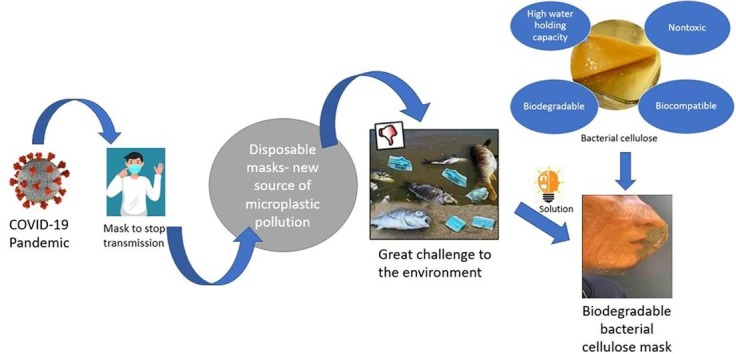

Graphical abstract

Keywords: Disposable masks, Biodegradable, Bacterial cellulose, COVID-19, Pandemic

Abstract

The use of face masks aids to stop the transmission of various deadly communicable ailments, and therefore widespread mask wearing habit is advocated by nearly all health organisations including the WHO to curb the COVID-19 pandemic. Recent studies predicted a shocking requirement of masks globally, approximately billions of masks per week in a single country, and maximum of them are disposable masks, which are made up of nonbiodegradable material such as polypropylene. With expanding review on improper masks disposal, it is imperative to perceive this inherent environmental hazard and avert it from resulting in the subsequent problematic situation due to plastic. The shift towards biodegradable biopolymers alternatives such as bacterial cellulose and newly evolving sustainable scientific knowledge would be significant to dealt with upcoming environmental problem. Bacterial cellulose possesses various desirable properties to replace the conventional mask material. This review gives an overview of data about accumulation of waste masks and its potential harm on environment. It also focuses on diverse characteristics of bacterial cellulose which make it suitable material for making mask and the challenges in the way of bacterial cellulose production and their possible solution. The current review also discussed the report on global bacterial cellulose market growth.

1. Introduction

A novel corona virus called COVID-19 or 2019-nCoV was identified by the Chinese Centre for Disease Control and Prevention (CCDC), in December 2019, in China. Officially, it was named as Severe Acute Respiratory Syndrome Coronavirus 2 (SARS-CoV-2) (Xie and Chen, 2020). Initially in 2020, it was thought that the spread of coronavirus takes place only in some parts of the globe, however it is very unfortunate that COVID-19 spread can be seen worldwide over time. It was announced that COVID-19 could be identified as a pandemic by World Health Organization (WHO) (Covid CDC, 2020).

Coronaviruses are known to cause respiratory infections, that can be as mild as common colds and as severe as the SARS (severe acute respiratory syndrome) and the MERS (Middle East Respiratory Syndrome). In the year 2019 the disease named coronavirus was caused by SARS-CoV-2, therefore it is also known as COVID-19. While coughing, sneezing or exhaling droplets are generated from an infected person, through which coronaviruses are transmitted. One can get infection by touching the nose, mouth or eyes without cleaning their hands in proper way, after touching surfaces contaminated with virus or making contact with person having infection Throat infection, dry cough, fever, tiredness, loss of infection, etc are some common symptoms of COVID-19. However, in asymptotic patients, these symptoms may not appear. Specific drug or vaccine for coronavirus is not available at present. Although, the recovery rate from this disease is quite higher, that is 70–80 % people recover without any special treatment.

The COVID-19 pandemic is so devastating and highly contagious, which results in irreversible and immense socioeconomic losses, by infecting hundreds of millions of people (Zhou et al., 2020). Use of PPE (personal protective equipment) like masks, is considered as a significant approach to put the screws on spread of SARS-CoV-2, to mitigate this pandemic disaster (Ortega et al., 2020). A huge burden of plastic pollution (i.e., nonbiodegradable polypropylene plastic) has been raised due to increased consumption of disposable, nonbiodegradable face masks. Current, face masks consumption is more than 200 million masks per day (Klemeš et al., 2020). Therefore, the increased plastic pollution due to this pandemic, prompt scientist the significance of replacing non-degradable things by the degradable materials typically related with biopolymers for example cellulose, starch, lignin, and chitin (Morganti and Morganti, 2020). By substituting the polypropylene-based face mask by several kinds of masks made up of cloth can report the problem associated with the environmental hazard caused by nonbiodegradable masks. However, it has been reported that cloth masks show less filtration efficiency, i.e., nearly 80 % for aerosols <300 nm and nearly 90 % for >300 nm (Konda et al., 2020). Whereas, N95, KN95, FFPs, etc masks normally shows good filtration efficiency against more than 95 % of airborne particulate matter (Yim et al., 2020, Gope et al., 2020). But still there is no biocidal activity in all these masks and therefore, after disposal they could serve as origin of virus which may cause secondary transmission of infection. Consequently, it is important to take step towards manufacture of biocidal (bactericidal and/or virucidal) masks assured safety of mask disposal (Tuñón-Molina et al., 2021; Alba Cano-Vicent et al., 2021, Martí et al., 2021).

To limit the spread of coronavirus, various steps have been employed such as use of facemask, following social distancing norms, lockdown and travel restrictions (Rubio-Romero et al., 2020, Sun et al., 2020). Additionally, WBE (waste water-based epidemiology) played a crucial role as a surveillance scheme and initial warning outbreaks of contagious diseases caused by harmful SARS-CoV-2 with pandemic potential (Soni et al., 2022a, Soni et al., 2022b). This COVID-19 pandemic teaches us that wearing mask is essential for every human being. In these circumstances, SUP (single use plastics) requirements have raised because COVID-19 is highly contagious. Subsequently, various governments have delayed SUP bans and have supported population to utilise them supposing to circumvent cross-contamination (Silva et al., 2020). In numerous countries personal protective equipment (which includes gloves and facial masks) are compulsory for all citizens outdoors as well as indoors, hence, there is an increase in manufacture of mask (e.g. China manufactured 200 million units of masks per day in June 2020, that is 20 folds the number they completed in the beginning of February 2020 (Aragaw, 2020). Uncritical usage of masks all over the world results in a monthly demand of nearly-one hundred twenty-nine billion masks (Prata et al., 2020), in view of nearly 8 billion populations (Worldometers.info, 2021). Various types of masks are in use: KN95, cotton, FFP2, surgical, FFP3, or activated carbon masks are few of the extensively used masks. Though, out of all these, surgical masks are used more than others. People should follow correct way of using mask such as a mask should be used for 4 h or so, and then should be discarded in an adequate manner. Usually, used masks are disposed of without protective measures which leads to the accumulation and pilling up of contaminated plastic in the environment. If we assume that only 1 % disposal of mask is not in proper manner, about ten million masks are being accumulated in the environment per month which is about 30–40,000 kilo gram of plastic (Fadare and Okoffo, 2020). Thus, huge amount of microplastics would be piled up and persist within the ecosystem endlessly. It is stated heaps of microplastics from the chief constituents of masks (polypropylene, polyethylene) in marine environment signifying huge build-ups in short span (Abbasi et al., 2020). So, the percentage of microplastics contributed by masks is probable to rise the coming time. On the bases of this it can be inferred that recent pandemic rises the ecological pollution and adversely affect the animal and human health. Hence, there is necessity of sustainable solutions to cut the ecological effects, despite matching the current demand of mask.

Cellulose is the main component of plant cell walls, and it is renewable and most abundant natural polymer on the earth. It can be isolated from a various source, for example wood, grasses, seed fibers, bast fibers, invertebrates, aquatic animals, bacteria, fungi and algae (Asim et al., 2015, Jawaid and Khalil, 2011). Table 1 shows the different sources of cellulose. Cellulose produced by bacteria is known as bacterial cellulose (BC), which shows unique properties and conformation. If compared with cellulose obtained from other sources, BC shows many advantageous properties such as high purity (free from hemicellulose, lignin, pectin, etc), nanofiber mesh structure, mechanical strength, and high-water holding capacity. As the bacterial cellulose is produced in almost pure form and in the form of nano material, it would be preferred material over cellulose obtained from other sources. Bacterial cellulose can be obtained in diverse forms or shapes and can be modified easily by physical and chemical methods, therefore its use in the production of new materials and nanocomposites for manufacturing masks with high filtration efficiency and biocidal activity, have been in the focus of many researchers.

