Abstract

Recent events such as Covid-19 vaccine distribution issues and the blockage of the Ever Given ship in the Suez Canal raised concerns about how fragile the traditional supply chain is. Last-mile personalized fulfillment can have a catalyst role in the proliferation of the Industry 4.0. This growing trend will reduce standard production, bringing manufacturing closer to the client and, ultimately, boiling down the supply chain to the last mile. However, the literature is not clear about the breakdown of the supply chain to enhance cities’ sustainability and reducing the number of transports and circulating vehicles.

Stemming from an empirical study to simulate the existing gap in the market and the development of a case study through structured interviews with privileged interlocutors complemented by the document analysis, this paper highlights how the integration of local stakeholders can efficiently enhance a personalized service based on dynamic collaborations to set up the supply chain, by introducing the Last-Mile-as-a-Service (LMaaS) concept. This concept relies on a revenue-sharing framework based on an open marketplace composed by last-mile manufacturing, transport, and storage assets and stakeholders to disrupt the supply chain, enabling any company to provide personalized products in almost real-time to any location.

Keywords: Last-mile-as-a-service, Industry 4.0, Smart cities, Smart logistics, Smart manufacturing, Smart supply chain

1. Introduction

How many times did a client purchase a standard product because it was not possible to personalize it? How many times did a client order a product from the other side of the world based on price and it took months to be delivered? In the current technological context and in an era characterized by digitalization, these questions highlight an inefficiency on the supply chain performance where both companies and consumers are jeopardized. Over and above that, the environment is negatively impacted. Moreover, the collaboration and sharing of resources between agents is essential to provide a personalized service to consumers and combat climate change.

Nevertheless, if a client wants to purchase a product from a distant market, this action still represents a significant logistics effort, with the need to combine multiple urban and transcontinental modes of transportation to deliver the product to its final destination. Mass production has so far justified resorting to manufacturing in third-world countries, often extremely far away, derived from the cheap cost of production and labor. However, personalization and small-scale production are increasingly disabling the rationale for mass production and standard supply chains.

In 2050, around 70% of population will live in cities and neighboring regions United Nations (2015). Urban and freight logistics are some of the most heavy-duty activities in terms of consumer resources and greenhouse gas emissions, challenging cities’ sustainability (Bibri & Krogstie, 2017). With Green Deal, the European Commission has the ambition of achieving carbon neutrality in the European Union by 2050. Sustainable Industry and Sustainable Mobility are within the Green Deal's scope. Moreover, two of the Green Deal goals strive towards sustainable and smart mobility, thus pushing the industry to a clean and circular economy European Commission (2019).

Recent events such as the Covid-191 vaccine distribution issues and the blockage of the Ever Given ship in the Suez Canal2 raised concerns about the need for a global collaboration and knowledge sharing for local fulfillment. The Covid-19 pandemic also accelerated the necessity to re-think cities. The need to assist citizens with closer public services was noted by Moreno et. al (2021), who proposed a “15-minute city” conceptual approach to help policymakers plan cities towards the availability of essentials and basic needs, by foot or bicycle, promoting citizens' quality of life and avoiding the need to use the car. Furthermore, this concept may also be applied to the delivery of goods to citizens, breaking down the supply chain, reducing the circulating vehicles and their travelled distances, boiling down manufacturing and logistics activities to the last-mile.

Industry 4.0 is striving to base manufacturing on predictive analytics and the integration of the entire service from ideation and design to the delivery (Laplume, Petersen, & Pearce, 2016). 3D printing will allow companies to become more responsive to personalized requirements and enable production to be performed elsewhere (Kang et al., 2016).

Digital transformation in the supply chain enables sharing data between actors and real-time data analysis, breaking away from organizational silos, creating common goals, and increasing collaboration and communication. The path to a more sustainable supply chain involves transitioning to a circular model where additive manufacturing plays an important role, and all agents and individuals in the chain are integrated and can collaborate with each other.

Korczak & Kijewska (2019) noticed that the term “Smart Logistics” emerged at the beginning of the 21st century and was known as decentralizing decision-making to local systems. Furthermore, it was also associated to the capacity of planning and control logistics processes from the data gathered with the tracking and identification of elements until the detection of the problem, choice, and automatic execution of the solution (McFarlane, Giannikas, & Lu, 2016). Moreover, logistics platforms help in a cost-effective way to design, plan, implement and control the forward and reverse flow of goods from the origin point to the destination, guaranteeing resource efficiency, security of goods, sustainability and on-time distribution (Jabeur, Al-Belushi, Mbarki, & Gharrad, 2017). Barenji, Wang, Li and Guerra-Zubiaga (2019) proposed a multi agent-based platform to control and facilitate decision-making and the information exchange between end users, suppliers and the distribution center. Several authors conceptualized multiple collaborative frameworks to enable the collaboration between logistics stakeholders and individuals (Rožman, Vrabič, Corn, Požrl, & Diaci, 2019; Xu, Zheng, & Yu, 2018). However, these platforms and their related research are focused on distribution optimization and stock management, leaving aside the transfer of manufacturing and the focus on the last-mile fulfilment.

Moreover, the literature lacks a broader comprehension on the impact of local collaborations for all aspects of the supply chain rather than just the logistical optimization of freight distribution and last-mile deliveries. Furthermore, there is a gap on the provision of an end-to-end framework where manufacturing, storage and delivery are personalized, and the global supply chain is open and built upon the requirements of the client.

For this purpose, this article embraces the existing literature and enunciates an empirical case study to set the foundations and present an emergent model for last-mile optimization and fulfillment, named Last-Mile-as-a-Service (LMaaS). This innovative concept for the disruption of the supply chain relies on the collaboration and integration of assets and management capabilities of different entities to provide any company with a physical and virtual infrastructure capable of providing personalized products and delivery services to their clients at any location.

The following section performs a review of the literature about the topis of Industry 4.0 and 3D printing as well as smart supply chain and last-mile. Section 3 proposes a two-steps methodology. Moreover, it details the current challenge and proposes an example of local collaboration to provide a personalized supply chain. The findings of the methodology procedure base the innovative concept proposed in Section 4. Lastly, conclusions and avenues for future research are presented.

2. Theoretical background

This literature review chapter gives a brief explanation of the fundamentals of the Industry 4.0 concept and the current state of 3D printing, and explores the background on the supply chain management and last-mile fulfillment. Ultimately, the research findings are resumed, and the existing gap highlighted. The databases used for this research were Scopus and Web of Science. The search keywords were: Industry 4.0, 3D Printing, Last-mile, Smart Manufacturing, Smart Logistics, Smart Supply Chain, Logistics Platforms and Supply Chain Platforms.

2.1. Industry 4.0 and 3D printing

The consumers' ongoing desire to participate is pushing the mass customization of the third industrial revolution to a personalized production model (Bortolini, Ferrari, Gamberi, Pilati, & Faccio, 2017), with flexible manufacturing of small series (up to one sample) to respond to individual preferences (Hozdić, 2015; Prause, 2016).

Industry 4.0 (or Smart Manufacturing) aims to integrate and take advantage of advanced technologies and information to collect real-time data from the supply chain, thus enabling a rapid and flexible response at different levels to meet the clients’ needs in a highly dynamic and global market (Lu & Ju, 2017). Therefore, there is an increasing need for big data analytics (machine learning and predictive analytics), enabling timely and accurate insights to assist decision-making (Shin, Woo, & Rachuri, 2014).

Cyber-physical systems (CPS) and system integration (across all departments and parts of the process) are vital aspects to enable a flexible control production (and its constant changes) in real-time with the concern to the efficient usage of energy and resources, as well as the reduction of carbon emissions, maximizing sustainability, health, and safety (Kang et al., 2016). The decentralization of operations will permit facing unforeseen changing conditions. The integration of the horizontal (across stakeholders) and vertical (across organizational levels) axes will improve the efficiency of the supply chain (Erol, Jäger, Hold, Ott, & Sihn, 2016). Planning and scheduling can be fully integrated with operations featuring coordination and optimization models across the supply chain (Kang et al. 2016).

