Abstract

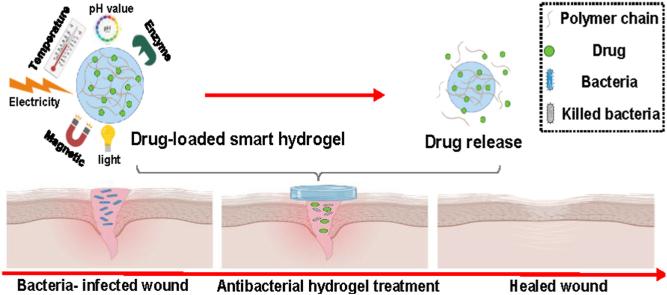

Millions of people die annually due to uncured wound infections. Healthcare systems incur high costs to treat wound infections. Tt is predicted to become more challenging due to the rise of multidrug-resistant conditions. During the last decades, smart antibacterial hydrogels could attract attention as a promising solution, especially for skin wound infections. These antibacterial hydrogels are termed ‘smart’ due to their response to specific physical and chemical environmental stimuli. To deliver different drugs to particular sites in a controlled manner, various types of crosslinking strategies are used in the manufacturing process. Smart hydrogels are designed to provide antimicrobial agents to the infected sites or are built from polymers with inherent disinfectant properties. This paper aims to critically review recent pre-clinical and clinical advances in using smart hydrogels against skin wound infections and propose the next best thing for future trends. For this purpose, an introduction to skin wound healing and disease is presented and intelligent hydrogels responding to different stimuli are introduced. Finally, the most promising investigations are discussed in their related sections. These studies can pave the way for producing new biomaterials with clinical applications.

Keywords: Hydrogels, Thermo-sensitive, Thermo-responsive, Wound infections, Burn wounds, Drug delivery

Graphical abstract

Abbreviations

Abbreviations-Definitions

- (Ag NPs)

Silver Nanoparticles

- (ANAs)

Ag Nanoparticle Assemblies

- (AA)

Acrylic acid

- (AL)

Alginate

- (AMD)

AA-co-MADA-co-DMAEMA

- (AADs)

Active adhesive dressings

- (ADA)

Oxidized alginate

- (AMP)

Antimicrobial peptide

- (Arg-PEUU/CS-GMA)

Arginine-based poly (ester urea urethane) (Arg-PEUU), glycidyl methacrylate-modified chitosan

- (AuNPs)

gold nanoparticles

- (ADH)

Adipic acid dihydrazide

- (AM)

Amikacin

- (ABWG)

Antibiofilm surfactant wound gel

- (bFGF)

Basic fibroblast growth factor

- (BTDA)

3,30,4,40-benzophenone tetracarboxylic dianhydride

- (BA)

Phenylboronic acid

- (brZnO)

Fusiform-like ZnO

- (CMC)

Carboxymethyl chitosan

- (CSDP)

Carboxymethyl chitosan and sodium alginate

- (CMC)

Catechol-modified methacryloyl chitosan

- (CTZ)

Carboxylated agarose/Tannic acid/Zinc salt

- (Cu NPs)

Cu nanoparticles

- (CMCS)

Carboxymethyl chitosan

- (CHA)

Chlorhexidine acetate

- (CA)

Citric acid

- (CEC)

N-carboxyethyl chitosan

- (CHG)

Chlorhexidine Gluconate

- (CW)

Chitin whisker

- (CMCS NPs)

Carboxymethyl chitosan nanoparticles

- (CSG-PEG)

polyethylene glycol monomethyl ether modified glycidyl methacrylate functionalized chitosan

- (Cip)

Ciprofloxacin

- (Cur)

Curcumin

- (CHX)

Chlorhexidine diacetate

- (CS)

Camellia sinensis

- (CeONs)

Cerium oxide nanoparticles

- (CB-Dex)

Carboxybetaine dextran

- (CS DABC)

Chitosan dialdehyde bacterial cellulose

- (CS, GG)

Chitosan/Guar Gum

- (CNF)

Cellulose nanofibers

- (CSA)

Cationic Steroid Antimicrobial

- (COF)

Covalent organic framework

- (DEG)

Diethylene glycol

- (DMAEMA)

2-(dimethylamino) ethyl methacrylate

- (DN)

Double-network

- (DMA)

Methacrylamide dopamine

- (DA)

Dopamine

- (DG)

Dipotassium glycyrrhizinate

- (OCMCDA)

Dopamine-grafted oxidized carboxymethyl cellulose

- (ECM)

Extracellular matrix

- (EPL)

Epsilon-poly-l-lysine

- (EPGF)

Epidermal growth factor

- (EGF)

Epidermal growth factors

- (EBS)

Ebselen

- (FGF)

Fibroblast growth factor

- (Fe3+)

Ferric ions

- (FA)

Folic acid

- (Gel-Cip)

Ciprofloxacin-loaded polydopamine NPs and glycol chitosan

- (GS)

Gentamicin sulfate

- (GC)

Glycol chitosan

- (GelMA)

Gelatin methacryloyl

- (Gel-MA/BACA-Cu NPs)

Methacrylate-modified gelatin and N, N-bis(acryloyl)cystamine-chelated Cu nanoparticles

- (Gel)

Gelatin

- (GMA)

Glycidyl methacrylate

- (Gel-Cat)

Catechol-modified gelatin

- (GTDA/chitosan/CNT)

Gelatin-grafted-dopamine and polydopamine-coated carbon nanotubes

- (HFFs)

Human foreskin fibroblast cell line

- (HRP)

Horseradish peroxidase

- (HOCL)

Hypochlorous acid

- (HPMC)

Hydroxypropyl methylcellulose

- (HA)

Hyaluronic acid

(HPMC) Hydroxypropyl methylcellulose

- (HBC)

Hydroxybutyl chitosan

- (HEMA)

2-hydroxyethyl methacrylate

- (HPCH)

Hydroxypropyl chitin

- (HFBS)

Human dermal fibroblasts

- (HA–PBA)

Phenylboronic acid-modified hyaluronic acid

- (HPCS)

Hydroxypropyl chitosan

- (HAOs)

Hyaluronan oligosaccharides

- (HA-CHO)

Oxidized hyaluronate

- (HCCP)

Hexachlorocyclic triphosphonitrile

- (rhFGF-2)

Human fibroblast growth factor 2 FGF-2

- (HS)

Hidradenitis Suppurativa

- (IA)

Itaconic acid

- (Irgel)

Iranian hydrogel sheet

- (JIS)

Japanese industrial standards

- (KGF)

Keratinocyte growth factor

- (KGM)

Konjac glucomannan

- (LCST)

Low critical solution temperature

- (LAP-DMA)

Laponite-dopamine

- (MUG)

4-methyllumbelliferyl ẞ-D- glucuronide

- (MMPs)

Matrix metalloproteinase

- (MRC-5)

Medical Research Council cell strain 5

- (MC)

Methacryloyl chitosan

- (MSSA)

Methicillin-sensitive Staphylococcus aureus

- (MDR)

Multi-drug resistance pathogens

- (MADA)

Methacrylamide dopamine

- (MRSA)

Methicillin-resistant Staphylococcus aureus

- (ML-D)

Multi-layer with drug

- (ML)

Multi-layer

- (mXG)

Modified xyloglucan

- (MC)

Methacryloyl chitosan

- (MUD)

Methylumbelliferyl-α-Dglucopyranoside acid

- (MeTro)

Methacryloyl tropoelastin

- (M-Arg)

Methacrylate arginine

- (Met)

Metformin

- (M-WELQK-M)

Methacrylate-WELQK-methacrylate

- (N, O-CMC/OCS)

N, O-carboxymethyl chitosan/oxidized chondroitin sulfate

- (NPs)

Nano-particles

- (NIR)

Near-infrared

- (NIPAAm)

N-isopropyl acrylamide

- (NMS)

Neomycin sulfate

- (NIM)

Nimesulide

- (NEO)

Neomycin

- (Nap)

Naproxen

- (OD)

Oxidized dextran

- (OSEA)

Oxidized salep and ethylene diamine-modified salep (SaHEA) chains

- (OHA-AT)

Oxidized hyaluronic acid-graft-aniline tetramer

- (OCMC)

Oxidized carboxymethyl cellulose

- (Octenisept®, OCT)

octenidine dihydrochloride and 2-phenoxyethanol

- (OKGM)

Oxidized Konjac glucomannan

- (PCA)

Polyvinyl alcohol/chitosan/silver nanoparticle

- (PNPG)

4-nitrophenyl ẞ-D- glucuronide

- (PDGF)

Platelet-derived growth factor

- (PVA)

Polyvinyl alcohol

- (PAM)

Polyacrylamide

- (PVP)

Polyvinylpyrrolidone

- (ε-PL)

ε-polylysine

- (PILs)

Polymerized ionic liquids

- (PEGS-FA)

Poly (glycerol sebacate) grafted 4-formylbenzoic acid

- (PNIPAAm)

Poly (N-isopropylacrylamide

- (PN)

Pomegranate

- (PAS)

poly (AAm-co-SVBA)

- (PF127)

Pluronic® F127

- (PACT)

Photodynamic antibacterial chemotherapy

- (PAA)

Poly acrylic acid

- (PEG)

Poly ethylene glycol

- (PEGD)

Poly ethylene glycol diacrylate

- (PEI)

Poly (ethylene imine)

- (PDA@ Ag NPs/CPHs)

Poly dopamine decorated silver nanoparticles/conductive polymer-based Hydrogels

- (PDEAEMA)

Poly (diethylaminoethyl methacrylate)

- (PDMAEMA)

Poly (dimethylaminoethyl methacrylate)

- (PMAA)

Poly (methacrylic acid)

- (γ-PGA)

γ-polyglutamic acid

- (PCBAA-1-C2 SA)

[poly(N-1-(ethoxycarbonylmethyl)-N- (3-acryloylamino-propyl)-N, N-dimethyl ammonium salicylate)]

- (PEP)

Poly (N-isopropylacrylamide166-co-n-butyl acrylate9)-poly (ethylene glycol)-poly (N-isopropylacrylamide166-co-n-butyl acrylate9) copolymer (P(NIPAM166-co-nBA9)-PEG-P(NIPAM166-conBA9)

- (PPY@PDA NWs)

polydopamine-coated polypyrrole nanowires

- (PDA@Ag NPs)

polydopamine decorated silver nanoparticles

- (PCDQ)

Phosphatidylcholine dihydroquercetin

- (PL)

Pluronic F127

- (PDEAAM)

Poly (N, N-diethylacrylamide)

- (PNIPA and PNIPAM)

Poly (N-isopropylacrylamide)

- (PEO)

Polyethylene Oxide

- (PDA/Cu-CS)

Polydopamine and copper-doped calcium silicate ceramic

- (PNIPAM)

poly(N-isopropylacrylamide)

- (PLGA)

Poly (lactic-co-glycolic acid)

- (PGMF)

Punica granatum peel ethanolic extract

- (QCS)

Quaternized chitosan

- (QCSP)

Quaternized chitosan polyaniline

- (QC)

Quaternized chitosan

- (QCS-M-PAM)

Quaternized chitosan-Matrigel-polyacrylamide

- (QCS-Polyaniline)

Quaternized Chitosan-graft-Polyaniline

- QP-(DMAPMA)

Quaternized N-[3(Dimethylamino) propyl] methacrylamide

- (ROS)

Reactive Oxygen Species

- (RAFT)

