Abstract

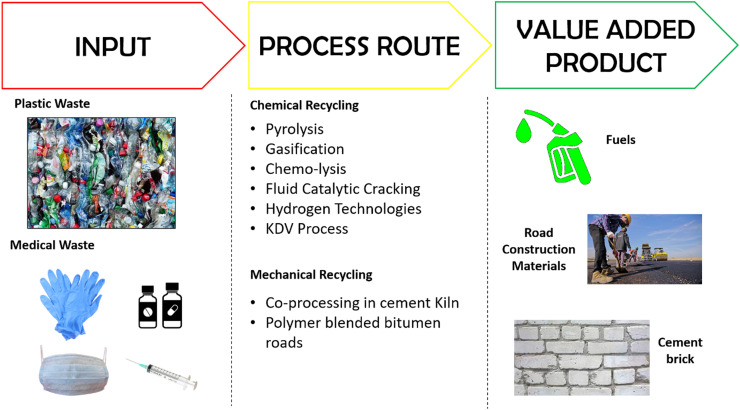

Coronavirus Diseases 2019 (COVID-19) pandemic has a huge impact on the plastic waste management in many countries due to the sudden surge of medical waste which has led to a global waste management crisis. Improper management of plastic waste may lead to various negative impacts on the environment, animals, and human health. However, adopting proper waste management and the right technologies, looking in a different perception of the current crisis would be an opportunity. About 40% of the plastic waste ended up in landfill, 25% incinerated, 16% recycled and the remaining 19% are leaked into the environment. The increase of plastic wastes and demand of plastic markets serve as a good economic indicator for investor and government initiative to invest in technologies that converts plastic waste into value-added product such as fuel and construction materials. This will close the loop of the life cycle of plastic waste by achieving a sustainable circular economy. This review paper will provide insight of the state of plastic waste before and during the COVID-19 pandemic. The treatment pathway of plastic waste such as sterilisation technology, incineration, and alternative technologies available in converting plastic waste into value-added product were reviewed.

Keywords: COVID-19, Plastic waste, Medical waste, Waste management, Value-added product

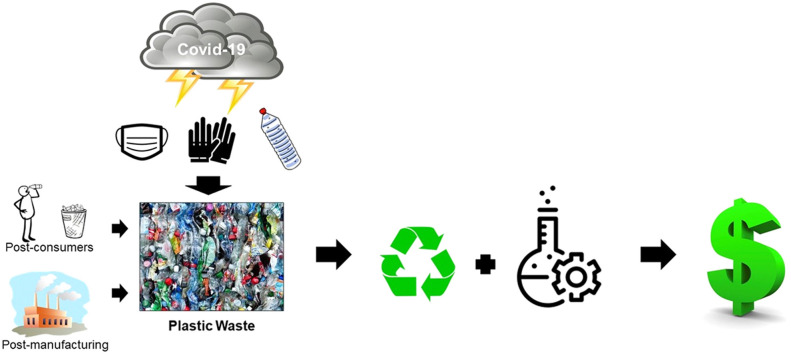

Graphical Abstract

1. Introduction

COVID-19 has a coronavirus-specific nucleic acid sequence that is different from previously known human coronaviruses caused by severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) (Gorbalenya et al., 1989) and is similar to those found in bats (Zhou et al., 2020a). COVID-19 is an airborne disease and the virus can be transmitted easily through air droplets exhale out from an infected person’s mouth or nose (Morawska et al., 2020). Most of the symptoms are mild. In severe cases, the patients will suffer from syndromes such as pneumonia, pulmonary oedema and organ failure, which could lead to death. Most cases in other part of the countries were originally caused by the foreigner travelling to the countries. As of 30th January 2020, the World Health Organization (WHO) declared COVID-19 pandemic as Public Health Emergency of International Concern (Acter et al., 2020) after an extensive assessment of the epidemic. The local transmissions were then increasing at an alarming rate. Due to the severity of the problem, WHO announced the diseases as a pandemic on 11th March 2020 (Acter et al., 2020). The epicentre of COVID-19 shifted to Europe and to the United States, with the highest number of active cases and deaths reported daily (Adegboye et al., 2020). As up to 19 March 2020, about 200,000 of confirmed cases from 176 countries have reported and more than 9000 deaths worldwide. China has successfully slowed down the spread of the disease and number of active cases within its borders after three months of lock down. The epicentre of the pandemic then shifted from China to United States and Europe. By 25th of April 2020, the total number of confirmed cases in those regions have exceeded 2.7 million cases (Wang et al., 2020) and this number continues to increase.

Governments in most countries have proposed several preventive measures to minimise the chances of spreading of COVID-19 in order to avoid another wave of transmission. Preventive measures such as wash hands frequently with soap and water or to sanitize with alcohol-based sanitizer that contain 75% of ethanol (Schwartz et al., 2020). By sanitizing our hands or washing with soap frequently, the virus can be killed, and will prevent it from entering the human body. When sanitising our hands, an adequate amount of hand sanitizer is applied and rub throughout the whole palm. In addition, “social distancing” or “physical distancing” at least 1 m between each individual have been enforced worldwide (Gupta and Wong, 2020). COVID-19 virus transmits through airborne in which liquid droplets are sprayed out from the mouth and nose when the person cough or sneeze. Most of the shopping malls has restrained their guidelines to ensure customers’ welfare by putting label on the floor to guide the position of customers when queuing up at their respective activities. Besides that, social gatherings neither large- and small-scale were prohibited during the lockdown. This is because when people come in crowded places, the ventilation of the enclosed space becomes poor. Some shops even limit the number of customers visiting at a period of time. Consequently, it is compulsory to wear face masks to reduce the chances of airborne virus entering the human body through nose or mouth. In addition, movements such as touching our eyes, nose and mouth should be avoided in public areas. This is due to a lot of bacteria and virus that could be presence on the surface of the hands after contacting with different objects.

The world not only facing the COVID-19 pandemic but also struggling with the increase of wastes mainly from plastics to both the society and healthcare sectors. Although the current preventive measures enforced by the governments was to prevent another wave of COVID-19 transmission. However, the occurrence of plastic waste is being rapidly generated unknowingly such as the plastic bottles of sanitiser, facial mask, and surgical gloves due to the high production and purchasing volume to meet the demand of the society. Plastics possess excellent strength, durability and versatile, especially in healthcare sector with major application in single-used plastic medical tools, equipment, and packaging (Chen et al., 2020). The composition of personal protective equipment (PPE) are composed of various types of plastics such as low-density polyethylene (LDPE), high density polyethylene (HDPE), polyethylene terephthalate (PET), polyvinyl chloride (PVC), polypropylene (PP), polycarbonate and polystyrene (PS). The usage of PPE may be life-saviour during this pandemic, yet the accumulation, mismanagement and littering of these plastic wastes would bring to an abrupt collapse of waste management chains which will cause severe environment pollution in terrestrial and marine ecosystem. Besides, the deluge of medical wastes has increased exponentially every day during the COVID-19 outbreak. For instance, Wuhan, a city in China have produced 200 tons of clinical trash on the exact day, 24th of February 2020. The amount of trash is four times the amount the city's only dedicated facility can incinerate per day (Saadat et al., 2020). According to Kalina and Tilley, (2020), the monthly consumption of facial mask and surgical gloves are estimated at 129 billion and 65 billion, respectively for 7.8 billion population across the globe (Kalina and Tilley, 2020). It has been estimated by the WHO in which the demand and supply of plastic-based PPE against the current pandemic has been expected to increase about 40% per month in the supply chain of different safety products worldwide (World Health Organization, 2020).

Hence, this review will discuss about the current state-of-the-art of plastic wastes before and during the COVID-19 pandemic. The outline and conceptualization of this review was conducted using online databases search to identify similar research studies, where five keywords (i.e., COVID-19, plastic waste, medical waste, waste management and value-added product) were subjected to identify related journal articles, organisational/institutional report and news article. Initial search was performed in Google Scholars and Google Search with various combinations of keywords. Search results showed about 3000 journals. Articles shown in the search results were screened based on their summary, abstracts and conclusion which are within the scope of this review paper. Finally, a total of 111 articles (98 journal articles, 5 organisational/institutional reports, 4 news articles, 1 book, 1 book chapter, 1 working paper and 1 patent) were selected and cited in this review paper. The technologies involved in the treatment pathway of plastic waste management were comprehensively evaluated. In addition, this review paper will also provide a brief insight of the technologies available in fate of converting plastic waste into value-added products such. As the global plastic waste continue to increase, instead of allowing it to pollute the environment, researchers should utilise these waste resources and convert them into value-added products by incorporating the current available technologies, turning the current crisis into opportunity for the future industries.

