Abstract

This paper presents the results of an experimental study on the acoustic efficiency of plastic surgical face masks. Since the very high number of disposable masks being used globally on a daily basis to face the Covid19 pandemic is posing new environmental risks, mainly connected to improper disposal, any possible improvements in the management of this waste stream is very important. In this work their potential use as sound porous absorber is discussed. Surgical face masks are mainly made of polypropylene fibers which show good acoustical properties. Their porous structure was studied through the measurement of some non-acoustic properties: bulk density, fiber diameter, porosity, flow resistivity and tortuosity. Moreover, the sound absorption performance of samples, made of scrapped face masks, with different thicknesses was evaluated using an impedance tube according to ISO 10534-2. The results obtained from the sound absorption spectra and two single indexes, Noise Reduction Coefficient and Sound Absorption Average showed a high sound absorption value over a frequency range of interest. Finally, the sound absorption spectra obtained for surgical face masks were compared with those obtained for fibrous materials currently used in building sector, suggesting that this fibrous waste could act as a possible substitute to traditional ones.

Keywords: Sound fibrous absorber, Surgical face masks, Acoustic properties, Polypropylene fibers

Graphical abstract

1. Introduction

During the last year, the SARS-CoV-2 disease spread has become the largest worldwide pandemic ever recorded. In order to avoid the numerous and severe threats to humanity that this pandemic supposes, the World Health Organisation (WHO) proposed, among numerous other policies, the necessity to reduce the spread of this virus into humans by using different types of face masks (WHO, 2020a). These can be mainly classified as surgical or medical disposable masks (SFMs), FFP2/FFP3/N95/KN95-type respiratory protection devices and cloth masks (non-certified mask) (Assefa Aragaw, 2020; Dharmaraj et al., 2021; Selvaranjan et al., 2021).

The extensive use of this Personal Protective Equipment (PPE) has been growing around the world during the last year and its demand is expected to increase at least in the next years (Rowan and Laffey, 2021). Africa is consuming more than twelve billions medical and fabric face masks monthly (Benson et al., 2021a). In Asia the number of these PPEs is pushing 2.2 billion everyday approximate (Saberian et al., 2021; Sangkham, 2020). Europe with 450 million, South America and North America with 380 and 250 million, respectively, and Oceania with 22 million (Benson et al., 2021b), contribute to the total number of disposal face masks used daily around the world. Therefore, the number of this PPEs used daily around the world is approximately of 4 billion. This represents more than 1000 tons of COVID-19 related waste generated daily, only taking into account SFMs. This large amount of waste, if not recycled or disposed of, may cause significant environmental pollution, as a result of a slowly degrading over years into smaller particles and under ambient conditions (Saliu et al., 2021) (Fig. 1 ). Numerous works have identified SFMs as potential sources of microplastics which have multiple and dangerous effects into all ecosystems worldwide (Assefa Aragaw, 2020; Fadare and Okoffo, 2020; Anastopoulos and Pashalidis, 2021; Dharmaraj et al., 2021). Therefore it is very important and necessary to study the feasibility of recycling and reusing of SFMs into new products or applications to avoid this waste littering the streets, environment or the oceans.

Fig. 1.

Photographs of surgical face masks lying on the floor.

Following the recommendations made by WHO (WHO, 2020b) and the Spanish Ministry of Health (Spanish Ministry of Health, 2020), disposal surgical face masks should not be reused or recycled once worn. They are considered as municipal or medical waste depending on the country and therefore this waste must be incinerated in a waste-to-energy plant before ending up in the landfill. However, some works have been looking at the best way to reuse the surgical face masks, disinfecting them through promising methods based on the use of hydrogen peroxide vapour, ultraviolet radiation, moist heat, dry heat or ozone gas (Rubio-Romero et al., 2020) trying to ensure a safe recycling process in order to obtain raw materials safe to reuse in different applications.

There are two possible ways to recycling SFMs; primary recycling and secondary or chemical recycling (Selvaranjan et al., 2021). The primary recycling can be considered when the product is used without previous treatment, preserving its original structure. The chemical recycling is considered when the SFM is re-melted and re-processed into new products. This latter is due to the SFMs are mainly composed by polypropylene (Assefa Aragaw, 2020; Kilmartin-Lynch et al., 2021; Saliu et al., 2021), a thermoplastic petroleum-based polymer that shows good chemical resistance and low photo-oxidative stability (Andreassen, 1999), hazardous to the environment and can take several years to breakdown in the environment.