Table 1.

Different sources of cellulose (Seddiqi et al., 2021).

| Variables | Plant | Bacteria | Algae | Tunicates |

|---|---|---|---|---|

| Derivatives or species | cotton, flax, pineapple leaf, corn, hemp, jute, bagasse, ramie, cereal straws,potato peel waste and different aggriculture waste. | Komagataeibacter xylinus, Agrobacterium, Achromobacter, Aerobacter, Azotobacter, Pseudomonas, and Rhizobium, and Sarcina | Posidonia Oceanica, Cladophora, and Gelidium elegans | Ascidiacea (sea squirts) |

| Purity | Not pure, (hemicellulose, lignin, and other impurities) | More than 90 % | Not pure, (associated mainly with hemicellulose, protein, and lignin) | Generally dry tunic contains approx. 60 % cellulose and 27 % nitrogen-containing components |

| Elastic modulus (GPa) | 5–130 | 60–115 | 110–200 | 60–220 |

| Degree of polymerization of cellulose | Up to 15,000 in cotton | 7000–16,000 | 2500–4300 | 700–3500 |

| Degree of crystallinity | Comparatively lower | High (80–90 %) | More than 95 % | High (95 %) |

It is evident that nanocellulose or micro fibrillated cellulose is beneficial for textile sector. In nanocellulose- based face masks properties which are significantly improved are as follows self-cleaning, durability, and dirt or moisture-repellent features. Nanocellulose based facemask shows antimicrobial property, which is particularly advantage in hospitals, where chances of cross-contamination of bacteria could dangerously affect immune suppressed people and elderly people. Nanocellulose and bacterial cellulose have high filtration efficiency, they are able to filter particle, having less than 100 nm size. Nanocellulose based masks have high breathability and less weight than conventional medical masks, because a skinny mask can be manufactured out of nanocellulose or bacterial cellulose, uncompromising other attributes, therefore they will prove to be very comfortable for wearer. And its biodegradable property is very crucial, when we talk about mask disposal as an environmental problem. Lately it has been reported that 100 percent NFC (Nano Fibrillar Cellulose)- based filter paper is capable to screen with up to 99.9980–99.9995 % efficacy, even the smallest viruses (Developing of Mask Material Using Nanocellulose to Fight against COVID-19, 2020). Non-toxic nature, high strength, and conductivity properties of bacterial cellulose would be furnished in manufacturing the face mask that can be worn easily for longer time. The conductive feature of bacterial cellulose-based mask could be utilized of its virucidal property when it interacts with virus. Additionally Metal oxide nanomaterials with oxidative capability can also be combined with these bacterial cellulose based masks, to improve their antiviral properties, as these materials proved to be effective material against various viral disease such as influenza, measles, ebola, herpes, and on-going COVID-19, etc (Soni et al., 2022a, Soni et al., 2022b). The current trends employed in the photosynthesis of metallic nanoparticles and their effective usage in controlling various endemic diseases such as cancer, malaria, hepatitis has been reviewed (Soni et al., 2021). Therefore, Biocellulose shows many advantageous characteristics by which it become a desirable material to be designated as a upcoming material for making masks.

2. Face mask- necessity and effectiveness

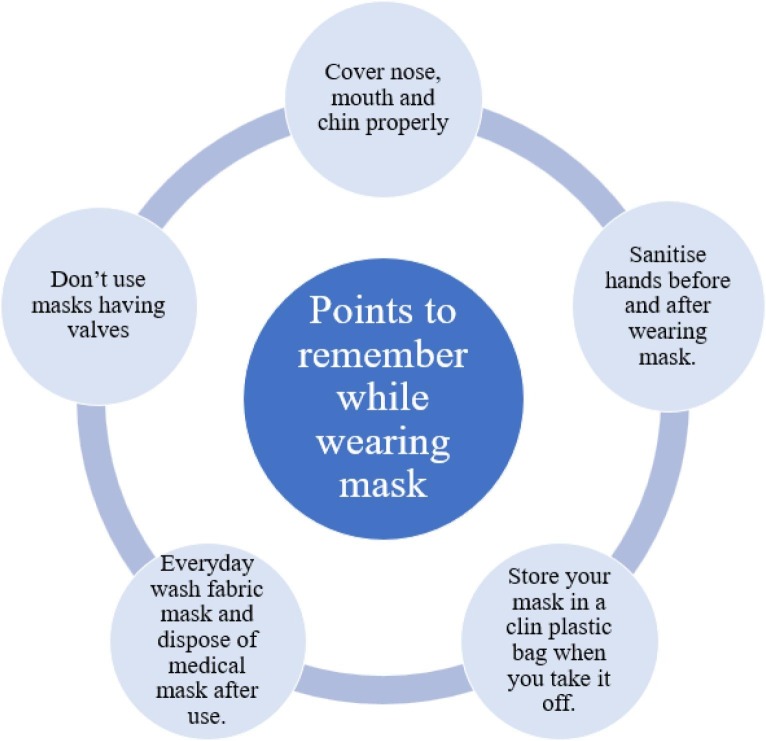

To lessen the exposure to numerous hazardous matters such as chemical, physical, biological, thermal, electrical, and airborne particulate matters, the mask is worn. A mask is one of the most important PPEs (Personal Protective Equipment) that can be used by healthy people for protecting themselves from getting infection, if they come in contact of infected person or can be used by the infected person to circumvent spread of diseases. Fig. 1 shows the important points which one should remember while wearing mask. Other type of Personal Protective Equipment are gloves, earplugs, helmets, goggles, and full-body suits, etc. The most PPE In COVID-19 epidemic is N95 (N95 S and Disposable air-purifying Masks-N95 3 M) are the most desirable mask of frontline worriers like health workers and doctors. These are generally-three-layered structures made of polypropylene fibers: external layer 40 μm, middle layer 8 μm, and inner layer 40 μm. The name of N95 mask comes from its basic feature, that it shows high filtration efficiency, and able to screen minute particles (around 0.1 μm in size) with more than 95 % efficiency. The Covid-19 virus is around 80–120 nm in size and it spreads in form of droplet (droplet size around 5–10 μm) (World Health Organization, 2020). The WHO (World Health Organization) and other worldwide health authorities, time to time, released advisories having recommendations for the use of facemask to stop spread of disease which can be transmitted through air such as flu. In the same way, during ongoing COVID-19 pandemic, various governments organisations and public protection organizations have given several recommendations for use of face masks to counter the COVID-19 pandemic. From above discussion, it can be inferred that the use of facemask can efficiently shield healthy individuals, healthcare personnel, patients, family members, co-workers, etc., from transmitting coronavirus through this ongoing COVID-19 pandemic and from other such viral epidemics.

Fig. 1.

Important points to remember while wearing mask.

