Abstract

Natural catastrophes include those of biological origin as the pandemic provoked by virus SARS CoV2, earthquakes, flooding and hurricanes among others, while provoked ones are mainly those related to wars and social movements. These situations may cause food shortage and challenge food safety and security systems. In this review, strategies to produce foods aimed to alleviate food needs before, during and after catastrophic conditions are described based on the supply of various processed, intermediate and low moisture foods and three categories of food supplies are depicted based on the nature of the adverse conditions, Also, relevant patents on on innovative food preparations and containers for disaster areas are discussed. Innovation to produce appropriate and nutritious foods for disaster zones may include food bags containing individual packages of high protein, high fiber/vitamins and carbohydrate/oils ingredients in dried/vitreous state. Additionally, the role of food structure on food preservation is mentioned in the context of ready to eat, nutritious and sensory acceptable food supplies during natural or provoked catastrophes is also reported.

Keywords: Catastrophes, Food supplies, Food safety, Vitreous state

1. Introduction

Food security and disasters are closely related in many ways. Disasters directly damage crops, livestock, and housing at the local level, while at the national or international level, supply chains and trade are severely challenged. For example, the COVID 19 pandemic has exacerbated global food prices, resulting in millions of families not being able to purchase nutritious food as they struggle to cope with concomitant income losses (Jiang, Chen, & Wang, 2021). In countries where the livelihoods of a large proportion of the population depend on agriculture and agri-food systems that are highly sensitive to rainfall, temperature variability and droughts, hunger and malnutrition will result. In 2020 alone, in countries with high exposure to climate shocks, the average level of malnutrition was 3 percentage points larger than in countries with low or no exposure to that impact (United Nations Office for Disaster Risk Reduction, 2022).

Natural disasters and those that had the biggest impact on the world during the last years (United Nations Office for Disaster Risk Reduction, 2020) include: Disasters generated by dynamic processes in the interior or surface of the earth as earthquakes (including tsunamis) and volcanic activity (geophysical events) accounted for a total of 9% of all events, of which the majority were earthquakes in the year 2020; Disasters provoked by meteorological or hydrological phenomena as floods (hydrological events). In 2020 it was reported that 44% of the total events worldwide corresponded to this disaster, including landslides which comprised 5% of the total events worldwide. The second most common type of disaster reported were storms accounting for 28% of the events worldwide and affected mainly seaside communities. Extreme temperatures events that accounted for 6% of incidents worldwide are also considered under this heading, have raised as result of climate change by the increase in global average temperature, which continues growing and led to variations in regional precipitation (Reddy, Devi, & Anbumozhi, 2019). The Intergovernmental Panel on Climate Change (IPCC) is currently moving from a static risk framework based on hazard, exposure and vulnerability to a more dynamic one in which more consideration is given to risk responses with possible secondary effects and interactions among risks (United Nations Office for Disaster Risk Reduction, 2022). Extreme temperature disasters tripled in the period 2000–2019 compared to the period 1980–1999, from 130 to 432, respectively. The global average temperature in 2021 was 1.11 °C above that in 1999 which brought an increase in the frequency of extreme weather events, including heat waves, droughts, floods, winter storms, hurricanes and wildfires (World Meteorological Organization, 2022). Disasters of biological origin such as the pandemic provoked by virus SARS CoV2. In January 2020, the World Health Organization (WHO) declared COVID-19 as a global health emergency for the first time and, on March 11 it officially became a pandemic, the highest level of health emergency. In mid-September 2021, a more virulent SARS-CoV-2 variant emerged (Omicron), becoming the most dominant strain of the virus worldwide (Jackson et al., 2021). As many as 528,816,317 infection by COVID-19 had been confirmed, including 6,294,969 deaths by June 3, 2022 (World Health Organization, 2022).

Considering the frequency and synergic effects of disaster consequences, this work is committed to the world-wide efforts to reduce the impact of these phenomena in food security and food safety aspects.

2. Food security, food safety and quality systems in food production under conditions of natural or provoked catastrophes

Food security is achieved when people have physical and economic access to sufficient, safe, and nutritious food to meet their dietary needs and food preferences for an active and healthy life (Cutter, 2017) and it is a policy issue of importance in about every country. The food security status of any group can be considered the principal outcome of food systems (Fung, Wang, & Menon, 2018; Reddy et al., 2019).

Food security is a multifaceted issue with multiple environmental, social, political, and economic causes that encompasses components of availability, access, and utilization of food supplies. A comprehensive and holistic analysis of how the current organization of food production, processing, distribution, and consumption contributes to food security requires broadening the concept of a food system beyond only those activities and should include other economic, social, and environmental aspects, and their interactions thus producing complex outcomes that must be studied by multi and interdisciplinary integrated approaches (Brouwer, McDermott, & Ruben, 2020).

Food safety, on the other hand, may be defined as the practical certainty that injury or damage will not result from a food or ingredient being consumed in a reasonable quantity and customary manner (Deshpande, 2002). During or following natural disasters, food in affected areas may become contaminated with dangerous microbiological and chemical agents making populations are prone to outbreaks of food-borne diseases, including hepatitis A, typhoid fever, and diarrheal diseases, such as cholera and dysentery (Todd, 2017). Food safety risks are mainly linked to unsafe food storage, handling, and preparation. In many cases, cooking may be impossible during natural disasters due to the lack of facilities and combustible materials. Poor sanitation and lack of safe water and toilet facilities can intensify these risks and, as persons suffer from the direct effects of the disaster, it becomes essential that the foods they consume are safe (International Food Safety Authorities Network (INFOSAN), 2005).

Quality systems are tools designed to assure food safety and become more important in crisis conditions. Proper management of raw materials and manufacturing of low and intermediate moisture food, ready to eat, should follow the principles of Good Manufacturing Practice (GMP) from farm to fork as well as the system hazard analysis and critical control points (HACCP) (Fung et al., 2018; Leisner, 1995).

The World Health Organization offers specific advice to those involved in food storage, handling, and preparation during disaster situations. The guide is modeled after the WHO Five Keys to Safer Food (World Health Organization, 2009), and intends: 1. To provide public health and other authorities with guidance on key food safety issues to be considered upon disaster situations; 2. Remind authorities of the need to restore and maintain basic support for food safety infrastructure; 3. Enhance vigilance against the introduction of new food borne risks; 4. Serve as a quick reference to those involved in providing emergency food aid, such as managers of refugee camps and food distribution centers, and 5. Provide guidance for the development of simple food safety messages to those involved in food handling and preparation in disaster areas, including all potential consumers.

In the case of pandemic disaster as that caused by the virus SARS COV2, the recommendations of the world and national health organizations as well as academia and industrial researchers become crucial since provide of state-of-the-art and accurate knowledge to better decide on the production and distribution of foods, particularly in schools, hospitals, refugee camps, work centres, as well in domestic facilities. In this respect, the survival of viruses in foods was studied by Rónai and Egyed (2020), who reported that the tick-borne encephalitis virus uses small rodents as vectors and large mammals as hosts. Humans may be infected through tick bites or the consumption of raw milk and its products. Infectious viral particles were detected in raw milk for 25 days and from unsalted cheese for 15 days. Both types of pasteurization, low temperature, long time (63 °C, 30 min) or high temperature, short time (72 °C, 15 s) destroyed viable virus particles. The same virus rates inactivation was obtained when virus inoculated cheeses were salted by immersion in a 25% weight salt bath for 6 h. As a conclusion, authors recommended to pasteurize milk and salt the cheeses to reduce the risk of transmission of viral infections since these processing prevents the infectious viral particles to disseminate and, it is reasonable to assume that processed food by pasteurization, sterilization, or dehydration and or salting does not transmit viruses. In the case of cold food as raw vegetables and fruits, the normal disinfection procedures recommended by the international regulations must be followed as well as the good manufacturing procedures (Centers for Disease Control and Prevention (CDC), 2022).

