Abstract

Food processing, from agricultural production to domestic consumption, is responsible for generating great amounts of waste per year, resulting in soil, water, and air pollution. These pollutants, together with the uses of petrochemical process inputs such as solvents, additives, or fuels, increase the food chain’s environment impacts resulting in wasted resources. In response to this scenario, the circular economy (CE) theory is presented in literature as a liable alternative for the design of more sustainable production chains. In this context, this work was aimed at evaluating the literature’s approach on the CE concept within the food processing and food waste management. The works show the centrality of “food waste” as a focus for the application of the CE. However, despite the relevance of management, reuse, or valuation of food waste, particularly due to its contribution to carbon footprint and decrease of food safety, studies have found other strategies for improvement of CE in the food chain. In this case, works in literature were allocated within the framework presented by the Ellen Macarthur Foundation called ReSOLVE, with proposals for modification of production chain to promote the CE. Among the proposals, one should highlight: modification of productive systems for mitigation of environmental impacts and greenhouse emissions, processes optimization for decreasing the use of natural resources and wastes, use of 4.0 Industry such as IoT, big data, or machine learning techniques for improvement of the whole supply chain, development of collaborative platforms for production and market, use of residues or co-products by design of intra- or inter-chain loops, and exchange of process or inputs with high environmental impacts for greener ones.

Keywords: Sustainability, Food products, Green alternatives, Bioeconomy

Introduction

According to Food and Agriculture and Organization, in 2018, one-third of the global agricultural land, calculated in 4.8 billion hectares [1], were designated to cropland. From post-harvest to distribution, losses of this production are estimated in up to 25%, depending on the food chain [2]. Indeed, food chains are responsible for the generation of a large amount of waste, as well as environmental impacts along their productive stages. This includes land production, animal farming, food processing, transport, market, and consumption, responsible for the disposal of organic residues, packages, greenhouse gases, waste waters, among others, throughout the route, representing wasted potential resources.

In 2019, the farming contribution in the global food chain carbon footprint was calculated in 13.35% of CO2 equivalent of greenhouse gases, land use change in 6.49%, and pre- and post-production in 10.79% [1], being the main contributors in the food chain environmental emissions. To deal with this, global initiatives have been made for reducing global impacts and achieving sustainable production systems. In 2015, through the Paris Agreement, during COP21, the signatory countries agreed to offer financial, technical, and infrastructural support to mitigate global climate change for decreasing 2 °C by 2030, promoting technological and social changes to achieve low carbon emissions. In this context, the United Nations gathered 17 Sustainable Developments Goals (SDG) for sustainable development, concerning the socio-economical and environmental changes necessary to achieve sustainable production models with zero-carbon emission, waste generation, and unrenewable resources use decrease [3]. Through the 12th SDG, namely “Responsible Consumption and Production,” alternative economical models of producing were proposed to reduce the use of natural resources without detriment of economic growth [4–7]. It means that, together with the food losses, consumption and production of non-renewable materials and energy sources during food production and processing should be targeted.

In this context, literature, governments, and national and international organizations have paid attention to the so-called circular economy (CE). As opposed to the traditional economical and production model, in which resources are used for product manufacturing and products are discarded, generating waste and pollution with net carbon emissions, the CE proposes a more circular model, in which resources are used more than once, prioritizing minimum or no use of no-renewable resources, as well as waste generation [8]. This model enables producers to address the matter ensuring production without detriment of the environment.

Other alternative models have been also explored in literature. Examples are the “Industrial Ecology,” in which goods production are based on the natural systems, considering the interaction among industrial production, environmental, and society, targeting the reducing of natural resources by reusing and recycling principles [9, 10]; the “Buen Vivir” (Living Well – free translation), a Latin American theory that questions the actual model of goods production and usage of natural resources (not be considered “resources” by this theory), directly dialoguing with indigenous cosmologies, economy undergrowth, and colonial perspectives [11]; the “Food-Energy-Water” (FEW) Nexus, an approach that considers food, energy, and water consumption/production are interrelated with a focus on (re)utilization of food waste by converting it to energy or other high valued chemicals [12].

Lately, gradual changes have been performed in several manufacturing chains, by promoting the CE concept. To ensure proper application of it, quantitative and qualitative tools have been developed to evaluate the level of circularity of production chains. Life Cycle Assessment (LCA) is one of the most used methods for evaluation of the environmental impacts of a production system, particularly in case of food systems. The assessment, described in the ISO 14,040 and 14,044 standards, is performed from “cradle to grave,” i.e., from raw materials to product consumption, with the calculation of environmental impacts categories such as global warming, land and water use and fossil resources depletion [13]. Other strategies as proposed by the “ReSOLVE” framework [14] described by Ellen Macarthur Institute, consists of “rules” or strategies to reach a full or partial circularity in the goods production, including the performance of up to six actions or “modifications” throughout the productive chain to REgenerate environment, Share processes and products, Optimize the systems, create Loops in the chain, Virtualise services and processes, and Exchange non-renewable and high environmental impact materials [15].

Therefore, considering the novelty of the concept and the important role displayed in the way of re-thinking productive systems and the economy itself, particularly in case of food systems, this work was aimed at performing bibliographical research on the occurrence of studies on CE applied to food production and food waste management, including works published in the last 5 years, evaluation of the main focuses. Also, considering the centrality of the theme “food waste” in the works, food waste was conceptualized by presenting three main categories, food waste itself, food surplus and food loss including the best environmental management options for each one. Finally, based on the ReSOLVE framework proposed by the Ellen Macarthur Foundation, works in literature were categorized within one of the six business actions of it, highlighting potential alternatives for enhancement of the circularity within the food chain.

Circular Economy in the Food Chain and Food Waste Management: Occurrence in Literature

