulating the actin and microtubule cytoskeleton. It is important to use highly selective LIMK inhibitors to understand the signaling pathway that might be upregulated or downregulated. In addition, differences in inhibitors on cellular signaling based on diverse binding modes have been well documented.25,32–34 To evaluate functional differences of the three chemical probes based on their diverse binding modes, we evaluated the developed LIMK inhibitors by analyzing differences in phosphorylation response using phosphoproteomics. All in all, over 4000 proteins were detected using HeLa cells, and over 10,000 phosphorylation sites were identified. Interestingly, phosphorylation sites that were significantly altered after inhibitor treatment differed between the allosteric inhibitors 15 and the negative control 26 and the type I inhibitor 1 and the type II inhibitor 48. The type III inhibitor (15) showed modest changes in phosphorylation compared to ATP competitive inhibitors (Figure 7).

Figure 7.

Results of quantitative phosphoproteomic data analysis. (A) At the top: volcano plot for LIMKi3 (1) revealing 4140 proteins with 10387 phosphosites. 362 sites were significantly regulated, of which 189 were upregulated and 173 were downregulated. In the middle: volcano plot for TH470 (48) revealing 4139 proteins with 10344 phosphosites. 339 sites were significantly regulated, of which 146 were upregulated and 193 were downregulated. At the bottom: volcano plot for TH257 (15) revealing 4076 proteins with 10158 phosphosites. 11 sites were significantly regulated, of which 4 were upregulated and 7 were downregulated. Most significant hits were marked in red. All kinases were highlighted in yellow. Remarkably, the known LIMK substrate cofilin (CFL1/2) was not significantly affected by any of the used chemical probes. (B) On the left: GO-term analysis revealed up- and downregulated genes that are involved in actin dynamics for LIMKi3 (1), TH470 (48), and TH257 (15). On the right: GO-term analysis revealed up- and downregulated genes that are involved in microtubule dynamics for LIMKi3 (1), TH470 (48), and TH257 (15).

We speculate that these differences are due to the diverse binding modes and the preferential inhibition of the unphosphorylated inactive state of LIMK1/2, causing minimal effects in unstimulated cells. Intriguingly, the ATP competitive type I inhibitor (1) and type II inhibitor (48) showed similar behavior with respect to up- and downregulated phosphorylation sites (Figure 7). As expected, GO-term analysis revealed a strong link to processes regulating the actin cytoskeleton or microtubules (Figure 8B). Surprisingly, we also found a strong link to phosphorylation changes in proteins involved in RNA processing and RNA binding function as well as mRNA processing (Figure 8). Thus, it is tempting to speculate that due to the role of FMRP, a regulator of the BMPR2-LIMK1 signaling axis, as an RNA binding protein that regulates mRNA metabolism,45 LIMK1/2 may modulate FMRP-dependent regulation of mRNA metabolism.

Figure 8.

Gene ontology (GO) term enrichment analysis of both ATP competitive inhibitors (1) and (48). Significant phosphosites were chosen for both compounds and analyzed using the analysis tool from the PANTHER classification system.35 Results were sorted by the gene ontology category biological process, molecular function, and cellular component. (A) Results for the type I inhibitor (1). (B) Results for the type II inhibitor (48).

Phenotypic Effects of LIMK Inhibitors in a Neurite Outgrowth Model.

To confirm the reported roles of LIMK1/2 in an FXS model, compounds 1, 15, 48, and 26 were evaluated in a neurite outgrowth model. Previously, it has been shown that both LIMK1 and LIMK2 activities are required for NGF-induced neurite extension.2,36 Therefore, N1E-115 cells were transfected with siRNAs against FMR1 (siFMR1) or control siRNAs (siCtr). LIMK inhibitors at different concentrations were added for 12 h followed by stimulation with BMP7 (10 ng/mL). The experiment showed that all inhibitors, compounds 1 (LIMKi3), 15 (TH257), and 48 (TH470) inhibited neurite outgrowth in a dose-dependent manner, whereas 26 (TH263; negative control) showed no inhibition in comparison to the control (siFMR1+BMP7), suggesting that the observed effect is due to the inhibition of LIMK1/2 activity (Figure 9). Interestingly, the type I inhibitor showed a small effect, whereas 15 and 48 revealed more robust dose-dependent effects on the neurite outgrowth, suggesting that allosteric inhibitors might be more effective in modulating neuronal phenotypes mediated by the deregulation of LIMKs.

Figure 9.

Inhibition of neurite outgrowth by the treatment with LIMK inhibitors. (A) N1E-115 cells were transfected with siFMR1 or siCtr. Cell culture media were replaced with 0.2% FBS-containing medium containing 0.05, 0.5, or 5 μM LIMK inhibitors or DMSO (mock) and incubated for 12 h, followed by 10 ng/mL of BMP7 treatment for 24 h. Representative pictures of each group of cells are shown. (B) The number of cells bearing neurite-like structure with longer than a cell body (neurite-positive, gray) was counted, and the fraction (%) of neurite-positive cells was plotted. A minimum of 100 cells were counted in each condition. Mean + SD was plotted (N = 4). *P < 0.05, **P < 0.01, ***P < 0.001, ****P < 0.0001, ns, no significance by ANOVA with post hoc Dunnett test.

CONCLUSIONS

In this manuscript, we reported the characterization of a LIMK1/2 chemical probe set covering all canonical binding modes (type I (1/LIMKi3), II (48/TH470), and III (15/TH257)), and the structure-based design for the type II and type III. All chemical probes had low nanomolar potency, robust cellular activity on target in NanoBRET assays, and excellent selectivity determined by a comprehensive selectivity panel (KINOMEscan). In addition, high selectivity was also observed in cellular lysates using the kinobead assay. Our SAR study also identified a suitable inactive negative control compound (26). The chemical probes were active in a phenotypic assay of neurite outgrowth but showed remarkable differences in signaling evaluated by phosphoproteomics. We have identified a number of significantly up- and downregulated phosphosites altered by the pharmacological inhibition of LIMKs, which give a basis for insights into the signaling pathways mediated by LIMKs. Interestingly, the allosteric inhibition of LIMKs appears to have little to no effect on the upstream and downstream phospho signaling pathways. However, functional and time course studies are needed to elucidate the details of mechanistic differences among the three types of LIMK inhibitors. The characterized chemical tool compounds will facilitate the elucidation of the roles of LIMKs and their mechanisms of action in pathogenesis and in normal physiology.

EXPERIMENTAL SECTION

Differential Scanning Fluorimetry Assay.

The assay was performed according to a previously established protocol.37 A 2 μM solution of the respective LIMK in assay buffer (20 mM HEPES pH 7.4, 150 mM NaCl, 0.5 mM TCEP, 5% glycerol) was mixed 1:1000 with SYPRO Orange (Sigma-Aldrich). The compounds to be tested were added to a final concentration of 10 μM. Twenty microliters of each sample were placed in a 96-well plate and heated from 25 to 95 °C. Fluorescence was monitored using an Mx3005P real-time PCR instrument (Stratagene) with excitation and emission filters set to 465 and 590 nm, respectively. Data were analyzed with the MxPro software.

Isothermal Titration Calorimetry (ITC).

Measurements were performed at 20 °C on a MicroCal VP-ITC (GE Healthcare). LIMK1330-637 was dialyzed overnight into assay buffer (20 mM HEPES pH 7.4, 150 mM NaCl, 0.5 mM TCEP, 5% glycerol). The syringe was loaded with 105 μM LIMK1330-637, and the cell was filled with assay buffer containing 10 μM of the respective inhibitor. Every 5 minutes, 10 μL of the protein solution was injected into the cell for a total of 28 injections. The heat flow data were analyzed with the MicroCal ORIGIN software package employing a single binding site model.

Protein Expression and Purification.

