Abstract

This research explores supply resilience through an equifinality lens to establish how buying organizations impacted differently by the same extreme event can strategize and all successfully secure supply. We conduct case study research and use secondary data to investigate how three European governments sourced for ventilators during the first wave of COVID-19. The pandemic had an unprecedented impact on the ventilator market. It disrupted already limited supply and triggered a demand surge. We find multiple paths to supply resilience contingent on redundant capacity and local sourcing options at the pandemic's onset. Low redundancy combined with limited local sourcing options is associated with more diverse strategies and flexibility. The most notable strategy is spurring supplier innovation by fostering collaboration among actors in disparate industries. High redundancy combined with multiple local sourcing options is associated with more focused strategies and agility. One (counter-intuitive) strategy is the rationalization of the supply base.

Keywords: Supply resilience, Extreme events, Equifinality, COVID-19, Public procurement

1. Introduction

Extreme events, such as the COVID-19 global pandemic, are difficult to predict and present unique risks to supply chains (Knight et al., 2022; Van Hoek and Loseby, 2021; Vanpoucke and Ellis, 2019). Such events threaten livelihoods and the continuity of supply due to their unprecedented impact in scale, duration, and scope (Craighead et al., 2020; Van Hoek, 2020). Buying organizations need to be resilient to overcome their disruptive effects (Tukamuhabwa et al., 2015; Walker, 2020). While “supply chain resilience” refers to supply chain-wide decisions and activities (e.g., Scholten et al., 2019), in this research we use the term “supply resilience” to highlight the focus on buying organizations and how they adapt to secure supply following disruptions caused by extreme events. Despite its widely recognized importance for dealing with major disruptions, the purchasing and supply chain management (SCM) literature is still grappling with what resilience entails (Hohenstein et al., 2015; Wieland and Durach, 2021; Wiedmer et al., 2021). We posit that, in part, this is because empirical research underplays the fact that investing in all types of resilience capabilities – encompassing at least 13 attributes and 84 managerial practices – is too costly (Ali et al., 2017). Buying organizations, therefore, make different trade-offs when allocating limited resources based on their priorities (Robinson and Sahin, 2006: in Mentzer et al., 2008). This leads to inherently varying (resilience) capabilities and vulnerabilities (Blackhurst et al., 2011; Pettit et al., 2013; Tukamuhabwa et al., 2017). By extension, buying organizations’ initial conditions, both in terms of challenges and opportunities, will differ at the onset of any extreme event. Therefore, considering the implications of different resource allocation decisions is crucial for understanding different paths to supply resilience.

This study explores the mechanisms underpinning different pathways to supply resilience given varying initial conditions at the onset of extreme events. We investigate two research questions: (1) How do the initial conditions of buying organizations following an extreme event influence the ways in which buyers employ sourcing strategy to respond to disruptions (i.e., response strategies)? (2) To achieve supply resilience, which response strategies are better aligned what initial conditions? To explore these relationships, we employ an equifinality lens. Equifinality relates to the situation whereby different organizations achieve similar performance outcomes through different strategies (Fernández and Kekäle, 2005; Jaspers, 2007; Katz and Kahn, 1978). To this end, we study how three governments with different initial conditions during the first wave of the COVID-19 pandemic in 2020 successfully secured supply for ventilators despite unprecedented demand surges globally and disrupted supply. We employ a qualitative, case-based research design to investigate the problem through an underexplored lens (i.e., resilience through an equifinality lens), address contextual complexity (Eisenhardt and Graebner, 2007), and enhance the quality of explanations for equifinal outcomes (Mills et al., 2013). Accordingly, we generate in-depth insights into how and why (Voss et al., 2002) buying organizations with different initial conditions successfully bridged an extraordinary demand-supply gap under exceptional circumstances.

Pre-COVID, the annual global demand for ventilators was stable at around 77,000. During the first-wave infections New York city, alone, needed an additional 33,000 ventilators (Netland, 2020). As ventilators are high-tech products, it was anticipated that already disrupted supply chains would not quickly match surging demand. In efforts to avoid shortages, governments applied different response strategies including agile procurement, fostering cross-sectoral collaboration and merging supply chains (Feizabadi et al., 2021; Fearne et al., 2021). The public procurement context is theoretically interesting because, unlike in private sector contracting, procurement professionals are typically constrained by rules, regulations, and norms that can hinder resilience, e.g., impede close collaboration with suppliers and discourage flexibility (Selviaridis and Spring 2022). At the same time, public procurement can be used strategically to help implement public policy goals such as innovation, and to coordinate response to emergency situations (Harland et al., 2021a; Selviaridis, 2021). In crisis periods such as the COVID-19 pandemic, governments have the power to override normal procurement processes, steer public-private collaboration and use more agile approaches to procurement of critical healthcare products and services (Harland et al., 2021b; Fearne et al., 2021).

Our study contributes to research at the intersection between strategic sourcing and supply resilience (e.g., Pereira et al., 2014) by exploring how procurement can enable adaptation to unprecedented changes. We also extend prior research addressing contingencies (e.g., Bode et al., 2011; Namdar et al., 2018; Roscoe et al., 2020; Wiedmer et al., 2021) and reconcile some conflicting empirical findings in the literature by showing that the most suitable response strategies depend on buying organizations’ initial conditions. To the best of our knowledge, this study is also the first to empirically investigate equifinality in public procurement. We add to research stressing the critical role of public procurement in responding to emergencies (e.g., Harland et al., 2021a) by unearthing different pathways leading to the same successful outcomes, despite varied approaches to allocation resources in this setting. Despite our focus on public procurement, our results are largely transferable to private-sector procurement settings given that governmental organizations and private-sector firms have some common characteristics as buying organizations e.g., level of procurement centralization. Consistent with the call of this Special Issue (Kähkönen et al., 2020), we further provide insights regarding how and why certain sourcing strategies foster innovation and enable rapid supply capacity development to bridge unprecedented demand-supply gaps.

The rest of this paper is organized as follows. The theoretical background is presented in Section 2 followed by the methodology in Section 3. Section 4 presents the key results of the study. The discussion and conclusions follow in Section 5.

2. Theoretical background

2.1. Supply chain resilience – A brief overview

The increasing occurrence and consequences of disruptions make resilience an important capability in supply chains (Brandon-Jones et al., 2014; Gunasekaran et al., 2015; Ponomarov and Holcomb, 2009). Despite differences in the understanding of what resilience entails (Wieland and Durach, 2021), most definitions stress the adaptive capability to quickly respond to unexpected disruptions, maintain some functionality, and recover to the original state or better (e.g., Ali et al., 2017; Mena et al., 2020; Sheffi and Rice, 2005). Even though recent works adopt new terminology for adaptation and transformation to a better state – e.g., Nikookar et al. (2021) introduce antifragility while Craighead et al. (2020) argue for transiliency – we view both terms as being captured in long-standing definitions of resilience.

Understanding resilience in the context of extreme events is essential for two reasons. Firstly, the required state before and after the disruption is often different (Ponomarov and Holcomb, 2009; Wieland and Durach, 2021). Thus, it is important to establish how organizations can adapt and/or transform themselves when extreme events bring inevitable change (Walker, 2020). Secondly, because investing in developing all resilience capabilities is expensive (Ali et al., 2017; Pettit et al., 2019) there are trade-offs to be made in the strategic allocation of resources (Jüttner and Maklan, 2011; Mentzer et al., 2008; Pereira et al., 2014). Subsequently, there can never be guarantees that risk mitigation measures will be sufficient to resist the unforeseen and/or unprecedented effects of extreme events. Indeed, some major vulnerabilities in most organizations’ supply chains became known during COVID-19 (Van Hoek and Loseby, 2021). Thus, a crucial question concerns how organizations can make different trade-offs and equally be resilient to the disruptive impact of extreme events.