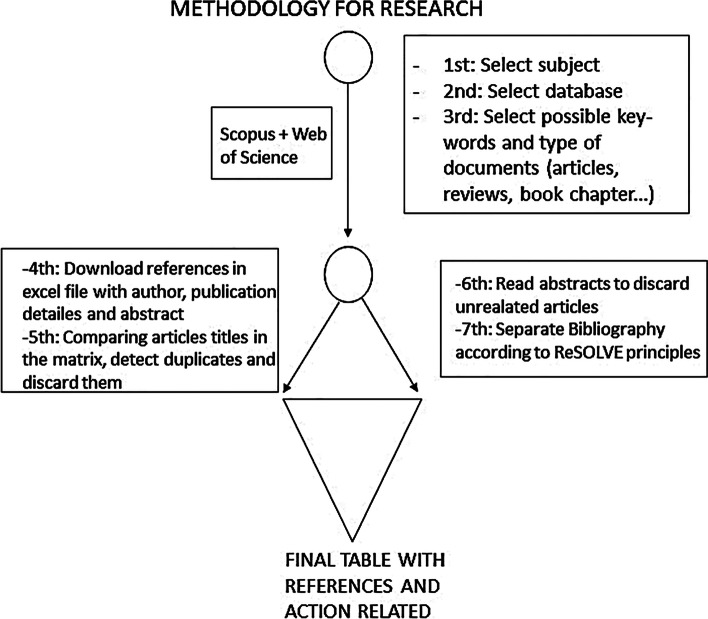

To assess the context and how often the literature has addressed the topic of CE in the food chain, bibliometric research was performed using two main academic databases, namely “Web of Science” (all databases) and “Scopus.” The keywords used in the research were “Circular Economy” associated with the terms “Food Chain” or “Food Waste” or “Agricultural Waste” or “Waste Valorisation” or “Food Processing.” “Food Chain” is the obvious main term in this research. Though the expressions “Food Waste” and “Agricultural Waste” do not represent the same concept, they are most likely to represent the same idea of “waste” in the food industry. The term “Valorisation” was chosen due to the frequency found in the works within the CE concept and therefore, it was also used in the research. The “Food Processing” term can most likely appear in the context of studies on the food manufacturing stage of the food chain, reason why it was used in the research. The period of analysis was the last 5 years (from 2017 to June, 2022) as an attempt to make the review as contemporary as possible. The type of document considered was original articles, reviews, conference papers, book chapters and editorials indexed in those two databases. Patents deposited within that period were also considered in the research in order to incorporate innovations and technological advances in the area. The flowchart presented in Fig. 1 shows how the bibliographical research was performed.

Fig. 1.

Flowchart regarding how bibliometric research was conducted in this study

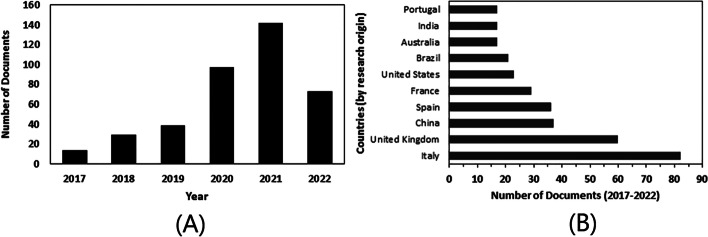

The number of results found in each database was 858 for Web of Science, 427 for Scopus from 2017 to June of 2022. Duplicates appeared when each base was cross-linked. The results were downloaded in the Excel software [16], the duplicates were excluded at the worksheet and data divided according to the theme. Some works, according to each category, will be further detailed in the next section. Also, works based on the ReSOLVE framework [14], further detailed in the next section, were highlighted. Excluding duplicates and unrelated work, the total works found was 1005. The distribution of citations per year, for keyword selected, and the distribution of documents published per country is shown in Fig. 2A and B. Figure 3 shows a tree map with the fields of knowledge of the journals that published the articles.

Fig. 2.

a Distribution of documents per year and b distribution of documents published per country (research origin)

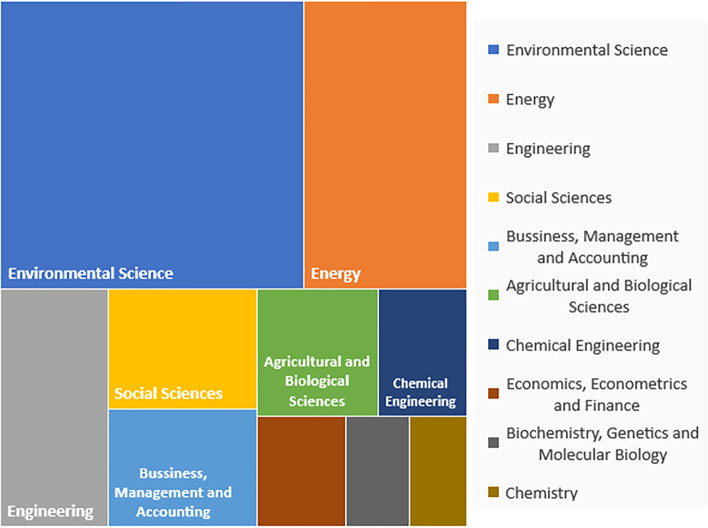

Fig. 3.

Tree map with the fields of knowledge of the journals

The number of documents significantly increased within 2017 to 2019, peaking by 2021. Considering that for year 2022 research was performed until June, the total number of works published, must probably increase possibly overcoming 2021. Considering the top 10 subject areas in the search, “Environmental Science” is the field of knowledge with the greatest number of works, reviews, or original articles, followed by “Energy” and “Engineering.” Subject areas more likely to study CE, particularly in Food Systems, such as “Economics, Econometrics and Finance” and “Agricultural and Biological Sciences” showed a low presence of works in this specific subject. “Chemistry” also appeared as the last of this list. Although the bibliographical research in CE showed an increase in publication, the total quantity regarding “Food Production” is still lower when compared to other fields of knowledge. Otherwise, results suggested a great contribution of the academic works on more sustainable technological development. Studies on theoretical application of the circular model into the industry were commonly found in “Business, Management and Accounting” and “Economical, Econometric and Finance” areas. Public policies towards a more circular economy, such as those with the principles of “green cities,” strategies for development of local markets, local farmers or producers have been also investigated, especially in the context of agricultural waste management and food processing.

Considering the countries where research on CE was performed in food chain (Fig. 2B), three main contributors were identified. Italy was the country with the greater production regarding the application of CE concepts in food waste management in the food production, followed by United Kingdom and Spain. These countries follow the European Directives for waste management and have specific policies to implement changes in the food chain to achieve the UN Sustainable Development Goals. Among the targets of such directives are the increase of at least 50% by weight of re-use and recycle of waste from households by 2020 with an increasing of the values by 2035. The United Kingdom is not a member of the European Union but has committed to the SDG and the Sustainable Development Agenda with investments in research and innovation in this area [17]. In 2020, particularly, a “Circular Economy Package Policy Statement” was developed by the UK Department for Environment, Food and Rural Affairs to ensure introduction of the CE concepts in the country.

China, USA, and Brazil were also listed among the top 10 countries focusing on CE studies for more sustainable food production and food waste management practices. These countries correspond to the largest food producers and consumers in the world, having the largest contribution to the waste generation and disposal throughout the food chain compared to other regions. China has governmental policies for waste collection recovery, with a centralized system for cities and small villages, as well as examples of public-private partnerships initiatives regarding the waste management of rural solid waste. However, the resistance of villagers is a bottleneck for reaching recycling targets [18] as well as market demands and fiscal transparency issues [19].

In USA, the US Environmental Protection Agency published a guidance for waste management of hazardous, non-hazardous, and solid waste, with recycling guidelines [20]. The guidelines include alternative methods for recycling material, solid waste and hazardous wastes, reuse and recovery, principles of CE and waste management. In 2010, a joint initiative between USA and Brazil were implemented, called “National Solid Waste Policy.” This policy is a public-private partnership and acts on the improvement of recycling policies, application of new technology for recycle, reuse and recovery of waste. The increase in organic waste digestors, composting and packing disposal techniques was one of main the goals of this policy [20].

