Abstract

COVID-19 has negative impacts on supply chain operations between countries. The novelty of the study is to evaluate the sectoral effects of COVID-19 on global supply chains in the example of Turkey and China, considering detailed parameters, thanks to the developed System Dynamics (SD) model. During COVID-19 spread, most of the countries decided long period of lockdowns which impacted the production and supply chains. This had also caused decrease in capacity utilizations and industrial productions in many countries which resulted with imbalance of maritime trade between countries that increased the freight costs. In this study, cause and effect relations of trade parameters, supply chain parameters, demographic data and logistics data on disruptions of global supply chains have been depicted for specifically Turkey and China since China is the biggest importer of Turkey. Due to this disruption, mainly exports from Turkey to China has been impacted in food, chemical and mining sectors. This study is helpful to plan in which sectors; the actions should be taken by the government bodies or managers. Based on findings of this study, new policies such as onshore activities should consider to overcome the logistics and supply chain disruptions in global supply chains. This study has been presented beneficial implications for the government, policymakers and academia.

Keywords: Global supply chain and logistics, Technology, COVID-19, Disruption, System dynamics, Turkey-China

1. Introduction

Expanding trade and investment operations around the world causes businesses to expand worldwide [1,2]. For this purpose, many businesses and sectors have adopted integrated global supply chains [3], through which overseas activities and outsourcing strategies are delivered, produced and distributed across national borders [4,5]. Therefore, with the development in supply chains, the supply chains become more vulnerable to risks consist of disruptions such as disasters (Majid, 2020; [6]. Especially, pandemics, a type of natural disasters can cause long-term disruptions and bring uncertainties in the global supply chain [7,8].

The COVID-19, one of the crucial pandemics, affects the global supply chain worldwide [9]. As mentioned earlier, the COVID-19 pandemic threatens not only human life but also businesses around the world (Ehlert et al., 2021). Within the pandemic environment, several disruptions have occurred, especially in global supply chains [10,11]. For example, global automotive brands such as General Motors, Nissan, Renault, Honda and Peugeot and global companies such as Toyota, Apple, Starbucks, and Ikea have either stopped their operations in China completely or have pulled them to a very limited point [12]; Majid, 2020). All of these biggest companies are shutting operations in the world since the lack of raw materials, which are produced or came from China [13]. Therefore, large losses are also expected in the economy due to lockdowns in companies and disruptions in production and supply chain [14,15]. With this epidemic, supply chains of almost all sectors are affected from production stages to consumers [16,17].

Recently, China is the most important actor in the global supply chain [18]. In fact, China is both the starting point and the ending point for the global supply chain, and the world has become dependent on China in production [7]. Besides being a large market, China is the main supplier country of the global automotive industry and electronics industry and, cars, auto spare parts, mobile phones, computers and electronic parts of many known brands are produced in China [18].

Like other countries, the supply chain management and the foreign trade operations of Turkey is affected by COVID-19 as negatively. One of the most important reasons for dealing with China and Turkey relations in the study is that Turkey is one of the emerging economies and China is the second biggest importer of the country and ranks first among the countries that Turkey exports the most. In addition, the problems experienced in the import of intermediate goods in China, the fluctuations in the world demand, the decrease in the production processes in Turkey and as a result, the decrease in exports and the increase in unemployment cause economic consequences [19]. At the same time, problems such as quarantine practices within the country and factories stopping production cause disruption in the country's supply chain.

Global supply chains act as a system due to the integrated structures and the deterioration in global supply chains directly affects many important factors in the country's economy and social life [20,21] and thus global supply chains requires a system perspective. Since it needs to be handled cause and effect relations of main groups such as logistics, trade, supply chain and demographic parameters. Thus, the biggest contribution of this study is to provide a holistic perspective for these main groups from the system thinking approach, the behaviour of the examined system against certain changes can be investigated and decisions can be made by determining the strategies to regulate this behaviour [22], which is crucial step to overcome the impacts of COVID-19 on systems. Therefore, it is very important to know how much the global supply chain structures of countries and sectors are affected by COVID-19 and subsequently how to determine the most appropriate solutions to manage them by considering system thinking approach. The systems thinking approach helps in analysing the causality relations between main groups and their system parameters. Besides, understanding behaviours of import and export data is also influenced by many logistics, trade, supply chain and demographic parameters. Hence, the main motivation of this study is to analyse the effects of outbreaks on global supply chains by integrated with the proposed parameters through the system thinking perspective.

As a result, the research question of the study is stated as;

-

•

How to analyse the effects of disruptions on supply chains of Turkey and China comparatively in a system thinking approach?

In this study, our aim is to explain the following research objectives:

-

I.

To analyse how main sectors of the countries are affected by COVID-19 based on the logistics, trade, supply chain and demographic aspects from the system thinking perspective.

-

II.

To make a short-term import forecast from China to Turkey considering logistics, trade, supply chain and demographic aspects through system thinking perspective.

-

III.

To embody the impacts of COVID-19 with an example of China and Turkey considering logistics, trade, supply chain and demographic aspects through the system thinking perspective.

To address the purpose of this research question, a detailed literature review about epidemic outbreaks impact on global supply chain, need for SD modelling on the basis of system thinking approach and COVID-19 impact on global supply chain was conducted. After that, SD modelling was formulated for showing sectoral impacts of COVID-19, short term forecast about the future state respectively. In order to show the impacts of COVID-19, a real-life case study was analysed between China and Turkey.

This study is unique in nature to make comparative analysis and to investigate the impact of pandemic on global supply chains by focusing on the foreign trade and logistics activities between countries using SD modelling based on system thinking approach. Moreover, this study fills gap by investigating the whole foreign trade and logistics activities and its actors with SD modelling, which was developed based on the systems thinking approach, and to show how the sectors was affected from pandemic by making comparative analyses and investigating of the impact of pandemics on the countries [23,24].

The rest of the paper is structured as follows. Section 2 exhibits the literature review about epidemic outbreaks impact on global supply chain, system thinking approach and need for SD modelling and COVID-19 impact on global supply chain. Section 3 highlights the SD methodology for the research. Section 4 covers a case study, which is comparative study between China and Turkey as an implementation of the study. Section 5 discusses the findings as well as exhibits the implications for managers and policymakers. Lastly, Section 6 concludes this study by discussions, limitations and scope for future works.

2. Literature review

The disruptive events are an important example of enabling learning and productivity in organizations. Learning effect to cope with disruptive events by investigating the causal relations between systems actors and related system components [22]. System thinking provide recognize the system and deeper insight into this system. Disruptions that affect the entire supply chain such as epidemic should also be taken from a holistic perspective [25]. studied on integration system analysis and disruption theory to analyse conditions that cause disruption. Developed causal relationships provide opportunity to see hidden structure also that create disruptions or to see causes that may lead to disruption through other actors [25]. There are several qualitative and quantitative research techniques for analysing the epidemics in global supply chain. Instead of quantitative techniques, there are limited studies that used qualitative techniques which are semi-structured interviews, focus groups, behaviour analysis, peer-reviewed studies since the methods are proper to investigate whether preventions work, or what causes unexpected results of preventions taken during the disruptions [26,27].

Besides this, to understand the effects of epidemics on global supply chain, quantitative techniques are used in the literature [28]. proposed a network-based modelling for indicating how disruptions affects supply chain process. This model provides several advantages for the supply chain system by improving response time, increasing flexibility and agility, decreasing inventory level and descending cost for all process in the supply chain. With the Petri net-based modelling approach termed as a Disruption Analysis Network (DA_NET), it is aimed to identify to determine how the disruptions spread to the supply chain and how the impact is calculated. All epidemic outbreak has adverse impacts on supply chain, trade and logistics [29] creating disruption in the operations and increasing response time for supply chain.