2. The state of plastic waste associated with COVID-19 pandemic

2.1. The state of plastic waste before COVID-19

In this era of modern technology, plastics have a role of modern workhorse materials as it is widely used in human activities due to its vast application. The production of plastic materials has consecutively increased for many decades since the 1950s (Curlee, 1986) due to the demand from the increasing human population. Based on federation of plastic producers “Plastics Europe”, approximately 311 million tons of long-duration degradability (200–1000 years) plastic were generated all around the world in 2014, compared with 299 million tons in 2013 (Halimi et al., 2017). Based on industry data, USA, Europe, and Asia account for 85% of plastic production, the amount of plastics production is estimated to double up in the next 20 years to 600 million tonne (Kumar, 2018). According to Grand View Research, the global plastic market is expected to have a compound annual growth rate (CAGR) of 3.2% from 2020 to 2027 (Plastics Market Size, Share & Trends Report, 2020–2027, 2020). Increasing plastic consumption in various sector ranging from healthcare, automotive, construction, electrical and electronic industries and packaging industries is projected to drive the market for plastic. The largest market for plastic is the packaging industry, occupying approximately 36.5% of overall plastic usage. This is due to the benefits of plastics such as thermal and chemical resistance, high strength and low-cost. These properties are favourable in industries in producing containers, bottles, plastic bags, plastic films and geomembranes.

There are various type of plastics produced in the industries such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polyvinylchloride (PVC) and polystyrene (PS). The most common type of plastic that can be found in the plastic waste streams are PE and PET (Awoyera and Adesina, 2020). PE can be further divided into low-density (LDPE), high-density (HDPE), linear low-density (LLDPE) and very low density (VLDPE) (Risch, 2009). Based on the application of PE and PET, it can only be used for one time, leading to consequential in generating plastic wastes. Table 1 shows the different type of thermoplastics and its application in our daily life.

Table 1.

The different type of thermoplastics and its uses (Raheem, 2012).

| Plastic type | Application |

|---|---|

| PET | mouthwash bottles, beverage bottles, boil-in-bag |

| LDPE | Bread bags, grocery bags, food wrap |

| HDPE | Milk jugs, trash bags, detergent bottles |

| PVC | Cooking oil bottles, packaging around meat |

| PP | Straws, diapers, yoghurt containers, shampoo bottles, margarine tubs |

| PS | Egg cartons, hot beverage cups, meat trays, take-home boxes |

Despite the growth of plastic markets, large quantities of plastic wastes were generated and disposed daily from human activities such as manufacturing and post-consumer which contribute the most to the plastic waste (Curlee, 1986). As there are many types of plastic waste, it can be classified into thermoplastics and thermosets. Thermosets are difficult to recycle due to the cross-linked bonds while thermoplastics are recyclable because it do not have cross-linked bonds can be melted by heat, friction and reformed into new products when cooled (Curlee, 1986, Raheem, 2012). Post-consumer contributes the most to plastic waste and thermoplastic is the main contribution of plastic waste. The generation of solid plastic wastes keep increasing whereas only a small amount of the generated wastes is being recycled. Based on the report by Environmental Protection Agency has shown that out of several tons of plastic wastes generated annually, only 7% is recycled, about 8% incinerated and the remaining are landfilled (Awoyera and Adesina, 2020). Generation of large amount of plastic wastes has become the major threat to the sustainability of the environment. An estimation of 300 million metric tons of plastics wastes are generated annually (North and Halden, 2013, Awoyera and Adesina, 2020, Tulashie et al., 2020). In 2016, United States has the highest plastic waste generation of 42 million metric tons (13.1% of solid waste) follow by EU-28 countries (30 million metric tons, 11.7% of solid waste), India (26 million metric tons, 9.5% of solid waste) and China (22 million metric tons, 9.8% of solid waste) (Law et al., 2020). The limited land-space becomes the main constraint when managing these wastes. Consequently, this has led to the huge amount of plastic wastes being deposited in the oceans, causing impact to the ecology, economy and aesthetics of aquatic ecosystem (Awoyera and Adesina, 2020). About 80% of the disposal plastics in ocean are from Asia (Kumar, 2018). Plastics pose severe pollution to the environment and human health problems. Before the outbreak of COVID-19 pandemic, a lot of countries are developing campaign to ban usage of plastics and shifting towards paper packaging products instead of single-used plastics.

2.2. The state of plastic waste during COVID-19 pandemic

COVID-19 pandemic has stopped the rolling ball and became a challenge in reducing the production of plastic waste. Due to the restricted movement control in many countries, governments have place restriction by preventing citizens to travel across states in the country and allow only one person from each family to buy grocery leading to less transportation on roads. This may have seemed to reduce the emission of greenhouse gases (GHGs), air pollution, environmental noise pollution, land and wildlife pressure. However, it is failing to consider the increase use and consumption of single-use-plastics (including PPE) and a shifted priority in waste management behavioural that is contrary to environmental sustainability. COVID-19 pandemic has left a lot of negative impacts such as increased in medical wastes and single used plastic wastes. PPE such as face masks, face shield and hand glove are mostly made from plastic materials. As everyone is concern of health and hygiene, the disposable plastics has caused improper management of used PPE during the COVID-19 pandemic resulting in the widespread of environmental pollution. Approximately 129 billion face masks and 65 billion gloves disposed was estimated within a month globally (Prata et al., 2020, Silva et al., 2021). It cannot be denied that single-use plastic has contribute in the war against COVID-19, especially for the front-liners. It has promoted adherence to social-distancing rules and regulation, enabling home delivery of groceries, especially food. Further to that, it also has aided to restrain transmission of virus, by using reusable coffee cups and shopping bags in many countries.

Countries with many confirmed COVID-19 cases also struggles in managing the large amount of medical waste produced. Based on the data collected from the King Abdullah University Hospital in Jordan, the amount of medical wastes produced are 10-fold higher compared with the average production before the pandemic. It is estimated for every 95 COVID-19 patients, approximately 650 kg of medical wastes are produced per day (Abu-Qdais et al., 2020, Silva et al., 2021). In order to avoid the transmission of the diseases, it is essential for everyone especially front-liners such as medical staffs to wear the adequate PPE. As PPE is essential for everyone, the demand greatly increase in every corner of the world. For instance, an estimated monthly use of 129 billion face masks and 65 billion gloves would be necessary to protect citizens worldwide. Due to improper handling and disposal of PPE, the indiscriminate use of the items by ordinary citizens has become controversial. Every single use of surgical masks and gloves cannot be worn more than 3–4 h. The surgical mask must be changed and discarded when exceeds 4 h to prevent cross-contamination. The contaminated PPE must be handled carefully before dispose to the landfills. It is recommended to seal it in the leak-proof garbage bag or treated through incineration process. However, the used masks ended up littered along everywhere in the public area with emptied hand sanitizers or other solid wastes without any precautionary measures. At Soko Islands beach in Hong Kong, masks can be seen in every 100 m reported by NGO Oceans Asia (Saadat et al., 2020, Silva et al., 2021). Besides that, the packaging wastes for pharmaceutical purposes increase as well as the usage of medication by patient increases. Moreover, research studies, experiments and blood tests are carried out in the laboratory contributes to the plastic wastes generation.

During this pandemic, the usage of single used plastics is increasing due to high production and purchasing volume. The demand of plastics for packaging purposes is estimated to increase by 40% and 17% in other applications such as medical use (Silva et al., 2021). At this timeline, everyone is concern of health and hygiene, most of the consumers and providers are more likely to prefer food to be packed in plastic containers or any single used food packaging. For the reassurance of every human health, most of the restaurants are replacing one time used bowls and cutleries to raise the health awareness. Supermarkets and groceries stores do provide home delivery services and pick up services to assure customers’ health and safety. Based on a survey collected from South Korea, the percentage of people doing online food purchases and groceries necessities has increased by 92.5% and 44.5% respectively, compared to year 2019 (Vanapalli et al., 2021). Other countries such as Vietnam, Italy and China also reported a tremendous increase in online shopping by 12–57% (Vanapalli et al., 2021). By taking the advantages of this preference, this induced the increase of plastic wastes production comprising of multi layered plastic, thin films and foams. During COVID-19, the end-of-life waste management for many single used plastics is likely as mixed municipal solid waste, as worldwide recycling streams are restricted. As the world begins to move ahead of this pandemic, we will realise that our increased reliance on plastics has resulted in a new plague of plastic waste that we have been struggling to come to terms against the expenses of our environment.