In Brazil, an important program for more sustainable industrial practices was the RENOVABIO program, implemented in 2016 by the Ministry of Mines and Energy of the Brazilian Government. This program stimulates companies to implement renewable energy technologies in exchange of Decarbonization Credits (CBIO), proportional to the amount of renewable energy produced [21] with includes the use of agricultural wastes for energy production. In this context, more technologies for the integration of biomasses within the Industrial Processes have been encouraged during past years, giving rise to the concept of “Bio-refinery” [22]. Within this concept the main products obtained by using wastes or biomasses are second generation bio-fuels from non-food crops or residues, biogas from industrial wastes, or lignocelluloses materials from agriculture and forestry, third generation bio-fuels using aquatic microorganism or fourth generation fuels by combining fuel production and CO2 capturing and storing [23, 24]. Indeed, the application of bio-refineries is considered highly feasible in Brazil that, within the CE values, are also highly encouraging in the context of other developing countries [23, 25].

Food Waste and Their Management

As observed in the literature review, there are few research regarding food production or processing systematically associated to CE. Most of the works indicates, as possible alternative for a circular production, the reuse/recycle of output streams (mainly food wastes) for manufacturing of valued products, followed by replacement of processes or feedstock for those with lower environmental impact [26–29]. Few works consider the full circularity concept, with the reintroduction of output streams in the same chain, what CE call as “closed-loops,” or the use of these outputs to another productive cycles, what CE call as “open-loops.” Reuse of water through wastewater treatment [30], use of bagasse [31] or other biomasses for energy generation [32–35] as well as replacement of volatile solvents by greener ones [36–38], are other CE alternatives proposed in literature for food production in the CE context.

Food waste and technologies for their management are still presented as one of the main focuses in the context of applying CE in the food chain. However, the comprehension of what is a food waste could influence in the choice of the best environmental alternative for their management. In fact, definition of waste in the food chain varies in literature, despite several attempts observed to harmonize such definition. In this context, a particular highlight could be given to the work of Teigiserova, Hamelin and Thomsen [39]. The authors divide “wastes” in food system in 5 categories: (1) agricultural production, (2) post-harvest activities, (3) processing and manufacturing, (4) retail and wholesale, (5) consumption and services. They also distinguished food surplus from food waste and food loss. According to them, after harmonization of literature works, the first refers to food for human consumption that are not expected to be “wasted,” most represented as household and food service leftovers, but also processed food with expired date not retailed or consumed. It also considers food bound to be wasted during its lifecycle whether by not being appealing to consumers, or for its bad appearance, such as deformed fruits and vegetables. The second group refers to some distinguish types: (i) inedible organic residues that is not expected or inappropriate to be eaten by humans, due to either natural inedibility or inedibility due to processing, such as leaves, bones, bagasse or frying oil; (ii) edible parts of fruits and vegetables or edible organic residues resulted from processing or consumption, such as peels, seeds, or whey; (iii) and spoiled food due poor storage conditions in households and retailing. The last refers to food unintentionally lost due spoilage throughout the food system (previous to household consumption or retailing storage) as a result of inappropriate post-harvest conditions, improper storage (temperature, atmosphere composition, time of storage), bad practices of logistic management or transportation.

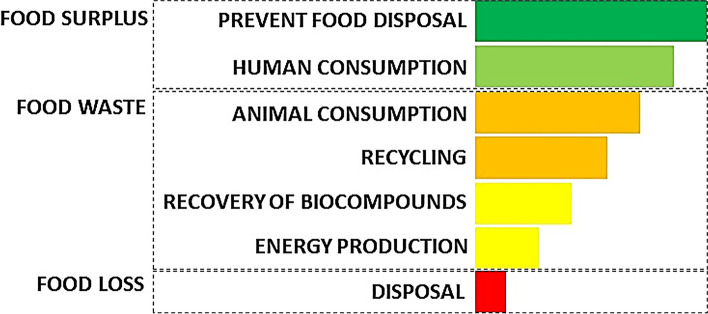

Based on these concepts, the authors proposed a hierarchy of alternatives for the management of each type of “waste.” The scheme proposed is sketched in Fig. 4. It is an inverted pyramid in which the best-environmental alternatives are closer to its top. By this hierarchy, management of food surplus are placed as the focus, focused on prevention of food disposal in households and retailing by allocating it for human consumption. Possibilities, in this context, are food banks for people in need, reinventing food dishes from leftovers, use of misshaped fruit and vegetable for cooking, encouraging their commercialization. Food processing is also considered an important and interesting alternative in this case, with the increasing in shelf-life of still edible fruits, vegetables or meets. Food waste is placed in the middle of the pyramid. In this case, depending on the waste quality, generally characterized by its edibility or inedibility, they should be designated firstly for animal feed followed by their uses in adding-value processes. Recycling of materials for production of other goods such as bio-plastics, composite materials or chemicals as well as the recovery of bio-compounds by extraction technologies are the main proposals. Renewable energy production is placed as the last option for management of food wastes, in contrast with the frequency of works found in literature. Food losses are in the bottom of the inverted pyramid, in which disposal should be avoided. Indeed, considering that food losses can be avoided by good post-harvest, storage, and transportation practices, from farming to retailing, their existence is questionable.

Fig. 4.

Inverted Pyramid showing a hierarchy of actions for food waste management, adapted from [39]. Green actions for food surplus, orange and yellow actions for wastes, and red for losses

As observed reuse/recycling is the most spread practice within literature works but also within the public polices for urban routines worldwide, considering the management of food “wastes” and mitigation of their environmental impacts. Indeed, avoidance or reduction of waste generation, and the recycling of waste into alternative products are often premises for waste management. Beyond management of disposed food packages, reuse/recycling activities mainly includes practices of composting, and more recently bio-energy production. According to the European Environment Agency (2021), 28 European countries recycle around 55% of total urban waste per year, in which residues from food consumption represents a significant fraction. In China, around 73% of total urban solid waste are reused and governances have planned to achieve 79% until 2025 [40]. In Brazil, only 3% of the recyclable solid waste is effectively recycled per year, approximately, despite the country has approved in 2010 the National Policy of Solid Waste, where reuse and recycle of waste, and reduction of landfills were some of the main targets of the law.

In the USA, 35.2% of municipal solid waste are recycled or use for composting. However, up to 2017, in USA, most of the solid waste was still thrown out in landfills (139 million) and the minority recycled, composted (94 million), or combusted (34 million) [41]. Indeed, recycling alternatives had been growing throughout decades. During 1970s, the environmentalist movement was strengthened with the evolution of public opinion towards reduction of water, land, and fossil fuel consumption [42, 43]. The problematic of waste management also arose in governmental and personal actions, motivated by popular opinion trough society movements and Non-Governmental Organizations (ONGs) environmental driven, such as Greenpeace and many others created at 1980s. Recycling became the substitute for landfills. Then, further in the late 1970s, the energy crisis provoked by the shortage of petroleum available, increased the fossil fuel prices and promoted severe impacts on the global economy due to the lack of energy source supplies. By the same time, the so called “green revolution,” promoted the mechanization of crops and agricultural production, increasing fossil fuel energy and other natural resources consumption. Therefore, the search for alternative sources of energy, together with reduction of water and emissions became an important issue. The production of energy by recovering agricultural and industrial wastes is portrayed as an important and viable alternative [42, 43]. Also, an expressive part of the academic community defend the substitution of the extensive agricultural, practised by large corporations, with great consumption of natural resources, by agro-ecological practices [44].