Simulation models ensure a virtual physical environment, which is significant to analyse analytic models. These models also enable real-life applications that are very risky, difficult and costly to be tested [30,31]. Besides, these models can be implemented to predict supply chain behaviours and investigate the impact of disruptions of supply chain over time [32,33]. Since global supply chain in real world need to deal with many unidentified risks and disruptions such as demand volatility, raw material shortages, natural disasters, transportation failures, fires, weather, wars and also pandemic, it is important to manage effectively and need to be captured real world complexity [34,35]. In particular, pandemics caused by many interrelated factors such as creating increased response time and disruption of transportation and have significant effects on the global supply chain. In order to tackle with these challenges and real-world complexity, simulation tools are recognized as a powerful tool to analyse and evaluate the systems.

Only a limited number of simulation models aim to analyse the impact of pandemic outbreaks that cause supply chain disruption. For example [7], examined and predicted the impacts of epidemic outbreaks as a unique type of risk on the SC performance both long term and short time via simulation-based methodology. According to their results, it was emphasized that the closing and opening time of facilities may be a significant factor determining the effect of the epidemic on SC performance. Inoue and Todo (2020) proposed an agent-based model to analyse the economic impacts of a possible lockdown to hinder spread of COVID-19 in Japan. The lockdown in Tokyo causes the indirect impact on other regions. Total production in Japan, the lockdown because of the disruptions will lead an 86% decrease in daily production in Japan in one month.

Observing and predicting system behaviours both in the long term and the short term are significant in the high uncertainty environments and unexpected disruption of supply chain [7,36]. Highly uncertain environments such as the COVID-19 outbreak force managers and practitioners to develop novel relationships and supply configurations for supply chains by re-evaluating the globalized systems that include the delivery of various components [37]. Crisis like Covid-19 is an example of how these systems affects each other [38]. The SD approach can provide an insight into complex global supply chain and allows predicting impacts of these changes in the system over time and further evaluate the consequences of policy interventions [38].

There are a few studies focuses on disruption of supply chain like pandemic outbreaks [39]. carried out SD model to measure the impact of an avian flu pandemic on global supply chains to show the effect of the flu epidemic effect on annual cumulative sales. The analysis also investigated cause and effects relations by providing reinforce and balance loop between inventory shortage and customer loss on the economic indicator as an annual cumulative sale during avian flu disaster. Since, business are vulnerable to supply chain disruptions by Refs. [[39], [40], [41]]. However, proposed models contribute to the preparation of a strategic business plan for the risks faced by the senior management. Pandemics such as avian influenza greatly affect the trade [42,43] and transportation system. Failure to manage the supply chain would lead to material shortages, resulting in many goods will not be supplied as normal and not meet demands on time [37]. In addition, disruptions such as pandemic has made important effects on all production, financial and transportation systems due to the disruptive effects. Since there is a strong causality relation between supply and demand [38]. [44] investigates impact of transportation disruption on SC performance by measuring supply system performance to investigate impacts of the value of a substitute supplier in the disruptions time [45]. has addressed the problem of transporting different goods from multiple aid providers to disaster areas over a network. Disruptions in communication between intermediaries caused the resources not to be managed effectively. Thus, lack of communication and inefficient allocation of resources lead to shortages of supplies in emergencies [46]. aims to explore community functioning and resilience after disaster to guide policy makers and managers. They developed a model to analyse community functioning after disruption and to calculate the components of resistance, recovery, and resilience.

Besides, Abdullah et al. [60] simulate three stages during supply chain to show that lead time changes and inventory have direct relationships. When the lead time is increased, the inventory level of system is increased. SD model is develop based on cause and effect relations between lead time and inventory. The proposed SD model and experimental results are vital to helps managers to provide their decision-making process such as inventory level and risk management in the disruptions time [44]. aim to analyse impact of transportation disruption on SC performance considering supplier, manufacturer and retailer that effected by export and import supply disruption. COVID-19 caused the global economic crisis since China's exports decrease more than 17% in the first two months in the year 2020, and world trade is anticipated to drop between 13 and 32% in 2020 [[37], [66]]. According to the OECD report, inhibition on the movement of people, goods and services, and business closures primarily caused a sharp decline in manufacturing demand in China, while rest of the world also being affected due to business travel, tourism and global supply chains in later periods [38]. [47] used the SD model to compare pre and post COVID-19, investigating the impact of the COVID era on individuals' income, commodity prices and demand, input cost, and finished goods supply. They indicated that different policies need to develop in terms of analysing pre and post pandemic system environment. According to results earnings could ascend demand, but interruptions in raw material and finished product supply outweighed the impact [48]. developed a SD model to understand the impacts of pandemic on Chinese hog and pork consumption, to assess the impact of disruptions in COVID-19 period. They underline effects of pandemic caused by delay in supply chain operations that hinder import and capacity expansion. The model consists of the five main variables which are live hog price, pork inventory, breeding stock and consumption demand and net import. This model uses main two main feedback loops. One of them is relations between among price, consumption and production decisions. The other feedback loops are relationship between time and capacity building and the time required for the price expectation process to achieve success in the market. After they uses four supply chain disruptions and assess their dynamic impact considering corn shortage and price jump, market hog transportation disruption, delay in breeding stock replacement and delay in pork import situations. Loske [62] aim to analyse the impact of German food retail sales volume and freight capacity dynamics during the COVID-19 period, and the changing volume and capacity dynamics of COVID-19 in retail logistics transportation. SD model is developed considering cause and effect relations between COVID-19 outbreak and freight market dynamics. Transport volume growth is directly affected by COVID-19. However, according to the results, it can be said that the increased freight volume for food in retail logistics is not only due to the pandemic time, but also to the strength measured using the total number of new infections. The paper offers suggestions to decision makers for possible future disruptions.

From literature, it can be said that there is still a need systems perspective for investigating effects spread of COVID-19 on the trade and logistics activities. Since these activities are affected by cause and effect relations of the various groups such as demographic data logistics data, supply chain parameters and economic data. Thus, understanding foreign trade and logistics activities’ dynamics actors and cause and effects relations requires system perspective by analysing causal and effect relations for different groups. Measuring impacts of disruptions in supply chains is crucial to find sustainable solutions which is practical and understandable to show the results of complex dynamics systems such as global supply chains [49]. Thus, his study aims to fill gap by presenting SD model how the sectors was affected from pandemic by making comparative analyses and investigating of the impact of pandemics on the countries.

This study is aimed to analyse the effects of disruptions on countries' supply chain comparatively using the SD modelling. During COVID-19 spread, most of the countries have been exposed to lockdowns which has disruptive impacts on the production and supply chains. This has also led to decrease in capacity utilizations and industrial productions in many countries which resulted with imbalance of maritime trade between countries that increased the freight costs. In order to achieve this purpose, this study considers cause and effect relations of the various groups such as demographic data logistics data, supply chain parameters and economic data on disruptions by focusing on trade and logistics activities for specifically Turkey and China which is the biggest importer of Turkey.

SD model as a solution methodology is discussed in the next section.

3. Research methodology

As developed by Jay Forrester, SD approach has been widely used for addressing complex dynamics systems such as global supply chains. SD provides flexibility for the decision makers to analyse the behaviour of changing system and investigate possible effects of variables, especially it is vital to deal with unexpected and unpredicted situations such as pandemic. In complex systems such as supply chains, it is difficult to know what changes or disruptions in the supply chain will cause disruptions [28]. However, it is essential for the handling dynamic nature of the supply chain that need to rapidly investigate the effects of changes or disruptions for the operations.

