Highlights

-

•

Circular economy (CE) can assist in the implementation of sustainable development in food industry.

-

•

Increasing population and regulatory criteria are pressuring the food industry to modify their working methods.

-

•

These techniques can help with the implementing CE and meeting the UN approved SDGs.

-

•

Collaboration between food producers and the food chain may make the food industry more circular.

Keywords: Circular economy, Non-thermal processing, Waste reduction, Sustainable Development Goals, Life cycle analysis, Food safety, Food recovery, Natural resources efficiency

Abstract

A circular economy promotes a world-friendly style of economic development, and the main aim is a closed-loop cycle of “resource-production-consumption-regeneration” economic activities. A circular economy can assist in implementing sustainable development in the food industry. During conventional food processing, the thermal effects degrade the food residues and make their wastes. Nonthermal processing has emerged as a promising, safe, and effective technique for extracting bioactive compounds from food residues. Nonthermal processing help in implementing a circular economy and meeting the United Nations approved Sustainable Development Goals (SDGs). Collaboration between food producers and the food chain may make the food industry more circular. This article motivates adopting nonthermal technologies to conserve natural resources, food safety, and energy in different food processing phases to meet SDGs.

Introduction

The effect of an ever-increasing population and regulatory criteria is pressuring the food industry to modify their processing procedures (Hartley et al., 2020, King et al., 2017). In the 20th century, food requirements created significant environmental issues that harmed people's well-being and potentially restricted development (Arshad, Abdul-Malek, Roobab, et al., 2021). People should understand that the current generation must conserve environmental and natural resources as much as possible for the good of future generations by utilising scarce natural resources to sustain society (Bengtsson et al., 2018, Sanchez-Zarco et al., 2020). Therefore, the conservation of water, energy, and natural resources should be an integral aspect of global ethics. Over the last few decades, nations have become worried about environmental concerns. However, for a long time, end-of-pipe treatment has been the primary method for mitigating emissions (Yizhong, Ye, Qunwei, Dequn, & Bin, 2021). However, experiments across the globe have shown that it is not a cost-effective solution due to increased energy and the vast volume of capital and operational costs required by end-of-pipe care (Yizhong et al., 2021). The food industry has been developing an ability to create large amounts of new consumer goods based on waste food (Arshad, Abdul-Malek, Roobab, et al., 2021).

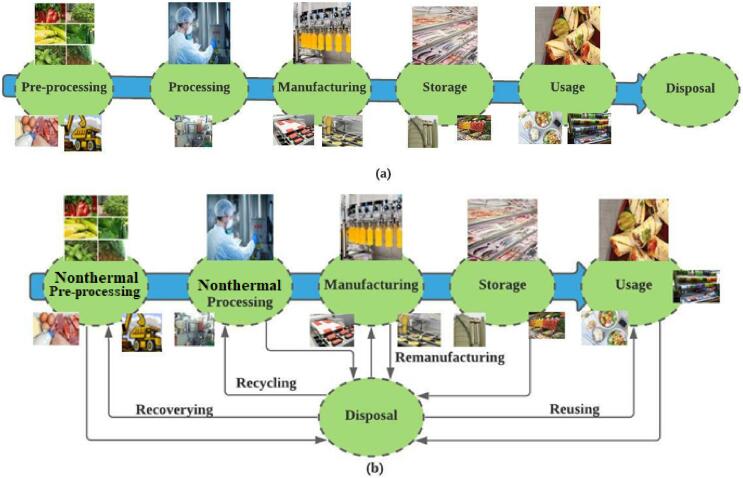

The conventional industrial economy is a linear (one-way) economy of “resource-production-consumption-disposal” in an open-loop process (Fig. 1a). This linear economy consumes materials and energy widely from the earth and dumps them into the air, water and soil as pollution and trash. This economic activity is characterised by high exploitation, poor utilisation and severe pollution. On the other hand, a circular economy (CE) promotes an earth-friendly economic development model. Its main aim is to organise an economic activity in a closed-loop process with the regeneration processes, such as resource production-consumption-regeneration (Fig. 1b) (Ogunmakinde, Sher, & Egbelakin, 2021). CE design loops eliminate waste and emissions by holding goods and materials for as long as possible and exploring opportunities to generate fresh energy from what is discarded (Geissdoerfer, Savaget, Bocken, & Hultink, 2017). As a result, all resources and energy must be utilised wisely and constantly in prolonged economic cycles, reducing the impact on the natural environment (Suárez-Eiroa, Fernández, Méndez-Martínez, & Soto-Oñate, 2019).

Fig. 1.

Different phases of the food industry; (a) linear food economy, (b) circular food economy.

The fundamental techniques to adopt CE have been addressed as eco-design, cleaner production (CP) and waste management (Gupta et al., 2021, Mendoza et al., 2019). CP is a method for tackling emissions and resource utilisation at all manufacturing phases (C. Almeida et al., 2013, Van Fan et al., 2020). CP practices form CE implementation at the industry level by linking the building blocks for facilitating the acceptance of the CE paradigm, namely the procedures, involved activities, and criteria to be calculated (Aranda-Usón et al., 2020, Shayganmehr et al., 2021). Organic materials, such as food by-products, are free of toxins in a circular economy and return to the land (Nie et al., 2019). Before this occurs, any by-products may be used to make different agricultural products, garments for the apparel industry, or bioenergy sources.

The current thermal treatment in the food industry is optimised to prevent adverse impacts on food properties and recover energy as much as possible. However, conventional food processing is inefficient based on energy use and waste management (Arshad, Abdul‐Malek, et al., 2021; N. Misra, 2015, Moreira et al., 2019, Zia et al., 2020). These conventional techniques have different adverse effects, such as the use of polluting solvents (Cunha & Fernandes, 2018), the decomposition of food (F.-L. Huang, Chiou, Chen, Ko, Lai, & Lin, 2016), and the loss of fruit juice volatile chemicals (Mastello et al., 2015, Saeed and Jafari, 2020). Solvents' adverse thermal effects and toxicity in extracting promote greener methods and materials in extracting bioactive substances and by-products from food waste (FW) (Gullón, Gullón, Romaní, Rocchetti, & Lorenzo, 2020). Consumers are ready to spend extra on natural goods devoid of synthetic chemicals or harsh processing with fewer components (Roobab, Inam-Ur-Raheem, Khan, Arshad, Zeng, & Aadil, 2021). These restrictions allow the food business to stay at the forefront of knowledge and strive to become a platform for scientists, researchers, industry and other food processing specialists.

Non-thermal is a general term that refers to techniques for food processing without direct heat (Arshad et al., 2020). These novel technologies, such as pulsed electric fields (PEF), high-pressure processing (HPP), ultrasound (US), pulsed light (PL), and cold plasma (CP), are widely regarded as novel food processing (Mena-García et al., 2019, Nabi et al., 2021, Roobab et al., 2018, Soquetta et al., 2018). Furthermore, these novel non-thermal technologies may be combined to replace traditional food processing to validate the FW's sensory quality, food nutrient, and organic component stability (Mena-García et al., 2019, Režek Jambrak et al., 2019, Soquetta et al., 2018). Therefore, NTP in the food industry has a bright future in implementing CE.

The United Nations approved the Sustainable Development Goals (SDGs) in 2015 as a worldwide call to action to eradicate poverty, protect the environment, and guarantee that by 2030, every-one will live in peace and prosperity. Nonthermal technologies target and align with SDGs to transform our world (Boluk, Cavaliere, & Higgins-Desbiolles, 2019). Here are some steps that NTP can help with implementing CE and meeting the SDGs, which are the main focus of this manuscript:

GOAL 1: No poverty-- it is important in every situation.

GOAL 2: Zero Hunger – by the circular economy, assure to go toward zero-waste production. In addition, nonthermal processing assures by-products and adds value to future products.

GOAL 3: Good Health and Well-being – We ensure healthy life systems and produce safe and quality food.

GOAL 4: Quality Education – this article will bring new knowledge.

GOAL 5: Gender Equality – it is important in every situation.

GOAL 6: Clean Water and Sanitation – we can process wastewater in the food industry using nonthermal technologies (PEF, ultrasound, plasma, high-pressure processing, hydrodynamic cavitation, Pulsed light, UV-C treatments etc.).

GOAL 7: Affordable and Clean Energy- circular economy concept is helping to ensure affordable and clean energy.

GOAL 9: Industry, Innovation and Infrastructure – jointly application of nonthermal processing, circular economy, lower carbon, waste and water footprints; we are improving and innovating in nonthermal processing and raising its' technology readiness level.

GOAL 12: Responsible Consumption and Production – responsible consumption, as previously mentioned.

GOAL 13: Climate Action – lower environmental footprints.

GOAL 14: Life Below Water – low wastewater and no deterioration of waters.

GOAL 15: Life on Land – by all means.

GOAL 17: Partnerships to achieve the Goal- in this interdisciplinary area, economy, engineering, and the social area will bring novelty and improve specific fields.

Sustainability assessment of nonthermal technologies

The measurement of circularity is the first step toward a circular system, as quoted by Peter Ducker: “what gets measured gets managed” (Haupt & Hellweg, 2019). However, there is no unique approach for measuring a circular economy in the food industry. The food industry's current circularity indicators (material circularity indicator: food loss and waste indicator; and material flow indicator) are insufficient as they generally emphasize material flows and end-of-life management. Therefore, there must be an effort to establish food circularity metrics and build a standardized Life Cycle Assessment (LCA) or Life Cycle Costing (LCC) based on the complexity of food-material flows to evaluate novel goods, technologies and business models. These essential steps are required for tracking the food industry's transition to a CE model while improving and guaranteeing sustainability.

