Abstract

This paper presents a new mathematical model of the green closed-loop supply chain network (GCLSCN) during the COVID-19 pandemic. The suggested model can explain the trade-offs between environmental (minimizing CO2 emissions) and economic (minimizing total costs) aspects during the COVID-19 outbreak. Considering the guidelines for hygiene during the outbreak helps us design a new sustainable hygiene supply chain (SC). This model is sensitive to the cost structure. The cost includes two parts: the normal cost without considering the coronavirus pandemic and the cost with considering coronavirus. The economic novelty aspect of this paper is the hygiene costs. It includes disinfection and sanitizer costs, personal protective equipment (PPE) costs, COVID-19 tests, education, medicines, vaccines, and vaccination costs. This paper presents a multi-objective mixed-integer programming (MOMIP) problem for designing a GCLSCN during the pandemic. The optimization procedure uses the scalarization approach, namely the weighted sum method (WSM). The computational optimization process is conducted through Lingo software. Due to the recency of the COVID-19 pandemic, there are still many research gaps. Our contributions to this research are as follows: (i) designed a model of the green supply chain (GSC) and showed the better trade-offs between economic and environmental aspects during the COVID-19 pandemic and lockdowns, (ii) designed the hygiene supply chain, (iii) proposed the new indicators of economic aspects during the COVID-19 outbreak, and (iv) have found the positive (reducing CO2 emissions) and negative (increase in costs) impacts of COVID-19 and lockdowns. Therefore, this study designed a new hygiene model to fill this gap for the COVID-19 condition disaster. The findings of the proposed network illustrate the SC has become greener during the COVID-19 pandemic. The total cost of the network was increased during the COVID-19 pandemic, but the lockdowns had direct positive effects on emissions and air quality.

Keywords: Supply chain management, CO2 emissions, Logistic network, Lockdowns, Multi-objective optimization, Weighted sum method

Introduction

It is possible to quickly transmit COVID-19 from one person to another [1]. As a result of pandemics, supply chains (SCs) worldwide can become chaotic [2]. Lockdown policies and reduced physical contact are among the basic principles of the World Health Organization (WHO) in the conflict over COVID-19 [3]. Closed-loop supply chains (CLSCs) provide an alternative logistical method for dealing with environmental destruction and resource scarcity. In CLSCs, materials are controlled, emissions and waste are reduced, and the production process is cost-effective. In a CLSC, the material can be stored to minimize the environmental impact of SC activities [4]. A green closed-loop supply chain network (GCLSCN) has been identified as an important issue given the growing attention paid to environmental problems [5]. COVID-19’s continuing outbreak also impacts emissions in fundamental ways [6]. The emergence of environmental protection, client awareness, desire, and the development of carbon policies have all made reducing CO2 emissions one of the primary objectives of supply chain design (SCD) [7]. During the COVID-19 pandemic and intense lockdowns, China reported a 25% reduction in CO2 emissions [8]. Virus infections can cause disease, so the best method is to prevent them [9]. Therefore, we have suggested the following hygiene protocols during the COVID-19 pandemic in SC:

In addition to the existing shower installations, all facilities must have water, soap, alcohol, hand sanitizer, tissues, and bins at the entry.

The personnel who engage in high-risk activities are assigned appropriate PPE, which may include medical masks, gloves, face shields, goggles, and gowns.

All cleaning staff should be trained and provided with the PPE suitable for the task.

Disposing of face masks and disposable tissues with closed bins hygienically.

Publishing brochures about personal hygiene instructions.

Wash your hands after sneezing or coughing, before caring for patients and preparing food, and after using the toilet, door buttons, bags, boot buttons, printers, keyboard and mouse, and tables.

Handwashing procedures: (A) Use soap (liquid if possible) and running water (warm if possible). (B) Rub your hands with soap and water on your nails, fingers, and wrists for 20–30 s. (C) Rinse your hands carefully. (D) If possible, dry your hands with a paper towel. (E) Turn off the faucet with a paper towel and open the bathroom door. (F) Dispose of paper towels in the trash/closed trash.

If your hands are not contaminated with dirt or dust, you can use a gel or an alcohol-based hand sanitizer when you are not near the bath.

If you need to cough or sneeze, cover your face with your elbow or use a disposable tissue and instantly dispose it in a closed container. Wear masks to protect yourself and others. (Surgical masks are suggested).

The Proper Procedure for Wearing Face Masks: (A) Wash your hands thoroughly before using the mask. (B) Make sure your nose and mouth are closed and correct openings or gaps between the face and mask. (C) Do not touch the face or mask without washing your hands or cleaning with an alcohol-based product. (D) When removing the face mask, clean your hands first. (E) Put your face mask in a basket/bag/container/bin and immediately clean your hands with soap and water or a hand cleanser.

Do not share your personal belongings with other persons.

Observe social distancing (keep 2 m apart from others).

Clean and disinfect the items and surfaces you are dealing with.

Avoid touching the money directly and replace cash payments with credit payments [10].1

Avoid unnecessary travel.

Avoid physical meetings and hold online meetings.

Reduce working hours as much as possible.

Allow employees to work from home and reduce the number of employees working (if it is possible).

Reduce the number of employees working from offices [11, 12].

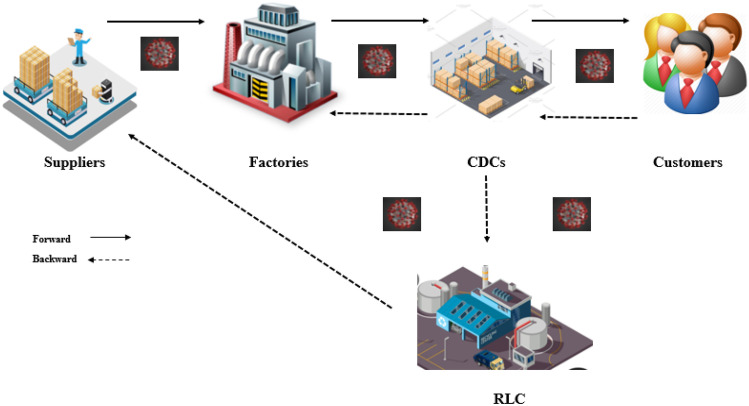

By incorporating economic and environmental performance indicators into the green supply chain network design (GSCND), the mathematical model of this paper aims to increase SC’s efficiency. Therefore, this study designed a new and hygienic GSCND model focusing on CO2 emissions. The model described above is considered to provide five types of facilities. The forward flow begins with the extraction of raw materials in supplier centers and consigning them to the factories for producing a new product. A new/remanufactured/refurbished product is transferred along the forward way to satisfy the customer’s needs. In river logistics, the returned products are collected from customers and shipped to the collection/distribution centers. The returned products are examined and classified as suitable for remanufacturing and refurbishing, which are sent to the factories and the recycling/landfill centers. This article’s novelty is presenting multi-objective mixed-integer programming (MOMIP) and COVID-19 pandemic issues in a CLSC framework.

Related Works and Contributions

The literature review section has divided the research into three groups. The first category deals with carbon policy in the SC, the second is the effect of COVID-19 limitations on CO2 emissions, and the third is recent supply chain issues.

Carbon Policy in the SC

The role of the carbon tax in a SC is to encourage the producer and the retailer to reduce emissions [13]. Zeballos et al. [14] dealt with various shipping costs in connection with real needs in CLSC design. Mohammed et al. [15] consider producing, warehousing, disposing, and recycling emissions in the CLSC. Different carbon rates are applied in each country, year, and analysis. According to Australia’s environmental policy in 2015, Zakeri et al. [16] applied a tax rate for CO2 emissions trading from SCD. At the same time, Fareeduddin et al. [17] mention how Australia’s tax rate affects the supply chain network design (SCND). Paksoy et al. [18] offer a model for SCN with a bi-objective (BO) function that considers transport costs, greenhouse gas (GHG) emissions, and fuel consumption. To control for CO2 emissions during transportation, determine the maximum CO2 emissions for each manufacturing and recycling final product. Martí et al. [19] mention CO2 emissions, including raw materials, production, storage, and transportation. Optimization and emission reduction in SC were based on carbon tax [20]. This policy is generally defined as the upper bound of carbon emission and must be enforced. The common carbon cap policy has been considered in some research for the GSCND. Many authors set a limitation in the manufacture, warehousing, transportation, and recycling [15, 17, 19, 21–24]. Other scholars consider the periodic or global carbon cap on the GSCND [25–29]. Coordination and decision-making in SC consider cap and trade [30]. The main source of GHG emissions is raw materials, considered by Abdallah et al. [31]. Kannan et al. [32] mention emissions in open facilities and transportation based on backward logistics, which minimizes the CO2 footprint. Transport emissions, raw materials, open facilities, manufacturing, distribution centers, and electricity consumption are all included in articles on cap and trade. Chaabane et al. [97] and Rezaee et al. present a linear programming (LP) model, which contacts the CO2 of production and transportation with the production scale [,]. In the context of cap and trade, outsourcing issues should be considered in SC [24, 32–35, 35]. Green supply chain concerns CO2 emissions for agricultural products [36]. Designing the GCLSCN model focuses on CO2 emissions [37].

CO2 Emissions During the COVID-19

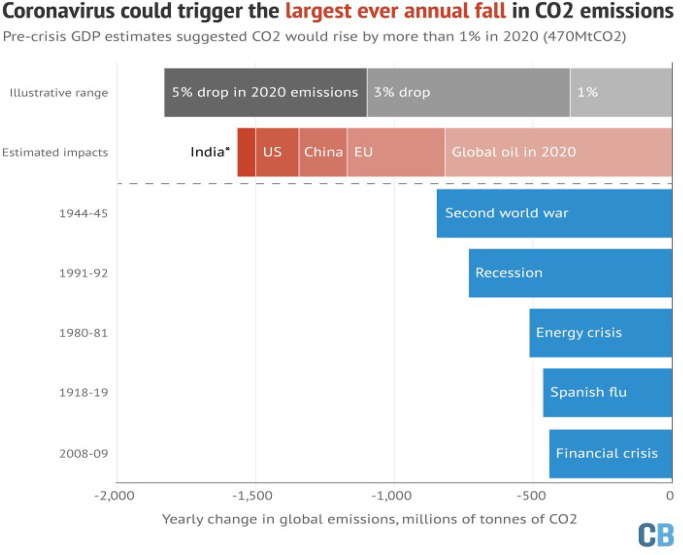

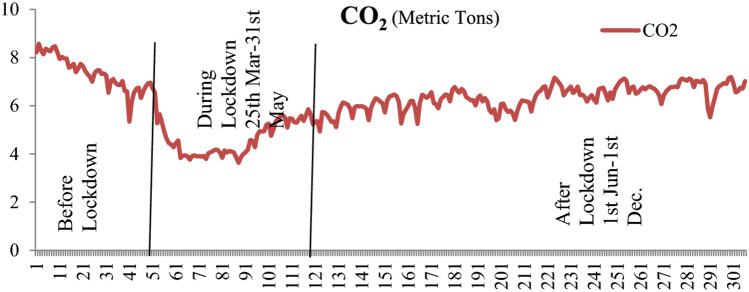

Information from the WHO demonstrates that GHG emissions rose to another record a couple of years ago. CO2 emissions were higher in the last 5 years than in the previous 5 years [38]. It is assessed that the emissions from the world’s biggest carbon producer (China) over the last few days lowered by about 25% compared to the pre-COVID-19 outbreaks (nationalgeographic.com). The International Energy Agency (IEA) has anticipated that the CO2 emission could fall by 8% during the lockdown days [39]. There is a possibility that emissions will fall by more than 5% in 2020, according to some estimates. It is the most significant yearly reduction so far [39]. Figure 1 analyzes the decrease in CO2 emissions during the current outbreak with pandemics’ past significant events. The maximum reduction in CO2 emissions during COVID-19 has been observed so far. In addition to reducing the spread of COVID-19, lockdowns also reduced human activity [40]. The new SC regarding hazardous gas emissions during the pandemic was proposed by Abbasi et al. [41]. As a result of the lockdown limitations, the amount of CO2 released into the atmosphere has temporarily decreased [42]. During this pandemic, many emissions may be reduced due to the current lockdown condition since all major transportation activities have been stopped.