Industry 4.0 is characterized by the fusion of the physical and virtual worlds (Kagermann, Wahlster, & Helbig, 2013), where the product will control production (Nick, Pongrácz, & Radács, 2018). Smart manufacturing revolves around a demand-driven, client-focused, and highly-optimized supply chain (O'Donovan, Leahy, Bruton, & O'Sullivan, 2015).

The realization of the Industry 4.0 may also be connected to the evolution of 3D printing. Moreover, several authors argue that 3D printing will lead to a new paradigm with a promising strategy in the one-of-a-kind products possible (Lipson & Kurman, 2013; Moilanen & Vadén, 2013).

Historically known as Additive Manufacturing (AM), 3D printing emerged in the 1970s and differs from Subtractive Manufacturing (SM) in the ability of building a product layer-to-layer instead of starting with a block material and removing the unnecessary material to build the final piece (Laplume et al., 2016). Thus, this technological driver of Industry 4.0 is seen as a way to achieve sustainable production — by improving resource efficiency, extending and reconfiguring value chains Ford & Despeisse (2016) — enabling personalization with shorter cycle-times and lower costs (Wang, Ma, Yang, & Wang, 2017). This can potentially have a great impact on the supply chain and society (Chen, Pan, & Ouyang, 2014; Taniguchi, Thompson, & Yamada, 2016). The large dimension printers, which could cost up to 300,000 USD, have evolved to affordable open-source home printers in the early years of the 21st century (Bradshaw, Bowyer, & Haufe, 2010).

From rapid prototyping and tooling, to the medical sector, the applications of 3D printing have spread throughout multiple areas. Laplume, Petersen & Pearce (2016) present a background of 3D printing where the evolution of the printer and their methods are studied, and a reflection on the impact of this technology may have on the supply chain and society is put forward. Moreover, 3D printing brings companies’ the ability to become more responsive, as production is brought closer to the client, reducing the lead time, ensuring the client's fundamental wishes and the planet's sustainability (Paritala, Manchikatla, & Yarlagadda, 2017).

2.2. Supply chain and the last-mile

The supply chain is becoming vertically connected. Thus, it is striving to the point of managing and delivering orders in real-time (Oztemel & Gursev, 2020).

New business models are emerging due to the infinite opportunities presented by emergent technologies and the interoperability between systems Prause (2016). Win-win business collaboration schemes are being increasingly considered to optimize urban transport (Nathanail, Gogas, & Adamos, 2016). Moreover, the supply chain is evolving into a shared-economy open cross-company network (Kirch, Poenicke, & Richter, 2017).

Based on the interconnection of systems, there is a possibility of creating an effective demand-oriented manufacturing process (Lom, Pribyl, & Miroslav Svitek, 2016). Thus, the embracement of networked manufacturing, adaptive logistics, and client co-design will render the value chain more complex, open, collective, and evolutionary Prause (2016). Therefore, last-minute and individual demand emerge the importance of defining new dynamic business models (Kagermann et al., 2013), embracing cooperation and integration among all stakeholders. There will be a promotion of global connection and understanding between individuals and agents of different locations and sectors through the supply chain (Oztemel & Gursev, 2020).

On the other hand, co-modality (or crowd shipping) can offer limitless combinations of transport modes (Gatta, Marcucci, Nigro, Patella, & Serafini, 2018) that can be fully dedicated to goods transportation or allocated simultaneously to other tasks, mostly passenger transportation, due to their underutilized capacity space (E Taniguchi & Thompson, 2014). Co-modality also presents the opportunity of replacing intermediaries warehouses with virtual exchanging points Ducret (2014). Lost packages, failure to deliver on time, sorting out parcels, misalignment of drivers and deliveries, and lack of interaction due to the inability to link and connect the different stakeholders compromise efficiency and flexibility of deliveries (Perboli, Rosano, Saint-Guillain, & Rizzo, 2018).

E-commerce, especially in the case of business-to-consumer (B2C) increases the difficulty of product distribution with direct impact on traffic congestion and accessibility as well as environmental pollution and climate change (Ducret, 2014; Morganti, Dablanc, & Fortin, 2014).

Nevertheless, it lacks a holistic perspective regarding the product journey since clients perceive the experience and the actors involved as one (Vakulenko, Shams, Hellström, & Hjort, 2019). The tracking is still not performed in real-time, neither there is information about the exact lead-time. The empirical study performed by Cao, Ajjan & Hong (2018) of online shoppers in China and Taiwan concludes that shipment and order tracking play a relevant role in online shopping.

Moreover, the rise of e-commerce over the past 20 years has created an increased need for a responsive omnichannel distribution to meet the last-mile challenge (Melacini, Perotti, Rasini, & Tappia, 2018).

The “last-mile” term emerged from the telecommunications industry to name the final leg of a network. Applied to the supply chain, it refers to the last segment of the delivery process from the last distribution center, consolidation point, or local warehouse (Xiao, Wang, Lenzer, & Sun, 2017). Synonyms such as final-mile, home-delivery, B2C distribution, and grocery delivery have also been found in the literature (Lim, Jin, & Srai, 2018).

Last-mile is considered in academia as the least efficient supply chain stage, comprising 28% of the total delivery cost ( Wang, Zhang, Liu, Shen, & Lee, 2016), and the least environmentally-friendly (Gevaers, Voorde, & Vanelslander, 2011). A literature review carried out about last-mile logistics in smart cities and urban areas considered collaborative urban logistics and optimization of transport management and routing as the main innovations to reduce transport costs and inefficiency (Ranieri, Digiesi, Silvestri, & Roccotelli, 2018).

Transport systems will increasingly be flexible and multi-modal (Prause & Atari, 2017). Several authors refer to the advantages of having a simultaneous and integrated approach between home delivery and client's pick-up (Zhou, Baldacci, Vigo, & Wang, 2018; Zhou, Wang, Ni, & Lin, 2016). Furthermore, large firms, including Amazon and UPS, are increasingly investing in the ridesharing service model's adaptation, where an entity procures transportation services via a mobile or computer application. The services are performed by independent contractors using a personally owned vehicle (Boysen, Fedtke, & Schwerdfeger, 2020; Castillo, 2018; Savelsbergh & Van Woensel, 2016).

2.3. Research findings

From the literature review, it is possible to conclude that although deliveries are striving for the real-time model, promoting the collaboration of different stakeholders and transportation means, at the same time that 3D printers are becoming available for households, there is not yet a concept nor a framework capable of bridging them and providing an open and harmonized solution to breakdown the standard supply chain, thus allowing the open collaboration between stakeholders and effectively bringing the manufacturing process closer to the client.

Therefore, in line with the above-mentioned gap, this article aims to conceptualize a supply chain service model based on the personalized fulfilment of the last-mile considering local and dynamic collaborations. Thus, the research challenge underlying this study seeks to answer the question “How can a consumer purchase a personalized product at any part of the globe and have it in (almost) real-time?”.

3. Empirical research

The solution to answer the previous mentioned research question will need to be based on an end-to-end real-time revenue-sharing service, at the disposal of consumers and enterprises, that integrates different modes of transportation, storage warehouses and manufacturing assets.

There are already entities that carry out steps of the process. However, they act in isolation and without coordination. The methodology chosen to carry out this study aims to simulate the existing problem and perform empirical research to identify local organizations that could support the theory that the combination of these type of entities would enable local manufacturing and delivery in real time with minimal environmental impact. The goal was not to base this research in a large-sized city location but to test the possibility of proposing a collaboration between already established companies from a small random city to provide a personalized service than it would likely be possible to extend it globally. Therefore, the corroboration of this theory for a small-sized city allows for the last step of the methodology to define a disruptive global concept.

