Abstract

Scrap tire recycling is a concern for local and national governments because of the associated environmental hazards. As motor vehicle use increases around the globe, fueled by booming demand in the emerging market, more governments are imposing stringent recycling rules for scrap tires. New and emerging technologies have been introduced to solve the recycling problem. Pyrolysis, which involves the decomposition of materials at elevated temperatures under inert conditions, converts scrap tires into gas and liquid fuels and these products can be used by other industries such as chemical, energy and transportation industries. The feasibility of pyrolysis depends on several factors, including the material content of the scrap tire and market value of the products. Current and past market conditions suggest that pyrolysis plants can be run profitably as independent operations. This study evaluated the economic potential of the pyrolysis industry based on evolving market conditions and forecasts the potential market size based on the volume of scrap tires expected to come into the market in the next 20 years. Separate models were used for market predictions for Europe and Turkey. The economic benefits of using scrap tire pyrolysis were discussed, including the potential monetary value of adopting such policies for Turkey.

Keywords: End-of-life tire (ELT), Tire recycling, Economy of pyrolysis, ELT forecasting

End-of-life tire (ELT); tire recycling; economy of pyrolysis; ELT forecasting.

1. Introduction

Each year, vast quantities of tire are scrapped worldwide, and how to manage worn-out tires has become a challenging global issue. In 2019, 3.2 billion units of tires were sold throughout the world [1]. In addition to being produced and sold in large volumes, tires are durable and non-biodegradable, which compounds the recycling task. Instead of using valuable space in landfills, different recycling strategies have been implemented in recent years, including novel technologies such as pyrolysis, a green chemical process that breaks scrap tire into four green products: carbon blacks, steel, oil, and combustible gas [2].

Pyrolysis is an efficient way of converting scrap tire into gases, liquids (pyrolytic-oil), and char at the temperature range of 300–600 °C. The yield and quality of pyrolysis products depend on process conditions like the heating rate, final pyrolysis temperature, residence time, ambient atmosphere, pressure, and the furnace [3, 4, 5, 6].

Numerous studies focus on the technical aspects of tire pyrolysis, and there are also several studies that cover the feasibility analysis of a single plant. However, the extent of the literature on pyrolysis does not fully reflect the importance of pyrolysis' economic potential at a macro level. As governments have attempted to shift their focus from traditional energy sources to green and renewable alternatives, a country's potential for scrap-tire-based pyrolytic products must be accurately forecasted for the use of investors, researchers, and energy policymakers. The purpose of this study was to evaluate the economic potential of scrap tire pyrolysis at the macro level and to determine the financial contribution of the emerging pyrolysis industry to the overall economy.

The paper is organized as follows. Section 2 presents terminology and the status of the tire recycling industry. Section 3 offers a forecasting model for scrap tire output for Europe. An extension of this model is used to generate a forecast for Turkey in section 4. An economic analysis of pyrolysis is given in section 5. Finally, concluding remarks are presented in section 6.

2. Tire recycling

The terminology used by the tire industry requires explanation. The term “ELT” stands for end-of-life tire—a used or worn-out tire that cannot fulfil its original purpose. Another term, used tire (UT), has a broader definition that includes not only ELT but also re-treatable tires and second-hand tires. The critical difference between the two terms is that a UT may function as a tire with or without some modification, whereas an ELT is a scrap product lacking its original functionality.

2.1. Current status of tire recycling

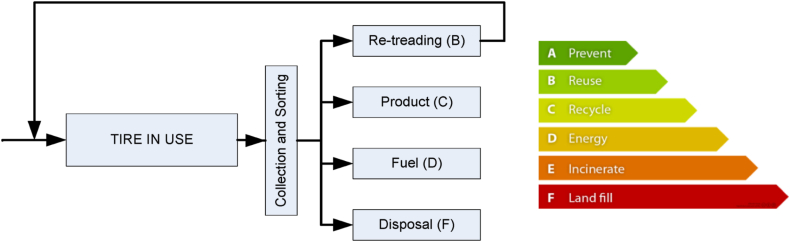

Figure 1 shows the lifecycle of a tire. A brand-new tire has a road-use lifespan of four-to-six years [7, 8], during which it loses 10%–15% of its original weight due to frictional wear between the rubber and asphalt [9, 10]. Worn-out tires are collected and sorted for recycling. There are four paths in the recycling process. Each of these paths is categorized according to Lansink's waste hierarchy ladder, which is given on the right-hand side of Figure 1. The Lansink ladder is a waste management hierarchy named for Dutch politician Ad Lansink. In categories ranging from A to F, six waste management options are ranked by their environmental impact.

Figure 1.

Life cycle of a tire [11].

For the tire industry, the least harmful option in terms of overall environmental impact is re-treading old tires. As indicated by the Lansink chart, re-treading is the least harmful alternative in the recycling process and falls into the reuse category (B), which is the second-best choice after prevention (i.e., prevention of wear). Although it is difficult to think of an “A-category” recycling measure for tires, designing and producing tires that will last longer in terms of road mileage would qualify. The worst options are incinerating (burning ELTs as waste material) and landfill dumping, which lie at the bottom of the Lansink chart. Disposal and re-treading are two categories that involve using ELTs as fuel or recycled material. In the developed world, more than 80% of ELT recovery involves these two categories [12]. Tire-derived material (TDM) refers to products made from recycled ELTs. Previous studies include various innovative TDM applications [13, 14, 15, 16, 17] such as tire-derived fuel (TDF), which is an alternative fuel made from ELTs used mainly in cement kilns and paper mills [18, 19].

Figure 2 presents historical recovery rates for Europe. As the graph indicates, Europe has made significant progress in terms of recycling policies. With the help of environmentally friendly legislation, a frequently cited target of 95% has been reached by many European countries [12]. The graph in Figure 2 is based on statistics in the annual report published by the European Tyre and Rubber Manufacturers' Association (ETRMA). The graph was prepared with data included in the ETRMA-Annual Report of 2017 mainly and information delivered from many other documents available on the website of ETRMA [20, 21, 22, 23, 24].

