Abstract

In view of the borehole instability during the drilling process of the thin sand and mud interbedded sections in the Shahejie Formation, the physicochemical and mechanical properties of sand and mud interbed rock were studied through a series of laboratory tests to determine the main factors influencing the formation instability. The effects of fracture development of interbed sand and mud, mechanical weak plane, borehole trajectory, and seepage effect on borehole stability were evaluated and analyzed through the established model. The results indicated that the microcracks are developed on the lithologic interface due to the change of lithology of the sand–mud interbed. The anisotropy of the mechanical properties of the rocks with interbedded sand and mud is obvious, which leads to the great mechanical weak plane effect on the wellbore stability. The bottom-hole pressure difference leads to the seepage effect, which reduces the effective supporting force of the drilling fluid on the borehole wall and promotes rock sliding and failure along the lithologic interface developed by the sand–mud thin interbedded layer. Considering the influence of the borehole trajectory, mechanical weak plane, and seepage effect, the recommended drilling fluid density in the deviated section is 1.69 g/cm3. The wellbore stability is the best when drilling along the direction of the minimum horizontal principal stress in the horizontal section. Further strengthening the plugging performance of the drilling fluid, drilling through the microfractures vertically on the interbedded lithologic interface, and reducing the lateral vibration of the drilling tools as far as possible are necessary. The research results provide a theoretical basis for the safe drilling of thin sand and mud interbedded strata.

1. Introduction

During the drilling process of an oil field in a block in China, downhole collapse occurs frequently, which seriously restricts the efficient development of oil and gas resources.1 By combining the field drilling data and logging data, it is found that the complex strata mainly occur in the Shahejie Formation. The rock mass of the Shahejie Formation is dense and hard as a whole, but the sand and mudstone interbeds are well developed, and the microfractures are developed on the lithologic interface where sand and mud interbedded.2 The angle of crossing the thin layer during the drilling process results in the intensification of the mechanical weak plane effect of bedding and fracture.3−5 At the same time, the variation of bottom hole exciting pressure under different working conditions aggravates the seepage behavior of the drilling fluid along the bedding fracture and further reduces the effective support effect of drilling a fluid column on the wellbore. These factors have great influence on the wellbore stability during drilling process, which leads to frequent accidents such as downhole collapse and lost circulation and leads to a long construction period, thus seriously hindering the effective exploration and development progress of reservoirs in this area.6

The wellbore stability of hard and brittle mudstone deeply affects the effective development of deep oil and gas resources. The thin sand–mud interbed developed in the hard and brittle mudstone formation has become the key problem that affects the wellbore stability of the mudstone.7,8 The scholars have studied the mechanical properties and wellbore stability of the sand–mud thin interbedded formation. Chen et al. used the high-resolution advantage of whole–hole microresistivity scanning imaging logging to calibrate the response of thin bed logging and summarize the development rules of thin bed sandstones and mudstones. Finally, the lithology identification chart and thin layer lithology logging response model were applied to the wellbore profile of the target layer, which effectively improves the interpretation accuracy of thin interbedded sand and mudstone.9 Libin et al. analyzed four types of Amplitude Versus Offset (AVO) response characteristics based on the theoretical study of seismic reflection characteristics of thin interbedding. The influences of the sand–mud ratio and interbedded structure on AVO reflection characteristics of thin interbedded layers are summarized, which can be used for fine interpretation of thin interbedded seismic data.10 Lin et al. used the numerical simulation method to calculate the density, opening, and porosity of fractures in the strata of different thicknesses; six fracture development models of sandstone and mudstone assemblages were also proposed. The numerical simulation results showed that the thinner the single layer thickness of sandstone and mudstone is, the more likely it is to produce fractures.11 Lu et al. established a fracture judgment criterion suitable for sand–mud interbedded strata through mathematical statistics and formula derivation and realized the quantitative evaluation of fracture penetration degree in sand–mud interbedded strata based on the quantitative relationship model between the tectonic stress field and fracture parameters.12 Wu et al. systematically studied the fabric and physical and chemical properties of downhole rock samples using X-ray diffraction, scanning electron microscopy (SEM), the cation exchange capacity test, and other experimental means. They analyzed the borehole wall collapse mechanism of the interbedded formation of sand and mud and proposed the principle of a “ternary synergistic” anti-slaving drilling fluid.13

At present, there are few studies on mechanical properties and failure laws of sand–mud interbedding lithologic interfaces. The micro-structure characteristics, physical and chemical properties, rock mechanical properties, and influencing factors of the Shahejie Formation rock samples were tested and analyzed by the experimental system, and a theoretical model was established to evaluate the wellbore stability combined with the experimental results. The effects of wellbore trajectory, mechanical weak surface effect of the bedding fracture, and pressure penetration effect on the wellbore stability of the Shahejie Formation were evaluated and analyzed. The rock mechanical properties and the mechanism of borehole wall failure and instability of the sand–mud interbedded lithologic interface were revealed. Finally, the countermeasures to stabilize the borehole wall of the Shahejie Formation were worked out.

