Abstract

Not only has the COVID-19 pandemic caused a global health crisis, but it has also changed the dynamics of waste generation around the world. This situation demands a productive solution for face mask (FM) waste management to solve several associated environmental issues. In the current study, a novel soil treatment method is proposed for the improvement of mechanical characteristics of fat clay by using FM as fiber reinforcement and silica fume (SF) as the cementitious agent in the form of a composite binary admixture (CBA). The performance of the proposed CBA is compared with SF and FM as the lone stabilizers by conducting extensive geotechnical testing. The SF treatment exponentially improves the strength characteristics of soil but it marginalizes the ductility of soil, inviting sudden failure and instability under dynamic loadings. It is observed that the proposed CBA not only improves the strength characteristics more than SF but also regulates the ductility and deformability of treated soil due to the presence of FM fibers. In addition, the policies and protocols on the logistics of collecting FM waste and making it ready for the proposed geotechnical application are reviewed; associated health risks, socioeconomic conditions and available technologies are the major governing factors to formulate and implement these policies. Moreover, the prolonged storage of COVID-19 FM waste for disinfection is found to be suitable for the proposed soil stabilization method as per the literature. The current study helps in achieving cost-effective filler/foundation material, solving COVID-19 FM waste problems and promoting resource conservation.

Keywords: COVID-19 face mask, Waste management, Composite binary admixture, Fat clay, Mechanical properties

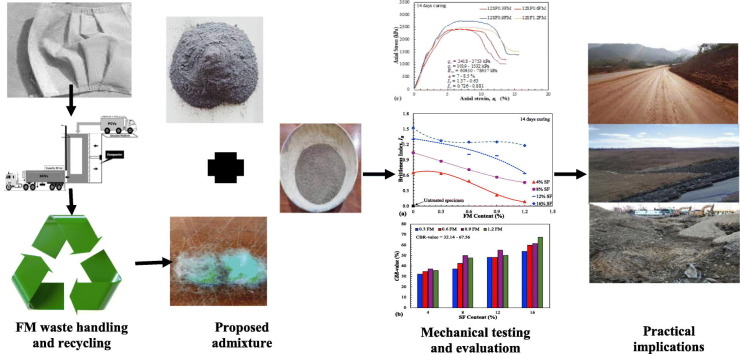

Graphical abstract

Nomenclature

- ASTM

American society for testing and materials

- C

Constant of σ y -q u relationship

- CBA

Composite binary admixture (SF + FM)

- CBR

California bearing ratio

- Cc

Compression index

- E50

Deformation modulus

- e

Void ratio

- e0

Initial void ratio

- GSD

Grain size distribution

- IB

Brittleness index

- ID

Deformability index

- IP

Plasticity index

- FM

Face mask

- NIMBY

Not in my backyard

- PPE

Personal protective equipment

- qu

Unconfined compressive strength

- qr

Residual compressive strength

- R2

Coefficient of determination

- USCS

Unified soil classification system

- SF

Silica fume

- w

Water content

- wL

Liquid limit

- wn

Natural water content

- wopt

Optimum moisture content

- we-opt

Equivalent optimum moisture content

- wP

Plastic limit

- εa

Axial strain

- εf

Strain at failure

- γd

Dry unit weight

- γdmax

Maximum dry unit weight

- η

Dimensionless parameter of E 50 -q u relationship

- σv’

Effective vertical stress

- σy

Yield stress

1. Introduction

Pandemic due to novel coronavirus, COVID-19, has posed several social, economic, and environmental challenges around the globe. This pandemic has proved to be disastrous for almost all sectors of life, hindering their smooth functioning. Similarly, this pandemic has altered the dynamics of waste generation making waste management rather challenging. The emergence of COVID-19 related waste byproducts in a large quantity is a major issue around the world these days due to the inadequacy of traditional waste management schemes to deal with the scale of this problem. Among the overall COVID-19 related waste generation, the portion of used surgical face mask (FM) waste is staggering because many countries have made it compulsory for the general public to wear FMs. This policy is a measure to delay the peak COVID-19 epidemic time by curbing down the blind community transmission of the virus since strong evidence suggests that COVID-19 could be transmitted by asymptomatic carriers unlike many other viral diseases making prevention trickier (Cheng et al., 2020).

This policy is probably helping to break the fast transmission chain of this virus (Gupta et al., 2020; Liao et al., 2021). However, it has resulted in a large amount of FM waste, which has become a challenge for conventional waste management systems all across the world. Consequently, the trashes of used FMs lying on the streets and roads have become a common observation these days especially in the developing world (Das et al., 2020). Estimations based on literature suggest that employment of the aforementioned policy regarding the use of FM at 80% assumed acceptance rate among public could yield 2228.2 million used FM daily in Asia alone, this shows the scale of FM waste management problem encountered by the pertinent authorities and practitioners these days, which is gigantic (Nzediegwu and Chang, 2020). Moreover, the gargantuan amount of FM waste is not the only waste management problem, the material of FM waste is also problematic as its bio-disintegration could take many years and burning could cause air pollution (Silva et al., 2020a, Silva et al., 2020b; Dharmaraj et al., 2021). Thus, this situation is demanding urgent solutions from researchers of different fields to viably and productively handle and possibly reuse the FM waste.

Soil is an important geo-material commonly used in the construction industry as a base, filler, foundation, and construction material. The stability of any civil engineering structure is dependent on the mechanical behavior of the base material on which the structure is being built. For this reason, a borrowed base material with stable mechanical characteristics is desirable for construction in areas having problematic soils. However, due to economic considerations, availability issues, and natural resource conservation constraints attached with borrowed material, the on-site problematic soils are often used as base material after suitable stabilization. Fat clays are the commonly available soil considered as a “hidden disaster” for the structures due to their unfavorable mechanical behavior. Such behavior can lead to failure of built structures over it e.g., foundation distress, highway surface cracking, sub-grade subsidence, and embankment leakage, etc.

Different cementing materials i.e., cement and lime are most commonly used by geotechnical engineers to improve the behavior of fat clays. However, the production of these cementing materials is uneconomical, non-environment friendly, and extensively utilizes precious natural resources (Barrios et al., 2021). Thus, to avoid these disadvantages, using the cementing material made of waste byproducts is a key research dimension as it holds a win-win situation for the construction industry and environmental management. In this regard silica fume (SF), a waste byproduct of the metal industry is a promising material used to enhance the mechanical properties of concrete by many researchers due to its ability to trigger a pozzolanic reaction (Ghavami et al., 2021). Similarly, it can also be used to ameliorate the strength characteristics of fat clays (AL-Soudany, 2018; Phanikumar, 2020; Singh et al., 2020a, Singh et al., 2020b). However, one major issue that remains with using SF alone as a stabilizer is the compromised ductility of the ameliorated soil even though the strength parameters may improve making soil prone to sudden failure and unsuitable against dynamic loadings (Phanikumar, 2020; Singh et al., 2020a, Singh et al., 2020b). Thus, an astutely designed admixture is needed which can properly ameliorate the mechanical properties of fat clays. Different studies have used polyethylene to enhance the ductility of the artificially cemented fact clays (Elkhebu et al., 2019). In the current study, the authors introduce a novel admixture by mixing Covid-19 FM and silica fume to ameliorate the mechanical properties of fat clays. It is envisaged that this novel admixture could not only improve the strength characteristics but could also enhance the ductility of cemented fat clay. To the best of our knowledge, no experimental study has been reported in the literature, hitherto, to use the COVID-19 FMs in fat clay stabilization.

Considering the foregoing discussion, the objectives of the current study are to i) utilize FM in developing a new composite binary additive (CBA) to ameliorate mechanical properties of fat clays by adding FM and SF together in suitable proportions; ii) investigate and compare the efficacy of this novel FM based CBA, FM, and SF independently in ameliorating the mechanical characteristics through various geotechnical tests i.e., compaction, unconfined compression, CBR, and consolidation tests; iii) report the optimum value of CBA (OCBA) required for the amelioration of mechanical properties of fat clays based on analysis of experimental results; iv) discuss the protocols that could be followed to safely use the FM waste in this geotechnical application by conducting a literature survey on the logistics of handling the contaminated FM waste for reuse. The current study provides a solution that helps both waste management and construction industry by recycling troubling COVID-19 FM waste in mitigating the disastrous impact of fat clays on civil engineering structures, i.e., roads, highways, and buildings, and report experimental results of unconfined compression, compaction, consolidation, and CBR tests to evaluate the efficacy of this solution for the first time. Thus, this study is of prime importance for the practitioners, researchers, and authorities dealing with the aforementioned waste management and construction industry related issues.

2. Materials and methods

2.1. Material characterization

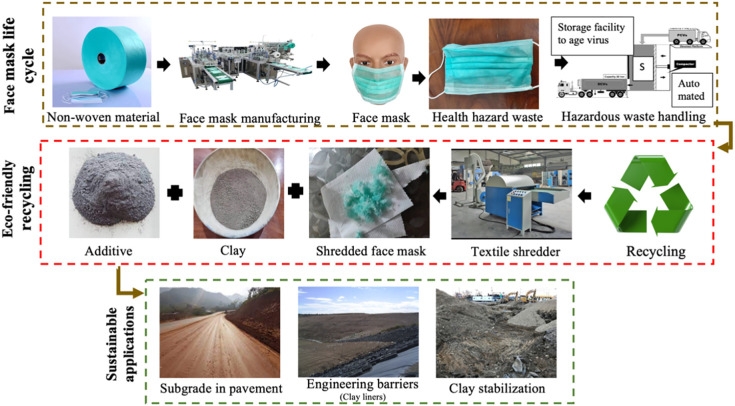

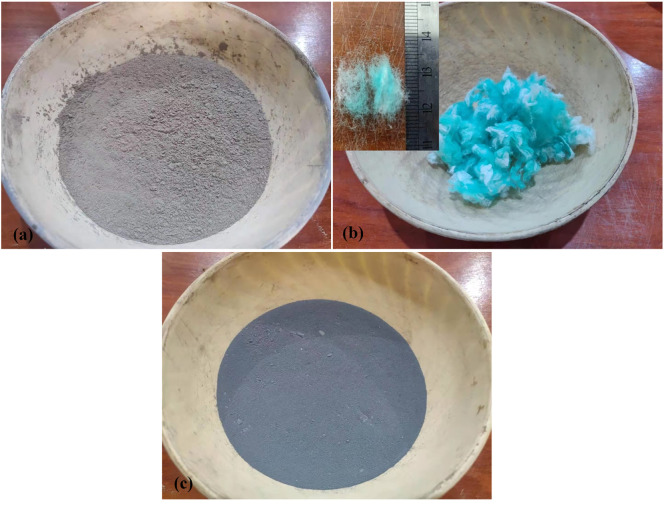

Fig. A.1 (appendix-A) presents all the materials used in the current study including selected soil, and materials used for the stabilization i.e., SF, shredded fibrous FM. The selected soil is prepared by mixing the natural soil obtained from the Sahiwal region in Pakistan and commercially available bentonite in an equivalent ratio (i.e., 50% natural soil+50% Bentonite). The purpose of this mixing was to test the solution proposed by authors in the current study for the possible worst-case scenario in terms of plasticity of clayey soils i.e., very high plastic clay (fat clay), which is regarded as problematic soil. Geotechnical and physical characteristics of natural soil, bentonite, and selected soil are determined and presented in Table 1 . As per the Unified Soil Classification System (USCS) (following ASTM D-2487), using grain size distribution analysis (based on sieve analysis and hydrometer analysis tests) and consistency limits data, the natural soil, bentonite, and selected soil were classified as the silty clay (CL-ML), fat clay (CH), and fat clay (CH), respectively. Thus, the selected soil represents the possible high plastic soil which practitioners could practically encounter in the field.