Among the positive aspects of recycling materials are the reduce of used resources inside the chain but also generation of jobs and increasing in other economic sectors such as energy and chemical industry [41]. Paperboard (46.9%) and yard trimmings (25.9%) are the main components recycled in USA, followed by metal, plastic, glass, wood and textile, along with food residues. The food chain contributes to a great part of the paperboard, plastic and glass residues. For this reason, regulatory agencies worldwide had been introducing specific rules for mitigating the impact of such food chain residues. For example, single-used plastic products have been restricted in European Union [45] with reduction of its consumption mainly through awareness campaigns, and introduction of labeling to instruct the consumers regarding plastic content, disposal options, and plastic harm to environment, including regulatory texts on composition and types of recycled bags. In Latin America and Caribbean countries, for mitigation of marine litter and plastic, waste governmental model guidelines for reference values, indicators and specific actions for plastic disposal was launched [46]. In Brazil, the Ministry of Environment in a partnership with the UN Environmental Program implemented a Sustainable Consumption and Production Project focused on recycling and development of innovation technologies for responsible waste reuse [46].

The work of Edwards et al. [47] exemplifies the environmental benefits of well managed urban solid wastes. The authors performed a LCA of a municipal waste management service for organic wastes, accessing its pathways (collection, pre-treatment, treatment, and end-use/disposal) for the production of high valued products or simple disposal. Classical scenarios were evaluated: disposal in landfills, composting a central facility for fertilizer production, domestic composting, and digestion for biogas and electricity production being the efficiencies inside the recycling or recovery system evaluated. The authors concluded that the bio-energy generation from digestion in landfills, from sewage waste management and from bio-solids composting had higher energy generation net value in comparison with the scenario without waste treatment techniques.

The ReSOLVE Framework on Food Production

Despite the great focus given by literature for food waste treatment or their valorisation, as the main alternatives for applying the CE principles in the food production, several other challenges in the food chain demands evaluation. These demands are highlighted in the three main CE principles: (i) preserving, restoring and enhancing natural capital; (ii) optimizing the yields of the productive systems by (re)circulating the products, materials and components; and (iii) design productive systems considering the mitigation of their negative externalities, i.e. negative social, economic and environmental impacts [8]. According to literature [15], industrial and other business practices could reach these principles by performing “actions” within a framework called as ReSOLVE. ReSOLVE is an anagram of “six actions,” namely Regenerate, Share, Optimize, Loop, Virtualise and Exchange. This framework is particularly assertive in proposing the introduction of new technologies or business systems for improvement of the circularity of a productive chain. Through the bibliographical research performed, the literature works were evaluated, and their scopes classified as being in one of the six ReSOLVE actions. Exemplary works are separated and presented in Table 1. In sequence, the six actions will be detailed explained with the examples proposed by those selected literature.

Table 1.

Some examples of more recent articles published regarding application of the ReSOLVE framework in the food chain in the period of 2017–2022

| ReSOLVE action | Examples | References |

|---|---|---|

| Regenerate | • Food production associating plantation or cattle raising with agro forestry | [48] |

| • Integration of carbon capture and food/biomass production | [49] | |

| • Use of alternative proteins in food formulation | [50] | |

| Share | • Shared food manufacturing facilities | [51] |

| • Food-sharing platforms to share surplus food | [52] | |

| • Shared practices in food waste management | [53] | |

| Optimize | • Energetic optimization in food processes | [54, 55] |

| • Food production optimization with minimization of food losses | [56] | |

| • Technologies to increase traceability and decrease food losses | [57] | |

| Loop | • Returnable packages technologies and management | [58, 59] |

| • Reutilization of food residues for production of other non-food materials, including biofuels | [35, 60–63] | |

| • Extraction of bioactive compounds from food residues | [64] | |

| • Extraction of macronutrients from food residues | [65] | |

| Virtualise | • Online food shopping technologies | [66] |

| • Food formulation using virtual reality | [67] | |

| • Use of GIS (Geographical Information System), big data, and other 4.0 Industry technologies to monitor food chain, avoiding losses and increasing quality | [68–73] | |

| Exchange | • Replacement of non-renewable solvents or other feedstock by renewable/more sustainable chemicals for food production | [74] |

| • Food formulation by 3D printing | [75] | |

| • Replacement of non-renewable energy sources by renewable ones in food processes | [76] |

Regenerate

The development of alternative productive systems to restore the biological resources of the ecosystems is point out by the ReSOLVE framework as one of the six actions for reaching the circularity of a productive chain. An interesting example in the food production chain is animal farming and monocultures. Animal farming, especially the extensive cattle raising, and large monocultures, such as soybean and corn croplands, have been associated to high environmental impacts due to land and water use, soil spoilage, greenhouse emissions among others. In this case, Miccolis et al. [48] states the impacts of both could be decreased by changing the productive system through the implementation of the agro forestry model, which could aid the regeneration of the biome. In the context of the environmental impacts of cattle raising, Grossmann and Weiss [50] suggest that regeneration could be potentially achieved by the replacement of animal protein in food formulation with the use of alternative sources of protein. This is the case of the so-called plant-based products, highly popular due to the costumer adoption of vegetarian or vegan diets increase. The authors explore the technological challenges for substitution of animal protein in food formulation, as well as how to adapt it to the customer acceptance.

Another quite interesting alternative for restoring of ecosystems are the use of technologies for carbon capture and sequestration. The CO2 capture can be achieved by several technologies such as solvents, membranes, or adsorbents, but Sillman et al. [49] describes the use of a H2-oxidizing bacterium as a feasible alternative for both carbon sequestration from productive systems, conversion into protein that could be used for food or feed production. This is also pointed out by the authors as in line with the global food security problem, by increasing protein production in a more efficient and sustainable way, considering the limited land and water resources.

Share

This action is more commonly related to products and services consumed or shared by more than one person or used by more than one goal. Examples of such practice are sharing rides, accommodation, cars or bicycles, actually promoted by mobile apps, including the use of second-hand products. In the food chain context, Lino de Araújo et al. [51] described how shared food production plants, in the context of small-scale productions, could represent benefits in economic and environmental point of view. In case of small-scale producers, capital costs are relevant bottlenecks, avoiding business and income generation growth. However, considering that several food products could use the same equipment or technologies to be processed, shared facilities could allow small producers in scaling up their production.

However, this concept can go beyond only physical goods and be transported to shared actions towards environmental benefit. Frey et al. [52] investigated the use of food-sharing computational platforms for food sharing and reduction of food loss. This sharing platform enable the users (both individuals and businesses such as producers or retailers) to share their surplus food in a “peer-to-peer” or “business-to-peer” relationships, with a profit- or non-profit-based market. This study could observe that the existence of these social or corporate-social sharing platforms, also described as social-eating platforms proved to be quite significant not only for food waste management and decreasing but also as a food security practice. This sharing practice was also evaluated in the study of Dora [53]. The author discusses the positive and collaborative contribution of shared sustainable practices of farmers and stakeholders in the food supply chain for efficient management of the food waste within the CE concept. This was achieved by sharing knowledge on more sustainable management in their farms but also sharing food surplus between themselves. The author also found that geographical distance is a very relevant factor for the success of this collaborative framework and, therefore, a robust local food supply chain facilitates the implementation of this CE practice.