The recombinant LIMK kinase domains LIMK1330-637 and LIMK2330-632 were expressed in insect cells and purified as previously described.16 In brief, exponentially growing TriEx cells (Novagen) at 2 × 106 cells/mL were infected 1:64 with baculovirus stock, incubated for 66 h at 27 °C under constant shaking, and harvested by centrifugation. Cells were then resuspended in lysis buffer (50 mM HEPES pH 7.4, 500 mM NaCl, 20 mM imidazole, 0.5 mM TCEP, 5% glycerol) and lysed by sonication. The lysate was cleared by centrifugation and loaded onto a Ni NTA column. After vigorous rinsing with lysis buffer, the His6-tagged proteins were eluted in lysis buffer containing 300 mM imidazole. While the proteins were subjected to dialysis to remove the imidazole, the N-terminal tags were cleaved by TEV protease. Contaminating proteins, the cleaved tags and TEV protease itself were removed with another Ni NTA step. Finally, the LIMK kinase domains were concentrated and subjected to gel filtration using an AKTA Xpress system combined with an S200 16/600 gel filtration column (GE Healthcare). The elution volumes of 91.8 mL (LIMK1330-637) and 91.6 mL (LIMK2330-632) indicated the proteins to be monomeric in solution. The final yields were 2.0 mg/L of insect cell medium for LIMK1330-637 and 0.2 mg/L of insect cell medium for LIMK2330-632.

Crystallization.

One hundred nanoliters of drops of the protein solution with the respective ligand were transferred to a 3-well crystallization plate (Swissci), mixed with 50 nL of the precipitant solution, and incubated at 4 °C (details in Table S1). Crystals appeared overnight and did not change appearance after 7 days. They were mounted with additional 25% ethylene glycol for cryoprotection. Data were collected at Diamond Light Source beamline I03, analyzed, scaled, and merged with Xia2.38 The structures were solved by molecular replacement with Phaser39 using a LIMK2 model as a template (PDB-ID 4TPT) and refined with Refmac5.40 The models were validated using MolProbity.41 A summary of data collection and refinement statistics is given in Table S1. The model and the structure factors have been deposited with the PDB IDs 5NXD,7QHG and 8AAU (crystallographic parameters are included in Table S1).

LIMK1/2 RapidFire Mass Spectrometry Assay.

RapidFire Mass Spectrometry Assay was performed as previously described.16 In brief, RapidFire mass spectrometry offers a high-throughput, label-free, and direct measurement of substrate modifications, including protein phosphorylation. This technology couples desalting by solid-phase extraction (SPE) with rapid automated sample injection and processing to achieve high sampling rates. For IC50 determination, the respective inhibitors in DMSO (11-point concentration series, all points in technical duplicates) were dispensed to a 384-well polypropylene plate using an ECHO 550 acoustic dispenser (Labcyte). Then, the LIMK1 kinase domain was added (final concentration 40 nM) to allow for a 10 min preincubation at room temperature. The phosphorylation reaction was initiated by adding a mixture of CFL1 (final concentration 2 mM) and ATP (final concentration 800 mM). After 60 min of incubation at room temperature, the reaction was stopped by adding formic acid to a final concentration of 1%. The reaction volume was 50 ml, and the assay buffer composition was 50 mM tris pH 7.5, 0.1 mM EDTA, 0.1 mM EGTA, 1 mM MgCl2. The plate was transferred to a RapidFire RF360 high-throughput sampling robot (Agilent). Samples were aspirated under vacuum and loaded onto a C4 SPE cartridge and washed for 5.5 s with 0.1% (v/v) formic acid in LC-MS grade water to remove nonvolatile buffer components. After the aqueous wash, analytes of interest were eluted from the C4 SPE onto a 6530 Q-TOF LC/MS (Agilent) in an organic elution step (85% acetonitrile in LC-MS grade water containing 0.1% formic acid). Ion data for the CFL1 substrate and the Phospho-CFL1 product were extracted, and peak area data were integrated using RapidFire integrator software (Agilent). Finally, IC50 curves were generated using GraphPad Prism 7.

NanoBRET.

The assay was performed as described previously.29–31 In brief, full-length LIMK1 and LIMK2 cloned in frame in a NanoLuc-vector (Promega) were transfected into HEK293T cells (ATCC CRL-1573) using FuGENE HD (Promega, E2312), and proteins were allowed to express for 20 h. The serially diluted inhibitor and NanoBRET Kinase Tracer (Promega) were pipetted into white 384-well plates (Greiner 781 207) using an ECHO 550 acoustic dispenser (Labcyte). All constructs and tracers used are summarized in Supporting Table S10. The corresponding transfected cells were added and reseeded at a density of 2 × 105 cells/mL after trypsinization and resuspension in Opti-MEM without phenol red (Life Technologies). The system was allowed to equilibrate for 2 h at 37 °C and 5% CO2 prior to BRET measurements. To measure BRET, NanoBRET NanoGlo Substrate + Extracellular NanoLuc Inhibitor (Promega, N2160) were added as per the manufacturer’s protocol, and filtered luminescence was measured on a PHERAstar plate reader (BMG Labtech) equipped with a luminescence filter pair (450 nm BP filter (donor) and 610 nm LP filter (acceptor)). Competitive displacement data were then plotted using GraphPad Prism 9 software using a normalized 3-parameter curve fit with the following equation: Y = 100/(1 + 10∧((X-Log IC50))).

Chemistry.

All starting materials, reagents, and solvents were purchased from commercial suppliers like Alfa-Aesar, Sigma-Aldrich, TCI, and Apollo Scientific Ltd., and used without further purification unless otherwise stated. Reactions were monitored by thin-layer chromatography (TLC) using precoated TLC sheets ALUGRAM Xtra SIL G/UV254 (thickness of layer: 0.20 mm; mean pore size: 60 Å) purchased from Machery-Nagel (Düren, Germany).

The structures of the presented compounds were verified by 1H-, 13C-NMR, mass spectrometry (ESI), and high-resolution mass spectrometry (HRMS); the purity of the final compounds (>95%) was determined by HPLC. Compound 1 (BMS-5/LIMKi3) was purchased from Tocris Bioscience. Compounds 8–48 were synthesized as described in Figure 2B and Schemes 1–3. All commercial chemicals and solvents are of reagent grade and were used without further purification. 1H- and 13C-NMR spectra were measured in DMSO-d6 or CDCl3 on a Bruker DPX 250 or AV 500 spectrometer. Chemical shifts (δ) are reported in parts per million (ppm) in the scale relative to the solvent signals: 2.50 ppm (1H-NMR) and 39.52 ppm (13C-NMR) for DMSO-d6, 7.26 ppm (1H-NMR) and 77.16 ppm (13C-NMR) for CDCl3. Coupling constants (J) were reported in hertz (Hz), and multiplicities were designated as follows: s (singlet), bs (broad singlet), d (doublet), dd (double doublet), ddd (doublet of doublet of doublets), t(triplet), dt (doublet of triplets), q (quartet), m (multiplet). Mass spectra were obtained on a Fisons Instruments VG Platform II spectrometer (ESI-MS system) or on a PerSeptive Biosystems Mariner biospectrometry workstation (nanospray ESI-MS system) measuring in the positive- and/or negative-ion mode. High-resolution mass spectra were recorded on a MALDI LTQ Orbitrap XL system from Thermo Scientific (Waltham, MA). Purity of the synthesized compounds was determined by HPLC with either method-A: on a Shimadzu (Duisburg, Germany) LC-20AD HPLC set at 254 and 280 nm equipped with a Shimadzu LC-MS-2020 detector using a Phenomenex LTD (Aschaffenburg, Germany) Luna 10 μm 21.2 × 250 mm reversed-phase (C18) column. As mobile phase, Milli-Q water (A) and acetonitrile (B) + 0.1% formic acid were used with a flow rate of 1 mL/min. The gradient was running over 25 min starting with 95% A and 5% B, going down on 10% A and 90% B, and finishing at 95% A and 5% B. Or method-B: on a Varian ProStar HPLC equipped with a MultoHigh100 RP18-5μ 240 mm + 4 mm column (CS-Chromatographie Service GmbH, Langerwehe, Germany) using a gradient (H2O + 0.1% formic acid/MeOH 80:20 isocratic for 5 min to MeOH after an additional 45 min and MeOH for an additional 10 min) at a flow rate of 1 mL/min and UV detection at 254 and 280 nm.

Scheme 1; Step a: general procedure for the formation of sulfonamides (compounds 8–13).