Similarly, in trade and logistics activities between countries, the participation of many stakeholders creates a dynamic and complex structure, and since these structures have a permanent flow of information, it should be considered as a system that should be handled with a holistic approach and managed effectively. Especially the pandemic process has negatively affected the trade and logistics activities between countries. In such environments, it is very useful to understand the behaviour of a constantly changing system to develop various policy strategies with the SD model, which provides both flexibility and resilient supply chain. Therefore, SD modelling approach can be useful to deal with complexity and dynamic nature of supply chain that represent multi-tiers structure.

In SD modelling approach these attributes can be examined with stock and flows, time delay, feedback mechanism of the system. Feedback loops are used to indicate reinforce and balance effects in the system. This modelling process begin with the determining model boundaries and identifying purposes. After this process, the second stage includes developing causal loop diagram to indicate the relationships among variables. In the third step, causal loop diagram is transforming into stock and flow diagram to quantify model and run the simulation. The last step involves implementation of the model, discussions and future insights.

Therefore, SD gives an opportunity for analyzing the system with a holistic view and systems perspective. Moreover, SD model aims to analyse the effect of the components that may cause by uncertain environments. Therefore, this paper proposes SD model to analyse the effects of disruptions such as COVID-19 on countries' supply chain.

4. A case study of trade between Turkey and China

With COVID-19, global supply chains have faced severe disruptions. These disruptions in global supply chains negatively affects the trade and logistics activities between countries. The emergence of the epidemic, especially in China, where almost every country is dependent on raw materials, has disrupted the material supply. Due to the COVID-19 effect across the globe, it has become extremely important to analyse the trade activities of countries. SD model provided in this article aims to represent the impact of COVID-19 on global supply chains by concentrating on the foreign trade and logistics activities between countries. As the starting point of COVID-19 pandemic, foreign trade of China has been negatively influenced as the disease began spreading in January 2020 [50]. China is the second biggest importer country of Turkey with 18.5 billion dollars (9.1% of total import) in 2019 and 88.9% of these imported goods are raw materials or semi-finished products or machinery and equipment [51]. Therefore, the disruption of foreign trade impacts global supply chains of many sectors in Turkey. The designed SD model considers the main sectors in Turkey that has the highest export and import relation with China. According to the import and export data of Turkey in 2016–2019, selected sectors shown in Table 1 accounts for approximately 80% of the trade between Turkey and China. Table 1. Sectors with highest export and import value in Turkey.

Table 1.

Sectors with highest export and import value in Turkey.

| IMPORT from China | EXPORT to China | ||

|---|---|---|---|

| Sector | % | Sector | % |

| Electronics | 29.8% | Mining Products | 54.5% |

| Machinery and accessories | 24.8% | Chemicals | 10.1% |

| Textile and raw materials | 7.1% | Machinery and accessories | 8.2% |

| Chemicals | 6.6% | Textile and raw materials | 5.0% |

| Plastics and rubber | 6.2% | Food | 3.2% |

| Iron and steel | 5.4% | ||

SD model starts with a causal loop diagram provided in Fig. 1 and it is based on Turkey perspective. It is modelled in STELLA software.

Fig. 1.

Causal Loop of COVID-19 model.

Data that has been gathered for SD Model study can be seen in Fig. 2 .

Fig. 2.

SD Model data.

Model is designed in order to anticipate the life cycle of COVID-19 and implications of COVID-19 disruption on the global supply chains by analysing the overall trade between countries. As it has been observed that there has been major lock-downs in countries with the spread of COVID-19 which creates decline in productivity of many industrial sectors. The evidence of the negative association between increased COVID-19 spread and the decrease of industrial productivity can be seen in the below Table 2 . In China, lock-down started with the increased number of patients in 23rd of January 2020 and 8th of April 2020 lock-down officially ended. In Turkey, restrictions started on 16th of March 2020 and still on-going while preparing this article.

Table 2.

Active patients and industrial production in China & Turkey (Source: National Bureau of Statistics of China & Turkish Statistical Institute).

| Average Active Patient Count | Industrial Production YoY | Average Active Patient Count | Industrial Production YoY | |

|---|---|---|---|---|

| 2019-December | 27 | 6.90% | – | 8.60% |

| 2020-January | 1514 | −13.50% | – | 7.90% |

| 2020-February | 42,193 | – | 7.50% | |

| 2020-March | 12,009 | −1.10% | 2763 | −2.00% |

| 2020-April | 1059 | 3.90% | 55,738 | −31.40% |

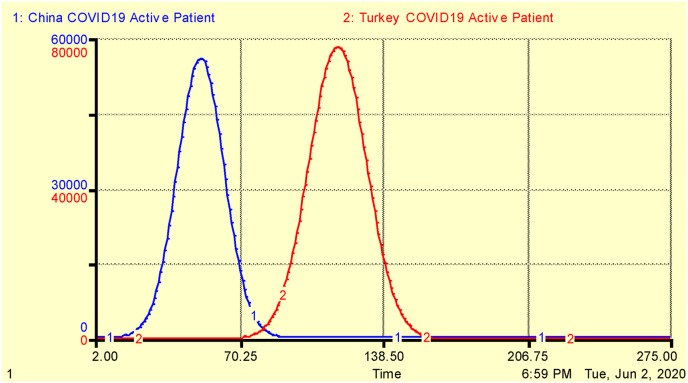

Model begins with the spread of COVID-19 in China at the start of 2020. Life cycle of the COVID-19 has been tracked with the active patients in the country. In this study, active patient counts have been used in order to represent life cycle of COVID-19, since the data is much smoother compared to new patient counts or death counts. It can be used in order to show the real burden in country economy and health system and active patient increase periods indicate the uncontrollable spread of the virus and overload in the country economy. COVID-19 has been reached its maximum in mid-February and decline afterwards. In the late-April, active patients dropped below a thousand and country starts to go back to work routine. With the spread of COVID-19 worldwide, many countries especially in Europe had been affected in February. First COVID-19 patient has been detected in Turkey in mid-March and reached the peak point in late April. In the model, active patients in both countries have been modelled as seen in Fig. 3 . Model has been simulated for 274 days from January 01 - September 30, 2020. It is expected to see Turkey going back to work routine in mid-June. Active patient counts have been derived from National Health Commission of China and Ministry of Health of Turkey between December-2019 and April-2020. Active patient count after May 01, 2020 had been forecasted ignoring an emergence of second wave.

Fig. 3.

Lifecycle of COVID-19 in China and Turkey.

As shown in Table 2, there has been a severe disruptive impact of COVID-19 on industrial productivity. For the Turkey case, since majority of the import from China is input for many sectors, it can impact performance of various supply chains which cannot be distinguished easily. The aggregated data gathered from Turkish Statistics Institute is used in the model and there is no detailed information showing which sector is exactly importing which specific raw material. For instance, as being approximately 30% of the total import, electronics is an important part of resource from China. However, electronic raw material can be a part of white good production, machinery production or any type of electronic equipment. Further, the productivity of a country has been impacted due to the excessive reliance on China [52]. The basis of the model relies on the assumption that the productivity decrease in a sector is proportional to the increase in the COVID-19 active patient count. However, there could be some sector specific dynamics that could change the impact of the severity. For example, textile raw material import from China has dramatically decreased by 28% during March & April 2020. The reasons could be the human dependent production in factories or as a sector including not critical products during pandemic time. On the other hand, electronics import has increased by 5% in the same period. Even though this increase is considerably small compared to the increase in January-February 2020 of the same year (which is 24%), this 5% increase is achieved since electronics products are still important (maybe more compared to a normal period) during pandemics and production environments for electronic products are more automated.

