Abstract

On January 30, 2020, COVID-19 outbreak, detected for the first time in Wuhan (China), was declared by WHO a Public Health Emergency. In a strongly connected world, the consequent slowdown of the Chinese economy contributed to disrupt the global supply chains of several products. In a post-pandemic scenario, the expected rapid increase in demand of critical raw materials (associated with the transition to more green energy sources), coupled with the problems that some mining activities are relegated only in certain countries and regions, must be considered in a sustainable perspective.

This work analyses the literature about (critical) raw materials and COVID-19, not only to present the impact of the pandemic on their supply, but also to propose some actions that should be pursued in a post-pandemic renaissance scenario, to increase raw materials availability, with great attention to most critical ones, in the frame of circular economy principles.

The post-pandemic possibilities are evaluated and suitable actions are suggested to secure the raw materials availability for the foreseen increase of investments in crucial and strategic sectors, in accord with the UN Sustainable Development Goals (SDGs).

The proposed actions can be summarized as policy, strategy, economy, and technology activities.

Keywords: Sustainability, Critical raw materials (CRMs), Circular economy, SDGs, COVID-19, SARS-CoV-2

Graphical abstract

1. Introduction

COVID-19 pandemic has created a global crisis with more than 178 millions of detected cases and more than 3,5 millions of reported deaths at the end of June 2021. It has disrupted economic, financial, political, and social structures all over the world. Undoubtedly, the main goal of almost all the political authorities was to limit the spread of the virus, with the consequence to put in place restriction measures that have impacted on the economic development. In particular, global GDP was evaluated to be decreased by 4.2% in 2020 (Gałas et al., 2021).

Research activities to face the pandemic were mainly devoted to develop effective ways to reduce the infection and to limit exposure risks, also in view of possible future epidemics due to similar viral agents (Coccia, 2020). In this frame great efforts were made to evaluate the possible sources of virus spread, that were attributed not only to human-to-human interactions, but also to environmental (as for example air pollution agents (Coccia, 2021a) (Coccia, 2021b), meteorological (Anand et al., 2021), and socio-economic factors (as for example trade exchanges (Bontempi et al., 2021b, Bontempi et al., 2021a) (Bontempi and Coccia, 2021).

However, despite that COVID-19 pandemic has globally caused major health, economic, and social difficulties, also some challenges and opportunities have been recognized (Shrestha et al., 2020) (Lurie et al., 2021) (Quitzow et al., 2021). As a consequence of containment measures, people have experimented the importance of technology diffusion, for information and communication, involving several typologies of activities, like working, learning, entertainment, and share news. The relevance of electronic devices was never so evident than during lockdown, when it was necessary to reduce (and often completely avoid) human interactions (Sarkis et al., 2020). Then, the pandemic was also recognized as an opportunity to develop new skills, adopt online education, employ telecommuting, and diffuse virtual meetings options, with also several consequent environmental advantages, associated to decrease of people transport and the reduction of derived emissions (Sarkis et al., 2020). The increase of digital connectivity is also one of the European Commission (EC) ambition for the next future, coupled with the aims to construct a more green and resilient society. In this context, it is fundamental to highlight that green and digital technologies are based on the use of several raw materials (RMs). Moreover, there are some natural resources, containing essential elements, with limited and/or restricted supply, that are defined critical raw materials (CRMs). They play a fundamental role mainly for industrialized regions in the world because several of these CRMs have contributed to revolutionary development of some recent technologies and are necessary for energy efficiency. Their economic importance is connected to their applications that are expected will be ulteriorly developed in green, defence, and high-tech sectors (Althaf and Babbitt, 2021). Considering some CRMs necessity in technological applications also for green energies and ecological transition, more than 30 metals are currently inserted in the list of critical raw materials (Akcil et al., 2020).

Even if COVID-19 has highlighted some market distortions connected with CRMs (as better discussed in Section 3), in the past two decades, climate events, as for example droughts and floods, rainfall variability, and extreme storms have caused major impacts in mining activities around the world (Ford et al., 2010). EC has the aspiration to reach 2050 climate neutrality and recognizes that the access to resources is strategic to fulfil this ambition. As a consequence, CRMs that have been already considered crucial for society, are now even defined super-critical (Heffron, 2020).

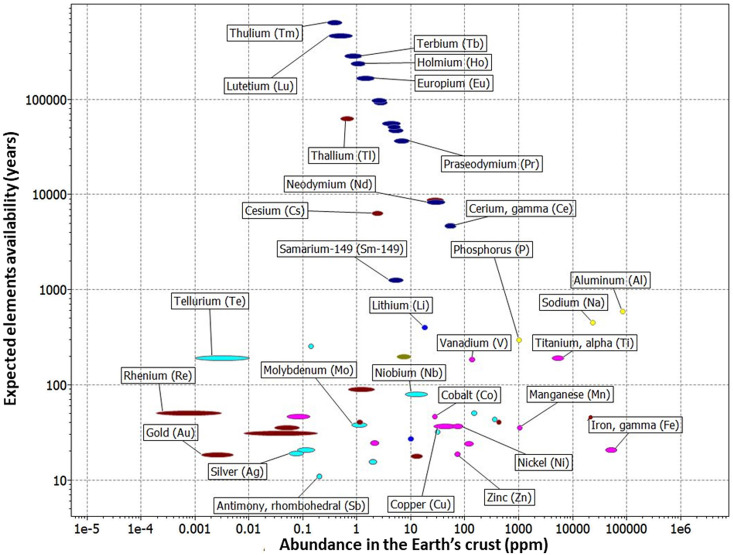

Fig. 1 reports the expected availability of major elements (in years), obtained by considering their world reserves divided by their annual world production (data were extracted from CES Selector database (Granta Design, 2019) referring to 2019, i.e. before COVID-19). These data are plotted versus the element's abundance in Earth's crust (in ppm), that accounts the elements availability in their minerals. Generally, CRMs are reported in the tables mainly highlighting their supply risks (European Commission, 2020a). Then, the results shown in Fig. 1 are very interesting because they don't account any risk correlated with the recyclability and/or geo-political situations where these materials are mined, that are the fundamental characters defining CRMs. As a consequence, only general considerations about the elements abundance and their use can be derived. For example, it is very interesting to highlight that, even if their low Earth concentrations, Rare Earth Elements (as for example Ce, Pr, and Nd) are expected to be available in mined sites for several years (more than 10000 years), based on their commercial interest.

Fig. 1.

Expected elements availability (in years), versus their abundance in the Earth's crust (ppm) not considering recycling. Data are extracted from CES Selector database – 2019 (Granta Design, 2019). Elements in the bottom may be not available in the next years if their supply will be based only on mining.

On the contrary, Fig. 1 shows that Sb, Au, and Ag are among the resources that may be still not available only by mining in the next years. As a consequence, considering the general perspective of limited time availability of some elements, it is clear that specific actions are necessary to guarantee the expected economic growth and prosperity in the post-pandemic.

For example, it results evident that it is mandatory to invest efforts in developing sustainable ways to recycle CRMs from waste, considering that some available natural resources are inappropriate to support the raw materials need of the next future. Indeed, supply of resources is considered no longer able to meet demand (Henckens, 2021). In this frame, the linear economy principles, based on the raw materials transformation into final products, and their subsequent discharge as a waste, cannot be longer followed (Rocchi et al., 2021). The circularity is defined a sustainable model offering a basis for a new approach waste management, allowing to save costs and obtain environmental benefits on the long run (Van Straten et al., 2021). Making a circular economy transformation means to decouple value creation and the use of virgin raw materials (Valve et al., 2021). While the implementation of circular economy in local production (for example at firm-level, till to eco-industrial parks) is often considered, a massive gap exists in how the circular economy is perceived at the global level (Rahman and Kim, 2020), representing a fundamental issue in the raw materials market.

However, it is also fundamental to guarantee the quality of the recycled material for direct re-employment (Oumarou Amadou et al., 2021).

For example, global annual production of electronic waste was estimated to be approximatively 50 million tonnes (Larmer, 2018), and is expected to grow continuously due to the increased use of electronics, as it was also demonstrated during pandemic (that for example forced people to adopt smart-working). By 2030, more than 1 million of batteries is expected to reach the end of their first-life (Ribeiro et al., 2018). The metals present in these devices (like lithium, copper, cobalt, silver, and gold) often go into landfilling, despite their value, with the consequence to originate soil contamination and water pollution (Ribeiro et al., 2018). Then, the generated electronic wastes, that provide several concerns related to their toxicity, offer an opportunity for recycling precious (Larmer, 2018).

The materials circularity is also a fundamental pillar of sustainable development. In particular, the strategies that will be chosen for these waste materials disposal or recover will be highly influential on the SDGs (mainly concerning SDG 12 for Responsible Consumption and Production) and the introduced circular economy agenda.

However, despite that in recent literature several concerns have been focalized on different environmental issues related to COVID-19, ranging from pollution (Bontempi, 2020a), to critical resources related to batteries availability (Panda and Akcil, 2021), energy supply, and climate change, few attentions has been devoted to suggest possible actions concerning raw materials (with great attention mainly to CRMs) that should put in place in post-pandemic scenario to be synergic with the ecological transition. Indeed, it was recently shown (Bontempi et al., 2021a, Bontempi et al., 2021b) that sustainable materials are strictly related with most of SDGs and offer the opportunity to construct collaborative actions involving several of their targets.

The mining sector, where raw materials are extracted, is very energy-intensive. The limits are co-determined by the large external costs of mining arising from the impact of ever deeper and remoter mining on climate change and on the mine's surrounding environment (Henckens, 2021). Then, it is necessary to revise some mining strategies and improve the recycling industry potentialities and support. In the next future, it will be fundamental to reallocate some resources to promote adaptation and development efforts (Church and Wuennenberg, 2019). As the basis of urban social-economic development, the resources are interrelated in the production and consumption activities of cities (Li et al., 2021). Increased raw materials recycling will contribute to reach the targets of SDGs 9 and 12, and to the adaptation-related objectives of SDG 13, by decreasing the reliance on mines, that are highly vulnerable to climate change.

