Abstract

Coronavirus disease 2019 (COVID-19) has placed tremendous pressure on supply chain risk management (SCRM) worldwide. Recent technological advances, especially machine learning (ML) technology, have shown the possibility to prevent supply chain risk (SCR) by decreasing the need for human labor, increasing response speed, and predicting risk. However, the literature lacks a comprehensive analysis of the relationship between ML and SCRM. This work conducts a comprehensive review of the relatively limited literature in this field. An analysis of 67 shortlisted articles from 9 databases shows that this area is still in the rapid development stage and that researchers have shown extraordinary interest in it. The main purpose of this study is to review the current research status so that researchers have a clear understanding of the research gaps in this area. Moreover, this study provides an opportunity for researchers and practitioners to pay attention to ML algorithms for SCRM during the COVID-19 pandemic.

Keywords: Machine learning, COVID-19, Supply chain risk management, Algorithm, Research status

1. Introduction

Past outbreaks of infectious diseases, earthquakes, and other natural catastrophic events have put the supply chain at risk on a small scale (Govindan et al., 2020, Kaur and Singh, 2020). However, coronavirus disease 2019 (COVID-19) has caused tremendous and continuous negative effects worldwide. According to a report from the Asian Development Bank, due to the COVID-19 pandemic, global economic losses have reached US$5.8 trillion to US$8.8 trillion, which is equivalent to 6.4–9.7 % of the global gross domestic product (ADB, 2020). The associated panic and lockdown policies have increased hoarding and herding behaviors, shut down resource suppliers, and led to bankruptcies. During the COVID-19 pandemic, people can no longer easily find vegetables, fruit, or toilet paper on supermarket shelves (Frances, 2020, Hobbs, 2021). The shortage of these resources and the surge in demand have left the supply chain vulnerable and triggered supply chain risk (SCR), leading to irreparable losses to enterprises.

The COVID-19 pandemic has also caused commodity shortages and aggravated researchers' concerns about supply chain deglobalization. Manufacturers and factory owners have found that they cannot receive a sufficient amount of supplies from domestic suppliers. For example, even if American companies increase the production of mask materials to fight the pandemic, the output of these mask materials by Chinese companies is still 15 times that of American companies (Bradsher, 2020). This situation has prompted managers in various countries to realize the shortcomings of supply chain globalization, which has led to increasing discussions about deglobalization after the COVID-19 pandemic. Moreover, some countries have introduced restrictive economic policies, such as export control, support for domestic enterprise relocation, and the tightening of foreign investment security reviews, during the COVID-19 pandemic. These economic policies exhibit strong economic nationalism and protectionism, which further promote economic nationalism and weaken support for supply chain globalization (Hameiri, 2021; Wang, 2021b). In addition, various relationships have formed a tight risk contagion network within the supply chain (Agca et al., 2021). Once an enterprise experiences a crisis, the risk spillover effect causes other enterprises in the supply chain to suffer losses, thus triggering a chain of SCR disasters (Roukny et al., 2018, Wu et al., 2021).

This precarious environment not only destroys the enterprise supply chain system but also causes enormous losses to upstream and downstream enterprises. Therefore, enterprises must implement practical risk management programs to prevent SCR and achieve effective SCR management (SCRM). To implement more effective SCRM programs, leading artificial intelligence technologies, such as machine learning (ML), can provide future predictions for SCRM. ML algorithms performs well in identifying abnormal risk factors and deriving predictive insights from historical datasets (Guo et al., 2021, Mohanty et al., 2021, Uthayakumar et al., 2020). Enterprises can use ML to identify risk factors and predict market demand and possible risk situations (Punia et al., 2020, Wu et al., 2021), which means that when the supply chain encounters challenges in terms of time, cost, and resource constraints, ML is an excellent approach to address them.

Because ML has excellent ability in risk identification and assessment, it has made breakthrough in other research fields, such as data mining and image recognition (Li et al., 2020, Saygili, 2021). However, this technology is not frequently used in SCRM. This phenomenon occurs because no ML guidelines are provided for supply chain researchers. Most SCRM researchers are in the field of management, while most ML researchers are in the field of engineering, such as computer science. There is a large gap between the two in terms of subject categories. As a result, supply chain researchers are far less familiar with ML than they are with other aspects, such as mathematical programming and stochastic optimization (Liu et al., 2019, Shahed et al., 2021). There are many types of ML algorithms, but a clear classification of these algorithms is lacking (Janiesch et al., 2021, Xu and Jackson, 2019). Therefore, when researchers attempt to apply ML algorithms to SCRM, they often cannot immediately find the appropriate ML algorithm. The knowledge gap between the two disciplines prevents researchers from making any further attempts.

A literature review is necessary for the interdisciplinary integration of the two fields to close this research gap and identify the value of ML for SCRM. Several literature reviews on SCRM-related topics have been performed in recent years (Gurtu et al., 2021; Ho et al., 2015). However, to the best of the author's knowledge, no attempt has been made to examine the SCRM literature in an ML environment. Previous SCRM literature reviews have focused mainly on risk definition (Ribeiro et al., 2018), risk classification (Shahbaz et al., 2019), and risk management strategies (Gurtu & Johny, 2021). These articles have not specifically examined the application of ML in SCRM and conducted a comprehensive analysis.

In view of the above shortcomings, this study reviews the academic literature on the application of ML algorithms in SCRM. The purpose of this study is to help researchers and practitioners learn more about the application of ML to SCRM by exploring the state of development of previous research. Moreover, this study analyzes the potential direction of the application of ML algorithms in the SCRM process by evaluating the application status of ML algorithms in SCRM. The present research aims to answer the following questions. (1) What is the current research status of ML algorithms in the SCRM field? (2) Which SCRM processes have used ML thus far, which algorithms have been used, and how effective have these algorithms been? (3) What are the current research gaps in ML algorithms in SCRM, and which areas need more attention?

To answer the above questions, this study conducts a comprehensive analysis of the research situation of ML algorithms in SCRM. The rest of this study is organized as follows. The second section is the methods of the literature review. The third section describes the results of bibliometric analysis realized by computer software. The fourth section introduces commonly used ML algorithms and their application scenarios in detail. The fifth section describes the application of ML in SCRM. The sixth section presents future research directions. Finally, the seventh section presents the conclusions of this study.

2. Methods

To allow researchers to have a clearer understanding of the analytical process of this paper, this section describes the article selection process and provides the descriptive analysis of the selected article.

2.1. Article selection process

In this study, we obtained articles from major journal databases to cover relevant fields as comprehensively as possible. There are mainly 6 steps. First, as indicated in Fig. 1 , this study used nine academic databases, namely, Science Direct, Scopus, Wiley Online Library, Springer Nature, JSTOR, Taylor & Francis, IEEE Xplore, Emerald, and Google Scholar. Second, we defined the search terms. The keywords used in the search were “machine learning” and “supply chain risk”. Third, to fully include the reviewed articles on the target topics, the search scope of this study did not take into account publication time limits and limited the end date of the article search to June 30, 2021. In other words, we collected all articles on ML algorithms and SCRM published in these authoritative databases before June 30, 2021. The number of targeted articles amounted to 48,000 articles. The search results were stored in the Research Information Systems (RIS) format and included all important article information, such as the title, author name, abstract, keywords, and references. Fourth, to achieve the highest level of relevance, only articles written in English and published in international journals were selected, thus excluding conference papers, editorials, textbooks, master's theses, etc., from the analysis. And to ensure that we captured every study relevant to ML and SCRM, we did not impose restrictions on the journal lists regardless of the journal in which an article was published. This selection approach reduced the number of articles collected to 8,000. Fifth, we identified and used several criteria to filter the articles. We examined abstracts and keywords to determine whether they covered one or more SCRM topics, including SCR factors and risk management processes. If an article did not meet one of these filtering criteria, it was excluded. We also carefully evaluated the list of references of the shortlisted articles to ensure that no other relevant articles were omitted from the search. The content of each article was thoroughly reviewed to ensure that it was studied in an ML environment, and 93 articles remained. Finally, we screened out duplicate articles that appeared simultaneously in multiple databases for a total of 67 articles.