From Turkey point of view, the impact of COVID-19 on import would be delayed by two months. Due to the geographical distances between countries, delays on transportation and customs clearance activities are considered in the model. From Turkey point of view, import from China would be delayed by two months which can be seen in Equation (1). Therefore, the impact of COVID-19 spread in China in January 2020, reflects to Turkey import figures in March 2020. On the other hand, export numbers are impacted by COVID-19 spread within the same month since Turkey active patient counts can decrease the capacity utilization of the country and this interrupts the trade between countries. It has been observed that with the spread of COVID-19, industrial production has been decreased by 13.5% compared to January-February 2019. Industrial production decline impacts the exports from China to Turkey. At the same time, COVID-19 spread in Turkey decreases industrial capacity utilization and demand on China products. So, all these factors have been represented in the model using the below equation (1):

| Import_SectorX (t+60) = Import_SectorX(t-365 + 60) * (1 + ImportGrowthRate) |

| * (1 -SectorX_Slowdown_China(t)) * (1-TurkeyDemandDecrease(t)) | (1) |

Based on this equation, import for any sector X has been calculated according to actual import value of 2019. Import_SectorX (t+60) represents the 60 days of delay due to transportation delay and shows that the COVID-19 disruption in China and Turkey will be visualized in import figures 60 days later. Import growth rate (ImportGrowthRate) for Turkey has been derived from OECD data as 2020 forecast (OECD, Trade data [63]). SectorX_Slowdown_China has been calculated by equation (2);

| SectorX_Slowdown_China(t) = China_IndustrialProduction_Index(t)*SectorX_IndustrialImpact |

Where

| China_IndustrialProduction_Index(t) = IndustrialProductionRate * ChinaActivePatient(t) / China_ActivePatientPeakNumber | (2) |

TurkeyDemandDecrease is estimated according to the spread of the COVID-19 in Turkey using equation (3);

| TurkeyDemandDecrease(t) = Turkey_IndustryCapacityUtilization(t)*DemandDecreaseRate |

| where Turkey_IndustryCapacityUtilization(t) = CapacityUtilizationRate * TurkeyActivePatient(t) / Turkey_ActivePatientPeakNumber | (3) |

Therefore, according to these formulas, active patient numbers in China and Turkey will guide the model in forecasting industrial production rate of China and industrial capacity utilization of Turkey respectively. For each sector, production rate would differ which is represented by SectorX_IndustrialImpact. All of the rates used in the models (SectorX_IndustrialImpact, IndustrialProductionRate, DemandDecreaseRate, CapacityUtilizationRate) are calculated based on the actual data between January to March 2020. Average values based on the existing data has been used since there is not sufficient data to perform statistical analysis. At any time, t, COVID-19 active patients in China and Turkey will impact production rate in China and demand rate in Turkey which will decrease the import value after two months in Turkey.

Similarly, equation (4) have been developed to calculate export in Sector Y from Turkey to China.

| Export_SectorY (t) = Export_SectorY (t-365) * (1 + ExportGrowthRate) |

| * (1 -SectorY_Slowdown_Turkey(t)) * (1-ChinaDemandDecrease(t)) | (4) |

Since China is the second biggest importer of Turkey after Russia and 90% of the logistics is based on maritime, disruption in the import affects the planning of maritime logistic activities severely. Decrease in arriving shipments from China to Turkey causes logistic companies to arrange additional ships for export activities, which increases the freight costs drastically. It has been reported that in March 2020, freight costs increased by 40% compared to last year. Model includes the freight cost forecast and the maritime logistic load between China and Turkey.

In model, for each specified sector, import and export forecasts are generated between January and September 2020. Import numbers are impacted after March 2020 due to transportation delay. In Fig. 4 , forecast for Electronics import has been shown until the end of September. COVID-19 will impact import numbers until the end of July 2020. Since model is developed using monthly import and export data and this data has been converted to daily values, there could be sharp increase and decreases between months such as in June and July; but COVID-19 related fluctuations are rather soft and bell-shaped decreases. In Fig. 5 , mining and chemical export from Turkey to China has been shown. First decrease is related with China COVID-19 related disruption, whereas the second decrease after April is related with the slowdown in industrial capacity of Turkey. Mining sector has not been impacted severely by Turkey COVID-19 disruption, but Chemical sector has been affected.

Fig. 4.

Electronics import ($) between March 2020 and September 2020.

Fig. 5.

Mining and Chemical export ($) between January 2020 and June 2020.

Based on the model output, import forecasts for March to June has been represented in Table 3 (since COVID-19 impact has been observed in import data starting from March). Model forecasts are prepared by considering the slowdown in March actual data. However, it should be considered that workforce can adapt to the situation and increase their productivity as time passes under COVID19 pandemic. Therefore, the forecast numbers represent the worst-case scenario for the sector in case they cannot adapt to the disruption. Table 3 shows the import forecasts from China to Turkey.

Table 3.

Import forecasts from China to Turkey.

| ACTUAL – January and February 2020 DATA |

FORECAST – March 2020 to June 2020 DATA |

||||

|---|---|---|---|---|---|

| Sector | % Growth Year on Year (January and February 2020) | Import Forecast $ (March and April 2020) | % Growth Year on Year (March and April 2020) | Import Forecast $ (May and June 2020) | % Growth Year on Year (May and June 2020) |

| Electronics | 24% | 733,392,066 | −7% | 755,384,431 | 1% |

| Machinery and accessories | 40% | 466,376,291 | −37% | 667,757,601 | −4% |

| Textile and raw materials | −6% | 97,479,545 | −57% | 194,321,000 | −16% |

| Chemicals | 0% | 210,005,373 | −6% | 233,319,676 | 2% |

| Plastics and rubber | 13% | 115,044,868 | −28% | 188,504,530 | −2% |

| Iron and steel | 45% | 128,524,852 | 41% | 176,840,282 | 45% |

| TOTAL | 23% | 1,750,822,996 | −22% | 2,216,127,520 | 0% |

In Table 4 , export forecasts from Turkey to China has been provided. Because of Chinese New Year, there is a drop down in February. But the expected dropdown is sharpened by the COVID-19 pandemic. Actual and model results for Q1 (January to March) has been provided to in order to represent model reliability. Export is expected to be impacted by COVID-19 until end of July 2020.

Table 4.

Export forecasts from Turkey to China.

| ACTUAL – Q1 DATA |

FORECAST – Q1 and Q2 DATA |

||||

|---|---|---|---|---|---|

| SECTOR | % Actual Growth Year on Year | Export Forecast $ Q1 | % Growth Year on Year |

Export Forecast $ |

% Growth Year on Year |

| Q1 | Q2 | Q2 | |||

| Mining Products | −15% | 252,008,696 | −15% | 208,477,532 | −38% |

| Chemicals | −31% | 52,615,272 | −31% | 54,045,728 | −42% |

| Machinery and accessories | −2% | 15,175,512 | −2% | 11,619,855 | −17% |

| Textile and raw materials | −2% | 21,173,933 | −2% | 20,963,366 | 14% |

| Food | −17% | 30,907,568 | −17% | 24,485,706 | −56% |

| TOTAL | −17% | 371,880,981 | −17% | 319,592,188 | −39% |

Based on TSI data, 90% of the import and 95% of export trade with China are transhipped with maritime logistics. With the decrease in the import shipments, logistic companies struggle with finding available ships in Europe and this increased the freight costs drastically in Turkey. Increased freight cost due to dropdown in import values are also forecasted in the model which can be seen in Table 5 and it can be realized that freight costs will return back to its original position by the end of June 2020.