3. Types of face mask

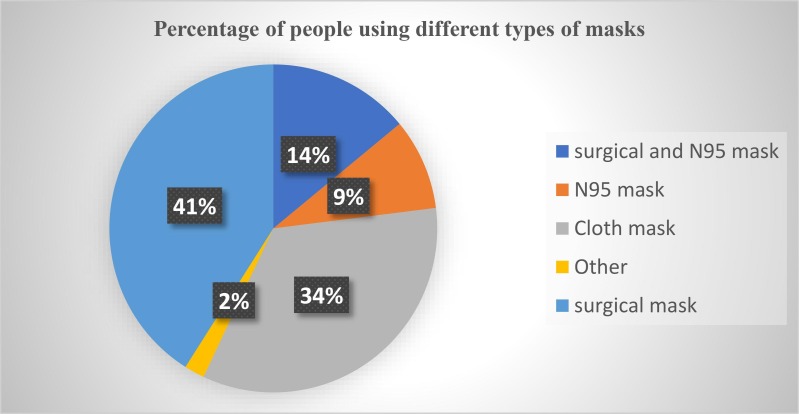

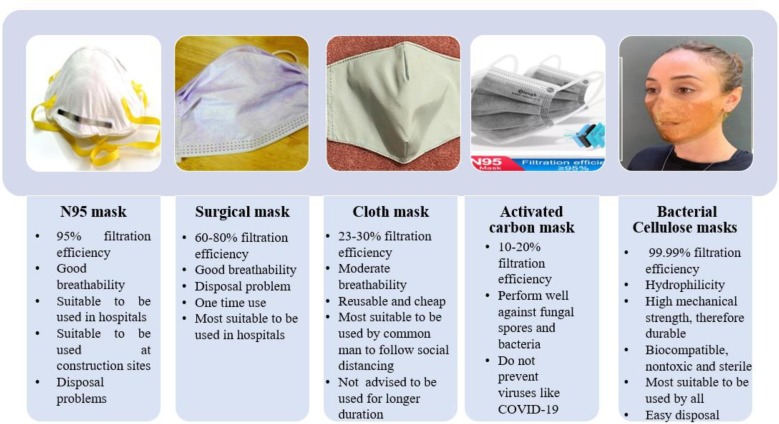

During current pandemic caused by coronavirus, four categories of face masks are utilised for the prevention of its spread. These are as follows surgical masks, activated carbon masks, N95 respirators and homemade cloth masks. Fig. 2 shows percentage of people using different types of masks. Now a days, several types of masks are in use which are made up of various materials and designs (Esposito et al., 2020, Bandi, 2020, American Chemical Society, 2020, Ray, 2020). If we talk about effectiveness of various masks, N95 mask is the most efficient (as it screens the elements of diameter of 0.3 μm up to 95 %) and Surgical masks are less efficient if compared with N95 and shows 60–80 % filtration for smaller particles. A unique property is shown by the activated C masks, which comprise an activated C filter, that aid in collection of the pollutants and germs, to filter out them. Homemade masks are not that efficient as they can screen just 23 to 33 percent of 0.3 µm particles and also shows less breathability because they are made up of dense materials (in order to enhance the filtration efficiency). The activated carbon masks functions well against bacteria and fungal spores, as well as against other pollutants and thus, prevent allergies. However, these masks do not prevent viruses like COVID-19, that efficiently. They are able to filter a few numbers of viruses (approximately 10–20 %) (Times of India, 2020). Many contradictory info is there about protection against coronavirus by wearing masks, i.e., masks are able to screen, as small as 0.007 μm particles. Research tells that N95 or surgical masks are capable to filter particle, which are as small as coronavirus or even 10 times smaller than coronaviruses. However, they lack many other features, which should be there in good quality masks. Homemade masks decrease the risk of spread of virus from the infected person. Though, the safety of these masks is unsure, as many aspects such as kinds of fabric used, permeability of fabrics used, and the mask design, etc., are not examined in a systematic way under diverse physical environments. It is also well understood that the various fabrics acts unpredictably under different conditions such as moisture and dry conditions. Fig. 3 demonstrate the Comprehensive features of different types of conventional masks (such as N95 mask, surgical mask, cloth mask, activated carbon mask) and biodegradable mask (bacterial cellulose mask).

Fig. 2.

Estimated percentage of people using different types of masks (Selvaranjan et al., 2021).

Fig. 3.

Comprehensive features of different types of conventional masks (such as N95 mask, surgical mask, cloth mask, activated carbon mask) and biodegradable mask (bacterial cellulose mask) (Gope et al., 2020, Gustafsson et al., 2018).

WHO indicates some possible problems and drawbacks of wearing masks by healthy people, such as potential hazard of self-infection because of mishandling of a mask (if reusable masks are not replaced by washed mask if they get damp), possible breathing difficulties or headache, and a pseudo sense of safety, which leads to possibly lesser obedience to another serious protective actions such as hand hygiene and physical distancing. In view of this, it is presently required to teach individuals about the advantages, disadvantages and appropriate existing material for masks that can offer all features of comfort as well as safety.

4. Accumulation of disposable masks- an environmental concern

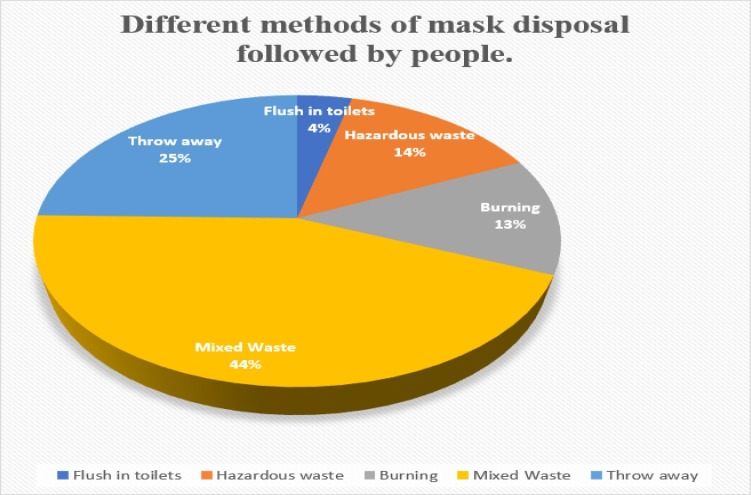

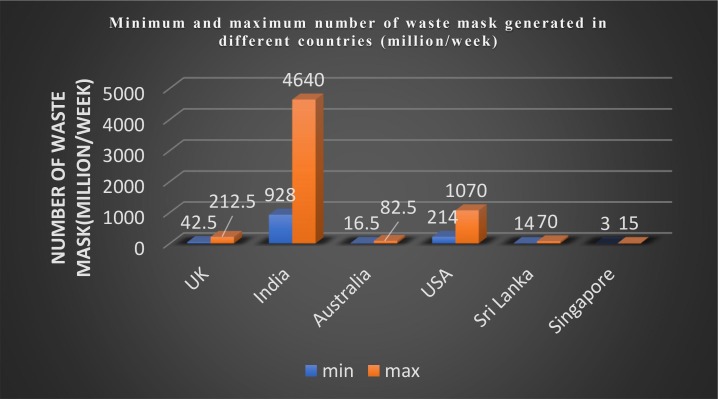

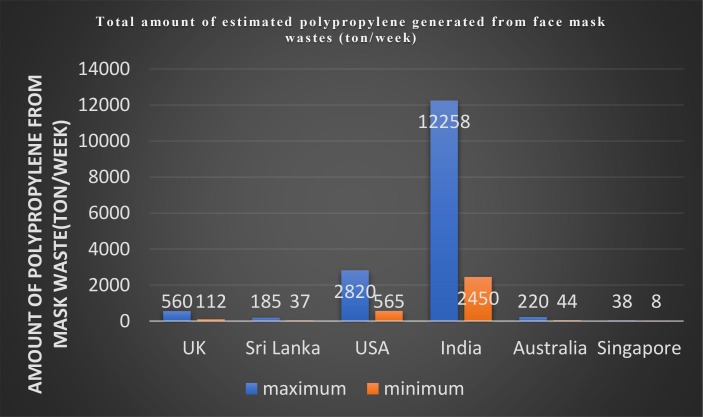

A report of World Health Organization (WHO), says that in USA approximately 89 million medical masks are estimated to be required to tackle the COVID-19 as this disaster is probably continue for some time (Xiang et al., 2020). In addition, according to the report of Plastic Innovation Hub, in UK, the domestic demand for the mask is approximately 24.37 billion per year (Liebsch, 2020). China has upstretched its everyday production of medical masks to 14.8 million till February 2020. Till April 2020, the requirement of more than 600 million face masks has been recorded by The Japanese ministry of finance, trade, and industry (Fadare and Okoffo, 2020). Fig. 4 Shows percentage of different method of disposal of waste mask followed by people. In Fig. 5 there is a graph which shows number of waste masks generated per week in different countries. In accordance with a research report, N95 and surgical masks comprise 9 g and 4.5 g of polypropylene, respectively. On the bases of mask wastes produced per week, the total minimum and maximum volume of polypropylene generated per week in different countries, is shown in Fig. 6 . The growing need of mask significantly rises the mask production and therefore, the higher amount of energy is consumed. Additionally, continually growing usages of face mask also upsurge the medical waste and landfills. These face mask wastes mostly contains either polypropylene and/or polyethylene, polystyrene, polyacrylonitrile, polycarbonate, polyurethane, etc. On disposal, these face masks add plastic or microplastic pollution to the environment (Akber AS et al., 2020). From this it can be inferred that current pandemic rises the environmental pollution and adversely affect the human and animal health. Hence, there is need of sustainable solutions to cut the environmental impacts, despite meeting the current demand of mask.