Fig. 1.

Paper selection process.

2.2. Descriptive analysis

To more clearly display the 67 articles selected for this study, this section conducts a descriptive analysis of annual publications, regional distribution, and research categories.

2.2.1. Annual publications

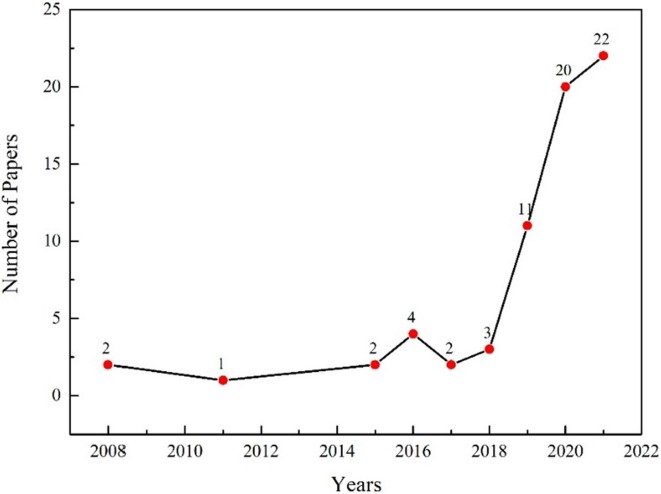

As mentioned, 67 articles were selected in our analysis and were written over a 14-year period (2008–2021). Although ML concepts have been emerging since the late 1990 s, there have been fruitful results in other areas (Li et al., 2020a). However, ML algorithms have seldom been used in SCRM. As shown in Fig. 2 , the first research paper on the application of ML in SCRM was published in 2008. There was a small spike in 2016, which was billed as the “hottest year for machine learning” in history, indicating that researchers were beginning to realize that the use of ML would make supply chains smarter and able to perform well beyond human limitations. Since 2018, researchers who have realized the benefits of ML have further applied it to SCRM, and relevant articles have shown a trend of a rapid increase in the number of such applications. It is worth noting that in the first half of 2021 alone, the number of related articles reached the number of articles published in 2020, showing that the new insights and knowledge that ML brings to enterprise supply chain operations are revolutionizing the SCRM approach.

Fig. 2.

Annual publication trend.

2.2.2. Regional distribution

Determining the geographical distribution of articles can help to clarify the situation of researchers conducting SCRM studies in each region. This section analyzes the geographical distribution of the author's correspondence addresses of all articles. For each affiliation, we obtained the city in which the organization was based and used GPS Visualizer to visually depict these city coordinates. As shown in Fig. 3 , existing ML studies in SCRM are concentrated mainly in Southeast Asia, Western Europe, and eastern North America. Because North America and Western Europe are famous supply chain centers, they contain most of the world's developed economies. The Southeast Asian countries that have benefited from the globalization of the supply chain due to their unique geographical advantages, coupled with their dual advantages of population and resources, have begun to transfer many labor-intensive industries to other Southeast Asian countries. The supply chain transfer of many companies has promoted Southeast Asia as an indispensable and important link in the global market. Therefore, these well-known global supply chain centers are taking the lead in using emerging technologies such as ML to solve SCRM problems to better prevent and mitigate the adverse effects of risk events.

Fig. 3.

Geographic distribution of contributing organizations.

3. Research categories

The analysis of research categories on this topic can help researchers clearly understand the research situation in this field. The specific research categories are shown in Fig. 4 . SCR can exist in all business activities, and supply chain enterprises are interdependent. Once a crisis occurs in one enterprise, it can spread and affect other enterprises. Although ML and the supply chain seem to be two unrelated disciplines, ML can realize a more intelligent SCRM by learning the data information in the supply chain through computer programs. Therefore, the most common research direction in this field is computer science interdisciplinary applications. Because interdisciplinary research transcends the previous categorical research methods, it can address the integration of problems to achieve better decision-making effects. The second most common research direction is operations research management science, which is closely related to the supply chain. This direction combines the optimization methods commonly used in supply chains with ML to guide production decisions. Because sophisticated ML tools can help managers predict production requirements accurately, they can also prevent inappropriate requirement assessments from causing managers to make incorrect decisions (Ni, 2019, Priore et al., 2019). It is worth noting that although the benefits of ML for SCRM are beginning to be recognized by many practitioners and managers, some business processes can exhibit misleading or missing information. Some algorithms cannot exclude incorrect information, leading to distorted learning results. Therefore, some researchers have focused on computer science artificial intelligence and are committed to writing more advanced and effective algorithms to improve ML algorithm accuracy.

Fig. 4.

Research categories and number of published articles.

4. Bibliometric analysis

To make the analysis of this paper more objective and scientific, this section uses computer software to quantitatively analyze the articles. Software, such as VOSviewer, is widely used in bibliometric analyses and has gradually become an important way for many scholars to conduct literature reviews. This section uses software to conduct bibliometric analysis, including citation and keyword analyses, to obtain convincing results. A description of this analysis is presented below.

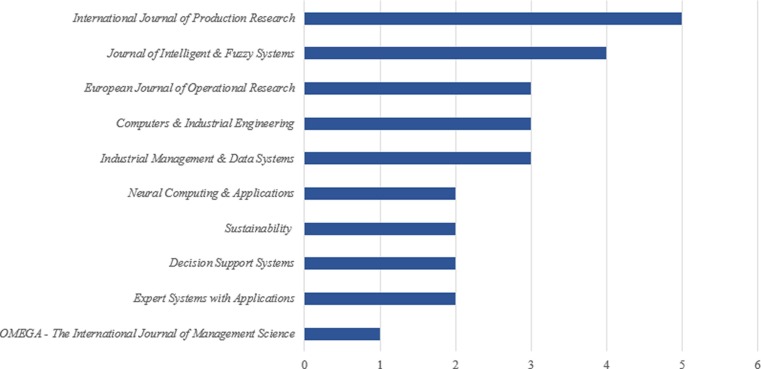

4.1. Publication sources

An analysis of the journals in which the reviewed articles are published is helpful for understanding the journal acceptance of papers in the field. Journals in various fields (e.g., computing, management, and production) publish articles on SCRM and ML algorithms. A total of 54 journals are included in this review. Fig. 5 shows the top 10 contributing journals from the 67 articles reviewed. Only 9 of the 67 journals have published more than two articles. These journals are scattered in the fields of management, computers, expert systems and other areas, indicating that there is no specific trend of journal publication in this field. Supply chain researchers have just begun to note the benefits of ML algorithms and have attempted to solve the SCRM problem with ML algorithms. Therefore, the International Journal of Production Research, European Journal of Operational Research and other management journals related to the supply chain appear in the top five journals. Moreover, it is possible that some ML algorithm researchers are very interested in SCRM problems. Their views on the field have appeared in several computer and interdisciplinary journals, such as the Journal of Intelligent & Fuzzy Systems and Computers & Industrial Engineering. In general, the concerns of supply chain and ML algorithm researchers in this field provide guidance in terms of solving crises and drive other researchers and practitioners to note the advantages of ML algorithms and apply them in practice.

Fig. 5.

Journal sources.

4.2. Citation analysis

A citation is considered an important indicator to measure the influence of an article and to determine the acceptability of research in the field. Table 1 shows the ten most frequently cited articles, including their cumulative and annual number of citations in the Web of Science (WOS) based on how often a particular article in the WOS is cited by other articles (the search scope includes the Science Citation Index, Social Science Citation Index, and Arts and Humanities Citation Index). These articles average approximately 13 citations per year. The most cited study is Sun et al. (2008), which has been cited 279 times. The second most cited article, Yu et al. (2011), has been cited 106 times. The third most cited article is the study by Garvey et al. (2015), with 97 citations in total. It is important to note that the article with the highest number of citations was published in 2008. However, during the ten-year time period of this study, no article received more than 300 citations. These articles are scattered in the fields of management, computer science and other areas across many disciplines and are not concentrated in a specific field, indicating that ML research in SCRM did not become a mainstream research direction in the first ten years of the study period. Moreover, most of the articles cited in the top 10 were published in 2015, 2017, 2019 and 2020, indicating that although ML and SCRM have been studied for a long time, the field has only recently gained attention. This may be due to the explosion in popularity of ML since 2016. In particular, the study of Nikolopoulos et al. (2021) was published in 2021 but has been cited 18 times on average, indicating that the application of ML algorithms in SCRM is attracting great interest among researchers.