2. Materials and Methods

2.1. Materials

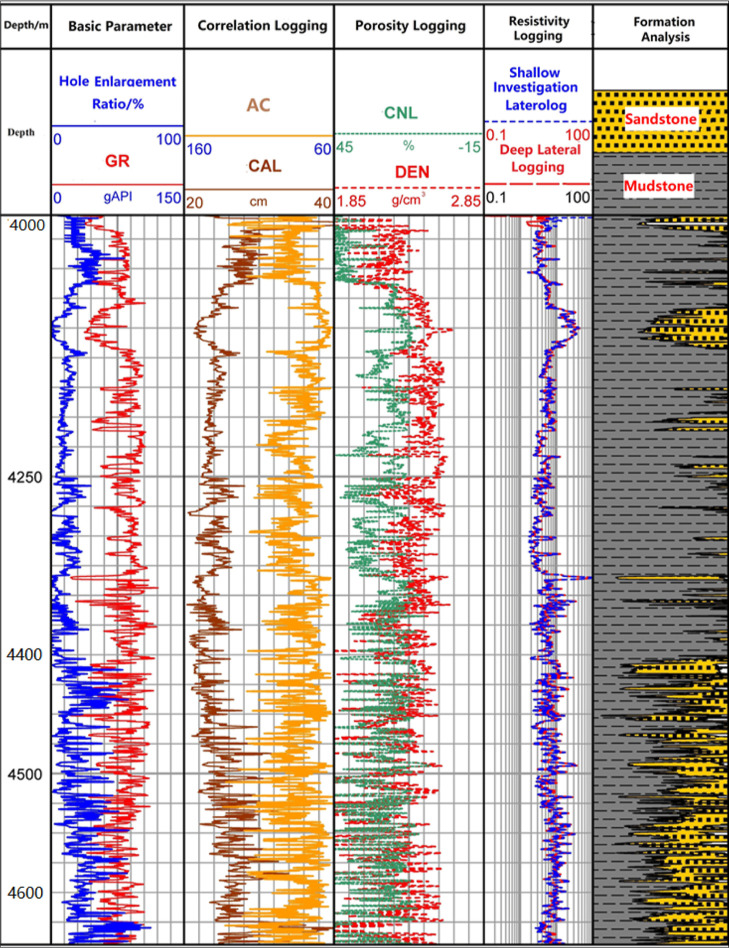

The Shahejie Formation of an oilfield in a block was taken as the research object. First, the engineering logging data of a well obtained on site were combed and analyzed, and the logging data were brought into Carbone software to obtain the logging profile. The complex formation lithology and borehole wall collapse as well as the diameter expansion information during the drilling process of the Shahejie Formation were studied and analyzed (Figure 1).

Figure 1.

Well borehole diameter profile of the Shahejie Formation in well X. (GR-natural gamma-ray; AC-acoustic time; CAL-caliper (borehole diameter); CNL-compensated neutron logging; DEN-density.)

The comparative analysis shows that well X has a low diameter expansion rate and good wellbore stability in the 4000–4400 m interval, but collapse diameter expansion exists in the 4440–4640 m interval (Figure 1). In this well section (4440–4640 m), the values of natural gamma, acoustic time difference, and rock density are in a saw-tooth shape, with frequent fluctuations and variable numerical changes. The caliper logging curve also fluctuates greatly, corresponding to the high natural gamma content at the borehole expansion, and the expansion layer should be a thin mudstone interval.14,15 The rock strength of the thin mudstone layer is low, and the stability is poor. Some thin sandstone layers are affected by the thin mudstone of the adjacent layer, so there is collapse and expansion diameter in the interbedded section of sand and mudstone.

From the core of the Shahejie Formation salvaged from underground (Figure 2), the sand and mudstone interbeds in the Shahejie Formation are relatively developed, and the deep black mudstone is obviously developed on the lithological interface. At the same time, many fractures are observed on the lithologic interface, most of which are low-angle fractures.16 The well-developed laminae and micro-cracks provide space for a drilling fluid filtrate to invade and hydrate. The drilling fluid filtrate invades the formation along the micro-cracks and causes mud shale hydration, which weakens the cementation force between particles on the one hand and causes the strong expansion pressure of hydration expansion to cause the borehole wall to lose balance, leading to collapse and block falling. The development of fractures is the main reason for the collapse of the borehole wall and the complexity of well leakage.

Figure 2.

Downhole core developed in the interbedded sand and mud of the Shahejie formation.

The mineral composition and content distribution of the rocks of the Shahejie Formation are tested and analyzed with the XRD experimental equipment. The rock minerals in the Shahejie Formation are mainly clay and quartz, and the average content of quartz minerals is 33.12% and that of clay minerals is 45.54%. Among them, the clay minerals are mainly illite and illite/smectite mixed beds, with an average interbed ratio of 25%. The rocks of the Shahejie Formation are hard and brittle mudstones with a high content of brittle minerals.17−19 For this hard brittle mudstone, it is easy to produce microfractures under a high external force environment. At the same time, the mineral composition and content of interbedded sand and mud are analyzed. The rock minerals are mainly quartz and feldspar; the content of quartz and feldspar is approximately 40%, and the average content of clay minerals is approximately 10%, among which the clay minerals are mainly chlorite and illite, which belong to sandstone. Through the analysis of mineral composition, it can be found that the Shahejie Formation is mainly composed of hard and brittle mudstone, but the thin sandstone layer is interbedded with sand and mudstone.

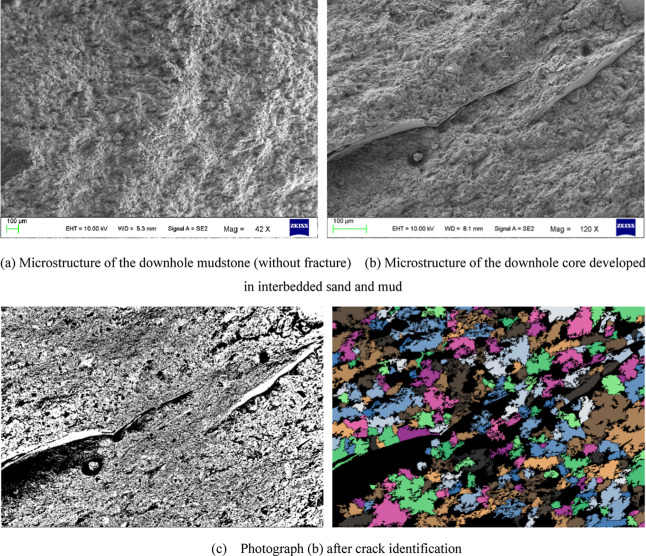

The microstructure of the mudstone in the Shahejie Formation is tested and analyzed by SEM, as shown in Figure 3a. The microstructure of sand and mud interbedded rocks is also tested and analyzed, as shown in Figure 3b.