2.3. Negative impacts of plastic to human health and environment

Plastics bring a lot of benefit to the society in innumerable ways. Due to the convenient of plastics, tons of plastic bags are manufactured daily. However, some properties of plastic such as non-biodegradable, low melting points and short service life are the drawbacks which may cause adverse effects to human health, environment and animals. Most of the plastics waste are non-biodegradable and has a life span between less than a year to 50 years of use (Potrykus et al., 2020). The intermolecular bonds joining the constitute plastics structure prevent it to corrode nor decay. Due to difficult decomposition of plastics, plastics waste not disposed properly will clog the waterways and be washed away into the drain or reservoirs. This causes pollution towards the environment and making the environment unsightly. Also, plastics have lower melting points compared to other substances. When substances with higher temperature in contact with plastic materials, plastics will decompose and releases harmful gases. Due to low melting point of plastics, plastics cannot be used at high temperature conditions. It is not suitable to use as a protective barrier for furnaces. Besides that, plastics are highly flammable as it contains fossil fuels properties, making them a fire hazard. In general, as compared to metal, plastics have shorter service life (e.g., disposables, food packaging, single use equipment) and are thrown away after every single use (Potrykus et al., 2020).

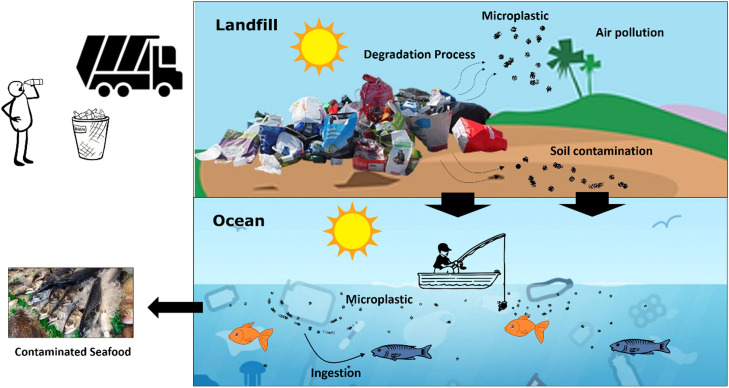

Recent studies of plastics revolved around the topic of human health and environmental concerns, including the endocrine-disrupting compounds presence in plastics as well as the long-term pollution of plastic waste to the environment (North and Halden, 2013). Plastics are mainly made up of natural gas and crude oil through addition polymerisation and condensation polymerisation process (Pan et al., 2020). Plastics used in packaging products intended for human consumption are chemically harmful as they contain dangerous compound (e.g. additives) making them potentially toxic. This will threaten human health when exposed in the long term. To achieve the desired properties of plastic in terms of density, hardness, tensile strength or resistance for various application. Common additives such as antistatic agent, colorants, coupling agents, fillers, flame retardants, peroxides, plasticizers, processing aids, reinforcing fibres and stabilizers are added during the process of plastic production (Deanin, 1975). Most of the plastic waste will ended up in landfill or ocean, although disposing the plastic might not seem to harm human but understanding the knowledge of food chain and the life cycle of plastic waste, it does have an indirect impact on human health shown in Fig. 1.

Fig. 1.

The negative impact of plastic waste on the environment and the ocean.

In Europe, there are about 125,000 to 500,000 landfills; it is estimated over 5.25 billion tonnes of waste has been deposited between 1995 and 2015, plastic represents about 5–25 wt% of the waste (Canopoli et al., 2018). Plastic waste disposed in landfill may be exposed to abiotic and biotic degradation processes (Potrykus et al., 2020). The degradation of plastic waste is a source of vast amount of secondary microplastics, this may lead to uncontrolled contamination of air and soil in waste landfill. Further to that, the presence of microorganisms such as bacterial form biofilm on the surface of the plastic can also cause plastic degradation (Potrykus et al., 2020). The process of plastic degradation may lead to various additives liberation and secondary microplastic which may be harmful to environment and human health. He et al. (2019) collected 12 landfill leachate samples from 4 active and 2 closed municipal solid waste landfill, all samples were found to contain 17 different types microplastics with calculated concentration ranging from 0.42 to 24.58 items/L. PE and PP were the predominant polymer types. Interestingly, Su et al. (2019) reported that secondary microplastics were more abundant in young and medium landfills compared to old landfill, this result might be attributed to the growing trend, application areas and product lifetime of different plastic products.

The poor handling of the plastic waste and disposal into oceans will threaten aquatic animals’ health such as turtles, corals and whales, thereby disrupting the ecosystem in the ocean. Jambeck et al. (2015) studies reported that 275 million metric tons of plastic waste was generated in 192 coastal countries in 2010 with 1.75–4.62% of the plastic waste entering the ocean. Animal such as turtle may consume the plastic debris as the food source resulting the waste entangled in it (University of Exeter, 2017). In 2014, a report from the secretariat of the Convention on Biological Diversity in Montreal, Canada shows that all sea turtle species, 45% of marine mammal species and 21% of seabird species are harmed this way (Rochman et al., 2013). Besides, large pieces of plastics will float to new habitat, injuring ecologically and commercially important species such as corals (Rochman et al., 2013). It is estimated that 11.1 billion plastic waste are entangled on coral reefs across the Asia-Pacific and this number is projected to increase 40% by 2025 (Lamb et al., 2018). Plastic waste which flow across the coral reefs may cause physical harm to the coral reefs and introduce foreign pathogens to the reefs (Plastic trash is sickening the world’s coral reefs, 2018). Consequently, these diseases will be transmitted to ocean animals living nearby the infected coral reefs. The consumption of infected seafood such as fish, prawn and crabs will then possibly lead to another virus strain outbreak. Further to that, if humans consume infected seafood such as fish, prawn and crabs may lead to another virus outbreak.

Moreover, plastic waste litter on the land and sea are exposed to UV-radiation and abrasive wave action may cause reaction known as photo and thermo-oxidative degradation producing microparticles that are within 10–500 µm in size as secondary microplastics or microbeads (Andrady, 2011, Prata et al., 2019). These poses adverse effects on marine organisms such as fish, prawn or crab that may accumulate ingested microplastic. Microplastic inherent a diverse range of harmful compounds such as organic contaminants including pesticides, flame retardant and PCBs additives that may bioaccumulate or ingest by phytoplankton and zooplankton at the base of the food chain and in turn become food for other organisms (Li et al., 2016). As humans are high up in the food chain, humans may very well accumulate the microplastics and toxic compounds that are present in the seafood which they had consumed resulting in serious health problems in the long term (Bradney et al., 2019).

Previous studies have reported on the additives in plastic which most people are exposed to contains phthalates, bisphenol A (BPA) and polybrominated diphenyl ethers (PBDE) (Kumar, 2018). These additives have entered deeply into the human daily activities. Huang et al., (2017) studies examined the urinary concentration data from 30 countries, the global estimated BPA daily intakes for children and pregnant women were 2 and 1.4 times respectively, that of the adult group. The top three countries reported with highest BPA daily intake were Italy, Sweden and Denmark. In addition, previous studies have also been reported that children are exposed to high levels of phthalates and PBDE compared to adults (Ni et al., 2013, Katsikantami et al., 2016). The accumulation of these additives in human body in the long term may results in serious health effects such as disruption of endocrine system, adult-onset diabetes, early puberty and obesity (Kumar, 2018). The new and future generation of children are in a high risk of exposing to toxic and harmful compounds. Therefore, there is a need to address the current waste management crisis and manage the plastic wastes properly.

