Abstract

Glycopeptide antimicrobials are a class of naturally occurring or semi-synthetic glycosylated products that have shown antibacterial activity against gram-positive organisms by inhibiting cell-wall synthesis. In most cases, these drugs are prepared in dry powder (lyophilized) form due to chemical and physical instability in aqueous solution; however, from an economic and practical point of view, liquid formulations are preferred. Researchers have recently found ways to formulate some glycopeptide antibiotic therapeutic drugs in aqueous solution at refrigerated or room temperature. Chemical degradation can be significantly slowed by formulating them at a defined pH with specific buffers, avoiding oxygen reactive species, and minimizing solvent exposure. Sugars, amino acids, polyols, and surfactants can reduce physical degradation by restricting glycopeptide mobility and reducing solvent interaction. This review focuses on recent studies on glycopeptide antibiotic drug stability in aqueous solution. It is organized into three sections: (i) glycopeptide antibiotic instability due to chemical and physical degradation, (ii) strategies to improve glycopeptide antibiotic stability in aqueous solution, and (iii) a survey of glycopeptide antibiotic drugs currently available in the market and their stability based on published literature and patents. Antimicrobial resistance deaths are expected to increase by 2050, making heat-stable glycopeptides in aqueous solution an important treatment option for multidrug-resistant and extensively drug-resistant pathogens. In conclusion, it should be possible to formulate heat stable glycopeptide drugs in aqueous solution by understanding the degradation mechanisms of this class of therapeutic drugs in greater detail, making them easily accessible to developing countries with a lack of cold chains.

Introduction

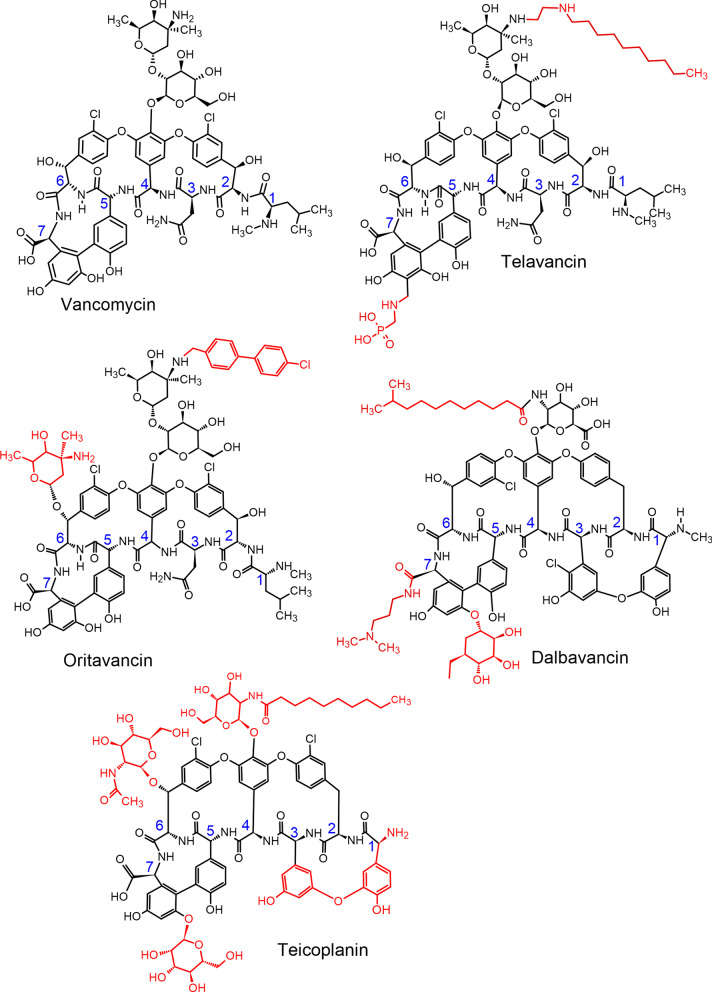

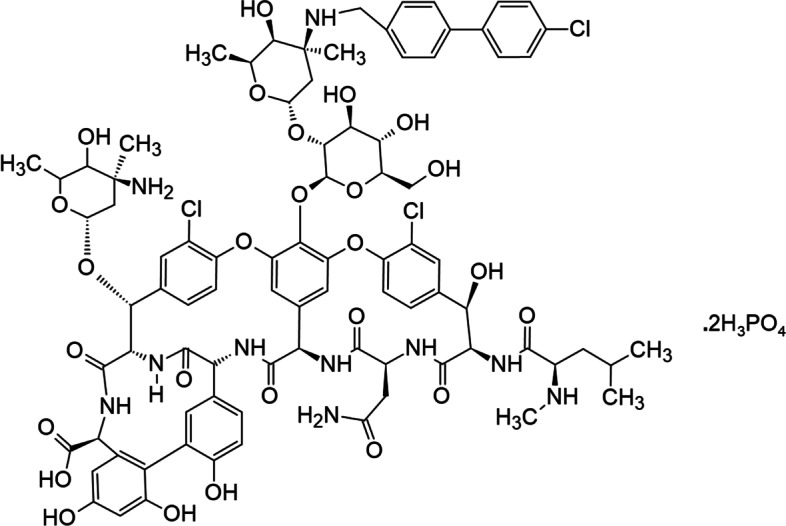

The clinical discovery of glycopeptides, a class of drugs of microbial origin based on glycosylated polycyclic nonribosomal peptides [1], as a therapeutic drug class has been a revolution in the infectious disease field. The first glycopeptide, vancomycin, was discovered during what is today known as the “Golden Age of Antibiotics,” and the use of therapeutic glycopeptides has expanded rapidly since then. This class of therapeutic drugs has rapidly grown in the drug market based on its higher efficiency and lower toxicity compared with other synthetic antibiotic drugs. Glycopeptides are natural products; however, in the last 20 years, semi-synthetic derivatives with better activity and pharmacokinetics properties have been developed [2–5], several of which are shown in Fig. 1. The shared framework of the natural glycopeptides is a cyclic peptide containing seven amino acids and two linked glycosides [6], which is shown in black in Fig. 1. Early structure function and NMR studies showed that the peptide backbone of vancomycin binds to the D-Ala-D-Ala terminus of certain peptidoglycan precursors, especially lipid II, via the formation of five hydrogen bonds, as summarized in references [6, 7]. A structural determination using the strategy of crystallizing a carrier protein bound to dalbavancin via an analog of the D-Ala-D-Ala substrate [8] showed that the drug adopts a folded-leaf structure around the substrate with residues 1–3 on one side and residues 5–7 on the other. The shared features of the cyclic peptide core of all the compounds shown in Fig. 1 suggest they all bind the D-Ala-D-Ala group in a similar fashion.

Fig. 1.

Structures of glycopeptide and lipoglycopeptide antibacterial drugs included in this review. The shared cyclopeptide frame of the drugs is shown in black, with the α-carbons of the residues numbered in blue. Key structural modifications of the basic vancomycin structure are highlighted in red [9]

Various modifications of the basic vancomycin structure, shown in red in Fig. 1, increase antibacterial potency and drug half-life in different ways. For example, the chlorine and sugar groups in oritavancin promote the formation of drug homodimers, resulting in the cooperative binding of the drug to the target [7, 10]. Interactions with the bacterial membrane have been increased semi-synthetically by modifying the lipophilic side chain of the drug [9].

Physical and chemical instability may significantly degrade glycopeptide drugs during the processing and storage of aqueous formulations [11]. Physical instability leads to processing problems such as clogged filters and precipitated solutions. Chemical instability leads to degradation during solution storage or processing. Due to their instability, these drugs must be stored at low temperatures during shelf storage and in transport. Therefore, such drugs are not easily accessible in developing countries, especially in rural and tropical areas lacking a cold chain [12, 13]. Freeze-dried (lyophilized) formulations are the preferred method to overcome peptide instability issues [14]. This is an expensive method due to high manufacturing costs and storage volumes, including vacuum-sealed vials of lyophilized powder and vials of sterile water for reconstitution.

Therefore, an aqueous preparation is preferable for peptide or glycopeptide drugs. However, stabilizing the peptide or glycopeptide drugs in aqueous formulation remains a challenge. The degradation products of peptides or glycopeptides are of concern owing to their potential for biological activity or therapeutic effects in competition with their parent drug molecule [15]. Several studies and reviews have been conducted regarding protein and peptide degradation; however, the degradation pathways of glycopeptide antibiotics currently in the market have not been characterized in depth [16, 17]. Physical instability such as adsorption [18] and aggregation, as well as chemical degradation such as hydrolysis, oxidation, and deamidation [19], are observed in peptide drugs. Information has been published on the instability and possible degradation pathways of peptides, including strategies for stabilizing them in aqueous preparations [16]. In general, peptide drugs must be stored and transported under a cold chain regimen [20].

