Abstract

Electric vehicle development is critical to achieve the sustainable goals, while the hit of COVID-19 strikes the market and brings challenges to the whole industry. China, among one of the earliest regions affected by COVID-19 and takes a great part in the global electric vehicle market, is attracting growing attention on its post-pandemic trends in the electric vehicle industry. This paper provides a comprehensive analysis of COVID-19 impacts on China's electric vehicle industry from both the demand side and the supply side. Both challenges and opportunities for China's electric vehicle development are revealed with emerging trend analysis. It is found that the COVID-19 outbreak has reduced electric vehicle sales in the short-term, but may also stimulate future electric vehicle demand especially for large electric cars with better performance. Meanwhile, travel restrictions caused by COVID-19 have interrupted electric vehicle material supplies that relying on imports, accelerating domestic substitute exploitation and inventory improvement for critical parts. Additionally, massive lockdowns for controlling COVID-19 have disrupted productions and operations, which tends to expel small brands out of the competitive market, concentrating China's electric vehicle industry to the leading brands. Finally, the social distancing trend after pandemic is bringing challenges to traditional EV distribution channels with dealers, pushing automakers to develop innovative online selling channels. These impacts are likely to lead to a reformation of China's electric vehicle industry towards a more advanced and reliable future.

Keywords: COVID-19 impacts, Electric vehicle, Market analysis, Supply chain, Policy trend, Future outlook

List of abbreviations:

- BEV

Battery Electric Vehicle

- CAAM

China Association of Automobile Manufacturers

- CADA

China Automobile Dealers Association

- CAEV

China Industry Technology Innovation Strategic Alliance for Electric Vehicle

- CNY

China Yuan

- COVID-19

Corona Virus Disease 2019

- CPCA

China Passenger Car Association

- EV

Electric Vehicle

- FCEV

Fuel Cell Electric Vehicle

- GACC

General Administration of Customs of the People's Republic of China

- HEV

Hybrid Electric Vehicle

- HS Code

The Harmonization System Code

- ICEV

Internal Combustion Engine Vehicle

- IGBT

Insulated Gate Bipolar Transistor

- MST

Ministry of Science and Technology of the People's Republic of China

- NBRC

National Bureau Statistics of China

- NDRC

National Development and Reform Commission of the People's Republic of China

- NEV

New Energy Vehicle

- OEM

Original Equipment Manufacturer

- PHEV

Plug-in Hybrid Electric Vehicle

- R&D

Research and Development

- SARS

Severe Acute Respiratory Syndrome Coronavirus

- SCC

The State Council of the People's Republic of China

- SME

Small and Medium-sized Enterprise

- UN

United Nations

- VIAI

Vehicle Inventory Alert Index

- VR

Virture Reality

- WHO

World Health Organization

- YoY

Year-over-Year

1. Introduction

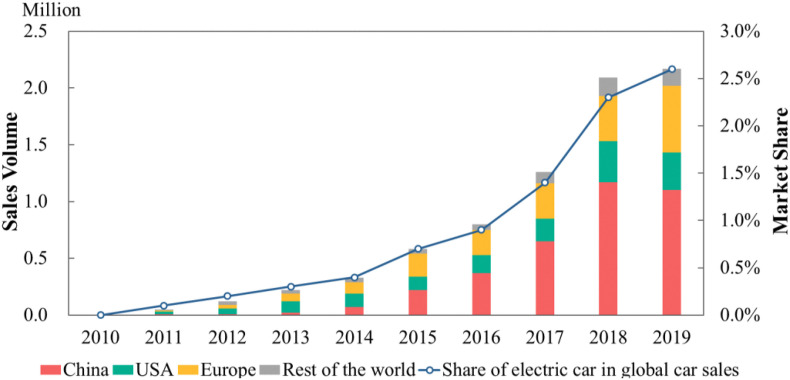

Transportation decarbonization is a critical path towards the UN Sustainable Development Goals, with electric mobility playing a significant role in this field [1]. Supported by governmental policies and technological advances, the electric vehicle (EV) industry has developed rapidly during the last decade [2]. The global annual sale of electric cars (either a battery EV or a plug-in hybrid EV within the light-duty passenger vehicle segment) has expanded by an annual average of 60% since 2014, reaching 2.1 million in 2019 (as shown in Fig. 1 ) [3]. Meanwhile, China, Europe and the United States have become the top 3 regional EV markets by taking approximately 90% of global EV sales. Counting both the light-duty passenger vehicles and the medium/heavy commercial vehicles, global EV stock has swelled to over 8 million at the end of 2019, over half of which were in China [4]. However, the growth rate of global EV sales turned to be sluggish in 2019, especially in the second half of the year, mainly due to car market contraction and EV subsidy reduction in the key markets [5]. Given the small proportion (2.6%) of EV share in the global car market, achievement of mobility electrification still has far to go.

Fig. 1.

Global sales of electric cars (2010–2019).

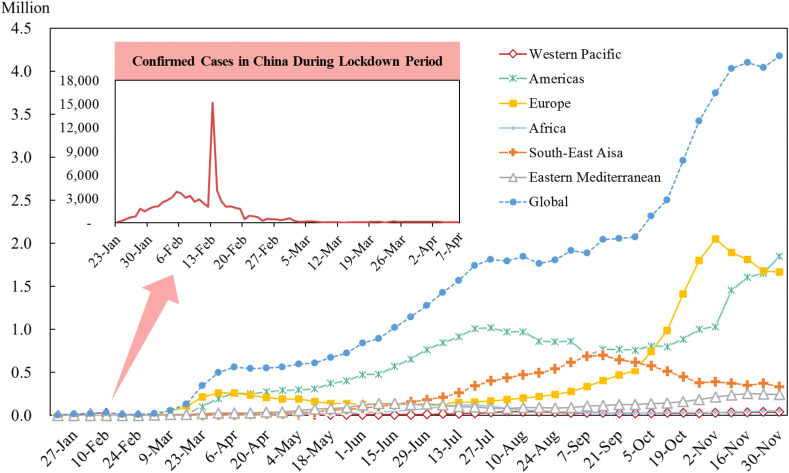

In December 2019, a novel coronavirus was reported causing infectious respiratory disease, which was named later as COVID-19 (Corona Virus Disease 2019) and declared to be a global pandemic on March 11, 2020 by the World Health Organization (WHO) [6]. The novel virus has spread fast, attacking most economic entities in world (as shown in Fig. 2 ). Accumulated to November 30, 2020, COVID-19 has caused over 62 million confirmed infections and over 1.4 million deaths within one year as of the day it was reported [7]. Massive lockdowns and travel restrictions have been taken for controlling the pandemic, which change human behaviors and interrupt industrial activities, bringing challenges and uncertainties to the world's economy and human societies [8]. The confinement policy has kept 81% of the global workforce at home by the beginning of April 2020 [9], making global manufacturing output drop by 20% in April 2020 [10]. Meanwhile, the travel demand was hitting near zero, leaving 90% of the global air fleets grounded [11]. Inevitably, the automobile industry has suffered greatly from COVID-19, with production lines halted, supply chains disrupted, and consumer demand contracted [12]. For the EV industry, which has already been in a difficult time, the sudden hit of COVID-19 has made things more unpredictable.

Fig. 2.

Confirmed cases of COVID-19 in world.

Actions should be taken, not only to protect public health but also to sustain the global economy and human societies [13], which calls for timely study of the COVID-19 impacts on different sectors [14]. Some scholars have put their efforts in this area. Graff et al. (2020) show that COVID-19 would decrease the level of energy security and increase the energy burden to low-income households [15]. Le Quéré (2020) indicates that COVID-19 might influence the global CO2 emissions path for decades by changing government actions and economic incentives [16]. Guan et al. (2020) find that supply chain losses related to COVID-19 lockdowns are largely dependent on the number of countries imposing restrictions while the complexity of global supply chains will further magnify such losses [17]. Kanda and Kivimaa (2020) argue that the economic effects of COVID-19 have significantly reduced EV sales in the short-term, but may be favorable to the diffusion of EVs in the long-term [18]. However, there is still a lack of thorough analysis on the impacts of COVID-19 on EV industry as well as forward-looking prospects in this field. It is the motivation of this study to shed some light on the direct/indirect and short/mid/long-term impacts of COVID-19 on the EV industry based on practical data from typical regions, and to put forward strategic implications for policy makers and stakeholders worldwide.

As China owns the world's biggest frontrunner EV market [19], and was among the earliest regions that affected by COVID-19, which has also implemented the strictest confinement policy [20], analyzing the impacts of COVID-19 on China's EV industry may help recognize the challenges and trends in global EV development. Given the above considerations, this paper intends to carry out a comprehensive investigation of the COVID-19 impacts on China's EV industry covering both the demand side and the supply side. On the demand side, the impacts of COVID-19 on EV markets are studied with sales decomposition and consumer preference analysis. On the supply side, the impacts of COVID-19 on EV supply chains are summarized from material supply, vehicle production and distribution channel perspectives. Based on the analysis, it extends to discuss the key challenges and opportunities faced by China's EV industry as well as the emerging trends. Implications for global EV development and future outlooks are then proposed with reference to the Chinese case.

The remainder of this paper is as follows. Section 2 provides an overview of China's EV industry. Section 3, 4 analyze the impacts of COVID-19 on China's EV markets and EV supply chains respectively. Section 5 discusses the challenges and opportunities faced by China's EV industry as well as its emerging trends and implications for global EV development. Section 6 concludes the paper. All the data sources and checking instructions are listed in the Appendix.

2. Overview of China's EV development

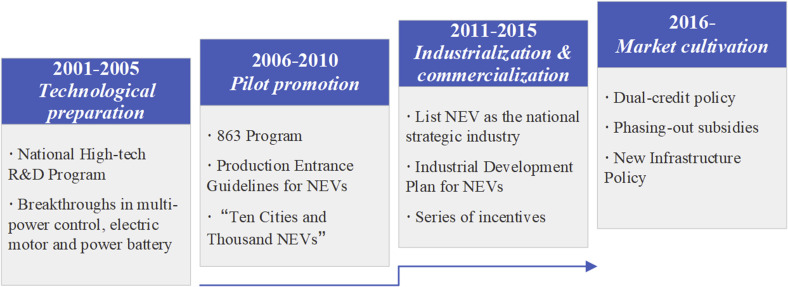

2.1. EV policy evolutions

China's national plan of EV development could trace back to the “Tenth Five-Year Plan” (from 2001 to 2005). Since then, the Chinese central government has kept renovating detailed EV plans according to different status of the industry [21]. Along with the “Five-Year Plans”, China's EV developing strategies could be categorized into four stages (as shown in Fig. 3 ). Various supportive policies have been carried out for achieving different goals in each stage.

Fig. 3.

The four stages of China's EV policy evolutions.

Stage I: Technological preparation (2001–2005).

In 2001, the Ministry of Science and Technology (MST) set up a key project for EV under the National High-tech R&D Program (863 Plan), declaring to accelerate the research and development (R&D) of three types of new vehicle technologies including battery electric vehicles (BEV), hybrid electric vehicles (HEV), and fuel cell electric vehicles (FCEV) [22]. With the efforts of major research institutes and enterprises, China has made breakthroughs in EV technologies during the “Tenth Five-Year Plan” period, especially in the areas of multi-power control, electric motor and power battery [23]. At the end of 2005, four types of pure electric buses and two types of pure electric cars were prepared for small batch production, with 112 pure electric cars exported to the United States.

Stage II: Pilot promotion (2006–2010).

During the “Eleventh Five-Year Plan” period (from 2006 to 2010), MST continued to support EV R&D with a newly launched “863” project named “National Key Program for Energy-saving and New Energy Vehicles (NEVs)”, which emphasized to expand the demonstration and application of EVs [24]. In 2007, the “Production Entrance Guidelines for NEVs” was issued by the National Development and Reform Commission (NDRC). Then in 2009, five state ministries united to initiate the “Ten Cities and Thousand NEVs” program, aiming to promote EV applications in the public sector (focusing on buses, taxis, official cars, sanitation vehicles, etc.) within pilot cities [25]. Next year, EV promotion was extended to the private sector with subsidies for listed passenger EVs [26]. During this period, 2600 EVs were put into operation, including 1320 electric cars, 1080 electric buses and 200 special EVs [27].