Table 5.

Freight cost increase forecast.

| Month | Freight Cost Increase % |

|---|---|

| March-2020 | 11.0% |

| April-2020 | 40.0% |

| May-2020 | 19.0% |

| June-2020 | 8.0% |

| July-2020 | 7.0% |

| August-2020 | 7.0% |

| September-2020 | 6.0% |

In Table 6 , import and export forecast values in terms of TEU units are provided. Based on the model, it is expected to observe decrease in the import shipment numbers in March and June due to COVID-19 spread in China and Turkey respectively. Similarly, export shipment values would be impacted in February and April.

Table 6.

Import and export shipment forecast.

| Month | Import Shipment (TEU) | Export Shipment (TEU) | |

|---|---|---|---|

| ACTUAL | January-2020 | 33,566 | 30,722 |

| February-2020 | 19,545 | 10,936 | |

| FORECAST | March-2020 | 18,646 | 25,493 |

| April-2020 | 22,701 | 16,235 | |

| May-2020 | 38,689 | 59,269 | |

| June-2020 | 6210 | 40,872 | |

| July-2020 | 35,302 | 47,206 | |

| August-2020 | 31,052 | 88,482 | |

| September-2020 | 57,653 | 48,587 |

The diagram represented in Fig. 1 is developed in order to explain the disruptive behaviour of the pandemic on the international trade of countries. Even though, the model represented in this study is for Turkey and China, the model can be enlarged to more countries. This study can be applied to depict the international trade between countries based on the overall import and export data. During the preparation of the study, limited amount of data is available (for Turkey, March-May 2020 COVID-19 data) and the model is developed in order to guide the decision makers the forecast the damaging impact of COVID-19 on the global supply chains.

5. Discussions

The results have presented that epidemic outbreaks causes supply chain disruptions in the world. This leads to major disruptions in the global supply chain, increased risk in global markets, and increased interest in safe ports such as gold [53]. Due to the pandemic, which has devastating effects around the world, the partial or complete lockdowns of many countries has caused many problems such as supply and demand imbalance in supply chains, as well as inability to reach raw materials [54]. Therefore, it is essential to analyse how sectors are affected by COVID-19 [55] and to make a short-term forecast for the future to take actions against the damages in the global supply chains of the countries, which is one of the most important contribution of the study. COVID-19 has led to create considerably inventory shortages due to unexpected increase demand and this caused that firms encountered shrink shortage of inventory due to the challenging access to raw materials [56]. have been revealed that different sectors should develop different recovery plans and strategies during the pandemic period for quick action and have been indicated that while the short-term effects of COVID-19 can be observed, the medium-long-term effects are complex and uncertain. By comparing with other studies, the study is unique since making comparative analysis and investigating the impact of pandemic on global supply chains by focusing on the foreign trade and logistics activities between countries using SD modelling based on system thinking approach. By making this, it is aimed to analyse how main sectors of the countries are affected by COVID-19 from system thinking perspective, to make a short-term import forecast from China to Turkey for the future from system thinking perspective and to embody the impacts of COVID-19 with an example of China and Turkey from system thinking perspective via answering research question of this study. Therefore, the biggest contribution to evaluate the sectoral impacts of COVID-19 on global supply chains from Turkey and China perspective.

Hence, it is needed to embody the impacts of COVID-19 in the business sectors within a nation. The scenario created with the help of SD modelling is the worst-case scenario for Turkey. With this scenario, which sectors are getting worse in the country are analysed. Turkey's is among the second largest importing countries of China, which has been adversely affected. Due to the pandemic, the disruptions in foreign trade have disrupted the supply of machinery, equipment, raw materials and semi-finished products. With the proposed model, it has been analysed which sectors will be affected by the pandemic. Accordingly, it is stated which sectors should take measures considering its negative effects.

Besides, the majority of imports and exports with China are carried out by maritime logistics. Because of the pandemic, the reduction of import shipments, for logistics companies in Europe revealed shortage of suitable ships and this greatly increased freight costs in Turkey. Increasing freight cost due to the decrease in import values was estimated and decision makers are suggested to make appropriate decisions. In line with the results obtained, the management and government bodies can plan for appropriate actions for different sectors. Therefore, with these implementations, research question is answered to have a knowledge about analysing the effects of disruptions on countries' supply chain comparatively in a system thinking approach.

6. Implications for decision makers and managers

The global supply chain disruptions caused by the pandemic affects the production processes to a large extent [57]. The pandemic, which begins in China, which is Turkey's 2nd biggest importer has negative impacts on final consumption of raw materials and semi-finished products more than final consumption process. Therefore, necessary actions and remedies should be taken by governments to prevent the negative impacts of the supply chain disruptions especially on the competitive sectors [58].

On the other hand, it is not only production of the countries that is affected by the disruptions. The decrease in the ratio of imports by maritime, which constitutes of 90% of Turkey's imports affects Turkish import and forwarding operations directly in a negative way. Means that disruptions in imports with maritime logistics causes “logistics and supply chain disruptions” such as increase in freight prices. Therefore, it is essential extra planning for logistics activities. In addition, in the pandemic period, from China to Europe, the first freight train has reached Turkey. This shows that trade can be done using alternative modes of transportation as intermodal, if not possible by maritime logistics.

One of the important implications that can be inferred from the result of the study is managing imbalance between import and export activities caused maritime logistics due to the lack of available containers and equipment which increased the freight cost dramatically in order to cope with disruptions. This showed that there is a need for an alternative transportation mode that can provide low-cost transportation for example one-belt-one road, which is a new transportation network between Asia and Europe.

Due to the pandemic, China which is the biggest importer of Turkey, was at a point that shipped raw materials or goods in 2 months, caused a delay of 2 months in the supply of goods. If we had been working with different suppliers at a closer distance during this disruptive time, we would not have had any raw material supply problems. From this perspective, new concepts emerging in supply chains should be considered, for example, supplier disruptions can be resolved by adopting onshore applications for problems arising from suppliers. As a managerial implication, this research also offers many implications for managers and decision makers. Companies should choose supplier diversification in order to struggle with possible disruptions. By identifying alternative suppliers from local suppliers or other countries, they can minimize the effects of a potential problem. In events those cause disruption in supply chains like pandemic, companies must select between a make or buy decision and make investment decisions accordingly.

Furthermore, due to the disruptions and fluctuations in the supply chains, production planning and process management should be done appropriately. Therefore, it should be taken into consideration for production planning and process management to overcome the difficulties in the important sectors. In addition, with the decrease in production due to the pandemic, companies should switch to flexible capacity planning in terms of human resource and machinery capacity.

Notably, due to fluctuations in raw material and components, proper inventory management is required. Safety stock calculations should be probabilistic and this should be considered in inventory management. Lastly, in terms of increased costs at the time of disruptions, managers should keep different combinations of intermodal ready.

Digitization can be an important solution measure for managers under such disruptions. Use of digital technologies can help management to manage supply chains more effectively and efficiently. In addition to that, the management can also evaluate the resilience of global supply chains and conduct effective risk management strategies.

As a theoretical implication, system thinking can be used to analyse the disruptions caused by global disruptions, such as COVID-19, on global supply chains. Hence system thinking has the ability to consider multiple stakeholders and multi-tiers within the global supply chain. However, it is also crucial to determine the suitable methodology to system thinking within the implementation.