Studies of peptide drug stabilization strategies thus provide a useful point of departure for considering the stability of glycopeptides. In this review, we discuss the factors that affect the chemical and physical integrity of glycopeptides in aqueous solution. The main difference between peptides and glycopeptides are the carbohydrate groups (glycans) linked to the side chains of the amino acid residues of the peptide core. Currently marketed glycopeptide drugs are mostly formulated in dry powder (lyophilized) form and stored at 2–8 °C, as shown in Table 1.

Table 1.

Therapeutic glycopeptide-based products in the USA

| Generic names | Trade names | Commercial source | Dosage forms | Shelf life and storage cond. | pH (adj. agent) |

Product Information |

|---|---|---|---|---|---|---|

| Vancomycin |

VANCOCIN VANCOMYCIN HCl Pulvules Firvanq |

AMI Pharmaceuticals, Inc. (VANCOCIN capsules) Mylan Institutional, LLC (VANCOMYCIN HCL powder) |

Capsule, powder for oral, powder for injection, and injection solution |

2 y at 2–8 °C |

2.5–5.5 (HCl or NaOH) |

[21, 22] |

| Telavancin | VIBATIV | Theravance Biopharma, Inc. | Powder for injection |

3 y at 2–8 °C |

4.0–5.0 | [23] |

| Dalbavacin | DALVANCE |

Allergan Pharmaceutical Company (Durata Therapeutics Inc.), Vicuron Pharmaceuticals LLC |

Powder for injection |

3 y at up to 25 °C |

4–5 (NaOH or HCl) |

[24, 25] |

| Oritavancin | ORVACTIV | Melinta Therapeutics | Powder for injection |

3 y at up to 25 °C |

3.1–4.3 (H3PO4) |

[26] |

| Teicoplanin |

TARGOCID (European Market only) |

Sanofi–Aventis | Powder for injection |

3 y at 2–8 °C |

7.2–7.8 (NaOH) |

[27] |

Results

Glycopeptide instability and degradation pathways

The integrity of glycopeptide drugs is affected by formulation, processing, storing, and shipping conditions. Like peptides, glycopeptides in aqueous solution undergo numerous degradation pathways that can be classified as chemical or physical instability. Chemical degradation of glycopeptides includes the types of bond cleavage undergone by peptides, such as hydrolysis, oxidation, and deamidization. In addition, their carbohydrate moieties may undergo racemization and isomerization reactions. Glycosylation may also modulate the precipitation and/or aggregation properties of glycopeptides relative to peptides. In this section, we review the known chemical and physical degradation pathways specific to glycopeptides.

Hydrolytic pathways

Acid-/base-catalyzed hydrolysis

Glycopeptide stability in aqueous solution depends strongly on pH. It is reported that vancomycin undergoes base-catalyzed hydrolysis at pH 8 to form a succinimide degradant (succinimide 11) [28]. Between pH 1 and 3, the acid-catalyzed reaction of vancomycin has been observed in aqueous solution [29]. The water-catalyzed reaction has been observed between pH 3 and 5.7, and between pH 5.7 and 7.0, vancomycin degradation was faster in phosphate-buffered solution, where HPO42- (K5) had the dominating catalytic effect [29] and K5 was the second order rate constant for the acid/base catalysis of vancomycin hydrochloride.

Deamidation of asparagine

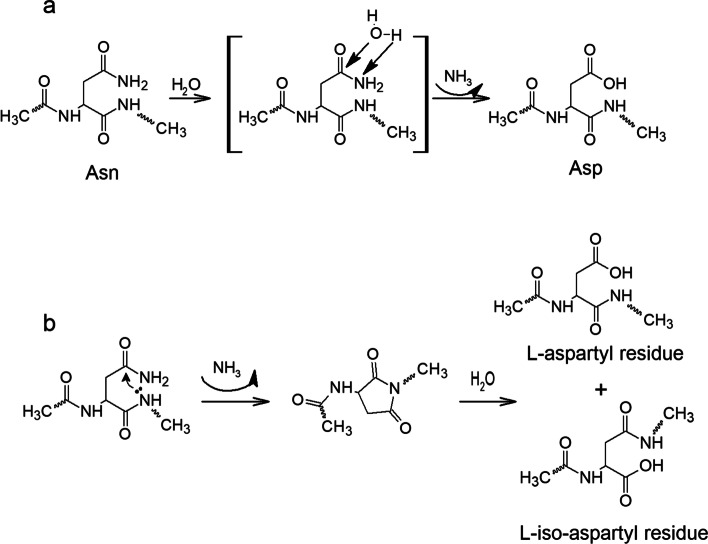

Peptides and glycopeptides containing the asparagine (Asn) residue readily undergo deamidation to form aspartic acid (Asp) under physiological conditions. Deamidation of asparagine can occur under acidic, basic, and neutral conditions. Under acidic conditions, the Asn side chain amide is directly hydrolyzed to form Asp; however, under basic and neutral conditions, a cyclic imide intermediate can be formed through an intermolecular reaction in which the carbonyl carbon of the Asn side chain is attacked by the backbone amide nitrogen of the following residue (Fig. 2b). The deamidation rate thus depends on the peptide’s amino acid sequence [30], with the highest rates observed when Asn is followed by glycine (Gly), alanine (Ala), serine(Ser), or Asp [31]. Direct hydrolysis or succinimide-mediated deamidation can also occur in peptide or glycopeptide drugs in aqueous solutions [32]. It is noteworthy that both reactions can occur in the absence of acid or base catalysis, as shown in Fig. 2 [16, 32].

Fig. 2.

Mechanisms for the deamidation of the asparagine residue via (a) direct hydrolysis and (b) formation of a succinimide intermediate [16, 28, 32]

Oxidative degradation

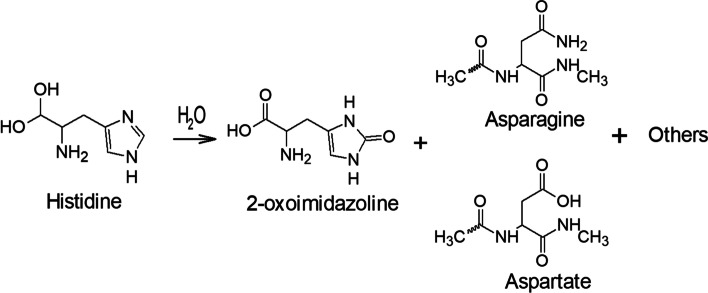

Chemical oxidation

Oxidation typically increases the electronegative atoms in a molecule, thereby producing oxygen or halogens as the electronegative heteroatoms [33]. Reactive oxygen species may react with amino acid residues such as cysteine (Cys), methionine (Met), histidine (His), tyrosine (Tyr), and tryptophan (Trp) in a peptide or glycopeptide. His, Tyr, and Trp undergo attack on their aromatic rings, whereas Cys and Met are attacked at their sulfur atoms [34]. The mechanism of His oxidation reaction is shown in Fig. 3 [16, 35].

Fig. 3.

Oxidation reaction of histidine through an oxometallocyclic intermediate to form various degradation products, such as 2-oxomidazoline, asparagine, and aspartate [35]

Light-induced oxidation

Light-induced oxidation can occur due to the absorption of ultraviolet light by aromatic side chains of a peptide or glycopeptide. As a result, the molecule is raised to an excited state, and energy transfer from the molecule to molecular oxygen converts oxygen to its reactive singlet state. Tyr can react to produce mono, di, tri, and tetrahydroxyl Tyr by-products [36]. In addition, peptide or glycopeptide aggregation can occur due to the crosslinking of oxidized Tyr residues [37].

Aggregation and precipitation

Aggregation of drug molecules may involve noncovalent forces, including ionic and hydrophobic interactions. There are five pathways via which proteins or peptides can form an aggregate, including (i) association of native monomers, (ii) aggregation of conformationally altered monomers, (iii) aggregation of chemically modified monomers, (iv) nucleation-controlled aggregation, and (v) surface-induced aggregation [38]. It is possible that precipitation can occur at higher peptide concentrations during shelf life due to these factors [39]. Peptide gel formation can also occur depending on the peptide’s amino acid sequence, concentration, interactions with salts in solution, temperature, time, pH, and agitation [40–42].

Factors to improve glycopeptide stability in aqueous formulations

Based on the above discussion, it is obvious that knowledge of a glycopeptide’s structure and its degradation pathways is key to improving its stability in aqueous solutions. The known degradation pathways, stabilization strategies, and relevant amino acid residues [16] for peptide and glycopeptide molecules are shown below.