3.1. Method design

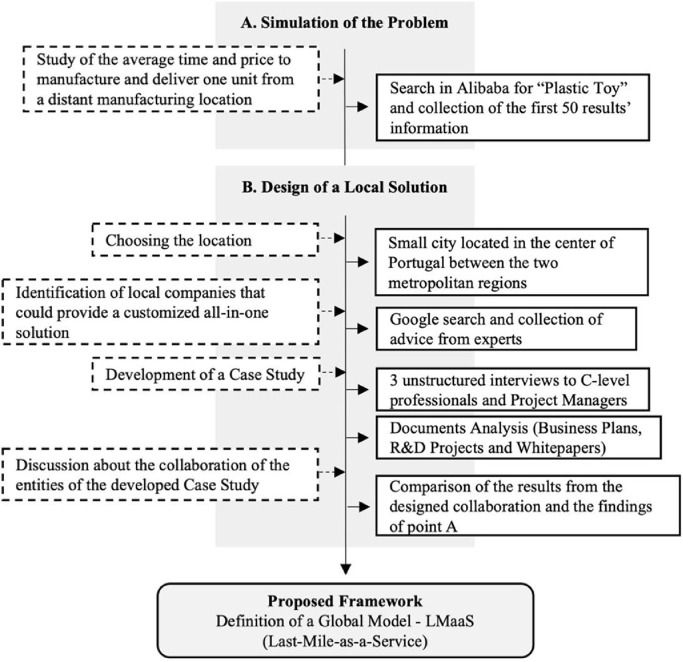

The methodology followed in this research, sketched in Fig. 1 , was divided in two steps: A) Simulation of the problem and B) Design of a local solution, combining quantitative and qualitative methods.

-

A)

Simulation of the problem - To highlight the existing problem in a real context, an empirical study was conducted; its purpose was to simulate a purchase of a product from a distant location from Portugal (in this case, China). Alibaba was used for the search because it is a platform that directly links (mostly) Chinese manufacturers to consumers, allowing them to give a production order when purchasing, according to the desired quantity. To collect data for this simulation, the product sought was “Plastic Toy”. The data about the costs and time of execution and delivery of the first 50 results were collected. The goal of this sub-section was to quantify the existing problem to compare it in sub-section B with the local collaboration proposed.

-

B)

Design of a local solution - To demonstrate the possibility to locally achieve a personalized and real-time response to any purchase, an empirical search in a city of Portugal (9,000 kilometers away from China) was carried out, looking for local stakeholders whose characteristics could provide the production of any personalized item as well as its delivery. Moreover, the city of Aveiro was chosen since it is a small city located in the center of Portugal, between the two metropolitan regions (Lisbon and Porto). A case study was performed to get a more in-depth insight about the local chosen entities. This research method examines complex phenomenon and intensively studies a subject with the goal of generalizing it to a broader perspective Gustafsson (2017). Moreover, the case study was based on structured interviews with privileged interlocutors of each organization where the topics explored went through the content of the organization's activity, their vision about their company and the collaboration with other companies to provide an integrated and personalized service, complemented by the analysis of documents (such as business plans, R&D proposals, and whitepapers) gently provided by the organizations. In summary, three structured interviews (adapted to each interviewee's activity) with C-level professionals and project managers were carried out. In general terms, the questions which based the interviews were: “What is the history of the company, its purpose and vision?”; “Is it (and how is it) possible to leverage your expertise to any part of the globe?”; “What are the requirements and limitations of your product/service?”; “What are the estimated costs and time?”; “What is your openness to integrate with other solutions and provide an end-to-end service?”. The overall goal was to understand the cost and time to manufacture and deliver a product in real-time within the last-mile, considering the collaboration of these entities. The results of the comparison between standard and personalized supply chains feed the discussion and ground the rationale for the model proposed in Section 4.

Fig. 1.

The framework of the research method.

3.2. Procedure and results

This sub-section details the undertaken procedure of the method design mentioned above. Moreover, on one side, Step A simulates the existing problem of traditional supply chains to perform real-time personalized requests. On the other side, Step B set up a solution that combines different local entities and compares it with Step A's results.

3.2.1. Step A: Simulation of the problem

From a sample of 50 products in Alibaba, the minimum quantity order was selected, and data were collected regarding the price of the product, its shipping cost, as well as the lead time and shipping time. From the results obtained (Annex 1) it is possible to notice that:

-

i

Only 7 products allowed for a single unit order;

-

ii

The average lead time is 11.52 days;

-

iii

The average minimum delivery time (average of the lower interval values) is 12.82 days;

-

iv

The average maximum delivery time (average of the upper interval values) is 19.94 days;

-

v

The average unit price is 5.06 USD;

-

vi

The average unit shipping price is 14.99 USD, representing a percentage of 296.4% of the product price;

Thus, for a “Plastic Toy” ordered in Alibaba, from China, it would take more than 32 days to be delivered to a client in Portugal, its cost averaging more than 20 USD. If the production would be carried out by a local 3D printer, it would use less raw material to produce the same product and the lead time would be lower. Also, it would allow the personalization of the product, unlike in the mentioned purhcase platform , given the inherent standardization focus.

In summary, it is noted that the traditional supply chain does not fit the needs of personalized requirements.

3.2.2. Step B: Design of a local solution

Based on the authors’ search, the following organizations were identified based on the problem they address, which could contribute to organize a personalized response to local consumer's requests. The openness to collaborate and promote a sustainable solution to eradicate unnecessary emissions, waste and the inefficiency throughout the supply chain was unanimous among the interviewees.

The content collected from the three structured interviews and the documents’ analysis of BeeVeryCreative (2021), LUGGit (2021) and EMBERS (2019) is detailed in Table 1 .

Table 1.

Brief characterization of the parties involved: BeeVeryCreative, LUGGit and EMBERS.

| Entity | Description |

|---|---|

| BeeVeryCreative (Personalized Manufacturing) | BeeVeryCreative was the first Portuguese company to build a 3D printer. The company sells printers and pieces to other manufacturers. The mindset has always been and continues to be the open-source and close collaboration between the various players in the market. The strategy is varied. The ability to develop new printers has been put at the service of innovation projects in which the main concern is not economic viability, but rather the disruption in a given sector with patenting and creating intellectual property. This also comes with the willingness to openly dispose of IPs at the service of the community. BeeVeryCreative started with the home-user segment, education and third-party manufacturers. In recent years, they have entered in the industry and space (with projects for the International Space Station) markets. Furthermore, the company is currently carrying out a project for skin printing (the largest and most personalized organ) with a very interesting survival rate of living cells. |

|

LUGGit (Personalized Logistics) |

LUGGit's vision is to allow everyone to travel without carrying their luggage. Moreover, LUGGit is a platform that allows anyone to request a Keeper (driver) in real-time to pick up their luggage and deliver it at the place and time they choose. Through a revenue-sharing model (the drivers act as service providers) the service can be performed in real-time or be scheduled (in advance). Unlike other carriers, LUGGit's algorithm has the premise of setting the exact time on which the client wants the delivery to happen. The optimization rule is always according to the chosen delivery time and not according to the location of the delivery. The operators at LUGGit are entities that have drivers, vehicles and storage warehouses. They can perform multiple collections, store for the desired time and deliver at the time the client wishes. |

|

EMBERS (Aggregated Platform) |

EMBERS was an EU-funded project under the Horizon 2020 program, which developed an aggregated, harmonized, standardized open-data mobility platform where everyone could access the city's data and their mobility services from different operators. Through a Mobility-as-a-Service (MaaS) model, the information about existing mobility services was aggregated and made available to citizens. This way, users could move smoothly from point A (start) to point B (end), without the discomfort of having to buy tickets from multiple vendors, wait in queues, or visit various platforms to coordinate transportation. EMBERS goal was to help cities break existing silos (proprietary solutions). EMBERS was responsible for aggregating mobility-related data, including parks and parking spaces, maps, route generators, points of interest, traffic, which would serve as the basis for third-party applications. |