4-(Chlorosulfonyl)benzoic acid (7) (1.00 equiv) was dissolved in 11 mL of THF/mmol 7. Amine (10 equiv) was added dropwise to the stirred solution at 20 °C. The mixture was stirred at room temperature for 18 h. The reaction was diluted with 100 mL of EtOAc. The organic layer was washed with 1 N HCl (3 × 50 mL). Afterward, the water layer was extracted once more with 50 mL of EtOAc and the combined organic layers were dried over MgSO4. The organic layer was concentrated under reduced pressure. The residue was recrystallized with hot MeOH/H2O.

Synthesis of 4-(phenylsulfamoyl)benzoic acid (8): synthesis Scheme 1; step a: 4-(chlorosulfonyl)benzoic acid (7; 1.00 g, 4.53 mmol), aniline (4.14 mL, 45.3 mmol); product: pale crystalline solid; yield: 1.12 g ≡ 89%. 1H-NMR (500 MHz, (CD3)2SO): δ = 13.44 (s, 1H), 10.43 (s, 1H), 8.06 (d, J = 8.5 Hz, 2H), 7.85 (d, J = 8.5 Hz, 2H), 7.23 (t, J = 7.9 Hz, 2H), 7.08 (d, J = 7.6 Hz, 2H), 7.04 (t, J = 7.4 Hz, 1H). 13C-NMR (126 MHz, (CD3)2SO): δ = 166.09, 143.08, 137.27, 134.55, 130.14, 129.26, 127.01, 124.46, 120.42. MS (ESI−): m/z = 276.07 [M – H]−.

Synthesis of 4-[(3-chlorophenyl)sulfamoyl]benzoic acid (9): synthesis Scheme 1; step a: 4-(chlorosulfonyl)benzoic acid (7; 500 mg, 2.27 mmol), 3-chloroaniline (2.89 g, 22.66 mmol); product: pale crystalline solid; yield: 0.54 g ≡ 76%. 1H-NMR (500 MHz, (CD3)2SO): δ = 13.48 (s, 1H), 10.74 (s, 1H), 8.09 (d, J = 8.6, 2H), 7.88 (d, J = 8.5, 2H), 7.27 (t, J = 8.4, 1H), 7.14–7.09 (m, 2H), 7.09–7.04 (m, 1H). 13C-NMR (126 MHz, (CD3)2SO): δ = 166.03, 142.67, 138.90, 134.84, 133.45, 131.08, 130.31, 127.01, 124.15, 119.41, 118.32. MS (ESI−): m/z = 309.94 [M – H]−.

Synthesis of 4-[(2-chlorophenyl)sulfamoyl]benzoic acid (10): synthesis Scheme 1; step a: 4-(chlorosulfonyl)benzoic acid (7; 500 mg, 2.27 mmol), 2-chloroaniline (2.89 g, 22.67 mmol); product: pale crystalline solid; yield: 0.35 g ≡ 50%. 1H-NMR (500 MHz, (CD3)2SO): δ = 13.47 (s, 1H), 10.23 (s, 1H), 8.08 (d, J = 8.6 Hz, 2H), 7.81 (d, J = 8.6 Hz, 2H), 7.41 (dd, J = 7.7, 1.1 Hz, 1H), 7.30 (ddd, J = 8.2, 7.0, 1.5 Hz, 1H), 7.26–7.19 (m, 2H). 13C-NMR (126 MHz, (CD3)2SO): δ = 166.21, 144.03, 134.52, 133.13, 130.14, 130.00, 129.60, 128.13, 128.10, 127.89, 126.98. MS (ESI−): m/z = 309.89 [M – H]−.

Synthesis of 4-[(4-chlorophenyl)sulfamoyl]benzoic acid (11): synthesis Scheme 1; step a: 4-(chlorosulfonyl)benzoic acid (7; 500 mg, 2.27 mmol); 4-chloroaniline (2.89 g, 22.67 mmol); product: pale crystalline solid; yield: 0.36 g ≡ 51%. 1H-NMR (500 MHz, (CD3)2SO): δ = 13.44 (s, 1H), 10.56 (s, 1H), 8.07 (d, J = 8.7 Hz, 2H), 7.85 (d, J = 8.7 Hz, 2H), 7.31 (d, J = 9.0 Hz, 2H), 7.09 (d, J = 9.0 Hz, 2H).

Synthesis of 4-(benzylsulfamoyl)benzoiinsights facilitated the rational design of a highly potentc acid (12): synthesis Scheme 1; step a: 4-(chlorosulfonyl)benzoic acid (7; 500 mg, 2.27 mmol); benzylamine (2.47 mL, 22.67 mmol); product: pale crystalline solid; yield: 0.55 g ≡ 83%. 1H-NMR (500 MHz, (CD3)2SO): δ = 13.43 (s, 1H), 8.35 (t, J = 6.3 Hz, 1H), 8.08 (d, J = 8.6 Hz, 2H), 7.89 (d, J = 8.6 Hz, 2H), 7.29–7.24 (m, 2H), 7.21 (dd, J = 9.9, 4.4 Hz, 3H), 4.02 (d, J = 6.3 Hz, 2H). 13C-NMR (126 MHz, (CD3)2SO): δ = 166.27, 144.49, 137.42, 134.01, 130.08, 128.25, 127.61, 127.21, 126.77, 46.13. MS (ESI−): m/z = 292.08 [M + H]+.

Synthesis of 4-[(2-phenylethyl)sulfamoyl]benzoic acid (13): synthesis Scheme 1; step a: 4-(chlorosulfonyl)benzoic acid (7; 500 mg, 2.27 mmol), 2-phenylethan-1-amine (2.85 mL, 22.67 mmol); product: pale crystalline solid; yield: 0.59 g ≡ 85%. 1H-NMR (500 MHz, (CD3)2SO): δ = 13.42 (s, 1H), 8.10 (d, J = 8.3 Hz, 2H), 7.91 (t, J = 5.8 Hz, 1H), 7.88 (d, J = 8.3 Hz, 2H), 7.25 (t, J = 7.3 Hz, 2H), 7.19 (d, J = 7.3 Hz, 1H), 7.15 (dd, J = 7.3, 5.9 Hz, 2H), 3.03–2.96 (m, 2H), 2.67 (t, J = 7.5 Hz, 2H). 13C-NMR (126 MHz, (CD3)2SO): δ = 166.27, 144.12, 138.57, 134.07, 130.15, 128.69, 128.33, 126.77, 126.28, 44.05, 35.28. MS (ESI+): m/z = 306.06 [M + H]+.

Synthesis of benzyl(propyl)amine (14): synthesis Scheme 1; step b: to a solution of benzaldehyde (711 mg, 6.70 mmol) and n-propylamine (396 mg, 6.70 mmol) in DCE was added glacial acetic acid (0.77 mL, 13.40 mmol) and the solution was stirred for 1 h at RT. After 1 h, NaHB(OAc)3 (1.99 g, 9.38 mmol) was added and the reaction was stirred for 20 h. Afterward, the reaction was quenched using 1 M NaOH and the product was extracted with Et2O. The organic layer was washed with brine, dried over MgSO4, and evaporated under a reduced pressure. The crude product was purified by column chromatography using n-hexane/EtOAc to obtain benzyl(propyl)amine as a yellow oil. Yield: 0.56 g ≡ 56%. 1H-NMR (500 MHz, (CD3)2SO): δ = 7.36–7.25 (m, 4H), 7.24–7.16 (m, 1H), 3.67 (s, 2H), 2.43 (t, J = 7.1, 2H), 1.48–1.37 (m, 2H), 0.86 (t, J = 7.4, 3H). 13C-NMR (126 MHz, (CD3)2SO): δ = 141.20, 128.02, 127.84, 126.37, 53.05, 50.70, 22.68, 11.85. MS (ESI+): m/z = 150.12 [M + H]+.

Scheme 1; step c: general procedure for the formation of amides (compounds 15–32).

Benzoic acid (1.00 equiv), EDC*HCl (1.20 equiv), and HOBT (1.00 equiv) were dissolved in 10 mL of CH2Cl2 and stirred at room temperature. After 1 h, amine (1.5 equiv) was added and the mixture was stirred at room temperature for 20 h. The reaction was quenched with 40 mL of H2O. The product was extracted with 50 mL of EtOAc. The organic layer was washed with 1 N HCl and brine and dried over MgSO4. The organic layer was concentrated under a reduced pressure. The residue was further purified by column chromatography, using n-hexane/ethyl acetate.