Reversible addition-fragmentation chain transfer

- (rGO)

Reduced graphene oxide

- (SD)

Sprague Dawley

- (SplB)

Serine protease-like B enzyme proteins

- (SA)

Salicylate

- (SNP-Cy3/Cy5)

Silica nanoparticles modified with Cyanin 3 and 5

- (SA)

Sodium Alginate

- (SPR)

Surface plasma resonance

- (SB-Dex)

Sulfobetaine dextran

- (SEA)

Sodium ethylene glycol alginate

- (SNC)

Silver nanocomposite

- (SVF)

Stromal vascular fraction

- (SVBA)

zwitterion poly[3-(dimethyl(4-vinylbenzyl) ammonium) propyl sulfonate

- (SS)

Sisomicin sulfate

- (GSNO)

S-nitrosoglutathione

- (TA)

Tannic acid

- (3T-CHO)

Trithiophene aldehyde

- (3 TT)

Tryptophan-modified trithiophene aldehyde

- (Try)

Trypsin

- (TEMPO)

2,2,6,6-tetramethylpiperidine-1-oxyl-doped

- (TOB)

Tobramycin

- (TEOS)

Tetraethoxysilane

- (UCNP)

Up-conversion nanoparticles

- (UCST)

Upper critical solution temperature

- (VL)

Visible light

- (VCM)

Vancomycin

- (VBIMBr)

1-vinyl-3-butylimidazolium

- (VEGF)

Vascular endothelial growth factor

- (WHO)

World Health Organization

- (XDR)

Extensively drug-resistant

- (ZOI)

Zone of inhibition

- (ZPFSA)

Piezoelectric hydrogel scaffold

- (ZnO NPs)

Zinc oxide nanoparticles

1. Introduction

Skin is the largest organ in the human body and plays a pivotal function in defending it from external damage (thermal and physical) and invasive microorganisms [1]. When the integrity and function of this organ are interrupted, skin wounds occur [2]. Wounds are divided into two groups: acute ones, such as burns, surgical wounds, and traumas and chronic ones, like venous legs, diabetes, and pressure ulcers [3,4]. According to the World Health Organization (WHO), around 265,000 deaths are reported annually just due to wounds created by burns [5]. Over and above that, microbial infections on the injured site are another significant problem, as they prolong the healing process of wounds and can be lethal for patients [5,6]. Additionally, overuse of antibiotics leads to increased antibiotic resistance while limiting the efficacy of therapeutic modalities [7,8]. Also, due to the widespread use of systemic antibiotics for local infections, antibiotic resistance has become an urgent global concern that requires effective treatments [9,10]. Wound management is mainly concerned with optimizing wound healing by preventing bacterial colonization. Over the last few decades, a great deal of effort has been put into developing dressings with antibacterial properties that can stimulate wound healing [11]. Thus, wound dressings must possess antibacterial or anti-fouling activities to prevent infections at the wound site. For instance, by controlling the adsorption of fibrinogen and its subsequent transformation into a fibrin gel, they can do wonders in terms of bypassing a potential haven for bacteria and unwanted inflammatory responses [12]. Applying these dressings that either contain antibacterial agents or are made from polymers with inherent antimicrobial properties leads to a reduced rate of antibacterial resistance [1]. Hydrogels have recently become more attractive among different types of novel antibacterial wound dressings due to their intrinsic drug delivery capacity [13]. The significant merit of hydrogels is that they are composed of hydrophilic chains, which maintain moisture around the wound site. A smart hydrogel, on the other hand, is, in simple terms, defined as a 3D structure that can significantly change its size or mechanical stability depending on environmental conditions and is among the most investigated types of biomaterials in the field [14]. This so-called smart hydrogels can control drug release and display sensitivity to stimuli such as light, pressure, magnetic fields, and temperature, plus chemical and biological stimuli such as enzymes and ROS [15,16]. Several hydrogels have already been developed as drug delivery systems and are capable of releasing antibacterial agents depending on environmental conditions in order to prevent wound infection [17]. Importantly, the main advantage of hydrogels for wound care is intimately related to their hydrophilic chains, which in turn maintain moisture around the wound site. Here, we will review some of these hydrogel systems and explore their characteristics while simultaneously discussing recent advancements in the manufacturing of smart hydrogels, especially their wound healing applications.

2. Skin and wound structure

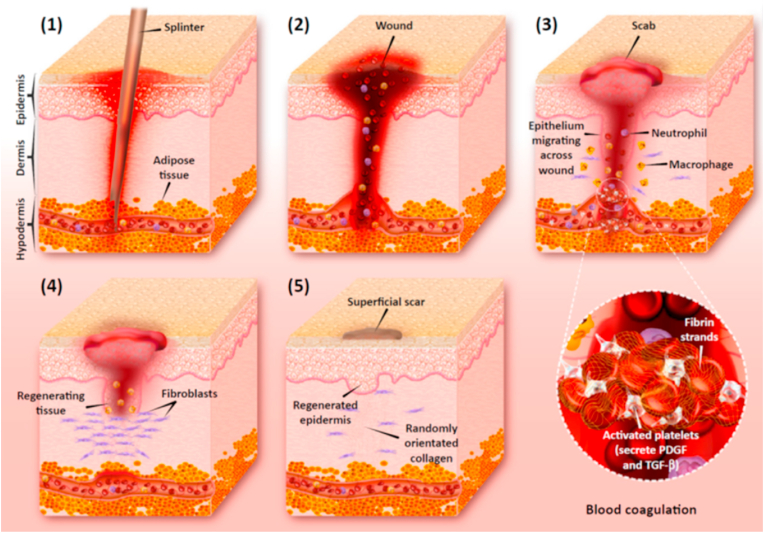

As a vital multi-layer organ, skin comprises three layers: epidermis, dermis, and subcutaneous tissue [18,19]. It acts as an interface between internal and external organs, regulates body temperature, and protects the body from injury and microbial invasion [20]. Damage to the physiological structure of the skin defines a wound, which can be extended to other tissues, including subcutaneous tissues and nerves [[21], [22], [23], [24]]. Dermal wounds are categorized into two main groups: acute and chronic. An accident, surgical injury, or burn causes an acute wound that usually leads to tissue damage. The skin recovers within an 8- to 12-week period with a minimum scar formation, depending on the scale of the injury to its layers [21]. In chronic wounds like diabetes and pressure ulcers, a considerable amount of tissue is lost. Usually, the duration of treatment for this type of wound is longer than 12 weeks [3,25]. Chronic wounds are a place to colonize some bacterial pathogens, including Pseudomonas aeruginosa, Staphylococcus epidermis, and Staphylococcus aureus. [17] with potentially devastating outcomes for the patient. According to statistics from the United States, more than 2% of the U.S. population complains about chronic wounds. More than 20 billion dollars is spent on treating these patients annually [26]. Hemostasis, inflammation, proliferation, and remodeling are the four categories that constitute a normal wound healing process (Fig. 1) [27,28]. Platelets are released at the site after an injury and adhere to the damaged blood vessel walls. The inflammatory response begins with the active absorption of neutrophils and inflammatory cytokines released from platelets, endothelial cells, etc. [29] Then, epithelialization occurs 48 h after the beginning of the wound healing process and continues for up to 14 days post-injury [30]. The remodeling phase occurs when collagen III is degraded and the synthesis of collagen I is increased. About two weeks post-injury, the wound becomes smaller, and a small scar forms at the site [31]. Also, many factors such as cytokines, the extracellular matrix (ECM), macrophages, neutrophils, fibroblasts, epidermal growth factors (EGFs), fibroblast growth factor (FGFs), and platelet-derived growth factors (PDGFs) participate in the process [32]. Environmental conditions around the wound site, such as humidity, infection, and diabetes, have been shown to affect the normal healing process, as well [33].

Fig. 1.

The structure of human skin contains three essential layers: the epidermis, the dermis, and the hypodermis (1); hemostasis, inflammation, proliferation, and remodeling are the four critical steps of the wound healing process. During hemostasis, platelets stick to one another, inducing clot formation (2); then, the inflammatory phase begins with the recruitment of immune cells, where they phagocyte dead cells, bacteria, and other pathogens or debris (3). At the proliferation stage, epithelialization occurs by replacing dead cells with epithelial cells, thus activating the angiogenesis process (4). Finally, tissue is regenerated by degrading the excessive collagen (5). Reproduced with permission [34]. Copyright 2018, Elsevier.

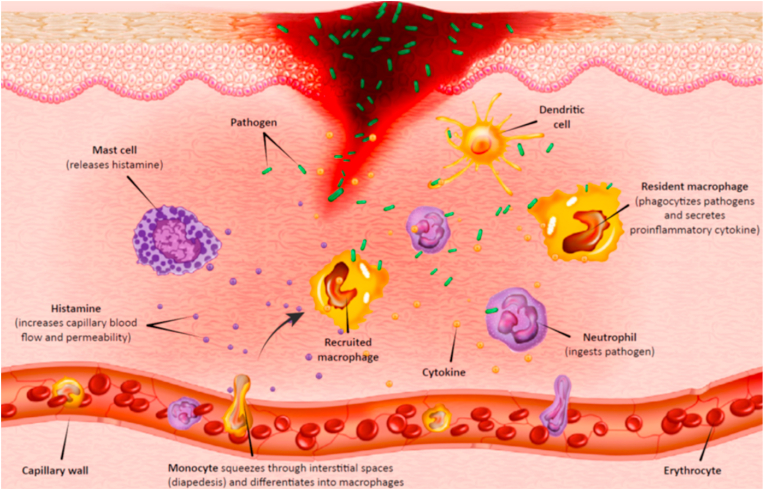

3. Post-wound infection

Wound infection is a severe concern in the healthcare system. Indeed, opportunistic pathogens can invade, colonize, and proliferate at the wound site in various types of wounds, like burns and traumas, which may cause infection (Fig. 2) [[35], [36], [37]]. A prolonged wound healing process and, in some cases, disability and death are the results of infected wounds [38]. P. aeruginosa, S. aureus, S. epidermidis, Escherichia coli, and Acinetobacter baumannii are some of the leading pathogens causing wound infections. Due to the misuse of antibiotics, some multi-drug resistant (MDR) strains have emerged in recent years [39,40]. For example, increased resistance to many antibiotic groups like carbapenems, aminoglycosides, and quinolones have been reported in P. aeruginosa isolates [41]. According to a CDC report, in the United States, about 13% of 51,000 cases infected by P. aeruginosa are MDR isolates, which result in more than 400 deaths annually. Therefore, effective treatment with antibiotics has been limited; in many cases, they cannot prevent infections completely [6]. For preventing antibiotic resistance and reducing mortality, it is essential to design new strategies and technologies that use antibiotics or antibacterial agents. For instance, small bioactive proteins like antimicrobial peptides (AMPs) have become the first-line defense against pathogens [42]. AMPs have several antimicrobial mechanisms such as their effect on the cytoplasm, the endocytosis of the bacterial plasma membrane, or interrupting their cell cycle via intracellular activities [[43], [44], [45]]. Another strategy is to use nanoparticles (NPs) like silver nanoparticles (AgNPs), gold nanoparticles (AuNPs) [46,47], and copper nanoparticles (CuNPs) [48], which are recommended as wound therapies to prevent the growth of biofilms on wound infections [49,50]. The primary mechanism of NPs is that they can penetrate the bacterial cell walls, then positive charges of NPs are linked to negatively-charged sectors at the surfaces of bacteria. As a result, hydrophobic interactions can lead to holes in bacteria's surfaces. Also, they adversely impact the proton efflux pumps and subsequently, with a modification in the pH range, destroy the membrane's surface charge [50]. Essential oils and honey are other well-known examples of materials in wound care [51,52]. Honey possesses a naturally acidic pH, provoking macrophages to reduce bacteria and biofilm levels. Essential oils like tea tree oil and chamomile oil have antibacterial activity and negatively impact the integration between bacterial cells and cellular membranes [53]. natural antibacterial agents more effectively reduce infections by mechanisms to which the pathogen cannot develop resistance by mutation as readily as they can to specific drugs [54]. In the past few decades, novel wound dressings with drug delivery capacity to the target sites have been developed to prevent bacterial infections and enhance wound healing [55].