2.2. Key resilience capabilities

The key resilience capabilities identified in prior literature are flexibility, redundancy, agility, collaboration, and visibility (Ali et al., 2017; Hohenstein et al., 2015). Since definitions of these capabilities differ (Rice and Caniato, 2003; Sheffi and Rice, 2005; Jüttner and Maklan, 2011), Table 1 presents those we adopt in this research. Resilience capabilities are interrelated and/or can be mutually reinforcing (e.g., Ali et al., 2017; Christopher and Peck, 2004; Pettit et al., 2013). Therefore, Table 1 also shows some of the identified linkages between them. Interestingly, we could not identify literature stating that flexibility contributes to other capabilities. Some definitions merge capabilities, e.g., incorporating agility in definitions of flexibility (Ali et al., 2017; Jüttner and Maklan, 2011). These observed interrelationships reinforce the idea of multiple pathways to resilience, as investing in one capability can enhance or lead to another.

Table 1.

Resilience capabilities and their definitions.

| Resilience capability | Definition and brief description | Relationships between capabilities |

|---|---|---|

| Flexibility | The ability of the supply chain to adapt by redeploying various resources in response to disruptions. Flexibility ensures adaptability. Sources: Ali et al. (2017); Jüttner and Maklan (2011); Rice and Caniato (2003); Jüttner and Maklan (2011); Wallace and Choi (2011). |

|

| Redundancy | The ability to reserve some resources for use if disruptions occur. For example, additional capacity or stock is often maintained before needed, even though it may not be used, to make up for the capacity loss that could be caused by disruptions. Redundancy ensures continuity of function when supply is disrupted. Sources: Rice and Caniato (2003); Sheffi and Rice (2005). |

Some redundancy strategies contribute to flexibility and agility, e.g., using backup suppliers and building buffers for essential components, respectively. Sources: Lee (2004); Xie et al. (2019). |

| Agility | The ability of the supply chain to respond quickly to sudden and unexpected changes in demand and/or supply. Sources: Christopher and Peck (2004); Lee (2004). |

Improves flexibility by accelerating processes for responding to disruptions. Sources: Ali et al. (2017); Christopher and Peck (2004). |

| Collaboration | The ability of supply chain members to work together effectively for their mutual benefit in the face of risk and uncertainty. Sources: Jüttner and Maklan (2011); Pettit et al. (2010) |

Some collaborative practices improve flexibility and agility, e.g., information-sharing and mutual knowledge creation. Sources: Christopher and Peck (2004); Scholten and Schilder (2015); Wieland and Wallenburg (2013). |

| Visibility | The ability to access relevant information between or across supply chain tiers and is largely seen as a capability that enables the identification of root causes of supply chain issues. Sources: Brandon-Jones et al. (2014); Azevedo et al., 2013. |

Visibility, like collaboration, improves situation awareness, warning strategies and recovery times. Although visibility may be less relevant for anticipating the manifestation and impact of extreme events, it provides a basis for collaboration and improves agility Sources: Brandon-Jones et al. (2014); Christopher and Peck (2004); Christopher and Rutherford (2004); Vanpoucke and Ellis (2019). |

2.3. Sourcing strategy and supply resilience

The strategic sourcing literature recognizes the unique impact of extreme events on supply (e.g., Arani et al., 2016; Mandal, 2020) and, hence, the need for buying organizations to be resilient. Although strategic sourcing decisions are enduring in nature, to achieve supply resilience they should also include supply risk mitigation strategies that increase response capabilities (Craighead et al., 2020; Vanpoucke and Ellis, 2019; Wieland and Durach, 2021).

Key decisions related to risk mitigation in strategic sourcing include supplier location, number of suppliers, buyer-supplier relationship types, and approaches to supplier development (Arani et al., 2016; Namdar et al., 2018; Pereira et al., 2014; Scholten and Schilder, 2015). Related sourcing practices are echoed in the resilience literature; for example, building a flexible supplier base, reserving excess capacity, information sharing, investing in suppliers’ capability to recover quickly from a disruption, and joint planning (Kochan and Nowicki, 2018; Namdar et al., 2018). Furthermore, practices such as cost-sharing or incorporating deductible elements (Erkoc and Wu, 2005), and revenue-sharing (Zeng and Xia, 2015) are essential. They improve collaboration and provide the means for suppliers to respond (Wiedmer et al., 2021; Zeng and Xia, 2015).

Resource scarcity implies the need to ensure that investments made match the risk level (Pettit et al., 2019) and that any combination of strategies will lead to trade-offs. For extreme events, the former only becomes apparent after the fact. For example, under-investments in pandemics only became clear when COVID-19 struck. The extant literature maps out some of the trade-offs made by adopting different sourcing strategies. In this study, we consider decisions on local vs. global sourcing (i.e., supplier location) and single vs. multiple sourcing (i.e., number of suppliers) as all other sourcing decisions follow from these.

2.3.1. Single versus multiple sourcing

Research on whether single or multiple sourcing is better for supply resilience is inconclusive, suggesting that there is no ideal strategy. Single sourcing, for instance, enables the establishment of collaborative relationships that promote mutual profit (Van Weele, 2010). However, it exposes the buying organization to greater risks of disruption if that sole supplier fails (Svensson, 2004). Incorporating redundancy, e.g., backup agreements whereby the supplier reserves a certain portion of products or capacity for the buying organization can mitigate this risk (Namdar et al., 2018). Multiple sourcing is the dominant strategy in uncertain contexts (Namdar et al., 2018) because it can facilitate responsiveness to disruptions (Mehrjerdi and Shafiee, 2020). In contrast, Wiedmer et al. (2021) find that multiple sourcing worsens the impact of a disruptive event at its onset but contributes to faster recovery of supply volumes ex post. Furthermore, it is only viable under certain conditions which may be difficult to assess ex ante, making it a complex strategy to implement. For example, suppliers must be selected based on their diversity of strategies for coping with disruptions (Kahiluoto et al., 2020). In conclusion, there are trade-offs associated with either strategy in general, and specifically in the case of extreme events.

2.3.2. Local versus global sourcing

Local sourcing ensures better responsiveness to disruptions by, for example, increasing agility and flexibility (Jüttner and Maklan, 2011; Van Hoek, 2020). Nevertheless, labor costs, local resource shortages (e.g., input materials and labor), and other restrictive conditions (e.g., regulations) have led to the rise of global sourcing which broadens supply options (Gunasekaran et al., 2015). Global supply chains, however, are susceptible to disruptions that are difficult to recover from, especially when triggered by extreme events (Gunasekaran et al., 2015). Thus, neither local nor global sourcing inherently improves a buying organization's potential supply situation in future extreme events. A compromise is to settle for geographical dispersion of suppliers. Even then, success further depends on adequate investment in supply chain visibility and flexibility to deal with heightened supply chain complexity, costs resulting from dealing with multiple geographically dispersed suppliers, and to enable product or process modification (Azevedo et al., 2013; Brandon-Jones et al., 2014; Sawik, 2021). In conclusion, there are trade-offs associated with either strategy in general and particularly in the case of extreme events.

2.4. Achieving supply resilience: An equifinality perspective

The essence of equifinality is that organizations can reach a common end state through different strategies (Gresov and Drazin, 1997; Katz and Kahn, 1978). Equifinality is based on the concept of fit (Bozarth and McDermott, 1998), aiming to help answer the question of “which strategies are best”. Our study argues that different initial conditions, i.e., sourcing strategies ahead of an extreme event (ex ante), are also essential and that buying organizations must adapt their response strategies to fit those initial conditions to secure supply. Hence, a key concern vis-à-vis supply resilience is which strategies are most aligned with what initial conditions.

Despite its recognized usefulness, research adopting the equifinality concept remains very limited in procurement and SCM (e.g., Cagliano et al., 2004; Fernández and Kekäle, 2005; Kosmol et al., 2018; Marcolin and Ross, 2005; Sousa and Voss, 2008). A few papers use it to explore internal or external strategic fit in manufacturing (Bozarth and McDermott, 1998; Cagliano et al., 2004; Fernández and Kekäle, 2005). Marcolin and Ross (2005) apply it to information systems sourcing while Kosmol et al. (2018) demonstrate how different supply quality management strategies can lead to similar quality achievements. To the best of our knowledge, there is no study linking sourcing strategy and equifinal outcomes in extreme events, nor did we identify any study in the context of public procurement. Our study seeks to provides theoretical and empirical insights to this end.

