Abstract

The COVID-19 pandemic has exerted great shocks and challenges to the environment, society and economy. Simultaneously, an intractable issue appeared: a considerable number of hazardous medical wastes have been generated from the hospitals, clinics, and other health care facilities, constituting a serious threat to public health and environmental sustainability without proper management. Traditional disposal methods like incineration, landfill and autoclaving are unable to reduce environmental burden due to the issues such as toxic gas release, large land occupation, and unsustainability. While the application of clean and safe pyrolysis technology on the medical wastes treatment to produce high-grade bioproducts has the potential to alleviate the situation. Besides, medical wastes are excellent and ideal raw materials, which possess high hydrogen, carbon content and heating value. Consequently, pyrolysis of medical wastes can deal with wastes and generate valuable products like bio-oil and biochar. Consequently, this paper presents a critical and comprehensive review of the pyrolysis of medical wastes. It demonstrates the feasibility of pyrolysis, which mainly includes pyrolysis characteristics, product properties, related problems, the prospects and future challenges of pyrolysis of medical wastes.

Keywords: COVID-19 pandemic, Medical wastes management, Biochar, Bio-oil, Environmental sustainability, Thermogravimetric analysis

Graphical abstract

Before the COVID-19 pandemic, medical wastes were often mixed with municipal solid waste and disposed of in waste landfills or improper treatment facilities. Many reviews have been devoted to the pyrolysis of plastics and other solid wastes. However, a review on the pyrolysis potential of medical wastes has not been reported previously, prompting its publication during this pandemic. Pyrolysis of medical wastes can deal with wastes and generate valuable products like bio-oil and biochar.

Nomenclature

- COVID-19

Coronavirus disease 2019

- DAEM

Distributed activation energy model

- EHI

Effective hydrogen index

- Eq

Equation

- FC

Fixed carbon

- Fig

Figure

- HDPE

High-density polyethylene

- HHV

Higher heating value

- LDPE

Low-density polyethylene

- LHV

Lower heating value

- MO

Moisture

- PAHs

Polycyclic aromatic hydrocarbons

- PCDDs

Polychlorinated dibenzo-p-dioxins

- PCDFs

Polychlorinated dibenzofurans

- PE

Polyethylene

- PET

Polyethylene terephthalate

- PMMA

Polymethyl methacrylate

- PO

Polyolefins

- PU

Polyurethanes

- PP

Polypropylene

- PS

Polystyrene

- PVC

Polyvinyl chloride

- Py-GC/MS

Pyrolysis–gas chromatography/mass spectrometry

- TGA

Thermogravimetric analysis

- US EPA

US Environmental Protection Agency

- VM

Volatile matter

- WHO

World Health Organization

1. Introduction

There is no doubt that the whole world has entered a new era since the global outbreak of Coronavirus Disease 2019 (COVID-19), as more than 109.47 million positive cases and over 2.41 million deaths have been confirmed at the moment of writing the paper (Johns Hopkins University (JHU), 2021). These numbers are increasing continuously every day because of the droplet and contact transmissions, which has an extensive impact on human lives (Wang et al., 2020a). This has also resulted in a series of health, socio-economic, and environmental problems (Mofijur et al., 2021). Among them, the disposal of medical wastes is a tremendous challenge for every nation. Before the global outbreak of COVID-19, it was reported that just hospitals in America produced over 5.9 million tons of medical wastes annually (Kargar et al., 2020b). Meanwhile, the amount of waste continues to rise because of many reasons other than the COVID-19, such as the increase of elderly population, the improvement of health awareness, the rise in medical services expenditure, and the development of medical technology (Patrício Silva et al., 2020; Peng et al., 2020). The global epidemic further exacerbated the situation, especially for the most affected countries like the USA, Brazil, India, the UK, France, Italy, China, and so on (Kumar et al., 2020b). For example, the generation of medical wastes explosively rose from 3.64 to 27.32 kg/day per 1000 persons in Wuhan since the outbreak of COVID-19, and the personal protective equipment like the protective suit, facemasks, nitrile gloves, safety goggles, and testing kits were the primary components of medical wastes (Di Maria et al., 2020; Singh et al., 2020; Yang et al., 2021).

World Health Organization (WHO) defines medical waste as the waste generated in the diagnosis, treatment or immunisation of human beings or animals (Mohee, 2005). They are hazardous and infectious refuse produced by hospitals, clinics and other medical institutions (Saeidi-Mobarakeh et al., 2020). The characteristics of these wastes include radioactivity, complexity, infectivity, and toxicity. These wastes have enormous potential to cause environmental pollution and health risks without proper management or treatment (Windfeld and Brooks, 2015). The novel coronavirus (SARS-CoV-2) has a high infection rate and strong survivability. People with minor symptoms or even asymptomatic infection possess the potential risk of transmitting the virus to others. Furthermore, the virus can survive for several days in numerous materials, including gloves, plastics, metal, silicon, and others, which significantly increases the risk and the difficulty of medical waste disposal (Lee et al., 2020b; van Doremalen et al., 2020). Therefore, considerable attention is required to be paid to every step, including medical wastes identification, collection, separation, storage, transportation, and final disposal (Sharma et al., 2020; Wei et al., 2020).

Due to the toxicity of medical wastes, countries worldwide have gradually enhanced the focus on the careful disposal of medical wastes. Subsequently, several technologies have been studied and developed (Moreira and Günther, 2013). Table 1 summarises the merits and demerits of the main seven disposal methods, including incineration, landfill, chemical disinfection, autoclaving, microwave, plasma, and pyrolysis (Hoque and Rahman, 2020). The incineration is the most extensively used technique, which can significantly cut down the mass of medical wastes with significant economic superiority and broad applicability. Unfortunately, ashes with toxic metals and poisonous gases are generated during the process, posing a severe threat to human health and the environment (Makarichi et al., 2018). Furthermore, the landfill is also widely applied due to its easy operation and low capital cost. However, it causes some undesirable effects like large land occupation, toxic gases release, and the risk of virus spread. With their pros and cons, the remaining four techniques have not been widely utilised in medical wastes disposal (Kargar et al., 2020a). In contrast to those traditional treatment technologies, clean and safe pyrolysis has shown enormous potential advantages, mainly associated with the improvement of efficiency, the generation of high value-added products, and environment-friendliness (Chand Malav et al., 2020; Imtenan et al., 2014).

Table 1.

The merits and demerits of the main disposal methods of medical wastes.

| Disposal methods | Advantages | Disadvantages |

|---|---|---|

| Incineration | Wide applicability, simple, mature, efficient technique, reduce the amount of waste largely | Toxic gas (especially dioxins, furans and mercury) release, produce ash with toxic metals |

| Landfill | Simple and mature technology, economical and convenient disposal method | Non-sustainability, risk of virus spread, large land occupation, poisonous gases emissions, dusts generation |

| Chemical disinfection | Small influence on the environment, broad sterilisation spectrum, high efficiency | High agent costs and equipment investment, produce toxic gases and liquids, residual disinfectants, cannot reduce the volume of medical wastes |

| Autoclaving | Well-established technology, good sterilisation, strong penetration | Produce toxic gases and liquids, cannot reduce the volume of medical wastes |

| Microwave disinfection | High efficiency, good sterilisation, low pollution | Huge capital investment, high running cost, reduce a small volume of medical wastes |

| Plasma | Reduce the volume of waste largely, good sterilisation | Huge capital investment and running cost, NOx generation |

| Pyrolysis | High efficiency and sustainability, high value-added products, broad applicability | High pre-treatment cost and energy consumption |

Pyrolysis is treated as a potential waste disposal technology and the best energy recovery method, which is thermal degradation of organic material by cracking the chemical bonds in an anaerobic environment (Sharifzadeh et al., 2019). Pyrolysis can produce a series of high value products, including biochar, bio-oil , biogas, and other chemicals. Based on the operating conditions, pyrolysis is divided into slow, fast and flash pyrolysis, and products distribution is highly affected by the type of pyrolysis (Ong et al., 2020a; Zhang et al., 2020). Thus, pyrolysis has been considered as a practical and cheap method to produce bio-oil and high value-added chemical products owing to the superiorities of high conversion efficiency, unstrict conditions and eco-friendly (Lee et al., 2020c). Meanwhile, the addition of catalyst can considerably improve the product quality via the reduction of oxygenous and nitrogenous compounds. Moreover, many studies have illustrated that co-pyrolysis with suitable feedstocks has a remarkable promotion on the properties of bio-oil, too (Ahmed et al., 2020; Sipra et al., 2018).

In the past, medical wastes were often mixed with municipal solid waste and disposed of in waste landfills or improper treatment facilities (Jang et al., 2006). However, this epidemic has shown the authorities worldwide the importance of proper management of medical wastes because of its potential in creating environmental hazards and public health risks. In consideration of the urgency of medical wastes disposal and the strengths of the pyrolysis process, pyrolysis is deemed as an optimal approach to deal with medical wastes and influence the environment positively. The literature on pyrolysis of plastics, microalgae, tire, lignocellulosic biomass and municipal solid waste have been published extensively (Anuar Sharuddin et al., 2016; Arabiourrutia et al., 2020; Azizi et al., 2018a; Dhyani and Bhaskar, 2018; Kumar et al., 2020a; Lee et al., 2020a; Li et al., 2019; Wang et al., 2017; Yang et al., 2019). However, a review on the pyrolysis of medical wastes has not been reported, even with the above-mentioned number of literature. Consequently, this paper provides a critical and comprehensive review of the medical wastes pyrolysis. The characterisation of medical wastes is presented. Moreover, the pyrolysis characteristics, products, and related problems of medical wastes pyrolysis are introduced. Finally, the prospects and future challenges of medical wastes pyrolysis are thoroughly discussed. Comprehensive analysis on the pyrolysis of medical wastes and the characteristics of products can provide the foundation for the sustainable management and scientific disposal of hazardous medical wastes.

2. Characteristics of medical wastes

Heterogeneity is the most overriding characteristic of medical wastes because the composition of medical wastes is extremely complex and dependent on many factors, such as season, location, hospital patterns, and so on (Zroychikov et al., 2018). Table 2 lists the range of each component contents based on the literature survey. Plastics, papers and textiles are the three main components of medical wastes. They are raw materials for the most common sanitary consumables in hospital, such as medical bottles, drug packaging, bedding, and toilet papers (Chen et al., 2013). Generally, the plastics existed in medical wastes are polyvinylchloride (PVC), polyurethanes (PU), polystyrene (PS), polyethylene terephthalate (PET), polyolefins (PO), and polyethylene (PE), all of them are ideal feedstocks for pyrolysis (Dash et al., 2015). In addition, papers and textiles are typical lignocellulosic biomasses, which are treated as environmental-friendly, economically feasible, and potentially carbon-neutral feedstock materials for generating the renewable biofuels (Abraham et al., 2020). Furthermore, it is reported that the bulk density of medical wastes is about 249 kg/m3, while and the content of moisture is around 44.75 wt% (Zhang et al., 2016).