Improving hydrolytic stability

Buffer species, pH, and oxidative optimization

The pH of a solution is the most critical factor for glycopeptide stability in aqueous formulations. For slow intravenous administration and other parenteral routes, the acceptable pH ranges are 3–10.5 and 4–9, respectively, to alleviate discomfort at the injection site [43, 44]. Hence, it is critical to study the pH range of 3–10 with different buffers during the development of a glycopeptide drug formulation [45, 46]The pH should not be less than 3.0 to avoid any direct hydrolysis of Asn side chains and to minimize hydrolytic fragmentation [38]. Deamidation is sensitive to buffer composition and concentration as well as to pH. Glycopeptide and peptide formulations with pH between 3 and 5 minimize deamidation [47–51], but hydrolysis of the Asn side chain amide can also be inhibited below neutral pH.

It is noteworthy that increased ionic strength can have either a stabilizing or a destabilizing effect, depending on the nature of the charge–charge interactions within the peptide [52–54]; however, there is no effect on deamidation or hydrolysis in small peptides [55]. Oxidative reactions can be caused by the presence of oxygen, metal ions, or light. To inhibit oxidation reactions, the use of antioxidants in solution and primary and secondary packaging is recommended to protect the sample from light and oxygen. Lower pH reduces oxidation of peptides containing Tyr and Trp [35]. Addition of an antioxidant such as bisulfite to the solution frequently results in unwanted reactions as it is a strong nucleophile and can react with peptides. Chelating agents such as EDTA, DTPA, O-hydroxyphenylacetic acid, TRIS, citric acid, and tartaric acid can be used to inhibit oxidation via complexation of copper trace metal ions, and desferal, DTPA, inositol hexaphosphate, and ethylenediamine bis(o-hydroxy-phenylacetic acid) can be used for iron ions [56]. Polyols such as mannitol, trehalose, sucrose, maltose, and raffinose can also be used to prevent peptide oxidation [57, 58].

Cosolvent effects

Polyhydric alcohols and carbohydrates can be used to reduce peptide degradation; polyols such as propylene glycol can improve stability with respect to hydrolysis [56]. Glycerol [55] and ethanol [59] can reduce deamidation in peptide aqueous formulations. Low molecular weight cosolvents such as polyethylene glycol (PEG) can also attenuate hydrolysis by reducing the aggregation of peptides[14, 39, 60].

Inhibiting aggregation and precipitation

Optimization of pH and ionic strength and the use of sugars, amino acids, and/or polyols, cyclodextrins, and surfactants can inhibit dimerization, aggregation, and precipitation [38, 61–63] Examples from the literature include the use of divalent metal ion salts such as MgCl2, CaCl2, and ZnCl2 with citrate buffer to inhibit Cys-mediated dimerization of oxytocin [64]. Polysorbate 20 and 80 reduce agitation-induced aggregation [65, 66]. Amino acids such as asparagine, glutamic acid, glycine, arginine, and lysine have been reported to reduce aggregation[67–69]. Extremolytes [70], such as polyol derivatives ectoin and hydroxyectoin [71], betain [72], trehalose [73], proline, and mannosylglycerate [74], can also be used to stabilize peptides. Extremolytes form solute hydrate clusters that are preferentially excluded from the hydrate shell of the peptide due to repulsive interactions between the extremolyte and peptide backbone. Water accumulation near peptide domains forms a compact structure with a reduced surface area that minimizes interactions, leading to aggregation [75–77].

Degradation pathways and formulation of currently marketed glycopeptide drugs

The available current research on each therapeutic glycopeptide drug (Table 1) will now be reviewed and discussed in terms of the degradation pathways summarized above.

Vancomycin

Vancomycin is the oldest and therefore one of the most commonly used glycopeptide antibiotics [1, 78, 79]. It is recommended for skin, bloodstream, and various bone and joint infections. The increasing prevalence of methicillin-resistant Staphylococcus aureus (MRSA) infections has made vancomycin the treatment of choice for such conditions, and it has been used extensively. However, the overuse of this antibiotic has produced S. aureus strains with reduced susceptibility to vancomycin, thereby compromising its antistaphylococcal activity and threatening to render vancomycin useless as a therapeutic [80].

A useful pharmacodynamic metric for vancomycin’s effectiveness in treating S. aureus, including methicillin-susceptible S. aureus (MSSA), MRSA, and vancomycin-intermediate S. aureus (VISA) strains, is the ratio of area under curve (AUC) to minimum inhibitory concentration (MIC) as measured in neutropenic mouse models [81]. An AUC/MIC ratio of ≥ 400 proves the clinical effectiveness of vancomycin [81]. Studies show that in vivo isolates of the drug develop decreased susceptibility but not of sufficient magnitude to cross a breakpoint threshold [81]. The resistance may be unstable and could result from selective processes that occur in MRSA clinical strains during vancomycin therapy, leading to a decrease in the apparent effectiveness of vancomycin in vivo [82]. Vancomycin is a tricyclic glycopeptide comprising a heptapeptide chain that forms a tricyclic structure along with an attached disaccharide that is composed of vancosamine and glucose, shown in Fig. 4 [83]. Commercial vancomycin is a hydrochloride salt and is most soluble at pH 3–5 [84]. Its solubility decreases at higher pH values, and it is unstable in alkaline solutions [84].

Fig. 4.

Structural formula of vancomycin [83]

Vancomycin in aqueous solution is unstable, forming degradation products that have been designated CDP-1 or CDP-1-M and CDP-1-m (collectively, the CDP-1s) [28, 84]. CDP-1 products result from hydrolysis, deamidation, and rearrangement of the asparagine moiety in the vancomycin structure, as shown in Fig. 5 [28]. These degradation products precipitate in aqueous solution and are therefore unsafe for injection. To avoid such degradation, vancomycin is formulated for therapeutic use as a dry powder in capsules for oral administration [21] and as a sterile dry powder in vials reconstituted with sterile water and diluted with dextrose or saline solution to a final concentration of 5 mg/mL [22].

Fig. 5.

Deamidation, hydrolysis, and rearrangement of vancomycin to form degradation products [28]

A stable, ready-to-use, room-temperature aqueous solution of vancomycin comprising vancomycin, Trp, and water has been developed [84]. Trp inhibits CDP-1 degradation by forming noncovalent, reversible, and dissociable molecular complexes via hydrophobic interactions with vancomycin [84]. The optimal molar ratio of vancomycin to Trp in this complex is between 5:1 and 1:1. Another ready-to-use formulation of this glycopeptide has been stabilized below 25 ºC using a cosolvent such as PEG, N-acetyl-D-alanine, and L-lysine hydrochloride (hydrophilic amino acid) in water at a pH between 4.5 and 5.5 [84, 85]. Additionally, sulfobutylether-betacyclodextrin inhibited chemical and physical degradation of vancomycin in aqueous solution for 4 weeks at room temperature [86].

Telavancin

Telavancin is a second-generation lipoglycopeptide that is essentially a chemical modification of vancomycin. It has a lipophilic tail to the vancosamine sugar and contains a hydrophilic group at the 4′ position of aromatic amino acid 7. It has been approved for the treatment of gram-positive complications of bacterial pneumonia caused by S. aureus and is being evaluated in patients with S. aureus and S. aureus right infective endocarditis [87]. Telavancin exhibits rapid bactericidal action that is thought to arise from cooperative binding of the nascent peptidoglycan to the acyl-D-Alanyl-D-Alanine subunit in combination with the insertion of its lipophilic tail into the bacterial membrane. This disrupts the membrane function by inducing and depolarizing the membrane although it apparently does not cause cell lysis [87].

Resistance to telavancin is similar to that for vancomycin, namely the VanA modification of D-Ala-D-Ala to D-Ala-D-Lac, and cell-wall thickening that characterizes the VISA strain and other VISA phenotypes. In vancomycin-resistant enterococci (VREs), telavancin induces the expression of VanA but not does induce VanB in VREs carrying that gene. In addition, telavancin reduces the level of the peptidoglycan precursor with terminal D-Ala-D-Ala in the vanA strain through its effect on the D, D-dipeptidase, but this does not occur in the vanB strain [87]. High levels of telavancin resistance in MRSA, MSSA, or VREs were not observed in in vitro resistance selection studies. Continuous monitoring shows that telavancin remains active in vivo against a range of gram-positive pathogens [87, 88]. In addition, telavancin remains effective against MRSA according to the results of Phase 3 clinical trials in vivo [89]. Use of telavancin may be a potential treatment option for patients with MRSA bacteremia as salvage therapy [90].