Figure 2.

Recovery rates for ELTs (adopted from ETRMA reports [20, 21, 22, 23, 24]).

2.2. Overview of scrap tire pyrolysis

Scrap tire pyrolysis has been extensively studied in the last decade [25, 26, 27, 28, 29, 30, 31, 32, 33, 34]. Reports claim that tire pyrolysis can produce numerous commercially valuable products. Several studies [35, 36, 37, 38, 39, 40, 41, 42, 43] have reported on chars, carbon blacks, and activated carbons obtained from pyrolysis of waste tires. These studies focus on the potential of char from the pyrolysis of waste tires as activated carbon or carbon blacks. They report that activated carbon derived from waste tires is useful as an adsorbent material possessing different textural characteristics. In addition, these recycled carbon blacks’ surface chemistries and activities are like other commercial carbon blacks. The gas products generated from the pyrolysis of waste tires have also been explored experimentally [44, 45, 46]. They expressed that pyrolysis gas products mainly consist of combustible components and it has a high heating value [47]. Czajczyńska and co-workers suggest that pyrolytic gas can be used to provide the energy required by the pyrolysis process [48]. Pyrolytic oil obtained from waste tires has been particularly interesting for a number of studies [27, 49, 50, 51, 52, 53] primarily because it consists of aromatics and aliphatic hydrocarbons. It can be used as fuel and chemical feedstock [47, 47, 50, 50, 54, 54].

3. Elt forecasting

Tire manufacturers publish statistics in unit numbers, but ELT statistics are expressed in tons. Conversion from tons to units or vice versa require unit weight information. For conversion, there are only a few, broad categories (auto, light truck, and heavy truck). There is no standard conversion factor in each category. In addition to the variety in tire size and the conversion factor, one must remember that a portion of the original tire mass is lost from road friction, which is often not considered.

Even though they are not consistently published, ETRMA's ELT statistics are the primary source for collecting historical ELT figures. Occasionally, ETRMA's reports break down ELT numbers by country, but statistics are usually given only for the European market. Furthermore, what is included in Europe may not be explicitly defined. In our reporting, Europe refers to the 28 member countries of the European Union. This, of course, excludes Switzerland, Norway, the Balkan countries, and Turkey.

3.1. Modeling approach

In the study a regression-based model has been chosen. Because it allows for linking the data of ELT to more stable factors that provides more readily available historical records. The auto industry is a major customer for tires as each new vehicle includes at least four new tires. On passenger cars, tires have a road life of four-to-five years [8]. All vehicles on roads continuously generate ELTs; thus, the number of vehicles on the road is the primary driver for ELT output.

The approach of forecasting is building a model that relates ELT output to the number of vehicles on the road. From one perspective, this adds complexity to the model as it requires forecasting another variable, i.e., the number of vehicles in use, as model input. However, this is a manageable issue because vehicle statistics are available and easily accessed. Since the automobile industry consumes more than 90% of tires, it is our primary focus.

The main independent variable of the model is the number of automobiles in use. Because of a four-to-six-year time lag between the production of a new tire and its scrapping as ELT. Statistics were included from previous years in the model. Additionally, variable for an annual change in GDP (Gross Domestic Product) was used in the model. The GDP is a measure of value added created through production and services, and ELT business activities can be related to overall changes in the economy. Eq. (1) shows the ELT raising at the t (year) period.

| (1) |

where.

: ELT raising at year .

: number of automobiles in use at year .

: GDP growth at year .

3.1.1. Partial least squares regression

Because of availability of a set of continuous predictors (i.e., independent variables) that are correlated to one another, partial least squares regression (PLS) was used to relate ELT (i.e., dependent variable) to two sets of predictors (time-lagged components of the number of vehicles in use and GDP growth). PLS reduces the number of variables in the original data to a smaller set of uncorrelated variables. Based on multivariate analysis, PLS removes weaker relationships from the model. The final least squares regression is based on this reduced data.

Table 1 shows model selection statistics for PLS. In addition to standard R2, the table includes two parameters, the prediction sum of square (PRESS), and the prediction R2, which determine the power of “prediction” for the selected model. Data analysis and regression is done by using MINITAB statistical software [55].

Table 1.

Model selection for PLS.

| Components | X Variance | Error SS | R-Sq | PRESS | R-Sq (pred) |

|---|---|---|---|---|---|

| 1 | 0,509701 | 0,179259 | 0,781937 | 0,366152 | 0,554588 |

| 2 | 0,770324 | 0,138017 | 0,832107 | 0,296178 | 0,639709 |

| 3 | 0,137841 | 0,832321 | 0,347485 | 0,577296 | |

| 4 | 0,133501 | 0,837600 | 0,505278 | 0,385345 |

The PRESS, prediction sum of square, was calculated by using the following steps. For n data points, the model runs n times. At each observation, a regression model was built, but the current observation was excluded from the model. Using the regression model, a fitted value (i.e., prediction) was calculated, and its corresponding error was recorded. This routine was repeated for n data points, and the PRESS was calculated by using Eq. (2). Table 1 indicates that a model's predictability peaks when the model includes two variables, and . At this level, the PRESS was minimized, and reached the maximum value (Formula 3).

| (2) |

where.

: observed value

: fitted response for the excluded observation.

| (3) |

where,

3.1.2. Best subset selection

As an alternative approach, a regression function was used that lists all possible combinations of one, two, three, and four variables. Since there are 10 potential independent variables, the exhaustive list of all regression functions, up to four variables, is brief, and there is a manageable number of candidate functions.

The available data was split into two sets for development and validation purposes. The last three observations were excluded from the set and are used for model validation. The regression was built on a truncated set that excludes the last three observations. The performance of each regression function was evaluated by calculating MAPE (mean absolute percent error) on the validation data set.