3. Methods

3.1. Research approach and setting

We adopt a case-based research approach as it is suitable for studying complex real-life phenomena in their natural setting and enables an in-depth exploration of “how and why” questions (Eisenhardt, 1989; Voss et al., 2002; Yin, 2014). A multiple case study design also lends itself well to investigations on equifinality because of its inherent assumption that individual cases have unique local details that have implications for realized outcomes (Jaspers, 2007; Mills et al., 2013).

Studying extreme or “unusual” events has been argued to lead to some of the most significant contributions to theory (Bamberger and Pratt, 2010; Craighead et al., 2020), making COVID-19 suitable for our purposes (Van Hoek, 2020; Sodhi et al., 2021). We chose to focus on the ventilator supply crisis because of the extraordinary demand-supply gap triggered by the pandemic (Netland, 2020) and the complexity of manufacturing ventilators with their hundreds of intricate parts coupled with the fact that suppliers are concentrated in a handful of countries (Elsahn and Siedlok, 2021; S080; S120). We focused on the first wave of the pandemic to ensure that our analysis covered a period of never-before-experienced impact.

3.2. Case design and selection

Our unit of analysis is the buying organization – a central government or a governmental agency with a procurement remit. Our case study design explicitly considered the theory-method link (Dubois and Araujo, 2007). Specifically, we embedded equifinality in the research design, and selected countries with different initial conditions but who all succeeded in avoiding ventilator shortages. Since we sought to make general statements about different paths to supply resilience, we selected cases of “polar types” varying significantly along important theoretical dimensions (Eisenhardt and Graebner, 2007; Miles and Huberman, 1994) of initial conditions: (1) Pre-existing redundancy measured by available ventilator capacity in healthcare systems at the onset of the pandemic; and (2) available sourcing strategies, i.e., local versus global and single versus multiple sourcing. Applying these case sampling criteria, we selected the United Kingdom (UK), Switzerland, and Germany. Furthermore, due to limited data during the first wave of COVID-19, we selected these three countries because we could access much publicly available data on their response pathways. Table 2 summarizes the cases and their initial conditions.

Table 2.

Case countries and initial conditions at the onset of the pandemic's first wave.

| Case Country | Hospital availability pre-COVID (per 100,000) (Proxy for redundancy) |

Global Market Share of Local Suppliers (Proxy for local Sourcing Options) |

|

|---|---|---|---|

| Emergency ventilatorsa | Mobile Ventilatorsb | ||

| UK | 7.49 Low redundancy |

«2% Very limited domestic sourcing options |

«2% Very limited domestic sourcing options |

| Switzerland | 9.88 Low redundancy |

22%c Multiple domestic sourcing options |

18%c Limited domestic sourcing options |

| Germany | 30.5 High redundancy |

19% Multiple domestic sourcing options |

45% Multiple domestic sourcing options |

Sweden highest at 22%, Germany second highest, China third highest at 10%.

Germany highest, Switzerland second highest, US third highest at 5%.

Contribution of a US/Switzerland firm. So, effective capacity could be less.

(Sources: S003; S004; S011; S016; S067; IPG Research in: S080; S085-6; S100; S109-11; S124)

Germany and the UK were the most polar cases, the UK having the least favorable initial conditions and Germany the most favorable ones. UK-based suppliers were few and mostly producing basic ventilators that could not be used for critical care (S012; S090; S099). In Germany there was high redundancy in hospitals (S011) and abundant local supply options including two large manufacturers of emergency ventilators for intensive care. Switzerland had relatively low redundancy in healthcare facilities but hosts the largest ventilator supplier in the world, Hamilton, among others (S079).

3.3. Data collection

We collected data from multiple reliable secondary data sources in two main stages to enhance completeness: (1) April–August 2020; and (2) April 2021–January 2022. For each of the countries, we searched for articles addressing ventilator supply and government response strategies using key words “Ventilator”, “Supply”, “Shortage”, “COVID-19 pandemic” in English and German. The main data sources are shown in Table 3 . In total, 124 online documents were used (numbered S001 to S124). The source links are available as a supplement and PDF files are available on request. Some of the data from these sources were instrumental in contextualizing key findings, thereby improving sensemaking and mitigating the risk of over-attributing outcomes (Eisenhardt, 1989; Miles and Huberman, 1994) to the response strategies we identified. For instance, we tracked data on demand management strategies employed in each country, e.g., postponing or cancelling some medical procedures to free up ventilator capacity and imposing lockdowns and cross-border restrictions to slow down infection rates (e.g., S003; S007; S014; S024-8; S031-2; S052-3; S056; S064; S089; S099; S109-10). This helped us to explain the differing ventilator needs in the three countries and assisted with validating findings from limited data. For example, the Swiss government did not publicly publish ventilator numbers but the evidence of an aggressive demand management approach leading to lower infection rates assured us that what we could glean from the limited sources on ventilator quantities was reliable.

Table 3.

Sources of the data for the case study.

| Case Country | Type of Data | Publication/Online Sources |

|---|---|---|

| United Kingdom (UK) |

News | CNN, BBC News, Financial Times, The Guardian, The Washington Post, Bloomberg |

| Government Websites | The Government Websites of the UK (gov.uk), Office for National Statistics | |

| Statements | The Statements of the Ventilator Challenge UK Consortium | |

| Company Websites | Smiths Medical Official Website, Penlon Official Website | |

| Germany |

News | Ärztezeitung, Tagesschau, BBC News, Die Zeit, Reuters, Der Spiegel, ZDF |

| Government Websites | The Website of the German Federal Government (Bundesregierung), The Website of The German Federal Parliament (Deutscher Bundestag) |

|

| Reports from Institutions | DIVI-Intensivregister | |

| Company Websites | Drägerwerk AG Official Website, Löwenstein Medical Official Website | |

| Switzerland | News | Tages-Anzeiger, Aargauer Zeitung, Handelszeitung, SWI swissinfo.ch |

| Government Websites | The Website of the Swiss Federal Government (Der Bundesrat admin.ch) | |

| Company Websites | Hamilton Medical Official Website | |

| Reports from Institutions | Swiss Society of Intensive Care Medicine | |

To ensure credibility and internal validity (Eisenhardt and Graebner, 2007; Voss et al., 2002), we triangulated data from different sources. In the few instances where we found conflicting accounts for the same piece of information, we gave more weight to official government publications. If different government publications provided different estimates and we could not ascertain the accuracy of any of the sources, we used a range. For example, we worked with a range of 700–850 ventilators for Switzerland after multiple searches and triangulation of sources did not yield a definitive result.

3.4. Data coding and analysis

We conducted a qualitative content analysis to analyze the data (Miles and Huberman, 1994). We deductively coded the data for information on initial conditions and the response strategies by each of the three governments. We also developed inductive codes for emerging themes that helped to refine insights of strategies and decisions made. One such example is the deployment of regulatory instruments by all the governments in efforts to improve their supply situation, in addition to sourcing-related strategies. Sample deductive and inductive codes for the strategies and decisions are provided in Supplement 2. Measures to ensure trustworthiness and generalizability (Miles and Huberman, 1994; Voss et al., 2002) include careful selection of secondary sources, coding by two of the co-authors, and iterating between the data and the literature during the analysis process.

We conducted both within- and cross-case analyses (Yin, 2014). Within-case analyses helped us to develop an in-depth understanding of the unique characteristics, initial conditions and response strategies in each country. We accounted for temporal aspects (Craighead et al., 2020) by constructing a timeline of response strategies against ventilator supply/availability for each country. We sought evidence of shortages defined as an instance whereby a ventilator could not be allocated to a patient in need. The timelines were also used to assess agility by comparing how long it took the different countries to initiate specific responses. Cross-case analysis subsequently helped us to identify theoretically important patterns across the three countries in terms of response strategies and paths to supply resilience.

