Abstract

Due to the COVID-19 pandemic, there is an unprecedented crisis for businesses. The small and medium enterprises (SMEs) have been impacted even more, due to their limited resources. Extant literature has prescribed many treatments on how SMEs could survive in post COVID-19 situation, but studies did not analyse how big data driven innovation could improve supply chain management (SCM) process in the post COVID-19 pandemic under the moderating influence of SME technology leadership support. Thus, there is a research gap in this important domain. The aim of this study is to examine the impact of big data driven innovation and technology capability of the SME on its supply chain system. The study also investigates the moderating role of SME technology leadership support on SME performance in the post COVID-19 scenario. With the help of literature and resource-based view (RBV) and dynamic capability view (DCV) theory, a theoretical model has been developed conceptually. Later the model is validated using structural equation modelling (SEM) technique with 327 usable respondents from SMEs from India. The study found that both big data driven innovation and the techno-functional capability of SME impacts supply chain capability which in turn impacts the SME performance in the post COVID-19 scenario. The study also finds that there will be a moderating impact of SME technology leadership support on SME performance.

Keywords: Big Data, IoT, SME Performance, COVID, Supply chain, Innovation, Sustainability, SME Leadership Support

1. Introduction

The outbreak of COVID-19 pandemic has adversely affected national and global economies (Piccialli et al., 2021, Elakkiya et al., 2021). In this crisis, all enterprises have been facing a series of problems. These include supply chain disruption, awful decrease in demand, shortage of raw materials, cancellation of export orders, severe transportation disruption and so on (Shafi et al., 2020). It is pertinent to mention here that SMEs perceive skill resource constrains, financial problems, as well as managerial issues. In such situation, the SMEs became the victims of COVID-19 apocalypse since they are not able to adequately combat the turbulent situation which continued longer than anticipated (Prasad et al., 2015, Bartik et al., 2020). In addition, SMEs are found to be highly dependent on their regular and routine business transactions with a meagre number of customers (Williams & Schaefer, 2013). In such COVID-19 scenario, SMEs are mostly running out of stock or some of the SMEs have been facing serious constraints to manage their supply chain (Handfield et al., 2020).

Data-driven innovation is a key pillar of growth especially for the SME sector (Del Giudice et al., 2021). There is a huge amount of data generated through different means such as sensors, supply chin related RFID, internet of things (IoT), and son on (Zhang et al., 2020). The confluence of different trends which includes internet of things and other technologies with declining in the cost of collection of data with its storage and processing, are also contributing to the generation of huge volumes of data which is termed as ‘big data’. This large volume of data which is known as big data is the core asset of SMEs (Kache and Seuring, 2017, Aryal et al., 2020). Big data driven capabilities and processes are increasingly influencing product and process innovation which is also providing significant competitive advantages to the SMEs.

SMEs are the main contributors for the improvement of a nation’s wealth and the SMEs help to enrich inventions and innovations (Massey et al., 2004, Stieglitz et al., 2019). SMEs are reported to have contributed to the economy of a nation since SMEs constitute on average 50% of employment and 90% of business worldwide (World Bank, 2020a, World Bank, 2020b). SMEs have been affected by COVID-19 pandemic adversely both on supply and demand side (Hallinger, 2020). On supply side, SMEs experienced the reduction of labour supply, raw materials and so on. Supply chains were interrupted culminating shortage of intermediate goods. On demand side, sudden loss of demand affected the SME abilities to function, and it also caused artificial liquidity shortage. For COVID-19 pandemic, all the enterprises were affected but SMEs had experienced higher levels of vulnerability and lower resilience because of their size and resource constraint (Dua et al., 2020, Kraus et al., 2020). Many studies have suggested how SMEs could sustain during COVID-19 pandemic by using modern technology like industry 4.0 to develop their supply chain (Bartik et al., 2020). But no studies investigated how big data driven innovation could help the SMEs to sustain their supply chain operations in post COVID-19 scenario with the support of their leadership. In this background, this research has following objectives:.

[i] To examine the impacts of big data driven innovation and technology capability on SME supply chain management system in post COVID-19 scenario.

[ii] To determine the influence of techno-functional capability (IoT, Big data, Cloud computing) on SME supply chain management system in post COVID-19 scenario.

[iii] To assess the influence of SME supply chain management capability on SME performance in post COVID-19 scenario.

[iv] To investigate the moderating role of SME technology leadership support on SME performance in post COVID-19 scenario.

2. Literature review

External environmental crisis like flood, earthquake, epidemic diseases, and other different issues severely impact business activities (Samantha, 2018, Asgary et al., 2020, Eggers, 2020). SMEs are seen to be more vulnerable to any turbulent situation since they are financially fragile with less resources compared to large enterprises (Bartik et al., 2020, El-Haddadeh et al., 2021). Several studies have shown the devastating effects of such turbulence like COVID-19 pandemic on SMEs. In 2011 because of flood in Thailand, 557,637 enterprises were affected and there were 2.5 million job losses, and it was ascertained that 90% of these affected enterprises were SMEs (Auzzir et al., 2018). Similarly, due to unprecedented flood in Malaysia during the end of 2014, more than 13,000 SMEs were severely affected (Auzzir et al., 2018). Due to foot and mouth disease (FMD) abrupt outbreak (2001), SMEs of UK sustained huge loss which were estimated as nearly 5 billion pounds (Bennett, & Phillipson, 2004). Moreover, for their small size and resource constraints, it has been observed that most of the SMEs could not fully survive in the post disaster stage (Samantha, 2018). In the post COVID-19 scenario, it has been experienced that SMEs try to manage the dislocation of supply chain with the help of advanced technology (Pang et al., 2015, Sharma et al., 2020; Chatterjee, 2020). However, it is observed that the stakeholders involved in SME business activities could not fully utilize the innovative technology in the supply chain context due to socio-material constraint in post COVID-19 Scenario (Pratono, 2016, Chatterjee et al., 2021c, Nandi et al., 2021).

In several studies it is seen that data driven innovation helps in business. Big data technology helps in data exploitation and creates value in a variety of supply chain related operations (Zonta et al., 2020, Bueno et al., 2020). Big data driven innovation also found to be helpful for optimisation of the global supply chain process for the manufacturing and services firms (Chatterjee and Nguyen, 2021, Zhu et al., 2021). It can also help for efficient usage of resources and supports in the process of tailoring customer and partner relationships management process (Brinch, 2018, Saleem et al., 2021).

It has been observed that SMEs will be able to address any unforeseen situation if they could strengthen their innovative technological abilities and develop their research and development capabilities (Lukić et al., 2017, Nath and Agrawal, 2020, Kumar et al., 2020). During the COVID-19 pandemic and even after that, SMEs could survive if they could strengthen their customer relationship management (CRM) technological ability and if the SMEs could provide flexibility of the working system so that the workers can work from any place at any time (Staples et al., 1999, Kalaitzi et al., 2017, Zimon and Madzík, 2019, Tan et al., 2016). Several studies have shown that if enterprises face such turbulent situation like COVID-19 pandemic, the enterprises would be able to quickly come out from that situation if they adopt appropriate strategies including usage of big data analytics, cloud computing optimization technology, IoT enabled technology and so on with the active support from the leadership of the SMEs for achieving better performance even in that scenario (Mishra et al., 2016, Thakur et al., 2016, Piccialli et al., 2021, Chatterjee et al., 2021d). Extant literature has demonstrated that how the COVID-19 pandemic could severely affect the business practices of the SMEs and how by using modern technologies, SMEs could address their supply chain interruption (Nandi et al., 2021). But no studies investigated how the innovative, technological, and financial abilities of the SMEs could impact their supply chain management ability to impact their performance during turbulence with the active support of SME technology leadership. Table 1 shows the summary of literature on supply chain management strategy in crisis.

Table 1.

Summary of literature on supply chain management strategy in crisis.

| Author(s) / Sources | Area of research | Key findings / Summary |

|---|---|---|

| Grewal, & Tansuhaj (2001) | This research investigated the role of market orientation and strategic flexibility for managing different turbulent situation. | - Role of market orientation and strategic flexibility - Managing turbulent situation. |

| Donate, & Guadamillas (2011) | This research focused on organizational factors to support the process of knowledge management in organization. This study also describes the importance of innovation. | - Importance of knowledge management in organization. - Innovation is the key factor for sustenance and effective knowledge management. |

| Kache, & Seuring (2017) | This study described the challenges and opportunities of the digital information at intersection between Big Data Analytics (BDA) and supply chain management system (SCM). | - Challenges and opportunities of the digital information - Shows the impact of BDA and SCM on digital information flow. |

| Brinch (2018) | This study described the value of big data in supply chain management. It also developed a conceptual framework. |

- Developed a conceptual framework - Application of big data in supply chain process |

| Basiouni, Hafizi, Akhtar, & Alojairi (2019) | The study did an assessment of Canadian Business IT Capabilities for Online Selling Adoption. The study used Net-Enabled Business Innovation Cycle approach. | - Assessment of Canadian organizations’ IT adoption - Online selling and importance of IT capability |

| Errassafi, Abbar, & Benabbou (2019) | This study described the mediating effect of internal integration between integration of supply chain and firm operational performance. The study took evidence from the Moroccan manufacturing organizations. |