Table 2 lists variables included in the best regression models (i.e., lowest MAPE) along with MAPE statistics for one-, two-, three-, and four-variable models. As anticipated, the most important predictor for the model was the current number of automobiles in use. Adding more than one or two variables results in marginal improvement in the MAPE value. Introducing the fourth variable did not add any value because the MAPE value remains flat. The findings of the exhaustive search approach concur with the findings of the PLS approach on the selection of significant variables.

Table 2.

Best performing model based on MAPE.

| Number of variables | Model variables | MAPE |

|---|---|---|

| 1 | 0.1200 | |

| 2 | 0.1148 | |

| 3 | 0.1100 | |

| 4 | 0.1098 |

Based on the findings of the exhaustive search and PLS approach, Vt and Gt were kept in the final regression model. A simple linear model with two independent predictors provides accuracy in forecasting and includes two primary ELT drivers. The regression function for the forecasting model is given in Eq. (4).

3.1.3. Final ELT forecast

Two inputs in the regression model given in Eq. (4) are automobiles in use () and expected GDP growth (), which is a critical parameter that shows overall economic growth in a country or region. Because of its crucial impact on society, many institutions and professionals work on this subject and regularly publish estimates regarding GDP growth, one of which is given in Table 3. The model uses statistics generated by professional organizations that monitor the economy and publish future estimates.

| (4) |

where.

Table 3.

Expected GDP growth in Europe [57].

| Year | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|---|

| Growth Rate | 1.8 | 1.2 | -8.7 | 5.2 | 3.3 | 3.0 |

: expected ELT arising (in millions of tons).

: automobile park (in millions of units).

: growth rate (percentage).

The second input required by the model is the number of automobiles in use, which is calculated by adding new registrations and subtracting de-listings to the previous total from one period to another. The incremental change, with respect to the total number of automobiles, has been stable. During the last 10 years, the average change was 1.5% percent, annually, with a 0.25 coefficient variation [56].

In generating forecasts, it was used three scenarios for the automobile market. The base scenario assumes that the growth will be 1.5%, annually, which is the historical average. For the second case (the positive outlook), growth is assumed to be 2% per year, which is two standard deviations above the historical average. On the negative side, it was assumed that growth will remain around 1% annually. Similarly, this is two standard deviations lower than the historical average, representing the pessimistic case.

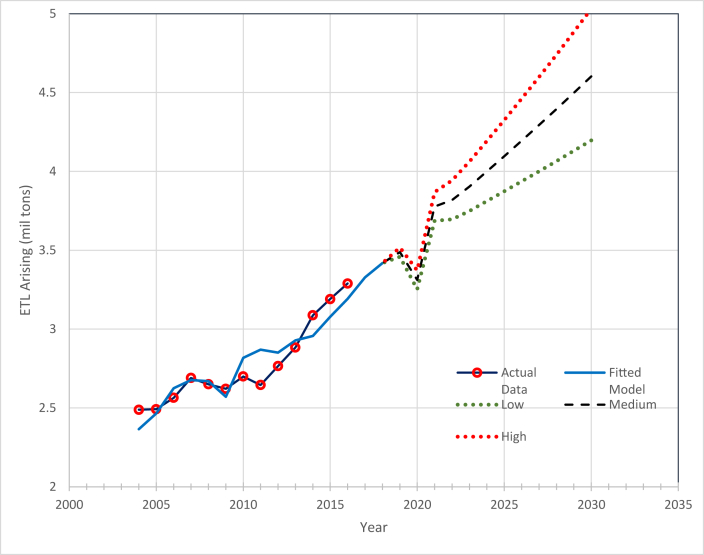

Figure 3 shows the forecast for ELT, along with historic data. The actual data and the model fitted on history are given in solid lines. Three dashed lines represent scenarios for high, low, and medium growth rates. For 2020, a sharp decline is expected for ELT arising because GDP growth is assumed to be negative. For the GDP growth rate beyond 2023, a constant growth rate of 3% is assumed until 2030.

Figure 3.

Historical ELT arising and forecast.

4. ELT forecasting for Turkey

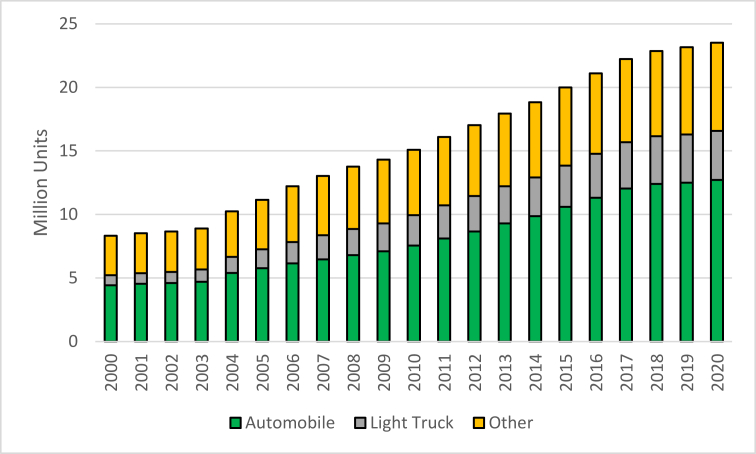

Turkey is one of the fastest growing auto market in Europe, with the number of vehicles rising from 8 million in 2000 to 24 million in June 2020 [58]. As of June 2020, of the 24 million vehicles registered in Turkey, 13 million are automobiles with the second-biggest category being “light trucks,” which are van-type vehicles originally designed for commercial use that now serve primarily as large family cars or SUV substitutes. According to recent statistics, there are 4 million light trucks in Turkey. Figure 4 shows the fast-growing auto market in Turkey since 2000 [58].

Figure 4.

Number of vehicles in Turkey [58].