Table 1.

Top 10 cited articles.

| R | Paper title | Publication source | Year | TC | TC/Y |

|---|---|---|---|---|---|

| 1 | Sales forecasting using extreme learning machine with applications in fashion retailing | Decision Support Systems | 2008 | 279 | 21.46 |

| 2 | An intelligent fast sales forecasting model for fashion products | Expert Systems with Applications | 2011 | 106 | 9.64 |

| 3 | An analytical framework for supply network risk propagation: A Bayesian network approach | European Journal of Operational Research | 2015 | 97 | 13.86 |

| 4 | A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing | International Journal of Information Management | 2019 | 55 | 18.33 |

| 5 | A data mining-based framework for supply chain risk management | Computers & Industrial Engineering | 2020 | 41 | 10.25 |

| 6 | Forecasting SMEs' credit risk in supply chain finance with an enhanced hybrid ensemble machine learning approach | International Journal of Production Economics | 2019 | 36 | 12 |

| 7 | Banking credit worthiness: Evaluating the complex relationships | OMEGA - The International Journal of Management Science | 2019 | 35 | 11.67 |

| 8 | Comparison of individual, ensemble and integrated ensemble machine learning methods to predict China's SME credit risk in supply chain finance | Neural Computing & Applications | 2017 | 31 | 6.2 |

| 9 | A credit risk assessment model based on SVM for small and medium enterprises in supply chain finance | Financial Innovation | 2015 | 25 | 3.57 |

| 10 | Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions | European Journal of Operational Research | 2021 | 18 | 18 |

Note: R: Ranking based on the total number of citations per paper. TC: Total number of citations per paper. TC/Y: Total number of citations per paper/year.

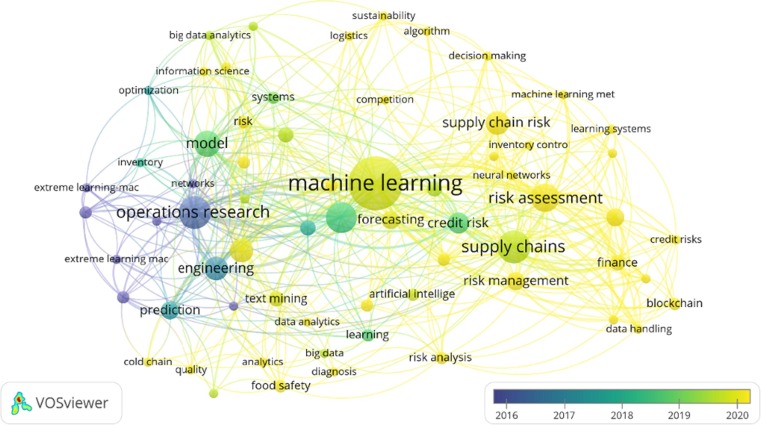

5. Keyword analysis

Coword analysis is a content analysis method based on the extant literature and is a common bibliometric method. Because the research content of each document cannot be summarized with a single word, multiple keywords are needed. At the same time, keywords in the same field are roughly limited to a certain range, and different kinds of literature often have similar keywords. Therefore, the coword analysis of high-frequency keywords can reflect the development trend of the research field. In this paper, VOSviewer was used to extract and analyze 523 keywords from 67 publications. Fig. 6 shows the co-occurrence network of keywords in recent years and indicates that researchers in the first few years had not yet formed a specific concept of ML algorithms. This is because some researchers find ML to be a better tool when performing SCRM, and these researchers choose this tool for risk management. Therefore, the application of the ML algorithm in SCRM is distributed across various industries, such as engineering, logistics, and the food industry. In fact, in the past two years, keywords such as “machine learning”, “supply chain risk”, “forecasting” and “risk assessment” have begun to receive widespread attention, showing that researchers in previous years did not know enough about the benefits of ML algorithms in SCRM and have only recently fully realized that ML algorithms can help business managers deal with supply chain crises. However, with the manifestation of this advantage, researchers and practitioners have developed stronger requirements for risk management and have begun to actively integrate new technologies for its implementation. For example, the new technology blockchain combined with ML algorithms has begun to be applied to SCRM decisions.

Fig. 6.

Co-occurrence network of keywords.

6. Commonly used ML algorithms

By analyzing the articles in this study, we find that 11 out of 40 commonly used ML algorithms are applied to SCRM (Sarker, 2021). Specifically, these ML algorithms include deep learning (DL), support vector machine (SVM), decision tree (DT), neural networks (NN), bayesian network (BN), logistic regression (LR), random forest (RF), ensemble learning (EL), clustering, extreme learning machine (ELM) and naive bayes (NB). These ML algorithms play very important roles in reducing risk and improving supply chain performance. To provide SCRM researchers with a clear introduction to ML algorithms, the characteristics of these 11 ML algorithms based on frequency are shown below.

Deep learning. The DL algorithm has recently become the most popular ML algorithm (Du et al., 2016). The DL algorithm originated from artificial NN. Its main idea is to simulate the structure of the human brain so that it can intelligently calculate (Schmidhuber, 2015). The most distinctive advantage of the DL algorithm is to quantify unstructured data such as images, sounds and text compared with other ML algorithms. In addition, compared to other ML algorithms that rely on feature selection, DL sometimes does not require feature engineering. It can directly learn efficient data representations from raw data, which saves the effort of manually constructing features. In a supply chain, the DL algorithm can detect risk information before a supply chain crisis through the automatic learning of comments, news and other unstructured data to achieve management in advance (Lee et al., 2021).

Neural networks. The NN algorithm has been a research hotspot in artificial intelligence since the 1980 s (Anderson, 1995). It has outstanding performance in processing nonlinear problems (Jordan et al., 2015). Compared with other algorithms, it finds the optimal solution with a higher accuracy. Moreover, the NN algorithm has good fault tolerance; the misfunction of one neuron does not affect the operation of the entire algorithm. The current supply chain environment is changing quickly because of COVID-19, technologies and policies. Enterprises must assess possible risk in advance to minimize the negative consequences of unexpected changes. In the process of risk assessment, the NN algorithm obtains the optimal solution by continuously adjusting the weights, and the predicted risk coefficient is very close to the actual risk coefficient (Lu, 2021).

Support vector machine. The SVM algorithm was developed by Dr. Vapnik et al. (1995). It maps the classification problem to a higher dimension space through the kernel function, which has a definite solution, unlike other black box algorithms. In particular, its optimization goal is to minimize the structural risk instead of experiencing minimization. Thus, the SVM algorithm shows unique advantages in solving small sample, nonlinear and high-dimensional problems and overcomes the dimension problem of the traditional statistical methods. Therefore, SVM is widely used in classification and prediction problems (Kianmehr and Alhajj, 2006, Ni et al., 2018). In the supply chain, the SVM algorithm can process small sample data in supply chain finance, which effectively reduces the probability of classification errors and improves the accuracy of risk prediction (Zhang et al., 2015).

Clustering. The clustering algorithm is a typical unsupervised learning algorithm (Jain, 2010). It does not have clear requirements for output data from the clients’ side and mainly classifies data with more similarity into one category according to the sample distance (Zhang et al., 2018). In SCRM, researchers mainly use KNN and K-means algorithms for clustering. The KNN algorithm can classify suppliers' on-time delivery and assign orders to suppliers with the highest on-time probability without requiring client data (Cavalcante et al., 2019). Moreover, the K-means algorithm is used to address the complex relationships among the characteristics of the agricultural supply chain and to detect the core factors to improve farmers' credit level (Bai et al., 2019).