Fig. 2.

Wound infection emerges by the presence of bacterial colonies on the wound site. Immune cells like macrophages and neutrophils are responsible for eliminating pathogens at the wound bed. Reproduced with permission [34]. Copyright 2018, Elsevier.

4. Dermal wound dressing

As the threat of wound infections spreads, optimizing the antibiotic or antibacterial agents has become essential [56,57]. Recently, the traditional ways of using antibiotics, like local or systemic therapies, have lost their entire bactericidal potential [58]. In these ways, antimicrobial resistance and risks of adverse side effects may rise further due to insufficient antibiotic dosage at the site of wounds [59,60]. Gauze, cotton, and bandages have been used for centuries as conventional wound dressings to overcome the health issue linked to wound infections. Many disadvantages include keeping the wound area dry, maintaining good adhesion to the underlying tissue, and assuring an easy bandage removal with minimal patient discomfort [21]. Today, novel wound dressings are prepared in various forms adapting to the type of wound, treatment duration, injury condition, and infection prevention purposes [21,[61], [62], [63]]. An ideal dressing for healing wounds requires some essential properties, such as strong mechanical properties and delivering a sufficiently strong barrier against microorganisms, while keeping the damaged site moistened and promoting angiogenesis [64]. In addition, improving suitable local delivery systems for antibiotics has attracted lots of attention [65]. An optimal drug carrier can keep a higher antibiotic dosage in the wound site for a long time, reduce the adverse effects of systematic administration in the host tissues, and decline the standard doses of antibiotics, which can enhance the race of antibiotic resistance. The sustained release of antibacterial agents is significantly vital in the process of wound healing [50]. Polymers with inherent antibacterial activity like chitosan or modified chitosan or an antibacterial agent such as antibiotics or NPs can be used to prepare various antibacterial wound dressings like hydrogels, foam, nanofibers, and membranes [66,67]. In this direction, hydrogels have multifunctional properties that make them desirable candidates as a novel wound dressing [64]. Thus, a suitable hydrogel should enable the repair of body tissues with the least demand for cell growth, proliferation, and vascularization [68]. However, scaffold degradation should happen through or immediately after the healing process. Also, the suitable hydrogels can be used as a drug delivery system to control the release of antibacterial agents and must possess a high porosity rate and a desirable swelling ability [[69], [70], [71]]. Despite the advantages of hydrogels, some of their limited properties, like mechanical behavior, strength, biocompatibility and stiffness, should be enhanced [72]. Several studies have been conducted to overcome these drawbacks. For instance, using argon micro-plasma as a neutral energy source for cross-linking has replaced the classical cross-linking processes. Another hydrogel-related dilemma is about its non-adherence; they need to be fixed by a secondary dressing, thus they may have low compatibility for moderate or high exudation wounds. The process of sterilization of synthetic hydrogels is complicated due to the proportion of water in these materials that can adversely affect this process [73].

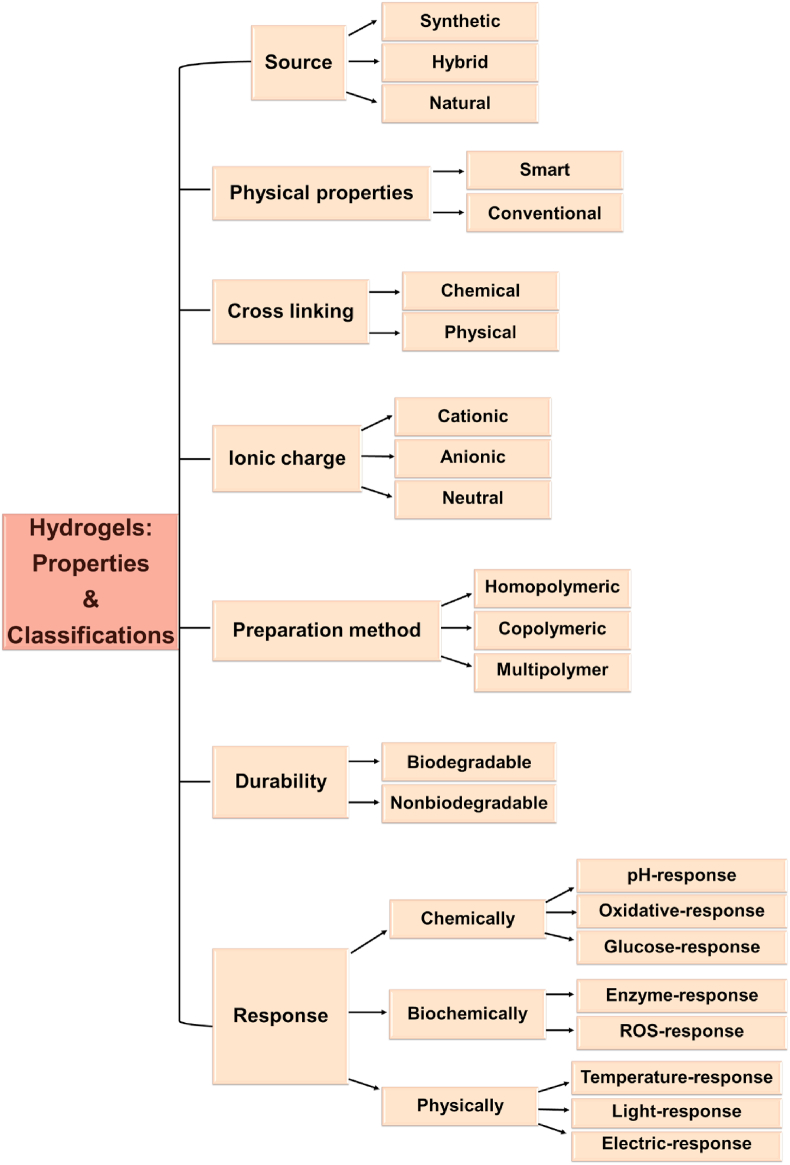

5. Hydrogels

Hydrogels are formed by water-soluble synthetic and/or natural polymers with a dynamic crosslinking composition that imitates the structure and functions of the ECM [74,75]. These biomaterials are attractive candidates for regenerative medicine because of their excellent mechanical properties like elasticity, swelling, and ability to transfer nutrients and waste quickly [76]. For wound healing purposes, a desirable hydrogel must repair tissues and provide an ideal environment for cell proliferation, vascularization, and host integration [77]. Hydrogels also enable good oxygen transfer between the wound site and atmosphere and possess favorable biocompatibility, biodegradability, sufficient swelling capacity to absorb wound exudates, and antibacterial properties; they are non-toxic and non-allergenic [[78], [79], [80]]. In drug delivery systems, hydrogels have a highly porous structure leading to a sustained release of drugs [81]. Hydrogels are divided into many categories. Based on polymer origin, hydrogels are split into three groups. Natural polymers like alginate, dextran, chitosan, pectin, chitin, cellulose, etc., produce highly biocompatible products, as some naturally exist in ECM [[82], [83], [84]]. Matrigel and Fibrinogel are commercially available as natural hydrogels [85,86]. Synthesized polymers such as polyvinyl alcohol (PVA), polyethylene oxide (PEO), and polyethylene glycol (PEG) are less biocompatible than natural hydrogels because of their physical and chemical properties [86,87]. The third group, hybrid hydrogels, is constructed of natural and synthetic polymers. These systems offer high biodegradability and biocompatibility. According to another classification, hydrogels are categorized depending on their cross-linking junctions, such as physical and chemical ones (Fig. 3). The physical ones encompass hydrogen bonds, and electrostatic and hydrophobic interactions, while the chemical ones are primarily made from various covalent bonding schemes [88]. They are also divided into two groups: non-bioactive and bioactive polymers. Despite advancements in using these hydrogels to respond sequentially to pathological and physiological changes that happen within the environment, there are still a number of obstacles to overcome. Thus, studies are designed to develop innovative bioactive hydrogels for biomedical applications to promote better tissue regeneration [89,90].

Fig. 3.

Classification of hydrogels depending on the different factors.

5.1. Smart hydrogels

Smart hydrogels contain specific functionality that increases cell proliferation, migration, differentiation, and blood vessel formation while significantly reducing the wound-healing period [[91], [92], [93]]. Specifically, they are three-dimensional networks constructed using various chemical, physical, and biological cross-linking systems. These crosslinkers enable them to respond to their surrounding environmental stimuli, including physical changes like temperature, light, magnetic and electric fields, and chemical alterations such as pH, ions and particular molecules, enzymes, and antigens. Innovative hydrogel responses include variations in swelling behavior, permeability, network architecture, mechanical properties, and sol-gel transition [[93], [94], [95]]. The following sections of the current review describe such stimuli-sensitive hydrogels for infected wound healing.

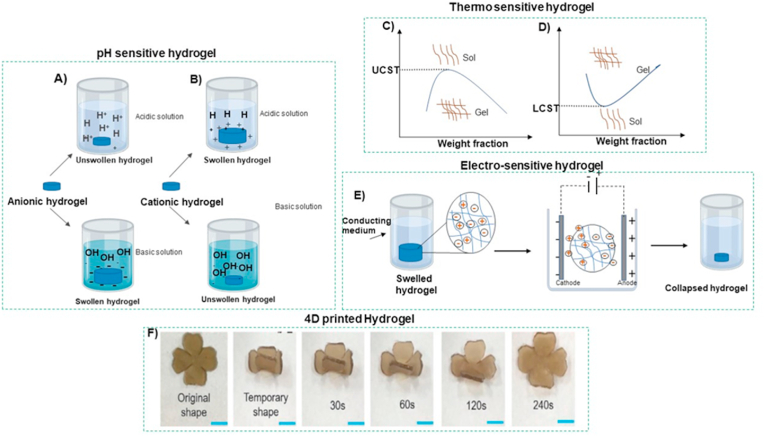

5.1.1. pH-sensitive hydrogels

pH-sensitive hydrogels are described as “ionic” when containing acidic pendant groups (such as carboxyl acid) or cationic groups (like amine). Some synthetic polymers such as poly (acrylic acid) (PAA), poly (methacrylic acid) (PMAA), polyacrylamide (PAM), poly (diethylaminoethyl methacrylate) (PDEAEMA), and poly (dimethylaminoethyl methacrylate) (PDMAEMA), and several natural ones like alginate (cationic), chitosan (anionic), albumin, and gelatin are designed as pH-responsive gels [97]. These gels' water swelling water capacity depends upon several factors, including hydrophilicity, pH of the external medium, ionic charge, degree of ionization, pKa or pKb values of ionizable groups, and polymer concentration. Among these factors, the nature of ionizable groups, pH, and ion composition is among the main factors determining the properties of smart hydrogels [98]. At low pH, polymers that contain carboxyl groups are unswollen because the acidic group will be protonated, and hydrophobic interactions between the chains of polymer cause volume shrinkage. As the pH increases, the carboxyl groups become highly ionized, resulting in a high internal charge repulsion, which leads to swelling [99]. In contrast to carboxyl-based polymers, the ionization of polybasic polymers will enhance under an acidic environment, and swelling in the overall dimensions of these hydrogels results. Fig. 4(A) and (B) respectively depict the swelling of anionic and cationic responses to pH in hydrogels. Thus, in reaction to the pH of the environment, drug release from these smart hydrogels shows a controlled-release pattern [100].