Table 1.

Geotechnical characteristics of subjected soils.

| Characteristics | Bentonite | Natural Soil | Selected Soil (50% B + 50% NS) |

|---|---|---|---|

| Liquid limit, wL (%) | 150 | 24.5 | 82.5 |

| Plastic limit, wp (%) | 39.53 | 18.31 | 30.86 |

| Plasticity index, Ip (%) | 111.5 | 6.2 | 52 |

| Clay content (%) | 84 | 50 | 66 |

| Silt content (%) | 16 | 30 | 33 |

| Sand content (%) | 0 | 20 | 10 |

| Maximum dry unit weight, γdmax (kN/m3) | 15.25 | 16.9 | 15.9 |

| Optimum water content, wopt (%) | 30.5 | 21.5 | 24.5 |

| Unconfined compression strength, qu (kPa) | – | – | 153.4 |

| CBR-value (%) | – | – | 3.06 |

| Compression index, Cc | – | – | 0.524 |

| Yield stress, σy (kPa) | – | – | 60 |

| Void ratio, e0 | – | – | 1.71 |

| USCS | CH | CL-ML | CH |

The proposed CBA in the current study is based on the combination of FM and SF. Wherein SF works as a cementing agent and FM works as a reinforcement agent, the former activates chemical interaction with soil. The cementitious material SF was obtained from the industrial waste derived from ferrosilicon alloy and silicon metal (Fig. A.1(b)). The density and specific gravity of SF used in the current study are determined to be 92.1 Mg/m3 and 2.21, respectively. The chemical analysis of SF was also conducted and its chemical compositions are tabulated in Table B.1 (appendix-B). The SF was observed to be majorly composed of amorphous silica (SiO2), this enables SF to be enriched in silica fume pozzolanic activity, which is a required attribute for the stabilization of soil by the cementing agents i.e., cement and lime (AL-Soudany, 2018). Thus, SF could reasonably be taken as a replacement of cement and lime as a cementing agent in soil stabilization.

Shredded FM is used as fibrous material for reinforcement purposes in the CBA (Fig. A.1(c)). It is important to mention here that due to COVID-19 restrictions, un-used FMs are used during the experiments. Moreover, the nose wire and ear bands of FM are removed to make it a homogenous material. In terms of the material characteristics, the top and bottom layers of the FM are made of non-woven fabric (spun-bond fabric), while meltdown polypropylene (melt-blown fabric) is the middle layer of the FM. The FM could be shredded by using a textile shredding machine (de-fibering machine). Different physical characteristics of FM used in the current study are supplemented in Table B.2.

2.2. Test scheme and methods

Different mechanical characteristics of the soil are examined in the current study including compaction, strength, and compressibility characteristics of the soil. To examine these mechanical characteristics of the soil, different Geotechnical tests are conducted including compaction tests, unconfined compression tests, CBR tests, and one-dimensional consolidation tests. To conduct these tests, the latest test standards of the American Society of Testing Material (ASTM) are followed. A detailed testing plan is supplemented in Table B.3. To conduct a compaction test, the standard effort is selected in the current study, which imparts compaction energy of 600 kN-m/m3 on a soil sample of 0.95-l equivalent volume in one trial to determine optimum moisture content, w opt, and maximum dry density, γ dmax of the soil sample. An unconfined compression test is conducted on a sample that is prepared in a mold with a dimension of 60 mm in height and 30 mm in diameter. Unconfined compression tests are conducted as per ASTM D2166; the strain-controlled axial load is applied to the sample at a loading rate of 1.0 ± 0.1 mm/min. The maximum load per unit area bared by sample or the load per unit area at 15% axial strain, whichever occurs first during the test, is used to calculate the unconfined compressive strength, q u, in the current study. Also, to examine the strength characteristics of soil for use in subgrade construction, un-soaked CBR tests are conducted using a 2.5 kg surcharge load as per ASTM D1883-14. Further, to evaluate compressibility characteristics of the soil one-dimensional (ID) consolidation test is performed by following ASTM D2435. In this test, a specimen of 6 cm in diameter and 2 cm in height is axially loaded with multiple stress increments and laterally restrained in an ID consolidation apparatus. A single stress increment is applied until pore water dissipation for that stress increment ceased after 24 h; eight increments of stress are applied this way. For each increment, the stresses are multiplied by two, resulting in a load increment ratio (LIR) of one. Maximum applied effective vertical stress, σ v ’, stress is set around 3200 kPa in the current study. Measurements of the change in the height of the specimen are taken during the ID consolidation test and the two most important compressibility characteristics, i.e., compression index, C c, and yield stress, σ y were determined by analyzing the test observations.

The aforementioned tests are performed for different soil samples by adding SF, FM alone, and CBA (SF + FM) at varying rates (Table B.3). For instance, initially, SF alone is added at 0, 2, 4, 6, 8 and 16% and FM alone is added at 0.3, 0.6, 0.9 and 1.2% in the selected soil and compaction, unconfined compression and CBR tests are conducted; these contents are selected based on literature review and experience. Afterward, 16 different percentages of CBA are tested by adding each selected content of SF (2, 4, 6, 8 and 16%) with varying content of FM i.e., 0.3, 0.6, 0.9, and 1.2%. For CBA, compaction, unconfined compression, CBR, and ID consolidation tests are conducted. Thus, extensive testing is carried out to evaluate the efficacy of CBA and its comparison with independent SF- and FM-based stabilization techniques.

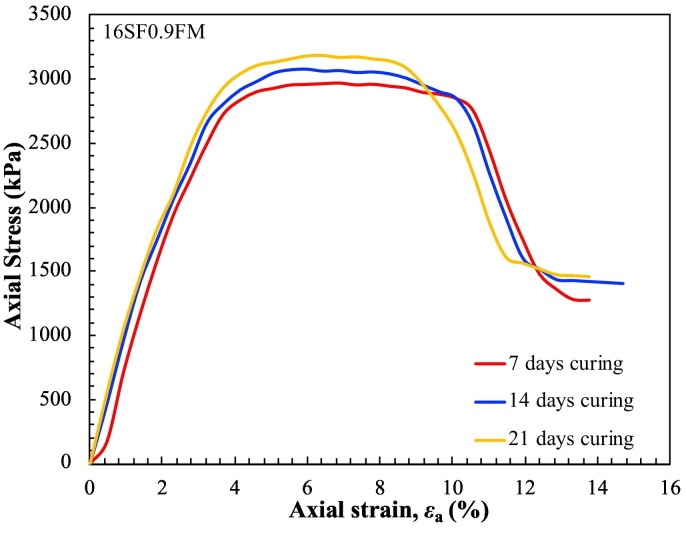

To evaluate curing impact for the cemented samples with SF, curing of samples with SF alone is done for the 7, 14, and 21 days and correspondingly unconfined compression tests are conducted. Literature reveals that the mechanical characteristics of soil stabilized with cementing material depend on the curing period; however, after a certain curing period, the amelioration of the mechanical properties becomes marginal. Therefore, for such stabilization, the curing period must be selected astutely to avoid large delays in the testing process and to gain proper strength. For CBA stabilized soil curing period is selected to be 14 days for the unconfined compression test and ID consolidation test based on trials conducted on SF stabilized soil. However, to avoid large delay, 7 days of curing was done to conduct CBR tests on CBA stabilized soil, as trials reveal that substantial strength is gained in 7 days for the SF stabilized soil. To prevent any excessive moisture loss, the soil samples were wrapped in a polythene cling sheet and placed in the desiccator jar for the curing procedure, as per past literature (Phanikumar, 2020).

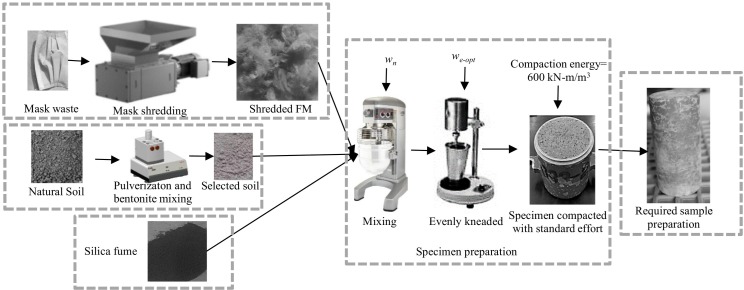

2.3. Specimen preparation

The stepwise schematic view of the specimen preparation procedure is supplemented in appendix A (Fig. A.2). To prepare CBA, unused FM (depicting FM waste) is shredded using a textile shredding machine; the mask is shredded into small fibers length of which is roughly 10 ± 5 mm. The natural soil is obtained from the field and oven-dried for 24 h and then pulverized using a soil pulverizing machine and mixed with bentonite to obtain selected soil for the current study. Finely grounded SF is obtained from the industry. One of the most common problems with fiber reinforcement of soil is the delicacy required during the mixing of fiber with soil to avoid segregation and attain the homogenous amount of fibers throughout a stabilized soil specimen. For that purpose, a mixing technique is developed in the current study, in which the selected soil, SF, and shredded FM fibers (referred to as FM in the later sections) are initially mixed for 5 min by adding natural moisture content, w n, of natural soil (4%) in a mixer to avoid dusting and loss of material, and then this mixture is stored in plastic bags for less than 30 min for the swelling and absorption of free water. Afterward, the mixture is evenly kneaded by adding equivalent optimum moisture content, w e-opt, (w opt- w n) in soil mixture; w opt is estimated through standard proctor test. After kneading the mixture at optimum moisture content, the sample is compacted in a standard proctor mold in a three-equivalent layer by employing overall 600 kN-m/m3 standard compaction energy. The soil mass is extracted from the compaction mold and samples for the unconfined compression test and ID consolidation test are extracted from the center of this compacted soil mass (compacted at standard γ dmax) by using specialized hydraulic sample extruders for sample preparation for each considered soil test. For CBR tests, to attain the γ dmax, samples are compacted in a mold having a volume of 2315.5 cm3.