Synthesis of N-benzyl-4-(benzylsulfamoyl)benzamide (15): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)benzoic acid (8; 150 mg, 0.54 mmol), EDC*HCl (124 mg, 0.65 mmol), HOBT (73 mg, 0.54 mmol), benzyl(butyl)amine (132 mg, 0.81 mmol); product: resinlike solid; yield: 0.17 g ≡ 74%. 1H-NMR (500 MHz, CDCl3, rotamers observed) δ: 0.71, 0.93 (t, 3H, J = 7.20 Hz), 1.00–1.07, 1.31–1.37 (m, 2H), 1.39–1.45, 1.59–1.62 (m, 2H), 3.01, 3.47 (t, 2H, J = 7.50 Hz), 4.37, 4.74 (s, 2H), 7.02–7.08 (m, 4H), 7.12 (t, 1H, J = 6.79 Hz), 7.18–7.23 (m, 2H), 7.28–7.37 (m, 4H), 7.41–7.45 (m, 2H), 7.69–7.78 (m, 2H). 13C-NMR (126 MHz, CDCl3, rotamers observed) δ: 170.43, 141.23, 141.10, 140.17, 140.01, 136.97, 136.33, 136.20, 129.54, 129.08, 128.91, 128.22, 127.96, 127.78, 127.62, 127.57, 127.26, 126.71, 125.97, 125.90, 122.31, 122.18, 52.49, 48.01, 47.56, 45.03, 30.32, 29.23, 20.30, 19.76, 13.99, 13.65. MS (ESI+): m/z = 423.13 [M + H]+. HRMS: m/z calcd for C24H27N2O3S1 [M + H]+ = 423.17369. Found [M + H]+ = 423.17329. HPLC (method-B): tR = 35.473, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-ethyl-4-(phenylsulfamoyl)benzamide (16): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)benzoic acid (8; 100 mg, 0.36 mmol), EDC*HCl (83 mg, 0.43 mmol), HOBT (49 mg, 0.36 mmol), benzyl(ethyl)amine (80 μL, 0.54 mmol); product: white solid; yield: 0.09 g ≡ 63%. 1H-NMR (500 MHz, CDCl3, rotamers observed) δ: 1.03, 1.21 (t, 3H, J = 6.70 Hz), 3.09, 3.54 (q, 2H, J = 6.82 Hz), 4.38, 4.75 (s, 2H), 6.56, 6.60 (s, 1H), 7.02–7.16 (m, 4H), 7.21–7.25 (m, 2H), 7.30–7.35 (m, 4H), 7.44–7.48 (m, 2H), 7.70–7.79 (m, 2H). 13C-NMR (126 MHz, CDCl3, rotamers observed) δ: 170.30, 170.21, 141.27, 141.04, 140.18, 140.12, 137.00, 136.32, 136.14, 129.58, 129.10, 128.92, 128.23, 127.97, 127.80, 127.67, 127.59, 127.34, 127.12, 126.72, 126.02, 122.33, 122.22, 52.10, 47.22, 42.92, 40.26, 13.75, 12.36. MS (ESI+): m/z = 395.15 [M + H]+. HRMS: m/z calcd for C22H23N2O3S1 [M + H]+ = 395.14239. Found [M + H]+ = 395.14218. HPLC (method-B): tR = 33.552, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(phenylsulfamoyl)-N-propylbenzamide (17): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)benzoic acid (8; 150 mg, 0.54 mmol), EDC*HCl (124 mg, 0.65 mmol), HOBT (73 mg, 0.54 mmol), benzyl(propyl)amine (12; 121 mg, 0.81 mmol); product: resinoid pale yellow solid; yield: 0.12 g ≡ 52%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 0.54, 0.85 (t, 3H, J = 7.20 Hz), 1.34–1.42, 1.52–1.59 (m, 2H), 2.93, 3.29 (t, 2H, J = 7.50 Hz), 4.34, 4.67 (s, 2H), 7.02–7.09 (m, 4H), 7.19–7.23 (m, 2H), 7.26–7.38 (m, 4H), 7.51, 7.57 (d, 2H, J = 7.80 Hz), 7.73, 7.79 (d, 2H, J = 7.80 Hz), 10.32 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.48, 169.42, 140.82, 139.82, 139.69, 137.55, 137.43, 129.17, 128.67, 128.56, 127.50, 127.15, 127.05, 126.95, 126.87, 124.45, 124.36, 120.60, 120.42, 51.69, 49.84, 46.92, 46.00, 21.00, 19.89, 11.18, 10.76. MS (ESI+): m/z = 409.12 [M + H]+. HRMS: m/z calcd for C23H24N2O3S1 [M] = 408.15076. Found [M] = 408.15235. HPLC (method-A): tR = 15.447, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-methyl-4-(phenylsulfamoyl)benzamide (4): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)benzoic acid (8; 120 mg, 0.43 mmol), EDC*HCl (100 mg, 0.52 mmol), HOBT (58 mg, 0.43 mmol), benzyl(methyl)amine (79 mg, 0.65 mmol); product: white solid; yield: 0.13 g ≡ 76%. 1H-NMR (500 MHz, CDCl3, rotamers observed) δ: 2.78, 3.05 (s, 3H), 4.39, 4.73 (s, 2H), 6.84, 6.87 (s, 1H), 7.03–7.14 (m, 4H), 7.20–7.25 (m, 2H), 7.32–7.36 (m, 4H), 7.47–7.49 (m, 2H), 7.72–7.79 (m, 2H). 13C-NMR (126 MHz, CDCl3, rotamers observed) δ: 170.66, 169.95, 140.78, 140.67, 140.38, 140.32, 136.53, 136.12, 135.94, 129.60, 129.17, 128.98, 128.38, 128.07, 127.93, 127.72, 127.60, 127.53, 126.68, 126.02, 122.28, 122.22, 55.13, 51.02, 36.96, 33.61. MS (ESI+): m/z = 381.04 [M + H]+. HRMS: m/z calcd for C21H21N2O3S1 [M + H]+ = 381.12674. Found [M + H]+ = 381.12608. HPLC (method-B): tR = 32.986, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-[(3-chlorophenyl)sulfamoyl]-N-propylbenzamide (18): synthesis Scheme 1; step c: 4-[(3-chlorophenyl)-sulfamoyl]benzoic acid (9; 150 mg, 0.48 mmol), EDC*HCl (111 mg, 0.58 mmol), HOBT (65 mg, 0.48 mmol), benzyl(propyl)amine (12, 108 mg, 0.72 mmol); product: resinoid pale solid; yield: 0.18 g ≡ 85%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 0.54, 0.86 (t, 3H, J = 7.26 Hz), 1.34–1.42, 1.53–1.60 (m, 2H), 2.93, 3.30 (t, 2H, J = 7.30 Hz), 4.35, 4.67 (s, 2H), 7.03–7.10 (m, 4H), 7.23–7.38 (m, 5H), 7.54, 7.61 (d, 2H, J = 8.10 Hz), 7.77, 7.83 (d, 2H, J = 8.00 Hz), 10.62 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.39, 169.34, 141.11, 139.40, 139.26, 139.02, 137.52, 136.83, 133.39, 130.97, 129.18, 128.65, 128.56, 127.50, 127.44, 127.33, 127.15, 127.07, 126.96, 126.86, 124.14, 124.08, 119.58, 119.44, 118.58, 118.39, 51.71, 49.83, 46.93, 46.03, 21.01, 19.88, 11.18, 10.74. MS (ESI+): m/z = 443.15 [M + H]+. HRMS: m/z calcd for C23H24ClN2O3S1 [M + H]+ = 443.11907. Found [M + H]+ = 443.11867. HPLC (method-A): tR = 16.164, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-[(3-chlorophenyl)sulfamoyl]-N-methylbenzamide (19): synthesis Scheme 1; step c: 4-[(3-chlorophenyl)-sulfamoyl]benzoic acid (9; 150 mg, 0.48 mmol), EDC*HCl (111 mg, 0.58 mmol), HOBT (65 mg, 0.48 mmol), benzyl(methyl)amine (87 mg, 0.72 mmol); product: pale yellow solid; yield: 0.14 g ≡ 70%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 2.74, 2.90 (s, 3H), 4.35, 4.66 (s, 2H), 7.04–7.11 (m, 4H), 7.23–7.39 (m, 5H), 7.58, 7.65 (d, 2H, J = 8.20 Hz), 7.78, 7.84 (d, 2H, J = 8.10 Hz), 10.55 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.38, 168.84, 140.81, 140.64, 139.70, 139.57, 139.03, 136.99, 136.51, 133.41, 131.04, 128.74, 128.65, 127.86, 127.64, 127.53, 127.29, 126.92, 126.80, 124.09, 119.43, 118.38, 53.96, 49.79, 36.67, 32.78. MS (ESI+): m/z = 415.07 [M + H]+. HRMS: m/z calcd for C21H20ClN2O3S1 [M + H]+ = 415.08777. Found [M + H]+ = 415.08763. HPLC (method-A): tR = 15.184, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-[(2-chlorophenyl)sulfamoyl]-N-methylbenzamide (20): synthesis Scheme 1; step c: 4-[(2-chlorophenyl)-sulfamoyl]benzoic acid (10; 150 mg, 0.48 mmol), EDC*HCl (111 mg, 0.58 mmol), HOBT (65 mg, 0.48 mmol), benzyl(methyl)amine (87 mg, 0.72 mmol); product: white solid; yield: 0.09 g ≡ 45%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 2.77, 2.91 (s, 3H), 4.39, 4.68 (s, 2H), 7.13–7.41 (m, 9H), 7.57, 7.63 (d, 2H, J = 8.20 Hz), 7.69, 7.75 (d, 2H, J = 8.10 Hz), 10.13 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.56, 169.02, 141.00, 140.83, 140.59, 140.41, 137.04, 136.54, 133.28, 129.96, 129.88, 129.46, 128.76, 128.66, 128.18, 128.08, 127.97, 127.85, 127.67, 127.61, 127.49, 127.29, 126.88, 126.80, 53.93, 49.79, 36.68, 32.69. MS (ESI+): m/z = 415.09 [M + H]+. HRMS: m/z calcd for C21H20ClN2O3S1 [M + H]+ = 415.08777. Found [M + H]+ = 415.08748. HPLC: tR = 14.837, purity ≥95% (UV: 254/280 nM).