4. Results

4.1. United Kingdom

The UK Government employed multiple response strategies, often simultaneously, to fill the demand-supply gap and improve supply (S079; S090). At the onset of the pandemic, official estimates for ventilator needs for seriously ill COVID-19 patients were at least 30,000, and there was far less than one third available (S070; S099). Despite its dire initial prognosis, the country avoided shortages (S082; S084). Fig. 1 shows the response and supply timeline with the initial conditions captured at the beginning. We present the response strategies in greater detail next.

Fig. 1.

Timeline of the UK's response strategies and supply in 2020

4.1.1. Reallocation of available ventilators

The first thing that the UK Government did was to work with private hospitals and the army to reallocate existing ventilators to the publicly funded NHS (National Health Service). The NHS reached agreements with private hospitals and the Ministry of Defence for the reallocation of thousands of ventilators (old and new stocks) to NHS hospitals (S007).

4.1.2. Local sourcing

The UK Government sought to secure supply locally in several ways with the bulk of the responses being initiated between mid-March and early April 2020. We present them in turn.

Developing new ventilator models - Due to global ventilator shortages, the main path of procurement from existing suppliers was going to be too slow to allow the Government to meet rapidly growing demand. For that reason, the Government set in motion initiatives to stimulate local product development and production in order to avoid disruption problems experienced by global supply chains (S041; S093). To facilitate a speedy response, the Medicines and Healthcare Products Regulatory Agency (MHRA), accelerated the approval process for new products (S090).

By mid-March, the UK Government turned to local companies to develop ventilators that could be mass-produced quickly and locally (S054; S093; S117; S123). Within one week, a Continuous Positive Airway Pressure (CPAP) device for less critically ill patients had been developed (S054; S087; S092; S096; S117; S123). This was the result of a collaboration between the University College London (UCL), University College London Hospitals (UCLH) and Mercedes Formula One (S087; S096). Formula One Teams were credited for their use of high-speed techniques to quickly generate solutions to a time-sensitive matter (S063). By the end of March, the device had been approved for use on hospitalized patients by the MHRA. There were several other innovative bids to address potential shortages through developing simple designs. For example, a team from Oxford University was developing vital related substitute devices for ventilators (S051).

The UK Government also incentivized domestic businesses to design new emergency ventilators. Actors from multiple industries participated. For example, a team of academics, engineers and doctors created a prototype of a ventilator to treat coronavirus patients (S097). The three main participants in this initiative were British companies Dyson and Meggitt as well as UK-based GTECH. The project of Dyson, a technology company known for its vacuum cleaners and hair dryers, started in partnership with the Technology Partnership, a Cambridge-based medical equipment company (S087; S092); the defense company Babcock later joined this project (S040). This partnership led to the design of the “CoVent” ventilator for treating COVID-19 patients. It could be produced at speed and at volume, and Dyson bore the full cost of development - more than £20 million (S005; S107). Meggitt, a firm specializing in producing components for the aerospace, defense and energy industries, led a consortium of aerospace and automotive companies (S095). GTECH, which specializes in cordless vacuum cleaners and garden power tools, worked on its own (S005).

Local manufacturing of existing and new models - The first set of new ventilators to be manufactured in the UK were the CPAP devices. Forty devices had been delivered to hospitals by the end of March (S054; S117; S123). Because of its simple design, the production rate of the CPAP device was as high as 1000 per day and 10,000 were subsequently procured by the government for the NHS (S051; S090; S099; S123).

To ramp up the local production of existing, modified, and new ventilator designs, the Government promoted collaboration between the few ventilator manufacturers and manufacturers from other industries (S010; S041; S092; S114). Some manufacturers were forced to close (some of) their production lines or factories (S038) due to a drastic decline in demand caused by loss of income and uncertainty for consumers (S085). Thus, there were manufacturers with idle capacity that repurposed their facilities for the production of ventilators (S005; S040-2; S092). Notably, the UK Ventilator Challenge was set up and commenced on March 14, 2020 (S093). A Ventilator Challenge UK consortium was formed consisting of technology and engineering companies from the aerospace, automotive and medical sectors (S094, S096, S113).

The consortium accelerated the production of two ventilator models: Smiths' paraPAC and Penlon's Prima ESO2 (S041; S092; S114). Smiths' paraPAC was a pre-existing lightweight mobile ventilator which can be used in ambulances or on arrival at the hospital, but not for long-term intensive care (S106). Penlon's Prima ESO2 was modified to conform to the rapid manufacturing specification and can be used on critically ill patients (S057). The Penlon Prima ESO2 devices are typically deployed in operating theatres and can be used for more acute patients (S057; S093). The typical combined manufacturing capacity of Penlon and Smiths was only between 50 and 60 ventilators a week. The Ventilator Challenge UK consortium scaled up the production of the models to more than 100 devices per day and peaked at more than 400 per day (S008; S012; S059; S099; S114).

“The Ventilator Challenge helped scale up the production of three models (paraPAC, Vivo65 and Nippy4+) and helped guide one newly adapted model, the Penlon ESO 2, all the way through regulatory approval.” (S059)

The Ventilator Challenge UK program was eventually opened to companies outside the UK. The ventilator models Vivo65 and Nippy4+ from the Swedish company Breas Medical were added to the list of Ventilator Challenge devices (S055). The UK government assisted Breas in “negotiating with suppliers to source critical components and expediting shipments of key parts from around the world” leading to the delivery of a first batch of 150 ventilators in early May (S055). Subsequently, these four models, i.e., Penlon ESO 2, paraPAC, Vivo65 and Nippy4+, received continued support from the UK Government while support for other devices ended. The main reasons were that the former had been approved by the MHRA and projections showed that the suppliers would meet remaining demand (S055; S059; S082). Dyson had received an initial order of 10,000 CoVent ventilators which was subsequently cancelled. The company later announced that they were hoping to make CoVent available to the global market and were not looking to recoup any costs from the government (S009; S044; S107).

Ultimately, the UK Government created local sourcing channels by substitution through funding innovation and supply chain compression. In addition, some regulations were relaxed and approval processes fast-tracked. All participants of the ventilator challenge were absolved of any legal liabilities and compensated for the direct costs incurred.

“Cabinet Office committed to covering participants' reasonable direct costs and indemnified them against legal actions from inadvertently breaching intellectual property rights, competition and procurement law, and some aspects of product failure. It estimates it will spend £113 million (excluding VAT) on design costs, components and factory capacity for ventilators it did not buy because the design was not viable or not needed to meet the government’s targets.” (S082, p. 11)

4.1.3. Global sourcing

To spread risk and complement the efforts of domestic companies to find solutions to the ventilator supply, the UK Government still placed orders for ventilators from the EU region and other nations (S041; S051). At the early stage of the outbreak, British embassies around the world were asked to help the UK Government to tackle the shortage problem of medical equipment in the NHS, including ventilators (S070).

To shorten lead time and boost supply through this international sourcing route, the UK Government temporarily lifted import duty requirements on vital medical items including ventilators (S039). This decision resulted in 8000 ventilators being brought into the UK duty-free (S039). In order to expedite the transportation process, some ventilators were transported to the UK by air instead of the normal sea freight mode (S041).

4.1.4. UK main outcomes

Shortages were avoided even if the bulk of the ventilators were supplied past the initial peak of the infections, as shown in Fig. 1 (S082; S084). By then, the demand estimate had been revised down to 18,000 (S090; S099). The UK Government ultimately spent £569 million (over US$780 million) on 20,900 new ventilators (S033; S035; S082). This figure excludes any investments or incentives towards boosting local ventilator development and production.