Fig. 4.

The swelling property of (A) anionic and (B) cationic polymers in response to pH. Curves show the sol-gel transition phenomenon for (C) upper critical solution temperature (LCST) and (D) lower critical solution temperature (UCST) phase transition of thermo-sensitive hydrogels. E) Schematic illustrating the electro-sensitive hydrogels' transition of volume when a voltage is applied. F) the photoresponse shape recovery activity of 4D printed F127DA/PLGA/graphene oxide hydrogel under NIR [96].

5.1.2. Thermo-sensitive hydrogels

These polymers are achieved through a synthetic process. A hydrophobic monomer region (e.g., methyl, ethyl, and propyl groups) is coupled to a hydrophilic segment (e.g., carboxyl and amide) to fabricate an amphiphilic polymer [101,102]. The polymeric network will change configuration above a particular temperature, also referred to as the low critical solution temperature (LCST). For instance, as the temperature decreases below the LCST, the structure shrinks by the aggregation of hydrophobic regions (Fig. 4C) [[103], [104], [105]]. Notably, the LCST can be controlled by altering the hydrophobic to the hydrophilic ratio in the polymer layout. Among temperature-responsive polymers, poly (N, N-diethylacrylamide) (PDEAAM) is the most commonly applied to fabricate controlled drug delivery systems because its LCST is around body temperature (25–32 °C) [106]. Also, some hydrogel structures are formed under a critical temperature, known as the upper critical solution temperature (UCST) (Fig. 4D). These types of polymers, such as poly (acrylic acid) (PAA), poly (n-isopropyl acrylamide), and poly (acrylamide-co-butyl methacrylate), enter an unfolded configuration above the UCST, and thereby their solubility is increased.

5.1.3. Light-sensitive hydrogels

Light-responsive hydrogels are composed of a photo-reactive functional group that can capture photo signals to regulate physical and chemical properties. Some of these hydrogels have been found helpful as ophthalmic drug delivery systems because the light stimulus may be applied accurately and promptly. However, such intelligent hydrogels' slow response time is a severe limitation [107]. Light-responsive hydrogels are divided into two groups: UV- and visible-light-sensitive. The former is prepared by attaching a leuco derivative molecule like bis (4-di- methylamino) phenylmethyl leucocyanide into the polymer structure. Under UV radiation, the triphenylmethane leuco dye is ionized into triphenylmethyl cations, and electrostatic repulsion between photogenerated ions causes photoinduced swelling. Light-active chromophores (azobenzene moieties, e.g., trisodium salt of copper chlorophyllin) can be incorporated into the polymer structure to synthesize a visible light hydrogel (e.g., 488 nm) [108,109]. The chromophore can absorb applied light, which is then disintegrated as heat, increasing the hydrogel's local temperature. The temperature increment changes the swelling behavior of thermo-sensitive hydrogel (e.g., poly(N-isopropylacrylamide) hydrogels). Several factors, such as the light intensity and the chromophore concentration, determine the amount of temperature increment [110,111].

5.1.4. Electro-sensitive hydrogels

Electric and magnetic field-responsive hydrogels are investigated as polyelectrolyte polymers with a high proportion of ionizable systems, as are pH-sensitive hydrogels [112,113]. Any variations in electric current or fields can cause hydrogels to swell, bend, or shrink. Such electro- and magnetic-responsive materials are typically made from synthetic polymers, including acrylic acid (AA) and PVA, as well as natural polymers like chitosan, alginate, and hyaluronic acid (HA) [114]. When the anode and cathode electrodes are placed in contact with hydrolyzed polyacrylamide hydrogels’ surface, the generated electrical potential collapses the volume of the hydrogels (Fig. 4E). Electro-sensitive hydrogels are utilized for drug delivery controlled by varying the electrical field intensity [115].

5.1.5. Biologically-sensitive hydrogels

Biomolecules (including ions, enzymes, and specific antigens) are used as the crosslinkers for hydrogel systems that are sensitive to the biological environment by being able to become cleaved under one particular biochemical reaction [116]. As an example, an ion-responsive hydrogel, poly (N-isopropylacrylamide) (PNIPA) gel, can transform to a collapsed state at a specific concentration of sodium chloride [117,118]. Specific antigen-responsive hydrogels are developed to fabricate biomedical devices that can respond to particular proteins. To this end, specific crosslinking interactions between antigens and antibodies are used to create these smart hydrogels. Antigen-antibody hydrogels' crosslinking density and swelling ratio are reversibly changed according to antigen density. The glucose-sensitive phase-reverse hydrogel is also among some of the most common biological-responsive hydrogels. Other systems are based on bonds that can become cleaved by the families of enzyme matrix metalloproteinases (MMPs) thereby opening pathways for controlled hydrogel degradation [119].

5.1.6. Four-dimensional (4D) printed hydrogels

The rapid development and interdisciplinary research of smart biomaterials and 3-dimensional (3D) bioprinting created 4D bioprinting as the next generation of biofabrication technology. At a 2013 TED Talk, the hypothesis of 4D printing was initially introduced by Skylar Tibbits as 3D printed construct which could undergo architectural changes in a time-dependent manner [120,121]. Compared to 3D printed structures, 4D printing allows for animated designs that can alter their configuration or function with time under specific external stimuli like pH, moisture, heat, and light. In addition, 4D-printed objects can respond to environmental interaction and stimuli with various outputs, including mechanical movements and biological reactions. Thus, the field of 4D printing, still in its infancy, has enticed growing interest from research and industry of various disciplines [122,123]. Among a wide range of materials, novel hydrogels with stimuli-responsiveness have gained more popularity for 4D printed systems because of their large deformability, excellent flexibility, desirable biocompatibility, straightforward manufacturing process, and inexpensiveness compared to metal and ceramics. Some polymers like poly(N-isopropylacrylamide) (PNIPAm), poly(N,N-dimethylacrylamide) (PDMAAm), alginate, hyaluronic acid, and gelatin have been intensively studied as stimuli-response hydrogels for 4D printing applications [124,125]. Moreover, extrusion-based strategies such as direct ink writing (DIW), fused deposition modeling (FDM), and vat polymerization methods like stereolithography (SLA), digital light synthesis (DLS), and digital light processing (DLP) are the most efficient printing techniques for hydrogels [126].

Dai et al. synthesized a double network-shaped memory hydrogel by chemical cross-linking of Pluronic F127 diacrylate macromer (F127DA) and physically blended poly(lactide-co-glycolide) (PLGA) with graphene oxide (GO, for near-infrared (NIR) irradiation conversion to thermal energy as an energy convertor. This hydrogel was fabricated with a 3D-printing technique using UV light polymerization and proposed for using in drug delivery purposes by NIR radiation (Fig. 4F) [96]. Larush and coworkers [127], employed the DLP method to manufacture an oral drug delivery system using acrylic acid monomers, polyethylene glycol diacrylate as the crosslinker, and photoinitiator (2,4,6-trimethylbenzoyl-diphenylphosphine oxide [TPO] nanoparticles). This study showed that the printed object could control the release of drugs with pH and by fine-tuning geometric variables. In summary, recent studies demonstrate that 4D-printed hydrogels could provide the potential to influence the localization and drugs’ release rate. Despite remarkable progress in the 4D printing technique, it is still facing several challenges and opportunities. Firstly, from the perspective of fabrication techniques, the most common printing methods for hydrogels (such as DIW, FDM, DLS, and DLP) have several disadvantages, including low resolution, the demand for expensive equipment, slow printing speed, and limited printing materials. The recent evidence suggests the material jetting and binder jetting methods as potential candidates because of their less restrictive material types and higher production rates [128,129]. Secondly, from the material perspective, the hydrogel response to stimuli is restricted to heat, moisture, and chemical environment. To expand the application of 4D-printed hydrogel devices, it is necessary to explore new types of stimuli. For instance, electrically conductive and stretchable hydrogels possess the potential to be employed as the matrix of electrical- and mechanical-responsive hydrogel composites [130].

6. Antibacterial smart hydrogels

Various types of intelligent hydrogels with antimicrobial activities have been created to prevent infection and enhance wound healing [131,132]. For example, smart hydrogels have been utilized as drug delivery systems enabling controlled drug release in response to environmental variables [133]. Recently, they also have been designed as a wound dressing to sustain the release of antibacterial agents and prevent the colonization of pathogens at the wound site [134,135]. Several strategies are used to prepare such smart antibacterial hydrogels. For example, polymers with inherent antibacterial activity like chitosan and/or loaded antibacterial agents such as nanoparticles, polypeptides, and antibiotics have been frequently used.