Despite the presence of some papers in literature devoted to the impact of pandemic on raw materials availability (Navon et al., 2021), only few are expressively devoted to CRMs (Akcil et al., 2020) (Gałas et al., 2021). In addition, current explorations lack a global vision of the problems deriving by pandemic and prepositive actions to face the crisis on CRMs availability.

The aim of this paper is to show an analysis of the impact of COVID-19 on raw material supply, with particular attention to CRMs, and propose a combination of measures devoted to increase the raw materials accessibility, with great attention to CRMs. An accurate analysis of all available literature about CRMs (also connected with COVID-19) is used for the basis of analysis. Through this investigation, post-pandemic challenges and opportunities that should be pursued to increase the access to raw materials, are proposed, in the frame of SDGs.

2. Study design

To provide a comprehensive assessment of the impacts of COVID-19 on raw materials, this work analyzed the articles related to this subject by a systematic literature review. Indeed, through the compression and integration of massive data analysis, literature investigation can provide the statistical mean in quantitative assessment of scientific information (Zhang et al., 2021).

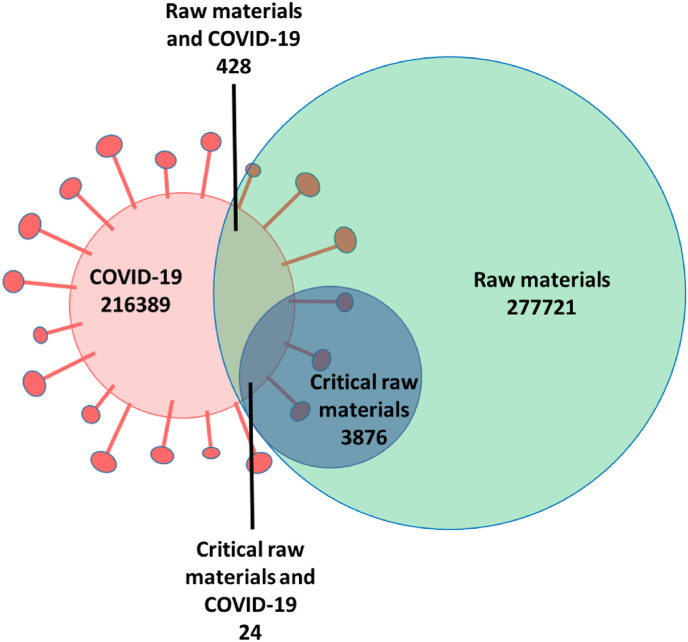

SARS-CoV-2 has attracted great attention in literature due to the exceptionality of the pandemic. Indeed, a search for COVID-19 (or SARS-CoV-2) with SCOPUS database showed the existence of more than 200,000 papers concerning to this argument. Currently, papers involving “critical raw materials” are 3876 (see Fig. 2 ). Pandemic had a great impact on materials availability and use, due to the economic crisis associated to COVID-19 global spread (Ibn-Mohammed et al., 2021). SCOPUS database allowed to identify 428 papers devoted to raw materials (RMs) and COVID-19 (or SARS-CoV-2). However, a similar search but concerning “critical raw materials” in all possible fields, has highlighted the existence of only 24 papers expressively devoted to this topic (see Fig. 2).

Fig. 2.

Summary of literature research about COVID-19 (or SARS CoV-2), raw materials and critical raw materials on SCOPUS database.

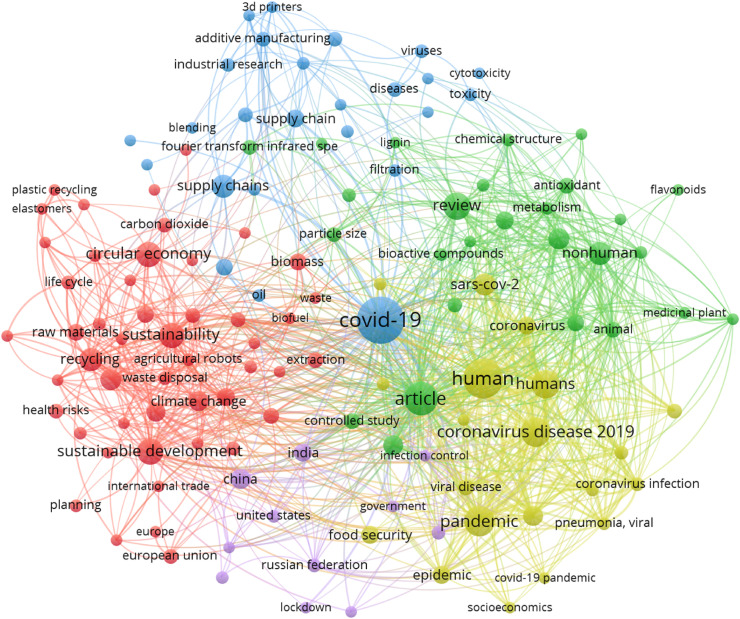

The information of the articles from SCOPUS platform included authors, title, keywords, abstract, and references for the data analysis, synthesis, and interpretation. In particular, an analysis of keywords co-occurrence network of papers devoted to RMs and COVID-19 (or SARS-CoV-2) allowed to perform a cluster analysis of the literature (see Fig. 3 ). The study design (with connected literature) was updated on June 10, 2021.

Fig. 3.

The keywords co-occurrence network of papers devoted to raw materials (RMs) and COVID-19 (or SARS-CoV-2). The study design was updated on June 10, 2021. Data analysis was performed by (“VOSviewer version 1.6.16,” 2020).

It results that the already available papers can be grouped in 5 clusters. The first one (49 items) is mainly devoted to circular economy principles, with great attention to sustainability and environmental impacts, involving waste management strategies. In this cluster raw materials extraction is also considered. The second cluster (27 items) is devoted to chemicals (compounds devoted to COVID-19) and their characterization. The third cluster (25 items) mainly concerns supply chain, with attention to raw materials commerce and manufacturing. The fourth one (20 items) essentially involves medical keyworks, related to pandemic disease. Finally, the last cluster (11 items) is centered on geographical locations (as for example China, Russian federation, India, and so on). It results that only few papers are expressly devoted to raw materials availability (they can be found in cluster 1).

Then, based on the results of cluster analysis, the last step was realized thorough reading the selected full text papers from the perspectives of the consequence of pandemic on RMs and CRMs. These papers were carefully analyzed with great attention to the resulting 24 papers expressly devoted to CRMs and COVID-19. All the available literature about CRMs allowed also to propose possible future directions, which are presented in detail in the next section.

The measures used in this study are the following:

-

•

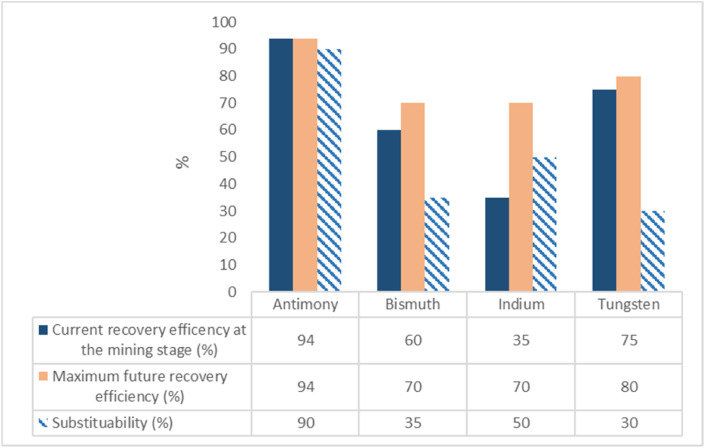

Data about the current recovery efficiency of 4 CRMs (antimony, bismuth, indium, and tungsten), their proposed future recovery efficiencies and their substitutability, that are extracted from (Henckens, 2021).

-

•

Data about mining operations at risk on June 25, 2020, reporting the material, the number of respective involved mines and total revenue at risk, that are provided from S&P Global Market Intelligence (MacDonald et al., 2020).

-

•

Data about monthly price change (%) of lithium carbonate, cobalt, rock phosphate, iron ore, copper and aluminum and Commodity Metals Price Index (2005 = 100, includes Cu, Al, iron ore, Sn, Ni, Zn, Pb, and U Price Indices) from January 2019 to February 2021, that were extrapolated from World Bank and Trading Economics.

3. Results and discussion

3.1. Summary about CRMs state of art

The EU industrial strategy poses raw materials as key enablers for a green, competitive, and digital Europe. EC has identified some critical raw materials (CRMs) that are considered crucial for EU economy. The number of these minerals is increasing in the classifications that were updated after the first introduction. In 2011 CRMs were 14, in 2014 the list was extended to 20 materials, and in 2017 CRMs increased till to 27 (European Commission, 2017). Currently CRMs are 30 (European Commission, 2020a). These resources play a fundamental role in 81 countries that collectively account for a quarter of world GDP (Heffron, 2020). Moreover, it is expected an increase of CRMs demand strongly related to the world's capacity from green sources needs, under the 2015 Paris climate agreement (European Commission, 2020b). In particular, more energy needs to be stored, more CRMs are necessary (Hund et al., 2020).

Regarding technological applications connected to green energy, several of the 30 CRMs are currently involved. For example, Al (extracted from bauxite) is used for turbine blades, wires and electrodes. Co, Ni, Fe, and Li are key metals for batteries (more than 60% of Co extracted from mines goes into rechargeable batteries). Rare metals like Ga and In are widely used in electronics components (to realize transistors and computer chips). Rare-earth elements (REEs) are widely used in high technology devices, including computer hard disks, flat screen televisions, smart phones, computer monitors, and digital cameras. They are also used in defence technologies and clean energy applications. For example, Nd and Dy are essential for magnets. The access to these resources, that are defined technology metals, is now fundamental and crucial for climate change combat. Indeed, it is estimated that 3 billion tonnes of metals and minerals will be mandatory to reach the objective to decarbonize the global energy system by 2050.