Fig. 1.

Change in the emission of CO2 during the pandemic [8]

Recent Supply Chain Issues

Abbasi et al. [43] recently focused on designing sustainable recovery networks during the COVID-19 outbreak. Mosallanezhad et al. [44] developed a multi-objective (MO) metaheuristics approach for personal protection during the COVID-19 outbreak. Relief supply chain network during the COVID-19 pandemic and using the Internet of things (IoT) optimize the developed approaches [45]. In designing a model, the social aspect in CLSC was considered for the avocado industry [46]. A metaheuristic method for a dual-channel CLSCD was used in the tire industry under uncertainty [47]. Abdi et al. [48] developed a new stochastic model using stochastic programming for a closed-loop supply chain network (CLSCN). The metaheuristic method was also used for sugarcane supply chain network [49]. Ivanov and Das [50] concentrate on supply chain managers (SCMs) and SC resilience during COVID-19. A model for disruption risk is managing the SC during COVID-19 [51]. Rowan and Laffey [52] researched the shortage of SC for PPE during the COVID-19 pandemic. Ivanov [53] determined the future effect of the COVID-19 pandemic on the global supply chain, with a risk management approach. A sustainable blood supply chain considers social and environmental impacts [54]. Mosallanezhad et al. [55] designed a NP-hard model for the shrimp supply chain. Hobbs [56] researched on food supply chains and SC resilience during the COVID-19 outbreak. Ivanov and Dolgui [57] analyzed intertwined supply networks during COVID-19. Hajiaghaei-Keshteli and Fathollahi Fard [58] designed the sustainable closed-loop supply chain network (SCLSCN) design with discount supposition in the transportation costs. Free and Hecimovic [59] researched on supply and demand during and after COVID-19. Liao et al. [60] designed a CLSCN new mixed linear mathematical model for citrus fruit crates considering environmental and economic issues. Abdi et al. [61] designed and solved a new model using the metaheuristic green supply chain (GSC) method with simultaneous pickup and split delivery. Cheraghalipour et al. [62] suggested and solved a model with metaheuristic algorithms for the rice SC. Samadi et al. [63] developed a new model for discount supposition considering metaheuristic approaches. Illahi and Mir [64] researched the efficient logistics and SCM during and after COVID-19. Chouhan et al. [65] suggested a CLSCN for handling uncertain demands. Salehi-Amiri et al. [66] designed a SCLSCN for the walnut industry by using mixed-integer linear programming. Nandi et al. [67] used blockchain for redesigning SC during COVID-19. Fasihi et al. [68] designed a fish CLSC by developing a BO mathematical model. Zahedi et al. [69] designed a CLSCN, considering multi-option transportation and multi-task sales agencies. The uncertainty of MO model for SC design considers reliability [70]. Fathollahi-Fard et al. [71] developed an objective model for a green home healthcare supply chain. The position of this research compared to that of previous research is shown in Table 1.

Table 1.

The recent research contribution of SC

| Authors | Reference | Year | Focused CO2 emission | Focused hygienic cost | Focused closed-loop network | Focused COVID-19 |

|---|---|---|---|---|---|---|

| Hajiaghaei-Keshteli and Fathollahi-Fard | [58] | 2019 | * | |||

| Samadi et al. | [63] | 2020 | * | |||

| Ivanov and Das | [50] | 2020 | * | |||

| Hobbs | [56] | 2020 | * | |||

| Liao et al. | [60] | 2020 | * | * | ||

| Rowan and Laffey | [52] | 2020 | * | |||

| Ivanov | [53] | 2020 | * | |||

| Chouhan et al. | [65] | 2020 | * | |||

| Ivanov and Dolgui | [57] | 2020 | * | |||

| Mosallanezhad et al. | [44] | 2021 | * | |||

| Zahedi et al. | [45] | 2021 | * | |||

| Fathollahi-Fard et al. | [47] | 2021 | * | |||

| Abdi et al. | [48] | 2021 | * | |||

| Chouhan et al. | [49] | 2021 | * | |||

| Shahed et al. | [51] | 2021 | * | |||

| Mousavi et al. | [54] | 2021 | * | |||

| Mosallanezhad et al. | [55] | 2021 | * | |||

| Free and Hecimovic | [59] | 2021 | * | |||

| Illahi and Mir | [64] | 2021 | * | |||

| Salehi-Amiri et al. | [66] | 2021 | * | |||

| Yachai et al. | [36] | 2021 | * | |||

| Kazancoglu et al. | [37] | 2022 | * | * | ||

| Nandi et al. | [67] | 2021 | * | |||

| Fasihi et al. | [68] | 2021 | * | |||

| Zahedi et al. | [45] | 2021 | * | |||

| Salehi-Amiri et al. | [46] | 2022 | * | |||

| Current research | 2022 | * | * | * | * |

Research Gap and Innovation

Due to the recency of the COVID-19 pandemic, there are still many research gaps. The research papers in Table 1 have not simultaneously considered CO2 emission, hygienic cost, and COVID-19 pandemic issues in the CLSC framework. In this paper, we develop concepts of GSCND. In summary, the suggested paper shows some concerns that cover the literature gaps, and innovation can be categorized as follows:

Designing a hygienic SC.

- Designing a new GSC considering pandemics in two dimensions of sustainability:

- Calculating COVID-19 hygiene costs in addition to the normal condition to develop economic aspects.

- Developing the environmental aspects by considering the reduction of CO2 emissions during the COVID-19 lockdowns.

In this paper, the distribution center is merged with the collection center to prevent physical contact with customers during the COVID-19 outbreak.

This paper presents a MOMIP model and COVID-19 pandemic issues in the CLSC framework.

Therefore, this study designed a new and hygienic GSC model to fill this gap in the COVID-19 disaster.

Mathematical Model

The GSC covers both aspects (economic and environmental) of sustainability. Recycling is an environmentally friendly process that can save costs and improve economic efficiency. CLSC integrates a forward supply chain (FSC) with a reverse supply chain (RSC). In this article, the distribution center (DC) is merged with the collection center (CC) during the COVID-19 pandemic for the following reasons: reducing building costs, reducing CO2 emission, reducing environmental pollution, and preventing physical contact of customers (observance of social distancing). To increase the efficiency of SC, this mathematical model has been designed by incorporating economic and environmental performance indicators into the GSCND during the COVID-19 pandemic. In addition to a total cost measure to calculate all the monetary expenditure in a specific SC design and environmental and social efficiency that are measured indexes used in a mathematical modeling method, multi-objective optimization (MOO) is fulfilled to create the GSC. The model will allow us to achieve the best design of the SC, determining which facilities (suppliers–factories–distribution/collection centers–recycling/landfill centers) should be included in the network, recognizing the flows of units of product among different echelons. This research provides useful information to DMs for helpful information, judgments, and ultimately creating more sustainable decisions during the pandemic. The explanation of the suggested mathematical model for GSC design is delineated in four subsections: problem statement and assumptions, model components, formulation process, and multi-objective (MO) approach.

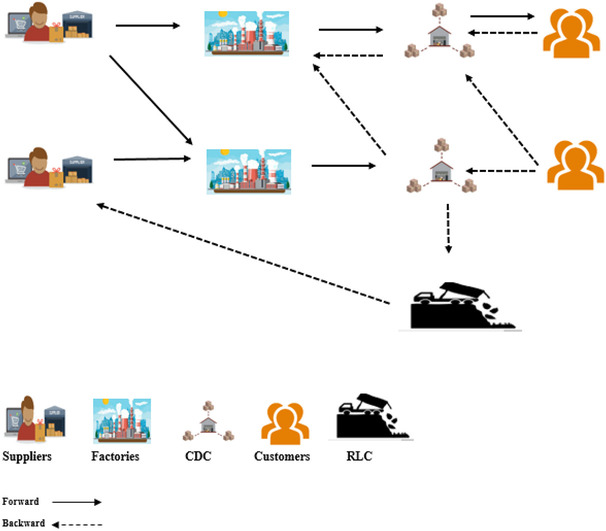

Problem Statement and Assumptions

The mathematical model described above is considered to provide five types of facilities:

Suppliers (S),

Production/Remanufacturing/Refurbishing centers (Factories) (F),

Collection/Distribution centers (CDC),

Customers (C),

Recycling/landfill centers (RLC).

In the forward flow, raw materials are extracted in supplier centers and consigned to factories for manufacture. To satisfy customer needs, new/remanufactured/refurbished products are transferred through the forward supply chain (from factories to CDCs and from CDCs to customers). Customer-returned products are collected by the reverse supply chain (RSC) and shipped to the CDCs. Those products that qualify for remanufacturing and refurbishing are sent to factories, while those that do not are sent to RLCs for landfilling and recycling. According to its specifications, this product is considered end of life (EOL). Figure 2 shows the designed schematic of the problem.

Fig. 2.

The logistics networks between echelons are depicted

It is necessary to make certain assumptions to design a mathematical model:

The COVID-19 outbreak is considered in the supply chain thoroughly.

The cost of the model includes regular and hygienic.

The DC is merged with the CC to observe social distancing during the COVID-19 pandemic.

All customer demand was always satisfied during the COVID-19 pandemic and lockdowns with every factory through every CDC.

It is assumed that a determined percentage of the total demand is disposed of.

The COVID-19 hygiene protocol is followed for all returned products that enter RLCs for disposal.

Customer demand and product returns are inevitable.

The locations of Fs, CDCs, and RLCs are potential.

The locations of suppliers and customers exist.

There are several shipping alternatives for each connection (e.g., road/rail/air/sea).

All shipping alternatives have unlimited capacities.

Distances between network nodes should be feasible.

The network consists of both forward and reverse flows (closed-loop).

Model Components

The SC model includes the sets, parameters, and variables described as follows: The sets S, F, I, B, and C contain the existing suppliers, the potential factories, the potential CDCs, the potential RLCs, and the existing customers, respectively. The sets TS, TF, TI, TC, and TB include the shipping options from suppliers, factories, CDCs, customers, and RLCs, respectively. The model’s parameters are technical parameters, economic parameters, and environmental parameters. Binary and non-negative, continuous decision variables are applied to implement the goals of the mathematical model, namely assign the GSC network and the number of units of products that flow through the network.

The hygiene costs for prevention and control of COVID-19 include the following:

Disinfection costs,

Hand sanitizer costs,

The costs of PPE (Shield–Mask–Gown–Gloves)

COVID-19 tests costs (Normal–Fast),

COVID-19 education costs,

The costs of COVID-19 medicines, vaccines, and vaccination [6, 72].

The following are positive impacts of COVID-19 and lockdown on the environment:

Reducing CO2 emissions and industrial activities

Reducing CO2 emissions and shipping activities

The negative impact of COVID-19 on the environment is as follows:

Increased medical waste during the COVID-19 pandemic.

. IncreasedPPE waste disposal increased during the COVID-19 pandemic (plastic waste–soil and water pollution) [73–79, 95].

Notations

In this section, notations for the mathematical model are explained (Tables 2, 3, 4, 5, and 6).

Table 2.

Indices

| Set of fixed locations for suppliers, | |

| Set of potential locations for factories, | |

| Set of potential locations for CDCs, | |

| Set of fixed locations for customers, | |

| Set of potential locations for RLCs, | |

| Set of shipping alternatives from suppliers, | |

| Set of shipping alternatives from factories, | |

| Set of shipping alternatives from CDCs, | |

| Set of shipping alternatives from customers, | |

| Set of shipping alternatives from RLCs, |

Table 3.