- Found the mediating effect of internal integration. - The study focused on the Moroccan manufacturing firms. |

| Aryal, Liao, Nattuthurai, & Li (2020). | This study investigated about the emerging big data analytics technology and application of IoT in the supply chain process. It is a systematic review. | - Application of big data in supply chain process. - Challenges of deployment of modern technology. - Applications of IoT in improving supply chain flow. |

| Asgary, Ozdemir, & Özyürek (2020) | This study explained about the Small and Medium Enterprises and their global risks. The study especially focused on the manufacturing SMEs in Turkey. | - SME enterprises and their global risks. - Discussed situation of SMEs in Turkey. |

| Dua, Jain, Mahajan, & Velasco (2020) | This study investigated the impact of COVID-19 on jobs at small businesses in the United States. | - Impact of COVID 19 on SME jobs in United States. |

| Eggers (2020) | This research investigated the issues to effectively manage disasters. It also documented the challenges and opportunities for SMEs in the times of turbulent situation. | - Disaster management of SMEs - Described the challenges and opportunities in times of crisis. |

| Farrell, Thow, Wate, Nonga, Vatucawaqa, Brewer, Sharp, Farmery, Trevena, Reeve, & Eriksson (2020) |

This research investigated the COVID-19 situation and the Pacific food system resilience. This study also documented the opportunities to build a robust response for the food security during turbulent situation. | - COVID-19 and food security - It documented the situation in Pacific food system. - Proposed some practical solution to overcome the challenges. |

| Koot, Mes, & Iacob (2020) | This study has shown a systematic literature review of the Supply Chain management process and decision-making process. This research also explained the importance of Internet of Things and Big Data Analytics in supply chain management process. |

- Described the importance of big data analytics and IoT in supply chain management process. |

| Del Giudice, Chierici, Mazzucchelli, & Fiano (2021) | This study explained the supply chain management process and its opportunity in the era of circular economy. The study also investigated the moderating effect of big data on supply chain management process. | - Supply chain management in the era of circular economy. - Moderating impacts of big data application on supply chain management process. |

3. Theoretical underpinning and development of conceptual model

3.1. Theoretical underpinning

This study has attempted to investigate how it is possible by the SMEs to develop and sustain their supply chain capability in the post COVID-19 situation when several governments have imposed extended lockdown and directed the people to keep social distancing. Technologies such as big data analytics, IoT enabled devices, cloud computing and other related technologies help to achieve such measures taken during such pandemic (Koot et al., 2020). In the post COVID-19 scenario, SMEs are needed to put much stress on how they could use the existing resources in the best possible way through the best use of innovative technology. This is in consonance with the resource-based view (RBV) theory (Barney, 1991). This theory suggests that best way to survive in any unforeseen situation is to utilize the different capabilities of the SMEs. This theory also suggests that SMEs should use both tangible and intangible knowledge and resources which should be valuable, rare, inimitable, not substitutable.

The SMEs in above situation should be technologically innovative and then the enterprise can sustain in such situation. RBV advocates that variability in the performance of an enterprise resides not only from the resources of the enterprises, but it also depends on how they are being deployed with variety of strategic options for garnering improved performance even in dynamic times (Grewal, & Tansuhaj, 2001). Thus, in any unforeseen scenario like post COVID-19 situation, all the capabilities of the SMEs are to be reviewed with backup options and flexibility. Also, such pandemic situation has forced many SMEs to use technologies such as big data analytics, IoT, cloud computing, and so on in a more efficient way.

To explain the situation how to sustain SME SCM in the post COVID-19 scenario, we have also taken help of dynamic capability view (DCV) theory (Teece et al., 1997). This theory nurtures strategic management abilities and dynamic capability of an enterprise so that it can integrate, build as well as reconfigure its technological and financial capabilities (big data analytics, IoT, cloud computing and so on) for addressing dynamic environmental issues. In this study, the objective is how SMEs can successfully sustain their SCM in the post COVID-19 scenario. In such context, the concept of DCV theory is seemed to be helpful. DCV theory suggests that to address any unforeseen dynamic situation, enterprises are needed to adopt congenial strategies by ameliorating their several competencies (Felix, & Lamar, 2018). DCV theory advocates that for addressing any uncertain situation like COVID-19 pandemic, enterprises are needed to successfully develop their different capabilities such as big data driven innovative capabilities, IoT capability, cloud computing capability and so on. In the context of this study, it is argued that such capabilities are perceived to be core innovative and technological capabilities along with techno-financial capabilities of a SME (Basiouni et al., 2019).

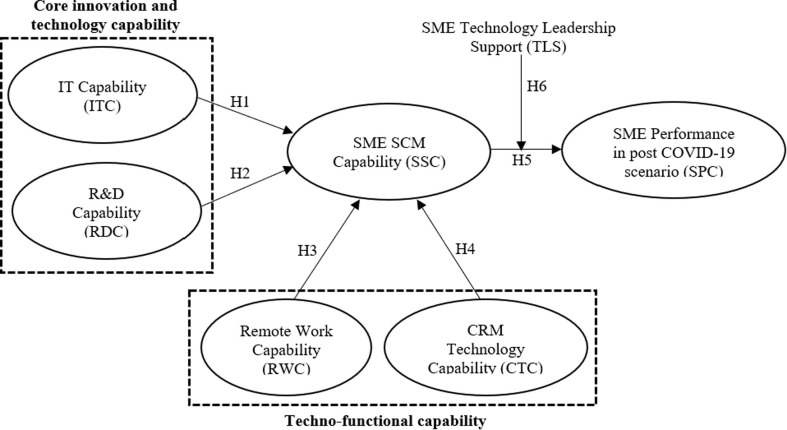

Thus, for sustaining the SCM by the SMEs during and post COVID-19 pandemic, the SMEs are needed to apply congenial strategies such as enabling more devices with IoT technology, applying big data driven innovation, using cloud computing for optimization, and so on to address the changed environment with the active support of leadership of the SMEs (Peter, 2007). In is context, a model is proposed conceptually as shown in Fig. 1 .

Fig. 1.

The conceptual model.

3.2. Formulation of hypotheses

By the help of studies of literature and theories, we have proposed the conceptual model. Now we will discuss the constructs and formulate the hypotheses.

3.2.1. Core innovation and technology capability

Several studies have suggested that a link is needed to be established between transportation, external suppliers, partners, and customers for ensuring collaboration in supply chain resilience (Panahifar et al., 2018). For establishing such collaboration, information exchange is needed among the different supply chain stakeholders (Errassafi et al., 2019). For uninterrupted information exchange, the SMEs are needed to improve its IT capabilities such as big data analytics, IoT technology and so on for its supply chain system that would mitigate the prevailing uncertainty in crisis like COVID-19 pandemic (Mofokeng, & Chinomona, 2019). The SMEs are needed to use its IT capability including big data analytics capability, IoT capability, cloud computing optimization capability and so on as important resources to address such uncertain dynamic situation which is in consonance with RBV theory as well as DCV theory. Thus, to smoothen the information flow for successful sustenance of SCM, IT capability is to be strengthened (Li et al., 2009). Accordingly, it is hypothesized as follows.

H1: IT capability (ITC) positively impacts SME supply chain management capability (SSC).

Besides, in such uncertain situation like COVID-19 pandemic and thereafter, the innovative capability of the SMEs is needed to be strengthened through improvement of research and development capability to enhance the SCM capability (Sarkis, 2020, Napoleone et al., 2020). Through improvement of research and development (R&D) activities, the SMEs should try to enhance their innovative capacity so that they can use Industry 4.0 technologies such as AI, big data capability, cloud computing, IoT technology, and so on to sustain SME SCM (Chatterjee et al., 2020). It is to be borne in mind that there is every possibility of occurrence of environmental and social crisis in future. With necessary data driven system supported with strong R&D capability, SMEs are expected to react and respond for facing such untoward crisis (Desjardine et al., 2019). Use of modern technology like Blockchain technology could help to improve data sharing activities which would help the supply chain managers to take quick and flawless decision for addressing any uncertain situation (van Hock, 2019). Technologies such as big data analytics can help the organizations for such quick and accurate decision-making process (Manavalan, & Jayakrishna, 2019). However, proper utilization of modern technologies such as big data, IoT, cloud computing, blockchain and so on for sustaining SCM in SMEs, it is obvious that the enterprises should improve their R&D capabilities (Saberi et al., 2019). Thus, development of supply chain resilience with limited resources is perceived to be ensured through improvement of R&D practices (Farrell et al., 2020). Accordingly, it is hypothesized follows.

H2: R&D capability (RDC) positively impacts SME supply chain management capability (SSC).

3.2.2. Techno-functional capability

Consequent upon outbreak of COVID-19 pandemic, government of different countries took lockdown measures when it was not possible by the employees to attend their scheduled workplaces. This situation is seen to have prevailed even after COVID-19 pandemic. For keeping the SMEs operationally active in such situation, the SMEs are to adopt remote work system for their employees (Carnevale, & Hatak, 2020). In a report (Accenture Report, 2021), it has been observed that 77% executives of the enterprises expect that remote working trend will continue even after COVID-19 pandemic. Concept of remote work can be interpreted as a “virtual operation that consists of individuals working towards a common goal, but without centralised building, physical plant, or other characteristics of a traditional organization” (Staples et al.,1999, p.758). Thus, even after COVID-19 pandemic, the SMEs must possess the functional ability to ensure that their workers can work remotely with the help of modern technology to keep the SMEs operationally active (Spreitzer et al., 2017). Accordingly, it is hypothesized as follows.

