Abstract

Damage to cartilage tissues is often difficult to repair owing to chronic inflammation and a lack of bioactive factors. Therefore, developing bioactive materials, such as hydrogels acting as extracellular matrix mimics, that can inhibit the inflammatory microenvironment and promote cartilage repair is crucial. Hyaluronic acid, which exists in cartilage and synovial fluid, has been extensively investigated for cartilage tissue engineering because of its promotion of cell adhesion and proliferation, regulation of inflammation, and enhancement of cartilage regeneration. However, hyaluronic acid-based hydrogels have poor degradation rates and unfavorable mechanical properties, limiting their application in cartilage tissue engineering. Recently, various multifunctional hyaluronic acid-based hydrogels, including alkenyl, aldehyde, thiolated, phenolized, hydrazide, and host–guest group-modified hydrogels, have been extensively studied for use in cartilage tissue engineering. In this review, we summarize the recent progress in the multifunctional design of hyaluronic acid-based hydrogels and their application in cartilage tissue engineering. Moreover, we outline the future research prospects and directions in cartilage tissue regeneration. This would provide theoretical guidance for developing hyaluronic acid-based hydrogels with specific properties to satisfy the requirements of cartilage tissue repair.

Keywords: Hyaluronic acid, Hydrogel, Functional modification, Cartilage tissue engineering

Graphical abstract

1. Introduction

Articular cartilage is a special soft tissue composed of chondrocytes and extracellular matrix (ECM) and is located on the surface of bone joints. It plays an important role in maintaining lubrication and joint movement [[1], [2], [3]]. Articular cartilage damage due to trauma, congenital anomalies, and diseases can often cause joint pain and motor dysfunction in patients [[4], [5], [6]]. Owing to the unique tissue structure of the articular cartilage, its repair and treatment after an injury has significant limitations and challenges; the limiting factors include the lack of blood vessels, nerves, and lymph, high ratio of ECM to cells, and elevated expression of proinflammatory factors [[7], [8], [9], [10], [11]]. A continuous provision of bioactive factors as well as the inhibition of the inflammatory response at the articular cartilage injury site is thus required.

Current treatment strategies for articular cartilage injury primarily rely on surgical treatments such as microfractures, subchondral drilling, and autologous chondrocyte transplantation. However, these strategies often have certain limitations, including infliction of trauma, low efficacy, and the formation of postoperative fibrocartilage, which can damage joint function [[12], [13], [14]]. Compared with the aforementioned strategies, biomedical hydrogels can provide a biomimetic ECM similar to natural cartilage. Hydrogels are a class of three-dimensional hydrophilic polymer networks with water in their matrix that can be loaded with cells, drugs, and bioactive molecules and maintain their activity; they have been widely used in cartilage damage repair [[15], [16], [17], [18]]. In cartilage tissue engineering, ideal hydrogels should have a biomimetic cartilage ECM to build an ecological microenvironment and multifunctional properties, including maintenance of cell viability and phenotype, reduction of fibrocartilage generation, suitable degradation rate, excellent biocompatibility, sustained release of drugs and growth factors, and reconstruction of the bone–cartilage interface [19].

Polysaccharides have significant application potential in cartilage tissue engineering because of their similar structures to that of cartilage ECM components, high rheology and water retention, excellent biocompatibility, and antioxidant and anti-inflammatory properties [20]. Hyaluronic acid (HA) is a polysaccharide composed of alternating d-glucuronic acid and N-acetylglucosamine, which are naturally present in cartilage and synovial fluid [21,22]. Compared with other polysaccharides, HA affects the regulation of cartilage function and repair of cartilage damage in many ways. Previous studies have demonstrated that HA can improve the lubricity of cartilage boundaries, regulate inflammation at cartilage lesions, promote cell adhesion and proliferation, and ameliorate cartilage ECM deposition and cartilage regeneration, all of which have excellent application prospects in cartilage tissue engineering [[23], [24], [25]]. Notably, HA can recognize the HA receptor (cluster of differentiation 44, CD44) to protect cartilage and participate in the regeneration of cartilage ECM during cartilage repair [20]. Therefore, HA-related commercial products, such as Artz®, Cingal®, Durolane®, Hyalgan®, Monovisc®, Orthovisc®, Sinovial®, Supartz®, and Synvisc®, have been widely used for cartilage-related diseases. Currently, most related clinical studies are still in progress (Table 1) (www.clinicaltrials.gov). In addition, functional modification of HA-based hydrogels can effectively promote cartilage repair and regeneration by enhancing the adhesion, proliferation, and chondrogenesis of encapsulated stem cells and chondrocytes, regulating the inflammatory microenvironment at the cartilage injury site, and promoting cartilage ECM deposition, such as glycosaminoglycan (GAG), collagen II, and proteoglycans [20,26] (Fig. 1). In recent years, functional modification based on HA hydrogels in cartilage tissue engineering has primarily focused on the modification of three reactive functional groups in the molecular structure of HA: 1) esterification and acylation of carboxyl groups, 2) esterification and divinyl sulfone (DVS) crosslinking of primary hydroxyl groups, and 3) oxidation reaction of secondary hydroxyl groups [27,28] (Fig. 2).

Table 1.

Clinical trials of HA in cartilage related disease (Source: www.clinicaltrials.gov).

| Gov identifier | Sponsor | Phase | Disease | Interventions | Purpose |

|---|---|---|---|---|---|

| NCT03101163 | KLSMC Stem Cells, Inc. | Phase 2 | Articular Cartilage Disorder | Peripheral blood stem cells combined with HA (PBSCs/HA) | Evaluating the therapeutic effects between PBSCs/HA and standard treatment after subchondral drilling surgery |

| NCT00988091 | Ferring Pharmaceuticals | Phase 3 | Knee osteoarthritis | 1.2% sodium hyaluronate | Evaluating the therapeutic effects of 1.2% sodium hyaluronate through intra-articular injections |

| NCT01319461 | Med Pharma Co., Ltd. | Phase 3 | Knee osteoarthritis | Hyalgan® (sodium hyaluronate); Sterile normal saline | Evaluating the therapeutic effects between Hyalgan® and sterile normal saline through intra-articular injections |

| NCT01295580 | Bioventus LLC | Not Applicable | Knee osteoarthritis | Artz® (HA); Durolane® (HA stabilized) | Evaluating the safety and therapeutic effects between Artz® and Durolane® through intra-articular injections |

| NCT00556608 | IBSA Institut Biochimique SA | Phase 4 | Knee osteoarthritis | Sinovial® (sodium hyaluronate); Synvisc® (Hylan G-F 20) | Evaluating the safety and therapeutic effects between Sinovial® and Synvisc® through intra-articular injections |

| NCT02211521 | Samsung Medical Center | Phase 3 | Knee osteoarthritis | HA; Autologous platelet-rich plasma | Evaluating the therapeutic effects between HA and autologous platelet-rich plasma through intra-articular injections |

| NCT04165902 | Taipei Medical University | Phase 4 | Knee osteoarthritis | Steroid plus HA; Dextrose plus HA | Evaluating the additional therapeutic effects of steroid and dextrose to HA through injection |

| NCT03062787 | Pharmascience Inc. | Not Applicable | Knee osteoarthritis | Cingal® (HA plus triamcinolone hexacetonide); Monovisc® (sodium hyaluronate) | Evaluating the early effects between Cingal® and Monovisc® through intra-articular injections |

| NCT03211650 | University of Milan | Phase 4 | Knee osteoarthritis | HA and platelet-rich plasma (PRP) combination | Evaluating the therapeutic effects of HA and PRP combination through intra-articular injections |

| NCT01557868 | American Orthopaedic Society for Sports Medicine | Phase 4 | Knee osteoarthritis | Synvisc® (Hylan G-F 20); 1% sodium hyaluronate | Developing the algorithm to predict the therapeutic effects of HA products through intra-articular injections |

| NCT02984228 | Hospital for Special Surgery, New York | Phase 4 | Glenohumeral osteoarthritis | HA; Platelet-rich plasma (PRP) | Evaluating the therapeutic effects between HA and PRP through ultrasound-guided injections |

| NCT00918736 | Kaohsiung Veterans General Hospital | Phase 2 | Ankle osteoarthritis | Sodium hyaluronate | Evaluating the therapeutic effects of sodium hyaluronate through three weekly intra-articular injections |

| NCT04204278 | Anika Therapeutics, Inc. | Not Applicable | Ankle osteoarthritis | Monovisc® (sodium hyaluronate) | Evaluating the therapeutic effects of Monovisc® through single injections |

| NCT00436969 | DePuy Mitek | Phase 3 | Shoulder osteoarthritis | Orthovisc® (HA); Corticosteroid | Evaluating the therapeutic effects between Orthovisc® and corticosteroid through injections |

| NCT00479687 | Bioventus LLC | Not Applicable | Shoulder osteoarthritis | Supartz® (HA); Phosphate buffered saline (PBS) | Evaluating the therapeutic effects between Supartz® and PBS through injections |

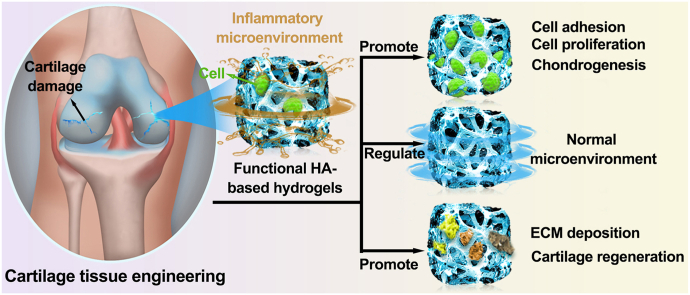

Fig. 1.

Synthesis and biological function of HA-based hydrogel for cartilage tissue engineering.

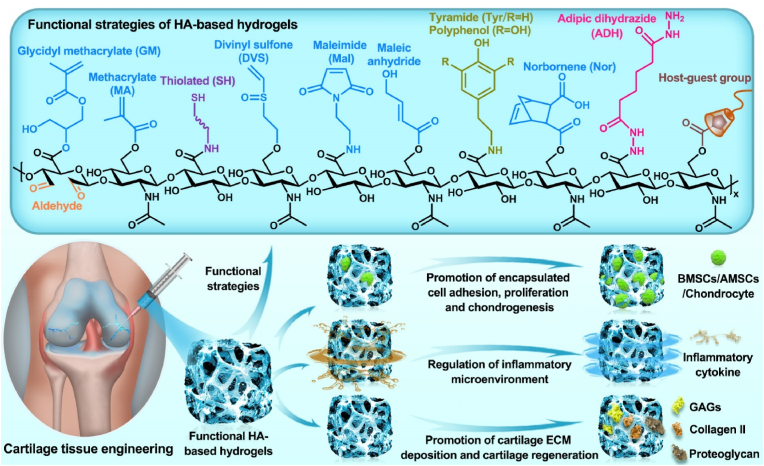

Fig. 2.

Functional modification of HA-based hydrogels.

In this paper, we discuss the functional molecular structure modification of HA-based hydrogels primarily containing alkenyl, aldehyde, thiolated, phenolized, hydrazide, and host–guest groups. We summarize their application in cartilage tissue engineering, and introduce the research status of HA-based hydrogels as 3D printing bioinks in cartilage engineering. We further elucidate the capacities and merits of different functionalized HA-based hydrogels to guide their research in cartilage tissue engineering. Finally, we highlight the advantages and challenges of current HA-based hydrogels for cartilage tissue-engineering applications.