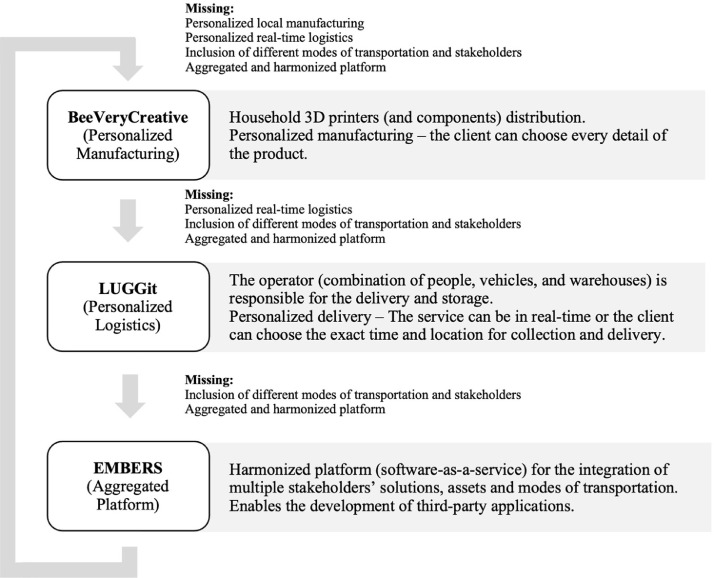

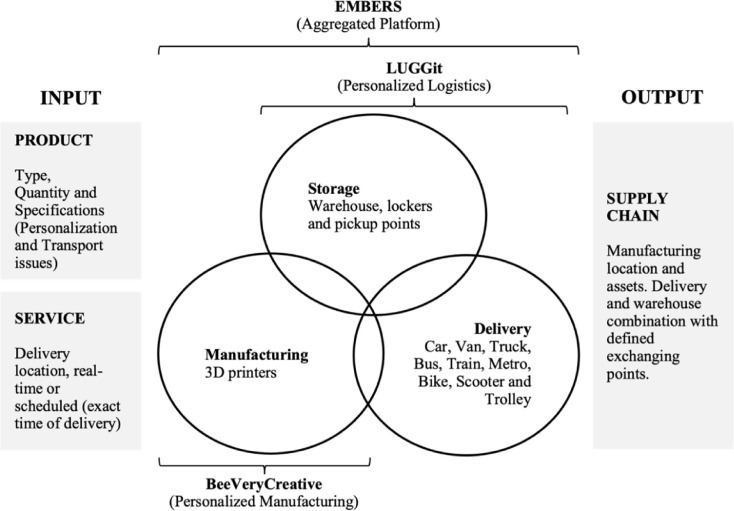

The empirical case study shows that BeeVeryCreative provides 3D printers (and components) that allow personalized manufacturing; LUGGit showcases how the service's personalization can be combined with logistics efficiency and the role of independent service providers to perform it, within the last-mile, and EMBERS provides a harmonized platform, as a service, open to all stakeholders and resources. In a nutshell, their best practices and interrelationship in the present solution can be resumed as demonstrated in Figure 2 (below).

Fig. 2.

Complementarity of the contributions of BeeVeryCreative, LUGGit and EMBERS.

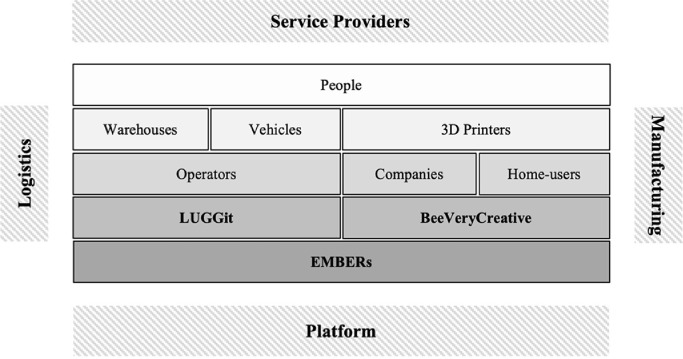

Considering the characteristics and complementarity of the contributions of each entity involved, the high-level architecture of the solution is defined and represented in Fig. 3 .

Fig. 3.

High-level architecture.

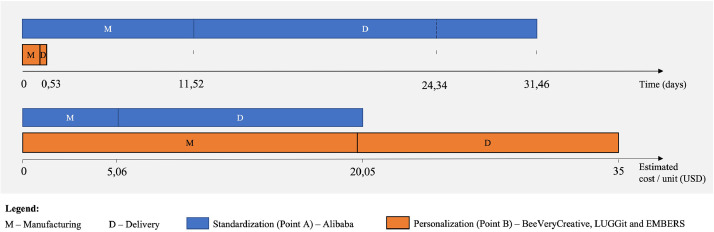

To compare the results obtained in sub-section A, during the interviews, the interlocutors of BeeVeryCreative and LUGGit were asked about the estimated cost and manufacture and delivery times, respectively, within the city of Aveiro, for the same type of “Plastic Toy” used in the Alibaba search.

BeeVeryCreative has 400 USD printers that could produce it in half of day with an average total cost of 20 USD considering labor, materials and other costs; LUGGit has drivers which could perform the service from any location in the city to the delivery destination in real-time for an average price of 15 USD.

Moreover, Fig. 4 compares the previous empirical example obtained from the Alibaba platform and the solution provided by the combination of the mentioned entities.

Fig. 4.

Simulation results for the associated time and estimated cost of standardization (sub-section A) and personalization (sub-section B).

As it is demonstrated in Fig. 4, the overall lead time of the traditional supply chain was decreased by 98% considering the proposed collaboration of the three entities in this sub-section.

From the interviews, it is clear that there will be no limits to what can be achieved by combining 3D printing with real-time logistical capacity and the integration of all stakeholders. However, it was also possible to note that personalized manufacturing is still not competitive for those who do not mind waiting several days to receive their purchases. Moreover, the estimated cost is approximately 74% higher in the proposed model.

Nevertheless, 3D printing evolution is expected to decrease manufacturing costs and reduce the lead time. Furthermore, only the designed solution allows the personalization of the product and real-time delivery.

The combination of the entities of the case study would allow same-day production and delivery of one of the products that based the sample for sub-section A, requiring only a BeeVeryCreative 3D printer and one LUGGit operator to respectively manufacture and deliver it according to the requirements. Furthermore, all this could be integrated into a single platform and charged as a service depending on the resources used, as well as the distance travelled from the manufacturing facilities to the delivery location, as well as time spent.

Based on the findings from the combination of the entities from a small Portuguese city, Aveiro, it is recommended that further efforts are put into place to scale and globally adopt this model.

4. Proposed framework

The main results of this study, described in this section, are presented and discussed according to the steps of the methodology previously outlined. In sub-section A, the results from the simulation of the problem to highlight the existing gap of the traditional supply chain are presented. Following this, on sub-section B, a study from the empirical search and the performed interviews to base a local collaboration to ultimately compare and discuss the standard and personalized supply chain results will be developed. Lastly, this section presents the concept of Last-Mile-as-a-Service (LMaaS) based on the results of the empirical research.

From the comparing results and the generalization of the designed local combined solution in sub-section B, a reflection about the future of the supply chain setup and fulfillment emerges. The relocation of the manufacturing process to the last-mile may eliminate a significant part of the traditional supply chain. The combination of all entities and individuals throughout the globe would allow a new industrial paradigm where the location of the clients would be the input to combine the local entities to manufacture and delivery the product quickly and sustainably. Moreover, any entity could resort to the last-mile created by the combination of the three mentioned entities to provide a product to be delivered to a client in the city of Aveiro. However, others could assure the fulfillment of the last-mile for purchases of clients located in different Portuguese city. Thus, this could be extended to any region. In general terms, this model will allow endless combinations between entities and individuals to meet the personalized requirements of any client anywhere in the globe.