SARS-CoV-2 and other respiratory pathogens have been detected in small respiratory droplets that travel in the form of aerosols that may spread among people that inhale them, thus becoming a risk of airborne transmission. It is strongly recommended that food preparation personnel use high quality masks (KN-95 or similar) capable of filtering aerosols and, in addition these masks should have a good fit between the space between mask and nose, preventing aerosols from escaping (Parvez & Parveen, 2022; Wang et al., 2021). In this respect, Trmčić, Demmings, Kniel, Wiedmann, and Alcaine (2021), proposed eight possible strategies organised by priority and effectiveness to mitigate possible SARS-CoV-2 transmission among workers: (1) vaccinate employees, (2) practice social distancing, (3) ensure employees wear face coverings, (4) screen employees for COVID-19 (5) ensure employees wash their hands frequently and avoid touching their faces, (6) clean frequently touched surfaces, (7) ensure adequate ventilation, and (8) minimise spread in the community. Besides, traditional hygiene practices should be kept and continuing being applied (Rizou, Galanakis, Aldawoud, & Galanakis, 2020). It is important to mention that HACCP Pre-requisites regarding personal hygiene, cleaning and sanitizing, preventative maintenance, among others should be observed at each step of the production of foodstuffs aimed at conditions of natural or provoked disasters (Oliveira, Rodrigues, & Henriques, 2021).

Food security responses after natural or provoked disasters involve a range of actions such as predicting adequate relief food supplies, appropriate handling of food items, health and nutritional considerations, various food assistance options, and appropriate distribution and storage methods of food aid (Ainehvand, Raeissi, Ravaghi, & Maleki, 2019). The following section reviews some aspects of the appropriate food items for disaster areas, including food stability, and some nutritional considerations.

3. Appropriate foods for disaster areas: Stability and nutritional considerations

Given the above, the proposals to achieve food security in different parts of the world should consider foods which are stable without refrigeration. A case of study is the Inventory of traditional intermediate moisture foods from Ibero-American countries, with several objectives as to identify, characterize and evaluate intermediate moisture foods from eleven countries of the region (Parada-Arias, 1995). Authors reported the characteristics of 260 food preparations which included meat, fish, cereals, dairy, fruit and vegetable products and miscellaneous preparations. The products were selected to meet the definitions of intermediate moisture foods in terms of their water activity which was reduced in respect to the fresh materials or ingredients as to give place to auto-stable preparations that may be consumed as such. Some of the traditional intermediate or low moisture foods are nowadays fabricated at industrial scale with homogeneous quality and large throughputs (Qiu, Zhang, Tang, Adhikari, & Cao, 2019),

Innovative foods targeted to disaster areas should also consider nutritional aspects and, in this respect, the mixing of high protein (dairy, nuts, meat, soy, beans and fish), high fiber and vitamins (dried fruits and vegetables) and carbohydrate and good-quality oils (nuts, cereals, grains) components may help to achieve the task. Some examples and nutritional aspects of various traditional products are presented next.

Pork rinds are a nutritious-low moisture food derived from pork skin. To dehydrate the skin strips, they are pressed, and oil-fried at high temperatures (200–220 °C). In addition, pork rinds contain no carbohydrates and are an excellent source of protein (≈ 70% w/w) and lipids (≈ 30% w/w) (Kõrge & Laos, 2019). Pork rinds and pork greaves have been reported to have a water activity (aw) of about 0.27 (Ingham, Buege, Dropp, & Losinski, 2004). By having a low water activity, this product is an excellent choice during disaster conditions given its long shelf life without refrigeration. Popcorn is a good alternative to supply maize nutriments that can be enriched by covering flakes with various fluid preparations as butter, caramel, fruit concentrates, etc., that may be added on the unpopped corns and will be retained in produced flakes (García-Pinilla et al., 2019; García-Pinilla et al., 2019). Crystalized fruits as plums, apricots, peaches, apples, pears, pineapples, and melon are a shelf-stable option to provide vitamins, fiber, antioxidants, and energy when supplied with dried vegetables like peas, string beans, carrots, etc. Grains as beans, broad beans, wheat, etc., may also be part of a support diet during catastrophic conditions, provided there is a minimum infrastructure, water and heat supplies as to incorporate them in the diet (Wien & Sabaté, 2015). Charcuterie or cold meats such as dried ham, salami, as well as smoked, dried and salted fish are excellent choices to be included in disaster areas diets as protein sources are preserved during relative long times without refrigeration (Hui, 2007). Dairy products as skim or whole powder milk, different salted-dried cheeses can also be included. Additioanlly, chocolate (bars or powder), honey and syrups are excellent sources of energy and other nutriments as vitamins and even candies and powdered or moulded sugar can be supplued as a self-preserving sources of energy. Roasted nuts (salted or not) and fried potatoes are another good source of high-quality proteins and oils and include pistachios, hazelnuts, cashews, walnuts, marcona almonds, macadamia nuts, peanuts, almonds, etc. Spices, Most of the above products are in the vitreous state and are self-preserving goods (Bonku & Yu, 2020; Ros, 2010). Also, canned and non-thermal processed goods as meat and vegetable and fruit products are excellent choices for providing foods to populations under threat.

4. Processing foods for disaster areas

Processing food to ensure adequate supplies of high-quality preparations should include assorted types of goods as to include proteins, carbohydrates and lipids in commodities that also should carry sufficient vitamins, minerals, and antioxidants. It would be convenient to classify ingredients by type and similar water activities and to pack them in separate pouches which in turn will be placed into a larger container that may be opened and sealed as often as necessary.

To achieve the above objective, it is necessary to process raw materials by considering existing traditional and industrial practices as depicted in Fig. 1 . Traditional practices such as salting, baking, and sun-drying are, nowadays considered high-throughputs methods and can be included in production lines aiming at obtaining foods for affected communities. Industrial processes as extrusion, canning, convective drying, production of micro and nano-emulsions carrying bioactive compounds (Fig. 1) are common methods to obtain large amounts of goods targeted to populations under threat due to catastrophic events of the type mentioned in the introduction to this work (Qiu et al., 2019; Shishir, Xie, Sun, Zheng, & Chen, 2018). When producing foods for natural or provoked catastrophes, it is very important that, supplies should be suitable for the type of disaster faced by considering statements given in Section 7 in a way that, sophisticated commodities should be kept to a minimum aiming at facilitate preparation and consumption at large scales. A brief description of processes included in Fig. 1 is given next within the context of producing high-quality supplies during catastrophic conditions.

Fig. 1.

Traditional and industrial methods for producing foods aimed for conditions of natural catastrophes.