2. Alkenyl HA-based hydrogels for cartilage tissue engineering

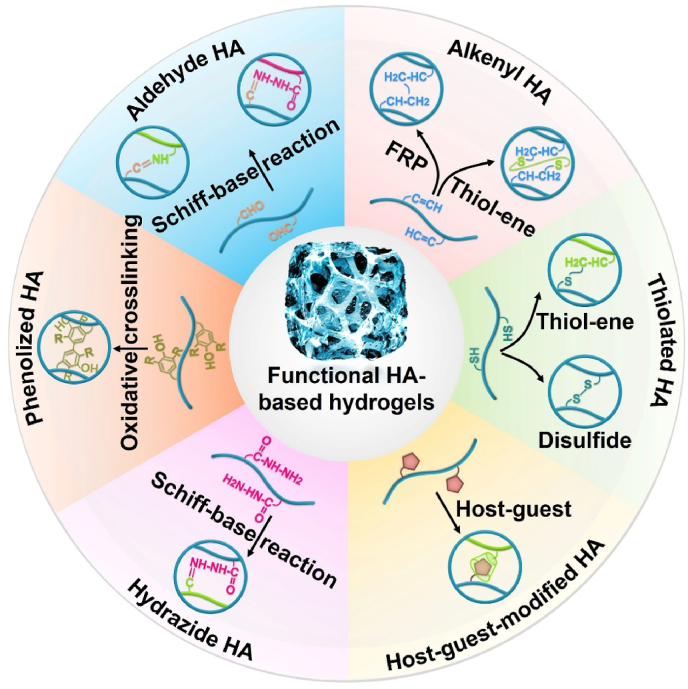

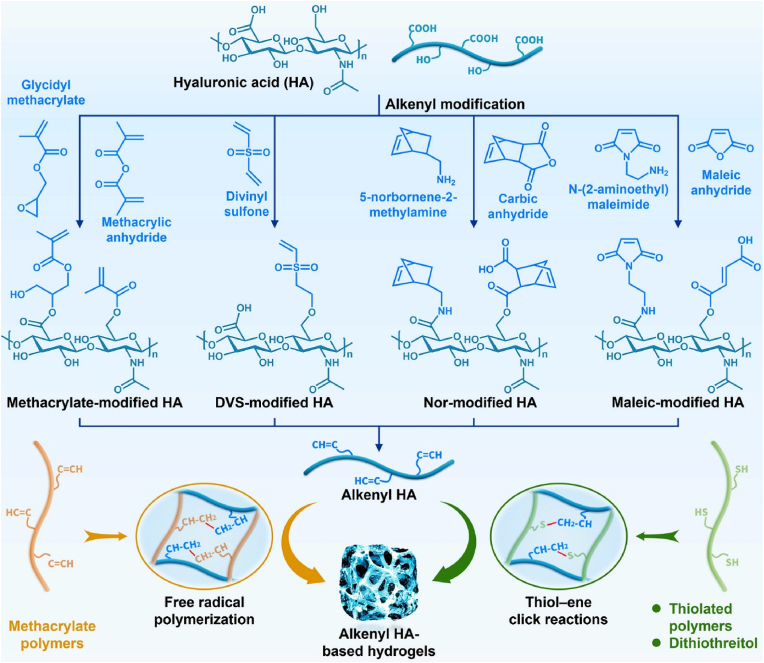

Alkenyl HA-based hydrogels have been widely studied in cartilage tissue engineering because they can be prepared easily by double bonds taking part in simple chemical reactions, such as self-polymerization through free-radical polymerization (FRP) reactions and click chemistry with sulfhydryl groups. The reactions often are fast speeds, occur in mild conditions, and exhibit desirable adaptability and high directional selectivity (Fig. 3 and Table 2).

Fig. 3.

Synthesis of alkenyl HA-based hydrogels for cartilage tissue engineering.

Table 2.

Alkenyl HA-based hydrogels for cartilage tissue engineering.

| Hydrogels | Components | Physicochemical properties | Biofunctions | Ref. |

|---|---|---|---|---|

| Methacrylated HA (HA-MA) | HA; methacrylic anhydride (MA) | Viscoelasticity; controlled pore size and degradation rate | Encapsulating cells; promoting MSCs proliferation, migration and chondrogenesis; promoting ECM deposition | [[30], [31], [32], [33], [34], [35]] |

| HA-MA/MeLAHA | HA, MA, MeLAHA | Hydrolytic degradation and enzymatic degradation | Promoting MSCs chondrogenesis and ECM deposition; ensuring stability of hydrogel scaffold | [36,37] |

| HA-MA/MMP7 | HA, MA, matrix metalloproteinase 7 | Tunable mechanical properties, swelling performance and degradation rates | Promoting MSCs chondrogenesis | [38,39] |

| HA-MA/Gel-MA | HA, MA, gelatin, | Improving the mechanical properties | Enhancing cell proliferation, aggregation and chondrogenesis; maintaining the chondrocyte phenotype; enhancing deposition and distribution of ECM; accelerating cartilage repair | [[40], [41], [42], [43], [44]] |

| HA-MA/Gel-MA/BC | HA, MA, gelatin, bacterial cellulose | Improving the mechanical properties and printing fidelity | Facilitating chondrocyte proliferation and protein expression | [45] |

| HA-MA/Gel-MA/AFnSi | HA, MA, gelatin, acrylate-functionalized nanosilica | Controllable pore sizes, swelling ratios and mechanical properties | Promoting the chondrogenic gene expression and ECM deposition | [46] |

| HA-MA/CNF | HA, MA, methacrylated cellulose nanofibers | Enhanced mechanical properties; decent restorability | Enhancing BMSCs proliferation and chondrogenesis; accelerating full-thickness cartilage repair | [48] |

| HA-MA/CF | HA, MA, chondrogenic fibrinogen | Ameliorating the compressive modulus | Enhancing BMSCs proliferation and early chondrogenesis; | [49] |

| HA-MA/ELP@ZnO | HA, MA, elastin-like polypeptide, zinc oxide | Adjustable mechanical strength, elasticity, and adhesion | Enhancing cell proliferation and migration; negligible inflammatory response; antibacterial ability | [50] |

| HA-MA/ROS-HP/PLGA | HA, MA, ROS-HP, poly (lactide-co-glycolide) | Suitable compressive modulus; good ROS scavenging ability | Regulating inflammation; promoting ECM deposition; accelerating hyaline cartilage regeneration and integration with surrounding tissues | [51] |

| HA-MA/F127DA | HA, MA, pluronic F127 diacrylate | Low swelling ratio; excellent stiffness, toughness and self-recovery | Enhancing thyroid cartilage regeneration of rabbit larynx | [52] |

| HA-MA/PRP | HA, MA, platelet-rich plasma | Suitable mechanical properties | Promoting ECM deposition and hyaline cartilage regeneration | [54] |

| HA-MA/SA/KGN-loaded PLGA | HA, MA, sodium alginate, kartogenin, poly (lactide-co-glycolide) | Microporous; promoting cells and tissues infiltration; sustained release of KNG | Regulating the inflammatory microenvironment; promoting migration and chondrogenesis of BMSCs; accelerating cartilage repair | [55,56] |

| HA-GM | HA, glycidyl methacrylate | Highly interconnected macroporous network; compression-recovery property | Maintaining the activity and phenotype of chondrocytes; promoting chondrocytes proliferation and ECM deposition | [57] |

| HA-DVS | HA, divinyl sulfone | Viscoelasticity; enzymatic degradation | Inducing the chondrogenic differentiation of AMSCs | [61] |

| HA-DVS/Li-BGF | HA, DVS, lithium bioactive glass fibers | Improving the elastic modulus | Promoting chondrocytes proliferation and chondrogenic behavior | [62] |

| HA-DVS/Gel-HS | HA, DVS, thiolated gelatin | Providing bioinspired microenvironment | Inhibiting vascularization and hypertrophy; promoting cartilage repair | [63] |

| HA-Nor/DTT | HA, 5-norbornene-2-methylamine, dithiothreitol | Controllable compressive moduli and CD44 binding | Promoting the deposition and distribution of ECM; promoting the chondrogenic differentiation of BMSCs | [[68], [69], [70], [71]] |

| HA-Nor/DTT | HA, carbic anhydride, dithiothreitol | Simple synthesis; controllable gelation properties, swelling and transmittance | Good cytocompatibility; encapsulating cells | [67] |

| HA-Mal/GelMA | HA, maleimide, gelatin, MA | Adjustable mechanical properties | Supporting the proliferation and chondrogenesis of BMSCs | [74] |

| HA-Mal/DTT | HA, maleimide, dithiothreitol | Adjustable mechanical strength | Maintaining BMSC stemness (lower strength), promoting BMSCs chondrogenesis (higher strength) | [75] |

| HA-Mal/PEG-SH | HA, maleic anhydride, thiol-terminated polyethylene glycol | High substitution degree; rapid gelation; regulatable degradation rate | Good cytocompatibility | [76] |

2.1. Methacrylate HA-based hydrogels

Methacrylic anhydride (MA) has a highly reactive anhydride group and photocrosslinkable C C double bonds, which can be easily grafted to natural polymers through the reaction of anhydride groups with amino groups or hydroxyl groups; moreover, functional polymers can be utilized to prepare hydrogels through photopolymerization [29]. Notably, an in situ photocrosslinkable methacrylate HA-based hydrogel with good viscoelasticity was prepared using esterification between the hydroxyl group of HA and the anhydride group of MA, which not only facilitated the encapsulation of cells but also reduced the mechanical stimulation of surrounding tissues [30]. The pore size, HA concentration, crosslinking density, and degradation rate of HA-MA-based hydrogels impact their application in cartilage tissue engineering [[31], [32], [33], [34], [35]]. Particularly, compared with other pore sizes, HA-MA-based hydrogels with medium pore sizes (200–250 μm) demonstrated the best promotion of endothelial cell proliferation and migration and exhibited the best vascularization behavior for cartilage repair [31]. Moreover, an increased concentration of HA in HA-MA-based hydrogels can enhance chondrogenesis and ECM deposition of encapsulated mesenchymal stem cells (MSCs), but it might cause the uneven distribution of the ECM [32,33]. In addition, the low crosslinking density (1% at 15 min exposure or 5% at 5 min exposure) of HA-MA (∼29% methacrylate modification)-based hydrogels can promote cartilage differentiation, whereas an increase in crosslinking density (5% at 15 min exposure) reduces the deposition and uniform distribution of cartilage ECM and induces hypertrophy and mineralization of MSCs [34]. In addition, the degradation rate of hydrogels plays an important role in cartilage repair. When the degradation rate is high, it is not beneficial for the retention of ECM; whereas when the degradation rate is low, it inhibits the formation of cartilage tissue [[35], [36], [37]]. Compared with collagen-based hydrogels, HA-MA-based hydrogels can maintain the proliferation of bone marrow MSCs (BMSCs) and the production of cartilage-related ECM in the later stages of cartilage tissue engineering because of their relatively stable physical microenvironment. However, the cartilage-inducing activity of HA-MA-based hydrogels cannot compete with that of collagen-based hydrogels in the early stages of cartilage tissue engineering [35]. To optimize the degradation rate of HA-MA-based hydrogels in vivo, Burdick et al. prepared a hybrid hydrogel using HA-MA and a novel HA macromer (MeLAHA, HA macromers with methacrylate modification and ε-caprolactone) with hydrolytic and enzymatic degradation performance, which promoted the chondrogenesis of MSCs by controlling the degradation property of the hydrogel. This is because faster degradation (complete degradation within 7 days) of MeCLHA provided void spaces for the deposition of ECM, and slower degradation (∼40% degradation in 56 days) of HA-MA ensured the stability of the hydrogel scaffold [36,37]. In addition, Tsanaktsidou et al. prepared another HA-MA-based hydrogel with two different crosslinking mechanisms, including FRP reaction and matrix metalloproteinase 7 (MMP7)-peptide-induced thiol-ene click reactions, which have tunable mechanical properties, swelling performance, and degradation rates. Interestingly, HA-MA-based hydrogels prepared using the MMP7-peptide in Dulbecco's modified Eagle's medium (DMEM) are beneficial for the chondrogenesis of human MSCs (hMSCs) because of their appropriate storage modulus of approximately 12 kPa [38]. Tsanaktsidou et al. further prepared a chondroitin sulfate (CS)-biofunctionalized HA-MA hydrogel by crosslinking the MMP7-peptide, which effectively enhanced hyaline cartilage regeneration by upgrading cartilage-related gene expression, GAG deposition, and chondrocyte cluster arrangement [39]. Therefore, the aforementioned reports provide significant guidance for the design and regulation of HA-MA-based hydrogels in cartilage tissue engineering.