6.1. pH-sensitive antibacterial hydrogels as wound dressings

Different pH-sensitive antibacterial hydrogels have been fabricated as wound dressings to inhibit or reduce infections and promote wound healing. pH-sensitive hydrogels change their swelling ratios dependent on pH changes [136]. Swelling is a unique parameter for the assessment of pH-sensitive hydrogels [137]. Several studies along these lines have reported numerous factors that affect the swelling rate of ionic hydrogels for drug release in physiological conditions, including pore size, ionic charge, cross-linking density, speed of ionization, and ionic stability [133,138]. The pH of the wound site acts as an essential parameter in the wound healing process. The pH of native skin is around 5.5. However, it may vary depending on the wound type, wound healing phase, and infection [139]. Different polymers with ionic functional groups are used to prepare pH-sensitive hydrogels [140]. Protonation of amino groups in cationic polymers like chitosan and poly (ethylene imine) (PEI) leads to swelling at low pH. Anionic hydrogels like carboxymethyl chitosan (CMC), with acidic groups' ionization, lead to swelling at higher pH values [133]. Ninan et al. [139] designed an antibacterial carboxylated agarose/tannic acid/zinc salt (CTZ) pH-sensitive hydrogel. To control the pH of tannic acid release, the zinc ions were used as across-linkers. At a low pH, protonation of the phenolic group of tannic acid (TA) led to a high release of TA from CTZ, but at a higher pH, the release of TA from CTZ was decreased due to its lower protonation degree. The antibacterial activities of TA were further tested using a disk diffusion assay against E. coli. TA possesses antibacterial activities through multiple mechanisms, such as enzyme inhibition, enhanced penetrance of the membrane, and an impaired cytoplasmic membrane. As a result, the zone of inhibition (ZOI) of CTZ2 was 8 mm in comparison to the gentamicin (positive control), which was 9 mm; no ZOI was observed for the PBS (negative control). TA is released from the hydrogel in response to pH. In another study conducted by Villanueva and colleagues [141], an antimicrobial pH-responsive keratin/zinc oxide nanoparticles (nZnO) hydrogel was fabricated with tunable properties depending on the concentration of nZnO loaded in hydrogel and pH. Compared to basic pH (7–8), an acidic pH of 4 led to a reduced release of ZnO. Moreover, the antibacterial property of hydrogels loaded with nZnO (1%, 5%, and 10%) against S. aureus and E. coli was evaluated by Japanese industrial standards (JIS) and the disk diffusion method. Results from the JIS assay at a pH of 7.0 demonstrated a desirable antibacterial activity of nZnO (5%) and nZnO (10%) against both bacterial strains. Also, the disk diffusion assay results revealed that ZOI against S. aureus was 1.35 mm, and 1.90 mm, while against E. coli, it was 0.77 mm, and 0.96 mm for 5% and 10% concentrations, respectively. Sou and coworkers [142] synthesized a HA hydrogel loaded with an antimicrobial peptide [AMP, KK(SLKL)3 KK] as a cross-linker. Phase transition in their antibacterial hydrogel occurred above ∼ pH 5.5–5.6. They also revealed that the AMP–HA-loaded hydrogel has no cytotoxicity with increased mechanical strength. The antibacterial property of their system was confirmed to kill both Gram-positive and negative strains. The AMP–HA-laden hydrogel also facilitated the infected wounds' healing procedure in an animal model. Khan and colleagues [143] produced a pH-sensitive blended hydrogel film as a wound dressing, which exhibited antibacterial properties. This novel hydrogel was developed by mixing PVA and Chitosan/Guar Gum (CS, GG) polymers. Also, Tetraethoxysilane (TEOS) was added as a cross-linker. The least swelling property of the hydrogels was observed around pH 7, whereas this behavior dramatically increased in acidic media (pH < 7). This increased swelling rate was due to the action of NH3+, a cationic group in acidic pH, which is related to the degree of protonation. Consequently, these hydrogels were introduced as candidates for drug delivery systems with the power to control the drugs’ sustained release. The antibacterial activity of hydrogels with different concentrations of TEOS against Gram-negative (P. aeruginosa) and (E. coli) and Gram-positive (S. aureus) and Bacillus cereus (B. cereus) strains was examined through disk diffusion. The obtained results demonstrated that the interaction between the cationic nature of CS and lipophilic components of the bacterial membrane led to reduced bacterial growth. Moreover, rising amounts of TEOS can boost hydrophobic behavior and increase antibacterial activities against all strains. In another project reported by Sudarsan et al. [144], investigated the antimicrobial properties of a pH-sensitive silver nanocomposite hydrogel. These properties were evaluated by the well diffusion method with different concentrations of sodium ethylene glycol alginate (SEA) (9 Mm) and silver nanocomposite (SNC) (2.5 and 50 Mm) killed (E. coli) and (S. aureus). Ciprofloxacin was used as the positive control. The results indicated that SEA-9/SNC-2.5 and SEA-9/SNC-50 hydrogels possessed more antibacterial activities against both strains than pure SEA hydrogel. It was concluded that this improved behavior is because of the interactions between Ag + ions and bacterial cells in SEA-9/SNC-2.5 and SEA-9/SNC-50 hydrogels. Table 1 reviews the studies on pH-sensitive antibacterial hydrogels from 2010 to 2022.

Table 1.

PH-sensitive antibacterial hydrogels as wound dressings.

| Material(s) | Antibacterial agent(s) | Major finding(s) | Year, ref |

|---|---|---|---|

| Ag NPs Embedded in Smart Poly (N-Isopropylacrylamide) |

Ag NPs | Significant antibacterial properties against Acinetobacter and P. aeruginosa | 2011 [145] |

| Hyaluronan/PVA embedded with Ag NPs | Ag NPs | Has high antibacterial activity against E. coli | 2013 [71] |

| Chitosan-PVA | Chitosan-PVA | Antibacterial effect against Bacillus subtilis, S. aureus, P. aeruginosa, and E. coli in pH 3 Antibacterial property against Bacillus subtilis, S. aureus, and E. coli in pH 7 |

2013 [146] |

| Synthesis of sodium alginate-based biodegradable pH-sensitive biopolymeric hydrogel | Sodium alginate- ethylene glycol- acrylic acid | Swelling properties at varied pH between acidic and alkaline Inherent Antibacterial activity against E. coli and S. aureus in vitro and in vivo |

2016 [137] |

| pH-sensitive silane crosslinked injectable hydrogel for controlled release of NMS | NMS | The peak of swelling at the acidic phase, lowest at basic and at pH 7 Nontoxic behavior on HeLa cell lines Antibacterial activity against E. coli |

2017 [147] |

| pH-Responsive 2-hydroxyethylmethacrylate/citraconic anhydride–modified collagen/ciprofloxacin | Ciprofloxacin | Antibacterial activity against S. aureus | 2017 [148] |

| Multifunctional dressing (Gel-Derma) represents a colorimetric pH sensing array and drug-eluting | Gentamicin | Antibacterial activity against P. aeruginosa Soft mechanical properties Biocompatibility properties |

2017 [149] |

| Carbon dots/chitosan | Carbon dot combination with chitosan | High mechanical properties Antibacterial activity against S. aureus Non-toxicity properties on L929 Improve wound healing |

2017 [150] |

| Chitosan/PVA/silver sulfadiazine | Chitosan/silver sulfadiazine | Antibacterial activity against E. coli | 2018 [14] |

| IA, AA/DEG | IA | Highly porous structure Antibacterial activity against S. aureus and Bacillus cereus |

2018 [151] |

| Chitosan/PVP/silver sulfadiazine | Silver sulfadiazine | Antibacterial activity against E. coli High biocompatibility The least swelling at acidic pH and the highest swelling at neutral pH |

2019 [10] |

| CaAlg/NPs/HAO | NPs/HAO |

In vivo and in vitro, high antibacterial activity against E. coli and S. aureus Accelerate formation of blood vessel and healing of wound |

2019 [152] |

| Oxidized starch/ZnO NPs | ZnO | Carboxylate anion leads to the highest swelling ratio at pH = 7 Antibacterial properties against S. aureus and E. coli |

2019 [153] |

| Silver(I)/Poly (2-hydroxyethyl acrylate/IA) | Silver/IA | Synergistic antibacterial effect of silver and IA against MRSA and MMSA Non-toxic on MRC-5 cells |

2019 [154] |

| Cellulosic/chitosan | Chitosan | Swelling occurs at the low level of pH because the amino group of chitosan was protonated Antibacterial activity against E. coli, S. aureus, and L. monocytogene |

2020 [155] |

| Chitosan with thyme oil cyclodextrin | Thyme oil and cyclodextrin | At pH = 4 showed an increased swelling ratio and enhanced drug release Cell viability on L929 cells Antibacterial ability against E. coli and S. aureus |

2020 [77] |

| CA cross-linked PVA/nano silver | Nano silver/CA | the pH of swelling depended on the amount of CA; drug release occurs at pH = 7.4 Synergistic antibacterial effect of CA and nano silver against E. coli and S. aureus |

2020 [78] |

| pH-responsive hydrogel-Ag NPs | AgNPs | Significant release at pH 7.4 or 10 Antibacterial activity against P. aeruginosa and S. epidermidis in vitro Cell viability on human foreskin fibroblast cell line (HFFs) |

2021 [156] |

| pH-sensitive based dextran and peptide/ceftazidime hydrogel | peptide/ceftazidime | Can inhibit multidrug-resistant bacteria colonizing Promote wound healing Boost the adhesion of epithelial cells |

2022 [157] |

| Self-healing/pH-responsive/polysaccharide/quaternised chitosan (QCS) -based hydrogel | QCS | Release drugs in acidic pH Antibacterial activity was increased by the photothermal-radiation method |

2022 [158] |

| chitosan–graft-poly (hydroxyethyl methacrylate) (HEMA) hydrogel | (CHI-HEMA) | Antimicrobial ability against gram-negative bacteria and gram-positive bacteria | 2022 [159] |

| PVA-bacterial cellulose-functionalized-Graphene oxide- Curcumin (PVA-BC-f-GO) | GO- Curcumin | Antibacterial activity against S. aureus, E. coli, and P. aeruginosa have physical-mechanical properties | 2022 [160] |

Abbreviations: (AA) Acrylic acid; (CA) Citric acid; (DEG) Diethylene glycol; (IA) Itaconic acid; (NMS) Neomycin sulfate; (PVA) Polyvinyl alcohol; (Ag NPs) Silver nanoparticles; (HFFs) Human foreskin fibroblast cell line; (ZnO NPs) Zinc oxide nanoparticles; (HAOs) hyaluronan oligosaccharides; (QCS) quaternised chitosan; (HEMA) hydroxyethyl methacrylate.

6.2. Thermo-sensitive antibacterial hydrogels as wound dressings

As already mentioned, some hydrogels are temperature-sensitive or thermo-responsive. Most of them are used for wound dressing and are also antibacterial. This antibacterial property could be due to metal nanoparticles or antibacterial drugs or the intrinsic property of polymers used in hydrogel structure. In recent decades, biomedical engineers have fabricated antibacterial thermo-responsive hydrogels and utilized them for different wound dressings. In this direction, in vitro, in vivo, and ex vivo experiments have shown that almost all improve wound healing (Table 2). For instance, Mi et al. [161] fabricated a thermo-sensitive multifunctional antimicrobial wound dressing hydrogel based on ABA triblock copolymers containing poly (N-isopropyl acrylamide) (PNIPAM) and [poly(N-1-(ethoxycarbonylmethyl)-N- (3-acryloylamino-propyl)-N,N-dimethyl ammonium salicylate)] (PCBAA-1-C2 SA) segments. It consists of a positive-charged hydrolyzable betaine ester loaded with an antimicrobial agent (inner B block) surrounded by two blocks of thermo-sensitive PNIPAM (outer A blocks). They synthesized it through reversible addition-fragmentation chain transfer (RAFT) polymerization. At body temperature, this copolymer solution is converted to a gel. In vitro studies have indicated that the use of this synthetic hydrogel with the controlled release of drugs and small molecules can diminish the risk of infection in wounds and enhance the healing process. Temperature-sensitive chitosan-agarose hydrogels were synthesized and characterized by Miguel et al. [162] have shown that this biocompatible hydrogel has antibacterial properties at doses greater than 188 μg/mL of chitosan. In vivo studies showed that the hydrogel could heal wounds without causing an undesirable inflammatory granulomatous reaction. Makvandi and colleagues [163] mixed Ag NPs, HA, and corn silk extract to fabricate an antibacterial thermo-sensitive hydrogel that enhanced wound closure and healing in vitro. A concentration of AgNPs≥1.7 μg/mL showed a 100% inhibitory effect on all tested microorganisms. Several smart hydrogels have been utilized for drug delivery systems and wound care. Also, Arafa and coworkers [164] assorted gold nanoparticles with Pluronic® F127 (PF127) and hydroxypropyl methylcellulose (HPMC) to fabricate a thermo-sensitive antibacterial hydrogel that can be used for burn wound healing and transdermal drug delivery. Xia et al. [64] developed an antibacterial chitin whisker (CW)/carboxymethyl chitosan nanoparticles (CMCS NPs)/thermo-responsive hydroxybutyl chitosan (HBC) composite hydrogel (CW/NPs/HBC-HG) for chronic wounds. They dissolved the wide-spectrum antibiotic (Linezolid) in the hydrogel before gelation and encapsulated recombinant human epidermal factor in the NPs. The in vivo study on chronic wounds in diabetic rats observed an acceleration in angiogenesis, collagen deposition, and enhanced re-epithelialization. Zhao et al. [165] fabricated a novel thermo-responsive antibacterial chitosan/β-glycerophosphate hydrogel loaded with β-cyclodextrin-curcumin. It also showed an anti-oxidative anti–NF–κB signaling capacity and improved cutaneous wound infection in rats. Another thermo-sensitive antibacterial hydrogel comprised of galactose modified xyloglucan (mXG) and hydroxybutyl chitosan (HBC) was developed by Zhang and colleagues [166], who demonstrated that this hydrogel not only exhibits good temperature sensitivity and effectively prevents recurrent adhesion after adhesion lysis but improves wound healing, reduces scarring, and prevents bacterial growth in the wound site in a rat model. The MIC value for P. aeruginosa is in the concentration range of HBC ≥500 μg/mL. This hydrogel inhibited the growth of Gram-negative strains such as E. coli and P. aeruginosa more than Gram-positive S. aureus. One of the important experiments in this section is on Methicillin-Resistant S. aureus-infected wound healing. Yan et al. [167] synthesized a smart sprayable in situ forming hydrogel that responds to skin temperature. It contains poly (N-isopropylacrylamide166-co-n-butyl acrylate9)-poly (ethylene glycol)-poly (N-isopropylacrylamide166-co-n-butyl acrylate9) copolymer (P(NIPAM166-co-nBA9)-PEG-P(NIPAM166-conBA9) (PEP) and Ag NPs-decorated reduced GO nanosheets (Ag@rGO, or AG). This PEP-AG hydrogel improved the healing of MRSA-infected wounds in vitro and in vivo. A NO-releasing thermo-sensitive hydrogel (GSNO-PL/AL) consisting of S-nitrosoglutathione (GSNO), pluronic F127 (PL), and alginate (AL) was designed and fabricated by Cao et al. [168] They showed wound repair in Gram-positive MRSA and Gram-negative multidrug-resistant P. aeruginosa (MRPA) infected wounds in the mouse burn wound model. In a study conducted by our group, a chitosan-based thermo-sensitive (TCTS) hydrogel was fabricated for non-healing extensively drug-resistant (XDR) clinical isolates of A. baumanii infected wounds [169]. Despite the intrinsic antibacterial property of chitosan, no antibacterial activity against investigated strains was observed from the results of disk diffusion assay. Surprisingly, a complete re-epithelialization on day 14 post-surgery in infected skin of rats was reported. The result of a colony count assay revealed that the TCTS hydrogel group depicted a remarkable reduction in the number as compared with the control (Fig. 5A).