Stage III: Industrialization and commercialization (2011–2015).

The “Twelfth Five-Year Plan” (from 2011 to 2015) officially listed NEV as one of the seven strategic rising industries in China, indicating large-scale industrialization and commercialization of NEV [28]. In 2012, the State Council of China (SCC) released the “Industrial Development Plan for Energy-saving and NEVs (2012–2020)”, which claimed to place more priority on the pure electrified vehicle development [29]. When the first period of pilot EV promotion programs ended in 2012, China's EV stock was only 23,000 in the public sector and 4400 in the private sector [30]. In order to expand EV market, the state ministries intensively issued a series of incentive policies including subsidy enhancement, tax exemption, license/road privileges, and so on [31]. With great governmental support, China became a leading country in global EV production and sales at the end of 2015 [32].

Stage IV: Market cultivation (2016-)

Realizing the heavy financial burdens from excess EV subsidies and potential side-effects on the industry, the Chinese government started to transform EV developing pattern to the market-driven path since the “Thirteenth Five-Year Plan” period [33]. In 2017, a dual-credit policy was carried out to motivate EV production by automakers [34]. Then the EV subsidies were gradually tightened with higher accessing thresholds and fewer amounts [35]. However, undesirable sales decline occurred upon implementation of the great subsidy reduction in 2019, pushing Chinese government to extend EV subsidies to the end of 2022 [36]. Meanwhile, the Chinese government turned to pay more attention to the construction of EV infrastructures which may improve consumer satisfaction for EV usage [37]. The “New Infrastructure” project proposed in the 2020 government working report by SCC emphasized expanding the EV charging network, indicating China's determination in promoting EV applications.

2.2. EV market structures

Along with the policy evolution, EVs have been commercially available in China since 2010 when the first official document on private EV incentives was issued. However, the public did not show much interest during the first 3 years due to uncertainties associated with this new technology. The EV sales were mainly contributed by governmental departments and firms for public usages at the beginning [38]. Until 2013 when great EV incentives started to be implemented, China's EV market stepped into a fast growing period, with annual sales increase over 200% in 2014 and 2015 [39]. The annual growth rate stayed over 60% until 2019 when the EV subsidy reduction was executed (as shown in Fig. 1). Although dropped by around 4%, China's total EV sales in 2019 still achieved 1.2 million and ranked first in the world, accounting for 52% of global EV sales [4,40]. Meanwhile, China's EV share in the national automobile market raised from 4.47% in 2018 to 4.68% in 2019 [40,41].

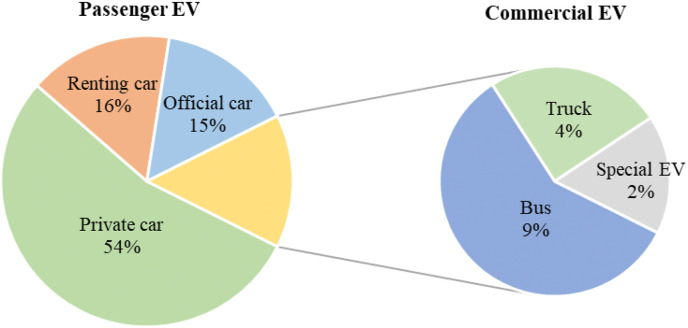

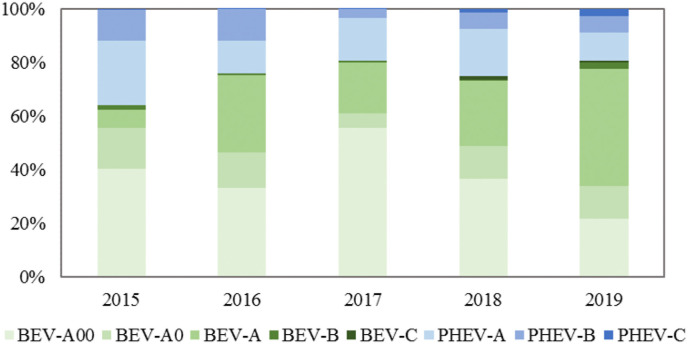

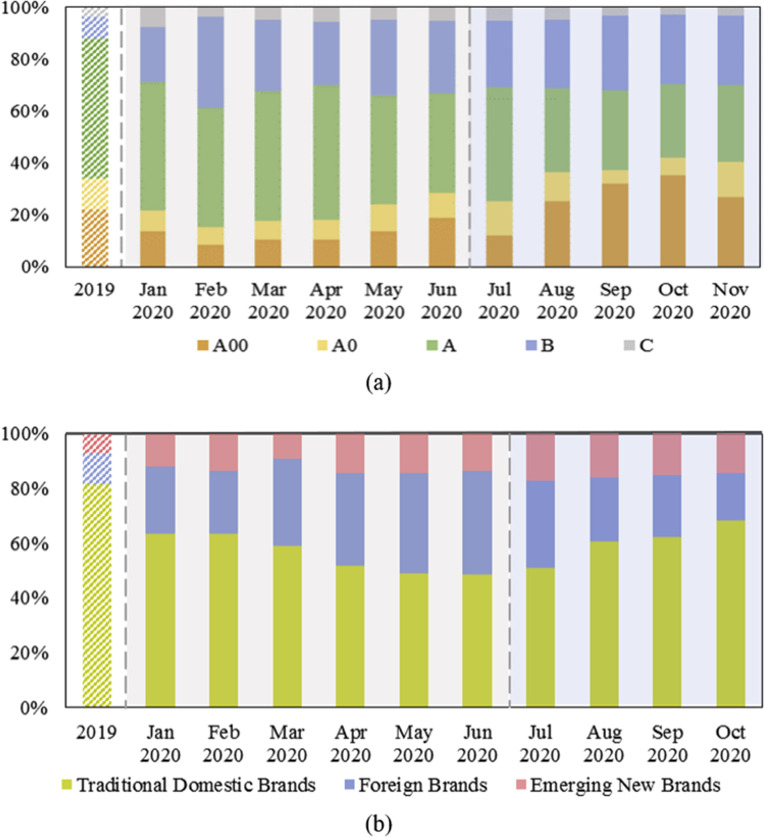

According to China Passenger Car Association (CPCA), EVs sold in China could be categorized into passenger EVs and commercial EVs, which could be further classified into different classes based on their sizes (as shown in Table 1 ). When China's annual EV sales reached its top in 2018, commercial EVs accounted for 15% of the total sales and the rest were contributed by passenger EVs (including 54% private cars, 16% renting cars and 15% official cars, as shown in Fig. 4 ) [42]. The great portion of non-private EV usage was mainly attributed to China's EV promotion strategies in the early stage and the emerging business models of car sharing [38]. In the passenger EV sector, market sales mainly concentrated in small electric cars within A00/A0/A classes, most of which were pure electrified BEVs (as shown in Fig. 5 ). Large passenger EVs belonging to the C class had started to emerge in recent years. By the end of 2019, small domestic BEVs had been the dominant contributor to China's EV growth, most of which were purchased by low- or mid-income consumers with prices less than 150,000 China Yuan (CNY) after subsidies [43]. In 2019, over 80% of China's EV sales were BEVs, with only 6% imported from overseas (over 80% of which were from the United States) [4].

Table 1.

China's EV classification according to CPCA.

| CPCA Classification | Class | Size | Example |

|---|---|---|---|

| Passenger EV | A00 | Minicompact | BAIC EC (BEV) |

| A0 | Subcompact | BYD Yuan (BEV) | |

| A | Compact | BYD E5 (BEV) | |

| B | Medium | Tesla Model 3 (BEV) | |

| C | Large | BMW 530e (PHEV) | |

| Commercial EV | Bus | – | Yutong ZK6710BEV3 |

| Truck | – | Geely E200 | |

| Special EV | – | Hualin HLT5320GSSEV |

Fig. 4.

China's EV sales decomposition by usage in 2018.

Fig. 5.

Market shares of different passenger EV classes in China (2015–2019).

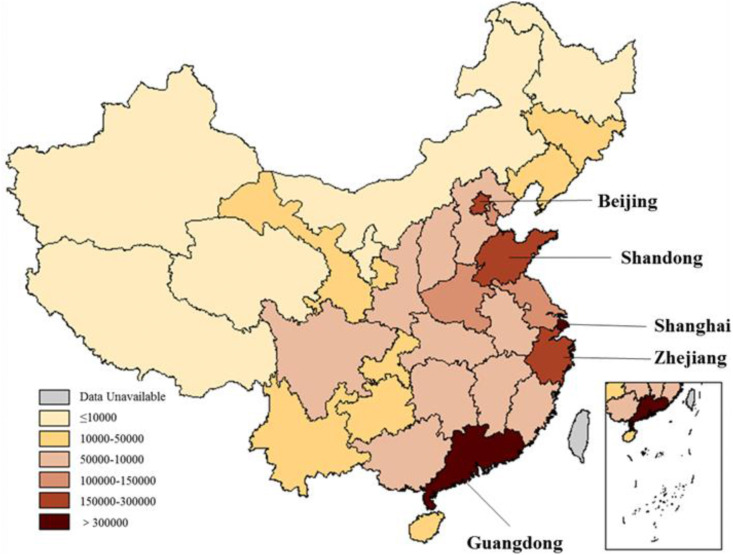

By taking a closer look at China's EV sales distribution, it is found that the EV stock mainly concentrates in the southeast area with Guangdong, Shanghai, Beijing, Zhejiang, Shandong being the top five provincial administrative regions which contributed to over half of China's total EV stock by the end of 2019 (as shown in Fig. 6 ) [44]. Meanwhile, the six cities (Shanghai, Beijing, Shenzhen, Guangzhou, Hangzhou, Tianjin) with vehicle purchasing restrictions for internal combustion engine vehicles (ICEVs) had held the most EV stock, together accounting for 43.52% of the national EV stock. The remaining EVs on road were mainly distributed in other sub-provincial cities or provincial capitals such as Zhengzhou, Changsha and Qingdao [45].

Fig. 6.

Regional passenger EV stock in China at the end of 2019.

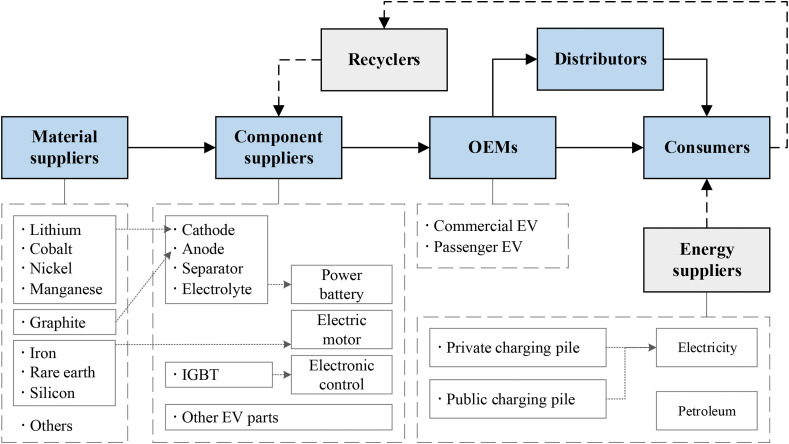

2.3. EV supply chains

A typical EV supply chain usually consists of material suppliers, component suppliers, automakers, distributors and consumers (as shown in Fig. 7 ) [46]. From a broader view, the energy (e.g., electricity and petroleum) suppliers and EV recyclers are also members of the EV industrial chain [47]. Automakers as the original equipment manufacturers (OEMs) procure essential EV parts from the component suppliers and sell finished EV products to distributors or directly to consumers. The component suppliers could be partitioned into multiple tiers if taking a closer view [48]. In addition to traditional vehicle parts (such as chassis, bodywork, interiors, etc.), EV component suppliers provide EV OEMs the core electric components (including power battery, electric motor, and electronic control) which usually contribute to three quarters of the EV production cost [27]. Cathode, anode, separator and electrolyte are the four key parts of power battery, which are usually made from lithium, cobalt, nickel, manganese, graphite and other materials provided by the upstream suppliers. Iron, rare earth and silicon are essential materials for electric motors [49]. IGBT (Insulated Gate Bipolar Transistor) as a critical high-tech part takes about 50% of the electronic control cost in China [50].