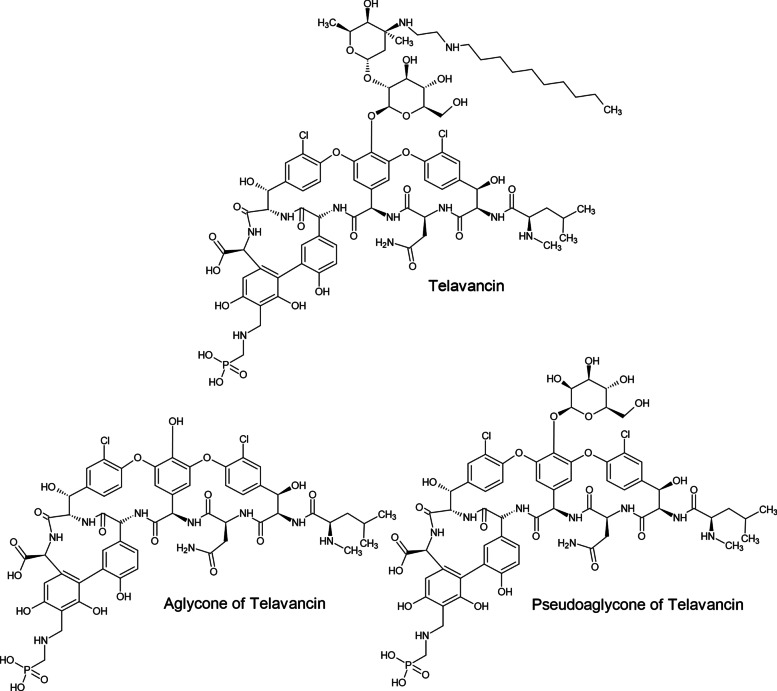

At ambient temperatures, telavancin hydrochloride salt forms two principal degradation products, pseudoaglycone and aglycone, which appear as impurities of telavancin in aqueous solution, as shown in Fig. 6 [91]. The pseudoaglycone degradant develops from the hydrolysis of the lipidated vancosamine moiety, and the aglycone degradant develops from the hydrolysis of the glucose moiety of telavancin [91]. To avoid these types of degradation, telavancin is formulated for therapeutic use as a dry powder filled in vials and stabilized in hydroxypropylbetadex and mannitol. It is generally reconstituted with sterile water, 5% dextrose injection or 0.9% sodium chloride injection to 15 mg/ml, pH adjusted to between 4.0 and 5.0 with sodium hydroxide or hydrochloric acid, and subsequently diluted with 5% dextrose injection or 0.9% sodium chloride injection or lactated ringer’s injection to a final concentration of 0.6–8 mg/mL for doses less than 150 mg or greater than 800 mg. For doses of 150–800 mg, the appropriate volume of reconstituted solution as per package inserts must be further diluted in 100–250 ml prior to infusion [23].

Fig. 6.

Structures of telavancin and its pseudoaglycone and aglycone degradation products [91]

Teicoplanin

Teicoplanin is another semi-synthetic glycopeptide antibiotic isolated from the fermentation broth of a strain of Actinoplanes teichomyceticus [92], consisting of five homologs with a common aglycone [93]. The aglycone contains seven amino acids bound by peptide and ether bonds to form a four-ring system and the homologs differ in the fatty acyl side chain attached to the sugar [94, 95] (Fig. 7 and Table 2). Teicoplanin usage in treatments showed fewer patient side effects in comparison with other glycopeptide antibiotics [92]. Teicoplanin is exceptional among the vancomycin-type lipoglycopeptides in that it has a membrane-anchoring tail but does not dimerize [95].

Fig. 7.

Structural formula of teicoplanin. The structures of the R group for the different major homologs of teicoplanin are given in Table 2 [92]

Table 2.

Lipophilic side chains for the different isoforms of teicoplanin according to the nomenclature of reference [92]

| Teicoplanin isoform | R side chain |

|---|---|

| A2-1 |

|

| A2-2 |

|

| A2-3 |

|

| A2-4 |

|

| A2-5 |

|

Teicoplanin degradation by oxidation and hydrolysis forms triphenyl ether, diphenyl ether, and diphenyl moieties [96]. Teicoplanin is formulated for therapeutic use as a dry powder filled in vials; it is generally reconstituted with sterile water to 67 mg/mL or 133 mg/mL and subsequently diluted with 0.9% sodium chloride, ringer solution, ringer-lactate solution, or injection solutions with 5% or 10% dextrose, 1.36% or 3.86% glucose, 0.18% saline with 4% glucose, or 0.45% saline with 5% glucose [27].

Dalbavancin

Dalbavancin was developed over 15 years by four different companies before receiving final approval for clinical use in 2014. It is a second-generation teicoplanin-type glycopeptide obtained via amidation of the peptide carboxyl group of amino acid 7 of a natural glycopeptide with 3-(dimethylamino)-1-propylamine. The introduction of this substituent enhances efficacy against staphylococci, especially those that are coagulase-negative [87]. It has been approved for treating acute gram-positive bacterial skin and skin structural infections in adult patients and has been evaluated for efficacy and safety in adult patients with osteomyelitis. In addition, it is the only Food and Drug Administration–approved product for treating infections via susceptible strains of S. aureus, such as MRSA, Streptococcus pyogenes, Streptococcus agalactiae, and the Streptococcus anginosus group [97]. Like other lipoglycopeptides, dalbavancin targets the C-terminal acyl-D-Ala-D-Ala subunit of the peptidoglycan precursor. It has in vitro bacteriocidal activity against a wide range of gram-positive bacteria and an extended half-life that attributed to its interaction with serum proteins [87]. In addition, the positively charged C-terminal of dimethylaminopropyl group can interact with the negative phospholipid headgroups of the bacterial membrane. Although vancomycin-type glycopeptides dimerize cooperatively with ligand binding, the dimerization of dalbavancin is strongly anti-cooperative with ligand binding [98]. Dalbavancin is a mixture of five closely related active factors that have been designated A0, A1, B0, B1, and B2, as summarized in Table 3. Factor B0 is the main component of dalbavancin [24]. It is worth noting that these homologs share the same core structure but differ by the presence of an additional methyl group (R2) on the fatty acid side chain and/or a terminal amino group of the structure of the N-acylaminoglucuronic acid moiety (R1) [24], as depicted in Fig. 8.

Table 3.

Substitution patterns for the homologs of dalbavancin according to the nomenclature of reference [24, 25]

| Dalbavancin | R1 | R2 | Molecular formula | Molecular weight (Daltons)a |

|---|---|---|---|---|

| A0 | CH(CH3)2 | H | C87H98N10O28Cl2 ·1.6 HCl | 1802.7 |

| A1 | CH2CH2CH3 | H | C87H98N10O28Cl2 ·1.6 HCl | 1802.7 |

| B0 | CH2CH(CH3)2 | H | C88H100N10O28Cl2 ·1.6 HCl | 1816.7 |

| B1 | CH2CH2CH2CH3 | H | C88H100N10O28Cl2 ·1.6 HCl | 1816.7 |

| B2 | CH2CH(CH3)2 | CH3 | C89H102N10O28Cl2 ·1.6 HCl | 1830.7 |

| Mannosyl aglycone [25] | N/A | H | C70H69N9O22Cl2b | 1459.27 |

a Specified molecular weight for anhydrous free base

b Molecular Formula derived from acylglucoronamine-free dalbavancin ([25], Structure II)

Fig. 8.

Structural formula of dalbavancin. The structures of the R1 and R2 groups for the different homologs of dalbavancin are given in Table 3 [24, 25]

Glycopeptides, particularly dalbavancin, are unstable in aqueous solution due to their glycosidic linkages [25]. The primary degradant of dalbavancin in aqueous solution is mannosyl aglycone (MAG), which is produced via hydrolysis of the glycosidic linkage. To avoid such degradation, dalbavancin is formulated for therapeutic use as a dry powder stabilized in mannitol and lactose, filled in vials, and generally reconstituted with sterile water and 5% dextrose to a concentration of 20 mg/ml followed by dilution with 5% dextrose to a final concentration of 1–5 mg/mL [24, 25]. In a 36-month study of lyophilized dalbavancin at 5 °C, MAG increased (2.9%) in proportion to the decrease in the primary dalbavancin factor B0 (3.6%). In addition, MAG increased (~ 10.2%) over 12 months at 25 °C as the primary dalbavancin factor B0 decreased (~ 8.5%); however, other dalbavancin factors such as A0, A1, B1, B2, and related substances, as well as the pH, remained unchanged, and the water content increased by 1.6% [25].

Oritavancin

Oritavancin is another second-generation semi-synthetic glycopeptide drug derived by chemically modifying the natural product chloroeremomycin and substituting N-alkyl-p-chlorophenylbenzyl on the disaccharide epi-vancosamine that is bound to the ring of amino acid 4 [87, 99]. These modifications were motivated by the vancomycin resistance reported in Enterococcus fesium and Enterococcus faecalis that motivated synthesis [99]. Oritavancin was clinically approved in 2014 for the treatment of gram-positive-related ABSSSI in adults [99]. As shown in Fig. 9, oritavancin differs from vancomycin in that it has two l-4-epi-vancosamine subunits [99] on amino acid rings 4 and 6 rather than a single l-vancosamine subunit at position 4. The addition of l-4-epi-vancosamine to chloroeremomycin provides additional benefits by enhancing antibacterial activity against vancomycin-sensitive bacteria relative to vancomycin.