Fig. 4.

Percentage of different methods of disposal of waste mask followed (Selvaranjan et al., 2021).

Fig. 5.

Number of waste masks generated per week in different countries (Selvaranjan et al., 2021).

Fig. 6.

Polypropylene generated from mask waste (Selvaranjan et al., 2021).

5. Bacterial cellulose – an answer to this problem

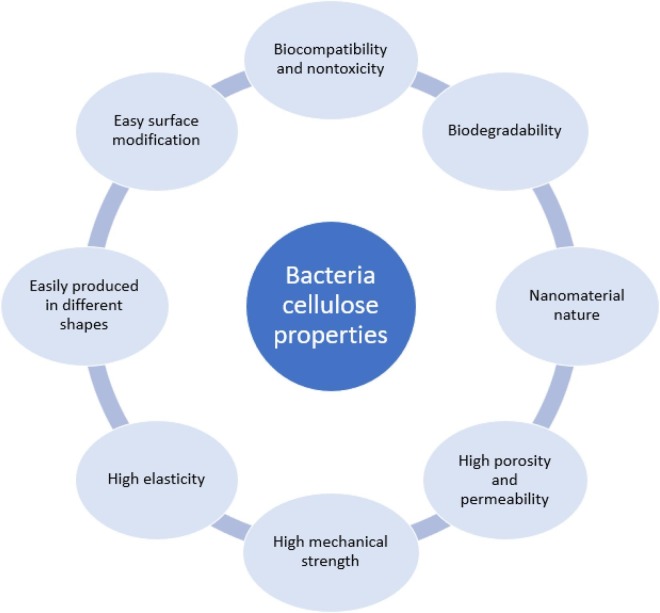

For numerous reasons, bacterial cellulose can be one of potential alternative material which can be used to replace conventionally utilized synthetic filter media, in the production of N95 masks, medical masks, as well as non-medical masks. Those reasons comprise high biodegradability, its high renewability, less production cost, effortless processing, abundance, changeable aspect ratio, high mechanical strength, lesser density, nanomaterial nature, high porosity, high elasticity, easy production in different shapes, high water-holding capacity, excellent biocompatibility, as compared to other materials. Due to these characteristics, bacterial cellulose has raised its extensive applications in food industry, medicine, pulp and paper industry, cosmetics, chemical industry, manufacture of unconventional acoustic membranes, and in the other diverse fields (Cacicedo et al., 2016, Campano et al., 2016, Gama and Dourado, 2016, Velásquez-Riaño and Bojacá, 2017, Volova et al., 2018, Hussain et al., 2019, Urbina et al., 2021, Provin et al., 2021). Both N95 and medical masks must possess some qualities, according to regulatory standards (CFR Part 84, 1995, Ippolito et al., 2020), which includes high filtration efficiency, better ability against penetration of pathogens, repellency to water (because droplets may possess viral material), lower pressure drop (i.e., higher permeability to air) to aid breathing, comfortable to wearer (Ristić et al., 2011, Zanoaga and Tanasa, 2014, Qin, 2015, Shimasaki et al., 2020, Osman, 2020). Conventional, synthetic fiber-based masks (N95 and medical masks) possess greater filtration efficiency (more than 95 %), but number of masks showing antiviral activity are less, which means that conventional masks only filter the microbes bud do not kill them. This leads to the higher risk of cross contamination, while using and disposing the masks, which further increases environmental problems due to its improper disposal practices (Zhou et al., 2020).

Cellulose based fibers give required features to filter media (for example, mechanical strength, bulk and permeability) as well as able to perform like a supporting material for the delicate filter media such as electro spun along with melt blown matrices (Hutten, 2007). Though it does not show intrinsic antimicrobial activities, but surface modification of cellulose fibers is known to be very good option for imparting antimicrobial activity to healthcare products and other medical applications. Due to its reactive surface cellulose can be modified chemically by grafting several functionalities in its structure (Tavakolian et al., 2020). Bacterial cellulose can be modified chemically due to presence of active sites on bacterial cellulose polymer, for example OH groups. Usually, the chemical treatments are carried out in water (aqueous medium), into which various functional groups remain active, and help them to react to other substances present in the medium. This leads to the surface of bacterial cellulose, physically or chemically, decked or grafted with moieties having some novel functional groups. These chemo-modifications able to impart the antimicrobial activities in bacterial cellulose and leads to the improved intrinsic features of bacterial cellulose membranes which proves to be very useful for diabetic ulcers, chronic wounds, and burns (Sulaeva et al., 2015). The diverse method of surface modification of bacterial cellulose are as follows (1) substituting the hydroxyl group of bacterial cellulose having some additional functional groups (2) by crosslinking the BC to another polymers (3) by making composite BC with metal/metal oxide nanoparticles (4) by making composite with carbon nanoparticles (Liu et al., 2020). The ion irradiation method has also showed the potential to form functionalized and surface modified bacterial cellulose. By incorporating a precursor of silver, bacterial cellulose-silver nanocomposite has been produced. This has been attained by only single step procedure, which involve surface modification and fabrication of silver nanocomposites of bacterial cellulose simultaneously, due to presence of energetic ions. These exclusive functionalization of BC surfaces combine various beneficial features bacterial cellulose (Jun et al., 2014, Arias et al., 2020), having the widely identified antimicrobial characteristics of nanoparticles of silver. Fig. 7 shows various properties of bacterial cellulose which make it suitable material for manufacture of mask.

Fig. 7.

Various properties of bacterial cellulose which make it suitable material for manufacture of mask.

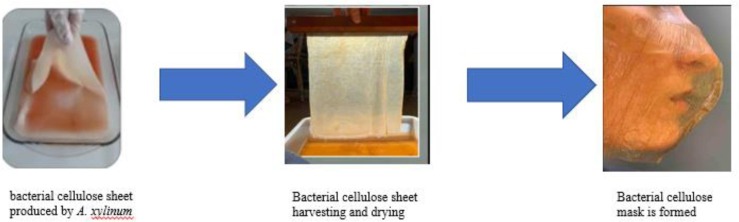

6. Home grown bacterial cellulose mask

In the race of providing suitable number of masks in this ongoing COVID-19 pandemic, manufacturers, designers, and individuals at home, united together to suggest various creative solutions such as 3D printed shields, and DIY face masks. In this context, Elizabeth Bridges and Garrett Benisch of Sum Studio, have planned to create an antimicrobial cellulose face mask. And for this they have looked to the nature, which has plenty of membranes, woven barriers and filters, that are ready to be used. They planned to make their own bacterial cellulose face mask in their home kitchen, just to prove that these materials are easily accessible to the common man. They worked in a manner that this sample could be reiterated to function same as the meltblown N95 fabric.

Bacterial cellulose is produced by certain bacteria, like Gluconacetobacter xylinum, on the liquid water interface in which they inhabit. These can be cultivated in a solution of water, sugar, tea and a small sample of inoculum and keep it in stationary conditions for some days. As the bacteria multiply, they produce cellulose in the form of pellicle on the surface of the culture media, which can be harvested and dried for further use. To add some softness and enhance strength of this thin leather like material, some natural oils can be applied. The whole process takes about two weeks; though it is a time-consuming process, but the creators advocate that it’s nothing if we compare it with the time taken by formation of fossil fuels and their environmental cost. With several lots staggered in time, they envision the manufacture of this material could be scaled up swiftly. In Fig. 8 , steps followed in manufacture of bacterial cellulose mask are shown.

Fig. 8.

A mask was made out of bacterial cellulose produced by Acetobacter xylinum grown in their home kitchen by bio-design studio (Bioeconomy News 10.06.2020).

Bacterial cellulose can be produced in in people’s homes, local municipalities, or even in the hospitals where masks are required in high number. As the bacterial cellulose pellicle takes the shape of the container they are grown in, products can be produced in precisely shaped moulds so that the sheets can be produced for typical requirement. The best part is that bacterial cellulose masks would degrade to produce compost easily like household vegetable waste.