Optimize

The enhancement of actions inside the productive chain for optimisation of energy, time, resources, reducing waste production and increasing yields is a powerful premise of the CE. An example of such action is the “Lean philosophy,” created by the Toyota industry. The reorganization of the productive system and the supply chain is a necessary practice to avoid unnecessary wastes, transport, inventory, over production and over processing, but also to mitigate “non-value” activities, and increase the real product value to the costumers [77, 78]. Several “Lean” methods, such as sustainable value stream mapping, green value stream mapping, inventory reduction, lean product flow, pre-production planning has been applied in areas of waste, energy, emission, water and chemical management concerning sustainable business [79].

Examples of the Optimize action in food industry can be exemplified by the works of Biasi et al. [54] and Meirelles et al. [55]. The authors proposed structural modifications in classical distillation and absorption/desorption columns for some food productive systems, such as ethanol production or deacidification of vegetable oils, decreasing capital and operational costs, energetic demands, and promoting the same or higher product yields. In the same way, Garre, Ruiz and Hontoria [56] evaluates the application of machine learning methods in food production to increase the efficiency of the production using less resources. This because, according to authors, some non-controlled variables in food production such as raw materials and ingredients variability, seasonality, atmospheric conditions, and a grade of randomness in products yield and market demand, can results in differences between planned and real productions, leading to unnecessary economical (and food) wastes and increases in the carbon footprint. Machine learning algorithms can be used to predict the food production variability by evaluation of the input data (types and quality of ingredients, process conditions, attributes of the raw materials, among others), mitigating wastes. Bouzembrak [57] also evaluated the use of computational techniques for food waste mitigation. In this case, “Internet of Things” platforms were used to manage the food chain and improve food safety. The authors showed the growing number of studies on technologies for monitoring food throughout the food chain for traceability, reduction of food losses, and improvement of food safety. Studies considered food production, transportation, food processing and shelf-life, the use of sensors for measurement of temperature, humidity, pH, viscosity, density, color, etc., as well as real-time communication platforms with Internet, radio frequency, and wireless sensor networks.

Loop

Development of “loops” within a productive chain is probably the most known action for achieving circularity within the CE framework. Loops could be comprehended as “recycling” or “reprocessing” the outputs of a production chain. Raw natural resources, chemicals, renewable or non-renewable materials, industrialized products, or energy are used inside the chain. Through the processes several outputs are generated: the final product is classically the most valued output. However, other co-products (or residues) not used in the processes itself are also produced. Those outputs can become inputs inside the same production chain or be introduced in others, creating “loops.”

In the context of creating loops by using outputs of the food production, Pontes et al. [64], and Sampaio Neto et al. [65] among many others authors found in literature, evaluated the development of methods for elaboration of new products with food residues. Those authors used solvent extraction (using solvents with lower environmental impacts, such as alcohols or other natural chemicals) for separation of antioxidants extracts, rich in polyphenols and vegetable oils from leaves and bagasse of oilseeds. These valued products can be produced in the same industry or the same productive chain, with the design of what CE call as “closed-loop,” but also designated to other productive chains, what CE call as an “open-loop.”

Production of renewable energy and high-valued bio-products from food waste have been also largely evaluated in literature considering designing of new destinations of residues for reduction of their impacts and nature contamination. Some examples are the extraction of organic particles from food’s processing waste, removal of inorganic contaminants in drinkable water [80] and the production of bio-energy by fermentation, aerobic or anaerobic digestion, and pyrolysis [35, 61]. Other highlight is the use of cooking-oil for manufacturing of other non-food products. Thushari and Babel [63] evaluated the environmental impacts of destining cooking-oil for production of soaps, bio-fuels and polymers. The impacts of each scenario showed that the high generation of solid and liquid wastes for production of soaps and polymers were not recommended over the utilization of the oil for biodiesel production. This is quite significant considering that production of bio-energy has been largely discussed nowadays in the context of bio-refinery, for improvement of the energy generation efficiency, but also for improvement of the CE character of the food chain and productive chains interlinked.

Some studies in literature have been also evaluating how implement these new intra or inter-chain loops, but also if they are viable in the social and environmental point of view. In the first case, Huang et al. [60] proposed a framework for evaluation of the alternatives for the reutilization of food residues. The method was based in evaluating and classifying the matrix of wastes generated in the process followed by product development using the matrix of wastes as raw material. In the second case, studies evaluate if the creation of new processes within a productive cycle could lead to more impacts than benefits. They mainly use LCA as the main tool to validate their findings: some of them evaluate the entire chain and others only parts of them [59, 81, 82].

Virtualise

Use of virtual platforms can reduce production costs by replacing physical facilities that are cost consuming and environment impacting. Share, optimize and virtualise strategies were used combined in several studies, with the use of big data [70], machine learning [71], Internet of Things (IoT) [72], and other technologies within the 4.0 Industry concept [73]. Aiming the virtualization of retailing in the food chain, Chang and Meyerhoefer [66] studied the increase of mobile apps in the food e-commerce as well as the consumer perceptions in this kind of retailing. The authors showed that the increase of the e-commerce importance and image was clearly observed in this study during past years, particularly due to Covid-19 pandemic situation (2020/2021). By virtualization of laboratory experiments for food products and development, Gouton [67] explored the digitalization of food senses as an alternative to decrease experimental essays in food formulation, mitigating time and cost aspects of it.

The use of artificial intelligence for integration production and supply chain was one of the main technologies used and evaluated. Artificial intelligence accomplished with the use of big data, Sensors or GIS (Geographic Information Systems) technologies are presented as interesting alternatives to help retailers, industry, and the supply chain in the reduction of food wastes and losses [68]. big data could have been used for the organization of market data, prices, number of sales, purchases and operations with management of their dynamics. Sensors, such as image, thermal or moisture detectors, could verify conditions to avoid spoilage of fruits, vegetables, meats and processed foods on the market shelves as well as along the supply chain. GIS technologies could promote traceability, reducing wastes, losses and improving food security [69].

Exchange

In this business action, non-renewable material, technologies, and services are replaced by renewable, advanced, and more efficient technologies and services. Some examples are as follows: the adaptation of processes to reduce waste or use of resources; replacement of non-renewable resources, such as fossil fuels or organic solvents to renewable ones in food processing in order to generate less waste and reduce environmental impacts [74]; use of 3D food printing for food formulation [75] that could save resources and decrease losses and environmental footprints; conversion of organic wastes into bio-energy, development of organic digestors tanks, and use of solar energy–based processes, replacing electric- or fossil fuel–based energy sources [76].

Final Remarks and Conclusions

Global initiatives to implement changes in the way goods are produced and commercialized dates from the last century. The food industry is one of the major sources of negative environmental footprints, due to high use of water, fossil fuel–based resources and non-renewable energy, generating great amount of waste. Due to international pressure and governmental incentive, great efforts to change the food industry have been made, with investment in research and development of new technologies. Indeed, they were encouraged since last century by several environmental agreements, including the well-known SDG framework, proposed in the UN Conference COP 21 [83]. However, there are still some bottlenecks regarding implementation and adaptation costs for new technologies and public adaptation. This highlights the great importance of public policies towards a more sustainable way of production.