Table 2.

The main components of medical wastes.

| Components | Samples | Contents (%) |

|---|---|---|

| Plastics | Syringe, blood bag, drug packaging, medical bottles, infusion set, one-off medical glove, bowls | 39.30–50.00 |

| Textiles | Gauze, bedding, cotton pads, disposable diapers, absorbent cotton, towels, caps, masks | 14.00–31.00 |

| Papers | Used tissue, toilet paper, printer paper | 11.15–25.10 |

| Glass | Used slides and cover glass, glass bottles | 0.30–22.70 |

| Woodware | Bamboo stick, swab | 3.17–20.00 |

| Rubber | Nitrile gloves, rubber tourniquet, catheter | 3.40–6.60 |

| Metals | Scalpel, scissors, needles, surgical saws | 0.30–5.00 |

| Others | Food waste, medicine, human tissue, vaccines | 1.40–18.60 |

On the other hand, Table 3 displays the elemental and proximate analyses of medical wastes or typical samples in the medical wastes. Plastic materials like medical bottles, infusion set, waste syringes, and packages have high carbon and hydrogen content, leading to a high calorific value. However, lignocellulosic biomasses in medical wastes, including bamboo stick, gauze, cotton, and tissues, do not show good performance on the HHV due to the high oxygen content. Furthermore, some specimens presented different characteristics. Due to the existence of nitrogen in the raw materials of butyronitrile, 12.90% nitrogen was detected in nitrile gloves. Moreover, 6.49% sulphur was determined in rubber tourniquet, mainly related to the process of vulcanisation, which is applied to improve its strength, hardness, and elasticity (Liu et al., 2018).

Table 3.

Elemental and proximate analyses of samples and medical wastes.

| Materials | Elemental analysis (dry basis, wt.%) |

Proximate analysis (wt.%) |

HHV (MJ/kg) | Reference | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | O | N | S | VM | MO | FC | Ash | |||

| Medical wastes | 58.00 | 9.33 | 25.35 | 0.73 | 0.14 | 82.20 | 5.65 | 5.70 | 6.45 | 28.89 | Yatsunthea and Chaiyat (2020) |

| Medical wastes | 56.82 | 7.83 | 29.87 | 0.35 | 0.08 | 86.28 | – | 8.67 | 5.05 | 27.95 | Xiong et al. (2006) |

| Plastic medical wastes | 72.56 | 11.17 | 10.22 | 5.82 | 0.23 | 62.70 | 0.82 | 32.31 | 4.17 | 33.30 | Som et al. (2018) |

| Cotton | 44.92 | 9.00 | 45.86 | 0.19 | 0.03 | 96.40 | 6.46 | 3.60 | 0.20 | 15.79 | Zhu et al. (2008) |

| Respirator | 51.28 | 6.69 | 41.71 | 0.18 | 0.14 | 92.47 | 7.01 | 7.53 | 4.14 | 18.10 | Zhu et al. (2008) |

| Bamboo stick | 50.76 | 5.91 | 42.98 | 0.28 | 0.07 | 82.17 | 9.77 | 17.83 | 1.96 | 17.45 | Zhu et al. (2008) |

| Paper | 45.71 | 5.96 | 37.18 | 0.16 | 0.13 | 82.43 | 7.01 | 3.85 | 6.71 | 18.14 | Zhu et al. (2015) |

| Gauze | 41.93 | 8.40 | 42.81 | 0.18 | 0.03 | 89.99 | 6.46 | 3.36 | 0.19 | 15.82 | Zhu et al. (2015) |

| Medical bottles | 84.71 | 13.81 | – | 0.00 | 0.07 | 98.27 | 0.05 | 1.65 | 0.03 | 45.51 | Ding et al. (2021) |

| Food waste | 42.39 | 6.27 | 47.49 | – | – | 71.50 | 1.26 | 24.65 | 2.59 | 15.65 | Gerasimov et al. (2019) |

| Tissues | 47.23 | 6.43 | 45.23 | – | – | 78.89 | 0.30 | 19.99 | 0.82 | 17.70 | Gerasimov et al. (2019) |

| Cotton wool | 45.34 | 6.84 | 47.23 | – | – | 79.32 | 0.23 | 20.09 | 0.36 | 17.27 | Gerasimov et al. (2019) |

| Bandage | 44.68 | 6.65 | 48.29 | – | – | 79.49 | 0.18 | 20.13 | 0.20 | 16.74 | Gerasimov et al. (2019) |

| Biomaterial container | 84.54 | 15.46 | – | – | – | 99.82 | – | 0.18 | – | 44.56 | Gerasimov et al. (2019) |

| Waste package | 80.83 | 15.97 | – | – | – | 66.14 | – | 30.66 | 3.20 | 43.83 | Gerasimov et al. (2019) |

| Nitrile gloves | 77.32 | 8.27 | – | 12.90 | – | 87.45 | – | 11.05 | 1.50 | 34.72 | Gerasimov et al. (2019) |

| Rubber tourniquet | 54.19 | 8.06 | – | – | 6.49 | 67.85 | – | 0.89 | 31.26 | 27.37 | Gerasimov et al. (2019) |

| PVC | 32.78 | 4.11 | – | – | 40.88 (Cl) | 62.72 | – | 15.04 | 22.24 | 15.34 | Gerasimov et al. (2019) |

| Infusion set | 81.81 | 12.17 | – | 0.15 | 0.11 | 99.13 | 0.32 | 0.55 | – | 42.65 | Qin et al. (2018a) |

| Syringes | 84.30 | 14.44 | 0.00 | 0.18 | 0.03 | 99.84 | 0.00 | 0.00 | 0.16 | 45.77 | Yan et al. (2008) |

| Pig liver | 53.66 | 7.96 | 15.21 | 11.62 | 0.33 | 81.54 | 6.68 | 7.24 | 4.54 | 22.12 | Yan et al. (2008) |

VM: Volatile matter; MO: Moisture; FC: Fixed carbon; HHV: Higher heating value (MJ/kg).

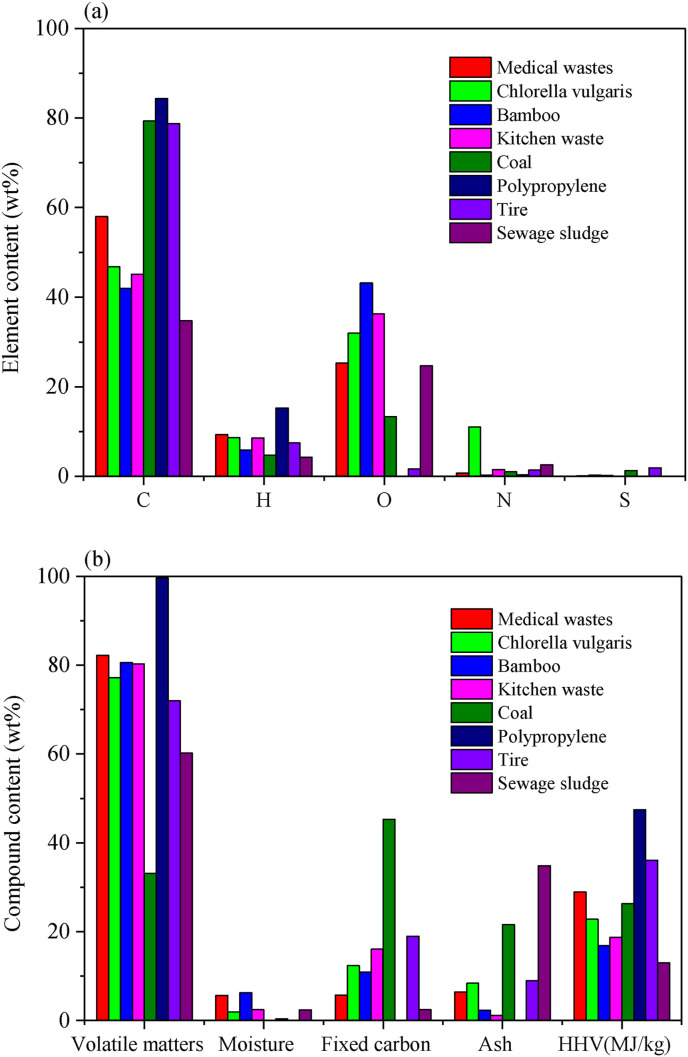

As shown in Fig. 1 , seven kinds of commonly used biomass materials were selected to show the differences in the properties of medical wastes and other biomass materials. Apparently, the integral medical wastes are promising feedstocks for energy recovery. They possess better utilisation potential than most traditional biomass materials because medical wastes have the second-highest hydrogen content and relatively high carbon content. While the oxygen content is lower than many biomasses, nitrogen and sulphur content are approximately close to zero. Consequently, medical wastes have the third-highest calorific value among them. Furthermore, medical wastes possess the second-highest volatile matter, which means that more bio-oil will be generated from the pyrolysis of medical wastes. Based on the above analyses, medical wastes are indeed optimal raw materials for the production of biofuels.

Fig. 1.

(a) Elemental and (b) proximate analyses of medical wastes and other materials (Azizi et al., 2018b; Chen et al., 2012, 2017, 2018a, 2018b; Duan et al., 2015; Wang et al., 2016; Yatsunthea and Chaiyat, 2020).

3. Pyrolysis characteristics of medical wastes

The heterogeneity and complexity of medical wastes result in the extreme complexity of its pyrolysis process. Furthermore, pyrolysis performance is prone to be affected by many factors such as atmosphere, heating rate, temperature range, residence time, particle size, sample dosage, and pressure. Thermogravimetric analysis has been widely used to obtain valuable pyrolysis data and explore the pyrolysis characteristics (Chong et al., 2019). Thus, this section mainly discusses the pyrolysis characteristics of medical wastes in terms of thermodynamic parameters and kinetic models.