7. Bacterial cellulose and its properties- an overview

Bacterial cellulose is a biopolymer extracellularly synthesized by several types of bacteria including Gluconacetobacter, Acetobacter, Pseudomonas, Azotobacter, Sarcina ventriculi and Salmonella (Shoda and Sugano (2005) . Out of these, the most significant cellulose producing bacteria are Gluconacetobacter hansenii, Gluconacetobacter xylinum, and Gluconacetobacter pasteurianus and therefore, for cellulose production these bacteria are used mostly (Schierbaum 2005). Cellulose biosynthesis begins with polymerization of glucose residues to form linear β-1,4-glucan chains within bacterial cell and then they secrete these formed chains extracellularly on its surface (Czaja et al., 2007). Finally, they gather and crystallize into the chains and then form ribbons. These steps results in the generation of an ultra-thin and coherent 3-D network of cellulose nanofibers, which are aligned parallelly on the surface of a liquid medium (see Fig. 1). This 3-D network is known as a cellulose pellicle and its geometry is defined by H-bonding (intra-molecular and intermolecular H-bonding), van der Waals interactions and hydrophobic interactions (Koizumi et al., 2008). Bacterial cellulose possesses crystallographic structure, characteristic of type Iα cellulose (Atalla and Vanderhart, 1984), having a high degree of crystallinity, which is around 90 % (Torres et al., 2019). The presence of OH groups on surface of bacterial cellulose, makes it a hydrophilic polymer (Gelin et al., 2007). The diameter of nanofibers of bacterial cellulose is about 20–100 nm and possesses greater surface area to volume ration than that of plant cellulose (Guo and Catchmark, 2012). Analysis of the mechanical properties of bacterial cellulose films reveals that, it has quite high tensile strength (on an average 241.42 ± 21.86 MPa), Young's modulus of 6.86 ± 0.32 GPa and a maximum elongation value of 8.21 ± 3.01 percent (Grande et al., 2008). Due to its amazing mechanical properties, high flexibility and functionality, BC have been emerging as a suitable biopolymer for several applications in the various fields in the past. Though, the current requirement for bacterial cellulose-based products with better features to satisfy the demand in various areas has become gradually apparent. Contemporary bio-composites of bacterial cellulose comprise the use of nanoparticles of specific properties. Subsequently bacterial cellulose exhibit a nanofibers arrangement, the synthesized product contain the interaction of two nano sized materials, which is called as nano-nano composites. Bacterial cellulose possesses high in vivo biocompatibility (Helenius et al., 2006), higher purity (Piatkowski et al., 2011), good flexibility, higher porosity and absence of lignin and hemicellulose (Pertile et al., 2010), which makes it suitable to be utilized in diverse fields. Moreover, bacterial cellulose owns special characteristics like higher hydrophilicity, water holding capacity, mechanical stability, and crystallinity (Zaborowska et al., 2010). BC can be moulded to any shape, size and thickness, on the bases of fermentation conditions and process followed. Therefore, it can be adequately changed for various applications.

8. Bacterial cellulose production

Komagataeibacter xylinus (former name Acetobacter xylinum) is a bacterium known to produce cellulose in highest amount. It is a member of the group of acetic acid bacteria (AAB) which are obligate aerobic and Gram-negative. For fermentation, optimum reaction conditions are the temperature between 25 and 30 °C, pH 3–7 and using sugars as a carbon source (Alemam et al., 2021).

Acetobacter xylinum converts several carbon compounds into cellulose (the end product of carbon metabolism), with nearly 50 % efficiency. The process of carbon metabolism comprises the pentose phosphate pathway (PPP), or the Krebs cycle coupled with gluconeogenesis. Bacterial cellulose production can be realised by employing different types of fermentations such as static, stirred or agitated fermentations, leading to production of diverse forms of cellulose. In static fermentation, BC is produced in the form of 3-D interconnected reticular pellicle and its yield depends on the carbon source concentration in the media. The fermentation is controlled by air supply from the surface of medium, because due to insufficient oxygen supply bacteria becoming inactive. For an industrial scale production of bacterial cellulose, static fermentation is recommended. Irregular shaped sphere-like cellulose particles (SCP), like spheres, fibrous suspension, pellets, or asymmetrical masses are produced in both stirred and agitated fermentation. Even though, the SPC has lesser mechanical strength, crystallinity, and degree of polymerization, maximum of cellulose employed in commercial applications is produced agitated type of fermentation (Sperotto et al., 2021). Due to the limited productivity of cellulose by identified bacterial strains and their expensive media requirements, cost of BC production is very high. And approximately 30 percent of the total production cost is due to the expensive synthetic media used for fermentation. Therefore, many researchers have attempted to find alternative culture media, which must be cost effective, in order to reduce the production cost of bacterial cellulose (Sperotto et al., 2021). In current years, numerous research projects have been carried out on the efficient production of BC. The best sources of carbon for BC production are Although, simple carbon sources such as glucose, glycerol and fructose are proved to be the best carbon source for the bacterial cellulose production but to decrease the cost of production, number of researchers advised to use the several waste materials such as spruce hydrolysate, fruit juices, rotten fruits, wine fermentation waste broth, wheat straw hydrolysate, and cotton-based textile wastes (Fatima et al., 2021).

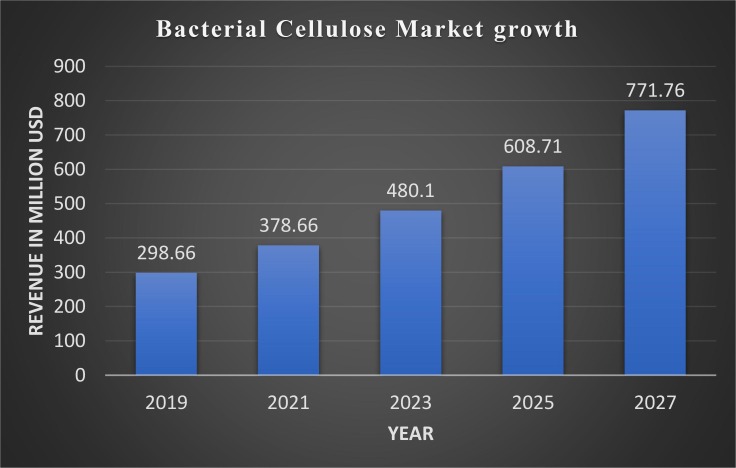

A study on global cellulose production market was conducted, according to the report provided the global Bacterial and Microbial Cellulose Production market in 2020 was valued at 506.8 million USD (US Dollar) and is projected to become 980.9 million USD by 2028, at a compound annual growth rate (CAGR) of 8.1 %. The increasing number of endless uses can be credited to the market's growth. The current progresses in microbial production and biosynthesis, for example, novel sources for culture medium and cellulose biochemistry, are powering the market. This report includes, overall analysis of progress and forecast of the Bacterial Cellulose Market on global and regional level. Another study encompasses historical data study from 2014 to 2017 and market forecast for 2019 to 2027, which is based on revenue generated. The study includes market value in terms of revenue in billion USD for years 2014–27 and compound annual growth rate (CAGR) in % for from 2019 to 2027. The market is expected to show constant growth between 2019–2027. Fig. 9 shows graph of expected growth of bacterial cellulose market from 2019 to 2027.

Fig. 9.

Expected growth of bacterial cellulose market from 2019 to 2027.

8.1. Challenges and future prospective

The mask use will turn out to be very obvious for a long time to come, as the current epidemic of COVID-19 is not yet over, and it will be very thoughtless and challenging to cut the use of mask indiscriminately. But at the same time, we should not forget that the rapid upsurge in the demand and consumption of these disposable and nonbiodegradable masks and other PPE, poses a devastating effect to the environment. This worldwide COVID-19 epidemic and the environmental pollution caused by rapid surge in mask disposal give a new opportunity to transform the social behavior to take interest and active participation in issues related to the environment. Further it leads to the reduction in “use and discard” behavior and correct poor waste management practices, also to increase awareness of other potentially bigger environmental problems. Some better efforts must be made by the government to encourage enterprises to utilize natural biodegradable materials in place of conventional non degradable materials to make PPE like masks. The government should provide some economic subsidies and preferential policies for the manufacture of biodegradable masks as the enterprises initially may face some issues regarding their higher production cost and indefinite safety of non-conventional materials used. The commercial non-biodegradable masks, which are currently in use possess higher filtration efficiency against harmful particles which includes bacteria and viruses, show adequate breathability and therefore, are comfortable to wear for longer duration. Therefore, it is more challenging to produce bacterial cellulose-based masks, which possess low pressure drop and high filtration efficiency, comparable to that possessed by conventional commercially available masks, and moreover, should have antibacterial properties to enhance safety to fight with viruses (Chawla et al., 2009). Though the bacterial cellulose possesses many properties such as nanofiber network structure, high-water holding capacity, high purity and mechanical strength, which make it suitable material to manufacture biodegradable masks. Still there is a problem to manufacture BC masks on commercial level due to its limits to produce on large scale. To tackle with this problem, development of cost-effective production system is required, which includes finding cheaper feed stock for media, discovering higher cellulose producing bacterial strains, and developing effortless downstream processes. In short, the use of bacterial cellulose offers numerous advantages for manufacture of medical masks and N95 masks, yet it raises several crucial technical challenges, which need to be resolved to meet the requirements for production of good quality and cheaper, biodegradable masks on large scale.