Figure 3.

SEM photos of downhole cores in the Shahejie Formation.

Figure 3a shows that the mudstone in the Shahejie Formation is very dense as a whole, and the rock is hard and brittle. Comparative analysis of Figure 3b shows that, due to lithologic changes, micro-fractures are more developed in rock samples with a thin interbedding of sand and mud on the lithologic interface. The SEM photo of Figure 3b is identified by the software, as shown in Figure 3c. The black part represents the fracture. Due to lithologic changes, microfractures develop significantly on the lithologic interface of the interbedded sand and mudstone, and the fracture strike is relatively uniform (Figure 3c).

2.2. Experimental Methods

The physicochemical and mechanical properties of sand and mud interbeds rock were studied through a series of laboratory tests to determine the main factors influencing the Shahejie Formation instability.

First, testing and analyzing the velocity of the P- and S-waves of reservoir cores can be used to study the dynamic changes of the rock pore structure and mechanical performance parameters. The velocities of the P- and S-waves of the downhole cores of the Shahejie Formation were tested using the acoustic wave test equipment.

Second, the porosity and permeability of the Shahejie Formation downhole cores were measured using the gas permeability and porosity tester. In addition, two cores with matrix mudstone and sand–mud interbeds were selected and soaked in a water-based drilling fluid for 24 h to observe the changes of the cores.

Rock mechanical parameters under downhole pressure can be accurately obtained through triaxial mechanical experimental tests, which can be used to evaluate the influences of different drilling fluid systems, fracture development, and fracture strike on the mechanical properties of borehole rock. These parameters can also be used to improve the evaluation and prediction accuracy of the formation borehole stability.20 All the tests on the rock samples were conducted in accordance with the national standard (GB/T 50266-99, engineering rock test method standard). The American Society for Materials and Testing Standard ASTMD2664-04 (triaxial test) and methods recommended by the International Society for rock mechanics tests (Part 1) were used as references21 The mechanical strength of the underground cores of the Shahejie Formation before and after the drilling fluid immersion was tested and analyzed using a triaxial mechanical experimental machine.

The microcracks were developed in thin interbedded sand and mud, and various discontinuous structural surfaces were widely present. Structural planes are considered one of the main channels for the drilling fluid to penetrate into the formation. Therefore, studying the strength characteristics of structural planes is necessary. These characteristics can be obtained through direct shear experiments.22 A direct shear experiment was completed on the rock direct shear instrument. The shear strength of rock body and weak structural plane such as the bedding plane and fracture plane of a standard plunger sample or cube sample were measured under a simulated stratum condition. The shear strength can be obtained by direct shear tests under different normal stresses on the shear plane. Applying a certain normal load to the shear surface and then increasing the shear force step by step, the maximum shear stress can be sustained before failure. Finally, the prepared block rock samples with homogeneous mudstone and interbedded sand and mud were tested using the direct shear instrument.

3. Results and Discussion

3.1. Physical and Chemical Experimental Testing of Underground Cores

The downhole homogeneous mudstone in the Shahejie Formation was relatively dense. The average longitudinal and shear wave velocities were 4.11 and 2.42 km/s, respectively. However, there were microcracks in the lithologic interface developed in the thin sand–mud interbedding, which affects the propagation velocity of the P-waves and S-waves and leads to a larger acoustic time difference. The average P-wave and S-wave velocities were 2.88 and 1.73 km/s, respectively. The mudstone of the Shahejie Formation is dense as a whole with low porosity and permeability parameters. The porosity of homogeneous mudstone is about 0.8%, the permeability is about 0.05 mD, and the porosity and permeability of sand–mud interbedded cores are as high as 2.8% and 0.5 mD. The lithology on the interface of the sand–shale interbedded rock sample changed, resulting in the development of microcracks on the sand–mud interbedded lithology interface, which lowered the internal structural cementation strength of the rock sample, and the rock sample was relatively loose, resulting in relatively low velocities of the P- and S-waves and high porosity and permeability parameters.23

The changes of the two cores with matrix mudstone and sand–mud interbeds after being immersed for different times are shown below (Figure 4).

Figure 4.

Photos of the downhole core developed in interbedded sand and mud and matrix mudstone after soaking in a water-based drilling fluid for different times.

The rock sample with interbedded sand and mud cracked after 5 min of immersion, reached the maximum value at 8 h, and remained stable at 24 h (Figure 4a); the matrix rock sample was immersed for 8 h before microcracks appeared and then stabilized (Figure 4b). Microfractures could be seen on the lithological interface developed by the interbedded sand and mud. During the drilling process, the working fluid filtrate easily invaded the formation along the lithologic interface microfractures under the action of the bottom-hole pressure difference and capillary force. Meanwhile, micro-fractures may induce a pressure penetration effect, which will aggravate the rock fragmentation and reduce the rock mechanical strength of formation, resulting in borehole instability.24,25

3.2. Mechanical Experimental Testing of Underground Cores

The mechanical strength of the underground cores of the Shahejie Formation before and after drilling fluid immersion was tested, and the test results are presented in Table 1.