Fig. 7.

EV supply chain structure with key players.

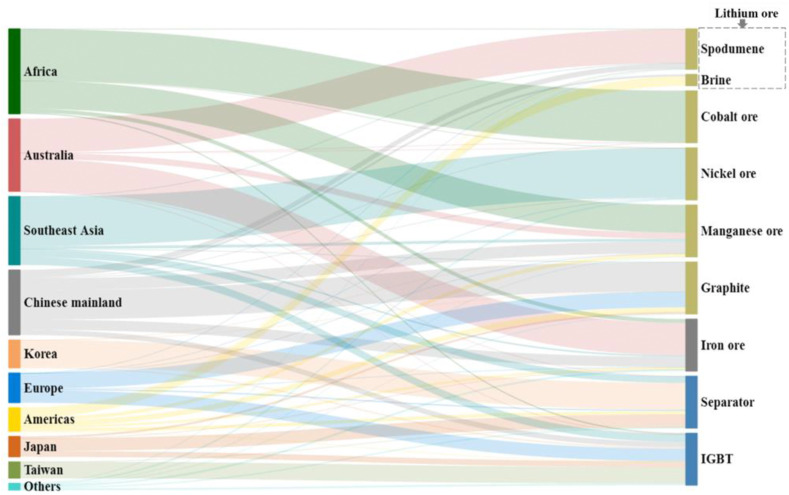

Power battery, electric motor and electric control are the three core components of EVs, whose suppliers play significant roles in the EV supply chain. With rapid development during the last decade, China has become one of the global leaders in lithium-ion battery production with 71 GWh power batteries produced in 2019, taking a share of 55.47% in the global market [51]. However, some of the key materials for power battery production were heavily relied on imports (as shown in Fig. 8 ), including over 80% battery-used lithium ores,1 over 95% cobalt ores, over 90% nickel ores, and about 75% manganese ores. Besides, the separators for power battery production (which have high-quality standards) were mainly imported from Korea and Japan. Similar to the power battery industry, China's electric motors could be supplied by domestic firms including both EV OEMs (e.g., BYD and BAIC) and motor makers (e.g., Founder Motor) [53]. The raw materials (such as rare earth and silicon) for electric motor production were almost domestic supplied, except that two thirds of the iron ores were imported from Australia. In the field of electronic control, Chinese firms could only supply half of the domestic needs mainly due to technical limitations, with over 90% of the IGBTs importing from Taiwan, Europe, Japan, and other trading areas.

Fig. 8.

Supply structure of key materials and parts for EV production in China (2019).

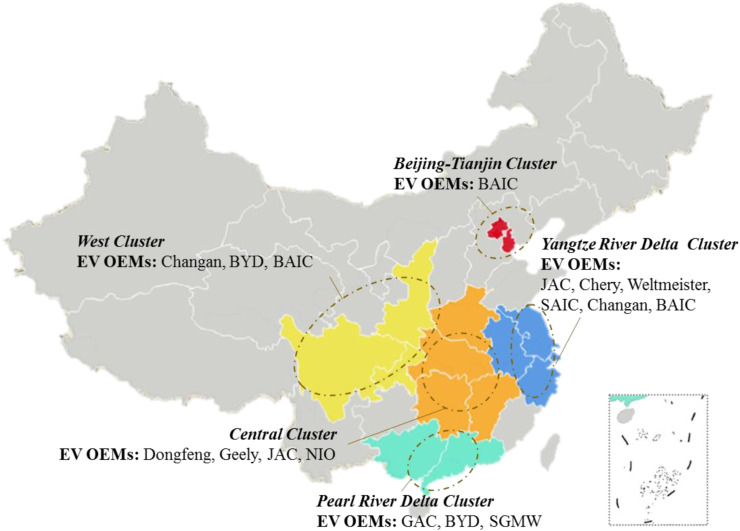

In line with the classification shown in Table 1, China's EV OEMs could be categorized into commercial EV makers and passenger EV makers. The commercial EV supply used to concentrate in domestic brands, with Yutong taking first in EV bus and Geely being top in special EV during 2019 [54]. On the contrary, China's passenger EV OEMs are diversified with traditional domestic brands (e.g., BYD, BAIC and SAIC), foreign brands (e.g., Tesla, BMW and Volkswagen), and emerging new brands (e.g., NIO, Weltmeister and Xiaopeng). According to the domestic sales data in 2019, BYD took the first position in both BEV and PHEV market, while the other traditional domestic brands mainly contributed to BEVs. Most of the foreign-funded brands have been focusing on China's PHEV market, except that Tesla performed well in China's BEV market ranking fourth by sales in 2019. The emerging new brands have been growing fast in recent years which contributed to about 10% of the passenger EV sales in 2019. Based on major EV OEMs, regional EV industrial clusters have gradually been formed as shown in Fig. 9 . Accompanied by the fast growth of EV industry, China's charging infrastructure has also developed rapidly in recent years, especially in the Yangtze River Delta, Pearl River Delta, and Beijing-Tianjin region [55].

Fig. 9.

EV industrial clusters in China.

3. Impacts of COVID-19 on China's EV markets

3.1. Impacts on total EV sales and consumer demands

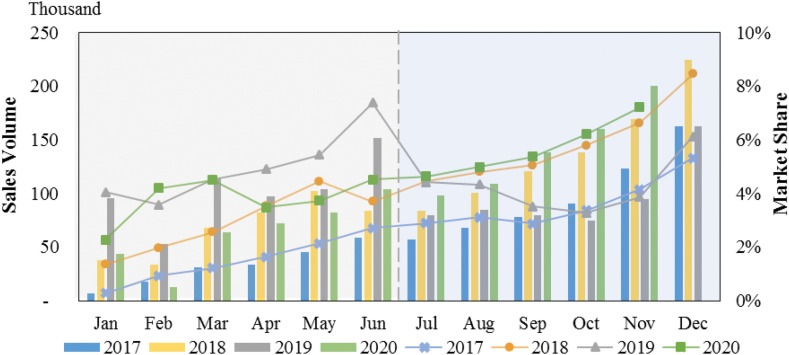

As the initial city with confirmed COVID-19 cases in China, Wuhan had been locked down from 23 January to April 8, 2020. Meanwhile, the whole country had implemented strict confinement policies that kept people at home and factories closed. During the lockdown period, China's economic activities were greatly disrupted. Inevitably, China's EV sales volume had decreased sharply during the first half of 2020 with a negative year-over-year growth rate of −40.26% [56]. According to the data from China Association of Automobile Manufacturers (CAAM), China's monthly EV sales in February 2020 reached the lowest point within the last four years (as shown in Fig. 10 ). Although starting to recover since March, China's EV market share dropped to below 4% in April and May, indicating a more adverse effect of COVID-19 on China's EV market than on the ICEV market. However, the Chinese government had reacted fast and put forward the “NEVs to Countryside” policy in July, which offers great incentives on small-sized EVs to the rural areas [57]. The policy has worked efficiently, pushing China's EV sales up to a record level in the second half of 2020.

Fig. 10.

Monthly EV sales and market shares in China (2017–2020).

A direct and short-term effect of COVID-19, especially during the lockdown period, is the decline of travel demands, which may consequently decrease consumer's willingness to buy cars. Furthermore, loss of confidence in economic development after the pandemic makes consumers more cautious in making purchasing decisions for expensive durable goods like cars [58]. According to a survey conducted by J.D. POWER, about 1/5 of the car purchasing plans had been cancelled due to the outbreak of COVID-19 and nearly half of the purchasing plans had been postponed [59]. On the contratry, risks of public transportation concerning pandemic infections may increase people's willingness to own a private car, stimulating future car sales to first-time car buyers [60]. However, China's urban car markets have been saturated in recent years, transforming from the “seller's market” to the “buyer's market” with diversified consumer preferences [61]. Enhancing EV sales will need to focus on either meeting new preferences or exploiting new markets. The “NEVs to Countryside” policy was timely to explore China's rural markets, which reactivating the post-pandemic EV sales.

Compared to the ICEV market, China's EV market has suffered more from the outbreak of COVID-19 in the first half of 2020 due to several reasons. Firstly, public utilizations have contributed to about 50% of China's historical EV sales but only 10% of ICEV sales [54]. To avoid infection risks, citizens tend to resist public transportations including buses, taxis and sharing cars which used to be major applications of EVs. Due to sharp decline of end-users in the secondary market (as shown in Fig. 11 ), the cumulative sales of passenger EVs for renting from January to April 2020 had decreased 71% compared to the same period in 2019 [62]. Secondly, low and mid-income consumers used to be the main buyers of private EVs in China, who are usually more sensitive to price fluctuations and income variations [63]. During the pandemic lockdown period, economic entities especially small and medium-sized enterprises (SMEs) had suffered great damages, causing widespread income collapse and unemployment [64]. Meanwhile, the slump of oil price caused by COVID-19 further reduced the competitive cost advantage of EVs to ICEVs. Thirdly, as a type of emerging new product that still exists some technological concerns such as range and charging anxieties, the EV market tend to be more vulnerable to external shocks. With deficient charging infrastructure, the refueling of EV is much inconvenient than that of ICEV [65], especially during the pandemic when private charging piles are more difficult to be approved and constructed. However, the situations have changed in the second half of 2020. With effective control of COVID-19, China's general economic activities as well as public transportation have gradually recovered, rising demand for sharing EVs. The implementation of the “NEVs to Countryside” policy targeting low-income consumers has successfully relieved the economic concerns of potential EV buyers. In addition, the “New Infrastructure” policy has started to work, which may relieve the charging concerns of potential EV buyers. These governmental efforts together lead to a recovery of EV sales in the second half of 2020.

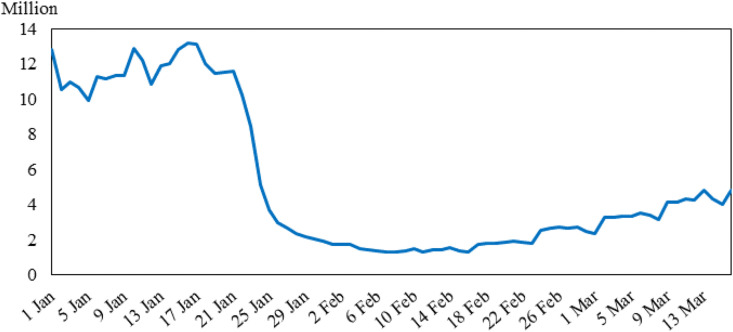

Fig. 11.

Number of active daily users of Didi (a major ride-hailing APP in China).