Throughout the last decades, several theories on how to implement such changes in business, political, and social context such as “Industrial Ecology,” “Buen Vivir,” and the “Food-Energy-Water” Nexus shed light to important changes in the classical relationship among industry, community, and environment, proposing different ways human could better face the use of nature resources in their life. However, CE has been seen as the most known and esteemed in literature to be able to reach such targets among academic work in diverse spheres of knowledge.

EU countries, for example, built directives regarding environmental welfare and sustainable production tackling diverse topics, such as the use of petroleum-based inputs, such as polymers in food packaging, politics for waste disposal, or environmental conservation. In March 2020, they launched a new “Circular Economy Action Plan,” based on the “Green Deal,” aiming to reduce 55% of greenhouse gas (GHG) emissions by 2030 and ensure less waste, focusing efforts to enforce circularity on sectors with large production of waste and consumption of resources, including food production [84].

Using the Ellen Macarthur’s ReSOLVE framework [14], this work could categorize some bibliographic findings according to practical approaches towards a food production within the CE context. In doing so, food waste was observed as the main target in several works. Examples are as follows: processing of bio-products using biotechnology or other chemical processes; energy generation using technologies of composting, digestion, or pyrolysis; use of 4.0 Industry technologies such as IoT, AI, or GIS as well as sensors to detect and avoid generation of waste, improvement in market or production strategies using shared systems. However, one could observe that along with the food waste problem, one of the main targets in literature, other actions have been explored to promote a more circular food production. Examples in this case are as follows: the use of extraction techniques to explore the production of nutraceutical compounds from co-products along food production chain; techniques to increase efficiency within production stages, using methods such as the “Lean concept” and optimization by simulation techniques as a way of reducing cost and disposal of natural resources; use of big data science to organize information on sales and stocks among food supply chain; use of market sharing food platforms; practice of sharing knowledge between farmers and retailers regarding sustainable methods of production; exchange methods of production or energy sources by introducing new technologies more environmental friendly.

Implementation of new food production methods and retailing sustainable alternatives defy the “status-quo” or the “business as usual” way of thinking, which is the common practice for most of the food companies that rules the food market structure worldwide. Indeed, structural and adaptation costs need for implementation of circular economy practices in goods production are not instantly perceived as beneficial to most of enterprises [8, 14]. In this case, notably, modifications will only be implemented through incentives towards this structural adaptation. For such, public policies and directives are paramount to ensure the success of CE in long term.

Acknowledgements

The authors wish to acknowledge the national funding agencies: The São Paulo Research Foundation (FAPESP) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES).

Author Contribution

Validation, formal analysis, investigation, writing—original draft preparation: M.L.M.B.B.G.; visualization, supervision, project administration, funding acquisition, writing—review and editing, resources: G.J.M.; conceptualization, methodology, data curation: M.L.M.B.B.G. and G.J.M.

Funding

This research was funded by the São Paulo Research Foundation (FAPESP), Brazil, Grant No. 2014/21252-0. This study was also financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Brasil (CAPES) - Finance Code 001.

Data Availability

Not applicable

Declarations

Ethics Approval and Consent to Participate

Not applicable

Consent for Publication

All authors have read and agreed to the published version of the manuscript.

Conflict of Interest

The authors declare no competing interests.

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Food and Agriculture Organization (2019) FAOSTAT Database 2019

- 2.Food and Agriculture Organization (2020) FAOSTAT Database 2020

- 3.United Nations (2015) Transforming our world: the 2030 Agenda for Sustainable Development. https://sdgs.un.org/2030agenda. Accessed 10 Dec 2022

- 4.Blomsma F, Brennan G. The emergence of circular economy: a new framing around prolonging resource productivity. J Ind Ecol. 2017;2:603–614. doi: 10.1111/jiec.12603. [DOI] [Google Scholar]

- 5.Jurgilevich A, et al. Transition towards circular economy in the food system. Sustainability. 2016;8:1–14. doi: 10.3390/su8010069. [DOI] [Google Scholar]

- 6.Kirchherr J, Reike D, Hekkert M (2017) Conceptualizing the circular economy: an analysis of 114 definitions. Res Cons Recycl 127:221-232

- 7.Stahel WR. The circular economy. Nature. 2016;531:435–438. doi: 10.1038/531435a. [DOI] [PubMed] [Google Scholar]

- 8.Macarthur E, et al. Towards the circular economy. J Ind Ecol. 2013;2:23–44. [Google Scholar]

- 9.Saavedra YM, Iritani DR, Pavan AL, Ometto AR. Theoretical contribution of industrial ecology to circular economy. J Clean Prod. 2018;170:1514–1522. doi: 10.1016/j.jclepro.2017.09.260. [DOI] [Google Scholar]

- 10.Weisz H, Suh S, Graedel TE. Industrial ecology: the role of manufactured capital in sustainability. Proc Nat Acad Sci. 2015;112:6260–6264. doi: 10.1073/pnas.1506532112. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Acosta A (2019) O bem viver: uma oportunidade para imaginar outros mundos. Elefante, São Paulo

- 12.D’odorico P, et al. The global food-energy-water Nexus. Rev Geo. 2018;56:456–531. [Google Scholar]

- 13.Finknbeiner M, et al. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Intern J Life Cycle Assess. 2016;11:80–85. doi: 10.1065/lca2006.02.002. [DOI] [Google Scholar]

- 14.Ellen Macarthur Foundation (2015) Growth within: a circular economy vision for a competitive Europe. SUN, Ellen MacArthur Foundation and McKinsey Center for Business and Environment.https://ellenmacarthurfoundation.org/growth-within-a-circular-economy-vision-for-a-competitive-europe. Accessed 12 Dec 2022

- 15.Weetman C. Economia circular: conceitos e estratégias para fazer negócios de forma mais inteligente e lucrativa. São Paulo: Autêntica Business; 2019. [Google Scholar]

- 16.Microsoft (2019) Microsoft Excel for Microsoft 365

- 17.Department for Environment, Food and Rural Affairs (2020) Circular Economy Package policy statement. London. https://www.gov.uk/government/publications/circular-economy-package-policy-statement. Accessed 11 Dec 2022

- 18.Wang A, et al. Rural solid waste management in China: status, problems and challenges. Sustainability. 2017;9:506. doi: 10.3390/su9040506. [DOI] [Google Scholar]

- 19.Pan D, et al. Determinants of public-private partnership adoption in solid waste management in rural China. Int J Env Res Pub Health. 2020;17:5350. doi: 10.3390/ijerph17155350. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.United States Environmental Protection Agency (1976) Resource Conservation and Recovery Act (RCRA) Laws and Regulations. https://www.epa.gov/rcra. Accessed 10 Dec 2022.