Table 1. Triaxial Mechanical Experimental Test Results of Mudstone in the Shahejie Formation.

| core no. | lithology | sample type | confining pressure/MPa | elasticity modulus/GPa | Poisson ratio | compressive strength/MPa |

|---|---|---|---|---|---|---|

| 1 | homogeneous mudstone | 20 | 20.023 | 0.259 | 139.5 | |

| 2 | homogeneous mudstone | dry | 60 | 31.089 | 0.223 | 184.5 |

| 3 | sand–mud interbed | 20 | 5.999 | 0.296 | 76.341 | |

| 4 | sand–mud interbed | 60 | 7.808 | 0.264 | 115.643 | |

| 5 | homogeneous mudstone | 20 | 18.733 | 0.261 | 103.213 | |

| 6 | homogeneous mudstone | drilling fluid | 60 | 28.796 | 0.235 | 148.327 |

| 7 | sand–mud interbed | immersion | 20 | 7.333 | 0.332 | 41.846 |

| 8 | sand–mud interbed | 60 | 7.034 | 0.327 | 78.806 |

The comparative analysis (Table 1) shows that the compressive strength of the homogeneous non-cracked rock sample is as high as 184.5 MPa in the downhole pressure environment. The drilling fluid immersion effect has little influence on the mechanical strength of the homogeneous mudstone, and the mechanical strength is slightly reduced to 148.3 MPa. Microcracks are found on the lithological interface of the interbedded sand and mud, and the development of the cracks has a significant impact on the mechanical properties of hard and brittle mudstone. Specifically, the mechanical strength is low after drilling fluid soaking, the maximum mechanical strength of rock before soaking is 115.6 MPa, and the mechanical strength is reduced to 42 MPa after soaking. The photo of the core after the failure is shown below (Figure 5).

Figure 5.

Downhole cores of the Shahejie Formation after the triaxial mechanical experiment.

The homogeneous mudstone mainly suffered tensile splitting failure (Figure 5a), and the rock samples developed in the interbedding of sand and mud mainly suffered slippage failure along the microcracks on the interface (Figure 5b). From the perspective of rock mechanics, microcracks exist on the lithological interface developed in thin sand and mud interbeds, which will destroy the integrity of the rock and weaken the mechanical properties. Under the action of the positive pressure difference at the bottom of the well and capillary force, the working fluid filtrate intrudes into the formation along the microfractures, which causes lost circulation during the drilling process. Microfractures may induce hydraulic fracturing, which intensifies the fracture degree of the borehole wall rock, reduces the mechanical strength of the formation rock, and leads to borehole wall instability.

Direct shear tests were carried out on rock samples with uniform mudstone and interbedded sand and mud with direct shear apparatus. The experimental results are shown in Table 2.

Table 2. Downhole Core Direct Shear Test Results of the Shahejie Formation.

| core no. | lithology | normal stress/MPa | shear stress/MPa | internal cohesion/MPa | internal friction angle/deg |

|---|---|---|---|---|---|

| 1 | homogeneous mudstone | 4.01 | 43.5 | 40.13 | 40.1 |

| 2 | homogeneous mudstone | 12.08 | 50.23 | ||

| 3 | homogeneous mudstone | 3.98 | 42.7 | 40.16 | 39.83 |

| 4 | homogeneous mudstone | 12.01 | 49.87 | ||

| 5 | sand–mud interbed | 4.01 | 6.09 | 4.01 | 26.57 |

| 6 | sand–mud interbed | 12.03 | 10.16 | ||

| 7 | sand–mud interbed | 4.03 | 6.12 | 4.15 | 26.06 |

| 8 | Sand–mud interbed | 11.98 | 10.01 |

The results reveal that the homogeneous mudstone has a higher shear strength and higher cohesion and internal friction angle than that of the rock sample with thin interbedded sand and mud. Because of the change of lithology at the interface of sand–mud interbedded rock samples, the micro-cracks develop at the interface of the sand–mud interbedded rock, which leads to the failure of rock along the weak plane structure and lower cohesion and internal friction angle. According to the above series of experimental tests, the rock samples developed by thin interbedded sand and mud have low mechanical strength, and the rock samples are more likely to slip and fail along the microfractures developed on the lithologic interface.

4. Calculations

During the process of drilling in a deep formation, the drilling fluid flows between the wellbore and formation under the complex multipotential field, which changes the distribution of pore pressure and effective stress field near the wellbore, thus affecting its stability.26 The first is the study of the mathematical model of the radial seepage capacity of the borehole wall. The formation with developed bedding fractures is regarded as transversely isotropic. When the permeability tensor overlaps with the coordinate axis direction, the equivalent permeability tensor can be expressed as follows27

| 1 |

Among them,

|

where kxx, kyy, and kxy are the components of the permeability tensor, D; k11 is the permeability in the transversely isotropic plane, D; k33 is the vertical permeability, D; θ1 is the included angle between bedding plane and X-axis, °; kyy is a mathematical model of the radial seepage capacity of the borehole wall.

The angle relationship between the radial seepage direction of the wellbore wall and the normal direction of the bedding fracture surface in different sections of horizontal wells is shown as follows28

| 2 |

Among them,

|

where ξ is the included angle between the radial flow direction of the borehole wall and the fracture surface, ◦; αs is the fracture dip angle, ◦; βs is the fracture tendency, ◦; α0 is the inclination angle of the borehole trajectory, ◦; β is the azimuth of the borehole trajectory, ◦; and θ is the well circumference angle, ◦.

The migration of the drilling fluid changes the distribution of the pore pressure and effective stress field near the wellbore and then affects the wellbore stability of formation. The mathematical model of borehole pore pressure transfer is shown as follows.

| 3 |

| 4 |

where P is the formation pore pressure, MPa; k* is the effective permeability coefficient, dimensionless; k is the formation permeability, mD; Di* is the effective diffusion coefficient of multicomponent minerals, cm2/s; Di is the effective diffusion coefficient of the single component mineral, cm2/s; ci is the molar concentration of the single component mineral, mol/L; ci* is the molar concentration of multicomponent minerals, mol/L; e is the viscosity, Pa s; ϕ0 is the porosity, %; λi is the coupling coefficient, dimensionless.