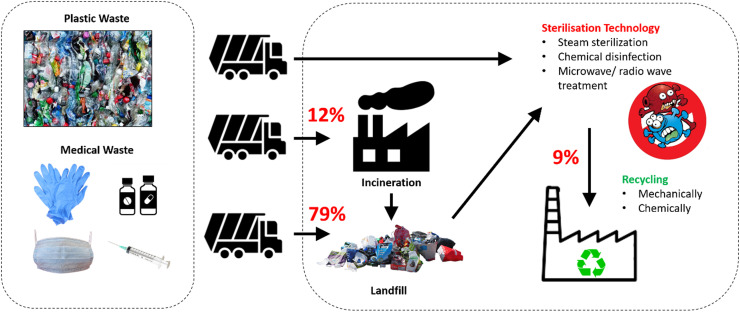

2.4. Alternative ways to reduce the usage of plastics

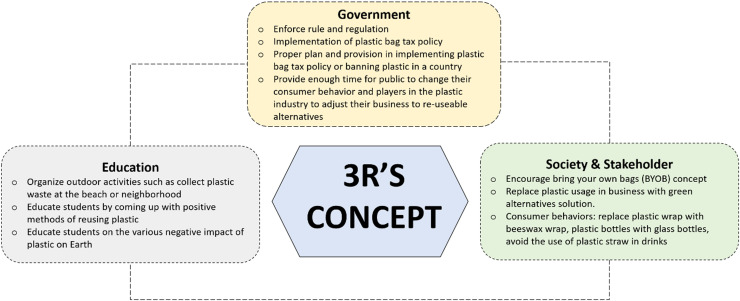

Plastic pollution is the main global issue which existed persistently in the life of humankind for decades. Since the 1950s, the usage of plastic has skyrocketed and has a pivotal status in this modern era because of its beneficial and convenience. Plastics has strong decomposition resistant leading to overloaded of plastic wastes generation. Up to year 2015, the amount of plastic wastes generated is approaching the combined weight of human weight. This preliminary figure is stunning. Among the amount of plastic wastes produced, about 10% of the plastic wastes enter the marine ecosystem. Plastic contains toxic pollutants such as additives accumulated from the manufacturing process. Plastics may bring the toxic pollutants around the environment, causing deleterious effects to the surrounding such as plastic debris depositing in the sediment and entangling marine animals. The issue became more serious during and after the COVID-19 pandemic. It takes quite a while to accurately collect data of the amount of additional plastic waste that has been produced during the pandemic. Considering the negative impacts of plastics to environmental and human health, governments have more awareness in solving this problem at the local, national, and international levels. Most of the countries are trying to find out different waste management systems to curb this canker. Plastic wastes are the most difficult wastes to be solved as they are difficult to biodegrade. Only approximately 9% and 12% of plastic wastes have been recycled and incinerated respectively, leaving 79% ended in the landfill or the natural environment (Payne et al., 2019). At this moment, everyone is fighting against COVID-19 pandemic and the preventive measures implemented to control the spread of diseases required apprehensible number of plastic products. As human health is put at the priority, policies of plastic reduction and waste management tactics have recently been temporarily delayed. However, there will always be some solution to handle the issue to ensure the long-term health of the Earth. One solution is the implementation of 3 R’s which are Reduce, Reuse and Recycle.

2.4.1. Reduce, reuse, and recycle solution with the collaboration from external sector

It has become synonymous that single-used plastic such as plastic straw, plastic bag and bottles are a significant issue for plastic pollution. These unintended environmental impacts such as entanglement and ingestion of aquatic and terrestrial species has yet to be addressed by the life cycle assessment (LCA). Therefore, it is urged to adopt reuse and recyclable alternative packaging material. Reduce means try to avoid usage of plastics in daily routine by changing consumer behaviour and only use it when necessary. To reduce the plastics usage, shopping at bulk stores or visiting to the shops with bring your own bags (BYOB) concept are highly encouraged. Not only that, shopper can bring their own recycle bag to pack their items while protecting the environment, but it also affects the consumer behaviour by being more awareness of their health. Studies have reported that bringing your own bag concept increases the probability of consumer purchasing organic product from 5.95% to 6.74% and the probability of purchasing indulgent item from 17.9% to 19.2% (Karmarkar and Bollinger, 2015). Besides the BYOB concept, plastic wrap can be replaced with beeswax wrap, choose glasses bottles instead of plastic bottles when buying drinks and try not to use plastic straw when having any drinks.

These are some of the consumer behaviours which can contribute in reducing the usage of packaging plastics. However, to change the consumer behaviours in a country remains a challenge. Many countries failed to ban plastic bag or implement plastic bag policy were due to poor communication with public and no national campaigns were held to properly inform the public (Adam et al., 2020). Further to that, governments has insufficient plans and provisions in which unrealistically time period is given to public to adjust their consumer behaviour and players in the plastic industry to adjust their business to re-useable alternatives (Adam et al., 2020). Without enough time, they may oppose such policies which could jeopardise the implementation such as no plastic bag and plastic bag policy. Therefore, government need to have a proper plan and provision for the implementation. In 2018, Malaysian Government has launched the Malaysia’s Roadmap to Zero Single-Use Plastics 2018–2030 (Zheng et al., 2020) to solve the mounting plastic pollution problem in the country. The implementation would require the collaboration and support from various sectors and channels such as education, government, stakeholders, and society. For instance, green consumerism in which academician, celebrity environmentalists, CEOs, governments, and big companies may be the central message of green initiative of plastic usage via mainstream media, books, interviews and social media feed.

Governments need to enforce rules and regulation in order to effectively reduce the usage of plastic bags. Penalty will be imposed for those who neglected the rules and regulation. Many countries such as England, New York City and Canada have taken the initiative to banned the usage of plastic bags and implemented plastic bag tax policy (Zen et al., 2013, Xanthos and Walker, 2017, Thomas et al., 2019). As early as 1991, Germany has implemented plastic bag policy, retail stores which provides plastic bags must pay tax or levy about 5–10 Euro cents per plastic bag. Moreover, in 2013, Australia has implemented the charges of 15–30 cents per plastic bags (Turner et al., 2012). Since then, the consumption of plastic bags in Australia dropped from 5.95 billion to 2.92 billion within 2 years (Turner et al., 2012). The implementation of this policy can greatly reduce the usage of plastic bags, leading to the inception of new positive environmental policies. However, Rivers et al., (2016) reported that the implementation of plastic bag tax policy has significant impact on people who already used recycle bags to use them more frequently, while having no effect on infrequent users. Further to that, it also shows no significant impact on respondent which had limited education while having a significant impact on respondents who had started or completed post-secondary and university degree. Therefore, effort is required from the education sector to educate and nurtured the new and future generation of the importance of protecting the environment.

2.4.2. Eco-consumerism of plastics through education

Education plays an important role in order to reduce uses of plastics. Young children who are still in the process of habit formation, can exert a particularly important positive impact on their peers and with time, on the next generations (Marazzi et al., 2020). Studies have revealed that education affects the knowledge, attitudes and behaviours of a children growth (Scott and Willits, 1994, Olofsson and Öhman, 2006, Mobley et al., 2010). Clubs and societies in the school can organise outdoor activities such as bringing students to the beach to collect plastic wastes as one of the club activities. Through that, teachers can educate them how serious the Earth is polluted by the plastic waste. In classroom, teachers can educate students on the type of plastics that can be recycled and exchange suggestion to think of more positive methods to reuse plastics such as initiating the school garden property incorporating with household plastic items for improving the gardens production purpose. The students and teachers can make full use of plastic products, such as fruit cups, to start seedlings in the garden. Plastics cutleries can be used as digging tools or as a marker for the position of certain plants. Through these various activities, studies have shown to significantly improve student’s knowledge while outdoor activities facilitate attitudes and behaviour (Chow et al., 2017). Fig. 2 shows a comprehensive evaluation of the 3 R’s concept in Government, Education, Stakeholder and Society.

Fig. 2.

Evaluation of 3R’s concept in Government, Education, Stakeholder and Society.

2.4.3. Alternative sources of bioplastics production

It is impossible to totally banned the usage of plastics in daily life, but there are some choices on the horizons to replace the plastics. It is encouraged to use reusable bags made of paper or cloth. Besides, research on microalgae-based bioplastics recently are made up of biosynthesis materials and 40% of energy in production can be saved up. There are a few types of biopolymer from microalgae which are polyhydroxyalkanoates (PHAs), polyhydroxybutyrates (PHBs) and poly-lactic acids (PLAs) currently commercialized in the market namely Biopol, Nodax, Degr Pol and Biogreen (Anjum et al., 2016, Dietrich et al., 2017). PHAs and PHBs are biosynthesis from neutral lipids that are accumulated in cell deposition of microalgae under control cultivation condition using vinasse and molasses from waste sugar production and waste frying oil (Cavalheiro et al., 2009, Benesova et al., 2017). Other ways of PHAs production can be performed through environmental stress condition and thermo-mechanical polymerization of protein obtained from the microalgae biomass (Zeller et al., 2013, García et al., 2020). Besides, microorganism such as microbial can produced PHA, PHB or PLA via the fermentation process (Mohammed et al., 2019, Cinar et al., 2020). For instance, the production of PLA begins from the microbial fermentation of feedstocks rich in starch such as corn and sugar to produce lactic acid. The lactic acid will then undergo polycondensation reaction to produce PLA. However, the production rate is time consuming due to the process of microbial fermentation which requires about 3–6 days of fermentation (Payne et al., 2019). On the other hand, the source of nutrients for the fermentation process uses sugar beet, corn, sugarcane or wheat (Chidambarampadmavathy et al., 2017). Due to increasing human population, the current food production rate may not even meet the human population demand thus it is not sustainable to use food source to produce bioplastic. Alternative source such as keratin from chicken feather, rice straw and microalgae biomass have been studied on the production of bioplastic (Bilo et al., 2018, Ramakrishnan et al., 2018, Payne et al., 2019). Further research is required on increasing the production rate of bioplastic to meet the demands of the increasing human population and replaced the conventional plastic in the industry.