From a social perspective, sustainability assessment refers to monetary and non-monetary effects. For example, environmental advantages such as reducing greenhouse gas emissions, easing the effects of eutrophication, or diverting waste from landfills might result in societal benefits. On the other hand, the economic viability of a technology depends on its development cost, cost of natural/energy resources, market demand and value of extracted products (Arshad, Abdul-Malek, Roobab, et al., 2021). Furthermore, any nonthermal technology may be economically viable for one or limited foods but not necessarily for others Režek Jambrak et al. (2018). In the next part, however, we utilise little literature in our quest for a sustainable-term answer.

These technologies are often evaluated on a small scale (either in a lab or a pilot plant) without thoroughly examining the whole process (Hospido, Davis, Berlin, & Sonesson, 2010). The challenges in assessing the effectiveness of these technologies are due to (i) lab-scale information or theoretical data used at the inventory phase; (ii) the functional unit for comparative studies must be defined, as new products or processes may have novel properties; and (iii) production or processes may not begin for several years, requiring assumptions about the surrounding systems. Once technologies are developed from laboratories to real production facilities, then these technologies may be compared with established commercial options (Bevilacqua et al., 2018, Ekezie et al., 2018, Režek Jambrak et al., 2021, Roobab et al., 2022, Rosario et al., 2021).

There have been various LCA studies comparing conventional and nonthermal technologies. Pardo and Zufía (2012) assessed the effects of several conventional and nonthermal technologies to create more sustainable food products. Some basic improvements were found, and environmental criteria were offered to pick the most appropriate food preservation technique. (Valsasina, Pizzol, Smetana, Georget, Mathys, & Heinz, 2017) contrasted ultrahigh-pressure with thermal milk treatment and revealed an increased efficiency and 88 % carbon footprint reduction. (Aganovic et al., 2017) evaluated the energy balance and LCA of pulsed electric fields and high-pressure processing technologies compared with standard thermal processing used to preserve tomato and watermelon juices. At a pilot scale, PEF and HPP technologies had greater energy consumption per litre of juice, recommending further optimization. Cacace, Bottani, Rizzi, and Vignali (2020) compared HPP's environmental/economic performance with thermal and modified atmosphere packaging (MAP) utilising LCC and LCA. In terms of cost, HPP looks to be more costly than thermal but less expensive than MAP. On the other hand, HPP was shown to have the least detrimental effect on the environment. Nutrizio, Režek Jambrak, Rezić, and Djekic (2022) compared the LCA of high voltage electrical discharge (HVED) to standard extraction procedures such as infusion and maceration. Depending on voltage and treatment duration, HVED extraction with nitrogen yielded 2.19–34.04 % more phenolic compounds than infusion and 6.13–90.95 % more than maceration. Based on LCA results, HVED was found to be the most sustainable solution for the food industry.

Nonthermal technologies enable sustainable food production by lowering processing costs, energy consumption, waste and improving resource utilization. In addition, compared to traditional thermal treatments, these technologies often allow for higher preservation of foods' functional ingredients and antioxidant qualities. A sustainable biorefinery process on food wastes and by-products requires maximizing product production, reducing energy usage, and considering economic and environmental factors. By considering these social benefits in economic evaluations and decision-making, non-thermal technologies are seen as better than traditional alternatives.

Non-thermal processing (NTP) in the circular economy

Many research articles have been found about the advantages of non-thermal technologies in the food industries (Bevilacqua et al., 2018, Ekezie et al., 2018, Režek Jambrak et al., 2021, Roobab et al., 2022, Rosario et al., 2021). Table 1 shows that NTP can be used in the food industry for a variety of purposes, including (a) preservation/decontamination and shelf life extension, (b) food modification (gelatinisation), (c) stress induction (increased biosynthetic activities), and (d) mass transfer modification (extraction) (Arshad, Abdul-Malek, Munir, et al., 2021; Režek Jambrak et al., 2019). Table 1 shows the most effective application of NTP in food processing and manufacturing. However, not all nonthermal technologies are appropriate for all types of foods but optimised for a particular food. For example, HPP, oscillating magnetic fields, light pulses, and hurdle technologies are used to process liquid and solid foods. At the same time, PEF is more suited to liquid foods, and irradiation is better suited to solid foods. Therefore, HPP, laser pulses, irradiation, and magnetic fields are utilised to prepare packed foods, minimising the danger of cross-contamination or post-process contamination.

Table 1.

Effective non-thermal technologies in the food industry.

| Non-thermal Technology | Equipment | Treatment parameters | Major food application | Advantages | Limitations | Reference |

|---|---|---|---|---|---|---|

| HPP | High-pressure vessel, pressure generation system, temperature monitoring and control unit, material handling unit | Processing time, temperature, pressure level, vessel size | Meat and fish industry | It can be applied to solid and liquid food samples irrespective of shape, extended shelf life, controlled textural changes, minimal texture loss in high moisture foods, possible in-packaging processing, no evidence of toxicity, reduced processing times, Independent of food shape or size. Uniformity of treatment throughout the food. | Little effect on food enzyme activity, changes in quality, some microbes may survive | (H.-W. Huang et al., 2017, Roobab et al., 2021). |

| PEF | Treatment chamber, PEF generation system, temperature monitoring and control unit, material handling unit | Electric field strength, treatment chamber geometry, pulse width, treatment time, sample food acidity, conductivity | Liquid food pasteurization, recovery of metabolites | High-voltage pulses are applied for a short period, so minimal heat generation and requires a smaller amount of energy, minimal impact on nutrients, flavour or pigment compounds, enhancing extraction and bioactive compounds, short processing time, less processing cost, No evidence of toxicity. | It cannot be applied to food samples with high conductivity or air bubbles, does not affect enzymes and spores, electrolysis may adversely affect foods | (Arshad et al., 2020) |

| US | Ultrasound generator, piezoelectric transducer, thermo-sonication or pressurized vessels | Ultrasound intensity, treatment time, sample food volume, sample composition | Meat processing, fruits and vegetables mass transfer processes | Improve treatment time, minimal alteration in the existing processing, energy-efficient, combined with other processes, batch and continuous. | Ultrasound has a negligible effect on smaller molecules and is responsible for the change in colour or flavour. | (Cui & Zhu, 2020) |

| Ionizing radiation | Radiation source mainly includes gamma rays, X-rays and electron beams | Exposure rate, water activity, sample food composition and particle size, in combination with other technologies | Flour and cereals, the meat industry | Effective for several foods (gamma rays, electron beam), Excellent penetration into foods. Possible in-packaging processing. Suitable for large-scale processing. | Limited public acceptance of Lipid oxidation of meat products | (Fei et al., 2020) |

| CP | Application of an electric or electromagnetic field to a gas; various types of apparatus are used | Applying electromagnetic waves on air or gas at lower pressure | Inactivates surface microflora and spores on packaging materials/food surfaces | Effective with temperature-sensitive products, reduce cross-contamination and prevent biofilms on equipment, minimal effects on food quality and appearance of the product. | No commercial instrument is available for disinfection of food products and packaging materials; the interaction of electronically excited molecules with the food or packaging materials needs to be identified. | (Ekezie, Sun, & Cheng, 2017) |

| UV Light/Pulsed light | Generation of pulsed light, photodiode detectors | Power wavelength, samples' transmissivity, reactors' configuration, flow profile | In the dairy industry, the shelf-life extension of ready-to-eat cooked meat products, surface decontamination of eggs and chicken | No chemicals are used, non-heat related method, lesser changes in quality attributes of food, medium cost, short processing time, minimal collateral effects on foods, suitable for high and low moisture food. | Long-term exposure can harm industrial workers, and the material should be transparent to allow the light to pass into the food. | (Pedrós-Garrido et al., 2018) |

Non-thermal technologies utilised commercially should be distinguished from those not used commercially for different reasons. Implementing a circular economy in the food industry requires commercially accessible technology. Table 1 shows that NTP operates in various ways, depending on the energy transmission source. They are employed in the production of radicals (ozonation, UV light), mechanical effects (US and plasma), electric and magnetic fields (PEF, CP, and oscillating magnetic fields), and HHP that cause micro-organisms to rupture and explode. In addition, the effects on food's physicochemical, microstructural, and sensory properties are discussed. Recent reviews have been published on many aspects of NTP, including the techniques, processes, potential applications, and efficacy in food processing (Arshad et al., 2020, Hernández-Hernández et al., 2019, Rosario et al., 2021, Varalakshmi, 2021, Zhao et al., 2019). The following subsections highlight the vital roles of circular economy through NTP in the food industry.

Effects of processing on food compounds

The modification of production technologies in the food industry is required to adopt a circular economy approach. Food processing often begins at the macroscopic level and advances to the macromolecular level, followed by the extraction of certain micro-molecules before their purification and encapsulation (E. Xu, Campanella, Ye, Jin, Liu, & BeMiller, 2020). Among the different approaches that have been documented in the literature, five basic processing stages may be identified in general; however, processes may be removed or added to one another in certain cases.