Fig. 9.

Structural formula of oritavancin [99]

Unlike telavancin and dalbavancin, oritavancin is the only lipoglycopeptide with potent activity against both VRSA and VanA-type VREs most likely because of its multiple mechanisms of action. It can also interfere with peptide transfer by binding to the pentaglycyl crosslinking segment of lipid II, thereby maintaining its affinity for the modified terminus of the peptidoglycan precursor in vancomycin-resistant strains. Furthermore, enhancement of its interaction with lipid II was achieved by fixing oritavancin to the cell membrane via the hydrophobic N-alkyl-p-chlorophenylbenzyl substituent, thereby promoting oritavancin dimerization by increasing its affinity to the target [100, 101]. Thus, the interaction of oritavancin with the membrane provides its third mechanism of action, namely, disrupting the bacterial membrane integrity by depolarization and increasing its permeability [101].

During formulation processing, oritavancin is broken down into impurities by deglycosylation, hydrolysis of amide bonds, and changes in configuration at numerous structural elements within the molecule [102]. To avoid such degradation, therapeutic oritavancin is prescribed as a dry powder that is stabilized with mannitol and filled into vials. After reconstitution with water to 10 mg/mL, the pH is usually adjusted to 3.1–4.3 with phosphate buffer and diluted with a 5% dextrose injection to a final concentration of 1.2 mg/mL [26].

Discussion

According to the World Health Organization (WHO), drug resistance could cause 10 million deaths annually by 2050, and by 2030, antimicrobial resistance (AMR) could force up to 24 million people into extreme poverty. In 2019, the deaths of 4.95 million people were associated with drug resistant bacterial infections, and 1.27 million deaths were directly caused by AMR [103]. It is possible to reduce these deaths substantially by providing tropical countries with heat stable aqueous solution therapeutic antibiotic glycopeptide drugs. Use of lyophilized drug products is a challenge due to the absence of cold chains.

Dalbavancin (a second generation lipoglycopeptide antibiotic) is the only approved FDA product for treating infections caused by susceptible strains of S. aureus including MRSA, Streptococcus pyogenes, Streptococcus agalactiae, and the Streptococcus anginosus group [97]. In addition, dalbavancin is an emerging treatment option for most of the multidrug-resistant (MDR) and extensively drug-resistant (XDR) Gram-positive cocci bacteria [104]. Moreover, this important antibiotic lipoglycopeptide drug is also a novel candidate for COVID-19 treatment, where it blocks SARS-CoV-2 binding to its receptor ACE2 and reduces viral spread and pathogenesis in animal models [105]. Dalbavancin forms mannosyl aglycone (MAG), the hydrolyzed glycosidic linkage degradant in aqueous solution, and is therefore formulated in lyophilized form to avoid the formation of MAG. To reduce AMR deaths, especially in tropical countries due to a lack of cold chain, a heat stable injection of this important therapeutic drug is a necessity.

Besides dalbavancin, other glycopeptide therapeutic drugs such as vancomycin, telavancin, teicoplanin, and oritavancin have potential for reducing AMR deaths; however, except vancomycin, all other glycopeptides are in lyophilized form. In recent development, a stable, ready to use, room-temperature aqueous solution of vancomycin comprising, Trp, and water has been developed, where Trp inhibits CDP-1 degradation products by forming noncovalent, reversible, and dissociable molecular complexes via hydrophobic interaction with vancomycin. Another ready to use formulation has been stabilized below 25 °C using a cosolvent such as PEG, N-acetyl-D-alanine, and L-lysine hydrochloride in water at a pH between 4.5 and 5.5.

It is obvious from above discussion that a heat stable liquid solution of antibiotic glycopeptide drugs is urgently needed to reduce AMR deaths in developing countries, including dalbavancin, which is the only FDA-approved drug for MRSA, Streptococcus pyogenes, Streptococcus agalactiae, and the Streptococcus anginosus group, as well as a promising treatment option for most Gram-positive cocci with MRD/XRD.

Conclusion

Most glycopeptides in aqueous solutions are unstable for long-term storage. However, a careful, thorough understanding of each glycopeptide structure and its degradation pathways such as hydrolysis of the glycosidic bond in most cases, oxidation, and deamidation or deamination should help to design formulations with specific buffer, sugar, amino acids, and excipients to significantly overcome the challenges of chemical and physical degradations. The growing number of AMR deaths predicted by 2050 makes it essential to develop a heat-stable glycopeptide antibiotic therapeutic drugs in aqueous solution that can reduce death rates worldwide, particularly in tropical countries. Aqueous solutions of vancomycin, the oldest antibiotic glycopeptide, are stable at room temperature, although other glycopeptides are yet to be evaluated. In order to formulate this important class of pharmaceuticals for heat stability in aqueous solutions and easy accessibility in developing countries without cold chains, a deeper understanding of degradation reaction mechanisms across the range of glycopeptide drugs must be developed.

The description and discussion of degradation pathways and strategies to improve the stability of aqueous solutions of glycopeptides in this review has largely been based on available literature for peptide and protein formulations. Because glycopeptides differ from proteins in several important respects, a complete understanding of glycopeptide drug degradation mechanisms of glycopeptide drugs has yet to be reached, particularly for chemically modified natural products, which may undergo reactions quite different from proteins. Since all glycopeptide antibiotic drugs contain the basic core structure of vancomycin, the development of a heat stable liquid solution for any one of them should provide better strategies for improving aqueous formulations for the entire family of glycopeptide antibiotic drugs.

Acknowledgements

This work is supported by Hikma Pharmaceuticals.

Authors’ contributions

Sardar M. Jakaria conducted the initial literature review and drafted the work. David E. Budil and James Murtagh critically reviewed and revised the draft for intellectual content. All authors agree to be accountable for all aspects of this work and investigate and resolve any questions regarding the accuracy or integrity of any part of this work.

Funding

The authors have received no payment for the preparation of this manuscript.

Availability of data and materials

Not applicable.

Declarations

Competing interests

The authors declare that they have no competing interests.

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Sardar M. Jakaria, Email: sjakaria@hikma.com

David E. Budil, Email: d.budil@northeastern.edu

James Murtagh, Email: jimmur55@gmail.com.

References

- 1.Large DG, Warren CD. Glycopeptides and related Compounds: synthesis, analysis and applications. Boca Raton, FL: CRC Press; 1997. [Google Scholar]

- 2.Kahne D, Leimkuhler C, Lu W, Walsh C. Glycopeptide and lipoglycopeptide antibiotics. Chem Rev. 2005;105:425–448. doi: 10.1021/cr030103a. [DOI] [PubMed] [Google Scholar]

- 3.Malabarba A, Ciabatti R. Glycopeptide derivatives. Curr Med Chem. 2001;8:1759–1773. doi: 10.2174/0929867013371716. [DOI] [PubMed] [Google Scholar]

- 4.van Bambeke F, van Laethem Y, Courvalin P, Tulkens PM. Glycopeptide antibiotics: from conventional molecules to new derivatives. Drugs. 2004;64:913–936. doi: 10.2165/00003495-200464090-00001. [DOI] [PubMed] [Google Scholar]

- 5.van Bambeke F. Glycopeptides in clinical development: pharmacological profile and clinical perspectives. Curr Opin Pharmacol. 2004;4:471–478. doi: 10.1016/j.coph.2004.04.006. [DOI] [PubMed] [Google Scholar]

- 6.van Bambeke F, Virgincar N, MacGowan A Glycopeptides (dalbavancin, oritavancin, teicoplanin, telavancin, vancomycin): antimicrobe.org; 2010 [Available from: http://www.antimicrobe.org/d14.asp

- 7.Müller A, Klöckner A, Schneider T. Targeting a cell wall biosynthesis hot spot. Nat Prod Rep. 2017;34:909–932. doi: 10.1039/C7NP00012J. [DOI] [PubMed] [Google Scholar]

- 8.Economou NJ, Nahoum V, Weeks SD, Grasty KC, Zentner IJ, Townsend TM, et al. A carrier protein strategy yields the structure of dalbavancin. J Am Chem Soc. 2012;134(10):4637–4645. doi: 10.1021/ja208755j. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Zeng D, Warren CD, Hartsell TL, Cano RJ, Adams S, Schuyler JA, et al. Approved glycopeptide antibacterial drugs: mechanism of action and resistance. Cold Spring Harb Perspect Med. 2016;6(12):a026989. doi: 10.1101/cshperspect.a026989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Beauregard DA, Williams DH, Gwynn MN, Knowles DJ. Dimerization and membrane anchors in extracellular targeting of vancomycin group antibiotics. Antimicrob Agents Chemother. 1995;39:781–785. doi: 10.1128/AAC.39.3.781. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Manning MC, Patel K, Borchardt RT. Stability of protein pharmaceuticals. Pharm Res. 1989;6:903–918. doi: 10.1023/A:1015929109894. [DOI] [PubMed] [Google Scholar]