3. The technologies involved in the treatment pathway of plastic waste

As we all know that the amount of medical waste generated during the COVID-19 pandemic has a huge impact on the plastic waste management. Countries such as China, India, Pakistan and Bangladesh have reported difficulties in managing the plastic wastes generated by the citizens including the sudden surge of medical wastes (Marinković et al., 2008). Medical waste which are contaminated due to possible pathogen and virus is a challenge. This is because medical wastes are require to undergo a sterilisation stage before further processing the waste and this process would involve additional cost for sterilisation.

Healthcare wastes are categorized as two group, hazardous and non-hazardous waste. They are mainly generated from the immunization, treatment or diagnosis of humans and animals (Marinković et al., 2008). Based on World Health Organisation (WHO), approximately 80% of medical wastes are under non-hazardous group while the remaining 20% are hazardous. Non-hazardous medical wastes are similar to household wastes such as paper, packaging, leftover foods and other inert substances. Hazardous medical wastes are toxic, infectious and carcinogenic. It can be grouped into a few categories; category which contains plastic waste are pharmaceutical waste, genotoxic waste and chemical waste (Khan et al., 2019). Genotoxic wastes are syringes or vial that contain cytostatic drugs or chemicals which have been used for the treatment of patients. Wastes with high percentage of heavy metals such as mercury are usually from pharmaceutical wastes and chemical wastes. Besides, plastic waste collected from landfill also requires sterilisation. This is due to the presence of high level of ash, impurities, heavy metals, organic and inorganic contaminants on the surface of the plastic which may cause biological activity or chemical decomposition (Canopoli et al., 2018, Avolio et al., 2019). Whether is hazardous medical wastes or plastic waste from landfill, it should be sorted out based on their properties and undergo sterilisation process before further management. Improper management of plastic wastes can impact public health and environment pollution. As COVID-19 pandemic is spreading all around the world, it is extremely important to disinfect or sterilise and handle properly the plastic waste coming from medical wastes.

A lot of plastics made items can be recycled. Recycling can be divided into mechanical and chemical. Most of the time, mechanical recycling is couple with chemical recycling. As there are different types of plastics, plastics wastes need to go through mechanical separation. Plastic waste is sorted out according to the characteristics and colour and as not all type of plastics undergoes same recycle process. After sorting out, the plastic wastes need to be cleaned or sterilise to remove impurities on the plastic waste. Then the plastics will be tested to evaluate the quality. Quality testing will be conducted based on the density, air classification, melting point and colour. The final step will be compounding. All the small plastics particles will then be assembled for future production. Fig. 3 shows the flow of plastic waste which may ended up in landfill, incineration or recycling; recycling can be further divided into mechanical recycling and chemical recycling.

Fig. 3.

The overall flow of plastic waste management.

3.1. Sterilisation technology

Sterilisation technology is important in treating the contaminated plastic waste or medical waste for further application. There are a few sterilisation technologies such as steam sterilisation, chemical disinfection, microwave/radio-wave treatment, and high temperature heat disinfection used for sterilising medical waste. Table 2 summarises the advantages and disadvantages of different sterilisation technology currently available in the industries. The later section will discuss in details of the working principle of the respective sterilisation technologies.

Table 2.

The advantages and disadvantages of different sterilisation technologies.

| Sterilisation technology | Advantages | Disadvantages |

|---|---|---|

| Steam sterilisation |

|

|

| Chemical disinfection |

|

|

| Microwave/ radio-wave treatment |

|

|

3.1.1. Steam sterilisation

Steam sterilization treatment method is an indispensable procedure to sterile the used and unused medical devices (Tankeshwar, 2013). The treatment is non-toxic, economical, effective and recognised way to sterilise disposable medical products due to its better environmental compatibility. It is in contrast to the sterilisation approach using gamma radiation or ETO 0003 (Guide to Steam Sterilization Cycles - Steam Flush Pressure Pulse, 2018). Medical products are set up separately on the stainless-steel racks and placed into the autoclave. The medical items are usually packaged in a versatile, partly steam-permeable and bacteria-proof package. However, steam sterilization still depends on the type of materials. Steam sterilization treatment method is suitable to be applied on heat and moisture resistant items. It is good in preventing transmission of pathogen. Steam sterilization with longer exposure time is needed in medical sector to clean the healthcare facilities and decontaminate microbiological waste and sample container.

The basic principle of steam sterilization is exposure of each parts directly in contact with steam at certain temperature and pressure for the specified time. Steam, pressure, temperature and time are the basic parameters required for steam sterilization. Different temperature and pressure will cause the need of exposure time to be different. For steam sterilisation, the ideal condition of the steam must be dry and saturated, entrained water. Microorganisms can be killed at a high speed under high temperatures and pressures. Proteins within the cells coagulate and denature under high temperature. To achieve the maximum efficiency, steam must have direct contact with the microorganisms for a specific duration depending on the temperature of the steam. Less time is required to kill the microorganisms if the temperature is higher. Bacterial endospores have natural defences’ against steam sterilization and they are known as most difficult killed organisms (Ames, 2019). In fact, they can be used to test the effectiveness of the steam sterilization cycle. Three of the most basic and specific phases of a steam (What is Bowie Dick Test?, 2017) sterilization cycle is conditioning, exposure and drying (Guide to Steam Sterilization Cycles - Steam Flush Pressure Pulse, 2018). In the conditioning process, air is evacuated from the wastes followed by the heating of the wastes to the optimum temperature. If the air is not removed from the loads, it may lead to sterilization failure due to unavailability of sterilant contacting with the wastes. To guarantee the microbial activities showing the best results, specific temperatures must be maintained between 121 °C and 132 °C are the most common steam sterilizing temperatures in the shortest period (15 min) that are most effective in killing microorganisms (Guide to Steam Sterilization Cycles - Steam Flush Pressure Pulse, 2018). Removal of steam from the chamber and drying of wastes are required after the exposure process so that the “clean” wastes will not contaminate again by the microorganisms on the wet wrap.

Based on the Association for the Advancement of Medical Instrumentation (AAMI), steam sterilizers are categorized as three different group (Guide to Steam Sterilization Cycles - Steam Flush Pressure Pulse, 2018). These include gravity displacement autoclave, high speed pre-vacuum sterilization and steam flush pressure pulse (SFPP). All these group have different steam sterilization cycles and operating approach. Normally, it is differed by the way of expelling the air from the loads and duration of exposure time based on the type of loads. High speed pre-vacuum sterilization and steam flush pressure pulse (SFPP) also considered as Dynamic Air Removal cycles (Ames, 2019).

3.1.1.1. Gravity displacement autoclave

Steam is added from the top of the chamber, in order to force out the colder air which has higher density, via the drain vent located at the bottom. It usually requires longer exposure time as it is a more passive method of removing air in nature as compare with other methods applied in high speed pre-vacuum and steam flush pressure pulse (SFPP). Gravity displacement autoclaves normally used in the laboratory, pharmaceutical products and regulated medical waste. The penetration time into porous items will be longer because the air is not completely removed. Minimum 45 min at 112 °C is required decontaminating 4.54 kg of microbiological waste as the air trapped block the steam permeation and heating efficiency (What is Bowie Dick Test?, 2017, Ames, 2019).