In addition to the pore size, HA concentration, crosslinking density, and degradation rate of HA-MA-based hydrogels, mechanical properties and swelling rate influence cartilage tissue engineering. Studies have reported that suitable mechanical properties and a low swelling rate of HA-MA-based hybrid hydrogels can be achieved by incorporating natural polymers, which can effectively promote cartilage repair. For instance, Levett et al. prepared a hybrid hydrogel (HA-MA/Gel-MA) using HA-MA and gelatin (porcine skin) methacrylamide (Gel-MA) via photoinduced polymerization. The HA-MA component significantly improved the mechanical properties of the hydrogel, maintained the chondrocyte phenotype with rounded cell morphologies, and enhanced the deposition and distribution of ECM components, including collagen II and aggrecan, to accelerate cartilage formation. In addition, they incorporated CS methacrylate into an HA-MA/Gel-MA hybrid hydrogel to improve its mechanical properties, which enhanced chondrogenesis as well as the spatial distribution of the ECM [40,41]. Moreover, Lin et al. further demonstrated that the HA-MA/Gel-MA hybrid hydrogel can accelerate cartilage repair in vivo by promoting the chondrogenesis of hMSCs and the production of GAG when the concentration ratio of HA-MA and Gel-MA is 1:9 [42]. Interestingly, Wang et al. used HA-MA/Gel-MA hybrid hydrogels to encapsulate chondrocyte spheroids prepared using the hanging drop method for cartilage repair. Compared with chondrocytes, chondrocyte spheroids can form structures similar to native cartilage tissue, which can enhance cell proliferation and aggregation, maintain the cellular phenotype, and promote the deposition of abundant ECM [43]. Furthermore, compared with porcine-derived Gel-MA, the HA-MA/Gel-MA hybrid hydrogel constructed using bovine-derived Gel-MA and HA-MA through irgacure 2959-induced photocrosslinking (365 nm) exhibited the best similarity to native articular cartilage after 28 days of chondrocyte cultivation [44]. The mechanical properties of HA-MA/Gel-MA hybrid hydrogels can be further optimized by incorporating organic polymers or inorganic nanoparticles [45,46]. For example, Sang et al. incorporated bacterial cellulose (BC) into an HA-MA/Gel-MA hybrid hydrogel, which not only improved the mechanical properties and printing fidelity of the hydrogel but also facilitated chondrocyte proliferation and specific protein expression [45]. Nedunchezian et al. used acrylate-functionalized nanosilica (AFnSi) to crosslink HA-MA/Gel-MA hybrid hydrogels, and the obtained hydrogels exhibited controllable pore sizes, swelling ratios, and mechanical properties. Moreover, the hydrogels could promote the gene expression of chondrogenic markers, including SOX9, proteoglycan, and collagen II, in human adipose-derived MSCs (AMSCs) and increase the formation of sulfated GAG (sGAG) and collagen II [46].

In addition to Gel-MA, the incorporation of other natural polymers into HA-MA-based hydrogel matrices can optimize their mechanical properties and promote the chondrogenesis of cells [47]. For example, Zhao et al. fabricated a nanocomposite hydrogel (HA-MA/CNF) through the co-crosslinking of HA-MA and methacrylated cellulose nanofibers (CNFs); the HA-MA/CNF hydrogel exhibited enhanced mechanical properties with a compressive modulus of ∼0.46 MPa, a compressive strength of ∼0.198 MPa, and satisfactory restorability. Moreover, biological experiments have indicated that the nanocomposite hydrogel can have positive effects on the proliferation and chondrogenesis of BMSCs as well as accelerate full-thickness cartilage repair in vivo [48]. Snyder et al. developed a hybrid hydrogel comprising HA-MA and chondrogenic fibrinogen to ameliorate the compressive modulus of HA-MA-based hydrogels, which provided a suitable microenvironment for the proliferation and delivery of BMSCs as well as increased expression of SOX9 and decreased collagen I, suggesting that it was favorable for early chondrogenesis [49]. Sani et al. prepared a bioactive hydrogel (HA-ELP) using HA-MA and elastin-like polypeptide (ELP), which had adjustable mechanical properties including mechanical strength, elasticity, and adhesion. Meanwhile, the HA-ELP hydrogel supported cell proliferation and migration but had a negligible inflammatory response in vivo. Moreover, the HA-ELP hydrogel exhibited high antibacterial activity against drug-resistant bacteria after doping with zinc oxide (ZnO) nanoparticles, demonstrating good application potential in tissue engineering such as cartilage repair [50]. In addition, compared with natural polymers, synthetic polymers have also been reported to optimize mechanical properties and endow multifunctionality to HA-MA-based hydrogels [51,52]. Wu et al. designed a novel hybrid scaffold by filling an antioxidant hydrogel composed of HA-MA and reactive oxygen species (ROS)-responsive hyperbranched polymers (ROS-HP) into a poly (lactide-co-glycolide) (PLGA) scaffold with radial orientation. The hybrid scaffold had a suitable compressive modulus (1.5 MPa), good ROS-scavenging ability, and ability to regulate inflammation to accelerate hyaline cartilage regeneration. Moreover, the incorporation of hydrogel had a positive impact on the deposition of GAG and collagen II to integrate with surrounding tissues for neocartilage [51]. Ren et al. developed a stiff micelle-crosslinked hydrogel using HA-MA and Pluronic F127 diacrylate (F127DA), which exhibited a low swelling ratio and excellent mechanical properties, including stiffness, toughness, and self-recovery. The built hydrogel was further used in thyroid cartilage defects of rabbit larynx, and animal studies showed that the hydrogel effectively contributed to cartilage regeneration [52].

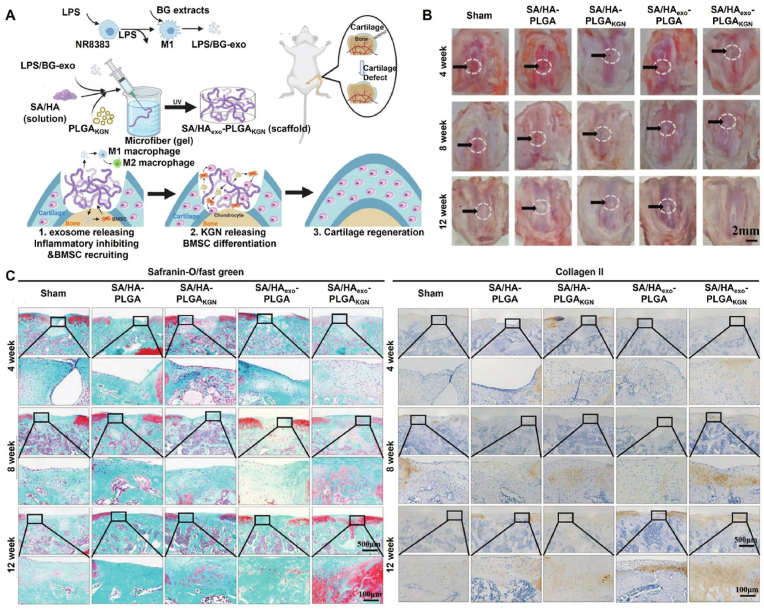

Cartilage can generally be divided into three types: hyaline, elastic, and fibrocartilage. Notably, the regeneration of hyaline cartilage is crucial in articular cartilage repair [53]. Yan et al. encapsulated platelet-rich plasma (PRP) in an HA-MA hydrogel to increase the deposition of GAG and collagen II. In addition, the regeneration of hyaline cartilage was verified without hypertrophic cartilage formation in a porcine femoral condyle cartilage injury model [54]. Shi et al. incorporated small molecule kartogenin (KGN)-loaded nanoparticles into HA-MA hydrogels to recruit and facilitate chondrogenesis of different endogenous cells (BMSCs, synovium-derived MSCs (SMSCs), and chondrocytes). Furthermore, the hydrogel could fill the defect and release KGN continuously to promote the formation of hyaline cartilage in a cartilage defect model of rabbit knee joints [55]. To avoid poor cell and tissue infiltration caused by nanoporous hydrogels, Ma et al. prepared a microporous hydrogel using HA-MA, sodium alginate (SA), and KGN-loaded PLGA microspheres using photopolymerization after crosslinking HA-MA/SA into microfibers to effectively promote the infiltration of cells and tissues. In addition, the hydrogel can gradually release exosomes and KGN-loaded PLGA microspheres, which can regulate the inflammatory microenvironment, enhance the migration of endogenous BMSCs, induce chondrogenesis of BMSCs, and promote cartilage repair (Fig. 4) [56].

Fig. 4.

Schematic illustration of the fabrication of SA/HAexo-PLGAKGN scaffold for cartilage regeneration. (A) Preparation of SA/HAexo-PLGAKGN scaffold and its biological function; (B) gross images of the cartilage defects in different groups at weeks 4, 8, and 12 after surgery; (C) immunohistochemical staining images of cartilage defects in different groups after surgery for 4, 8, and 12 weeks [56]; Copyright 2022, John Wiley and Sons.

In addition to the HA-MA hydrogel, He et al. fabricated a shape-memory-capable cryogel (HA-GM) using HA and glycidyl methacrylate (GM). Compared with HA-GM hydrogels, HA-GM cryogels with a highly interconnected macroporous network structure and compression-recovery property can provide a suitable microenvironment to maintain the activity and phenotype of chondrocytes during injection, as well as promote the proliferation of chondrocytes and the deposition of cartilage ECM [57]. Hsieh et al. developed a biomimetic scaffold using HA-GM, methoxy poly (ethylene glycol)-block-poly (ε-caprolactone) (mPEG-PCL), and hydroxyapatite loaded with transforming growth factor-β1 (TGF-β1) for the regeneration of hyaline cartilage and the ingrowth of bone tissue into the scaffold after implantation [58].