3. Tests results and discussions

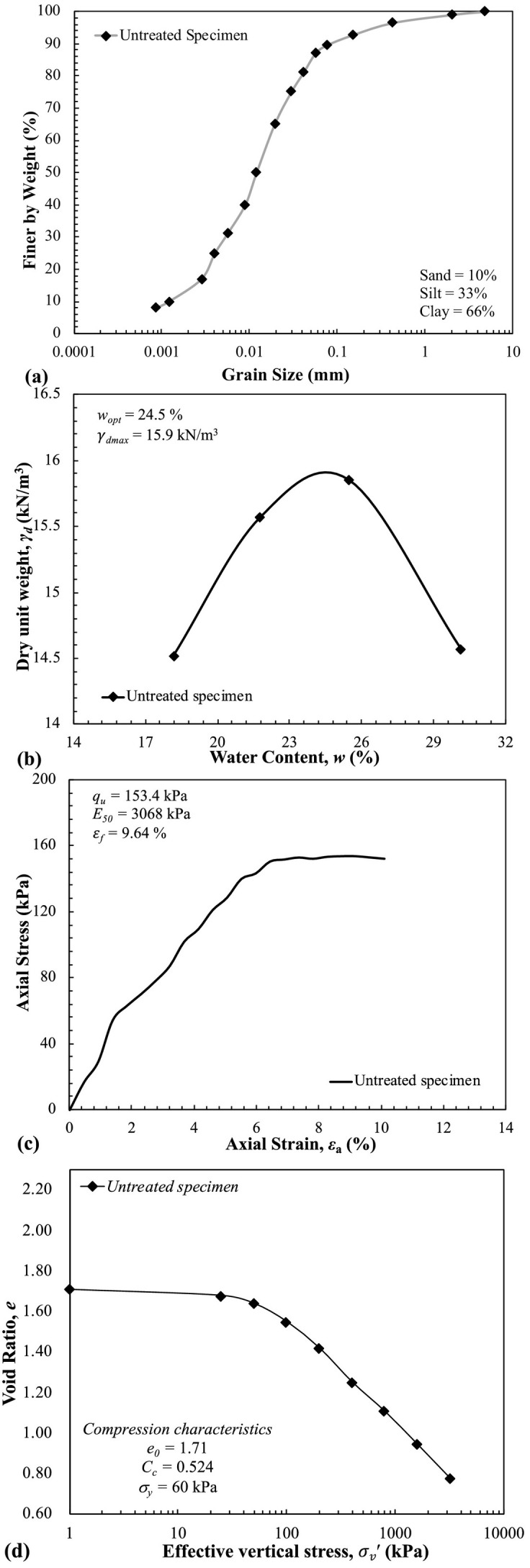

3.1. Mechanical characteristics of selected soil

The mechanical properties of the selected soil are investigated through various tests described in the aforementioned section. Fig. A.3 and Table 1 present different test results of the mechanical characteristics of the selected soil. Grain size distribution analysis based on the sieve analysis and hydrometer analysis tests results show that soil contains 60% of clay fraction (Fig. A.3(a)), which is a substantial amount to impart fat clay behavior, owing to which a high liquid limit, w L, and plasticity index, I p i.e., 82.5% and 52%, respectively, is observed (Tiwari et al., 2020). A domed shape compaction curve is achieved through standard compaction test, this shape of compaction curve is associated with the clayey soil (Fig. A.3(b)) (Khalid and Rehman, 2018); consequently, a high w opt i.e., 24.5 is observed for the selected soil as more water is required to lubricate the clayey soil grains due to its high water-absorbent quality (Khalid et al., 2019). The results obtained from the unconfined compression test show that q u of the selected soil is only 153.4 kPa at its standard compaction parameters, and failure occurs at a 9.4% of axial strain (Fig. A.3(c)). This compressive strength could be regarded as a low strength value for high loaded structures, thus needs improvement (Mujtaba et al., 2020). The shape of the stress-strain curve is observed to be hyperbolic in nature with a distinct stress failure point without any post-softening showing ductile behavior. ID consolidation test result of the selected soil shows that the soil has the initial void ratio, e 0, and yield stress, σ v, around 1.71 and 60 kPa respectively (Fig. A.3(d)). Also, the e-log σ v ’ curve shows that the selected soil possesses a large value of C c (0.524) even after the compaction, which shows that selected soil is prone to large consolidation. Thus, these results show that with the addition of 50% bentonite in the natural soil, the mechanical characteristics of silty clay change to that of fat clay; these results are in line with Khalid et al. (2019) and Mujtaba et al. (2020).

3.2. Mechanical characteristics of stabilized soil

3.2.1. Compaction characteristics

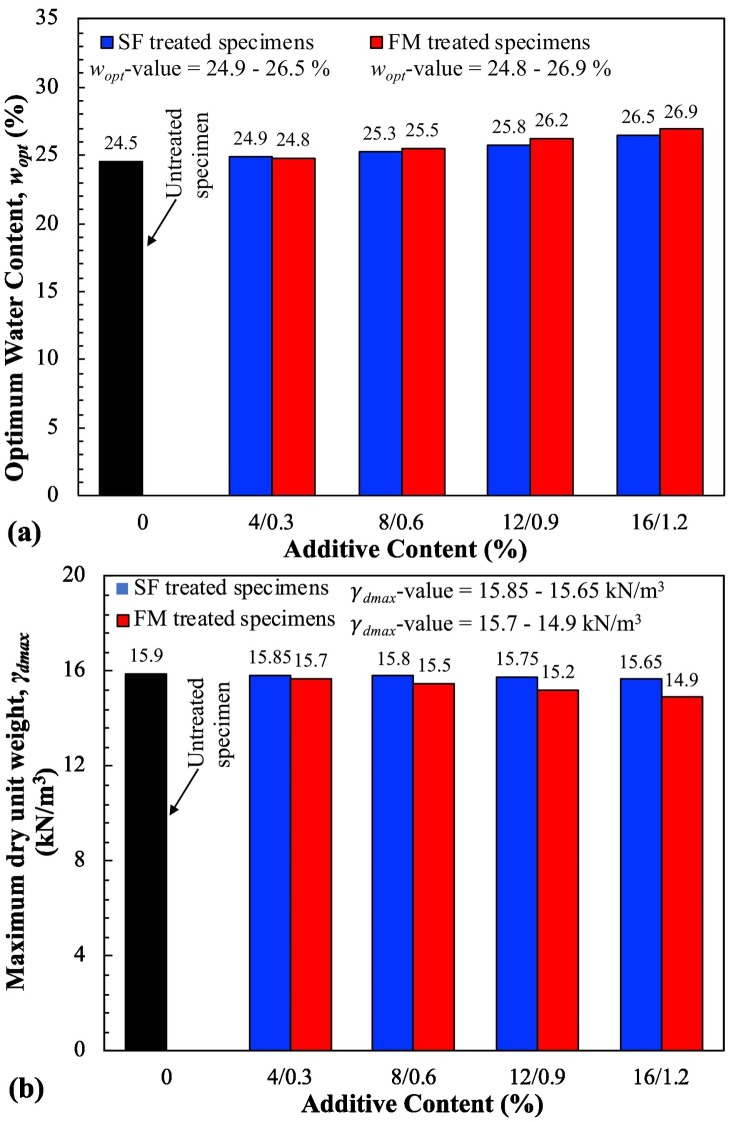

3.2.1.1. Effect of SF and FM as independent stabilizers

Fig. A.4 presents the effect of SF and FM as the independent stabilizers on the compaction characteristics of the selected soil. It is observed that w opt, slightly increases with the addition of SF and FM as the lone stabilizers, wherein decrease is slightly more pronounced for the latter (Fig. A.4(a)). With the addition of SF from 0 to 12% and FM from 0 to 1.2% the w opt increases by approximately 8 and 9% respectively. Further, γ dmax is slightly decreased with the addition of SF and FM as the lone stabilizers in the selected soil (Fig. A.4(b)); a decrease of 1.5% and 6.2% is observed in γ dmax for the increase in the afore-specified amount of the SF and FM. Numerous researchers have reported similar results for the cementitious stabilization and fiber reinforcement of clayey soils (Abdi et al., 2021; Ikeagwuani and Nwonu, 2019). The formation of cementitious products and coarser fiber addition than native soil fabric slightly increases the porosity for SF and FM stabilization, respectively, which thereby slightly decreases the γ dmax of stabilized soil (Moghal et al., 2018). The increase in the w opt could be associated with the increase in the water absorption capacity of the treated soil and an increase in the void spaces with the addition of SF and FM individually (Abdi et al., 2021).

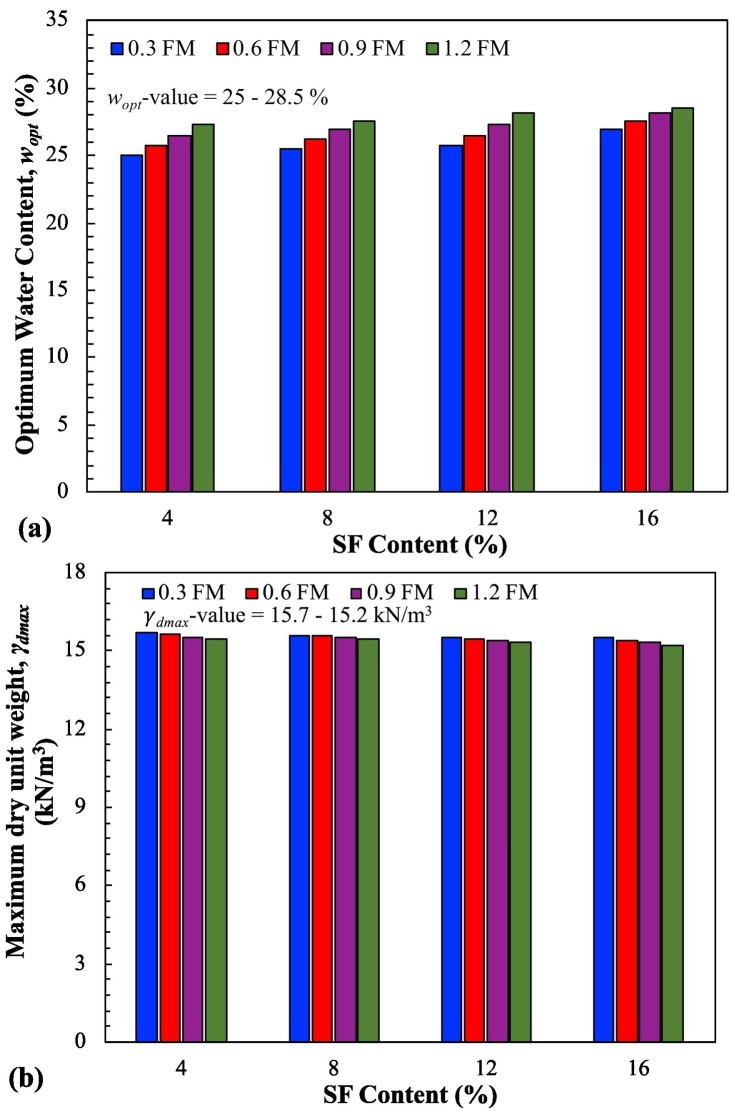

3.2.1.2. Effect of CBA

Fig. A.5 presents the effect of different proportions of the proposed CBA on the compaction characteristics of the selected soil. It is observed that w opt, increases with the addition of SF and FM in combination (Fig. A.5(a)). For CBA, with the increase in FM considering an individual and increasing amount of SF, the w opt increases; wherein, comparatively, the former trend poses more increase in the w opt than the latter trend. Overall, w opt of selected soil is increased by 16%, as CBA having 16% SF and 1.2% FM is added in the selected soil. Further, γ dmax is slightly decreased with the addition of SF and FM in combination in the selected soil (Fig. A.5(b)). A maximum decrease of 4% is observed when CBA having the highest SF and FM amount considered in the current study (i.e., 16% SF +1.2% FM) is added in the selected soil. The reduction in γ dmax is due to the rapid formation of early chemical reaction products at particle contact points due to SF and alteration of soil fabric due to FM, jointly; as this causes the increase in the void spaces in the soil skeleton and thereby decreases the γ dmax. Part of the water added to the soil–CBA mixture is consumed in filling these voids, hydration of CaO due to the chemical reaction of SF, and FM fiber soaking, raising the w opt (Syed and GuhaRay, 2021; Moghal et al., 2018); due to the joint effect, decrease in w opt is more pronounced for the CBA than SF and FM as the lone stabilizers.