4.2. Germany

Germany had the most favorable initial conditions at the start of the pandemic. Starting off with high redundancy compared with other countries (Table 2), and having aggressively sought to control the spread of COVID (S029; S032; S089; S109; S110; the government no longer needed additional ventilators after the 4000 (from emergency orders for 20,000) units were delivered (S011).

“Compared with other European states, Germany is by far best equipped to deal with the outbreak. Not only does it have a good number of intensive care beds — around 28,000 — it also possesses 25,000 ventilators, with 10,000 more on the way.” (S011)

The Federal Government of Germany initiated one major response to fill the potential demand-supply gap. In particular, they secured early supply/manufacturing capacity from local suppliers, at the first month of the pandemic outbreak (S001; S077). Fig. 2 shows the response and supply timeline as well as the initial conditions. We present the details of this response strategy next.

Fig. 2.

Timeline of Germany's response strategies and supply in 2020

4.2.1. Local sourcing

In Germany, prior to COVID-19, ventilator suppliers directly transacted with hospitals and clinics. When COVID-19 was declared a pandemic, the Federal Government swiftly centralized procurement and secured supply for meeting pandemic-driven demand, which was projected to exceed existing capacity (S001; S030).

“It’s unusual for a government to order medical gear directly (…). Normally customers in Germany are hospitals and clinics.” (S078)

The Federal Government sought to learn from the COVID-19 treatment experience of China and Italy where infections peaked well ahead of other countries. Based on lessons learned, it ordered ventilators suitable for three performance levels: high-end intensive care, life-support intensive care, and simple ventilators (S046). Before April 2020, the Ministry of Health had concluded contracts for more than 20,000 ventilators with several suppliers. Most of the ventilators were procured from two domestic ventilator manufacturers: Drägerwerk was to supply 10,000 (S010; S049; S050; S073; S078-9; S118)1 while Löwenstein Medical was to supply 6500. Due to supply issues and the unprecedented demand, the production process and lead times were expected to take several months (S004; S047). Löwenstein Medical was to manufacture and deliver the ventilators to the Federal Government for distribution to health facilities over a three-month period (S075). The order of 10,000 ventilators was the largest Drägerwerk had ever received and equivalent to their annual production volume (S078). To ensure delivery in full within 12 months (S062; S078; S111), Drägerwerk expanded its production capacity in Lübeck (S049).

4.2.2. Germany main outcomes

Shortages were avoided during the initial peak of the infections because Germany already had high redundancy within healthcare facilities. In addition, the country faced very low infection numbers and hospitalizations compared to most other countries (S011; S073). The bulk of the ventilators were procured at the start of the pandemic, but delivery was spread over a one-year period. In response to lower demand than initially expected, the German government reduced order quantities with several suppliers and retained some of the ventilators as emergency stock for future emergencies (S001).

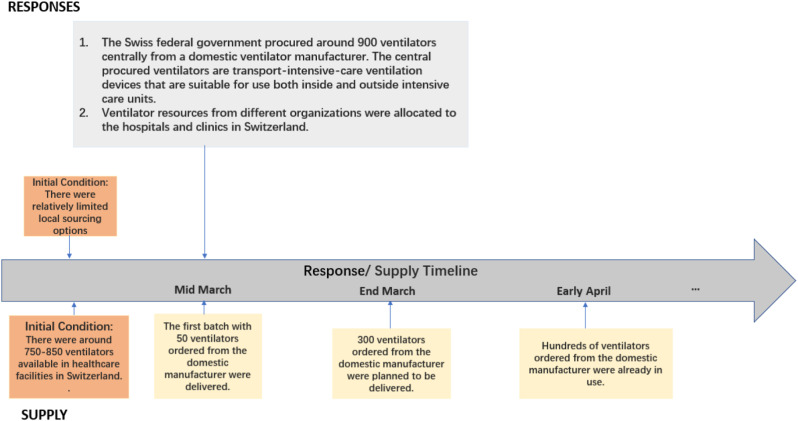

4.3. Switzerland

Switzerland initiated two key responses to fill the demand-supply gap caused by the COVID-19 pandemic: reallocating ventilators to potential pressure points and used local sourcing to secure supply. Ultimately, and partially because of its highly aggressive infection control strategy (S017-19), the country successfully avoided ventilator shortages: there was overcapacity in the healthcare industry, and most hospital beds prepared for COVID-19 patients remained vacant (S069). Fig. 3 shows the Swiss Federal Government's initial conditions, its response strategy, and the supply timeline.

Fig. 3.

Timeline of Switzerland's response strategies and supply in 2020

4.3.1. Reallocation of available resources

At the start of the pandemic, it turned out that the Swiss Intensive Care Medicine Association, SGI, had reserves of mobile ventilation devices as well as portable ventilation devices which could be immediately added to the hospital capacity; there was also sufficient capacity in the rescue services and emergency stations (S100, S102). The Koordinierter Sanitätsdienst (KSD), another Swiss medical services organization, also had additional ventilation equipment (S102). The existing ventilator capacity of these organizations and others were allocated to hospitals and clinics as frontline care providers S102).

4.3.2. Local sourcing

In mid-March 2020, the Federal Government entered an exclusive supply arrangement with a Swiss medical technology company and the largest ventilator supplier in the world, Hamilton Medical. The Government purchased 900 ventilators from Hamilton Medical in response to rapidly rising infection rates (S065; S066; S103). Ventilators of the type HAMILTON-T1 Military, which are transport-intensive-care ventilation devices suitable for use both inside and outside intensive care units, were ordered for Swiss hospitals. The Federal Government further instructed Hamilton Medical to supply locally manufactured ventilators exclusively to the Government. Therefore, during the duration of the contract, Hamilton Medical could not process other individual local or international orders. Swiss hospitals could only purchase these devices through the Federal Resources Administration. Effectively – although the government stated that this was not the case (S105) – exports were banned. Nonetheless, Hamilton was reported to have delivered 400 ventilators to Italy around mid-March (S079) and were engaging with stakeholders impacting their ability to source for components or supply different customers. For example, they had indicated that they would contest an export ban. The company's CEO, Andreas Wieland, was quoted as saying:

“The Federal Council could ban us from exporting on the basis of the extraordinary measures introduced. But we would try to oppose that. If they let us do our work and support us, we will do everything we can to make enough material available for Switzerland.” (S103)

Hamilton also stocked up on components in anticipation of a sudden increase in demand when they heard about a mysterious respiratory virus from Chinese associates (S078) and prioritized customers most in need of ventilators (S103, S105).

4.3.3. Switzerland main outcomes

Switzerland avoided ventilator shortages during the first wave of the pandemic and even had excess capacity between its healthcare facilities, rescue services, and emergency stations (S069; S100). Given the relatively low infection rates recorded in the country largely because of stringent lockdown measures (S024-8; S100), the redundant capacity in multiple locations already covered a substantial amount of the demand.

4.4. Cross-case analysis

Table 4 summarizes each government's initial conditions and how they adapted their sourcing strategies in response to the ventilator supply crisis. We find that governments, as buying organizations, were responsible for setting the supply objectives and facilitating their achievement, while the suppliers put in the work necessary to close the demand-supply gap.

Table 4.

Initial conditions and response strategies per buying organization.

| Case Country |

|||

|---|---|---|---|

| UK | Switzerland | Germany | |

| Initial Conditions |

|

|

|

| Government response strategies |

Ensure continuity

|

Ensure continuity

|

Ensure continuity No evidence found Secure additional supply

|

| Supplier response strategies |

Product Innovation (to enable manufacturing at scale)

|

Product Innovation No evidence found Ramp up supply

|

Product Innovation No evidence found Ramp up supply

|

4.4.1. Response strategies – buying organizations

Our first RQ refers to initial conditions of buying organizations and how these conditions influenced their response strategies to the same extreme event. Ultimately, all strategies were employed to bridge the demand-supply gap. There are similarities and differences among the three cases in relation to sourcing strategy as a route to supply resilience, and the enduring effects of the employed strategies.