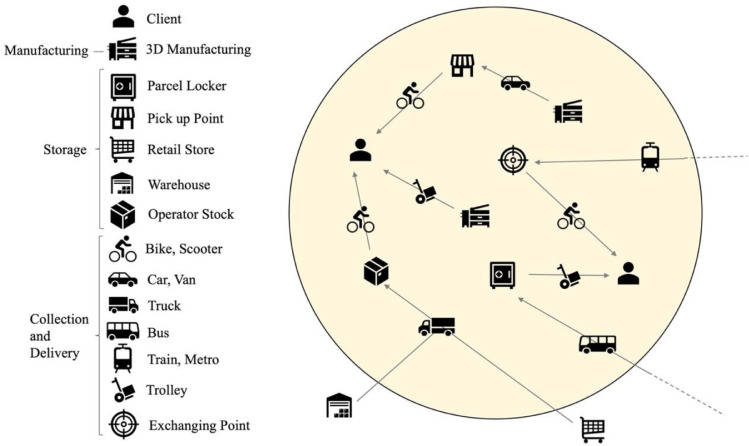

Therefore, a Last-Mile-as-a-Service (LMaaS) should emerge, where stakeholders with delivery, storage and manufacturing capabilities are integrated to perform an end-to-end service within the last-mile. The empirical case study of the previous section can ground this global model that promotes and makes available an open resource-sharing platform based on a marketplace of last-mile collaborations that enables any company to allow their products and services to be personalized and delivered to any location through the cooperation of local stakeholders (Fig. 5 below). This model suits the interests of the clients by allowing them to choose the exact requirements for product and delivery service.

Fig. 5.

Last-Mile-as-a-Service (LMaaS) marketplace.

The marketplace shall contemplate the transparent and open collaboration between stakeholders, fostered by a single platform to find the best combination of means to perform the last-mile for a specific request.

Table 2 (below) highlights and compares the relevant features of BeeVeryCreative, LUGGit, EMBERS to ultimately aggregat them,thus forming the foundations of the LMaaS. The indicated features in Table 1 were based on the relationship between each of the entities' most significant attributes, and the mentioned gap in the Introduction and the Theoretical Background about the lack of an open and end-to-end integrated and personalized supply chain based on the dynamic collaboration of multiple and local stakeholders.

Table 2.

BeeVeryCreative (BVC), LUGGit (L), EMBERS (E), and LMaaS features comparison.

| BVC | L | E | LMaaS | ||

|---|---|---|---|---|---|

| Features | Non-proprietary Solution | X | X | ||

| Open Source | X | X | X | ||

| Integration of Third-Party Services | X | X | |||

| Revenue Share Model | X | X | X | ||

| Multiple Transportation Modes | X | X | |||

| End-to-end Service | X | X | X | ||

| Real-time Service | X | X | |||

| Prediction Analytics | X | X | X | ||

| Goods Transportation | X | X | |||

| Passenger Transportation Modes | X | X | |||

| Tracking (GPS) | X | X | X | ||

| Storage Warehouses | X | X | |||

| Stock Control and Management | X | X | |||

| (Personalized) Manufacturing | X | X | |||

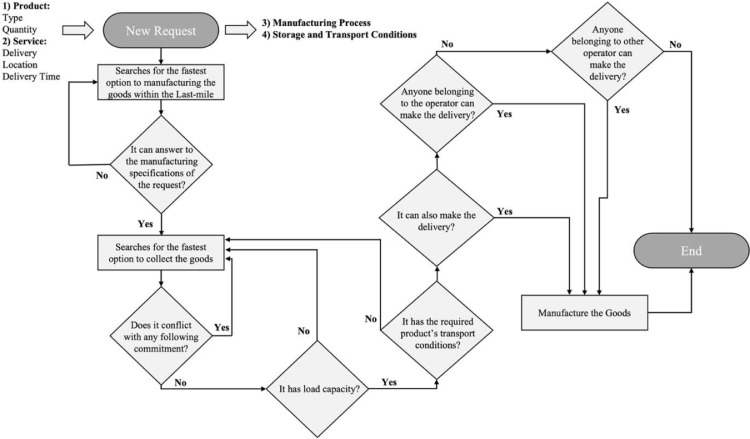

Last-mile collaborations will dynamically change, since this concept (LMaaS) is based on a marketplace where individuals or entities can provide their assets so they can be made available to any company that wants to sell (manufacture) their products in a given location. The specific collaboration to each purchase will consist of the best available options capable of responding to the client's requirements of the product and service. Different people can perform the collection of the manufactured goods and the delivery to the client; however, the supply chain needs to be created prior to the manufacturing order. The LMaaS starting point will be dependent on the manufacturing capacity close to the client. A new request will go through the decision journey represented in Fig. 6 (below), where manufacturing only starts after the algorithm has determined that delivery will also be fulfilled based on the requirements of the client.

Fig. 6.

Last-mile-as-a-Service (LMaaS) flow chart diagram.

Personalization is characterized by producing what the client wants and delivering it at the desired place and time. To ultimately achieve that and be at all times capable of providing an immediate response is necessary to integrate additive manufacturing techniques with logistics, merging the physical and the cyber layer, enhancing the exchanging of information throughout the value chain from the prediction of the order to manufacturing and its delivery (Correia, Teixeira, & Marques, 2021).

Moreover, taking the product specifications, the marketplace will return the most suitable option to manufacturing it (considering the manufacturing process), and combine it with the logistics best options to deliver (and store if needed) the product at the place and time the client chooses. Multiple scenarios and combinations of last-mile fulfillment can be found in Fig. 7 (below).

Fig. 7.

Last-mile scenarios examples.

Fig. 7 also acknowledges that standardization and personalization manufacturing processes will continue to coexist. Therefore, the last-mile fulfillment must consider the ability to perform real-time deliveries and enhance the collaboration between stakeholders and modes of transportation, even if it follows the manufacturing of a standard product.

In summary, unlike the existing mass production paradigm that has reasonably justified moving the manufacturing process to other countries, with the LMaaS model the collaboration between stakeholders and the associated technologies can represent a significant decrease on emissions and help combat climate change. At the manufacturing level, the needed raw materials can be considerably reduced, up to 100% of the existing waste, and, at the transport level, fewer vehicles will be needed to perform the deliveries and traveled distances will be shortened. Replacing private vehicles with smooth modes of transportation will leverage cities’ footprint towards zero. Thus, this model responds unequivocally to the initial question of this research.

5. Conclusions and future work

Industry 4.0 is striving to allow clients to purchase personalized products in terms of their requirements and the associated delivery service. Personalization brings several challenges that can only be overtaken with the integration and sharing of resources among organizations. This paradigm can lead manufacturing in the destination country to be easier and cheaper. Moreover, 3D printers can produce personalized components for the open network and relocate the manufacturing process closer to the client, reducing lead time, transport costs and customs fees, with significant impact on economy, environment and society.

Nowadays, if a company wanted to provide an end-to-end personalized service at any location, it would struggle to do it. Based on an empirical study of Alibaba, it was noted that standard supply chains do not present a solution to the research question. After simulating the problem, companies who could provide personalized (and immediate) deliveries and manufacturing were looked for within the local ecosystem. The rationale of the methodology was to choose a small-sized city to study if the collaboration of local companies could be more competitive than the standard mass production supply chain. The corroboration of the theory for the local example would allow a global model to overcome the existing gap and respond to the research question.

From the combination of the manufacture assets of BeeVeryCreative, the operational aspect of LUGGit and the open integration promoted by EMBERS it was possible to reduce the overall lead time by 98%.