Bayesian network. The BN algorithm is a network structure that describes the dependencies between variables with conditional probability (Friedman et al., 1997). It can directly calculate the probability of the posterior between variables without any assumptions. In addition, the BN algorithm reveals the causal relationship between variables by extracting the most relevant features (Gopnik et al., 2007). In the supply chain, previous risk measures were almost specific to a particular problem and lacked a standard. Therefore, many researchers have ignored their own network structure and lack of measurement on risk transmission throughout the network (Garvey et al., 2015). However, the BN algorithm can describe the interdependence of different risks and quantify risk transmission in the supply chain (Chu et al., 2020).

Random forest. The RF algorithm is a classifier that contains multiple DTs, and its output is determined by the random selection of individual trees (Breiman, 2001). Instead of simply averaging the predictions of all trees, the algorithm combines a certain number of DTs. It obtains the prediction results by averaging the predictions of each tree. The RF algorithm can provide an effective method to deal with unbalanced datasets by randomly selecting trees. In the supply chain, since crisis events are rare, there may be an imbalanced distribution of datasets. The RF algorithm can better address the imbalance of supply chain data and improve the accuracy of risk prediction (Brintrup et al., 2020).

Decision tree. The DT algorithm is a traditional data mining method to display the choices and probability in the training set by constructing a DT (Coadou, 2010), which generates multiple branches and child nodes with different probabilities. In practical applications, most studies have focused on the predictive performance and ignored the importance of interpretability. Therefore, the DT algorithm can help supply chain practitioners understand the results of risk assessment and make decisions to mitigate or prevent risk (Baryannis et al., 2019, Priore et al., 2019). In addition, it is easy for DTs to cooperate with other algorithms to build a powerful model for risk prediction in supply chain management. For example, Zhu et al. (2017b) used the DT algorithm as a basic classifier to predict credit risk in the supply chain. Because of the powerful model performance, it can help financial institutions improve cash flow.

Ensemble learning. The EL algorithm is not an individual ML algorithm but combines several individual models (Dietterich, 2000). The EL algorithm is mainly used to improve the performance of a model by choosing the best result of the basic classifiers. In the supply chain, when enterprises cannot obtain supply chain data information in a timely manner, this can cause the algorithm to misclassify. In addition, the EL algorithm can combine multiple classifiers to increase the fault tolerance of the model (Islam et al., 2020b).

Logistic regression. The LR algorithm is generated from a linear regression, but the LR algorithm introduces nonlinear factors through the sigmoid function; therefore, it can easily handle the relationships among variables (Gillet et al., 2011). The feature data can be continuous, classified variables. Moreover, LR allows these variables to have dummy variables. The LR algorithm is currently a commonly used ML algorithm in industry and is mainly used to estimate the possibility of latency. In the supply chain, the LR algorithm estimates the impact of a bank's potential risk factors on loans by considering the nonlinear relationships among assets, cash flow and other characteristics (Ying et al., 2020).

Extreme learning machine. The ELM algorithm is a new fast-learning algorithm (Huang et al., 2004). This algorithm is a single-layer NN, and its greatest characteristic is that it can randomly initialize input weights and bias and obtain corresponding output weights at a faster speed (Huang et al., 2012, Huang et al., 2006). Because there are many uncertain factors in the supply chain, such as supply and demand, managers especially need to quickly understand consumer’ demand. Thus, they can use the ELM algorithm to predict demand data quickly, which greatly reduces supply and demand uncertainty (Yu et al., 2011).

Naive bayes. The NB algorithm is a supervised ML algorithm, and each training sample requires a corresponding label (Murphy, 2006). For a given item to be classified, this algorithm classifies the category into the highest possibility. Compared to other classification methods, it performs best when features are less related. In practical applications, the NB algorithm can be used to classify real and fake chips with low correlation in the supply chain to reduce a product’s flaw rate (Frazier et al., 2018).

In addition to the characteristics of ML algorithms in the SCRM process introduced above, the number of times that they are used is also described in Fig. 7 , which shows the number and frequency of ML algorithm use in the articles reviewed. The DL algorithm is the most commonly used algorithm for the period from 2008 to 2021, with a 17.5 % frequency. Because of recent improvement in calculation ability, DL has more stages to perform in SCRM. It can not only process numerical information but also interpret unstructured data such as images, sound and text, which traditional algorithms cannot handle. The NN and SVM algorithms are used 18 and 17 times, respectively. This may be because many articles set them as benchmarks, but in SCRM, the good fault tolerance rate of the NN algorithm (Lu, 2021) and the advantage of the SVM algorithm in handling small sample datasets (Zhang et al., 2015) cannot be ignored. Additionally, other new algorithms, such as ELM, are used less frequently. However, the lack of the application of less-used algorithms does not mean that they are meaningless for SCRM, as they can become a niche to supply chain researchers.

Fig. 7.

Algorithm usage.

7. Application of ML in SCRM

From the analysis of the commonly used ML algorithms, the potential of ML to solve complex problems in SCRM has not been fully explored. However, the benefits of ML for SCRM have indeed been fully recognized. Based on the analysis in the previous three sections, we find that ML algorithms are mainly applied in the supply chain for risk identification, risk assessment, risk mitigation, risk monitoring, etc. The specific categories can be found in Table 2 . In this section, we describe which SCRM processes require ML most, and the specific details are shown below.

Table 2.

Application of ML in SCRM.

7.1. Risk identification

As the first step of SCRM, the correct identification of potential risks is very important for enterprises to actively avoid losses. However, in previous studies, the Delphi method, system analysis, and interviews were used by practitioners and researchers to identify risks. In fact, most of these empirical methods cannot accurately quantify risk probability. In this case, ML algorithms can autonomously identify risk factors and quantify risk through mathematical modeling. For example, Li et al. (2021) used the RF algorithm to identify risk factors such as web page color, information, and some redundant risk factors in the online service supply chain. The RF algorithm reduces the time overhead for suppliers. With the rapid development of internet technology, consumers tend to express their true opinions about products and services on social media. This network information is often more authentic than the information obtained from questionnaires (Liu and Zhang, 2020, Liu and Huang, 2020). Meanwhile, these network data are normally unstructured, with a low value density, and are large in both variety and quantity. Therefore, it is difficult to identify risk easily with these data. However, ML algorithms can use computers to process unstructured data such as text and voice data and extract valuable information from them. For example, Ying et al. (2020) used the DL algorithm and 4,014 bank evaluation reports to analyze the risk situation of bank financial service providers. In this way, they identified four important risk management factors, such as supply chain collaboration and cash flow monitoring, to achieve economically optimal risk management. In addition, Chu et al. (2020) proposed an SCRM framework based on text mining and used the BN model combined with news to classify risk and guide supplier selection. In general, the ML algorithm can be used in the first step of SCRM to determine the risk factors, which can prevent potential risks in advance.

7.2. Risk assessment

Accurate risk assessment helps managers take timely actions to reduce SCR. However, risk assessment generally relies on experienced practitioners. In the actual evaluation, practitioners’ experience and bias can have a great impact on the evaluation accuracy. This evaluation lacks objectivity and sometimes cannot be repeated. However, ML by computers, instead of inferences from experience, provides neutrality and objectivity. For example, Lu (2021) used the NN algorithm to build a multilevel supply chain inventory control model. The risk coefficient estimated is close to the actual risk coefficient, which effectively improves supply chain efficiency. In addition, the supply chain is a dynamic system. Static evaluation methods, such as the fuzzy evaluation method and analytic hierarchy process, cannot accurately describe the dynamic complexity. Therefore, researchers urgently need a tool to overcome the shortcomings of subjectivity. ML can fit the complex characteristics of the supply chain. For example, Sang and Mathematics (2021) used SVM and back-propagation NN to evaluate banks’ multiple risk characteristics, such as policy, operation and credit risks. This approach greatly reduces the probability of negative effects on bank profits. It can be seen from the above factors that the ML algorithm can objectively and quickly assess risk events.