3.2.2. Strength characteristics

3.2.2.1. Unconfined compression test

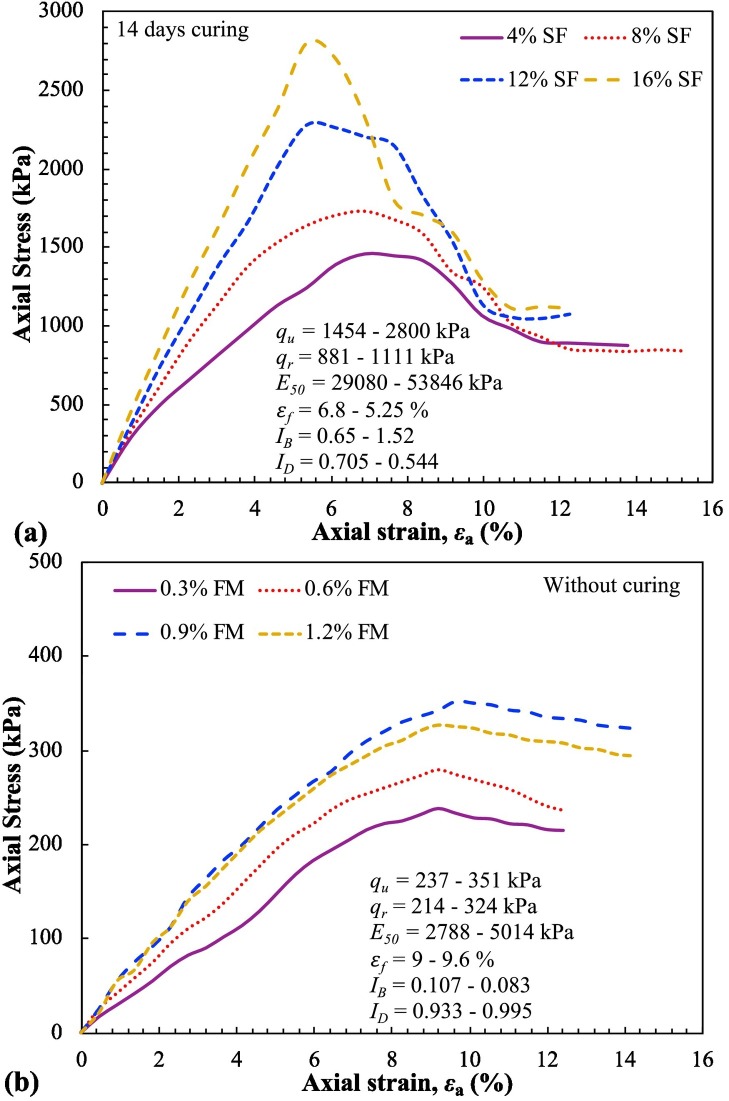

3.2.2.1.1. Effect of SF and FM as independent stabilizers

Fig. A.6 presents the effect of SF and FM as the independent stabilizers on the stress-strain response of the selected soil in the unconfined compression test after 14 days curing period. It is observed that for all samples, initially, stress increases with the increase in the axial strain, ε a, linearly, and then attain a maximum value or stable value which is regarded as q u for certain ε a. It can be also observed that q u of selected soil substantially increases with the addition of SF and FM as the lone stabilizers, wherein increase is more pronounced for the former (Fig. A.6). With the addition of SF from 0 to 12% and FM from 0 to 0.9%, the q u increases almost by 1725% and 128%, respectively. A staggering amount of increase in q u is observed with this stabilization, especially for SF. However, for SF stabilized soil the stress-strain curves show that after reaching the peak strength, with an increase in ε a, there occurs a sudden decrease in stress value and the sample shows a softening response and attain a residual unconfined compression strength, q r. In addition, q u is decreased by 39%–40% to reach q r, and axial strain, for which q u is maintained, is decreased by 2.1%–0.7% with the addition of SF from 4%–16% in the selected soil (Fig. A.6(a)). This shows that even though strength characteristics of SF treated soil are substantially improved but it undergoes more and more brittle failure mode as SF content is increased. The brittleness of soil is undesirable mechanical behavior, for instance, when exposed to lateral earth pressures or seismic loads, the brittleness of soil causes a soil column fracture, which fails under tensile stress (Elkhebu et al., 2019). The addition of the SF results in a major increase in the calcium content in the soil (Table A.2), which is responsible for the formation of the hardened calcium silicate hydrate, C-S-H, gel on the curing, similar to the cement-based stabilization. The large formation of C-S-H is mainly attributed to the exponential increase in q u of the soil (AL-Soudany, 2018). The chemical reaction between SF and calcium also causes the soil sample to become more brittle due to the inclusion of hardened C-S-H gel.

On the other hand, the stress-strain curves of FM-treated soil show that after reaching maximum strength, the soil sample nearly maintains it with marginal decrease for large axial strain till failure without showing significant softening, almost identical to untreated soil (Fig. A.6(b)). This shows that even though the strength increase capacity of the FM treatment method is less than SF but it maintains ductility of the selected soil. Moreover, FM treated soil shows an increase in the q u up to 0.9% of FM content, and beyond 0.9% the q u starts to decrease, which implies that 0.9% of FM is the optimum value of FM in terms of q u (Fig. A.6(b)). For FM treated soil, the increase in q u is associated with the inclusion of fiber which enhances soil properties against deformation as the FM used in the current study has a good resistance against rupture and tensile loads (Table A.2). However, excess fiber addition in the soil may cause segregation of soil particles which could subsequently slightly decrease the q u. Further, the tensile strength of fibers of FM is responsible for the ductile behavior of the treated soil. However, in comparison to SF, the strength increase in FM treatment is less because of the absence of chemical interaction with the soil. These shortcomings of SF and FM as lone stabilizers make authors envisaged that high strength can be achieved without compromising the ductility of fat clays by using SF and FM in the right combination.

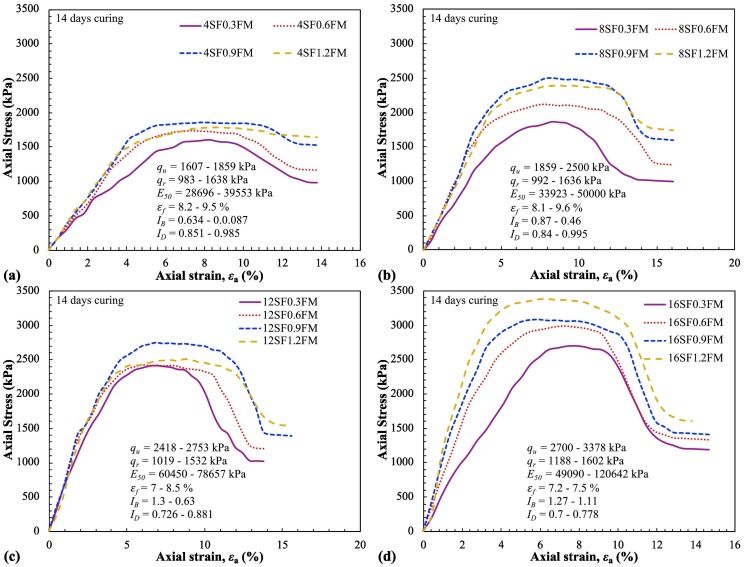

3.2.2.1.2. Effect of CBA

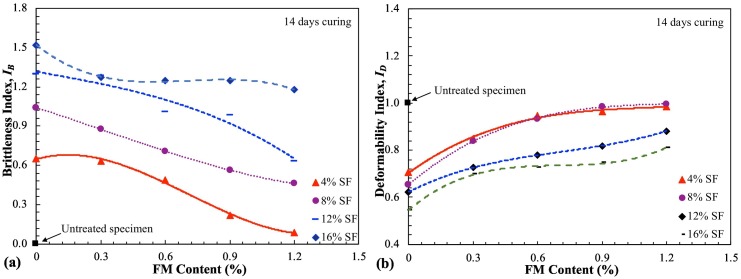

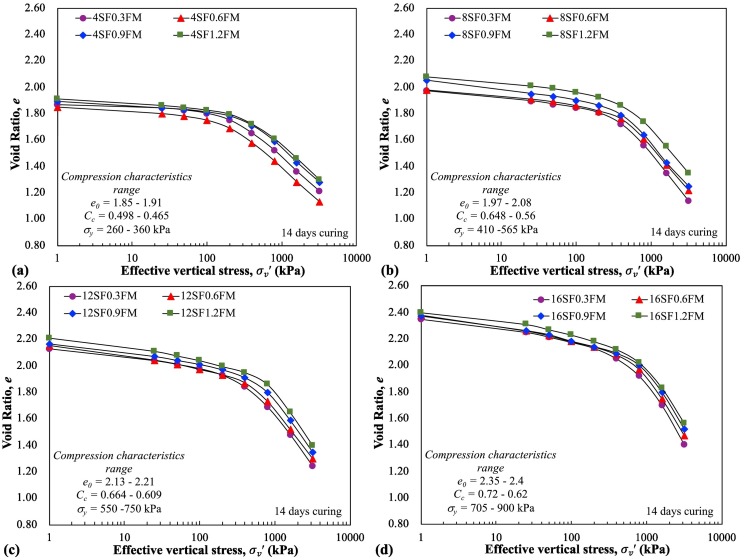

Fig. 1 presents the effect of different combinations of SF and FM in the CBA on the stress-strain response of the CBA treated soil in the unconfined compression test after 14 days curing period. It can be observed that q u of CBA treated soil is increased as the FM is increased up to 0.9% with a specific amount of the SF in CBA. For instance, for 8% of SF in a CBA, the q u is increased up to 43% as the FM is increased from 0 to 0.9%; after 0.9% a slight decrease is however observed (Fig. 1(b)). A similar trend is followed for SF content up to 12%, at 16% the increase in q u also widen up to 1.2% of FM and segregation impact of FM at this content is covered up by large SF content, thus, the highest value of q u is observed for this CBA mixture (i.e., 16%SF + 1.2%FM) (Fig. 1(d)). Conversely, the brittleness of the CBA treated soil is decreased in comparison to the SF treated soil. For instance, for a similar amount of SF i.e., 12%, the ε a to which soil sample maintains its q u increased from 2.3% to 6.3% with an increase in the FM from 0 to 1.2%. Thus, ductility of the soil, as well as strength characteristics of soil, ameliorate with the addition of SF and FM in combination, shows the efficacy of the proposed CBA. To further evaluate the amelioration of the ductility of CBA treated soil the brittleness index, I B, is evaluated for different combinations of SF and FM in CBA using the following equation (Fig. 2(a)).

| (1) |

Fig. 1.

Stress-strain curves of soil treated with CBA.

Fig. 2.

Effect of additives on (a) IB; (b) ID.

It can be observed that generally for a specific amount of SF the I B decreases with the increase in the FM content (Fig. 2(a)). Similarly, deformability index, I D, is evaluated for different combinations of SF and FM in the CBA using the following equation (Fig. 2(b)).

| (2) |

where ε f(untreated) and ε f(treated) are the strain at failure for the treated and untreated soils respectively. The I D of the native soil is decreased with the increase in SF content alone; however, as the FM content increases in the CBA for a particular amount of SF the deformability index tends to improve and attain native value (Fig. 2(b)). This shows the amelioration of the ductility and deformation response of the treated soil by proposed CBA which are curtailed by the SF treatment. Thus, the proposed CBA not only exponentially improves the strength characteristics but also curtails the brittleness caused by SF.