3.2. Impacts on categorized EV sales and consumer preferences

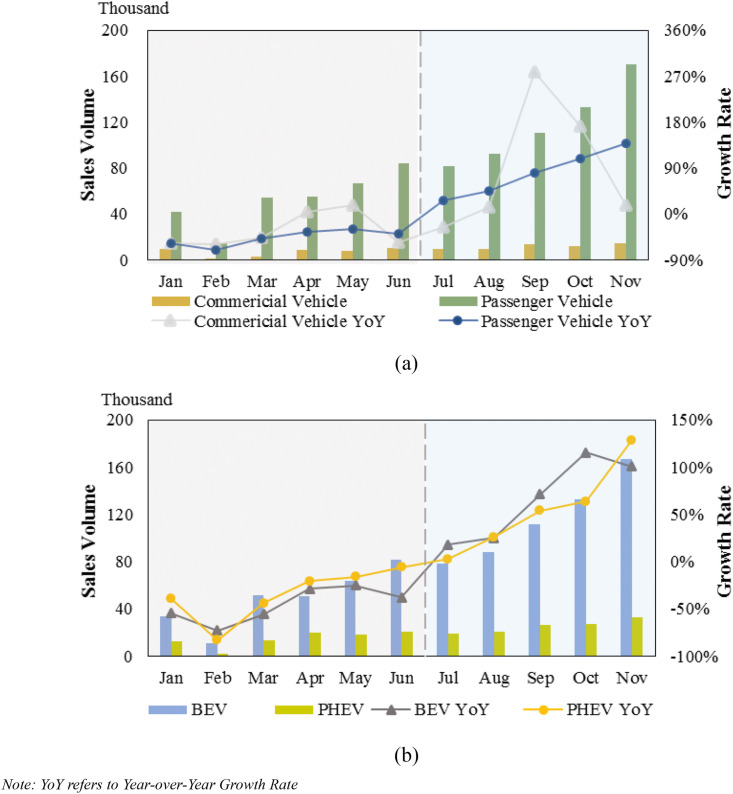

By taking a closer look at the segmented EV markets, more details of the COVID-19 impacts on China's EV sales and consumer preferences could be observed. As shown in Fig. 12 a, commercial EV sales volume was relatively small and stable after the pandemic. Although a negative growth rate has occurred in the first half of 2020 (mainly due to production interruptions and transaction limitations), the lossing sales have been made up during the second half of 2020 when the pandemic was under control in China. The underlying reasons may be attributed to China's official targets of EV utilization in commercial vehicles, which tend to keep the annual sales of commercial EV at stable level [66]. In the passenger EV segmentation, market sales had been hit much heavier, leading to negative monthly year-over-year growth rates below −30% from January to June 2020. However, stimulated by the “NEVs to Countryside” policy, China's monthly passenger EV sales has kept breaking historical levels during the second half of 2020.

Fig. 12.

Comparisons of segmented monthly EV sales in China.

Compared to BEV sales, PHEV sales dropped more dramatically but recovered faster, exceeding historical levels since June 2020 (as shown in Fig. 12b). According to the available EV models in Chinese market, PHEVs mainly concentrate in larger vehicles with longer driving distances and higher prices which usually possess better performance. The greater sales decline of PHEVs in February reflects consumer's cautiousness in making expensive purchasing decisions when facing the sudden hit of COVID-19. After the pandemic being controlled, consumers started to rethink their needs and turned to be willing to pay more for safer vehicles with larger inner-space and more functional appliances such as air purifiers, air circulation systems, and air quality monitors [59]. On the other hand, as the major buyers of BEV, low and mid-income citizens as well as car renting companies have suffered a much greater hit from the pandemic, until the implementation of the “NEVs to Countryside” policy since July. The growth in PHEV sales indicates the shift of consumer preference after COVID-19, while the growth in BEV sales reflects the effectiveness of the “NEVs to Countryside” policy. A further decomposition and comparison of passenger EV market shares as shown in Fig. 13 could depict the shift in consumer preference more clearly.

Fig. 13.

Comparisons of segmented passenger EV market shares in China.

As shown in Fig. 13a, the shares of mini passenger EVs within A00 and A0 classes had contracted greatly during the first half of 2020, while the shares of larger passenger EVs had expanded significantly (e.g., the sales volume of passenger BEVs within B class has increased 506% comparing to the same period in 2019). In addition to consumer's increasing desire for qualified private cars after the pandemic, the release of Tesla's Model 3 (BEV within B class) has attracted growing attention in China. Compared to most traditional domestic EV brands in China targeting the low-end market, reputable foreign brands (e.g., Tesla, BMW, Volkswagen) targeting the high-end market seem to have more solid customers when facing external shocks. The hit of COVID-19 had reallocated the market shares for different EV brands, contracting the passenger EV market share of traditional domestic brands from 81% in 2019 to be 46% in the first half of 2020 (as shown in Fig. 13b). However, the implementation of the “NEVs to Countryside” policy has motivated great sales of EVs within A00 and A0 classes which were made by domestic brands. The changes in segmented market shares further imply that the recovery of EV sales in the second half of 2020 was mainly driven by consumer's preference shift to high-end EVs after COVID-19 and the great incentives provided by the “NEVs to Countryside” policy.

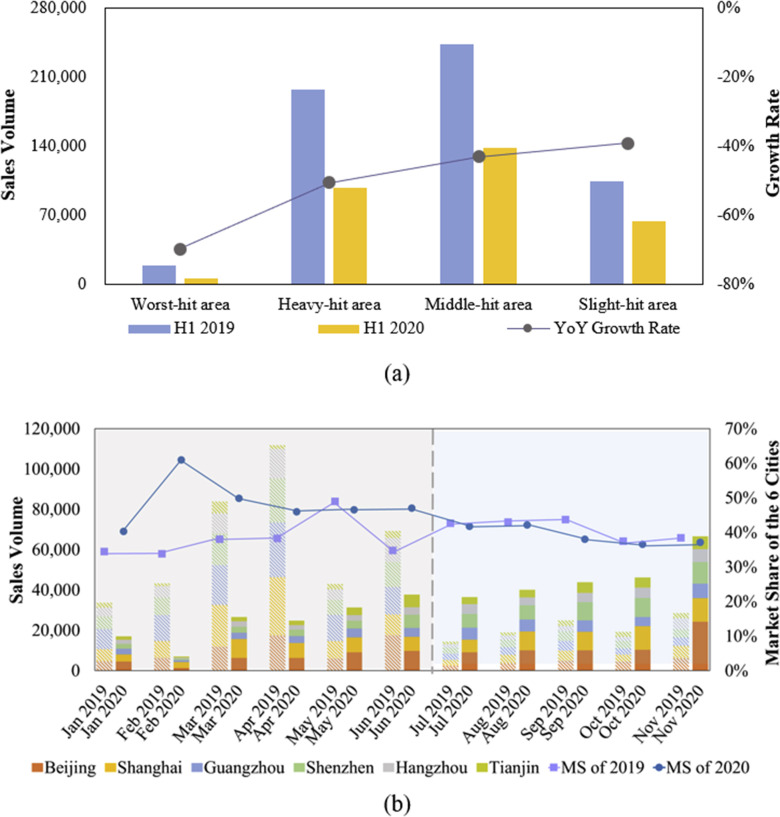

3.3. Impacts on regional EV sales and promoting strategies

Applying the K-means clustering method, the provincial administrative regions in China could be categorized into four clusters according to the numbers of their confirmed COVID-19 cases by the end of June 2020. Ranking by the clustering center, the four clusters could be categorized into the worst-hit area (68,135), heavy-hit area (1323), middle-hit area (795), and slight-hit area (185). Comparing passenger EV sales in the first half of 2020 to the historical data in 2019, the decrease rate of the worse-hit area is much greater than that of the slighter-hit area (as shown in Fig. 14 a), indicating a positive correlation between regional pandemic severity and passenger EV sales decline. In the worst-hit area (i.e., Hubei Province), passenger EV sales had dropped 70% while the corresponding decline rate in the slight-hit area was about 40%. It should be noted that the provincial EV sales structure in China did not change much by the pandemic. The EV sales during the first half of 2020 still concentrate in the eastern area, with Guangdong, Shanghai, Beijing, Zhejiang being the top four provincial administrative regions in EV sales. Meanwhile, Hainan as member of the slight-hit area had been the only province that achieved positive EV sales growth rate due to its great local governmental efforts in EV promotions.

Fig. 14.

Comparisons of regional passenger EV sales in China.

At the city level, the six cities with ICEV purchasing restrictions have been staying on the monthly lists of China's “Top 10 Cities” in passenger EV sales, together contributing to 46.3% of China's total passenger EV sales during the first half of 2020. As shown in Fig. 14b, the negative effects of COVID-19 on passenger EV sales had been relatively slighter in the six cities, while the other cities were more affected. When the strictest confinement policy was implemented in February 2020, 61% of China's passenger EV sales were concentrated in the six license-limited cities. With the relief of national confinement policies, the regional concentration ratio of EV sales has been gradually reducing, especially after the implementation of the “NEVs to Countryside” policy. The other cities that have relatively good performance on EV sales are those implementing either strict EV targets or high EV incentives. For instance, over 65% of the EV sales in Changchun and Changsha during the first half of 2020 were purchased by organizations with EV targets. Liuzhou, a city keeping to develop distinctive EV models and promotion policies suitable for the local market, have recovered soon from the COVID-19 strike. Such phenomenons suggest that China's EV market still relies heavily on governmental policies, either compulsory ones or incentive ones.

To help domestic EV market recover better, the Chinese central government and local governments have carried out a series of EV promoting strategies. In addition to nationwide EV purchasing subsidy extension, the applications of EVs in commercial and official usages have been further strengthened [66]. Meanwhile, the construction of charging piles for EVs has been officially listed in China's “New Infrastructure” plan with expectations to meet EV charging demands and consumer satisfactions. To make up the loss of sales in small-sized passenger EVs during the first half of 2020, the “NEVs to Countryside” policy has been issued, driving regional promotion activities in the rural areas [67]. Considering the characteristics of local demand, Beijing has issued 20,000 additional EV license quotas in the second half of 2020 [68]. Other EV promoting strategies with regional heterogeneities are also emerging across China, which may lead to diversified regional EV markets in the future.

4. Impacts of COVID-19 on China's EV supply chains

4.1. Impacts on EV component and material supplies

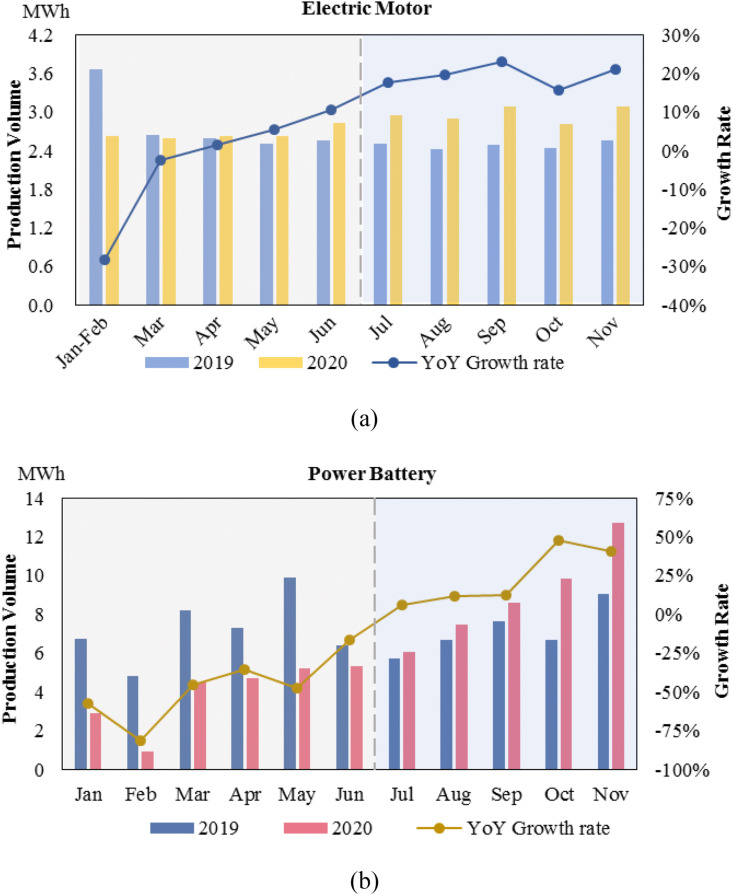

As China has been one of the world's manufacturing centers for automobile parts, most of the traditional vehicle components could be domestically supplied [44]. Although the production lines were disturbed in the severe-lockdown February, it is not necessarily leading to a supply shortage for the downstream firms due to similar production suspensions during the same period. After the relief of the lockdown, China's domestic production of traditional vehicle components including electric motor has recovered rapidly since March (as shown in Fig. 15 a). However, the production recovery of special EV components such as power battery seems to be lagged (as shown in Fig. 15b), not only because of the supply pressure from upstream raw materials (e.g., cobalt and nickel), but also due to the demand contraction in downstream markets caused by COVID-19. The capacity utilization ratios of most Chinese battery manufacturers (except CATL) had dropped to below 50% during the first half of 2020 [66,69]. Meanwhile, the market share of the top 10 brands in China's electronic control field had increased from 67.6% in 2019 to 73.8% in the first half of 2020, with Tesla ranking the first [50]. With groups of vulnerable SMEs facing bankruptcy, the outbreak of COVID-19 may accelerate the update and replacement of EV component suppliers, concentrating the market to leading enterprises.