3.1.1.2. High speed pre-vacuum

For high speed pre-vacuum sterilizers, the loads undergo series of pressurization along with the steam. The entrapped air is removed out of the chamber via a vacuum pump fitted in the sterilizing chamber. This is known as mechanical vacuum systems. Steam is then added to the chamber to increase the penetration percentage of steam into porous loads. Mechanical vacuum system is effective to remove steam especially lumened loads. The pressure in the chamber will drop to a level that lower than atmospheric pressure which is 101,325 Pa. However, there is a possibility that the air will re-enter the chamber again if leakage is found in the piping or sterilizer steal. To prevent the leakage and make sure the mechanical vacuum system is functioning under a good condition, Bowie Dick Test will be performed every week.

3.1.1.3. Steam Flush Pressure Pulse (SFPP)

In 1998, SFPP cycle was discovered and has been used for terminal steam sterilisation since 1990 in healthcare sector (Medical Waste Incineration, 1993). This process uses steam flush-pressure pulsing, which eliminates air promptly by repeatedly changing a steam flush and a pressure pulse higher than atmospheric pressure. Air is expeditiously eliminated from the waste along with the pre-vacuum sterilizer. However, the process would not be affected by the leakage of air due to the steam in the sterilizing chamber is always higher than atmospheric pressure. Most common range of sterilization temperatures are 132–135 °C within 3–4 min of exposure time for porous wastes and items. Hence, the air will not enter back to the chamber and reducing the possibility of recontamination. Some advantage of utilising SFPP is shorter operating period and low cost. In SFPP cycle, no vacuum drawn is needed in conditioning phase. Hence, Bowie-Dick Test is not required. Condition to run SFPP cycle is the pressure of the loads must be higher than atmospheric pressure. This means the removed air cannot enter back to the chamber through leakage of the sterilizer piping. Sterilizer downtime related to the leaks can be wiped out. Hence, cost of Bowie-Dick Test can be saved.

As like the common sterilisation systems, the steam cycle is guided by biological, chemical, and mechanical monitors. Steam sterilisers are guided using a printout by calibrating the temperature and time taken to reach certain temperature and pressure. Generally, chemical indicators are glued to the outside and incorporated into the pack to monitor the time and temperature. The effectiveness of steam sterilization is monitored with a biological indicator containing spores of GeoBacillus stearothermophilus (formerly Bacillus stearothermophilus). Positive spore test results seldom occur and can be associate to operator error, lack of steam delivery or malfunction of the equipment.

For the usage of rural clinics, outpatient, and dental clinics, they usually use portable type of steam sterilizers. This kind of sterilisers are mainly designed for small instruments, such as dental instruments, hypodermic syringes and needles. The capability of the steriliser to reach physical specification is crucial and should be monitored by mechanical, chemical, and biological indexes. There are some disadvantages of steam sterilisation. As the medical wastes must put in manually and set up the sterilisation racks manually, it needs quite a long time. Hence, it is very time consuming and labour intensive. Not only that, the surface of the medical products may cover with germ as they are handled manually and exposed to the surrounding before packaging (Medical Waste Incineration, 1993).

3.1.2. Chemical disinfection

Chemical disinfection is commonly used in health care sector. It usually combines with mechanical crushing treatment. Chemicals such as chlorine dioxide, ethylene oxide, sodium hypochlorite and formaldehyde are charged and leave for a while during chemical disinfection process. The purpose of disinfection is to kill virus, microorganisms or inactive the pathogens available in the waste, sanitise the facilities in the hospital and treat the medical waste such as surgical mask to a satisfactory level. Chemical disinfection treatment is the highly recommended in treating waste in liquid form such as urine, blood, saliva and hospital sewage.

3.1.2.1. Chlorine dioxide

Chlorine dioxide is a strong oxidising agent with high oxidation capability under most of the condition as well as acidic condition (Ogata, 2007). It kills microorganisms by oxidising those dangerous chemical constituents. Chlorine dioxide is very soluble compare with chlorine. It has 2.63 times stronger oxidisation capacity than chlorine gas (Ghernaout and Elboughdiri, 2020) thus small amount is sufficient to kill microorganisms. Chlorine dioxide will trigger the active site of enzyme and protein causing denaturation. Anabolic pathways of proteins will be destroyed and thus the microorganisms are killed. Chlorine dioxide is reddish-yellow colour and gas state at ambient temperature. Hydrochloric acid is formed when in contact with water or steam which is corrosive. When chlorine dioxide is exposed to skin, it will cause irritants to skin and provoke respiratory tract. Hence, the storage of chlorine dioxide should be stored in a safe place which has a good ventilation.

3.1.2.2. Ethylene oxide

Ethylene oxide treatment is commonly used to sterilised medical equipment’s that will be reused and for the treatment of medical waste (Held and Sharp, 1992, Mendes et al., 2007). Ethylene oxide gas will infiltrate packages to inactivate pathogens left during packaging processes. Nowadays, the usage of ethylene oxide as a chemical disinfectant are reduced due to the significant hazards during handling. This is due to its physical properties such as flammable, explosive and reactive at ambient temperature, it remains at gaseous state when temperature is higher than 10 °C. Moreover, the odour threshold is around 320–700 ppm. The most suitable condition for ethylene dioxide to undergo disinfection process is approximately temperature of 37–55 °C, humidity of 60–80% along period of 4–12 h (Wang et al., 2020).

Ethylene oxide in liquid and aqueous solutions may cause irritant when in contact to skin and eyes. According to internal Agency for Research on Cancer, ethylene oxide is classified as a human carcinogen of skin. If direct skin contacts with ethylene oxide, the exposed must immediately rinsed with cold water for 15 min before medical examination. However, hospital attention must be sought immediately if accidentally inhale or ingest ethylene oxide. Therefore, precautions should be taken during handling to prevent inhalation. Proper PPE such as goggles, masks and gloves should be put on. Ethylene oxide is corrosive when in contact to plastics or rubber. It needs to be stored in a pressurized metal container. If in any case of fire accidents caused by ethylene oxide, gas flow must be stopped immediately as it is difficult to extinguish the fire.

3.1.2.3. Sodium hypochlorite (NaClO)

Sodium hypochlorite can be prepared through standard NaClO generator which can greatly reduce the costs. Sodium hypochlorite contain 5–20% of chlorine. NaClO is only effective for 6–12 months after opening. NaClO can kill most of the bacteria and virus. However, it is not practical in disinfecting liquids containing high organic. To treat the waste, the parameters must be modified based on bacteriological tests. NaClO always in aqueous state. It will slowly turn into sodium chlorate at room temperature. When NaClO direct exposed to light, it will decompose very fast. It produces chlorine gas when reacts with any acid. When sodium hypochlorite is exposed to skin, it will cause irritants to skin and provoke respiratory tract. Proper PPE such as goggles, masks and gloves must be worn when handling it. NaClO must be stored in a plastic container that are well ventilated as aqueous sodium hypochlorite solutions will cause corrosion to metal material. Usage of sodium hypochlorite only left mild impact on human health and is considered safe level. Hence, it can be widely used during treatment of waste.

3.1.2.4. Formaldehyde

Formaldehyde is a colourless gas with a pungent, suffocating odour. It remains as gas state at ambient temperature, the odour threshold for formaldehyde is between 0.06 and 0.5 ppm. If formaldehyde is mixed with air, it will ignite fire and explode easily. In addition, irritant effect towards skin, eyes or respiratory tract will be triggered if the concentration of formaldehyde is more than 1 ppm (Gerberich and Seaman, 2013). Goggles and gloves must be worn when handling it to provide protection on skin and eyes. Formaldehyde is effective when treating dry and solid waste under condition of 80 °C steam for a period of 45 min. Solution containing 37% of formaldehyde is called formalin. It is corrosive to metals excluding stainless steel and aluminium. Hence, formaldehyde only encouraged to be used under a safe situation.

Limitations of chemical disinfection: -

-

(i)

The waste cannot be large. Shred the waste into smaller pieces before undergoing disinfection process. The weak point of the treatment chain is the shredder part, causing the machine to breakdown frequently. Frequent mechanical failure or breakdown.

-

(ii)

Strong chemicals are required to act as powerful disinfectants such as chlorine. Strong chemicals are very dangerous and toxic. Hence, it needs to be handled in care. Person in charge must be well trained and make sure the rules and regulations are followed. Adequate protected personnel equipment (PPE) must be worn throughout the process.

-

(iii)

Disinfection efficiency of the machine depends on the operating conditions of the machine.

-

(iv)

Can only disinfect the surface of intact solid waste. Human body parts and animal should not disinfect using chemicals.