Non-thermal treatment is a potential green option for many applications such as diffusion extraction, pressurisation, drying and freezing (Bassey, Cheng, & Sun, 2021). Osae et al. (2020) have recently evaluated using several non-thermal pretreatments, including PEF, osmotic dehydration, US, and HPP, and minimising the detrimental impacts on dried food quality. Table 2 shows the practical applications of NTP in the processing phase.

Table 2.

NTP pretreatment in the food industry.

| NTP | Treatment condition | Food product | Food application | Advantages | Reference |

|---|---|---|---|---|---|

| US | Unique DES500, São Paulo, Brazil | Red cashew apples | Drying | Improve drying rates of cashew apple bagasse, decrease the rehydration rates of dried product, and enhance the nutritional quality. | (Fonteles et al., 2016) |

| PEF | Modulator PG, ScandiNova, Uppsala, Sweden | Blueberries | Pressing | Enhance antioxidant property and yield of blueberries, recover bioactive compounds from blueberries. | (Bobinaitė, Pataro, Lamanauskas, Šatkauskas, Viškelis, & Ferrari, 2014) |

| Microwave | AMT, Edinburgh, UK | Tomato juice | Heating/Pasteurization | Physiochemically and microbiologically stable products possess high antioxidant properties and lower processing time. | (Stratakos, Delgado-Pando, Linton, Patterson, & Koidis, 2016) |

| HPP | Hiperbaric, Burgos, Spain | Soy smoothie | Processing | Retain colour and freshness improves the quality characteristics of soy smoothie. | (V. Andrés, Mateo-Vivaracho, Guillamón, Villanueva, & Tenorio, 2016) |

| CP | DBD-ACP, Phenix (ISRE Instrumentation Sales & Rentals) | Prebiotic orange juice | Preparation | Act as a novel technique to process prebiotic orange juice and substitute conventional thermal techniques. | (F. D. L. Almeida et al., 2017) |

| Pulsed UV light | Subjected to fluences between 3.6 and 10.8 J/cm2 | Mango | Drying | Higher vitamin C and carotenoids concentrations in dried mangoes in the pretreatment were between 10 and 40 % higher than in the untreated dried mango. | (Braga, Silva, Rodrigues, & Fernandes, 2019) |

PEF processing improves the diffusion coefficient of water before drying, reduces the time needed to freeze and dry up and maintains rehydrated and thawed food quality for a more extended period. PEF also enhances potato starch's physical and chemical qualities (Hong, Chen, Zeng, & Han, 2016) and oatmeal features, such as polysaccharides and proteins (Feng, Mu, Zhang, & Ma, 2020). For example, PEF (0.6 kV.cm−1 and treatment time of 0.1 s) reduced the drying time of carrots by 55 % at 25 °C and 33 % at 90 °C (Liu, Pirozzi, Ferrari, Vorobiev, & Grimi, 2020). In addition, the PEF-treated sample showed good textural properties and colour after pretreatment compared to the untreated sample.

Nonthermal pretreatment process

Conventional pretreatment includes hot water blanching, steam blanching, hyperosmotic, alkaline, sulphating, and acid liquor (Xiao, Lin, Yao, Du, Lou, & Gao, 2009). Although these pretreatments improve drying time and quality, they may also cause chemical absorption, quality deterioration, poor rehydration, structural collapse, nutritional losses, and excessive energy consumption, particularly during protracted drying (Deng et al., 2019). Thermal drying at high temperatures has been used to dry sugar beet pulp and apple pomace. Still, mechanical pressing could be used to avoid thermal-induced yield loss and loss of functionality (E. Xu et al., 2020). An ideal pretreatment method needs no/little heating, no chemical additives, and fast processing. Other methods like centrifugation or microfiltration have also been recommended in the pretreatment step since they may remove particles, oils and fats (Gerschenson, Deng, & Cassano, 2021). These components are prone to autoxidation, induce substrate degradation, and hinder mechanical processing such as substrate flow, mixing, and homogenisation (Abdullah et al., 2022, Bindes et al., 2019).

Drying might be accomplished using the foam-mat approach has recently gained attention owing to attempts to reduce thermal processes (Araújo et al., 2020). This simple alternative approach is useful as heat-sensitive and viscous substrates like mango pulp or apple puree need to be dried at lower temperatures and for shorter periods to remove water (N. Misra et al., 2021). Traditional pressure consolidation is combined with electrostatic phenomena in the moisture levelling procedure. Electro-osmotic dewatering doesn't dry the surface of the substrate too much, so it can be better for gelatinous mixtures of solids and liquids.

Ultrasonic pretreatment reduced the blended FW particle size considerably, resulting in better interaction with the enzyme (Carmona-Cabello et al., 2019, Li et al., 2019, Zeynali et al., 2017). Mothibe, Zhang, Nsor-atindana, and Wang (2011) used the US treatment (25 kHz and 15 min) as a primary processing phase before the dehydration of apples, which reduced drying time and improved the texture of the dried apple. Tao et al. (2019) showed that US-treated white cabbage exhibited a higher rehydration rate than untreated. Alarcon-Rojo, Janacua, Rodriguez, Paniwnyk, and Mason (2015) utilised the US in the meat sector to tenderise meat, accelerate ripening and mass transfer, save cooking energy, and increase food shelf life without compromising other quality characteristics.

Molecule's separation

Conventional separation techniques using acid, alkali, solvents, and supercritical fluids are safe if the induced materials occur naturally in food or possess food-grade nature. Alcohol precipitation is the most common approach for separating smaller compounds from macromolecules (Szczepaniak et al., 2020). Partial vaporisation has been used to separate liquid mixtures over a solid barrier, a semi-selective membrane (H. Xu et al., 2021). It has many advantages over traditional methods, such as avoiding heat damage to aroma heat sensitivity, low energy consumption, and no need for separate steps because there are no solvents. However, if the supply includes suspended particles or salts, membrane fouling may develop, necessitating a pretreatment step. Finally, liquid membranes might be used to elute aromas and solutes. Liquid membranes provide higher selectivity and consume less energy than other separation techniques, but their instability has restricted commercial application.

Molecules extraction

Solvent extraction is highly convenient in the conventional extraction phase as the solvent offers a physical carrier to move the target molecules across distinct phases (i.e. solid, liquid and vapour). Phenols are readily solubilised in polar protic media such as hydroalcoholic mixtures, whereas matching fractions may be formed by altering alcohol concentration (Rajhard, Hladnik, Vicente, Srčič, Grilc, & Likozar, 2021). However, the solvent should be eliminated from the extract before re-utilising food items. Pressurised and distillation methods may speed up the extraction of phenols, carotenoids, and flavourings while also extracting volatile compounds. On the other hand, enzyme-assisted extraction has been employed as a pretreatment step to weaken botanical materials' structural integrity (Gligor, Mocan, Moldovan, Locatelli, Crișan, & Ferreira, 2019). The difficulties in extracting polar compounds without adding modifiers and, in certain situations, co-extraction of non-target groups of compounds are disadvantages of supercritical fluid extraction.

The cavitational impact of ultrasound waves promotes heat and mass transmission by shattering plant cell walls and releasing extractable substances, such as phenolic compounds from the citrus peel or coconut shells, and hemicelluloses from wheat straw (Zhang, Jiang, Zhou, Shen, He, & Xiao, 2020). Ultrasounds allow rapid extraction with great repeatability and minimal solvent use, albeit filtering is still necessary. PEF may cause hole formation, disintegration, and enhanced cell permeability (Arshad, Abdul‐Malek, et al., 2021). The rapid mass transfer generated by pulsed electric fields has been employed for the improved extraction of phenols from grape seeds, water-soluble pigments (betalains) from red beets and pectin from apple pomace (Encalada et al., 2019, Maza et al., 2020, Visockis et al., 2021). Pulsed ohmic heating, high-voltage electrical discharges and laser irradiation have also been suggested for extraction. These technologies use partial vaporisation to separate liquid mixtures over a solid barrier.

Purification

Membrane processes are better at making direct and specific separations than nanofiltration. They can also make lactic acid purification more efficient while getting whey proteins out of the concentrate stream (Nazir, Khan, Maan, Zia, Giorno, & Schroën, 2019). Nanofiltration may also be used to remove polymerised phenolic components from an olive mill wastewater beverage (Ochando-Pulido, Corpas-Martínez, & Martinez-Ferez, 2018). Electrodialysis uses alternating ion-exchange membranes in a direct current field to separate particles based on their charges.

Final product formation

The last step in downstream processing is to make the final product (encapsulation or drying). Encapsulation is putting the final food product inside a biological coating material. Drying is used instead of encapsulation when polysaccharide Starch, celluloses, fibres, or proteins are found.

Food safety

Although the technological output is crucial for the industrialization of CE, other elements like product safety and overall method cost are also crucial (Matthews, Moran, & Jaiswal, 2021). Food safety is ensured by every-one involved in the food supply chain. CE may cause a pathogen accumulation in the recovered nutrients, and people can't take these unsafe nutrients. In addition, food safety ensures the absence of harmful micro-organisms and other micro-organisms that might cause spoiling during transportation and storage. Hence, biological and chemical food safety is important for the future of food production, especially from food residues.

Conventional processing, such as thermal techniques, effectively maintains adequate microbiological stability (Varalakshmi, 2021) but cannot ensure chemical safety due to the production of hazardous chemicals (Heterocyclic aromatic amines, Polycyclic aromatic hydrocarbons, Acrylamide etc) and may create secondary contamination (Yigit & Velioglu, 2020). Furthermore, they substantially decrease the nutritional value and freshness of the food (Varalakshmi, 2021). Therefore, nonthermal technologies are an alternative to conventional thermal processing (Arshad, Abdul-Malek, Roobab, et al., 2021).