To the best knowledge of the authors, some works have showed that SFMs can be applied without previous treatment. One of these uses is the incorporation of small quantities of shredded face masks in the manufacture of concrete, decreasing the number of micro-cracks and therefore, improving the mechanical properties and the overall quality of this (Kilmartin-Lynch et al., 2021). Other possible use is the addition of low percentages (0 to 5% by weight of soils) of shredded SFMs in the manufacture of materials for road, providing more ductility and flexibility for the pavement base and sub-base layers (Saberian et al., 2021).

This work provides an experimental investigation of the acoustic performance of fibers coming from SFMs for using as sound absorbers since polypropylene fibers have previously shown good acoustic performance (Hariprasad et al., 2020). Sound porous absorbers are widely used in building, automotive, aerospace or industrial noise control applications in order to reduce noise pollution inside dwellings, educational buildings, living and commercial spaces or offices, obtaining an acoustic comfort level inside them (Hariprasad et al., 2020; Taban et al., 2020; Thai et al., 2020; Yun et al., 2020; Rubino et al., 2021). In order to thoroughly investigate the acoustic performance of this material, the evaluation of the sound absorption coefficient at normal incidence and its non-acoustic properties were required. For this purpose, the direct measurement of the sound absorption coefficient, through an impedance tube was used. Physical properties such as porosity, flow resistivity, fiber diameter and skeletal density were obtained.

The paper is structured as follows: Section 2 presents the sample preparation of the SFMs object of this work and the experimental methodology used to obtain the physical and the acoustic properties of the SMFs; Section 3 reports the results of the sound absorption coefficient and the comparison between SFMs fibers and commercial sound fibrous absorbers; and Section 4 reports some concluding remarks.

2. Materials and methods

2.1. Sample preparation

The materials used in this work were used surgical face masks coming from the authors of this work. Eighty face masks from the same brand, collected during eight days, were used. This type of disposable mask was composed by three layers; an outer coloured non-woven layer (black, blue or white) repelling water (hydrophobic), a middle melt-blown layer acting as a filter and an inner soft non-woven layer for absorbing moisture. Even though it is not recommended washing or disinfecting these non-reusable hygienic masks for their re-use as face masks (Rubio-Romero et al., 2020; UNE 0064-1, 2020; UNE 0064-2, 2020), in our case and for our purpose, previously to work with SFMs and in order to disinfect them, they were introduced in a vacuum oven for 30 min with a temperature of 70 °C and 80% relative humidity (3M, 2021). Subsequently when they were cooled and the moisture was removed; nose clip and elastic strap were separated manually from SFMs and shredded into short fibers using a cutting mill (Fig. 2 ). Finally, the fibers were compacted with the hard back termination of the impedance tube to reach different bulk densities. No bonding method was used although some authors showed that the bonding method had little effects on the sound absorption performance, only included in the bulk density (Lee and Joo, 2003; Maderuelo-Sanz et al., 2011). Nine different samples, having different bulk densities, porosities and thicknesses (Table 1 ) and therefore different acoustic performance, were used in this work. For each of these nine samples, three specimens, having the same properties, were tested and subsequently their values averaged.

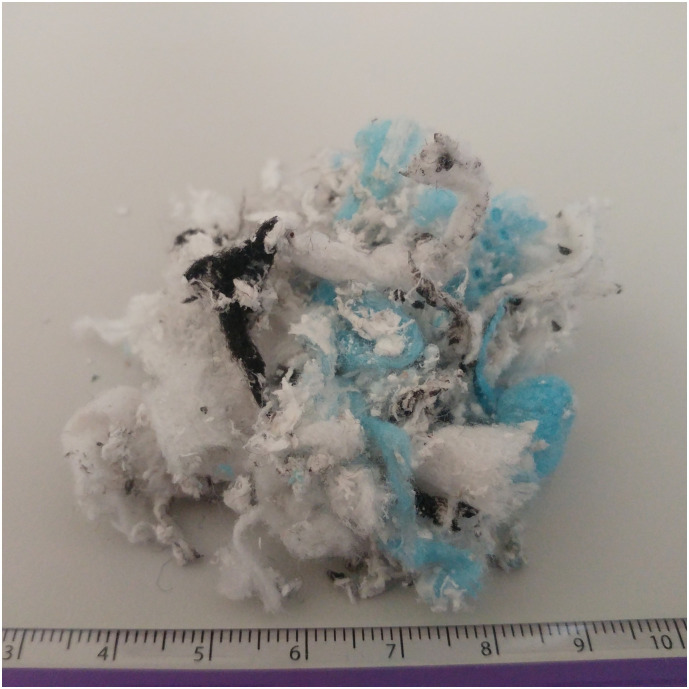

Fig. 2.