H3: Remote work capability (RWC) positively impacts SME supply chain management capability (SSC).

In the post COVID-19 scenario, to sustain the SMEs’ financial health, it is essential that the SMEs strengthen their customer relationship management (CRM) technology capability (Kale et al., 2000). This will help to improve supply chain resilience in any awkward situation (Paulraj et al., 2008). CRM technology capability improvement of the SMEs is expected to tighten the relationship between the customers and the SMEs which would embolden the online sales system improving the financial health of the SMEs (Park, 2015). Improvement of CRM technology capability of SMEs will ensure to enhance the trust of the customers on the SMEs and will also strengthen the supply chain system with enhancement of coordination among the stakeholders (Wu et al., 2014, Chatterjee and Kar, 2018). Relationship Immersion, trust as well as communication are deemed to be the principal elements of CRM technology capability that would help to adopt better supply chain strategy ameliorating the relationship among the stakeholders of the SMEs (Wittmann et al., 2009, Chatterjee et al., 2020). With all these inputs, the following hypothesis is formulated.

H4: CRM technology capability (CTC) positively impacts SME supply chain management capability (SSC).

3.2.3. SME SCM capability (SSC)

How the SMEs could use their SCM as a strategic asset, helps to measure the SCM capability of the SMEs (Ketchen, & Hult, 2007). Supply chain process is a pervasive process, and its success depends upon its flexibility and speed (Bowersox et al., 2002). Flexibility in SCM is conceptualised as to how the SCM could assess the impending uncertainty it might have to encounter and how it could articulate an effective strategy to overcome the impediment (Schlittgen et al., 2016, Chatterjee et al., 2021b). Technologies such as IoT and big data could help in improving such SME SCM capability. Speed of SCM can be estimated by the time needed between placement of order by a customer and the delivery of the product to the customer (Chatterjee et al., 2021a). Tracking through IoT enable devices could help such delivery of products much faster and in an accurate way (Mishra et al., 2018). Appropriate maintenance of speed and flexibility of SCM of the SME during and post COVID-19 pandemic is construed as the secret of success of the SMEs to improve their overall performance (Ringle, & Serstedt, 2016). Accordingly, it is hypothesized as follows.

H5: Improvement of SME supply chain management capability (SSC) positively influences SME performance in post COVID-19 scenario (SPC).

3.2.4. SME technology leadership support (TLS)

SME technology leadership support (TLS) is considered to have an effective impact on the innovative ability of enterprises for addressing any untoward environmental situation to improve the performance (Zhang et al., 2018). Leadership of SMEs adopts specific strategy depending on the nature of the turbulent environment to address the sustenance of SCM (Le, & Lei, 2018). Big data driven technology innovation strategy, IoT embedded system designing strategy, cloud computing optimization strategy and other related modern technology implementation strategy needs effective technology leadership support from the SME leadership team (Nakayama et al., 2020). To implement that strategy, the TLS establishes a conducive atmosphere in the SME so that there is no impediment to execute that strategy (Smart et al., 2017). TLS acts as an effective catalyst to execute this strategy for improving the efficiency of the SCM process which would help to improve the performance of the SMEs (Donate, & Guadamillas, 2011). Accordingly, it is hypothesized as follows.

H6: SME technology leadership support (TLS) moderates the relationship between SME supply chain management capability (SSC) and SME performance in post COVID-19 scenario (SPC).

3.3. Research methodology

For testing of hypothesis and for the analysis of data, partial least square (PLS) structural equation modelling (SEM) technique has been preferred. This technique has been preferred because it can yield better result to analyse an exploratory study like this (Aktar, & Pangil, 2017). This technique allows to analyse such data which are not normally distributed. This is not allowable for CB-SEM analysis (Hair et al., 2018). This technique does not require any sample restriction (Willaby et al., 2015, Richter et al., 2016). This technique requires quantification of feedback received from the usable respondents while conducting survey. The quantification is done by 5-point Likert scale. 5-point Likert scale has been preferred because it is simple to understand, it takes less time and efforts for completion, it allows lower margin of error, delivers deeper insights into what the people have been feeling and thinking. Also, it allows the respondents to keep them neutral by opting ‘neither disagree nor not agree’ option.

3.4. Research instruments

Since the model and the hypotheses needed to be validated through quantitative study by conducting survey, a questionnaire is required to be prepared. From the knowledge of literature, theories and the constructs, questionnaire has been prepared. The questionnaire (a set of questions) has been prepared using all the items which would represent the constructs selected for the model. The context of the questions has been designed for representing the measures for all the constructs. The questionnaire was scrutinised by some experts having knowledge in the domain of this study. This was done to improve the comprehensiveness of the questions which were prepared in the form of statements. Again, the questionnaire was piloted with the help of some other experts to refine the wordings and understandability of the questions. This was done so that the respondents may understand the measures and can provide appropriate responses. In this way, a total of 34 items concerning all the relevant constructs were designed. A response sheet containing the 34 questions with five options for each question has been prepared for the respondents where each of the respondents was to put one tick mark in one option out of five options for each question. The instruments along with their sources are provided in the appendix.

3.5. Data collection strategy

To collect data, SEMs of four cities of India have been selected. These cities are Chennai, Bengaluru, Mumbai and Gurugram. It is learnt that in these cities, there are many SMEs (Crisil Report, 2020). Some SMEs from these cities have been selected at random. We selected 716 employees of these enterprises. These employees are reported to have been involved in the process of supply chain in their respective SMEs. We collected details of these 716 employees. Each of these prospective respondents was provided with a response sheet along with a guideline as to how to fill it up. With the response sheet, each of the prospective respondents was assured that the confidentiality and anonymity of each respondent will be strictly preserved. All the prospective respondents were requested to respond within 60 days from the date of receipt of the communication (January and February 2021). Within the scheduled time window, 338 respondents responded. The response rate was 47.2%. We scrutinized these replies. We found that out of 338 responses, 11 responses were incomplete. We did not consider these 11 incomplete responses. We started our PLS-SEM analysis with 327 usable responses against 34 items. This is within allowable range (Dev & David, 2014). The demographic profile of these 327 usable respondents is shown in Table 2 .

Table 2.

Demographic profile (N = 327).

| Types of enterprises | Hierarchy of employees | Number | Percentage (%) |

|---|---|---|---|

| Small and Medium Enterprises (SMEs) |

Top Executives | 15 | 4.6 |

| Senior Managers | 66 | 20.2 | |

| Midlevel Managers | 109 | 33.3 | |

| Junior Managers | 137 | 41.9 |

4. Analysis of data and results

4.1. Measurement properties and discriminant validity test

For assessing content validity of each item, loading factor (LF) of each item has been estimated. To ascertain validity, reliability, and internal consistency of the construct, and multicollinearity defect of each construct, we estimated average variance extracted (AVE), composite reliability (CR), Cronbach’s alpha (α) and variance inflation factor (VIF) of each construct, respectively. It was observed that all the estimated values are within the permissible range. Details of the results are shown in Table 3 .

Table 3.

Measurement properties.

| Constructs / Items | LF | AVE | CR | α | VIF | t-values | No. of items |

|---|---|---|---|---|---|---|---|

| ITC | 0.86 | 0.89 | 0.93 | 3.9 | 6 | ||

| ITC1 | 0.92 | 21.22 | |||||

| ITC2 | 0.88 | 24.07 | |||||

| ITC3 | 0.96 | 33.11 | |||||

| ITC4 | 0.94 | 32.02 | |||||

| ITC5 | 0.90 | 30.14 | |||||

| ITC6 | 0.95 | 26.66 | |||||

| RDC | 0.87 | 0.89 | 0.94 | 4.6 | 6 | ||

| RDC1 | 0.90 | 17.89 | |||||

| RDC2 | 0.95 | 28.01 | |||||

| RDC3 | 0.95 | 29.29 | |||||

| RDC4 | 0.94 | 36.04 | |||||

| RDC5 | 0.97 | 24.68 | |||||

| RDC6 | 0.89 | 22.10 | |||||

| RWC | 0.84 | 0.88 | 0.91 | 4.3 | 6 | ||

| RWC1 | 0.87 | 26.12 | |||||

| RWC2 | 0.89 | 22.17 | |||||

| RWC3 | 0.97 | 29.11 | |||||

| RWC4 | 0.90 | 29.41 | |||||

| RWC5 | 0.95 | 27.22 | |||||

| RWC6 | 0.93 | 36.11 | |||||

| CTC | 0.84 | 0.87 | 0.91 | 3.8 | 6 | ||

| CTC1 | 0.91 | 26.11 | |||||

| CTC2 | 0.90 | 27.29 | |||||

| CTC3 | 0.87 | 38.01 | |||||

| CTC4 | 0.89 | 24.22 | |||||

| CTC5 | 0.96 | 26.12 | |||||

| CTC6 | 0.97 | 27.17 | |||||

| SSC | 0.85 | 0.89 | 0.92 | 4.1 | 6 | ||

| SSC1 | 0.94 | 26.29 | |||||

| SSC2 | 0.96 | 29.12 | |||||

| SSC3 | 0.95 | 27.32 | |||||

| SSC4 | 0.87 | 24.17 | |||||

| SSC5 | 0.89 | 25.28 | |||||

| SSC6 | 0.90 | 28.33 | |||||

| SPC | 0.87 | 0.91 | 0.93 | 3.7 | 4 | ||

| SPC1 | 0.96 | 25.13 | |||||

| SPC2 | 0.90 | 22.17 | |||||

| SPC3 | 0.95 | 17.27 | |||||

| SPC4 | 0.92 | 19.01 |

We also applied Fornell and Larcker criteria for verifying the discriminant validity of each construct. It has been found that square roots of all the AVEs are greater than the corresponding bifactor correlation coefficients which satisfies the Fornell and Larcker criteria (Fornell, & Larcker, 1981). It establishes discriminant validity of the constructs. The entire results are shown in Table 4 .