In addition, other technologies development, such as 5G digital communications, is improving the pressures on other resources (Akcil et al., 2020).

As a consequence, by 2030 the Li and Co demand is expected to increase up to 18 and 37 times respectively, considering the corresponding requests in 2015 (Jones et al., 2020). In particular, to satisfy its manufacturing batteries necessities, the Chinese market will increase the demand for both lithium and cobalt reaching about 68% of the global need (Jones et al., 2020). Also other alternative energies sources, based on solar cells, panels, and wind turbines will be more diffused in the next years, with an expected significant increase in demand of raw materials due to the both wind and solar photovoltaics technologies (Vidal et al., 2013), at global level. This also will contribute to produce strong concerns related to all CRMs associated with energy generation technologies.

Considering data reported in Fig. 1, it is evident that an increase higher than 1 order of magnitude in the Li and Co demand, will risk limiting their availability to about 30 years for Li and less than 10 years for Co (only considering mining resources).

In this frame it is then fundamental to evaluate the recovery efficiency and the possible substitutability of these materials, to evaluate the opportunities due to wastes valorisation and materials replacement. Fig. 4 reports the current recovery efficiency of some CRMs, their proposed future recovery efficiencies and their substitutability (Henckens, 2021). It results that some of these elements (as for example Sb) are recovered with efficiency higher than 80%. On the contrary, some elements are recovered with low efficiency (as for example In, that is recovered with an efficiency lower than 50%). Higher recovery efficiency may need too energy resulting a not sustainable process (Henckens, 2021), with an expected need of technological improvements aimed to enhance their recovery. Fig. 4 also shows the reported CRMs substitutability, i.e. the possibility to be replaced by another material. The results are very different considering Sb (that can be substituted for 90%) and W (that can be substituted only for 30% by another material).

Fig. 4.

The current recovery efficiency of some CRMs, their proposed future recovery efficiency and their substitutability (data were extracted from Henckens, 2021).

In this frame it is important to highlight that some concerns are also related to metals that aren't CRMs. Some researches, more focalized on specific elements, suggest, for example, a future increasing demand not only for Li, Co, and Al (it is extracted from bauxite), but also for Fe, Mn, Ni, and Pb (World Bank Group, 2017a). In particular, electrification is supposed to cause the increase the Ni and Mn request for new vehicles batteries by five times the 2015 level (Jones et al., 2020).

In addition, there are metals that are necessary for vehicles productions, not considering batteries; they are for example steel and aluminium. Due to stainless-steel composition, for vehicle production also Cr, Mn, and Ni will be necessary. Al will be fundamental to reduce the vehicle weight (it is mainly used for car bodies and battery cases), allowing to meet the stringent emissions legislation, making possible also a gradual reduction of steel use for mobility. Key uses of this element not only include the transport sector, but also building industry (for example Al is used to realize windows, doors, and facades), and packaging (where Al is used for beverage cans, and for foil applications). Literature estimates an annual global demand increase in 2030 (then not considering batteries sector) by 30.4%, 8.4% and 6.3% respectively for Ni, Al and Cu, on the basis of 2017 production (Jones et al., 2020). Moreover, in 2050 the Al request is estimated to increase till to 40%.

In addition to studies related to global necessities, that are summarized in this section, the request for the critical raw materials, associated with the transition to green technologies for low carbon economy, have been also analyzed in literature considering the specific frameworks of some countries (Ciacci et al., 2016) (Moss et al., 2011) (Hatayama and Tahara, 2015).

Phosphate rocks (PR) have been also inserted in the CRMs list, due to their fundamental contribution for the P supply chain (European Commision, 2014). Although scarcity and provisions risk are common aspect for critical raw materials, when phosphorus is considered, it is fundamental to highlight that this element is linked to food production and thus its scarcity may compromise the access to food. This risk is then correlated to SDG 2.

Literature about inorganic P production and connected use reports an 80% of phosphorus loss from mine to fork (Cordell et al., 2009) with the evaluation that only 10% of the processed fertilizers can be digested by humans (Scholz et al., 2014) and more than half of the losses from fertilizer application on soil to fork are in runoff from agricultural land (Scholz and Wellmer, 2015). The digested phosphorous is generally found in wastewater and can be also discharged outside of a wastewater collection system (Ducoli et al., 2021).

The processes connected to PR mining and processing have several negative impacts on air and water qualities, and climate effects (Nedelciu et al., 2020).

In addition to the pollution and eutrophication effects, the P supply chain produces large amount of waste deriving from the processing of PR to synthesize final products (as for example phosphoric acid) (Nedelciu et al., 2020).

Several activities and technologies are proposed to recover phosphorus from waste, as for example from sewage sludge (Fahimi et al., 2021) (Pasquali et al., 2018) (Benassi et al., 2015) and poultry litter ashes (Fiameni et al., 2021) (Fahimi et al., 2020). Moreover, developing processes to recycle phosphate from the growing phosphogypsum stocks, derived from phosphoric acid synthesis, may also play a fundamental role in providing suitable qualities of fertilizers on the market (Nedelciu et al., 2020). Great attention should be also devoted in the loss reduction of P supply (Nedelciu et al., 2020).

In this scenario some actions can be envisaged that can be linked to understanding and improve mining potential, recover resources, and secure job (Panda and Akcil, 2021).

For example, an international network in raw materials i.e. EIT (“EIT Raw Material,” 2021) was instituted by EU and funded by the European Institute of Innovation and Technology (EIT). The aim of this network is to support innovation schemes addressed to mining, exploration, recycling, processing, and substitution of raw materials, in the frame of circular economy principles.

3.2. Pandemic impact on raw materials supply

The analysis of the literature allowed to summarise the pandemic impact on raw materials supply (see Fig. 2). Indeed, the majority of available papers about this argument concerns the impact of pandemic on natural resources management (Laing, 2020) (Cai and Luo, 2020) (World Bank Group, 2017b). Some of these works show that the global international trade can be also associated to higher virus diffusion, then to higher negative effect (Bontempi, 2021) (Bontempi, 2020b) (Bontempi et al., 2020).

On the basis of literature analysis (see Fig. 2) it results that: 1) exploration works for new mine sites were delayed (Gałas et al., 2021), 2) the metals demand was significantly reduced, 3) the international supply chain was almost completely destroyed, 4) the production sector stopped, due to reduced consumption, and 5) the price of several raw materials have been (also drastically) changed (some decrease and other increase). For example, it was reported that an unexpected price increase occurred for epoxy and polyester resins (Coating World, 2021) due to COVID-19 restrictions.

Then, an economic shock was reflected on both the demand and the supply of raw materials (Panda and Akcil, 2021).

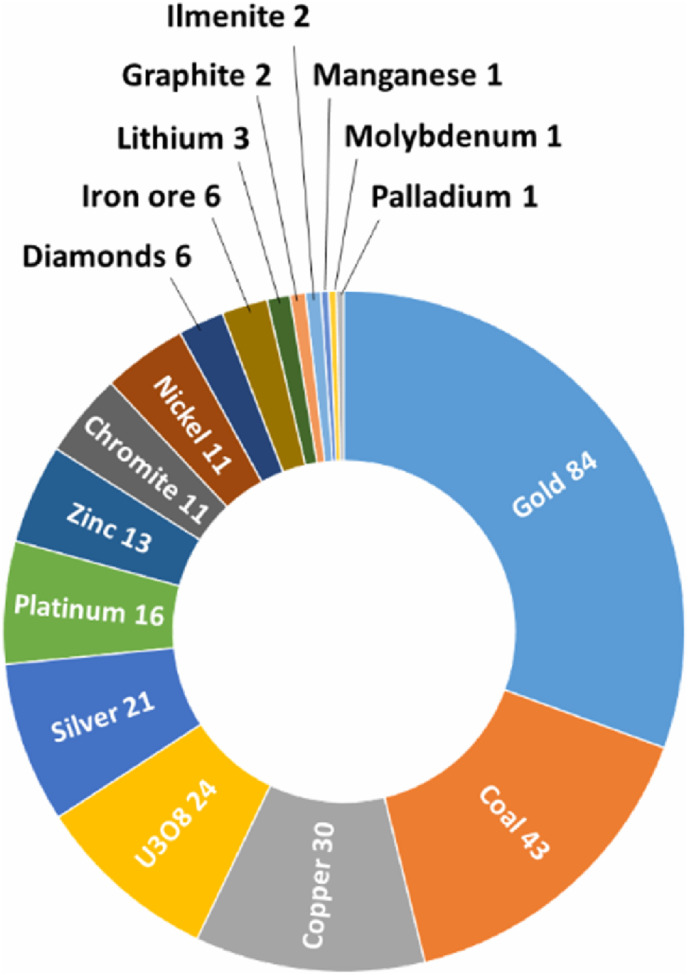

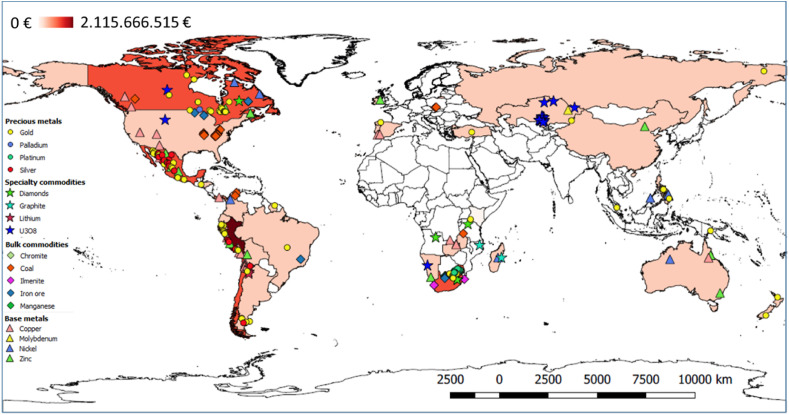

In particular, considering the mining sector, COVID-19 caused several negative impacts across the world, with the consequence to several sites closure. For example, on June 25, 2020, it was found that 275 mining operations were globally disrupted as shown in Fig. 5 . Most of these mining sites were closed to comply with anti-contagion measures (MacDonald et al., 2020).