Image of polypropylene fibers coming from surgical face masks.

Table 1.

Physical properties of the SFM samples studied in this work.

| Sample | Thickness (cm) | Bulk density ρm (g cm−3) | Surface density ρA (g cm−2) | Porosity ϕ (%) | Tortuosity | Flow resistivity (Pa s m−2) |

|---|---|---|---|---|---|---|

| M#1 | 3.0 | 0.0505 ± 0.0027 | 0.1514 ± 0.0021 | 93.27 ± 0.36 | 1.036 | 12,065 ± 214 |

| M#2 | 3.0 | 0.1009 ± 0.0051 | 0.3028 ± 0.0042 | 86.54 ± 0.68 | 1.078 | 45,549 ± 624 |

| M#3 | 3.0 | 0.1514 ± 0.0087 | 0.4542 ± 0.0063 | 79.81 ± 1.16 | 1.126 | 68,106 ± 736 |

| M#4 | 6.0 | 0.0757 ± 0.0024 | 0.4542 ± 0.0063 | 89.91 ± 0.32 | 1.056 | 22,487 ± 233 |

| M#5 | 6.0 | 0.1009 ± 0.0052 | 0.6056 ± 0.0084 | 86.54 ± 0.69 | 1.078 | 40,480 ± 547 |

| M#6 | 6.0 | 0.1262 ± 0.0054 | 0.7570 ± 0.0105 | 83.18 ± 0.72 | 1.101 | 65,061 ± 677 |

| M#7 | 9.0 | 0.0505 ± 0.0012 | 0.4542 ± 0.0063 | 93.27 ± 0.16 | 1.036 | 7,817 ± 154 |

| M#8 | 9.0 | 0.0841 ± 0.0047 | 0.7570 ± 0.0105 | 88.79 ± 0.63 | 1.063 | 23,743 ± 336 |

| M#9 | 9.0 | 0.1178 ± 0.0080 | 1.0598 ± 0.0146 | 84.30 ± 1.07 | 1.093 | 40,878 ± 512 |

2.2. Infrared spectroscopy

In order to know the nature of the SMFs, the Fourier Transform Infrared (FTIR) Spectroscopy analysis was carried out. FTIR spectra were taken by a Nicolet 6700 with an incorporated microscopy spectrometer covering the 400–4000 cm−1 range, by placing of SMFs samples in a diamond of attenuated total reflection (ATR) cell. The spectra were registered with a resolution of 4 cm−1. For each sample 64 scans were signal-averaged in each interferogram.

2.3. Fiber size

Average fibers diameters were determined using an optical microscopy (Leica Leitz Laborlux 12 POL S in transmission) using a 5× and 50× objectives, being the images recorded digitally with a JVC camera model TK-C1480E. At least 15 specimens of fibers were measured and diameters were averaged. The areal density was determined following the ASTM D-3776 (2007), Standard Test Method for Mass per Unit Area (Weight) of Fabric. Samples were weighed using a Mettler Toledo Precision Weighing balance (AX 205).

2.4. Porosity

The porosity of the samples was defined as the relationship between the skeletal of the sample and the air surrounded it. The higher porosity, the higher dissipation of sound energy will occur inside the porous absorber. In this work, porosity was evaluated non-acoustically through the measurement of the skeletal volume of the surgical face mask by inert gas displacement, helium, using the volume-pressure relationship of Boyle's Law and subsequently applying the next expression:

| (1) |

where ρ m is the bulk density of the sample (kg m−3) and ρ s the skeletal density of the porous material (kg m−3). Porosity values were obtained according Maderuelo-Sanz et al. (2018) using a helium pycnometer (Quantachrome SPY-3) with a calibrated cell having a volume of 35.39 cm3. The measurement process was repeated three times for each samples and subsequently averaged.