Table 4.

Discriminant validity test (Fornell and Larcker criteria).

| Construct | ITC | RDC | RWC | CTC | SSC | SPC | AVE |

|---|---|---|---|---|---|---|---|

| ITC | 0.92 | 0.86 | |||||

| RDC | 0.17 | 0.93 | 0.87 | ||||

| RWC | 0.19 | 0.32*** | 0.91 | 0.84 | |||

| CTC | 0.22** | 0.29 | 0.32 | 0.91 | 0.84 | ||

| SSC | 0.24* | 0.21 | 0.37* | 0.18** | 0.92 | 0.85 | |

| SPC | 0.27 | 0.28** | 0.17 | 0.26 | 0.24*** | 0.93 | 0.87 |

To supplement the Fornell and Larcker criteria, for confirming discriminant validity of each construct, we have also preferred Heterortrait and Monotrait (HTMT) correlation coefficient test (Henseler et al., 2014). From the analysis, it is seen that all the values of the constructs are<0.85 (Voorhees et al., 2016). This result also confirms discriminant validity of the constructs. The results are shown in Table 5 .

Table 5.

Heterotrait - Monotrait test (HTMT criteria).

| Construct | ITC | RDC | RWC | CTC | SSC | SPC |

|---|---|---|---|---|---|---|

| ITC | ||||||

| RDC | 0.27 | |||||

| RWC | 0.32 | 0.16 | ||||

| CTC | 0.44 | 0.18 | 0.27 | |||

| SSC | 0.33 | 0.29 | 0.24 | 0.36 | ||

| SPC | 0.41 | 0.17 | 0.32 | 0.39 | 0.24 |

4.2. Common method bias (CMB)

The findings of this study depend on the inputs of the respondents who responded against structured set of questions (questionnaire) concerned with the constructs. Hence, there is possibility of replies which might be biased. To remove this defect of biased responses, the respondents at the time of survey were assured that their identity would not be disclosed. This was done as a pre-emptive measure. To confirm that those replies were unbiased, CMB has been performed. By conducting the Harman’s single factor test it was found that the first factor emerged as 39.21%. It is less than the highest cut off value of 50% as recommended by Podsakoff et al. (2003). It confirms that the data did not distort the prediction.

4.3. Moderating effect of top management team support (MGA)

To verify the effects of SME technology leadership support (TLS) on the linkage H5, multi group analysis (MGA) has been performed with bootstrapping process considering 5000 resamples. The effects of TLS have been analysed by consideration of Strong TLS effects and Weak TLS effects on H5. It is known that if the p-value difference for the 2 categories of effects of a moderator on a linkage is found to be either greater than 95% or<5%, it is said that the effects of the moderator on the linkage are significant (Hair et al., 2016). The results after MGA are found to be significant as the p-value difference is 0.02 (which is<0.05).

4.4. Hypothesis testing (SME)

For hypothesis testing, bootstrapping procedure with consideration of 5000 resamples has been followed (Henseler et al., 2009). This procedure has been preferred since this process for hypothesis testing can be applied without conducting parametric tests (Chin, 2010). Omission separation 5 has been considered for ascertaining cross validated redundancy. On analysis, Stone-Geisser value emerged as 0.61 (Stone, 1974, Geisser, 1975). This confirms that the results have predicted relevance. Also, for verifying if the model is in order or not, SRMR (standardised root mean square residual error) has been considered as a standard index. On computation, the SRMR values come out to be 0.063 for PLS end 0.032 for PLSc. Both these estimates are less than the highest value of 0.08 (Hu, & Bentler, 1998). This confirms that the model is fit and acceptable. This process helped us to assess the path coefficients for the several linkages along with p-values and values. The results are shown in Table 6 .

Table 6.

Path coefficients, p-values, R2 values, and remarks.

| Linkages | Hypotheses | R2 values / Path coefficients | p-values | Remarks |

|---|---|---|---|---|

| Effects on SSC | R2 = 0.51 | |||

| By ITC | H1 | 0.31 | p < 0.001(***) | Supported |

| By RDC | H2 | 0.28 | p < 0.01(**) | Supported |

| By RWC | H3 | 0.46 | p < 0.01(**) | Supported |

| By CTC | H4 | 0.21 | p < 0.05(*) | Supported |

| Effects on SPC | R2 = 0.72 | |||

| By SSC | H5 | 0.49 | p < 0.001(***) | Supported |

| (SSC → SPC) × TLS | H6 | 0.27 | p < 0.05(*) | Supported |

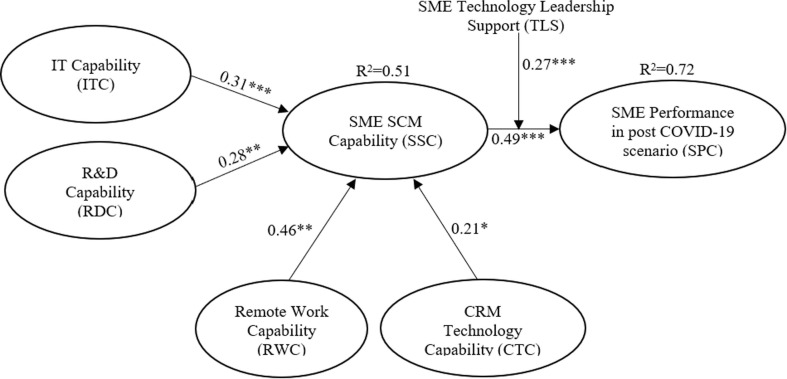

After all these inputs, the validated model (SEM) is provided in Fig. 2.

4.5. Results

This study has formulated six hypotheses. Out of six hypothesis, one hypothesis is concerned with the moderating effect of TLS on H5. After PLS-SEM analysis, it appears that all these six hypotheses have been supported. The results show that ITC, RDC, RWC, and CTC impact SSC significantly since the concerned path coefficients are 0.31, 0.28, 0.46, and 0.21 respectively with levels of significance as p < 0.001(***), p < 0.01(**), p < 0.01(**), and p < 0.05(*) respectively. The results show that SSC could impact SPC (H5) significantly as the concerned path coefficient is 0.49 with level of significance p < 0.001(***). The moderator TLS positively and significantly impacts on the linkage H5 since the concerned path coefficient is 0.27 with level of significance p < 0.05(*). So far as coefficient of determination are concerned, it appears that ITC, RDC, RWC, and CTC could explain SSC to the tune of 51% whereas SPC could be interpreted by SSC to the extent of 72% which is the predictive power of the theoretical model.

5. Discussion on results

Supply chain residence has become a well accepted area of research in the field of operation management. Unexpected, abrupt, and unprecedented outbreak of COVID-19 pandemic across the globe has caused ominous disruption in supply chain management system. In this situation, the SMEs have become the worst affected since they suffer from various constraints. This study has taken a holistic attempt to provide a road map as to how the SMEs could survive in the post COVID-19 pandemic scenario to sustain their supply chain resilience by ameliorating their innovative and technological capabilities such as big data analytics, cloud computing optimization, IoT technology and so on.

This study has shown that the improvement of IT capability such as big data analytics, cloud computing, IoT and so on of the SMEs could help to improve their supply chain system (H1). Our results further suggest that by developing the communication system in such awkward situation by the help of technological innovation, it may be possible for the SMEs to keep the flow of supply chain activities which is also supported by other study (Mofokeng, & Chinomona, 2019). This study has shown that by improving their R&D activities especially in the data driven approach, big data related applications, IoT technology and so on, the SMEs can improve and moderate their supply chain strategy in such unfavourable situation (post COVID-19 scenario) (H2). The concept has also been supplemented in another study (Farrell et al., 2020). This study has also highlighted that during and after such pandemic situation, several countries have taken total or partial lockdown measures. In such situation, to keep the operations and functions of the SMEs active, the SMEs must have the flexible policy. Such policy could help their employees to avail the option of remote work flexibility (H3). This has been supplemented in other study (Spreitzer et al., 2017).

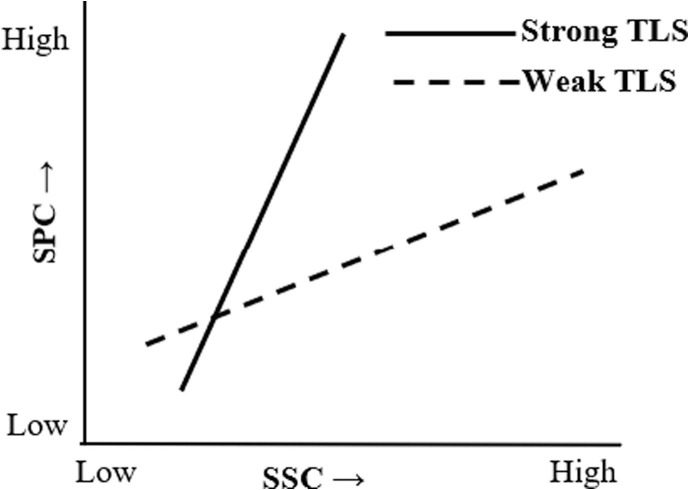

This study has highlighted that SMEs should embolden their CRM technology capability embedded with big data analytics to keep their supply chain flow active (H4) which has been supplemented in another study (Paulraj et al., 2008). This study has also highlighted that the SME supply chain management technology efficiency could improve their performance even in the post COVID-19 scenario (H5). This concept has received support from another study (Schlittgen et al., 2016). This study has also shown that for keeping the supply chain flow of SMEs active to improve the firm performance in the post COVID-19 scenario, support of leadership acts as a positive catalyst (H6). This idea has also been supplemented by another study (Le, & Lei,2018). In this study, the leadership support has been considered as an effective moderating variable. The effect of Strong TLS and Week TLS on H5 are being discussed here graphically as shown in Fig. 3 .

