Abstract

Every industry need helps to modify its working style quickly with the improvement of existing technology. New developing technologies improve production speed, reduce industrial process costs, etc. Technical specialists carry out continuous research and development to increase efficiency. A significant advance in 4D printing over 3D Printing is its capacity to alter shape over time because external elements such as pressure, air, heat, water, etc., use controlled impact. 4D Printing has one “D" instead of 3D Printing, and the fourth aspect is time. Therefore, its capacity to alter shape over time is a significant advancement of 4D printing over 3D printing technologies. It is evident that 4D printing will be of tremendous value to manufacturers regarding features and advances in dentistry. Its applications cover medical modelling, surgical guides manufacture, prosthodontics, dentistry, orthodontics, implantology, and dentistry instruments. This paper is brief about 4D printing and its printing of smart materials through 4D printing. Process workflow and Bio-Oriented 4D printable smart materials for dentistry are presented diagrammatically. Further, the paper identifies and discusses the significant potential of 4D printing for dentistry. 4D printing is an innovative technology that uses the inputs from smart materials, and the 3D printed item becomes another structure via the impact of external energy sources such as temperature, light, or other environmental stimuli. The objective is to integrate technology and design to create self-assembly and programmable material technologies that better design, production, and performance.

Keywords: 3D printing, 4D printing, Dentistry, Design, Materials

Graphical abstract

1. Introduction

The introduction of 3D printing has changed the health industry in numerous ways. However, as 3D printing outputs are stiff, flexible goods from 4D printing technology give way to personalising organ parts according to their look. An item made with 4D printing technology utilising smart materials in touch with external sources such as heat, water, etc., responds and changes shape and dimensions as planned.1,2 It allows us to manufacture items considerably more significant than the printer size. The design of individual patient devices is a highly skilled and labour-intensive, multidisciplinary procedure. 4D printing technology has many applications in various fields and has caused a significant transformation in healthcare and dentistry. It has expanded its range of chemotherapeutic, self-assembly, and tissue engineering applications.3,4

4D printing is suited to manufacture innovative dosing forms and drugs, bones, ears, exoskeletons, windpipes, jawbones, eyeglasses, cell cultures, sternum cells, arteries, circulatory systems, and tissues and bodies. Compared to 3D printing, 4D Printing technology employs sophisticated and programmable materials that add warm water, light, or heat to execute diverse functionalities.5,6 So, a non-living thing can, over time, modify its 3D form and behaviour. Commercial 3D printers like polyjet 3D printers are used in 4D printing technologies.7 The input is an intelligent substance, a hydrogel or a memory polymer. Due to its thermo-mechanical characteristics and material qualities, intelligent materials are distinguished from ordinary 3D printing materials by attributes of shape change.8, 9, 10

4D printing technique also uses stereolithographic principles that regulate how UV light may be employed throughout the printing process to cure a material layer by layer. Even though the 3D printing system is created similarly, it can change a 4D printing device over time. 4D printing technique employs a variety of features when they are combined with hot water, light, or heat. The most direct benefit of 4D printing is that items greater than printers may be produced as only one piece via computer folding. Since the 4D items created may change the form, decrease and unfold, things too large to fit a printer can be compressed into a secondary form for 3D printing. The use of potentially relevant materials is another benefit of 4D printing technology. 4D printing has a huge potential to change the material world.11, 12, 13

The forming time under thermal/physical conditions is another significant element. Patients with new 4D printed types of equipment were observed because the plying time may range from minutes to days and when changing the material into a final form and position. Biocompatibility, elasticity modulus, and thermosphere expansion coefficients, which should simulate body structures to prevent undesirable body reactions such as swell, inflammation, or ischemia reactions, are also the main features of 4D printing. Moreover, 4D printing materials should be resistant to prevent overtime breakage, requiring a revision operation. 4D printing supports the manufacture over time or space of shape-shifting materials with the possibility of controlling their tiny alterations for application in biomechanics.14, 15, 16 This paper is brief about 4D printing and its potential in the field of dentistry.

2. What is 4D printing?

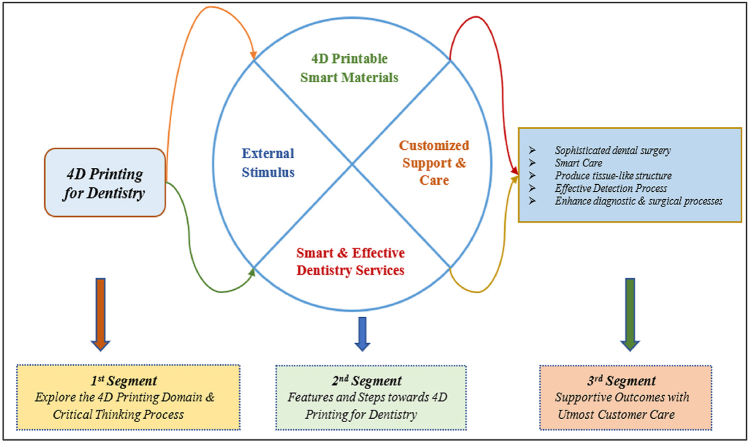

4D printing refers to adding and managing the fourth dimension in three-dimensional printing. It is an advanced/updated/new form of additive manufacturing in which we control the fourth dimension when producing any part/component/machine, etc. Heat, time, humidity, light, water, wind, electric energy, magnetic field, or any other kind of energy may all be considered in the fourth dimension. The fourth dimension acts as a stimulus, causing the 3D printed material to alter its shape, colour, functionality, etc. Materials are essential in 4D printing because they can alter the shape, colour, and functionality in response to an external input.17, 18, 19 Fig. 1 elaborates the working process circle of 4D printing.

Fig. 1.

Working process circle of the 4D Printing.

3. Need of the study

In 4D printed structures, the shape change behaviour is caused by variations in the proportions of dimensional changes of the internal components. Modifying the behaviour of the materials at the microscale can allow their usage for the construction of scaffolds in stem cell research and tissue engineering. In all fields of dentistry, 4D printing may have a significant influence. In 4D printing, there is a need to initiate the transformation with some stimuli or triggers. Water, heat, light, or electricity can be included. The abilities in tiny structures are used for this technique. The intended macro-structure deformation becomes apparent when properly designed.20,21

In removable prosthetic dentistry, 4D printing can be employed. This technique can manufacture materials similar to the hard and soft natural tissues in dentistry. Furthermore, 4D printed materials may be adapted to the stresses in the mouth cavity. The pre-printed 4D materials may possess dependable fitting and retention qualities and optimum dynamic features depending on their self-folding nature. Specific structures which have the flexibility and thermal criteria comparable to periodontal ligaments or excessive mucus can be built into the denture foundation.22, 23, 24 Furthermore, a range of design choices for particular requests can be offered and responds to specific environmental characteristics in dentistry.