Fig. 5.

Representation of 275 mining operations at risk on June 25, 2020. Metals and the number of respective mines are reported.

It was found that the most impacted mines concerned gold, coal, copper, U308 and silver. In summary, the global impacted projects worldwide due to pandemic, connected to mining sector, was evaluated to be more than 7 billion of € (around US$ 9 billion) (MacDonald et al., 2020). Fig. 6 shows, according to (MacDonald et al., 2020), where the most endangered mining sites are located highlighting the countries that have suffered the greatest losses. The most affected country was Peru, with losses of more than 2 billion of €, followed by Mexico and Chile. Data analysis was performed by Qgis software (“Qgis,” 2018). Moreover, in the supplementary material of this work, all files necessary to create a Qgis map of mining sites and revenue at risk per country are available. With temporary closing of mining operations expected to reduce the 20% production in 2020 compared to 2019 (Habib et al., 2021).

Fig. 6.

Representation of the most endangered mining sites (divided into precious metals, specialty commodities, bulk commodities, and base metals) and the countries that have suffered the greatest losses. Data analysis was performed by Qgis software.

In addition, there were also some potential markets crisis that may be originated by the limited availability of some primary resource sectors to provide raw materials, when markets were closed to reduce safety risks.

The prices of several metals can be associated to economic cycles: the decrease in some raw resource production is more likely associated to a decline of demand, rather than the falling of geological resources availability (Graedel et al., 2013).

The metal market is extremely volatile, influenced by economic and political factors. The pandemic has exacerbated this trend, leading to a disruption of world balances which have had a major impact on world markets. In fact, when the COVID-19 has spread, to mitigate its impact, China introduced some strategic actions that have caused an important decrease in demand in the market of large consumers (Moore et al., 2020).

The COVID-19 pandemic had a strong impact on industrial production. In the first quarter of 2020, the drop of 20% in the Chinese economy due to Wuhan's manufacturing shutdown generated a reduction in the raw material prices (Akcil et al., 2020). This trend, according to (Laing, 2020), shows an analogy with the Great Financial Crash of 2008–2009.

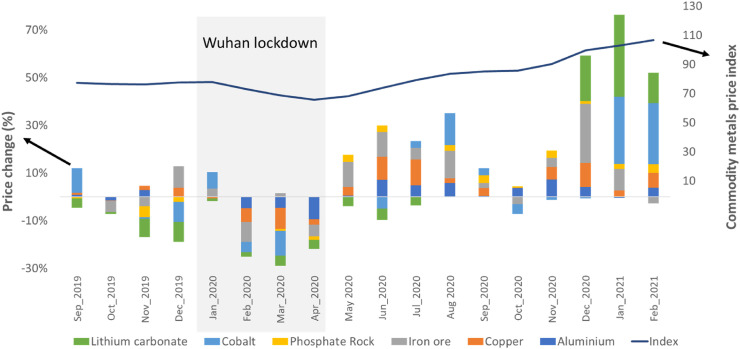

The rapid decline in demand generated a reduction in the prices particularly for aluminium and copper (Laing, 2020). Fig. 7 shows the monthly price variation from September 2019 to February 2021 of some CRMs, such as lithium carbonate, cobalt, phosphate rock (PR), and other key metals for batteries such as iron ore, copper and aluminium. In addition, a commodity metals price index was inserted (Cu, Al, iron ore, Sn, Ni, Zn, Pb, and U are considered).

Fig. 7.

Monthly price change (%) of lithium carbonate, cobalt, rock phosphate, iron ore, copper and aluminum and Commodity Metals Price Index (2005 = 100, includes Cu, Al, iron ore, Sn, Ni, Zn, Pb, and U Price Indices) from January 2019 to February 2021. The Wuhan lockdown period was from 23 January to April 8, 2020. Data source: World Bank and Trading Economics.

As reported in Fig. 7, in April 2020 the price of aluminium has dropped more than 9% respect to March 2020, while the price of copper slumped more than 8% between February and March 2020. In the same period the lithium carbonate price is reduced more than 4%, respectively.

The closure of Mutanda mine site, the largest cobalt field in the world, in November 2019 (Mining weekly, 2020), generated a slight rise of Co price from December 2019 to January 2020. On the other hand, the COVID-19 pandemic caused a decrease in prices between February and March 2020 about 10%.

The exposure on the stock market of the metal sector can be defined by the Commodity Metal Price Index (CMPI). This index represents a general level of metals price. CMPI is a weighted average of the prices of some reference metals respect to their prices in a base year. In Fig. 7 is reported the Commodity Metals Price Index of Cu, Al, iron ore, Sn, Ni, Zn, Pb, and U, from 2019 to February 2021.

Following the droop in process between February and April due to COVID-19 pandemic, metal prices recovered strongly reflecting a recovery in global industrial demand largely driven by consumption in China (World Bank Group, 2017b) exciding the pre-pandemic values.

Indeed, as reported in Fig. 7, the price of aluminium, copper, iron ore, PR and cobalt is increased in the third quarter of 2020 of 14%, 22%, 25%, 6% and 9%, respectively compared to second quarter of 2020. On the other hand, the price of lithium carbonate is decreased of 8% in the same period. However, from December 2020 to February 2021 lithium carbonate price increased due to the high demand of lithium ion batteries (Mining.com, 2021).

Due to lockdown, the demand for electronic devices such as PCs and tablets, needed for smart working and distance learning, has strongly increased by 13.1% in 2020 and the trend is still growing (IDC, 2021). Some of the materials used for their manufacture, already present in limited quantities, are part of the sites at risk.

Compared to previously economic crisis, the rolling spread of the pandemic has led to different outcomes. For example, in 2011 the prices of some metals peaked sharply after an abrupt and almost total supply disruption (Habib et al., 2021). On the contrary, after the pandemic diffusion, in 2020, the prices of some RMs initially went down slightly because demand was disrupted even more, and then they increased.

3.3. Proposed actions able to increase raw materials availability

The dependence on natural resources extraction has shown several fragilities for local economies, that were enhanced during the pandemic crisis. However, over the next years an increase in the demand for some mineral resources is expected. To face the post-pandemic it is necessary to learn from past supply chain limits and propose active improvements to give a positive impulse to a sustainable renaissance. Indeed, even if COVID-19 pandemic has highlighted some fragilities in raw materials supply, this experience can also be used to suggest new strategies in their management, in view of a desired increased resilience.

Literature analysis, mainly concerning the papers devoted to CRMs (see Fig. 2), allows to propose some actions, that may be pursued, to increase CRMs availability, also on the basis of past experiences. In this frame, for example, the strategies that were putted in place to better manage the Al supply can represent an example that may be followed for other natural resources, if possible.

As reported in Section 3.1, Al represents a strategic element for the EU Green Deal policy. Currently Al industry is able to recover and reuse about 36% of secondary Al (European Aluminium, 2020). Al recycling involves only 5% of the energy that is used for primary production. To meet the next years increased request of this metal, both primary (mined) and secondary Al production will be necessary (European Aluminium, 2020). However, even if an increased demand is expected, a feasible scenario shows that EU can reduce its dependence on imported Al from 29% to 15% in 2030 by rising its domestic production. This will be possible if the right competences will be in place (European Aluminium, 2020), to improve collection and sorting, with the result to ensure higher recycling rates and better quality of the obtained output. It was already shown that a suitable scenario will require additional legal constrains and investments for better collection and sorting technologies, to limit Al components destined to incineration and/or landfilling. For example, the current shredding treatment process aimed to recover steel from vehicles, need to be improved to better recover also Al.

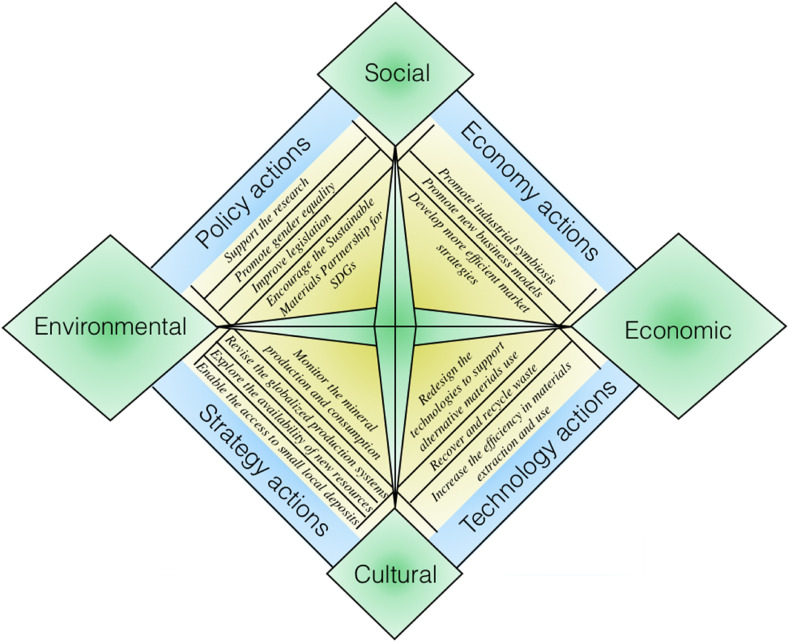

Also considering this representative example, governments, industries, associations, and consumers have some possibilities to reduce the pressure on raw materials in a post-pandemic era. The actions that can be proposed, derived by analysing the available literature about CRMs (see Fig. 2), can be summarized as policy, strategy, economy, and technology activities, and they are summarized in Fig. 8 , with great attention to the involved sustainability pillars.

Fig. 8.