- 21.Grassi MCB, Pereira GAG. Energy-cane and RenovaBio: brazilian vectors to boost the development of Biofuels. Ind Crops Prod. 2019;129:201–205. doi: 10.1016/j.indcrop.2018.12.006. [DOI] [Google Scholar]

- 22.Taylor G. Biofuels and the biorefinery concept. Energy Policy. 2008;36(12):4406–4409. doi: 10.1016/j.enpol.2008.09.069. [DOI] [Google Scholar]

- 23.Nizami A, et al. Waste biorefineries: enabling circular economies in developing countries. Bioresour Technol. 2017;241:1101–1117. doi: 10.1016/j.biortech.2017.05.097. [DOI] [PubMed] [Google Scholar]

- 24.Maneesha P, Bhaskarwar AN. Biomass conversion: the interface of biotechnology, chemistry and materials science. Berlin Heidelberg: Springer; 2012. p. 90. [Google Scholar]

- 25.Klein BC et al (2019) Low carbon biofuels and the new Brazilian National Biofuel Policy (RenovaBio): a case study for sugarcane mills and integrated sugarcane-microalgae biorefineries. Renew Sust Energy Rev 115:109365

- 26.Cotton CAR, et al. Renewable methanol and formate as microbial feedstocks. Curr opin biotechnol. 2020;62:168–180. doi: 10.1016/j.copbio.2019.10.002. [DOI] [PubMed] [Google Scholar]

- 27.Haas W, et al. How circular is the global economy?: An assessment of material flows, waste production, and recycling in the European Union and the World in 2005. J Ind Ecol. 2015;19(5):765–777. doi: 10.1111/jiec.12244. [DOI] [Google Scholar]

- 28.Linder M, Williander M. Circular business model innovation: inherent uncertainties. Bussiness Strategy Environ. 2017;26(2):182–196. doi: 10.1002/bse.1906. [DOI] [Google Scholar]

- 29.Nizetic S, et al. Smart technologies for promotion of energy efficiency, utilization of sustainable resources and waste management. J Clean Prod. 2019;231:565–591. doi: 10.1016/j.jclepro.2019.04.397. [DOI] [Google Scholar]

- 30.Chen W et al (2020) Hybrid life cycle assessment of agro-industrial wastewater valorisation. Water Res 170:115275 [DOI] [PubMed]

- 31.Allegue LD, Puyol D, Melero JA (2020) Food waste valorization by purple phototrophic bacteria and anaerobic digestion after thermal hydrolysis. Biomass Bioenerg 42:105803

- 32.D’Adamo I et al (2021) A circular economy model based on biomethane: what are the opportunities for the municipality of Rome and beyond? Renew Energy 163:1660–1672

- 33.Hubenov V, et al. Biomethane production using ultrasound pre-treated maize stalks with subsequent microalgae cultivation. Biotechnol and Biotechnol Equip. 2020;34(1):800–809. doi: 10.1080/13102818.2020.1806108. [DOI] [Google Scholar]

- 34.Paul S, et al. Municipal food waste to biomethane and biofertilizer: a circular economy concept. Waste Biomass Valoriz. 2018;9(4):601–611. doi: 10.1007/s12649-017-0014-y. [DOI] [Google Scholar]

- 35.Vlachikostas C, et al. Decision support system to implement units of alternative biowaste treatment for producing bioenergy and boosting local bioeconomy. Energies. 2021;13:9. [Google Scholar]

- 36.Choi YH, Verpoorte R. Green solvents for the extraction of bioactive compounds from natural products using ionic liquids and deep eutectic solvents. Curr Opin in Food Sci. 2019;26:87–93. doi: 10.1016/j.cofs.2019.04.003. [DOI] [Google Scholar]

- 37.Paiva A, et al. Natural deep eutectic solvents–solvents for the 21st century. ACS Sustain Chem Eng. 2014;2(5):1063–1071. doi: 10.1021/sc500096j. [DOI] [Google Scholar]

- 38.Zhao H, Xia S, Ma P. Review use of ionic liquids as “green” solvents for extractions. J Chem Technol Biotechnol. 2005;80:1089–1096. doi: 10.1002/jctb.1333. [DOI] [Google Scholar]

- 39.Teigiserova DA, Hamelin L, Thomsen M (2020) Towards transparent valorization of food surplus, waste and loss: clarifying definitions, food waste hierarchy, and role in the circular economy. Sci Total Environ 706:136033 [DOI] [PubMed]

- 40.Statista (2016). Share of reused solid industrial waste as targeted by “Made in China 2025” 2013–2025. https://www.statista.com/statistics/1010307/china-reuse-of-solid-industrial-waste-as-targeted-by-made-in-china-2025-plan/. Accessed 10 Dec 2022

- 41.United States Environmental Protection Agency (2020) Recycling Economic Information (REI) Report. https://www.epa.gov/sites/default/files/2020-11/documents/rei_report_508_compliant.pdf . Accessed 09 Dec 2022

- 42.Pimentel D, Hurd LE, Bellotti AC, Forster MJ, Oka IN, Sholes OD, Whitman RJ. Food production and the energy crisis. Science. 1973;182(4111):443–449. doi: 10.1126/science.182.4111.443. [DOI] [PubMed] [Google Scholar]

- 43.Pimentel D, et al. Food production and the energy crisis. Science. 1973;78(4):443–449. doi: 10.1126/science.182.4111.443. [DOI] [PubMed] [Google Scholar]

- 44.Horlings LG, Marsden TK. Towards the real green revolution? Exploring the conceptual dimensions of a new ecological modernisation of agriculture that could ‘feed the world’. Global Environ Change. 2011;21(2):441–452. doi: 10.1016/j.gloenvcha.2011.01.004. [DOI] [Google Scholar]

- 45.Foschi E, Bonoli A. The commitment of packaging industry in the framework of the european strategy for plastics in a circular economy. Admin Sci. 2019;9(1):18. doi: 10.3390/admsci9010018. [DOI] [Google Scholar]

- 46.United Nations Environmental Program (2017) Annual Report. UNEP. https://www.unep.org/resources/annual-report/united-nations-environment-programme-annual-report-2015. Acessed 02 Oct 2022

- 47.Edwards J, Othman M, Crossin E, Burn S. Life cycle inventory and mass-balance of municipal food waste management systems: decision support methods beyond the waste hierarchy. Waste Manag. 2017;69:577–591. doi: 10.1016/j.wasman.2017.08.011. [DOI] [PubMed] [Google Scholar]

- 48.Miccolis A, et al. Restoration through agroforestry: options for reconciling livelihoods with conservation in the cerrado and caatinga biomes in Brazil. Exp Agric. 2019;55(S1):208–225. doi: 10.1017/S0014479717000138. [DOI] [Google Scholar]

- 49.Sillman, Jani, et al. Bacterial protein for food and feed generated via renewable energy and direct air capture of CO2: can it reduce land and water use? Glob Food Sec. 2019;22:25–32. doi: 10.1016/j.gfs.2019.09.007. [DOI] [Google Scholar]

- 50.Grossmann L, Wiss J. Alternative protein sources as technofunctional food ingredients. Annu Rev Food Sci Technol. 2021;12(1):93–117. doi: 10.1146/annurev-food-062520-093642. [DOI] [PubMed] [Google Scholar]

- 51.Araújo AL et al (2018) Agricultura Familiar e Gênero: o benefício da economia solidária na fabricação de produtos processados nas cozinhas comunitárias. Rev Mundi Engenharia Tecnol Gestão 3:100.1–100.20