Technical parameters

| The demand of customer c, | |

| Maximum supplier extraction capacity, | |

| Maximum factory production capacity, | |

| Maximum CDC collection/distribution capacity, | |

| Maximum RLC recycling/landfilling capacity, | |

| Maximum factory remanufacturing and refurbishing capacity, | |

| Minimum percentage of the returned product to be remanufactured (unit), | |

| Minimum percentage of the returned product to be recycled and landfilled (unit), | |

| Shipping rate from the supplier s to factory f with shipping alternative ts, | |

| Shipping rate from factory f to CDC i with shipping alternative tf, | |

| Shipping rate from CDC i to factory f with shipping alternative ti, | |

| Shipping rate from CDC i to customer c with shipping alternative ti, | |

| Shipping rate from customer c to CDC i with shipping alternative tc, | |

| Shipping rate from CDC i to RLC b with shipping alternative ti, | |

| Shipping rate from RLC b to supplier s with shipping alternative tb, | |

| Distance between supplier s and factory f, | |

| Distance between factory f and CDC i, | |

| Distance between CDC i and factory f, | |

| Distance between CDC i and customer c, | |

| Distance between customer c and CDC i, | |

| Distance between CDC i and RLC b, | |

| Distance between RLC b and supplier s, |

Table 4.

Economic parameters

| Fixed cost for opening factory f during the COVID-19 pandemic, | |

| Fixed cost for opening CDC i during the COVID-19 pandemic, | |

| Fixed cost for opening RLC b during the COVID-19 pandemic, | |

| The variable cost for extracting a unit of raw material from the supplier s, | |

| The variable cost for producing a unit of product in the factory f, | |

| The variable cost for distribution a unit of product in the CDC i, | |

| The variable cost for collecting, inspecting, consolidating, and sorting a unit of the returned product in the CDC i, | |

| The variable cost for recycling and landfilling a unit of the returned product in RLC b, | |

| The variable cost for remanufacturing and refurbishing a unit of the returned product in the factory f, | |

| The shipping cost of a unit of raw material from the supplier s to factory f with alternative shipping ts, | |

| The shipping cost of a unit product from factory f to CDC i with alternative shipping tf, | |

| The shipping cost of a unit of product from CDC i to customer c with alternative shipping ti, | |

| The shipping cost of a unit of the returned product that is collected from customer c to CDC i with alternative shipping tc, | |

| The shipping cost of a unit of the returned product that is available for remanufacturing and refurbishing from CDC i to factory f with alternative shipping ti, | |

| The shipping cost of a unit of returned product that is unsuitable for remanufacturing and refurbishing, from CDC i to RLC b with alternative shipping ti, | |

| The shipping cost of a unit of recycled product from RLC b to supplier s with alternative shipping tb, | |

| The cost of COVID-19 prevention and control while extracting a unit of raw material from the supplier s, | |

| The cost of COVID-19 prevention and control during production of a unit of product in the factory f, | |

| The cost of COVID-19 prevention and control for distributing a unit of product from the CDC i, | |

| The cost of COVID-19 prevention and control for collecting, inspecting consolidation, and sorting a unit of the returned product in the CDC i, | |

| The cost of COVID-19 prevention and control for recycling and landfilling a unit of the returned product in the RLC b, | |

| The cost of COVID-19 prevention and control for remanufacturing and refurbishing a unit of the returned product in the factory f, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of raw material from the supplier s to factory f with alternative shipping ts, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of product from factory f to CDC i with alternative shipping tf, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of product from CDC i to customer c with alternative shipping ti, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of returned product from customer c to CDC i with alternative shipping tc, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of the returned product that is available for remanufacturing and refurbishing from CDC i to factory f with alternative shipping ti, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of returned product that is unsuitable for remanufacturing and refurbishing from CDC i to RLC b with alternative shipping ti, | |

| The cost of COVID-19 prevention and control during the shipping of a unit of recycled product from RLC b to supplier s with alternative shipping tb, |

Table 5.

Environmental parameters

| The rate of CO2 released to extract a unit of raw material in supplier s during the COVID-19 pandemic and lockdown days, | |

| The rate of released CO2 to produce a unit of product in factory f during the COVID-19 pandemic and lockdown days, | |

| The rate of CO2 released to handle and distribute 1 unit of product in the CDC i during the COVID-19 pandemic and lockdown days, | |

| The rate of CO2 released to collect, inspect, consolidate, and sort 1 unit of the returned product in the CDC i during the COVID-19 pandemic and lockdown days, | |

| The rate of CO2 released to remanufacture 1 unit of the returned product in the factory f during the COVID-19 pandemic and lockdown days, | |

| The rate of CO2 released to recycle and landfill 1 unit of the returned product in RLC b during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative ts to send a unit of raw material from supplier s to factory f for a unit distance during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative tf to send a unit of product from factory f to CDC i for a unit distance during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative ti to send a unit of product from CDC i to customer c for a unit distance during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative tc to collect a unit of returned production from customer c to CDC i for a unit distance during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative ti to send a unit of the returned product to be remanufactured from CDC i to factory f for a unit distance during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative ti to send a unit of returned production from CDC i to RLC b for a unit distance during the COVID-19 pandemic and lockdown days, | |

| CO2 released by shipping alternative tb to send a unit of returned production from RLC b to supplier s for a unit distance during the COVID-19 pandemic and lockdown days, |

Table 6.

Variables

| If factory f is open, equals 1; otherwise 0. | |

| If CDC i is open, equals 1; otherwise 0. | |

| If RLC b is open, equals 1; otherwise 0. | |

| Quantity of units of raw material sent from supplier s to factory f with shipping alternative ts, | |

| Quantity of units of product sent from factory f to CDC i with shipping alternative tf, | |

| Quantity of units of product sent from CDC i to customer c with shipping alternative ti, | |

| Quantity of units of returned product collected from customer c to CDC i with shipping alternative tc, | |

| Quantity of units of returned product available for remanufacturing and refurbishing sent from CDC i to factory f with shipping alternative ti, | |

| Quantity of units of returned product unsuitable for remanufacturing and refurbishing sent from CDC i to RLC b with shipping option ti, | |

| Quantity of units of recycled product sent from RLC b to supplier s with shipping option tb, |

Formulation Process

A mathematical optimization model consists of two parts: objective functions and constraints. The model’s objectives are to minimize costs (economic aspect) and CO2 emissions (environmental aspect) during COVID-19 lockdown days. The bi-objective design of the network during the pandemic and lockdown periods is formulated as follows: The mathematical formulation of the objective functions is described in Eqs. (1)–(2), and the constraints of the mathematical model are given in Eqs. (3)–(18). The total cost is the summation of the total fixed cost (TF), the total variable cost (TV), the total hygiene cost (TH), and the total shipping cost (TS). The total emission of CO2 is calculated by adding the total CO2 due to working facilities (EM), such as extracting raw materials, producing, remanufacturing, refurbishing, recycling, and landfilling, and the total CO2 due to shipping (ES). It is assumed that all emissions of CO2 are in this model with the observance of hygienic protocol during the COVID-19 pandemic and lockdowns.

| 1 |

| 1.1 |

| 1.2 |

| 1.3 |

| 1.4 |

| 2 |

| 2.1 |

| 2.2 |

Subject to:

| 3 |

Constraint (3) describes the total number of row material units that enter a factory from any suppliers via any transportation options which should be lower or equal to the maximum capacity of the respective factory.

| 4 |

Constraint (4) states that the total number of product units that enter a CDC from any factories via any transportation options should be lower or equal to the maximum capacity of the respective CDC.

| 5 |

Constraint (5) shows that the total number of returned product units to be recycled, incinerated, and landfilled collected from any customers to an RLC via any transportation options should be lower or equal to the maximum capacity of the respective RLC.

| 6 |

Constraint (6) presents the total number of returned product units shipped from a CDC to any factories via any transportation options which should be lower or equal to the respective factory’s maximum remanufacturing and refurbishing capacity.

| 7 |

Constraint (7) describes the total number of returned product units shipped from a customer to any CDCs via any transportation options which should be lower or equal to the maximum collecting capacity of the respective CDC.

| 8 |

Constraint (8) explains that the total number of product units shipping from a factory to any CDCs via any transportation options should be lower or equal to the total number of raw material units shipping from a supplier to any factories.

| 9 |

Constraint (9) illustrates that the total number of product units shipping from a CDC to any customers via any transportation options should be lower or equal to the total number of products shipping from a factory to any CDCs.

| 10 |

Constraint (10) shows that the total number of product units shipping from a CDC to any RLCs via any transportation options should be lower or equal to the total number of products shipping from a factory to any CDCs.

| 11 |

Constraint (11) describes that the total number of returned product units shipping from a CDC to any factories via any transportation options should be lower or equal to the total number of product units shipping from a factory to any CDCs.

| 12 |

Constraint (12) states that the total number of returned product units shipping from a customer to any CDCs via any transportation options should be lower or equal to the total number of product units shipping from a CDC to any customers.

| 13 |

Constraint (13) shows that the total number of product units distributed from any CDCs via any transportation options to satisfy a customer’s demand should be higher or equal to the respective demand of the customer.

| 14 |

Constraint (14) describes that the total number of returned product units collected from a customer to any CDCs via any transportation options should be lower than the respective customer demand.

| 15 |

Constraint (15) states that the total number of product units to be recycled, incinerated, and landfilled sent to any RLCs via any transportation options from a customer should be higher or equal to the minimum percentage of restitution from the total number of demands of the respective customer.

| 16 |

Constraint (16) shows that the total number of products units to be refurbished and remanufactured delivered to any factories from a CDC via any transportation options should be greater or equal to the minimum percentage of product units to be remanufactured from the total amount of units of returned product.

| 17 |

Constraint (17) describes the total number of raw materials, products, and returned products that flowed from a supplier to a factory via transportation options, a factory to a CDC via transportation options, a CDC to a customer center via transportation options, a customer center to a CDC via transportation options, and a CDC to a RLC and a factory via transportation options should be higher or equal to zero.

| 18 |

Constraint (18) explains the binary numbers used to describe the potential of facilities (Factories, CDCs, and RLCs).

Multi-objective optimization problem (MOOP) Approach

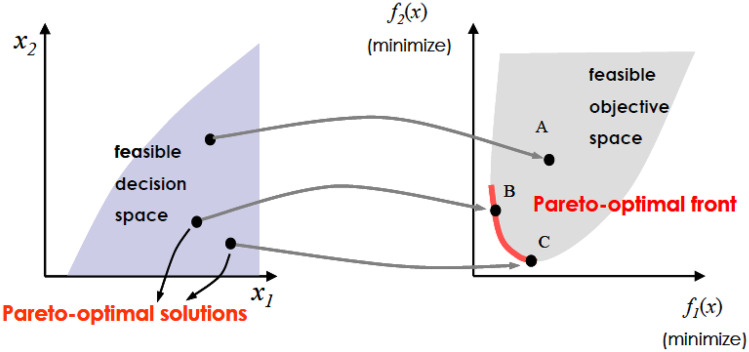

The multi-objective optimization problems (MOOPs) consist of two or more objective functions that must be minimized or maximized. A set of solutions defines the best trade-offs between competing objectives in a single-objective optimization problem (SOOP). Considering a set of solutions, the non-dominant solution set is the set of all solutions that the members of the solution group do not dominate. The non-dominant group of fully feasible decision space is called the Pareto-optimal set (POS). The boundary defined by the set of all mapped points in the POS is called the Pareto-optimal front (POF).

The aims of MOOP are as follows:

To achieve a set of solutions as close to POF as possible.

To achieve a set of solutions as diverse as possible [80].

Scalarization Methods

MOOP is traditionally solved by scalarization, which involves formulating a SOOP corresponding to the MOOP [81].

| 19 |

| 20 |

The weighted sum method (WSM) uses the vector of weights λ ∈ Rp ≥ as a parameter [81].

| 21 |

| 22 |

An approach to managing WSM is to weigh each aspect and minimize the weighted sum of all elements. The main advantage of this approach is to model and solve MOP with SO methods [82]. Figure 3 illustrates the Pareto concept in more detail. The mathematical model for solving with two objective functions (OFs) is shown in Sect. 3.4.2.

Fig. 3.