Summary of the proposed actions, grouped as policy, strategy, economy, and technology activities, proposed in the frame of sustainability pillars (Environmental, Social, Economic, and Cultural pillars).

3.3.1. Strategy actions

3.3.1.1. Monitor the mineral production and consumption

Mineral extraction is an energy intensive activity, difficult to decarbonize (Ali et al., 2017). There is a compelling necessity to propose and adopt a framework for tracking mineral use along the entire value chain, from source to end of life, that should account the energies and emissions involved in all the lifecycle (Bontempi, 2017). This system may promote a notion of ‘metal miles’, aimed for example to reduce the transport costs of these resources, promoting the local products consumption (SDG 12). The framework should also consider transparency and ethical schemes: in such a monitoring also the social conditions of mine workers should be accounted, to consider all the pillars of sustainability in the frame of SDGs 5, 8, 10 and 16.

For example, some natural resources (like cobalt minerals) are mined in the Democratic Republic of Congo, where also women and children often work in mines, without basic safety equipment, and where from years the population is plagued by armed conflicts (Amnesty International, 2016) (SDG 16).

Even if we must be conscious that complete traceability schemes may be impossible and the proposed framework risks to be a pure exercise (Sovacool et al., 2020), the established public relations to compile this schema may transform in a support to improved outcomes for miners and better governance management. Mining Local Procurement Reporting Mechanism was already introduced to report information about local procurement of mining companies, as well as detail on mining procurement processes and due diligence practices (Geipe and Kaiser-Tedesco, 2018).

3.3.1.2. Revise globalized production systems

The current production and consumption system are constructed onto on extremely interconnected value chains based on international exchanges and shipment of the basic components. This may increase the vulnerability to pandemic (Bontempi, 2020b), highlighting that more local supply configurations can contribute not only to decrease the local dependence on materials, but also increase local resilience (also to pandemic) (SDG 11). For example, for the polyester and epoxy resins, a complex mix of prices increase, high demand, supply problems also connected to the restricted possibilities of resources transport, had the consequence to increase the market uncertainty and contribute to the materials prices sharply growth (Coating World, 2021). The possibilities of the occurrence of these situations must be reduced, by the revision of the globalisation production system.

3.3.1.3. Explore the availability of new resources

Even if it is mandatory to give primary emphasis on resource efficiency and recycling, it will be necessary to find additional primary resource mines (Sovacool et al., 2020).

New resource streams may be found not only in new deposits or mines, but also in other matrices, such as groundwater (geothermal brines) and seawater (desalination).

In this context new technologies for mineral exploration, from deep in the crust to the bottom of the ocean may be developed (SDGs 8). Geochemical and geophysical data must be shared in greater detail through dynamic databases (Ali et al., 2017).

Moreover, also waste must be considered, as for example landfilling sites, to promote recovery and recycling of some resources, with great advantage in terms of environmental sustainability (SDGs 11, 12).

3.3.1.4. Enable the access to small local deposits

Although large-scale mining is often economically efficient, it has several drawbacks (Sovacool et al., 2020). In a post-pandemic context, small deposit mining by small-scale operations may be more attractive, if compared to multiple mining operations (that probably may need additional capital costs to re-open mine sites), due to the lower investment required, to secure production, even if limited, in a market of low prices (Moore et al., 2020).

Ore deposits are located on all continents including Europe (Goodenough et al., 2016), but in this case, the Europe strict regulation makes their use extremely complicated (Moore et al., 2020). EC must consider the possibility to take advantage of internal mines, with the result to increase its market resources.

Domestic mineral extraction is fundamental to reduce critical raw materials import and increase the resilience of EU territories and their subsistence capability in extreme events, like pandemic (SDGs 8,12) (Bontempi, 2020b).

In this frame, a focus on more local supply chains may be investigated and prioritized.

3.3.2. Technology actions

3.3.2.1. Redesign the technologies to support alternative materials use

This necessity should be constantly pursued. However, it may result fundamental for CRMs. For example, cobalt abundance in Earth's crust is not sufficient to produce all the batteries that will be required by the markets in the next years (as shown in Section 3.1).

Some manufacturers companies (for example Tesla and CATL in China) are pursuing new batteries, with the aim to make them cobalt-free (Akcil et al., 2020). In particular, in the last years, Tesla has reduced its dependency on Co for EV batteries by approximately 60% (Chen, 2018) (SDGs 7, 9, 12). Currently the proposed replacements consist in materials containing Ni or Fe, which still result less efficient, but decrease the pressure on Co. Na-ion batteries are also under study.

3.3.2.2. Recover and recycle waste

In 2017, more than 10 million of tons of electric wastes were generated in Europe (Panda and Akcil, 2021). Unfortunately, only about 31% is currently recycled. Recycling for recovery of precious resources is one of the main activities with high potentialities, it but need to be more explored and supported.

In addition to the landfill mining, the possibility to recycle devices before they are discharged must be encouraged and better investigated (SDG 12). Repair must be a valid option, with also the advantage to generate new jobs positions.

On the other hand, obsolete devices and spent batteries have interesting amount of precious and rare metals, with high potential to allow to meet the growing demands for CRMs, making their extraction from waste potentially economical. Indeed, the activity could be implemented with low logistical and supply chain costs. For example, countries with high amount of electronic waste typologies may establish dedicated markets to reprocess some CRMs domestically (Işıldar et al., 2019). Hummingbird International estimated that materials recycling electronic waste may generate more than one order of magnitude jobs in comparison to those that are dedicated for traditional disposal activities (Sampson, 2015) thereby contributing to SDG 8, with also great advantage in terms of avoided GHG emissions (SDG 13).

In this frame, the secondary Al management strategy can represent a valid example that must be promoted, also for the result that could be acquired in terms of avoided CO2 emissions (up to 39 million ton per year by 2050 (European Aluminium, 2020).

To reach this aim new regulatory measures and improvements in legal constrains may be necessary, for example, to make electronics manufacturers responsible for recycling the products they make also from a legal point of view (SDG 12) (Akcil et al., 2020).

Moreover, the recycling potential of a material used in a specific product depends on some factors, as for example its concentration and the product composition. Indeed, it is evident that a higher concentration generally results in a higher recycling potential. It also depends on eventual dissipative use of the material and possible contamination arising by its use (Henckens, 2021).

3.3.2.3. Increase the efficiency in materials extraction and use

It was estimated that more than 70% of GHG emissions are originated in energy-intensive raw material production, and processing (McKinsey, 2020). It is evident that a higher efficiency in materials extraction, processing, and use is a fundamental step to address the climate neutrality (SDGs 7, 13).

In a full-monitoring procedure of CRMs lifecycle it would be possible to highlight the sectors and steps that may be improved to limit materials loss and increase the efficiency in materials use (SDG 12).

Concerning mining, for example, it is fundamental to minimize waste and the consumption of water during extraction processes, to maximize the amount of extracted materials, and reduce involved energies and emissions (SDG 14) (Lederer et al., 2020). Since 1980s, responsible mining has been addressed as a fundamental criterion in mining. Even if mining should be not defined sustainable, due to its nature that involve resources depleting, the attention towards less polluting technologies for metals extraction was increased in the last 20 years (Spooren et al., 2020). Ore grades is continuously reducing, increasing the necessities of more efficient extraction technologies, producing mineral residues that can be valorised (SDG 12). For example, many conventional separation technologies were considered inefficient for the treatment of low-grade ores, that need to be milled into very fine size grains to guarantee sufficient mineral separation (Dermont et al., 2008). The use of flotation technique (with the development of suitable floating agents) allowed to concentrate fine interest minerals, contributing to reach higher revenues in metals extraction (SDG 14) (Lopéz et al., 2019). Other possibilities to increase materials extraction efficiency will be dependent on the development of digitalization of some processes as for example sensor-based detection and separation of mineral streams (Robben and Wotruba, 2019), and the possibilities of machine learning implementation (SDG 12) (McCoy and Auret, 2019).

Materials efficiency can be improved also by reducing their use in a product, assuring the required functional properties of the final component. This needs a suitable design strategy. In addition, also the reduction of the in-use dissipation (that involves the loss of a resource through and during its consumption, for example by corrosion) can be improved (Henckens, 2021).

3.3.3. Economy actions

3.3.3.1. Promote industrial symbiosis

The possibility to recycle a material derived from a different supply chain sector must be better investigated and promoted. The circular economy principles require a gradually decoupling of economic activity from the natural resources consumption. Metals recycling from RAEE, for example, can offer the possibility to reduce the dependence from mined metals import. However, mineral recycling can be acquired also by using wastes derived from other sectors, such as for example municipal solid waste incineration ash, that can be reused in several other applications (SDGs 9, 12) (Bosio et al., 2013) (Benassi et al., 2017) (Benassi et al., 2015) (Assi et al., 2019) (Zanoletti et al., 2018).

3.3.3.2. Promote new business models

The circular economy approach must be encouraged: materials must be retained within productive use, for as long as it is possible (SDG 9) (“Towards a Circular Economy: Business Rationale for an Accelerated Transition,” 2015). In this business model the waste must be limited and possibly re-introduced in the productive system. In a circularity scheme the waste assumes a new value, in a system that is designed to repair the previous damage (SDG 12) (Murray et al., 2017) (Zanoletti et al., 2018). The evolution in a different business models, that can be defined “circular business model” (Mohammad Ebrahimi and Koh, 2021), modifies the link between the members of supply chain: the cooperation between the actors is necessary and need their involved in long-term learning processes, to achieve the know-how necessary for the new industrial model (Krook and Baas, 2013), to support the urban mining process (Sharma et al., 2021). However, at the beginning of the activities, political intervention, with adequate supporting actions (as for example the provision of green certificates, with a similar mechanism that it is currently proposed for COVID-19 vaccinations certification) is fundamental to ensure that economic benefits outweigh costs (Van Passel et al., 2013). This is clearly evident in the current situation, where inter-regional flows of waste materials have been disrupted by lockdown restriction measures due to pandemic. However, the new business model initiatives, mainly involving small industries and start-ups have been estimated to be able realizing value higher than 230 billion € per year by 2030 (SDG 17) (Klevnäs et al., 2020).