Chemical food safety

Chemical residues dent the circular economy as the thermal treatment creates chemical toxicants, such as hydroxy methyl furfural, and damages the human body (Khaneghah et al., 2020, Koszucka and Nowak, 2019). In addition, thermal processing resulted in the loss of water from food, the oxidation of lipids, and modifications in the fatty acid composition (Soladoye et al., 2017). Therefore, the food industry demands such technologies that decompose pesticides into their harmless metabolites without affecting processed items' physical and organoleptic qualities, primarily fruits and vegetables, are needed to meet the rising global demand for pesticide-free meals. The reduction in pesticides through non-thermal technologies such as PEF, gamma irradiations, ozone, US, HPP and CP demonstrated the potential and scope of these technologies to induce lesser residual pesticides under the maximum allowable residual limit (MRLs) (TK, PS, & Radhakrishnan, 2020). The influence of non-thermal technologies on pathogen inactivation as well as their impact on sensory modifications for certain commodities, is well documented in the research literature (Agcam et al., 2016, Dong and Yang, 2019, Gao et al., 2016, Khademi et al., 2019). However, all the assessments have not yet been completed due to the enormous number of various technologies, target pathogens, and commodities evaluated.

Akdemir Evrendilek, Keskin, and Golge (2020) combined PEF (24.7 kV/cm for 655 ms), ozone treatment (concentration 20.2 g/m3 for 3 min), and US (35 kHz of ultrasound for 3 min) to optimise the best treatment conditions to obtain significant pesticides and microbial reduction. This study proves that when combinations of non-thermal technologies are used, the commodity's chemical and microbial safety is assured due to their synergistic working mechanism with lesser treatment time.

The pesticide is degraded into simpler forms when the unstable ozone molecules react. The amount of pesticide molecules eliminated is determined by the number of ozone molecules accessible for the degradation reaction; process factors such as ozone concentration and flow rate significantly impact the degradation percentage. Sadło, Szpyrka, Piechowicz, Antos, Józefczyk, and Balawejder (2017) discovered that gaseous ozone reduced pesticides (captan, boscalid, and pyraclostrobin) in apples more effectively than ozonated water washing. However, compared to ordinary tap water washing, ozonated water (10 ppm of ozone for 120 min' exposure) provided a significant pesticide reduction percentage (de Souza, Faroni, Heleno, Pinto, de Queiroz, & Prates, 2018).

The whole degradation of investigated pesticides was described in research examining the impact of plasma released by the surface-gassing gas phase to decrease pesticides such as omethoate (99.5 %) and dichlorvos (96.83 %) in goji berry (Zhou et al., 2018). According to (Zheng et al., 2019), 30 min of preparation time for plasma-activated water followed by 10 min of treatment time was needed to achieve a 73.60 % decrease in phoxim concentration using 5 L/min plasma-activated water. The author found no significant changes in the main physicochemical parameters. (Mousavi, Imani, Dorranian, Larijani, & Shojaee, 2017) studied the impact of DBD on diazinon and chlorpyrifos degradation in apples and cucumbers. The pesticide detoxification was boosted by increasing the treatment duration (2–10 min) and voltage (10–13 kV). At 500 ppm, 13 kV, and 10 min, diazinon and chlorpyrifos detoxification was 87.4 and 87.0 % in apples, and 82.2 and 33.7 % in cucumbers, respectively. NTP inactivates thermophilic bacteria that are resistant to traditional means of destruction. NTP does this by altering the structural properties of thermophilic proteins (Ravash, Peighambardoust, Soltanzadeh, Pateiro, & Lorenzo, 2020).

Microbial food safety

All elements of microbiological food safety must be monitored, including ensuring FDA regulatory compliance with the 5-log reduction requirement for preservation methods. NTP may be integrated with antimicrobial compounds or moderate heating to achieve the desired results (H. Lee, Choi, Kim, Kim, Lee, & Lee, 2021). HPP and PEF have been extensively studied and effectively marketed for the non-thermal inactivation of micro-organisms (Akdemir Evrendilek et al., 2021, Soltanzadeh et al., 2020).

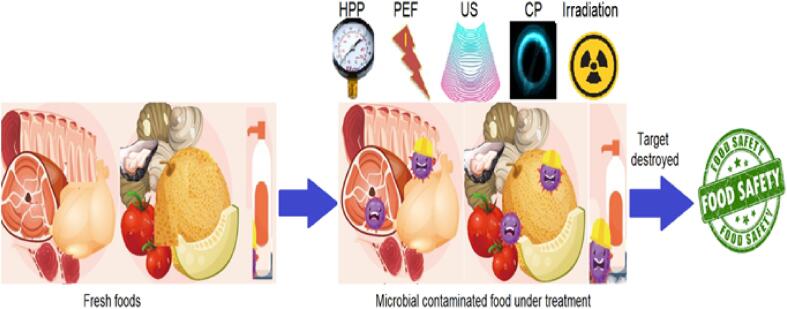

Non-thermal technologies have been utilised to increase shelf life and preserve food residues from decomposition and contamination (Fig. 2). For example, PEF processing increased the shelf life of juices and other items by up to 240 %, increasing the shelf life from 8 to 9 days to 3 weeks (Koubaa et al., 2018). These findings show fewer losses across the supply chain, particularly at the market level. However, about 40 % of overall Micro-organisms often infect fruit and vegetables, including herbs, and are HPP-treated for better food safety rather than being cooked, which destroys their fresh colour, taste, and nutritional value (Yamamoto, 2017). Prokaryotic cells are more pressure-resistant than eukaryotic cells (H.-W. Huang, Hsu, & Wang, 2020). Yeasts and moulds are more HPP-sensitive than bacteria. Gram-positive and cocci bacteria are more resistant to HPP treatment than Gram-negative and rod-shaped bacteria (Y.-C. Lee, Tsai, Chen, Kung, Arakawa, & Wei, 2020). Endospores, however, may sustain pressures above 1,000 MPa (Aouadhi, Simonin, Prévost, De Lamballerie, Maaroufi, & Mejri, 2012).

Fig. 2.

A non-thermal treatment for microbial inactivation.

Table 3 shows that PEF has been investigated to reduce pathogenic and spoilage microorganisms' risks. PEF treatment has been shown to significantly reduce the growth of pathogenic microorganisms such as Staphylococcus aureus, E. coli, Salmonella typhimurium, Listeria monocytogenes and Salmonella Enteritidis, as well as spoilage microorganisms such as Acetobacter spp. and Saccharomyces cerevisiae (Pallarés, Tolosa, Gavahian, Barba, Mousavi-Khaneghah, & Ferrer, 2020).

Table 3.

Few examples showing contribution in food safety.

| Non-thermal technology | Equipment | Food material | Preservation benefits | References |

|---|---|---|---|---|

| US | Ultrasonic Instrument Co., Falk., Italy | Banana fruit, Salmon, mackerel, and cod fillets | Prevent the polyphenol oxidase enzyme activity in bananas and preserve the quality during cold storage by reducing chilling injury. | (Khademi et al., 2019) |

| PEF | PEF OSU-4A system | Orange juice | To prevent microbial growth, preserve quality attributes of orange juice and ascorbic acid with a half-life of 1112 days. | (Agcam et al., 2016) |

| CP sterilization | Nanjing Su Man Electronics Co., ltd., China | Blueberry, Beef jerky | Enhance the shelf life and quality characteristics of blueberries and reduce the bacteria and fungi growth. | (Dong et al., 2019) |

| HPP | HHP-700, Baotou Kefa Co., ltd., | Strawberry, Chicken fillets | Prevent mould growth, inactivate bacterial growth during storage, and preserve the quality of strawberries. | (Gao et al., 2016) |

US can tenderise meat, accelerate maturation and mass transfer, and extend the shelf life in the meat processing industry. Furthermore, US reduced salt use in processed meats (Inguglia, Zhang, Tiwari, Kerry, & Burgess, 2017) and enhanced emulsification and gel characteristics, potentially decreasing the need for chemical additives such as phosphates (Thangavelu, Kerry, Tiwari, & McDonnell, 2019). Furthermore, non-thermal techniques are impeded by micro-organisms trapped in the fat matrix, one of the most difficult challenges to resolve. It reduces the intensity of penetrating energy targeting micro-organisms in a protective fat environment, preventing penetration when water-based antimicrobial treatments are used. However, some nonthermal techniques are ineffective against spores and viruses because they cannot cause microbial cells to be inhibited or sub lethally damaged rather than destroyed (Wu et al., 2020). Furthermore, it risks food safety since micro-organisms may re-grow in the post-processing stage when favourable circumstances are restored. Thus, combining hurdle technologies is suggested to enhance their synergistic impact and minimise the negative consequences of particular methods. However, the operating cost rises when several technologies are used, and the practicality becomes questionable.