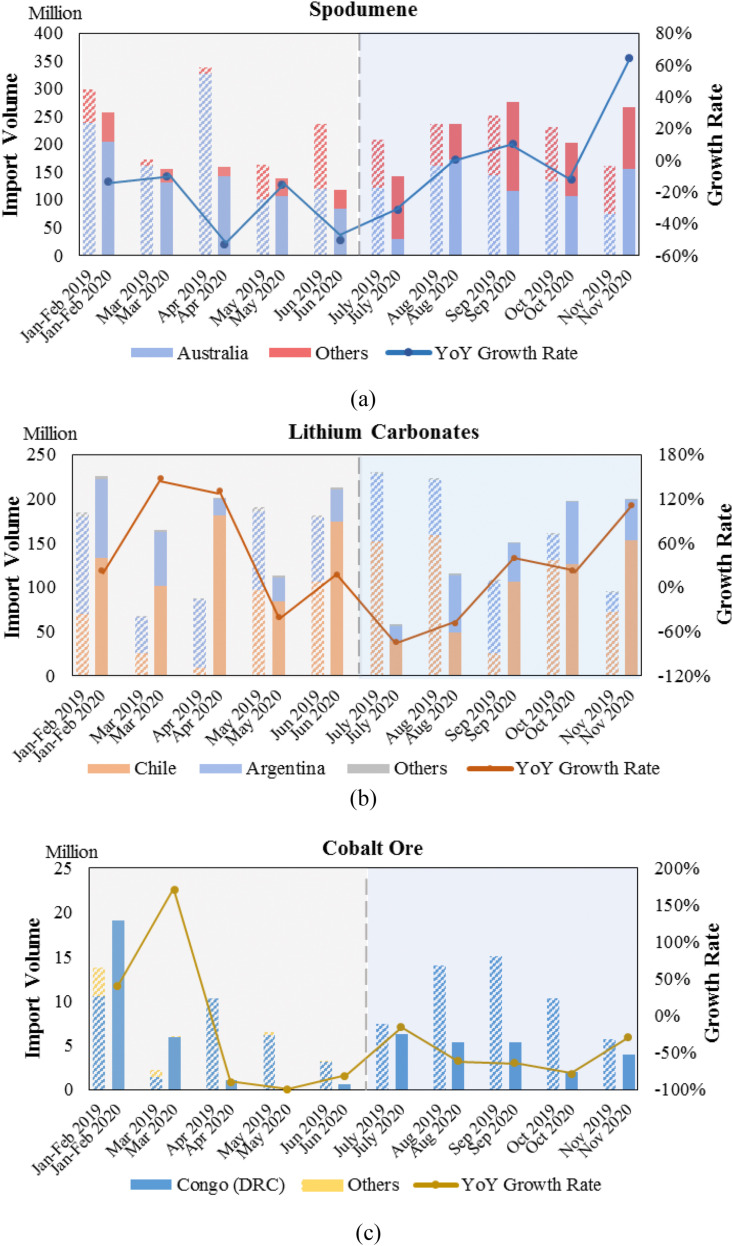

Fig. 15.

Comparisons of monthly electric motor and power battery production in China.

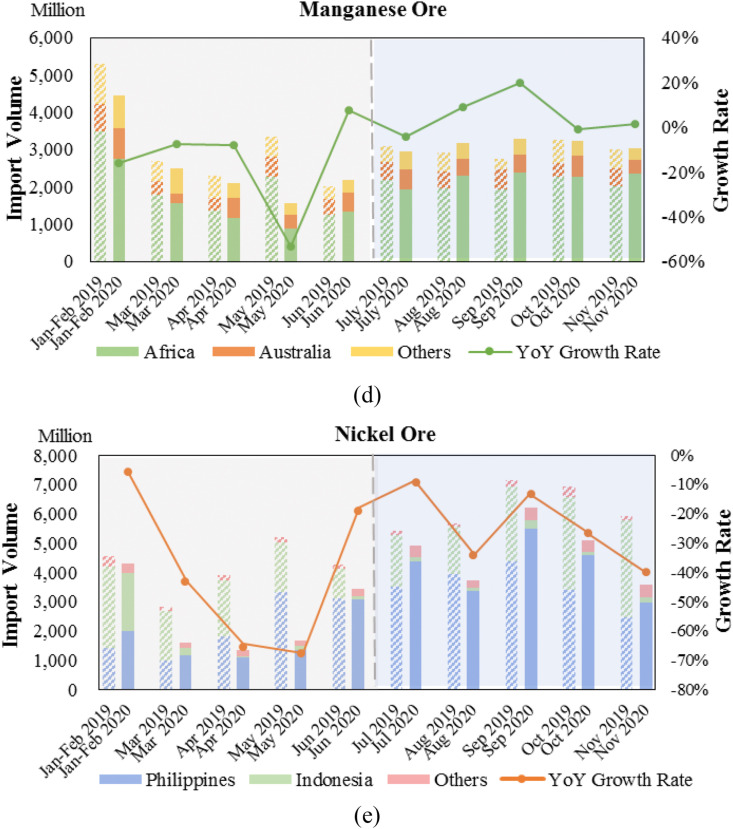

Lithium, cobalt, nickel, and manganese ores are the four types of key mineral resources for lithium-ion battery production that highly depending on imports in China. Due to the global outbreak of COVID-19, the supply of these four types of materials had encountered unprecedented challenges correlating to the epidemic situation in the origin countries [70]. The import volume of spodumene, for example, incurred sharp declines in April and June 2020 (as shown in Fig. 16 a) when the outbreak of COVID-19 was taking place in Australia (i.e., the major origin country of spodumene to China). Meanwhile, the decline of lithium carbonate (i.e., major constituent of brine) import to China was obvious in July 2020 (as shown in Fig. 16b), right after the outbreak of COVID-19 in Chile (i.e., the major origin country of brine to China). Nevertheless, China had not suffered the shortage of lithium supply due to the surplus inventory and timely replenishment from diverse sources [71]. Similarly, China's manganese ore import had been affected by the pandemic during the first half of 2020 (as shown in Fig. 16c), but not likely to result in a supply shortage. However, the supply of cobalt and nickel had been hit tremendously (as shown in Fig. 16d and e). The monthly import of cobalt ore has drastically decreased to near zero in May 2020, which was mainly attributed to the export restrictions in Congo (DRC) and the port closures in South Africa during April. Although starting to recover in July, the supply of cobalt was still below average during the second half of 2020. Meanwhile, the outbreak of COVID-19 in Southeast Asia had led to continuous falls in China's monthly nickel import, with a year-over-year decrease rate of 68% in May. With stricter nickel export restrictions in Indonesia, Philippines had become the major nickel ore supplier of China during the second half of 2020. Threatened by the potential shortage of cobalt and nickel, EV producers including BYD and Tesla have been trying to develop cobalt-free and nickel-free batteries [72].

Fig. 16.

Comparisons of monthly lithium, cobalt, nickel, and manganese ore imports to China.

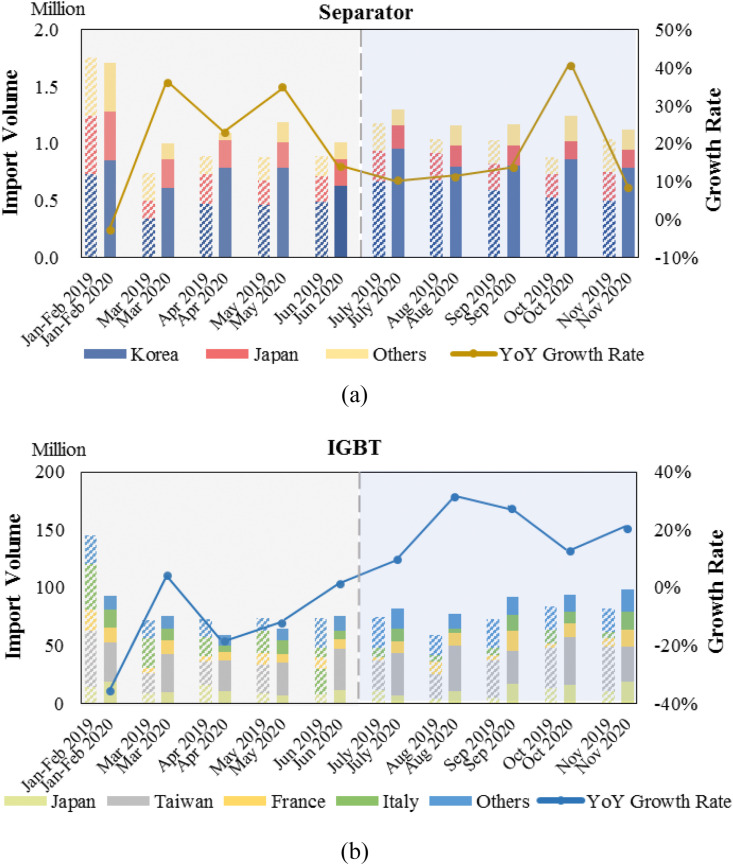

In addition to the mineral resources, Chinese firms also have high reliance on the import of high value-added separators and IGBTs for EV production. Fortunately, the import of separators to China has not been negatively affected by COVID-19 (as shown in Fig. 17 a), which may be attributed to the effective control of infections in Western Pacific areas and relatively short traveling distances from the major origin countries (i.e., Korea and Japan) to China. Meanwhile, the monthly decreasing rates of IGBT import were within tolerable level (e.g., 10%). However, the potential risk of supply interruption brought by COVID-19 is likely to stimulate the domestic R&D for high-end separators and IGBTs in China. The pressure from COVID-19 may help to accelerate technological improvement through the EV supply chain in China.

Fig. 17.

Comparisons of monthly separator and IGBT imports to China.

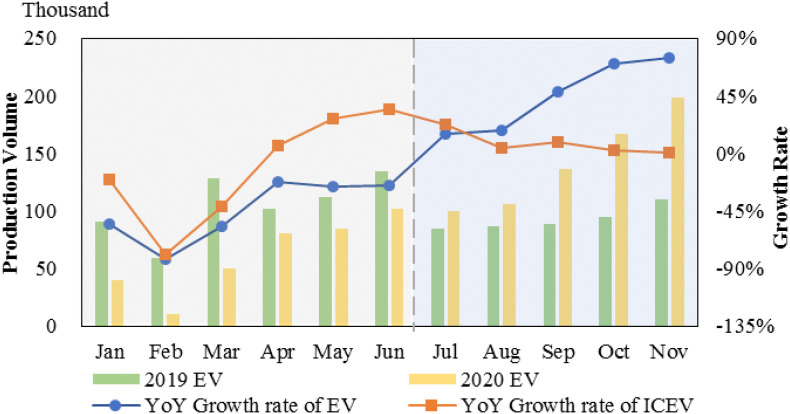

4.2. Impacts on EV productions

According to the production data released by CAAM, both China's ICEV production and EV production suffered great collapse in February when strict lockdown policy was put into effect (as shown in Fig. 18 ). However, the production of ICEV had recovered much faster reaching historical levels since April, while the monthly growth rate of EV production in China had stayed negative during the first half of 2020. The underlying reasons may be consistent with previous evidences that the supply of certain special EV material and component was worse interrupted than the traditional vehicle parts and that the downstream EV market was more affected by the pandemic than ICEV. Interestingly, the growth rate of EV production has been far higher than ICEV in the second half of 2020, which may be mainly driven by the downstream market explosion arising from the “NEVs to Countryside” policy.

Fig. 18.

Comparisons of monthly EV production in China.