Synthesis of N-methyl-N-(2-phenylethyl)-4-(phenylsulfamoyl)-benzamide (21): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)-benzoic acid (8; 250 mg, 0.90 mmol), EDC*HCl (207 mg, 0.11 mmol), HOBT (122 mg, 0.90 mmol), methyl(2-phenylethyl)amine (183 mg, 1.35 mmol); product: pale yellow solid; yield: 0.18 g ≡ 49%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 10.34, 10.30 (s, 1H), 7.78–7.64 (m, 2H), 7.46–7.03 (m, 11H), 6.87 (d, J = 6.9 Hz, 1H), 3.65, 3.26 (t, J = 7.1 Hz, 2H), 3.01, 2.73 (s, 3H), 2.88, 2.71 (t, J = 7.3 Hz, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.08, 168.45, 140.78, 140.67, 139.94, 139.43, 138.98, 138.21, 137.42, 129.21, 129.15, 128.77, 128.73, 128.39, 127.42, 126.95, 126.83, 126.61, 126.35, 126.25, 124.39, 124.35, 120.44, 120.32, 52.05, 48.23, 37.13, 33.47, 32.56, 32.23. MS (ESI+): m/z = 395.16 [M + H]+. HRMS: m/z calcd for C22H23N2O3S1 [M + H]+ = 395.14239. Found [M + H]+ = 395.14200. HPLC (method-A): tR = 14.435, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(benzylsulfamoyl)-N-methylbenzamide (22): synthesis Scheme 1; step c: 4-(benzylsulfamoyl)benzoic acid (12; 200 mg, 0.69 mmol), EDC*HCl (158 mg, 0.82 mmol), HOBT (93 mg, 0.69 mmol), benzyl(methyl)amine (125 mg, 1.03 mmol); product: colorless crystals; yield: 0.22 g ≡ 81%. 1H-NMR (500 MHz, CDCl3, rotamers observed) δ: 2.83, 3.07 (s, 3H), 4.15 (t, 2H, J = 7.00 Hz), 4.45, 4.76 (s, 2H), 4.83–4.87 (m, 1H), 7.14–7.25 (m, 5H), 7.28–7.40 (m, 5H), 7.56 (d, 2H, J = 7.50 Hz), 7.85, 7.91 (d, 2H, J = 8.05 Hz), 10.32 (s, 1H). 13C-NMR (126 MHz, CDCl3, rotamers observed) δ: 170.69, 170.01, 141.23, 141.14, 140.69, 140.54, 136.60, 136.04, 129.20, 128.99, 128.91, 128.87, 128.41, 128.22, 128.10, 128.03, 127.93, 127.83, 127.63, 127.53, 126.71, 55.16, 51.01, 47.47, 36.98, 33.48. MS (ESI+): m/z = 395.07 [M + H]+. HRMS: m/z calcd for C22H23N2O3S1 [M + H]+ = 395.14239. Found [M + H]+ = 395.14212. HPLC (method-A): tR = 14.541, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-[(4-chlorophenyl)sulfamoyl]-N-methylbenzamide (23): synthesis Scheme 1; step c: 4-[(4-chlorophenyl)-sulfamoyl]benzoic acid (11; 150 mg, 0.48 mmol), EDC*HCl (111 mg, 0.58 mmol), HOBT (65 mg, 0.48 mmol), benzyl(methyl)amine (87 mg, 0.72 mmol); product: white solid; yield: 0.10 g ≡ 50%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 2.74, 2.90 (s, 3H), 4.35, 4.66 (s, 2H), 7.07–7.11 (m, 3H), 7.27–7.39 (m, 6H), 7.57, 7.64 (d, 2H, J = 8.00 Hz), 7.75, 7.81 (d, 2H, J = 8.00 Hz), 10.51 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.42, 168.86, 140.68, 140.52, 139.81, 139.67, 137.00, 136.52, 136.43, 129.24, 128.75, 128.65, 128.50, 127.81, 127.65, 127.47, 127.29, 126.90, 126.78, 121.94, 53.96, 49.80, 36.70, 32.79. MS (ESI +): m/z = 415.07 [M + H]+. HRMS: m/z calcd for C21H20ClN2O3S1 [M + H]+ = 415.08777. Found [M + H]+ = 415.08755. HPLC: tR = 15.207, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(phenylsulfamoyl)benzamide (24): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)benzoic acid (8; 141 mg, 0.51 mmol), EDC*HCl (117 mg, 0.61 mmol), HOBT (69 mg, 0.51 mmol), benzylamine (83 μL, 0.76 mmol); product: white solid; yield: 0.16 g ≡ 83%. 1H-NMR (500 MHz, (CD3)2SO) δ: 4.46 (d, 2H, J = 5.95 Hz), 7.03 (t, 1H, J = 7.30 Hz), 7.09 (d, 2H, J = 7.50 Hz), 7.21–7.25 (m, 3H), 7.29–7.33 (m, 4H), 7.83 (d, 2H, J = 8.50 Hz), 7.99 (d, 2H, J = 8.50 Hz), 9.21 (t, 1H, J = 5.95 Hz), 10.38 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO) δ: 165.05, 141.65, 139.22, 138.21, 137.38, 129.24, 128.32, 128.19, 127.28, 126.85, 126.79, 124.36, 120.30, 42.75. MS (ESI+): m/z = 367.05 [M + H]+. HRMS: m/z calcd for C20H19N2O3S1 [M + H]+ = 367.11109. Found [M + H]+ = 367.11121. HPLC (method-A): tR = 14.112, purity ≥95% (UV: 254/280 nM).