4. Research objectives

4D printing is the overtime process under temperature and moisture fluctuations. This builds spontaneous modification in the form of smart 3D models under temperature and humidity conditions. 4D printing depends on multi-material, and the transformation process may be evaluated and controlled by assessing the stress characteristics of each component in the printed model. 4D printing in dentistry is the victor among all the digital processing methods, which can help to sort out various challenges. Its increased efficiency, passivity, flexibility, and superior material use are distinguished. 4D printing transforms digital dentistry with broad diagnostic, treatment, and education options. The increased research and excitement in this field would open up additional avenues for the digital dental revolution.25, 26, 27 The primary research objectives of this paper are as under:

RO1: - To brief about the 4D printing and its capabilities;

RO2: - To discuss the printing of Smart materials through 4D printing and illustrate the process workflow of the 4D printing concept for dentistry;

RO3: - To study the Bio-oriented 4D printable smart materials for dentistry;

RO4: - To identify and discuss the significant potential of 4D printing for dentistry.

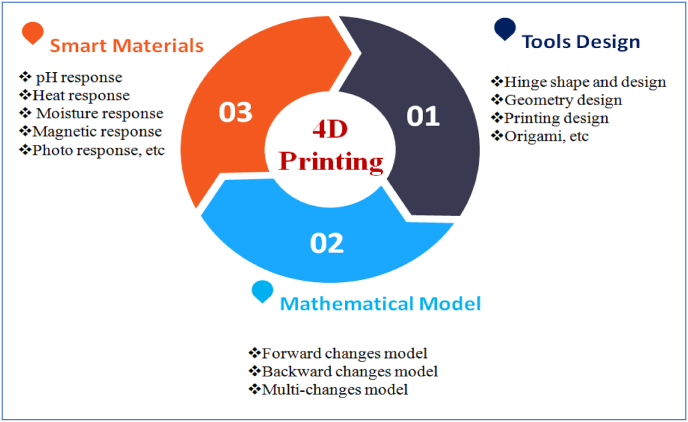

5. Printing of smart materials through 4D printing

Smart Materials for 4D printing are a new topic of study in which diverse materials are synthesised for deformation mechanisms based on their reactivity to various environmental stimuli. Shape memory polymers, Electro-responsive polymers, Magnetic shape memory alloys, Smart inorganic polymers, Shape memory alloys, Temperature responsive polymers, Photoresponsive polymers, and electroactive polymers are all examples of smart materials. Biocompatibility is another crucial attribute for biomedical applications, and other defining factors may take precedence depending on the printing technology used and the intended end-use. Photopolymerisation procedures, for example, necessitate the use of light-curable liquid resins. The time it takes for a structure to return to its permanent shape is called response time, and it varies depending on the printing materials employed.28, 29, 30

4D-printed filler materials can be designed to slide lower toward the cavity's fitting surface to achieve maximal adaptability. Furthermore, 4D-printed fillings can be used in inaccessible parts of the oral cavity where existing restorative materials are challenging to manipulate and maintain. Removable prosthetic dentistry can benefit from 4D printing. The method can create materials with qualities similar to genuine hard and soft tissues.31, 32, 33

4D-printed materials can also adjust to the different types and orientations of forces in the oral cavity. Because of their self-folding nature, 4D-printed prosthetic materials can have dependable fitting and retention features and excellent dynamic properties.34, 35 The denture base can be structured with the same elasticity and thermal properties as periodontal ligaments or the overlying mucosa. In addition, for patients with specific needs, a range of design choices are available. Patients with areas of residual ridge resorption, for example, can benefit from including materials that compensate for bone loss.34,36

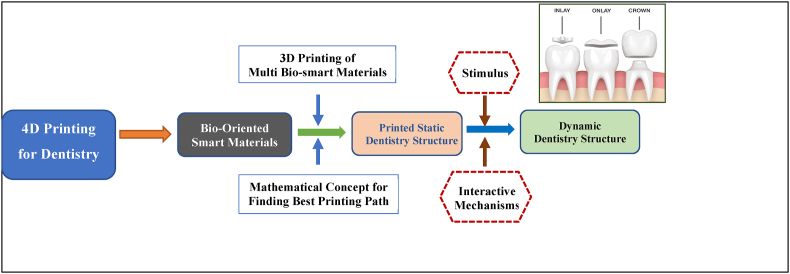

6. Concept of process work-flow of 4D printing for dentistry

Fig. 2 exemplifies the basic workflow processing steps of the 4D printing methodology for the dentistry domain. This process fundamentally starts with the 3D printing of available and suitable bio smart multiple materials for the fabrication and development of final dental components. It is further forwarded through a mix-up step of mathematical analysis and directions for preparing the under-process product for realistic and actual working situations.37, 38, 39, 40 External stimuli such as humidity, temperature, forces, moisture, and photo-sensitive, and these practical cases are often affected by external stimuli. These 4D printed dentistry products would be able to carry their basic functioning under the influential conditions of the stimulus as mentioned above and perform satisfactorily. The end step in Fig. 2 is highlighted with the developed smart 4D dentistry product, i.e., crown, tooth in/on-lay, etc., for their intended meanings and significances.41, 42, 43

Fig. 2.

Basic steps for 4D printing for dentistry.

The material in a 3D printer is a significant distinction between three-dimensional and four-dimensional printing methods. While 3D printer supplies materials from plastics to metal, the distinction between input items is that the input objects are configured to change shape during the 4D printing method. These materials can be a hydrogel or even a form of memory polymer. 4D printing is still in progress in its earliest phases, with very high expenses associated. As technology is becoming newer and newer, research is undertaken to examine this technology's business prospects. Conventional autonomous production processes such as milling produce significant waste by nature. Combined with additive manufacturing, these methods minimise waste.44, 45, 46, 47

In the present situation in architecture, 4D Printing uses its typical, adaptable façades and opening roofs for the correct imagination. In addition to its application in architecture, the usage in biomedicine has been a significant step forward in using 4D printed liquid resin. The resin has characteristics that retrieve its original form within a particular temperature range and contribute to biological scaffolding growth.48,49 With future advances in this technology and the costs being cut by technological specialists, the application of this technology will quickly rise. Light cure resin is used for stereolithography, photopolymer jetting, and digital light processing. A light-curated resin vat containing a photopolymer and a light-sensitive laser can be used to construct consecutive layers. A print head sprays light-sensitive polymer on a platform with gradually increasing lays in photopolymer jetting. Digital light processing uses liquid resin and a light source on an elevating platform to create the item upside down.50, 51, 52