3.3.3.3. Develop more efficient market strategies

Sometimes consumers have the perception that recycled materials may not guarantee the same performances and qualities as virgin resources (Church and Wuennenberg, 2019), or that some devices can be considered old, even if they can be perfectly working. For example, in a recent experiment, considering 148 out-of-use laptops, it was shown that only few units were found to be completely unusable, with most batteries able to retain 89% of their original capacity (Furtkamp Julian, 2017).

This may result in a barrier for the market of secondary materials, that can be overcome by the promotion of suitable dissemination campaigns. In addition, also incentives must be used to encourage consumers to address its electronic waste towards suitable collection and recycling schemes (SDG 9).

It was shown that, for example, if in Japan all used mobile phones would be collected and recycled, the annual consumption of palladium, silver, and gold may be reduced by 2–3% (SDGs 11, 12) (Mishima et al., 2016).

3.3.4. Policy actions

3.3.4.1. Support the research

The investments in research activities devoted to raw materials substitution and exploration, and aiming to find new production technologies, must be suitably addressed before to reach the feedstocks scarcity.

Research activities must also cover the development and/or improvement of the extraction processes. Also the complete metals extractions must be fulfilled to avoid raw materials loss in ore (for example, indium or germanium can be recovered in zinc ores, or gallium can be recovered in bauxite) (SDGs 9, 12) (Ali et al., 2017).

Finally, the priority must be addressed towards funding research activities devoted to secondary resources recycle, considering the increase of global amount of these wastes. The researchers role in developing suitable recovery technology is crucial.

3.3.4.2. Promote gender equality

COVID-19 pandemic has caused several negative aspects. In particular, the effects of the pandemic have hit women the hardest. Concerning raw materials, in many countries mining laws and regulations neither fully mainstream the principle of gender equality nor acknowledge women as active participants in the sector (SDGs 5, 10) (Tekinbas and Deonandan, 2021). The gender equality is one of the SDGs (SDG 5). Post-pandemic conditions give the opportunity to revise legislation, priorities, and governance principles in raw materials sector, as proposed by Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development (Intergovernmental Forum on Mining, Minerals, 2020).

3.3.4.3. Improve legislation

Legislation is currently in evolution to consider the most suitable instruments to address national investment strategies toward a post-pandemic reconstruction. The priority areas to address resources are in discussion. Literature has shown that best practices in responsible mining (related to environmental protection) need resources (Moore et al., 2020).

Legislation has a fundamental role for example in promoting the raw materials traceability, with attention to sources that are responsibly acquired (SDG 16) (Young and Dias, 2012).

In this frame, precautionary measures need attention to avoid illegal mining activities and secure the import and export of critical raw materials, associated with their sustainable supply (SDGs 10, 16) (Panda and Akcil, 2021).

Clear regulatory actions must be designed to incentive eco-design and discourage linear business models in private industries. There is a strong necessity to support product manufacturers in the developing of new business models, taking advantage of economic opportunities due to circular solutions.

As already suggested in this paper, governments can propose economic incentives to improve innovation and support new markets, including low-interest financing, tax abatements, tax revenue sharing, infrastructure assistance, and grants (Tilly, 2017) and ensure more certainty to investors.

Extended producer responsibility (EPR) was introduced in the last years, in some sectors, as a governance mechanism destined to targeted producers, increasing their responsibility in collection, recycling, and waste disposal (Organisation for Economic Co-operation and Development (OECD)., 2016).

Inclusion of mining waste treatment in EPR may be a fundamental action to promote the business for secondary raw material production and management as a fundamental part of the environmental cost of mining (Armstrong et al., 2019), allowing to take into account also environmental costs of raw materials extraction in economic planning (SDG 12).

EPR has the aim to shift the responsibility for valuable resources collecting from consumers to companies that use these materials. This mechanism is expected to introduce some improvements in the materials use and recovery, like as increased eco-design strategies, higher opportunity of recover and repair, and extended product lifetimes and durability.

3.3.4.4. Encourage the Sustainable Materials Partnership for SDGs (Bontempi et al., 2021a, Bontempi et al., 2021b)

SDG 17 (Partnership for the Goals) encourages activities devoted to promote actions across different sustainability goals.

Collaboration between the public and private sectors, involving civil society must be envisaged.

It was recently shown how the connection between sustainable development and materials is extremely strong. The institution of a “Sustainable Materials Partnership” involving all the stakeholders (from researchers, to industries, from clusters to people), may help to support SDGs achievement in all the countries, with great attention to the raw materials connected activities. A first basic example of a similar action may be found in the International Council on Mining and Metals guidelines, proposing the implementation of social actions of local populations of the territories where raw materials are extracted (Parra, 2020). Another example is the EIT RawMaterials initiative, established in 2018, with the mission to enable sustainable competitiveness of the European raw materials sector along all the value chain (“EIT Raw Material,” 2021).

An informal accord, the “Green Recovery Alliance”, to accelerate the ecological transition in a post-pandemic, was recently launched by some members of European Parliament (Frédéric, 2020).

However, more generally, the proposed partnership (SDG 17) should be devoted to all sustainable materials, and not only to CRMs. This will allow to establish a framework able to support all SDGs.

4. Conclusions

CRMs play a key role for the progress of the industrialized regions in the world. They have contributed to recent technological development and energy efficiency improvement. They serve as essential RM for high-technology, sustainable, and green applications. COVID-19 disease has contributed to reduce the availability of several of these materials. However, the pandemic has also demonstrated the need of structured and global efforts to face crisis, because individual actions are pointless. The post-pandemic recovery period could be an opportunity to develop new prosperity models, based on green principles needs and priorities: a more resilient economy, able to catch the new opportunities of digitization, and meet the environment and climate targets.

We have recently marked the 150th anniversary of the periodic table formulation and we are addressed towards SGDs. It is time to realize that a sustainable development needs more attention to some elements, and, in particular, to the minerals where necessary resources are embedded. Despite all the complexities, the humanity must be ready to face this challenge.

After an analysis of reduced supply of RMs due to the pandemic, this work proposes some actions devoted to secure a more balanced resources distribution. This should happen in particular in terms of natural resources revenue that could be more equally shared across all the business value and supply chains (Heffron, 2020). The paper shows that the diversity of CRMs that are need for manufacturing future technologies necessitate a change in their extraction and manufacturing approaches. The materials production and consumption must be secured in a sustainable way, that probably will need a revision of giant ore deposits management strategies. Technology will be a fundamental player of this innovation, but also mining code and practices need strict revisions and improvements.

Finally, increased materials recycle will help to fulfil some of the circular economy aims, by reducing reliance on finite resources and mitigating permanent waste disposal. The expected post-pandemic scenario will contribute to SDGs 5, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 and 17 fulfil among others.

This study presents some limits. One of the main limitations of this research is due to the data source, which was confined to articles collected from SCOPUS till a certain data (June 10, 2021). The information about COVID-19 and raw materials obtained from the following periods may provide additional data that are not considered in this work. Another limitation of this work concerns the social pillar of sustainability, that is not considered in the study: “social sustainability” is linked to the social outcomes and values, such as equality, social responsibility, children's work, gender equality, community resilience, freedom from poverty, that is often connected with population living and working in mining sites.

Author contributions

Conceptualization: E.B.; Data curation: E.B., A.C., A.Z.; Formal analysis: A.C., A.Z.; Investigation: E.B., A.C., A.Z.; Supervision: E.B.; Roles/Writing - original draft: E.B, A.C., A.Z; Writing - review & editing: A.C., A.Z.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported under the scope of the ERA-MIN2 Joint Call (2018) “Novel Circular Economic Approaches for Efficient Extraction of Valuables from Spent Li-Ion Batteries (NEXT-LIB)”.

References

- Akcil A., Sun Z., Panda S. COVID-19 disruptions to tech-metals supply are a wake-up call. Nature. 2020;587:365–367. doi: 10.1038/d41586-020-03190-8. [DOI] [PubMed] [Google Scholar]

- Ali S.H., Giurco D., Arndt N., Nickless E., Brown G., Demetriades A., Durrheim R., Enriquez M.A., Kinnaird J., Littleboy A., Meinert L.D., Oberhänsli R., Salem J., Schodde R., Schneider G., Vidal O., Yakovleva N. Mineral supply for sustainable development requires resource governance. Nature. 2017;543:367–372. doi: 10.1038/nature21359. [DOI] [PubMed] [Google Scholar]

- Althaf S., Babbitt C.W. Disruption risks to material supply chains in the electronics sector. Resour. Conserv. Recycl. 2021;167 doi: 10.1016/j.resconrec.2020.105248. [DOI] [Google Scholar]

- Amnesty International . 2016. THIS is What We Die for: Human Rights Abuses in the Democratic Republic of the Congo Power the Global Trade in Cobalt. Afr 62/3183/2016 88. [Google Scholar]

- Anand U., Cabreros C., Mal J., Ballesteros F., Sillanpää M., Tripathi V., Bontempi E. Novel coronavirus disease 2019 (COVID-19) pandemic: from transmission to control with an interdisciplinary vision. Environ. Res. 2021;2019 doi: 10.1016/j.envres.2021.111126. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Armstrong M., Petter R., Petter C. Why have so many tailings dams failed in recent years? Resour. Pol. 2019;63 doi: 10.1016/j.resourpol.2019.101412. [DOI] [Google Scholar]