Local versus global sourcing - Local sourcing played the most critical role in securing supply in all three cases. The UK had major challenges with sourcing globally. Curiously, the bulk of its supply came from new local market entrants. While Germany and Switzerland secured supply through a rationalized supply base, the existing suppliers significantly ramped up supply. The German supplier Drägerwerk, for example, reported that it was ramping up supply to meet Germany's demand which accounted for one year of their capacity and demand from other countries.

Single versus multiple sourcing – There was divergence in the number of suppliers the three governments used to secure supply. The UK Government dealt with three broad categories of ventilator suppliers: international, existing domestic, and new domestic, most of whom participated in the UK Ventilator Challenge. The number of suppliers was eventually rationalized to four once demand had stabilized. Switzerland opted for a single-sourcing approach. Germany placed orders with different suppliers but relied mainly on two suppliers for more than 80% of the ventilators ordered.

Diversity of strategies to secure supply - The three governments implemented different response strategies or used the same strategies differently to achieve secure supply. The UK Government employed the most strategies (see Table 4). In addition to pursuing global sourcing, the Government provided the financial incentives and regulatory space and pace needed to spur innovation. This led to increased local availability. Innovation needs in this setting entailed product modification, new product development, and repurposing of manufacturing. In turn, suppliers engaged in collaborative ventures (mostly horizontal and spanning multiple sectors) and developed product and manufacturing flexibility capabilities at record speed. This is evidenced by, for example, the fact that lead times of the new market entrants were better than those of existing suppliers (S082). Germany did more of the same: enhance redundancy. Disregarding the demand control measures of Switzerland, the same conclusion can be drawn for this case: the focus of the Swiss Government was on building further redundancy.

Regulatory instruments - Regulations were crucial for enabling all three governments to achieve their objectives. The UK employed regulatory instruments the most to increase supplier agility and flexibility. Switzerland and Germany applied fewer such instruments to preclude competition for scarce supplier resources (through import restrictions) and control local sourcing channels (through centralized procurement) and enhance coordination.

4.4.2. Response strategies - suppliers

All suppliers of the three governments, new and old, had to supply unprecedented volumes. We identified different ways in which they achieved this.

Increasing manufacturing capacity - For most established ventilator suppliers, the use of conventional strategies of increasing production capacity were the most dominant. The exception comprised UK suppliers that also modified their existing designs so that they could be manufactured at scale. Even then, they could not produce at a higher level than the new entrants. This points to a systemic scalability challenge for established suppliers.

Adapting ventilators for manufacturing at scale – Upon realizing that existing ventilator models could not be produced fast enough to close the demand-supply gap, UK-based suppliers embarked on the task of changing the ventilator products instead. With UK Government support and intense collaboration with others including universities and medical professionals, the first such ventilators (CPAP) had been reverse-engineered, approved by the MHRA, manufactured, and delivered to healthcare facilities within a matter of weeks.

Proactively managing risks – From a demand and supply perspective, our data shows that at least one of the suppliers managed risks both before and during the pandemic (we imagine that they were not unique in this respect). They foresaw the demand surge and stocked up on components which enabled them to immediately ramp up supply when the crisis hit. They also engaged with stakeholders impacting their ability to source for components or supply different customers and/or prioritized customers most in need of ventilators.

4.4.3. Different paths to resilience

Our second RQ concerned the ways in which different response strategies led to supply resilience. Although all three cases successfully closed the demand-supply gap, there were differences in the resilience capabilities linked to the adopted response strategies. Table 5 shows the main resilience capabilities linked to each government and its suppliers.

Table 5.

Comparison of dominant supply resilience capabilities across the three cases.

“+” relatively strong, “-” relatively weak.

“++” relatively much stronger, “--” relatively much weaker.

Combining the cross-case findings and time lines of each country, several patterns emerge. All countries appeared to achieve visibility through centralized control and coordination. Suppliers had different visibility concerns, e.g., UK suppliers focused more on upstream collaboration and Switzerland's suppliers focused more on establishing actual ventilator demand downstream. German and Swiss governments were more agile, issuing contracts very early. The UK Government was comparatively slower to initiate its response strategies (lower agility). However, they were comparatively more agile than the UK Government, having taken the initial decision to secure supply far sooner. The UK, though, implemented a wider range of strategies (higher flexibility) and worked closely with diverse stakeholders (more intense collaboration) to secure supply. However, the most significant collaborations were observed on the supply-side (e.g., consortiums with participants from multiple sectors including universities and manufacturing organizations). Since the UK Government was slower to make the critical sourcing decisions (based on their timeline and compared to the other two countries), UK-based suppliers had less time to close the demand-supply gap compared to their German- and Switzerland-based counterparts. Thus, fittingly, the UK's suppliers were highly agile, adapting/developing new ventilator models and producing them at record speed. The Ventilator Challenge UK closed within four months of being established, having successfully bridged the demand-supply gap. In comparison, Germany's biggest supplier had been given a year to produce the required quantities. It appears that the early government response eased the pressure on suppliers to dramatically ramp up supply, making agility less critical.

In sum, all three countries were successful but for different reasons. Germany had highly redundant ventilator capacity at the start of the pandemic and Switzerland ran a successful infection control campaign leading to lower demand. To maintain their advantageous positions and minimize the use of resources, they had to move fast. In contrast, because of its disadvantageous position, the UK needed to adopt more diverse strategies and invest more.

5. Discussion

Our results show different paths to supply resilience of three governments contingent on their initial conditions following supply-side disruptions and a demand surge for ventilators during the first wave of the COVID-19 pandemic. In line with previous research, local sourcing was crucial for all three governments (e.g., Jüttner and Maklan, 2011; Van Hoek, 2020). New suppliers contributed the most to rapidly ramping up supply. Although existing suppliers were eager to close the demand-supply gap, there were limits to what they could achieve in terms of ramping up supply. This may reflect the difficulty of increasing production capacity in high-tech industries (Elsahn and Siedlok, 2021); meaningful capacity improvement costs can range from hundreds of millions to billions of dollars and can take years to achieve (Trivedi, 2021). However, it raises questions about how new entrants could outperform existing suppliers both in developing new models and manufacturing at scale. We discuss these and other differences in more depth next and formulate related propositions for validation in future research.

5.1. Propositions

In the context of extreme events, generally speaking, strategies that entail investments before or after an extreme event has occurred carry inherent risks and trade-offs. A pertinent question is how to move forward when the event does occur. We now discuss the different paths to supply resilience and present the accompanying propositions.

5.1.1. Low versus high redundancy

The risk appetite of buying organizations can help explain differences in resource allocation for extreme events (Namdar et al., 2018). Higher risk aversion is associated with prioritizing reliability over costs and more diverse strategies to mitigate risks. Conversely, lower risk aversion is related to a greater focus on cost and a tendency to improve relationships and collaborate with a few preferred suppliers (Namdar et al., 2018). Research also suggests that risk propensity may be determined by environmental factors, e.g., if there are high risks but low response capacity, buying organizations tend to be risk averse (Mena et al., 2020).

Our results do not lend support to these findings in relation to strategies in place pre-COVID as well as in response to the pandemic. Specifically, the countries we studied had arm's-length relationships with ventilator suppliers pre-COVID (e.g., S012, S065, S078). They neither had collaborative relationships with suppliers nor multiple strategies in place. This may be because, pre-COVID, the ventilator market was deemed stable. However, since the ventilator supply chain typically works on a make-to-order basis, with lead times of at least a few months (S082), risk averse countries would likely have built more redundancy into their systems. Alternatively, countries with lower redundancy may have shared the same concerns but allocated their resources differently.

From this starting point, it is interesting that the buying government with the lowest redundancy (the UK) took the longest to act and secure more supply. This further supports the risk aversion argument. That said, given the ventilators are a high-tech product and that sourcing from existing suppliers was difficult, lower redundancy might imply that the options available for securing supply under conditions where demand far outstrips supply can be highly costly and risky (e.g., sourcing poor quality from non-vetted suppliers). As a result, more time would be needed to carefully weigh options. Thus, we argue that lower redundancy is positively associated with less agile decision-making at first (primarily because of increased risks and costs) while higher redundancy (primarily driven by risk aversion) is associated with more agile decision-making in relation to securing additional supply. We thus propose:

Proposition 1

At the onset of an extreme event, agile execution is better aligned with high redundancy, while flexibility is better aligned with low redundancy.