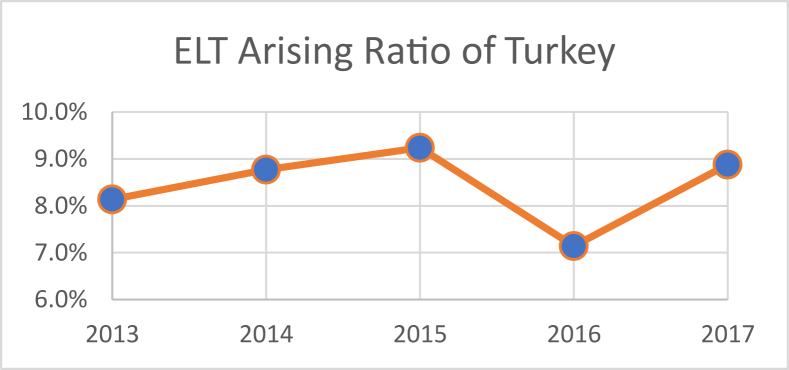

Based on the statistics published in ETRMA reports, the ratio of ELT arising in Turkey, with respect to EU28, is shown in Figure 5.

Figure 5.

Ratio of ELT arising of Turkey to ELT arising of EU28 [20–24].

As Figure 5 shows, Turkey's ELT arising as a percentage, compared to that of EU28, ranges between 7% and 9%, based on statistics from 2013 to 2017. Considering the recent expansion of Turkey's motor vehicle market, the ratio is likely to remain on the upper side of the historical range. In my projections of future ELT arising in Turkey, it is assumed that the ratio will be around 9% during the forecasting horizon.

Figure 6 depicts ELT arising forecasts. Future projections are based on three different growth scenarios: high-, low-, and medium-growth environments. The negative impact of COVID-19 is expected to last another year or two, but the market will eventually stabilize, and steady growth will resume. The ELT arising is expected to reach 0.4 million tons by 2030.

Figure 6.

ELT arising projection for Turkey.

5. Economic analysis of pyrolysis

Economic analysis of tire pyrolysis has several different aspects. First, the pyrolysis plant produces several outputs with commercial value. As in any other business establishment, these products are sold for profit. Secondly, it recycles auto tires, one of the most abundant waste products in the world. Globally 2.3 billion tires are produced in 2021 [1], and scrap tires constitute two percent of the whole solid waste [59]. The third aspect is related to energy efficiency. Most pyrolysis plants are self-sufficient in energy use. Byproducts of the pyrolysis process are feedback to fire furnace, and frequently byproducts are also used to generate electricity to supply power to the plant [60].

5.1. Pyrolysis outputs

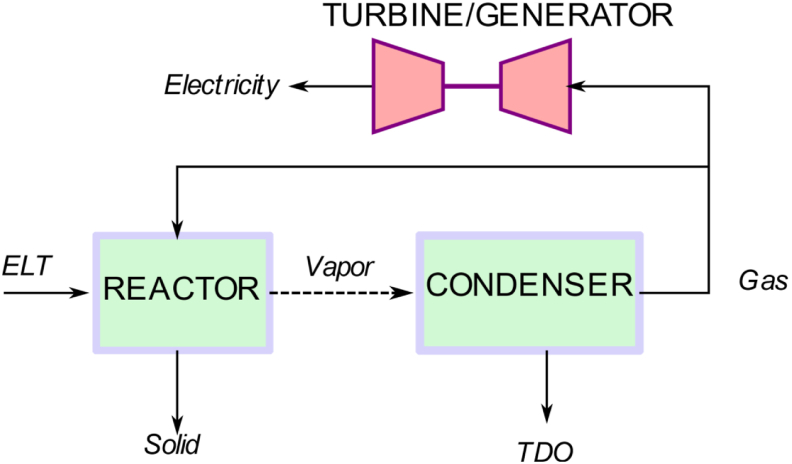

Pyrolysis outputs can be categorized into three groups—solid, liquid, and gas—based on the form of the final product (Figure 7). Depending on the reactor type, scrap tires are fed either as whole tires or pre-shredded pieces. The solid output that comes from the reactor is called char. Vapor output is fed into the condenser for distillation. The liquid output from the condenser is called tire-derived oil (TDO). The third component is a hydrocarbon-rich gas like natural gas, in terms of energy content.

Figure 7.

Major outputs of the pyrolysis process.

Each output category—solid, liquid, and gas—has a different economic value, and the commercial potential of each category is discussed separately. Since the gas product is the most difficult to transport, it is used in the plant to power the reactor and the remaining gas may be used to power a small turbine-generator combination to produce electricity for the plant.

The pyrolytic char content of an ELT ranges between 22% to 49% by weight, as reported in the review of previous studies [61]. Although the range seems wide, most studies report a percentage figure between the high 30s to low 40s. The char is mostly a high carbon that composes 90% of the char material, followed by sulfur with a ratio between 1.9% to 2.7% by weight. The remaining part is dirt, which reportedly ranges between 8.3% and 15.3% [61] and comes from additive materials used in manufacturing and dirt found in waste tires.

As a commercial product, the char has limited potential compared to liquid and gas components. It cannot be reused as raw material because of impurities in its content. Sulfur, ash and dirt make it less appealing to be recycled back into tire manufacturing. However, char has the potential as a reinforcement agent. It can be used as reinforcement material in the rubber industry, particularly in the production of shoes, conveyor belts, and dock fenders [22, 60, 60]. Char material can be upgraded to higher quality carbon to be used as fuel [60]. The other apparent solid output is steel which is directly sold as scrap material.

The liquid product of pyrolysis is commonly named tire-derived oil (TDO) and has a dark-brown color and sulfuric odor like petroleum extractions. TDO is a complex mixture of high carbons with aromatic and aliphatic compounds [47]. Depending on the tire type and materials used in manufacturing, the energy content of TDO can reach up to 44 M.J./kg, which is equal to the energy consumed to manufacture a tire [62, 63].

The yield of liquid products obtained from the pyrolysis of scrap tires is sensitive to operational parameters like reactor type, particle size, heating rate, pyrolysis temperature, and holding time. Among these, the pyrolysis temperature has a significant impact on the yield. Previous work in this area emphasizes that the liquid output is maximized at about 450–550 °C, with an approximate yield of 50 wt. % [30, 50, 64].