- 12.Hawe A, Poole R, Romeijn S, Kasper P, van der Heijden R, Jiskoot W. Towards heat-stable oxytocin formulations: analysis of degradation kinetics and identification of degradation products. Pharm Res. 2009;26:1679–1688. doi: 10.1007/s11095-009-9878-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.International conference on harmonisation; stability data package for registration applications in climatic zones III and IV; stability testing of new drug substances and products; availability. Notice. Fed Regist. 2003;68:65717–8 [PubMed]

- 14.Hovgaard L, Frokjaer S, van de Weert M. Pharmaceutical formulation and development of peptides and proteins. Boca Raton: CRC Press; 1999. [Google Scholar]

- 15.Lee AC, Harris JL, Khanna KK, Hong JH. A comprehensive review on current advances in peptide drug development and design. Int J Mol Sci. 2019;20(10):2383–2405. doi: 10.3390/ijms20102383. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Avanti C (2012) Innovative strategies for stabilization of therapeutic peptides in aqueous formulations. University of Grönigen. https://www.academia.edu/10381034/Innovative_strategies_for_stabilization_of_therapeutic_peptides_in_aqueous_formulations

- 17.Zapadka KL, Becher FJ, Gomes dos Santos AL, Jackson SE. Factors affecting the physical stability (aggregation) of peptide therapeutics. Interface Focus. 2017;7(6):20170030. doi: 10.1098/rsfs.2017.0030. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Anik ST, Jiin-Yu H. Adsorption of D-Nal (2) Int J Pharm. 1983;16:181–190. doi: 10.1016/0378-5173(83)90055-8. [DOI] [Google Scholar]

- 19.Badelin VG, Kulikov OV, Vatagin VS, Udzig E, Zielenkiewicz A, Zielenkiewicz W, et al. Physico-chemical properties of peptides and their solutions. Thermochim Acta. 1990;169:81–93. doi: 10.1016/0040-6031(90)80135-L. [DOI] [Google Scholar]

- 20.Zahn M, Kållberg PW, Slappendel GM, Smeenge HM. A risk-based approach to establish stability testing conditions for tropical countries. J Pharm Sci. 2006;95:946–965. doi: 10.1002/jps.20584. [DOI] [PubMed] [Google Scholar]

- 21.VANCOCIN® (vancomycin hydrochloride capsules USP) [package insert] nlm.nih.gov: ANI Pharmaceuticals, Inc.; [cited 2022 8/5/2022]. Available from: https://www.anipharmaceuticals.com/products-detail.php?group=VANCOCIN%C2%AE+%28vancomycin+hydrochloride+capsules+USP%29&

- 22.VANCOMYCIN HYDROCHLORIDE injection, powder, lyophilized, for solution [package insert] nlm.nih.gov: Mylan Institutional LLC; [cited 2022 8/5/2022]. Available from: https://dailymed.nlm.nih.gov/dailymed/lookup.cfm?setid=2dc7b3d6-3874-40ac-b8aa-7bcfe2dc0cdf

- 23.VIBATIV, Telavancin hydrochloride injection, powder, lyophilized for solution (label) National Library of Medicine: Theravance, Inc.; (2009). [Available from: https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=9fc67b76-9ba1-45ec-9749-ca3f3a6477d9]

- 24.DALVANCE, Dalbavancin injection, powder, lyophilized for solution [package insert]: Durata Therapeutics Inc (2014) ; [Available from: https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=4b4674d8-4d1e-4728-8465-d42ada33fa5c]

- 25.Stogniew M, Colombo L (2012) R. C, inventors; Vicuron Pharmaceuticals LLC, assignee. Dalbavancin compositions for treatment of bacterial infections patent US8143212B2.

- 26.ORVACTIV, Oritavancin injection, powder, lyophilized for solution [package insert] Melinta Therapeutics, LLC (2014) ; [Available from: https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=ff09a726-9f9b-4e30-b509-396781293220]

- 27.TARGOCID (teicoplanin) 400 mg powder for solution for injection/infusion or oral solution [package insert]: Sanofi 2021 [Available from: https://www.medicines.org.uk/emc/product/2927/smpc

- 28.Harris CM, Kopecka H, Harris TM (1983) Vancomycin: structure and transformation to CDP-I. J Am Chem Soc 105(23):6915–22

- 29.Mathew M, Gupta VD. Stability of vancomycin hydrochloride solutions at various pH values as determined by high-performance liquid chromatography. Drug Dev Ind Pharm. 1995;21:257–264. doi: 10.3109/03639049509048108. [DOI] [Google Scholar]

- 30.Patel K, Borchardt RT. Chemical pathways of peptide degradation. III. Effect of primary sequence on the pathways of deamidation of asparaginyl residues in hexapeptides. Pharm Res. 1990;7:787–793. doi: 10.1023/A:1015999012852. [DOI] [PubMed] [Google Scholar]

- 31.Payne RW, Manning MC. Peptide formulation: challenges and strategies. Innov Pharm Technol. 2009;28:64–68. [Google Scholar]

- 32.Catak S, Monard G, Aviyente V, Ruiz-López MF. Deamidation of asparagine residues: direct hydrolysis versus succinimide-mediated deamidation mechanisms. J Phys Chem A. 2009;113:1111–1120. doi: 10.1021/jp808597v. [DOI] [PubMed] [Google Scholar]

- 33.March J. Advanced organic chemistry—reactions, mechanisms, and structure (localized chemical bonding) 4. New York: Wiley; 1992. [Google Scholar]

- 34.Li S, Schöneich C, Borchardt RT. Chemical pathways of peptide degradation. VIII. Oxidation of methionine in small model peptides by prooxidant/transition metal ion systems: influence of selective scavengers for reactive oxygen intermediates. Pharm Res. 1995;12:348–355. doi: 10.1023/A:1016240115675. [DOI] [PubMed] [Google Scholar]

- 35.Li S, Schöneich C, Borchardt RT. Chemical instability of protein pharmaceuticals: mechanisms of oxidation and strategies for stabilization. Biotechnol Bioeng. 1995;48:490–500. doi: 10.1002/bit.260480511. [DOI] [PubMed] [Google Scholar]

- 36.Zhang J, Kalonia DS. The effect of neighboring amino acid residues and solution environment on the oxidative stability of tyrosine in small peptides. AAPS Pharm Sci Tech. 2007;8:E102. doi: 10.1208/pt0804102. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Rathore N, Rajan RS. Current perspectives on stability of protein drug products during formulation, fill and finish operations. Biotechnol Prog. 2008;24:504–514. doi: 10.1021/bp070462h. [DOI] [PubMed] [Google Scholar]

- 38.Manning MC, Chou DK, Murphy BM, Payne RW, Katayama DS. Stability of protein pharmaceuticals: an update. Pharm Res. 2010;27:544–575. doi: 10.1007/s11095-009-0045-6. [DOI] [PubMed] [Google Scholar]

- 39.Powell MF, Sanders LM, Rogerson A, Si V. Parenteral peptide formulations: chemical and physical properties of native luteinizing hormone-releasing hormone (LHRH) and hydrophobic analogues in aqueous solution. Pharm Res. 1991;8:1258–1263. doi: 10.1023/A:1015847628047. [DOI] [PubMed] [Google Scholar]

- 40.Tan MM, Corley CA, Stevenson CL. Effect of gelation on the chemical stability and conformation of leuprolide. Pharm Res. 1998;15:1442–1448. doi: 10.1023/A:1011914007940. [DOI] [PubMed] [Google Scholar]

- 41.Braun GA, Ary BE, Dear AJ, Rohn MCH, Payson AM, Lee DSM, et al. On the mechanism of self-assembly by a hydrogel-forming peptide. Biomacromolecules. 2020;21:4781–4794. doi: 10.1021/acs.biomac.0c00989. [DOI] [PubMed] [Google Scholar]

- 42.Nanda J, Biswas A, Banerjee A. Single amino acid based thixotropic hydrogel formation and pH-dependent morphological change of gel nanofibers. Soft Matter. 2013;9:4198–4208. doi: 10.1039/c3sm27050e. [DOI] [Google Scholar]

- 43.Brazeau GA, Cooper B, Svetic KA, Smith CL, Gupta P. Current perspectives on pain upon injection of drugs. J Pharm Sci. 1998;87:667–677. doi: 10.1021/js970315l. [DOI] [PubMed] [Google Scholar]