3.1. Thermogravimetric analysis

Thermogravimetric analysis is the most widely applied technology to reveal the pyrolysis characteristics of biomass materials, a ScienceDirect search on 1/1/2021 with the keywords “thermogravimetric analysis and pyrolysis” yielded 30260 articles. With the help of thermobalance, the relationship between sample mass and temperature or time can be continuously recorded under the control of temperature program. Some valuable information like initial reaction temperature, peak temperature, final temperature, weight loss, decomposition degree, and thermal stability range can be obtained during the process (Gao et al., 2020). Moreover, according to the data, thermal stability, decomposition process and products of the raw materials can be evaluated, activation energy and pre-exponential factor can be calculated to investigate the reaction kinetics. Thermogravimetric analysis is fast, simple, convenient and accurate, which is the primary method to study the pyrolysis characteristics of materials (Xiao et al., 2020).

Table 4 summarises the pyrolysis characteristic parameters of twenty-one typical samples. The common types of those materials are macromolecule; some are synthetic macromolecule, like PVC, syringes, and infusion set. Simultaneously, the others are natural macromolecules, such as cotton, bamboo stick, and pig liver. In this regard, the pyrolysis of medical wastes can be treated as the pyrolysis of high macromolecule compounds to a certain extent (Ding et al., 2021). Based on Table 4, apparently, most of the typical samples such as gloves, paper, gauze presented one main weight loss stage. However, other specimens like syringes, respirator, infusion tube, urine collector, catheter, dressing displayed two decomposition stages with two weight loss peaks. Lignocellulose biomass bamboo stick showed three weight loss stages, mainly due to those materials’ unique physical and chemical composition. Generally, ingredients with poor stability in the materials tend to decompose at a low temperature. In contrast, ingredients with high stability are prone to experience the degradation process at a high temperature (Wu et al., 2020). For instance, PVC (Polyvinyl chloride) is the main component of urine collector and infusion tube (Deng et al., 2008). Previous studies have reported that PVC pyrolysis proceeds in two stages: dehydrochlorination and hydrocarbon formation (Kim, 2001; McNeill et al., 1995). In the first stage, dehydrochlorination is the primary reaction leading to the release of HCl and the formation of a volatile organic compound such as conjugated polyene (Zhou et al., 2016). However, other opinions regarding the mechanism of first stage degradation also prevail (Karayildirim et al., 2006). In the second stage, toluene is produced with a small number of alkyl aromatics which yields a residual char (Marcilla and Beltrán, 1995). The aliphatic hydrocarbons are formed from the decomposition of alkyl aromatics on some occasions.

Table 4.

Pyrolysis characteristic parameters for samples in medical wastes.

| Samples | K | T1 (°C) | Tp1 (°C) | Tf1 (°C) | DTG1 | WL1 (%) | T2 (°C) | Tp2 (°C) | Tf2 (°C) | DTG2 | WL2 (%) | T3 (°C) | Tp3 (°C) | Tf3 (°C) | DTG3 | WL3 %) |

R (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Syringes | 20 | 394.40 | 467.30 | 501.00 | 40.53 | 73.90 | 661.90 | 738.30 | 759.50 | 2.99 | 10.74 | – | – | – | – | – | 9.96 | Ding et al. (2021) |

| Medicine bottles | 20 | 417.90 | 477.90 | 517.00 | 62.03 | 97.60 | – | – | – | – | – | – | – | – | – | – | 2.40 | Ding et al. (2021) |

| Absorbent cotton | 30 | 291.00 | 384.00 | 432.00 | – | 89.19 | – | – | – | – | – | – | – | – | – | – | 10.81 | Zhu et al. (2008) |

| Respirator | 30 | 280.00 | 381.00 | 409.00 | – | – | 465.00 | 494.00 | 516.00 | – | – | – | – | – | – | – | 11.43 | Zhu et al. (2008) |

| Bamboo stick | 30 | 200.00 | 313.00 | 320.00 | – | – | 320.00 | 363.00 | 400.00 | – | – | 468.00 | 494.00 | 520.00 | – | – | 17.91 | Zhu et al. (2008) |

| Infusion tube | 20 | 288.86 | 320.32 | 342.86 | 25.80 | 72.40 | 461.92 | 470.41 | 491.27 | 6.60 | 14.99 | – | – | – | – | – | 12.70 | Deng et al. (2008) |

| Urine collector | 20 | 295.34 | 309.93 | 329.97 | 33.00 | 58.21 | 454.58 | 472.31 | 493.00 | 11.40 | 24.52 | – | – | – | – | – | 17.27 | Deng et al. (2008) |

| Medical glove | 20 | 429.40 | 476.81 | 493.99 | 31.20 | 95.14 | – | – | – | – | – | – | – | – | – | – | 4.86 | Deng et al. (2008) |

| Operating glove | 20 | 373.42 | 395.88 | 422.94 | 32.40 | 92.35 | – | – | – | – | – | – | – | – | – | – | 7.65 | Deng et al. (2008) |

| Catheter | 20 | 365.72 | 395.80 | 430.46 | 13.20 | 46.51 | 717.21 | 755.45 | 768.13 | 4.80 | 14.03 | – | – | – | – | – | 39.46 | Deng et al. (2008) |

| Cotton swabs | 20 | 327.12 | 382.50 | 394.59 | 20.40 | 69.76 | – | – | – | – | – | – | – | – | – | – | 30.24 | Deng et al. (2008) |

| Toilet paper | 20 | 344.72 | 372.51 | 383.81 | 39.60 | 78.94 | – | – | – | – | – | – | – | – | – | – | 21.06 | Deng et al. (2008) |

| Gauze | 20 | 351.41 | 381.75 | 397.51 | 35.40 | 81.01 | – | – | – | – | – | – | – | – | – | – | 18.99 | Deng et al. (2008) |

| Absorbent cotton | 20 | 353.21 | 382.57 | 397.20 | 37.80 | 82.89 | – | – | – | – | – | – | – | – | – | – | 17.11 | Deng et al. (2008) |

| Catgut suture | 20 | 309.30 | 351.28 | 382.69 | 11.40 | 48.89 | – | – | – | – | – | – | – | – | – | – | 51.11 | Deng et al. (2008) |

| Muscle of rat | 20 | 308.27 | 346.71 | 369.91 | 13.80 | 66.38 | – | – | – | – | – | – | – | – | – | – | 33.62 | Deng et al. (2008) |

| Dressing filling | 20 | 329.35 | 358.97 | 371.26 | 12.60 | 29.16 | 431.49 | 455.50 | 475.03 | 20.40 | 48.13 | – | – | – | – | – | 22.71 | Deng et al. (2008) |

| Adhesive plaster | 20 | 365.24 | 384.38 | 408.49 | 23.40 | 66.59 | – | – | – | – | – | – | – | – | – | – | 33.41 | Deng et al. (2008) |

| Dressing | 20 | 332.23 | 363.67 | 376.04 | 52.13 | 19.20 | – | 413.25 | 440.58 | 13.20 | 32.39 | – | – | – | – | – | 15.48 | Deng et al. (2008) |

| Glove | 20 | 253.81 | 394.79 | 394.79 | – | 92.71 | – | – | – | – | – | – | – | – | – | – | 7.29 | Deng et al. (2013) |

| Catheter | 20 | 240.08 | 394.10 | 513.12 | – | 47.59 | – | 769.54 | 799.90 | – | 15.50 | – | – | – | – | – | 36.91 | Deng et al. (2013) |

K: Heating rate (°C/min); Tn: Initial reaction temperature in stage n; Tpn: Peak decomposition temperature in stage n; Tfn: Final decomposition temperature in stage n; DTGn: Maximum rate of weight loss in stage n (%/min); WLn: Weight loss in stage n; R: Residues.

Furthermore, syringes are mainly composed of PP, whose pyrolysis follows the free-radical irregular degradation reaction (Dash et al., 2015). A bamboo stick is a typical lignocellulose material, primarily consists of cellulose, hemicellulose and lignin, while each component has different thermal decomposition temperature interval (Zhao et al., 2019). The catheter mainly consists of natural rubber and CaCO3 (Deng et al., 2014). Reinforcing natural rubber with ultrafine calcium carbonate improved tear strength, modulus, and tensile strength of natural rubber (Cai et al., 2003). The primary degradation is related to the depolymerisation of natural rubber, whereas the secondary degradation corresponds to the decomposition of CaCO3 (Dollimore et al., 1996). The dressing is made from various materials, including gauze, paper, and synthetic fibre. Deng et al. (2008) reported a two-stage degradation of dressing filling in their work.

Due to the various pyrolysis characteristics of each material, the initial reaction temperature as well as peak decomposition temperature of different samples are different. With the rise of temperature, rubber, plastic, protein, cellulose, and synthetic fibre entered the pyrolysis process in succession. Subsequently, all samples got into a substantial weight loss process between 240 and 430°C successively. Furthermore, most of the samples finished the process at 600°C except syringes and catheter, whose weight loss still occurred between 660 and 800°C, all samples finished the pyrolysis process eventually up to 800°C. Correspondingly, in engineering design, the furnace temperature of the pyrolysis reactor ought to be 800°C or higher to make sure that the degradation process is able to be fully completed (Deng et al., 2008).

The significant weight loss of plastics occurred between 300 and 500°C. In addition, noticeable weight loss of rubber materials took place in 240–400°C, the remarkable degradation of protein and cellulose showed up in 300–480°C and 300–350°C, respectively. Medical bottles had maximum weight loss, and only 2.4% of residues left, while catgut suture possessed the maximal residues. However, the weight loss of most samples was up to 80%, which verified that pyrolysis technology could cut down the volume of medical wastes drastically. Furthermore, it is observed that the peak decomposition temperature of all samples locates in the range of 370–520°C. Correspondingly, prolonging reaction time in the above temperature interval is conducive to maximise the degree of degradation of medical wastes.

3.2. Kinetic analysis

According to the data from TGA, the kinetic parameters of typical samples in medical wastes can be determined via the Coats–Redfern method, which is widely applied to predict mass loss evolution (Anca-Couce, 2016). Based on the Arrhenius law, the rate of heterogeneous solid-state reactions can be described as Eq. (1):

| (1) |

where A represents the pre-exponential factor, E refers to the apparent activation energy (kJ/mol), x is the conversion extent and n represents reaction order, t refers to the reaction time (s), T and R represent the absolute temperature (K) and the universal gas constant [J/(mol·K)], respectively (Dai et al., 2019).