2.2. Divinyl sulfone-modified HA-based hydrogels

Recently, DVS has attracted considerable interest because of its hydrolysis resistance and broad-spectrum reactivity. It can modify biochemical molecules by reacting with sulfhydryl, amino, and hydroxyl groups under certain conditions [59,60]. Mondal et al. prepared an injectable hydrogel (HA-DVS) using HA and different concentrations of DVS via the reaction between hydroxyl and vinyl sulfone groups. The HA-DVS hydrogel exhibited viscoelasticity and enzymatic degradation ability and could induce the chondrogenesis of AMSCs [61]. Riveiro et al. further significantly improved the elastic modulus of HA-DVS hydrogels by doping them with lithium bioactive glass fibers (Li-BGF), which promoted the proliferation and chondrogenic behavior of chondrocytes [62]. Feng et al. developed a BMSC-laden bio-inspired hydrogel using HA-DVS and thiolated gelatin (Gel-HS) to enhance cartilage repair. The obtained hydrogels provided a good microenvironment for cell loading and minimally invasive delivery, protecting and maintaining the viability of BMSCs, and demonstrating positive effects on proliferation, chondrogenesis, and self-assembly into cartilage-like tissues, ultimately through interconnected cells. In addition, hydrogels can inhibit vascularization and hypertrophy, and contribute to cartilage repair [63]. HA-DVS-based hydrogels exhibited promising potential for the treatment of knee osteoarthritis (OA) in clinical trials. Park et al. evaluated the therapeutic effect of a novel HA-DVS hydrogel (YYD302) produced by biological fermentation on human knee OA after intra-articular injection. Compared with Synovian®, an HA-based hydrogel crosslinked with 1,4-butanediol diglycidyl ether, YYD302, could reduce the weight-bearing pain of patients after a single injection for 12 weeks and exhibited a better treatment effect at 2 weeks. In addition, YYD302 demonstrated good biosafety in local and systemic adverse drug reaction (ADR) evaluations [64]. In et al., the efficacy and safety of a single intra-articular injection of YYD302 in patients with knee OA were evaluated. Compared with phosphate-buffered saline, YYD302 effectively reduced pain and improved knee function, and the efficacy of a 2 mL dose was better than that of a 3 mL dose [65].

2.3. Norbornene-modified HA-based hydrogels

Norbornene (Nor)-thiol photocurable hydrogels, another type of material system with high application value in tissue engineering, are typically prepared using Nor-modified macromolecules (HA, gelatin, and polyethylene glycol (PEG)) and sulfhydryl-containing linkers. Such hydrogels have been demonstrated to have tunable biophysical and biochemical properties and good biocompatibility [66]. Compared with the widely studied HA-MA-based hydrogels, nor-modified HA (HA-Nor)-based hydrogels have attracted significant interest in biomedical research because of their low photoinitiator requirements and more stable and tailored structures [67]. Galarraga et al. prepared HA-Nor using HA and 5-norbornene-2-methylamine using a two-step method, including ion-exchange resins and catalytic reaction, and further crosslinked HA-Nor with dithiothreitol (DTT) to prepare hydrogels (HA-Nor-DTT) with different compressive moduli. Compared with stiffer (∼6–60 kPa) hydrogels, softer hydrogels (∼2 kPa) can provide a favorable local microenvironment to promote the deposition and distribution of ECMs, which promotes the chondrogenesis of encapsulated BMSCs. Moreover, the doping of polycaprolactone (PCL) microfibers produced by melt-electrowriting into softer hydrogels can solve the problems of poor initial mechanical properties and poor stability and promote neocartilage regeneration and integration [68]. The HA-Nor-DTT hydrogel has been used as a 3D bioprinting ink for cartilage tissue engineering [69]. Vega et al. further developed a combinatorial hydrogel platform with a biochemical gradient using an HA-Nor-DTT hydrogel and monothiolated peptides, which can be used to analyze early gene expression and long-term cartilage ECM of encapsulated MSCs. This platform can function as a scalable high-throughput technique for screening 3D cellular microenvironments [70]. Subsequently, to elucidate the influence of HA modification on CD44 binding, Kwon et al. evaluated the interaction of HA-Nor or HA-MA with different degrees of modification of CD44 and the effect on chondrogenesis of encapsulated MSCs. The results showed that the degree, type, and site of HA modification affected the binding of CD44. Low (∼10%) and moderately (∼20%) modified HA significantly promoted binding to CD44 and upregulate chondrogenesis of encapsulated MSCs [71]. The abovementioned synthesis of HA-Nor involved multiple synthetic steps, which were time-consuming and caused undesired contamination. To realize the simple synthesis of HA-Nor, Xiao et al. designed a simple and green method to synthesize HA-Nor using HA and carbic anhydride through esterification and further crosslinked HA-Nor with DTT to prepare hydrogels. The hydrogel exhibited controllable gelation properties, swelling, and transmittance and was suitable for cell encapsulation owing to its good cytocompatibility. Notably, the additional carboxyl group in HA-Nor prepared using this method provided a reactive site for further modification [67].

2.4. Maleic-modified HA-based hydrogels

In addition to the abovementioned molecules for grafting double C C bond groups, maleic derivatives are other widely used reagents for modifying polymers with amino or hydroxyl groups [72,73]. Ren et al. prepared a hydrogel with a double network structure crosslinked between maleimide-modified HA (HA-Mal) and Gel-MA to support the proliferation and chondrogenesis of BMSCs, where cells were seeded on the surface or inside the hydrogel [74]. Ren et al. further evaluated the effect of hydrogels with different mechanical strengths prepared using HA-Mal with different molecular weights (4, 10, and 90 kDa) and DTT on the stemness and chondrogenesis of BMSCs. Hydrogels with lower mechanical strength can maintain the stemness properties of BMSCs, whereas hydrogels with higher mechanical strength can promote chondrogenesis of BMSCs by increasing the expression of SOX9 and collagen II [75]. In addition, in contrast to the low methacrylate substitution (<30%) due to the hydrolysis of methacrylic anhydride and sensitivity to pH and temperature, Zhang et al. prepared a photocrosslinked porous hydrogel using maleic anhydride-modified HA with a high substitution degree (2.27) of acrylate groups and thiol-terminated PEG (PEG-SH). The designed hydrogel exhibited a rapid gelation time of only 15 s, regulatable degradation rate, and good cytocompatibility [76].

3. Aldehyde HA-based hydrogels for cartilage tissue engineering

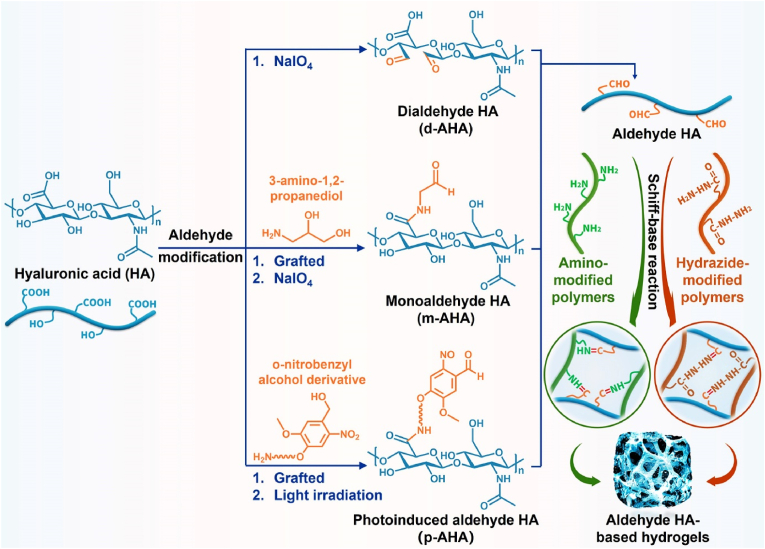

Aldehyde HA-based hydrogels have been widely studied in cartilage tissue engineering because the aldehyde group can undergo a Schiff-base reaction with polymers containing amino and hydrazide groups. The reactions often exhibit the advantages of high speed, simple and mild conditions, and no chemicals. Aldehyde HA can be divided into dialdehyde HA (d-AHA), monoaldehyde HA (m-AHA), and photoinduced aldehyde HA (p-AHA) (Fig. 5 and Table 3).

Fig. 5.

Synthesis of aldehyde HA-based hydrogels for cartilage tissue engineering.

Table 3.

Aldehyde HA-based hydrogels for cartilage tissue engineering.

| Hydrogels | Components | Physicochemical properties | Biofunctions | Ref. |

|---|---|---|---|---|

| d-AHA/Chitosan | Dialdehyde HA, chitosan | Controllable stiffness; loading gapmer oligonucleotides | Maintaining chondrocytes spherical morphology and uniform distribution; promoting ECM deposition; inhibiting inflammation | [79,80] |

| d-AHA/Glycol chitosan | Dialdehyde HA, glycol chitosan, cartilage ECM particles | Suitable compression stress; degradability | Promoting ECM deposition; accelerating cartilage regeneration and integration with surrounding tissues | [81] |

| d-AHA/water-soluble chitosan | Dialdehyde HA, succinic anhydride-modified chitosan | Tunable degradation rate and mechanical properties | Supporting the adhesion and proliferation of chondrocytes; maintaining the chondrocytes phenotype | [82] |

| d-AHA/RSV | Dialdehyde HA, amino-functionalized resveratrol | Interconnecting pores | maintaining the chondrocyte phenotype, promoting ECM deposition; reducing inflammation | [84] |

| d-AHA-MA | Dialdehyde HA, methacrylic anhydride | Higher adhesive strength and adhesion | Accelerating cartilage repair | [85] |

| m-AHA/Gel-CDH | Monoaldehyde HA, carbohydrazide-modified gelatin | Higher stability; slower degradation rate | Good biocompatibility | [86,87] |

| m-AHA (aldol crosslinked) | Enolizable monoaldehyde HA, nonenolizable monoaldehyde HA | Fast gelation; excellent hydrolytic stability; good tissue adhesion | Good cytocompatibility | [88] |

| m-AHA/HA-CDH and HA/CSA·dHCl | Monoaldehyde HA, carbohydrazide-modified HA; HA; cysteamine dihydrochloride | Biphasic, porous and dominant elasticity | Layer-specific inducibility; promoting chondrogenesis of BMSCs and ECM deposition; promoting the osteogenesis of BMSCs | [89] |

| HA-NB/PRP | HA, o-nitrobenzyl alcohol, platelet-rich plasma | Tissue adhesion, controlled release property of growth factor | Accelerating hyaline cartilage regeneration | [90] |

d-AHA was synthesized through the oxidation of secondary hydroxyl groups using sodium periodate (NaIO4) and then crosslinked with polymers with amino groups using a Schiff-base reaction to engineer hydrogels [77]. In cartilage tissue engineering, chitosan-based hydrogels with many amino groups can provide a suitable microenvironment for chondrocyte adhesion, proliferation, and differentiation [78]. Thus, Thomas et al. proved that the stiffness of a hydrogel (HA/chitosan) prepared using d-AHA and chitosan through a Schiff-base reaction had important effects on the growth and functionality of encapsulated chondrocytes. The chondrocytes exhibited a spherical morphology and uniform distribution in the HA/chitosan hydrogel group with less stiffness, whereas better deposition of ECM components, such as GAG and collagen II, was observed in the stiffer hydrogel group [79]. Cai et al. further used HA/chitosan hydrogels loaded with gapmer oligonucleotides to inhibit inflammation in OA chondrocytes [80]. Owing to the strong interactions among intermolecular hydrogen bonds, chitosan is almost insoluble in physiological solvents. Liu et al. developed a hydrogel with a compression stress of 90 kPa at 60% compression strain and with degradable ability using d-AHA, water-soluble glycol chitosan, and cartilage ECM particles incorporated with BMSCs for cartilage repair. The encapsulated BMSCs demonstrated positive activity and proliferation, along with better deposition of GAG and collagen II, which could accelerate cartilage regeneration and integration with surrounding tissues [81]. Tan et al. prepared a composite hydrogel with a tunable degradation rate and mechanical properties consisting of d-AHA and water-soluble chitosan modified with succinic anhydride, which could support the adhesion and proliferation of chondrocytes as well as maintain their phenotype [82]. In addition, Heirani-Tabasi et al. prepared a chitosan-functionalized HA hydrogel through acylation between carboxyl and amino groups loaded with chondrocyte extracellular vesicles, and the developed hydrogel could upgrade the chondrogenic gene (SOX9 and COL2A1) expression of encapsulated AMSCs and induce the deposition of collagen II and GAG to accelerate hyaline cartilage regeneration in OA cartilage injury [83]. In addition to the aforementioned hydrogels prepared using HA and chitosan, Sheu et al. used d-AHA and amino-functionalized resveratrol (RSV) to prepare hydrogels to maintain the chondrocyte phenotype, promote the deposition of cartilage ECM, and reduce lipopolysaccharide-induced inflammation and chondrocyte injury, making them ideal candidates for use as chondrocyte carriers [84]. Chen et al. developed a tissue-adhesive one-component hydrogel (d-AHA-MA) that could promote the proliferation and migration of BMSCs. Compared with the adhesive strength of commercial fibrin glue (∼10 kPa) and HA-MA hydrogel (∼20 kPa), the d-AHA-MA hydrogel exhibited higher adhesive strength (more than 40 kPa) and could adhere to native cartilage tissue stably and assist the integration between neo-cartilage and host tissues, facilitating better cartilage regeneration [85].