Considering the findings of this empirical study and the technological potential of Industry 4.0, this article proposed an innovative concept for the disruption of the Supply Chain — Last-Mile-as-a-Service (LMaaS), where different modes of transportation, storage, and manufacturing resources can be integrated and managed to allow immediate deliveries and resume the supply chain to the Last-mile fulfillment. LMaaS aims to provide to any entity the chance of allowing the personalization of their products and delivery at any location. The standard supply chain, where manufacturing is performed 10,000 kilometers away from the consumer's location, would cease to exist.

The proposal of this disruptive concept to bring the supply chain to the last-mile will allow the breakdown of the traditional supply chain and help combat greenhouse gas emissions in cities caused by urbanization and logistics activities. The number of circulating vehicles and their travelled distances will reduce at the same time that they will be replaced by last-mile smooth modes of transportation.

However, this new proximity model, due to its complexity and disruptive nature, can bring some challenges. On the one hand, there is the short-term transition challenge for the reality because the concept is grounded in the culture of sharing and cooperation of enterprises. On the other hand, the associated overall estimated cost is still quite high when compared with the traditional supply chain for the consumer. Additionally, this concept may not be applied to all products. Mass production for various sectors and realities will not cease to be present since it will continue to be more competitive for standard products. Moreover, in the future, there may be a close relationship between additive and subtractive manufacturing, in a hybrid model, to the point where the second serves only as support for the production and maintenance of the first.

As future work, the proposed framework shall be validated in practice to measure its impact on the macro and micro economy and provide information about the challenges encountered in the process. In addition, this paper can lead to further conceptual and empirical studies while developing connections with local stakeholders in different regions of the globe to realize the concept in a proof-of-concept prototype.

The role of the city can be also further studied. The city can play a catalyst role in the adoption of this concept by putting at the community's disposal the needed resources and materials. The role of society shall be further studied, as well as the impact this concept will have in its organization and labor needs.

The supply of the raw materials and equipment components as well as the assembly of larger products must be further studied. Autonomous vehicles (in their various forms) may also bring new challenges and opportunities.

Evolving into a system where there is the chance of individuals producing everything at any location, it will also be important to study what will be the role of brands and how they will differentiate themselves.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The research was supported by Institute of Electronics and Informatics Engineering of Aveiro (UIDB/00127/2020) and by the research unit on Governance, Competitiveness and Public Policy (UIDB/04058/2020), both funded by national funds through FCT — Foundation for Science and Technology.

Biographies

Diogo Correia is a Ph.D. candidate in Management and Industrial Engineering at the Department of Economics, Management, Industrial Engineering and Tourism (DEGEIT) at the University of Aveiro, Portugal. His research interests and scientific publications cover the areas of Smart Cities , Industry 4.0, Logistics and Supply Chain. In the past, he worked as Smart Cities Manager in a technological company. Presently, he is an experienced entrepreneur, and member of the research unit on Governance, Competitiveness and Public Policy (GOVCOPP). He is also the Consortia Director in a joint R&D project with the University of Aveiro named SCALUM Scalable, efficient and abstract luggage mobility infrastructure and the Project Director of the R&D project SEAA Seamless Luggage All-around Solution.

Leonor Teixeira graduated in Industrial Engineering and Management, received a MSc. degree in Information Management, and a PhD in Industrial Management, from the University of Aveiro, Portugal. She is currently an Associate Professor at the Department of Economics, Management, Industrial Engineering and Tourism (DEGEIT) at the University of Aveiro. She is also a researcher (Integrated Member) at the Institute of Electronics and Informatics Engineering of Aveiro (IEETA) and collaborator at Research Unit on Governance, Competitiveness and Public Policies (GOVCOPP) of University of Aveiro. Her current research interests include Industrial Management in general, and in Information Systems applied to Industry in particular. She has over 200 publications in peer-reviewed journals, book chapters and proceedings, and has several communications at international scientific conferences, some of which as invited speaker. She serves as a member of Program Board and Organizing Committees for several Scientific Committees of International Conferences and has collaborated as reviewer with several journals. She is associated member of IIIS, IEEE Society and APSI/PTAIS.

João Lourenço Marques is assistant professor at the Department of Social, Political and Territorial Sciences of the University of Aveiro, lecturing courses in the areas of Urban and Regional Planning (quantitative methods and techniques to support decision making). He received his PhD degree in Social Sciences from the University of Aveiro (European PhD) by the same university. Currently he is integrated member of the Research Unit in Governance, Competitiveness and Public Policies, coordinating the Research Group of Systems for Decision Support. He has been conducting and coordinating several research and projects in the fields of strategic spatial planning, decision support systems, spatial competitiveness analysis, demographic dynamics and forecast, econometric and economic models for regional development.

Footnotes

The COVID-19 is the global pandemic of the Severe Acute Respiratory Syndrome Coronavirus-2 (SARS-CoV-2) infectious disease that emerged in 2019.

Ever Given ship blocked the Suez Canal in March 2021 over 6 days which had a significant impact on global economy.

Annex 1

| Product | MOQ | Price (USD) | Delivery Price (USD) | Transaction Fee (USD) | Execution Time | Delivery Time |