Microcracks are found on the lithologic interface of the thin interbedded sand and mud in the Shahejie Formation. For the microfractures developed in the Shahejie Formation, the Jaeger model of the mechanical weak surface criterion can be used to evaluate the influence of a weak surface on the mechanical properties of rock mass along the borehole wall. This criterion can also be used to evaluate and analyze the wellbore stability of the formation. The criterion is presented as follows29−31

| 5 |

Among them,

|

6 |

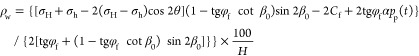

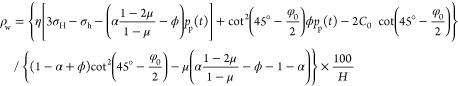

When the borehole wall rock slips along the fracture surface, the calculation formula of the equivalent density of the borehole collapse pressure is as follows

|

7 |

If the above conditions are not met, then the failure criterion of rock mass follows the Mohr–Coulomb strength criterion, that is,

| 8 |

Among them,

|

When the borehole wall rock does not slip along the fracture surface, the calculation formula of the equivalent density of the borehole collapse pressure is as follows

|

9 |

where τ and σn are, respectively, the shear stress and normal stress

on the

shear plane, MPa; σH is the horizontal maximum principal

stress, MPa; σh is the horizontal minimum principal

stress, MPa; σ1 is the maximum principal stress,

MPa; σ3 is the minimum principal stress, MPa; C0 is the cohesive force of the matrix rock,

MPa; Cf is the weak surface cohesion of

the rock, MPa; φ0 is the internal friction angle

of the matrix rock, °; φf is the internal friction

angle of the weak surface of the rock, °; μ is the Poisson’s

ratio, dimensionless; ϕ is the porosity, %; α is the effective

stress coefficient, dimensionless; η is the stress nonlinear

correction factor, dimensionless; β0 is the angle

between the normal of the weak plane and the maximum principal stress,

°; θ0 is the rock fracture angle, °;  ; pp(t) is the formation pore pressure at time t.

; pp(t) is the formation pore pressure at time t.

4.1. Influence of the Seepage Effect on the Wellbore Pore Pressure

With the change of borehole azimuth and inclination angles, the included angle between the radial direction of borehole wall and the direction of the bedding fracture changes constantly, so the radial seepage capacity of the borehole wall also changes. As there is a difference on the radial seepage capacity of the borehole wall rock, it is inevitable that there are differences in the seepage capacities between the borehole and formation under a bottomhole pressure environment and its influence on the pore pressure distribution and effective stress field near the borehole wall.32−36 It is assumed that there are horizontal fractures at the lithologic interface of the sand–mud interbedding, and the azimuth angle of the well track is 90°; the variation law of radial seepage capacity of the borehole wall is evaluated and analyzed, as shown in Figure 6. Figure 7 shows the geometric relationship between the angles.

Figure 6.

Variation law of the radial seepage capacity of the borehole wall.

Figure 7.

Geometric relationship between the angles.

As shown in Figure 6, the well inclination angle is 0°, which means that the radial direction of each position point around the well is parallel to the fracture. With the increase of the well inclination angle, the angle between the radial direction of each position point around the well and the strike of the fracture surface changes. When the well inclination angle is 90°, that is, the horizontal well section, and the well circumference angle is 90 and 270°, the radial seepage ability of the borehole wall is the maximum, and the permeability is 0.5 mD. When the well circumference angle is 0 and 180°, the radial seepage ability of the borehole wall is the minimum, and the permeability is 0.05 mD. The comparison figure of pore pressure changes around the borehole wall is shown as follows (Figure 8).

Figure 8.

Comparison of pore pressure changes around the borehole wall (r = 0.5 m).

As can be seen from Figure 8, the radial seepage capacity of the borehole wall rock changes with the change of the borehole inclination angle. Under the environment of a bottomhole pressure difference, the fluid flow velocity between the borehole and the formation and its influence on the pore pressure near the borehole wall are completely different. The higher the radial permeability is, the greater the influence on the pore pressure of the formation is. When the bottomhole pressure is higher than the formation pore pressure, the wellbore fluid flows into the formation, resulting in an increased pore pressure near the borehole wall (Figure 8a). Conversely, the formation fluid flows into the wellbore, resulting in a decrease in the pore pressure near the wellbore, which is the formation pressure relief (Figure 8b).

4.2. Influence of the Fracture Development and Occurrence of Interbed Sand and Mud on the Wellbore Stability

Based on the above calculation formula, combined with the in situ stress of the Shahejie Formation (the minimum horizontal principal stress gradient is 1.89 MPa/100 m, the maximum horizontal principal stress gradient is 2.48 MPa/100 m, and the overburden pressure gradient is 2.45 MPa/100 m) and the test results of rock mechanical strength, the influences of the borehole trajectory, fracture occurrence, mechanical weak plane, and pressure penetration on the wellbore stability of mudstone in the Shahejie Formation were evaluated and analyzed. Microfractures were developed on the lithological interface of the thin interbedded sand and mud in the Shahejie Formation. The fracture tendency was evaluated as 0° (consistent with the direction of the maximum horizontal principal stress), including the influence of the borehole trajectory change on the stability of the borehole wall at different fracture dip angles, as shown in Figure 9.

Figure 9.

Influences of the fracture development and occurrence on the wellbore stability.

The comparative analysis (Figure 9) shows that the microfractures and occurrences that developed on the lithological interface of the thin interbedded sand and mud of the Shahejie Formation have a significant impact on the wellbore stability of the formation. For homogeneous and nonfractured formations (Figure 9a), the borehole stability of the formation is related to the wellbore trajectory and the magnitude of the ground stress. The borehole stability of an inclined or a horizontal well is worse than that of a vertical well. The collapse pressure equivalent density of a vertical well is approximately 1.23 g/cm3. The stability of drilling horizontal wells in the direction of the minimum horizontal principal stress is better than that of the maximum horizontal principal stress. Cracks are found in the formation, and the spatial occurrence of the cracks has an obvious influence on the stability of the formation borehole wall. When the fracture strike is 0° (Figure 9b), the formation collapse pressure equivalent density of the inclined horizontal well is 1.58–1.59 g/cm3, and the formation collapse pressure is the highest along the direction of the maximum horizontal principal stress. As the inclination angle increases, the formation collapse pressure increases first and then decreases. Relatively speaking, the formation collapse pressure is slightly lower along the direction of the minimum horizontal principal stress, and the wellbore stability is better than that of the maximum horizontal principal stress. At the same time, the stability of the maximum horizontal principal stress direction in the horizontal section is better than that of the minimum horizontal principal stress direction. This suggests that the fracture tendency affects the stability of the formation borehole wall, and the wellbore stability is best when it crosses the fracture surface nearly vertically.