2.5. Flow resistivity

Flow resistivity, beside porosity, is other non-acoustic parameters influencing the sound absorption properties of a porous absorber. It is directly related to the capability to absorb sound energy by a material, so the sound absorption value is highly dependent on this parameter. It is defined as the resistance experimented by the air flowing inside a porous material. Therefore it indicates how much sound energy can be lost inside the porous absorber due to viscous and thermal effects when air passes through it. Bulk density determines the flow resistivity value so both are inversely proportional (Yang et al., 2015; Kucuk and Korkmaz, 2016; Maderuelo-Sanz et al., 2016). Low values of flow resistivity are associated with low resistance to air flowing through the material whilst high values can indicate a complex porous structure and therefore high resistance to air flow so low sound absorption values may be expected (Bies and Hansen, 1980). In this work, the Ingard and Dear (1985) method was used to obtain the flow resistivity of the samples. For each sample, the measurement process was repeated three times and the averaged value was obtained.

2.6. Tortuosity

The tortuosity (α ∞), a dimensionless structural parameter, indicates how direct the path is taken by the sound wave inside the porous absorber (Maderuelo-Sanz et al., 2016). It depends only on the pore geometry (Johnson et al., 1982). A higher fiber density leads to a more complex path inside the porous absorber therefore it implies higher interaction between sound waves and fibers. This results in higher dissipation of the sound energy. Tortuosity can be evaluated by using an empirical formula (2) in terms of porosity ϕ as follows (Attenborough, 1993):

| (2) |

In general, tortuosity mainly affects the position and height of the sound absorption spectrum peaks (Attenborough, 1983).

2.7. Measurement of sound absorption coefficient

In order to obtain the acoustic properties of the biocomposites, sound absorption coefficient at normal incidence measurements were carried out according to ISO standard 10534-2 (1998). In this work a Brüel & Kjær impedance tube type 4206T were used. Signals were analysed with a portable Brüel & Kjær PULSE System. In order to accomplish accurate measurements in the frequency range of 50–6400 Hz, two different tubes having different diameters were used, one for measurements over the frequency range 50 Hz - 1600 Hz (100 mm in diameter) and other for frequency range of 500 Hz - 6400 Hz (29 mm in diameter). Previously to start any measurement and after the sample positioning, the influencing environmental parameters (atmospheric pressure, air temperature and relative humidity) were measured and introduced in the software. For each measurement five different samples were used and subsequently averaged.

In order to evaluate the sound absorption capability of the samples, single number grading methods which are independent of frequencies were used. These indexes are useful for a practical evaluation of the performance of sound porous absorbers. For this purpose, the ASTM C423 (2017) defines the Noise Reduction Coefficient (NRC), defined as the average of the sound absorption coefficients for 250, 500, 1000 and 2000 Hz and rounded off to the nearest multiple of 0.05, and the Sound Absorption Average (SAA), defined as the average of the sound absorption coefficients for 200, 250, 315, 400, 500, 630, 800, 1000, 1250, 1600, 2000 and 2500 Hz and rounded off to the nearest 0.01.

3. Results and discussion

The infrared spectrum in the range of 400–4000 cm−1 of the outer, middle and inner layers is showed in Fig. 3 . All referred absorption peaks indicate that each filter is mainly made of atactic polypropylene. Absorption peak located at 840 cm−1 and 2863 cm−1 is assigned to C–CH3 stretching vibration. Absorption peaks displayed at 969, 998 and 1170 cm−1 are assigned to –CH3 rocking vibration. Symmetric bending vibration mode of –CH3 group is detected at 1375 cm−1. Absorption peak observed at 2944 cm−1 is related to –CH3 asymmetric stretching vibration. The peaks at 1455, 2827 and 2917 are attributed to –CH2– symmetric bending, –CH2– symmetric stretching and –CH2– asymmetric stretching, respectively.

Fig. 3.

FTIR spectra of the different layers which surgical face masks are made of.

Measurements based on the optical microscope revealed some differences between middle layer and the outer and the inner layer. The diameter of the fibers from the internal and external layers was within the range of 22–25 μm (Fig. 4 a) whilst the diameter of the fibers from the middle layer ranging from 2 μm to 8 μm (Fig. 4b), values in accordance with previous works (Zhang et al., 2021). In addition, the first layer, the filter, shows higher fiber density than the other two layers (Fig. 4c and d). There is a great heterogeneity between the fibers diameters mainly in the middle layer. This could affect to the values of the physical properties of the samples such as flow resistivity, tortuosity or porosity. It is well known that the sound absorption coefficient of the non-woven fabric improves when increasing the diameter or the fibers length (Lee and Joo, 2003) so in future works it will be necessary to take into account how the fibers might be sorted on large scale.