- Assi A., Federici S., Bilo F., Zacco A., Depero L.E., Bontempi E. Increased sustainability of carbon dioxide mineral sequestration by a technology involving fly ash stabilization. Materials. 2019;12 doi: 10.3390/ma12172714. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benassi L., Franchi F., Catina D., Cioffi F., Rodella N., Borgese L., Pasquali M., Depero L.E., Bontempi E. Rice husk ash to stabilize heavy metals contained in municipal solid waste incineration fly ash: first results by applying new pre-treatment technology. Materials. 2015;8:6868–6879. doi: 10.3390/ma8105346. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benassi L., Dalipi R., Consigli V., Pasquali M., Borgese L., Depero L.E., Clegg F., Bingham P.A., Bontempi E. Integrated management of ash from industrial and domestic combustion: a new sustainable approach for reducing greenhouse gas emissions from energy conversion. Environ. Sci. Pollut. Res. 2017;24:14834–14846. doi: 10.1007/s11356-017-9037-y. [DOI] [PubMed] [Google Scholar]

- Bontempi E. A new approach for evaluating the sustainability of raw materials substitution based on embodied energy and the CO2 footprint. J. Clean. Prod. 2017;162:162–169. doi: 10.1016/j.jclepro.2017.06.028. [DOI] [Google Scholar]

- Bontempi E. First data analysis about possible COVID-19 virus airborne diffusion due to air particulate matter (PM): the case of Lombardy (Italy) Environ. Res. 2020;186 doi: 10.1016/j.envres.2020.109639. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bontempi E. Commercial exchanges instead of air pollution as possible origin of COVID-19 initial diffusion phase in Italy: more efforts are necessary to address interdisciplinary research. Environ. Res. 2020;188 doi: 10.1016/j.envres.2020.109775. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bontempi E. The europe second wave of COVID-19 infection and the Italy “strange” situation. Environ. Res. 2021;193 doi: 10.1016/j.envres.2020.110476. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bontempi E., Coccia M. International trade as critical parameter of COVID-19 spread that outclasses demographic, economic, environmental, and pollution factors. Environ. Res. 2021;201 doi: 10.1016/j.envres.2021.111514. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bontempi E., Vergalli S., Squazzoni F. Understanding COVID-19 diffusion requires an interdisciplinary, multi-dimensional approach. Environ. Res. 2020;188 doi: 10.1016/j.envres.2020.109814. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bontempi E., Coccia M., Vergalli S., Zanoletti A. Can commercial trade represent the main indicator of the COVID-19 diffusion due to human-to-human interactions? A comparative analysis between Italy, France, and Spain. Environ. Res. 2021;201 doi: 10.1016/j.envres.2021.111529. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bontempi E., Sorrentino G.P., Zanoletti A., Alessandri I., Depero L.E., Caneschi A. Sustainable materials and their contribution to the sustainable development goals (SDGs): a critical review based on an Italian example. Molecules. 2021;26 doi: 10.3390/molecules26051407. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bosio A., Rodella N., Gianoncelli A., Zacco A., Borgese L., Depero L.E., Bingham P.A., Bontempi E. A new method to inertize incinerator toxic fly ash with silica from rice husk ash. Environ. Chem. Lett. 2013;11:329–333. doi: 10.1007/s10311-013-0411-9. [DOI] [Google Scholar]

- Cai M., Luo J. Influence of COVID-19 on manufacturing industry and corresponding countermeasures from supply chain perspective. J. Shanghai Jiao Tong Univ. (Sci.) 2020;25:409–416. doi: 10.1007/s12204-020-2206-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen A. 2018. Elon Musk Wants Cobalt Out of His Batteries — Here's Why That's a Challenge.https://www.theverge.com/2018/6/21/17488626/elon-musk-cobalt-electric-vehicle-battery-science [WWW Document]. URL. [Google Scholar]

- Church C., Wuennenberg L. 2019. Sustainability and Second Life 10. [Google Scholar]

- Ciacci L., Nuss P., Reck B.K., Werner T.T., Graedel T.E. Metal criticality determination for Australia, the US, and the planet-comparing 2008 and 2012 results. Resources. 2016;5 doi: 10.3390/resources5040029. [DOI] [Google Scholar]

- Coating World Raw material price increases pile pressure on paint manufacturers. Focus Powder Coating. 2021;2021:2. doi: 10.1016/j.fopow.2021.02.005. [DOI] [Google Scholar]

- Coccia M. An index to quantify environmental risk of exposure to future epidemics of the COVID-19 and similar viral agents: theory and practice. Environ. Res. 2020;191 doi: 10.1016/j.envres.2020.110155. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coccia M. High health expenditures and low exposure of population to air pollution as critical factors that can reduce fatality rate in COVID-19 pandemic crisis. Environ. Res. 2021;199 doi: 10.1016/j.envres.2021.111339. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coccia M. The relation between length of lockdown, numbers of infected people and deaths of Covid-19, and economic growth of countries: lessons learned to cope with future pandemics similar to Covid-19 and to constrain the deterioration of economic system. Sci. Total Environ. 2021;775 doi: 10.1016/j.scitotenv.2021.145801. [DOI] [Google Scholar]

- Cordell D., Drangert J.O., White S. The story of phosphorus: global food security and food for thought. Global Environ. Change. 2009;19:292–305. doi: 10.1016/j.gloenvcha.2008.10.009. [DOI] [Google Scholar]

- Dermont G., Bergeron M., Mercier G., Richer-Laflèche M. Soil washing for metal removal: a review of physical/chemical technologies and field applications. J. Hazard. Mater. 2008;152:1–31. doi: 10.1016/j.jhazmat.2007.10.043. [DOI] [PubMed] [Google Scholar]

- Ducoli S., Zacco A., Bontempi E. Incineration of sewage sludge and recovery of residue ash as building material: a valuable option as a consequence of the COVID-19 pandemic. J. Environ. Manag. 2021;282 doi: 10.1016/j.jenvman.2021.111966. [DOI] [PubMed] [Google Scholar]

- European Aluminium . 2020. A Strategy for Achieving Aluminium's Full Potential for Circular Economy by 2030. [Google Scholar]

- European Commision . 2014. COMUNICAZIONE DELLA COMMISSIONE AL PARLAMENTO EUROPEO, AL CONSIGLIO, AL COMITATO ECONOMICO E SOCIALE EUROPEO E AL COMITATO DELLE REGIONI concernente la revisione dell’elenco delle materie prime essenziali per l’UE e l’attuazione dell’iniziativa "materie p. [Google Scholar]

- European Commission Communication from the commission to the European Parliament, the Council, the Eurpean economic and social committee and the committee of the regions on the 2017 list of critical raw materials for the EU. Off. J. Eur. Union COM. 2017;2017:8. [Google Scholar]

- European Commission . 2020. Resilienza delle materie prime critiche: tracciare un percorso verso una maggiore sicurezza e sostenibilità 1–26. [Google Scholar]

- European Commission . 2020. Annex 15 Horizon 2020 Work Programme 2018-2020. Climate Action , Environment , Resource Efficiency and Raw Materials. [Google Scholar]

- Fahimi A., Bilo F., Assi A., Dalipi R., Federici S., Guedes A., Valentim B., Olgun H., Ye G., Bialecka B., Fiameni L., Borgese L., Cathelineau M., Boiron M.C., Predeanu G., Bontempi E. Poultry litter ash characterisation and recovery. Waste Manag. 2020;111:10–21. doi: 10.1016/j.wasman.2020.05.010. [DOI] [PubMed] [Google Scholar]

- Fahimi A., Federici S., Depero L.E., Valentim B., Vassura I., Ceruti F., Cutaia L., Bontempi E. Evaluation of the sustainability of technologies to recover phosphorus from sewage sludge ash based on embodied energy and CO2 footprint. J. Clean. Prod. 2021;289 doi: 10.1016/j.jclepro.2020.125762. [DOI] [Google Scholar]

- Fiameni L., Assi A., Fahimi A., Valentim B., Moreira K., Predeanu G., Slăvescu V., Vasile B., Nicoară A.I., Borgese L., Boniardi G., Turolla A., Canziani R., Bontempi E. Simultaneous amorphous silica and phosphorus recovery from rice husk poultry litter ash. RSC Adv. 2021;11:8927–8939. doi: 10.1039/d0ra10120f. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ford J.D., Pearce T., Prno J., Duerden F., Ford L.B., Beaumier M., Smith T. Perceptions of climate change risks in primary resource use industries: a survey of the Canadian mining sector. Reg. Environ. Change. 2010;10:65–81. doi: 10.1007/s10113-009-0094-8. [DOI] [Google Scholar]

- Frédéric S. 2020. ‘Green Recovery Alliance’ Launched in European Parliament.https://www.euractiv.com/section/energy-environment/news/green-recovery-alliance-launched-in-european-parliament/ [WWW Document]. EURACTIV.com. URL. [Google Scholar]

- Furtkamp Julian . 2017. Aceleron: Giving Old Batteries a Second Lease of Life.https://en.reset.org/blog/aceleron-giving-old-batteries-second-lease-life-10092017 [WWW Document] [Google Scholar]

- Gałas A., Kot-Niewiadomska A., Czerw H., Simić V., Tost M., Wårell L., Gałas S. Impact of covid-19 on the mining sector and raw materials. Resources. 2021;10:1–23. [Google Scholar]

- Geipe J., Kaiser-Tedesco J. 2018. Mining Local Procurement Reporting Mechanism What is the Local Procurement Reporting Mechanism (LPRM)? [Google Scholar]

- Goodenough K.M., Schilling J., Jonsson E., Kalvig P., Charles N., Tuduri J., Deady E.A., Sadeghi M., Schiellerup H., Müller A., Bertrand G., Arvanitidis N., Eliopoulos D.G., Shaw R.A., Thrane K., Keulen N. Europe's rare earth element resource potential: an overview of REE metallogenetic provinces and their geodynamic setting. Ore Geol. Rev. 2016;72:838–856. doi: 10.1016/j.oregeorev.2015.09.019. [DOI] [Google Scholar]

- Graedel T.E., Gunn G., Tercero Espinoza L. Critical Metals Handbook. John Wiley & Sons; Oxford: 2013. Metal resources, use and Criticality; pp. 1–19. [DOI] [Google Scholar]

- Granta Design . CES) Software; 2019. Cambridge Engineering Selector. [Google Scholar]