According to the identification of United States Environmental Protection Agency (EPA), the most useful method to handle liquid medical wastes is chemical disinfection. Liquid wastes that had been handled can be discharged to the sewer system. Part of the liquid waste will go to a holding tank for examination before discharge to the sewer system to make sure it does not bring harm to the environment. It should be considered to use of chemical disinfection for the final disposal of the residues. The leakage of chemical disinfectants from the residues may cause environmental pollution if it is not handled properly. However, chemical disinfection may not be a long-term solution because it has been reviewed that microorganisms or viruses may grow resistant towards chemical disinfectants. The groups of microorganisms which is most resistant to least resistant are listed as follows: bacterial spores, mycobacteria, hydrophilic viruses, lipophilic viruses, vegetative fungi, fungal spores and vegetative bacteria (Ascenzi, 1995). For disinfectants which are effective against a particular group of microorganisms will also be effective towards groups of microorganisms which are less powerful or resistant. The rates of survival of the indicator organisms in the standard microbiological tests measure the effectiveness of chemical disinfectants. Chemical disinfection is a good option especially for handling hazardous physiological fluids, for example patients’ stools in case of cholera outbreaks or blood of HIV patients. It is more common for chemical disinfection to be used in hospitals. It is because chemical disinfection required for hospital sewage involves less vigorous and less risky chemicals.

Effectiveness of chemical disinfection depends on the operational conditions such as the type of chemical used, the volume of chemical used, the time and exposure contact between chemical disinfectants and wastes, temperature, humidity and pH system. The reasons of shredding solid healthcare waste before disinfection were to increase the total exposed surface area between chemical disinfectants and wastes, to prevent adverse visual effects caused by unrecognisable parts during disposal and to minimise the amount of waste disposed to the landfills.

Usually, it is compulsory to add water during shredding process to avoid increase in temperature and eases consecutive contact with the chemical disinfectant. Rotating-blade shredders are frequently use, and it is made up of blades adhered to two wheels rotating in opposite order. Excessive volume of sharps objects in waste causes the shredders to deteriorate. If the wastes undergo shredding process and consecutively compacting before disinfection, the volume of the wastes can be reduced by 60 – 90% compared to its initial volume. It is essential to identify the target microorganisms to be destroyed because some microorganisms can only be killed by using specific disinfectants.

3.1.3. Microwave or radio-wave treatment

Microwave are a form of electromagnetic wave. It has a wavelength of 1–1000 mm and a frequency of 3000 MHz. Microwave treatment is a sterilisation technology that came up recently to treat biohazardous waste, including healthcare and medical wastes. Microwave frequencies used for disinfection are generally (2450 ± 50) MHz and (915 ± 25) MHz (Wang et al., 2020). The molecules in the substance vibrate and collided for billions of times in one second to generate heat to a high temperature. Normally, microwave treatment is mainly for the inactivation of pathogen, which only effective for certain applications but for use not applicable to inactive the “dry” solid waste. Conventional microwave has no means to restrain the inactivation process specifically water content. The sophisticating technologies of the microwave treatment with pertinent measurements grant a legalized inactivation of biohazardous items. These advanced technologies are very useful and effective to inactivate the pathogens, and some can be found easily in the market. To inactivate the pathogens available on the waste, the waste must meet the conditions required. The waste is preferred to inactivate directly on the spot where it is generated. For biohazardous wastes, they should transport in closed systems. Not only that, autoclaves which are more common are high energy consumption while microwave technology can cut down quite an amount of energy costs. To heat up the wastes, microwave energy is charged directly to microwave-absorbing materials. Various problems such as long heating time, decrease of temperature, heat loss to the surrounding and loss of energy to the environment can be avoided. These characteristics fulfil the industrial sector requirement and is suitable to be another choice to conventional processing mechanism. Microwave processing of waste is a new technique that bring new ways to boost the sterilization process compared with classical technique.

3.1.4. High temperature heat disinfection

High temperature steam disinfection which also known as wet heat treatment process. It uses steam with high temperature to kill microorganisms available on the medium. Hospital wastes are exposed under the moist environment with certain temperature for a certain period. Protein of pathogenic microorganisms will denature and coagulate due to latent heat from the water vapour. This causes the inhibition of microorganisms. In China, the logarithmic value of the killing of thermophilic lipobacillus spores should be larger than 5 (Wang et al., 2020). There are some limiting factors cause the temperature of sterilisation room can only be set to 134 °C and with a fluctuation range lesser than 3 °C (Wang et al., 2020). At this temperature, the time needed for achieving the disinfection effect at 134 °C does not go beyond 20 min. The time needed for saturated gas to penetrate through the packaging is depending on the loading capacity and disinfection capacity of the sterilisation chamber. High temperature steam disinfection method has low volume reduction rate causing toxic volatile organic compounds to form during disinfection. Hence, not all types of hospital wastes can disinfect using high temperature heat disinfection method.

3.2. Incineration

Based on EPA research data, incineration is the best option to overcome the waste problem recently. It has the potential to carry an important role on waste disposal option in the upcoming days. This clearly acknowledge by the data showing that it can reduce 90% of the original volume and 91% of the original weights and 100% destroy the pathogens and hazardous microorganisms (Silva et al., 2005, Mohamed et al., 2006, Jiang et al., 2019). It renders the waste till unable to be identified in the form of ash. Incinerator is fired with burners and the energy of the waste material. Supplemental fuel is compulsory due to low heating value of the wastes. Usually, there is delay in ramming up process in primary chamber which has results more auxiliary fuel from design value is being used up before the chamber reach the minimum required temperature. The presence of high moisture level was found to be a reason of this phenomenon. Therefore, Mohamed et al. (2006) developed a High Temperature Recirculating Pump (HTRP) to solve this issue; some energy saving could be realized through flue gas recirculation method in an incinerator. The experimental results of HTRP from cold fluid and hot fluid tests have confirmed the potential of application of HTRP as a recirculation engine to overcome the current situation. Consolidating of the results into starved air incinerator model has result in lower amount of auxiliary fuel consumption in primary chamber up to 25.91%.

The technique applied in incinerator is called mass burn. It followed by five general steps. Waste preparation is the first step. The oversized wastes and metal made wastes are filtered out. The other waste will undergo shredding process until it cannot be identified in the form of ash before the ashes goes into the incinerator. In the incinerator, all the ashes are burned in the single combustion chamber with the supply of oxygen. The unwanted items are burned at a relatively high temperature in a range of 1800–2000 Fahrenheit (Medical Waste Incineration, 1993). The waste will burn out completely turning into ashes and releasing heat and gases. Through heat recovery, part of the gases is then cooled with water to generate steam. The steam can be used to supply electric to the electrical generators. The other leftover gases are filtered through scrubbers to eliminate pollutants before releasing to the environment. The residuals formed will be disposed to the landfills. There are a few major types of incinerator which are starved air incinerators, excess air incinerators and rotary kilns (Lee and Huffman, 1996).

3.2.1. Starved air incinerators

Starved air incinerator also known as controlled air incinerator applies starved air combustion process. The waste becomes smoulder, generating off-gas rich in organics when inadequate amount of oxygen is provided for combustion. If air is injected into hot, combustible gas stream, the stream will self-combust, and the entrained organic components will burn. Starved air incinerator includes two furnace chambers. Each furnace chamber undergoes one combustion stage. The wastes require lesser amount of oxygen (less than stoichiometric amount) in the primary combustion chamber. The required air, known as underfired air, will enter from the bottom part of the incinerator. The drying and volatilisation of the wastes are facilitated by the low air to fuel ratio, resulting in higher content of residual carbon in the ash. The combustion gas temperatures are relatively low, approximately 760–980 °C (Medical Waste Incineration, 1993). The off gas from the primary chamber is then passed and burned out in the secondary combustion chamber with excess air. Secondary combustion chamber has a temperature of 980–1095 °C (Wang et al., 2020). Extra amount of heat supplied by the auxiliary burners which are installed at the entrance of the secondary chamber may be needed depending on the moisture content and heating value of the wastes. At least one burner is needed in the primary chamber to bring the temperature of the chamber to the required operating temperature. Adequate amount of air is injected into the chamber to make sure combustion can occur and heat required is generated by the process. In primary chamber, combustion air fan is installed to supply air flow. In secondary chamber, air supply fan provides air while the burner ensures continuous burning in the secondary combustion chamber. The burner is always ignited, to make sure the maintenance of a flame in the chamber under all conditions of feed and operation. The injection into the primary combustion chamber of only a fraction of the air required for full burnout produces relatively little carry-over of particulate from the primary chamber. Starved air system has a chamber temperature control feature. The temperature will reach to the maximum level when enough amount of oxygen is available in the chamber when burning the waste. The excess oxygen that is pumped into the chamber will cool the gas stream to a lower temperature. Heat will be released when air is injected to the primary chamber. Hence, the more the amount of air in the primary unit, the higher the temperature. Starved air furnaces operate as batch units, semi-automated or continuously operating systems. For batch unit system, the waste is added after complete burn out followed by one another. In semi-continuous process, the addition of waste will undergo several rounds in one-day operation. However, the trash will not remove itself and daily cleaning is a necessary. In continuous mode of operation, waste is burn out before loading into the charging hopper frequently for at least two to six times per hour. Charging ram hauls the waste into the furnace and as the waste enters the furnace chamber, the previous waste will be bumped towards the chamber exit. In this operation, the ash will remove by its own nature.