7.3. Risk mitigation

The modern supply chain is faced with unavoidable risks while it must meet customer demand in a timely manner. Natural disasters, sudden equipment failures, transportation delays, and international policies can challenge the expected lead time and cost for enterprises. People around the world have been affected by the shortages caused by COVID-19, which have posed enormous challenges to the supply chain. Therefore, the estimation of risk in advance is more effective than remedying them after they occur. The ML algorithm is considered an excellent method that can provide effective advice for SCRM. For example, Nikolopoulos et al. (2021) correctly predicted excessive demand for daily necessities and electronic products during COVID-19 using the DL algorithm, which can help policy makers make better decisions during current pandemics. In addition, Berloco et al. (2021) used the EL, RF, and SVM algorithms to capture the risk spillover in supply chain. Similarly, Zhao et al. (2020) used the KNN algorithm to predict the legitimacy of online drugstores with 98.6 % accuracy. Accurate prediction helps government departments crack down on illegal drugstores and provides patients with reliable choices. In general, the ML algorithm can help enterprises develop appropriate strategies to avoid risk and improve the robustness of the supply chain.

7.4. Risk monitoring

Risk monitoring refers to taking regular measures to detect adverse events in the supply chain. Compared with the studies on risk identification and risk assessment, the research on risk monitoring is fewer in terms of the number of papers. However, the small amount of studies in this area does not mean that they are meaningless; rather, it is possible that not enough advanced technology has been found to replace risk monitoring. In practice, supply chain enterprises often need to recruit a large number of workers to carry out risk monitoring. Some products even require 24/7 inspections to prevent sudden equipment failures. ML can also make the daily monitoring of the production process intelligent. For example, Zhang et al. (2021a) adopted an SVM algorithm to monitor purchased fake electronic components, with an accuracy of 100 %. This approach prevented fake electronic components from flowing into the subsequent production process. In addition, it is often impossible to immediately perceive the occurrence of abnormal conditions. For example, when monitoring hazardous products, workers often observe the surface of the products, but it is difficult to monitor the quality of the products with only eyes. ML can help enterprises automate risk monitoring with “intelligent eyes”. For example, Goldberg et al. (2020) proposed a safety monitoring system for the food industry by using the DL algorithm. Through real-time monitoring, the algorithm was able to discover information on foods that consumers consider dangerous and detect dangerous products with a high accuracy of 90 %. Similarly, Lee et al. (2021) used the DL algorithm and blockchain technology to conduct real-time data monitoring on Twitter, which helps enterprises share emergency information and achieve risk management in advance. In general, the ML algorithm can reduce the costs of manual monitoring.

In this study, Table 2 shows the distribution of the ML algorithm in the above four SCRM processes. As shown in the table, ML algorithms significantly favor risk mitigation processes. Risk mitigation contains the largest number of articles in the four SCRM processes, followed by risk assessment, risk identification and risk monitoring. Researchers are most concerned with risk mitigation. They are not limited to mining risk information from the supply chain’s internal data but actively use advanced ML algorithms to mine valuable information from external data to actively avoid risks (Feuerriegel & Gordon, 2019). Notably, ML algorithms do not apply to just one SCRM process. The application of the ML algorithm in a supply chain can achieve many benefits. For example, researchers can predict consumer demand while mining potential risk factors (Marvin et al., 2020, Merve et al., 2020). This section not only helps managers identify potential risk factors, but also provides a guide and map for researchers and practitioners with appropriate references.

8. Future research directions

In this section, we summarize the potential future research directions based on previous analyses of ML algorithms and SCRM. Specifically, this section mainly includes the four points below.

Enhancement of ML interpretability. From the analysis of Fig. 1, Fig. 2, Fig. 3 in Section 2, compared with the period prior to 2016, the article publication trend has risen sharply in recent years. It demonstrates that supply chain managers have recognized the benefits of ML algorithms in SCRM and have been actively involved in research in this field. However, judging from the total number of articles, which is only 67, there is not much application in this field. This can be because even though ML algorithms are becoming mainstream research tools, they still confuse many supply chain practitioners and researchers, and these algorithms create a black box that can be understood only by designers (Weinan, 2020). Many researchers argue that ML algorithms from data input to result comprise a very confusing process (Handelman et al., 2019). Specifically, in the field of high-dimensional prediction, black-box models represented by the NN and EL algorithms can more accurately predict complex datasets than white-box models such as DT (Zhang et al., 2021b). Thus, although ML algorithms in risk assessment or risk prediction achieve accurate results, the lack of interpretability is unacceptable for managers with no technical background. Since 2019, the explainable AI (XAI) has become a heated topic (Fernandez et al., 2019). The sensitivity (how results change according to input) has been explained by the Shapley value of game theory for tree models (Lundberg et al., 2020). Moreover, more ML algorithms have been recently explained by XAI (Tallón-Ballesteros and Chen, 2020, Zhang, et al., 2021b). Therefore, researchers can consider building XAI algorithms by combining visualization, proxy models, knowledge graphs, etc., to enhance managers’ trust in the algorithms’ results in the future.

More advanced technologies. From the analysis in Section 3, we find that some of the latest technologies, including blockchain, have been introduced into SCRM. In practice, although companies in the supply chain have long-term partnerships, they also compete with one another. These companies sometimes deliberately misreport data because of self-interest (Islam et al., 2020a). Entering this inaccurate data can mislead algorithms. Moreover, these new technologies, such as blockchain, are believed to help increase the transparency of supply chain enterprises. Notably, some studies suggest that these techniques may present data security and privacy risks (Narwane et al.; Vafadarnikjoo et al.). Therefore, in future research, we must give more attention to the safety assessment of new technologies and then apply them to SCRM.

Involvement of more external data. From the analysis in Section 4, we confirm that ML algorithms can process unstructured data such as texts and comments. With the technological development, from the enterprise’s perspective, any enterprise can focus not only on itself but also on the external environment, such as the market, competitors, and partners. Therefore, in addition to obtaining risk information from internal supply chain data, external data such as the finance status, online news, social media comments of the market, competitors, and partners should also be considered. Moreover, these data can help quickly detect risky behaviors and give early warnings. However, the current studies that process these data give more attention to the algorithm’s effectiveness, such as its accuracy, recall and other indicators, instead of applying these indicators appropriately. Therefore, in future research, researchers and practitioners can consider exploiting the advantages of ML algorithms in processing external data and improving the efficiency of the algorithm.

Increased targeting of COVID-19. The impact of the COVID-19 pandemic has made supply chain practitioners deeply aware of the importance of SCRM. From the analysis in Section 5, it is found that with the development of ML, blockchain and other technologies, enterprises can combine these advanced technologies to realize intelligent risk management. Specifically, enterprises can monitor supply chain status in real time through the ML algorithm and then adjust supply chain inventory and production plans. In this way, the supply chain can start a timely emergency plan. Moreover, enterprises can evaluate suppliers through the ML algorithm in advance, which decreases supply chain disruptions.

Furthermore, since the COVID-19 outbreak, researchers have given more attention to supply chain interruption, but few scholars have considered supply chain production in an emergency. When COVID-19 first emerged, there was an unexpected surge in the demand for masks, and original mask manufacturers were faced with great pressure. At the same time, some automobile manufacturers also began to produce masks to meet the surge in requirements (Park et al., 2020). Therefore, in future risk management, enterprises can continuously enhance their flexibility with the support of new technologies such as ML and blockchain to deal with “black swan” events.

9. Conclusions

This study systematically reviews the current state of the development of ML algorithms in SCRM and answers the three questions raised in Section 1. This study collected 67 articles on the application of ML algorithms in SCRM published by 9 authoritative databases as of the first half of 2021. 2, 3 provide a comprehensive analysis of the years, journals, citations, keywords, etc. and answer the research status of ML algorithms in the SCRM field in question 1. 4, 5 respond to question 2 and show that ML algorithms have been applied to SCRM, such as for risk identification, risk assessment, risk mitigation and risk monitoring, and have proven to be an excellent tool to help supply chain managers better deal with risk. Section 6 gives the future research directions in question 3 that require more attention to ML interpretability, more advanced technologies and external supply chain data, etc. Furthermore, from the analysis in Section 6, it can be concluded that the impact of the COVID-19 pandemic has made supply chain practitioners deeply aware of the importance of SCRM. Enterprises can continuously enhance their flexibility with the support of new technologies, such as ML and blockchain, to better respond to the changes in the supply chain environment brought about by the COVID-19 pandemic.