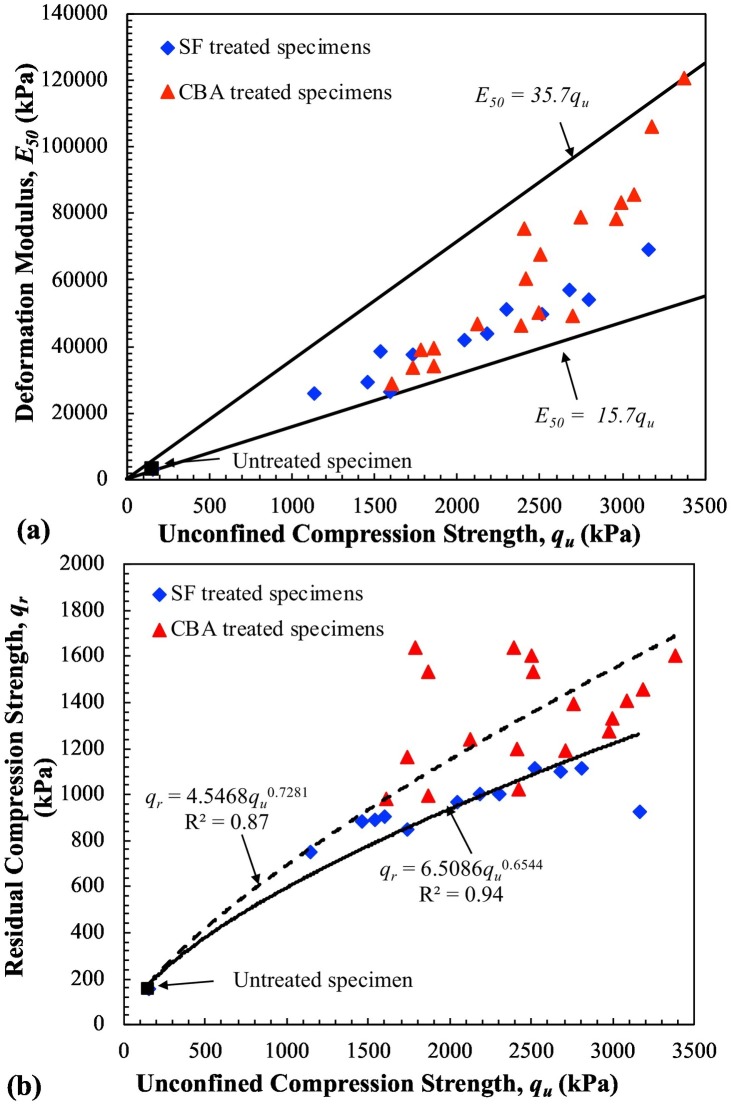

Other important parameters, such as E 50 and q r, determined from the unconfined compression test are also evaluated for the CBA-treated soil and compared with the SF-treated soils. The E 50 is a critical parameter for analyzing the output of treated soil since it describes the sample's resistance to elastic-plastic deformation. The E 50 is defined as the ratio of the values of axial stress to ε a determined at 50% of the q u. It is observed that E 50 is increased with an increase in q u for both SF and CBA-based treatment of soil (Fig. A.7(a)). However, an increase is more pronounces for the CBA treatment endorsing its superiority in ameliorating mechanical behavior over the SF treatment. Similarly, it is observed that q r increases with an increase in q u for SF and CBA-based treatment of soil with higher q r values for the latter (Fig. A.7(b)). Different relationships are also evaluated among different important parameters from the unconfined compression test for SF and CBA treated soils and supplemented in Fig. A.7. The relationship among E 50 and q u is observed to be linear and could be given as follows:

| (3) |

where η is the model parameter, for proposed CBA its value is determined to be between 15.7 and 35.7. Also, following relationships among q r and q u with a high coefficient of determination (R 2) are observed for the SF and CBA respectively.

| (4) |

| (5) |

The effect of curing is also evaluated for the CBA-based treatment on the strength characteristics of the treated soil (Fig. A.8). It is observed that after 7 days of curing small increase in the q u is observed for the 14 days and 21 days of curing period. Thus 7 or 14 days could be regarded as the optimum curing period for the proposed CBA.

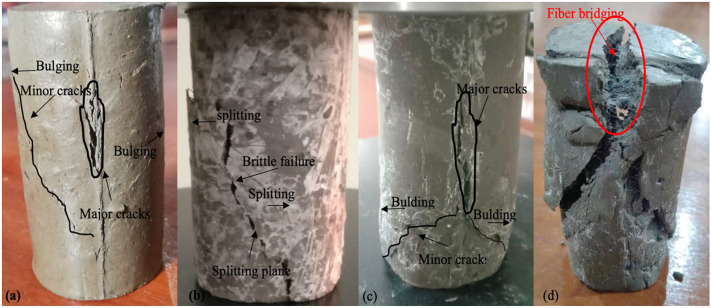

Also, the failure pattern of the tested samples is analyzed to understand the failure and stabilization mechanism of the proposed SF and CBA-based treatment of the soil. Fig. A.9 shows the representative failure pattern of the untreated and SF and CBA treated samples. It is observed that a bulging failure occurs for the untreated soil with a major crack on the center of the sample and some minor surficial cracks on the sides of the sample, this shows a ductile failure mode of the sample (Fig. A.9(a)). On the contrary, for SF treated sample, splitting of sample is observed on failure along the failure plane this shows a brittle failure mode of the sample (Fig. A.9(b)). On the other hand, the failure pattern of the CBA-treated soil shows a bulging failure almost identical to the untreated soil (Fig. A.9(c)). A close examination shows that added FM creates the fiber bridging in the tension cracks which avoid splitting of the sample on failure and assist sample to maintain ductility; it efficiently impedes the large openings, splitting plane and development of major cracks and accordingly averts sample from an ample failure (Fig. A.9(d)). Thus, FM plays a major role in curtailing the brittleness imposed by SF in CBA-treated soil. For CBA treated soil, the exponential increase in the strength could be associated with pozzolanic reaction caused by the SF with soil, and amelioration of the ductility and deformation behavior in comparison to the SF treated soil could be attributed to the fiber bridging in the tension cracks by the FM fibers. A similar failure response is observed in literature by various studies which used fibrous material in combination with cementitious additive for the amelioration of different soils (Abdi et al., 2021; Tiwari et al., 2020).

3.2.2.2. Subgrade strength test

3.2.2.2.1. Effect of SF and FM as independent stabilizers

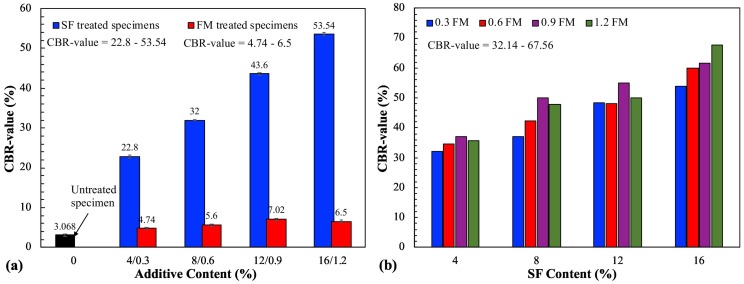

Fig. 3(a) presents the effect of SF and FM as the independent stabilizers on the CBR-value of the selected soil after 7 days of curing to evaluate the suitability of these treatment methods for subgrade of roads and highways. It can be observed that CBR-value exponentially increases with the addition of SF (1667 folds increase for 0–16% for SF) and FM imparts a reasonable increase (133%) in CBR-value till 0.9% and beyond this content, it shows a slight decrease in the CBR-value (Fig. 3(a)). These results are in line with the strength behavior obtained in the unconfined compression test.

Fig. 3.

Behavior of CBR-values (a) FM and SF treated soils; (b) CBA treated soils.

3.2.2.2.2. Effect of CBA

Fig. 3(b) presents the effect of the proposed CBA on the CBR-value of the selected soil after 7 days of curing to evaluate the suitability of CBA as a stabilizer for the subgrade of roads and highways. It can be observed that CBR-value is exponentially increased with the addition of CBA, showing better performance than SF and FM alone. For instance, at 12% content of SF in the CBA, the CBR-value is increased by 1733% with an increase in FM to 0.9% and after 0.9% a slight decrease in CBR-value is observed due to slight segregation of grains caused by the abundant FM. At 0.9% content of FM, the CBR-value is almost 28% and 628% higher than SF and FM as the lone stabilizers, respectively. Also, at 16% content of SF in CBA, the increase in the CBR-value is observed till 1.2% of FM content which means that this SF content curtails the negative impact on the strength caused by high FM content due to slight segregation of grains. Thus, CBA could be regarded as a better stabilizer than SF for the construction of roads and highways as it imparts both cementation and fiber reinforcement impact on soil.