The SD model developed is a starting point incorporating the pandemic spread in forecasting the impact on global supply chains. Model guides the decision makers to consider sector specific dynamics into the calculations. In case of a second or more waves of pandemic spread or a new pandemic, this model can be used by adapting the numbers to the new situation. Even though in this model the demand decrease for Turkey and China is impacted by COVID-19 active patient counts only, in the future it should be considered that the managers will learn and adapt to the changing conditions. Therefore, the variable representing demand decrease will not be as sharp as today due to learning factors. For example, the automation increase in a sector can be incorporated into the model, if a longer forecast is required.

Further, studies that cover such global supply chains, especially in the field of COVID-19, will open new areas to explore in logistics and supply chain management.

7. Conclusions

The COVID-19, which continues to spread worldwide, harms the supply chains of countries in terms of labour, parts and government constraints [59]. For this purpose, to show sectoral impacts of COVID-19 and to have knowledge about future state with short- and long-term forecast, SD modelling on the basis of system thinking approach is developed in the study. Using system thinking approach and the SD modelling, it is aimed to investigate whole system and its actors and to make comparative analysis to show the impact of pandemics on global supply chain of the countries with a real-life example of China and Turkey as a case study. The implementation of the study is made with SD model and according to results, it is expected to see Turkey going back to work routine in mid-June. According to results, it has been revealed which sectors will be adversely affected by the pandemic and which measures should be taken. However, according to forecasts of COVID-19 on the selected sectors, there is decrease in electronic imports. For the mining and chemical export from Turkey to China, there is two decreases in export rate of Turkey caused by COVID-19 disruption firstly, and then slowdown in industrial capacity of Turkey after April. In addition, while mining sector has not been impacted by Turkey COVID-19 disruption, chemical sector has been affected.

Besides, it can be stated that a large part of the import and export with China is planned with maritime logistics, but import shipments have been decreased due to the pandemic. This has led to an increase in freight costs in Turkey due to the lack of suitable ships in Europe. Furthermore, according to forecasting, it is seen that freight costs will return back to its original position by the end of June 2020. Thus, it is analysed that there will be a decrease in import and export shipments. To sum up, the pandemic process affects the economic economy, global supply chains and sectors negatively and causes supply chain disruptions in the countries. This study can be useful to describe the international trade between countries based on the overall import and export data.

As a limitation of the study, the needed dataset to apply in SD modelling is not reachable because of the country's limitations. For example, it is not available to get data about January and February months without cumulative values. Moreover, in this study, there are lots of variables are added in the model. In previous studies, the relations of trade and logistics activities were not investigated in depth, which created difficulties in integrated relations in the system. However, large number of variables in the study can be increased the complexity of the model. For further researches, not only two countries or emerging economies, but also the global effects of the pandemic can be analysed by addressing intercontinentally. In addition, comparative studies between countries can be diversified and the effects of pandemics can be examined. For further researches, second and also third waves of COVID-19 can be considered to see the results in a comprehensive manner. Apart from marine logistics, alternative mode selections can also be evaluated during downtime. Intermodal methods can be researched more and the collapse in logistics can be minimized during disruption. Besides, various policies can be adapted to the SD model to observe the impact of established policies. Studies can be planned to compare the possible future waves of the pandemic. Finally, one belt one road initiatives can be further investigated.

Author statement

Prof. Yigit KAZANCOGLU conceived of the presented idea. Research Assistant Muruvvet Deniz SEZER developed the theory and Dr. Esra Ekinci & Research Assistant Melisa OZBILTEKIN-PALA performed the computations. Prof. Yigit KAZANCOGLU, Dr. Sachin Kumar Mangla encouraged Research Assistant Melisa OZBILTEKIN-PALA and Research Assistant Muruvvet Deniz SEZER to investigate and supervised the findings of this work. All authors discussed the results and contributed to the final manuscript.

Declarations of competing interest

None.

Biographies

Author 1. Prof. Dr. Yigit Kazançoglu received his B.S. degree from Eastern Mediterranean University, Dept. of Industrial Engineering. He has graduated from Coventry University, UK, MBA and Izmir University of Economics MBA programs, respectively in 2003 and 2004. Kazancoglu has received his PhD. at Ege University (Operations Management). He was an Asst Prof Dr between 2008 and 2013; and Assoc Prof Dr between January 2014–2016 in Izmir University of Economics, Dept. of Business Administration. Between December 2016 - May 2019 he worked as Assoc Prof Dr in Yasar University, Logistics Management Department. Since May 2019, he is Full Professor Dr in the same department. His research areas are: Operations Management, Supply Chain Management, Total Quality Management, Sustainability, Circular Economy, MCDM multi criteria decision making methods. He has published over 50 articles on the SCI & SSCI indexed international refereed journals such as International Journal of Production Research, Journal of Cleaner Production, Transportation Research Part-E, Resource Conservation and Recycling, Production Planning and Control, Computers & Operations Research, International Journal of Logistics Management, Journal of Manufacturing and Technology Management, Science of the Total Environment, Business Strategy and the Environment, Expert Systems with Applications, Agribusiness, Industrial Management and Data Systems, and Journal of Enterprise Information Management.

Author 2. Assist.Prof. (PhD) Esra Ekinci graduated from Industrial Engineering department of Middle East Technical University in 2000 and had Msc and PhD degrees in Dokuz Eylul University in Industrial Engineering in 2002 and 2016 respectively. She had worked in Izmir Institute of Technology between 2002 and 2004 as instructor. Starting from year 2005, she had ten years of working experience in Netsis Software, Tesco Kipa and Dirinler Metal Casting. In the mentioned companies, she had the opportunity take roles in IT, project management, finance, inventory planning and process improvement areas. She has started working in Yasar University International Logistics Management department in November 2016.

Author 3. Dr. Sachin Kumar Mangla is working in the field of Green and Sustainable Supply Chain and Operations; Industry 4.0; Circular Economy; Decision Making and Simulation. He has a teaching experience of more than five years in Supply Chain and Operations Management and Decision Making, and currently associated in teaching with various universities in UK, Turkey, India, China, France, etc. He is the director of Centre for "Digital Circular Economy for Sustainable Development Goals (DCE-SDG), O.P. Jindal Global University, India. He is committed to do and promote high quality research. He has published/presented several papers in repute international/national journals (Journal of Business Research; International Journal of Production Economics; International Journal of Production Research; Computers and Operations Research; Production Planning and Control; Business Strategy and the Environment;; Annals of Operations Research; Transportation Research Part-D; Transportation Research Part-E; Renewable and Sustainable Energy Reviews; Resource Conservation and Recycling; Information System Frontier; Journal of Cleaner Production; Management Decision; Industrial Data and Management System) and conferences (POMS, SOMS, IIIE, CILT – LRN, MCDM, GLOGIFT). He has an h-index 61, i10-index 121, Google Scholar Citations of more than 10000. He is involved in several editorial positions and editing couple of Special issues as a Guest Editor in top tier journals. Currently, he is working as an Associate Editor at Journal of Cleaner Production, International Journal of Logistics Management, Sustainable Production and Consumption, and IMA Journal of Management Mathematics journals. He is also involved in several research projects on various issues and applications of Circular economy, Industry 4.0 and Sustainability. Among them, he contributed to the knowledge based decision model in “Enhancing and implementing knowledge based ICT solutions within high risk and uncertain conditions for agriculture production systems (RUC-APS)”, European Commission RISE scheme, €1.3M. Recently, he has also received a grant as a PI from British Council – Newton Fund Research Environment Links Turkey/UK – Circular and Industry 4.0 driven solutions for reducing food waste in supply chains. He is also working in several projects on Food Waste and Circular Economy and Industry 4.0 issues, sponsored by ICSSR, Government of India. He received project funding for Food Waste Management in Circular Economy from the USERC, Government of India. He has also won the first prize for the prestigious Basant Kumar Birla Distinguished Scholar Award 2021. He was ranked 404 in the world and 10 in United Kingdom and was recognized with 2022 Rising Star of Science Award by Research.com. He was also ranked among the top 2% scientists in the world by the Stanford University. Recently, he has also been awarded as a High End Foreign Expert Talent Grant from Minisrty of Science and Technology, China.