There are still limitations to this study that need to be addressed before concluding. First, although a total of 9 relevant scholarly databases were included for article screening, this study reviewed only international journal articles written in English and excluded conference papers, textbooks, and unpublished articles and notes. Second, this study was based on a keyword search, so the results are limited to keyword combinations, and some work may not have been captured by the keywords.

Despite these limitations, this study summarizes the current research status of this field. For researchers, this study demonstrates the application of various algorithms in this field and can provide a reference for choosing further research topics. For practitioners, this study provides an opportunity to understand how ML algorithms can benefit SCRM, helping them better respond to the supply chain changes caused by the COVID-19 pandemic.

CRediT authorship contribution statement

Mei Yang: Investigation, Writing – original draft, Validation, Visualization. Ming K. Lim: Conceptualization, Project administration, Validation. Yingchi Qu: Validation, Visualization. Du Ni: Conceptualization, Investigation, Validation. Zhi Xiao: Conceptualization, Methodology, Project administration.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

This work was supported by the National Natural Science Foundation of China [grant No. 72071021, 71671019], the Graduate Research and Innovation Foundation of Chongqing, China [grant No. CYS21047], and the Chongqing Social Science Planning Program [grant No.2022NDQN44]. The authors declare no competing interests.

Data availability

Data will be made available on request.

References

- Abdollahnejadbarough H., Mupparaju K.S., et al. Verizon Uses Advanced Analytics to Rationalize Its Tail Spend Suppliers. Interfaces. 2020;50(3):197–211. [Google Scholar]

- ADB. (2020). COVID-19 Economic Impact Could Reach $8.8 Trillion Globally — New ADB Report. Asian Development Bank.

- Agca, S., Babich, V., et al. (2021). Credit Shock Propagation Along Supply Chains: Evidence from the CDS Market. Management Science.

- Anderson, J. A. (1995). An introduction to neural networks: MIT press.

- Bai C.G., Shi B.F., et al. Banking credit worthiness: Evaluating the complex relationships. Omega-International Journal of Management Science. 2019;83:26–38. [Google Scholar]

- Baryannis G., Dani S., et al. Predicting supply chain risks using machine learning: The trade-off between performance and interpretability. Future Generation Computer Systems-the International Journal of Escience. 2019;101:993–1004. [Google Scholar]

- Belhadi A., Mani V., et al. Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: An empirical investigation. Ann. Oper. Res. 2021:1–26. doi: 10.1007/s10479-021-03956-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Berloco, C., de Francisci Morales, G., et al. (2021). Predicting corporate credit risk: Network contagion via trade credit. PLoS ONE, 16(4 April). [DOI] [PMC free article] [PubMed]

- Bouzembrak Y., Marvin H.J.P. Impact of drivers of change, including climatic factors, on the occurrence of chemical food safety hazards in fruits and vegetables: A Bayesian Network approach. Food Control. 2019;97:67–76. [Google Scholar]

- Bradsher K. China Dominates Medical Supplies, in This Outbreak and the Next. The. New York Times. 2020 [Google Scholar]

- Breiman L. Random forests. Machine Learning. 2001;45(1):5–32. [Google Scholar]

- Brintrup A., Pak J., et al. Supply chain data analytics for predicting supplier disruptions: A case study in complex asset manufacturing. International Journal of Production Research. 2020;58(11):3330–3341. [Google Scholar]

- Cao W., Zhang X. Supply chain risk assessment based on support vector machine. Revista Ibérica de Sistemas e Tecnologias de. 2016;Informação(E5):310. [Google Scholar]

- Cavalcante I.M., Frazzon E.M., et al. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. International Journal of Information Management. 2019;49:86–97. [Google Scholar]

- Chatzidimitriou K.C., Symeonidis A.L., et al. Agent Mertacor: A robust design for dealing with uncertainty and variation in SCM environments. Expert Systems with Applications. 2008;35(3):591–603. [Google Scholar]

- Chen C.-S., Narani A., et al. Ensemble models of feedstock blend ratios to minimize supply chain risk in bio-based manufacturing. Biochemical Engineering Journal. 2020;107896 [Google Scholar]

- Chu C.-Y., Park K., et al. A global supply chain risk management framework: An application of text-mining to identify region-specific supply chain risks. Advanced Engineering Informatics. 2020;45 [Google Scholar]

- Coadou, Y. (2010). Decision trees. In A. Lucotte & F. Melot (Eds.), Sos 08: In2p3 School of Statistics (Vol. 4).

- Coyle J.J., Ruamsook K., et al. Weatherproofing Supply Chains: Enable Intelligent Preparedness with Data Analytics. Transportation Journal. 2016;55(2):190–207. [Google Scholar]

- Dietterich, T. G. (2000). Ensemble methods in machine learning. In J. Kittler & F. Roli (Eds.), Multiple Classifier Systems (Vol. 1857, pp. 1-15).

- Du, X. D., Cai, Y. H., et al. (2016). Overview of Deep Learning.

- Feng J.Y., Yuan B.Y., et al. Evaluation on risks of sustainable supply chain based on optimized BP neural networks in fresh grape industry. Computers and Electronics in Agriculture. 2021;183:11. [Google Scholar]

- Fernandez A., Herrera F., et al. Evolutionary fuzzy systems for explainable artificial intelligence: Why, when, what for, and where to? IEEE Computational intelligence magazine. 2019;14(1):69–81. [Google Scholar]

- Feuerriegel S., Gordon J. News-based forecasts of macroeconomic indicators: A semantic path model for interpretable predictions. European Journal of Operational Research. 2019;272(1):162–175. [Google Scholar]

- Frances M. BBC; 2020. Pneumonia epidemic: Why is toilet paper a rush to buy? [Google Scholar]

- Frazier P.D., Gilmore E.T., et al. A novel counterfeit detection approach for integrated circuit supply chain assurance. Journal of Hardware. 2018;2(3):240–250. [Google Scholar]

- Frey G.P., West T.A.P., et al. Simulated Impacts of Soy and Infrastructure Expansion in the Brazilian Amazon: A Maximum Entropy Approach. Forests. 2018;9(10):23. [Google Scholar]

- Friedman N., Geiger D., et al. Bayesian network classifiers. Machine Learning. 1997;29(2–3):131–163. [Google Scholar]

- Fu W., Chien C.F. UNISON data-driven intermittent demand forecast framework to empower supply chain resilience and an empirical study in electronics distribution. Computers and Industrial Engineering. 2019;135:940–949. [Google Scholar]

- Garvey M.D., Carnovale S., et al. An analytical framework for supply network risk propagation: A Bayesian network approach. European Journal of Operational Research. 2015;243(2):618–627. [Google Scholar]

- Gillet A., Brostaux Y., et al. Main models used in logistic regression. Biotechnologie Agronomie Societe Et Environnement. 2011;15(3):425–433. [Google Scholar]

- Goldberg D.M., Khan S., et al. Text Mining Approaches for Postmarket Food Safety Surveillance Using Online Media. Risk Analysis. 2020;00:1–20. doi: 10.1111/risa.13651. [DOI] [PubMed] [Google Scholar]

- Gopnik A., Tenenbaum J.B. Bayesian networks, Bayesian learning and cognitive development. Developmental Science. 2007;10(3):281–287. doi: 10.1111/j.1467-7687.2007.00584.x. [DOI] [PubMed] [Google Scholar]

- Govindan K., Mina H., et al. A decision support system for demand management in healthcare supply chains considering the epidemic outbreaks: A case study of coronavirus disease 2019 (COVID-19) Transportation Research Part E-Logistics and Transportation Review. 2020;138 doi: 10.1016/j.tre.2020.101967. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guo Y.H., Fu Y.S., et al. Integrated phenology and climate in rice yields prediction using machine learning methods. Ecological Indicators. 2021;120 [Google Scholar]

- Gurtu A., Johny J. Supply Chain Risk Management: Literature Review. Risks. 2021;9(1) [Google Scholar]

- Hajian Heidary M., Aghaie A. Risk averse sourcing in a stochastic supply chain: A simulation-optimization approach. Computers & Industrial Engineering. 2019;130:62–74. [Google Scholar]