Control of water content and water activity in foods is an important factor to consider when designing foods for disaster situations as these products have a longer shelf life than those in which these factors have not been adequately controlled. In general, reducing moisture content and water activity to values below 0.6.-0.8 has been considered adequate to achieve long storage periods without the need for a cold chain (Food and Agriculture Organization of the United Nations, 2002). In addition, knowledge of food condition diagrams allows the determination of specific formulations of edible raw materials aimed at providing food under conditions of natural and provoked contingencies. In particular, the production of materials with high glass transition temperatures is desirable to decrease the rate of deteriorative biochemical reactions and microbial activity in food preparation (Amit, Uddin, Rahman, Islam, & Khan, 2017; Roos, 2010).

The methods and processes for obtaining dehydrated and intermediate moisture foods and for controlling the water status of foods aimed at obtaining a high glass transition temperature are based on the elimination of water and on the control of the formulation of the selected materials (Qiu et al., 2019; Roos, 2010).

5. Traditional methods

5.1. Formulation control

The addition of water binding compounds is an old practice that decreases the water vapor pressure, hence aw, and not necessarily the moisture content of the material (Vaclavik, Christian, & Campbell, 2021). The most common ingredients are salt, pectin, carbohydrates as dextrins and sucrose (Cai, Choi, & Jeon, 2021), glycerol or propylene glycol (Bokov et al., 2022). Curing of meats uses salts (nitrite and nitrates) that can inhibit or control growth as well as microbial activity. The use of the salting method is useful to increase the shelf-life quality of foods by reducing aw and inactivating or inhibiting growth of undesirable microorganisms. Pectin in combination with sugars (high concentration) can inhibit bacterial growth, which is due to a higher concentration of sugars causing inhibition of bacterial viability and may be related to the increased osmotic pressure generated by a higher concentration of sugars (Cai et al., 2021). A typical Mexican food that combines these two binding compounds (pectin and sugar) is fruit paste (ate). It is a mixture of fruit pulp and sugar that has been concentrated to a point that when cooled it forms a solid mass. Sugar aids improving physical, chemical, and microbiological characteristics of the product as well as enhenced stability. Although ate is an important artisanal food, there are no studies on its processes and its physical, chemical, nutritional, sensory, and microbiological characteristics (Medellín-Cruz et al., 2019). The paste made from pulp (quince, hawthorn, or guava pulp), which main ingredients include a very high sugar content and pectin (the sugar activates the pectin), like jam preparations, can inhibit microbial growth and subsequent deterioration. Sugars have a high affinity for water and can therefore reduce aw. This product is very stable during storage and transport, as it does not require refrigeration (Ali, Babikir, Alqahtani, & Makki, 2021).

5.2. Baking and roasting

Baking and roasting remove most of the water present in the food and reduce aw. In addition, these processes induce biochemical changes that aid preservation, such as enzyme inactivation, gluten coagulation, starch denaturation, and browning, among other processes (Landberg & Scheers, 2021) and reduction of microbial load also occurs (Fellows, 2009). Baked goods such as brownies, blondies, sponge cakes, muffins, cupcakes, and the like, usually have a water activity between 0.5 and 0.75 before packaging (Thulin, Couttenye, & Coleman, 2011). Biscuits are good examples of long shelf-life foods, given their low water activity and may be stored for approximately half a year. Also, pastries are an example of a baked product having a soft filling that preserve during relatively long times without refrigeration. (Fellows, 2009).

5.3. Frying

Frying involves dehydration, oil absorption, browning, crusting and modification of macro, micro and nanostructures (Costa, Oliveira, & Boutcheva, 2001; Gallegos-Marin, Méndez-Lagunas, Rodríguez-Ramírez, & Martinez-Sánchez, 2020). When frying, water activity is reduced and destruction of microorganisms occurs due to high temperatures (Grasso, Stam, Anderson, & Krishnamurthy, 2014). Frying gives place to products with a crispy texture, aromatic flavour, and a typical example are pork rinds. To dehydrate the skin, strips are pressed and fried at high temperatures (200–220 °C). In addition, pork rinds contain no carbohydrates and are an excellent source of protein and fat. Pork rinds and pork cracklings have been reported to have a water activity of about 0.27 (Ingham et al., 2004) which makes them an excellent choice as a disaster situations feed because of their long shelf life without refrigeration. Additionally, there is a wide variety of vegetables and fruits that can be subjected to frying such as potatoes, carrots, red beets, taro, celery bulbs, pumpkins, aubergines, pineapples, apples, bananas, peaches, grapes, guavas, and mangoes, among others (Aida, Noriza, Haswani, & Mya, 2016; Al Faruq, Zhang, & Adhikari, 2019; Kasahara, Osorio, Moyano, Pizarro, & Beltran, 2002; Wanakamol & Poonlarp, 2018) and once, properly packed are excellent alternatives for disatreous conditions.

5.4. Sun drying

Sun drying is an ancient method of food preservation and is based on the amount of radiation for a particular location, the time of year and the natural ventilation of the area, which determine the heat and mass transfer driving forces and the respective transport coefficients (Hii, Ong, Chiang, & Menon, 2019). By this method, water activity is reduced to safe levels for the proper preservation of food materials. Foods such as fruits, vegetables, meat, and fish can be dried by exposing them to direct sunlight (open air exposure) and this process has been used for centuries. For example, to carry out the sun drying of cod, fresh fish is washed, then stacked in layers separated by dry salt and undergoes an ageing process during which aw decreases. After salting, the cod is washed out and sun dried in the open air and the evaporated water is, then removed by natural convection and wind force (Alam, 2007; Van Nguyen, Arason, & Eikevik, 2013). Finally, the dried cod is salted again and packaged.

6. Industrial processing

6.1. Thermal and non-thermal processing

Thermal processes include canning, pasteurization, microwave, and blanching whereas non-thermal ones are those that use high pressure, electric fields, ultrasound and ligh pulses (Jadhav, Annapure, & Deshmukh, 2021; Kubo et al., 2021). A wide variety of preservation levels are achieved and the vast diversity of products enable their application as fodds for cathastrophic conditions. Canned foods are excellent options when long-term storage is necessary and easy to open tin and aluminium cans and various pouches make these products a firs-choice supply under nearly all types of natural or provoked disasters, whereas their main disadvantage bneing their heavy weigh as often, canning media is brine or syrup that together with the can and product contribute to the weight of the final product.

6.2. Extrusion

During extrusion, the ingredients are fed to a continuous cooker by means of one or more driving screws that move the feed through the extruder where numerous physical and biochemical changes occur that help to decrease water activity, transform components such as proteins and carbohydrates and in this sense, modern trends are towards the use of the extruder as a feed bioreactor that performs a reactive extrusion process (Cotacallapa-Sucapuca et al., 2021; García-Armenta et al., 2021; Moreno, Fernández, Rodríguez, Carrillo, & Rochín, 2018). Applications of this technology include increasing the hydrophobicity of carbohydrates and proteins for their use as wall materials to produce surfactant-free emulsions of oil and oil-soluble bioactives (Allen, Carpenter, & Walsh, 2007). Extruded products are of the ready-to-eat/cook type such as pastas, breakfast cereals, breadcrumbs, biscuits, croutons, baby food, snacks, confectionery, textured vegetable protein, modified starch, dry soups, and dry drink mixes. The water activity in hot and cold extruded food products ranges between 0.1 and 0.4 and due to this they can be preserved for a long time (Shelar & Gaikwad, 2019).

6.3. Convective air drying

Convective air drying is a popular industrial method for producing low-moisture food preparations that are stable for long periods of time without the need of refrigeration or additives. Many fruits, vegetables and meat products are often dried by this method and the critical parameters to be controlled for a given type of equipment are airflow and temperature (Guiné, 2018). Typical equipment used are tunnel, cabinet, rotary, spray and drum dryers (Raj, Srinivas, Sravya, O'Donovan, & Reddy, 2021).