Fig. 2.

The validated model (SEM).

Fig. 3.

Effects of TLS on H5.

Fig. 3 shows that with increase of SSC, the rate of increase of SPC is more for the effect of Strong TLS compared to the effect of Weak TLS since the gradient of the continuous line representing effects of a Strong TLS is more than the gradient of the dotted line representing the effects of Weak TLS.

5.1. Theoretical contributions

This study has shown that SMEs’ capability comprising of technological, innovative, flexible as well as relationship management capability could impact SME supply chain resilience in the post COVID-19 scenario which in turn could impact positively on SME performance in the turbulent situations. This study has also discussed how the SME technology leadership support could provide laudable help to sustain SCM activities for improving SME performance even in post COVID-19 pandemic scenario. No other studies did exhaustively investigate how several SME capabilities like IT capability, R&D capability, remote work capability, and CRM capability could help the SMEs to sustain their SCM resilience to improve their performance in the post COVID-19 scenario duly supported by the SME technology leadership support. Leadership can support in developing and deploying big data-based applications, cloud computing optimization, IoT enabled technologies and so on in the SMEs. In this context, our study may be deemed to be a unique study and is claimed to have added values to the extant literature.

By providing the concept that IT and big data driven innovative capabilities of SMEs could sustain the SCM resilience of SMEs even in post COVID-19 turbulent scenario, it has theorized the novel idea that digitalised supply chain management is seemed to be considered as a permanent and long-term strategy for ensuring a resilient supply chain management that could ameliorate the SME performance even in post COVID-19 scenario.

This study has shown that the IT, innovation, remote work, and CRM capabilities of SMEs are the core resources to be utilised efficiently by the SMEs to address the evolving dynamic situation in the post COVID-19 period to sustain their supply chain residence. This has been explained with the help of RBV and DCV theory. This endeavour is claimed to be a specified theoretical contribution of our study. In the study of Nandi et al. (2021), it has been observed that using blockchain technology, it is possible to sustain SCM in organization during COVID-19 pandemic situation. This idea has been extended in our study which concludes that IT capability of SMEs should be considered as a core competency of SMEs to sustain their SCM even in the post COVID-19 scenario to improve their overall performances. This has added values to the extant literature. This idea has also been corroborated by another study (Saberi et al., 2019). Another study of Zhu and Kindarto (2016) has shown that government IT-related projects such as big data analytics related projects, IoT applications related projects, blockchain related projects and so on can be implemented efficiently in developing countries by the active support of the leadership team. This idea has been lent in our study and we have shown that leadership support moderates the performance of SMEs in post COVID-19 scenario by effectively sustaining their SCM resilience. This is deemed to be a theoretical contribution of our study.

5.2. Practical implication

This study has been able to provide several practical implications. This study has highlighted that IT capability and R&D capability, being the core innovation and technology capability of SMEs, could impact positively and significantly the supply chain capability of SMEs (H1 and H2). This implies that practitioners are required to think for using digital technologies such as big data analytics, AI integrated CRM technology, cloud computing technology, IoT enabled technology and so on to develop the SMEs’ supply chain resilience which would improve SME performance in post COVID-19 pandemic scenario. The management of the SMEs is required to focus on infrastructural development of their enterprises by proper investment. To improve the infrastructure, SMEs are needed to take help of innovative technologies like artificial intelligence, internet of things, blockchain and so forth to accelerate the process of communication to sustain the supply chain resilience.

To help realise full potential of these ground-breaking technologies, the practitioners and managers of SMEs are needed to strengthen their R&D wing so that even in any untoward situation, the SMEs may not face any impediment to sustain their supply chain. This study has also shown that the SMEs are needed to embolden their flexibility by allowing the employees to work remotely during such lockdown situation as a culmination of outbreak of COVID-19 pandemic (H3). This implies that the SMEs must have proper policy so that the employees can have the option to work from home (remote working) to keep the SMEs’ operations active during and after any turbulent environment. The managers of the SMEs must arrange the option of work flexibility so that the employees can easily use the SMEs’ infrastructure even when they would work remotely.

This study has shown that CRM technology capability helps to sustain SME SCM (H4). This implies that the managers of SMEs should develop an integrated database for ameliorating the relationship with the potential customers through necessary exchange of information with the assistance of online CRM platforms. The SME technology leadership supports to facilitate, sponsor, and deploy big data related applications, IoT enabled applications, cloud computing optimization and so on, which is seen to have impacted the SME performance by improving SCM system even after COVID-19 pandemic (H5 and H6). This implies that it will be the duty of the leadership of the SMEs to establish a collaborative as well as conducive atmosphere which will help the employees to be more proactive to combat any untoward situation like COVID-19 pandemic to sustain the SCM activities to improve the SME performance. Thus, it is seen that the outbreak of COVID-19 apocalypse has disrupted the businesses of SMEs. The shock has forced the SMEs to change their style of business. The SMEs will come out successful if they can withstand the present situation and can continue their businesses in such constrained circumstances. The SMEs are needed to learn how to recover, and such learning may help them to become stronger towards business success. The SMEs should also get themselves prepared to succeed in the ‘new normal’ environment for sustainability. Hence, to survive and flourish in future, the SMEs need to have the strategy of respond-recover-thrive.

5.3. Conclusion, limitations, and future scope

The present research study has collected data which are cross-sectional or data which could capture views of the respondents at a single point of time (Malhotra, 2014). This creates defects of endogeneity which means that endogeneity bias may be caused due to simultaneous impact of causality, that is, when independent and dependent variables simultaneously impact each other, and causal effects run reciprocally (Wooldridge, 2002). By conducting longitudinal studies through proper econometric analysis, the future researchers may verify the linkages of causality between the constructs more accurately. This study is based on the inputs of the employees of SMEs of 4 cities of India. Naturally, the results do not portray the generic scenario. To arrive at a generic result, the future researchers should obtain inputs of respondents from the different parts of the globe. The predictive power of the model is 72%. Here in this study, SME technology leadership support (TLS) has been considered as a moderating variable. Apart from this, future researchers can explore moderating variables like technology turbulence, government policies, environmental dynamism, and so on which could influence the SME performance in the post COVID-19 scenario. Future researchers could explore these moderating variables to investigate if inclusion of such boundary conditions could enhance the explanative power of the proposed model. This study has taken help of DCV theory (Teece et al., 1997). But this theory suffers from the defects of context insensitivity (Ling Yee, 2007). This theory is not able to identify the conditions where the organizational capabilities will be most valuable (Dubey et al., 2019). Hence, it is suggested that the future researchers should explore the optimum conditions in which BDA innovation could sustain SME SCM in post COVID-19 scenario under the moderating influence of SME technology leadership support. This study has considered four capabilities of SMEs, which could impact SME SCM in post COVID-19 scenario. Future researchers may consider other supply chain related capabilities of SMEs to examine how that could improve the results. Such technological abilities of the SMEs could be blockchain capability integrated in supply chain management process, applications of artificial intelligence, and neural networking technology in supply chain management process and so on. Whatever might be the limitations of this study, this study is expected to help the practitioners as well as the managers of SMEs to understand how it is possible by the SMEs to sustain their supply chain resilience during and after any turbulent environment like COVID-19 pandemic.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix: Summary of questionnaire

| Items | Source | Statements | Response [SD][D][N][A][SA] |

|---|---|---|---|

| ITC1 | Panahifar et al., 2018 | I believe that IT capability is important to improve SME SCM ability. | [1][2][3][4][5] |

| ITC2 | Errassafi et al., 2019 | I understand that IT capability can sustain SCM flow during turbulent situation. | [1][2][3][4][5] |

| ITC3 | Mofokeng, & Chinomona, 2019 | Information exchange is essential among different supply chain stakeholders. | [1][2][3][4][5] |

| ITC4 | Li et al., 2009 | Big data analytics capability plays a crucial role to improve SME SCM ability. | [1][2][3][4][5] |

| ITC5 | Panahifar et al., 2018 | To smoothen the information flow during uncertain environment, effective IT capability is essential for the organization. | [1][2][3][4][5] |

| ITC6 | Errassafi et al., 2019 | Industry 4.0 capability is important to improve the competitiveness. | [1][2][3][4][5] |

| RDC1 | Sarkis, 2020, Napoleone et al., 2020 | Innovative capability of the SMEs is essential to sustain during turbulent situation. | [1][2][3][4][5] |

| RDC2 | Chatterjee et al., 2020 | I believe that SMEs should try to enhance their innovative capacity so that they can effectively use Industry 4.0. | [1][2][3][4][5] |

| RDC3 | Desjardine et al., 2019 | I believe that improvement of research and development capability will enhance the SCM capability of the SMEs. | [1][2][3][4][5] |

| RDC4 | van Hock, 2019 | I believe that SME innovation capability will enhance their profitability. | [1][2][3][4][5] |

| RDC5 | Manavalan, & Jayakrishna, 2019 | Data driven system supported with strong R&D capability will help SMEs to remain competitive during turbulent situation. | [1][2][3][4][5] |

| RDC6 | Saberi et al., 2019, Farrell et al., 2020 | I believe that SMEs should invest adequately to enhance their R&D capability. | [1][2][3][4][5] |

| RWC1 | Carnevale, & Hatak, 2020 | I believe techno-functional capability of SMEs can provide remote working flexibility during turbulent situation. | [1][2][3][4][5] |

| RWC2 | Staples et al.,1999 | Techno-functional capability of the SMEs can help improving remote working capability. | [1][2][3][4][5] |

| RWC3 | Spreitzer et al., 2017 | I believe that SMEs should invest adequately to improve their remote working capability. |