9. Conclusion

As warned by the WHO, COVID-19 might never get over rather it will turn out to be one of the pandemic viruses in our community (source: “Coronavirus may never go away, World Health Organization warns” on BBC News, 14 May 2020). Therefore, there is a rapid increase in use of disposable mask and other PPE. These stuffs together with face masks are inimitable in safeguarding against the current pandemic, as well as the apprehensions that these disposable masks as vector for infectious agent have resulted in delayed reprocessing plans and ‘use and through’ plastic guidelines implications. Moreover, the considerable upsurge in dumping of such nondegradable masks leads to a potential hazard to the environment. Therefore, the ecological research community required to quicken to recognize and alleviate the above-mentioned hazards. Serious reconsidering of the 3- ‘Rs’ could be appreciated: Regulate (assessment of life-cycle of manufacture, discard, and sanitization of masks), Reuse (reusable masks), and Replace (replace nonbiodegradable to degradable materials for mask). In the present context, integrative study is instantly required on the ecological hazards of one-use masks, standardization, strategies, and strict employment of waste disposal management for face mask wastes must be taken under keen consideration. The current review highlighted the number of different types of face masks usage, the total number of waste mask generated as well as the amount of polypropylene generated per week in various countries. A sustainable approach to mitigate these hazards imposed by accumulation of disposable nondegradable mask, is focused in this review article, that is by replacing the conventional nondegradable mask with bacterial cellulose mask. Similarly, a focus should be on replacement of conventional polypropylene based plastics with bioplastics or paper for vaccine packaging. The use of bio-plastics as a material for packaging along with biodegradable face masks can aid in achieving the zero-waste approach (Hasija et al., 2022). Bacterial cellulose possesses various properties which make it suitable material to replace the conventional mask material, such as high renewability, high biodegradability, low production cost, abundance, effortless processing, changeable aspect ratio, high mechanical strength, low density, nanomaterial nature, high porosity, high elasticity, easy production in different shapes, high water-holding capacity, excellent biocompatibility, as compared to other materials. Though the BC possesses many properties which make it suitable material to manufacture biodegradable masks, still there is a problem to manufacture BC masks on commercial level due to its limits to produce on large scale. To tackle with this problem, development of cost-effective production system is required. Despite of many obstacles, there is hope that we can rely on bacterial cellulose, to tackle with the problem raised by nondegradable mask accumulation (by replacing them), as it can be seen that Bacterial Cellulose Market shows constant growth. Lastly, it can be suggested that it is crucial to launch harmonized efforts from medical agencies, environmental scientists, and solid waste management authorities and the general community to curtail the negative effects of nondegradable disposal mask, and ultimately prevent it from becoming another huge problem to solve.

Funding

This research was funded by the University Grant Commission (UGC), New Delhi; Reg. no. 834/ (CSIR- UGC NET JRF JUNE 2019). One of the authors, Poonam Sharma had received financial support from University Grant Commission (UGC), New Delhi.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The author gratefully acknowledge the financial support from fellowship funded by University Grant Commission as well as Kurukshetra University Kurukshetra for providing all the necessary amenities for research work.

Data availability

No data was used for the research described in the article.

References

- Abbasi S.A., Khalil A.B., Arslan M. Extensive use of face masks during COVID-19 pandemic:(micro-) plastic pollution and potential health concerns in the Arabian Peninsula. Saudi J. Biol. Sci. 2020;27:3181–3186. doi: 10.1016/j.sjbs.2020.09.054. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alemam A.M., Shaheen T.I., Hassan S.E.D., Desouky S.E., El-Gamal M.S. Production enhancement of bacterial cellulose nanofiber using local Komagataeibacter xylinus SB3. 1 under static conditions. Egypt. J. Chem. 2021;64(4):2213–2221. doi: 10.21608/ejchem.2021.52972.3096. [DOI] [Google Scholar]

- American Chemical Society. The best material for homemade face masks may be a combination of two fabrics. ScienceDaily. 2020 Apr 24. Available from: www.sciencedaily. com/releases/2020/04/200424081648.htm.

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Arias S.L., Devorkin J., Spear J.C., Civantos A., Allain J.P. Bacterial Envelope Damage Inflicted by Bioinspired Nanostructures Grown in a Hydrogel. ACS Appl. Bio Mater. 2020;3(11):7974–7988. doi: 10.1021/acsabm.0c01076. [DOI] [PubMed] [Google Scholar]

- Asim M., Abdan K., Jawaid M., Nasir M., Dashtizadeh Z., Ishak M.R., Hoque M.E. A review on pineapple leaves fibre and its composites. Int. J. Polymer Sci. 2015;2015 doi: 10.1155/2015/950567. [DOI] [Google Scholar]

- Atalla R.H., Vanderhart D.L. Native cellulose: a composite of two distinct crystalline forms. Science. 1984;223(4633):283–285. doi: 10.1126/science.223.4633.283. [DOI] [PubMed] [Google Scholar]

- Bandi M.M. N95-electrocharged filtration principle based face mask design using common materials. Okinawa Institute of Science and Technology Graduate University. 2020 https://groups.oist.jp/nnp/diy-face-mask [Google Scholar]

- Bioeconomy News (10.06.2020) Face mask made of bacterial cellulose. https://biooekonomie.de/en/news/face-mask-made-bacterial-cellulose.

- Cacicedo M.L., Castro M.C., Servetas I., Bosnea L., Boura K., Tsafrakidou P., Dima A., Terpou A., Koutinas A., Castro G.R. Progress in bacterial cellulose matrices for biotechnological applications. Bioresour. Technol. 2016;213:172–180. doi: 10.1016/j.biortech.2016.02.071. [DOI] [PubMed] [Google Scholar]

- Campano C., Balea A., Blanco A., Negro C. Enhancement of the fermentation process and properties of bacterial cellulose: a review. Cellul. 2016;23(1):57–91. doi: 10.1007/s10570-015-0802-0. [DOI] [Google Scholar]

- Cano-Vicent A., Tuñón-Molina A., Martí M., Muramoto Y., Noda T., Takayama K., Serrano-Aroca Á. Antiviral face mask functionalized with solidified hand soap: Low-cost infection prevention clothing against enveloped viruses such as SARS-CoV-2. ACS Omega. 2021;6(36):23495–23503. doi: 10.1021/acsomega.1c03511. [DOI] [PMC free article] [PubMed] [Google Scholar]

- CFR Part 84 (1995). “Approval of respiratory protective devices,” Code of Federal Regulations, U.S. Government Printing Office, Office of the Federal Register, Washington, DC, USA.

- Chawla P.R., Bajaj I.B., Survase S.A., Singhal R.S. Microbial cellulose: fermentative production and applications. Food Technol. Biotechnol. 2009;47(2) [Google Scholar]

- Covid, C.D.C., Team, R., COVID, C., Team, R., Bialek, S., Boundy, E., Bowen, V., Chow, N., Cohn, A., Dowling, N., Ellington, S., 2020. Severe outcomes among patients with coronavirus disease 2019 (COVID-19)—United States, February 12–March 16, 2020. Morbidity and mortality weekly report. 69(12), 343. doi: 10.15585/mmwr.mm6912e2. [DOI] [PMC free article] [PubMed]

- Czaja W.K., Young D.J., Kawecki M., Brown R.M. The future prospects of microbial cellulose in biomedical applications. Biomacromolecules. 2007;8(1):1–12. doi: 10.1021/bm060620d. [DOI] [PubMed] [Google Scholar]

- Developing of Mask Material Using Nanocellulose to Fight against COVID-19. 2020 Apr 28. Available from: http:// sugar-asia.com/developing-of-mask-material-using-nanocellulose-.