In addition, unlike d-AHA, m-AHA can be obtained by oxidizing the diol groups grafted onto HA. For example, Hozumi et al. used 3-amino-1,2-propanediol to premodify HA, followed by the oxidation of NaIO4 to fabricate m-AHA, which was reacted with carbohydrazide (CDH)-modified gelatin (Gel-CDH) to prepare a novel injectable hydrogel (m-AHA/Gel-CDH) through a Schiff-base reaction. Compared with the hydrogels formed from d-AHA and Gel-CDH or adipic dihydrazide (ADH)-modified gelatin (Gel-ADH), the m-AHA/Gel-CDH hydrogel exhibited higher stability and a slower degradation rate because the Schiff-base bond formed by CDH and monoaldehyde was more stable, and the ring-opening structure of polysaccharides was susceptible to hydrolysis. Moreover, the m-AHA/Gel-CDH hydrogel had a pore size of 15–55 μm, a shear storage modulus of 0.1–1 kPa, and good biocompatibility, which are appropriate for hydrogel scaffolds for soft tissue engineering [86]. Martinez-Sanz et al. further demonstrated that a hydrazone-crosslinked hydrogel with insignificant cytotoxicity formed from hydrazide-modified HA and m-AHA was stable under physiological conditions and degradable by hyaluronidase. The hydrogel can controllably release the encapsulated protein and maintain its activity, which has good application prospects in tissue engineering [87]. Bermejo-Velasco et al. prepared the first aldol-crosslinked HA-based hydrogel composed of two different m-AHAs: an enolizable m-AHA (HA-Eal) and a nonenolizable m-AHA (HA-Nal). The hydrogel had controllable gelation time, excellent hydrolytic stability, hyaluronidase degradability, good tissue adhesion, and good cytocompatibility. Note that the addition of HA-Nal can improve the crosslinking efficiency of the hydrogel owing to the formation of an intramolecular loop in pure HA-Eal hydrogels [88]. Under cartilage tissue engineering, Chen et al. prepared an HA-based biphasic hydrogel scaffold using different cross-linking methods to promote osteochondral defect regeneration owing to its layer-specific inducibility. The upper layer of the scaffold with stress relaxation was composed of m-AHA and CDH-modified HA, which can significantly promote the chondrogenesis of BMSCs and deposition of cartilage ECM. The lower layer of the scaffold with porous and dominant elasticity was prepared by retaining the gas generated during the gelation process of HA and cysteamine dihydrochloride, which effectively promoted the osteogenesis of BMSCs. The biphasic hydrogel significantly promoted osteochondral regeneration, similar to native osteochondral tissue in vivo [89].

Distinct from the Schiff-base reaction, the photopolymerization reaction is also a typical method for fabricating p-AHA-based hydrogels. For example, Liu et al. developed an in situ photocrosslinkable composite hydrogel consisting of PRP and o-nitrobenzyl alcohol (NB)-modified HA (HA-NB, NB graft ratio: ∼6.0%) that can generate aldehyde groups under light irradiation. The photoinduced crosslinked hydrogel exhibited a tissue adhesive strength of approximately 25 kPa and a controlled release of growth factors for hyaline cartilage regeneration [90].

4. Thiolated HA-based hydrogels for cartilage tissue engineering

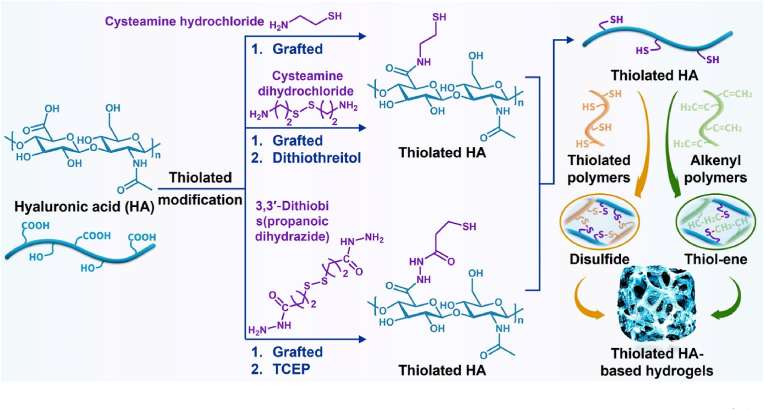

Thiolated polymers have a high reactive activity because of their thiol groups and can be further used to prepare hydrogels by self-crosslinking intrachain disulfide bonds or thiol-ene click reactions with rapid gelling time, which have been extensively studied in tissue engineering [91]. Therefore, thiolated HA-based hydrogels have been widely studied for cartilage tissue engineering applications (Fig. 6 and Table 4).

Fig. 6.

Synthesis of thiolated HA-based hydrogels for cartilage tissue engineering. TCEP: Tris (2-carboxyethyl)phosphine hydrochloride.

Table 4.

Thiolated HA-based hydrogels for cartilage tissue engineering.

| Hydrogels | Components | Physicochemical properties | Biofunctions | Ref. |

|---|---|---|---|---|

| HA-SH | HA, cysteamine hydrochloride | Regulatable gelling time, mechanical properties, swelling and degradability | Supporting the culture and delivery of chondrocytes | [92] |

| HA-SH/peptides | HA, cysteamine hydrochloride, supramolecular peptides | Excellent mechanical properties; abundant cell adhesion sites | Enhancing cartilage-related gene expression and ECM deposition; inhibiting chondrocyte hypertrophy | [93] |

| HA-SH/TGF-β1 | HA, 3,3′-dithiobis (propanoic dihydrazide), transforming growth factor-β1 | Suitable gelation and swelling behavior, sustained release of TGF-β1 | Promoting chondrogenic gene expression and ECM deposition and distribution | [94,95] |

| HA-SH/PEG-DVS | HA, cysteamine dihydrochloride, 4-arm polyethylene glycol, divinyl sulfone | Adjustable gelling time; enzymatic degradation | Maintaining the viability and proliferation of chondrocytes; promoting ECM deposition | [96] |

| HA-SH/HB-PEG | HA, 3,3′-dithiobis (propanoic dihydrazide), hyperbranched polyethylene glycol diacrylate | Regulatable mechanical properties; appropriate degradation rates | Supporting chondrogenic differentiation; promoting hyaline cartilage regeneration | [[97], [98], [99]] |

| HA-SH/p (HPMAm-lac)-PEG | HA, 3,3′-dithiobis (propanoic dihydrazide), thermosensitive triblock copolymers | Sustained release of HA | Anti-inflammatory ability; inducing chondrogenic differentiation of BMSCs and neo-cartilage formation | [100,101] |

| HA-SH/Col | HA, cysteamine hydrochloride, collagen I | Improving the adhesion of cells | Maintaining chondrocytes phenotype; promoting ECM deposition | [103] |

| HA-SH/Col/BCP | HA, cysteamine hydrochloride, collagen I, biphasic calcium phosphate ceramics | Double-layer structure to mimic the condylar osteochondral | Enhancing the regeneration of fibrocartilage and subchondral bone | [104] |

| HA-SH/Col/icariin-SH | HA, cysteamine hydrochloride, collagen I, thiolated icariin | Controlled-release of bioactive molecules | Inhibiting chondrocyte hypertrophy and dedifferentiation | [105] |

| HA-SH/Col/HA-Mal | HA, cysteamine hydrochloride, collagen I, maleimide | Biomimetic injectable hydrogel; double-crosslinked network | Promoting the adhesion and proliferation of chondrocytes, GAG deposition and hyaline cartilage formation | [106] |

| HA-SH/Gel | HA, cysteamine hydrochloride, gelatin | Different bonding intensities | Promoting chondrocyte proliferation; maintenance of the hyaline cartilage phenotype; (strong bonding strength) | [107] |

Bian et al. fabricated an injectable thiolated HA (HA-SH) hydrogel with regulatable gelling time, mechanical properties, swelling, and degradability through self-crosslinking, which could serve as a 3D scaffold for the culture and delivery of chondrocytes [92]. Wang et al. developed a bionic composite hydrogel based on HA-SH and supramolecular peptides using noncovalent supramolecular self-assembly, and the self-assembled hydrogel exhibited excellent mechanical properties and abundant cell adhesion sites. These peptides had beneficial effects on hyaline cartilage formation and phenotype maintenance by promoting cell adhesion and proliferation, enhancing cartilage-related gene expression and ECM deposition, and inhibiting chondrocyte hypertrophy [93]. In contrast to noncovalent crosslinking, Böck et al. and Hauptstein et al. introduced TGF-β1 into HA-SH based hydrogels using covalent bonds via Traut's reagent. Better chondrogenesis of BMSCs was verified by promoting chondrogenic gene expression and ECM deposition and distribution [94,95].

Hydrogels prepared based on double C C bond-functionalized PEG and HA-SH via the thiol-ene Michael addition reaction have been widely studied in cartilage tissue engineering. For example, Jin et al. prepared an injectable hydrogel with an adjustable gelling time (less than ∼5 min) and enzymatic degradation consisting of HA-SH and 4-arm PEG-DVS, which could be advantageous for the viability and proliferation of bovine chondrocytes and deposition of GAG and collagen II [96]. Li et al. fabricated a rapid in situ crosslinkable hydrogel (HA-SH/HB-PEG) comprising HA-SH and hyperbranched PEG diacrylate with encapsulated arthroscopic flushing fluid-derived MSCs. The obtained hydrogel can support chondrogenesis and hyaline cartilage regeneration in full-thickness cartilage injuries in rats [97]. In addition, the HA-SH/HB-PEG hydrogel can serve as a cellular carrier with an anti-inflammatory ability to aid the viability and proliferation of cartilage-derived progenitor cells (CPCs), together with ECM deposition [98]. Wang et al. designed an injectable drug delivery system based on an HA-SH/HB-PEG hydrogel loaded with RSV-containing PLGA microspheres, which exhibited regulatable mechanical properties and appropriate degradation rates for ECM deposition. The delivery system quickly filled cartilage defects in vivo for hyaline cartilage regeneration through the controlled and sustained release of RSV [99]. Sabbieti et al. and Agas et al. prepared a hybrid hydrogel (HA-p (HPMAm-lac)-PEG) according to HA-SH and thermosensitive triblock copolymers (p (HPMAm-lac)-PEG) (composed of poly (N-(2-hydroxypropyl) methacrylamide lactate) and PEG) by thermal gelation and Michael addition. The hybrid hydrogel can be used as a carrier for cells and proteins and exhibits good biocompatibility and anti-inflammatory ability through the sustained release of HA. In addition, the HA-p (HPMAm-lac)-PEG hydrogel can also induce chondrogenesis of BMSCs and neo-cartilage formation [100,101].