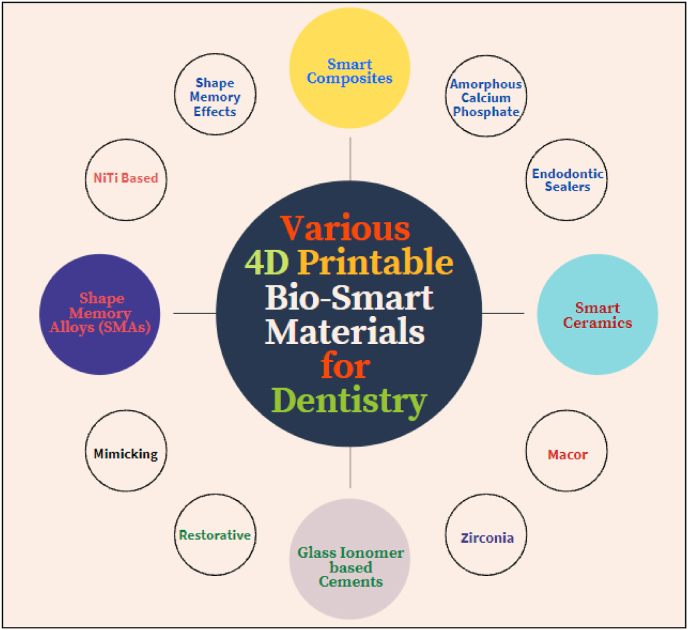

7. Bio-Oriented 4D printable smart materials for dentistry

Fig. 3 explores the various advanced and smart bio-inspired materials employed to fabric dentistry-related utilities through four-dimensional printing. The majorly revealed smart biomaterials have been categorised: as shape memory alloys, smart ceramics, smart composites, glass ionomer-based cement, etc. These biomaterials are found based on their applications in fabricating orthodontic crowns and tooth developments.53, 54, 55 The self-shape modification features of these elaborated smart biomaterials for dentistry have been further relevant and highly demanded in a different perspective of 4D printing and its allied biomedical applications. Any provided external stimulus further impacts its reliability and durability under the several practical situations under which these 4D printed dental products are required to perform their functions satisfactorily.56, 57, 58, 59, 60

Fig. 3.

Illustration of various 4D printable bio-smart materials for dentistry.

In the few years, considerable efforts have been made to introduce and develop materials with shape memory. These materials are essentially created for finite dimensions, held under specific heat or strain momentarily. There are improvements in materials science and improved knowledge of polymerisation and cross-linking. Several common aspects of the 4D printing process with memory form eliminate manufacturing. In large-scale undertakings, 4D printing would be much more beneficial. It can have exciting uses in settings like space. 3D printing has a method-specific cost, efficiency, and energy consumption problems in space. So 4D printed materials might be employed to use their transformable shape rather than utilising 3D printed materials. They might give the solution for building bridges, shelters, or other facilities, as in cases of weather damage, they would either build up or repair themselves.61, 62, 63, 64

Every day there are unbelievable internal possibilities for 4D printing. Besides replacement bones, both muscle and cartilage are now received. A specialised 4D printer called a bioprinter can produce cells in forms comparable to the original tissue by utilising different polymer materials. The cells have a microchannel lattice in the tissues themselves. This makes it possible to provide nutrition and oxygen as usual. The cells are continuously nourished and hence continue to develop.65, 66, 67, 68, 69 The tissue, cartilage, and blood arteries that support structures were implanted under the skin in several animal studies. Blood vessels and complicated nerves have been developed to sustain specific 4D printed objects. Facial prosthetics are used in patients with eye cancer by combining the facial scan of the patient with 4D printing. The cells can be recreated, and the material may be produced for a 4D printer. One of the most common uses of 4D medical printing is surgical models that physicians may use during their studies at medical institutions and prepare for complicated and demanding procedures.70, 71, 72, 73, 74

8. The significant potential of 4D printing for dentistry

The 4D printing method produces parts with varied physical characteristics and physical stimulus over time, auto-folding features of the 3D printable format. A structured hybrid of smart materials is the end item of 4D prints. Each of these materials offers an elongation direction and quantity difference, such that the finished product moves with time.75, 76, 77 Motion or elongation might be the primary stimulus in the oral cell and substantially impact future 4D printing applications in therapeutic, electric, and magnet stimuli, radiation, or moisture. The fusion of biological and electronic features indicates a change from the existing state of affairs to the replication and the strengthening of human capacities.78, 79, 80 Table 1 briefs the significant potential of 4D printing for dentistry.

Table 1.

Significant potential of 4D printing for dentistry.

| S No | Potential | Description |

|---|---|---|

| 1 | Denture removal | 4D printing uses smart materials to manufacture smart dentures, arranging the occlusion forces, ages, eating, and drinking patterns. It can result from performing daily activities to develop removable prosthesis dentures. Filling materials may be adapted to constant movements and designed to overcome the inconveniences of dental practitioners' dimensional alterations using the available market materials for a long time. In addition, 4D printing can be used to improve temporomandibular joint problems. Injected or surgically implanted into the joint space might be manufactured by these intelligent materials. |

| 2 | Smart Orthodontics | 4D printed parts have various features in order to adjust for dimensional variations and deceleration. This beneficial feature might assist in preventing marginal leakage. This technology can be utilised in orthodontics as functional equipment. Intelligent, mobile, and detachable appliances that maintain overtime movements might rectify dental inequalities. Various applications such as arch extension equipment and bite-raising devices might be implemented. Intelligently moving bands and wires that move teeth in the appropriate direction might improve fixed orthodontic systems with desired results over time and with atraumatic reactions in bones and periodontal ligaments. |

| 3 | Dental scaffolds | Tissue cultural engineering uses 3D printing to create scaffolds for implantation in live cells or stem cells. 4D printing can strengthen these processes since the dental scaffolds are mobile to ensure that stem cells are delivered to the target regions for specific functions. Further, 4D printing in implant dentistry might boost existing research into producing a fully 3D printed tooth, thereby allowing the coating base to move in harmony with the surrounding periodontia. In addition, this can produce a general 4D dental implant that simulates those with natural teeth with mobile characteristics. 4D printed organic scaffolds in the human body enable tissue to develop in this scaffolding and surround it, therefore essentially initiating new bone formation. Biological tissue and functioning electronics would be used to build multi-dimensional bionic organs that have improved sensory functions. |

| 4 | Surgical drill guides | 4D printing is state-of-the-art technology to manufacture anything from plastic to metal with precision and speed. Dentists can design and press surgical drill guides, temporary and permanent corners and bridges, orthodontic devices, implants, and drug mouthguards in the latest advancements in 4D printing technology in dentistry and maxillofacial surgery. Several 4D printing technologies are accessible for dental usage and used to generate self-folding materials. Introducing materials such as functional items can be highly beneficial in medicine and dentistry. This method might allow physicians to modify the dental scope and give other treatment choices. |

| 5 | Enhance diagnostic and surgical processes | 4D printing has made it possible for physicians to enhance their diagnostic and surgical processes, making better viewing, realistic training, and surgical planning possible. The dental practice has revolutionised this technology since it can deliver maximum precision with minimum clinical setup and fast operating time. 4D printing in dentistry is necessary and plays the leading role in facial reconstruction operations and temporomandibular problems, which necessitate surgery. In medical terms, 4D printing linked to a scanning approach used to monitor different organs' dynamic features showed significant advantages in positioning dynamic tissues during radiation treatment and monitoring thumb movements for arthroplasty. |