- 44.Extemp.ie. Formulation of Parenteral Products 2021 [cited 2022 8/3/2022]. Available from: http://www.extemp.ie/general-methods/sterile-preparations/parenterals

- 45.Jorgensen L, Hostrup S, Moeller EH, Grohganz H. Recent trends in stabilising peptides and proteins in pharmaceutical formulation–considerations in the choice of excipients. Expert Opin Drug Deliv. 2009;6:1219–1230. doi: 10.1517/17425240903199143. [DOI] [PubMed] [Google Scholar]

- 46.Cleland JL, Powell MF, Shire SJ. The development of stable protein formulations: a close look at protein aggregation, deamidation, and oxidation. Crit Rev Ther Drug Carrier Syst. 1993;10:307–377. [PubMed] [Google Scholar]

- 47.Patel K, Borchardt RT. Chemical pathways of peptide degradation. II. Kinetics of deamidation of an asparaginyl residue in a model hexapeptide. Pharm Res. 1990;7:703–711. doi: 10.1023/A:1015807303766. [DOI] [PubMed] [Google Scholar]

- 48.Good NE, Winget GD, Winter W, Connolly TN, Izawa S, Singh RMM. Hydrogen ion buffers for biological research. Biochemistry. 1966;5:467–477. doi: 10.1021/bi00866a011. [DOI] [PubMed] [Google Scholar]

- 49.Wang W, Martin-Moe S, Pan C, Musza L, Wang YJ. Stabilization of a polypeptide in non-aqueous solvents. Int J Pharm. 2008;351:1–7. doi: 10.1016/j.ijpharm.2007.09.012. [DOI] [PubMed] [Google Scholar]

- 50.Bell LN. Peptide stability in solids and solutions. Biotechnol Prog. 1997;13:342–346. doi: 10.1021/bp970057y. [DOI] [Google Scholar]

- 51.Jacob S, Shirwaikar AA, Srinivasan KK, Alex J, Prabu SL, Mahalaxmi R, et al. Stability of proteins in aqueous solution and solid state. Indian J Pharm Sci. 2006;68(2):154–163. doi: 10.4103/0250-474X.25708. [DOI] [Google Scholar]

- 52.Zheng K, Middaugh CR, Siahaan TJ. Evaluation of the physical stability of the EC5 domain of E-cadherin: effects of pH, temperature, ionic strength, and disulfide bonds. J Pharm Sci. 2009;98:63–73. doi: 10.1002/jps.21418. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Bursakov SA, Carneiro C, Almendra MJ, Duarte RO, Caldeira J, Moura I, et al. Enzymatic properties and effect of ionic strength on periplasmic nitrate reductase (NAP) from Desulfovibrio desulfuricans ATCC 27774. Biochem Biophys Res Commun. 1997;239:816–822. doi: 10.1006/bbrc.1997.7560. [DOI] [PubMed] [Google Scholar]

- 54.O’Neill P, Davies S, Fielden EM, Calabrese L, Capo C, Marmocchi F, et al. The effects of pH and various salts upon the activity of a series of superoxide dismutases. Biochem J. 1988;251:41–46. doi: 10.1042/bj2510041. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Tyler-Cross R. Effects of amino acid sequence, buffers, and ionic strength on the rate and mechanism of deamidation of asparagine residues in small peptides. J Biol Chem. 1991;266:22549–22556. doi: 10.1016/S0021-9258(18)54607-X. [DOI] [PubMed] [Google Scholar]

- 56.Parkins DA, Lashmar UT. The formulation of biopharmaceutical products. Pharm Sci Technol Today. 2000;3:129–137. doi: 10.1016/S1461-5347(00)00248-0. [DOI] [PubMed] [Google Scholar]

- 57.Li S, Patapoff TW, Nguyen TH, Borchardt RT. Inhibitory effect of sugars and polyols on the metal-catalyzed oxidation of human relaxin. J Pharm Sci. 1996;85:868–872. doi: 10.1021/js9504550. [DOI] [PubMed] [Google Scholar]

- 58.Kamberi M, Kim YJ, Jun B, Riley CM. The effects of sucrose on stability of human brain natriuretic peptide [hBNP (1–32)] and human parathyroid hormone [hPTH (1–34)] J Pept Res. 2005;66:348–356. doi: 10.1111/j.1399-3011.2005.00290.x. [DOI] [PubMed] [Google Scholar]

- 59.Brennan TV, Clarke S. Spontaneous degradation of polypeptides at aspartyl and asparaginyl residues: effects of the solvent dielectric. Protein Sci. 1993;2:331–338. doi: 10.1002/pro.5560020305. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Neelon K, Schreier HJ, Meekins H, Robinson PM, Roberts MF. Compatible solute effects on thermostability of glutamine synthetase and aspartate transcarbamoylase from Methanococcus jannaschii. Biochim Biophys Acta Proteins Proteom. 2005;1753:164–173. doi: 10.1016/j.bbapap.2005.08.009. [DOI] [PubMed] [Google Scholar]

- 61.Bak A, Leung D, Barrett SE, Forster S, Minnihan EC, Leithead AW, et al. Physicochemical and Formulation Developability Assessment for therapeutic peptide Delivery—A primer. AAPS J. 2015;17:144–155. doi: 10.1208/s12248-014-9688-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Maggio ET. Use of excipients to control aggregation in peptide and protein formulations. J Excipients and Food Chem. 2010;1:40–49. [Google Scholar]

- 63.Loftsson T, Brewster ME. Pharmaceutical applications of cyclodextrins: basic science and product development. J Pharm Pharmacol. 2010;62:1607–1621. doi: 10.1111/j.2042-7158.2010.01030.x. [DOI] [PubMed] [Google Scholar]

- 64.Avanti C, Permentier HP, Dam AV, Poole R, Jiskoot W, Frijlink HW, et al. A new strategy to stabilize oxytocin in aqueous solutions: II. Suppression of cysteine-mediated intermolecular reactions by a combination of divalent metal ions and citrate. Mol Pharm. 2012;9:554–562. doi: 10.1021/mp200622z. [DOI] [PubMed] [Google Scholar]

- 65.Chou DK, Krishnamurthy R, Randolph TW, Carpenter JF, Manning MC. Effects of Tween 20® and tween 80® on the stability of albutropin during agitation. J Pharm Sci. 2005;94:1368–1381. doi: 10.1002/jps.20365. [DOI] [PubMed] [Google Scholar]

- 66.Lahlou A, Blanchet B, Carvalho M, Paul M, Astier A. Mechanically induced aggregation of the monoclonal antibody cetuximab. Ann Pharm Fr. 2009;67:340–352. doi: 10.1016/j.pharma.2009.05.008. [DOI] [PubMed] [Google Scholar]

- 67.Arakawa T, Prestrelski SJ, Kenney WC, Carpenter JF. Factors affecting short-term and long-term stabilities of proteins. Adv Drug Deliv Rev. 2001;46:307–326. doi: 10.1016/S0169-409X(00)00144-7. [DOI] [PubMed] [Google Scholar]

- 68.Matsuoka T, Tomita S, Hamada H, Shiraki K. Amidated amino acids are prominent additives for preventing heat-induced aggregation of lysozyme. J Biosci Bioeng. 2007;103:440–443. doi: 10.1263/jbb.103.440. [DOI] [PubMed] [Google Scholar]

- 69.Quinn R, Andrade JD. Minimizing the aggregation of neutral insulin solutions. J Pharm Sci. 1983;72:1472–1473. doi: 10.1002/jps.2600721227. [DOI] [PubMed] [Google Scholar]

- 70.Lentzen G, Schwarz T. Extremolytes: natural compounds from extremophiles for versatile applications. Appl Microbiol Biotechnol. 2006;72:623–634. doi: 10.1007/s00253-006-0553-9. [DOI] [PubMed] [Google Scholar]

- 71.Yu I, Jindo Y, Nagaoka M. Microscopic understanding of preferential exclusion of compatible solute ectoine: direct interaction and hydration alteration. J Phys Chem B. 2007;111:10231–10238. doi: 10.1021/jp068367z. [DOI] [PubMed] [Google Scholar]

- 72.Knapp S, Ladenstein R, Galinski EA. Extrinsic protein stabilization by the naturally occurring osmolytes β-hydroxyectoine and betaine. Extremophiles. 1999;3:191–198. doi: 10.1007/s007920050116. [DOI] [PubMed] [Google Scholar]

- 73.Hédoux A, Willart JF, Paccou L, Guinet Y, Affouard F, Lerbret A, et al. Thermostabilization mechanism of bovine serum albumin by trehalose. J Phys Chem B. 2009;113:6119–6126. doi: 10.1021/jp900330r. [DOI] [PubMed] [Google Scholar]