The conversion degree x can be calculated by Eq. (2), where w 0 refers to the original mass of the sample, w t and w f represent the mass at time t and the mass at the end, respectively. For a constant heating rate k during pyrolysis, k = dT/dt, after reorganisation and integration, the following expression can be observed as Eq. (3) and Eq. (4):

| (2) |

| (3) |

| (4) |

Generally, , and the expression is essentially constant in the temperature interval of pyrolysis. Thus, the line with slope and intercept can be determined by the left side of the equation. The activation energy and pre-exponential factor are obtained by this mean.

Table 5 presents the kinetic parameters of twenty-six typical samples from the literature. Most of them were calculated by Coats–Redfern. While Distributed Activation Energy Model (DAEM) was also applied to analyse the evolution of different volatile species in pyrolysis, like CO, CO2, H2O, hydrocarbon, ketone, acid, and aldehyde.It assumed the pyrolysis of specimen involves several independent chemical reactions, each one affecting the whole process (Fang et al., 2018). Apparently, the correlation coefficient of the line is in the range of 0.960–0.999. The activation energy values of all specimens are distributed between 80.62 and 306.00 kJ/mol in the first stage. Meanwhile, the secondary process’s activation energy is ranged from 206.60 to 412.92 kJ/mol, which is much higher than that of the primary process.

Table 5.

Pyrolysis kinetic parameters for samples in medical wastes.

| Samples | K | E1(kJ/mol) | A1(min−1) | n1 | R1 | E2(kJ/mol) | A2(min−1) | n2 | R2 | Methods | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Syringes | 20 | 247.03 | 1.00 × 1017 | 2 | 0.998 | 213.84 | 3.47 × 1017 | 2 | 0.999 | Integral master-plots | Ding et al. (2021) |

| Medical bottles | 20 | 269.66 | 5.23 × 1018 | 1.2 | 0.994 | – | – | – | – | Integral master-plots | Ding et al. (2021) |

| Absorbent cotton | 30 | 188.50–289.00 | 1014–1022 | – | 0.984–0.999 | – | – | – | – | DAEM | Yan et al. (2009) |

| Respirator | 30 | 184.50–294.50 | 1013–1023 | – | 0.960–0.999 | – | – | – | – | DAEM | Yan et al. (2009) |

| Bamboo stick | 30 | 107.50–295.50 | 108–1025 | – | 0.987–0.999 | – | – | – | – | DAEM | Yan et al. (2009) |

| Infusion tube | 20 | 110.42 | 3.28 × 109 | 1 | 0.998 | 246.94 | 9.87 × 1016 | 1 | 0.982 | Coats–Redfern | Deng et al. (2008) |

| Urine collector | 20 | 130.62 | 2.09 × 1011 | 1 | 0.975 | 208.27 | 2.19 × 1014 | 1 | 0.982 | Coats–Redfern | Deng et al. (2008) |

| Medical glove | 20 | 181.36 | 2.15 × 1012 | 0 | 0.999 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Operating glove | 20 | 148.81 | 1.74 × 1011 | 1 | 0.993 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Catheter | 20 | 117.61 | 5.70 × 108 | 1 | 0.992 | 412.92 | 1.35 × 1021 | 1 | 0.999 | Coats–Redfern | Deng et al. (2008) |

| Cotton swabs | 20 | 84.45 | 4.07 × 106 | 1 | 0.993 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Toilet paper | 20 | 170.11 | 6.91 × 1013 | 1 | 0.992 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Gauze | 20 | 185.85 | 7.62 × 1014 | 1 | 0.998 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Absorbent cotton | 20 | 198.23 | 7.70 × 1015 | 1 | 0.999 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Catgut suture | 20 | 85.47 | 6.02 × 106 | 1.5 | 0.993 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Rat muscle | 20 | 80.62 | 2.09 × 106 | 1.5 | 0.992 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Dressing filling | 20 | 147.90 | 1.69 × 1012 | 1 | 0.998 | 228.12 | 2.02 × 1016 | 1 | 0.999 | Coats–Redfern | Deng et al. (2008) |

| Adhesive plaster | 20 | 128.60 | 9.45 × 109 | 1 | 0.994 | – | – | – | – | Coats–Redfern | Deng et al. (2008) |

| Dressing | 20 | 135.98 | 1.14 × 1011 | 1 | 0.994 | 285.31 | 1.14 × 1021 | 1 | 0.994 | Coats–Redfern | Deng et al. (2008) |

| Infusion set | 20 | 132.38 | 1.42 × 109 | 1 | 0.999 | – | – | – | – | Coats–Redfern | Qin et al. (2018a) |

| PVC | 20 | 125.50 | 8.07 × 1010 | 1 | – | 206.60 | 2.28 × 1014 | 1 | – | Coats–Redfern | Dudkina et al. (2019) |

| PE | 20 | 305.00 | 6.15 × 1020 | 1 | 0.999 | – | – | – | – | Coats–Redfern | Paraschiv et al. (2015) |

| PP | 20 | 301.00 | 3.71 × 1020 | 1 | 0.999 | – | – | – | – | Coats–Redfern | Paraschiv et al. (2015) |

| PS | 20 | 256.00 | 5.50 × 1018 | 1 | 0.999 | – | – | – | – | Coats–Redfern | Paraschiv et al. (2015) |

| Latex | 20 | 107.00 | 6.72 × 107 | 1 | 0.990 | – | – | – | – | Coats–Redfern | Paraschiv et al. (2015) |

| PMMA | 20 | 306.00 | 6.72 × 1015 | 1 | 0.999 | – | – | – | – | Coats–Redfern | Paraschiv et al. (2015) |

K: Heating rate (°C/min); Em: Activation energy in stage m; Am: Pre-exponential factor in stage m; nm: Reaction order in stage m; Rm: Correlation coefficient in stage m.

4. Characteristics of products from medical wastes pyrolysis

The production of valuable final products is the predominant characteristic and distinct superiority of the pyrolysis process, which is the main feature that distinguishes it from other technologies. Bio-oil and biochar are the primary outputs of this process. Among these products, bio-oil has a considerable potential to substitute for fossil fuels and solves a series of environmental problems caused by reckless fossil fuels consumption. Besides, biochar is rich in carbon with favourable porous structure and high surface functionality, which is used as a supercapacitor, anode material, photocatalytic support, and adsorbent (Fakayode et al., 2020). As such, many experimentalists tried to maximise the bio-oil yield by optimising the reaction conditions. Under optimised condition for bio-oil, very little biogas can be generated, and most of which are either released into the air or reused into the pyrolysis process (Ong et al., 2019). Consequently, many researchers have explored in-depth and made numerous achievements during the pyrolysis of medical wastes. Table 6 presents pyrolysis products characteristics of medical wastes or some typical samples.

Table 6.

Pyrolysis products characteristics of medical wastes or typical samples.

| Samples | Conditions | Liquid products |

Solid products |

Gas products |

Reference | |||

|---|---|---|---|---|---|---|---|---|

| Yields (wt.%) | HHV (MJ/kg) | Yields (wt.%) | HHV (MJ/kg) | Yields (wt.%) | LHV (MJ/Nm3) | |||

| Medical wastes | 500°C, 0.05 MPa | 42.00 | 37.56 | 50.69 | 22.80 | 7.31 | 46.18 | Fang et al. (2020) |

| Medical wastes | 700°C, 145 s, N2 | 73.40 | – | 24.10 | – | 2.50 | – | Mohseni-Bandpei et al. (2019) |

| Medical wastes | 600°C, 10 °C/min, N2 | 50.00 | – | – | – | – | – | Gerasimov et al. (2019) |

| Plastic medical wastes | 260°C, N2 | 53.00 | 41.33 | 29.00 | – | 18.00 | – | Som et al. (2018) |

| Plastic medical wastes | 390°C, N2, FCC-R1 | 3.80 | – | 11.70 | – | 82.40 | – | Lin et al. (2010) |

| Plastic medical wastes | 390°C, N2, Silicalite | 1.40 | – | 85.10 | – | 13.50 | – | Lin et al. (2010) |

| Plastic medical wastes | 390°C, N2, HUSY | 3.30 | – | 8.60 | – | 85.60 | – | Lin et al. (2010) |

| Plastic medical wastes | 390°C, N2, ZSM-5 | 3.40 | – | 6.40 | – | 88.30 | – | Lin et al. (2010) |

| Plastic medical wastes | 390°C, N2, SAHA | 3.60 | – | 10.50 | – | 84.10 | – | Lin et al. (2010) |

| Facemask | 600°C, 10°C/min, CO2 | 51.00 | – | 6.00 | – | 43.00 | – | Jung et al. (2020) |

| Syringe | 450°C, 20°C/min, He | 83.30 | 42.54 | 0.00 | – | 16.70 | – | Dash et al. (2015) |

| PE | 5–7°C/min, 20 min, N2 | 68.50 | 45.70 | 10.50 | – | 21.00 | 69.22 | Paraschiv et al. (2015) |

| PP | 5–7°C/min, 20 min, N2 | 82.00 | 46.80 | 0.00 | – | 18.00 | 64.30 | Paraschiv et al. (2015) |

| PS | 5–7°C/min, 20 min, N2 | 89.00 | – | 0.00 | – | 11.00 | 48.46 | Paraschiv et al. (2015) |

| Latex | 5–7°C/min, 20 min, N2 | 63.20 | 46.40 | 25.20 | – | 11.60 | 39.16 | Paraschiv et al. (2015) |

| PMMA | 5–7°C/min, 20 min, N2 | 98.00 | 27.17 | 0.00 | – | 2.00 | – | Paraschiv et al. (2015) |

| PVC | 800°C, 350°C/min, N2 | 31.30 | – | 15.60 | – | 44.40 | – | Zhou et al. (2015) |

| PET | 800°C, 350°C/min, N2 | 38.20 | – | 4.50 | – | 47.20 | – | Zhou et al. (2015) |

HHV: Higher heating value (MJ/kg); LHV: Lower heating value (MJ/Nm3).

Many studies have shown that pyrolysis of medical wastes is able to generate a considerable yield of bio-oil and biochar with high quality. Fang et al. (2020) selected the organic substances in the medical wastes as the experimental materials and pyrolysed them in the furnace at 500°C. 42.00 wt% bio-oil was obtained at the optimal conditions. It contained 60% hydrocarbons and lipids, and the carbon chain length was between C6 and C28. The calorific value was as high as 37.56 MJ/kg, which was very close to gasoline. During the pyrolysis, 50.69 wt% biochar was gained with a high HHV of 22.80 MJ/kg. In addition, the effect of vacuum degree and condensing temperature on final products were explored, the optimum vacuum degree was 0.04 MPa, and the condensing temperature was 70°C in the first stage to achieve the maximum yield of bio-oil. Mohseni-Bandpei et al. (2019) and Gerasimov et al. (2019) gained 73.40 and 50.00 wt% bio-oil during the pyrolysis of medical wastes, respectively, mainly owing to the high content of volatile matter in the medical wastes.