Synthesis of N-methyl-N-phenyl-4-(phenylsulfamoyl)benzamide (25): synthesis Scheme 1; step c: 4-(phenylsulfamoyl)benzoic acid (8; 200 mg, 0.72 mmol), EDC*HCl (166 mg, 0.87 mmol), HOBT (97 mg, 0.72 mmol), N-methylaniline (117 μL, 1.08 mmol); product: white solid; yield: 0.23 g ≡ 86%. 1H-NMR (500 MHz, (CD3)2SO) δ: 10.19 (s, 1H), 7.52 (d, J = 8.1, 2H), 7.36 (d, J = 7.9, 2H), 7.24–7.08 (m, 7H), 7.05 (t, J = 7.4, 1H), 6.94 (d, J = 7.6, 2H), 3.35 (s, 3H). 13C-NMR (126 MHz, (CD3)2SO) δ: 168.18, 143.66, 140.61, 139.53, 137.22, 129.13, 129.10, 128.66, 127.14, 126.80, 126.19, 124.50, 120.75, 37.52. MS (ESI+): m/z = 367.14 [M + H]+. HRMS: m/z calcd for C20H19N2O3S1 [M + H]+ = 367.11109. Found [M + H]+ = 367.11132. HPLC (method-A): tR = 14.116, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(benzylsulfamoyl)benzamide (26): synthesis Scheme 1; step c: 4-(benzylsulfamoyl)benzoic acid (12; 114 mg, 0.39 mmol), EDC*HCl (90 mg, 0.47 mmol), HOBT (53 mg, 0.39 mmol), benzylamine (63 mg, 0.59 mmol); product: white solid; yield: 0.08 g ≡ 55%. 1H-NMR (500 MHz, (CD3)2SO) δ: 9.25 (t, J = 6.0 Hz, 1H), 8.28 (s, 1H), 8.04 (d, J = 8.5 Hz, 2H), 7.88 (d, J = 8.5 Hz, 2H), 7.37–7.31 (m, 4H), 7.31–7.19 (m, 6H), 4.50 (d, J = 6.0 Hz, 2H), 4.00 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO) δ: 165.10, 142.99, 139.34, 137.62, 137.50, 128.35, 128.27, 128.13, 127.60, 127.27, 127.21, 126.87, 126.57, 46.13, 42.76. MS (ESI+): m/z = 381.07 [M + H]+. HRMS: m/z calcd for C21H21N2O3S1 [M + H]+ = 381.12674. Found [M + H]+ = 381.12615. HPLC (method-A): tR = 14.245, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-methyl-4-[(2-phenylethyl)sulfamoyl]-benzamide (27): synthesis Scheme 1; step c: 4-[(2-phenylethyl)-sulfamoyl]benzoic acid (13; 150 mg, 0.49 mmol), EDC*HCl (113 mg, 0.59 mmol), HOBT (66 mg, 0.49 mmol), benzyl(methyl)amine (89 mg, 0.74 mmol); product: brownish solid; yield: 0.15 g ≡ 75%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ: 2.63–2.70 (m, 2H), 2.80, 2.91 (s, 3H), 2.98–3.02 (m, 2H), 4.43, 4.69 (s, 2H), 7.11–7.41 (m, 10H), 7.61, 7.66 (d, 2H, J = 8.00 Hz), 7.78–7.97 (m, 3H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ: 169.67, 169.11, 141.08, 140.06, 139.93, 138.61, 137.08, 136.59, 128.77, 128.66, 128.33, 127.67, 127.49, 127.37, 127.30, 126.78, 126.71, 126.26, 54.01, 49.82, 44.04, 36.76, 35.27, 32.70. MS (ESI+): m/z = 409.15 [M + H]+. HRMS: m/z calcd for C23H25N2O3S1 [M + H]+ = 409.15804. Found [M + H]+ = 409.15779. HPLC (method-A): tR = 14.926, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(N-(3-chlorophenyl)sulfamoyl)-N-(2-cyanoethyl)benzamide (28): synthesis Scheme 2; step b: 4-(N-(3-chlorophenyl)sulfamoyl)benzoic acid (9; 250 mg, 0.80 mmol), EDC*HCl (184 mg, 0.96 mmol), HOBT (108 mg, 0.80 mmol), 3-(benzylamino)propanenitrile (128 mg, 1.20 mmol); product: white solid; yield: 0.25 g ≡ 70%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.64 (s, 1H), 7.83 (d, J = 6.3 Hz, 2H), 7.61 (d, J = 7.2 Hz, 2H), 7.43–7.22 (m, 5H), 7.17–7.01 (m, 4H), 4.74, 4.44 (s, 2H), 3.62, 3.35 (s, 2H), 2.86, 2.76 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.78, 140.22, 139.79, 138.98, 136.87, 136.31, 133.41, 130.99, 128.73, 127.81, 127.61, 127.46, 127.05, 126.92, 124.11, 119.50, 118.90, 118.42, 51.91, 46.30, 43.72, 40.37, 16.30, 15.36. MS (ESI+): m/z = 454.12 [M + H]+. HPLC (method-A): tR = 14.877, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(N-(3-chlorophenyl)sulfamoyl)-N-(prop-2-yn-1-yl)benzamide (29): synthesis Scheme 3; step d: 4-(N-(3-chlorophenyl)sulfamoyl)benzoic acid (9; 200 mg, 0.64 mmol), EDC*HCl (148 mg, 0.77 mmol), HOBT (87 mg, 0.64 mmol), N-benzylprop-2-yn-1-amine (41; 140 mg, 0.96 mmol); product: white solid; yield: 0.21 g ≡ 75%. 1H-NMR (500 MHz, CDCl3, rotamers observed) δ 7.82–7.79 (m, 2H), 7.64–7.55 (m, 2H), 7.44–7.28 (m, 4H), 7.24–6.97 (m, 5H), 6.93 (d, J = 6.5 Hz, 1H), 4.86, 4.54 (s, 2H), 4.30, 3.76 (s, 2H), 2.37, 2.29 (s, 2H). 13C-NMR (126 MHz, CDCl3, rotamers observed) δ 170.09, 169.67, 140.57, 140.09, 137.48, 135.86, 135.21, 130.60, 129.72, 129.21, 129.04, 128.80, 128.20, 127.85, 127.67, 127.11, 125.94, 121.69, 119.58, 77.92, 73.98, 72.92, 51.86, 47.90, 38.23, 34.04. MS (ESI−): m/z = 437.04 [M-H]−. HPLC (method-A): tR = 15.573, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-phenethyl-4-(N-phenylsulfamoyl)-benzamide (30): synthesis Scheme 2; step b: 4-(N-phenylsulfamoyl)-benzoic acid (8; 150 mg, 0.54 mmol), EDC*HCl (124 mg, 0.65 mmol), HOBT (73 mg, 0.54 mmol), benzyl(2-phenylethyl)amine (171 mg, 0.81 mmol); product: white solid; yield: 0.22 g ≡ 84%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.33 (s, 1H), 7.77–7.68 (m, 2H), 7.48–6.98 (m, 16H), 6.80 (d, J = 6.9 Hz, 1H), 4.76, 4.24 (s, 2H), 3.54, 3.19 (t, J = 7.1 Hz, 2H), 2.86, 2.68 (t, J = 7.1 Hz, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.50, 169.31, 140.65, 140.46, 139.94, 139.67, 138.95, 138.05, 137.46, 136.66, 129.18, 128.72, 128.68, 128.63, 128.45, 127.69, 127.54, 127.25, 127.16, 126.98, 126.81, 126.40, 126.34, 124.40, 120.49, 120.41, 52.01, 49.79, 46.70, 46.08, 33.65, 32.71. MS (ESI+): m/z = 471.09 [M + H]+. HRMS: m/z calcd for C28H27N2O3S1 [M + H]+ = 471.17369. Found [M + H]+ = 471.17302. HPLC (method-A): tR = 16.167, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(N-phenylsulfamoyl)-N-(prop-2-yn-1-yl)-benzamide (31): synthesis Scheme 3; step d: 4-(N-phenylsulfamoyl)-benzoic acid (8; 250 mg, 0.90 mmol), EDC*HCl (207 mg, 1.08 mmol), HOBT (122 mg, 0.90 mmol), N-benzylprop-2-yn-1-amine (41, 196 mg, 1.35 mmol); product: white solid; yield: 0.33 g ≡ 91%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.37 (s, 1H), 7.83–7.76 (m, 2H), 7.64–7.55 (m, 2H), 7.44–6.98 (m, 10H), 4.71, 4.44 (s, 2H), 4.19, 3.85 (s, 2H), 3.28 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.18, 140.60, 140.36, 139.50, 137.40, 136.48, 135.86, 129.23, 128.65, 127.78, 127.45, 127.02, 124.42, 120.46, 78.78, 78.67, 76.04, 74.97, 51.59, 47.79, 38.66, 34.03. MS (ESI+): m/z = 405.02 [M + H]+. HRMS: m/z calcd for C23H21N2O3S1 [M + H]+ = 405.12674. Found [M + H]+ = 405.12639. HPLC (method-A): tR = 14.926, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)-benzamide (32): synthesis Scheme 3; step d: 4-(N-phenylsulfamoyl)-benzoic acid (8; 130 mg, 0.47 mmol), EDC*HCl (108 mg, 0.56 mmol), HOBT (63 mg, 0.47 mmol), benzyl(but-3-yn-1-yl)amine (42, 112 mg, 0.70 mmol); product: white solid; yield: 0.15 g ≡ 74%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.33 (s, 1H), 7.83–7.72 (m, 2H), 7.65–7.49 (m, 2H), 7.39–7.17 (m, 6H), 7.16–6.96 (m, 4H), 4.71, 4.41 (s, 2H), 3.46, 3.16 (t, J = 6.7 Hz, 2H), 2.88 (d, J = 14.2 Hz, 1H), 2.36 (s, 1H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.69, 169.53, 140.37, 140.01, 139.94, 137.39, 137.17, 136.54, 129.21, 128.73, 128.60, 127.60, 127.26, 126.98, 126.94, 124.50, 124.38, 120.64, 120.44, 81.64, 81.00, 73.47, 72.61, 52.08, 46.38, 43.25, 17.40, 16.41. MS (ESI+): m/z = 419.08 [M + H]+. HRMS: m/z calcd for C24H23N2O3S1 [M + H]+ = 419.14239. Found [M + H]+ = 419.14198. HPLC (method-A): tR = 14.967, purity ≥95% (UV: 254/280 nM).