Food material efficiency

According to FAO, one-third of all food generated for human consumption is missing or discarded along the entire supply chain, amounting to about 1.3 billion tons each year de los Mozos et al. (2020). The food lost and wasted volume differs significantly across the food chain, from production to the food sector, delivery, restaurants, and households. Food production and processing are among the industries that generate significant quantities of FW (Ravindran & Jaiswal, 2016). A simple calculation of the material balance could be done with the following equation:

Raw material = Finished Product + Wastes Produced + Emissions generated

According to (Scherhaufer, Moates, Hartikainen, Waldron, & Obersteiner, 2018), the primary processing phase produces three-quarters of the overall global FW's possible effect. For example, in Europe, 186 Mt CO2 was traced to FW. Furthermore, global initiatives promote food loss and waste reduction, valorisation, and management techniques. For example, by 2030, the United Nations Sustainable Development Goal 12.3 plans to cut per capita FW and management costs in half while increasing the value of unavoidable FW and packaging materials (Scherhaufer et al., 2015).

Reducing food wastes

The food industry generates a significant amount of waste: fruit/vegetable leftovers and discarded products from sugar refining molasses and flakes, meat, blood and skin from meat processing, whey from milk, remainders from wineries, breweries, and distilleries, and milk products such as whey (Ahmad et al., 2019, Bevilacqua et al., 2018, Chanioti et al., 2021, Rosario et al., 2021, Scherhaufer et al., 2015). The thermal processing and toxicity of solvents during conventional extraction degrade the food residues and make them trash. FW in NTP is less harmful because of its organic nature and can be contributed to food recovery.

Recovering by-products

The “recoverability” of discarded food is described as the ability to use it with little additional effort. This is one of the CE's core requirements and is accomplished using non-thermal technologies. Since global supplies are becoming increasingly scarce, the availability of new raw materials is becoming a critical concern for maintaining food chains' long-term survival. Solvent diffusion in the cell is traditionally required to extract metabolites from vegetative cells and subsequent mass transport of metabolites in the bulk of the extractor medium (Chemat et al., 2017). The extraction process is speeded up by changing the physical characteristics of the sample (e.g., moulding, maceration and peeling) or adding extraction devices such as heat, sound, and agitation. Novel NTP methods have been developed to recover valuable chemicals from these waste streams, decrease environmental emissions of organic substances, and produce extra revenues. Thus, these novel NTT are used to transform into a more circular nutrient economy relevant to SDGs 6 and 14.

Like natural regeneration systems, a circular economy for food eliminates waste and replaces it with feedstock for a new cycle. In addition, NTP is recognised to be helpful for the better extraction of natural extracts. PEF technology has been used to handle waste in sustainable bio-refinery development. For example, over the grape pomp with an electric field intensity of 13.3 kV.cm−1, polyphenols (2-time rise) and anthocyanins (55 %) were recovered (Barba et al., 2015, El Kantar et al., 2018). (Franco et al., 2020) utilised radical PEF (1.40 kV.cm−1) for ferric-reducing antioxidant power test (35.8 %) of fish residues. PEF was found to be a cost-effective and ecologically sustainable way to extract antioxidants from low-value by-products of fish processing. As a result, the maximum FW phenolic compound recuperates from free radical damage, cancer, and cardiovascular disease resistance (Krishan Kumar, Yadav, Kumar, Vyas, & Dhaliwal, 2017). In addition, the ability of the PEF treatment to monitor electroporation and the pores utilised for the selective extraction of bioactive compounds with higher purity (Parniakov et al., 2015).

HPP is considered a potentially helpful tool for increasing the efficiency of enzymatic hydrolysis and generating high-value-added peptide fractions from various complex biomass (Marciniak, Suwal, Naderi, Pouliot, & Doyen, 2018). de Jesus, Cristianini, Dos Santos, and Júnior (2020) reported that HPP could also be effectively utilised to extract antioxidants, anthocyanins, and phenolic compounds with various nutraceutical properties in food. Víctor Andrés, Villanueva, and Tenorio (2016) showed that following HPP (650 MPa/3 min), the total polyphenol and total carotenoid concentrations of soy smoothies rose, with the total polyphenol content rising from 444 mg GAE/L in the control group to 503 mg GAE/L in the HPP group. (Du, He, Yu, Zhu, & Li, 2013) investigated the use of HPP to extract astaxanthin from shrimp (Litopenaeus vannamei) shells and heads at ambient temperature using ethanol as the extraction solvent. Applying pressure of 210 MPa for 10 min and a liquid-to-solid ratio of 32 mL/g resulted in the greatest extraction yield (89.12 g/g).

Fan, Li, Liu, and Xi (2020) found that US (20 kHz for 30 min) with pulsed-discharge (14 kV) extracted protein (saponins yield of 51.30 ± 0.08 mg/g with 10 min) had better particle size, emulsification power, and structure. de Sousa et al. (2020) used US (39.5 min) to extract bioactive phenolic compounds from Kunth leaves. The authors found a 94 % increased yield of extracted bioactive using effective, quick, and easy indirect ultrasonication. US has been proven to be an intensified extraction process to extract oil from olive fruit, soybean, and flaxseed (Chanioti et al., 2021, Laurora et al., 2021). Thus, US is employed to extract bioactive from different parts of plants, fruits, and vegetable wastes (Kshitiz Kumar et al., 2020, Rezende et al., 2021).

Organic resources in the FW derived from NTP are devoid of pollutants and may be safely returned to the land as organic fertiliser (Boye & Arcand, 2013). These cycles help replenish living systems like soil, offering renewable resources and sustaining biodiversity. NTP is an example of a regenerative technique that includes moving from synthetic to organic fertiliser, utilising crop rotation and increasing crop variations to support biodiversity.

Biofuel generation

Plant and agricultural residual waste lignocellulosic biomass (LCBs) is a globally accessible, plentiful, and possibly carbon–neutral, sustainable feedstock with sugar-rich platforms (Baruah et al., 2018). LCB is already extensively utilised for biogas generation, and it may be converted to other biofuels or used in a biorefinery to recover specialised goods. On the other hand, the lignin-polysaccharide matrix is resistant to biodegradation and chemical extraction due to its composition (Xie, Chen, Cheng, Zhu, & Xu, 2021). Physicochemical and biological characteristics of food waste influence anaerobic digestion. Anaerobic fermentation has four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Hydrolysis is the rate-limiting phase in the fermentation process. Therefore, food waste's anaerobic fermentation cycle reduces processing efficiency and economic advantages (Rouches, Herpoël-Gimbert, Steyer, & Carrere, 2016).

The lipid fraction may significantly impact anaerobic digestion (AD) economic viability since it is a limiting component in methane production. Lipid fraction must be separated from solid FW, which is expensive and time-consuming. Non-thermal processing has been explored to improve biogas generation with low economic expenses, minimum energy consumption, and no adverse environmental effect (Atelge et al., 2020). Feedstock pretreatment uses US-generated cavitation to enhance the AD process for biogas generation (Joshi & Gogate, 2019). Sáez-Bastante, Pinzi, Arzamendi, De Castro, Priego-Capote, and Dorado (2014) showed that transesterification with US assistance decreased response inputs (methanol to oil molar, energy, and reaction time). As a result, the energy needs are lower than with traditional transesterification.

PEF pretreatment at 34 kWh/m3 enhanced CH4 production by 33 % and dissolved organic carbon removal by 18 %, respectively, whereas CH4 generation from co-digestion of wastewater and agro-food sector sludge rose by 44 and 8 %, respectively, at 50 and 15 kWh/m3 (Capodaglio, 2021). PEF (2–150 kWh/m3) intensity was used on Chlorella Vulgaris, with maximal solubilisation of soluble COD improving to 830 %. It raises a biogas generation of approximately 27 % at a field intensity 5.4 kWh/m3, which rose by 110 % at 35 kWh/m3 field intensity (Garoma & Shackelford, 2014). FW (sorted from municipal solid waste), when treated with electroporation (400 pulses), yielded 20–40 % higher biogas production due to substrate cell breakage (Carlsson, Lagerkvist, & Ecke, 2008). Thus, PEF effectively speeds up the hydrolysis step, allowing for easier interaction with external bacteria for conversion to methane or extraction for further processing.

Environment-Friendly packaging

Another central area of emphasis for proponents of the circular economy in the food industry is packaging. Food packaging is vital in the food industry because it maintains food safety during storage and transportation for commercialisation (Rehman, Jafari, Aadil, Assadpour, Randhawa, & Mahmood, 2020). Thus, sterilised packing materials or disinfection packages are critical for preventing germs from growing on food items and extending their shelf life. In addition, according to studies, the form of packaging and components used in goods significantly affects their environmental impact (White & Lockyer, 2020).

NTP is an effective disinfection method for various materials, including heat and chemically sensitive materials, because of its cheap operating costs, quick treatment time, low temperatures, and non-toxicity (Ziuzina, Patil, Cullen, Keener, & Bourke, 2013). Furthermore, NTP allows for more effective usage of packaging content and reduces the need for repacking. One study showed that NTP might inactivate a high quantity of E. coli in liquids confined within sealed containers within a few seconds (Ziuzina, Patil, Cullen, Keener, & Bourke, 2013). Another research used a dielectric barrier discharge (DBD) plasma reactor to produce NTP within cherry tomato packaging (N. N. Misra, Keener, Bourke, Mosnier, & Cullen, 2014). The packaging acts as the dielectric material in this configuration of DBD devices. According to that research, this configuration aids in preserving food items without impairing their quality. Another research developed a DBD gadget that generates NTP within sealed pouches to sterilise single-use medical equipment (Ben Belgacem et al., 2017).