An illustration of the Pareto solutions [80]

WSM

Subject to:

Where w1 ≥ 0 and w2 ≥ 0 are weights such that w1 + w2 = 1, and f1 and f2 are the OFs.

Implementation and Evaluation

Case Study

The first cases of COVID-19 were confirmed in Iran on February 19, 2020. The model’s validity and the solution method’s functionality are assessed through the data for the considered case study. The Iranian automotive industry will become the most critical industry in Iran over the years. We are collecting data from the company’s SC. A real case study has evaluated the outcomes of the model. The accuracy of the created model and the solution method’s functionality are assessed through the data for the considered case study. At last, it should be referenced that the proposed model is a dependable and responsive closed-loop SCND model. Tables 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, and 19 show the required data for modeling.

Table 7.

Supplier’s data

| Supplier’s locations (City) | Average variable cost before February 19, 2020 (Rials) (100,000 units) | Average variable and hygiene cost during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (Rials), including: Disinfection and sanitizer costs + PPE costs + COVID-19 test cost + costs of COVID-19 education + Costs of COVID-19 vaccine (100,000 units) | Specific net CO2 emission before February 19, 2020 (kg CO2 per tonne of material) | Specific net CO2 emission during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (kg CO2 per tonne of material) | Average CO2 emissions = average CO2 released average distance average shipping rates before February 19, 2020 (road/rail/air, tonnes) | Average CO2 emissions = average CO2 released Average distance Average shipping rates during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (road/rail/air, tonnes) |

|---|---|---|---|---|---|---|

| Isfahan | 11,000,000,000 | 13,000,000,000 | 486.7 | 470.2 | 7800 | 6905 |

| Yazd | 12,700,000,000 | 14,500,000,000 | 399.6 | 384.2 | 6500 | 6070 |

| Tehran | 18,000,000,000 | 19,200,000,000 | 376.0 | 369.2 | 8500 | 7605 |

Table 8.

Data of factories

| Factory location (City) | Average fixed cost during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (Rials) | Average variable cost before February 19, 2020 (Rials) (100,000 units) | Average variable and hygiene cost during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (rials), including disinfection and sanitizer costs + PPE costs + COVID-19 test cost + costs of COVID-19 education + costs of COVID-19 vaccine (100,000 units) | Specific net CO2 emission before February 19, 2020 (kg CO2 per tonne of material) | Specific net CO2 emission during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (kg CO2 per tonne of material) | Average CO22 emissions = average CO2 released average distance average shipping rates before February 19, 2020 (road/rail/air; tonnes) | Average CO2 emissions = average CO2 released average distance average shipping rates during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (road/rail/air; tonnes) |

|---|---|---|---|---|---|---|---|

| Tehran | 500,000,000,000 | 18,000,000,000 | 22,000,000,000 | 686.7 | 670.2 | 10,400 | 9880 |

| Saveh | 190,000,000,000 | 10,000,000,000 | 13,000,000,000 | 596.2 | 574.1 | 9600 | 8763 |

| Kashan | 350,000,000,000 | 14,000,000,000 | 17,000,000,000 | 476.0 | 469.2 | 8820 | 7900 |

Table 9.

Data of recycling/landfilling

| Recycling/landfilling location (Tehran Province) | Average fixed cost during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (rials) | Average variable cost before February 19, 2020 (rials) (100,000 units) | Average variable and hygiene costs during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (rials), including disinfection and sanitizer costs + PPE costs + COVID-19 test cost + costs of COVID-19 education + costs of COVID-19 vaccine (100,000 units) | Specific net CO2 emission before February 19, 2020 (kg CO2 per tonne of material) | Specific net CO2 emission during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (kg CO2 per tonne of material) | Average CO2 emissions = average CO2 released average distance average shipping rates before February 19, 2020 (road/rail/air; tonnes) | CO2 emissions = average CO2 released average distance average shipping rates during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (road/rail/air; tonnes) |

|---|---|---|---|---|---|---|---|

| Damavand | 25,000,000,000 | 10,000,000,000 | 12,900,000,000 | 286.7 | 160.3 | 7300 | 6201 |

| Km 17 Jade Makhsous | 16,070,000,000 | 8,000,000,000 | 11,500,000,000 | 496.2 | 374.1 | 5690 | 4080 |

| Tehran | 32,000,000,000 | 12,000,000,000 | 13,400,000,000 | 576.0 | 469.8 | 9401 | 9000 |

Table 10.

Data of Saipa collection/distribution

| Collection/Distribution locations (Tehran Province) | Average fixed cost during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (rials) | Average variable cost before February 19, 2020 (rials) (100,000 units) | Average variable and hygiene costs during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (rials), including disinfection and sanitizer costs + PPE costs + COVID-19 test cost + costs of COVID-19 education + costs of COVID-19 vaccine (100,000 units) | Specific net CO2 emission before February 19, 2020 (kg CO2 per tonne of material) | Specific net CO2 emission during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (kg CO2 per tonne of material) | Average CO2 emissions = average CO2 released average distance average shipping rates before February 19, 2020 (road/rail/air; tonnes) | Average CO2 emissions = average CO2 released average distance average shipping rates during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (road/rail/air; tonnes) |

|---|---|---|---|---|---|---|---|

| Damavand | 40,000,000,000 | 8,000,000,000 | 10,000,000,000 | 296.7 | 100.9 | 5800 | 4905 |

| Abali | 99,000,000,000 | 19,000,000,000 | 22,000,000,000 | 200.0 | 180.0 | 3500 | 4100 |

| Islamshahr | 65,000,000,000 | 7,000,000,000 | 9,000,000,000 | 376.0 | 250.0 | 2500 | 3905 |

| Baqershahr | 45,000,000,000 | 2,000,000,000 | 4,000,000,000 | 586.7 | 400.1 | 1820 | 6002 |

| Bumehen | 99,000,000,000 | 3,000,000,000 | 3,800,000,000 | 396.2 | 301.3 | 7510 | 6040 |

| Robat Karim | 65,000,000,000 | 13,000,000,000 | 15,000,000,000 | 400.0 | 370.0 | 6506 | 7756 |

| Pakdasht | 48,000,000,000 | 4,500,000,000 | 9,500,000,000 | 776.4 | 676.4 | 5937 | 4999 |

| Rudehen | 99,000,000,000 | 15,000,000,000 | 17,000,000,000 | 296.7 | 201.7 | 6500 | 6020 |

| Chahar Dangeh | 65,000,000,000 | 4,000,000,000 | 8,000,000,000 | 200.0 | 187.0 | 8500 | 7805 |

| Tehran | 110,000,000,000 | 8,900,000,000 | 14,300,000,000 | 576.0 | 486.0 | 10,800 | 8999 |

| Kahrizak | 29,000,000,000 | 9,000,000,000 | 11,000,000,000 | 296.2 | 156.2 | 2200 | 1021 |

| Lavasan | 65,000,000,000 | 6,800,000,000 | 8,700,000,000 | 696.3 | 506.3 | 3570 | 2705 |

| Pardis | 40,000,000,000 | 10,000,000,000 | 12,000,000,000 | 340.0 | 300.0 | 5605 | 4936 |

| Shahr-e Qods | 99,000,000,000 | 12,000,000,000 | 14,600,000,000 | 390.0 | 376.5 | 7529 | 6001 |

| Varamin | 85,000,000,000 | 8,500,000,000 | 10,500,000,000 | 196.7 | 177.7 | 6692 | 6025 |

| Fardis | 70,000,000,000 | 5,600,000,000 | 7,700,000,000 | 220.0 | 179.0 | 5500 | 5009 |

| Shahr-e Rey | 49,000,000,000 | 11,000,000,000 | 14,000,000,000 | 479.0 | 379.8 | 4900 | 3000 |

Table 11.

Shipping costs

| Average unit shipping cost before February 19, 2020 (road/rail/air/sea) (Rials/Ton) | Average unit shipping cost during the COVID-19 pandemic (February 19, 2020–June 26, 2021) (road/rail/air) (Rials/Ton) | |