4.3. Influences of Borehole Trajectory and Mechanical Weak Surface on the Wellbore Stability

During the process of drilling in a deep formation, under the complex multipotential energy field, the seepage migration of the drilling fluid along microfractures is promoted. In turn, the migration changes the distribution of the pore pressure and effective stress field near the borehole wall around the well, thereby affecting the stability of the borehole wall. The effects of borehole trajectory, mechanical weak surface, and pressure penetration on the wellbore stability of the mudstone in the Shahejie Formation were evaluated and analyzed. Without considering the seepage effect, the influences of the borehole trajectory (drilling in different directions along the maximum horizontal principal stress) and mechanical weak surface on the wellbore stability of the Shahejie Formation were first evaluated and analyzed (Figure 10).

Figure 10.

Influences of the wellbore trajectory and mechanical weak plane on the wellbore stability.

The wellbore stability of the mudstone in the Shahejie Formation is closely related to the effects of the borehole trajectory and mechanical weak surface. Regardless of the weak surface effect of mudstone mechanics, that is, the homogeneous formation, the wellbore stability of the mudstone in the Shahejie Formation is better, and the collapse pressure equivalent density of the vertical well is approximately 1.23 g/cm3. As the well inclination angle increases, the wellbore stability improves. Considering the weak mechanical surface effect caused by the microcracks developed on the lithological interface of the interbedded sand and mud, the formation collapse pressure increases to varying degrees. Drilling along the direction of the minimum horizontal principal stress, the equivalent density of the inclined well collapse pressure increases to 1.42 g/cm3 (Figure 10a). When drilling in the direction of the maximum horizontal principal stress, the equivalent density of the collapse pressure of the inclined well can be increased to 1.55 g/cm3 (Figure 10d). At the same time, drilling along different directions of the maximum horizontal principal stress increases the equivalent density of collapse pressure in an inclined well to 1.44–1.52 g/cm3 (Figure 10b,c), which proves that the borehole wall stability is better when drilling in the direction of the minimum horizontal principal stress.

4.4. Influence of the Coupling Action of the Mechanical Weak Plane and Seepage Effect on the Wellbore Stability

Considering the seepage effect caused by the microfractures developed on the interbedded lithologic interface of sand and mud, the influence of the coupling action of the mechanical weak surface and pressure penetration on the mudstone wellbore stability of the Shahejie Formation was evaluated and analyzed, as shown in Figure 11.

Figure 11.

Influence of the coupling action of the mechanical weak plane and pressure penetration on the wellbore stability.

Microfractures are developed on the interbedded lithologic interface of sand and mud. The bottom-hole pressure penetration effect reduces the effective supporting force of the drilling fluid on the borehole wall. The effect also further aggravates the collapse and instability of the borehole wall. Compared with the case without considering the pressure penetration effect caused by cracks, coupled with fracture mechanics of the weak plane effect and pressure penetration effect, the equivalent density of collapse pressure increases by 0.12–0.13 g/cm3, and the equivalent density of collapse pressure is generally higher than 1.5 g/cm3 (Figure 11a). The equivalent density of the formation collapse pressure is as high as 1.55 g/cm3 along the direction of the minimum horizontal principal stress. The density is also as high as 1.67 g/cm3 along the direction of the maximum horizontal principal stress (Figure 11d). Drilling along different directions of the maximum horizontal principal stress increases the equivalent density of collapse pressure in an inclined well to 1.56–1.64 g/cm3 (Figure 11b,c), which proves that the borehole wall stability is better when drilling in the direction of the minimum horizontal principal stress.

Microcracks are developed on the interbedded lithologic interface of thin sand and mud in the Shahejie Formation, and the rock mechanical strength is low. Considering the effects of mechanical weak surface and pressure penetration, controlling the drilling fluid density in the deflection section/horizontal section of the Shahejie Formation at approximately 1.69 g/cm3 is suggested. At the same time, the wellbore trajectory deviates to the direction of the minimum horizontal principal stress, and the borehole wall stability is good. When crossing the interbedded sand–mud interface, it should be as close as possible to vertically cross the fracture surface developed on the interbedded interface.

Due to the development of microfractures on the interbedded lithologic interface of sand and mud in the Shahejie Formation, if the drilling fluid cannot be effectively blocked, the higher the drilling fluid density, the greater the pressure penetration effect of the drilling fluid. This causes fractures in the wellbore wall to crack and extend, resulting in the wellbore rock to fall and collapse. Under the condition of ensuring that the drilling fluid used on site has a good inhibition and plugging performance, combining the downhole imaging logging data to determine the width of the bedding fracture under the downhole stress environment and then the size of the plugging material particles is recommended to further improve the ability of the existing drilling fluid to seal the bedding fracture. During the drilling process, the horizontal vibration of the drilling tool should be reduced. The connection force between the microfractures developed on the interbedded lithologic interface of sand and mud in the Shahejie Formation is low, and the rock easily falls along the fracture surface under the vibration of the drilling tool.

5. Conclusions

Through experimental testing and theoretical evaluations, the mechanism of the borehole wall collapse and instability of the well section with thin interbedded sand and mud was analyzed. The measures for wellbore stability are given, and the following conclusions are obtained:

-

(1)

In the Shahejie Formation, the borehole wall collapse mainly occurs in the thin interbedded sections of sand and mud. Due to the change of the lithology of the thin sand–mud interbedded section, the microcracks on the lithologic interface are developed, and the strength of the rock is much lower than that of the mudstone bedrock. The sand–mud thin interbedded section is obviously affected by the mechanical weak plane effect, which leads to the poor wellbore stability.