Along with disinfecting sealed bags inside, some investigations have shown that NTP disinfects packaging materials. NTP has the potential to enhance the biodegradability and physicochemical properties of food packaging materials without compromising performance (Song, Oh, Roh, Kim, & Min, 2016). Furthermore, HPP processing can be used after the product has been prepared; as a result, repacking is not needed and significantly lowers food recontamination risk (Ravash et al., 2020). These findings suggest that NTP may be used to sterilise and cleanse the insides of sealed containers and enhance the characteristics of packaging materials used to preserve food.

Footsteps to embrace a circular economy in the food industry

There should be a clear difference between nonthermal technologies deployed on a commercial scale and those that, although their impacts may be of interest to the food business, have not been applied in the food industry for various reasons. It is critical because implementing a circular economy in the food industry would need commercially accessible solutions. The intensity of the final processing conditions at the pilot scale would likely not be surpassed in an industrial context. Thermal processing based on theoretical models at the pilot scale and actual experimental data may provide somewhat different outcomes, particularly when used on a large scale (Aganovic et al., 2017). Therefore, comprehensive research of products with substantial industrial production capacity is required.

Food industries must be restorative and regenerative in structure to achieve a circular economy while implementing system-wide innovations. Essentially, the food sector should strive to redefine goods and services so that waste is reduced, and the negative environmental effects are minimised. These R&D initiatives are currently underway worldwide, showing that the food business is rethinking how it uses, reuses, and recycles its resources.

Companies may consider using regenerative food production methods to guarantee that they grow food in a manner that benefits rather than harms the environment. Collaboration between food producers and the rest of the food chain can make the food and beverage sector more circular rather than linear. Companies may alter food design and marketing in the circular economy to make food manufacturing processes more efficient and effective. Plant-based proteins, for example, use fewer natural resources, such as soil and water, than animal proteins.

Waste may be reduced by improving production processes with improved technology and worker training. Food that would otherwise be thrown out might be recycled back into the manufacturing process, or leftover by-products and ingredients could be used to produce new goods. Furthermore, leftover food isn't fit for sale, but most of it is still edible, and food producers may divert excess food via other channels such as food donation partners and marketplaces. Finally, food losses seem unavoidable along the supply chain since food and packaging are readily destroyed by land and water travel.

Governments should need to work together to accomplish this. With numerous supply chains in the food sector, knowledge of these NTP techniques will affect stakeholders. The state of the planet's ecology provides a compelling argument for reform and the complete realisation of this goal. Other national governments will launch similar efforts, pushing local food companies to adjust.

Conclusion

Given the predicted global population development, the food sector dramatically raises demand, eventually increasing waste generation. As a result, waste resources could have a lot of important bioactive compounds that won't be used. FW is not wasting in the true sense of the term but rather a raw material that can be used in other processes, thereby satisfying the circular economy's principles of recycling and circulation. There has been an increasingly apparent connection between dietary, physical and environmental health and the economy. It has been demonstrated that nonthermal processing help in implementing a circular economy and meeting the United Nations approved Sustainable Development Goals (SDGs). Collaboration between food producers and the food chain may make the food industry more circular. This article motivates adopting nonthermal technologies to conserve natural resources, food safety, and energy in different food processing phases to meet SDGs.

These techniques are safe and may boost extraction yield while decreasing processing time. However, many of these techniques haven't been well-developed or suited for some products and lack industrial-scale standards. The food industry should focus on the sustainability of zero-waste processing, waste management, and food packaging.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

Acknowledgements

This research was funded by Universiti Teknologi Malaysia (4B482, 05G88 and 05G89). Thanks to GAIN (Axencia Galega de Innovación) for supporting this research (grant number IN607A2019/01).

Funding for open access charge Universidade de Vigo/CISUG.

Contributor Information

Zulkurnain Abdul-Malek, Email: zulkurnain@utm.my.

Jose Manuel Lorenzo, Email: jmlorenzo@ceteca.net.

Rana Muhammad Aadil, Email: muhammad.aadil@uaf.edu.pk.

Data availability

No data was used for the research described in the article.

References

- Abdullah S., Karmakar S., Pradhan R.C., Mishra S. Pressure-driven crossflow microfiltration coupled with centrifugation for tannin reduction and clarification of cashew apple juice: Modeling of permeate flux decline and optimization of process parameters. Journal of Food Processing and Preservation. 2022;e16497 [Google Scholar]

- Aganovic K., Smetana S., Grauwet T., Toepfl S., Mathys A., Van Loey A., Heinz V. Pilot scale thermal and alternative pasteurization of tomato and watermelon juice: An energy comparison and life cycle assessment. Journal of Cleaner Production. 2017;141:514–525. [Google Scholar]

- Agcam E., Akyildiz A., Akdemir Evrendilek G. A comparative assessment of long-term storage stability and quality attributes of orange juice in response to pulsed electric fields and heat treatments. Food and Bioproducts Processing. 2016;99:90–98. doi: 10.1016/j.fbp.2016.04.006. [DOI] [Google Scholar]

- Ahmad, T., Aadil, R. M., Ahmed, H., ur Rahman, U., Soares, B. C., Souza, S. L., . . . Esmerino, E. A. (2019). Treatment and utilization of dairy industrial waste: A review. Trends in Food Science & Technology, 88, 361-372.

- Akdemir Evrendilek G., Bakay S., Uzuner S. High pressure processing of licorice drink with respect to quality characteristics, microbial inactivation, and shelf-life extension. Journal of food processing and preservation. 2021;45(5):e15465. [Google Scholar]

- Akdemir Evrendilek G., Keskin E., Golge O. Interaction and multi-objective effects of multiple non-thermal treatments of sour cherry juice: Pesticide removal, microbial inactivation, and quality preservation. Journal of the Science of Food and Agriculture. 2020;100(4):1653–1661. doi: 10.1002/jsfa.10178. [DOI] [PubMed] [Google Scholar]

- Alarcon-Rojo A., Janacua H., Rodriguez J., Paniwnyk L., Mason T.J. Power ultrasound in meat processing. Meat science. 2015;107:86–93. doi: 10.1016/j.meatsci.2015.04.015. [DOI] [PubMed] [Google Scholar]

- Almeida C., Bonilla S., Giannetti B., Huisingh D. Elsevier; 2013. Cleaner Production initiatives and challenges for a sustainable world: An introduction to this special volume. [Google Scholar]

- Almeida F.D.L., Gomes W.F., Cavalcante R.S., Tiwari B.K., Cullen P.J., Frias J.M.…Rodrigues S. Fructooligosaccharides integrity after atmospheric cold plasma and high-pressure processing of a functional orange juice. Food Res Int. 2017;102:282–290. doi: 10.1016/j.foodres.2017.09.072. [DOI] [PubMed] [Google Scholar]

- Andrés V., Mateo-Vivaracho L., Guillamón E., Villanueva M.J., Tenorio M.D. High hydrostatic pressure treatment and storage of soy-smoothies: Colour, bioactive compounds and antioxidant capacity. LWT - Food Science and Technology. 2016;69:123–130. doi: 10.1016/j.lwt.2016.01.033. [DOI] [Google Scholar]

- Andrés V., Villanueva M.-J., Tenorio M.-D. Influence of high pressure processing on microbial shelf life, sensory profile, soluble sugars, organic acids, and mineral content of milk-and soy-smoothies. LWT-Food Science and Technology. 2016;65:98–105. [Google Scholar]

- Aouadhi C., Simonin H., Prévost H., De Lamballerie M., Maaroufi A., Mejri S. Optimization of pressure-induced germination of Bacillus sporothermodurans spores in water and milk. Food microbiology. 2012;30(1):1–7. doi: 10.1016/j.fm.2011.12.006. [DOI] [PubMed] [Google Scholar]

- Aranda-Usón A., Portillo-Tarragona P., Scarpellini S., Llena-Macarulla F. The progressive adoption of a circular economy by businesses for cleaner production: An approach from a regional study in Spain. Journal of Cleaner Production. 2020;247 [Google Scholar]

- Araújo, C. d. S., Corrêa, J. L. G., Dev, S., Macedo, L. L., Vimercati, W. C., Rodrigues de Oliveira, C., & Pio, L. A. S. (2020). Influence of pretreatment with ethanol and drying temperature on physicochemical and antioxidant properties of white and red pulp pitayas dried in foam mat. Drying Technology, 1-10.

- Arshad, R. N., Abdul-Malek, Z., Munir, A., Buntat, Z., Ahmad, M. H., Jusoh, Y. M., . . . Aadil, R. M. (2020). Electrical systems for pulsed electric field applications in the food industry: An engineering perspective. Trends in food science & technology.