|---|---|---|

| Tehran–Kashan | 921,400 | 1,008,000 |

| Tehran–Saveh | 550,004 | 582,099 |

| Isfahan–Kashan | 701,300 | 812,000 |

| Isfahan–Saveh | 1,689,000 | 1,940,300 |

| Isfahan–Tehran | 2,886,000 | 2,997,030 |

| Yazd–Kashan | 1,759,007 | 2,000,001 |

| Yazd–Saveh | 3,571,060 | 3,762,080 |

| Yazd–Tehran | 4,589,005 | 5,589,900 |

| Damavand–Tehran | 370,010 | 391,500 |

| Damavand–Saveh | 801,300 | 853,040 |

| Damavand–Kashan | 1,255,000 | 1,307,999 |

| Abali–Tehran | 340,033 | 363,501 |

| Abali–Saveh | 700,000 | 800,000 |

| Abali–Kashan | 1,677,000 | 1,899,304 |

| Islamshahr–Tehran | 180,901 | 190,512 |

| Islamshahr–Saveh | 500,102 | 560,088 |

| Islamshahr–Kashan | 900,030 | 1,000,012 |

| Baqershahr–Tehran | 160,961 | 170,662 |

| Baqershahr–Saveh | 540,203 | 575,067 |

| Baqershahr–Kashan | 910,000 | 1,030,010 |

| Bumehen–Tehran | 310,035 | 332,009 |

| Bumehen–Saveh | 680,200 | 730,400 |

| Bumehen–Kashan | 1,507,070 | 1,820,900 |

| Robat Karim–Tehran | 270,739 | 282,011 |

| Robat Karim–Saveh | 450,122 | 472,077 |

| Robat Karim–Kashan | 870,040 | 920,033 |

| Pakdasht–Tehran | 280,032 | 292,001 |

| Pakdasht–Saveh | 590,003 | 622,033 |

| Pakdasht–Kashan | 890,033 | 940,088 |

| Rudehen–Tehran | 310,901 | 335,888 |

| Rudehen–Saveh | 690,300 | 744,000 |

| Rudehen–Kashan | 1,600,200 | 1,705,009 |

| Chahar Dangeh–Tehran | 121,700 | 142,287 |

| Chahar Dangeh–Saveh | 570,601 | 592,111 |

| Chahar Dangeh–Kashan | 920,200 | 1,140,090 |

| Kahrizak–Tehran | 180,900 | 190,500 |

| Kahrizak–Saveh | 520,101 | 544,013 |

| Kahrizak–Kashan | 870,012 | 990,077 |

| Lavasan–Tehran | 220,999 | 239,980 |

| Lavasan–Saveh | 620,202 | 720,501 |

| Lavasan–Kashan | 1,500,330 | 1,605,440 |

| Pardis–Tehran | 270,999 | 289,918 |

| Pardis–Saveh | 650,100 | 702,100 |

| Pardis–Kashan | 1,300,060 | 1,770,010 |

| Shahr-e Qods–Tehran | 180,988 | 190,555 |

| Shahr-e Qods–Saveh | 580,999 | 619,187 |

| Shahr-e Qods–Kashan | 1,400,280 | 1,420,477 |

| Varamin–Tehran | 320,035 | 333,014 |

| Varamin–Saveh | 610,204 | 700,203 |

| Varamin–Kashan | 700,098 | 771,695 |

| Fardis–Tehran | 280,012 | 299,977 |

| Fardis–Saveh | 490,302 | 521,016 |

| Fardis–Kashan | 890,150 | 935,222 |

| Shahr-e Rey–Tehran | 141,821 | 165,220 |

| Shahr-e Rey–Saveh | 585,024 | 598,080 |

| Shahr-e Rey–Kashan | 990,400 | 1,170,056 |

| Tehran–Km 17 Jade Makhsous | 141,722 | 162,222 |

| Damavand–Km 17 Jade Makhsous | 470,144 | 490,011 |

| Abali–Km 17 Jade Makhsous | 390,212 | 405,200 |

| Abali–Damavand | 150,856 | 170,999 |

| Islamshahr–Km 17 Jade Makhsous | 180,902 | 190,514 |

| Islamshahr–Damavand | 453,941 | 467,254 |

| Baqershahr–Damavand | 400,314 | 419,100 |

| Baqershahr–Km 17 Jade Makhsous | 240,213 | 259,315 |

| Bumehen–Damavand | 150,888 | 170,944 |

| Bumehen–Km 17 Jade Makhsous | 361,220 | 391,020 |

| Robat Karim–Damavand | 555,009 | 580,070 |

| Robat Karim–Km 17 Jade Makhsous | 241,999 | 254,987 |

| Pakdasht–Damavand | 430,212 | 450,200 |

| Pakdasht–Km 17 Jade Makhsous | 330,033 | 343,802 |

| Rudehen–Damavand | 150,759 | 171,216 |

| Rudehen–Km 17 Jade Makhsous | 376,870 | 399,600 |

| Chahar Dangeh–Damavand | 390,999 | 417,765 |

| Chahar Dangeh–Km 17 Jade Makhsous | 270,013 | 289,222 |

| Kahrizak–Damavand | 441,947 | 457,200 |

| Kahrizak–Km 17 Jade Makhsous | 240,249 | 259,329 |

| Lavasan–Damavand | 350,044 | 372,901 |

| Lavasan–Km 17 Jade Makhsous | 366,822 | 389,110 |

| Pardis–Damavand | 210,300 | 220,040 |

| Pardis–Km 17 Jade Makhsous | 470,100 | 489,012 |

| Shahr-e Qods–Damavand | 469,199 | 488,510 |

| Shahr-e Qods–Km 17 Jade Makhsous | 230,210 | 240,322 |

| Varamin–Damavand | 540,001 | 570,010 |

| Varamin–Km 17 Jade Makhsous | 350,033 | 372,522 |

| Fardis–Damavand | 585,109 | 590,570 |

| Fardis–Km 17 Jade Makhsous | 151,788 | 172,217 |

| Shahr-e Rey–Damavand | 368,021 | 389,990 |

| Shahr-e Rey–Km 17 Jade Makhsous | 220,210 | 229,920 |

| Tehran–Tehran | 101,222 | 120,000 |

| Damavand–Damavand | 70,012 | 80,015 |

| Shemiranat–Tehran | 180,923 | 190,533 |

| Shemiranat–Damavand | 360,020 | 481,148 |

| Shemiranat–Abali | 330,034 | 353,281 |

| Shemiranat–Islamshahr | 190,934 | 210,521 |

| Shemiranat–Baqershahr | 170,231 | 185,600 |

| Shemiranat–Bumehen | 324,044 | 342,777 |

| Shemiranat–Robat Karim | 280,799 | 292,200 |

| Shemiranat–Pakdasht | 290,044 | 311,004 |

| Shemiranat–Rudehen | 320,888 | 346,877 |

| Shemiranat–Chahar Dangeh | 123,900 | 144,555 |

| Shemiranat–Kahrizak | 188,000 | 200,100 |

| Shemiranat–Lavasan | 220,000 | 229,080 |

| Shemiranat–Pardis | 270,000 | 280,000 |

| Shemiranat–Shahr-e Qods | 182,444 | 185,321 |

| Shemiranat–Varamin | 340,022 | 363,011 |

| Shemiranat–Fardis | 289,088 | 310,247 |

| Shemiranat–Shahr-e Rey | 144,679 | 170,000 |

| Malard–Tehran | 280,011 | 295,911 |

| Malard–Damavand | 585,222 | 591,364 |

| Malard–Abali | 470,238 | 490,666 |

| Malard–Islamshahr | 490,101 | 530,222 |

| Malard–Baqershahr | 230,944 | 348,960 |

| Malard–Bumehen | 470,208 | 490,019 |

| Malard–Robat Karim | 180,550 | 186,502 |

| Malard–Pakdasht | 390,127 | 417,744 |

| Malard–Rudehen | 470,121 | 492,023 |

| Malard–Chahar Dangeh | 271,711 | 283,019 |

| Malard–Kahrizak | 320,951 | 345,877 |

| Malard–Lavasan | 380,016 | 391,505 |

| Malard–Pardis | 430,122 | 442,000 |

| Malard–Shahr-e Qods | 170,700 | 180,201 |

| Malard–Varamin | 401,312 | 421,109 |

| Malard–Fardis | 80,200 | 88,201 |

| Malard–Shahr-e Rey | 310,022 | 320,800 |

| Pishva–Tehran | 340,248 | 369,711 |

| Pishva–Damavand | 480,120 | 502,011 |

| Pishva–Abali | 470,144 | 492,555 |

| Pishva–Islamshahr | 350,022 | 372,966 |

| Pishva–Baqershahr | 320,035 | 352,001 |

| Pishva–Bumehen | 450,140 | 480,015 |

| Pishva–Robat Karim | 390,280 | 411,255 |

| Pishva–Pakdasht | 210,990 | 229,911 |

| Pishva–Rudehen | 469,188 | 488,544 |

| Pishva–Chahar Dangeh | 331,031 | 351,211 |

| Pishva–Kahrizak | 320,901 | 355,800 |

| Pishva–Lavasan | 410,322 | 439,103 |

| Pishva–Pardis | 400,994 | 410,122 |

| Pishva–Shahr-e Qods | 430,814 | 419,101 |

| Pishva–Varamin | 50,824 | 60,813 |

| Pishva–Fardis | 440,814 | 479,101 |

| Pishva–Shahr-e Rey | 540,814 | 579,122 |

Table 12.

Capacity of facilities

| Suppliers | |

| Isfahan | 500,000 |

| Yazd | 300,000 |

| Tehran | 600,000 |

| Factories | |

| Tehran | 1,000,000 |

| Saveh | 800,000 |

| Kashan | 500,000 |

| Recycling/landfilling | |

| Damavand | 300,000 |

| Tehran | 4,500,000 |

| Km 17 Jade Makhsous | 260,000 |

Table 13.

The capacity of facilities

| Collection/Distribution | |

|---|---|

| Damavand | 320,000 |

| Abali | 100,000 |

| Islamshahr | 300,000 |

| Baqershahr | 500,000 |

| Bumehen | 400,000 |

| Robat Karim | 600,000 |

| Pakdasht | 660,400 |

| Rudehen | 370,000 |

| Chahar Dangeh | 200,000 |

| Tehran | 802,000 |

| Kahrizak | 530,000 |

| Lavasan | 570,000 |

| Pardis | 609,000 |

| Shahr-e Qods | 800,090 |

| Varamin | 302,000 |

| Fardis | 430,000 |

| Shahr-e Rey | 505,800 |

| Damavand | 779,000 |

Table 14.

Distance between facilities (suppliers–factories)

| Km | f1: Kashan | f2: Saveh | f3: Tehran |

|---|---|---|---|

| S1: Tehran | 246 | 135 | 14.8 |

| S2: Isfahan | 209 | 310 | 437 |

| S3: Yazd | 381 | 563 | 624 |

Table 15.

Distance between facilities (factories–CDCs)

| Km | f1: Kashan | f2: Saveh | f3: Tehran |

|---|---|---|---|

| CDC1: Tehran | 246 | 135 | 15.5 |

| CDC2: Damavand | 313 | 209 | 73 |

| CDC3: Abali | 302 | 200 | 64 |

| CDC4: Islamshahr | 229 | 111 | 27 |

| CDC5: Baqershahr | 230 | 130 | 24 |

| CDC6: Bumehen | 293 | 189 | 52 |

| CDC7: Robat Karim | 221 | 95 | 41 |

| CDC8: Pakdasht | 230 | 146 | 43 |

| CDC9: Rudehen | 295 | 191 | 54 |

| CDC10: Chahar Dangeh | 239 | 122 | 14 |

| CDC11: Kahrizak | 225 | 125 | 27 |

| CDC12: Lavasan | 276 | 172 | 37 |

| CDC13: Pardis | 288 | 183 | 46 |

| CDC14: Shahr-e Qods | 264 | 127 | 28 |

| CDC15: Varamin | 207 | 166 | 56 |

| CDC16: Fardis | 254 | 124 | 47 |

| CDC17: Shahr-e Rey | 243 | 139 | 17 |

Table 16.

Distance between facilities (CDCs–Customers)

| Km | Customer 1, Tehran (Center) | Customer 2, Tehran (Center) | Customer 3, Tehran (Center) | Customer 4, Shemiranat (North) | Customer 5, Baqershahr (South) | Customer 6, Pardis (East) | Customer 7, Malard (West) | Customer 8, Pishva (Southeast) | Customer 9, Islamshahr (Southwest) | Customer 10, Lavasan (Northeast) |

|---|---|---|---|---|---|---|---|---|---|---|

| CDC1: Tehran | 9.6 | 20 | 2.5 | 16 | 24 | 45 | 44 | 64 | 26 | 45 |

| CDC2: Damavand | 75 | 70.9 | 80 | 70 | 85 | 31.5 | 119 | 117 | 98 | 31 |

| CDC3: Abali | 64 | 60 | 69 | 61 | 74 | 20 | 106 | 107 | 84.6 | 20 |

| CDC4: Islamshahr | 32 | 41 | 26 | 41.5 | 25 | 73.6 | 37 | 68 | 6 | 73 |

| CDC5: Baqershahr | 30 | 40.2 | 27.4 | 40 | 4.5 | 60 | 59 | 49 | 27.1 | 60 |

| CDC6: Bumehen | 53.3 | 49 | 59 | 49 | 64 | 9.3 | 96 | 96 | 74 | 9.3 |

| CDC7: Robat Karim | 46 | 56 | 41 | 56 | 64 | 87 | 26 | 80 | 18 | 87 |

| CDC8: Pakdasht | 43 | 52 | 45 | 52 | 38 | 69.2 | 80 | 32 | 53 | 69 |

| CDC9: Rudehen | 57 | 53.2 | 62 | 53.4 | 68 | 13 | 103.4 | 100 | 78.7 | 13 |

| CDC10: Chahar Dangeh | 18 | 27.9 | 13 | 32 | 18.3 | 59 | 40 | 60 | 12 | 59 |

| CDC11: Kahrizak | 28 | 38 | 26 | 41 | 5.2 | 65 | 57 | 54 | 24 | 65 |

| CDC12: Lavasan | 36 | 26 | 41 | 26 | 50 | 41 | 79 | 82 | 60 | 41 |

| CDC13: Pardis | 45.2 | 41 | 50 | 40 | 55 | 5.1 | 87.2 | 87 | 66 | 3 |

| CDC14: Shahr-e Qods | 33 | 38 | 25 | 38.2 | 42 | 76 | 22 | 84 | 35 | 76 |

| CDC15: Varamin | 57 | 67.4 | 57 | 67 | 45 | 85 | 88 | 9.9 | 58 | 85 |

| CDC16: Fardis | 49 | 55.4 | 44 | 55 | 58 | 93 | 8.4 | 100 | 39 | 93 |

| CDC17: Shahr-e Rey | 22 | 31 | 20 | 31 | 10.7 | 52 | 51 | 47 | 25 | 52 |

We have selected ten customers as a sample, among too many customers

Table 17.

Distance between facilities (CDCs–RLCs)

| Km | RLC1: Damavand | RLC2: Tehran | RLC3: Km 17 Jade Makhsous |

|---|---|---|---|

| CDC1: Tehran | 71 | 10 | 17 |

| CDC2: Damavand | 6.8 | 71 | 103 |

| CDC3: Abali | 21 | 64 | 83 |

| CDC4: Islamshahr | 96 | 27 | 27 |

| CDC5: Baqershahr | 85 | 24 | 37 |

| CDC6: Bumehen | 21 | 52 | 73 |

| CDC7: Robat Karim | 111 | 41 | 39 |

| CDC8: Pakdasht | 94 | 43 | 61 |

| CDC9: Rudehen | 21 | 54 | 77 |

| CDC10: Chahar Dangeh | 84 | 14 | 44 |

| CDC11: Kahrizak | 91 | 27 | 38 |

| CDC12: Lavasan | 68 | 37 | 74 |

| CDC13: Pardis | 31 | 46 | 69 |

| CDC14: Shahr-e Qods | 101 | 28 | 35 |

| CDC15: Varamin | 110 | 56 | 68 |

| CDC16: Fardis | 119 | 47 | 21 |

| CDC17: Shahr-e Rey | 75 | 17 | 33 |

Table 18.