Fig. 4.

Microscopic images of polypropylene fibers coming from inner and outer layers (a, c) and middle layer (b, d) obtained with 50× and 5× objectives, respectively.

The skeletal density obtained for SFMs samples was 0.750 ± 0.004 g cm−3. With this value and the bulk density it was possible to determine the porosity using Eq. (1). The open porosities of the samples were showed in Table 1. These values ranged from 79.81% to 93.27% showing, as it was obvious, that a significant decrease in bulk density led to a substantial increase in porosity due to higher number of voids in the material. The Ingard and Dear (1985) method was used to obtain the flow resistivity. These values ranged from 7817 Pa s m−2 to 65,061 Pa s m−2. As it was expected, the higher the bulk density, the higher the flow resistivity is (Fig. 5 ).

Fig. 5.

Relationship between bulk density and experimental flow resistivity for SFM samples.

3.1. Effect of thickness on sound absorption performance

In order to study the effect of the thickness on the sound absorption performance of the SFM, samples 3, 4 and 7, having different thicknesses (3, 6 and 9 cm, respectively), were studied. Fig. 6 shows the sound absorption spectra for these samples. It could be seen that increasing the thickness, the first maximum of the sound absorption spectra shifted toward low frequencies, increasing the value of the sound absorption coefficient, growing up the amplitude of the first peak. The values of the absorption coefficient for the first maximum were 0.750, 0.925 and 0.995 achieved at 912 Hz, 712 Hz and 624 Hz for thicknesses of 30 mm, 60 mm and 90 mm, respectively. At higher frequencies the thickness has slightly effect, tending asymptotically to a value ranging between 0.95 and 1. As already well known, increasing the thickness of the sound porous absorber the absorption coefficient improves, both in terms of the amplitude and the frequency bandwidth. This improvement toward low frequency range is associated to a greater dissipation of the sound wave passing through the sample mainly due to the viscothermal interactions contributing to a greater sound absorption coefficient.

Fig. 6.

Measured sound absorption spectra for SFM samples with different thicknesses.

3.2. Effect of bulk density on sound absorption performance

Fig. 7 shows the effect of the bulk density on the sound absorption spectra of SFM samples having the same thicknesses. The higher the bulk density, the first maximum shifts to lower frequencies decreasing the amplitude of this peak. This can be associated to the high values of flow resistivity of samples with high bulk density values, where the vibrations by viscous effects show more efficient damping of the vibrations, and therefore improving the sound absorption at low frequencies being this improvement rather limited. Likewise, at medium to high frequencies, the value of the sound absorption coefficient tends to decrease but always maintaining relatively high values, above 0.900.

Fig. 7.

Measured sound absorption spectra for SFM samples with different densities and thickness = 3 cm.

In order to evaluate the acoustic performance of SFM samples, NRC and SAA were evaluated according ASTM C423 (2017). Table 2 shows NRC and SAA values for the SFM samples. NRC values ranges from 0.45 to 0.85 whilst SAA values ranges from 0.43 to 0.83. As it was expected it could be observed that the NRC increased when the thickness of the sample increased, because of the interaction between the sound waves and fibers of the sound absorber was greater when increasing the thickness. The higher the thickness, the higher the thermal-viscous effects were because of friction, so the NRC was higher. Moreover, it could be observed a relationship between SAA and the flow resistivity where the higher the SAA, the lower the flow resistivity is, except for sample M#1 that showed anomalous results.

Table 2.