Author 4. Research Assistant Muruvvet Deniz Sezer is currently working as a Research Assistant at Yaşar University, Department of Business Administration. She received her Bachelor's Degree from Eskişehir Osmangazi University, Department of Industrial Engineering in 2014. She also completed the Double Major Program at Eskişehir Osmangazi University, Department of Business Administration. She received her master's degree from Dokuz Eylül University, Department of Industrial Engineering in 2019. Deniz Sezer, who continues her Phd study in Yaşar University, Department of Business Administration, focuses on supply chain management, system dynamics, sustainability, and circular economy.

Author 5. Research Assistant Melisa Ozbiltekin-Pala completed her undergraduate degree at Izmir Kâtip Çelebi University International Trade and Marketing Department in 2017, and received her master's degree from Yaşar University International Logistics Department in 2020. Melisa Özbiltekin Pala, who continues her doctoral studies at Ege University, Department of Business Administration, conducts researches on supply chain management, reverse logistics, sustainability, circular economy and digitalization. She has been working as a Research Assistant at Yaşar University Logistics Management Department since 2019.

Data availability

No data was used for the research described in the article.

References

- 1.OECD . 2020. OECD interim economic assessment: coronavirus: The world economy at risk”, 2 March 2020; pp. 1–18. (March) [Google Scholar]

- 2.Ehlert A. Socio-Economic Planning Sciences; 2021. The socio-economic determinants of COVID-19: a spatial analysis of German county level data. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Shafi M., Liu J., Ren W. Impact of COVID-19 pandemic on micro, small, and medium-sized Enterprises operating in Pakistan. Res Globalization. 2020;2 [Google Scholar]

- 4.Remko V.H. Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int J Oper Prod Manag. 2020;40(4):341–355. [Google Scholar]

- 5.Yu K.D.S., Aviso K.B. Modelling the economic impact and ripple effects of disease outbreaks. Proces Integrat Optim Sustain. 2020;4:183–186. [Google Scholar]

- 6.Al Humdan E., Shi Y., Behnia M. Supply chain agility: a systematic review of definitions, enablers and performance implications. Int J Phys Distrib Logist Manag. 2020;50(2):287–312. [Google Scholar]

- 7.Ivanov D. Predicting the impacts of epidemic outbreaks on global supply chains: a simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transport Res E Logist Transport Rev. 2020;136 doi: 10.1016/j.tre.2020.101922. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Ruiz Estrada M.A., Park D., Lee M. The evaluation of the final impact of Wuhan COVID-19 on trade, tourism, transport, and electricity consumption of China. SSRN Electron J. 2020:1–13. [Google Scholar]

- 9.Golan M.S., Jernegan L.H., Linkov I. Trends and applications of resilience analytics in supply chain modeling: systematic literature review in the context of the COVID-19 pandemic. Environ Syst Decision. 2020;40:222–243. doi: 10.1007/s10669-020-09777-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Haren P., Simchi-Levi D. How coronavirus could impact the global supply chain by midMarch. Harv Bus Rev. 2020;28 [Google Scholar]

- 11.Panarello D., Tassinari G. Socio-Economic Planning Sciences; 2021. One year of COVID-19 in Italy: are containment policies enough to shape the pandemic pattern? [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.He P., Huang Z. World Economic Forum Beijing, and World Economic Forum; 2020. Automotive and autonomous mobility.https://www.weforum.org/agenda/2020/02/coronavirus-china-automotive-industry/ (n.d.). This industry was crippled by the coronavirus - here's how it's fighting back.” Retrieved from. [Google Scholar]

- 13.Fernandes N. IESE Business School Spain; 2020. Economic effects of coronavirus outbreak (COVID-19) on the world economy”. 2020. 0–29. [Google Scholar]

- 14.Gormsen N.J., Koijen R.S.J. Coronavirus: Impact on stock Prices and growth expectations”. BFI Working. 2020:1–27. Paper No. 2020-22. [Google Scholar]

- 15.Khan S.A.R., Razzaq A., Yu Z., Shah A., Sharif A., Janjua L. Socio-Economic Planning Sciences; 2021. Disruption in food supply chain and undernourishment challenges: an empirical study in the context of Asian countries. [Google Scholar]

- 16.Nikolopoulos K., Punia S., Schäfers A., Tsinopoulos C., Vasilakis C. Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions. Eur J Oper Res. 2020;290(1):99–115. doi: 10.1016/j.ejor.2020.08.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Paul S.K., Chowdhury P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int J Phys Distrib Logist Manag. 2020 doi: 10.1108/IJPDLM-04-2020-0127. ahead-of-print No. ahead-of-print. [DOI] [Google Scholar]

- 18.Ayittey F.K., Ayittey M.K., Chiwero N.B., Kamasah J.S., Dzuvor C. Economic impacts of Wuhan 2019‐nCoV on China and the world. J Med Virol. 2020;92(5):473–475. doi: 10.1002/jmv.25706. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Handfield R.B., Graham G., Burns L. Corona virus, tariffs, trade wars and supply chain evolutionary design. Int J Oper Prod Manag. 2020;40(10):1649–1660. [Google Scholar]

- 20.Mariia H., Henryk D., Nataliia T., Yuliya S. Substantiation of expediency of the complex approach for supply chains management in the Covıd-19 conditions. Intellectualization of logistics and Supply Chain Management. 2021;(5) [Google Scholar]

- 21.Sadiq M., Hsu C.C., Zhang Y., Chien F. COVID-19 fear and volatility index movements: empirical insights from ASEAN stock markets. Environ Sci Pollut Control Ser. 2021:1–18. doi: 10.1007/s11356-021-15064-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Queiroz M.M., Ivanov D., Dolgui A., Wamba S.F. Impacts of epidemic outbreaks on supply chains: mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Ann Oper Res. 2020:1–38. doi: 10.1007/s10479-020-03685-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Rauner M.S., Schaffhauser-Linzatti M.M. Impact of the new Austrian inpatient payment strategy on hospital behavior: a system-dynamics model. Soc Econ Plann Sci. 2002;36(3):161–182. [Google Scholar]

- 24.van Ackere A., Schulz P.J. Explaining vaccination decisions: a system dynamics model of the interaction between epidemiological and behavioural factors. Soc Econ Plann Sci. 2020;71 [Google Scholar]

- 25.Burt G. Why are we surprised at surprises? Integrating disruption theory and system analysis with the scenario methodology to help identify disruptions and discontinuities. Technol Forecast Soc Change. 2007;74(6):731–749. [Google Scholar]

- 26.Yamanis T., Nolan E., Shepler S. Fears and misperceptions of the ebola response system during the 2014-2015 outbreak in Sierra Leone. PLoS Neglected Trop Dis. 2016;10(10) doi: 10.1371/journal.pntd.000507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Fugerson A.G., Sutton Y.M., McCree H.D. Social and structural determinants of HIV treatment and care among hispanic women and latinas living with HIV infection in the United States: a qualitative review: 2008–2018. Health Equity. 2019;3(1):581–587. doi: 10.1089/heq.2019.0039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Wu T., Blackhurst J., O’grady P. Methodology for supply chain disruption analysis. Int J Prod Res. 2007;45(7):1665–1682. [Google Scholar]