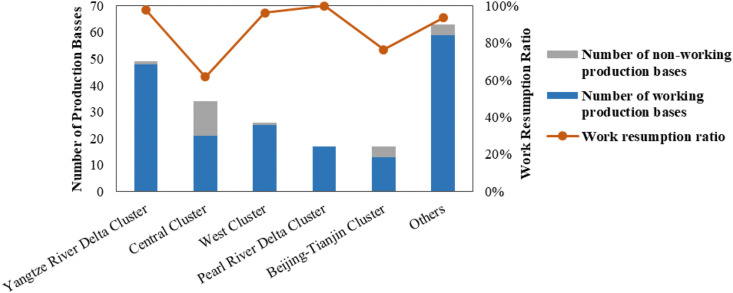

A major reason for the production decline of automobiles during the first half of 2020 is the confinement policy for controlling COVID-19. With labor-intensive characteristics, China's automobile industry has been greatly dependent on work force. According to a survey conducted by CAAM [73], the work resumption rate of China's automobile OEMs had gradually increased to 90% on March 11, 2020 with about 77% employees back to work. However, some of the EV industrial clusters (especially the Central Cluster and the Beijing-Tianjin Cluster) had suffered more than other regions (as shown in Fig. 19 ). As the main production base for Dongfeng, Hubei Province was once the worst-hit area of COVID-19 in China. Meanwhile, the other provinces (e.g., Henan and Hunan) bordering Hubei had also been greatly affected by the pandemic, together resulting in huge damage to the EV production in the Central Cluster. In addition, the strict control in Beijing and Tianjin may also lead to a lag in EV production recovery in the Bejing-Tianjin Cluster. The greater hit of COVID-19 on major EV industrial clusters may add to the explanation of why China's EV production recovery had been slower than the ICEV industry. Generally, the industrial cluster of EV production could create cost advantages through scale effects, while it may also increase potential vulnerabilities to regional black-swan events.

Fig. 19.

Regional automobile OEMs' work resumption rates in China on March 11, 2020.

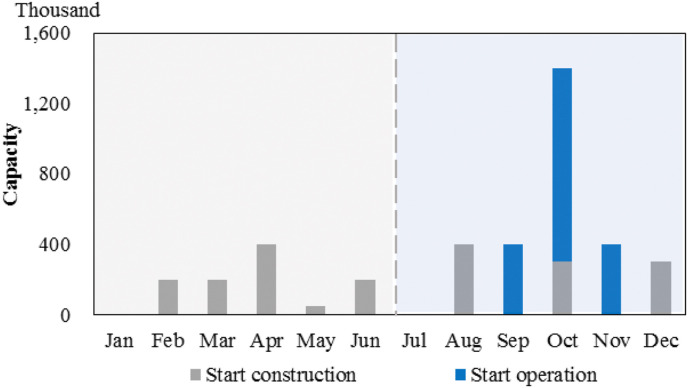

Due to the previous low entry barrier of EV production and supportive governmental policies in China, a large number of SMEs have entered into the EV industry, which tend to be more vulnerable to external strikes. Some of the SMEs (e.g., BYTON and BORDRIN) did not survive through the hit of COVID-19, abandoning production and quitting China's EV market in 2020 [74]. On the other hand, the leading companies such as BYD and SGMW had temporarily converted their production lines to produce facial masks in support of the national epidemic control [75]. Nevertheless, new EV factory construction plans had been scheduled through the year 2020, adding over 2 million potential capacities to China (as shown in Fig. 20 ). Affected by COVID-19, none of the new established EV factories had been put into operation during the first three quarters of 2020, while near 2 million production capacity had been initiated in the last quarter of 2020 due to the demand explosion after July [76]. However, a bundle of overseas plans for new EV factory establishment had been cancelled. Great Wall, SAIC and Haima had delayed their new projects in India because of the depressed local EV market caused by COVID-19. The pandemic had hold Chinese EV OEMs back from the overseas market, being more focused on the domestic market.

Fig. 20.

China's new added and planned capacities for EV production during 2020.

4.3. Impacts on EV distributions

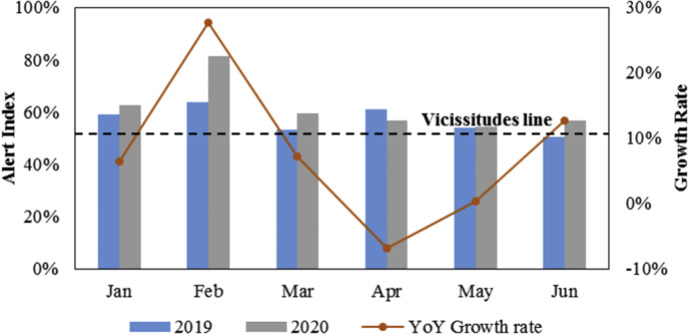

Traditionally, automobiles have been sold through dealers with physical stores and offline distribution channels. Most of the traditional EV brands in China have been using such face-to-face selling modes, which had met great challenges during the outbreak of COVID-19. Due to social distancing policies, auto shows had been cancelled and auto stores had been closed, sharply reducing EV access to new customers. According to the Vehicle Inventory Alert Index (VIAI) released by China Automobile Dealers Association (CADA), the monthly VIAI for China's automobile dealers had been above the vicissitudes line during the first half of 2020 [77], especially in the dark February (as shown in Fig. 21 ). In particular, the average VIAI was the highest in the northern part of China where the epidemic had repeated within small ranges. A high VIAI above the vicissitudes line implies great pressures on the automobile dealers' inventory and financial capacities, which may transmit along the supply chains to the upper stream EV OEMs.

Fig. 21.

Comparisons of monthly vehicle inventory alert index for China's automobile dealers.

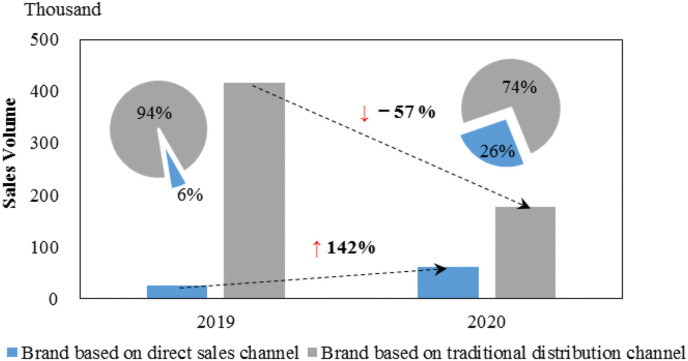

Driven by the surge of online selling, some EV OEMs have tried to develop direct selling channels to consumers with online platforms, mainly represented by Tesla and emerging new brands in China (e.g., NIO and Xiaopeng). Taking Tesla as an example, consumers who are interested in Tesla models can access the detailed technical descriptions and usage instructions of the EV products through official websites or mobile platforms [78]. If further driving experience is desired, consumers are able to reserve test drives in the experiencing centers. Orders are made online and the purchased EV products are delivered directly from OEMs to customers. Even after-sales services could be provided through online platforms. With less interpersonal contact, the online direct selling channels had been less affected by COVID-19. Meanwhile, the reduced inventory and labor costs associated with shortened supply chains could alleviate the financial burden on EV OEMs. Comparing to the last year, the traditional EV brands with dealer channels in China had suffered a total decline of 57% in EV sales during the first half of 2020, while the emerging new brands with direct selling channels had made an increase of 142% in EV sales (as shown in Fig. 22 ). As a result, Tesla, NIO, and Xiaopeng had been frequently named on the list of top 10 brands for monthly EV sales during 2020.

Fig. 22.

Comparisons of EV sales for brands with different distribution channels in China.

Facing the continuous social distancing trend and consumer's unwillingness to shop in crowds, more and more EV OEMs are trying to develop online business models and contactless selling channels. On May 17, 2020, Chinese EV producer NIO hosted a livestream event lasting about 40 min on the e-commerce platform of Taobao, which had attracted more than 20 million views and raked in a total of 320 orders totaling 18 million dollars [79]. In addition, the development of new technologies such as Virture Reality (VR) is creating growing opportunities for online exhibitions and other business model innovations. However, not all EV brands could achieve good performance through livestream or other online promotions, mainly due to immature online selling systems and unprofessional online platforms specialized in EV sales.

5. Discussions and future outlooks

5.1. Challenges and opportunities brought by COVID-19 to China's EV industry

Through the above analysis, negative as well as potential positive impacts of COVID-19 have been revealed, indicating both challenges and opportunities to China's EV industry. From the demand side, it is found that the outbreak of COVID-19 has reduced EV sales sharply in the short term mainly due to travel restrictions and income contractions (Section 3.1). However, the emerging concerns of infection risks associated with public transportation have also driven personal willingness for buying private cars. In addition, Chinese car buyers have shown a preference transition from small EVs (within A00 and A0 classes) to larger EVs (within A, B, and C classes) which seems to be more secure and reliable to get through external risks after the pandemic (Section 3.2). Such transition in consumer preference has put great pressure into Chinese traditional EV OEMs who used to target the low-end market, but brought opportunities to the foreign-funded brands and emerging domestic new brands focusing on the high-end market. Regionally, the decline of EV sales has been positively related to the pandemic severity of COVID-19 according to China's data during the first half of 2020, while the cities with vehicle license limitations have been less affected (Section 3.3). In the second half of 2020, great actions have been taken by the Chinese government to get rid of the negative impacts of COVID-19 on the domestic EV market. With the “NEVs to Countryside” policy reactivating the low-end market and consumer's growing attention in the high-end market after COVID-19, China's EV sales have made unprecedented progress during the second half of 2020. Supporting by sustaining governmental policies including additional EV license quotas, extended EV subsidies, consistent official EV targets, and improving charging infrastructures, China's EV market may continue to expand till an ambitious level.

From the supply side, it is found that some of the upstream mineral materials (e.g., lithium, cobalt, nickel, and manganese ores) and high value-added components (e.g., separators and IGBTs) that highly relying on imports have been interrupted by the global outbreak of COVID-19 to varying degrees positive correlated to the pandemic severity in the origin countries (Section 4.1). Although the interruptions are not likely to cause supply shortages for China's EV production in a short time, the potential risks aroused by COVID-19 have driven Chinese producers to develop substitutes for non-domestic materials and to improve technologies for high-end component production. Meanwhile, the production of EV OEMs have been inevitably disrupted due to the lockdown policy for preventing pandemic diffusion, especially in the badly-hit areas (e.g., the Central Cluster and the Beijing-Tianjin Cluster for EV production) with the strictest confinement policies for the longest time (Section 4.2). The suspension of daily operation has caused capital pressure and even financial crisis to SMEs, expelling them out of China's EV market. In addition, the global pandemic has stopped Chinese firms from building factories overseas, pushing them back to the fierce competition of domestic market. Moreover, the distancing society after the COVID-19 outbreak has brought great challenges to traditional EV dealers who have been used to applying face-to-face promotions with physical stores (Section 4.3). On the other hand, brands with innovative online selling channels (e.g., Tesla and NIO) tend to benefit from the post-pandemic marketing trend. In conclusion, although the COVID-19 outbreak has made non-negligible negative impacts on China's EV industry during the early stage, it may also provide opportunities for reshaping a more advanced and robust EV industrial chain in China, leading to a prosperous EV future.

5.2. Emerging trends of China's EV industry

With effective control of COVID-19 and timely policy support to the EV market, China's EV industry has recovered fast. Facing the challenges and opportunities brought by COVID-19, several emerging trends tend to arise in China's EV industry.

-

●

On the demand side, official customers will continue to play significant roles in EV adoption and diffusion, while the part of car rental companies tends to shrink due to consumer's aversion towards public transportation in the secondary market. Meanwhile, private car buyers are playing growing part in the EV market, with diversifying preferences and market segmentations.

-

●

On the supply side, EV OEMs tend to pay more attention to large car models, developing differentiated products targeting different consumer groups. Particularly, inner-car air purifiers, air circulation systems and air quality monitors are earning growing attentions after the pandemic. In addition, direct selling and online selling models would be further developed and applied, potentially forming integrated online EV trading platforms. At the upstream level, the development of cobalt-free and nickel-free power batteries as well as battery recycling techniques will be accelerated for coping with potential material shortages.