The pyrolysis of typical samples in medical wastes also achieved numerous remarkable results. Jung et al. (2020) proposed a new approach to the disposal of the used facemask during the pandemic. After analysis and pyrolysis of the disposable COVID-19 mask, they figured out that PP (73.33 wt%), PE (13.77 wt%), nylon (8.27 wt%) were the main chemical constituents, and about 51.00 wt% bio-oil was generated. As for the quality of bio-oil, long-chain hydrocarbons were the major chemical components, while the carbon chain length was between C6 and C46. Furthermore, syngas was produced too, H2, CH4, C2H4, and C2H6 were the main components. While the accession of Ni/SiO2 further promoted the formation of H2 and CH4, additional CO was generated in the atmosphere of CO2. They made a conclusion that pyrolysis of disposable face mask in the presence of CO2 was a safe and environmentally benign method to get rid of COVID-19 relevant plastic waste and produce valuable products.

As mentioned above, plastics are the major components of medical wastes. Therefore, many researchers have put attention to the pyrolysis of plastic materials in medical wastes and achieved fruitful results. Som et al. (2018) conducted the pyrolysis of plastic medical waste (PWM) and got a high-grade bio-oil. The properties of bio-oil were close to commercial fuel such as petrol and diesel. As the calorific value was 41.31 MJ/kg, the density was 840 kg/m3, the flash point and pour point were 39 and 14°C, respectively. Furthermore, Paraschiv et al. (2015) chose several representative plastic materials in hospital solid wastes and studied their pyrolysis products. Firstly, the yield of bio-oil was in the range of 63.20 and 98.00 wt% because the high volatiles content was favourable for the formation of liquid products. Furthermore, the obtained bio-oil was rich in hydrocarbons and led to a high calorific value ranged from 27.17 to 46.80 MJ/kg. 11.00 to 21.00 wt% biogas with high quality were generated during the process too, and CH4, C2H4, C2H6, C3H6, C3H8 were the chief components, the biogas LHV was between 39.16 and 69.22 MJ/Nm3, which was close to the natural gas, and could replace the natural gas for urban and industrial utilisation. The high carbon and hydrogen content in plastic materials were the main reason. Moreover, less yield of biochar was obtained due to the low content of ash in the plastics. Qin et al. (2018b) pyrolysed medical plastic wastes (medicinal plastic bottles and plastic infusion bag) consisted of PS and PP and observed the thermal degradation process. Wastes started vitrifying at around 100°C, began degrading at about 300°C, and reached the maximum near 400°C. Styrene monomer, benzene, toluene, and C1–C4 hydrocarbons were the main products at the initial stage of pyrolysis. They held a view that the aromatic compounds were primarily originated from PP degradation, while alkanes and alkenes mainly came from PS degradation.

In addition, Ding et al. (2021) detected the molecular structures of gases from discarded syringes and medicine bottles by Py-GC/MS analysis. During discarded syringes pyrolysis, C4–C24 alkenes (51.28% peak areas) were the chief products, diene (23.63% peak areas) and alkanes (1.04% peak areas) were also determined simultaneously. As for the medicine bottles, C8–C41 alkenes (49.94% peak areas) and C6–C41 (31.91% peak areas) alkanes were the major products. Moreover, the accession of a large mass of catalysts is beneficial to the production of biogas. Lin et al. (2010) detected that the addition of acidic cracking catalysts (FCC-R1, HUSY, ZSM-5 and SAHA) (30 wt%) in the pyrolysis of hospital plastic wastes generated more than 82.00 wt% biogas. This was because the secondary cracking broke the long carbon chain into a short carbon chain owing to the presence of the catalyst, and C1–C4 was the primary product. Meanwhile, silicalite increased the biochar yield to 85.10 wt%.

Table 7 presents the bio-oil physicochemical characteristics from the pyrolysis of medical wastes. The typical physicochemical properties include density, viscosity, flash point, pour point, and HHV. Bio-oil can be directly used in combustors or converted into biodiesel via transesterification process (Fattah et al., 2020; Ong et al., 2020b; Suchocki et al., 2021). In general, bio-oil physicochemical characteristics produced from the pyrolysis of medical wastes are very close to traditional fossil fuels like diesel or gasoline. As such, those can be blended with petroleum-based fuels. However, the bio-oil from PVC has low HHV due to the high content of chlorine in the PVC. The viscosity of the bio-oil originated from medical waste is a little higher than the viscosity of commercial fuels. Furthermore, the bio-oil from pyrolysis of latex and PMMA has a lower flash point than regular petroleum-based fuels.

Table 7.

Physicochemical characteristics of the bio-oil from pyrolysis of medical wastes or typical samples.

| Materials | Density (kg/m3) | Viscosity (mPa·s) | Flash point (°C) | Pour point (°C) | HHV (MJ/kg) | Reference |

|---|---|---|---|---|---|---|

| Medical wastes | – | 9.10 | – | – | 37.56 | Fang et al. (2020) |

| Plastic medical wastes | 840.00 | – | 39.00 | 14.00 | 41.33 | Som et al. (2018) |

| Waste syringe | 828.10 | 2.97 | −6.00 | −18.00 | 42.54 | Dash et al. (2015) |

| PP | 740.00 | 5.70 | −3.00 | – | 45.80 | Paraschiv et al. (2015) |

| Latex | 860.00 | 2.57 | <-10.00 | – | 46.40 | Paraschiv et al. (2015) |

| PMMA | 900.00 | 0.91 | <-10.00 | – | 27.17 | Paraschiv et al. (2015) |

| HDPE | 890.00 | 4.52 | 48.00 | – | 40.50 | Anuar Sharuddin et al. (2016) |

| LDPE | 780.00 | 4.34 | 41.00 | – | 39.50 | Anuar Sharuddin et al. (2016) |

| PVC | 840.00. | 5.34 | 40.00 | – | 21.10 | Anuar Sharuddin et al. (2016) |

| PS | 850.00 | 1.19 | 26.10 | – | 43.00 | Anuar Sharuddin et al. (2016) |

| Diesel | 830.00–840.00 | 2.07–2.64 | – | – | 42.50 | Singh et al. (2021) |

| Diesel (EU Standard) | 860.00–900.00 | 3.00–4.50 | 120.00 | <0.00 | – | Samuel et al. (2020) |

| Biodiesel | 867.00–928.50 | 3.96–4.99 | 67.00–242.00 | −6.00-15.00 | 37.50–51.50 | Rahman et al. (2021) |

| Gasoline | 750.0–765.0s | 0.60 | −45.00–−13.00 | – | 47.30 | Masum et al. (2014) |

In short, the pyrolysis of plastic-based medical wastes possesses great strengths and generates a considerable amount of bio-oil with favourable physicochemical characteristics. The oils can replace traditional fossil fuels and solve a series of ecological, environmental and social problems.

5. Problems associated with the pyrolysis of medical wastes

Noxious gas emission is the main problem during the pyrolysis of medical wastes, such as PAHs, HCl, SO2, and NOx, which poses tremendous threat to public health and ecological security. Based on this, many researchers have concentrated on the issue and tried to limit toxic gases released.

5.1. PAHs generation

Based on the US Environmental Protection Agency (US EPA), 16 kinds of polycyclic aromatic hydrocarbons (PAHs), including anthracene, acenaphthene, fluorene, phenanthrene, fluoranthene, pyrene, were confirmed to be hazardous to the environment and healthiness considering their carcinogenic, mutagenic, teratogenic and genotoxic potentials (Kim et al., 2013). In addition, PAHs are possibly involved in the formation of polychlorinated dibenzo-p-dioxins (PCDDs) and polychlorinated dibenzofurans (PCDFs) in the fly ash as intermediate reactants (Chin et al., 2012). The persistent toxicity and threat to the circumstance are mainly related to the molecular structure of PAHs, which may include nitro, chlorinated and oxy groups (Imtenan et al., 2014; Zhou et al., 2019).

Many studies have indicated that the presence of plastics, lignocellulose biomass or other macromolecule organic compounds in pyrolysis are prone to the generation of PAHs. Font et al. (2003) studied the pyrolysis of PE and found the formation of PAHs in the bio-oil at a high temperature. Small molecules were formed firstly during the pyrolysis; then, PAHs were produced by the rapid cyclic reaction of small molecules. Onwudili et al. (2009) identified naphthalene in the bio-oil during the pyrolysis of low-density polyethylene (LDPE). They figured out that the rise of reaction temperature and residence time exerted a positive impact on the formation of naphthalene. Furthermore, Li et al. (2013) pointed out that the pyrolysis of cellulose (3.87%) produced more naphthalene than LDPE (0.79%) with the help of ZSM-5 at 650°C. However, plastics, lignocellulose biomass are the major components of medical wastes, the release of PAHs during the pyrolysis should not be overlooked.

Many researchers have focused on the issue and reported that the operating conditions greatly influenced the production of PAHs. Mohseni-Bandpei et al. (2019) detected that the concentration of PAHs was 121–29440 mg/lit in the bio-oil, 223–1610 mg/kg in the biochar via the pyrolysis of medical wastes. Additionally, particles size, reaction temperature and residence time had a huge impact on the yield of PAHs. The maximum PAHs yield was detected at 2 cm and 145 s. The rising particles size increased the formation of PAHs in the liquid products significantly, whereas more PAHs were absorbed in the biochar with the high temperature and long residence times. Zhou et al. (2015) pyrolysed a series of medical typical solid wastes including cellulose, xylan, lignin, pectin, starch, PS, PVC, PE, and PET and observed the formation of PAHs. A high concentration of PAHs was determined from the pyrolysis of plastic materials, and most of the PAHs were produced by the pyrolysis of PS, followed by PVC, PET, and lignin. As for the composition of PAHs, the content of naphthalene was the highest.