- Atelge M., Atabani A., Banu J.R., Krisa D., Kaya M., Eskicioglu C.…Unalan S. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel. 2020;270 [Google Scholar]

- Barba F.J., Puértolas E., Brnčić M., Panchev I.N., Dimitrov D.A., Athès-Dutour V.…Souchon I. Emerging extraction. Elsevier; 2015. pp. 249–272. [Google Scholar]

- Baruah J., Nath B.K., Sharma R., Kumar S., Deka R.C., Baruah D.C., Kalita E. Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Frontiers in Energy Research. 2018;6:141. [Google Scholar]

- Bassey E.J., Cheng J.-H., Sun D.-W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends in Food Science & Technology. 2021 [Google Scholar]

- Ben Belgacem Z., Carré G., Charpentier E., Le-Bras F., Maho T., Robert E.…Boudifa M. Innovative non-thermal plasma disinfection process inside sealed bags: Assessment of bactericidal and sporicidal effectiveness in regard to current sterilization norms. PLoS One. 2017;12(6):e0180183. doi: 10.1371/journal.pone.0180183. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bengtsson M., Alfredsson E., Cohen M., Lorek S., Schroeder P. Transforming systems of consumption and production for achieving the sustainable development goals: Moving beyond efficiency. Sustainability science. 2018;13(6):1533–1547. doi: 10.1007/s11625-018-0582-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bevilacqua A., Petruzzi L., Perricone M., Speranza B., Campaniello D., Sinigaglia M., Corbo M.R. Nonthermal technologies for fruit and vegetable juices and beverages: Overview and advances. Comprehensive Reviews in Food Science and Food Safety. 2018;17(1):2–62. doi: 10.1111/1541-4337.12299. [DOI] [PubMed] [Google Scholar]

- Bindes M.M.M., Cardoso V.L., Reis M.H.M., Boffito D.C. Maximisation of the polyphenols extraction yield from green tea leaves and sequential clarification. Journal of Food engineering. 2019;241:97–104. [Google Scholar]

- Bobinaitė R., Pataro G., Lamanauskas N., Šatkauskas S., Viškelis P., Ferrari G. Application of pulsed electric field in the production of juice and extraction of bioactive compounds from blueberry fruits and their by-products. Journal of Food Science and Technology. 2014;52(9):5898–5905. doi: 10.1007/s13197-014-1668-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Boluk K.A., Cavaliere C.T., Higgins-Desbiolles F. Taylor & Francis; 2019. A critical framework for interrogating the United Nations Sustainable Development Goals 2030 Agenda in tourism. [Google Scholar]

- Boye J.I., Arcand Y. Current trends in green technologies in food production and processing. Food Engineering Reviews. 2013;5(1):1–17. [Google Scholar]

- Braga T.R., Silva E.O., Rodrigues S., Fernandes F.A. Drying of mangoes (Mangifera indica L.) applying pulsed UV light as pretreatment. Food and bioproducts processing. 2019;114:95–102. [Google Scholar]

- Cacace F., Bottani E., Rizzi A., Vignali G. Evaluation of the economic and environmental sustainability of high pressure processing of foods. Innovative Food Science & Emerging Technologies. 2020;60 [Google Scholar]

- Capodaglio A.G. Pulse Electric Field Technology for Wastewater and Biomass Residues’ Improved Valorization. Processes. 2021;9(5):736. [Google Scholar]

- Carlsson M., Lagerkvist A., Ecke H. ORBIT 2008: Moving Organic Waste Recycling Towards Resource Management and Biobased Economy 13/10/2008-15/10/2008. 2008. Electroporation for enhanced methane yield from municipal solid waste. [Google Scholar]

- Carmona-Cabello M., Sáez-Bastante J., Pinzi S., Dorado M. Optimization of solid food waste oil biodiesel by ultrasound-assisted transesterification. Fuel. 2019;255 [Google Scholar]

- Chanioti S., Katsouli M., Tzia C. Novel Processes for the Extraction of Phenolic Compounds from Olive Pomace and Their Protection by Encapsulation. Molecules. 2021;26(6):1781. doi: 10.3390/molecules26061781. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chemat F., Rombaut N., Meullemiestre A., Turk M., Perino S., Fabiano-Tixier A.-S., Abert-Vian M. Review of green food processing techniques. Preservation, transformation, and extraction. Innovative Food Science & Emerging Technologies. 2017;41:357–377. [Google Scholar]

- Cui R., Zhu F. Ultrasound modified polysaccharides: A review of structure, physicochemical properties, biological activities and food applications. Trends in Food Science & Technology. 2020 [Google Scholar]

- Cunha S.C., Fernandes J.O. Extraction techniques with deep eutectic solvents. TrAC Trends in Analytical Chemistry. 2018;105:225–239. [Google Scholar]

- de Jesus A.L.T., Cristianini M., Dos Santos N.M., Júnior M.R.M. Effects of high hydrostatic pressure on the microbial inactivation and extraction of bioactive compounds from açaí (Euterpe oleracea Martius) pulp. Food Research International. 2020;130 doi: 10.1016/j.foodres.2019.108856. [DOI] [PubMed] [Google Scholar]

- de los Mozos, E. A., Badurdeen, F., & Dossou, P.-E. (2020). Sustainable consumption by reducing food waste: A review of the current state and directions for future research. Procedia Manufacturing, 51, 1791-1798.

- de Sousa, C. B. d. C., dos Anjos, G. L., Nobrega, R. S., Magaton, A. d. S., de Miranda, F. M., & Dias, F. d. S. (2020). Greener ultrasound-assisted extraction of bioactive phenolic compounds in Croton heliotropiifolius Kunth leaves. Microchemical Journal, 159, 105525.

- de Souza L.P., Faroni L.R.D.A., Heleno F.F., Pinto F.G., de Queiroz M.E.L.R., Prates L.H.F. Ozone treatment for pesticide removal from carrots: Optimization by response surface methodology. Food Chemistry. 2018;243:435–441. doi: 10.1016/j.foodchem.2017.09.134. [DOI] [PubMed] [Google Scholar]

- Deng L.-Z., Mujumdar A.S., Zhang Q., Yang X.-H., Wang J., Zheng Z.-A.…Xiao H.-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes–a comprehensive review. Critical reviews in food science and nutrition. 2019;59(9):1408–1432. doi: 10.1080/10408398.2017.1409192. [DOI] [PubMed] [Google Scholar]

- Dong X.Y., Yang Y.L. A Novel Approach to Enhance Blueberry Quality During Storage Using Cold Plasma at Atmospheric Air Pressure. Food and Bioprocess Technology. 2019;12(8):1409–1421. doi: 10.1007/s11947-019-02305-y. [DOI] [Google Scholar]

- Du J., He J., Yu Y., Zhu S., Li J. Astaxanthin extracts from shrimp (Litopenaeus vannamei) discards assisted by high pressure processing. American Society of Agricultural and Biological Engineers; 2013. p. (p. 1):. [Google Scholar]

- Ekezie F.-G.-C., Cheng J.-H., Sun D.-W. Effects of nonthermal food processing technologies on food allergens: A review of recent research advances. Trends in Food Science & Technology. 2018;74:12–25. [Google Scholar]

- Ekezie F.-G.-C., Sun D.-W., Cheng J.-H. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends in Food Science & Technology. 2017;69:46–58. [Google Scholar]

- El Kantar S., Boussetta N., Lebovka N., Foucart F., Rajha H.N., Maroun R.G.…Vorobiev E. Pulsed electric field treatment of citrus fruits: Improvement of juice and polyphenols extraction. Innovative Food Science & Emerging Technologies. 2018;46:153–161. [Google Scholar]

- Encalada A.M.I., Pérez C.D., Flores S.K., Rossetti L., Fissore E.N., Rojas A.M. Antioxidant pectin enriched fractions obtained from discarded carrots (Daucus carota L.) by ultrasound-enzyme assisted extraction. Food chemistry. 2019;289:453–460. doi: 10.1016/j.foodchem.2019.03.078. [DOI] [PubMed] [Google Scholar]

- Fan Y., Li Z., Liu L., Xi J. Combination of liquid-phase pulsed discharge and ultrasonic for saponins extraction from lychee seeds. Ultrasonics sonochemistry. 2020;69 doi: 10.1016/j.ultsonch.2020.105264. [DOI] [PubMed] [Google Scholar]

- Fei X., Chen T., Jia W., Shan Q., Hei D., Ling Y.…Feng H. Enhancement effect of ionizing radiation pretreatment on biogas production from anaerobic fermentation of food waste. Radiation Physics and Chemistry. 2020;168 [Google Scholar]

- Feng Y.-Y., Mu T.-H., Zhang M., Ma M.-M. Effects of different polysaccharides and proteins on dough rheological properties, texture, structure and in vitro starch digestibility of wet sweet potato vermicelli. International journal of biological macromolecules. 2020;148:1–10. doi: 10.1016/j.ijbiomac.2019.12.225. [DOI] [PubMed] [Google Scholar]

- Fonteles T.V., Leite A.K., Silva A.R., Carneiro A.P., Miguel Ede C., Cavada B.S.…Rodrigues S. Ultrasound processing to enhance drying of cashew apple bagasse puree: Influence on antioxidant properties and in vitro bioaccessibility of bioactive compounds. Ultrason Sonochem. 2016;31:237–249. doi: 10.1016/j.ultsonch.2016.01.003. [DOI] [PubMed] [Google Scholar]

- Franco D., Munekata P.E., Agregán R., Bermúdez R., López-Pedrouso M., Pateiro M., Lorenzo J.M. Application of pulsed electric fields for obtaining antioxidant extracts from fish residues. Antioxidants. 2020;9(2):90. doi: 10.3390/antiox9020090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gao G., Ren P., Cao X., Yan B., Liao X., Sun Z., Wang Y. Comparing quality changes of cupped strawberry treated by high hydrostatic pressure and thermal processing during storage. Food and Bioproducts Processing. 2016;100:221–229. doi: 10.1016/j.fbp.2016.06.017. [DOI] [Google Scholar]