There are several issues involved in using TDO as fuel. First, it has a lower flashpoint (temperature at which flammable gases are produced) than refined petroleum products, and the ignition of these gases will create a fire hazard. Unlike petroleum products, TDO is an unrefined product that includes more than 100 identified compounds [61]. Some of those compounds include volatile hydrocarbons that may ignite at lower temperatures. Although TDO has a viscosity comparable to that of diesel fuel, its high sulfur content makes it less appealing as an alternative fuel [50].

The gas component of the pyrolysis is primarily composed of hydrocarbons, which account for 80% of the content by volume. The remaining 20% includes CO, CO2, and SH2 [47]. The energy content of the pyrolytic gas is 38–41 MJ/kg, which is close to that of natural gas [64].

5.2. Cost analysis of a pyrolysis plant

In the economic analysis of the pyrolysis system, there are three components that require discussion: investment costs, revenue streams, and general costs. The first, the initial investment cost, is the lump-sum money committed at the beginning of the investment and is generally proportional to the size of the investment (i.e., output capacity). Although there is a positive relationship between capacity and investment cost, the relationship is not linear. As capacity increases, the marginal cost of investment declines. Building bigger plants is more economical because the investment cost per unit capacity declines with the size of the investment. Of course, this is not the only factor in deciding the capacity of a plant. Other significant factors include potential market demand or availability of capital for investment.

Building a pyrolysis plant is a long-term investment. In feasibility studies of such plants, an investment life of 15–20 years is typical [65, 66, 67]. With such a long investment horizon, the initial investment cost becomes less relevant, and a constant factor based on per unit production is sometimes used in feasibility studies to account for initial investment cost. Islam and co-workers calculate the unit production costs for three different scenarios with daily ELT processing capacities of 3.6, 36, and 144 tons per day, respectively [64]. These calculations are based on investment and fixed and variable costs, and then converted to unit production cost (i.e., US dollars per ton).

The second and third factors of the economic analysis are revenue and general costs. In terms of direct cost, personnel and energy are two major items. For all other costs, a fraction of personnel or personnel plus energy is added to the cost list.

When building a pyrolysis plant, there are four potential revenue streams: the carbon coming out of the reactor; the steel used in rubber tires, which is extracted at pre-processors; TDO, which is similar to heavy fuel oil; and a gas output that is rich in hydrocarbons and has an energy value equal to that of natural gas.

For the economic analysis, an additional factor that must be considered is the tipping fee, which is a cost associated with dumping tires into a landfill. Some EU countries have already banned the use of landfills; in others, the current fee is approximately €100 per ton. As rules regarding opening and maintaining landfills become more stringent throughout the world, this cost is expected to increase. From a broader perspective, the tipping fee can be considered a disposal fee for the user; however, in our modeling, the fee was considered to be a revenue item.

Table 4 shows unit prices for the products that are extracted through the pyrolysis process and includes both prices reported in the literature and the current market prices for steel and TDO. The percentage of each component by weight is also included in the table.

Table 4.

Figure 8 shows the schema for a tire pyrolysis plant. It is common practice in the industry to use the gas output as fuel for the reactor. The gas can also be used to generate electricity through a gas turbine generator combination. Mini- and micro-power generation has spread recently, and prices have decreased to affordable levels. There are even gas turbine-generator combinations priced at $10,000 that are promoted for household use [70]. Considering that gas produced through pyrolysis and natural gas have almost identical characteristics [64], a turbine-generator combination that can burn both gases can be built to power auxiliary systems throughout a facility.

Figure 8.

Proposed pyrolysis plant.

As reported in the literature, the weight percentage of solid, liquid, and gas contents vary depending on the incoming scrap tire mixture. A similar variation is also observed in the energy content of output products. There is a spread in the reported caloric output of pyrolytic liquids and gases [62]. Table 5 lists price and weight ratio of each pyrolysis component used in the analysis. Assumptions regarding price and weight ratio are based on the analysis reported in previous studies [62, 64, 65, 68]. An obvious advantage of adding an electricity generation capability to a system is to take advantage of variations in inputs and outputs. When scrap quality is high, there will be excess gas, which will be used in electricity generation. In case of a deficit, a plant can use urban natural gas to fire turbines or electricity from the grid.

Table 5.

| Pyrolysis Output | Price | Wt. Ratio | Revenue |

|---|---|---|---|

| Oil | 400.00 | 0.45 | 180.00 |

| Char | 37.00 | 0.30 | 11.00 |

| Steel | 310.00 | 0.10 | 31.00 |

| TOTAL | 222.10 | ||

For cost analysis, the initial capital cost is the first to consider. Islam and his co-workers cites several previously built plants and gives the cost and capacity for each [64]. A plant in Shanghai, with a capacity of 25 tons/day of scrap tire, had an initial investment cost of $2.5 million. A similar plant in Taiwan was built for $3.5 million. Another factory in Taiwan has a capacity of 30 tons/day and was constructed for $3 million. A larger plant in the US with a capacity of 100 tons/day had a cost of $4.863 million.

Islam and co-workers standardized various cost items and expressed them as unit production costs at various production capacities [64]. Table 6 gives unit production costs for three different production capacities.

Table 6.

| Plant Capacity | 144 tons/day | 36 tons/day | 3.6 tons/day |

|---|---|---|---|

| Annualized capital cost (per ton) | 37.87 | 59.10 | 119.54 |

| Salary (per ton) | 27.51 | 63.58 | 101.43 |

| Direct cost (per ton) | 19.18 | 30.63 | 61.43 |

| General overhead (per ton) | 16.50 | 38.15 | 60.86 |

| Electricity (per ton) | 21.71 | 26.01 | 43.47 |

| Total cost (exc. electricity) | 101.06 | 191.46 | 342.25 |

A mid-sized pyrolysis plant with a capacity of recycling 30–40 tons of scrap tires per day generates $222 per ton. Processing one ton of scrap tires costs around $200 per ton, with the assumption that gas generated through the pyrolysis process can power the reactor and the gas turbine. The difference between revenue and cost is $22 per ton, which may be regarded as an unappealing profit margin. Considering the price volatility of outputs, the plant may not be profitable, at least during the periods when the demand for pyrolysis products is depressed. Even with the small profit margin of $22 per ton, there is a potential profit of $6.6 million if all 0.3 million tons of ELT is sent to pyrolysis plants. This potential is expected to reach $4.4 million in 2030, with increasing ELT output.

6. Concluding remarks

The economic analysis of pyrolysis plants evaluates the problem from an investor's perspective. It involves economic analysis of a chemical plant in which the raw material is processed into several products. The revenue from products minus all costs is the basis of our analysis. Calculations indicate that there is a balance between cost and revenue at the current state, and the long-term profitability of the investment is not guaranteed. However, there are several factors either currently in practice or consideration, which may soon shift the balance in favor of building the plant.

The first is the tipping fee, which is the cost associated with disposing of ELTs. The EU has already banned dumping ELTs into landfills and similar practices are gaining traction in other countries. This creates an opportunity for pyrolysis plants to charge higher fees for scrap tire processing. Thus, the tipping fee may be considered as another revenue stream for plants. Charging an additional €100 per ton (the recent tipping rate in Europe) would improve the economic feasibility of building a plant.

Another factor favoring building plants is the green status of the pyrolysis process. Many countries categorize the pyrolysis of scrap tires as a part of the green manufacturing circle, which gives pyrolysis plants access to government support in terms of financial incentives and subsidies.

There is also the potential to upgrade pyrolysis products. Pyrolysis oil can be further processed to extract high-value products. For example, limonene, which can be extracted through pyrolysis, is used in many industrial applications. Other potential high-value products include indene, styrene, xylene, and naphthalene.

Declarations

Author contribution statement

Fatma Pinar GOKSAL: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interest's statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.IMARC Tire market: global industry trends, share, size, growth, opportunity and forecast 2020–2025. 2019. https://www.imarcgroup.com/tyre-manufacturing-plant

- 2.Roy C., Labrecque B., de Caumia B. Recycling of scrap tires to oil and carbon black by vacuum pyrolysis. Resour. Conserv. Recycl. 1990;4(3):203–213. [Google Scholar]

- 3.Bridgewater A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy. 2012;38:68–94. [Google Scholar]

- 4.Özbay G. Catalytic pyrolysis of pine wood sawdust to produce bio-oil: effect of temperature and catalyst additives. J. Wood Chem. Technol. 2015;35(4):302–313. [Google Scholar]

- 5.Rutkowski P. Chemical composition of bio-oil produced by co-pyrolysis of biopolymer/polypropylene mixtures with K2CO3 and ZnCl2 addition. J. Anal. Appl. Pyrol. 2012;95:38–47. [Google Scholar]

- 6.Zhang Q., Chang J., Wang T., Xu Y. Review of biomass pyrolysis oil properties and upgrading research. Energy Convers. Manag. 2007;48(1):87–92. [Google Scholar]

- 7.Western Tire Recyclers The life cycle of a tire: from rubber to mulch. 2014. westerntirerecyclers.com/the-life-cycle-of-a-tire/

- 8.Car, Driver How long should a new set of tires last? 2020. https://www.caranddriver.com/news/a15339994/how-long-should-a-new-set-of-tires-last/

- 9.Kole P.,J., Lohr A.,J., Van Belleghem F., G A.,J., Ragas A., M J. Wear and tear of tyres: a stealthy source of microplastics in the environment. Int. J. Environ. Res. Publ. Health. 2017;14(10):1265. doi: 10.3390/ijerph14101265. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.TyreStewardship Australia. (n.d.). Equivalent passenger unit ratios. https://www.tyrestewardship.org.au/wp-content/uploads/2020/06/Scheme-Guidelines-EPU-Ratios.pdf.

- 11.Recycling.com [Electronic resource], https://www.recycling.com/downloads/waste-hierarchylansinks-ladder/.

- 12.WBCD Report, Global ELT Management – A Global State of Knowledge on Collection Rates, Recovery Routes, and Management Methods. Tire Industry Project (TIP) of World Business Council for Sustainable Development (WBCD); June 2018. [Google Scholar]

- 13.Chiu C.-T. Use of ground tire rubber in asphalt pavements: field trial and evaluation in Taiwan. Resour. Conserv. Recycl. 2008;52(3):522–532. [Google Scholar]

- 14.Lin C., Huang C.-L., Shern C.-C. Recycling waste tire powder for the recovery of oil spills. Resour. Conserv. Recycl. 2008;52(10):1162–1166. [Google Scholar]

- 15.Onuaguluchi O., Banthia N. Scrap tire steel fiber as a substitute for commercial steel fiber in cement mortar: engineering properties and cost-benefit analyses. Resour. Conserv. Recycl. 2018;134:248–256. [Google Scholar]

- 16.Shalaby A., Khan R.A. Design of unsurfaced roads constructed with large-size shredded rubber tires: a case study. Resour. Conserv. Recycl. 2005;44(4):318–332. [Google Scholar]

- 17.Van de Lindt J.W., Carraro J.A.H., Heyliger P.R., Choi C. Application and feasibility of coal fly ash and scrap tire fiber as wood wall insulation supplements in residential buildings. Resour. Conserv. Recycl. 2008;52(10) [Google Scholar]

- 18.De Souza C.D.R., D'Agosto M., de A. Value chain analysis applied to the scrap tire reverse logistics chain: an applied study of co-processing in the cement industry. Resour. Conserv. Recycl. 2013;78:15–25. [Google Scholar]

- 19.Prisciandaro M., Mazziotti G., Veglió F. Effect of burning supplementary waste fuels on the pollutant emissions by cement plants: a statistical analysis of process data. Resour. Conserv. Recycl. 2003;39(2):161–184. [Google Scholar]

- 20.ETRMA Annual Report European tyre and rubber industry. 2017. https://www.etrma.org/news-resources/library/ 2017, 09, 13.

- 21.ETRMA Statistics Edition European tyre and rubber industry manufacturers’ association. 2014. https://www.etrma.org/news-resources/library/ 2014, 10, 13.

- 22.ETRMA Statistics Edition European tyre and rubber industry manufacturers’ association. 2015. https://www.etrma.org/news-resources/library/ 2014, 12, 16.

- 23.ETRMA Statistics Edition European tyre and rubber industry manufacturers’ association. 2016. https://www.etrma.org/news-resources/library/ 2017, 01, 23.

- 24.ETRMA Statistics Edition European tyre and rubber industry manufacturers’ association. 2017. https://www.etrma.org/news-resources/library/ 2017, 09, 33.

- 25.Ahoor A.,H., Zandi-Atashbar N. Fuel production based on catalytic pyrolysis of waste tires as an optimized model. Energy Convers. Manag. 2014;87:653–669. [Google Scholar]

- 26.Aslan D.,I., Parthasarathy P., Goldfarb J.,L., Ceylan S. Pyrolysis reaction models of waste tires: application of Master-Plots method for energy conversion via devolatilization. Waste Manag. 2017;68:405–411. doi: 10.1016/j.wasman.2017.06.006. [DOI] [PubMed] [Google Scholar]

- 27.Ayanoğlu A., Yumrutaş R. Production of gasoline and diesel like fuels from waste tire oil by using catalytic pyrolysis. Energy. 2016;103:456–468. [Google Scholar]

- 28.Cheung K., Lee K., Lam K.L., Lee C.W., Hui C.W. Integrated kinetics and heat flow modeling to optimize waste tyre pyrolysis at different heating rates. Fuel Process. Technol. 2011;92:856–863. [Google Scholar]

- 29.Heidari A., Younesi H. Synthesis, characterization and life cycle assessment of carbon nanospheres from waste tires pyrolysis over ferrocene catalyst. J. Environ. Chem. Eng. 2020;8(2) [Google Scholar]

- 30.Kar Y. Catalytic pyrolysis of car tire waste using expanded perlite. Waste Manag. 2011;31:1772–1782. doi: 10.1016/j.wasman.2011.04.005. [DOI] [PubMed] [Google Scholar]

- 31.Liu B., Jiang J., Chen B., Yao S. Study on purification of pyrolytic oil derived from pilot-scale pyrolysis of waste tires in multilevel reactor. J. Basic Sci. Eng. 2006;14:529–534. [Google Scholar]

- 32.Menares T., Herrera J., Romero R., Osorio P., Arteaga-Pérez L.,E. Waste tires pyrolysis kinetics and reaction mechanisms explained by TGA and Py-GC/MS under kinetically controlled regime. Waste Manag. 2020;102:21–29. doi: 10.1016/j.wasman.2019.10.027. [DOI] [PubMed] [Google Scholar]

- 33.Unapumnuk K., Keener T.,C., Lu M., Liang F. Investigation into the removal of sulfur from tire derived fuel by pyrolysis. Fuel. 2008;87:951–956. [Google Scholar]

- 34.Undri A., Meini S., Rosi L., Frediani M., Frediani P. Microwave pyrolysis of polymeric materials: waste tires treatment and characterization of the value-added products. J. Anal. Appl. Pyrol. 2013;103:149–158. [Google Scholar]

- 35.Acevedo B., Barriocanal C. Texture and surface chemistry of activated carbons obtained from tyre wastes. Fuel Process. Technol. 2015;134:275–283. [Google Scholar]

- 36.Acevedo B., Barriocanal C., Lupul I., Gryglewicz G. Properties and performance of mesoporous activated carbons from scrap tyres, bituminous wastes and coal. Fuel. 2015;151:83–90. [Google Scholar]

- 37.Acosta R., Fierro V., Martinez De Yuso A., Nabarlatz D., Celzard A. Tetracycline adsorption onto activated carbons produced by KOH activation of tyre pyrolysischar. Chemosphere. 2016;149:168–176. doi: 10.1016/j.chemosphere.2016.01.093. [DOI] [PubMed] [Google Scholar]

- 38.Acosta R., Nabarlatz D.A., Sanchez-Sanchez A., Jagiello J., Gadonneix P., Celzard A., Fierro V. Adsorption of Bisphenol A on KOH-activated tyre pyrolysis char. J. Environ. Chem. Eng. 2018;6(1):823–833. [Google Scholar]

- 39.Li S.Q., Yao Q., Wen S.E., Chi Y., Yan J.H. Properties of pyrolytic chars and activated carbons derived from pilot-scale pyrolysis of used tires. J. Air Waste Manag. Assoc. 2005;55(9):1315–1326. doi: 10.1080/10473289.2005.10464728. [DOI] [PubMed] [Google Scholar]

- 40.Li L., Liu S., Zhu T. Application of activated carbon derived from scrap tires for adsorption of Rhodamine B. J. Environ. Sci. 2010;22(8):1273–1280. doi: 10.1016/s1001-0742(09)60250-3. [DOI] [PubMed] [Google Scholar]

- 41.López G., Olazar M., Artetxe M., Amutio M., Elordi G., Bilbao J. Steam activation of pyrolytic tyre char at different temperatures. J. Anal. Appl. Pyrol. 2009;85(1–2):539–543. [Google Scholar]

- 42.Merchant A.,A., Petrich M.,A. Pyrolysis of scrap tires and conversion of chars to activated carbon. AIChE J. 1993;39(8):1370–1376. [Google Scholar]

- 43.Trubetskaya A., Kling J., Ershag O., Attard T.,M., Schröder E. Removal of phenol and chlorine from wastewater using steam activated biomass soot and tire carbon black. J. Hazard Mater. 2019;365:846–856. doi: 10.1016/j.jhazmat.2018.09.061. [DOI] [PubMed] [Google Scholar]