Minimum percentage of units of the returned product to be remanufactured, recycled, and landfilled

| 0.3 | |

| 0.2 |

Table 19.

Demand of customers

| Average demand of customers in a month | 120 |

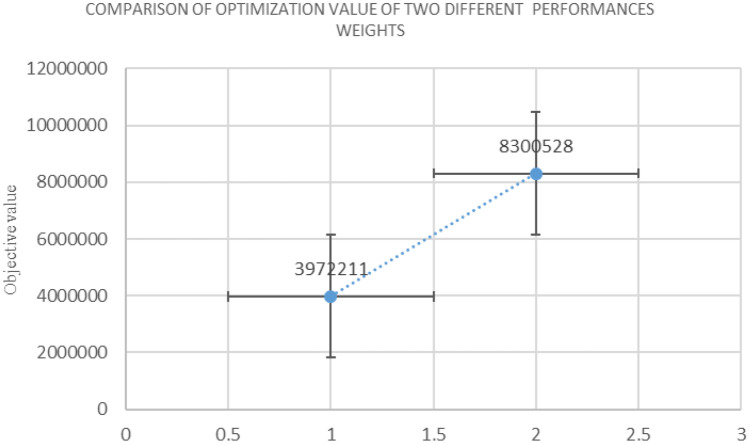

The software output of the case study is illustrated in Table 20 and Fig. 4.

Table 20.

Weighted sum method outputs

| Environment performance weight | Economic performance weight | Environment optimization value | Economic optimization value | |

|---|---|---|---|---|

| 1 | 0.1 | 0.9 | 11.27E + 13 | 1.08E + 13 |

| 2 | 0.2 | 0.8 | 9.44E + 13 | 2.17E + 13 |

| 3 | 0.3 | 0.7 | 8.50E + 13 | 3.25E + 13 |

| 4 | 0.4 | 0.6 | 7.20E + 13 | 4.33E + 13 |

| 5 | 0.5 | 0.5 | 7.11E + 13 | 5.41E + 13 |

| 6 | 0.6 | 0.4 | 6.02E + 13 | 6.49E + 13 |

| 7 | 0.7 | 0.3 | 4.09E + 13 | 7.58E + 13 |

| 8 | 0.8 | 0.2 | 3.17E + 13 | 8.66E + 13 |

| 9 | 0.9 | 0.1 | 2.08E + 13 | 9.74E + 13 |

Fig. 4.

Software output for economic and environment optimization values

Numerical Example

The efficiency of the mathematical model in small dimensions is demonstrated and analyzed through a numerical example. There are five types of facilities in the closed-loop network (CLN) in the numerical example, namely suppliers (S), factories (F), collection/distribution centers (CDC), recycling/landfill centers (RLC), and customers (C). There are three potential locations for supply chain facilities (F, CDC, RLC), and existing S and C are given. Tables 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34,and 35 show the required data for modeling and the results, as follows:

S, suppliers (s = 1, 2, 3, 4, 5, 6, 7)

F, potential factories (f = 1, 2, 3, 4, 5, 6, 7, 8, 9, 10)

I, potential CDCs (i = 1, 2, 3, 4, 5, 6, 7, 8)

C, customers (c = 1, 2, 3, 4, 5)

B, potential RLCs (b = 1, 2, 3, 4)

TS, shipping alternatives from suppliers (ts = 1, 2, 3, 4, 5, 6)

TF, shipping alternatives from factories (tf = 1, 2, 3, 4, 5, 6, 7, 8, 9)

TI, shipping alternatives from CDCs (ti = 1, 2)

TC, shipping alternatives from customers (tc = 1, 2, 3)

Table 21.

Data sources

Table 22.

The computational process for optimization purposes is conducted through Lingo software

| Lingo version | 19.0 |

| Operating system | Windows |

| Bit size | 64 |

| CPU | × 64 |

| File size | 40.3 MB |

Table 23.

The demand of customers

| d1 | 15 |

| d2 | 18 |

| d3 | 20 |

| d4 | 25 |

| d5 | 17 |

Table 24.

Fixed costs for opening facility

| In € | |

|---|---|

| f1 | 60,000 |

| f2 | 210,500 |

| f3 | 100,000 |

| f4 | 230,000 |

| f5 | 190,000 |

| f6 | 80,100 |

| f7 | 200,400 |

| f8 | 206,000 |

| f9 | 50,500 |

| f10 | 170,300 |

| i1 | 15,000 |

| i2 | 16,500 |

| i3 | 17,000 |

| i4 | 18,000 |

| i5 | 20,000 |

| i6 | 19,100 |

| i7 | 14,400 |

| i8 | 18,000 |

| b1 | 10,000 |

| b2 | 10,500 |

| b3 | 12,000 |

| b4 | 13,500 |

Table 25.

Variable and hygienic costs

| Vs in €/ton | HVs in €/ton | Vf in €/ton | HVf in €/ton | Vrf in €/ton | HVrf in €/ton | Vi in €/ton | HVi in €/ton | Vri in €/ton | HVri in €/ton | Vb in €/ton | HVb in €/ton | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| s1 | 60.10 | 10.18 | ||||||||||

| s2 | 75.12 | 12.18 | ||||||||||

| s3 | 88.12 | 09.14 | ||||||||||

| s4 | 47.98 | 06.18 | ||||||||||

| s5 | 97.18 | 06.18 | ||||||||||

| s6 | 42.98 | 14.17 | ||||||||||

| s7 | 55.19 | 13.15 | ||||||||||

| f1 | 60.18 | 12.04 | 40.18 | 17.18 | ||||||||

| f2 | 30.08 | 14.19 | 57.22 | 09.87 | ||||||||

| f3 | 36.00 | 09.18 | 58.13 | 08.13 | ||||||||

| f4 | 82.19 | 08.18 | 32.19 | 12.29 | ||||||||

| f5 | 23.12 | 11.10 | 45.20 | 10.03 | ||||||||

| f6 | 32.18 | 10.09 | 42.17 | 11.28 | ||||||||

| f7 | 37.19 | 14.13 | 38.18 | 17.17 | ||||||||

| f8 | 66.18 | 15.10 | 31.14 | 13.18 | ||||||||

| f9 | 32.18 | 16.12 | 32.10 | 19.13 | ||||||||

| f10 | 70.18 | 18.32 | 33.18 | 10.92 | ||||||||

| i1 | 24.13 | 17.25 | 30.14 | 03.186 | ||||||||

| i2 | 27.18 | 16.08 | 42.11 | 07.107 | ||||||||

| i3 | 50.17 | 10.11 | 52.16 | 09.08 | ||||||||

| 4 | 10.45 | 09.22 | 31.12 | 09.99 | ||||||||

| i5 | 29.90 | 11.92 | 39.10 | 11.16 | ||||||||

| i6 | 30.00 | 08.18 | 40.10 | 13.88 | ||||||||

| i7 | 31.11 | 08.19 | 60.18 | 15.10 | ||||||||

| i8 | 23.72 | 10.00 | 29.78 | 16.10 | ||||||||

| b1 | 18.10 | 12.10 | ||||||||||

| b2 | 20.55 | 13.73 | ||||||||||

| b3 | 15.70 | 05.14 | ||||||||||

| b4 | 42.99 | 08.08 |

Table 26.

Unit shipping cost with a hygiene protocol

| In €/ton | |

|---|---|

| ts1 | 11.24 |

| ts2 | 08.56 |

| ts3 | 18.56 |

| ts4 | 38.56 |

| ts5 | 18.56 |

| ts6 | 28.56 |

| tf1 | 20.56 |

| tf2 | 50.56 |

| tf3 | 58.56 |

| tf4 | 07.56 |

| tf5 | 18.56 |

| tf6 | 19.56 |

| tf7 | 58.08 |

| tf8 | 14.98 |

| tf9 | 19.53 |

| ti1 | 70.56 |

| ti2 | 19.56 |

| tc1 | 30.56 |

| tc2 | 32.56 |

| tc3 | 43.56 |

Table 27.

CO2 released due to the activities of facilities

| Emission in kg | |

|---|---|

| s1 | 814,200 |

| s2 | 900,005 |

| s3 | 712,235 |

| s4 | 700,205 |

| s5 | 812,235 |

| s6 | 700,205 |

| s7 | 800,205 |

| f1 | 794,185 |

| f2 | 994,111 |

| f3 | 854,182 |

| f4 | 630,283 |

| f5 | 752,889 |

| f6 | 894,180 |

| f7 | 794,185 |

| f8 | 792,889 |

| f9 | 994,185 |

| f10 | 894,185 |

| erf1 | 412,235 |

| erf2 | 308,205 |

| erf3 | 212,295 |

| erf4 | 500,205 |

| erf5 | 401,207 |

| erf6 | 420,000 |

| erf7 | 407,205 |

| erf8 | 518,805 |

| erf9 | 312,139 |

| erf10 | 508,205 |

| i1 | 612,235 |

| i2 | 508,205 |

| i3 | 712,295 |

| i4 | 500,205 |

| i5 | 401,207 |

| i6 | 420,000 |

| i7 | 607,205 |

| i8 | 618,805 |

| eri1 | 212,239 |

| eri2 | 204,405 |

| eri3 | 213,395 |

| eri4 | 302,205 |

| eri5 | 101,207 |

| eri6 | 120,000 |

| eri7 | 212,235 |

| eri8 | 308,205 |

| b1 | 712,235 |

| b2 | 860,203 |

| b3 | 612,212 |

| b4 | 700,205 |

Table 28.

Shipping rates (Emission factors)

| Transport mode | gCO2 (tonnes/km) |

|---|---|

| ts1 | 62.3 |

| ts2 | 22.8 |

| ts3 | 16.9 |

| ts4 | 34.6 |

| ts5 | 31.5 |

| ts6 | 21.3 |

| tf1 | 80.3 |

| tf2 | 22.8 |

| tf3 | 16.9 |

| tf4 | 34.6 |

| tf5 | 31.5 |

| tf6 | 100.3 |

| tf7 | 62.4 |

| tf8 | 62.3 |

| tf9 | 16.9 |

| ti1 | 22.8 |

| ti2 | 21.8 |

| tc1 | 34.6 |

| tc2 | 18.8 |

| tc3 | 21.3 |

CO2 emissions = CO2 released by shipping alternative distance shipping rates

Table 29.

CO2 released by a shipping alternative

| Transport mode | Emission in tonnes |

|---|---|

| ts1 | 0.35 |

| ts2 | 0.40 |

| ts3 | 0.36 |

| ts4 | 0.37 |

| ts5 | 0.27 |

| ts6 | 0.42 |

| tf1 | 0.52 |

| tf2 | 0.40 |

| tf3 | 0.36 |

| tf4 | 0.37 |

| tf5 | 0.27 |

| tf6 | 0.67 |

| tf7 | 0.39 |

| tf8 | 0.35 |

| tf9 | 0.20 |

| ti1 | 0.40 |

| ti2 | 0.44 |

| tc1 | 0.37 |

| tc2 | 0.19 |

| tc3 | 0.42 |

Table 30.

Minimum percent of the returned product to be remanufactured, recycled, and landfilled

| 0.4 | |

| 0.3 |

Table 31.