In addition, many studies have shown that the accession of catalysts possesses a negative effect on the PAHs generation. Wu et al. (2013) detected naphthalene during the pyrolysis of cellulose, xylan and lignin, and the pyrolysis of lignin gained the highest concentration of naphthalene without any catalyst. In comparison, the addition of nickel-based catalysts hindered the production of PAHs effectively. This result is supported by the research of Wang et al. (2018). They pyrolysed polyethylene and corn stover with the addition of nickel-modified HZSM-5 and determined Ni-HZSM-5 reduced the content of PAHs and increased the production of aromatics effectively. Therefore, the concentration of PAHs can be cut down effectively by reducing particles size, lessening the residence time, controlling the reaction temperature and adding the proper catalysts.

5.2. HCl generation

In general, chlorine mainly originated from an organic form like PVC or inorganic form such as physiological saline in medical wastes, while participating in the chemical reaction and generating HCl . HCl is another hazardous gaseous pollutant during the pyrolysis of medical wastes, which is corrosive and harmful and can lead to acid rain. Also, the HCl in the bio-oil is prone to cause several problems like high acidity, low stability and HHV, damage the gasoline engine, and cut down the value of bio-oil dramatically. In addition, some reports have demonstrated that Cl might lead to the generation of highly toxic dioxins and furans during the pyrolysis (Hunsinger et al., 2002).

Therefore, the fixation of HCl or Cl is a critical research topic, and the addition of alkaline additives like Ca(OH)2, ZnO, CaO, and Fe2O3 during the pyrolysis is the major approach to remove the HCl. Kaminsky and Kim (1999) pyrolysed the mixed plastics in a fluidised reactor and observed the evolution of chlorine. In the bio-oil, most of the chlorine existed in the form of calcium chloride with the addition of Ca(OH)2. This was because Ca(OH)2 converted the HCl into CaCl2 with the reaction as Eq (5):

| Ca(OH)2+ 2HCl = CaCl2 + 2H2O | (5) |

Zhu et al. (2015) conducted an experiment on the pyrolysis of simulative medical wastes with PVC or NaCl to explore the evolution route of chlorine. Firstly, no HCl was detected during the pyrolysis of medical wastes with NaCl because ionic bond energy of NaCl was too high to reach. As for the addition of PVC, HCl emitted in both thermal degradation stage. Furthermore, the accession of Ca-based additives (CaCO3, CaO, Ca(OH)2) inhibited the concentration of HCl, a remarkable negative correlation between Ca/Cl molar ratio and HCl concentration was observed, and Ca(OH)2 had the highest HCl removal efficiency among those additives.

Apart from that, some researchers tried to figure out the relationship between the experimental conditions and the emission of HCl. Dudkina et al. (2019) studied the pyrolysis of chlorine-containing medical wastes and found that most of the HCl (88.5%) were released at temperatures above 350°C. Lin et al. (2010) pyrolysed hospital plastic wastes with five kinds of catalysts (FCC-R1, silicalite, HUSY, ZSM-5, SAHA) and explored the catalytic effect on the yield of HCl. It was detected that the catalyst hindered the yield of HCl, and silicalite decreased the content of HCl to 1.4 wt%. However, with the addition of additives or the adjustment of operation conditions, the inhibition of the generation of toxic gases, including PAHs, HCl, NOx, SO2, is still limited. In this regard, a gas cleaning system is necessary to be fixed at the end of the pyrolysis equipment, which can remove those hazardous gaseous pollutants and protect the environment or human beings (Roy et al., 1992).

6. Prospects and future challenges

In contrast to the traditional medical wastes treatment method, pyrolysis is an environmentally friendly treatment method for disposing of medical wastes. In view of the large number of medical wastes produced in the world since the outbreak, the application of pyrolysis to reduce the medical waste amount and generate various value-added products has huge potentials (Al-Salem et al., 2017). Bio-oil obtained from the pyrolysis of medical wastes is used to replace fossil fuels. Biochar holds wide application in many fields as a catalyst, adsorbent, anode material, and photocatalytic support. Furthermore, the emission of toxic gases can be solved by an additional gas cleaning system (Isahak et al., 2012).

Consequently, pyrolysis has presented a remarkable economic and environmental performance on the disposal of solid waste. For instance, Elkhalifa et al. (2019) compared several treatment methods, including landfilling, composting, incineration, gasification and pyrolysis, to deal with food waste and concluded that pyrolysis process manifested significant economic superiorities owing to the production of biofuel and biochar efficiently. Additionally, Al-Salem et al. (2017) analysed the disposal means of plastic solid waste such as incineration, landfilling, gasification and pyrolysis, then pointed out pyrolysis possessed distinct environmental advantages, which was conducive to the reduction of the emission of toxic gases, including dioxins, carbon monoxide, and dioxide emissions. Microwave-assisted pyrolysis presented a better economic benefit due to the decrease in operational costs and heating time. Hong et al. (2018) conducted a life-cycle economic and environmental assessment of medical waste pyrolysis. Investment, electricity cost, labour cost, and human health protection were considered. Pyrolysis scenario had a net profit of $189.96/t.

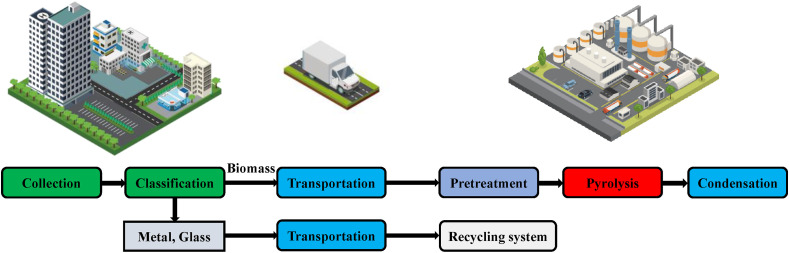

Fig. 2 presents the workflows of medical wastes recovery and recycling systems. The entire workflows are divided into three main processes. The first one is the preliminary collection and classification, then metal, glass, and other recycled materials will be transported and stored for the application in the downstream industries after disinfection. Biomass materials will be transported to the related factory as raw materials for pyrolysis, producing valuable bioproducts.

Fig. 2.

Workflows of medical wastes recovery and recycling systems.

There are many challenges associated with the medical wastes recovery and recycling systems. Usually, medical wastes are broadly divided into domestic wastes, pathological wastes, infectious wastes, pharmaceutical wastes, chemical wastes, radioactive wastes, and sharp wastes. Most of them do not require disinfection or particular disposal treatment due to its nontoxicity. However, disinfection or special treatment is needed when the toxic medical wastes are mixed with those nontoxic ones. In this regard, the classifying medical wastes and preventing secondary pollution are quite important. Moreover, high infectious and strong survivable viruses possess significant risks for the associated workers. Therefore, the cost of disinfection, personnel protection and training is massive. Furthermore, the collection fee and transportation cost are tremendous because of the wide distribution of hospitals (Klemeš et al., 2020).

Since the complex nature and structure of medical wastes, pre-treatment methods are quite important. As mentioned above, high water content does not favour the production of high-grade bio-oil. Furthermore, on the basis of surface chemistry, small particles size is beneficial to improve the reaction efficiency, reduce the yield of PAHs, and promote the production of biofuels (Zhu et al., 2019). Hence, drying and grinding are required to be conducted before pyrolysis. However, pre-treatment is the most expensive process because of the massive energy consumption, which means that energy cost will be huge during the process (Liu et al., 2020).

As shown in Table 5, the whole pyrolysis reaction is endothermic. Thus, the energy content of the final products ought to exceed that of the raw material owing to the endothermic characteristics of pyrolysis. At the same time, synergism between different materials in medical waste is significant to reach the exergy surplus. However, in highly heterogeneous mixture environments, the primary barrier of synergism is the lack of knowledge in a multi-component complex reaction network of medical waste pyrolysis. The synergistic mechanism of medical wastes pyrolysis needs to be further explored (Lee et al., 2020a).

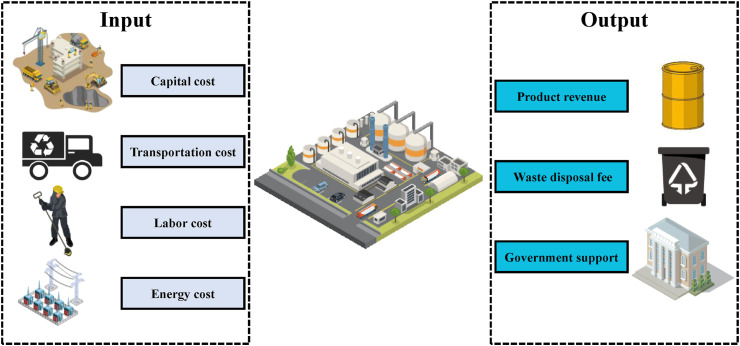

Fig. 3 shows the primary input and output of the whole recycling systems. However, the high cost is still the main barrier to the promotion and application of the integral medical wastes recovery and recycling systems. Generally, capital-related costs are the chief cost contributed with 30–40% of the input (Sipra et al., 2018). Furthermore, transportation cost is exceptionally high due to the wide distribution of each medical facilities. Many studies have indicated that pyrolysis is an energy-intensive technology, especially for the pre-treatment process, which has been explained before. Reusing the generated biogas has the potential to alleviate the situation. Moreover, labour cost cannot be ignored, which accounts for 12–15% of the entire cost based on some researches (Meyer et al., 2020).

Fig. 3.

Input and output of medical wastes recovery and recycling systems.

As for the output of the system, firstly, the product revenue is the major proceeds sources, and the quality and yield of target products are particularly important to ensure and increase the income. Furthermore, the treatment of medical wastes during the pyrolysis can bring the waste disposal fee from the government (Chen et al., 2021). The pyrolysis of medical wastes also produces numerous social, economic and environmental benefits, which will benefit from government support like economic support, tax break, and subsidies for production and infrastructure. Those supports will stimulate the development of relevant industries significantly. In addition, the improvement of equipment, the new design of process and the application of new catalysts are required to maximise economic and environmental benefits via the maximum production of valuable products and the minimum emission of toxic gases (Goh et al., 2019). Furthermore, increasing the scalability and duplication of the facility is also critical to reduce the cost of production by large-scale production. A comprehensive design framework is required to combine many proposals for pyrolysis synergy into the whole synthesis and analysis. All efforts ought to develop an energy-saving medical wastes pyrolysis process, treating medical wastes at low cost, produce valuable products as much as possible, recover valuable resources, and minimise the impacts on the environment (Lu et al., 2020).