A major implication of this scenario is that, since buying organizations starting off with low redundancy lose time agonizing on the best approaches or seeking alternatives, their suppliers must be much more agile to make up for lost time. Our results show such agility by the UK’s local suppliers and, not surprisingly, this comes at a significant cost to the UK Government.

An issue that reduces the options of buying organizations is the intense competition for resources. Therefore, buying organizations with low redundancy must be more creative. In case of global products, other governments can take measures that worsen the situation (Craighead et al., 2020). Indeed, some countries temporarily imposed export bans on ventilator suppliers based in their countries (Hodgson, 2020). This meant that some countries had to build the supply chain from scratch, and do so fast. Because of the complexity of ventilator products, all necessary changes entailed innovation: new product development, product modification, repurposing and scaling up of manufacturing (Elsahn and Siedlok, 2021). Buying organizations with high redundancy, however, could take less drastic measures because of the high redundancy (excess finished products on hand) that enables continuity (e.g., Jüttner and Maklan, 2011; Wallace and Choi, 2011). In the face of diminishing global sourcing options, though, they also had to boost supply capacity at the very least. Entering into early contract arrangements with suppliers would have signaled to suppliers how much they needed to expand capacity and enabled them to ascertain if the subsequent volume targets were realistic. Therefore, we further argue that buying organizations with lower redundancy can only significantly improve their supply position by spurring innovation by local suppliers, while those with higher redundancy may, ceteris paribus, need to facilitate scaling up of supply through early contracting of local suppliers. Accordingly, we propose:

Proposition 2

At the onset of an extreme event, the type of supplier incentives is related to the level of existing redundancy: spurring local supplier innovation is better aligned with low redundancy, while early contracting of suppliers is better aligned with high redundancy.

5.1.2. Limited versus multiple sourcing options

The strategic sourcing literature largely focuses on the decision about how many suppliers to use for a single product as a risk mitigation strategy. Single sourcing is argued to improve responsiveness because of the intimacy of the buyer-supplier relationship which increases supplier willingness to respond fast to buyer's changing needs (Van Weele, 2010). Multiple sourcing can improve responsiveness too, but in a different way: by providing multiple supply options (Mehrjerdi and Shafiee, 2020). In high-tech industries, it is preferable to have supplier switching capabilities and a flexible sourcing strategy, e.g., in volume, mix, and delivery (Azevedo et al., 2013). Furthermore, major capacity constraints make it sensible to split orders and/or reserve capacity with multiple suppliers (Erkoc and Wu, 2005). The literature, however, appears to be silent on what happens if some buying organizations find themselves with fewer sourcing options than others as the result of varied implications of the same extreme event.

Our findings are counter-intuitive in that the case with the least sourcing options (UK Government) combined innovation with a broad base of horizontally collaborating suppliers, new and old, originating in disparate industries. Given that multiple sourcing is inherently complex, the combination with the need for innovation is an intriguing finding. Equally interesting is that the other two countries with multiple sourcing options chose to further rationalize their supply base and sourced the bulk of their ventilators from one or two suppliers. Under high uncertainty, the tendency is to increase the supply base (Namdar et al., 2018). A possible explanation for this outcome is that the limited suppliers available to the UK neither had the technical expertise nor the capacity to meet the UK's demand. Consequently, the UK Government had the herculean task of building both the expertise and production capacity rapidly. For Germany and Switzerland, however, all the suppliers available to them had sufficient technical expertise and could ramp up supply to meet their needs if they could focus solely on their government customers, respectively. However, there was competition for the suppliers' available capacity and the two governments were faced with the choice to either impose export bans or motivate a few suppliers to focus on satisfying their demand. Ultimately, and partly because of the backlash from earlier decisions to impose export bans, rationalizing supply by picking the best performing suppliers was the chosen route to securing supply. It would be more efficient for the contracted suppliers to process one big order from the same customer than to split and manage supply among multiple customers with small orders. In turn, this would increase reliability under uncertainty. Therefore, we argue that for high-tech products like ventilators, having limited sourcing options at the onset of the extreme event require greater flexibility to innovate and to extend the supply base. On the other hand, if there are multiple sourcing options, the concern is how to ensure supplier reliability and commitment. The latter appears to be achieved by reducing the number of suppliers. Thus, we propose:

Proposition 3

At the onset of an extreme event, the intensity of collaboration is related to the number of sourcing options available: intense collaboration (horizontal and vertical) is better aligned with having limited sourcing options, while limited collaboration is better aligned with having multiple sourcing options.

5.1.3. The role of regulations

A major capability that governments have as buying organizations is to wield regulatory instruments to encourage or discourage specific supplier behaviors. In the UK, local supplier flexibility and agility were needed. Flexible regulatory processes appear to facilitate agility as, for example, suppliers do not have to worry about breaking competition laws or being liable for unforeseen product failure further down the road. However, stringent approval processes remained in place for safety-related aspects of new or modified ventilator designs. Flexibility in this regard would otherwise set a dangerous precedent and could cost lives (Elsahn and Siedlok, 2021). Agility in implementing regulatory processes like product approval, however, could enhance supplier flexibility. Suppliers would be willing to expend more effort and resources if they know that their efforts have a good chance of paying off. It also gives the assurances needed for suppliers to bear risks on behalf of the buying organization.

The opposite effects are observed in countries with multiple local sourcing options where the main concern is to guarantee supply from already capable, but highly sought after, suppliers. Thus, regulations were tightened more (lower regulatory flexibility) and this negatively impacted suppliers' agility as they could not take any decisive action while obliged by law not to sell to other parties (S104). The speed with which these regulations were imposed also reduced supplier flexibility. For instance, pursuing measures to dramatically ramp up supply would be futile if those restrictions were not lifted for a long time. Suppliers in this sector are generally less keen to build stocks (S082) and would, therefore, likely not increase flexibility (significantly) under such conditions. This is partly supported by the finding that delays in imposing export bans in Switzerland enhanced the key supplier's flexibility (Hamilton) who declared that they would improve supply to serve customers in Switzerland and other countries. This suggests that not imposing bans would be better for flexibility and, by extension, availability. All governments also quickly moved to take direct charge of procurement and became the go-between for supplier and healthcare providers. This enabled buying governments to have oversight over demand and supply while also allowing them to respond rapidly to emerging issues. In sum, we propose:

Proposition 4

At the onset of the extreme events, regardless of their sourcing options, buying organizations can improve:

- a.

supplier flexibility and agility through higher regulatory flexibility.

- b.

their own visibility and agility through centralized control of procurement

5.2. Research implications and contributions

Our study introduces equifinality in supply resilience research. We make four key contributions to the literature. Firstly, we extend research at the intersection between strategic sourcing and resilience (e.g., Mandal, 2020; Namdar et al., 2018; Pereira et al., 2014) by employing an equifinality perspective to demonstrate that there are different pathways to supply resilience and to develop theoretical insights accordingly (see propositions). More generally, we respond to calls for the use of equifinality in procurement and supply research (e.g. Cagliano et al., 2004; Fernández and Kekäle, 2005; Kosmol et al., 2018) and demonstrate the analytical usefulness of this approach in relation to supply risk management and supply resilience.