| 6 | Useful for the oral environment | In dentistry, 4D printing has a significant influence on many specialities because, under constantly changing circumstances of temperature and humidity, the technology can generate dynamic and adaptive materials that are useful in the oral environment. Unwanted dimensional changes, heat instability, polymerisation reduction, and microleakage are contemporary dental issues that may be addressed with 4D printing technology. For dental restorative materials, 4D printing can be employed. The biomechanical qualities of dentures have long been a major subject; strength, colour stability, adherence, durability, and insufficiency are essential features of dental fillings. |

| 7 | Specific patient dental prosthesis | Objects self-folding may be used for dental, surgical, and medical functionally. Given the extensive use of such materials, there is a major advancement in dentistry. The prosthesis may be set to adjust for age and everyday activities, designed and adjusted for specific patients. Prosthetic cardiac valves have been conceived in line with blood flow with programmed motion behaviour. There is a rise and a reduction of blood via the valve depending on the blood pressure. In contrast to conventional 3D valves, 4D valves can handle blood pressure fluctuations. |

| 8 | Devices adjusted as per patient's mouth | 4D printing may be applied in dentistry in various applications based on its mobile nature and can become helpful. The mouth constantly changes so that 4D print items may be folded and kept folding continuously. 4D printing provides items that can be used for a positive effect. This may be converted into a joint implant in orthopaedics, where mobile discs replace standard plastic discs to act in the cushions of knees, hips, ankles, and shoulder joints. For the health business, shape memory polymer looks like customisable forms. |

| 9 | Replace lost tooth structure | The oral environment is challenging to replace lost tooth structures, both in its dynamic character and functional and balance factors. Materials breakdown usually results in dimension changes on the edges leading to instability or complete loss of dental fillings. The result of 4D printing can be materials with a constant adaptation to self-folding, that is to say, materials that can move towards the peripheries to prevent microleakage or marginal overhangs. 4D printing enabled the improved visualising of deep structures such that possible problems, including longer surgical time and resultant infection or blood loss, were minimised during surgery. This technology contributes to the manufacture of detachable dentures and prostheses in the simple aesthetic and restaurant daily job. |

| 10 | Produce tissue-like structure | 4D printing finds uses in organ printing via individual production or layers of cells and biomaterials that produce a tissue-like structure. It might assist in overcoming the enormous deficit in donor organ production once it occurs from childhood. Further, 4D printing is also possible to manufacture individualised medications in novel formulations, such as multilayer, multi-reservoir, microcapsules, nanosuspensions, and multilayer drug delivery systems, which comprise several active substances. 4D printing is carried out utilising organic components, including stem cells, proteins, and factors for growth. In the future, doctors may replace sections of the body like tissues, arteries, and organs easier after using such materials has been completely established for 4D printing. |

| 11 | Smart dental implants | 4D printing can be used to produce smart implants quickly. The appropriate implanter design layer is produced by concentrating a high-power laser beam that fuses metal particles to a powder bed without any post-processing processes. Other dental uses include crown coping, frameworks for partial dentures, surgical tools, oral and maxillofacial implants, and forensic odonatological and simulation models for educational purposes. In healthcare, 4D printing offers enormous promise. Biocompatible materials like hydrogels and polymers might be utilised during the 4D impressions. In 4D printed orthodontic devices, the position of the teeth could vary by undergoing a regulated automatic self-folding motion which can be undertaken by using this technology. |

| 12 | Sophisticated dental surgery | 4D printed models allow more sophisticated dental surgery. This also benefits in as many sectors, from medical to electronics and much beyond. 4D printing focus adds a more intuitive, intelligent aspect to the manufacturing. 4D printing is divided into medical and research models, operating manuals, and patient-specific implants based on their use. 4D printing technology's capacity to produce smart health models will significantly alter the medical sector and assist in expanding this area throughout the predicted period. Our digital future includes other diagnostic instruments and treatment methods that increase and extend the use of speciality. |

| 13 | Human bone structure | A new development in 4D bioengineering technology allows the human bone structure to be shaped. 4D printing may also modify tissue of the nerve, skeletal muscles, and skeleton ligaments which can print form-changing materials. Due to the growing availability of print personalisation, the medical and health sectors actively explore the areas of 4D printing. 4D printing includes implants, artificial bones, artificial organs, and medical assistance. 4D printing has emerged as an upgrade in medicine, making it an anticipatory alternative. Active materials such as memory polymers are utilised to generate a solid form that changes its current shape and returns to the original form if activated in a regulated fashion. This is due to the chemical interaction of the ingredients employed in production. After printing, the material responds to the environment, such as heat, humidity, and other factors, and changes its shape, size, etc., which is a programmable substance. |

| 14 | Successful patient treatment | 4D printed models may be customised according to the patient's disease so that patient treatment could become efficient and successful. 4D technology has demonstrated its capacity to revolutionise the dental sector in developing smart models. The primary use of the therapeutic medication supplied in a specific human body position is targeted drug supply. 4D printed devices can transport medicinal medicines where the exact triggers are activated. Now, 4D Printing's core notion retains 3D printing intact and adds a whole new element. With 4D Printing, we can alter the structures that have been produced throughout time. 4D printing is utilised on 3D printers fed with some smart material. This intelligent substance is a memory polymer hydrogel or form that helps perform the various intended functions. |

| 15 | Improve quality, efficiency and performance | 4D printing technology extends 3D printing and provides increased quality, efficiency, and performance. Due to strong rivalry, the desire to lower production and processing costs should be a major driver in speeding up the global 4D printers market in the future years. Numerous technologies are now combined to contribute to 4D printing material performance breakthroughs. The technologies include materials science, 3D/4D multi-material printing, and novel optimisation and simulation software capabilities. These functions have enabled a variety of materials to be fully programmed to alter appearance, form, or other qualities as required. |

4D biologic printing on human organs will lead to a bold new age for pioneering and inventive medication discovery. Pharmaceutical companies may safely test novel medication formulae on 4D printed human organs in the earliest developmental life stage, resulting in more precise findings. In dentistry of implants, 4D-printed objects can be utilised as fused in the dental implants that are already available by changing the apical part of the implant to become a soft basis. This can help to protect the implant site against damage to critical issues like the maxillary sinus and lower alveolar nerve. This method can therefore overcome complex operations like sinus increases in implant situations. Stem cells can also be transported to natural teeth through 4D implants and tooth-shaped scaffolds.81, 82, 83, 84

9. Other broad areas of 4D printing

4D printing has enormous potential; it will uniquely change all industries. The automobile industry looks to be revolutionised by 4D printing technology. The promise lies in a standard memory alloy that can readily recover the previous form by heat or vibration stimulation. In addition, 4D printing may change wheel form based on the road's surroundings. The heart of 4D printing is the technology for self-modification and assembly. Intelligent materials should be utilised, such as form memory alloys which can be changed. The range of intelligent materials employed in 4D printing, as many anticipate, extends human life with further scientific advances.85,86 Table 2 discusses some of the broad options offered by 4D printing using smart materials.

Table 2.

Other broad areas of 4D Printing.

| S. No | Areas | Description |

|---|---|---|

| 1 | Fashion |

|

| ||

| ||

| ||

| 2 | Medical |

|

| ||

| ||

| 3 | Aerospace |

|

| ||

| ||

| 4 | Automotive |

|

| ||

| 5 | Electronics |

|

| 6 | Constriction |

|

| ||

| ||

| 7 | Defence |

|

| ||

| 8 | Education |

|

Using a more robust material to provide accurate overturn during form change is revolutionary, as the reversible 4D printer alone is an excellent breakthrough since it enables us to build complicated structures that cannot be accomplished simply through conventional production. 4D printing technique uses, due to its various characteristics and other features, materials such as single-form memory polymers, fluid crystal elastics, hydrogel composites, SMP composites, multi-material SMP, and other multifunctional materials. 4D printing in the real world might use tubes of a plumbing system, which would alter their diameter dynamically in response to the flow rate and water demand. Pipes can automatically mend themselves if they break or fracture because they can change in reaction to changing environment.87,88 As the size of the printer limits the 3D printing furniture, 4D printing can only enable a flat shell to be printed, which can curl in a chair simply by adding light or water.

10. Discussion

4D printing adds the extra element of time inspired by the capacity of live creatures to react to and adapt to their environments. Exposed to an external trigger, whether this pressure, humidity, temperatures, electricity, heat, or light, 4D dynamic composite prints may modify their shape on order and even revert to their original proportions. This succession to 3D printing ensures that 4D medication supplies are intended only to release a string payload. The body temperature may be used to activate 4D drug supplies. 4D printing in areas such as medicine is utilised on a microscopic scale. 4D printed proteins might be an excellent application for the medical area. The programmed stents wandered about the human body and opened up when they reached their target. Only specific directions, programmed before manufacturing, can move the materials produced by 4D printing. 4D printed materials are adjusted during restorative dentistry; dental adhesives may be eliminated since the materials can rely more on mechanical conservation methods than chemical assistance. In addition, the inaccessible places in the mouth cavity where manipulation and lifespan of existing materials are problematic can be employed with 4D-printed fillers.

Detachable and fixed braces may be transferred from 3D orthodontic software. Self-training wires or self-folding detachable can result in continuous over time motion for orthodontic equipment that ends in the desired position and angulations with positioning and the alignment of teeth. 4D printing is an intriguing study subject that can influence medical and dental applications practically and well. The production process is based on the 4D printing of various materials that may change over time under varied thermal/physical conditions, with increased digital form-memory characteristics. In 4D printing, the order and route of the moves are crucial, which determines the pattern of self-folding. The circumferential structures around the 4D printed prosthetic apparatus were considered in the design. For instance, in addition to the possible side features of high/low blood pressure, the design of a cardiac valve considers the contractile movement and motion of the muscles of the cardiac and pulmonary vasculatures.

11. Future scope

The subsequent development in 4D printing may use to produce out-of-the-box materials. While typical 3D printers generate a three-dimensional space to produce desired forms, 4D printers add a different dimension; time. 4D printing technology has evolved and increased its application to produce functioning parts in dentistry. The future for orthodontics is in 4D printing to transform a static procedure into a dynamic appliance. 4D printing is a digital technique achieved by movement in the 3D printed components and production of dental devices. The future of digital orthodontic treatment can be revolutionised by 4D printing. 4D printed devices, fixed or detachable, would increase treatment efficiency and leverage digital processes to include imaging and diagnostic tools. All these possible uses appear to be quite inspirational and promising in the future. 4D printed material characteristics have much to offer and undoubtedly help its growth in the additive manufacturing sector. This technology has already changed its traditional fabrication and how it will impact the future.

12. Conclusion

4D printing is an essential application in the dentistry sector. It is used to manufacture 3D smart aligner devices in the dental profession. The growing use of dental implants using 4D printers such as prostheses, bridges, crowns, etc., creates profitable prospects for the expansion of the target sector. While 3D printing technology is utilised in many sectors, the growing material complexity creates opportunities for technical breakthroughs. 4D printing utilises intelligent materials to produce items that can be built, flexible, or respond to changing environments. The technology is still in research and development in the automotive, medical, and aviation industries. 4D technologies is a new business model based on 3D printing technology, which will respond to current company requirements with decreased capital, inventory, and time-to-market requirements and therefore increase corporate efficiency. Among all 4D printing materials, shape memory polymers are regarded as one of the most promising 4D materials, increasing rigidity and a quicker reaction rate. The application of 4D printing in dentistry enables dentistry parts, medicines, and equipment to be personalised for the benefit of healthcare professionals and patients. Custom 4D implants, devices, and operating equipment decrease surgery and recuperation times and enhance operational and implant success. In future, this technology will provide great opportunities to fulfil the various challenges in dentistry.

Declaration of competing interest

None.

Contributor Information

Mohd Javaid, Email: mjavaid@jmi.ac.in.

Abid Haleem, Email: ahaleem@jmi.ac.in.

Ravi Pratap Singh, Email: singhrp@nitj.ac.in.

Shanay Rab, Email: shanayrab753@gmail.com.

Rajiv Suman, Email: dr.r.suman@gbpuat-tech.ac.in.

Lalit Kumar, Email: rathee.lalit.2007@gmail.com.

References

- 1.Shie M.Y., Shen Y.F., Astuti S.D., et al. Review of polymeric materials in 4D printing biomedical applications. Polymers. 2019 Nov;11(11):1864. doi: 10.3390/polym11111864. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Khorsandi D., Fahimipour A., Abasian P., et al. 3D and 4D printing in dentistry and maxillofacial surgery: printing techniques, materials, and applications. Acta Biomater. 2020 Dec 26 doi: 10.1016/j.actbio.2020.12.044. [DOI] [PubMed] [Google Scholar]

- 3.Schweiger J., Beuer F., Stimmelmayr M., Edelhoff D., Magne P., Güth J.F. Histo-anatomic 3D printing of dental structures. Br Dent J. 2016 Nov;221(9):555–560. doi: 10.1038/sj.bdj.2016.815. [DOI] [PubMed] [Google Scholar]

- 4.Zhang Z., Demir K.G., Gu G.X. Developments in 4D-printing: a review on current smart materials, technologies, and applications. Int J Soc Netw Min. 2019 Jul 3;10(3):205–224. [Google Scholar]

- 5.Choong Y.Y., Maleksaeedi S., Eng H., Wei J., Su P.C. 4D printing of high performance shape memory polymer using stereolithography. Mater Des. 2017 Jul 15;126:219–225. [Google Scholar]

- 6.Momeni F., Liu X., Ni J. A review of 4D printing. Mater Des. 2017 May 15;122:42–79. [Google Scholar]

- 7.Jeong H.Y., Woo B.H., Kim N., Jun Y.C. Multicolor 4D printing of shape-memory polymers for light-induced selective heating and remote actuation. Sci Rep. 2020 Apr 10;10(1) doi: 10.1038/s41598-020-63020-9. 1-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Choudhary H., Vaithiyanathan D., Kumar H. A review on additive manufactured sensors. MAPAN. 2021;36:405–422. doi: 10.1007/s12647-020-00399-w. [DOI] [Google Scholar]

- 9.Mitchell A., Lafont U., Hołyńska M., Semprimoschnig C.J. Additive manufacturing—a review of 4D printing and future applications. Addit Manuf. 2018 Dec 1;24:606–626. [Google Scholar]

- 10.Lee A.Y., An J., Chua C.K. Two-way 4D printing: a review on the reversibility of 3D-printed shape-memory materials. Engineering. 2017 Oct 1;3(5):663–674. [Google Scholar]

- 11.Javaid M., Haleem A. Exploring smart material applications for COVID-19 pandemic using 4D printing technology. J. Indus. Integrat. Manag. 2020 Dec 19;5:481–494. 04. [Google Scholar]

- 12.Javaid M., Haleem A. 4D printing applications in medical field: a brief review. Clin Epidemiol Global Health. 2019 Sep 1;7(3):317–321. [Google Scholar]

- 13.Zhang Y., Josien L., Salomon J.P., Simon-Masteron A., Lalevée J. Photopolymerization of zeolite/polymer-based composites: toward 3D and 4D printing applications. Clin. Polym. Mater. 2020 Dec 11;3(1):400–409. [Google Scholar]

- 14.Shin D.G., Kim T.H., Kim D.E. Review of 4D printing materials and their properties. Int J Prec Eng Manuf Green Technol. 2017 Jul;4(3):349–357. [Google Scholar]

- 15.Subash A., Kandasubramanian B. 4D printing of shape memory polymers. Eur Polym J. 2020 Jul 5;134 [Google Scholar]

- 16.Bajpai A., Baigent A., Raghav S., Brádaigh C.Ó., Koutsos V., Radacsi N. 4D printing: materials, technologies, and future applications in the biomedical field. Sustainability. 2020 Jan;12(24) [Google Scholar]

- 17.Zarek M., Mansour N., Shapira S., Cohn D. 4D printing of shape memory‐based personalised endoluminal medical devices. Macromol Rapid Commun. 2017 Jan;38(2) doi: 10.1002/marc.201600628. [DOI] [PubMed] [Google Scholar]

- 18.Trenfield S.J., Awad A., Madla C.M., et al. Shaping the future: recent advances of 3D printing in drug delivery and healthcare. Expet Opin Drug Deliv. 2019 Oct 3;16(10):1081–1094. doi: 10.1080/17425247.2019.1660318. [DOI] [PubMed] [Google Scholar]

- 19.Haleem A., Javaid M., Singh R.P., Suman R. Significant roles of 4D printing using smart materials in the field of manufacturing. Adv. Indus. Eng. Polym. Res. 2021 May 31 [Google Scholar]

- 20.Liu G., He Y., Liu P., et al. Development of bio implants with 2D, 3D, and 4D additive manufacturing materials. Engineering. 2020 Nov 1;6(11):1232–1243. [Google Scholar]

- 21.Manikandan N., Rajesh P.K., Harish V. An analysis of the methods and materials for 4-dimensional printing. Mater Today Proc. 2021 Jan 1;38:2167–2173. [Google Scholar]

- 22.Sharma D., Mathur V.P., Satapathy B.K. Biodegradable and biocompatible 3D constructs for dental applications: manufacturing options and perspectives. Ann Biomed Eng. 2021 Jul 27:1–27. doi: 10.1007/s10439-021-02839-3. [DOI] [PubMed] [Google Scholar]

- 23.Piedra-Cascón W., Krishnamurthy V.R., Att W., Revilla-León M. 3D printing parameters, supporting structures, slicing, and post-processing procedures of vat-polymerisation additive manufacturing technologies: a narrative review. J Dent. 2021 Mar 5 doi: 10.1016/j.jdent.2021.103630. [DOI] [PubMed] [Google Scholar]

- 24.Li Y., Zhang F., Liu Y., Leng J. 4D printed shape memory polymers and their structures for biomedical applications. Sci China Technol Sci. 2020 Feb 28;63:545–560. [Google Scholar]

- 25.Wei H., Zhang Q., Yao Y., Liu L., Liu Y., Leng J. Direct-write fabrication of 4D active shape-changing structures based on a shape memory polymer and its nanocomposite. ACS Appl Mater Interfaces. 2017 Jan 11;9(1):876–883. doi: 10.1021/acsami.6b12824. [DOI] [PubMed] [Google Scholar]

- 26.Ghomi E.R., Khosravi F., Neisiany R.E., Singh S., Ramakrishna S. Future of additive manufacturing in healthcare. Curr. Opin. Biomed. Eng. 2020 Oct 25 [Google Scholar]

- 27.Kapoor A., Chopra P., Sehgal K., Sood S., Jain A., Grover V. 3D Printing in Biomedical Engineering. Springer; Singapore: 2020. Novel and emerging materials used in 3D printing for oral health care; pp. 317–336. [Google Scholar]

- 28.Haleem A., Javaid M., Vaishya R. 4D printing and its applications in orthopaedics. J Clin Orthop Trauma. 2018 Jul;9(3):275. doi: 10.1016/j.jcot.2018.08.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Liaw C.Y., Guvendiren M. Current and emerging applications of 3D printing in medicine. Biofabrication. 2017 Jun 7;9(2) doi: 10.1088/1758-5090/aa7279. [DOI] [PubMed] [Google Scholar]

- 30.Arefin A.M., Khatri N.R., Kulkarni N., Egan P.F. Polymer 3D printing review: materials, process, and design strategies for medical applications. Polymers. 2021 Jan;13(9):1499. doi: 10.3390/polym13091499. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Scheithauer U., Weingarten S., Johne R., et al. Ceramic-based 4D components: additive manufacturing (AM) of ceramic-based functionally graded materials (FGM) by thermoplastic 3D printing (T3DP) Materials. 2017 Dec;10(12):1368. doi: 10.3390/ma10121368. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Das U., Mohanty G., Nayak R. 4D bioprinting, newer prospects in regeneration. Indian J Forensic Med Toxicol. 2020 Oct 1;14(4) [Google Scholar]

- 33.Vates U.K., Mishra S., Kanu N.J. Biomimetic 4D printed materials: a state-of-the-art review on concepts, opportunities, and challenges. Mater Today Proc. 2021 Jul 21 [Google Scholar]

- 34.Larush L., Kaner I., Fluksman A., et al. 3D printing of responsive hydrogels for drug-delivery systems. J. 3D Print. Med. 2017 Oct;1(4):219–229. [Google Scholar]

- 35.Hart L.R., He Y., Ruiz-Cantu L., et al. 3D and 4D Printing of Polymer Nanocomposite Materials. Elsevier; 2020 Jan 1. 3D and 4D printing of biomaterials and biocomposites, bioinspired composites, and related transformers; pp. 467–504. [Google Scholar]

- 36.Ahmed J. 2019 Feb 19. Recent Advances of Novel Materials for 3D/4D Printing in Biomedical Applications. 3D and 4D Printing in Biomedical Applications: Process Engineering and Additive Manufacturing; pp. 239–271. [Google Scholar]

- 37.Zhou W., Qiao Z., Nazarzadeh Zare E., et al. 4D-printed dynamic materials in biomedical applications: chemistry, challenges, and their future perspectives in the clinical sector. J Med Chem. 2020 Apr 7;63(15):8003–8024. doi: 10.1021/acs.jmedchem.9b02115. [DOI] [PubMed] [Google Scholar]

- 38.Huang J., Xia S., Li Z., Wu X., Ren J. Applications of four-dimensional printing in emerging directions: review and prospects. J Mater Sci Technol. 2021 May 1 [Google Scholar]

- 39.Cristache C.M., Totu E.E. Reactive and Functional Polymers Volume Three. Springer; Cham: 2021. 3D printing-processed polymers for dental applications; pp. 141–164. [Google Scholar]

- 40.Nesic D., Durual S., Marger L., Mekki M., Sailer I., Scherrer S.S. Could 3D printing be the future for oral soft tissue regeneration? Bioprinting. 2020 Sep 15 [Google Scholar]

- 41.Sinha S.K. 3D and 4D Printing of Polymer Nanocomposite Materials. Elsevier; 2020 Jan 1. Additive manufacturing (AM) of medical devices and scaffolds for tissue engineering based on 3D and 4D printing; pp. 119–160. [Google Scholar]

- 42.Rastogi P., Kandasubramanian B. Breakthrough in the printing tactics for stimuli-responsive materials: 4D printing. Chem Eng J. 2019 Jun 15;366:264–304. [Google Scholar]

- 43.Langford T., Mohammed A., Essa K., Elshaer A., Hassanin H. 4D printing of origami structures for minimally invasive surgeries using functional scaffold. Appl Sci. 2021 Jan;11(1):332. [Google Scholar]

- 44.Wu J.J., Huang L.M., Zhao Q., Xie T. 4D printing: history and recent progress. Chin J Polym Sci. 2018 May 1;36(5):563–575. [Google Scholar]

- 45.Kanu N.J., Gupta E., Vates U.K., Singh G.K. An insight into biomimetic 4D printing. RSC Adv. 2019;9(65):38209–38226. doi: 10.1039/c9ra07342f. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.González-Henríquez C.M., Sarabia-Vallejos M.A., Rodriguez-Hernandez J. Polymers for additive manufacturing and 4D-printing: materials, methodologies, and biomedical applications. Prog Polym Sci. 2019 Jul 1;94:57–116. [Google Scholar]

- 47.del Barrio J., Sánchez‐Somolinos C. Light to shape the future: from photolithography to 4D printing. Adv Opt Mater. 2019 Aug;7(16) [Google Scholar]

- 48.Li A., Challapalli A., Li G. 4D printing of recyclable lightweight architectures using high recovery stress shape memory polymer. Sci Rep. 2019 May 20;9(1):1–3. doi: 10.1038/s41598-019-44110-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Ahmed A., Arya S., Gupta V., Furukawa H., Khosla A. 4D printing: fundamentals, materials, applications and challenges. Polymer. 2021 Jun 6 [Google Scholar]

- 50.Bonifacich F.G., Lambri O.A., Recarte V., Sánchez-Alarcos V., Perez-Landazabal J.I. Magnetically tunable damping in composites for 4D printing. Compos Sci Technol. 2021 Jan 5;201 [Google Scholar]

- 51.Grinberg D., Siddique S., Le M.Q., Liang R., Capsal J.F., Cottinet P.J. 4D Printing based piezoelectric composite for medical applications. J Polym Sci B Polym Phys. 2019 Jan 15;57(2):109–115. [Google Scholar]

- 52.Zhou H., Bhaduri S.B. Biomaterials in Translational Medicine. Academic Press; 2019 Jan 1. 3D printing in the research and development of medical devices; pp. 269–289. [Google Scholar]

- 53.Adam G., Benouhiba A., Rabenorosoa K., Clévy C., Cappelleri D.J. 4D printing: enabling technology for microrobotics applications. Adv. Intell. Syst. 2021 May;3(5) [Google Scholar]

- 54.Javaid M., Haleem A. Significant advancements of 4D printing in the field of orthopaedics. J. Clin. Orthop. Trauma. 2020 Jul 1;11:S485–S490. doi: 10.1016/j.jcot.2020.04.021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Al-Dulimi Z., Wallis M., Tan D.K., Maniruzzaman M., Nokhodchi A. 3D printing technology as innovative solutions for biomedical applications. Drug Discov Today. 2020 Nov 16 doi: 10.1016/j.drudis.2020.11.013. [DOI] [PubMed] [Google Scholar]

- 56.Das U., Mohanty G., Mohanty R., Nayak R. 3D printing, innovative approach in dentistry. Indian J. Publ. Health Res. Dev. 2019 Nov 1;10(11) [Google Scholar]

- 57.Tan D., Nokhodchi A., Maniruzzaman M. 2019 Feb 19. 3d and 4d Printing Technologies: Innovative Process Engineering and Smart Additive Manufacturing. 3D and 4D Printing in Biomedical Applications: Process Engineering and Additive Manufacturing; pp. 25–52. [Google Scholar]

- 58.Deshmukh K., Muzaffar A., Kovářík T., Křenek T., Ahamed M.B., Pasha S.K. 3D and 4D Printing of Polymer Nanocomposite Materials. Elsevier; 2020 Jan 1. Fundamentals and applications of 3D and 4D printing of polymers: challenges in polymer processing and prospects of future research; pp. 527–560. [Google Scholar]

- 59.Shakibania S., Ghazanfari L., Raeeszadeh-Sarmazdeh M., Khakbiz M. Medical application of biomimetic 4D printing. Drug Dev Ind Pharm. 2021 Apr 3;47(4):521–534. doi: 10.1080/03639045.2020.1862179. [DOI] [PubMed] [Google Scholar]

- 60.Chen Q., Han L., Ren J., Rong L., Cao P., Advincula R.C. 4D printing via an unconventional fused deposition modeling route to high-performance thermosets. ACS Appl Mater Interfaces. 2020 Oct 26;12(44):50052–50060. doi: 10.1021/acsami.0c13976. [DOI] [PubMed] [Google Scholar]