- 52.Frey M et al (2017) Food sharing: making sense between new business models and responsible social initiatives for food waste prevention. Econ Policy Energy Env 1:123–134

- 53.Dora M (2019) Collaboration in a circular economy: learning from the farmers to reduce food waste. J Enterp Info Manag 33:769–789

- 54.Biasi LCK, et al. Parastillation and metastillation applied to bioethanol and neutral alcohol purification with energy savings. Chem Eng Process - Process Intensif. 2021;162:108334. doi: 10.1016/j.cep.2021.108334. [DOI] [Google Scholar]

- 55.Meirelles AJA et al (2018) A simplified and general approach to absorption and stripping with parallel streams. Sep Purif Technol 203:93–110

- 56.Garre A, Ruiz MC, Hontoria E. Application of machine learning to support production planning of a food industry in the context of waste generation under uncertainty. Oper Res Perspect. 2020;7:100147. [Google Scholar]

- 57.Bouzembrak Y, et al. Internet of things in food safety: literature review and a bibliometric analysis. Trends Food Sci Technol. 2019;94:54–64. doi: 10.1016/j.tifs.2019.11.002. [DOI] [Google Scholar]

- 58.Coelho PM, et al. Sustainability of reusable packaging–current situation and trends. Resour Conserv Recycl. 2020;6:100037. [Google Scholar]

- 59.Marrucci L, Marchi M, Daddi T. Improving the carbon footprint of food and packaging waste management in a supermarket of the italian retail sector. Waste Manag. 2020;105:594–603. doi: 10.1016/j.wasman.2020.03.002. [DOI] [PubMed] [Google Scholar]

- 60.Huang, Yuan, et al. Designing a framework for materials flow by integrating circular economy principles with end-of-life management strategies. Sustainability. 2022;14(7):4244. doi: 10.3390/su14074244. [DOI] [Google Scholar]

- 61.Matrapazi VK, Zabanitou A. Experimental and feasibility study of spent coffee grounds upscaling via pyrolysis towards proposing an eco-social innovation circular economy solution. Sci Total Environ. 2020;718:137316. doi: 10.1016/j.scitotenv.2020.137316. [DOI] [PubMed] [Google Scholar]

- 62.Al-Wahaibi A et al (2020) Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci Rep 10(1):15719 [DOI] [PMC free article] [PubMed]

- 63.Thushari I, Babel S. Comparative study of the environmental impacts of used cooking oil valorization options in Thailand. J Environ Manag. 2022;310:114810. doi: 10.1016/j.jenvman.2022.114810. [DOI] [PubMed] [Google Scholar]

- 64.Pontes PVA et al (2021) Choline chloride-based deep eutectic solvents as potential solvent for extraction of phenolic compounds from olive leaves: extraction optimization and solvent characterization. Food Chem 352:129346 [DOI] [PubMed]

- 65.Neto OZS et al (2020) Oil extraction from semi-defatted babassu bagasse with ethanol: liquid-liquid equilibrium and solid-liquid extraction in a single stage. J Food Eng 276:109845

- 66.Chang HH, Meyerhoefer CD. COVID-19 and the demand for online food shopping services: empirical evidence from Taiwan. Am J Agric Econ. 2021;103(2):448–465. doi: 10.1111/ajae.12170. [DOI] [Google Scholar]

- 67.Gouton MA, et al. Validation of food visual attribute perception in virtual reality. Food Qual Prefer. 2021;87:104016. doi: 10.1016/j.foodqual.2020.104016. [DOI] [Google Scholar]

- 68.De Souza M et al (2021) A digitally enabled circular economy for mitigating food waste: understanding innovative marketing strategies in the context of an emerging economy. Technol Forecast Social Change 173:121062

- 69.Parlato MCM, et al. Livestock wastes sustainable use and management: Assessment of raw sheep wool reuse and valorization. Energies. 2022;15(9):3008. doi: 10.3390/en15093008. [DOI] [Google Scholar]

- 70.Mangla SK, et al. Barriers to effective circular supply chain management in a developing country context. Prod Plan Control. 2018;29(6):551–556. doi: 10.1080/09537287.2018.1449265. [DOI] [Google Scholar]

- 71.Nascimento DLM et al (2019) Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context A business model proposal. J Manuf Technol Manag 30(3):607–627

- 72.Nizetic S et al (2019) Smart technologies for promotion of energy efficiency, utilization of sustainable resources and waste management. J Clean Prod 231:565–591

- 73.Witjes S, Lozano R. Towards a more circular economy: proposing a framework linking sustainable public procurement and sustainable business models. Resour Conserv Recycl. 2016;112:37–44. doi: 10.1016/j.resconrec.2016.04.015. [DOI] [Google Scholar]

- 74.Potrich E, et al. Replacing hexane by ethanol for soybean oil extraction: modeling, simulation, and techno-economic-environmental analysis. J Clean Product. 2020;244:118660. doi: 10.1016/j.jclepro.2019.118660. [DOI] [Google Scholar]

- 75.Nachal N, et al. Applications of 3D printing in food processing. Food Eng Rev. 2019;11(3):123–141. doi: 10.1007/s12393-019-09199-8. [DOI] [Google Scholar]

- 76.Allam SZ. De-carbonized energy initiative with bio-cell-distributed stations using GIS geodesic tools towards circular economy. Energy Environ. 2022;33:562–581. doi: 10.1177/0958305X211013438. [DOI] [Google Scholar]

- 77.Florida R. Lean and green: the move to environmentally conscious manufacturing. Calif Manag Rev. 1996;39(1):80–105. doi: 10.2307/41165877. [DOI] [Google Scholar]

- 78.Ohno T (2008) Toyota production system: beyond large-scale production. Productivity Press, New York

- 79.Cristóbal J, et al. Techno-economic and profitability analysis of food waste biorefineries at european level. Bioresour Technol. 2018;259:244–252. doi: 10.1016/j.biortech.2018.03.016. [DOI] [PubMed] [Google Scholar]

- 80.Maddaloni M, Alessandri I, Vassalin I. Food-waste enables carboxylated gold nanoparticles to completely abat hexavalent chromium in drinking water. Environ Nanotechnol Monit Manag. 2022;18:100686. [Google Scholar]

- 81.Kusumowardani N, et al. A circular capability framework to address food waste and losses in the agri-food supply chain: the antecedents, principles and outcomes of circular economy. J Bus Res. 2022;142:17–31. doi: 10.1016/j.jbusres.2021.12.020. [DOI] [Google Scholar]

- 82.Rado I (2022) Getting to the bottom of food waste: identifying obstacles to effective circular economy practices in a thai semi-urban context. J Mater Cycles Waste Manag 24(2):824–834

- 83.Schmidt-Traub G, et al. National baselines for the sustainable development goals assessed in the SDG index and dashboards. Nat Geosci. 2017;10(8):547–555. doi: 10.1038/ngeo2985. [DOI] [Google Scholar]

- 84.European Comission (2022) Circular economy action plan. https://ec.europa.eu/environment/strategy/circular-economy-action-plann. Accessed 15 June 2022

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable