Abstract

The microstructure of steel greatly influences the mechanical properties. For 9 wt% Cr steels, which are widely used in the power generation industry, the steels have a ferritic and martensitic microstructure which can be altered by heat treating and chemical composition variations. Fully martensitic steels typically having high yield strengths but low ductility. Tempering can reduce the amount of martensite in the steel lowering the yield strength but increasing the ductility of the alloy. Alloying can alter the time required for a martensitic transformation. In authors’ previously published research, the authors used machine learning methodology to predict room temperature tensile properties from scanning electron microscopy (SEM) images of the initial steel microstructures from a wide range of steel compositions. This data-in-brief supplies the raw image files and the associated tensile properties for the authors’ previously published research utilized to predict tensile properties of steels [1].

Keywords: 9% steel, Martensite, Microstructure, Carbides, Machine learning

Specifications Table

| Subject | Materials Science / Material Characterization |

| Specific subject area | • Martensitic steel • Ferritic steel • 9% wt Cr steel |

| Type of data | • Table • Image |

| How the data were acquired | Original research from the authors. Metallic specimens were cast, forged, rolled, cut, polished, and imaged in house as described in the companion article. Imaging was acquired on an FEI Inspect F SEM utilizing Aztec software. Tensile tests were done in house on an Instron 5882 frame with BlueHill software. Chemical compositions were acquired with a Wavelength Dispersive X-ray Fluorescence (WDXRF) detector from Rigaku Corp. model: ZSX Primus II WDXRF spectrometer. |

| Data format | Raw |

| Description of data collection | Dataset contains initial microstructure, elemental composition and mechanical properties of various 9%Cr steels. • Images are backscatter scanning electron micrographs. • Elemental composition is reported in% weight. • Mechanical properties include tensile and yield strengths, elongation, and reduction in area. |

| Data source location | • Institution: National Energy Technology Laboratory • City/Town/Region: Albany, Oregon • Country: USA • Latitude and longitude (and GPS coordinates, if possible) for collected samples/data: 44.62340483755279, −123.1205935498697 |

| Data accessibility | Repository name: NETL EDX Data identification number: 10.18141/1,843,846 Direct URL to data: https://edx.netl.doe.gov/dataset/machine-learning-microstructures-9crsteel-data-in-brief Scroll down to ‘Data and Resources’ section, check the 3 zip files and 1 csv file, click the blue ‘Download checked’ button, complete the captcha and download to your desktop for viewing. |

| Related research article | Z. Pei, K. A. Rozman, Ö. N. Doğan, Y, Wen, N, Gao, E, A. Holm, J, A. Hawk, D, E. Alman, M. C. Gao, Machine-Learning Microstructure for Inverse Material Design, Advanced Science, 8(23), (2021), 2,101,207 https://doi.org/10.1002/advs.202101207 |

Value of the Data

-

•

This dataset includes relationships between initial microstructure, alloy composition and tensile properties for various composition ranges of 9 wt.% Cr steel alloys. This dataset is important as microstructure-properties relationships can be directly found.

-

•

Alloy designers will benefit from the relationships between composition, microstructure and tensile properties.

-

•

Dataset is beneficial for determining microstructure-properties relationships via machine learning or other modeling methodologies.

-

•

Dataset is beneficial to improve alloy design.

1. Data Description

This dataset collected the initial microstructure, alloy composition and mechanical properties of various compositions of 9 wt% Cr steels. For each steel the mechanical properties, chemical composition and initial microstructures are supplied. This directly enables researches to ascertain the relationship between the mechanical properties of the steels with the chemistry and graphical representation of the initial microstructure as found in the authors’ prior publication [1].

For the file “tensile-properties-from-jeffs-ml-sheet-20,220,208.csv”, mechanical properties of the steels are organized by the following:

-

•

The “Alloy” column is the metallic alloy. The image file folders correspond to this column.

-

•

The “Temperature” is the temperature in degree Celsius (°C) which the mechanical test was performed at.

-

•

The “Yield Stress” and “Ultimate Tensile Stress” are mechanical properties evaluated from the test in units of MPa.

-

•

“Tensile elongation” and “Reduction of Area” are also mechanical properties reported in percentage.

-

•The rest of the columns are elemental composition in percentage of weight of the overall alloy.

-

○Blank entries should be considered as below detection limits or “not detected”.

-

○

The file “hr_alloys20220208.zip” is a compressed file of the initial microstructure for HR alloys. The zip file contains 11 folders with folder titles corresponding to the specific alloy. The “.bmp” files are the raw microstructure images for that specific alloy.

The file “CPJ_alloys.zip” is a compressed file of the initial microstructure for CPJ alloys. The zip file contains 18 folders with folder titles corresponding to the specific alloy. The “.bmp” files are the raw microstructure images for that specific alloy.

The file “p92_alloys.zip” is a compressed file of the initial microstructure for P92 alloys. The zip file contains 4 folders with folder titles corresponding to the specific alloy. The “.bmp” files are the raw microstructure images for that specific alloy.

Fig. 1 shows the data organization from the EDX depository. There are four main files, with the CSV file containing the mechanical properties and wt% of each alloying element. This file should be referenced to correlate the mechanical properties to the initial microstructure image. Each *.zip file contains the raw images in “.bmp” format of the initial microstructure for the alloys The corresponding folder is titled with the relevant alloy name, which should be referenced in the “Alloy” column of the CSV file for the mechanical properties and chemical composition associated with the image in the folder directory.

Fig. 1.

Schematic of the dataset.

Table 1 shows the first row of the mechanical properties dataset. The researcher may use these values to interpret the relationships between the initial microstructure (see Fig. 2) and the mechanical properties of the individual alloy or the chemical composition. The authors’ published research [1] used this dataset to predict an optimum composition and microstructure.

Table 1.

First row of the larger data set showing mechanical properties and chemical composition.

| Alloy | Temperature, [C] | Yield Stress, [MPa] | Ultimate Tensile Stress, [MPa] | Tensile elongation [%] | Reduction area [%] | Fe | C | Cr | Mn | Si | Ni | Co | Mo | W | Nb | Al | P | Cu | Ti | Ta | Hf | Re | V | B | N | O | S | Zr | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CPJ-7 | 23.9 | 847.64 | 1010.5 | 24.1 | 60.7 | 85.44 | 0.15 | 9.83 | 0.41 | 0.09 | 0.27 | 1.48 | 1.26 | 0.482 | 0.056 | 0.016 | 0.001 | 0.003 | NaN | 0.279 | NaN | NaN | 0.209 | 0.01 | 0.02 | 0.0036 | 0.005 | NaN | NaN |

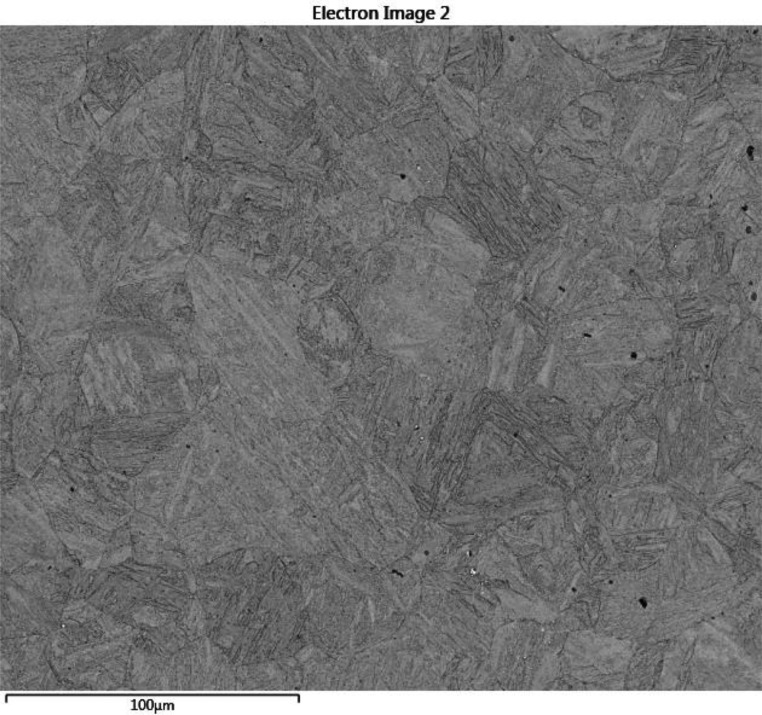

Fig. 2.

Example initial microstructure image for CPJ7 alloy with corresponding mechanical properties in Table 1 for this Data-in-brief.

Fig. 2 shows a representative raw image of the initial microstructure for CPJ7. For this Data-in-brief the corresponding mechanical properties for Fig. 2 is provided in Table 1. However, the mechanical properties associated with the initial microstructure for the other alloys in the dataset should be referenced in the CSV file in the EDX directory for the rest of the dataset. The authors used these images for the training set of the published machine learning model [1]. These images were cropped to remove irrelevant features such as titles and scale bars, and contrast was increased to differentiate between features [1].

2. Experimental Design, Materials and Methods

This dataset was compiled with original research from the authors.

Metallographic specimens were prepared by mounting into conductive media and were then ground/polished starting at 120 grit abrasive and finishing with 1200 grit abrasive. At this point the specimen sections were polished using silica and alumina media.

Images were collected on a FEI Inspect F SEM. Accelerating voltage was 10–20 keV. Imaging was automated in a raster pattern with Atzec software covering an area of 0.1 mm x 0.12 mm with 0% overlap between images in electron backscatter mode (BSE). To mitigate charging samples were grounded with copper tape.

Chemical compositions were acquired with a Wavelength Dispersive X-ray Fluorescence (WDXRF) detector from Rigaku Corp. model: ZSX Primus II WDXRF spectrometer.

Mechanical properties were collected on an Instron 5882 load frame with Bluehill software. Mechanical specimens were extracted from a hot-rolled, normalized and tempered plate manufactured at NETL [2], [3], [4]. Mechanical specimens had a gage diameter of 6.35 mm and a gage length of 31.25 mm. Mechanical testing conformed to ASTM E-8 with a strain rate of 6.26 × 10−5 s−1 until yielding and 6.26×10−4 s−1 until failure.

Ethics Statements

The authors have no conflicts of interest to declare. Studies were done in an ethical manor.

CRediT authorship contribution statement

Kyle A. Rozman: Writing – original draft, Investigation, Data curation, Visualization. Ömer N. Doğan: Conceptualization, Supervision, Project administration. Richard Chinn: Investigation. Paul D. Jablonksi: Conceptualization, Supervision, Project administration. Martin Detrois: Supervision, Project administration. Michael C. Gao: Conceptualization, Supervision, Project administration, Writing – review & editing.

Declaration of Competing Interest

Please tick the appropriate statement below and declare any financial interests/personal relationships which may affect your work in the box below.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests:

Please declare any financial interests/personal relationships which may be considered as potential competing interests here.

Acknowledgments

Acknowledgments

This work was performed in support of the U.S. Department of Energy's Fossil Energy Crosscutting Technology Research Program. The Research was executed through the NETL Research and Innovation Centers Advanced Alloy Development Field Work Proposal. Research performed by Leidos Research Support Team staff was conducted under the RSS contract 89243318CFE000003. This research was supported in part by an appointment to the U.S. Department of Energy (DOE).

The authors wish to acknowledge Matt Fortner for help with metallographic preparation, and Edward Argetsinger and Joseph Mendenhall for production of the alloys and Christopher Powell for mechanical testing.

Disclaimer

This project was funded by the United States Department of Energy, National Energy Technology Laboratory, in part, through a site support contract. Neither the United States Government nor any agency thereof, nor any of their employees, nor the support contractor, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Data Availability

References

- 1.Pei Z., Rozman K.A., Doğan Ö.N., Wen Y.i, Gao N., Holm E.A., Hawk J.A., Alman D.E., Gao M.C. Machine-learning microstructure for inverse material design. Adv. Sci. 2021;8(23) doi: 10.1002/advs.202101207. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Jablonski P.D., Hawk J.A. Homogenizing advanced alloys: thermodynamic and kinetic simulations followed by experimental results. J. Mater. Eng. Perform. 2017;26(1):4–13. [Google Scholar]

- 3.J.A. Hawk, P.D. Jablonski, C.J. Cowen, U.S. Patent US9181597B1.

- 4.J.A. Hawk, P.D. Jablonski, C.J. Cowen, U.S. Patent US9556503B1.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.