[1][2][3][4][5] |

| RWC4 | Carnevale, & Hatak, 2020 | To keep the SMEs operationally active during turbulent situation, it is essential to have remote working capability. | [1][2][3][4][5] |

| RWC5 | Staples et al.,1999 | I believe that remote working capability could help SMEs to attract talent. | [1][2][3][4][5] |

| RWC6 | Spreitzer et al., 2017 | I believe that remote working capability is essential to keep supply chain flow active during turbulent situation. | [1][2][3][4][5] |

| CTC1 | Kale et al., 2000 | CRM technology capability can improve supply chain flow ability of SMEs during turbulent situation. | [1][2][3][4][5] |

| CTC2 | Paulraj et al., 2008 | I believe that improvement of techno-functional capability can enhance CRM technology ability. | [1][2][3][4][5] |

| CTC3 | Park, 2015 | Enhancement in CRM ability can improve financial health of the SMEs. | [1][2][3][4][5] |

| CTC4 | Wu et al., 2014, Chatterjee and Kar, 2018 | Improvement of CRM technology capability will ensure enhancement of trust of the customers on the SMEs. | [1][2][3][4][5] |

| CTC5 | Wittmann et al., 2009 | Improvement of CRM ability of the SMES will strengthen the supply chain system. | [1][2][3][4][5] |

| CTC6 | Chatterjee et al., 2020 | I believe that superior functionality of CRM application will help the coordination activity among the stakeholders of the SMEs. | [1][2][3][4][5] |

| SSC1 | Ketchen, & Hult, 2007 | I believe that SME SCM capability can enhance the profitability. | [1][2][3][4][5] |

| SSC2 | Bowersox et al., 2002 | I believe that superior SME SCM capability can improve competitiveness. | [1][2][3][4][5] |

| SSC3 | Schlittgen et al., 2016, Chatterjee et al., 2021b | SCM capability is essential to keep the SMEs operationally active during turbulent situation. | [1][2][3][4][5] |

| SSC4 | Mishra et al., 2018 | Superior SCM capability will help to deliver products faster and in an accurate way to the customers. | [1][2][3][4][5] |

| SSC5 | Chatterjee et al., 2021a | Modern technology like artificial intelligence embedded with SCM process will improve overall efficiency of the process. | [1][2][3][4][5] |

| SSC6 | Ringle, & Serstedt, 2016 | I believe that adequate investment is required to improve the SCM capability of the SMEs. | [1][2][3][4][5] |

| SPC1 | Schlittgen et al., 2016; | I believe that improvement in techno-functional capability will improve SME performance in post COVID-19 scenario. | [1][2][3][4][5] |

| SPC2 | Mishra et al., 2018 | I believe that it is essential that SME leadership team should adequately invest in R&D capability so that its performance in post COVID-19 can be further improved. | [1][2][3][4][5] |

| SPC3 | Ketchen, & Hult, 2007 | To remain competitive in post COVID-19 situation, SMEs are required to enhance their performance by improving supply chain flow. | [1][2][3][4][5] |

| SPC4 | Wittmann et al., 2009 | I believe that SME leadership team support is essential to improve SME performance in post COVID-19 situation. | [1][2][3][4][5] |

SD = Strongly Disagree; D = Disagree; N = Neither agree nor disagree; A = Agree; SA = Strongly Agree.

References

- Accenture Report. (2021). Technology Vision 2021. Available at: https://www.accenture.com /us-en/insights/technology/technology-trends-2021. (Accessed on 14 March 2021).

- Aktar A., Pangil F. The relationship between employee engagement, HRM practices and perceived organizational support: Evidence from banking employees. International Journal of Human Resource Studies. 2017;7(3):1–22. doi: 10.5296/ijhrs.v7i3.11353. [DOI] [Google Scholar]

- Aryal A., Liao Y., Nattuthurai P., Li B. The emerging big data analytics and IoT in supply chain management: A systematic review. Supply Chain Management. 2020;25(2):141–156. doi: 10.1108/SCM-03-2018-0149. [DOI] [Google Scholar]

- Asgary A., Ozdemir A.I., Özyürek H. Small and Medium Enterprises and Global Risks: Evidence from Manufacturing SMEs in Turkey. International Journal of Disaster Risk Science. 2020;11(1):59–73. doi: 10.1007/s13753-020-00247-0. [DOI] [Google Scholar]

- Auzzir Z., Haigh R., Amaratunga D. Impacts of Disaster to SMEs in Malaysia. Procedia Engineering. 2018;212:1131–1138. doi: 10.1016/j.proeng.2018.01.146. [DOI] [Google Scholar]

- Barney J. Firm resources and sustained competitive advantage. Journal of Management. 1991;17(1):99–120. [Google Scholar]

- Bartik, A., Bertrand, M., Cullen, Z. B., Glaeser, E. L., Luca, M. & Stanton, C. (2020). How Are Small Businesses Adjusting to COVID-19? Early Evidence From a Survey. Harvard Business School Working Paper, 20(102), 1-37. https://doi.org/ 10.3386/w26989.

- Basiouni A., Hafizi A., Akhtar N., Alojairi A. Assessing Canadian Business IT Capabilities for Online Selling Adoption: A Net-Enabled Business Innovation Cycle (NEBIC) Perspective. Sustainability. 2019;11(13):3662. doi: 10.3390/su11133662. [DOI] [Google Scholar]

- Bennett K., Phillipson J. A Plague Upon their Houses: Revelations of the Foot and Mouth Disease Epidemic for Business Households. Sociologia Ruralis. 2004;44(3):261–284. doi: 10.1111/j.1467-9523.2004.00275.x. [DOI] [Google Scholar]

- Bowersox D.J., Closs D.J., Cooper M.B. McGraw Hill; Irwin, NY, USA: 2002. Supply Chain Logistics Management. [Google Scholar]

- Brinch M. Understanding the value of big data in supply chain management and its business processes: Towards a conceptual framework. International Journal of Operations & Production Management. 2018;38(7):1589–1614. doi: 10.1108/IJOPM-05-2017-0268. [DOI] [Google Scholar]

- Bueno A.F., Godinho Filho M., Frank A.G. Smart production planning and control in the industry 4.0 context: A systematic literature review. Computers & Industrial Engineering. 2020;149(11) [Google Scholar]

- Carnevale J.B., Hatak I. Employee adjustment and well-being in the era of COVID-19: Implications for human resource management. Journal of Business Research. 2020;116:183–187. doi: 10.1016/j.jbusres.2020.05.037. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chatterjee S. AI strategy of India: Policy framework, adoption challenges and actions for government. Transforming Government: People, Process and Policy. 2020;14(5):757–775. doi: 10.1108/TG-05-2019-0031. [DOI] [Google Scholar]

- Chatterjee S., Kar A.K. Effects of successful adoption of information technology enabled services in proposed smart cities of India: From user experience perspective. Journal of Science and Technology Policy Management. 2018;9(2):189–209. doi: 10.1108/JSTPM-03-2017-0008. [DOI] [Google Scholar]

- Chatterjee S., Nguyen B. Value co-creation and social media at bottom of pyramid (BOP) The Bottom Line, In Press. 2021 doi: 10.1108/BL-11-2020-0070. [DOI] [Google Scholar]

- Chatterjee S., Chaudhuri R., Vrontis D., Thrassou A., Ghosh S.K. ICT-enabled CRM system adoption: A dual Indian qualitative case study and conceptual framework development. Journal of Asia Business Studies. 2021;15(2):257–277. doi: 10.1108/JABS-05-2020-0198. [DOI] [Google Scholar]

- Chatterjee S., Ghosh S.K., Chaudhuri R. Knowledge management in improving business process: An interpretative framework for successful implementation of AI–CRM–KM system in organizations. Business Process Management Journal. 2020;26(6):1261–1281. doi: 10.1108/BPMJ-05-2019-0183. [DOI] [Google Scholar]

- Chatterjee, S., Rana, N.P. & Dwivedi, Y.K. (2021c). Assessing Consumers’ Co‐production and Future Participation on Value Co‐creation and Business Benefit: a F-P-C-B Model Perspective. Information Systems Frontiers, In Press. https://doi.org/10.1007/s10796-021-10104-0.

- Chatterjee, S., Rana, N.P., & Dwivedi, Y.K. (2021d). How does business analytics contribute to organizational performance and business value? A resource-based view. Information Technology & People, In Press. https://doi.org/10.1108/ITP-08-2020-0603.