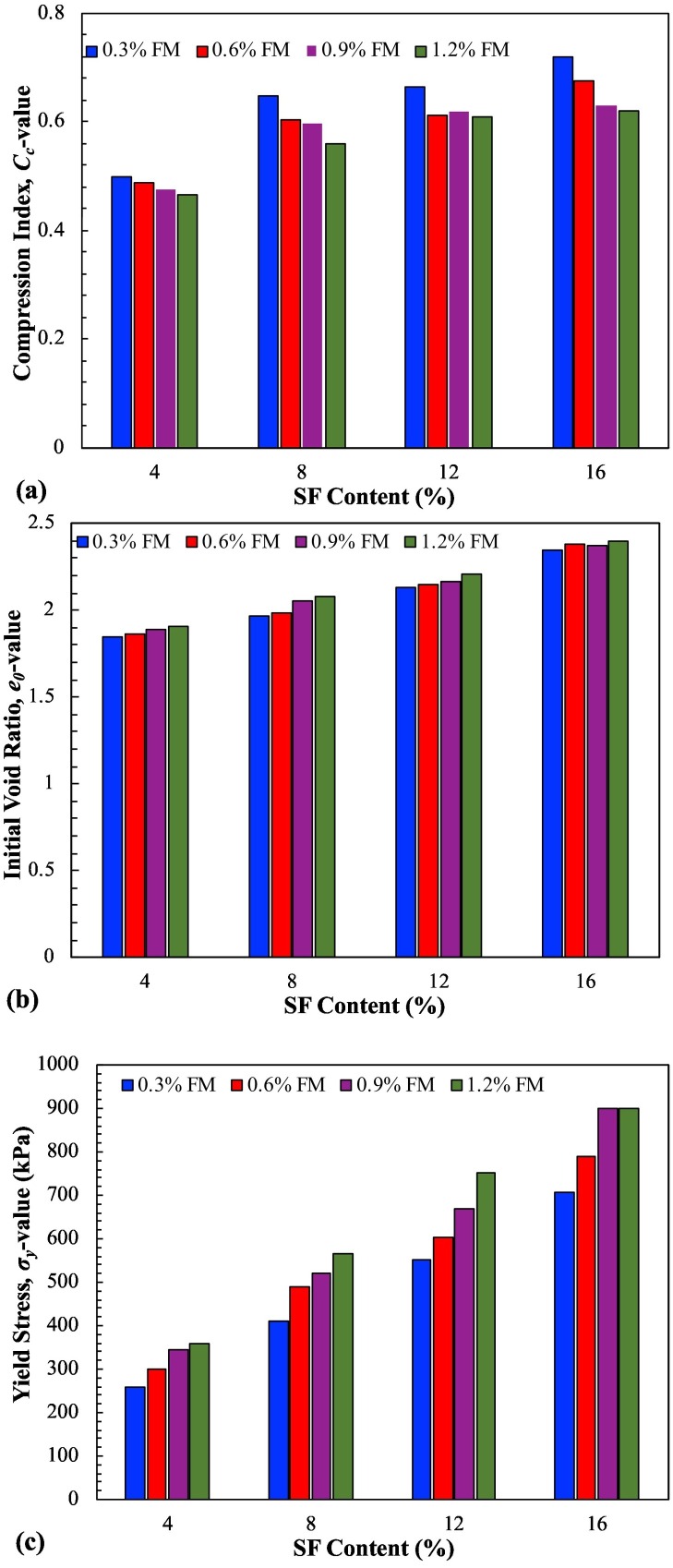

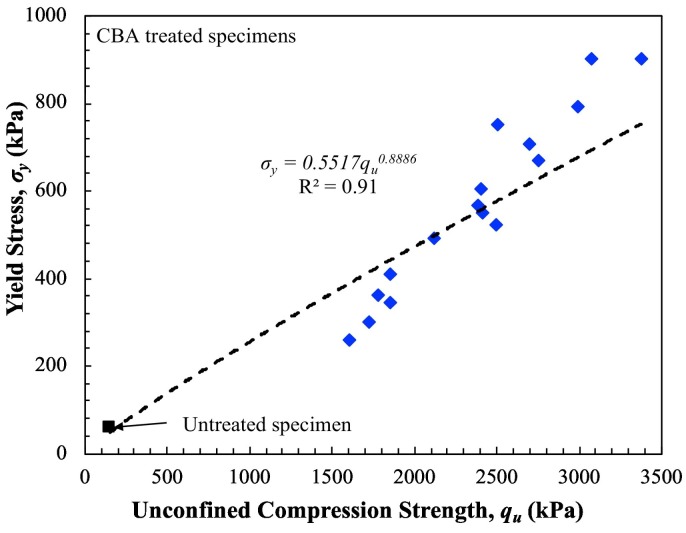

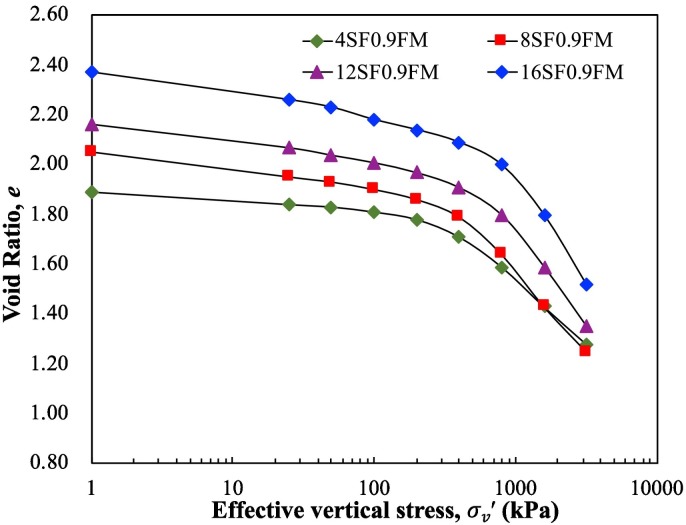

3.2.3. Compressibility characteristics

Fig. 4, Fig. A.10 present the effect of different mixes of proposed CBA on the compressibility characteristics of the selected soil after 14 days of curing to using test results ID consolidation tests. It can be observed that the initial void ratio, e0 and yield stress, σy, of the sample increase with an increase in the SF and FM content in the CBA (Fig. 4, Fig. A.10(b), (c), the increase in the former can be attributed to the increase in the void spaces that also causes a decrease in γdmax and later can be attributed to the increase in the cementitious and reinforcement products in the soil that enhances soil stiffness (Rehman et al., 2018, Rehman et al., 2021). A linear relationship is observed between σy and qu for CBA treated soil (Fig. A.11) and can be quantified by the following equation with a very high R2 value.

| (6) |

Fig. 4.

Compression curves of soil treated with CBA

Besides, the SF content in the CBA imparts more consolidation settlement as C c increases with an increase in SF content due to enhancement of flocculation in the soil matrix (Fig. 4, Fig. A.10(a), A.12(a)). However, for a specific amount of SF in CBA the increase in the FM curtails the consolidation settlement, for instance for 8% SF in CBA, C c decreases by 13.5% with the addition of FM content from 0.3 to 1.2% (Figs. 4(b) and A.10(a)).

4. Field implications

4.1. Environmental and economic implications

Following major immediate threats are arising due to rise in the FM waste, having negative environmental and social consequences (Penteado and de Castro, 2021); a) FM waste is threatening to escalate micro-plastic pollution and fossil plastic (Aragaw, 2020); b) dumping and burning of FM waste, which are traditional waste disposal schemes, bear emission of toxic compounds, posing both long- and short-term environmental risks (Torres and De-la-Torre, 2021); c) widespread dumping grounds due to rise in the discarded FMs, posing a threat not only to our pandemic response efforts, but to the overall ecosystem (Rahman et al., 2020); d) FM waste is becoming floating marine debris due to mismanagement, posing a threat to the marine environment and food chain (De-la-Torre and Aragaw, 2021); e) a rise in the amount of disposed of FM waste is leading to an increase in the demand for incinerator and landfill capacity, not only posing environmental and economic threats, but also the social concerns i.e., NIMBY conflict (Zambrano-Monserrate et al., 2020). Moreover, the production of traditional stabilizers i.e., cement and lime are also criticized for posing various environmental issues in the literature, i.e., natural resources consumption, greenhouse gas emission, air pollution and global warming (Abdi et al., 2021; Barrios et al., 2021). The proposed solution of using FM waste as a soil stabilizer could help in minimizing all the aforementioned environmental issues by productively managing the FM waste and the construction sector could become a promising avenue of reusing this waste. The proposed soil treatment methodology has the potential of pragmatic implementation in the construction of roads, highways, clay liners, and clay stabilization for the foundation of the buildings and other load-bearing structures since economic benefits urge to use in-situ fat clays after cost-effective improvement, instead of using borrowed material. Thus, this study presents a sustainable solution for the emerging FM waste problems since it manifests a win-win economic scenario for both the construction and waste management industries. The complete recycling flowchart of the FM waste proposed in the current study is presented in Fig. 5 .

Fig. 5.

The recycling flow chart of FM for eco-friendly utilization in Civil engineering projects.

4.2. Estimation of required and available FM waste

The authors also intuitively estimated the required FM waste for an effective field application using the current soil stabilization methodology and available FM waste in the biomedical waste stream. For instance, for a 1 km two-lane road section, to treat 0.5 m thick and 7 m wide subgrade layer, about 70 tons of FM waste could be required using the proposed soil stabilization methodology. Similarly, for a structure/foundation having a 100 m2 covered area, to treat 1 m layer of fat clay, 1.7 tons of FM waste could be required. Whereas, by introducing a single FM weight factor in the Nzediegwu and Chang (2020) model, and assuming the weight of a single FM as of 3 g, the authors estimated the amount of daily FM waste generation of most populated countries of Asia i.e., China, India, Indonesia, and Pakistan to be around 4214, 2331, 740 and 375 tons, respectively. Thus, a substantial amount of FM waste is available for effective geotechnical application, and the current methodology has a promising potential of averting a large amount of discarded FMs from ending up in landfills or incinerators.

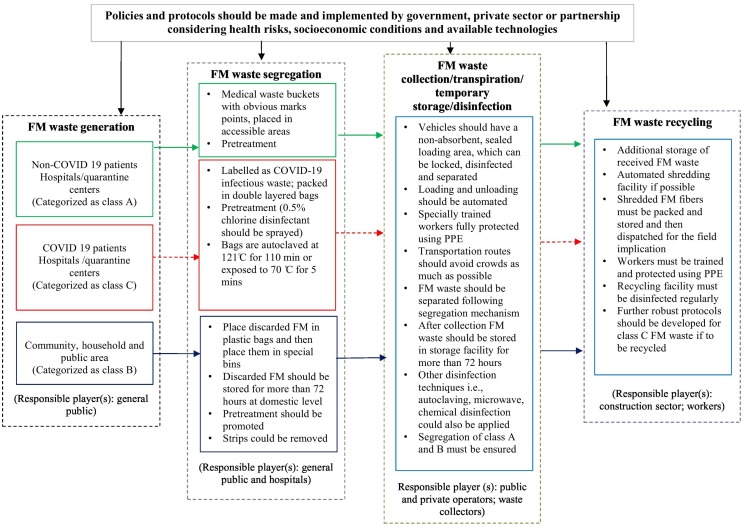

4.3. Discussion on FM waste handling

The current study presents a solution for the problems of the construction and waste management industries and promotes the resources conservation scheme. However, for practical implementation of the proposed solution, the COVID-19 FM waste handling needs careful consideration. To encounter this, proper handling of COVID-19 FM waste is required from the initial consumer level to the final geotechnical application of this waste, and appropriate protocols are needed to be established. Based on the literature, the authors identified that safe practices are needed to be adopted at the following stages to make FM waste ready for geotechnical application: a) waste generation; b) segregation; c) collection, transportation, and treatment; d) recycling (Hantoko et al., 2021). The policies and protocols to manage COVID-19 related waste should be made and implemented by the government, involved private sector and responsible players or by their partnership considering associated health risks, socioeconomic conditions, and available technologies (Vanapalli et al., 2021). Different safe practices and protocols are being reported in the recent literature for COVID-19 related waste management, based on which a detailed proposed protocol scheme is presented in Fig. 6 to manage FM waste for recycling. In terms of waste generation, authors categorize FM waste into three classes referring to care required in their handling; wherein, class A, C and B represent waste generated by non-COVID 19 patients at hospitals/quarantine facilities, COVID-19 patients at hospitals/quarantine facilities and the general public at public areas, community and homes, etc., respectively (Sangkham, 2020). The most important step in waste management for the current recycling scheme is the segregation of FM waste at the initial consumer level. Various strategies are already being implemented by various countries to segregate discarded FM from other wastes; for instance, discarded FM are collected in special garbage cans in Wuhan (Rongmeng and Jianguo, 2020) and the Bangkok Metropolitan Administration has designated special red bins for used FMs in public areas (MOPH, 2020). Thus, separate bins or collection points should be designated to collect FM waste in hospitals, quarantine centers, and public areas. Class C FM waste should be labeled as the COVID-19 infectious waste in hospitals or quarantine facilities and it must undergo pretreatment with disinfectant and sealed in double-layered plastic bags by specific personnel (Das et al., 2020). These plastic bags should also be autoclaved or microwaved (Ma et al., 2020). Since the Class A and B FM waste are also susceptible of being infectious, they must also undergo pretreatment at the initial consumer level (Sharma et al., 2020). For this purpose, FM waste must be stored in hospitals at a temporary restricted storage area for 72 h along with other biomedical wastes, and collection of class B FM waste must be delayed by the same amount of time (Nghiem et al., 2020). For instance, in India, this strategy is in implementation, where, in quarantined homes or other households, the used FMs are stored in a paper bag for 72 h before being disposed of as waste, and their strips are removed to avoid reuse (Bandela, 2020). In addition, the public must also be encouraged to disinfect the used FMs before discarding them in bins. The next stage is the collection and transportation of FM waste; in this stage, human interference must be reduced as much as possible by engaging in automated loading and unloading of waste. Involved workers must be trained and protected with personal protective equipment (PPE). Involved vehicles must be automated, sealed, regularly disinfected and have a non-absorbent loading area (Sangkham, 2020). Care must also be taken while deciding transportation routes and timings to avoid crowds. After collection, FM waste is first brought to a disinfection facility where it should be stored for more than 72 h and also may be disinfected through other methods i.e., chemical and thermal disinfection as well (Singh et al., 2020a, Singh et al., 2020b). Moreover, the segregation of FM waste from other biomedical waste must not be compromised as much as possible at any stage. The disinfected FM waste is then brought to a recycling facility where it should be stored before shredding it for geotechnical application. At the recycling facility, the workers involved must also be trained and protected with PPE. The shredded FM could be packed and dispatched for the field application where human interference should be minimized and personnel involved must be trained and protected (Torres and De-la-Torre, 2021). As a result, FM waste could be employed in geotechnical application with curtailed COVID-19 spread chances during handling it. It is important to mention that these protocols may change depending on socio-economic and health risk scenarios; more continuous efforts are needed to improve these protocols (Penteado and de Castro, 2021).