- Garoma T., Shackelford T. Electroporation of Chlorella vulgaris to enhance biomethane production. Bioresource technology. 2014;169:778–783. doi: 10.1016/j.biortech.2014.07.001. [DOI] [PubMed] [Google Scholar]

- Geissdoerfer M., Savaget P., Bocken N.M., Hultink E.J. The Circular Economy–A new sustainability paradigm? Journal of Cleaner Production. 2017;143:757–768. [Google Scholar]

- Gerschenson L.N., Deng Q., Cassano A. Food Waste Recovery. Elsevier; 2021. Conventional macroscopic pretreatment; pp. 71–87. [Google Scholar]

- Gligor O., Mocan A., Moldovan C., Locatelli M., Crișan G., Ferreira I.C. Enzyme-assisted extractions of polyphenols–A comprehensive review. Trends in Food Science & Technology. 2019;88:302–315. [Google Scholar]

- Gullón P., Gullón B., Romaní A., Rocchetti G., Lorenzo J.M. Smart advanced solvents for bioactive compounds recovery from agri-food by-products: A review. Trends in Food Science & Technology. 2020;101:182–197. [Google Scholar]

- Gupta H., Kumar A., Wasan P. Industry 4.0, cleaner production and circular economy: An integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. Journal of Cleaner Production. 2021;295 [Google Scholar]

- Hartley K., van Santen R., Kirchherr J. Policies for transitioning towards a circular economy: Expectations from the European Union (EU) Resources, Conservation and Recycling. 2020;155 [Google Scholar]

- Haupt M., Hellweg S. Measuring the environmental sustainability of a circular economy. Environmental and Sustainability Indicators. 2019;1 [Google Scholar]

- Hernández-Hernández H., Moreno-Vilet L., Villanueva-Rodríguez S. Current status of emerging food processing technologies in Latin America: Novel non-thermal processing. Innovative Food Science & Emerging Technologies. 2019;58 [Google Scholar]

- Hong J., Chen R., Zeng X.-A., Han Z. Effect of pulsed electric fields assisted acetylation on morphological, structural and functional characteristics of potato starch. Food Chemistry. 2016;192:15–24. doi: 10.1016/j.foodchem.2015.06.058. [DOI] [PubMed] [Google Scholar]

- Hospido A., Davis J., Berlin J., Sonesson U. A review of methodological issues affecting LCA of novel food products. The international journal of life cycle assessment. 2010;15(1):44–52. [Google Scholar]

- Huang F.-L., Chiou R.-Y.-Y., Chen W.-C., Ko H.-J., Lai L.-J., Lin S.-M. Dehydrated basella alba fruit juice as a novel natural colorant: Pigment stability, In vivo food safety evaluation and anti-inflammatory mechanism characterization. Plant Foods for Human Nutrition. 2016;71(3):322–329. doi: 10.1007/s11130-016-0563-4. [DOI] [PubMed] [Google Scholar]

- Huang H.-W., Hsu C.-P., Wang C.-Y. Healthy expectations of high hydrostatic pressure treatment in food processing industry. journal of food and drug analysis. 2020;28(1):1–13. doi: 10.1016/j.jfda.2019.10.002. [DOI] [PubMed] [Google Scholar]

- Huang H.-W., Wu S.-J., Lu J.-K., Shyu Y.-T., Wang C.-Y. Current status and future trends of high-pressure processing in food industry. Food Control. 2017;72:1–8. [Google Scholar]

- Inguglia E.S., Zhang Z., Tiwari B.K., Kerry J.P., Burgess C.M. Salt reduction strategies in processed meat products–A review. Trends in Food Science & Technology. 2017;59:70–78. [Google Scholar]

- Joshi S.M., Gogate P.R. Intensifying the biogas production from food waste using ultrasound: Understanding into effect of operating parameters. Ultrasonics sonochemistry. 2019;59 doi: 10.1016/j.ultsonch.2019.104755. [DOI] [PubMed] [Google Scholar]

- Khademi O., Ashtari M., Razavi F. Effects of salicylic acid and ultrasound treatments on chilling injury control and quality preservation in banana fruit during cold storage. Scientia Horticulturae. 2019;249:334–339. doi: 10.1016/j.scienta.2019.02.018. [DOI] [Google Scholar]

- Khaneghah A.M., Gavahian M., Xia Q., Denoya G.I., Roselló-Soto E., Barba F.J. Pulsed electric fields to obtain healthier and sustainable food for tomorrow. Elsevier; 2020. Effect of pulsed electric field on Maillard reaction and hydroxymethylfurfural production; pp. 129–140. [Google Scholar]

- King T., Cole M., Farber J.M., Eisenbrand G., Zabaras D., Fox E.M., Hill J.P. Food safety for food security: Relationship between global megatrends and developments in food safety. Trends in Food Science & Technology. 2017;68:160–175. [Google Scholar]

- Koszucka A., Nowak A. Thermal processing food-related toxicants: A review. Critical reviews in food science and nutrition. 2019;59(22):3579–3596. doi: 10.1080/10408398.2018.1500440. [DOI] [PubMed] [Google Scholar]

- Koubaa M., Barba F.J., Kovačević D.B., Putnik P., Santos M.D., Queirós R.P.…Saraiva J.A. Fruit juices. Elsevier; 2018. Pulsed electric field processing of fruit juices; pp. 437–449. [Google Scholar]

- Kumar K., Srivastav S., Sharanagat V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrasonics sonochemistry. 2020;105325 doi: 10.1016/j.ultsonch.2020.105325. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar K., Yadav A.N., Kumar V., Vyas P., Dhaliwal H.S. Food waste: A potential bioresource for extraction of nutraceuticals and bioactive compounds. Bioresources and Bioprocessing. 2017;4(1):1–14. [Google Scholar]

- Laurora A., Lund M.N., Tiwari B.K., Poojary M.M. Design and Optimization of Innovative Food Processing Techniques Assisted by Ultrasound. Elsevier; 2021. Application of ultrasound to obtain food additives and nutraceuticals; pp. 111–141. [Google Scholar]

- Lee H., Choi S., Kim E., Kim Y.-N., Lee J., Lee D.-U. Effects of Pulsed Electric Field and Thermal Treatments on Microbial Reduction, Volatile Composition, and Sensory Properties of Orange Juice, and Their Characterization by a Principal Component Analysis. Applied Sciences. 2021;11(1):186. [Google Scholar]

- Lee Y.-C., Tsai Y.-H., Chen S.-L., Kung H.-F., Arakawa O., Wei C.-I. Inactivation and Damage of Histamine-Forming Bacteria by Treatment with High Hydrostatic Pressure. Foods. 2020;9(3):266. doi: 10.3390/foods9030266. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li X., Mettu S., Martin G.J., Ashokkumar M., Lin C.S.K. Ultrasonic pretreatment of food waste to accelerate enzymatic hydrolysis for glucose production. Ultrasonics sonochemistry. 2019;53:77–82. doi: 10.1016/j.ultsonch.2018.12.035. [DOI] [PubMed] [Google Scholar]

- Liu C., Pirozzi A., Ferrari G., Vorobiev E., Grimi N. Impact of pulsed electric fields on vacuum drying kinetics and physicochemical properties of carrot. Food Research International. 2020;137 doi: 10.1016/j.foodres.2020.109658. [DOI] [PubMed] [Google Scholar]

- Marciniak A., Suwal S., Naderi N., Pouliot Y., Doyen A. Enhancing enzymatic hydrolysis of food proteins and production of bioactive peptides using high hydrostatic pressure technology. Trends in Food Science & Technology. 2018;80:187–198. [Google Scholar]

- Mastello R.B., Janzantti N.S., Monteiro M. Volatile and odoriferous compounds changes during frozen concentrated orange juice processing. Food Research International. 2015;77:591–598. [Google Scholar]

- Matthews C., Moran F., Jaiswal A.K. A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. Journal of cleaner production. 2021;283 [Google Scholar]

- Maza M.A., Pereira C., Martínez J.M., Camargo A., Álvarez I., Raso J. PEF treatments of high specific energy permit the reduction of maceration time during vinification of Caladoc and Grenache grapes. Innovative Food Science & Emerging Technologies. 2020;63 [Google Scholar]

- Mena-García A., Ruiz-Matute A.I., Soria A.C., Sanz M.L. Green techniques for extraction of bioactive carbohydrates. TrAC Trends in Analytical Chemistry. 2019;119 [Google Scholar]

- Mendoza J.M.F., D'aponte F., Gualtieri D., Azapagic A. Disposable baby diapers: Life cycle costs, eco-efficiency and circular economy. Journal of Cleaner Production. 2019;211:455–467. [Google Scholar]

- Misra N. The contribution of non-thermal and advanced oxidation technologies towards dissipation of pesticide residues. Trends in Food Science & Technology. 2015;45(2):229–244. [Google Scholar]

- Misra N., Cullen P.J., Barba F.J., Hii C.L., Jaeger H., Schmidt J.…Yoshida H. Food Waste Recovery. Elsevier; 2021. Emerging macroscopic pretreatment; pp. 173–193. [Google Scholar]

- Misra N.N., Keener K.M., Bourke P., Mosnier J.-P., Cullen P.J. In-package atmospheric pressure cold plasma treatment of cherry tomatoes. Journal of bioscience and bioengineering. 2014;118(2):177–182. doi: 10.1016/j.jbiosc.2014.02.005. [DOI] [PubMed] [Google Scholar]