Scheme 3; step e: general procedure for CuAAc reaction (compounds 33–40).

Alkyne (1 equiv) and azide (1 equiv) were dissolved in 6 mL of H2O/t-BuOH (1:1). Copper (II) sulfate pentahydrate (0.01 equiv, 0.1 M in H2O) and sodium ascorbate (0.1 equiv, 0.1 M in H2O) were added to this solution, and the reaction was stirred at room temperature until all starting material was consumed (identified per TLC, about 24–72 h). The reaction was quenched with saturated NH4Cl solution, and the product was extracted with EtOAc. The organic layer was dried over MgSO4 and concentrated under a reduced pressure. The residue was further purified by column chromatography using n-hexane/ethyl acetate as an eluent.

Synthesis of N-benzyl-N-[(1-benzyl-1H-1,2,3-triazol-4-yl)methyl]-4-(phenylsulfamoyl)benzamide (33): synthesis Scheme 3; step e: N-benzyl-4-(phenylsulfamoyl)-N-(prop-2-yn-1-yl)benzamide (31; 50 mg, 0.12 mmol), (azidomethyl)benzene (247 μL, 0.5 M in DCM, 0.12 mmol), copper (II) sulfate pentahydrate (12.36 μL, 0.1 M in H2O, 1.24 μmol), sodium ascorbate (124 μL, 0.1 M in H2O, 12.4 μmol); product: white solid; yield: 0.06 g ≡ 97%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.35, 10.32 (s, 1H), 8.12, 8.02 (s, 1H), 7.82–7.67 (m, 3H), 7.53 (d, J = 7.4 Hz, 1H), 7.40–7.18 (m, 11H), 7.11–6.97 (m, 4H), 5.58, 5.55 (s, 2H), 4.58 (s, 2H), 4.36, 4.29 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.42, 142.37, 140.13, 137.38, 136.82, 129.20, 128.76, 128.68, 128.53, 128.11, 127.87, 127.76, 127.65, 127.30, 126.93, 124.40, 123.98, 120.47, 52.80, 51.79, 47.13, 43.47. MS (ESI+): m/z = 538.09 [M + H]+. HRMS: m/z calcd for C30H28N5O3S1 [M + H]+ = 538.19074. Found [M + H]+ = 538.19018. HPLC (method-A): tR = 15.004, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-[2-(1-benzyl-1H-1,2,3-triazol-4-yl)ethyl]-4-(phenylsulfamoyl)benzamide (34): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)benzamide (32; 50 mg, 0.12 mmol), (azidomethyl)benzene (287 μL, 0.5 M in DCM, 0.14 mmol), copper (II) sulfate pentahydrate (23.89 μL, 0.1 M in H2O, 2.38 μmol), sodium ascorbate (239 μL, 0.1 M in H2O, 23.89 μmol); product: white solid; yield: 0.06 g ≡ 83%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.33, 10.30 (s, 1H), 8.03–7.63 (m, 3H), 7.47–7.15 (m, 13H), 7.11–6.97 (m, 4H), 5.55, 5.51 (s, 2H), 4.71, 4.22 (s, 2H), 3.58, 3.29 (t, J = 6.9 Hz, 2H), 2.94, 2.79 (t, J = 7.0 Hz, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.48, 144.23, 143.31, 140.58, 140.42, 139.87, 139.77, 137.33, 136.59, 136.28, 136.08, 129.18, 128.75, 128.69, 128.61, 128.15, 128.02, 127.97, 127.79, 127.55, 127.21, 127.13, 127.03, 126.86, 124.48, 124.38, 122.74, 122.65, 120.74, 120.38, 52.70, 51.88, 47.70, 46.55, 44.11, 23.80, 22.83. MS (ESI+): m/z = 552.11 [M + H]+. HRMS: m/z calcd for C31H30N5O3S1 [M + H]+ = 552.20639. Found [M + H]+ = 552.20668. HPLC (method-A): tR = 14.860, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-((1-(2-chlorobenzyl)-1H-1,2,3-triazol-4-yl)methyl)-4-(N-phenyl-sulfamoyl)benzamide (35): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)-benzamide (31; 100 mg, 0.25 mmol), 1-(azidomethyl)-2-chlorobenzene (494 μL, 0.5 M in MTBE, 0.25 mmol), copper (II) sulfate pentahydrate (0.6 mg, 3.0 μmol), sodium ascorbate (9.8 mg, 49 μmol); product: white solid; yield: 0.09 g ≡ 41%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.34 (s, 1H), 8.09, 7.99 (s, 1H), 7.85–7.68 (m, 3H), 7.53 (d, J = 7.8 Hz, 2H), 7.45–7.24 (m, 6H), 7.20 (t, J = 7.8 Hz, 2H), 7.17–6.98 (m, 5H), 5.69, 5.66 (s, 2H), 4.62, 4.59 (s, 2H), 4.37, 4.30 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.48, 142.88, 142.28, 140.12, 137.40, 136.82, 133.20, 132.50, 130.25, 130.20, 129.62, 129.19, 128.68, 128.53, 127.74, 127.66, 127.29, 126.94, 124.38, 120.47, 51.81, 50.61, 47.15, 43.44. MS (ESI+): m/z = 572.20 [M + H]+. HRMS: m/z calcd for C30H27ClN5O3S1 [M + H]+ = 572.15176. Found [M + H]+ = 572.15251. HPLC (method-A): tR = 15.411, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-4-(N-phenylsulfamoyl)-N-((1-(pyridin-4-ylmethyl)-1H-1,2,3-triazol-4-yl)methyl)benzamide (36): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)-benzamide (31; 100 mg, 0.25 mmol), 4-(azidomethyl)pyridine (494 μL, 0.5 M in MTBE, 0.25 mmol), copper (II) sulfate pentahydrate (0.6 mg, 3.0 μmol), sodium ascorbate (9.8 mg, 49 μmol); product: white solid; yield: 0.10 g ≡ 74%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.34 (s, 1H), 8.56 (s, 2H), 8.19, 8.09 (s, 1H), 7.85–7.69 (m, 3H), 7.54 (d, J = 7.4 Hz, 1H), 7.39–7.24 (m, 4H), 7.22–7.17 (m, 3H), 7.13–6.97 (m, 5H), 5.67, 5.64 (s, 2H), 4.63, 4.62 (s, 2H), 4.38, 4.33 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO) δ 169.43, 150.03, 144.79, 142.54, 140.12, 137.41, 136.84, 129.19, 128.67, 128.52, 127.74, 127.61, 127.32, 126.95, 124.56, 124.37, 122.14, 120.46, 51.49, 47.21, 43.54. MS (ESI+): m/z = 539.20 [M + H]+. HRMS: m/z calcd for C29H27N6O3S1 [M + H]+ = 539.18599. Found [M + H]+ = 539.18606. HPLC (method-A): tR = 11.654, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-((1-(3,4-dichlorobenzyl)-1H-1,2,3-triazol-4-yl)methyl)-4-(N-phenylsulfamoyl)benzamide (37): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)-benzamide (31; 100 mg, 0.25 mmol), 4-(azidomethyl)-1,2-dichlorobenzene (494 μL, 0.5 M in MTBE, 0.25 mmol), copper (II) sulfate pentahydrate (0.6 mg, 3.0 μmol), sodium ascorbate (9.8 mg, 49 μmol); product: white solid; yield: 0.09 g ≡ 63%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.35 (s, 1H), 8.17, 8.07 (s, 1H), 7.84–7.68 (m, 3H), 7.65–7.59 (m, 2H), 7.53 (d, J = 7.7 Hz, 1H), 7.35–7.17 (m, 7H), 7.11–6.97 (m, 4H), 5.60, 5.58 (s, 2H), 4.60, 4.59 (s, 2H), 4.36, 4.30 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.45, 143.17, 142.53, 140.33, 140.06, 137.57, 137.06, 136.89, 136.81, 136.21, 131.28, 131.01, 130.91, 130.09, 129.17, 128.65, 128.49, 128.37, 128.30, 127.70, 127.64, 127.51, 127.28, 127.18, 126.93, 124.27, 124.15, 124.04, 120.47, 51.84, 51.42, 47.14, 43.49. MS (ESI+): m/z = 606.25 [M + H]+. HRMS: m/z calcd for C30H26Cl2N5O3S1 [M + H]+ = 606.11279. Found [M + H]+ = 606.11353. HPLC (method-A): tR = 16.068, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-((1-(imidazo[1,2-a]pyrimidin-2-ylmethyl)-1H-1,2,3-triazol-4-yl)methyl)-4-(N-phenylsulfamoyl)benzamide (38): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)benzamide (31; 100 mg, 0.25 mmol), 2-(azidomethyl)imidazo[1,2-a]pyrimidine (494 μL, 0.5 M in MTBE, 0.25 mmol), copper (II) sulfate pentahydrate (0.6 mg, 3.0 μmol), sodium ascorbate (9.8 mg, 49 μmol); product: white solid; yield: 0.08 g ≡ 53%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.32 (s, 1H), 8.97 (dd, J = 6.8, 1.9 Hz, 1H), 8.55 (dd, J = 4.1, 2.0 Hz, 1H), 8.14, 8.04 (s, 1H), 7.88–7.72 (m, 4H), 7.53 (d, J = 7.8 Hz, 1H), 7.33–7.18 (m, 6H), 7.12–6.96 (m, 5H), 5.74, 5.72 (s, 2H), 4.60, 4.58 (s, 2H), 4.36, 4.29 (s, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.44, 150.88, 147.65, 144.46, 142.78, 142.14, 141.77, 141.67, 140.23, 140.11, 137.45, 136.80, 135.47, 129.18, 128.69, 128.52, 127.70, 127.30, 127.16, 126.93, 124.35, 124.23, 120.47, 109.91, 109.01, 51.68, 47.72, 46.99, 43.36. MS (ESI+): m/z = 579.24 [M + H]+. HRMS: m/z calcd for C30H27N8O3S1 [M + H]+ = 579.19213. Found [M + H]+ = 579.19159. HPLC (method-A): tR = 12.533, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-((1-((2-methylthiazol-4-yl)methyl)-1H-1,2,3-triazol-4-yl)methyl)-4-(N-phenylsulfamoyl)benzamide (39): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)benzamide (31; 100 mg, 0.25 mmol), 4-(azidomethyl)-2-methylthiazole (494 μL, 0.5 M in MTBE, 0.25 mmol), copper (II) sulfate pentahydrate (0.6 mg, 3.0 μmol), sodium ascorbate (9.8 mg, 49 μmol); product: white solid; yield: 0.10 g ≡ 71%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.34 (s, 1H), 8.07, 7.97 (s, 1H), 7.84–7.68 (m, 3H), 7.57–7.16 (m, 8H), 7.13–6.98 (m, 4H), 5.61, 5.59 (s, 2H), 4.58 (s, 2H), 4.36, 4.28 (s, 2H), 2.61 (s, 3H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.43, 166.47, 149.60, 149.53, 142.19, 140.20, 140.14, 137.41, 136.82, 136.23, 129.21, 128.70, 128.54, 127.73, 127.67, 127.54, 127.30, 127.23, 126.94, 124.40, 124.12, 123.93, 120.47, 118.01, 117.85, 51.74, 48.92, 47.03, 43.36, 18.73. MS (ESI+): m/z = 559.21 [M + H]+. HRMS: m/z calcd for C28H27N6O3S2 [M + H]+ = 559.15806. Found [M + H]+ = 559.15812. HPLC (method-A): tR = 14.084, purity ≥95% (UV: 254/280 nM).