- Chin, W.W. (2010). How to write up and report PLS analyses. In Vinzi, V. E., Chin, W. W., Henseler, J., & Wang, H. (Eds.), Handbook of partial least squares. 655–690. Berlin, Heidelberg, Springer.

- Crisil Report. (2020). CRISIL Research SME Report 2020. Available at: https://www.crisil.com/en/home/our-analysis/reports/2020/11/crisil-research-sme-report-2020.html (Accessed on 11 May 2021).

- Deb M., David E.L. An empirical examination of customers’ adoption of m-banking in India. Journal of Marketing Intelligence & Planning. 2014;32(4):475–494. [Google Scholar]

- Del Giudice M., Chierici R., Mazzucchelli A., Fiano F. Supply chain management in the era of circular economy: The moderating effect of big data. The International Journal of Logistics Management. 2021;32(2):337–356. doi: 10.1108/IJLM-03-2020-0119. [DOI] [Google Scholar]

- DesJardine M., Bansal P., Yang Y. Bouncing back: Building resilience through social and environmental practices in the context of the 2008 global financial crisis. Journal of Management. 2019;45(4):1434–1460. doi: 10.1177/0149206317708854. [DOI] [Google Scholar]

- Donate, M.J., & Guadamillas, F. (2011). Organizational factors to support knowledge management and innovation. Journal of Knowledge Management, 15(6), 890-914. https://doi.org/ 10.1108/13673271111179271.

- Dua, A., Jain, N., Mahajan, D., & Velasco, Y. (2020). COVID-19’s effect on jobs at small businesses in the United States. https://www.mckinsey.com/industries/socialsector/our-insights/covid-19s-effect-on-jobs-at-small-businesses-in-the-unitedstates.

- Dubey R., Gunasekaran A., Childe S.J., Blome C., Papadopoulos T. Big Data and Predictive Analytics and Manufacturing Performance: Integrating Institutional Theory and Resource Based View. British Journal of Management. 2019;30(2):341–361. [Google Scholar]

- Eggers F. Masters of disasters? Challenges and opportunities for SMEs in times of crisis. Journal of Business Research. 2020;116:199–208. doi: 10.1016/j.jbusres.2020.05.025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Elakkiya R., Vijayakumar P., Karuppiah M. COVID_SCREENET: COVID-19 Screening in Chest Radiography Images Using Deep Transfer Stacking. Information Systems Frontiers. 2021 doi: 10.1007/s10796-021-10123-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- El-Haddadeh, R., Fadlalla, A. & Hindi, N.M. (2021). Is There a Place for Responsible Artificial Intelligence in Pandemics? A Tale of Two Countries. Information Systems Frontiers, In Press. https://doi.org/10.1007/s10796-021-10140-w. [DOI] [PMC free article] [PubMed]

- Errassafi M., Abbar H., Benabbou Z. The mediating effect of internal integration on the relationship between supply chain integration and operational performance: Evidence from Moroccan manufacturing companies. Journal of Industrial Engineering and Management. 2019;12(2):254–273. doi: 10.3926/jiem.2794. [DOI] [Google Scholar]

- Farrell P., Thow A.M., Wate J.T., Nonga N., Vatucawaqa P., Brewer T.…Eriksson H. COVID-19 and Pacific food system resilience: Opportunities to build a robust response. Food Security. 2020;12(4):783–791. doi: 10.1007/s12571-020-01087-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Felix A., Lamar P. The behavioral and evolutionary roots of dynamic capabilities. Industrial and Corporate Change. 2018;27(2):413–424. doi: 10.1093/icc/dtx050. [DOI] [Google Scholar]

- Fornell C., Larcker D.F. Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research. 1981;18(1):39–50. doi: 10.1177/002224378101800104. [DOI] [Google Scholar]

- Geisser S. The predictive sample reuse method with applications. Journal of the American Statistical Association. 1975;70(350):320–328. [Google Scholar]

- Grewal R., Tansuhaj P. Building Organizational Capabilities for Managing Economic Crisis: The Role of Market Orientation and Strategic Flexibility. Journal of Marketing. 2001;65:67–80. doi: 10.1509/jmkg.65.2.67.18259. [DOI] [Google Scholar]

- Hair J.F., Risher J., Sarstedt M., Ringle C.M. When to use and how to report the results of PLS-SEM. European Business Review. 2018;31(1):2–24. [Google Scholar]

- Hallinger P. Analyzing the intellectual structure of the Knowledge base on managing for sustainability, 1982–2019: A meta-analysis. Sustainable Development. 2020;28(5):1493–1506. doi: 10.1002/sd.2071. [DOI] [Google Scholar]

- Hair J.F., Jr., Hult G.T.M., Ringle C., Sarstedt M. Sage Publications; London: 2016. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM) [Google Scholar]

- Handfield R.B., Graham G., Burns L. Corona virus, tariffs, trade wars and supply chain evolutionary design. International Journal of Operations and Production Management. 2020;40(10):1649–1660. doi: 10.1108/IJOPM-03-2020-0171. [DOI] [Google Scholar]

- Henseler J., Ringle C.M., Sinkovics R.R. The use of partial least squares path modeling in international marketing. Advances in International Marketing. 2009;20(1):277–319. [Google Scholar]

- Henseler J., Ringle C.M., Sarstedt M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. Journal of the Academy of Marketing Science. 2014;43(1):115–135. [Google Scholar]

- Hu L., Bentler P.M. Fit indices in covariance structure modeling: Sensitivity to under parameterized model misspecification. Psychological Methods. 1998;3(4):424–453. [Google Scholar]

- Kache F., Seuring S. Challenges and opportunities of digital information at the intersection of Big Data Analytics and supply chain management. International Journal of Operations & Production Management. 2017;37(1):10–36. doi: 10.1108/IJOPM-02-2015-0078. [DOI] [Google Scholar]

- Kalaitzi D., Matopoulos A., Bourlakis M., Tate W.L. Supply chain strategies in an era of natural resource scarcity. International Journal of Operations & Production Management. 2017;38(3):784–809. doi: 10.1108/IJOPM-05-2017-0309. [DOI] [Google Scholar]

- Kale P., Singh H., Perlmutter H. Learning and protection of proprietary assets in strategic alliances: Building relational capital. Strategic Management. 2000;21(3):217–237. doi: 10.1002/(SICI)1097-0266(200003)21:33.3.CO;2-P. [DOI] [Google Scholar]

- Ketchen D.J., Hult G.T.M. Bridging organization theory and supply chain management: The case of best value supply chains. Journal of Operations Management. 2007;25(2):573–580. doi: 10.1016/j.jom.2006.05.010. [DOI] [Google Scholar]

- Koot M., Mes M.R., Iacob M.E. A Systematic Literature Review of Supply Chain Decision Making supported by the Internet of Things and Big Data Analytics. Computers & Industrial Engineering. 2020;154(4) [Google Scholar]

- Kraus S., Clauss T., Breier M., Gast J., Zardini A., Tiberius V. The economics of COVID-19: Initial empirical evidence on how family firms in five European countries cope with the corona crisis. International Journal of Entrepreneurial Behavior & Research. 2020;26(5):1067–1092. doi: 10.1108/IJEBR-04-2020-0214. [DOI] [Google Scholar]

- Kumar A., Sharma K., Singh H., Naugriya S.G., Gill S.S., Buyya R. A drone-based networked system and methods for combating coronavirus disease (COVID-19) pandemic. Future Generation Computer Systems. 2020;115:1–19. doi: 10.1016/j.future.2020.08.046. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Le P.B., Lei H. The mediating role of trust in stimulating the relationship between transformational leadership and knowledge sharing processes. Journal of Knowledge Management. 2018;22(3):521–537. doi: 10.1108/JKM-10-2016-0463. [DOI] [Google Scholar]

- Li G., Yang H., Sun L., Sohal A.S. The impact of IT implementation on supply chain integration and performance. International Journal of Production Economics. 2009;120(1):125–138. doi: 10.1016/j.ijpe.2008.07.017. [DOI] [Google Scholar]

- Ling-Yee L. Marketing resources and performance of exhibitor firms in trade shows: A contingent resource perspective. Industrial Marketing Management. 2007;36(3):360–370. [Google Scholar]

- Lukić J., Radenković M., Despotović-Zrakić M. Supply chain intelligence for electricity markets: A smart grid perspective. Information Systems Frontiers. 2017;19:91–107. doi: 10.1007/s10796-015-9592-z. [DOI] [Google Scholar]

- Malhotra N.K. 4th ed. Pearson Education Limited; Essex, UK: 2014. Basic marketing research. Pearson new international edition. [Google Scholar]

- Manavalan E., Jayakrishna K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Computers & Industrial Engineering. 2019;127(1):925–953. [Google Scholar]

- Massey C., Cameron A., Cheyne J., Harris C., Tweed D., Wallace C., Warriner V. Speaking Up: Stories of Growth in Small & Medium Enterprises in New Zealand. 2004 doi: 10.1191/0969733005ne800oa. [DOI] [Google Scholar]

- Mishra D., Gunasekaran A., Papadopoulos T., Childe S.J. Big Data and supply chain management: A review and bibliometric analysis. Annals of Operations Research. 2018;270(1):313–336. [Google Scholar]