| 1 | 1000 | $1,210.00 | $1,068.72 | $80.74 | 15 | 16-44 |

| 2 | 12 | $84.00 | $78.02 | $5.35 | 12 | 18-23 |

| 3 | 20 | $220.00 | $58.55 | $11.46 | 15 | 16-44 |

| 4 | 1 | $13.00 | $56.15 | $2.04 | 15 | 18-23 |

| 5 | 2 | $18.76 | $262.10 | $8.29 | 15 | 7-15 |

| 6 | 2 | $70.00 | $51.47 | $3.59 | 7 | 6-10 |

| 7 | 600 | $90.00 | $53.03 | $4.22 | 25 | 18-23 |

| 8 | 2 | $26.74 | $56.15 | $2.45 | 12 | 20-35 |

| 9 | 4 | $16.80 | $85.90 | $3.03 | 10 | 3-10 |

| 10 | 1000 | $120.00 | $72.57 | $5.69 | 3 | 6-10 |

| 11 | 1 | $4.60 | $26.82 | $0.93 | 7 | 5-10 |

| 12 | 100 | $10.00 | $46.60 | $1.67 | 7 | 25-30 |

| 13 | 200 | $12.00 | $37.89 | $1.48 | 7 | 5-10 |

| 14 | 200 | $40.00 | $29.84 | $2.30 | 7 | 5-10 |

| 15 | 288 | $187.20 | $232.57 | $12.36 | 7 | 5-8 |

| 16 | 1 | $24.63 | $55.92 | $2.38 | 7 | 25-30 |

| 17 | 200 | $40.00 | $46.39 | $2.55 | 5 | 5-10 |

| 18 | 2 | $3.82 | $21.58 | $1.05 | 7 | 25-30 |

| 19 | 1200 | $2,232.00 | $209.81 | $72.04 | 15 | 9-12 |

| 20 | 10000 | $1,600.00 | $321.31 | $62.72 | 15 | 18-23 |

| 21 | 500 | $2,995.00 | $4,597.00 | NA | 15 | 4-15 |

| 22 | 1 | $27.50 | $82.00 | $3.24 | 10 | 6-10 |

| 23 | 1 | $15.50 | $37.16 | $1.56 | 10 | 6-10 |

| 24 | 50 | $110.50 | $55.92 | $4.91 | 10 | 25-30 |

| 25 | 2 | $17.90 | $26.58 | $1.32 | 7 | 9-12 |

| 26 | 2 | $37.70 | $118.00 | $4.60 | 15 | 3-7 |

| 27 | 2 | $7.28 | $52.10 | $1.76 | 7 | 25-30 |

| 28 | 15000 | $900.00 | $742.80 | NA | 10 | 7-15 |

| 29 | 500 | $115.00 | $213.08 | $9.68 | 5 | 5-8 |

| 30 | 1 | $10.00 | $32.00 | $1.30 | 15 | 6-10 |

| 31 | 1500 | $1,350.00 | $5,589.44 | NA | 15 | 16-44 |

| 32 | 120 | $51.60 | $53.59 | $3.11 | 3 | 25-30 |

| 33 | 10 | $8.50 | $54.00 | $1.85 | 10 | 5-10 |

| 34 | 300 | $1,377.00 | $1,140.40 | $74.27 | 15 | 16-44 |

| 35 | 500 | $450.00 | $627.22 | $31.78 | 15 | 25-30 |

| 36 | 10 | $2.50 | $40.10 | $60.00 | 60 | 5-10 |

| 37 | 100 | $80.00 | $148.87 | $6.76 | 15 | 5-10 |

| 38 | 500 | $2,500.00 | $1,140.40 | $107.40 | 7 | 25-30 |

| 39 | 10 | $5.50 | $39.64 | $1.34 | 15 | 4-7 |

| 40 | 1 | $8.00 | $51.26 | $1.75 | 15 | 25-30 |

| 41 | 20 | $16.60 | $37.77 | $1.61 | 15 | 25-30 |

| 42 | 100 | $17.00 | $55.92 | $2.16 | 5 | 18-23 |

| 43 | 200 | $30.00 | $14.00 | $1.30 | 15 | 09-25 |

| 44 | 100 | $198.00 | $297.68 | $14.63 | 15 | 25-30 |

| 45 | 50 | $16.50 | $62.88 | $2.35 | 4 | 5-8 |

| 46 | 10 | $2.70 | $7.04 | $0.29 | 5 | 20-35 |

| 47 | 50 | $60.00 | $72.23 | $3.91 | 5 | 3-7 |

| 48 | 50 | $115.00 | $93.44 | $6.15 | 7 | 5-10 |

| 49 | 24 | $36.00 | $763.74 | $23.60 | 3 | 9-12 |

| 50 | 2000 | $200.00 | $322.00 | $15.40 | 15 | 10-15 |

Legend:

MOQ – Minimum Order Quantity

N/A – Not Available

References

- Barenji A.V., Wang W.M., Li Z., Guerra-Zubiaga D.A. Intelligent E-commerce logistics platform using hybrid agent based approach. Transportation Research Part E: Logistics and Transportation Review. 2019;126:15–31. doi: 10.1016/j.tre.2019.04.002. May 2018. [DOI] [Google Scholar]

- BeeVeryCreative. (2021). BeeVeryCreative. Retrieved March 1, 2021, from https://beeverycreative.com/index.php.

- Bibri S.E., Krogstie J. Smart sustainable cities of the future: An extensive interdisciplinary literature review. Sustainable Cities and Society. 2017;31:183–212. doi: 10.1016/j.scs.2017.02.016. [DOI] [Google Scholar]

- Bortolini M., Ferrari E., Gamberi M., Pilati F., Faccio M. Assembly system design in the Industry 4.0 era: a general framework. IFAC-PapersOnLine. 2017;50(1):5700–5705. doi: 10.1016/j.ifacol.2017.08.1121. [DOI] [Google Scholar]

- Boysen N., Fedtke S., Schwerdfeger S. Springer; Berlin Heidelberg: 2020. Last-mile delivery concepts: a survey from an operational research perspective. OR Spectrum. [DOI] [Google Scholar]

- Bradshaw, S., Bowyer, A., & Haufe, P. (2010). The Intellectual Property Right Implications of Consumer 3D Printing, 7(1). 10.2966/scrip.070110.5. [DOI]

- Cao Y., Ajjan H., Hong P. Post-purchase shipping and customer service experiences in online shopping and their impact on customer satisfaction: An empirical study with comparison. Asia Pacific Journal of Marketing and Logistics. 2018;30(2):400–416. doi: 10.1108/APJML-04-2017-0071. [DOI] [Google Scholar]

- Castillo, V. E. (2018). An Inquiry into Supply Chain Strategy Implications of the Sharing Economy for Last Mile Logistics, 200.

- Chen J.E., Pan S.L., Ouyang T.H. Routine reconfiguration in traditional companies’ e-commerce strategy implementation: A trajectory perspective. Information and Management. 2014;51(2):270–282. doi: 10.1016/j.im.2013.11.008. [DOI] [Google Scholar]

- Correia D., Teixeira L., Marques J. Proceedings of the international conference on industrial engineering and operations management Singapore. 2021. The Hourglass Model: From Consumer's Behavior to Delivery. March 9-11, 2021. [Google Scholar]

- Ducret R. Parcel deliveries and urban logistics: Changes and challenges in the courier express and parcel sector in Europe - the French case. Research in Transportation Business and Management. 2014;11:15–22. doi: 10.1016/j.rtbm.2014.06.009. [DOI] [Google Scholar]

- EMBERS. (2019). EMBERS. Retrieved January 1, 2021, from https://embers.city/index.htm.

- Erol S., Jäger A., Hold P., Ott K., Sihn W. Tangible industry 4.0: A scenario-based approach to learning for the future of production. Procedia CIRP. 2016;54:13–18. doi: 10.1016/j.procir.2016.03.162. [DOI] [Google Scholar]

- European Commission. (2019). The European Green Deal. 10.2307/j.ctvd1c6zh.7. [DOI]

- Ford S., Despeisse M. Additive manufacturing and sustainability: an exploratory study of the advantages and challenges. Journal of Cleaner Production. 2016;137:1573–1587. doi: 10.1016/j.jclepro.2016.04.150. [DOI] [Google Scholar]

- Gatta V., Marcucci E., Nigro M., Patella S.M., Serafini S. Public transport-based crowdshipping for sustainable city logistics: Assessing economic and environmental impacts. Sustainability (Switzerland) 2018;11(1):1–14. doi: 10.3390/su11010145. [DOI] [Google Scholar]

- Gevaers R., Voorde E.Van de, Vanelslander T. In: City Distribution and Urban Freight Transport. Macharis C., Melo S., editors. Edward Elgar Publishing; 2011. Characteristics and typology of last-mile logistics from an innovation perspective in an urban context. [Google Scholar]

- Gustafsson J. Single case studies vs. multiple case studies: A comparative study. Academy of Business, Engineering and Science Halmstad University, Sweden. 2017 http://www.diva-portal.org/smash/record.jsf?pid=diva2:1064378%0Ahttp://www.diva-portal.org/smash/get/diva2:1064378/FULLTEXT01.pdf Retrieved from. [Google Scholar]

- Hozdić E. Smart factory for industry 4.0: A review. International Journal of Modern Manufacturing Technologies. 2015;7(1):28–35. [Google Scholar]

- Jabeur N., Al-Belushi T., Mbarki M., Gharrad H. Toward leveraging smart logistics collaboration with a multi-agent system based solution. Procedia Computer Science. 2017;109(2016):672–679. doi: 10.1016/j.procs.2017.05.374. [DOI] [Google Scholar]

- Kagermann H., Wahlster W., Helbig J. Securing the future of German manufacturing industry: Recommendations for implementing the strategic initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group, (April) 2013;1–84 [Google Scholar]

- Kang H.S., Lee J.Y., Choi S., Kim H., Park J.H., Son J.Y., Noh …, Do S. Smart manufacturing: Past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing - Green Technology. 2016;3(1):111–128. doi: 10.1007/s40684-016-0015-5. [DOI] [Google Scholar]

- Kirch, M., Poenicke, O., & Richter, K. (2017). RFID in Logistics and Production -Applications, Research and Visions for Smart Logistics Zones. Procedia Engineering, 178, 526–533. https://doi.org/10.1016/j.proeng.2017.01.101.