6.4. Freeze drying

During freeze drying, water is firstly frozen and then sublimated (Guiné, 2018). The advantage of using freeze-dried foods is that they are easy and quick to prepare meals and often, most of these foods just require rehydration before consumption. In addition, these foods retain their original shape, texture, and colour. Freeze-dried products have a very long shelf life, due to their low moisture content (2–8%) and water activity (0.10–0.25) (Batt, 2014).

6.5. Encapsulation of nutrients

Encapsulation is generally carried out by drying (spray or freeze drying) emulsions containing nutritious oils and oil-soluble bioactive compounds as vitamins and various antioxidants (Quintanilla-Carvajal et al., 2011). Firstly, the oil phase is mixed with a dispersion of the wall material by using a low-energy method and then a high energy method as microfluidization (Villalobos-Castillejos et al., 2018) or rotor-stator like Ultraturrax may be used as to produce a micro or nano-emulsion which is, in turn are dried to seal and form the capsules that may be part of the food supplies for disaster conditions and consumed by incorporating them to solid or liquid products depending on the availability of potable water (Mohammed, Tan, Manap, Muhialdin, & Hussin, 2020; Plazola-Jacinto, Pérez-Pérez, Pereyra-Castro, Alamilla-Beltrán, & Ortiz-Moreno, 2019).

By applying the above methods, the vitrous state of foods is favored by lowering water content, modification of their structure and by adding anti-plastifying ingredients and changes in the state-diagram of the material will change as illustrated in Fig. 2 in which solid and dotted lines correspond to the shifting of the glass transition and BET or (GAB) monolayer of the non-trated food (solid-blue lines) as a consequence of processing aimed at producing highlystable foodstuffs. Displacement of monolayer moisture content towards higher values is commonly found in micro and nano-porous materials as described in Section 8.

Fig. 2.

Typical state-diagram of a food, showing the glass transition and BET (or GAB) monolayer displacements towards regions of higher temperatures and solids mass fractions respectively that favor the preservation of foods suitable for disaster conditions. Solid (blue) and dotted (red) lines correspond to the shifting of the glass transition temperature and monolayer of the non-trated food (solid-blue lines) as a consequence of processing aiming to increase food stability. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

7. Food preservation by micro and nanostructuring

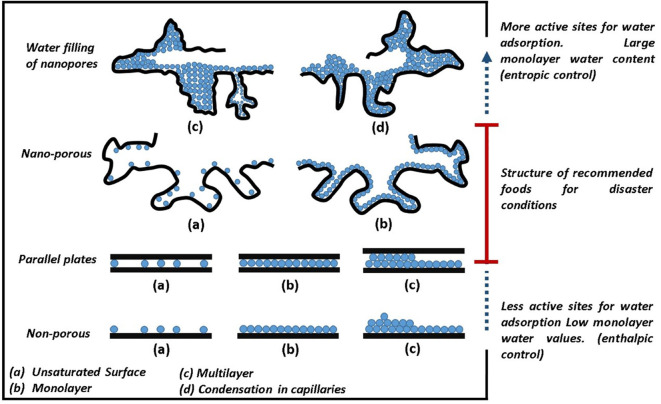

Foods with the same overall composition but different structures will differ in their shelf lives since structure plays an important role in water binding into micro- and nano-pores, cracks or capillaries of diverse shapes so reducing their vapor pressure and becoming unavailable to undesired biochemical degradation and microbial spoilage (Alamri, Mohamed, Hussain, Ibraheem, & Abdo Qasem, 2018). In this respect, it is possible to prepare micro and nano structured materials by various methods including cold and heat shock, microfluidization, and by formulation of food preparations that include porous materials. When water is trapped in micro- and nano-pores (Fig. 3 ), the control of its adsorption is driven by entropic factors such as the arrangement of water molecules on the surface of the materials and maximum stability is, often found at the water activity and moisture content corresponding to the minimum differential entropy (Flores-Andrade et al., 2018). By achieving a control of water mobility, also its state is often displaced from a rubbery to a glassy state that prevents chemical deterioration and microbial spoilage. A consequence of this process is the displacement of monolayer values (BET and or GAB to larger values of moisture content which was illustrated in Fig. 2. Foods prepared by this method are suitable to be part of a diet for disaster and emergency situations as their stability is increased by a proper controlling of solid-moisture interactions.

Fig. 3.

Different manners in which water may be trapped in porous structures of food materials, highlighting those that favor the preservation by water bindings to nano- and micro-pores.

Based on the above, three main food categories of food supplies can be proposed.

Category 1: Canned, bottled or pouched; no refrigeration needed. High water content, solely liquid and solid and liquid contents.

Category 2: Bottled or pouched; refrigeration is needed. High water content, solely liquid and solid and liquid contents.

Category 3: Intermediate and low moisture foods; in general these products do not require refrigeration or special storage conditions if correctly packed. May need rehydration and heating prior to consumption.

Food acceptance is closely related to sovereignty aspects given that food supplies in times of natural or provoked catastrophes should, be sufficient and consider, when possible, cultural, and traditional aspects of food consumption. Food sovereignty is a key aspect when aiming to reducing the vulnerability of communities and support coping before, during and after natural or provoked disasters, as it implies stable food provisions accessible in the long term so making a significant contribution to addressing food insecurity (Blom, Steegeman, Voss, & Sonneveld, 2022; Gibb & Veuthey, 2011). This is especially important when considering vulnerable sectors of the population as children, older and sick people who should be treated with special care (Basurto, 2021; Jones, Fink Shapiro, & Wilson, 2015). Countries that have well-established forms of planning and risk management strategies during unstable periods as disasters will be better cope and respond in a shorter time-frame to natural or provoked catastrophes which will, naturally result in improved food sovereignty, thus reducing casualties, and damage to the infrastructure of the whole country (Lassa, Teng, Caballero-Anthony, & Shrestha, 2019).

Critical factors in deciding the type of supplies needed for a given emergency are the availability or not of water, electricity, sunlight, cooking facilities, and presence of microbial outbreaks as a consequence (or as primary cause) of natural and provoked disasters. In general, Category 1 foods are suitable during conditions of water, electricity and gas shortage, while those foods in categories 2 and are appropriated when only electricity (thus refrigeration) is available. Category 3 supplies will be mainly recommended when water, electricity and, in general, cooking supplies are accessible.

8. Patents of foods for disaster areas

Some innovations protected by patents, on food production for natural disasters have been published in the 21st century. Table 1 depicts a selection of documents which were divided in tree main categories: instant foods, methods for food preservation and devices for water storage.

Table 1.