- Esposito S., Principi N., Leung C.C., Migliori G.B. Universal use of face masks for success against COVID-19: evidence and implications for prevention policies. Eur. Respir. J. 2020;55(6) doi: 10.1183/13993003.01260-2020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fatima A., Yasir S., Khan M.S., Manan S., Ullah M.W., Ul-Islam M. Plant extract-loaded bacterial cellulose composite membrane for potential biomedical applications. J. Bioresour. Bioproducts. 2021;6(1):26–32. doi: 10.1016/j.jobab.2020.11.002. [DOI] [Google Scholar]

- Gama, F., Dourado, F., Bielecki, S. eds., 2016. Bacterial nanocellulose: from biotechnology to bio-economy. Elsevier. 260. Book Google Scholar.

- Gelin K., Bodin A., Gatenholm P., Mihranyan A., Edwards K., Strømme M. Characterization of water in bacterial cellulose using dielectric spectroscopy and electron microscopy. Polymer. 2007;48(26):7623–7631. doi: 10.1016/j.polymer.2007.10.039. [DOI] [Google Scholar]

- Gope D., Gope A., Gope P.C. Mask material: challenges and virucidal properties as an effective solution against coronavirus SARS-CoV-2. Open Health. 2020;1(1):37–50. doi: 10.1515/openhe-2020-0004. [DOI] [Google Scholar]

- Grande C.J., Torres F.G., Gomez C.M., Troncoso O.P., Canet-Ferrer J., Martinez-Pastor J. Morphological characterisation of bacterial cellulose-starch nanocomposites. Polym. Polym. Compos. 2008;16(3):181–185. 10.11772F096739110801600302. [Google Scholar]

- Guo J., Catchmark J.M. Surface area and porosity of acid hydrolyzed cellulose nanowhiskers and cellulose produced by Gluconacetobacter xylinus. Carbohydr. Polym. 2012;87(2):1026–1037. doi: 10.1016/j.carbpol.2011.07.060. [DOI] [Google Scholar]

- Gustafsson O., Manukyan L., Mihranyan A. High-performance virus removal filter paper for drinking water purification. Global Chall. 2018;2(7):1800031. doi: 10.1002/gch2.201800031. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hasija V., Patial S., Kumar A., Singh P., Ahamad T., Khan A.A.P., Hussain C.M. Environmental impact of COVID-19 Vaccine waste: A perspective on potential role of natural and biodegradable materials. J. Environ. Chem. Eng. 2022;107894 doi: 10.1016/j.jece.2022.107894. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Helenius G., Bäckdahl H., Bodin A., Nannmark U., Gatenholm P., Risberg B. In vivo biocompatibility of bacterial cellulose. J. Biomed. Mater. Res. Part A. 2006;76(2):431–438. doi: 10.1002/jbm.a.30570. [DOI] [PubMed] [Google Scholar]

- Hussain Z., Sajjad W., Khan T., Wahid F. Production of bacterial cellulose from industrial wastes: a review. Cellul. 2019;26(5):2895–2911. [Google Scholar]

- Hutten I.M. Elsevier; 2007. Handbook of Nonwoven Filter Media. [Google Scholar]

- Ippolito M., Gregoretti C., Cortegiani A., Iozzo P. Counterfeit filtering facepiece respirators are posing an additional risk to health care workers during COVID-19 pandemic. Am. J. Infect. Control. 2020;48(7):853. doi: 10.1016/j.ajic.2020.04.020. doi: 10.1016%2Fj.ajic.2020.04.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jawaid M.H.P.S., Khalil H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohydr. Polym. 2011;86(1):1–18. doi: 10.1016/j.carbpol.2011.04.043. [DOI] [Google Scholar]

- Jun Y., Tripathy S.K., Narayanareddy B.R., Mattson-Hoss M.K., Gross S.P. Calibration of optical tweezers for in vivo force measurements: how do different approaches compare? Biophys. J. 2014;107(6):1474–1484. doi: 10.1016/j.bpj.2014.07.033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Klemeš J.J., Van Fan Y., Tan R.R., Jiang P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sustain. Energy Rev. 2020;127 doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Koizumi S., Yue Z., Tomita Y., Kondo T., Iwase H., Yamaguchi D., Hashimoto T. Bacterium organizes hierarchical amorphous structure in microbial cellulose. Eur. Phys. J. E. 2008;26(1):137–142. doi: 10.1140/epje/i2007-10259-3. [DOI] [PubMed] [Google Scholar]

- Konda A., Prakash A., Moss G.A., Schmoldt M., Grant G.D., Guha S. Aerosol filtration efficiency of common fabrics used in respiratory cloth masks. ACS Nano. 2020;14(5):6339–6347. doi: 10.1021/acsnano.0c03252. [DOI] [PubMed] [Google Scholar]

- Liebsch, T., 2020. The rise of the face mask: What’s the environmental impact of 17 million N95 masks. Ecochain www. ecochain. com.

- Liu W., Du H., Zhang M., Liu K., Liu H., Xie H., Zhang X., Si C. Bacterial cellulose-based composite scaffolds for biomedical applications: a review. ACS Sustain. Chem. Eng. 2020;8(20):7536–7562. doi: 10.1021/acssuschemeng.0c00125. [DOI] [Google Scholar]

- Martí M., Tuñón-Molina A., Aachmann F.L., Muramoto Y., Noda T., Takayama K., Serrano-Aroca Á. Protective face mask filter capable of inactivating SARS-CoV-2, and methicillin-resistant Staphylococcus aureus and Staphylococcus epidermidis. Polymers (Basel) 2021;13:207. doi: 10.3390/polym13020207. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Morganti P., Morganti G. Post-COVID-19: an opportunity to produce biodegradable goods & surgical masks to save the environment. J. Health Care Res. 2020;1(3):157. doi: 10.36502/2020/hcr.6174. [DOI] [Google Scholar]

- Ortega R., Gonzalez M., Nozari A., Canelli R. Personal protective equipment and Covid-19. N. Engl. J. Med. 2020:e105. doi: 10.1056/NEJMvcm2014809. [DOI] [PubMed] [Google Scholar]

- Osman, E., 2020. Nanofinished medical textiles and their potential impact to health and environment. In Nanoparticles and their biomedical applications (pp. 127-145). Springer, Singapore. doi: 10.1007/978-981-15- 0391-7_5.

- Pertile R.A., Andrade F.K., Alves C., Jr, Gama M. Surface modification of bacterial cellulose by nitrogen-containing plasma for improved interaction with cells. Carbohydr. Polym. 2010;82(3):692–698. doi: 10.1016/j.carbpol.2010.05.037. [DOI] [Google Scholar]

- Piatkowski A., Drummer N., Andriessen A., Ulrich D., Pallua N. Randomized controlled single center study comparing a polyhexanide containing bio-cellulose dressing with silver sulfadiazine cream in partial-thickness dermal burns. Burns. 2011;37(5):800–804. doi: 10.1016/j.burns.2011.01.027. [DOI] [PubMed] [Google Scholar]

- Prata J.C., Silva A.L., Walker T.R., Duarte A.C., Rocha-Santos T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Tech. 2020;54(13):7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- Provin A.P., dos Reis V.O., Hilesheim S.E., Bianchet R.T., de Aguiar Dutra A.R., Cubas A.L.V. Use of bacterial cellulose in the textile industry and the wettability challenge—a review. Cellul. 2021;28(13):8255–8274. [Google Scholar]

- Qin Y., editor. Medical Textile Materials. Woodhead Publishing; 2015. [Google Scholar]

- Ray D. Different types of fabrics used in making face mask. 2020 Jun 03. Available from: https://www. onlineclothingstudy.com/2020/06/types-of-fabrics-used-inmaking- face.html.