- Korczak J., Kijewska K. Smart logistics in the development of smart cities. Transportation Research Procedia. 2019;39(2018):201–211. doi: 10.1016/j.trpro.2019.06.022. [DOI] [Google Scholar]

- Laplume A.O., Petersen B., Pearce J.M. Global value chains from a 3D printing perspective. Journal of International Business Studies. 2016;47(5):595–609. doi: 10.1057/jibs.2015.47. [DOI] [Google Scholar]

- Lim S.F.W.T., Jin X., Srai J.S. Consumer-driven e-commerce: A literature review, design framework, and research agenda on last-mile logistics models. International Journal of Physical Distribution and Logistics Management. 2018;48(3):308–332. doi: 10.1108/IJPDLM-02-2017-0081. [DOI] [Google Scholar]

- Lipson H., Kurman M. John Wiley & Sons; 2013. Fabricated: The new world of 3D printing. [Google Scholar]

- Lom, M., Pribyl, O., & Miroslav Svitek. (2016). Industry 4.0 as a Part of Smart Cities, (June), 0–11. 10.1177/2158244016653987. [DOI]

- Lu Y., Ju F. Smart manufacturing systems based on cyber-physical manufacturing services (CPMS) IFAC-PapersOnLine. 2017;50(1):15883–15889. doi: 10.1016/j.ifacol.2017.08.2349. [DOI] [Google Scholar]

- LUGGit. (2021). LUGGit. Retrieved January 1, 2021, from https://luggit.app/.

- McFarlane D., Giannikas V., Lu W. Intelligent logistics: Involving the customer. Computers in Industry. 2016;81:105–115. doi: 10.1016/j.compind.2015.10.002. [DOI] [Google Scholar]

- Melacini M., Perotti S., Rasini M., Tappia E. E-fulfilment and distribution in omni-channel retailing: A systematic literature review. International Journal of Physical Distribution & Logistics Management. 2018;48(4):391–414. doi: 10.1108/IJPDLM-02-2017-0101. [DOI] [Google Scholar]

- Moilanen J., Vadén T. 3D printing community and emerging practices of peer production. First Monday. 2013;18(8) doi: 10.5210/fm.v18i8.4271. [DOI] [Google Scholar]

- Moreno C., Allam Z., Chabaud D., Gall C., Pratlong F. Introducing the “15-Minute City”: Sustainability, Resilience and Place Identity in Future Post-Pandemic Cities. Smart Cities. 2021;4(1):93–111. doi: 10.3390/smartcities4010006. [DOI] [Google Scholar]

- Morganti E., Dablanc L., Fortin F. Final deliveries for online shopping: The deployment of pickup point networks in urban and suburban areas. Research in Transportation Business and Management. 2014;11:23–31. doi: 10.1016/j.rtbm.2014.03.002. [DOI] [Google Scholar]

- Nathanail E., Gogas M., Adamos G. Smart Interconnections of Interurban and urban freight transport towards achieving sustainable city logistics. Transportation Research Procedia. 2016;14:983–992. doi: 10.1016/j.trpro.2016.05.078. [DOI] [Google Scholar]

- Nick G., Pongrácz F., Radács E. Interpretation of disruptive innovation in the era of smart cities of the fourth industrial revolution. Deturope. 2018;10(1):53–70. [Google Scholar]

- O'Donovan P., Leahy K., Bruton K., O'Sullivan D.T.J. An industrial big data pipeline for data-driven analytics maintenance applications in large-scale smart manufacturing facilities. Journal of Big Data. 2015;2(1):1–26. doi: 10.1186/s40537-015-0034-z. [DOI] [Google Scholar]

- Oztemel E., Gursev S. Literature review of Industry 4.0 and related technologies. Journal of Intelligent Manufacturing. 2020;31(1):127–182. doi: 10.1007/s10845-018-1433-8. [DOI] [Google Scholar]

- Paritala P.K., Manchikatla S., Yarlagadda P.K.D.V. Digital manufacturing- applications past, current, and future trends. Procedia Engineering. 2017;174:982–991. doi: 10.1016/j.proeng.2017.01.250. [DOI] [Google Scholar]

- Perboli G., Rosano M., Saint-Guillain M., Rizzo P. Simulation-optimisation framework for city logistics: An application on multimodal last-mile delivery. IET Intelligent Transport Systems. 2018;12(4):262–269. doi: 10.1049/iet-its.2017.0357. [DOI] [Google Scholar]

- Prause G. Sustainable business models and structures for industry 4.0. Journal of Security and Sustainable Issues. 2016;2 doi: 10.9770/jssi.2015.5.2(3)CITATIONS. December 2015. [DOI] [Google Scholar]

- Prause G., Atari S. On sustainable production networks for industry 4.0. Entrepreneurship and Sustainability Issues. 2017;4(4):421–431. doi: 10.9770/jesi.2017.4.4(2). [DOI] [Google Scholar]

- Ranieri L., Digiesi S., Silvestri B., Roccotelli M. A review of last mile logistics innovations in an externalities cost reduction vision. Sustainability (Switzerland) 2018;10(3):1–18. doi: 10.3390/su10030782. [DOI] [Google Scholar]

- Rožman N., Vrabič R., Corn M., Požrl T., Diaci J. Distributed logistics platform based on blockchain and IoT. Procedia CIRP. 2019;81:826–831. doi: 10.1016/j.procir.2019.03.207. [DOI] [Google Scholar]

- Savelsbergh M., Van Woensel T. 50th anniversary invited article—city logistics: Challenges and opportunities. Transportation Science. 2016;50(2):579–590. doi: 10.1287/trsc.2016.0675. [DOI] [Google Scholar]

- Shin S.J., Woo J., Rachuri S. Predictive analytics model for power consumption in manufacturing. Procedia CIRP. 2014;15:153–158. doi: 10.1016/j.procir.2014.06.036. [DOI] [Google Scholar]

- Taniguchi, E, & Thompson, R. (2014). City logistics: mapping the future.

- Taniguchi Eiichi, Thompson R.G., Yamada T. New opportunities and challenges for city logistics. Transportation Research Procedia. 2016;12(June 2015):5–13. doi: 10.1016/j.trpro.2016.02.004. [DOI] [Google Scholar]

- United Nations. (2015). World Urbanization Prospects.

- Vakulenko Y., Shams P., Hellström D., Hjort K. Service innovation in e-commerce last mile delivery: Mapping the e-customer journey. Journal of Business Research. 2019;101(June 2018):461–468. doi: 10.1016/j.jbusres.2019.01.016. [DOI] [Google Scholar]

- Wang Yi, Ma H.S., Yang J.H., Wang K.S. Industry 4.0: A way from mass customization to mass personalization production. Advances in Manufacturing. 2017;5(4):311–320. doi: 10.1007/s40436-017-0204-7. [DOI] [Google Scholar]

- Wang Yuan, Zhang D., Liu Q., Shen F., Lee L.H. Towards enhancing the last-mile delivery: An effective crowd-tasking model with scalable solutions. Transportation Research Part E: Logistics and Transportation Review. 2016;93:279–293. doi: 10.1016/j.tre.2016.06.002. [DOI] [Google Scholar]

- Xiao Z., Wang J.J., Lenzer J., Sun Y. Understanding the diversity of final delivery solutions for online retailing: A case of Shenzhen, China. Transportation Research Procedia. 2017;25:985–998. doi: 10.1016/j.trpro.2017.05.473. [DOI] [Google Scholar]

- Xu X., Zheng Y., Yu L. A bi-level optimization model of LRP in collaborative logistics network considered backhaul no-load cost. Soft Computing. 2018;22(16):5385–5393. doi: 10.1007/s00500-018-3056-6. [DOI] [Google Scholar]

- Zhou L., Baldacci R., Vigo D., Wang X. A multi-depot two-echelon vehicle routing problem with delivery options arising in the last mile distribution. European Journal of Operational Research. 2018;265(2):765–778. doi: 10.1016/j.ejor.2017.08.011. [DOI] [Google Scholar]

- Zhou L., Wang X., Ni L., Lin Y. Location-routing problem with simultaneous home delivery and customer's pickup for city distribution of online shopping purchases. Sustainability (Switzerland) 2016;8(8) doi: 10.3390/su8080828. [DOI] [Google Scholar]