- 29.Chen H., Jin Y., Huo B. Understanding logistics and distribution innovations in China. Int J Phys Distrib Logist Manag. 2020;50(3):313–322. [Google Scholar]

- 30.Tan W.J., Cai W., Zhang A.N. Structural-aware simulation analysis of supply chain resilience. Int J Prod Res. 2019;58:5175–5195. [Google Scholar]

- 31.Huang C., Wang M., Rafaqat W., Shabbir S., Lian L., Zhang J.…Song W. Socio-economic planning sciences; 2021. Data-driven test Strategy for COVID-19 using machine learning: a study in Lahore, Pakistan. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Klibi W., Martel A. Modelling approaches for the design of resilient supply networks under disruptions. Int J Prod Econ. 2012;135(2):882–898. [Google Scholar]

- 33.Ivanov D. Springer; New York: 2018. Structural dynamics and resilience in supply chain risk management”. [Google Scholar]

- 34.Simchi-Levi D., Schmidt W., Wei Y., Zhang P.Y., Combs K., Ge Y.…Zhang D. Identifying risks and mitigating disruptions in the automotive supply chain. Interfaces. 2015;45(5):375–390. [Google Scholar]

- 35.Marin G., Modica M., Paleari S., Zoboli R. Socio-Economic Planning Sciences; 2021. Assessing disaster risk by integrating natural and socio-economic dimensions: a decision-support tool. [Google Scholar]

- 36.Xu H. Minimizing the ripple effect caused by operational risks in a make-to-order supply chain. Int J Phys Distrib Logist Manag. 2020;50(4):381–402. [ahead-of-print No. ahead-of-print] [Google Scholar]

- 37.Sarkis J., Cohen M.J., Dewick P., Schröder P. A brave new world: lessons from the COVID-19 pandemic for transitioning to sustainable supply and production. Resour Conserv Recycl. 2020;159 doi: 10.1016/j.resconrec.2020.104894. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Hynes W., Trump B., Love P., Linkov I. Bouncing forward: a resilience approach to dealing with COVID-19 and future systemic shocks. Environ Syst Decision. 2020;40:174–184. doi: 10.1007/s10669-020-09776-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Kumar S., Chandra C. Supply chain disruption by avian flu pandemic for US companies: a case study. Transport J. 2010;49(4):61–73. [Google Scholar]

- 40.Wieland A., Wallenburg C.M. The influence of relational competencies on supply chain resilience: a relational view. Int J Phys Distrib Logist Manag. 2013;43(4):300–320. [Google Scholar]

- 41.Kumar S., DuFresne C., Hahler K. Managing supply chain risks in US-China trade partnership. Inf Knowl Syst Manag. 2007;6(4):343–362. [Google Scholar]

- 42.Baldwin R., Tomiura E. Thinking ahead about the trade impact of COVID-19. Economics in the Time of COVID-19. 2020;13(1):59–71. [Google Scholar]

- 43.Yoon J., Talluri S., Yildiz H., Ho W. Models for supplier selection and risk mitigation: a holistic approach. Int J Prod Res. 2018;56(10):3636–3661. [Google Scholar]

- 44.Huang M. Yang, Zhang Y., Liu B. System dynamics modelling-based study of contingent sourcing under supply disruption. Syst Eng Procedia. 2012;4:290–297. [Google Scholar]

- 45.Diedrichs D.R., Phelps K., Isihara P.A. Quantifying communication effects in disaster response logistics: a multiple network system dynamics model. J Humanit Logist Supply Chain Manag. 2017;6(1):24–45. [Google Scholar]

- 46.Links J.M., Schwartz B.S., Lin S., Kanarek N., Mitrani-Reiser J., Sell T.K.…Kendra J.M. COPEWELL: a conceptual framework and system dynamics model for predicting community functioning and resilience after disasters. Disaster Med Public Health Prep. 2018;12(1):127–137. doi: 10.1017/dmp.2017.39. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Sinha D., Bagodi V., Dey D. The supply chain disruption framework post COVID-19: a system dynamics model. Foreign Trade Rev. 2020;55(4):511–534. [Google Scholar]

- 48.Wang Y., Wang J., Wang X. COVID-19, supply chain disruption and China's hog market: a dynamic analysis. China Agricult Econ Rev. 2020;12(3):427–443. [Google Scholar]

- 49.Demirel G., MacCarthy B.L., Ritterskamp D., Champneys A., Gross T. Identifying dynamical instabilities in supply networks using generalized modelling. J Oper Manag. 2019;65(2):133–159. [Google Scholar]

- 50.Demir B., Javorcik B. Trade finance matters: evidence from the COVID-19 crisis. Oxf Rev Econ Pol. 2020;36(Supplement_1):397–S408. 2020. [Google Scholar]

- 51.TSI . 2020. Foreign trade Statistics”.https://biruni.tuik.gov.tr/disticaretapp/menu.zul Retrieved from. [Google Scholar]

- 52.Javorcik B. Global supply chains will not be the same in the post-COVID-19 world. COVID-19 and trade policy: Why turning inward won’t work. 2020;111:1–199. [CEPR Press] [Google Scholar]

- 53.Verikios G. The dynamic effects of infectious disease outbreaks: the case of pandemic influenza and human coronavirus. Soc Econ Plann Sci. 2020;71 doi: 10.1016/j.seps.2020.100898. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Montoya-Torres J.R., Muñoz-Villamizar A., Mejia-Argueta C. Mapping research in logistics and supply chain management during COVID-19 pandemic. Int J Logist Res Appl. 2021:1–21. [Google Scholar]

- 55.Mastronardi L., Cavallo A., Romagnoli L. Socio-Economic Planning Sciences; 2021. How did Italian diversified farms tackle Covid-19 pandemic first wave challenges? [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Shi X., Liu W., Zhang J. Present and future trends of supply chain management in the presence of COVID-19: a structured literature review. Int J Logist Res Appl. 2021:1–30. [Google Scholar]

- 57.Malefors C., Secondi L., Marchetti S., Eriksson M. Socio-Economic Planning Sciences; 2021. Food waste reduction and economic savings in times of crisis: the potential of machine learning methods to plan guest attendance in Swedish public catering during the Covid-19 pandemic. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 58.Yao H., Liu W., Wu C.H., Yuan Y.H. Socio-Economic Planning Sciences; 2021. The imprinting effect of SARS experience on the fear of COVID-19: the role of AI and big data. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Burris C., Nikolaev A., Zhong S., Bian L. Socio-Economic Planning Sciences; 2021. Network effects in influenza spread: the impact of mobility and socio-economic factors. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Abdullah M.A., Hishamuddin H., Bazin N. A System Dynamics Approach to Investigate the Effects of Disruption on The Supply Chain with A Mitigation Strategy. In IOP Conference Series: Mater Sci Eng. 2019;697(1):1–12. [Google Scholar]

- 62.Loske D. The impact of COVID-19 on transport volume and freight capacity dynamics: an empirical analysis in German food retail logistics. Transp Res Interdiscip Perspect. 2020;6:1–6. doi: 10.1016/j.trip.2020.100165. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.OECD Trade data. https://data.oecd.org/trade/trade-in-goods-and-services-forecast.htm#indicator-chart Retrieved from:

- 66.World Trade Organization (WTO) 2020. Trade set to plunge as COVID-19 pandemic upends global economy”. Press Release April 8. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.