- Hameiri S. COVID-19: Is this the end of globalization? International Journal. 2021;76(1):30–41. [Google Scholar]

- Han C., Zhang Q. Optimization of supply chain efficiency management based on machine learning and neural network. Neural Computing and Applications. 2021;33(5):1419–1433. [Google Scholar]

- Handelman G.S., Kok H.K., et al. Peering into the black box of artificial intelligence: evaluation metrics of machine learning methods. 2019;212(1):38–43. doi: 10.2214/AJR.18.20224. [DOI] [PubMed] [Google Scholar]

- Handfield R., Sun H., et al. Assessing supply chain risk for apparel production in low cost countries using newsfeed analysis. Supply Chain Management-an International Journal. 2020;25(6):803–821. [Google Scholar]

- Ho W., Zheng T., et al. Supply chain risk management: A literature review. International Journal of Production Research. 2015;53(16):5031–5069. [Google Scholar]

- Hobbs J.E. The Covid-19 pandemic and meat supply chains. Meat Science. 2021;181 doi: 10.1016/j.meatsci.2021.108459. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huang G.B., Zhou H.M., et al. Extreme Learning Machine for Regression and Multiclass Classification. Ieee Transactions on Systems Man and Cybernetics Part B-Cybernetics. 2012;42(2):513–529. doi: 10.1109/TSMCB.2011.2168604. [DOI] [PubMed] [Google Scholar]

- Huang G.B., Zhu Q.Y., et al. Extreme learning machine: Theory and applications. Neurocomputing. 2006;70(1–3):489–501. [Google Scholar]

- Islam, S., & Amin, S. H. J. J. o. B. D. (2020a). Prediction of probable backorder scenarios in the supply chain using Distributed Random Forest and Gradient Boosting Machine learning techniques. 7(1), 1-22.

- Islam, S., & Amin, S. H. J. J. o. B. D. (2020b). Prediction of probable backorder scenarios in the supply chain using Distributed Random Forest and Gradient Boosting Machine learning techniques. Journal of Big Data, 7(1), 1-22.

- Jain A.K. Data clustering: 50 years beyond K-means. Pattern Recognition Letters. 2010;31(8):651–666. [Google Scholar]

- Janiesch C., Zschech P., et al. Machine learning and deep learning. Electronic Markets. 2021;31(3):685–695. [Google Scholar]

- Ji G., Hu L., et al. A study on decision-making of food supply chain based on big data. Journal of Systems Science. 2017;26(2):183–198. [Google Scholar]

- Jordan M.I., Mitchell T.M. Machine learning: Trends, perspectives, and prospects. Science. 2015;349(6245):255–260. doi: 10.1126/science.aaa8415. [DOI] [PubMed] [Google Scholar]

- Kaur H., Singh S.P. Disaster resilient proactive and reactive procurement models for humanitarian supply chain. Production Planning & Control. 2020 [Google Scholar]

- Kianmehr, K., & Alhajj, R. (2006). Support vector machine approach for fast classification. In A. M. Tjoa & J. Trujillo (Eds.), Data Warehousing and Knowledge Discovery, Proceedings (Vol. 4081, pp. 534-543).

- Kouadio L., Byrareddy V.M., et al. Probabilistic yield forecasting of robusta coffee at the farm scale using agroclimatic and remote sensing derived indices. Agricultural and Forest Meteorology. 2021;306 [Google Scholar]

- Lau H., Tsang Y.P., et al. Risk quantification in cold chain management: A federated learning-enabled multi-criteria decision-making methodology. Industrial Management & Data Systems. 2021;20 [Google Scholar]

- Lee C.H., Yang H.C., et al. Enabling blockchain based scm systems with a real time event monitoring function for preemptive risk management. Applied Sciences (Switzerland) 2021;11(11) [Google Scholar]

- Li L., Ma S.J., et al. Data-driven online service supply chain: A demand-side and supply-side perspective. Journal of Enterprise Information Management. 2021;34(1):365–381. [Google Scholar]

- Li X., Zhang W., et al. Diagnosing Rotating Machines With Weakly Supervised Data Using Deep Transfer Learning. Ieee Transactions on Industrial Informatics. 2020;16(3):1688–1697. [Google Scholar]

- Li Z., Guo H., et al. A sustainable production capability evaluation mechanism based on blockchain, LSTM, analytic hierarchy process for supply chain network. International Journal of Production Research. 2020;58(24):7399–7419. [Google Scholar]

- Liu X., Zhang N. Research on customer satisfaction of budget hotels based on revised IPA and online reviews. Science Journal of Business and Management. 2020;8(2):50. [Google Scholar]

- Liu Y., Huang L. Supply chain finance credit risk assessment using support vector machine–based ensemble improved with noise elimination. International Journal of Distributed Sensor Networks. 2020;16(1) [Google Scholar]

- Liu Z.B., Gao R., et al. Two-period pricing and strategy choice for a supply chain with dual uncertain information under different profit risk levels. Computers & Industrial Engineering. 2019;136:173–186. [Google Scholar]

- Lu S. Enterprise supply chain risk assessment based on improved neural network algorithm and machine learning. Journal of Intelligent and Fuzzy Systems. 2021;40(4):7013–7024. [Google Scholar]

- Lundberg S.M., Erion G., et al. From local explanations to global understanding with explainable AI for trees. Nature machine intelligence. 2020;2(1):56–67. doi: 10.1038/s42256-019-0138-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marvin H.J.P., van Asselt E., et al. Expert-driven methodology to assess and predict the effects of drivers of change on vulnerabilities in a food supply chain: Aquaculture of Atlantic salmon in Norway as a showcase. Trends in Food Science & Technology. 2020;103:49–56. [Google Scholar]

- McClements D.J., Barrangou R., et al. Building a Resilient, Sustainable, and Healthier Food Supply through Innovation and Technology. Annual Review of Food Science and Technology. 2021;12:1–28. doi: 10.1146/annurev-food-092220-030824. [DOI] [PubMed] [Google Scholar]

- Merve E.K., Oktay Fırat S.Ü., et al. A data mining-based framework for supply chain risk management. Computers & Industrial Engineering. 2020;139 [Google Scholar]

- Mohanty D.K., Parida A.K., et al. Financial market prediction under deep learning framework using auto encoder and kernel extreme learning machine. Applied Soft Computing. 2021;99 [Google Scholar]

- Murphy K.P. Naive bayes classifiers. University of British Columbia. 2006;18(60):1–8. [Google Scholar]

- Narwane, V. S., Raut, R. D., et al. Risks to Big Data Analytics and Blockchain Technology Adoption in Supply Chains. Annals of Operations Research.

- Nayal K., Raut R.D., et al. Are artificial intelligence and machine learning suitable to tackle the COVID-19 impacts? An agriculture supply chain perspective. International Journal of Logistics Management. 2021 [Google Scholar]

- Ni D., Xiao Z., et al. Multiple Human-Behaviour Indicators for Predicting Lung Cancer Mortality with Support Vector Machine. Scientific Reports. 2018;8 doi: 10.1038/s41598-018-34945-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ni Y. Comprehensive Assessment of Logistics Financial Risk in Port Regional Supply Chain. Journal of Coastal Research. 2019:198–204. [Google Scholar]

- Nikolopoulos K., Punia S., et al. Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions. European Journal of Operational Research. 2021;290(1):99–115. doi: 10.1016/j.ejor.2020.08.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Palander T., Eronen J., et al. Development of a wood damage monitoring system for mechanized harvesting. Annals of Forest Research. 2018;61(2):243–258. [Google Scholar]

- Park, C.-Y., Kim, K., et al. (2020). Global shortage of personal protective equipment amid COVID-19: supply chains, bottlenecks, and policy implications: Asian Development Bank.