Moreover, enhancing the quality and yield of target products is significant too. Catalytic pyrolysis or co-pyrolysis is an effective route to reach the goal. Many catalysts like HZSM-5, CaO, MgO, biochar, and activated carbon have been widely applied into the pyrolysis of plastics, microalgae, lignocellulosic biomass and made remarkable achievements (Chen et al., 2015). Numerous researches have already proven that the accession of catalysts can lower the activation energy, reduce the oxygenous and nitrogenous compounds, decrease the toxic gases emission, and enhance the production of the desired product (Ooi et al., 2019). In addition, the presence of co-feedstocks has a great positive influence on the properties of bio-oil. The addition of raw materials with high volatile matter content is favourable to the enhancement of the formation of bio-oil. In contrast, co-feedstock with high effective hydrogen index (EHI) is conducive to the improvement of the bio-oil quality (Ahmed and Hameed, 2020). However, more studies need to be conducted to search for the optimal catalyst and co-feedstock for the pyrolysis of medical wastes.

7. Conclusions

This review focuses on the pyrolysis of medical wastes to produce the bioenergy. The literature survey has illustrated that medical wastes possess tremendous potential to be ideal raw material for biofuel production by analysing its physicochemical and pyrolysis characteristics. Meanwhile, safe and clean pyrolysis technology is an emerging optimal way to reduce the number of medical wastes. It is also one of the possible responses to manage the medical wastes in this global epidemic situation due to its potential advantages of high efficiency, extensive applicability and the generation of high value-added products. The bio-oil from medical wastes pyrolysis possesses remarkable properties and great potentials to substitute for fossil fuels. Furthermore, the problem of toxic gases emissions, PAHs and HCl in particular, cannot be overlooked. Proper experiment conditions, appropriate catalysts and gas cleaning system are essential to handle the issues mentioned above. However, the cost of entire medical wastes recovery and recycling systems is still the main bottleneck which inhibited the promotion and application. This can be solved by the improvement in equipment, the design of process, the increase in scalability, duplication of the facility, and the enhancement of target products properties via catalytic pyrolysis or co-pyrolysis. Furthermore, it is notable that pyrolysis is an optimal solution to realise the valorisation of medical wastes.

Credit author statement

Guangcan Su: Conceptualization, Formal analysis, Writing – original draft. Hwai Chyuan Ong: Conceptualization, Supervision, Resources, Writing- Reviewing and Editing. Shaliza Ibrahim: Visualization, Supervision. I. M. Rizwanul Fattah: Validation, Writing- Reviewing and Editing. M. Mofijur: Formal analysis, Revision and formatting of paper. Cheng Tung Chong: Investigation, Writing- Reviewing and Editing

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

We acknowledge the contribution of research development fund of School of Information, Systems and Modelling, Faculty of Engineering and Information Technology, University of Technology Sydney, Ultimo, 2007 NSW, Australia.

Footnotes

This paper has been recommended for acceptance by Jörg Rinklebe.

References

- Abraham A., Mathew A.K., Park H., Choi O., Sindhu R., Parameswaran B., Pandey A., Park J.H., Sang B.-I. Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour. Technol. 2020;301:122725. doi: 10.1016/j.biortech.2019.122725. [DOI] [PubMed] [Google Scholar]

- Ahmed M.H.M., Batalha N., Mahmudul H.M.D., Perkins G., Konarova M. A review on advanced catalytic co-pyrolysis of biomass and hydrogen-rich feedstock: insights into synergistic effect, catalyst development and reaction mechanism. Bioresour. Technol. 2020:123457. doi: 10.1016/j.biortech.2020.123457. [DOI] [PubMed] [Google Scholar]

- Ahmed M.J., Hameed B.H. Insight into the co-pyrolysis of different blended feedstocks to biochar for the adsorption of organic and inorganic pollutants: a review. J. Clean. Prod. 2020:121762. [Google Scholar]

- Al-Salem S.M., Antelava A., Constantinou A., Manos G., Dutta A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW) J. Environ. Manag. 2017;197:177–198. doi: 10.1016/j.jenvman.2017.03.084. [DOI] [PubMed] [Google Scholar]

- Anca-Couce A. Reaction mechanisms and multi-scale modelling of lignocellulosic biomass pyrolysis. Prog. Energy Combust. Sci. 2016;53:41–79. [Google Scholar]

- Anuar Sharuddin S.D., Abnisa F., Wan Daud W.M.A., Aroua M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016;115:308–326. [Google Scholar]

- Arabiourrutia M., Lopez G., Artetxe M., Alvarez J., Bilbao J., Olazar M. Waste tyre valorization by catalytic pyrolysis – a review. Renew. Sustain. Energy Rev. 2020;129:109932. [Google Scholar]

- Azizi K., Keshavarz Moraveji M., Abedini Najafabadi H. A review on bio-fuel production from microalgal biomass by using pyrolysis method. Renew. Sustain. Energy Rev. 2018;82:3046–3059. [Google Scholar]

- Azizi K., Keshavarz Moraveji M., Abedini Najafabadi H. Simultaneous pyrolysis of microalgae C. vulgaris, wood and polymer: the effect of third component addition. Bioresour. Technol. 2018;247:66–72. doi: 10.1016/j.biortech.2017.09.059. [DOI] [PubMed] [Google Scholar]

- Cai H.-H., Li S.-D., Tian G.-R., Wang H.-B., Wang J.-H. Reinforcement of natural rubber latex film by ultrafine calcium carbonate. J. Appl. Polym. Sci. 2003;87:982–985. [Google Scholar]

- Chand Malav L., Yadav K.K., Gupta N., Kumar S., Sharma G.K., Krishnan S., Rezania S., Kamyab H., Pham Q.B., Yadav S., Bhattacharyya S., Yadav V.K., Bach Q.-V. A review on municipal solid waste as a renewable source for waste-to-energy project in India: current practices, challenges, and future opportunities. J. Clean. Prod. 2020:123227. [Google Scholar]

- Chen C., Ma X., He Y. Co-pyrolysis characteristics of microalgae Chlorella vulgaris and coal through TGA. Bioresour. Technol. 2012;117:264–273. doi: 10.1016/j.biortech.2012.04.077. [DOI] [PubMed] [Google Scholar]

- Chen D., Yin L., Wang H., He P. Reprint of: pyrolysis technologies for municipal solid waste: a review. Waste Manag. 2015;37:116–136. doi: 10.1016/j.wasman.2015.01.022. [DOI] [PubMed] [Google Scholar]

- Chen L., Yu Z., Fang S., Dai M., Ma X. Co-pyrolysis kinetics and behaviors of kitchen waste and chlorella vulgaris using thermogravimetric analyzer and fixed bed reactor. Energy Convers. Manag. 2018;165:45–52. [Google Scholar]

- Chen L., Yu Z., Liang J., Liao Y., Ma X. Co-pyrolysis of chlorella vulgaris and kitchen waste with different additives using TG-FTIR and Py-GC/MS. Energy Convers. Manag. 2018;177:582–591. [Google Scholar]

- Chen W.-H., Lin B.-J., Lin Y.-Y., Chu Y.-S., Ubando A.T., Show P.L., Ong H.C., Chang J.-S., Ho S.-H., Culaba A.B., Pétrissans A., Pétrissans M. Progress in biomass torrefaction: principles, applications and challenges. Prog. Energy Combust. Sci. 2021;82:100887. [Google Scholar]

- Chen W., Chen Y., Yang H., Xia M., Li K., Chen X., Chen H. Co-pyrolysis of lignocellulosic biomass and microalgae: products characteristics and interaction effect. Bioresour. Technol. 2017;245:860–868. doi: 10.1016/j.biortech.2017.09.022. [DOI] [PubMed] [Google Scholar]

- Chen Y., Zhao R., Xue J., Li J. Generation and distribution of PAHs in the process of medical waste incineration. Waste Manag. 2013;33:1165–1173. doi: 10.1016/j.wasman.2013.01.011. [DOI] [PubMed] [Google Scholar]

- Chin Y.-T., Lin C., Chang-Chien G.-P., Wang Y.-M. PCDD/F formation catalyzed by the metal chlorides and chlorinated aromatic compounds in fly ash. Aerosol and Air Quality Research. 2012;12:228–236. [Google Scholar]

- Chong C.T., Mong G.R., Ng J.-H., Chong W.W.F., Ani F.N., Lam S.S., Ong H.C. Pyrolysis characteristics and kinetic studies of horse manure using thermogravimetric analysis. Energy Convers. Manag. 2019;180:1260–1267. [Google Scholar]

- Dai M., Yu Z., Fang S., Ma X. Behaviors, product characteristics and kinetics of catalytic co-pyrolysis spirulina and oil shale. Energy Convers. Manag. 2019;192:1–10. [Google Scholar]

- Dash A., Kumar S., Singh R.K. Thermolysis of medical waste (waste syringe) to liquid fuel using semi batch reactor. Waste and Biomass Valorization. 2015;6:507–514. [Google Scholar]

- Deng N., Cui W.-q., Wang W.-w., Zhang Q., Zhang Y.-f., Ma H.-t. Experimental study on co-pyrolysis characteristics of typical medical waste compositions. J. Cent. S. Univ. 2014;21:4613–4622. [Google Scholar]

- Deng N., Wang W.-w., Chen G.-w., Zhang Y., Zhang Y.-f., Ma H.-t. Pyrolysis characteristics of rubber compositions in medical waste. J. Cent. S. Univ. 2013;20:2466–2471. [Google Scholar]

- Deng N., Zhang Y.-f., Wang Y. Thermogravimetric analysis and kinetic study on pyrolysis of representative medical waste composition. Waste Manag. 2008;28:1572–1580. doi: 10.1016/j.wasman.2007.05.024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dhyani V., Bhaskar T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy. 2018;129:695–716. [Google Scholar]

- Di Maria F., Beccaloni E., Bonadonna L., Cini C., Confalonieri E., La Rosa G., Milana M.R., Testai E., Scaini F. Minimization of spreading of SARS-CoV-2 via household waste produced by subjects affected by COVID-19 or in quarantine. Sci. Total Environ. 2020;743:140803. doi: 10.1016/j.scitotenv.2020.140803. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ding Z., Chen H., Liu J., Cai H., Evrendilek F., Buyukada M. Pyrolysis dynamics of two medical plastic wastes: drivers, behaviors, evolved gases, reaction mechanisms, and pathways. J. Hazard Mater. 2021;402:123472. doi: 10.1016/j.jhazmat.2020.123472. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dollimore D., Tong P., Alexander K.S. The kinetic interpretation of the decomposition of calcium carbonate by use of relationships other than the Arrhenius equation. Thermochim. Acta. 1996;282–283:13–27. [Google Scholar]