Table 2.

Thermo-sensitive antibacterial hydrogels as wound dressings.

| Material(s) | Antibacterial agent(s) | Major finding(s) | Year, ref |

|---|---|---|---|

| N-isopropylacrylamide and Ag NPs | Ag NPs | Antibacterial against Gram-positive (S. epidermidis) and Gram-negative (E. coli) bacteria in vitro Thermo-responsive behavior |

2014 [172] |

| Chitosan and Poly (N, N-diethylacrylamide) loaded gentamicin/ciprofloxacin | Chitosan and gentamicin or ciprofloxacin | Thermo-responsive hydrogel with proper adhesion of the dressing Drug loading capacity In vitro antibacterial activity against S. aureus and P. aeruginosa |

2014 [173] |

| Chitosan/PNIPAAm modified cotton | Modified cotton fabrics | A drastic decrease in colonization of E. coli and S. aureus up to 99% | 2016 [174] |

| Poly(N-isopropylacrylamide), poly(l-lactic acid-co-ϵ-caprolactone), and ciprofloxacin | Ciprofloxacin | Thermo-responsive swelling behavior Antibacterial activity killed E. coli and S. aureus Biocompatible and nontoxic on L929 Improve in vivo wound closure |

2017 [175] |

| Poly(N-isopropylacrylamide), cellulose nanocrystals, and metronidazole | Metronidazole | Drug loaded potential Thermo-responsive hybrid gel Antimicrobial effect |

2017 [176] |

| Poly (di (ethylene glycol) methyl ether methacrylate, poly (l-lactic acid-co-e-caprolactone), and ciprofloxacin | Ciprofloxacin | Thermo-responsive and drug-loaded capacity Antibacterial activity against E. coli and S. aureus In vitro safety on L929 cells and biocompatibility In vivo wound healing |

2017 [177] |

| M-Arg, NIPAAm, N, N′-methylene bisacrylamide, CHX, and polyhexamethylene guanidine phosphate | CHX | Antibacterial thermo-sensitive hydrogel (killed S. aureus and E. coli) Non-toxicity in vivo and in vitro Anti-protein adsorption property Accelerated the full-thickness treatment of the wound |

2018 [178] |

| Methylcellulose and silver oxide nanoparticles | Silver oxide nanoparticles | Injectable thermo-sensitive hydrogel About 99.9% of antibacterial activity In vivo burned skin treatment |

2018 [179] |

| PNIPAm-alginate and AgNPs | AgNPs | Thermo-responsive antibacterial AADs in vivo wound healing | 2019 [180] |

| Thermo-responsive chitosan | Chitosan | Cell viability on Hu02 fibroblast cells Antibacterial activity against XDR Acinetobacter baumannii in vitro and in vivo Promote re-epithelialization |

2020 [169] |

| Poloxamer 188 and poloxamer 407 and gentamicin | Gentamicin | Injectable hydrogel with antibacterial activity against E. coli, B. cereus, S. aureus, and MRSA | 2021 [181] |

| Cotton fibers, cyclodextrins (HP-β-CD, DM-β-CD, and β-CDP), curcumin, (CS-g-PVCL) polymer, and citric acid | Cyclodextrins and curcumin | Non-toxic, antibacterial, and antioxidant properties | 2021 [182] |

| Pluronic F-68 and Pluronic F-127, loaded with glucose oxidase (GOx@F68/F127) | glucose oxidase | 100% antibacterial activity for Staphylococcus aureus at 0.65 μg/mL and 100% for Escherichia coli at 0.6 μg/mL High biocompatibility promote wound healing; (GOx@F68/F127) 98% VS control group 30% |

2022 [183] |

| hydroxypropyl chitosan (HPCS) and poly(N-isopropylacrylamide) (PNIPAM) cross-linking by β-cyclodextrin (β-CD) and adamantyl (AD) and dipotassium glycyrrhizinate (DG); (HP-3/DG10) | dipotassium glycyrrhizinate (DG) | Antibacterial activity against S.aureus and anti-inflammatory properties Biocompatibility Improved tissue remolding and collagen deposition |

2022 [184] |

| RA-Amps, RADA16 with (Amps), PNIPAM, MGF E peptide (PNI/RA-Amps/E) | antibacterial peptide (Amps) | Thermo-responsive, injectable and compatible with good mechanical properties Enhance collagen generation and accelerate epithelialization at the wound site |

2022 [185] |

| vinyl carboxymethyl chitosan (CG) and graphene (GM) and N-isopropylacrylamide (NIPAM) and Ciprofloxacin Hydrochloride; (NIPAM-CG/GM) | Ciprofloxacin Hydrochloride | Thermo-responsive with drug release at a physiological temperature of 37 °C and antibacterial activity against S. aureus or E. coli | 2022 [186] |

| Pluronic F127, PF127 and a complex of zinc and metformin (ZnMet); (ZnMet-PF127) | zinc and metformin (ZnMet) | The sparable, thermo-responsive hydrogel Acceleration in the healing of traumatic skin defect and burn skin injury by enhancing cell proliferation, angiogenesis, collagen formation Anti-bacterial activity against S. aureus or E. coli at the wound site |

2022 [187] |

Abbreviations: (AADs) Active adhesive dressings; (CHX) Chlorhexidine diacetate; (CW/NPs/HBC-HG) Chitin whisker and carboxymethyl/chitosan nanoparticles and hydroxybutyl chitosan; (GS) Gentamicin sulfate; (M-Arg) Methacrylate arginine; (NIPAAm) N-isopropyl acrylamide monomers; (XDR) Extensively drug-resistant.

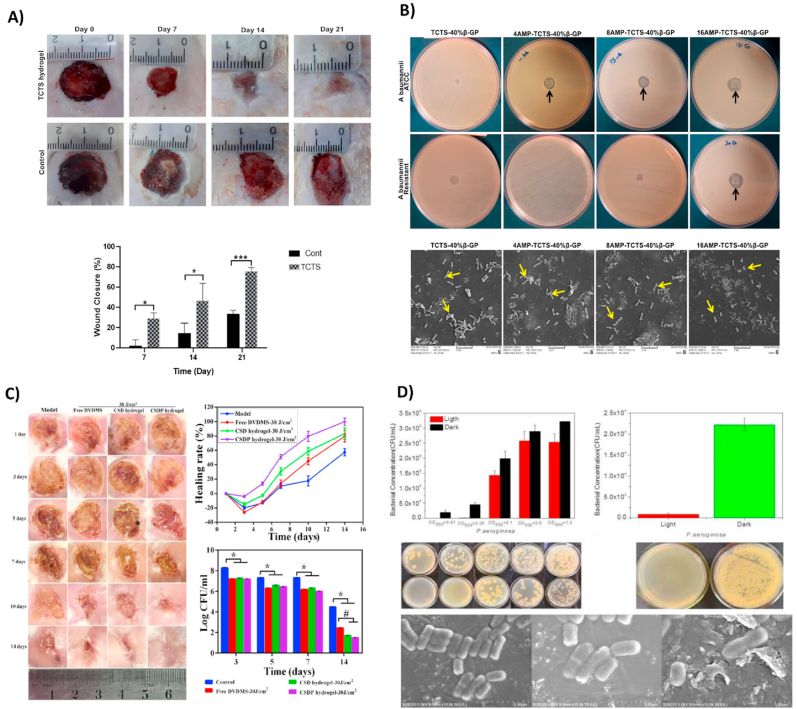

Fig. 5.

(A) Wound closure after treatment with TCTS hydrogel and gauze as control at days 7, 14, and 21. Reproduced with permission [169]. Copyright 2020, Elsevier. (B) Antibacterial behavior of TCTS -40%β -GP and AMP -TCTS -40%β -GP hydrogels against ATCC and resistant A. baumannii. All AMP -TCTS -40%β -GP hydrogels possess antibacterial activity against strains. SEM images of resistant A. baumannii are treated with TCTS -40%β -GP and AMP -TCTS - 40%β -GP hydrogels. Reproduced with permission [171]. Copyright 2020, Elsevier. (C) Evaluation of antibacterial activity in infected wound treated by CSDP hydrogel-PACT against MDR-S. aureus at days 1, 3, 5, 7, 10, and 14. Reproduced with permission [5]. Copyright 2020, American Chemical Society. (D) Antibacterial activity of the vesicles and prototype (20% TCDA vesicles contain photosensitive antibacterial agents) hydrogel against P. aeruginosa. SEM micrographs of P. aeruginosa bacteria grown on vesicles containing photosensitizer. (Right: P. aeruginosa with irradiated vesicles; Middle: P. aeruginosa with vesicles, in the dark; Left: P. aeruginosa). Reproduced with permission [197]. Copyright 2020, WILEY.

An Amikacin encapsulated smart hydrogel was fabricated recently with antibacterial activity and suitable mechanical properties and accelerated the wound healing processes in vivo. These studies showed that wound closure was achieved entirely in 21 days in a rat model [170].