- Mishra D., Sharma R.R.K., Kumar S., Dubey R. Bridging and buffering: Strategies for mitigating supply risk and improving supply chain performance. International Journal of Production Economics. 2016;180:183–197. doi: 10.1016/j.ijpe.2016.08.005. [DOI] [Google Scholar]

- Mofokeng T.M., Chinomona R. Supply chain partnership, supply chain collaboration and supply chain integration as the antecedents of supply chain performance. South African Journal of Business Management. 2019;50(1):1–10. doi: 10.4102/sajbm.v50i1.193. [DOI] [Google Scholar]

- Nakayama R.S., de Mesquita Spínola M., Silva J.R. Towards I4. 0: A comprehensive analysis of evolution from I3.0. Computers & Industrial Engineering. 2020;144(6) [Google Scholar]

- Nandi S., Sarkis J., Hervani A.A., Helms M.M. Redesigning supply chains using blockchain-enabled circular economy and COVID-19 experiences. Sustainable Production and Consumption. 2021;27:10–22. doi: 10.1016/j.spc.2020.10.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Napoleone A., Macchi M., Pozzetti A. A review on the characteristics of cyber-physical systems for the future smart factories. Journal of manufacturing systems. 2020;54(1):305–335. [Google Scholar]

- Nath V., Agrawal R. Agility and lean practices as antecedents of supply chain social sustainability. International Journal of Operations and Production Management. 2020;40(10):1589–1611. doi: 10.1108/IJOPM-09-2019-0642. [DOI] [Google Scholar]

- Panahifar F., Byrne P.J., Salam M.A., Heavey C. Supply chain collaboration and firm’s performance: The critical role of information sharing and trust. Journal of Enterprise Information Management. 2018;31(3):358–379. doi: 10.1108/JEIM-08-2017-0114. [DOI] [Google Scholar]

- Pang Z., Chen Q., Han W. Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion. Information Systems Frontiers. 2015;17:289–319. doi: 10.1007/s10796-012-9374-9. [DOI] [Google Scholar]

- Park C. Emergence of Inter-organizational Collaboration Networks: Relational Capability Perspective. Journal of the Korean Operations Research and Management Science Society. 2015;40:1–18. doi: 10.7737/JKORMS.2015.40.4.001. [DOI] [Google Scholar]

- Paulraj A., Lado A.A., Chen I.J. Inter-organizational communication as a relational competency: Antecedents and performance outcomes in collaborative buyer–supplier relationships. Journal of Operations Management. 2008;26(1):45–64. doi: 10.1016/j.jom.2007.04.001. [DOI] [Google Scholar]

- Peter N. SAGE Publishing; Thousand Oaks: 2007. Contingency Theory. Leadership: Theory and practice; pp. 74–87. [Google Scholar]

- Piccialli F., di Cola V., Giampaolo F. The Role of Artificial Intelligence in Fighting the COVID-19 Pandemic. Information Systems Frontiers, In Press. 2021 doi: 10.1007/s10796-021-10131-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Prasad S., Su H.-C., Altay N., Tata J. Building disaster-resilient micro enterprises in the developing world. Disasters. 2015;39(3):447–466. doi: 10.1111/disa.12117. [DOI] [PubMed] [Google Scholar]

- Pratono A.H. Strategic orientation and information technological turbulence: Contingency perspective in SMEs. Business Process Management Journal. 2016;22(2):368–382. doi: 10.1108/BPMJ-05-2015-0066. [DOI] [Google Scholar]

- Richter N.F., Sinkovics R., Ringle C.M., Schlägel C. A critical look at the use of SEM in international business research. International Marketing Review. 2016;33(3):376–404. [Google Scholar]

- Ringle C.M., Sarstedt M. Gain more insight from your PLS-SEM results: The importance-performance map analysis. Industrial Management & Data Systems. 2016;116(9):1865–1886. doi: 10.1108/IMDS-10-2015-0449. [DOI] [Google Scholar]

- Saberi S., Kouhizadeh M., Sarkis J., Shen L. Blockchain technology and its relationships to sustainable supply chain management. International Journal of Production Research. 2019;57(7):2117–2135. doi: 10.1080/00207543.2018.1533261. [DOI] [Google Scholar]

- Saleem H., Li Y., Ali Z., Ayyoub M., Wang Y., Mehreen A. Big data use and its outcomes in supply chain context: The roles of information sharing and technological innovation. Journal of Enterprise Information Management. 2021;34(4):1121–1143. doi: 10.1108/JEIM-03-2020-0119. [DOI] [Google Scholar]

- Samantha G. The Impact of Natural Disasters on Micro, Small and Medium Enterprises (MSMEs): A Case Study on 2016 Flood Event in Western Sri Lanka. Procedia Engineering. 2018;212:744–751. doi: 10.1016/j.proeng.2018.01.096. [DOI] [Google Scholar]

- Sarkis J. Supply chain sustainability: Learning from the COVID-19 pandemic. International Journal of Operations & Production Management. 2020;41(1):63–73. doi: 10.1108/IJOPM-08-2020-0568. [DOI] [Google Scholar]

- Schlittgen R., Ringle C.M., Sarstedt M., Becker J.-M. Segmentation of PLS Path Models by Iterative Reweighted Regressions. Journal of Business Research. 2016;69(10):4583–4592. doi: 10.1016/j.jbusres.2016.04.009. [DOI] [Google Scholar]

- Shafi, M., Zoya, Lei, Z., Song, X. & Sarker, M. N. I. (2020). The effects of transformational leadership on employee creativity: Moderating role of intrinsic motivation. Asia Pacific Management Review. 25(3), 166-176. https://doi.org/10.1016/j.apmrv.2019.12.002.

- Sharma R., Shishodia A., Kamble S., Gunasekaran A., Belhadi A. Agriculture supply chain risks and COVID-19: Mitigation strategies and implications for the practitioners. International Journal of Logistics Research and Applications. In Press. 2020 doi: 10.1080/13675567.2020.1830049. [DOI] [Google Scholar]

- Smart P., Hemel S., Lettice F., Adams R., Evans S. Pre-paradigmatic status of industrial sustainability: A systematic review. International Journal of Operations and Production Management. 2017;37(10):1425–1450. doi: 10.1108/IJOPM-02-2016-0058. [DOI] [Google Scholar]

- Spreitzer G.M., Cameron L., Garrett L. Alternative work arrangements: Two images of the new world of work. Annual Review of Organizational Psychology and Organizational Behavior. 2017;4:473–499. [Google Scholar]

- Staples D.S., Hulland J.S., Higgins C.A. A self-efficacy theory explanation for the management of remote workers in virtual organizations. Organization Science. 1999;10(6):758–776. [Google Scholar]

- Stieglitz S., Mirbabaie M., Ross B., Neuberger C. Social media analytics – Challenges in topic discovery, data collection, and data preparation. International Journal of Information Management. 2019;39:156–168. doi: 10.1016/j.ijinfomgt.2017.12.002. [DOI] [Google Scholar]

- Stone M. Cross validatory choice and assessment of statistical predictions. Journal of the Royal Statistical Society. 1974;36(2):111–147. [Google Scholar]

- Tan K.H., Wong W.P., Chung L. Information and Knowledge Leakage in Supply Chain. Information Systems Frontiers. 2016;18:621–638. doi: 10.1007/s10796-015-9553-6. [DOI] [Google Scholar]

- Teece D., Pisano G., Shuen A. Dynamic Capabilities and Strategic Management. Strategic Management Journal. 1997;18(7):509–533. [Google Scholar]

- Thakur R., Angriawan A., Summey J.H. Technological opinion leadership: The role of personal innovativeness, gadget love, and technological innovativeness. Journal of Business Research. 2016;69(8):2764–2773. [Google Scholar]

- van Hoek R. Exploring blockchain implementation in the supply chain. International Journal of Operations and Production Management. 2019;39(6/7/8):829–859. doi: 10.1108/IJOPM-01-2019-0022. [DOI] [Google Scholar]

- Voorhees C.M., Brady M.K., Calantone R., Ramirez E. Discriminant validity testing in marketing: An analysis, causes for concern, and proposed remedies. Journal of the Academy of Marketing Science. 2016;44:119–134. [Google Scholar]

- Willaby H.W., Costa D.S.J., Burns B.D., McCAnn C., Roberts R.D. Testing complex models with small sample sizes: A historical overview and empirical demonstration of what partial least squares (PLS) can offer differential psychology. Personality and Individual Differences. 2015;84:73–78. [Google Scholar]

- Williams S., Schaefer A. Small and Medium-Sized Enterprises and Sustainability: Managers' Values and Engagement with Environmental and Climate Change Issues. Business Strategy and the Environment. 2013;22(3):173–186. doi: 10.1002/bse.1740. [DOI] [Google Scholar]

- Wittmann C.M., Hunt S.D., Arnett D.B. Explaining alliance success: Competences, resources, relational factors, and resource-advantage theory. Industrial Marketing Management. 2009;38(7):743–756. doi: 10.1016/j.indmarman.2008.02.007. [DOI] [Google Scholar]

- Wooldridge J.M. MIT Press; USA: 2002. Econometric Analysis of Cross Section and Panel Data. [Google Scholar]

- World Bank. (2020). East Asia and Pacific in the Time of COVID-19. East Asia and Pacific Economic Update (April). Washington, DC: World Bank.

- World Bank. (2020). Small and medium enterprises (SMEs) finance. https://www.worldbank.org/en/topic/smefinance.