NRC and SAA values for SFM samples and some commercial sound fibrous absorbers.

| M#1 | M#2 | M#3 | M#4 | M#5 | M#6 | M#7 | M#8 | M#9 | RW-3 cm | RW-5 cm | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NRC | 0.45 | 0.60 | 0.55 | 0.75 | 0.70 | 0.65 | 0.85 | 0.80 | 0.70 | 0.55 | 0.70 |

| SAA | 0.43 | 0.58 | 0.56 | 0.75 | 0.68 | 0.64 | 0.83 | 0.81 | 0.73 | 0.54 | 0.69 |

In order to compare SFMs with some commercial sound fibrous absorbers, two different fibrous materials made of rock wool; RW-3 cm (ρ B = 0.030 g cm−3; fiber diameter = 10 μm; σ = 8248 Pa s m−2) and RW-5 cm (ρ B = 0.110 g cm−3; fiber diameter = 15 μm; σ = 12,547 Pa s m−2), were tested and compared with samples M#2 and M#4. Fig. 8 shows the sound absorption spectra for the commercial samples and the samples M#2 and M#4. The results obtained showed that sound absorption spectra for samples M#2 and RW-3 cm, having the same thickness, were similar. In the case of sample M#2 it could be seen that values of sound absorption coefficient were slightly higher for frequencies greater than 650 Hz. In the case of samples M#4 and RW-5 cm, despite having different thicknesses, 6 cm and 5 cm respectively, it could be noted that the first maximum of the sample M#4 was lower than for sample RW-5 cm, but achieved relatively similar sound absorption values, 0.930 and 0.980 respectively. Table 2 shows the NRC and SAA values obtained for these samples. Samples M#2 and M#4 showed higher NRC and SAA values than samples RW-3 cm and RW-5 cm and taking into account that the higher the NRC or the SAA values, the better will be the material capability in sound absorption, this suggested that the SFM samples acted as very effective sound absorber, comparable in many cases with some commercial sound porous absorbers.

Fig. 8.

Comparison between sound absorption spectra for commercial sound fibrous absorbers and samples M#2 and M#4.

4. Conclusions

In this work, an experimental study of the acoustic properties of polypropylene fibers coming from surgical face masks were carried out in order to reduce this type of pandemic-generated waste. Nine fibrous samples, composed of atactic polypropylene fibers coming from surgical face masks, were acoustically characterised by means of an impedance tube. Non-acoustic properties such as bulk density, porosity and flow resistivity were firstly measured. Tortuosity was evaluated according a prediction-based equation. It was found that SFM samples showed different physical properties, providing different fibrous microstructures and therefore different acoustic performance. In general this type of sound absorber was very effective at mean-high frequencies. Increasing the thickness caused an improvement of the sound absorption at low frequencies. Therefore, this suggested that the SFM samples acted as very effective sound porous absorber.

Moreover, the sound absorption performance of SFM samples was compared with some commercial fibrous absorbers. The results suggested that SFM, could show better acoustic performance than those fibrous absorbers used actually in the building sector, even having lower thicknesses. Therefore, the recycled of the used surgical face masks, duly disinfected, could be considered good sound porous absorber to be used in building construction, such as acoustic ceiling panels, perforated panel absorbers, sandwich structures, or in the core of noise barriers. Finally, some of the practicalities of using surgical masks for noise control applications are the large amount of available raw material, their low density and good acoustic properties.

CRediT authorship contribution statement

Rubén Maderuelo-Sanz: Writing – original draft, Writing – review & editing, Conceptualization, Methodology, Supervision, Validation. Patricia Acedo-Fuentes: Conceptualization, Investigation. Francisco José García-Cobos: Investigation, Validation. Francisco José Sánchez-Delgado: Investigation, Validation. María Isabel Mota-López: Investigation, Writing – review & editing. Juan Miguel Meneses-Rodríguez: Investigation, Validation, Visualization.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

Acknowledgements

The author is grateful to INTROMAC and the Regional Office of Economics, Science and Digital Agenda of the Government of Extremadura.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Editor: Damia Barcelo

References

- 3M Decontamination Methods for M N95 Respirators. M Science. Applied to Life. Technical Bulletin. Revision 10. 2021. https://multimedia.3m.com/mws/media/1824869O/decontamination-methods-for-3m-filtering-facepiece-respirators-technical-bulletin.pdf

- Anastopoulos I., Pashalidis I. Single-use surgical face masks, as a potential source of microplastics: do they act as pollutant carriers? J. Mol. Liq. 2021;326:115247. doi: 10.1016/j.molliq.2020.115247. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Andreassen, E., 1999. Infrared and Raman spectroscopy of polypropylene. In: KargerKocsis J. (eds) Polypropylene. Polymer Science and Technology Series, vol. 2. Springer, Dordrecht. doi: 10.1007/978-94-011-4421-6_46. [DOI]

- Assefa Aragaw T. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159:111517. doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- ASTM C423, 2017, Standard test method for sound absorption and sound absorption coefficients by the reverberation room method. ASTM Stand. doi: 10.1520/C0423-17. [DOI]