- Duan P., Jin B., Xu Y., Wang F. Co-pyrolysis of microalgae and waste rubber tire in supercritical ethanol. Chem. Eng. J. 2015;269:262–271. [Google Scholar]

- Dudkina L.M., Gerasimov G.Y., Khaskhachikh V.V. vol. 272. 2019. Thermogravimetric and kinetic study of pyrolysis of chlorine-containing medical waste; p. 22117. (IOP Conference Series: Earth and Environmental Science). [Google Scholar]

- Elkhalifa S., Al-Ansari T., Mackey H.R., McKay G. Food waste to biochars through pyrolysis: a review. Resources, Conserv. Recycl. 2019;144:310–320. [Google Scholar]

- Fakayode O.A., Aboagarib E.A.A., Zhou C., Ma H. Co-pyrolysis of lignocellulosic and macroalgae biomasses for the production of biochar – a review. Bioresour. Technol. 2020;297:122408. doi: 10.1016/j.biortech.2019.122408. [DOI] [PubMed] [Google Scholar]

- Fang S., Jiang L., Li P., Bai J., Chang C. Study on pyrolysis products characteristics of medical waste and fractional condensation of the pyrolysis oil. Energy. 2020;195:116969. [Google Scholar]

- Fang S., Yu Z., Ma X., Lin Y., Chen L., Liao Y. Analysis of catalytic pyrolysis of municipal solid waste and paper sludge using TG-FTIR, Py-GC/MS and DAEM (distributed activation energy model) Energy. 2018;143:517–532. [Google Scholar]

- Fattah I.M.R., Ong H.C., Mahlia T.M.I., Mofijur M., Silitonga A.S., Rahman S.M.A., Ahmad A. State of the art of catalysts for biodiesel production. Frontiers in Energy Research. 2020;8 [Google Scholar]

- Font R., Aracil I., Fullana A., Martín-Gullón I., Conesa J.A. Semivolatile compounds in pyrolysis of polyethylene. J. Anal. Appl. Pyrol. 2003;68–69:599–611. [Google Scholar]

- Gao N., Sipra A.T., Quan C. Thermogravimetric analysis and pyrolysis product characterization of municipal solid waste using sludge fly ash as additive. Fuel. 2020;281:118572. [Google Scholar]

- Gerasimov G., Khaskhachikh V., Kornilieva V., Tarasov G. Study of pyrolysis of components and mixture of medical waste. Chemical Engineering Transactions. 2019;76:1423–1428. [Google Scholar]

- Goh B.H.H., Ong H.C., Cheah M.Y., Chen W.-H., Yu K.L., Mahlia T.M.I. Sustainability of direct biodiesel synthesis from microalgae biomass: a critical review. Renew. Sustain. Energy Rev. 2019;107:59–74. [Google Scholar]

- Graikos A., Voudrias E., Papazachariou A., Iosifidis N., Kalpakidou M. Composition and production rate of medical waste from a small producer in Greece. Waste Manag. 2010;30:1683–1689. doi: 10.1016/j.wasman.2010.01.025. [DOI] [PubMed] [Google Scholar]

- Hong J., Zhan S., Yu Z., Hong J., Qi C. Life-cycle environmental and economic assessment of medical waste treatment. J. Clean. Prod. 2018;174:65–73. [Google Scholar]

- Hoque M.M., Rahman M.T.U. Landfill area estimation based on solid waste collection prediction using ANN model and final waste disposal options. J. Clean. Prod. 2020;256:120387. [Google Scholar]

- Hunsinger H., Jay K., Vehlow J. Formation and destruction of PCDD/F inside a grate furnace. Chemosphere. 2002;46:1263–1272. doi: 10.1016/s0045-6535(01)00256-9. [DOI] [PubMed] [Google Scholar]

- Ilyas S., Srivastava R.R., Kim H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020;141652 doi: 10.1016/j.scitotenv.2020.141652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Imtenan S., Varman M., Masjuki H.H., Kalam M.A., Sajjad H., Arbab M.I., Rizwanul Fattah I.M. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: a review. Energy Convers. Manag. 2014;80:329–356. [Google Scholar]

- Isahak W.N.R.W., Hisham M.W.M., Yarmo M.A., Yun Hin T.-y. A review on bio-oil production from biomass by using pyrolysis method. Renew. Sustain. Energy Rev. 2012;16:5910–5923. [Google Scholar]

- Jang Y.-C., Lee C., Yoon O.-S., Kim H. Medical waste management in Korea. J. Environ. Manag. 2006;80:107–115. doi: 10.1016/j.jenvman.2005.08.018. [DOI] [PubMed] [Google Scholar]

- Johns Hopkins University (JHU) COVID-19 dashboard by the center for systems science and engineering (CSSE) at johns Hopkins university (JHU) 2021. https://coronavirus.jhu.edu/map.html Date accessed: 13th January, 2021.

- Jung S., Lee S., Dou X., Kwon E.E. Valorization of disposable COVID-19 mask through the thermo-chemical process. Chemical Engineering Journal. 2020 doi: 10.1016/j.cej.2020.126658. 126658. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaminsky W., Kim J.-S. Pyrolysis of mixed plastics into aromatics. J. Anal. Appl. Pyrol. 1999;51:127–134. [Google Scholar]

- Karayildirim T., Yanik J., Yuksel M., Saglam M., Vasile C., Bockhorn H. The effect of some fillers on PVC degradation. J. Anal. Appl. Pyrol. 2006;75:112–119. [Google Scholar]

- Kargar S., Paydar M.M., Safaei A.S. A reverse supply chain for medical waste: a case study in Babol healthcare sector. Waste Manag. 2020;113:197–209. doi: 10.1016/j.wasman.2020.05.052. [DOI] [PubMed] [Google Scholar]

- Kargar S., Pourmehdi M., Paydar M.M. Reverse logistics network design for medical waste management in the epidemic outbreak of the novel coronavirus (COVID-19) Sci. Total Environ. 2020;746:141183. doi: 10.1016/j.scitotenv.2020.141183. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim K.-H., Jahan S.A., Kabir E., Brown R.J.C. A review of airborne polycyclic aromatic hydrocarbons (PAHs) and their human health effects. Environ. Int. 2013;60:71–80. doi: 10.1016/j.envint.2013.07.019. [DOI] [PubMed] [Google Scholar]

- Kim S. Pyrolysis kinetics of waste PVC pipe. Waste Manag. 2001;21:609–616. doi: 10.1016/s0956-053x(00)00127-6. [DOI] [PubMed] [Google Scholar]

- Klemeš J.J., Fan Y.V., Tan R.R., Jiang P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sustain. Energy Rev. 2020;127:109883. doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar R., Strezov V., Weldekidan H., He J., Singh S., Kan T., Dastjerdi B. Lignocellulose biomass pyrolysis for bio-oil production: a review of biomass pre-treatment methods for production of drop-in fuels. Renew. Sustain. Energy Rev. 2020;123:109763. [Google Scholar]

- Kumar V., Singh S.B., Singh S. COVID-19: environment concern and impact of Indian medicinal system. Journal of Environmental Chemical Engineering. 2020;8:104144. doi: 10.1016/j.jece.2020.104144. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee D.-J., Lu J.-S., Chang J.-S. Pyrolysis synergy of municipal solid waste (MSW): a review. Bioresource Technology. 2020 doi: 10.1016/j.biortech.2020.123912. 123912. [DOI] [PubMed] [Google Scholar]

- Lee S., Kim T., Lee E., Lee C., Kim H., Rhee H., Park S.Y., Son H.-J., Yu S., Park J.W., Choo E.J., Park S., Loeb M., Kim T.H. Clinical course and molecular viral shedding among asymptomatic and symptomatic patients with SARS-CoV-2 infection in a community treatment center in the Republic of Korea. JAMA Internal Medicine. 2020;180:1447–1452. doi: 10.1001/jamainternmed.2020.3862. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee X.J., Ong H.C., Gan Y.Y., Chen W.-H., Mahlia T.M.I. State of art review on conventional and advanced pyrolysis of macroalgae and microalgae for biochar, bio-oil and bio-syngas production. Energy Convers. Manag. 2020;210:112707. [Google Scholar]

- Li F., Srivatsa S.C., Bhattacharya S. A review on catalytic pyrolysis of microalgae to high-quality bio-oil with low oxygeneous and nitrogenous compounds. Renew. Sustain. Energy Rev. 2019;108:481–497. [Google Scholar]

- Li X., Zhang H., Li J., Su L., Zuo J., Komarneni S., Wang Y. Improving the aromatic production in catalytic fast pyrolysis of cellulose by co-feeding low-density polyethylene. Appl. Catal. Gen. 2013;455:114–121. [Google Scholar]

- Lin H.-T., Huang M.-S., Luo J.-W., Lin L.-H., Lee C.-M., Ou K.-L. Hydrocarbon fuels produced by catalytic pyrolysis of hospital plastic wastes in a fluidizing cracking process. Fuel Process. Technol. 2010;91:1355–1363. [Google Scholar]

- Liu S., Yu J., Bikane K., Chen T., Ma C., Wang B., Sun L. Rubber pyrolysis: kinetic modeling and vulcanization effects. Energy. 2018;155:215–225. [Google Scholar]

- Liu Y., Zhai Y., Li S., Liu X., Liu X., Wang B., Qiu Z., Li C. Production of bio-oil with low oxygen and nitrogen contents by combined hydrothermal pretreatment and pyrolysis of sewage sludge. Energy. 2020;203:117829. [Google Scholar]

- Lu J.-S., Chang Y., Poon C.-S., Lee D.-J. Slow pyrolysis of municipal solid waste (MSW): a review. Bioresource Technology. 2020 doi: 10.1016/j.biortech.2020.123615. 123615. [DOI] [PubMed] [Google Scholar]

- Ma D., Feng Q., Chen B., Cheng X., Chen K., Li J. Insight into chlorine evolution during hydrothermal carbonization of medical waste model. J. Hazard Mater. 2019;380:120847. doi: 10.1016/j.jhazmat.2019.120847. [DOI] [PubMed] [Google Scholar]

- Makarichi L., Jutidamrongphan W., Techato K.-a. The evolution of waste-to-energy incineration: a review. Renew. Sustain. Energy Rev. 2018;91:812–821. [Google Scholar]

- Marcilla A., Beltrán M. Thermogravimetric kinetic study of poly(vinyl chloride) pyrolysis. Polym. Degrad. Stabil. 1995;48:219–229. [Google Scholar]