Synthesis of N-benzyl-N-((1-((2-oxooxazolidin-5-yl)methyl)-1H-1,2,3-triazol-4-yl)methyl)-4-(N-phenylsulfamoyl)benzamide (40): synthesis Scheme 3; step e: N-benzyl-N-(but-3-yn-1-yl)-4-(phenylsulfamoyl)benzamide (31; 100 mg, 0.25 mmol), 5-(azidomethyl)oxazolidin-2-one (494 μL, 0.5 M in MTBE, 0.25 mmol), copper (II) sulfate pentahydrate (0.6 mg, 3.0 μmol), sodium ascorbate (9.8 mg, 49 μmol); product: white solid; yield: 0.06 g ≡ 44%. 1H-NMR (500 MHz, (CD3)2SO, rotamers observed) δ 10.34 (s, 1H), 8.07, 7.98 (s, 1H), 7.89–7.70 (m, 3H), 7.62–7.49 (m, 2H), 7.41–7.26 (m, 4H), 7.09–7.03 (m, 2H), 7.13–6.97 (m, 4H), 4.95 (s, 1H), 4.73–4.48 (m, 4H), 4.32, 4.28 (s, 2H), 3.61, 3.27 (t, J = 9.0 Hz, 2H). 13C-NMR (126 MHz, (CD3)2SO, rotamers observed) δ 169.43, 158.01, 142.76, 142.13, 140.23, 140.11, 137.41, 136.74, 136.15, 129.22, 128.73, 128.60, 127.79, 127.71, 127.57, 127.30, 126.97, 124.77, 124.61, 124.40, 120.46, 73.35, 73.25, 52.12, 51.54, 48.61, 46.74, 43.12, 42.12. MS (ESI+): m/z = 569.20 [M + Na]+. HRMS: m/z calcd for C27H27N6O5S2 [M + H]+ = 547.17582. Found [M + H]+ = 547.17560. HPLC (method-A): tR = 12.640, purity ≥95% (UV: 254/280 nM).

Synthesis of benzyl(prop-2-yn-1-yl)amine (41): synthesis Scheme 3; step b: 3-bromoprop-1-yne (3.0 mL, 26.9 mmol) was added slowly to benzylamine (17.65 mL, 162 mmol) over 30 minutes via addition funnel. The reaction was stirred at room temperature for 72 h. The reaction was diluted in Et2O and extracted with saturated aq. NaHCO3. The organic layer was dried over MgSO4 and concentrated under a reduced pressure. The residue was further purified by column chromatography using n-hexane/EtOAc 9:1 as an eluent. Yield: 2.35 g ≡ 60%. 1H-NMR (250 MHz, (CD3)2SO) δ 7.43–7.07 (m, 5H), 3.74 (s, 2H), 3.27 (d, J = 2.4 Hz, 2H), 3.07 (t, J = 2.4 Hz, 1H), 2.44 (s, 1H). MS (ESI+): m/z = 146.12 [M + H]+.