Recent patents on food production for natural disasters.

| Patent | Subject | Application | Year | Ref |

|---|---|---|---|---|

| US /0072672 A1 | The patent describes to, inter alia, a dehydrated and aerated food product, methods of making and using the dehydrated and aerated food product, and combination food products that include the dehydrated and aerated food product. | Instant food | 2014 | Nisbet et al. (2014) |

| EP 2959781 A1 | The invention relates to a rice-based instant food product that can be easily cooked simply by pouring hot water and waiting for a while or simply by pouring cold or hot water and heating in a microwave | Instant food | 2014 | Saeki, Komatsu, and TanakaA (2014) |

| US 7,897,187 B2 | The invention relates to a material consisting of a powder selected from a thickening agent and lecithin powder (“powder), and a syrup. It is Suitable, in particular, for producing food and fodder. The invention further describes a process for producing said material, the use of said material, and products obtained from said material. | Instant food | 2011 | Thelen (2011) |

| US 0185163 A1 | This invention relates to food provided for emergencies like natural disasters or accidents in general. Dried bread is generally known as food provided for emergencies. The dried bread has less water than the ordinary bread, using the wheat flour (especially of medium stickiness) as a material and it should be baked well, being suitable for preserving and taking out. | Instant food | 2004 | Takaoka (2004) |

| US 6,149,939 | The field of this invention is healthful tablets and mini bars which will dissolve in the mouth. The tablets and mini-bars contain active ingredients which maintain or improve health. The tablets may be mounted on lollipop Sticks. The ingredients are oxygen Supplement, Vitamins, minerals, healthful herbs, and dehydrated healthful foods | Instant food | 2000 | Strumor and Hartman (2000) |

| WO 2012048713 A2 |

Food preservation method that has a component based on a container that can be made of stainless steel, plastic, that allow it to be submerged inside the container in question without the possibility of floating in a solution consisting of pure honey for a period of about seven days or more at the same time, it allows a good part of the water that contains the food to rise towards the upper end of the container, from where it is extracted through a conduit or manually. Any | Method for food preservation | 2012 | Hernandez (2012) |

| US/0227028 A1 |

According to a first aspect the present invention concerns a method for preparation of a dry instant food comprising two or more components which rapidly is rehydrated upon addition of warm or tempered liquid and thereby ready be served in a few seconds. | Method for food preservation | 2010 | Huitfeldt (2010) |

| US 0000922 A1 | The present invention relates generally to water storage devices and particularly to a water storage device preferably for use in emergency situations. | Device for water storage | 2008 | Nevils and Nevils (2008) |

Concerning Instant Food patents, Nisbet et al. (2014) were granted the patent US 2014/0072672 A (hydrocolloid stabilized dry food foam). The invention relates to a new hydrocolloid stabilized dehydrated food foam that combines a plant puree mixture with a hydrocolloid. As described, the hydrocolloid stabilized dehydrated food foam has advantages over existing food foams, including, the preservation of natural coloration and nutritive qualities of fruits or vegetables used to prepare a puree mixture. The hydrocolloid stabilized dehydrated food foam also is less friable and more stable than existing food foams. Further, the hydrocolloid stabilized dehydrated food foam does not require preservatives or artificial coloring and may be stored for at least two years, depending on the packaging and can be used as a source of nutritious food in everyday situations (daily snack), recreational situations (camping), and more long-term conditions (survival food, and as a source of food during natural/provoked disasters or other emergencies).

Saeki et al. (2014) obtained the patent EP 2959781 A1 that describes an instant food product containing puffed dried rice, which can be quickly cooked. The product is cooked and eaten by pouring hot or cold water. Authors claim that, the instant food product, has an excellent storage stability and, may be used as stockpiled rice in case of disasters. In this case, the puffed dried rice may be packed not in a large-capacity container.

Thelen (2011) was granted the patent US 7,897,187 B2. The product consists of two main components: a powder selected from thickening agents (especially starch flour) and lecithin powder, and a syrup, preferably glucose or fructose syrup. This base material is readily prepared and handled and has a long shelf life and a wide variety of applications as a food supplement or as a component of a fitness, astronaut, or hospital food. Also, it can be used as emergency supply (e.g., in famines or natural disasters). The material can be advantageously employed because it can be easily stored, handled, and shipped even under extreme conditions.

Takaoka (2004) was granted the patent US 2004/0185163 A1. The invention describes a food for emergencies, suitable for eating in times of natural disasters and accidents and consists of a germinated cereal to which a certain amount of powders of young rice leaves as well as leaves of coleseeds were added and baked so keeping their nutritious value providing vitamins, minerals and fiber and becomes effective as a food for emergencies and disastrous situations.

Strumor and Hartman (2000) were granted the patent 6,149,939 (Dissolvable oral tablets and mini bars which contain healthful ingredients). The product contains various discrete, extruded sections containing different healthful ingredients. Many active ingredients include, oxygen enhancers, vitamins, enzymes, dehydrated foods, pycnogenols, food supplements, soy proteins, herbs, roots, and mints. The tablets and mini-bars may be prepared by extruding discrete sections and matrices containing active ingredients, and coating with dehydrated food. The tablets and mini bars may supply needed active ingredients after natural disasters or prior to surgery or even may be recommended for general use. The products may be stored in a thermally insulating luminous canteen container with a primary package with a removable cover and a a variety of secondary containers affixed to the outer wall of the primary one, which also holds water and first aid supplies and may be supplied to survivors of natural disasters.

Concerning food processing, Hernandez (2012) was granted the patent WO 2012048713 A2. The invention relates to a food preservation method including a container that can be made from stainless steel, plastic or any other suitable material. In addition to a standard lid, the container includes a second one that is a few millimeters smaller than the first one and has holes allowing the contents of the container to be submerged, without the possibility of floating in a solution of honey for approximately seven days or longer depending on whether meat, fruit, vegetables or shellfish are involved. Products may be supplied during natural disasters when the traditional methods fail because of their high dependence on hydrocarbon derived energy.

Huitfeldt (2010) obtained the patent US 2010/0227028 A1 which describes a method for preparing ready-to-serve meals that allows long shelf life when stored at ambient temperatures has a low weight, and an environmentally friendly and robust package. It provides a method for preparing ready-to-serve dinner portions of infant food with their nutrients preserved. It is well suited for distribution and use during natural disasters and in situations where the foodstuff is not likely to be handled with due care.

Concerning devices related to foods for disaster conditions, Nevils and Nevils (2008) were granted the patent US 20080000922 A1. A device for safely storing water for human consumption and other uses comprising a bladder sized to fit in the desired location, such as a bathtub or kitchen sink. It includes a sleeve-like member that serves as a water entry or filling point. It can be inserted a pump to remove the water stored and the storage device allows the liquid to be available for use and consumption during an emergency or when safe water is unavailable.

9. Conclusions

Innovation to produce foods for disaster zones should include food safety issues and focus on the developing of intermediate moisture foods, safe, auto stable, and ready to eat by employing industrial and traditional processes and applying food quality systems that include predictive microbiology and hazard analysis and critical control points HACCP, as well as appropriate packaging. In this respect, traditional intermediate moisture foods are excellent choices. Nutrimental aspects should be meet and to achieve this, assorted materials should be supplied into food bags containing, in turn individual packages with high protein content (dairy, red meat, soy, beans, and fish), high fiber and vitamins supplies (fruits and vegetables) and sources of proteins, carbohydrates and oils as nuts, cereals, grains, fried potatoes among others and three categories of food supplies were depicted based on the nature of the adverse conditions. When producing foods for natural or provoked catastrophes, it is very important that, supplies should be suitable for the type of disaster and sophisticated commodities should be kept to a minimum aiming at facilitating preparation and consumption at large scales. Additionally, the role of food structure on food preservation must be considered in the context of ready to eat, nutritious and sensory acceptable food supplies during natural or provoked catastrophes by including micro and nano-structured materials with increased monolayer values. Sensory and palatable requirements must be considered throughout the whole supplying task.

Funding

Author IC-G thanks CONACYT for a stydy grant. Authors received support from CONACYT and Instituto Politécnico Nacional, Secretaría de Investigación y Posgrado, Mexico.