Collagen I has been extensively used in cartilage tissue engineering owing to its high biocompatibility, low immunogenicity, biodegradability, and availability. However, its poor mechanical properties and rapid degradation rate cannot be ignored [102]. To resolve these limitations, Chen et al. fabricated an injectable hybrid hydrogel (HA-SH/Col) by combining collagen I with an HA-SH hydrogel to alleviate the contraction of collagen I and improve the adhesion of cells on the HA-SH hydrogel. The HA-SH/Col hydrogel can be useful for the proliferation and phenotype of chondrocytes as well as the deposition of ECM [103]. Wang et al. prepared a double-layer hybrid scaffold based on HA-SH/Col hydrogel and biphasic calcium phosphate (BCP) ceramics to mimic the structure of rabbit condylar osteochondral bone. In a condylar osteochondral injury model, the scaffold enhanced the regeneration of fibrocartilage and subchondral bone with a similar structure and thickness to host cartilage and seamless integration by loading BMSCs and chondrocytes on the upper and lower layers, respectively [104]. Liu et al. developed an injectable thiolated icariin-functionalized HA-SH/Col hydrogel for chondrocyte proliferation and cartilage ECM secretion and integration while inhibiting chondrocyte hypertrophy and dedifferentiation [105]. Yao et al. prepared a biomimetic injectable hydrogel scaffold combined with collagen I and a double-crosslinked network hydrogel (self-crosslinking of HA-SH and click-crosslinking between HA-SH and HA-Mal) to simulate cartilage ECM and promote the adhesion and proliferation of chondrocytes, GAG deposition, and hyaline cartilage formation [106]. Based on HA-SH and gelatin derivatives, Wang et al. prepared three composite hydrogels with different bonding intensities, including physical mixing, weak, and strong bonds. They further evaluated the influence of bonding strength on chondrogenic phenotypes. Compared with hydrogels with physical mixing and weak bonding strength, hydrogels with strong bonding strength exhibit better physical properties, such as a uniform pore structure, water retention performance, and anti-degradation ability. As a result, they can promote chondrocyte proliferation and phenotypic maintenance of hyaline cartilage [107].

5. Phenolized HA-based hydrogels for cartilage tissue engineering

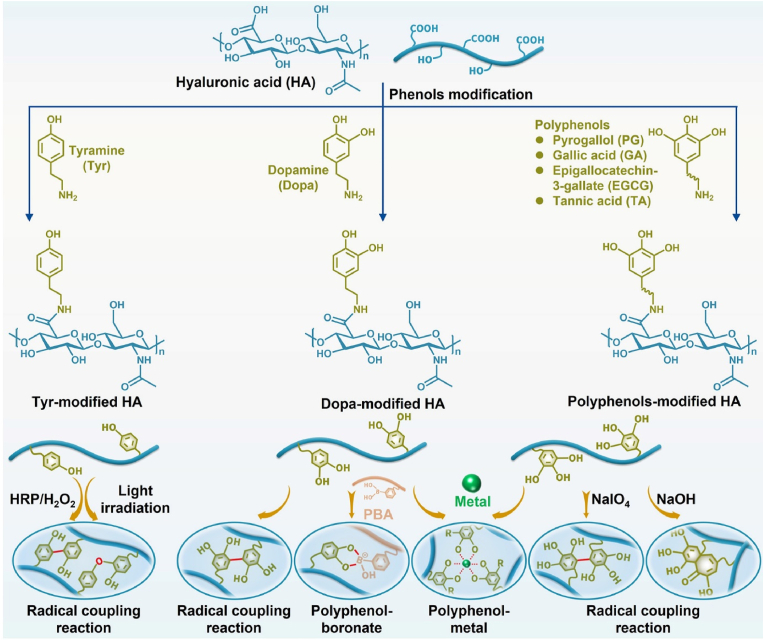

Polyphenols are widely found in nature and exhibit good biocompatibility, bioadhesion, and antioxidant properties. Owing to their unique polyphenolic structure, polyphenols can bind other molecules through covalent interactions (Michael addition, Schiff-base reaction, radical coupling reaction, and coordination interactions) and noncovalent interactions (hydrogen bonds and electrostatic and π–π interactions). Therefore, research on polyphenol-modified biomaterials, such as dopamine (Dopa), pyrogallol (PG), gallic acid (GA), epigallocatechin-3-gallate (EGCG), and tannic acid (TA), has gained wide interest [108]. Notably, tyramine (Tyr), a phenolic chemical, also undergoes a radical coupling reaction. Therefore, phenolized HA-based hydrogels have been widely studied in cartilage tissue engineering (Fig. 7 and Table 5).

Fig. 7.

Synthesis of phenolized HA-based hydrogels for cartilage tissue engineering.

Table 5.

Phenolied HA-based hydrogels for cartilage tissue engineering.

| Hydrogels | Components | Physicochemical properties | Biofunctions | Ref. |

|---|---|---|---|---|

| HA-Tyr | HA, tyramine | Controllable crosslinking degree; bioadhesive; delivering cells and bioactive molecules | Promoting formation of hyaline cartilage (lower crosslinked) and fibrocartilage (higher crosslinked); anti-inflammatory ability; enhancing ECM deposition; accelerating cartilage repair | [[109], [110], [111], [112], [113]] |

| HA-Tyr/SF | HA, tyramine, silk fibroin | Adjustable mechanical properties; sustained release of the drug | Promoting chondrogenic marker genes expression and ECM deposition | [116,118] |

| HA-Tyr/Gel-Tyr | HA, tyramine, gelatin | Suitable mechanical properties; electrical conductivity | Enhancing the chondrogenic differentiation of BMSCs under electrical stimulation | [119] |

| HA-Dopa | HA, dopamine | Enhanced adhesion | Reducing cartilage friction and wear to protect cartilage | [126] |

| d-AHA-Dopa | Dialdehyde HA, dopamine | Higher tissue bonding strength than HA-Dopa; rapid gel formation | Good cytocompatibility | [127] |

| HA-MA-Dopa | HA, methacrylic anhydride, dopamine | Tissue adhesion; enhanced cell-tissue interaction | Promoting chondrogenesis of hMSCs and cartilage-like matrix formation | [128,129] |

| HA-MA-Dopa/Fe3+ | HA, methacrylic anhydride, dopamine, Fe3+ | Increasing mechanical strength and rapid self-healing performance | As a soft and tough scaffold in the replacement of biological tissues | [130] |

| HA-furan-Dopa/HA-furan-PBA | HA, furfurylamine, dopamine, phenylboronic acid | pH responsiveness; adhesion; anti-degradation and superior mechanical properties | Maintaining the viability and proliferation of cells; reducing the cell death caused by dopamine oxidation | [131] |

| HA/Dopa/Col | HA, dopamine, collagen | ECM-mimicking; double crosslinked network | Inhibiting inflammation, promoting full-thickness cartilage repair | [132] |

| HA-PG | HA, pyrogallol | Different gelation kinetics, mechanical properties, degradability and tissue adhesion | Good biocompatibility | [133] |

| HA-GA | HA, gallic acid | Tissue-adhesive; enhanced stability; antioxidant | Inhibiting inflammation | [134] |

| HA-EGCG | HA, ethylamine-grafted epigallocatechin-3-gallate | Resistance to hyaluronidase-mediated degradation; scavenging of free radicals | Inhibiting inflammation; protecting cartilage | [135,136] |

5.1. Tyramine-modified HA-based hydrogels for cartilage tissue engineering

Tyr-modified HA (HA-Tyr) is synthesized using the acylation reaction between the carboxyl group of HA and the amine group of Tyr, which can be used to prepare HA-Tyr-based hydrogels through catalytic reactions with either hydrogen peroxide (H2O2) and horseradish peroxidase (HRP) or vitamin B2 derivatives and visible-light-induced photocrosslinking [109,110]. Subsequently, Toh et al. indicated that a less crosslinked HA-Tyr-based hydrogel was beneficial to hyaline cartilage formation by enhancing the aggregation and chondrocyte phenotype of BMSCs and increasing the deposition of GAG and collagen II. In contrast, the highly crosslinked HA-Tyr-based hydrogel facilitated the fibrous phenotype of BMSCs and fibrocartilage formation [111]. Behrendt et al. suggested that bioadhesive HA-Tyr-based hydrogels can efficiently load and deliver cells to reduce the potential harm caused by cell invasion. The HA-Tyr-based hydrogel maintains its mechanical properties and activates endogenous TGF-β1 under joint loading to benefit cartilage repair [112]. Moreover, HA-Tyr-based hydrogels were more favorable for the proliferation and pluripotency of human embryonic stem cells (hESCs) than Tyr-modified dextran hydrogels [113]. However, compared with the HA-Tyr hydrogel, the fibrinogen-HA-based hydrogel had a better effect in promoting endogenous BMSCs migration and cartilage formation. The fibrinogen-HA-based hydrogel can further accelerate the chondrogenesis of endogenous BMSCs by inhibiting the expression of miR-221 [114,115].

In addition to single HA-Tyr-based hydrogels, other natural polymers have been reported to be combined with HA-Tyr for cartilage tissue engineering. As a typical example, Ziadlou et al. developed an injectable hybrid hydrogel (HA-Tyr/SF) based on HA-Tyr and silk fibroin (SF) for drug delivery and cartilage tissue engineering. The HA-Tyr/SF hydrogel exhibited adjustable mechanical properties and sustained release of the drug and promoted chondrogenic marker gene expression and ECM deposition [116]. Wang et al. further promoted the recruitment of MSCs and cartilage repair using aptamer-functionalized HA-Tyr/SF-based hydrogels [117]. Weitkamp et al. developed a highly tunable hybrid hydrogel based on HA-Tyr and SF matrices to maintain the long-term viability of encapsulated chondrocytes and upgrade the expression of chondrogenic marker genes, as well as ECM deposition [118]. In addition, Vaca-González et al. prepared an injectable hydrogel with Tyr-functionalized gelatin and HA-Tyr to enhance chondrogenesis of encapsulated BMSCs by promoting the expression of chondrogenic markers and deposition of GAG and collagen II under electrical stimulation [119].

HA-Tyr-based hydrogels have also been extensively investigated for the sustained release of bioactive molecules. For instance, Kim et al. prepared a dexamethasone (DMT)-loaded HA-Tyr-based hydrogel to optimize the therapeutic effect on collagen-induced rheumatoid arthritis (RA) by reducing interleukin-6 (IL-6), prostaglandin E2, and the levels of four cytokines, including IL-8, IL-1β, tumor necrosis factor-α (TNF-α), and CD 14 [120]. Jooybar et al. utilized platelet lysate (PL)-loaded HA-Tyr-based hydrogels to promote the adhesion and spreading of BMSCs and enhance the deposition of cartilage-like ECM, including collagen II and proteoglycans. Notably, the simultaneous degradation of the hydrogel and deposition of the ECM facilitated the formation of a dense and tough matrix [121]. Ren et al. prepared a thermally triggered injectable hydrogel comprising HA-Tyr, HRP-encapsulated thermoresponsive liposomes, and H2O2 to achieve gelation in vivo through the release of HRP because of the phase transition behavior of the liposomes at body temperature. The hydrogel exhibited a controlled gelation rate and desirable activity of encapsulated chondrocytes to support the deposition of GAG and collagen II [122,123].