-

●

From an integral perspective of China's EV industry, the increasing competition caused by the economic effects of COVID-19 and the entrance of reputable foreign brands are driving domestic SMEs out of the market, concentrating China's EV OEMs as well as the upstream component producers to the leading brands. In the long term, domestic EV component R&D and material exploitations will be strengthened for constructing a more reliable and flexible EV supply chain in China.

-

●

From the perspective of Chinese governmental policy, diversified market incentives will last in recent years for stimulating various terminal demands in different regions (e.g., target for official EV utilization ratio, promotion for low-end EVs in rural areas, increasing quota for EVs in cities with vehicle purchasing restrictions). In addition, great effort has been putting into the construction of EV charging facilities as well as the establishment of reliable EV supply chains.

5.3. Implications for global EV development and future outlooks

Globally, regional EV markets have been affected by COVID-19 to different extents. Take Europe as an example, the pandemic had been under control during the first half of 2020 (as shown in Fig. 2). With continuous implementation of ambitious EV targets, the European EV market had been hit less than the ICEV market, remaining positive growth rates in EV sales, which led to a larger EV market share of 7.8% during the first half of 2020 compared to 3.6% in 2019 [80]. However, a more fierce second wave of pandemic hit Europe again in the second half of 2020, imposing great pressures on the EV development in Europe. Based on Chinese experience, European countries may try to control the pandemic with stricter quarantine policies and further promote EV adoptions by differentiated positioning in detailed market segments. On the other hand, the EV industry in the United States has been hit heavily by COVID-19 with intensifying infections. The pandemic has brought challenges to basic vehicle part supplies in the US that depend on imports, and created difficulties for core part exports to overseas factories in the meantime. For instance, Tesla's Shanghai factory had to stop production in the second quarter of 2020 due to the supply shortage of core components. In the post-pandemic period, reallocation of global supply chains might need to be considered by the US enterprises such as Tesla for improving flexibilities. For those emerging EV markets, the hit of COVID-19 is likely to suspend their EV promotions in the short term, but also provide a window phase for their regulators to make better plans by learning from the experience of frontrunner markets. Looking into 2020, although the COVID-19 outbreak has encumbered EV industry development, the strengthening EV promoting policies in key markets (i.e., China and Europe) tend to keep global EV market share over the 2019 level. From a long-term perspective, the electrification trend of mobility is irreversible, which will be accompanied by improving technologies and diversifying demands.

6. Concluding remarks

As the most widespread global pandemic in the past century, COVID-19 has caused irreversible impacts on human society and the economic system, with no exception for the EV industry. China, among one of the earliest regions affected by COVID-19 and takes a great part in the global EV market, is attracting global attention on how China's EV industry cope with this difficult period. This paper provides a comprehensive analysis of COVID-19 impacts on China's EV industry from the demand side to the supply side based on collected data from the industry. Through the study, post-pandemic challenges and opportunities, as well as emerging trends in China's EV industry are revealed. In addition, the possible implications for global EV development and future outlooks are discussed.

Several main findings of the study are highlighted as follows. i) COVID-19 outbreak has reduced EV sales in the short-term, but may also stimulate future EV demands especially for large passenger EV models with better performance. ii) Travel restrictions driven by COVID-19 have interrupted EV material supplies that relying on imports, accelerating domestic substitutes exploitation and inventory improvement for critical EV parts. (iii) Massive lockdowns for controlling COVID-19 have disrupted EV productions and operations, which tends to expel SMEs out of the competitive EV market, concentrating China's EV industry to the leading brands. (iv) The distancing trend in post-pandemic period is bringing great challenges to traditional EV distribution channels with dealers, pushing EV OEMs to develop innovative online selling channels. The above impacts caused by COVID-19 together lead to a reformation of China's EV industry towards a more advanced and reliable future.

Generally, this paper provides a timely overview of the COVID-19 impacts on the frontrunner EV market and proposes possible implications for the countermeasures. The existing data, however, is limited, revealing that further trends of EV development in different regions after the COVID-19 outbreak remain to be observed. In addition, more in-depth studies should be carried out in the future for digging how the COVID-19 affects the EV industry. Nevertheless, the global mobility electrification trend is affirmative, which keeps giving rise to new problems faced by the expanding EV industry and calls for continuous studies in the academic field.

Credit author statement

Wen, W.: Conceptualization, Methodology, Software, Formal analysis, Data curation, Writing – original draft preparation, Project administration. Yang, S.: Software, Formal analysis, Data curation, Writing – original draft preparation. Zhou, P.: Conceptualization, Supervision, Funding acquisition, Writing – review & editing, Project administration. Gao, S.Z.: Data curation, Formal analysis, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

The authors are grateful for the financial support provided by the National Natural Science Foundation of China (Nos. 71934007, 71625005, and 72004228).

Footnotes

Battery-used lithium ores here refer to spodumene and brine, which have been applied in battery production for extracting lithium. Lithium could also be extracted from other lithium ores such as lepidolite, but they have not been widely used in battery production yet [52].

Appendix A. Data Explanations

Table A.1.

The HS Codes used for searching import data

| Name | HS Code |

|---|---|

| Spodumene * | 25309099 |

| Brine * | 283691, 282520 |

| Cobalt ore | 26050000 |

| Nickel ore | 26040000 |

| Manganese ore | 26020000 |

| Graphite | 27131210 |

| Iron ore | 26011110 |

| Separator | 39201010 |

| IGBT | 85413000 |

*Note: The HS codes of spodumene and brine refer to the following report: LaRocca, G. M. Global value chains: Lithium in lithium-ion batteries for electric vehicles. U.S. International Trade Commission, 2020.

Table A.2.

The source of data used in this article and corresponding figures

| Data | Source | Website | Corresponding Figures |

|---|---|---|---|

| Data of global EV sales | EV Volumes | https://www.ev-volumes.com/ | Fig. 1 |

| Data of global COVID-19 cases | WHO | https://covid19.who.int/ | Fig. 2 |

| Data of EV sales in China | CPCA | http://www.cpcaauto.com/ | Figs. 5, Fig. 12, Fig. 13, Fig. 22 |

| Data of regional EV sales in China | SOUCHE | https://zhiyun.souche.com/welcome | Figs. 6 and 14 |

| Data of material imports to China | GACC | http://43.248.49.97/ | Figs. 8, Fig. 16, Fig. 17 |

| Data of China's domestic EV material production | SMM | https://www.smm.cn/ | Fig. 8 |

| Data of China's domestic EV part production | GGII | http://www.gg-ii.com/ | Fig. 8 |

| Data of vehicle production and sales in China | CAAM | http://www.caam.org.cn/ | Figs. 10 and 18 |

| Data of active daily users of Didi | Iimerdia | https://data.iimedia.cn/page-category.jsp?nodeid=30408635/ | Fig. 11 |

| Data of electric motor production in China | NBRC | https://data.stats.gov.cn/easyquery.htm?cn=A01 | Fig. 15a |

| Data of power battery production in China | CAEV | http://www.caev.org.cn/ | Fig. 15b |

| Data of work resumption rates for automakers | CAAM | http://autoreview.com.cn/show_article-5800.html | Fig. 19 |

| Data of China's new added and planned EV capacities | Gasgoo | https://auto.gasgoo.com/ | Fig. 20 |

| Data of VIAI for China's automobile dealers | CADA | http://data.cada.cn/main/stock.do | Fig. 21 |

References

- 1.Chu S., Majumdar A. Opportunities and challenges for a sustainable energy future. Nature. 2012;488:294–303. doi: 10.1038/nature11475. [DOI] [PubMed] [Google Scholar]

- 2.Gnann T., Stephens T.S., Lin Z.H., Plötz P., Liu C.Z., Brokate J. What drives the market for plug-in electric vehicles? - a review of international PEV market diffusion models. Renew Sustain Energy Rev. 2018;93:158–164. [Google Scholar]

- 3.International Energy Agency . 2020. Global EV outlook 2020.https://www.iea.org/reports/global-ev-outlook-2020 [Google Scholar]

- 4.EV-volumes . 2020. Global BEV & PHEV sales for 2019.http://www.ev-volumes.com/news/global-bev-phev-sales-for-2019/ [Google Scholar]

- 5.Sheldon T.L., Dua R. Effectiveness of China's plug-in electric vehicle subsidy. Energy Econ. 2020;88:104773. [Google Scholar]

- 6.Sohrabi C., Alsafi Z., O'Neill N., Khan M., Kerwan A., Al-Jabir A., et al. World Health Organization declares global emergency: a review of the 2019 novel coronavirus (COVID-19) Int J Surg. 2020;76:71–76. doi: 10.1016/j.ijsu.2020.02.034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.World Health Organization . 2021. WHO coronavirus disease (COVID-19) dashboard.https://covid19.who.int/ [PubMed] [Google Scholar]

- 8.Chakraborty I., Maity P. COVID-19 outbreak: migration, effects on society, global environment and prevention. Sci Total Environ. 2020;728:138882. doi: 10.1016/j.scitotenv.2020.138882. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.International Labour Organization . second ed. 2020. ILO Monitor: COVID-19 and the world of work.https://www.ilo.org/global/about-the-ilo/WCMS_740877/lang--it/index.htm [Google Scholar]

- 10.United Nations Industrial Development Organization . 2020. Coronavirus: the economic impact – 10 July 2020.https://www.unido.org/stories/coronavirus-economic-impact-10-july-2020 [Google Scholar]

- 11.International Civil Aviation Organization . 2020. Economic impact analysis of COVID-19 on aviation.https://www.icao.int/sustainability/Pages/Economic-Impacts-of-COVID-19.aspx [Google Scholar]

- 12.Ivanov D. Viable supply chain model: integrating agility, resilience and sustainability perspectives—lessons from and thinking beyond the COVID-19 pandemic. Ann Oper Res. 2020 doi: 10.1007/s10479-020-03640-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.McKee M., Stuckler D. If the world fails to protect the economy, COVID-19 will damage health not just now but also in the future. Nat Med. 2020;26:640–642. doi: 10.1038/s41591-020-0863-y. [DOI] [PubMed] [Google Scholar]

- 14.Klemeš J.J., Van Fan Y., Tan R.R., Jiang P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew Sustain Energy Rev. 2020;127:109883. doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Graff M., Carley S. COVID-19 assistance needs to target energy insecurity. Nat Energy. 2020;5:352–354. [Google Scholar]

- 16.Le Quéré C., Jackson R.B., Jones M.W., Smith A.J.P., Abernethy S., Andrew R.M., et al. Temporary reduction in daily global CO2 emissions during the COVID-19 forced confinement. Nat Clim Change. 2020;10:647–653. [Google Scholar]

- 17.Guan D.B., Wang D.P., Hallegatte S., Davis S.J., Huo J.W., Li S.P., et al. Global supply-chain effects of COVID-19 control measures. Nat Hum Behav. 2020;4:577–587. doi: 10.1038/s41562-020-0896-8. [DOI] [PubMed] [Google Scholar]

- 18.Kanda W., Kivimaa P. What opportunities could the COVID-19 outbreak offer for sustainability transitions research on electricity and mobility? Energy Res Soc Sci. 2020;68:101666. doi: 10.1016/j.erss.2020.101666. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Crabtree G. The coming electric vehicle transformation. Science. 2019;366:422–424. doi: 10.1126/science.aax0704. [DOI] [PubMed] [Google Scholar]

- 20.Kupferschmidt K., Cohen J. Can China's COVID-19 strategy work elsewhere? Science. 2020;367:1061–1062. doi: 10.1126/science.367.6482.1061. [DOI] [PubMed] [Google Scholar]

- 21.Zhang X.P., Liang Y.L., Yu E.H., Rao R., Xie J. Review of electric vehicle policies in China: content summary and effect analysis. Renew Sustain Energy Rev. 2017;70:698–714. [Google Scholar]

- 22.Helveston J.P., Wang Y.M., Karplus V.J., Fuchs E.R.H. Institutional complementarities: the origins of experimentation in China's plug-in electric vehicle industry. Res Pol. 2019;48:206–222. [Google Scholar]

- 23.Zheng J., Mehndiratta S., Guo J.Y., Liu Z. Strategic policies and demonstration program of electric vehicle in China. Transport Pol. 2012;19:17–25. [Google Scholar]