- 74.Faria TQ, Knapp S, Ladenstein R, Maçanita AL, Santos H. Protein stabilisation by compatible solutes: effect of mannosylglycerate on unfolding thermodynamics and activity of ribonuclease A. ChemBioChem. 2003;4:734–741. doi: 10.1002/cbic.200300574. [DOI] [PubMed] [Google Scholar]

- 75.Galinski EA, Stein M, Amendt B, Kinder M. The kosmotropic (structure-forming) effect of compensatory solutes. Comp Biochem Physiol A. 1997;117:357–365. doi: 10.1016/S0300-9629(96)00275-7. [DOI] [Google Scholar]

- 76.Arakawa T, Timasheff SN. The stabilization of proteins by osmolytes. Biophys J. 1985;47:411–414. doi: 10.1016/S0006-3495(85)83932-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 77.Bolen DW, Rose GD. Structure and energetics of the hydrogen-bonded backbone in protein folding. Annu Rev Biochem. 2008;77:339–362. doi: 10.1146/annurev.biochem.77.061306.131357. [DOI] [PubMed] [Google Scholar]

- 78.Álvarez R, López Cortés LE, Molina J, Cisneros JM, Pachón J. Optimizing the clinical use of vancomycin. Antimicrob Agents Chemother. 2016;60:2601–2609. doi: 10.1128/AAC.03147-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 79.Rybak MJ. The pharmacokinetic and pharmacodynamic properties of vancomycin. Clin Infect Dis. 2006;42:S35–S39. doi: 10.1086/491712. [DOI] [PubMed] [Google Scholar]

- 80.Tsuji BT, Leonard SN, Rhomberg PR, Jones RN, Rybak MJ. Evaluation of daptomycin, telavancin, teicoplanin, and vancomycin activity in the presence of albumin or serum. Diagn Microbiol Infect Dis. 2008;60:441–444. doi: 10.1016/j.diagmicrobio.2007.11.011. [DOI] [PubMed] [Google Scholar]

- 81.Rybak MJ, Lomaestro B, Rotschafer JC, Moellering R, Jr, Craig W, Billeter M, et al. Therapeutic monitoring of vancomycin in adult patients: a consensus review of the American Society of Health System pharmacists. Am J Health Syst Pharm. 2009;66:82–98. doi: 10.2146/ajhp080434. [DOI] [PubMed] [Google Scholar]

- 82.Okano A, Isley NA, Boger DL. Total syntheses of vancomycin-related glycopeptide antibiotics and key analogues. Chem Rev. 2017;117:11952–11993. doi: 10.1021/acs.chemrev.6b00820. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 83.Chen S, Wu Q, Shen Q, Wang H. Progress in understanding the genetic information and biosynthetic pathways behind Amycolatopsis antibiotics, with implications for the continued discovery of novel drugs. ChemBioChem. 2016;17:119–128. doi: 10.1002/cbic.201500542. [DOI] [PubMed] [Google Scholar]

- 84.Chen AX (2016) Inventor; Pentec Health, Inc., assignee. Aqueous solution formulations of vancomycin. USA patent WO2016127087A1.

- 85.VANCO READY® Vancomycin Injection, USP Premix [package insert] : Xellia Pharmaceuticals; [Available from: https://xellia.com/us/vancoready]. Accessed 8 May 2022

- 86.Keser S, Jasprica I, LeCunff J (2019) Inventors; Xellia Pharmaceuticals ApS, assignee. Stabilized glycopeptide antibiotic formulations patent US 2019/0175632 A1.

- 87.Blaskovich MAT, Hansford KA, Butler MS, Jia Z, Mark AE, Cooper MA. Developments in glycopeptide antibiotics. ACS Infect Dis. 2018;4:715–735. doi: 10.1021/acsinfecdis.7b00258. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 88.Duncan LR, Sader HS, Smart JI, Flamm RK, Mendes RE. Telavancin activity in vitro tested against a worldwide collection of Gram-positive clinical isolates (2014) J Glob Antimicrob Resist. 2017;10:271–276. doi: 10.1016/j.jgar.2017.03.018. [DOI] [PubMed] [Google Scholar]

- 89.Cumberland Pharmaceuticals. Phase A. 3 telavancin Staphylococcus aureus (S. aureus) bacteremia Trial (identifier NCT02208063): National Library of Medicine, NIH (2020) ; [Available from: https://clinicaltrials.gov/ct2/show/NCT02208063]

- 90.Garcia B, Gonzalez J, Chaudhry S. Clinical outcomes for telavancin for salvage therapy in methicillin-resistant Staphylococcus aureus bacteremia: a case series. Infect Dis Clin Pract. 2021;29:e385–e389. doi: 10.1097/IPC.0000000000001021. [DOI] [Google Scholar]

- 91.Liu J, Lee J (2011) Inventors; Theravance Inc:, assignee. Hydrochloride salts of a glycopeptide phosphonate derivative. USA patent US8003755.

- 92.Khamesipour F, Hashemian SM, Velayati AA, Tabarsi P. A review of teicoplanin used in the prevention and treatment of serious infections caused by Gram-positive bacteria and compared its effects with some other antibiotics. Biomed Pharmacol J. 2015;8:513–521. [Google Scholar]

- 93.Jung HM, Jeya M, Kim SY, Moon HJ, Kumar SR, Zhang YW, et al. Biosynthesis, biotechnological production, and application of teicoplanin: current state and perspectives. Appl Microbiol Biotechnol. 2009;84:417–428. doi: 10.1007/s00253-009-2107-4. [DOI] [PubMed] [Google Scholar]

- 94.Cryle MJ, Staaden J, Schlichting I. Structural characterization of CYP165D3, a cytochrome P450 involved in phenolic coupling in teicoplanin biosynthesis. Arch Biochem Biophys. 2011;507:163–173. doi: 10.1016/j.abb.2010.10.017. [DOI] [PubMed] [Google Scholar]

- 95.Butler MS, Hansford KA, Blaskovich MAT, Halai R, Cooper MA. Glycopeptide antibiotics: back to the future. J Antibiot (Tokyo) 2014;67:631–644. doi: 10.1038/ja.2014.111. [DOI] [PubMed] [Google Scholar]

- 96.Coronelli C, Bardone MR, DePaoli A, Ferrari OP, Tuan G, Gallo GG. Teicoplanin, antibiotics from actinoplanes teichomyceticsu Nov. SP. V aromatic constituents. J Antibiot. 1984;6:621–626. doi: 10.7164/antibiotics.37.621. [DOI] [PubMed] [Google Scholar]

- 97.Leuthner KD, Buechler KA, Kogan D, Saguros A, Lee HS. Clinical efficacy of dalbavancin for the treatment of acute bacterial skin and skin structure infections (ABSSSI) Ther Clin Risk Manage. 2016;12:931–940. doi: 10.2147/TCRM.S86330. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 98.Cheng M, Ziora ZM, Hansford KA, Blaskovich MA, Butler MS, Cooper MA. Anti-cooperative ligand binding and dimerisation in the glycopeptide antibiotic dalbavancin. Org Biomol Chem. 2014;12:2568–2575. doi: 10.1039/C3OB42428F. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 99.Allen NE. From vancomycin to oritavancin: the discovery and development of a novel lipoglycopeptide antibiotic. Anti-Infect Agents Med Chem. 2010;9:23–47. doi: 10.2174/187152110790886745. [DOI] [Google Scholar]

- 100.Brade KD, Rybak JM, Rybak MJ. Oritavancin: a new lipoglycopeptide antibiotic in the treatment of Gram-positive infections. Infect Dis Ther. 2016;5:1–15. doi: 10.1007/s40121-016-0103-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 101.Zhanel GG, Schweizer F, Karlowsky JA. Oritavancin: mechanism of action. Clin Infect Dis. 2012;54:S214–S219. doi: 10.1093/cid/cir920. [DOI] [PubMed] [Google Scholar]

- 102.Far AR, Krishna G, Ding M, Chemburkar SR, Knable CM, Petzel JP et al (2019) inventors; AbbVie Inc; Melinta Therapeutics Inc, assignee. High purity oritavancin and method of producing same patent US10864249B2.

- 103.Editorial Antimicrobial resistance: time to repurpose the global fund. Lancet. 2022;399(10322):335. doi: 10.1016/S0140-6736(22)00091-5. [DOI] [PubMed] [Google Scholar]

- 104.Giurazza R, Mazza MC, Andini R, Sansone P, Pace MC, Durante-Mangoni E. Emerging treatment options for multi-drug-resistant bacterial infections. Life (Basel) 2021;11(6):519. doi: 10.3390/life11060519. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 105.Hoffmann M, Jin Y, Pöhlmann S. Dalbavancin: novel candidate for COVID-19 treatment. Cell Res. 2021;31(3):243–244. doi: 10.1038/s41422-020-00459-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.