Fig. 6.

Proposed FM waste management scheme and protocols.

4.4. Discussion on disinfection methods

It is important to note that different studies have been reported thus far, advocating various disinfection methods of the used FM for any further processing (Ilyas et al., 2020). However, these disinfection methods need a detailed careful investigation before adopted as a custom (You et al., 2020). For used FM, one method of disinfection before recycling could be chemical disinfection with a 1% NaOCl solution or 0.5% chloride disinfectant, this could be an in-situ procedure at FM waste collection point or even at the primary consumer level (maybe implemented through proper legislation or social encouragement) (CPCB, 2020a, CPCB, 2020b). However, the impact of NaOCl or any other chemical disinfectant on the pozzolanic reaction caused by SF in the proposed CBA is unknown, although it is envisaged to be minimal as these solutions may dilute quickly and are not much chemically active during geotechnical application (Jing et al., 2020). The second disinfection method advocated in literature is the exposure to high heat e.g., heating through microwave could be a useful method for sanitizing FM that can be recycled and reused (Doan, 2020), while incineration could also useful when tackling a larger COVID FM waste, because of high operating temperatures it is an energy-efficient and reliable process (Xiang et al., 2020); however, former may cause a major change in the physical and mechanical characteristics of FM fibers in comparison to the later. For the soil treatment, the heating could impart a negative impact on the tensile and rupture strength of the FM fibers and may decrease the strength of the treated soil. However, in the current methodology, the FM is mainly used to improve the ductility of the treated soil, and strength is mainly gained through SF, therefore, it is envisaged that a small impact on the strength would occur through disinfection through heating; this argument is also supported by Saberian et al. (2021), they determine that microwave heating has a small impact on the strength of FM fiber and corresponding soil treatment. There could be another disinfection or handling method of FM waste before recycling to store it for a prolonged period in the automated restricted facility having less human interference as the literature suggest that virus could only be active on a surface for a certain period (e.g., almost 72 h on plastics and 24 h on disposable gowns) (Ilyas et al., 2020). Thus, astute prolonged storage of the FM waste in a specialized and restricted facility with due diligence before recycling also has the potential to disinfect the FM waste (Singh et al., 2020a, Singh et al., 2020b; Suman et al., 2020). This method could maintain the physical and mechanical characteristics and suits the current methodology more than other methods. However, careful investigations are required to authenticate this method and make protocols for it (Van-Fan et al., 2021). Validation of any disinfection method for FM waste is beyond the scope of this study; astutely designed and careful studies are further required even though good literature is available to advocate different disinfection methods (Naughton, 2020).

4.5. Future research aspects and limitations

Due to COVID-19 restrictions, unused FMs are utilized in this study, and the disinfection method is not incorporated, it could be regarded as the limitation of the current study. The authors would incorporate the effect of different disinfection methods on the mechanical behavior of FM fibers and their consequent impacts on the proposed soil stabilization in future studies. Moreover, the current study presents an initial assessment of the proposed treatment, more geotechnical aspects could be evaluated in future studies. Also, this treatment method could be extended for the treatment of other pertinent problematic soils i.e., soft soils in future studies.

5. Conclusions

In the current study, a novel soil treatment method is proposed for the improvement of mechanical characteristics of fat clay by using the face mask, FM, as fiber reinforcement and silica fume, SF, as the cementitious additive. The performance of the proposed composite binary admixture, CBA, is compared with SF and FM as the lone stabilizers. The current study provides solutions for achieving cost-effective construction material and emerging COVID-19 FM waste management problems. Extensive geotechnical testing is carried out in the current study and the following main findings are drawn.

-

•

The γ dmax is slightly decreased and w opt increased with the addition of SF and FM as the lone stabilizers in the selected soil, a similar but slightly more pronounced effect is observed when SF and FM are mixed as CBA in the selected soil.

-

•

The selected soil shows a q u value which could be regarded as low for highly loaded structure and ductile failure behavior. The SF treatment of soil exponentially improves the q u of the selected soil due to its ability to generate cementitious products by interaction with soil; however, the brittleness of the sample is increased with the increase in SF content in the soil. The FM treatment also imparts a reasonable improvement of the q u but minor than SF, as the FM is added from 0 to 0.9%; beyond this FM content, a decrease in q u is observed. The sample is observed to nearly maintaining the ductile behavior due to FM treatment, unlike SF treatment. When SF and FM are mixed in different proportions as CBA in the soil, an exponential increase in the q u is observed that is more than SF treated soil. The q u is increased with an increase in the SF and FM content in CBA; however, till 12% SF, the q u slightly is decreased as FM increases beyond 0.9%, which could be regarded as the optimum value of FM for the considered SF content till 12% in the CBA. However, as SF is increased beyond 12% the sample tends to show gain in q u beyond 0.9% i.e., 1.2%, as well.

-

•

The brittleness and deformability of the CBA-treated soil are improved in comparison to the SF-treated soil as the FM content is increased in the CBA. The sample tends to regain its ductility as the FM content is increased in the CBA. This makes CBA a desirable admixture as it improves strength and increases the ductility of the treated soil sample, unlike SF treatment which improves former and deteriorates later. The failure mechanism of the sample is also analyzed which endorse brittle failure mode for the SF treated soil and ductile failure mode for the CBA treated soil.

-

•

CBR-value is improved exponentially by SF addition in the soil, whereas FM also tends to improve CBR-value marginally. The improvement in CBR-value for the CBA treated soil is observed to be superior to the SF treated soil, which endorses CBA as a good admixture for the subgrade construction with fat clays.

-

•

The CBA treatment increases the σ y and e 0 of the soil. The C c of the sample is increased with an increase in the SF content in a CBA, however, FM content in the soil curtails the C c.

-

•

FM waste generation estimation of most populated countries of Asia i.e., China, India, Indonesia, and Pakistan is around 4214, 2331, 740 and 375 tons per day, respectively. Whereas for a 1 km two-lane road section, to treat 0.5 m thick and 7 m wide subgrade layer, and for a foundation having a 100 m2 covered area to treat 1 m layer of fat clay, about 70 and 1.7 tons of FM waste is required, respectively, using the proposed stabilization methodology. Thus, a significant proportion of FM waste is available in the biomedical waste stream for an effective geotechnical application, and the current technology has the potential to save a huge volume of discarded FMs from being disposed of in landfills.

-

•

For practical implementation of the proposed solution, the handling of COVID-19 FM waste needs careful consideration. To encounter this, proper protocols are needed to be followed to ensure safe collection, transportation, disinfection, storage, and recycling of this waste. The policies and protocols to manage COVID-19 related waste should be made and implemented by the government, involved private sector and responsible players or by their partnership considering associated health risks, socioeconomic conditions, and available technologies. Various disinfection methods are presented in the literature, the methodology of the current study suits well with the prolonged storage strategy of disinfection; however, intense care and more studies are required to validate disinfection methods. Besides, studies are required to evaluate FM performance in soil treatment with various disinfection methods.

CRediT authorship contribution statement

Zia ur Rehman: Conceptualization, Methodology, Validation, Investigation, Writing – original draft, Formal analysis, Visualization. Usama Khalid: Investigation, Data curation, Resources, Validation, Writing – review & editing, Formal analysis, Visualization.

Declaration of competing interest

No conflict of interest exits in the submission of this manuscript.

Acknowledgment

COMSATS University Islamabad, Sahiwal Campus is acknowledged for providing technical support during the experimental phase of this study.

Editor: Damià Barceló

Appendix A.

Fig. A.1.

Materials used in current study (a) selected soil; (b) shredded face mask; (c) silica fume.

Fig. A.2.

Specimens preparation method.

Fig. A.3.

Geotechnical characteristics of selected soil (a) grain size distribution curve; (b) compaction curve; (c) stress-strain curve; (d) compression curve.

Fig. A.4.

Compaction characteristics of soil treated with SF and FM(a) wopt; (b) γdmax.

Fig. A.5.

Compaction characteristics of soil treated with CBA (a) wopt; (b) γdmax.

Fig. A.6.

Stress-strain curves of soil treated with (a) SF; (b) FM.

Fig. A.7.

Behavior of SF and CBA treated soil (a) E50-qu; (b) qr-qu.

Fig. A.8.

Effect of curing on stress-strain curves of CBA treated soil.

Fig. A.9.

Failure behavior of untreated and treated soil samples at 14 days of curing (a) untreated sample; (b) SF treated sample; (c) CBA treated sample (d) fiber bridging effect across the tension cracks.

Fig. A.10.

Compressibility characteristics of CBA treated soil (a) Cc; (b) e0; (c) σy.

Fig. A.11.

The σy-qu relationship of CBA treated clay.

Fig. A.12.

Effect of SF on compression curves of FM treated soil.

Table B.1.

Chemical characteristics of silica fume (SF).

| Compound name | Silica fume |

|---|---|

| % | |

| Calcium oxide (CaO) | 1.5 |

| Silicon dioxide (SiO2) | 92.23 |

| Aluminum oxide (Al2O3) | 0.6 |

| Ferric oxide (Fe2O3) | 0.55 |

| Magnesium oxide (MgO) | 0.41 |

| Loss of ignition | 3.1 |

| Potassium oxide (K2O) | 0.49 |

| Sodium oxide (Na2O) | 0.75 |

| Manganese oxide (MnO) | 0.35 |

| Titanium dioxide (TiO2) | – |

Table B.2.

Physical characteristics of face mask (FM).

| Physical characteristics | FM |

|---|---|

| Melting point (°C) | 155 |

| Specific gravity | 1.02 |

| Water absorption 24 h (%) | 7.2 |

| Tensile strength (MPA) | 3.2 |

| Rupture force (kN) | 0.013 |

Table B.3.

Detailed experimental plan of this study.

| Analysis | Tests | Additives | Content (%) | Curing (days) |

|---|---|---|---|---|

| Compaction characteristics | Standard Proctor test | Silica fume | 0, 4, 8, 12, 16 | No curing |

| Face mask | 0.3, 0.6, 0.9. 1.2 | |||

| Silica fume + Face mask | SF (4, 8, 12, 16) + FM (0.3, 0.6, 0.9. 1.2) | |||

| Strength characteristics | Unconfined compression test | Silica fume | 0, 4, 8, 12, 16 | 7, 14, 21 |

| Face mask | 0.3, 0.6, 0.9. 1.2 | No curing | ||

| Silica fume + Face mask | SF (4, 8, 12, 16) + FM (0.3, 0.6, 0.9. 1.2) | 14 | ||

| California bearing ratio test | Silica fume | 0, 4, 8, 12, 16 | 7 | |

| Face mask | 0.3, 0.6, 0.9. 1.2 | No curing | ||

| Silica fume + Face mask | SF (4, 8, 12, 16) + FM (0.3, 0.6, 0.9. 1.2) | 7 | ||

| Compression characteristics | One-dimensional oedometer test | Silica fume + Face mask | 0, SF (4, 8, 12, 16) + FM (0.3, 0.6, 0.9. 1.2) | 14 |

References

- Abdi M.R., Abbas G., Leila S.C. An investigation into the effects of lime on compressive and shear strength characteristics of fiber-reinforced clays. J. Rock Mech. Geotech. Eng. 2021 doi: 10.1016/j.jrmge.2020.11.008. (press) [DOI] [Google Scholar]

- AL-Soudany K.Y. Improvement of expansive soil by using silica fume. Kufa J. Eng. 2018;9(1):222–239. [Google Scholar]

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bandela D.R. COVID-19: Here is what you should do to safely dispose your used mask. 2020. https://www.downtoearth.org.in/news/waste/covid-19-here-is-what-you-should-do-to-safely-dispose-your-used-mask-71006