- 24.Yuan X.L., Liu X., Zuo J. The development of new energy vehicles for a sustainable future: a review. Renew Sustain Energy Rev. 2015;42:298–305. [Google Scholar]

- 25.Qiu Y.Q., Zhou P., Sun H.C. Assessing the effectiveness of city-level electric vehicle policies in China. Energy Pol. 2019;130:22–31. [Google Scholar]

- 26.Zhang X., Bai X. Incentive policies from 2006 to 2016 and new energy vehicle adoption in 2010–2020 in China. Renew Sustain Energy Rev. 2017;70:24–43. [Google Scholar]

- 27.Du J.Y., Ouyang M.G., Chen J.F. Prospects for Chinese electric vehicle technologies in 2016–2020: ambition and rationality. Energy. 2017;120:584–596. [Google Scholar]

- 28.Li W.B., Long R.Y., Chen H. Consumers' evaluation of national new energy vehicle policy in China: an analysis based on a four paradigm model. Energy Pol. 2016;99:33–41. [Google Scholar]

- 29.Du J.Y., Ouyang D.H. Progress of Chinese electric vehicles industrialization in 2015: a review. Appl Energy. 2017;188:529–546. [Google Scholar]

- 30.National Energy Administration of China . 2013. New energy vehicles have been promoted to 27400 units.http://www.nea.gov.cn/2013-01/07/c_132085761.htm [Chinese] [Google Scholar]

- 31.Wang Y.S., Sperling D., Tal G., Fang H.F. China's electric car surge. Energy Pol. 2017;102:486–490. [Google Scholar]

- 32.Qiao Q.Y., Zhao F.Q., Liu Z.W., He X., Hao H. Life cycle greenhouse gas emissions of electric vehicles in China: combining the vehicle cycle and fuel cycle. Energy. 2019;177:222–233. [Google Scholar]

- 33.Wang N., Tang L.H., Pan H.Z. Effectiveness of policy incentives on electric vehicle acceptance in China: a discrete choice analysis. Transp Res Part A Policy Pract. 2017;105:210–218. [Google Scholar]

- 34.Ou S.Q., Lin Z.H., Qi L., Li J., He X., Przesmitzki S. The dual-credit policy: quantifying the policy impact on plug-in electric vehicle sales and industry profits in China. Energy Pol. 2018;121:597–610. [Google Scholar]

- 35.Dong F., Liu Y. Policy evolution and effect evaluation of new-energy vehicle industry in China. Resour Pol. 2020;67:101655. [Google Scholar]

- 36.State Council of China . 2020. Notice on improving financial subsidies for new energy vehicle applications.http://www.gov.cn/zhengce/zhengceku/2020-04/23/content_5505502.htm [Chinese] [Google Scholar]

- 37.Knez M., Zevnik G.K., Obrecht M. A review of available chargers for electric vehicles: United States of America, European Union, and Asia. Renew Sustain Energy Rev. 2019;109:284–293. [Google Scholar]

- 38.Shen Z.J.M., Feng B., Mao C., Ran L. Optimization models for electric vehicle service operations: a literature review. Transp Res Part B Methodol. 2019;128:462–477. [Google Scholar]

- 39.Wang N., Pan H.Z., Zheng W.H. Assessment of the incentives on electric vehicle promotion in China. Transp Res Part A Policy Pract. 2017;101:177–189. [Google Scholar]

- 40.China Association of Automobile Manufacturers . 2020. Performance of China's automobile industry in 2019.http://www.caam.org.cn/chn/1/cate_3/con_5228367.html [Chinese] [Google Scholar]

- 41.China Association of Automobile Manufacturers . 2018. 2019. Performance of China's automobile industry in.http://www.caam.org.cn/chn/3/cate_16/con_5221202.html [Chinese] [Google Scholar]

- 42.Evergrande Research Institute . 2019. China's new energy vehicle development report: 2019.http://pdf.dfcfw.com/pdf/H3_AP201909231365565692_1.pdf [Chinese] [Google Scholar]

- 43.Du J.Y., Meng X.F., Li J.Q., Wu X.G., Song Z.Y., Ouyang M.G. Insights into the characteristics of technologies and industrialization for plug-in electric cars in China. Energy. 2018;164:910–924. [Google Scholar]

- 44.SOUCHE . 2019. China's new energy vehicle stock in the city level in.https://zhiyun.souche.com/dataQuery?typeId=24&prodId=45; 2020 [Chinese] [Google Scholar]

- 45.Ou S.Q., Hao X., Lin Z.H., Wang H.W., Bouchard J., He X., et al. Light-duty plug-in electric vehicles in China: an overview on the market and its comparisons to the United States. Renew Sustain Energy Rev. 2019;112:747–761. [Google Scholar]

- 46.Kalaitzi D., Matopoulos A., Clegg B. Managing resource dependencies in electric vehicle supply chains: a multi-tier case study. Supply Chain Manag An Int J. 2019;24:256–270. [Google Scholar]

- 47.Günther H.-O., Kannegiesser M., Autenrieb N. The role of electric vehicles for supply chain sustainability in the automotive industry. J Clean Prod. 2015;90:220–233. [Google Scholar]

- 48.Masiero G., Ogasavara M.H., Jussani A.C., Risso M.L. The global value chain of electric vehicles: a review of the Japanese, South Korean and Brazilian cases. Renew Sustain Energy Rev. 2017;80:290–296. [Google Scholar]

- 49.Elshkaki A. Long-term analysis of critical materials in future vehicles electrification in China and their national and global implications. Energy. 2020;202:117697. [Google Scholar]

- 50.Evergrande Research Institute . 2020. Report of China's new energy vehicle development 2020: go through the darkest pandemic period.http://pdf.dfcfw.com/pdf/H3_AP202009231416468578_1.pdf [Chinese] [Google Scholar]

- 51.GGII . eighth ed. 2020. Research and analysis of China's lithium power battery 2020.http://www.gg-ii.com/art-2396.html accessed 10 January 2021 in Chinese. [Google Scholar]

- 52.Australia Trade and Investment Commission . 2018. The lithium-ion battery value chain: new economy opportunities for Australia.https://apo.org.au/node/210341 [Google Scholar]

- 53.China EV 100 . 2020. The white paper of China's new energy vehicle supply chain in 2020.https://www.rolandberger.com/publications/publication_pdf/New-Energy-Supply-Chain-2020-White-Paper-3.pdf [Chinese] [Google Scholar]

- 54.China Passenger Car Association . 2020. China's automobile market report in December 2019.http://www.cpcaauto.com/newslist.asp?types=csjd&id=10468 [Chinese] [Google Scholar]

- 55.China Electric Vehicle Charging Infrastructure Promotion Alliance . 2020. Annual report of China's charging infrastructure development (2019-2020)http://chuneng.bjx.com.cn/news/20200225/1047092.shtml [Chinese] [Google Scholar]

- 56.China Association of Automobile Manufacturers . 2020. Performance of China's automobile industry in June 2020.http://www.caam.org.cn/chn/53/cate_388/chn/3/cate_17/con_5231057.html [Chinese] [Google Scholar]

- 57.Ministry of Commerce (People’s Republic of China) 2020. Notice on new energy vehicles to the countryside.http://www.mofcom.gov.cn/article/h/redht/202007/20200702983138.shtml [Chinese] [Google Scholar]

- 58.Wagner A.F. What the stock market tells us about the post-COVID-19 world. Nat Hum Behav. 2020;4:440. doi: 10.1038/s41562-020-0869-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Power J.D. 2020. Impact of COVID-19 on consumer's willingness to buy cars.https://china.jdpower.com/zh-hans/press-releases/Impact-of-COVID19-on-consumers-willingness-to-buy-cars [Chinese] [Google Scholar]

- 60.KPMG . 2020. How novel coronavirus affects various industries and future development trends.https://assets.kpmg/content/dam/kpmg/cn/pdf/zh/2020/02/how-novel-coronavirus-affects-various-industries-and-future-development-trends.pdf [Chinese] [Google Scholar]

- 61.Habich-Sobiegalla S., Kostka G., Anzinger N. Citizens' electric vehicle purchase intentions in China: an analysis of micro-level and macro-level factors. Transport Pol. 2019;79:223–233. [Google Scholar]

- 62.Iimerdia . 2020. Daily active users of Didi travel app from january 1 to March 16 2020.https://data.iimedia.cn/page-category.jsp?nodeid=30408635/ [Chinese] [Google Scholar]

- 63.Ma S.C., Xu J.H., Fan Y. Willingness to pay and preferences for alternative incentives to EV purchase subsidies: an empirical study in China. Energy Econ. 2019;81:197–215. [Google Scholar]

- 64.Lu Y., Wu J., Peng J., Lu L. The perceived impact of the Covid-19 epidemic: evidence from a sample of 4807 SMEs in Sichuan Province, China. Environ Hazards. 2020;19:323–340. [Google Scholar]

- 65.Maia S.C., Teicher H., Meyboom A. Infrastructure as social catalyst: electric vehicle station planning and deployment. Technol Forecast Soc Change. 2015;100:53–65. [Google Scholar]

- 66.National Development and Reform Commission of China . 2020. Suggestions for speeding up the establishment of green production and consumption laws and policy schemes.https://www.ndrc.gov.cn/xxgk/zcfb/tz/202003/t20200317_1223470.html [Chinese] [Google Scholar]

- 67.Ministry of Industry and Information Technology of China . 2020. Notice on NEV promotions in the rural areas.http://www.mofcom.gov.cn/article/h/redht/202007/20200702983138.shtml [Chinese] [Google Scholar]

- 68.Beijing Municipal Commission of Transport . 2020. Proposals for increasing new energy passenger car quotas.http://jtw.beijing.gov.cn/ztlm [Chinese] [Google Scholar]

- 69.China Automotive Battery Innovation Alliance . 2020. Power battery information in June 2020.http://chuneng.bjx.com.cn/news/20200713/1088432.shtml [Chinese] [Google Scholar]

- 70.Ballinger B., Stringer M., Schmeda-Lopez D.R., Kefford B., Parkinson B., Greig C., et al. The vulnerability of electric vehicle deployment to critical mineral supply. Appl Energy. 2019;255:113844. [Google Scholar]

- 71.Kaunda R.B. Potential environmental impacts of lithium mining. J Energy Nat Resour Law. 2020:1–8. [Google Scholar]

- 72.European Commission . 2020. Lithium-ion battery value chain and related opportunities for Europe.https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/lithium-ion-battery-value-chain-and-related-opportunities-europe [Google Scholar]

- 73.AUTOIFO . 2020. Important information of automobile industry on March 12 2020.http://www.autoinfo.org.cn/autoinfo_cn/content/lsnews/20200312/1864375.html [Chinese] [Google Scholar]

- 74.Gasgoo . 2020. BYTON and BORDRIN went bankrupt while Saleen's chairman fled.https://auto.gasgoo.com/a/70192324.html [Chinese] [Google Scholar]

- 75.Global Times . 2020. Hard to buy masks? These car companies began to produce masks.https://china.huanqiu.com/article/9CaKrnKphdi [Chinese] [Google Scholar]

- 76.EV Homes By 2022 . 2020. China will increase the production capacity of 5 million new energy vehicles, and the competition will be more intense.https://baijiahao.baidu.com/s?id=1689287512154126004&wfr=spider&for=pc; [Chinese] [Google Scholar]

- 77.China Automobile Dealers Association . 2020. The monthly VIAI for China's automobile dealers.http://data.cada.cn/main/stock.do [Chinese] [Google Scholar]

- 78.Perkins G., Murmann J.P. What does the success of tesla mean for the future dynamics in the global automobile sector? Manag Organ Rev. 2018;14:471–480. [Google Scholar]

- 79.INSIDEEVs . 2020. COVID-19 sales techniques: NIO locks in $18 million in business from livestream event.https://insideevs.com/news/424189/nio-generates-18-million-sales-from-livestream/ [Google Scholar]

- 80.Sales E.V. 2020. Europe June 2020.http://ev-sales.blogspot.com/2020/07/europe-june-2020.html [Google Scholar]