Author Statement

Iram Cisneros-García, Validation, Investigation, Analysis, Corrections to first draft.

Lidia Dorantes-Álvarez: Conceptualization, formal analysis, methodology, investigation, drafting original manuscript, Supervision of corrections, Writing and revision of original and revised submissions.

Efrén Parada-Arias: Advise in laying out cooperation actions to produce intermediate moisture foods and water activity evaluations.

Liliana Alamilla-Beltrán: Advise in preservation and encapsulation techniques, revision of original and revised submissions.

Alicia Ortíz-Moreno: Revision and analysis of relevant patents and revision of original and revised submissions.

Hugo Necoechea Mondragón: Revision and analysis of relevant patents and economic aspects of formulating foods for catastrophic situations.

Gustavo F. Gutiérrez-López: Conceptualization, formal analysis, supervision, writing review and editing.

Declaration of Competing Interest

None.

Data availability

No data was used for the research described in the article.

References

- Aida S.A., Noriza A., Haswani M.M., Mya S.M.Y. A study on reducing fat content of fried banana chips using a sweet pretreatment technique. International Food Research Journal. 2016;23(1):68–71. [Google Scholar]

- Ainehvand S., Raeissi P., Ravaghi H., Maleki M. Natural disasters and challenges toward achieving food security response. Iranian Journal of education and health promotion. 2019;8(51) doi: 10.4103/jehp.jehp_256_18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Al Faruq A., Zhang M., Adhikari B. Ultrasonics Sonochemistry. Vol. 52. Elsevier B.V; 2019. A novel vacuum frying technology of apple slices combined with ultrasound and microwave. [DOI] [PubMed] [Google Scholar]

- Alam N. Participatory Training of Trainers- A New Approach Applied in Fish Processing. 2007. Traditional sun-drying of fish; p. 329. [Google Scholar]

- Alamri M.S., Mohamed A.A., Hussain S., Ibraheem M.A., Abdo Qasem A.A. Determination of moisture sorption isotherm of crosslinked millet flour and oxirane using GAB and BET. Journal of Chemistry. 2018;2018:1–8. doi: 10.1155/2018/2369762. [DOI] [Google Scholar]

- Ali D.O.M., Ahmed R., Babikir E.B., Alqahtani N.K., Makki H.M.M. Effects of storage on the quality characteristics of guava (Psidium guajava L.) fruit concentrates. Pakistan Journal of Nutrition: PJN. 2021;20(2):70–75. doi: 10.3923/pjn.2021.70.75. [DOI] [Google Scholar]

- Allen K.E., Carpenter C.E., Walsh M.K. Influence of protein level and starch type on an extrusion-expanded whey product. International Journal of Food Science & Technology. 2007;42(8):953–960. doi: 10.1111/j.1365-2621.2006.01316.x. [DOI] [Google Scholar]

- Amit S.K., Uddin M.M., Rahman R., Islam S.M.R., Khan M.S. A review on mechanisms and commercial aspects of food preservation and processing. Agriculture and Food Security. 2017;6(1):1–22. doi: 10.1186/s40066-017-0130-8. [DOI] [Google Scholar]

- Basurto S.Y.H. Children’s Environmental Rights Initiative; 2021. Food sovereignty means defending our right to a healthy environment.https://www.childrenvironment.org/blog/food-sovereignty mayo 21. [Google Scholar]

- Batt C. 2a ed. Academic Press; 2014. Encyclopedia of food microbiology. [Google Scholar]

- Blom C.D.B., Steegeman P., Voss C., Sonneveld B.G.J.S. Food in the cold: Exploring food security and sovereignty in Whitehorse, Yukon. International Journal of Circumpolar Health. 2022;81(1):2025992. doi: 10.1080/22423982.2022.2025992. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bokov D., Al-Ethafa L.F.M., Abilmazhinov Y., Thangavelu L., Surendar A., Pokrovskii M., Abdelbasset W.K. Study on the preservative properties of glycol on food. Food Science and Technology. 2022;42 doi: 10.1590/fst.39021. [DOI] [Google Scholar]

- Bonku R., Yu J. Health aspects of peanuts as an outcome of its chemical composition. Food Science and Human Wellness. 2020;9(1):21–30. doi: 10.1016/j.fshw.2019.12.005. [DOI] [Google Scholar]

- Brouwer I.D., McDermott J., Ruben R. Food systems everywhere: Improving relevance in practice. Global Food Security. 2020;26 doi: 10.1016/j.gfs.2020.100398. [DOI] [Google Scholar]

- Cai J.-N., Choi H.-M., Jeon J.-G. Relationship between sucrose concentration and bacteria proportion in a multispecies biofilm: Short title: Sucrose challenges to a multispecies biofilm: Short title: Sucrose challenges to a multispecies biofilm. Journal of Oral Microbiology. 2021;13(1):1910443. doi: 10.1080/20002297.2021.1910443. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Centers for Disease Control and Prevention (CDC) Centers for Disease Control and Prevention; 2022. Fruit and vegetable safety.https://www.cdc.gov/foodsafety/communication/steps-healthy-fruits-veggies.html [Google Scholar]

- Costa R.M., Oliveira F.A.R., Boutcheva G. Structural changes and shrinkage of potato during frying. International Journal of Food Science & Technology. 2001;36(1):11–23. doi: 10.1046/j.1365-2621.2001.00413.x. [DOI] [Google Scholar]

- Cotacallapa-Sucapuca M., Vega E.N., Maieves H.A., Berrios J.D.J., Morales P., Fernández-Ruiz V., Cámara M. Extrusion process as an alternative to improve pulses products consumption. A review. Foods (Basel, Switzerland) 2021;Vol. 10(5):1096. doi: 10.3390/foods10051096. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cutter S.L. The perilous nature of food supplies: Natural hazards, social vulnerability, and disaster resilience. Environment: Science and Policy for Sustainable Development. 2017;59(1):4–15. doi: 10.1080/00139157.2017.1252603. [DOI] [Google Scholar]

- Deshpande S.S. Handbook of food toxicology. Marcel Dekker; 2002. Principles of toxicology; p. 11. [Google Scholar]

- Fellows P.J. Food processing technology: Principles and practice. 3a ed. Woodhead Publishing; 2009. Baking and roasting; pp. 538–550. [Google Scholar]

- Flores-Andrade E., Pascual-Pineda L.A., Quintanilla-Carvajal M.X., Gutiérrez-López G.F., Beristain C.I., Azuara E. Fractal surface analysis and thermodynamic properties of moisture sorption of calcium–sucrose powders. Drying Technology. 2018;36(9):1128–1141. doi: 10.1080/07373937.2017.1387793. [DOI] [Google Scholar]

- Food and Agriculture Organization of the United Nations . Food & Agriculture Organization of the United Nations (FAO); 2002. Handling and preservation of fruits and vegetables by combined methods for rural areas: Technical manual (FAO agricultural services bulletin) [Google Scholar]