- Piccialli F., Giampaolo F., et al. Artificial intelligence and healthcare: Forecasting of medical bookings through multi-source time-series fusion & nbsp. Information Fusion. 2021;74:1–16. [Google Scholar]

- Priore P., Ponte B., et al. Applying machine learning to the dynamic selection of replenishment policies in fast-changing supply chain environments. International Journal of Production Research. 2019;57(11):3663–3677. [Google Scholar]

- Punia S., Singh S.P., et al. From predictive to prescriptive analytics: A data-driven multi-item newsvendor model. Decision Support Systems. 2020;136:11. [Google Scholar]

- Ribeiro J.P., Barbosa-Povoa A. Supply Chain Resilience: Definitions and quantitative modelling approaches - A literature review. Computers & Industrial Engineering. 2018;115:109–122. [Google Scholar]

- Rishehchi F.M., Rasouli M.R., et al. A data-driven and network-aware approach for credit risk prediction in supply chain finance. Industrial Management and Data Systems. 2021;121(4):785–808. [Google Scholar]

- Rodgers, M., & Singham, D. J. J. o. P. i. (2020). A framework for assessing disruptions in a clinical supply chain using Bayesian belief networks. Journal of Pharmaceutical innovation, 15(3), 467-481.

- Roukny T., Battiston S., et al. Interconnectedness as a source of uncertainty in systemic risk. Journal of Financial Stability. 2018;35:93–106. [Google Scholar]

- Sang, B. J. J. o. C., & Mathematics, A. (2021). Application of genetic algorithm and BP neural network in supply chain finance under information sharing. Journal of Computational Applied Mathematics, 384, 113170.

- Sarker I.H. Machine learning: Algorithms, real-world applications and research directions. SN Computer Science. 2021;2(3):1–21. doi: 10.1007/s42979-021-00592-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saygili A. A new approach for computer-aided detection of coronavirus (COVID-19) from CT and X-ray images using machine learning methods. Applied Soft Computing. 2021;105 doi: 10.1016/j.asoc.2021.107323. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schmidhuber J. Deep learning in neural networks: An overview. Neural Networks. 2015;61:85–117. doi: 10.1016/j.neunet.2014.09.003. [DOI] [PubMed] [Google Scholar]

- Shahbaz M.S., Sohu S., et al. A Novel Classification of Supply Chain Risks. Engineering Technology & Applied Science Research. 2019;9(3):4301–4305. [Google Scholar]

- Shahed K.S., Azeem A., et al. A supply chain disruption risk mitigation model to manage COVID-19 pandemic risk. Environmental Science and Pollution Research. 2021 doi: 10.1007/s11356-020-12289-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun G. Quantitative analysis of enterprise chain risk based on SVM algorithm and mathematical fuzzy set. Journal of Intelligent and Fuzzy Systems. 2020;39(4):5773–5783. [Google Scholar]

- Sun H. Analysis of risk factors in financial supply chain based on machine learning and IoT technology. Journal of Intelligent and Fuzzy Systems. 2021;40(4):6421–6431. [Google Scholar]

- Sun X.L., Choi T.M., et al. Sales forecasting using extreme learning machine with applications in fashion retailing. Decision Support Systems. 2008;46(1):411–419. [Google Scholar]

- Tallón-Ballesteros A., Chen C. Explainable AI: Using Shapley value to explain complex anomaly detection ML-based systems. Machine learning and artificial intelligence. 2020;332:152. [Google Scholar]

- Thota M., Kollias S., et al. Multi-source domain adaptation for quality control in retail food packaging. Computers in Industry. 2020;123 [Google Scholar]

- Uthayakumar J., Metawa N., et al. Intelligent hybrid model for financial crisis prediction using machine learning techniques. Information Systems and E-Business Management. 2020;18(4):617–645. [Google Scholar]

- Vafadarnikjoo, A., Ahmadi, H. B., et al. Analyzing blockchain adoption barriers in manufacturing supply chains by the neutrosophic analytic hierarchy process. Annals of Operations Research.

- Vapnik V., Cortes C. SUPPORT-VECTOR NETWORKS. Machine Learning. 1995;20(3):273–297. [Google Scholar]

- Wang J., Swartz C.L.E., et al. Supply Chain Monitoring Using Principal Component Analysis. Industrial & Engineering Chemistry Research. 2020;59(27):12487–12503. [Google Scholar]

- Wang, Y. (2021a). Research on Supply Chain Financial Risk Assessment Based on Blockchain and Fuzzy Neural Networks. Wireless Communications and Mobile Computing, 2021.

- Wang Z.Y. From Crisis to Nationalism? The Conditioned Effects of the COVID-19 Crisis on Neo-nationalism in Europe. Chinese Political Science Review. 2021;6(1):20–39. [Google Scholar]

- Weinan E. Machine Learning and Computational Mathematics. Communications in Computational Physics. 2020;28(5):1639–1670. [Google Scholar]

- Wichmann P., Brintrup A., et al. Extracting supply chain maps from news articles using deep neural networks. International Journal of Production Research. 2020;58(17):5320–5336. [Google Scholar]

- Wu J., Zhang Z.C., et al. Credit Rating Prediction Through Supply Chains: A Machine Learning Approach. Production and Operations Management. 2021 [Google Scholar]

- Xu C., Jackson S.A. Vol. 20. Springer; 2019. Machine learning and complex biological data; pp. 1–4. (In). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xuan F. Regression analysis of supply chain financial risk based on machine learning and fuzzy decision model. Journal of Intelligent & Fuzzy Systems. 2021;40(4):6925–6935. [Google Scholar]

- Ying, H., Chen, L., et al. (2020). Application of text mining in identifying the factors of supply chain financing risk management. Industrial Management Data Systems.

- Yu L.A., Yang Z.B., et al. Prediction-Based Multi-Objective Optimization for Oil Purchasing and Distribution with the NSGA-II Algorithm. International Journal of Information Technology & Decision Making. 2016;15(2):423–451. [Google Scholar]

- Yu Y., Choi T.M., et al. An intelligent fast sales forecasting model for fashion products. Expert Systems with Applications. 2011;38(6):7373–7379. [Google Scholar]

- Zhang F., Paul S.D., et al. On Database-Free Authentication of Microelectronic Components. Ieee Transactions on Very Large Scale Integration (Vlsi) Systems. 2021;29(1):149–161. [Google Scholar]

- Zhang G., Li G., et al. Risk assessment and monitoring of green logistics for fresh produce based on a support vector machine. Sustainability (Switzerland) 2020;12(18) [Google Scholar]

- Zhang L., Hu H., et al. A credit risk assessment model based on SVM for small and medium enterprises in supply chain finance. Financial Innovation. 2015;1(1):1–21. [Google Scholar]

- Zhang S.C., Li X.L., et al. Efficient kNN Classification With Different Numbers of Nearest Neighbors. Ieee Transactions on Neural Networks and Learning Systems. 2018;29(5):1774–1785. doi: 10.1109/TNNLS.2017.2673241. [DOI] [PubMed] [Google Scholar]

- Zhang, Y., Xu, F., et al. (2021b). XAI Evaluation: Evaluating Black-Box Model Explanations for Prediction. Paper presented at the 2021 II International Conference on Neural Networks and Neurotechnologies (NeuroNT).

- Zhao H., Muthupandi S., et al. Managing illicit online pharmacies: Web analytics and predictive models study. Journal of Medical Internet Research. 2020;22(8) doi: 10.2196/17239. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhu Y., Xie C., et al. Predicting China's SME Credit Risk in Supply Chain Finance Based on Machine Learning Methods. Entropy. 2016;18(5):8. [Google Scholar]

- Zhu Y., Xie C., et al. Comparison of individual, ensemble and integrated ensemble machine learning methods to predict China's SME credit risk in supply chain finance. Neural Computing & Applications. 2017;28:S41–S50. [Google Scholar]

- Zhu Y., Xie C., et al. Comparison of individual, ensemble and integrated ensemble machine learning methods to predict China’s SME credit risk in supply chain finance. Neural Computing and Applications. 2017;28:41–50. [Google Scholar]

- Zhu Y., Zhou L., et al. Forecasting SMEs' credit risk in supply chain finance with an enhanced hybrid ensemble machine learning approach. International Journal of Production Economics. 2019;211:22–33. [Google Scholar]

- Zigiene G., Rybakovas E., et al. Artificial Intelligence Based Commercial Risk Management Framework for SMEs. Sustainability. 2019;11(16):23. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.