- 61.Willemen N.G., Morsink M.A., Veerman D., et al. From oral formulations to drug-eluting implants: using 3D and 4D printing to develop drug delivery systems and personalised medicine. Bio-Des Manuf. 2021 Sep 4:1–22. [Google Scholar]

- 62.Ali M.H., Abilgaziyev A., Adair D. 4D printing: a critical review of current developments, and future prospects. Int J Adv Manuf Technol. 2019 Nov;105(1):701–717. [Google Scholar]

- 63.Zafar M.Q., Zhao H. 4D printing: future insight in additive manufacturing. Met Mater Int. 2019 Sep 17:1–22. [Google Scholar]

- 64.Fahimipour A., Sedaghati M. Success rate of treatment by reviewing 4D printers in maxillofacial surgeries. Int Dent J. 2021 Sep 1;71:S44. [Google Scholar]

- 65.Eshkalak S.K., Ghomi E.R., Dai Y., Choudhury D., Ramakrishna S. The role of three-dimensional printing in healthcare and medicine. Mater Des. 2020 Jul 10 [Google Scholar]

- 66.Haleem A., Javaid M. Expected role of four-dimensional (4D) CT and four-dimensional (4D) MRI for the manufacturing of smart orthopaedics implants using 4D printing. J Clin Orthopaed Trauma. 2019 Oct 1;10:S234–S235. doi: 10.1016/j.jcot.2019.01.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Dodziuk H. Applications of 3D printing in healthcare. Kardiochirurgia i torakochirurgia polska. Pol. J. Cardio. Thorac. Surg. 2016 Sep;13(3):283. doi: 10.5114/kitp.2016.62625. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.Reddy C.S., Reddy A.M., Shantipriya P., Solomon R.V. 3D printing-an advancing forefront in imprinting the inner dimensions of tooth with precision. J. Acad. Dental Educ. 2017 Jun 1;3(2):19–24. [Google Scholar]

- 69.Nugroho W.T., Dong Y., Pramanik A., Leng J., Ramakrishna S. Smart polyurethane composites for 3D or 4D printing: general-purpose use, sustainability and shape memory effect. Compos B Eng. 2021 Jun 24 [Google Scholar]

- 70.Dhokar A.A., Atre S.Y., Bhatnagar S., Bhanushali N.V. Knowledge and practices of 3d printing in dental practitioners of Maharashtra: a cross-sectional study. J Indian Acad Oral Med Radiol. 2020 Apr 1;32(2):127. [Google Scholar]

- 71.Kafle A., Luis E., Silwal R., Pan H.M., Shrestha P.L., Bastola A.K. 3D/4D printing of polymers: fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA) Polymers. 2021 Jan;13(18):3101. doi: 10.3390/polym13183101. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 72.Saska S., Pilatti L., Blay A., Shibli J.A. Bioresorbable polymers: advanced materials and 4D printing for tissue engineering. Polymers. 2021 Jan;13(4):563. doi: 10.3390/polym13040563. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 73.Arcila L.V., de Carvalho Ramos N., Bottino M.A., Tribst J.P. Indications, materials and properties of 3D printing in dentistry: a literature overview. Res. Soc. Dev. 2020 Dec 4;9(11) [Google Scholar]

- 74.Papageorgiu M. Sculpteo; 2017. 4D Printing: A Technology Coming from the Future. [online] Available at. [Google Scholar]

- 75.Hamza H. Dental 4D printing: an innovative approach. Innovation. September 2018;1(9):e17. doi: 10.30771/2018.4. [DOI] [Google Scholar]

- 76.Bardakova K.N., Kholkhoev B.C., Farion I.A., et al. 4D printing of shape‐memory semi‐interpenetrating polymer networks based on aromatic heterochain polymers. Adv. Mater. Technol. 2021 [Google Scholar]

- 77.Dawood A., Marti B.M., Sauret-Jackson V., Darwood A. 3D printing in dentistry. Br Dent J. 2015 Dec;219(11):521–529. doi: 10.1038/sj.bdj.2015.914. [DOI] [PubMed] [Google Scholar]

- 78.Li H., Fan W., Zhu X. Three‐dimensional printing: the potential technology widely used in medical fields. J Biomed Mater Res. 2020 Nov 1;108(11):2217–2229. doi: 10.1002/jbm.a.36979. [DOI] [PubMed] [Google Scholar]

- 79.Haleem A., Javaid M. 4D printing applications in dentistry. Curr Med Res Pract. 2019;9:41–42. [Google Scholar]

- 80.Deshmukh K., Houkan M.T., AlMaadeed M.A., Sadasivuni K.K. Introduction to 3D and 4D printing technology: state of the art and recent trends. 3D and 4D Print Polym Nanocompos Mater. 2020 Jan 1:1–24. [Google Scholar]

- 81.Bagheri A., Ling H., Bainbridge C.W., Jin J. Living polymer networks based on a RAFT cross-linker: toward 3D and 4D printing applications. Clin. Polym. Mater. 2021 May 19 [Google Scholar]

- 82.Özcan M., Hotza D., Fredel M.C., Cruz A., Volpato C.A. Materials and manufacturing techniques for polymeric and ceramic scaffolds used in implant dentistry. J Compos Sci. 2021 Mar;5(3):78. [Google Scholar]

- 83.Ghilan A., Chiriac A.P., Nita L.E., Rusu A.G., Neamtu I., Chiriac V.M. Trends in 3D printing processes for biomedical field: opportunities and challenges. J Polym Environ. 2020 May;28(5):1345–1367. doi: 10.1007/s10924-020-01722-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 84.Babbar A., Sharma A., Kumar R., Pundir P., Dhiman V. Functionalized biomaterials for 3D printing: an overview of the literature. Addit Manuf Funct Nanomater. 2021 Jan 1:87–107. [Google Scholar]

- 85.Chen D., Liu Q., Han Z., et al. 4D printing strain self‐sensing and temperature self‐sensing integrated sensor–actuator with bioinspired gradient gaps. Adv Sci. 2020 Jul;7(13) doi: 10.1002/advs.202000584. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 86.Baddam Y., Uddin M.N., Don T., Asmatulu E. 2019 ASEE Midwest Section Conference. 2020 May 6. Integrating 4D printing processes into STEM education. [Google Scholar]

- 87.Koch H.C., Schmelzeisen D., Gries T. vol. 10. Multidisciplinary Digital Publishing Institute; 2021 Feb. 4D textiles made by additive manufacturing on pre-stressed textiles—an overview; p. 31. (Actuators). No. 2. [Google Scholar]

- 88.Khoo Z.X., Teoh J.E., Liu Y., et al. 3D printing of smart materials: a review on recent progress in 4D printing. Virtual Phys Prototyp. 2015 Jul 3;10(3):103–122. [Google Scholar]