- Fung F., Wang H.S., Menon S. Food safety in the 21st century. Biomedical Journal. 2018;41(2):88–95. doi: 10.1016/j.bj.2018.03.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gallegos-Marin I., Méndez-Lagunas L.L., Rodríguez-Ramírez J., Martinez-Sánchez C.E. Influence of osmotic pretreatments on the quality properties of deep-fat fried green plantain. Journal of Food Science and Technology. 2020;57(7):2619–2628. doi: 10.1007/s13197-020-04298-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- García-Armenta E., Picos-Corrales L.A., Gutiérrez-López G.F., Gutiérrez-Dorado R., Perales-Sánchez J.X.K., García-Pinilla S.…Armenta-Manjarrez M.A. Preparation of surfactant-free emulsions using amaranth starch modified by reactive extrusion. Colloids and Surfaces. A, Physicochemical and Engineering Aspects. 2021;608(125550) doi: 10.1016/j.colsurfa.2020.125550. [DOI] [Google Scholar]

- García-Pinilla S., Gutiérrez-López G.F., Hernández-Sánchez H., Cáez-Ramírez G., García-Armenta E., Alamilla-Beltrán L. Quality parameters and morphometric characterization of hot-air popcorn as related to moisture content. Drying Technology. 2019;39(1):77–89. doi: 10.1080/07373937.2019.1695626. [DOI] [Google Scholar]

- García-Pinilla S., Gutiérrez-López G.F., Hernández-Sánchez H., González-Barbosa J.J., García-Armenta E., Alamilla-Beltrán L., Dorantes-Álvarez L. Desarrollo de la morfología de palomitas de maíz en 2 dimensiones por aire caliente. Journal of Food Engineering. 2019;259(diciembre 2018):29–33. doi: 10.1016/j.jfoodeng.2019.04.012. [DOI] [Google Scholar]

- Gibb C., Veuthey J. How do disasters shape food sovereignty in the Philippines? Exploring the reciprocal relationships between food and disaster. Kasarinlan: Philippine. Journal of Third World Studies. 2011;26(1–2):341–360. https://journals.upd.edu.ph/index.php/kasarinlan/article/view/3504/pdf_159 [Google Scholar]

- Grasso E.M., Stam C.N., Anderson N.M., Krishnamurthy K. In: The microbiological safety of low water activity foods and spices. Food microbiology and food safety. Gurtler J., Doyle M., Kornacki J., editors. Springer; New York, NY: 2014. Heat and steam treatments. [DOI] [Google Scholar]

- Guiné R.P.F. The drying of foods and its effect on the physical-chemical, sensorial and nutritional properties. ETP International Journal of Food Engineering. 2018:93–100. doi: 10.18178/ijfe.4.2.93-100. [DOI] [Google Scholar]

- Hernandez, V. R. D. (2012). WO2012048713A3: WIPO.

- Hii C.L., Ong S.P., Chiang C.L., Menon A.S. IOP Conference Series. Earth and Environmental Science. 292(1) 2019. A review of quality characteristics of solar dried food crop producst. [DOI] [Google Scholar]

- Hui Y.H., editor. Handbook of food products manufacturing. John Wiley & Sons, Inc.; 2007. [DOI] [Google Scholar]

- Huitfeldt, N. K. M. (2010). US Patent No. US 2010/0227028A1: US.

- Ingham S.C., Buege D.R., Dropp B.K., Losinski J.A. Survival of listeria monocytogenes during storage of ready-to-eat meat products processed by drying, fermentation, and/or smoking. Journal of Food Protection. 2004;67(12):2698–2702. doi: 10.4315/0362-028x-67.12.2698. [DOI] [PubMed] [Google Scholar]

- International Food Safety Authorities Network (INFOSAN) FAO; 2005. Food Safety in Natural Disasters Information Note No. XXX/2005.https://www.paho.org/disasters/dmdocuments/FoodSafetyinDisasters.pdf Retrieved from. [Google Scholar]

- Jackson J.K., Weiss M.A., Schwarzenberg A.B., Nelson R.M., Sutter K.M., Sutherland M.D. Fas.org; 2021. Global economic effects of COVID-19.https://sgp.fas.org/crs/row/R46270.pdf [Google Scholar]

- Jadhav H.B., Annapure U.S., Deshmukh R.R. Non-thermal technologies for food processing. Frontiers in Nutrition. 2021;8 doi: 10.3389/fnut.2021.657090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jiang X., Chen Y., Wang J. Global food security under COVID-19: comparison and enlightenment of policy responses in different countries. Foods (Basel, Switzerland) 2021;10(11):2850. doi: 10.3390/foods10112850. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jones A.D., Fink Shapiro L., Wilson M.L. Assessing the potential and limitations of leveraging food sovereignty to improve human health. Frontiers in Public Health. 2015;3:263. doi: 10.3389/fpubh.2015.00263. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kasahara I., Osorio F., Moyano P., Pizarro G., Beltran J. Study of texture and glass transition of french fried potatoes pretreated with soaking solutions. Journal of Food Processing and Preservation. 2002;26(4):237–257. doi: 10.1111/j.1745-4549.2002.tb00482.x. [DOI] [Google Scholar]

- Kõrge K., Laos K. The influence of different packaging materials and atmospheric conditions on the properties of pork rinds. 2019. https://scholarworks.rit.edu/cgi/viewcontent.cgi?article=1161&context=japr Rit.edu.

- Kubo M.T.K., Baicu A., Erdogdu F., Poças M.F., Silva C.L.M., Simpson R.…Augusto P.E.D. Thermal processing of food: Challenges, innovations and opportunities. A position paper. Food Reviews International. 2021;1–26 doi: 10.1080/87559129.2021.2012789. [DOI] [Google Scholar]

- Landberg R., Scheers N., editors. Whole grains and health. 2a ed. John Wiley & Sons; 2021. [Google Scholar]

- Lassa J.A., Teng P., Caballero-Anthony M., Shrestha M. Revisiting emergency food reserve policy and practice under disaster and extreme climate events. International Journal of Disaster Risk Science. 2019;10(1):1–13. doi: 10.1007/s13753-018-0200-y. [DOI] [Google Scholar]

- Leisner L. In: Food Preservation by Moisture Control: Fundamentals and Applications. Barbosa-Cánovas G.V., Welti-Chanes J., editors. Technomic Publishing Company; 1995. Use of hurdle technology in food processing: recent advances; pp. 377–396. ISBN: 1–56676–358-4. [Google Scholar]

- Medellín-Cruz L.D.C., Cruz-Monterrosa R.G., Rayas-Amor A.A., Mena-Martínez M.E., León-Espinosa E.B., Hernández-Jabalera A.…Díaz-Ramírez M. Sensory evaluation of ate made with orange peel pectin. Evaluación. 2019;12:61–65. doi: 10.32854/agrop.vi0.1502. [DOI] [Google Scholar]

- Mohammed N.K., Tan C.P., Manap Y.A., Muhialdin B.J., Hussin A.S.M. Spray drying for the encapsulation of oils-A review. Molecules (Basel, Switzerland) 2020;25(17):3873. doi: 10.3390/molecules25173873. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Moreno C.R., Fernández P.C.R., Rodríguez E.O.C., Carrillo J.M., Rochín S.M. En Extrusion of Metals, Polymers and Food Products. InTech; 2018. Changes in nutritional properties and bioactive compounds in cereals during extrusion cooking. [DOI] [Google Scholar]

- Nevils, M., & Nevils, K. (2008). US 2008/0000922 A1.

- Nisbet, M., Cullinan, D., Aucella, C., Halabi, L., Zhao, D., & McKeever, M. M. (2014). US patent no. US 2014/0072672 A1.