All of the mentioned studies involved some antibacterial experiments (in vivo or in vitro) on their synthetic thermo-sensitive hydrogels, and most of them confirmed an inhibitory growth effect against E. coli or S. aureus or both of them. In another study, a thermo-responsive chitosan hydrogel was fabricated and loaded with different concentrations of AMP [171]. Recent studies have demonstrated the antibacterial effects of AMPs, which are promising novel antibiotics for treating multi-drug-resistance bacteria. The antibacterial activity of AMPs varies widely, such as increasing bacterial membrane permeability, preventing intracellular activities, and leakage of cytoplasmic ingredients, which leads to bacterial cell death. Antibacterial properties of hydrogels containing different concentrations of AMPs (0, 4, 8, and 16 μg ml-1) against both standard strain and resistant A. baumannii bacteria were evaluated by disk diffusion method and SEM (Fig. 5B). Results from disk diffusion indicated ZOI against both bacterial strains and resistance for hydrogel with AMP (16 μg ml – 1). Also, the observation from SEM proved that there is an inverse connection between the growing number of bacteria and AMP concentration. Thus, the bacteria growth was dramatically lowered when the concentration of AMP in the hydrogel was increased.

6.3. Radiation/photo-sensitive antibacterial hydrogels as wound dressings

Some synthetic antibacterial hydrogels for healing purposes are sensitive to radiation or light. This smart hydrogel shows antibacterial activity based on photo-thermal inactivation in bacteria and controllable drug/NPs release in the lesion [188]. What's more, radiation can trigger photo-biochemical reactions that inhibit infection and boost the healing process at the chronic wound site. Table 3 summarizes different antibacterial radiation-sensitive hydrogels synthesized for wound treatment between 2010 and 2020. Along these lines, Hong and Sun [26] fabricated a rose bengal (RB)/PVA hydrogel by the freeze-thawing process. This photo-induced hydrogel showed antibacterial behavior under UVA (365 nm) and fluorescence exposure against E. coli and S. aureus. However, the study was not performed on the wound site. Shi et al. [189] designed a photo-cleavable caged ciprofloxacin PEG hydrogel. Under UVA exposure (365 nm), 23.4 ± 5.2% of ciprofloxacin was released and limited the growth of S. aureus in vitro. It was considered a promising “spray-on” hydrogel for wound dressing applications. Similarly, Zhang and coworkers [190] combined a small amphiphilic peptide with a fullerene derivative to enhance mechanical properties. This hydrogel was exposed to white light (0.1 W cm-1) for 10 min and showed antibacterial activity against a multiantibiotic-resistant S. aureus strain. Another cross-linkable hydrogel sensitive to blue light was fabricated by Wang et al. [191] designed a double-network hydrogel with two different chitosan chains (catechol-modified methacryloyl chitosan, CMC; methacryloyl chitosan, MC). This light-sensitive hydrogel demonstrated nearly 100% antibacterial activity towards E. coli and S. aureus and showed favorable hemostatic performance and a boost in combating wound infection in vivo (Fig. 7D). For MDR burn infections, Mai et al. [5] developed a multifunctional intelligent hybrid hydrogel of carboxymethyl chitosan and sodium alginate (CSDP) that was used for photodynamic antibacterial chemotherapy (PACT). They confirmed about 100% bacterial elimination, reduced inflammation, and promoted tissue regeneration after light exposure in vitro and in vivo. Near-infrared (NIR) can induce photo-thermal inactivation in bacteria and also release drugs from some synthetic hydrogels. Tao et al. [13] also confirmed that a hydrogel formed by methacrylate-modified gelatin and N, N-bis(acryloyl) cystamine-chelated Cu nanoparticles (Gel-MA/BACA-Cu NPs) could promote wound closure and decrease bacterial growth in vivo. Photo-thermal-induced bactericidal activity to reduce P. aeruginosa biofilm and the suspension was shown via the use of a gold nanorod-loaded poloxamer 407 hydrogel system after NIR exposure in vitro by Al-Bakri and Mahmoud [192]. They concluded that this hydrogel nanosystem could be effective for treating common skin infections. One of the fascinating multifunctional composite hydrogels for use as a dressing and drug carrier was developed by Liang et al. [31] This gel is injectable and contains hyaluronic acid-graft-dopamine and reduced GO via a horseradish peroxidase (H2O2/HPR) system. In addition to having excellent biochemical and biomechanical properties, this hydrogel system exhibited strong antibacterial effects against E. coli and S. aureus in vitro and in vivo.

Table 3.

Radiation/photo-sensitive antibacterial hydrogels as wound dressings.

| Material(s) | Antibacterial agent(s) | Major finding(s) | Year, ref |

|---|---|---|---|

| SA, PEO, Pluronic F127, and lavender oil |

Lavender oil | Nontoxic on HFF-1 cells Proper mechanical properties UVB-triggered hydrogel Antibacterial property against S. aureus Anti-inflammation behavior |

2016 [199] |

| GelMA, MeTro, and antimicrobial peptide Tet213 |

Antimicrobial peptide Tet213 | Antimicrobial activity against Gram (−) and (+) bacteria (MRSA and E. coli) Improve porosity, degradability, swellability, mechanical property, and adhesiveness Sprayable visible-light-responsive crosslinking hybrid hydrogel Biocompatibility, biodegradation, and nontoxic in vivo and in vitro (NIH-3T3 cells and rat subcutaneous skin) |

2017 [200] |

| BTDA, HEMA, PEGD, chitosan, and methylene blue | Chitosan | Post-UV irradiation responsive (660 nm) Antibacterial activity against E. coli and S. aureus in vitro and in vivo |

2018 [201] |

| Rose bengal/polypyrrole hybrid poly(vinyl alcohol) hydrogel and rhEGF | Rose Bengal | Antibacterial activity against E. coli and S. aureus in vitro and in vivo at mild temperatures (45 °C) under dual light irradiation (808 nm NIR light and 550 nm VL irradiation) | 2021 [202] |

| Graphene hybrid supramolecular hydrogel | Photothermally responsive active Graphene | Antibacterial behavior against MRSA Promote granulation-tissue formation by reducing inflammation, enhancing angiogenesis and collagen deposition in an acute wound infection model |

2021 [203] |

| Ag2S quantum dot/mSiO2 NPs and 3-(trimethoxylmethosilyl) propyl methacrylate | Ag+ | NP hydrogel with photothermal and photodynamic characteristics under 808 nm (NIR) light irradiation, with a photothermal conversion efficiency of 57.3% for releasing the Ag+ Antibacterial activity E. coli & MRSA (inhibition rate of 99.7% and 99.8%, respectively) Enhancing collagen coverage area and bacterial clearance in vivo |

2022 [204] |

| Ag nanoparticles/phosphotungstic acid-polydopamine nano-flowers and chitosan (CS)/gelatin (GE) | Ag+ | Anti-bacterial activity against both gram-negative E. coli and gram-positive S. aureus with releasing Ag + under NIR and accelerating wound healing in vivo | 2022 [205] |

Abbreviations: (BTDA) 3,30,4,40-benzophenone tetracarboxylic dianhydride; (GelMA) Gelatin methacryloyl; (HEMA) 2-hydroxyethyl methacrylate; (MeTro) Methacryloyl tropoelastin; (PEGD) Poly ethylene glycol diacrylate; (GT-DA/chitosan/CNT) gelatin-grafted-dopamine and polydopamine-coated carbon nanotubes; (PDA/Cu-CS) polydopamine (PDA) and copper-doped calcium silicate ceramic (Cu-CS).

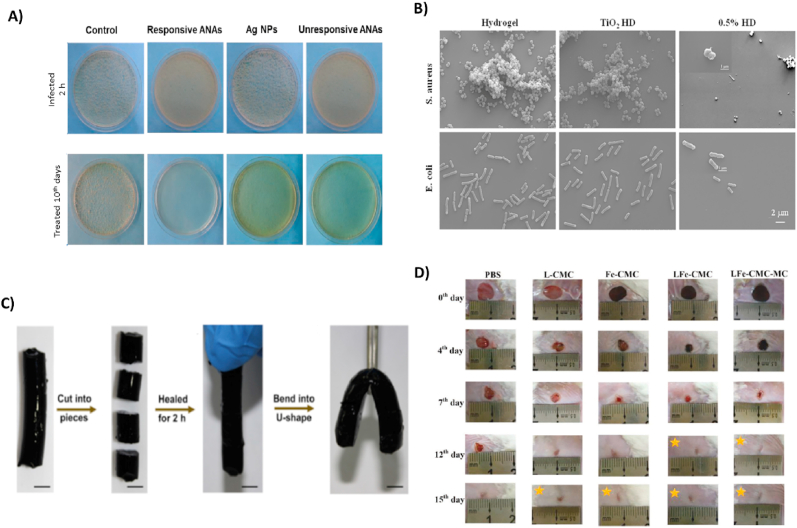

Fig. 7.

(A) Cultured MRSA-infected wounds of a rat wound healing model after ten days. Reproduced with permission [239]. Copyright 2020, American Chemical Society. (B) SEM micrographs of E. coli and S. aureus bacteria are grown on TiO2 hydrogel. An increased TiO2 concentration resulted in a significant reduction in the number of bacteria on hydrogels. Reproduced with permission [216]. Copyright 2017, Elsevier. (C) A hydrogel was cut into four pieces and reassembled after 2 h incubation at 25 °C. Reproduced with permission [1]. Copyright 2019, Elsevier. (D) Macroscopic images of S. aureus-infected rat skin after 15 days of treatment with PBS solution (as the control group), L-CMC, Fe-CMC, LFe-CMC, and LFe-CMC-MC hydrogels. Reproduced with permission [240]. Copyright 2019, WILEY.

In summary, all of these radiation-sensitive composite hydrogels that can be used for wound dressing were biocompatible and showed excellent antibacterial activity even against some MDR bacteria in vitro, in vivo, or both [193].