- Habib K., Sprecher B., Young S.B. COVID-19 impacts on metal supply: how does 2020 differ from previous supply chain disruptions? Resour. Conserv. Recycl. 2021;165 doi: 10.1016/j.resconrec.2020.105229. [DOI] [Google Scholar]

- Hatayama H., Tahara K. Criticality assessment of metals for Japan's resource strategy. Mater. Trans. 2015;56:229–235. doi: 10.2320/matertrans.M2014380. [DOI] [Google Scholar]

- Heffron R.J. The role of justice in developing critical minerals. Extr. Ind. Soc. 2020;7:855–863. doi: 10.1016/j.exis.2020.06.018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Henckens T. Scarce mineral resources: extraction, consumption and limits of sustainability. Resour. Conserv. Recycl. 2021;169 doi: 10.1016/j.resconrec.2021.105511. [DOI] [Google Scholar]

- Hund K., La Porta D., Fabregas T.P., Laing T., Drexhage J. Minerals for climate action: the mineral intensity of the clean energy transition. Clim. Smart Min. Initiat. - World Bank Gr. 2020:110. [Google Scholar]

- Ibn-Mohammed T., Mustapha K.B., Godsell J., Adamu Z., Babatunde K.A., Akintade D.D., Acquaye A., Fujii H., Ndiaye M.M., Yamoah F.A., Koh S.C.L. A critical review of the impacts of COVID-19 on the global economy and ecosystems and opportunities for circular economy strategies. Resour. Conserv. Recycl. 2021;164 doi: 10.1016/j.resconrec.2020.105169. [DOI] [PMC free article] [PubMed] [Google Scholar]

- IDC . 2021. PC Sales.https://www.idc.com/getdoc.jsp?containerId=prUS47274421 [WWW Document] (accessed 4.14.2021) [Google Scholar]

- Işıldar A., van Hullebusch E.D., Lenz M., Du Laing G., Marra A., Cesaro A., Panda S., Akcil A., Kucuker M.A., Kuchta K. Biotechnological strategies for the recovery of valuable and critical raw materials from waste electrical and electronic equipment (WEEE) – a review. J. Hazard. Mater. 2019;362:467–481. doi: 10.1016/j.jhazmat.2018.08.050. [DOI] [PubMed] [Google Scholar]

- Jones B., Elliott R.J.R., Nguyen-Tien V. The EV revolution: the road ahead for critical raw materials demand. Appl. Energy. 2020;280 doi: 10.1016/j.apenergy.2020.115072. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Klevnäs P., Kulldorf A., Enkvist P.-A. 2020. The Circular Economy and Covid-19 Recovery 13–27. [Google Scholar]

- Krook J., Baas L. Getting serious about mining the technosphere: a review of recent landfill mining and urban mining research. J. Clean. Prod. 2013;55:1–9. doi: 10.1016/j.jclepro.2013.04.043. [DOI] [Google Scholar]

- Laing T. The economic impact of the Coronavirus 2019 (Covid-2019): implications for the mining industry. Extr. Ind. Soc. 2020;7:580–582. doi: 10.1016/j.exis.2020.04.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Larmer B. 2018. E-waste Offers an Economic Opportunity as Well as Toxicity. [Google Scholar]

- Lederer J., Michal Š., Franz-Georg S., Margarida Q., Jiri H., Florian H., Valerio F., Johann F., Roberto B., Elza B., Anna B., Dominik B. What waste management can learn from the traditional mining sector: towards an integrated assessment and reporting of anthropogenic resources. Waste Manag. 2020;113:154–156. doi: 10.1016/j.wasman.2020.05.054. [DOI] [PubMed] [Google Scholar]

- Li Z., Zhou Y., Li K., Xiao H., Cai Y. The spatial effects of city-level water-energy nexus: a case study of Hebei Province, China. J. Clean. Prod. 2021;310 doi: 10.1016/j.jclepro.2021.127497. [DOI] [Google Scholar]

- Lopéz R., Jordão H., Hartmann R., Ämmälä A., Carvalho M.T. Study of butyl-amine nanocrystal cellulose in the flotation of complex sulphide ores. Colloids Surfaces A Physicochem. Eng. Asp. 2019;579 doi: 10.1016/j.colsurfa.2019.123655. [DOI] [Google Scholar]

- Lurie N., Keusch G.T., Dzau V.J. Urgent lessons from COVID 19: why the world needs a standing, coordinated system and sustainable financing for global research and development. Lancet. 2021;397:1229–1236. doi: 10.1016/s0140-6736(21)00503-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- MacDonald A., Lam P., Penchev D. 2020. COVID-19 Mining Impacts — Mining Projects with At-Risk Production.https://www.spglobal.com/marketintelligence/en/news-insights/blog/covid19-mining-impacts-mining-projects-with-at-risk-production [WWW Document] [Google Scholar]

- McCoy J.T., Auret L. Machine learning applications in minerals processing: a review. Miner. Eng. 2019;132:95–109. doi: 10.1016/j.mineng.2018.12.004. [DOI] [Google Scholar]

- McKinsey . vol. 52. McKinsey Co; 2020. Fashion on Climate: How the Fashion Industry Can Urgently Act to Reduce its Green House Gas Emission. [Google Scholar]

- Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development . 2020. IGF Promotes Gender Equality and Environmental Management through Goxi Consultations. ([WWW Document]) [Google Scholar]

- Mining weekly . 2020. Covid-19 to Contribute to Lower Lithium Prices, but Higher Cobalt Prices.https://www.miningweekly.com/article/covid-19-to-contribute-to-lower-lithium-prices-but-higher-cobalt-prices-2020-06-19 [WWW Document] (accessed 4.14.2021) [Google Scholar]

- Mining.com . 2021. Lithium Prices Continue to Soar – up 88% in 2021.https://www.mining.com/lithium-prices-continue-to-soar-up-88-in-2021/ [WWW Document] (accessed 4.14.2021) [Google Scholar]

- Mishima K., Rosano M., Mishima N., Nishimura H. End-of-life strategies for used mobile phones using material flow modeling. Recycling. 2016;1 doi: 10.3390/recycling1010122. [DOI] [Google Scholar]

- Mohammad Ebrahimi S., Koh L. Manufacturing sustainability: institutional theory and life cycle thinking. J. Clean. Prod. 2021;298 doi: 10.1016/j.jclepro.2021.126787. [DOI] [Google Scholar]

- Moore K.R., Whyte N., Roberts D., Allwood J., Leal-Ayala D.R., Bertrand G., Bloodworth A.J. The re-direction of small deposit mining: technological solutions for raw materials supply security in a whole systems context. Resour. Conserv. Recycl. X. 2020;7 doi: 10.1016/j.rcrx.2020.100040. [DOI] [Google Scholar]

- Moss R.L., Tzimas E., Kara H., Willis P., Kooroshy J. Critical metals in strategic energy technologies, JRC-scientific and strategic reports. European Commission Joint Research Centre Institute for Energy and Transport. 2011 doi: 10.2790/35716. [DOI] [Google Scholar]

- Murray A., Skene K., Haynes K. The circular economy: an interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics. 2017;140:369–380. doi: 10.1007/s10551-015-2693-2. [DOI] [Google Scholar]

- Navon A., Machlev R., Carmon D., Onile A.E., Belikov J., Levron Y. Effects of the COVID-19 pandemic on energy systems and electric power grids—a review of the challenges ahead. Energies. 2021;14 doi: 10.3390/en14041056. [DOI] [Google Scholar]

- Nedelciu C.E., Ragnarsdottir K.V., Schlyter P., Stjernquist I. Global phosphorus supply chain dynamics: assessing regional impact to 2050. Glob. Food Sec. 2020;26 doi: 10.1016/j.gfs.2020.100426. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Organisation for Economic Co-operation and Development (OECD) 2016. Extended Producer Responsibility Updated Guidance for Efficient Waste Management. [Google Scholar]

- Oumarou Amadou A., De Gaudenzi G.P., Marcheselli G., Cara S., Piredda M., Spiga D., Matharu A.S., De Gioannis G., Serpe A. A new facile solvometallurgical leaching method for the selective Co dissolution & recovery from hard metals waste. Int. J. Refract. Metals Hard Mater. 2021;98 doi: 10.1016/j.ijrmhm.2021.105534. [DOI] [Google Scholar]

- Panda S., Akcil A. Securing supplies of technology critical metals: resource recycling and waste management. Waste Manag. 2021;123:48–51. doi: 10.1016/j.wasman.2021.01.021. [DOI] [PubMed] [Google Scholar]

- Parra . 2020. Mining, Materials, and the Sustainable Development Goals (SDGs): 2030 and beyond. [Google Scholar]

- Pasquali M., Zanoletti A., Benassi L., Federici S., Depero L.E., Bontempi E. Stabilized biomass ash as a sustainable substitute for commercial P-fertilizers. Land Degrad. Dev. 2018;29:2199–2207. doi: 10.1002/ldr.2915. [DOI] [Google Scholar]

- Qgis, 2018.

- Quitzow R., Bersalli G., Eicke L., Jahn J., Lilliestam J., Lira F., Marian A., Süsser D., Thapar S., Weko S., Williams S., Xue B. The COVID-19 crisis deepens the gulf between leaders and laggards in the global energy transition. Energy Res. Soc. Sci. 2021;74 doi: 10.1016/j.erss.2021.101981. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rahman S.M.M., Kim J. Circular economy, proximity, and shipbreaking: a material flow and environmental impact analysis. J. Clean. Prod. 2020;259 doi: 10.1016/j.jclepro.2020.120681. [DOI] [Google Scholar]

- Ribeiro H., Kinch D., Zhang X., Franke A., Goldenberg M. 2018. Recycling to Be Key for Future Battery Raw Materials Supply. [Google Scholar]

- Robben C., Wotruba H. Sensor-based ore sorting technology in mining—past, present and future. Minerals. 2019;9:1–25. doi: 10.3390/min9090523. [DOI] [Google Scholar]