5.2. Polyphenol-modified HA-based hydrogels for cartilage tissue engineering

As a mussel biomimetic material, Dopa can significantly improve tissue adhesion and cell affinity; therefore, it has been widely studied in tissue engineering [124,125]. To improve the adhesion of HA to the surface of articular cartilage, Ren et al. developed Dopa-conjugated HA (HA-Dopa) using Dopa and HA through an acylation reaction. Compared with HA, HA-Dopa can effectively adhere to the cartilage surface and enhance boundary lubrication, which can reduce cartilage friction and wear to protect cartilage [126]. However, the HA-Dopa hydrogel suffered from insufficient adhesiveness and overfast degradation owing to the low grafting rate of Dopa. To solve these problems, Zhou et al. developed a high-tissue-adhering hydrogel (d-AHA-Dopa) using d-AHA and Dopa via a Schiff-base reaction. The d-AHA-Dopa hydrogel exhibited a higher tissue bonding strength (∼90 kPa) than the HA-Dopa hydrogel (∼10 kPa), rapid gel formation (less than 60 s), degradability, and good cytocompatibility, making it a promising bioadhesive [127]. Salzlechner et al. prepared a Dopa-biofunctionalized HA-MA (HA-MA-Dopa) hydrogel with tissue adhesion at the defect site. As a result, the adhesive hydrogel presented enhanced cell-tissue interaction owing to the presence of the Dopa group, and it had significant positive influences on the chondrogenesis of hMSCs and the formation of the cartilage-like matrix [128,129]. Notably, compared with single-crosslinked hydrogels, double-crosslinked hydrogels exhibit better mechanical properties, stability, and antidegradability. Guo et al. further demonstrated a dynamic reversible double-crosslinked network hydrogel through the catechol of HA-MA-Dopa and Fe3+ and photopolymerization to increase its mechanical strength and rapid self-healing performance, and biological studies further indicated promising application prospects of the obtained hydrogel as a soft and tough scaffold for the replacement of biological tissues such as cartilage [130]. Yu et al. prepared a dual-crosslinked HA-based hydrogel using Dopa/furfurylamine (furan)-modified HA (HA-furan-Dopa) and phenylboronic acid (PBA)/furan-modified HA (HA-furan-PBA) via a Diels–Alder click reaction and phenylboronic ester bond. The hydrogel exhibited injectability, pH responsiveness, adhesion, anti-degradation, and superior mechanical properties. In addition, the hydrogel can maintain the viability and proliferation of encapsulated cells, and the introduced PBA group can reduce cell death caused by Dopa oxidation, which exhibits good application prospects in cartilage tissue engineering [131]. Gan et al. prepared an ECM-mimicking hydrogel using Dopa noncovalently modified HA (HA/Dopa) and collagen with a double-crosslinked network for growth factor-free cartilage regeneration. The hydrogel exhibited a better affinity for cells, inhibition of the expression of inflammatory factors, and M2 polarization of macrophages, which significantly promoted full-thickness cartilage repair of a rabbit knee [132].

In addition to Dopa, other polyphenols have been extensively studied for the functional modification of HA. Similar to the synthesis of HA-Dopa, Cho et al. prepared a fast-forming hydrogel (HA-PG) using HA and PG through dual modes of oxidative crosslinking, including oxidant and pH control. Based on the different crosslinking modes, the HA-PG hydrogels exhibited different gelation kinetics, mechanical properties, degradability, and tissue adhesion. Furthermore, both HA-PG hydrogels exhibited good biocompatibility, providing multifunctional hydrogels for tissue engineering, drug delivery, and stem cell therapy [133]. GA, a small molecule polyphenol, has various biological activities, such as anticarcinogenic, antimutagenic, and anti-inflammatory properties. Samanta et al. designed a tissue-adhesive antioxidant HA-based hydrogel (HA-GA) using HA and GA via covalent crosslinking. The HA-GA hydrogel exhibited enhanced stability owing to the crosslinked GA network. HA-GA hydrogels can polarize macrophages to an immunosuppressive phenotype and inhibit the expression of pro-inflammatory factors, which has significant potential in inflammation-related biomedical applications [134]. EGCG is a polyphenol in green tea with anticancer and anti-inflammatory activities. Jin et al. prepared an injectable hybrid hydrogel based on HA-Tyr and gelatin to load EGCG for cartilage repair in OA patients. The hybrid hydrogel inhibited inflammation and protected the cartilage in surgery-induced OA [135]. Lee et al. prepared an HA-EGCG conjugate using HA and ethylamine-grafted EGCG. Compared with HA, the EGCG-HA conjugate exhibited resistance to hyaluronidase-mediated degradation and scavenging of free radicals, which has good application prospects in arthritis treatment [136]. TA is a large molecular polyphenol with various intrinsic properties, such as antioxidant, metal chelation, and polymerization properties. Gwak et al. and Lee et al. demonstrated that the addition of TA can enhance the adhesion, compression properties, and biostability of HA-based hydrogels owing to strong hydrogen bonding and covalent crosslinking [137,138].

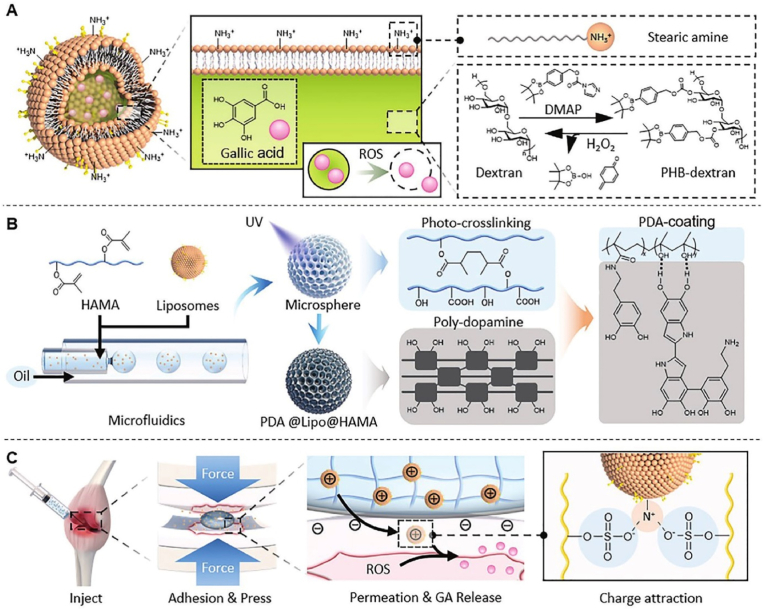

Because the cartilage ECM has a dense structure and a high density of negative charges, the delivery of drugs into cartilage is a challenge. To address this problem, Lin et al. fabricated charge-guided nanohydrogel microspheres through HA-MA, Dopa, and liposomes using microfluidic technology to penetrate the cartilage matrix. The microspheres were surface-modified with Dopa to optimize their adhesion to the cartilage surface. Moreover, the positively charged liposomes prepared from stearyl amine and borate-dextran deeply penetrated the cartilage ECM and achieved ROS-responsive release of GA on chondrocytes. In addition, in a rat OA model, microspheres significantly alleviated OA progression by enhancing the infiltration of cartilage ECM, antioxidant efficacy, and inhibiting oxidative stress-induced chondrocyte apoptosis (Fig. 8) [139].

Fig. 8.

Schematic illustration of the fabrication of charge-guided nanohydrogel microsphere to penetrate the cartilage matrix. (A) Preparation of positive charges liposomes; (B) preparation of PDA@Lipo@HAMA nanohydrogel microsphere; (C) design of charge-guided microsphere for cartilage tissue engineering [139]; Copyright 2021, John Wiley and Sons.

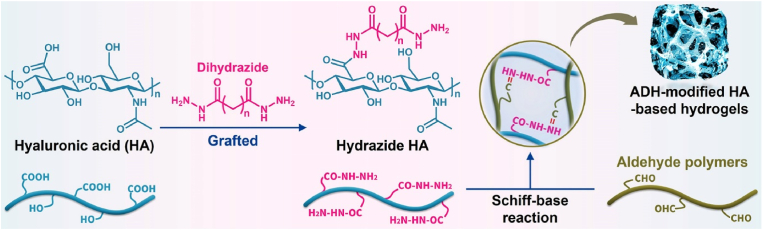

6. Hydrazide HA-based hydrogels for cartilage tissue engineering

Polymers can be modified by hydrazide to endow them with abundant hydrazide groups [140]. Among the various hydrazide compounds, ADH is commonly used to modify HA, and ADH-modified HA-based hydrogels have been widely studied in cartilage tissue engineering (Fig. 9 and Table 6).

Fig. 9.

Synthesis of hydrazide HA-based hydrogels for cartilage tissue engineering.

Table 6.

Hydrazide HA and host-guest group-modified HA-based hydrogels for cartilage tissue engineering.

| Hydrogels | Components | Physicochemical properties | Biofunctions | Ref. |

|---|---|---|---|---|

| HA-ADH/d-AHA | HA, adipic dihydrazide, dialdehyde HA | Shear-responsive; boundary lubricated; anti-inflammatory; injectable; self-healing; controlled-release of bioactive molecules | Reducing friction; alleviating the progression of OA; inhibiting inflammation; protecting chondrocytes | [141,142] |

| HA-ADH/dextran | HA, adipic dihydrazide, dialdehyde dextran | ROS depletion, sustainable drug release; viscosupplementation | Inhibiting inflammation; alleviating the progression of OA; protecting cartilage | [143] |

| HA-ADH/pectin | HA, adipic dihydrazide, oligopeptide-grafted dialdehyde pectin | Short gel times; controllable mechanical properties and degradation capacity | Providing a suitable microenvironment for the phenotype of chondrocytes and chondrogenesis | [144] |

| HA-Fur/CS-Mal/ACS/ADH | Methylfuran-modified HA, maleimide-modified chondroitin sulfate, adipic dihydrazide, dialdehyde chondroitin sulfate | Double-network; controllable viscoelasticity and stress relaxation; good processability; self-healing ability; high swelling capacity and stability | Negligible inflammatory response | [145] |

| HA-Ad/β-CD-Ac | HA, adamantane, monoacrylated β-cyclodextrin | Good self-healing properties, compressibility; sustained release of TGF-β1 | Rapidly integrating with the defect tissue; promoting the chondrogenesis of MSCs and cartilage regeneration | [146] |

| HA-Ad/β-CD-SH/HA-Mal | HA, adamantane, thiolated β-cyclodextrin, maleimide | Tunable viscoelasticity | Maintaining 3D spreading and intracellular interactions of encapsulated MSCs | [147] |

| HA-β-CD/PAA-Fer | HA, β-cyclodextrin, ferrocene, polyacrylic acid | Magnetic navigation; controlled release of glutathione | Promoting the columnar arrangement of chondrocytes and the repair of cartilage damage | [148] |

| HA-CB [6]/HA-PA | HA, cucurbit [6]uril, polyamines | Good mechanical stability; enzymatic degradability | Biocompatibility | [149] |

Lei et al. developed a shear-responsive, boundary-lubricated, anti-inflammatory, injectable, and self-healing HA-based hydrogel (HA-ADH/d-AHA) using ADH-modified HA (HA-ADH) and d-AHA through a Schiff-base reaction to deliver celecoxib (CLX)-loaded liposomes. The hydrogel can be restructured to expose the internal liposome on the outer surface under shear induction and form a stable lubricated boundary layer to reduce friction while alleviating the progression of OA by releasing CLX [141]. Zhou et al. further used an HA-ADH/d-AHA hydrogel to load bovine serum albumin-modified dioxide manganese nanoparticles and PRP. Biological experiments have indicated that the hydrogel can significantly increase the proliferation of chondrocytes and alleviate OA in vivo by inhibiting inflammation and protecting chondrocytes from oxidative stress [142]. Zhou et al. prepared a novel multifunctional complex hydrogel with ROS depletion, sustainable drug release, and viscosupplementation for combinatorial therapy of osteoarthritis. The complex hydrogel was fabricated using HA-ADH and aldehyde dextran through a Schiff base reaction, which can achieve the loading and sustained release of dexamethasone acetate-encapsulated ROS-scavenging micelles (PDMs). The HDH@PDM hydrogels exhibited good biodegradability, similarity to synovial components, and antioxidant and anti-inflammatory properties. Furthermore, in a rat OA model, the HDH@PDM hydrogel inhibited inflammation by polarizing macrophages to the anti-inflammatory M2 phenotype to alleviate OA progression and protect cartilage [143]. Chen et al. used HA-ADH and oligopeptide-grafted dialdehyde pectin to prepare an injectable hydrogel with short gel times (112–399 s), controllable mechanical properties, and degradation capacity, which provided a suitable microenvironment for chondrogenesis and chondrogenesis [144]. In addition, Mihajlovic et al. prepared a double-network hydrogel based on Diels–Alder adducts between methylfuran-modified HA (HA-Fur) and maleimide-modified CS (CS-Mal), and hydrazone bonds between ADH and dialdehyde CS. The hydrogel exhibited controllable viscoelasticity and stress relaxation, good processability and self-healing ability, and a high swelling capacity and stability. In addition, the hydrogel had mechanical properties similar to those of cartilage tissue to support the activity and proliferation of BMSCs. Interestingly, the degradation products of the manufactured hydrogel did not cause an inflammatory response in macrophages, laying the foundation for its further application in cartilage tissue engineering [145].

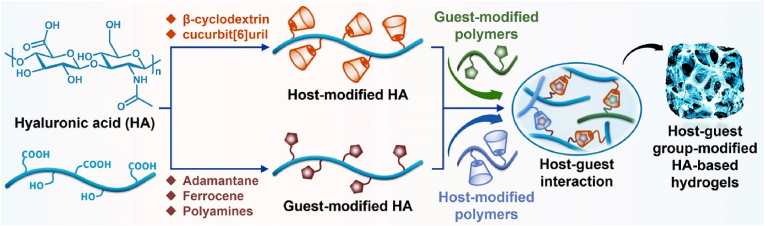

7. Host–guest group-modified HA-based hydrogels for cartilage tissue engineering

In addition to the abovementioned methods for preparing HA-based hydrogels via covalent bonding, noncovalent crosslinking, such as host–guest interactions, has also been investigated to create HA-based hydrogels for cartilage tissue engineering (Fig. 10 and Table 6).

Fig. 10.

Synthesis of host–guest-modified HA-based hydrogels for cartilage tissue engineering.

As a typical example, Wei et al. prepared a supramolecular hydrogel based on adamantane-functionalized HA (HA-Ad) and monoacrylated β-cyclodextrin (β-CD-Ac) through host–guest interactions and radical polymerization. The hydrogel exhibited excellent self-healing properties, compressibility, and sustained release of TGF-β1. Moreover, the hydrogel could rapidly integrate with the defective tissue and promote chondrogenesis of MSCs and cartilage regeneration in vivo [146]. Jing et al. prepared a highly dynamic network hydrogel with tunable viscoelasticity using HA-Ad, HA-Mal, and thiolated β-CD through host–guest interactions and thiol-ene click reactions. The hydrogel can maintain the 3D spreading and intracellular interactions of encapsulated MSCs [147]. Chiang et al. first developed a smart injectable composite hydrogel using β-CD-modified HA (HA-β-CD) and ferrocene-modified polyacrylic acid through host–guest interactions to encapsulate glutathione (GSH)-loaded magnetic microcapsules. The hydrogel exhibited magnetic navigation and controlled release of GSH, which can effectively promote the columnar arrangement of chondrocytes and the repair of cartilage damage [148]. Park et al. prepared a biocompatible hydrogel using cucurbit [6]uril (CB [6])-conjugated HA and polyamine (1,6-diaminohexane or spermine)-conjugated HA, which achieved in situ gelation through host–guest interaction after subcutaneous injection into nude mice. The hydrogels exhibited excellent mechanical stability, enzymatic degradability, and biocompatibility, and they have application potential in cell culture and various tissue engineering applications [149].

8. HA-based 3D bioprinted hydrogels for cartilage tissue engineering

Articular cartilage is lubricated lamellar tissue with anisotropy and heterogeneity [150]. Artificial cartilage scaffolds prepared using traditional engineering methods have difficulty precisely mimicking the biomechanics and tissue composition of natural cartilage [151]. On one hand, a novel 3D bioprinting method can control the geometry and microstructure of hydrogel scaffolds, which has a prosperous application in regulating the mechanical properties of hydrogel scaffolds and maintaining the viability and function of loaded cells, drugs or cytokines [152,153]. On the other hand, the HA solution has an ideal viscous modulus for 3D printing, but it cannot be used as a bioink for 3D printing alone because of the lack of specific shape-retaining ability. Therefore, HA has been integrated with other components to create bioinks for 3D printing, and HA-based bioinks can be divided into hybrid and chemically modified bioinks [154] (Table 7).

Table 7.

HA-based 3D bioprinted hydrogels for cartilage tissue engineering.

| 3D bioprinted hydrogels | Components | Physicochemical properties | Biofunctions | Ref. |

|---|---|---|---|---|

| HA/PU | HA, polyurethane | High elastic recovery; processability | Promoting self-aggregation and chondrogenesis of MSCs | [155] |

| HA/alginate | HA, alginate | Printability; biodegradability | Promoting chondrogenic genes expression and ECM deposition | [157] |

| HA/elastin/Gel | HA, elastin, gelatin | Printability with reproducible outcomes | Supporting the penetration, proliferation and chondrogenesis of chondrocytes | [158] |

| HA-MA/Gel-MA | HA, gelatin, methacrylic anhydride (MA) | Controllable pore structure; optimum degradation rate | Maintaining chondrocyte phenotype, promoting ECM deposition; accelerating mature cartilage regeneration | [[160], [161], [162]] |

| HA-MA/PCL | HA, MA, polycaprolactone | Biomimetic multiphase structure; sustained release of drugs | Inhibiting inflammation, repairing osteochondral damage; restoring motor function of joints | [163] |

| HA-MA/ECM | HA, MA, ECM | Improving the compressive strength and modulus | Providing a suitable microenvironment to encapsulate and cultivate cells | [164] |

| HA-MA/p (HPMAm-lac)-PEG | HA, MA, triblock copolymers | Thermosensitive, improving printability | Promoting formation of hyaline cartilage (lower concentrations) and fibrocartilage (higher concentrations) | [165] |

| HA-MA-PBA/Gel-MA/HA-Dopa | HA, MA, phenylboronic acid, gelatin, dopamine | Microporosity; injectability; tissue adhesion; sustained release of drug | Promoting chondrogenesis of BMSCs; accelerating articular cartilage repair and regeneration | [166] |

| HA-Ac-PBA/PVA/Gel-HS | Acrylated HA, phenylboronic acid, polyvinyl alcohol, thiolated gelatin | Tunable viscoelasticity; shear thinning property; high structural fidelity | Maintaining chondrocyte phenotype; promoting chondrogenesis and ECM deposition; alleviating chondrocyte damage | [167] |

| HA-GM/Gel-MA | HA, glycidyl methacrylate, gelatin, MA | Excellent stable mechanical properties and printability | Good biocompatibility; providing a suitable microenvironment for the chondrogenesis | [168] |

| HA-SH/P (AGE-co-G) | Thiolated HA, allyl-modified polyglycidol | Improving the stiffness of hydrogel | Promoting the deposition and uniform distribution of ECM | [169,170] |

| hmHA-HS/PEG | Thiolated high molecular weight HA, acrylated PEG, allylated PEG | Better stiffness of the hydrogel | Promoting homogeneous distribution of ECM | [171] |

| HA-SH/ECM | Thiolated HA, ECM particles | Customizable specific shapes; biomimetic mechanical properties | Enhancing the viability of the encapsulated chondrocytes | [173] |

| HA-ADH/SAV and SA/Ca2+ (HBSAC) | biotinylated HA-ADH, streptavidin, sodium alginate, Ca2+ | Better printability and structural integrity | Promoting the chondrogenic marker genes expression and ECM deposition | [174] |

| d-AHA/glycol chitosan/ADH and HAH/Ca2+ | Dialdehyde HA, glycol chitosan, ADH, hyaluronate-alginate hybrid, Ca2+ | improving the mechanical properties and stability | Enhancing the chondrogenesis of chondroprogenitor cells | [175] |

| HA-ADH/d-AHA/Gel-MA | HA-ADH, dialdehyde HA, gelatin, MA | Self-healing; shear-thinning properties; improving mechanical properties | Maintaining the survival and proliferation of BMSCs | [176] |

| HA-Tys | HA, tyramine | Controllable porosity; enhanced the mechanical strength; | Loading and delivering stem cells and chondrocytes with appropriate cell activity for a long time | [177,178] |

| d-AHA/CMC and Gel/PEG-SG | Dialdehyde HA, N-carboxymethyl chitosan, gelatin, PEG succinimidyl glutarate | Viscoelastic; time-sharing structure-supporting; high permeability | Preserving the long-term viability and morphology of chondrocytes | [179] |

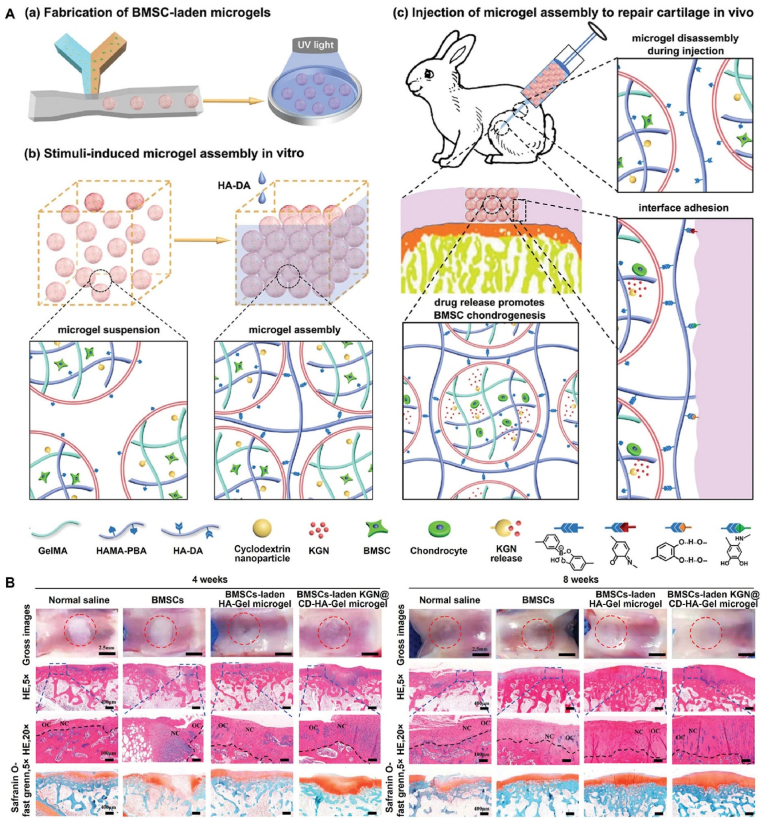

8.1. 3D bioprinted hydrogels based on hybrid HA