- Barrios A.M., Vega D.F., Martínez P.S., Atanes-Sánchez E., Fernández C.M. Study of the properties of lime and cement mortars made from recycled ceramic aggregate and reinforced with fibers. J. Build. Eng. 2021;35 [Google Scholar]

- Cheng V.C.C., Wong S.C., Chuang V.W.M., So S.Y.C., Chen J.H.K., Sridhar S.…Yuen K.Y. The role of community-wide wearing of face mask for control of coronavirus disease 2019 (COVID-19) epidemic due to SARS-CoV-2. J. Inf. Secur. 2020;81(1):107–114. doi: 10.1016/j.jinf.2020.04.024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- CPCB Guidelines for handling, treatment and disposal of waste generated during treatment/diagnosis/quarantine of COVID-19 patients. 2020. https://cpcb.nic.in

- CPCB Guidelines for handling, treatment and disposal of waste generated during treatment/diagnosis/quarantine of COVID-19 patients: revision 1. 2020. https://www.mohfw.gov.in/pdf/63948609501585568987wastesguidelines.pdf

- Das A., Garg R., Ojha B., Banerjee T. Biomedical waste management: the challenge amidst COVID-19 pandemic. J. Lab. Physician. 2020;12(2):161. doi: 10.1055/s-0040-1716662. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Aragaw T.A. What we need to know about PPE associated with the COVID-19 pandemic in the marine environment. Mar. Pollut. Bull. 2021;163 doi: 10.1016/j.marpolbul.2020.111879. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dharmaraj S., Ashokkumar V., Hariharan S., Manibharathi A., Show P.L., Tung C.C., Ngamcharussrivichai C. The COVID-19 pandemic face mask waste: a blooming threat to the marine environment. Chemosphere. 2021;272 doi: 10.1016/j.chemosphere.2021.129601. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Doan H.N. Medical face masks can be reused with microwave method: expert. 2020. https://vietnamnews.vn/society/654072/medical-face-masks-can-be-reused-with-microwave-%20method-expert.html

- Elkhebu A., Zainorabidin A., Asadi A., Bakar I.H., Huat B.B., Abdeldjouad L., Dheyab W. Effect of incorporating multifilament polypropylene fibers into alkaline activated fly ash soil mixtures. Soils Found. 2019;59(6):2144–2154. [Google Scholar]

- Ghavami S., Naseri H., Jahanbakhsh H., Nejad F.M. The impacts of nano-SiO2 and silica fume on cement kiln dust treated soil as a sustainable cement-free stabilizer. Constr. Build. Mater. 2021;285 [Google Scholar]

- Gupta M., Gupta K., Gupta S. The use of facemasks by the general population to prevent transmission of Covid 19 infection: a systematic review. medRxiv. 2020 doi: 10.1101/2020.05.01.20087064. [DOI] [Google Scholar]

- Hantoko D., Li X., Pariatamby A., Yoshikawa K., Horttanainen M., Yan M. Challenges and practices on waste management and disposal during COVID-19 pandemic. J. Environ. Manag. 2021;286 doi: 10.1016/j.jenvman.2021.112140. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ikeagwuani C.C., Nwonu D.C. Emerging trends in expansive soil stabilisation: a review. J. Rock Mech. Geotech. Eng. 2019;11(2):423–440. [Google Scholar]

- Ilyas S., Srivastava R.R., Kim H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020;749 doi: 10.1016/j.scitotenv.2020.141652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jing J.L.J., Pei Yi T., Bose R.J., McCarthy J.R., Tharmalingam N., Madheswaran T. Hand sanitizers: a review on formulation aspects, adverse effects, and regulations. Int. J. Environ. Res. Public Health. 2020;17(9):3326. doi: 10.3390/ijerph17093326. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Khalid U., Rehman Z. Evaluation of compaction parameters of fine-grained soils using standard and modified efforts. Int. J. Geo-Eng. 2018;9(1):1–17. [Google Scholar]

- Khalid U., Rehman Z., Liao C., Farooq K., Mujtaba H. Compressibility of compacted clays mixed with a wide range of bentonite for engineered barriers. Arab. J. Sci. Eng. 2019;44(5):5027–5042. [Google Scholar]

- Liao M., Liu H., Wang X., Hu X., Huang Y., Liu X.…Lu J.R. A technical review of face mask wearing in preventing respiratory COVID-19 transmission. Curr. Opin. Colloid Interface Sci. 2021;52 doi: 10.1016/j.cocis.2021.101417. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ma Y., Lin X., Wu A., Huang Q., Li X., Yan J. Suggested guidelines for emergency treatment of medical waste during COVID-19: Chinese experience. Waste Dispos. Sustain. Energ. 2020;2:81–84. doi: 10.1007/s42768-020-00039-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Moghal A.A.B., Chittoori B.C., Basha B.M. Effect of fibre reinforcement on CBR behaviour of lime-blended expansive soils: reliability approach. Road Mater. Pavement Design. 2018;19(3):690–709. [Google Scholar]

- MOPH Ministry of Public Health, Recommendation on Disposal of a Used Mask in Situations of Coronavirus Infection (COVID-19) 2020. https://www.anamai.moph.go.th/ewt_dl_link.php?nid=1672 2020, (Accessed: 26 July 2021)

- Mujtaba H., Khalid U., Farooq K., Elahi M., Rehman Z., Shahzad H.M. Sustainable utilization of powdered glass to improve the mechanical behavior of fat clay. KSCE J. Civ. Eng. 2020;24(12):3628–3639. [Google Scholar]

- Naughton C.C. Will the COVID-19 pandemic change waste generation and composition: the need for more real-time waste management data and systems thinking. Resour. Conserv. Recycl. 2020;162 doi: 10.1016/j.resconrec.2020.105050. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nghiem L.D., Morgan B., Donner E., Short M.D. The COVID-19 pandemic: considerations for the waste and wastewater services sector. Case Stud. Chem. Environ. Eng. 2020;1 doi: 10.1016/j.cscee.2020.100006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nzediegwu C., Chang S.X. Improper solid waste management increases potential for COVID-19 spread in developing countries. Resour. Conserv. Recycl. 2020;161 doi: 10.1016/j.resconrec.2020.104947. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Penteado C.S.G., de Castro M.A.S. Covid-19 effects on municipal solid waste management: what can effectively be done in the Brazilian scenario. Resour. Conserv. Recycl. 2021;164 doi: 10.1016/j.resconrec.2020.105152. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Phanikumar B.R. Silica fume stabilization of an expansive clay subgrade and the effect of silica fume-stabilised soil cushion on its CBR. Geomech. Geoeng. 2020;15(1):64–77. [Google Scholar]

- Rahman M.M., Bodrud-Doza M., Griffiths M.D., Mamun M.A. Biomedical waste amid COVID-19: perspectives from Bangladesh. Lancet Glob. Health. 2020;8:1262. doi: 10.1016/S2214-109X(20)30349-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rehman Z., Khalid U., Farooq K., Mujtaba H. On yield stress of compacted clays. Int. J. Geo-Eng. 2018;9(1):1–16. doi: 10.1186/s40703-018-0090-2. [DOI] [Google Scholar]

- Rehman Z., Farooq K., Mujtaba H., Khalid U. Unified evaluation of consolidation parameters for low to high plastic range of cohesive soils. Mehran Univ. Res. J. Eng. Technol. 2021;40(1):93–103. [Google Scholar]

- Rongmeng J., Jianguo J. Discarded masks must be properly disposed of: China daily contributors. 2020. https://www.straitstimes.com/asia/discarded-masks-must-be-properly-disposed-of-china-daily-contributors?fbclid=IwAR3gYoymzqZ0aQ%200roE58xeNI8uM7Ejswygyh8h9CRtxYnI9YuWgmLqqt6k

- Saberian M., Li J., Kilmartin-Lynch S., Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021;769 doi: 10.1016/j.scitotenv.2021.145527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sangkham S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Stud. Chem. Environ. Eng. 2020;2 doi: 10.1016/j.cscee.2020.100052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharma H.B., Vanapalli K.R., Cheela V.S., Ranjan V.P., Jaglan A.K., Dubey B.…Bhattacharya J. Challenges, opportunities, and innovations for effective solid waste management during and post COVID-19 pandemic. Resour. Conserv. Recycl. 2020;162 doi: 10.1016/j.resconrec.2020.105052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silva A.L.P., Prata J.C., Walker T.R., Campos D., Duarte A.C., Soares A.M.…Rocha-Santos T. Rethinking and optimising plastic waste management under COVID-19 pandemic: policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Sci. Total Environ. 2020;742 doi: 10.1016/j.scitotenv.2020.140565. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silva A.L.P., Prata J.C., Walker T.R., Duarte A.C., Ouyang W., Barcelò D., Rocha-Santos T. Increased plastic pollution due to COVID-19 pandemic: challenges and recommendations. Chem. Eng. J. 2020;126683 doi: 10.1016/j.cej.2020.126683. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh P., Dash H.K., Samantaray S. Effect of silica fume on engineering properties of expansive soil. Mater. Today: Proc. 2020;33:5035–5040. [Google Scholar]

- Singh N., Tang Y., Zhang Z., Zheng C. COVID-19 waste management: effective and successful measures in Wuhan, China. Resour. Conserv. Recycl. 2020;163 doi: 10.1016/j.resconrec.2020.105071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Suman R., Javaid M., Haleem A., Vaishya R., Bahl S., Nandan D. Sustainability of coronavirus on different surfaces. J. Clin. Exp. Hepatol. 2020;10(4):386–390. doi: 10.1016/j.jceh.2020.04.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Syed M., GuhaRay A. Effect of natural fiber reinforcement on strength response of alkali activated binder treated expansive soil: experimental investigation and reliability analysis. Constr. Build. Mater. 2021;273 [Google Scholar]

- Tiwari N., Satyam N., Singh K. Effect of curing on micro-physical performance of polypropylene fiber reinforced and silica fume stabilized expansive soil under freezing thawing cycles. Sci. Rep. 2020;10(1):1–16. doi: 10.1038/s41598-020-64658-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Torres F.G., De-la-Torre G.E. Face mask waste generation and management during the COVID-19 pandemic: an overview and the Peruvian case. Sci. Total Environ. 2021;786 [Google Scholar]

- Vanapalli K.R., Sharma H.B., Ranjan V.P., Samal B., Bhattacharya J., Dubey B.K., Goel S. Challenges and strategies for effective plastic waste management during and post COVID-19 pandemic. Sci. Total Environ. 2021;750 doi: 10.1016/j.scitotenv.2020.141514. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Van-Fan Y., Jiang P., Hemzal M., Klemeš J.J. An update of COVID-19 influence on waste management. Sci. Total Environ. 2021;754 doi: 10.1016/j.scitotenv.2020.142014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xiang Y., Song Q., Gu W. Decontamination of surgical face masks and N95 respirators by dry heat pasteurization for one hour at 70 C. Am. J. Infect. Control. 2020;48(8):880–882. doi: 10.1016/j.ajic.2020.05.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- You S., Sonne C., Ok Y.S. COVID-19’s unsustainable waste management. Science. 2020;368(6498):1438. doi: 10.1126/science.abc7778. [DOI] [PubMed] [Google Scholar]

- Zambrano-Monserrate M.A., Ruano M.A., Sanchez-Alcalde L. Indirect effects of COVID-19 on the environment. Sci. Total Environ. 2020;728 doi: 10.1016/j.scitotenv.2020.138813. [DOI] [PMC free article] [PubMed] [Google Scholar]