-

(2)

In the sand–mud thin interbedded section of the Shahejie Formation, the drilling fluid tended to penetrate along the micro-cracks on the lithologic interface. The downhole pressure difference aggravated the seepage behavior of the drilling fluid, resulting in the increase of the pore pressure near the borehole wall, and reduced the effective support force of the drilling fluid column pressure on the borehole wall rock. The “pressure penetration effect” further promoted the slip and failure of the rock along the fracture surface developed on the lithologic interface, leading to the instability of the borehole.

-

(3)

For the Shahejie Formation with thin interbedded sand and mud, the effective plugging performance of the drilling fluid is low. Adding plugging additives in time during the drilling process is suggested to ensure the good plugging performance of the drilling fluid. When an interbedded lithologic interface of thin sand and mud is encountered during the drilling process, drilling along the direction of the minimum horizontal principal stress and nearly vertical through the microcracks developed on the lithologic interface can achieve better wellbore stability and reduce the transverse vibration of drilling tools as much as possible.

The authors declare no competing financial interest.

References

- Zeynali M. Mechanical and physico-chemical aspects of wellbore stability during drilling operations. J. Petrol. Sci. Eng. 2012, 82–83, 120–124. 10.1016/j.petrol.2012.01.006. [DOI] [Google Scholar]

- Xiaojun P.; Chengmin N.; Xiaofeng D.; Qingbin W.; Liming D. Quantitative characterization of differences in glutenite reservoir in the Member 1 and 2 of Shahejie Formation in the northeastern margin of Shijiutuo uplift, Bohai Sea. Acta Pet. Sin. 2020, 41, 1073–1088. 10.7623/syxb202009004. [DOI] [Google Scholar]

- Ding Y.; Luo P.; Liu X.; Liang L. Wellbore stability model for horizontal wells in shale formations with multiple planes of weakness. J. Nat. Gas Sci. Eng. 2018, 52, 334–347. 10.1016/j.jngse.2018.01.029. [DOI] [Google Scholar]

- Liu H.; Cui S.; Meng Y.; Sun H.; Yu X. Study on Rock Mechanics and Wellbore Stability of Igneous Formation in the Shunbei Area. ACS Omega 2022, 7, 23899–23909. 10.1021/acsomega.2c02608. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Du J.; Chen X.; Liu P.; Zhao L.; Chen Z.; Yang J.; Chen W.; Wang G.; Lou F.; Miao W. Numerical Modeling of Fracture Height Propagation in Multilayer Formations Considering the Plastic Zone and Induced Stress. ACS Omega 2022, 7, 17868–17880. 10.1021/acsomega.2c01131. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cui S.; Liu H.; Meng Y.; Fan Y.; Wang J.; Han Z. Study on mechanical properties and wellbore stability of deep brittle shale. J. Petrol. Sci. Eng. 2020, 194, 107500. 10.1016/j.petrol.2020.107500. [DOI] [Google Scholar]

- Huang T.; Cao L.; Cai J.; Xu P. Experimental investigation on rock structure and chemical properties of hard brittle shale under different drilling fluids. J. Petrol. Sci. Eng. 2019, 181, 106185. 10.1016/j.petrol.2019.106185. [DOI] [Google Scholar]

- Wei J.; Weifong S.; Guiting H. Insights into the Tectonic Fractures in the Yanchang Formation Interbedded Sandstone-Mudstone of the Ordos Basin Based on Core Data and Geomechanical Models. Acta Geol. Sin. 2015, 89, 1986–1997. 10.1111/1755-6724.12612. [DOI] [Google Scholar]

- Chen K.; Yan J.; Zhao Z.; Fu L.; Geng B.; Li X. Identification of thin interbedded sand and shale with electrical imaging logging in Ordos Basin. Well Logging Technol. 2020, 44, 576–583. [Google Scholar]

- Libin L.; Yanguang W.; Chengyu S. Thin inter-bed AVO characteristics analysis based on forward model. Oil Geophys. Prospect. 2019, 54, 1246–1253. [Google Scholar]

- Lin S.; Junsheng D.; Jianwei F.; Xuejun Y.; Ke W.; Baoshun S.. Effect of strata thickness on fracture development in sand-mud interbed. Xinjiang Pet. Geol. 2015, 36, ( (01), ), pp. 35−41. 10.7657/XJPG20150107 [DOI] [Google Scholar]

- Lu H. S.; Zhang J. F.; Li S. Y.; Zou J.; Liu A. Best selection among crack criterions to sandstone-mudstone formation and its application to fracture penetration ability evaluation. J. Univ. Pet. 2012, 36, 14–18. [Google Scholar]

- Wu X.-s.; Zhao W.; Li B.; Huang W. Study on collapsing mechanism of sand slime stratum borehole wall in He8 Section in Sulige gas-field and anti-sloughing countermeasure. Sci. Technol. Eng. 2013, 13, 6072–6075. [Google Scholar]

- Liu Y.; Zhao H.; Xu H.; Yang X.; Li B.; Luo H. Thin inter-bed prediction with poststack frequency improvement and multi-attribute analysis An example of Carboniferous sand-mudstone member in Lunnan Area. Oil Geophys. Prospect. 2018, 53, 196–200. [Google Scholar]

- Guo C.-X.; Guo S.-W.; Zhu W. F.; Yuan X.-H.; Peng X.-M.; Xing X.; Chen M.-X. Research and application of fluvial sand-shale thin interbedding prediction method. Geophys. Geochem. Explor. 2018, 42, 594–599. 10.11720/wtyht.2018.1091. [DOI] [Google Scholar]