Secondly, we add to prior research addressing contingency factors (e.g., Bode et al., 2011; Namdar et al., 2018; Roscoe et al., 2020) in two ways. Whereas the equifinality literature considers fit between enduring strategies and enduring environmental characteristics, our research considers fit between initial conditions following the onset of an adverse event (i.e., environmental disturbance) and subsequent response strategies. Thus, we extend the equifinality concept to include fit during periods of disturbance and subsequent change. Furthermore, we unveil specific conditions under which certain strategies are effective. In doing so, we reconcile conflicting empirical findings in the literature, e.g., with respect to the effectiveness of multiple sourcing strategies as opposed to using one or two suppliers (Wiedmer et al., 2021). Our focus on the buying organizations' diverse response pathways shows that the most suitable strategies depend on the buying organization's initial conditions. Hence, single and multiple sourcing, as well as local and global sourcing, can help avoid shortages but through different pathways.

Thirdly, to the best of our knowledge this is the first study applying an equifinality perspective in the context of public procurement. We add to research stressing the imperative role of public procurement in responding to crisis situations (Harland et al., 2021a; Fearne et al., 2021) by showing that public buying organizations such as government departments can make different resource allocation decisions in preparedness for extreme events and still be able to achieve desired outcomes – in this case, avoid ventilator shortages – by employing different strategies at an event's onset.

Fourthly, our study generates empirical insights with respect to how and why some sourcing strategies foster innovation and help create new market entrants in a very short space of time, thereby responding to the call of this Special Issue (Kähkönen et al., 2020) to advance knowledge concerning the implications of the COVID-19 pandemic for capacity building in the supply market, and for supplier-enabled innovation. Our results show the merits of pursuing adaptive and transformative routes to supply resilience (Feizabadi et al., 2021; Nikookar et al., 2021), as these paths hold promise for rapidly closing the demand-supply gap in unforeseen future global crises.

5.3. Implications for practice

Our results and propositions point to a need for practitioners to rethink supply resilience to extreme events. Preparing for the unknowable might be a fool's errand and may deplete resources that will be needed when the unthinkable manifests. Whatever the future entails, there are three clear messages for practitioners.

Firstly, Proposition 1, Proposition 2, Proposition 3 collectively suggest that buying organizations facing unfavorable initial conditions (e.g. in terms of low redundancy and limited sourcing options) need to facilitate unlikely, yet intense, collaborations; take decisive action to increase agility; continuously evaluate decisions and options; and be open to explore new solutions. In other words, survival and success will increasingly depend on rapid innovation from unlikely places. Our study shows that public buying organizations have a pivotal role to play in fostering cross-sectoral collaboration, building the innovative capacity of available suppliers, and helping to on-board new suppliers. Proposition 4 highlights the relevance of procurement centralization for increasing the buying organization's visibility. In addition, public organizations should be prepared to accept regulatory flexibilities (e.g. regarding competition) as these can increase suppliers' ability to respond to emergency situations in an agile fashion.

Secondly, those buying organizations that are fortunate enough to have favorable initial conditions should work with others to address the problems caused by the extreme event, or at least do no harm. For instance, the export bans not only worsened ventilator shortages but also may have robbed existing suppliers of the opportunity to adapt and transform themselves and become more resilient to similar future events. Buying organizations must also consider the long-term implications of addressing immediate concerns through short-term measures. For critical supplies, if a buying organization undermines other organizations’ ability to secure supply, this can also stifle innovation which could enable equitable access to scarce resources. Stated differently, especially for global crises, supply resilience of one organization should not be achieved at the detriment of others.

Thirdly, given the challenges facing practitioners with respect to scarce resources, the essence of allocating these resources strategically is to determine those aspects of procurement and SCM that are worth expending resources on now, while having a good understanding of the limits and risks they pose for responding to future extreme events. For governments, the key question relates to the critical public goods that should be prioritized as part of emergency preparedness and the associated immediate and opportunity costs. For example, in addition to health, food security and infrastructure are other key areas of concern given the expected impact of climate change.

5.4. Limitations and future research

Our research approach was suitable for the purpose at hand, i.e., establishing how buying organizations with different initial conditions can achieve supply resilience to the same extreme event. Future research could test our propositions, using primary data in other contexts. For example, because our study focuses on public procurement, we unearth insights into the implications of trade-offs made ex ante in allocating limited resources to secure the supply of life-saving public goods ex post following the onset of extreme events. However, public procurement is distinct from commercial procurement in that organizations can specialize in their product offering and target specific segments of the population. Furthermore, the power dynamics are different. Governments can compel supplier behavior through regulatory instruments, while private companies mostly rely on the power dynamics of the relationship. Given this key difference, it is worthwhile investigating how equifinality of outcomes is achieved in extreme events that impact the private sector.

Our study raised multiple other important questions. Firstly, under which conditions are different strategies cost effective? For example, there are conflicting findings in the literature regarding cost efficiency of different sourcing strategies, such as single and multiple sourcing (Van Weele, 2010). Another is the cost trade-off between preparedness through redundancy and responsiveness through flexibility and agility. The former involves amortizing the cost of preparedness over a long time period while the latter entails expending vast resources in a short space of time. For extreme events, picking the best strategy is difficult because it is not possible to predict if/when the resources are needed.

Secondly, our case countries are all well-resourced and have large procurement budgets. Future research can include resource-poor settings where the capacity to increase supply is diminished (Craighead et al., 2020). These would be interesting cases for developing a deeper understanding of supply resilience and, potentially, its limits. A comparative study on both settings could further reveal the impact of the behavior of well-resourced buying organizations (e.g., hoarding, accepting unjustified price hikes, and imposing export bans) on system outcomes (e.g., equitable distribution).

Finally, there is also a need for longitudinal and multidisciplinary research to better understand the wider and long-term implications of varied response strategies for supply resilience to global crises. In addition to its relevance for the aforementioned research directions, longitudinal research can help to uncover the causes and effects of different approaches over time. This is crucial given the complexity of global supply chains and the enduring effects of extreme events on their functioning.

Funding

This work was supported by the Research Council of Norway – GLOBVAC, grant number 312715.

Author statement

All authors listed have contributed substantially to the project.

Nonhlanhla Dube: Supervision, Conceptualization, Formal Analysis, Methodology, Visualization, Validation, Investigation, Writing (Original draft, Review and Editing).

Qiujun Li: Methodology, Investigation, Formal Analysis, Data curation, Visualization, Writing (Original draft).

Kostas Selviaridis: Methodology, Writing (Original draft, Review and Editing), Validation, Supervision.

Marianne Jahre: Writing (Original draft, Reviewing and Editing), Funding acquisition.

Declaration of competing interest

The research is partially funded by the Research Council of Norway – GLOBVAC (grant number 312715). Nonetheless, to the best of our knowledge, no conflict of interest, financial or otherwise, exists.

Biographies

Dr. Nonhlanhla Dube is an Assistant Professor of Operations Management at Lancaster University in the UK. Her areas of research interest are operations and supply chain management in the humanitarian and public sectors. Her research explores resilience in humanitarian and medicine supply chains as well as the implications of insecurity for logistics and operations strategy in the humanitarian sector. At present, she is also part of a large research group investigating cost-effective measures for dealing with shortages in medicine supply chains. Her maiden work is published in the Journal of Operations Management and Risk, Hazards & Crisis in Public Policy.

Qiujun Li completed a double degree in Logistics and Supply Chain Management (ISM Frankfurt) and Marketing Analytics (Lancaster University) in 2021. Prior to this, she did a Bachelor in Biomedical Engineering. She is interested in combining theories and analytical techniques from her studies to understand and solve problems in medicine supply chains.

Dr. Kostas Selviaridis is an Associate Professor of Operations Management at the Department of Management Science, Lancaster University Management School. His research concerns the governance of inter-organizational relationships in the supply chain, with a focus on contracting. His current work places particular emphasis on public contracting and its role in promoting innovation, resilience and sustainability goals in supply chains. Through such research Kostas has cultivated an interest, more broadly, in the interplay between supply chain management and public policy. Kostas’ research has attracted external funding from multiple sources including the British Academy for Humanities and Social Sciences and the Research Council of Norway. His work has appeared in international outlets such as the Journal of Supply Chain Management and the International Journal of Operations and Production Management. Kostas serves as an Associate Editor in the Journal of Purchasing and Supply Management.