Maximum capacity limits of facilities

| s1 | 700 |

| s2 | 800 |

| s3 | 720 |

| s4 | 670 |

| s5 | 700 |

| s6 | 780 |

| s7 | 900 |

| Mf1 | 500 |

| Mf2 | 450 |

| Mf3 | 630 |

| Mf4 | 700 |

| Mf5 | 530 |

| Mf6 | 550 |

| Mf7 | 600 |

| Mf8 | 610 |

| Mf9 | 500 |

| Mf10 | 400 |

| i1 | 590 |

| i2 | 550 |

| i3 | 400 |

| i4 | 620 |

| i5 | 750 |

| i6 | 890 |

| i7 | 750 |

| i8 | 480 |

| b1 | 290 |

| b2 | 355 |

| b3 | 420 |

| b4 | 320 |

| Mrf1 | 400 |

| Mrf2 | 420 |

| Mrf3 | 620 |

| Mrf4 | 680 |

| Mrf5 | 410 |

| Mrf6 | 540 |

| Mrf7 | 520 |

| Mrf8 | 390 |

| Mrf9 | 400 |

| Mrf10 | 260 |

Table 32.

Distance between facilities (Suppliers–Factories)

| Km | s1 | s2 | s3 | s4 | s5 | s6 | s7 |

|---|---|---|---|---|---|---|---|

| f1 | 100 | 210 | 350 | 500 | 620 | 650 | 700 |

| f2 | 210 | 90 | 500 | 49 | 410 | 109 | 69 |

| f3 | 380 | 420 | 320 | 120 | 400 | 59 | 870 |

| f4 | 422 | 80 | 320 | 950 | 610 | 520 | 300 |

| f5 | 30 | 700 | 870 | 532 | 273 | 100 | 501 |

| f6 | 670 | 320 | 189 | 983 | 901 | 293 | 422 |

| f7 | 220 | 100 | 540 | 623 | 600 | 187 | 610 |

| f8 | 190 | 729 | 902 | 333 | 439 | 873 | 436 |

| f9 | 550 | 503 | 900 | 289 | 287 | 672 | 780 |

| f10 | 321 | 444 | 198 | 302 | 624 | 290 | 910 |

Table 33.

Distance between facilities (Factories–CDCs)

| Km | f1 | f2 | f3 | f4 | f5 | f6 | f7 | f8 | f9 | f10 |

|---|---|---|---|---|---|---|---|---|---|---|

| i1 | 327 | 629 | 102 | 320 | 211 | 155 | 114 | 320 | 210 | 765 |

| i2 | 134 | 219 | 199 | 160 | 140 | 140 | 320 | 410 | 420 | 346 |

| i3 | 325 | 382 | 134 | 560 | 610 | 167 | 605 | 204 | 211 | 211 |

| i4 | 267 | 218 | 122 | 750 | 640 | 124 | 328 | 258 | 320 | 257 |

| i5 | 378 | 346 | 989 | 420 | 860 | 108 | 888 | 932 | 406 | 315 |

| i6 | 901 | 200 | 700 | 600 | 210 | 153 | 620 | 510 | 603 | 852 |

| i7 | 108 | 130 | 166 | 128 | 180 | 120 | 413 | 120 | 130 | 210 |

| i8 | 222 | 210 | 720 | 800 | 269 | 113 | 190 | 220 | 210 | 311 |

Table 34.

Distance between facilities (CDCs–Customers)

| Km | i1 | i2 | i3 | i4 | i5 | i6 | i7 | i8 |

|---|---|---|---|---|---|---|---|---|

| c1 | 202 | 56 | 45 | 230 | 416 | 219 | 235 | 198 |

| c2 | 199 | 68 | 110 | 519 | 255 | 132 | 120 | 120 |

| c3 | 90 | 201 | 107 | 218 | 315 | 279 | 55 | 110 |

| c4 | 180 | 90 | 114 | 140 | 240 | 300 | 80 | 85 |

| c5 | 207 | 70 | 308 | 107 | 107 | 130 | 200 | 95 |

Table 35.

Distance between facilities (CDCs–RLCs)

| Km | i1 | i2 | i3 | i4 | i5 | i6 | i7 | i8 |

|---|---|---|---|---|---|---|---|---|

| b1 | 102 | 55 | 45 | 230 | 319 | 219 | 325 | 98 |

| b2 | 199 | 68 | 210 | 219 | 155 | 132 | 120 | 120 |

| b3 | 90 | 201 | 107 | 218 | 115 | 279 | 55 | 110 |

| b4 | 280 | 100 | 114 | 340 | 400 | 400 | 90 | 70 |

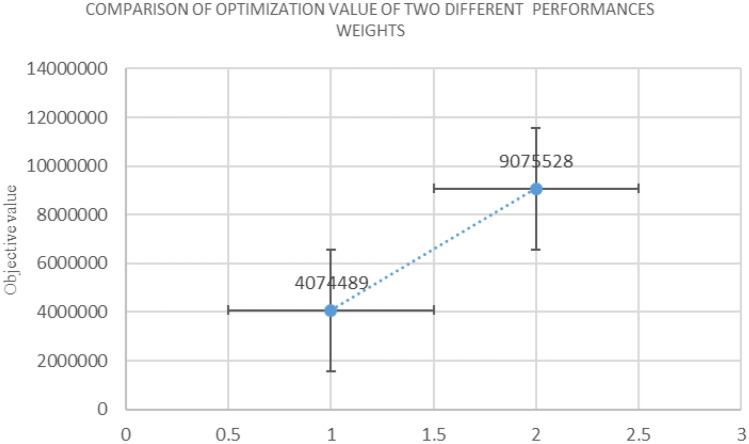

Table 36 shows the results of solving the model with LINGO for different objective weights.

Table 36.

Results of solving the GSC model with Lingo during the COVID-19 pandemic (Different objective weights)

| Objective | Σwi = 1 | Σwi = 1 |

| Economic performance | 0.7030 | 0.2970 |

| Environmental performance | 0.2970 | 0.7030 |

| Objective value | Z*1 = 4,074,489, Z*2 = 9,075,528 | Z*1 = 3,972,211, Z*2 = 8,300,528 |

wi is generated randomly or determined by the DMs

In Fig. 5, you can see the problem in the small dimension.

Fig. 5.

A closed-loop network in small dimensions displayed

Optimization values of numerical examples are illustrated in Figs. 6 and 7.

Fig. 6.

The comparison between economic and environmental performances of numerical examples based on the importance of economic factors

Fig. 7.

The comparison between economic and environmental performances of numerical examples based on the importance of environmental factors

Discussion and Analysis

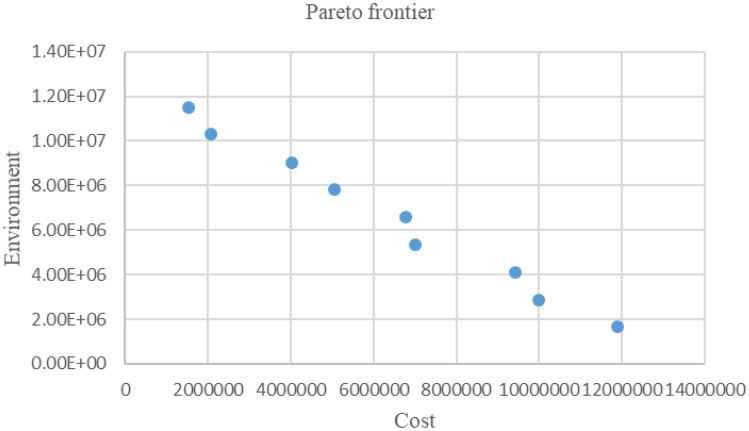

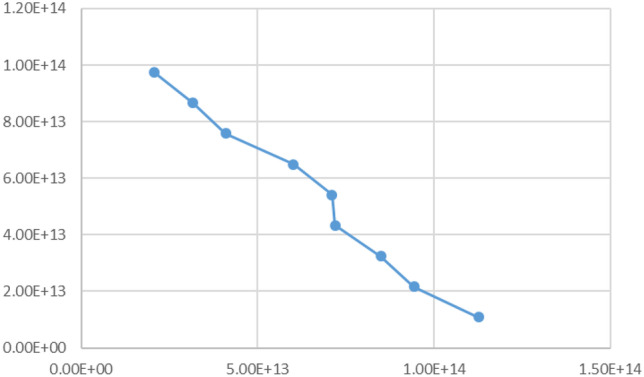

Sensitivity Analysis of wi

Lingo software is used to conduct the computation. The WSM determines different approximations of the POF. In this case, two weights (w1 and w2) exist because of two objective functions. It is noticeable that w1 and w2 are ≥ 0 and w1 + w2 is equal to 1. The performances with different weights are shown in Table 37, and the Pareto frontier is illustrated in Fig. 8.

Table 37.

Performances with different weights

| Pareto point | Environment performance weights | Economic performance weights | Environment optimization value | Economic optimization value |

|---|---|---|---|---|

| 1 | 0.1 | 0.9 | 1,522,877 | 1.15E + 07 |

| 2 | 0.2 | 0.8 | 2,079,644 | 1.03E + 07 |

| 3 | 0.3 | 0.7 | 4,018,883 | 9,038,574 |

| 4 | 0.4 | 0.6 | 5,043,115 | 7,806,791 |

| 5 | 0.5 | 0.5 | 6,775,999 | 6,575,008 |

| 6 | 0.6 | 0.4 | 7,006,990 | 5,343,225 |

| 7 | 0.7 | 0.3 | 9,432,224 | 4,111,443 |

| 8 | 0.8 | 0.2 | 1.00E + 07 | 2,879,660 |

| 9 | 0.9 | 0.1 | 1.19E + 07 | 1,647,877 |

Fig. 8.

Sensitivity analysis for different weights of environment and economic aspects

Comparison of Optimization Value

Economic and environmental aspects are compared separately for the optimization value (OV) of performance. Weights were assigned to other aspects in each step. The optimization value of the economic and environmental objectives is shown in Table 38.

Table 38.

Economic and environmental aspects

| Objective | w1 = 1 | w2 = 1 |

| Economic | 1 | 0 |

| Environmental | 0 | 1 |

| Optimization value | Z*1 = 416,094.0 | Z*1 = 451,170.0 |

| Z*2 = 0.1273392E + 0 | Z*2 = 0.1044302E + 0 |

Where w1 ≥ 0 and w2 ≥ 0 are weights such that w1 + w2 = 1, and f1 and f2 are the OFs.

The first assumption:

If w1 = 1, then:

The second assumption:

If w2 = 1, then:

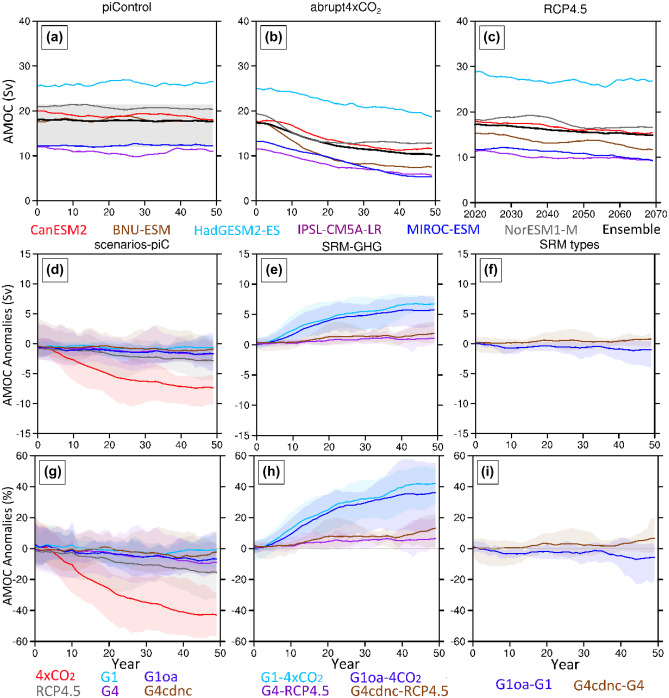

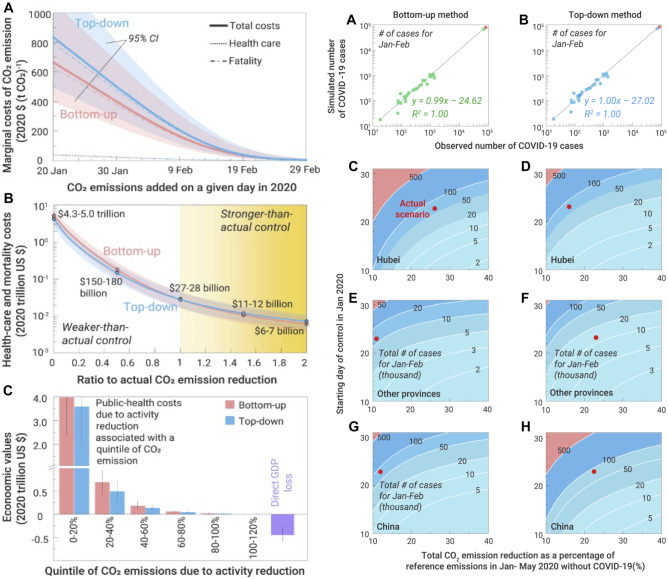

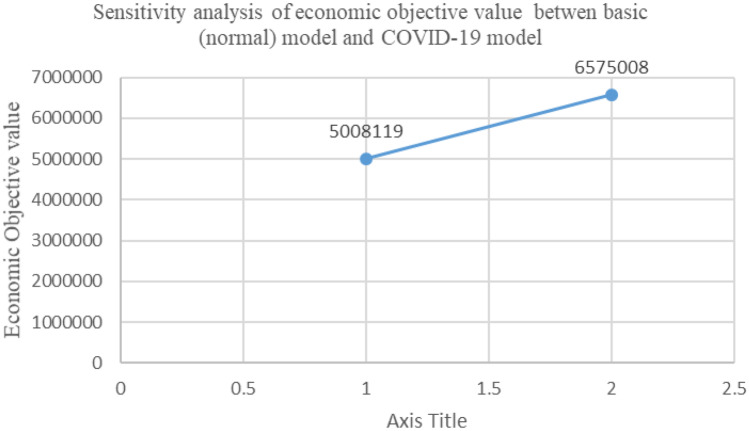

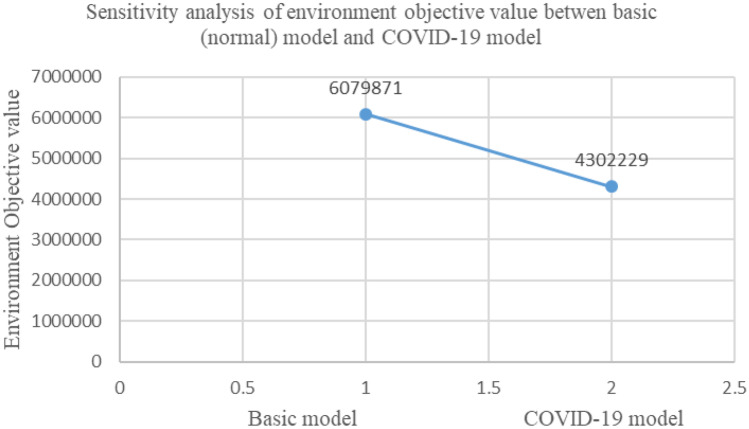

Sensitivity Analysis (Base Model/COVID-19 Model)

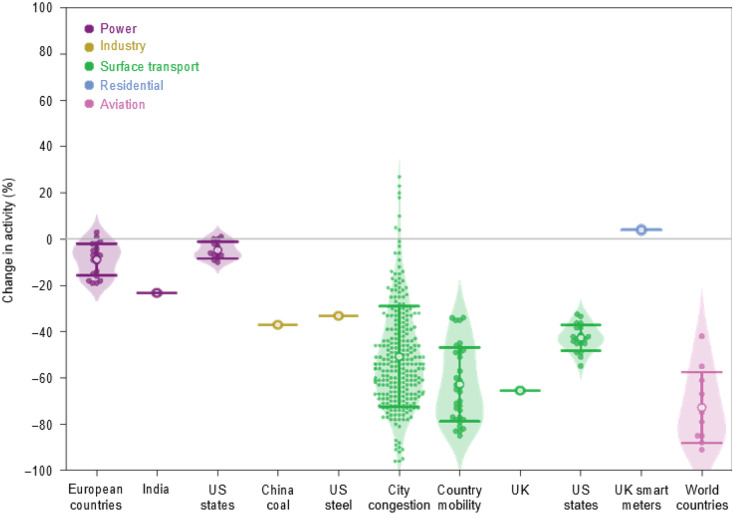

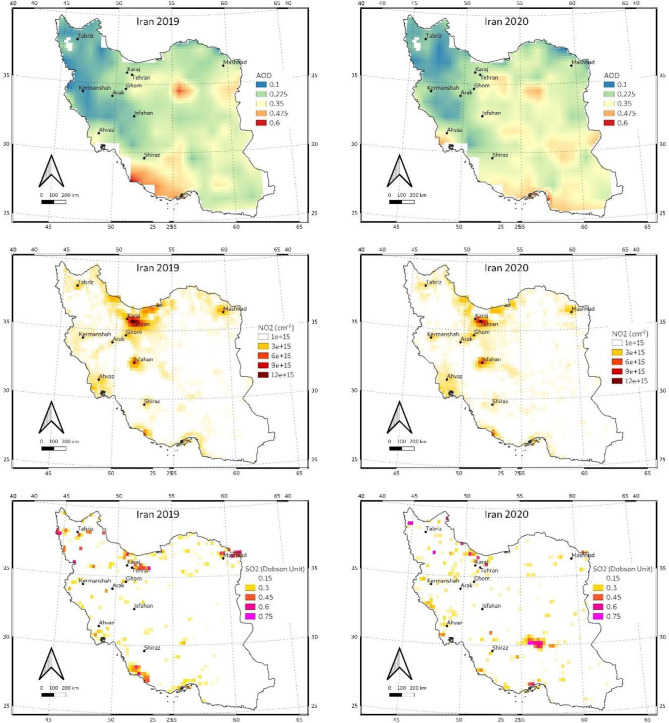

Optimal values have been compared between the COVID-19 condition model and the normal condition model. For more information, see Table 39. The mathematical model compared economic and environmental performances during the COVID-19 pandemic and under normal conditions. This paper presented a more realistic model. Figures 9, 10, 11, 12, and 13 show the relationships between COVID-19 and its environmental effects. The economic and environmental objective values are shown in Table 39 and Figs. 14 and 15.

Table 39.

Basic and COVID-19 condition model

| Without considering COVID-19 | Considering the COVID-19 (Current Research) |

|---|---|

| Normal fixed, variable, and shipping costs | Fixed, variable, shipping, and hygienic costs concerning prevention and control of COVID-19 (disinfection and sanitizer costs, PPE costs, COVID-19 test costs, costs of COVID-19 education, costs of COVID-19 medicines, vaccine, and vaccination) |

| Normal CO2 released | CO2 released concerning the lockdown days (reduction of CO2 emissions) |

| Economic objective value = 5,008,119 | Economic objective value = 6,575,008 |

| Environment objective value = 6,079,871 | Environment objective value = 4,302,229 |

Fig. 9.

a-i Relationship between gas emissions and COVID-19 [88]

Fig. 10.

- Analysis of the relationship between total CO2 emissions due to activities and COVID-19 [89]

Fig. 11.

CO2 emission in India during the COVID-19 pandemic [90]

Fig. 12.

Fig. 13.

Iran's average GHG emissions between March 21 and April 21, 2019 and 2020 [93]

Fig. 14.

Sensitivity analysis of the economic objective value

Fig. 15.

Sensitivity analysis of the environment objective value

Findings

The summary of the paper’s findings is as follows:

To determine the optimal trade-off between economic and environmental aspects during the COVID-19 pandemic and lockdowns, a mathematical model for GSC was designed.

Incorporating hygiene into the SC design

In this study, we examined two aspects of sustainability that are negatively and positively affected by COVID-19 and lockdowns.

Implications for Managers and Practical Suggestions

This research can lead to valuable policies for disaster management, particularly in COVID-19 conditions, such as:

-

i.

The proposed model allows managers to make informed decisions and determine the cost/CO2 emission trade-off during the COVID-19 pandemic.

-

ii.

In making their COVID-19 cost estimates, SC managers should account for hygienic costs.

-

iii.

When disasters or emergencies like COVID-19 occur, managers should be able to replace tools and methods.

This study’s results contribute to SC management’s performance during the COVID-19 pandemic.

Conclusion and Outlook

COVID-19 is an exceptional and extraordinary event that impacts the SC. In this study, we proposed a GCLSCN during the COVID-19 pandemic. The MOMIP model can show the trade-offs between total cost and total CO2 emissions during the pandemic and lockdowns. This model is sensitive to the cost structure. The cost includes two parts: normal cost without considering the coronavirus pandemic and the cost with considering coronavirus, including disinfection and sanitizer costs, PPE costs, COVID-19 test costs, costs of COVID-19 education, and costs of COVID-19 vaccine. A case study and numerical example have illustrated the validation of the presented model. The optimization value with different weight performances is calculated, and wi (weight) sensitivity analysis is also measured. The proposed model is solved with Lingo 19.0 software. For the optimization value of performance, we compare the economic and environmental aspects separately. In each step, we allocated the weight of the function to other aspects. The findings of the proposed network illustrate the SC has become greener during the COVID-19 pandemic. The total cost of new SC was increased during the COVID-19 pandemic, but the lockdowns during the COVID-19 pandemic had direct positive effects on emissions and air quality. The findings of this paper included the following: designing the applied mathematical model of GSC to show better the trade-offs between economic and environmental aspects during the COVID-19 pandemic and lockdowns, designing the hygiene SC during the COVID-19 pandemic and lockdowns, and proposing the new indicators of economic aspects during the COVID-19 outbreak and lockdowns. At last, we find the impacts of COVID-19 and lockdowns on two aspects of sustainability. This paper presents a MOMIP model and COVID-19 pandemic issues in the CLSC framework. Therefore, this study designed a new and hygienic GSC model to fill this gap in the COVID-19 disaster. This is a mathematical article with a green approach aiming to propose guidelines for managers and scholars addressing SCM challenges during the COVID-19 disaster [12, 94, 95].

Limitations

We have some limitations in our work, which can be addressed by future research:

Data from only one real company was available to us.

Models are based on single-product networks.

The network design is one-period.

Insights into Future Work

Perspectives for future work can be done:

In future research, consider supply chain agility concepts.

Add more environmental aspects to this model.

Add the social aspects to the model. It can lead to a sustainable supply chain.

For future research, upgrade the model to include the multi-products and multi-periods.

Add the stochastic parameters for this model.

Author Contribution

Sina Abbasi: conceptualization, software, methodology, formal analysis, writing of original draft, and visualization; Maryam Daneshmand-Mehr: methodology, supervision, data curation, and validation; Armin Ghane Kanafi: software, formulation, validation, and editing.

Availability of Data and Materials

Not applicable.

Code Availability

Custom code by Lingo software was written for this study. It is available on request.

Declarations

Ethical Approval and Consent to Participate.

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Footnotes

This protocol was prepared by CEMEX based on the recommendations of the World Health Organization (WHO), external consultants, and the experience of the company itself.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.ECDC (2020). An overview of the rapid test situation for COVID-19 diagnosis in the EU/EEA.

- 2.Farooq MU, Hussain A, Masood T, Habib MS. Supply chain operations management in pandemics: A state-of-the-art review inspired by COVID-19. Sustainability. 2021;13(5):2504. doi: 10.3390/su13052504. [DOI] [Google Scholar]

- 3.Končar J, Grubor A, Marić R, Vučenović S, Vukmirović G. Setbacks to IoT implementation in the function of FMCG supply chain sustainability during COVID-19 pandemic. Sustainability. 2020;12(18):7391. doi: 10.3390/su12187391. [DOI] [Google Scholar]

- 4.Chiu CY, Cheng CY, Wu TY. Integrated operational model of green closed-loop supply chain. Sustainability. 2021;13(11):6041. doi: 10.3390/su13116041. [DOI] [Google Scholar]