- Ristić T., Zemljič L.F., Novak M., Kunčič M.K., Sonjak S., Cimerman N.G., Strnad S. Antimicrobial efficiency of functionalized cellulose fibres as potential medical textiles. Science against microbial pathogens: communicating current research and technological advances. 2011;6:36–51. [Google Scholar]

- Rubio-Romero J.C., del Carmen Pardo-Ferreira M., Torrecilla-García J.A., Calero-Castro S. Disposable masks: Disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Saf. Sci. 2020;129 doi: 10.1016/j.ssci.2020.104830. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schierbaum, F., 2005. Book Review: Polysaccharides and polyamides in the food industry. Properties, production, and patents. by A. Steinbüchel and SK Rhee (Editors).

- Seddiqi H., Oliaei E., Honarkar H., Jin J., Geonzon L.C., Bacabac R.G., Klein-Nulend J. Cellulose and its derivatives: Towards biomedical applications. Cellul. 2021;28(4):1893–1931. https://doi.org/10.1007/s10570-020-03674-w(0123456789.,-volV 0123456789.,-volV) [Google Scholar]

- Selvaranjan K., Navaratnam S., Rajeev P., Ravintherakumaran N. Environmental challenges induced by extensive use of face masks during COVID-19: a review and potential solutions. Environ. Challenges. 2021;3 doi: 10.1016/j.envc.2021.100039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shimasaki N., Okaue A., Morimoto M., Uchida Y., Koshiba T., Tsunoda K., Arakawa S., Shinohara K. A multifaceted evaluation on the penetration resistance of protective clothing fabrics against viral liquid drops without pressure. Biocontrol Sci. 2020;25(1):9–16. doi: 10.4265/bio.25.9. [DOI] [PubMed] [Google Scholar]

- Shoda M., Sugano Y. Recent advances in bacterial cellulose production. Biotechnol. Bioprocess Eng. 2005;10(1):1–8. doi: 10.1007/BF02931175. [DOI] [Google Scholar]

- Silva A.L.P., Prata J.C., Walker T.R., Campos D., Duarte A.C., Soares A.M., Barcelò D., Rocha-Santos T. Rethinking and optimising plastic waste management under COVID-19 pandemic: policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Sci. Total Environ. 2020;742 doi: 10.1016/j.scitotenv.2020.140565. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soni V., Raizada P., Singh P., Cuong H.N., Rangabhashiyam S., Saini A., Nguyen V.H. Sustainable and green trends in using plant extracts for the synthesis of biogenic metal nanoparticles toward environmental and pharmaceutical advances: a review. Environ. Res. 2021;202 doi: 10.1016/j.envres.2021.111622. [DOI] [PubMed] [Google Scholar]

- Soni V., Khosla A., Singh P., Nguyen V.H., Van Le Q., Selvasembian R., Raizada P. Current perspective in metal oxide based photocatalysts for virus disinfection: a review. J. Environ. Manage. 2022;308 doi: 10.1016/j.jenvman.2022.114617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soni V., Paital S., Raizada P., Ahamad T., Khan A.A.P., Thakur S., Nadda A.K. Surveillance of omicron variants through wastewater epidemiology: latest developments in environmental monitoring of pandemic. Sci. Total Environ. 2022;156724 doi: 10.1016/j.scitotenv.2022.156724. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sperotto G., Stasiak L.G., Godoi J.P.M.G., Gabiatti N.C., De Souza S.S. A review of culture media for bacterial cellulose production: complex, chemically defined and minimal media modulations. Cellul. 2021;28(5):2649–2673. doi: 10.1007/s10570-021-03754-5. [DOI] [Google Scholar]

- Sulaeva I., Henniges U., Rosenau T., Potthast A. Bacterial cellulose as a material for wound treatment: Properties and modifications. A review. Biotechnol. Adv. 2015;33(8):1547–1571. doi: 10.1016/j.biotechadv.2015.07.009. [DOI] [PubMed] [Google Scholar]

- Sun C.X., Bin H.E., Di M.U., Li P.L., Zhao H.T., Li Z.L., Zhang M.L., Feng L.Z., Zheng J.D., Cheng Y., Ying C.U.I. Public awareness and mask usage during the COVID-19 epidemic: a survey by China CDC new media. Biomed. Environ. Sci. 2020;33(8):639–645. doi: 10.3967/bes2020.085. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tavakolian M., Jafari S.M., van de Ven T.G. A review on surface-functionalized cellulosic nanostructures as biocompatible antibacterial materials. Nano-Micro Letters. 2020;12(1):1–23. doi: 10.1007/s40820-020-0408-4to-fight-against-covid-19/. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Four types of common masks and how and if they help. Times of India. 2020 Apr 01. Available from: https://timesofindia. indiatimes.com/life-style/health-fitness/health-news/4-.

- Torres F.G., Arroyo J.J., Troncoso O.P. Bacterial cellulose nanocomposites: an all-nano type of material. Mater. Sci. Eng. C. 2019;98:1277–1293. doi: 10.1016/j.msec.2019.01.064. [DOI] [PubMed] [Google Scholar]

- Tuñón-Molina A., Takayama K., Redwan E.M., Uversky V.N., Andrés J., Serrano-Aroca Á. Protective face masks: current status and future trends. ACS Appl. Mater. Interfaces. 2021;13(48):56725–56751. doi: 10.1021/acsami.1c12227. types-of-common-masks-and-how-and-if-they-help/ photostory/74926268.cms. [DOI] [PubMed] [Google Scholar]

- Urbina L., Corcuera M.Á., Gabilondo N., Eceiza A., Retegi A. A review of bacterial cellulose: sustainable production from agricultural waste and applications in various fields. Cellul. 2021;28(13):8229–8253. [Google Scholar]

- Velásquez-Riaño M., Bojacá V. Production of bacterial cellulose from alternative low-cost substrates. Cellul. 2017;24(7):2677–2698. [Google Scholar]

- Volova T.G., Shumilova A.A., Shidlovskiy I.P., Nikolaeva E.D., Sukovatiy A.G., Vasiliev A.D., Shishatskaya E.I. Antibacterial properties of films of cellulose composites with silver nanoparticles and antibiotics. Polym. Test. 2018;65:54–68. [Google Scholar]

- World Health Organization. (2020). Modes of transmission of virus causing COVID-19: implications for IPC precaution recommendations: scientific brief, 29 March 2020 (No. WHO/2019-nCoV/Sci_Brief/Transmission_modes/2020.2). World Health Organization. https://apps.who.int/iris/h andle/10665/331616.

- Worldometers.info, (2021). Worldometer. From:. Dover, Delaware, U.S.A https://www.worldometers.info/world-population/. (Accessed 13 February 2021).

- Xiang Y., Song Q., Gu W. Decontamination of surgical face masks and N95 respirators by dry heat pasteurization for one hour at 70 C. Am. J. Infect. Control. 2020;48(8):880–882. doi: 10.1016/j.ajic.2020.05.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xie M., Chen Q. Insight into 2019 novel coronavirus—An updated interim review and lessons from SARS-CoV and MERS-CoV. Int. J. Infect. Dis. 2020;94:119–124. doi: 10.1016/j.ijid.2020.03.071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yim W., Cheng D., Patel S.H., Kou R., Meng Y.S., Jokerst J.V. KN95 and N95 respirators retain filtration efficiency despite a loss of dipole charge during decontamination. ACS Appl. Mater. Interfaces. 2020;12(49):54473–54480. doi: 10.1021/acsami.0c17333. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zaborowska M., Bodin A., Bäckdahl H., Popp J., Goldstein A., Gatenholm P. Microporous bacterial cellulose as a potential scaffold for bone regeneration. Acta Biomater. 2010;6(7):2540–2547. doi: 10.1016/j.actbio.2010.01.004. [DOI] [PubMed] [Google Scholar]

- Zanoaga M., Tanasa F. Antimicrobial reagents as functional finishing for textiles intended for biomedical applications. I. Synthetic organic compounds. Chem. J. Moldova. 2014;9(1):14–32. doi: 10.19261/CJM.2014.09(1).02. [DOI] [Google Scholar]

- Zhou Z., Ren L., Zhang L., Zhong J., Xiao Y., Jia Z., Guo L., Yang J., Wang C., Jiang S., Yang D. Heightened innate immune responses in the respiratory tract of COVID-19 patients. Cell Host Microbe. 2020;27(6):883–890. doi: 10.1016/j.chom.2020.04.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.