- Lianbo Z.; Zhengguo W.; Shurong X.; Guibin Z. The origin and geological significance of low dip-angle fractures in the thrust zones of the western basins of China. Acta Pet. Sin. 2008, 30, 56–60. 10.7623/syxb200901012. [DOI] [Google Scholar]

- Ding L.Tahe Oilfield Wellbore Stability Study in Hard Brittle Shale; China University of Petroleum (East China), 2020. [Google Scholar]

- Cheng S.; Yan J.; Cao P.; Yang M.; Zhou B.; Xu X.; Tang J.; Deng B. Study on instability mechanism of hard-brittle mudstone borehole wall at Sangtamu group in Halahatang block of Tarim oilfield and countermeasures. Drill. Prod. Technol. 2018, 41, 23–24. [Google Scholar]

- Yi-Sheng L.; Zheng-Ping Z.; Ren-Fang P.; Hei-Zhi W.; Ji-Neng J. Brittleness evaluation of Wufeng and Longmaxi Formation high-quality shale reservoir in southeast of Chongqing. Environ. Earth Sci. 2022, 81, 169. 10.1007/s12665-022-10274-3. [DOI] [Google Scholar]

- Wang P. Q.; Deng J.; Bai Y.; Wang J.; Qing S. Effect of drilling fluid soaking on the shale collapse pressure in Yanchang Formation. Spec. Oil Gas Reservoirs 2018, 25, 163–167. [Google Scholar]

- Cui S.; Liu H.; Meng Y.; Zhang Y.; Tao Y.; Zhang X. Study on fracture occurrence characteristics and wellbore stability of limestone formation. J. Petrol. Sci. Eng. 2021, 204, 108783. 10.1016/j.petrol.2021.108783. [DOI] [Google Scholar]

- Hencher S.; Richards L. Assessing the shear strength of rock discontinuities at laboratory and field scales. Rock Mech. Rock Eng. 2015, 48, 883–905. 10.1007/s00603-014-0633-6. [DOI] [Google Scholar]

- Chao Z.; Wang H.; Xu W.; Yang L.; Zhao K. Variation of permeability and porosity of sandstones with different degrees of saturation under stresses. Chin. J. Rock Mech. Eng. 2017, 36, 665–680. 10.13722/j.cnki.jrme.2016.0063. [DOI] [Google Scholar]

- Song F.; Hu X.; Ji K.; Huang X. Effect of fluid–solid coupling on shale mechanics and seepage laws. Nat. Gas. Ind. 2018, 5, 41–47. 10.1016/j.ngib.2017.12.001. [DOI] [Google Scholar]

- Liu H.; Liu T.; Meng Y.; Han X.; Cui S.; Yu A. Experimental study and evaluation for borehole stability of fractured limestone formation. J. Petrol. Sci. Eng. 2019, 180, 130–137. 10.1016/j.petrol.2019.05.045. [DOI] [Google Scholar]

- Ma T.; Chen P. A wellbore stability analysis model with chemical-mechanical coupling for shale gas reservoirs. J. Nat. Gas Sci. Eng. 2015, 26, 72–98. 10.1016/j.jngse.2015.05.028. [DOI] [Google Scholar]

- Tianshou M.; Ping C.; Xudong W.; Zhaoxue G.; Zhiqiang L. Numerical analysis method of pore pressure propagation around the borehole for shale gas reservoirs. Acta Pet. Sin. 2016, 37, 660–671. 10.7623/syxb201605010. [DOI] [Google Scholar]

- Jin Y.; Chen M.. Wellbore Stability Mechanics; Science Press: Beijing, 2012. [Google Scholar]

- Zeng Y.; Jiang H.; Ding S.; Chen J.; Wang Y.; Zheng J. Analytical and Experimental Investigations on Mechanical Properties of Weak Plane Bedding in Mudstone. Geofluids 2021, 2021, 5408701. 10.1155/2021/5408701. [DOI] [Google Scholar]

- Zhao W.; Liu Y.; Wang T.; Ranjith P. G.; Zhang Y. Stability analysis of wellbore for multiple weakness planes in shale formations. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 44. 10.1007/s40948-021-00228-7. [DOI] [Google Scholar]

- Chen Y.; Liu Z.; Zhang X.; He S.; Ma D.; Zhou J. Research on the collapse pressure of an elliptical wellbore considering the effect of weak planes. Energy Sources, Part A Recovery, Util. Environ. Eff. 2020, 42, 2103–2119. 10.1080/15567036.2019.1607929. [DOI] [Google Scholar]

- Lu Y.; Chen M.; Jin Y.; Zhang G. A Mechanical Model of Borehole Stability for Weak Plane Formation under Porous Flow. Pet. Sci. Technol. 2012, 30, 1629–1638. 10.1080/10916466.2010.514583. [DOI] [Google Scholar]

- Xu Z.; Liu Y.; Wang Y.; Chai J.; Li Y. Analysis of Coupled Three-Dimensional Seepage and Temperature Fields in Fracture Network of Rock Mass. Int. J. Comput. Methods 2020, 17, 1950005. 10.1142/s0219876219500051. [DOI] [Google Scholar]

- Song Z.; Zhang J. Progressive failure mechanical behaviour and response characteristics of sandstone under stress-seepage coupling. J. Geophys. Eng. 2021, 18, 200–218. 10.1093/jge/gxab008. [DOI] [Google Scholar]

- Ding Q.; Song B. An Experimental Study of Seepage Properties in Crushed Sandstone and Mudstone. Adv. Civ. Eng. 2019, 2019, 1–9. 10.1155/2019/6537571. [DOI] [Google Scholar]

- Ma D.; Cai X.; Zhou Z.; Li X. Experimental Investigation on Hydraulic Properties of Granular Sandstone and Mudstone Mixtures. Geofluids 2018, 2018, 1–13. 10.1155/2018/9216578. [DOI] [Google Scholar]