- ASTM D-3776 . Annual Book of ASTM Standards. 2007. Standard test methods for mass per unit area (weight) of fabric.www.astm.org [Google Scholar]

- Attenborough K. Acoustical characteristics of rigid fibrous absorbents and granular materials. J. Acoust. Soc. Am. 1983;73:785. doi: 10.1121/1.389045. [DOI] [Google Scholar]

- Attenborough K. Models for the acoustical characteristics of air filled granular materials. Acta Acust. 1993;64:27–30. [Google Scholar]

- Benson N.U., Fred-Ahmadu O.H., Bassey D.E., Atayero A.A. COVID-19 pandemic and emerging plastic-based personal protective equipment waste pollution and management in Africa. J. Environ. Chem. Eng. 2021;9(3):105222. doi: 10.1016/j.jece.2021.105222. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benson N.U., Bassey D.E., Palanisami T. COVID pollution: impact of COVID-19 pandemic on global plastic waste footprint. Heliyon. 2021;7(2) doi: 10.1016/j.heliyon.2021.e06343. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bies D.A., Hansen C.H. Flow resistance information for acoustical design. Appl. Acoust. 1980;13(5):357–391. doi: 10.1016/0003-682X(80)90002-X. [DOI] [Google Scholar]

- Dharmaraj S., Ashokkumar V., Hariharan S., Manibharathi A., Loke Show P., Chong C.T., Ngamcharussrivichai C. The COVID-19 pandemic face mask waste: a blooming threat to the marine environment. Chemosphere. 2021;272 doi: 10.1016/j.chemosphere.2021.129601. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737:140279. doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hariprasad K., Ravichandran K., Jayaseelan V., Muthuramalingam T. Acoustic and mechanical characterisation of polypropylene composites reinforced by natural fibres for automotive applications. J. Mater. Res. Technol. 2020;9(6):14029–14035. doi: 10.1016/j.jmrt.2020.09.112. [DOI] [Google Scholar]

- Ingard K.U., Dear T.A. Measurement of acoustic flow resistance. J. Sound Vib. 1985;103(4):567–572. doi: 10.1016/S0022-460X(85)80024-9. [DOI] [Google Scholar]

- ISO 10534-2 . International Organization for Standardization; Geneva: 1998. Acoustics Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes. Part 2: Transfer Function Method. [Google Scholar]

- Johnson D.L., Plona T.J., Scala C., Pasierb F., Kojima H. Tortuosity and acoustic slow waves. Phys. Rev. Lett. 1982;49:1840–1844. doi: 10.1103/PhysRevLett.49.1840. [DOI] [Google Scholar]

- Kilmartin-Lynch S., Saberian M., Li J., Roychand R., Zhang G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021;296 doi: 10.1016/j.jclepro.2021.126460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kucuk M., Korkmaz Y. Sound absorption properties of bilayered nonwoven composites. Fiber Polym. 2016;16:941–948. doi: 10.1007/s12221-015-0941-9. [DOI] [Google Scholar]

- Lee Y., Joo C. Sound absorption properties of recycled polyester fibrous assembly absorbers. Autex Res. J. 2003;3:78–84. http://www.autexrj.com/cms/zalaczone_pliki/5-03-2.pdf [Google Scholar]

- Maderuelo-Sanz R., Martín-Castizo M., Vilchez-Gómez R. The performance of resilient layers made from recycled rubber fluff for impact noise reduction. Appl. Acoust. 2011;72:823–828. doi: 10.1016/j.apacoust.2011.05.004. [DOI] [Google Scholar]

- Maderuelo-Sanz R., Nadal-Gisbert A.V., Crespo-Amorós J.E., Barrigón Morillas J.M., Parrés-García F., Juliá Sanchís E. Influence of the microstructure in the acoustical performance of consolidated lightweight granular materials. Acoust. Aust. 2016;44:149–157. doi: 10.1007/s40857-016-0048-5. [DOI] [Google Scholar]

- Maderuelo-Sanz R., Gómez Escobar V., Meneses-Rodríguez J.M. Potential use of cigarette filters as sound porous absorber. Appl. Acoust. 2018;129:86–91. doi: 10.1016/j.apacoust.2017.07.011. [DOI] [Google Scholar]