- 44.Leung D., Y C., Wang C.L. Fluidized-bed gasification of waste tire powders. Fuel Process. Technol. 2003;84(1–3):175–196. [Google Scholar]

- 45.Witpathomwong C., Longloilert R., Wongkasemjit S., Jitkarnka S. Improving light olefins and light oil production using Ru/MCM-48 in catalytic pyrolysis of waste tire. Energy Proc. 2011;9:245–251. [Google Scholar]

- 46.Luo S., Feng Y. The production of fuel oil and combustible gas by catalytic pyrolysis of waste tire using waste heat of blast-furnace slag. Energy Convers. Manag. 2017;136:27–35. [Google Scholar]

- 47.Rodriguez I., D M., Laresgoiti M.,F., Cabrero M.A., Torres A., Chomon M.,J., Caballero B. Pyrolysis of scrap tyres. Fuel Process. Technol. 2001;72(1):9–22. [Google Scholar]

- 48.Czajczyńska D., Krzyżyńska R., Jouhara H., Spencer N. Use of pyrolytic gas from waste tire as a fuel: a review. Energy. 2017;134:1121–1131. [Google Scholar]

- 49.Chang Y.M. On pyrolysis of waste tire: degradation rate and product yields. Resour. Conserv. Recycl. 1996;17(2):125–139. [Google Scholar]

- 50.Frigo S., Seggiani M., Puccini M., Vitolo S. Liquid fuel production from waste tyre pyrolysis and its utilisation in a Diesel engine. Fuel. 2014;116:399–408. [Google Scholar]

- 51.Singh R.,K., Ruj B., Sadhukhan A.,K., Gupta P. Springer; Singapore: 2020. Energy Recovery from Tyre Waste Pyrolysis: Product Yield Analysis and Characterization. Energy Recovery Processes from Wastes; pp. 33–43. [Google Scholar]

- 52.Tabinda A.B., Arshed F., Yasar A., Afzaal M., Iqbal A. Comparative analysis of desulphurization methods of tyre pyrolysis oil (TPO) Int. J. Environ. Sci. Technol. 2019;16(8):4013–4018. [Google Scholar]

- 53.Undri A., Rosi L., Frediani M., Frediani P. Upgraded fuel from microwave assisted pyrolysis of waste tire. Fuel. 2014;115:600–608. [Google Scholar]

- 54.Islam M.R., Haniu H., Beg M.R.A. Liquid fuels and chemicals from pyrolysis of motorcycle tire waste: product yields, compositions and related properties. Fuel. 2008;87(13–14):3112–3122. [Google Scholar]

- 55.Minitab (n.d.). Minitab online manual. Version 18. https://support.minitab.com/en-us/minitab/18/help-and-how-to/modeling-statistics/regression/how-to/partial-least-squares/before-you-start/overview/.

- 56.ACEA Report, Vehicles in use, Europe 2019 European automobile manufacturers association. 2019. https://www.acea.be/about-acea

- 57.European Central Bank Macroeconomic projections. 2020. https://www.ecb.europa.eu/pub/projections/html/index.en.html

- 58.TUIK Auto Stats Turkish statistical institute, transportation statistics. 2020. http://www.tuik.gov.tr

- 59.Dabic-Miletic S., Simic V., Karagoz S. End-of-life tire management: a critical review. Environ. Sci. Pollut. Control Ser. 2021:1–18. doi: 10.1007/s11356-021-16263-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Oliveira Neto G.C.D., Chaves L.E.C., Pinto L.F.R., Santana J.C.C., Amorim M.P.C., Rodrigues M.J.F. Economic, environmental and social benefits of adoption of pyrolysis process of tires: a feasible and ecofriendly mode to reduce the impacts of scrap tires in Brazil. Sustainability. 2019;11(7):2076. [Google Scholar]

- 61.Williams P.,T. Pyrolysis of waste tyres: a review. Waste Manag. 2013;33(8):1714–1728. doi: 10.1016/j.wasman.2013.05.003. [DOI] [PubMed] [Google Scholar]

- 62.Martinez J.,D., Puy N., Murillo R., Garcia T., Navarro M.,V., Mastral A.,M. Waste tyre pyrolysis – a review. Renew. Sustain. Energy Rev. 2013;23:179–213. [Google Scholar]

- 63.Tsiryapkina I. University of North Dakota; Grand Forks, ND: 2019. Technology and Economy Analysis of Waste Truck Tires Management. (Master’s Thesis) [Google Scholar]

- 64.Islam M.,R., Joardder M., U H., Hasan S.,M., Takai K., Haniu H. Feasibility study for thermal treatment of solid tire wastes in Bangladesh by using pyrolysis Technology. Waste Manag. 2011;31:2142–2149. doi: 10.1016/j.wasman.2011.04.017. [DOI] [PubMed] [Google Scholar]

- 65.Mulaudzi L. Stellenbosch University; Stellenbosch Central, South Africa: 2017. Process Modelling and Economic Evaluation of Waste Tyres to Limonene via Pyrolysis. (Master’s Thesis) [Google Scholar]

- 66.Pilusa J., Shukla M., Muzenda E. Economic assessment of waste tyres pyrolysis technology: a case study for Gauteng province, South Africa. International Journal of Research in Chemical, Metallurgical and Civil Engineering. 2014;1(1):41–49. [Google Scholar]

- 67.Turton R., Baile R.,C., Whiting W.,B., Shaeiwitz J.,A. Prentice-Hall PTR; Upper Saddle River, N. J.: 2008. Analysis, Synthesis, and Design of Chemical Processes. [Google Scholar]

- 68.Riedewald F., Sousa-Gallagher M. Technological and economical feasibility of a 40,000 t/y tyre pyrolysis plant: results of a H2020 SME Phase 1 study. ETRA Conference, March. 2016;18:2016. [Google Scholar]

- 69.London Metal Exchange Reports and Data, lme.com.

- 70.Natural Gas Now The future of natural gas – home generation of electricity? 2020. https://naturalgasnow.org/future-natural-gas-personal-generators/

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.