In these days, the most common type of incinerators used for medical waste among starved air incinerators are semi-continuous type. Starved air incinerators come in all sizes, shapes and design capacities ranging from 23 to 1800 kg/h (Wang et al., 2020). Some are either controlled by hand operation or operated at its nature for loading of and ash removal. The amount of air required in the primary chamber is low resulting in low flue gas velocities and lesser number of solids entrained in the off gas from primary chamber. Hence, it is not necessary to install gas cleaning devices.

3.2.2. Excess air incinerators

Excess air incinerators can also be termed as ‘retort, batch or multiple chamber incinerator’. It is a typically small modular unit. Wastes are added to the combustion chamber manually. The entrance will close, and the secondary chamber is heated to a temperature around 900 °C. When the temperature reaches 900 °C, the primary chamber starts to burn. Wastes are burnt in primary chamber. Heat is gained from the burner and radiant heat from the chamber walls. Volatile components and moisture are then removed out from primary chamber to secondary chamber. Secondary combustion chamber provides the settlement time and fuel for combustion of the organic which is not completely burnt taken up from the primary chamber. Gases coming out from secondary chamber will be directed to an air pollution device. The primary burner will automatically shut off when the wastes are completely consumed. The incinerator is enclosed with multiple internal baffles and cube shape from external view. The baffles are positioned so the combustion gases can flow through 90″ turns in both horizontal and vertical ways. The waste is added continuously to allow burn out over a period. The daily operation includes charging of the waste, waste firing, and burnout in the morning. The residue from the wastes are removed out from the incinerator first before daily charging. In the both chamber of excess air incinerator, it required excess air levels above stoichiometric (typically 60–200% excess air) to operate. Excess air incinerator has a capacity to hold the waste feed lesser than 3.8 kg/min (Wang et al., 2020). Through the supplementary fuel burners, air is charged into the primary and secondary combustion chambers. Each chamber normally has more than one burner to supply the heat needed to heat up and maintain the standard operating temperatures. To undergo continuous or automatic operation, it is not encouraged to use excess air incinerator.

3.2.3. Rotary kilns

Rotary kiln incinerators are larger in size compare to starved air incinerators and excess air incinerators. It has a long service life, simple and easy to operate continuous system, no professional is needed. Moreover, it can adapt to the complex condition of the industrial wastes and medical wastes. Rotary kiln incinerators are the main incineration equipment used, accounting about 85% of the market share in the field of industrial solid waste treatment (Liu et al., 2020). Rotary kiln incinerators are designed in different sizes ranging from 100 to 8000 lb/h. Kiln undergo counter flow process, waste is charged from the higher end of the kiln while hot air enters from the lower end of the kiln. Excess amount of hot air from the external furnace is provided to the kiln to help burn the waste. This make sure that the temperature of the waste constantly increases from the moment it enters until it exits the kiln. When the kiln is full of waste, it will be burned out, becoming ash with low in water content and discharged out into the water quench. The by-products ash generated during the burning process are collected to avoid air from outside enters the process. Air at room temperature may decrease the efficiency of the incinerator and causes the process to be unstable.

Rotary kiln incinerator consists of two chamber which are primary chamber and secondary chamber. Wastes are heated and volatile in the primary chamber while secondary chamber is a place to complete volatile fraction. In primary chamber, there is a cylinder bounded with horizontal refractory rotating at horizontal axis, one of the ends of the axis is slightly inclined (~3%) higher than another end (Weinberg et al., 2018). Waste enters directly from the higher side of the kiln and slides down while rotation mixing and stirring occurs in the primary chamber. As the waste flowrate increase, the speed of rotation in the range of 1–3 rpm of the kiln will increase. The wastes are affected by turbulence, where higher speed of rotation will cause a more uniform mixture of waste and air, leading to better incineration and more particulates added into the flue off-gases (Jiang et al., 2019). Off-gas released from the kiln consists of volatiles from the unburned waste, and complete burnout occur in the secondary chamber. The temperature of secondary chamber is controlled at about 1100 °C and the residence time is more than 3 s, allowing it to destroy all kinds of organic matters in waste (Liu et al., 2020). Usually, the kiln system needs more extensive air emission control compare to the modular units.

4. Alternative technologies converting plastic waste to value added products

Although incineration is a common practice for handling plastic waste, but it has many negative impacts on the environment. According to Alfarisi and Sutopo (2019) studies, waste incineration has about 50 impacts on the environment. The four highest environmental impact are marine aquatic ecotoxicity, marine sediment ecotoxicity, acidification and ionizing radiation (Alfarisi and Sutopo, 2019). Therefore, alternative technologies with less negative impacts on the environment and human health requires more research and development. Further to that, with the impact of medical waste on plastic waste due to the current COVID-19 pandemic. This may serve an opportunity for investor to invest in technologies for converting plastic waste into value added products. The increasing generation of plastic wastes and the increasing demand of plastic markets serve as a good economic indicator. Besides, the setup of new company may even generate more job opportunities. Due to the COVID-19 pandemic, as of 6th April 2020, 20 million jobs had been lost in the United States with an increase in the unemployment rate of 12.2% (Coibion et al., 2020). Therefore, the currently available alternative technologies for converting plastic waste into value added product might help the current COVID-19 pandemic crisis turning it into opportunities and reduce the negative impact of plastic waste on the environment and human health.

The conversion of plastic waste to fuel has been research and studied for many years and it’s not a new approach. Due to the increasing of plastic waste globally, there has been a shift in research focus where there has been many studies and research on improving the technologies involved in converting plastic waste to fuel. There are many types of technologies such as chemo-lysis, pyrolysis, fluid catalytic cracking, hydrogen technologies, KDV process and gasification shown in Table 3 (Ragaert et al., 2017).

Table 3.

Comprehensive evaluation of the various technologies in converting plastic waste to fuels.

| Technologies | Function | Conditions |

|---|---|---|

| Chemo-lysis | Depolymerise plastic into its monomer through various | Methanolysis: |

| depolymerisation routes: methanolysis, glycolysis, hydrolysis, ammonolysis and hydrogenation | Temperature: 180–280 °C | |

| Pressure: 20–40 atm | ||

| Hydrolysis: the reaction of plastic with water under neutral, acidic or basic conditions at high temperature and pressure | ||

| Glycolysis: | ||

| Temperature: 180–250 °C | ||

| With excess of glycol | ||

| Pyrolysis | Break down macrostructure of the polymer to form smaller molecules by depolymerisation or random fragmentation. The pyrolysis products of plastic waste can be in the forms of gas, liquid and solid residue. | Temperature: 500 °C |

| Pressure: 1–2 atm | ||

| Fluid catalytic cracking | Convert plastic waste into fuel, commodity chemicals and fine chemicals through thermal and catalytic decomposition process. | Temperature: 300–350 °C |

| Hydrogen technologies | Convert plastic waste into liquid fuel through hydrocracking reactions. | Temperature: 375–400 °C |

| Pressure: 70 atm | ||

| With the addition of hydrogen gas | ||

| KDV process | Catalytic depolymerisation conversion of biomass and plastic waste into liquid fuels such as diesel oil. | Temperature: 250–320 °C |

| Pressure: Atmospheric pressure | ||

| Gasification | Converts plastic waste to a gaseous mixture containing CO2, CO, H2, CH4 and other light hydrocarbons via partial oxidation. The gaseous mixture is known as syngas. | Temperature: 1200–1500 °C |

| Pressure: 50–100 atm | ||

| With oxygen and steam |