- Rowan N.J., Laffey J.G. Unlocking the surge in demand for personal and protective equipment (PPE) and improvised face coverings arising from coronavirus disease (COVID-19) pandemic – implications for efficacy, re-use and sustainable waste management. Sci. Total Environ. 2021;752 142259 doi: 10.1016/j.scitotenv.2020.142259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rubino C., Aracil M.B., Liuzzi S., Stefanizzi P., Martellotta F. Wool waste used as sustainable nonwoven for building applications. J. Clean. Prod. 2021;278 doi: 10.1016/j.jclepro.2020.123905. [DOI] [Google Scholar]

- Rubio-Romero J.C., Pardo-Ferreira M.C., Torrecilla-García J.A., Calero-Castro S. Disposable masks: disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Saf. Sci. 2020;129 doi: 10.1016/j.ssci.2020.104830. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saberian M., Li J., Kilmartin-Lynch S., Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021;769:145527. doi: 10.1016/j.scitotenv.2021.145527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saliu F., Veronelli M., Raguso C., Barana D., Galli P., Lasagni M. The release process of microfibers: from surgical face masks into the marine environment. Environ. Adv. 2021;4 doi: 10.1016/j.envadv.2021.100042. [DOI] [Google Scholar]

- Sangkham S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. CSCEE. 2020;2 doi: 10.1016/j.cscee.2020.100052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Selvaranjan K., Navaratnam S., Rajeev P., Ravintherakumaran N. Environmental challenges induced by extensive use of face masks during COVID-19: a review and potential solutions. Environ. Chall. 2021;3 doi: 10.1016/j.envc.2021.100039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Spanish Ministry of Health Recomendaciones sobre el uso de mascarillas en la comunidad en el contexto del COVID-19. 2020. https://www.mscbs.gob.es/en/profesionales/saludPublica/ccayes/alertasActual/nCov/documentos/Recomendaciones_mascarillas_ambito_comunitario.pdf

- Taban E., Soltani P., Berrardi U., Putra A., Mousavi S.M., Faridan M., Samaei S.E., Khavanin A. Measurement, modelling, and optimization of sound absorption performance of Kenaf fibers for building applications. Build. Environ. 2020;180 doi: 10.1016/j.buildenv.2020.107087. [DOI] [Google Scholar]

- Thai Q.B., Chong R.O., Nguyen P.T.T., Le D.K., Le P.K., Phan-Thien N., Duong H.M. Recycling of waste tire fibers into advanced aerogels for thermal insulation and sound absorption applications. J. Environ. Chem. Eng. 2020;8 doi: 10.1016/j.jece.2020.104279. [DOI] [Google Scholar]

- UNE 0064-1 . Spanish Association for Standardisation-UNE; 2020. Non-reusable Hygienic Masks. Materials, Design, Manufacturing, Marking and Use Requirements. Part 1: For Adult Use. [Google Scholar]

- UNE 0064-2 . Spanish Association for Standardisation-UNE; 2020. Non-reusable Hygienic Masks. Materials, Design, Manufacturing, Marking and Use Requirements. Part 2: For Children Use. [Google Scholar]

- WHO Coronavirus disease (COVID-19) advice for the public: when and how to use masks. 2020. https://www.who.int/emergencies/diseases/novel-coronavirus-2019/advice-for-public/when-and-how-to-use-masks

- WHO World Health Organization; 2020. Advice on the use of masks in the context of COVID-19: interim guidance, 5 June 2020. https://apps.who.int/iris/handle/10665/332293

- Yang Y., Chen Z., Chen Z., Fu R., Li Y. Sound insulation properties of sandwich structures on glass fiber felts. Fiber Polym. 2015;16:1568–1577. doi: 10.1007/s12221-015-5200-6. [DOI] [Google Scholar]

- Yun B.Y., Cho H.M., Kim Y.U., Lee S.C., Berardi U., Kim S. Circular reutilization of coffee waste for sound absorbing panels: a perspective on material recycling. Environ. Res. 2020;184 doi: 10.1016/j.envres.2020.109281. [DOI] [PubMed] [Google Scholar]

- Zhang Z., Ji D., He H., Ramakrishna S. Electrospun ultrafine fibers for advanced face masks. Mater. Sci. Eng. R. Rep. 2021;143 doi: 10.1016/j.mser.2020.100594. [DOI] [PMC free article] [PubMed] [Google Scholar]