- Oliveira R.S., Rodrigues M.J., Henriques A.R. Specific hygiene procedures and practices assessment: A cross-sectional study in fresh fishery product retailers of Lisbon’s traditional food markets. Foods (Basel, Switzerland) 2021;10(8):1805. doi: 10.3390/foods10081805. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Parada-Arias E. In: Food Preservation by Moisture Control: Fundamentals and Applications. Barbosa-Cánovas G.V., Welti-Chanes J., editors. Technomic Publishing Company; 1995. Food Technology in CYTED, an Ibero-American R&D Cooperative Program; pp. 443–448. ISBN: 1–56676–358-4. [Google Scholar]

- Parvez M.K., Parveen S. Airborne transmission of SARS-CoV-2 disease (COVID-19) Future Virology. 2022;17(5):261–264. doi: 10.2217/fvl-2021-0324. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Plazola-Jacinto C.P., Pérez-Pérez V., Pereyra-Castro S.C., Alamilla-Beltrán L., Ortiz-Moreno A. Microencapsulation of biocompounds from avocado leaves oily extracts. Revista Mexicana de Ingenieria Quimica. 2019;18(3):1261–1276. [Google Scholar]

- Qiu L., Zhang M., Tang J., Adhikari B., Cao P. Innovative technologies for producing and preserving intermediate moisture foods: A review. Food Research International. 2019;116:90–102. doi: 10.1016/j.foodres.2018.12.055. [DOI] [PubMed] [Google Scholar]

- Quintanilla-Carvajal M.X., Meraz-Torres L.S., Alamilla-Beltrán L., Chanona-Pérez J.J., Terres-Rojas E., Hernández-Sánchez H.…Gutiérrez-López G.F. Morphometric characterization of spray-dried microcapsules before and after α-tocopherol extraction. Revista Mexicana de Ingenieria Quimica. 2011;10(2):301–312. https://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S1665-27382011000200014 [Google Scholar]

- Raj S.P., Srinivas M., Sravya B., O’Donovan T.S., Reddy K.S. Design of tunnel drier for the non-centrifugal sugar industry. International Journal of Low Carbon Technologies. 2021;16(2):407–416. doi: 10.1093/ijlct/ctaa075. [DOI] [Google Scholar]

- Reddy V., Devi M.J., Anbumozhi V.J. In: Towards a Resilient ASEAN: Disasters, Climate Change, and Food Security: Supporting ASEAN Resilience. Anbumozhi V.J., Breiling M., Reddy V., editors. Vol. 1. 2019. Ensuring food and nutritional security in the face of disasters and climate change: What is the adaptive solution; pp. 290–330. [Google Scholar]

- Rizou M., Galanakis I.M., Aldawoud T.M.S., Galanakis C.M. Safety of foods, food supply chain and environment within the COVID-19 pandemic. Trends in Food Science & Technology. 2020;102:293–299. doi: 10.1016/j.tifs.2020.06.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rónai Z., Egyed L. Survival of tick-borne encephalitis virus in goat cheese and milk. Food and Environmental Virology. 2020;12(3):264–268. doi: 10.1007/s12560-020-09427-z. [DOI] [PubMed] [Google Scholar]

- Roos Y.H. Glass transition temperature and its relevance in food processing. Annual Review of Food Science and Technology. 2010;1(1):469–496. doi: 10.1146/annurev.food.102308.124139. [DOI] [PubMed] [Google Scholar]

- Ros E. Health benefits of nut consumption. Nutrients. 2010;2(7):652–682. doi: 10.3390/nu2070652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saeki K., Komatsu M., TanakaA M. 2014. EP 2 959 781 A1: EP. [Google Scholar]

- Shelar G.A., Gaikwad S.T. Extrusion in food processing: An overview. The Pharma Innovation Journal. 2019;8(2):562–657. [Google Scholar]

- Shishir M.R.I., Xie L., Sun C., Zheng X., Chen W. Advances in micro and nano-encapsulation of bioactive compounds using biopolymer and lipid-based transporters. Trends in Food Science and Technology. 2018;78:34–60. doi: 10.1016/j.tifs.2018.05.018. [DOI] [Google Scholar]

- Strumor, M. A., & Hartman, J. S. (2000). 6,149,939: US.

- Takaoka, T. (2004). US 2004/0185163 A1: US.

- Thelen, A. (2011). US 7,897,187 B2: US.

- Thulin, D. Z., Couttenye, R. A., & Coleman, E. C. (2011). Intermediate moisture shelf stable baked goods (Patent Núm. CA:2712650:A1). En Patent (CA:2712650:A1).

- Todd E.C.D. In: Water, Energy & Food Sustainability in the Middle East. Murad S., Baydoun E., Daghir N., editors. Springer; Cham: 2017. Foodborne disease in the Middle East. [DOI] [Google Scholar]

- Trmčić A., Demmings E., Kniel K., Wiedmann M., Alcaine S. Food safety and employee health implications of COVID-19: A review. Journal of Food Protection. 2021;84(11):1973–1989. doi: 10.4315/JFP-21-201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- United Nations Office for Disaster Risk Reduction . 2020. The human cost of disasters: an overview of the last 20 years (2000–2019) [DOI] [Google Scholar]

- United Nations Office for Disaster Risk Reduction . 2022. Global assessment report on disaster risk reduction 2022: Our world at risk: Transforming governance for a resilient future. United Nations. [Google Scholar]

- Vaclavik V.A., Christian E.W., Campbell T. Essentials of Food Science. Springer; Cham: 2021. Water; pp. 17–24. (Food Science Text Series). [DOI] [Google Scholar]

- Van Nguyen M., Arason S., Eikevik T.M. Seafood processing. John Wiley & Sons, Ltd; 2013. Drying of fish; pp. 161–175. [Google Scholar]

- Villalobos-Castillejos F., Granillo-Guerrero V.G., Leyva-Daniel D.E., Alamilla-Beltrán L., Gutiérrez-López G.F., Monroy-Villagrana A., Jafari S.M. Nanoemulsions. Elsevier; 2018. Fabrication of nanoemulsions by microfluidization; pp. 207–232. [DOI] [Google Scholar]

- Wanakamol W., Poonlarp P. Effects of frying temperature, frying time and cycles on physicochemical properties of vacuum fried pineapple chips and shelf life prediction. International Food Research Journal. 2018;25(6):2681–2688. [Google Scholar]

- Wang C.C., Prather K.A., Sznitman J., Jimenez J.L., Lakdawala S.S., Tufekci Z., Marr L.C. Airborne transmission of respiratory viruses. Science (New York, N.Y.) 2021;373(6558):eabd9149. doi: 10.1126/science.abd9149. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wien M., Sabaté J. Food selection criteria for disaster response planning in urban societies. Nutrition Journal. 2015;14(1):47. doi: 10.1186/s12937-015-0033-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- World Health Organization Five keys to safer food manual safer food manual. International Journal of Environmental Research and Public Health. 2009;6(11):2833–2842. doi: 10.3390/ijerph6112833. http://www.mdpi.com/1660-4601/6/11/2833/ [DOI] [PMC free article] [PubMed] [Google Scholar]

- World Health Organization . Who.Int; 2022. WHO Coronavirus (COVID-19) dashboard.https://covid19.who.int/ [Google Scholar]

- World Meteorological Organization . WMO Consolidated Data Shows. World Meteorological Organization; 2022. 2021 one of the seven warmest years on record.https://public.wmo.int/en/media/press-release/2021-one-of-seven-warmest-years-record-wmo-consolidated-data-shows [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.