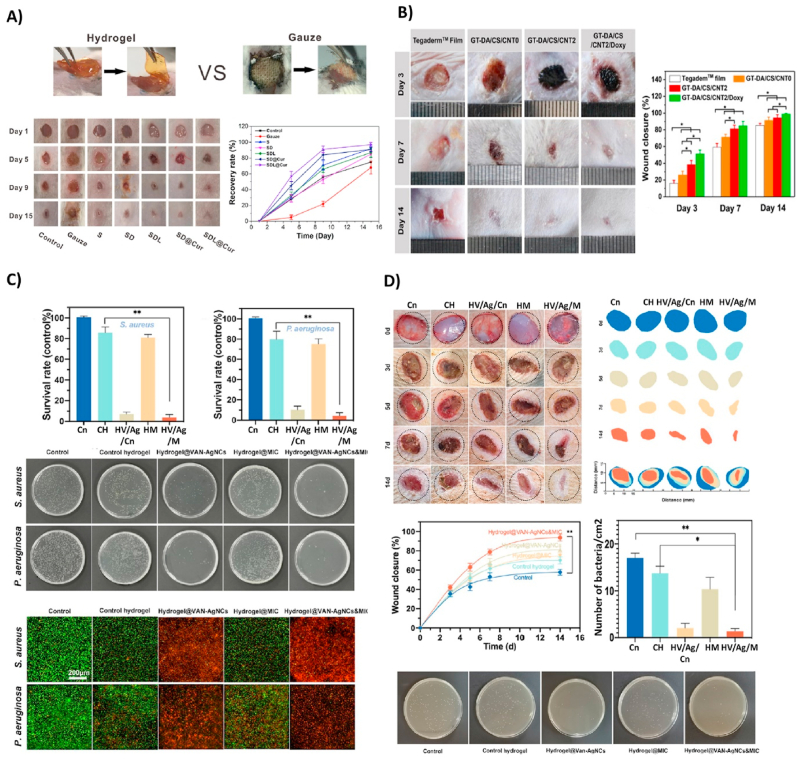

A multi-functional nanocomposite dressing made from tungsten disulfide nanosheets, dodecyl-modified chitosan (FCS), dialdehyde-functionalized PEG (PEG-CHO), and ciprofloxacin with high sensitivity to NIR irradiation showed a solid bactericidal effect both in vitro and, in a mouse infected wound model. The construct also revealed an anti-oxidation property, which caused reduced inflammation and subsequently promoted the wound-healing processes. Recently, Ma and coworkers [194], showed the in vitro and in vivo antibacterial activity of a hydroxypropyl chitin (HPCH), tannic acid (TA), and ferric ions (Fe3+) composite hydrogel under 10 min of NIR laser irradiation. This smart injectable hydrogel is cytocompatible and promotes wound healing. Another composite hydrogel consisting of gelatin-grafted-dopamine/chitosan/carbon nanotubes (GT-DA/chitosan/CNT) and doxycycline with photothermal antibacterial activity fabricated by Liang et al. [195] demonstrated an antioxidant, adhesive, and conductive characteristics. This study revealed that the GT-DA/chitosan/CNT under NIR irradiation could eradicate infection and boost healing of the full-thickness infected wound in vivo (Fig. 6B). The hot ions effect of Cu through the photothermal activity of a polydopamine/Cu/chitosan (PDA/Cu-CS) composite hydrogel greatly impacted antibiotic-resistant infection wound healing [196]. This synthesized hydrogel improved cell proliferation and angiogenesis in vitro and in vivo in methicillin-resistant S. aureus and E. coli wound infection models. Prospects for these antibacterial smart hydrogels could be the mixture of photodynamic and photothermal therapy to achieve more efficient strategies for wound treatment methods (Fig. 8A and B). In another study by Mai and coworkers, a hydrogel-based nano-delivery system was developed with antimicrobial and skin re-epithelialization properties. They was considered for photodynamic antimicrobial chemotherapy (PACT) in the treatment of burn wound and could be a biocompatible delivery system of various therapeutics and nanoparticles. These CSDP nanohybrids also displayed an effective inhibition against MDR S. aureus biofilm formation (Fig. 5C) [5]. A further smart photosensitive antibacterial hydrogel was fabricated by Zhou et al. [197] They designed a hydrogel containing tryptophan-modified trithiophene aldehyde (3T-CHO) (3 TT) as a photosensitizer to create a dressing with detection and antimicrobial applications. Experiments showed that the released 3 TT (photosensitizer and antibacterial agent) was associated with toxins (pyocyanin released by P. aeruginosa or hemolysin released by S. aureus). Toxin lysed the vesicles, which led to the release of fluorescein for the detection of infections and displayed bactericidal effects on P. aeruginosa after light irradiation (Fig. 5D).

Fig. 6.

(A) Representative imaging of S. aureus-infected wound in a mouse model (15-day wound healing treated with the SDL@Cur hydrogel SDL, SD, S, and gauze). Reproduced with permission [198]. Copyright 2021, American Chemical Society. (B) Wound infection treated with TegadermTM film, GT-DA/CS/CNT0, GT DA/CS/CNT2, and GT-DA/CS/CNT2/Doxy hydrogel and the percentage of wound closure for each group. Reproduced with permission [195]. Copyright 2019, Elsevier. (C) Antimicrobial activity treated with hydrogel VAN-AgNCs and hydrogel MIC@NIM, hydrogel VAN-AgNCs-MIC@NIM, and control against S. aureus (A) and P. aeruginosa. (D) Infected diabetic wound healing treated with hydrogel VAN-AgNCs, hydrogel MIC@NIM, hydrogel VAN-AgNCs-MIC@NIM, and the control. Also, the wound closure and colony count results after seven days are presented. Reproduced with permission [217]. Copyright 2021, American Chemical Society. (Cn: Control, CH: Control Hydrogel, HV/Ag/Cn: hydrogel VAN-AgNCs, HM: hydrogel MIC@NIM, HV/Ag/M: hydrogel VAN-AgNCs-MIC@NIM).

Fig. 8.

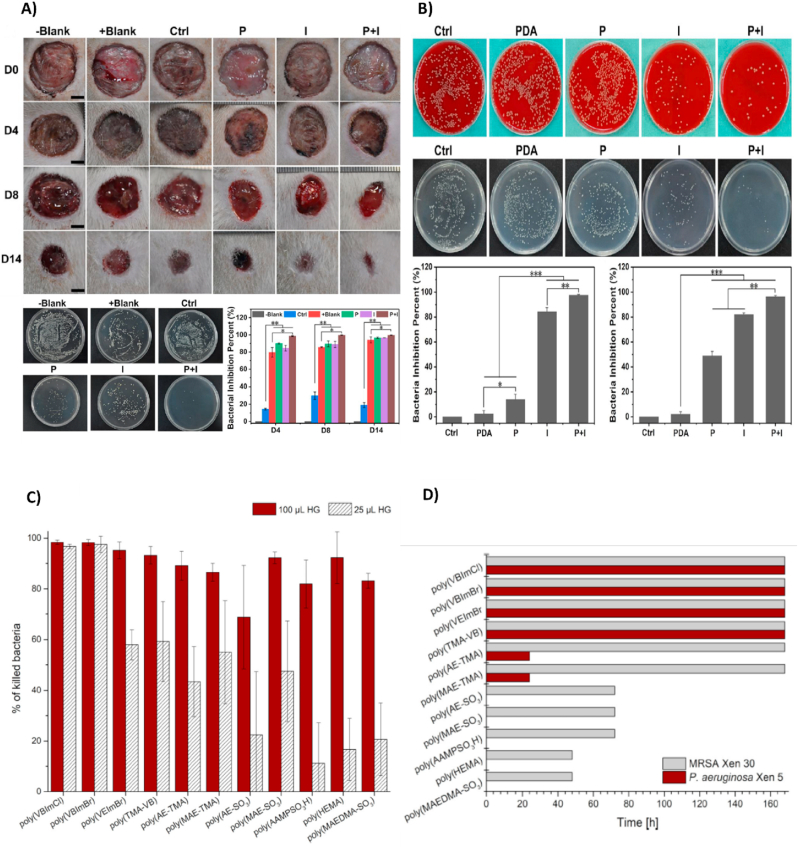

(A) Investigation of antimicrobial properties and wound healing percentage of hydrogels at different days 4,8 and 14, in vivo. Colony count assay against wound infection with E. coli, in vivo. (B) Images from the in vitro antibacterial activity of the hydrogels groups of Ctrl, PDA, P (PDA hydrogel with laser irradiation), I (PDA/Cu-CS hydrogel), and P + I (PDA/Cu-CS hydrogel with laser irradiation) against E. coli and MRSA. Reproduced with permission [196]. Copyright 2020, American Chemical Society. (C) Antibacterial effect's period of the hydrogels against P. aeruginosa and MRSA. (D) Antibacterial effect of hydrogels against MRSA. Reproduced with permission [288]. Copyright 2020, WILEY.

A multifunctional antifouling and antimicrobial zwitterionic sulfobetaine acrylamide hydrogel with laponite-dopamine (LAP-DMA) & curcumin was also fabricated by Dai et al. [198] The sustained release of curcumin happened under UV-irradiation. The SDL@Cur hydrogel, composed of SD (prepared by SBMA, MBA, and DMA monomers) with LAP and curcumin, was able to heal the infected wound with complete re-epithelialization and development of new connective tissue on day 15, in vivo (Fig. 6A).

6.4. Biological smart antibacterial hydrogels as wound dressings

6.4.1. Enzyme-responsive antibacterial hydrogels

Enzymes display a critical role in many biological processes in tissue engineering and drug delivery. Enzymes act as a signal for the drug delivery system when they are placed at a specific site in the human body. In tissue engineering, MMPs are a group of enzymes that degrade the ECM proteins [206]. In recent years, enzyme-sensitive hydrogels have been developed. Specific hydrolytic enzymes, like glycosidases, lipases, proteases, and oxidoreductases like peroxidases, have been utilized for several schemes. Enzyme-sensitive hydrogels show various advantages such as specificity, regioselectivity and stereoselectivity [207]. Zuo et al. [208] synthesized an enzyme-responsive antibacterial Ag NP hydrogel, and its antibacterial effects against S. aureus were evaluated in vitro and in vivo. Methacrylate-WELQK-methacrylate (M-WELQK-M) was synthesized as a cross-linker. Silver can inhibit the replication of DNA and RNA and destroy the cell membrane. In this study, silver was subjected to the serine protease-like protein B (SplB) secreted by S. aureus. The researchers used three models, i.e., responsive Ag NP assemblies (ANAs), unresponsive ANAs, and Ag NPs, in vitro. The result showed that responsive ANAs (4 μg × mL−1) had increased antibacterial activity against MRSA. The reduced rates of responsive ANAs, unresponsive ANAs, and Ag NPs were 86.7%, 74.1%, and 64.6%, respectively. Many studies have revealed that a smaller Ag NPs increases antibacterial activity. In this study, however, the size of responsive ANAs was more significant than that of Ag NPs, while they revealed stronger antimicrobial effects. The researchers concluded that enzyme responsiveness is somehow directly related to antibacterial properties. The colony count experiment was performed to investigate the antibacterial activity of the samples against MRSA in vivo. As a result, responsive ANAs indicated the highest antibacterial effects and reduced bacterial colonies; see (Fig. 7A).

6.4.2. ROS-responsive antibacterial hydrogels

Reactive Oxygen Species (ROS) play essential roles in metabolic processes, such as adjusting cell signaling, modulating inflammation, removing infections, and regulating protein functions [209]. Moderate ROS levels can affect physiological activities like promoting wound healing and eliminating bacterial invasions [210]. H2O2, HO−, O2−, and hypochlorous acid (HOCL) are critical ROS compounds [211,212]. The moderate values of H2O2 in the human body can activate cell signaling mediators such as vascular endothelial growth factor (VEGF), keratinocyte growth factor (KGF), and EGF [209,213]. Over-production of ROS may lead to incomplete wound healing, inflammation, scarring, and necrosis [214]. Infection throughout the inflammatory phase of wound healing is controlled with increased ROS levels [215]. Wang and coworkers [216], designed a PVA hydrogel incorporated with Ag/TiO2 by light-induced ROS and evaluated its antibacterial activity against Gram-negative and positive strains in vitro and in vivo. They used samples with different contents of Ag under two different ranges of visible light (VL). The results exhibited that the 0.5% Ag/TiO2 hydrogel could kill both S. aureus and E. coli strains in both ranges. However, the antibacterial activity of this hybrid hydrogel was significantly enhanced under 660 nm irradiation of VL. The morphology of both strains was observed under SEM (Fig. 7B). The results showed a decline in the number of bacteria in the sample treated with 0.5% Ag/TiO2 hybrid hydrogel. This may be due to the oxidized lipid membrane of bacteria under the ROS condition, which in turn can disrupt the bacterial membrane. As already mentioned, the photodynamic character of Ag/TiO2 hydrogel was evaluated under VL and 660 nm VL irradiation. The results showed that the amount of singlet oxygen (1O2) produced was directly related to Ag content under 660 nm laser radiation.